Oxidizer-rich liquid monopropellants for a dual mode chemical rocket engine

a technology of oxidizer-rich liquid monopropellants and chemical rocket engines, which is applied in the direction of cosmonautic components, weapons, cosmonautic parts, etc., can solve the problems of limited propellant performance suitable for both bipropellant and monopropellant engines, high safety requirements, and inability to meet the performance requirements of hydrazine propellants prior to the prior art, and achieve alternative propellants with performance comparable to hazardous hydrazine propel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The inventive oxidizer-rich monopropellant comprises 70-90% of ADN or HAN, 0-10% ammonia, and balance water.

[0024]According to the present invention the inventive oxidizer-rich monopropellant is used for further combusting, in a second reaction stage, fuel-rich gasses obtained from combustion of a fuel-rich monopropellant, such as a conventional ADN-based or HAN-based liquid monopropellant. The inventive liquid oxidizer-rich monopropellant is thus intended for use in bipropellant operation in a chemical rocket engine together with the fuel-rich liquid monopropellant.

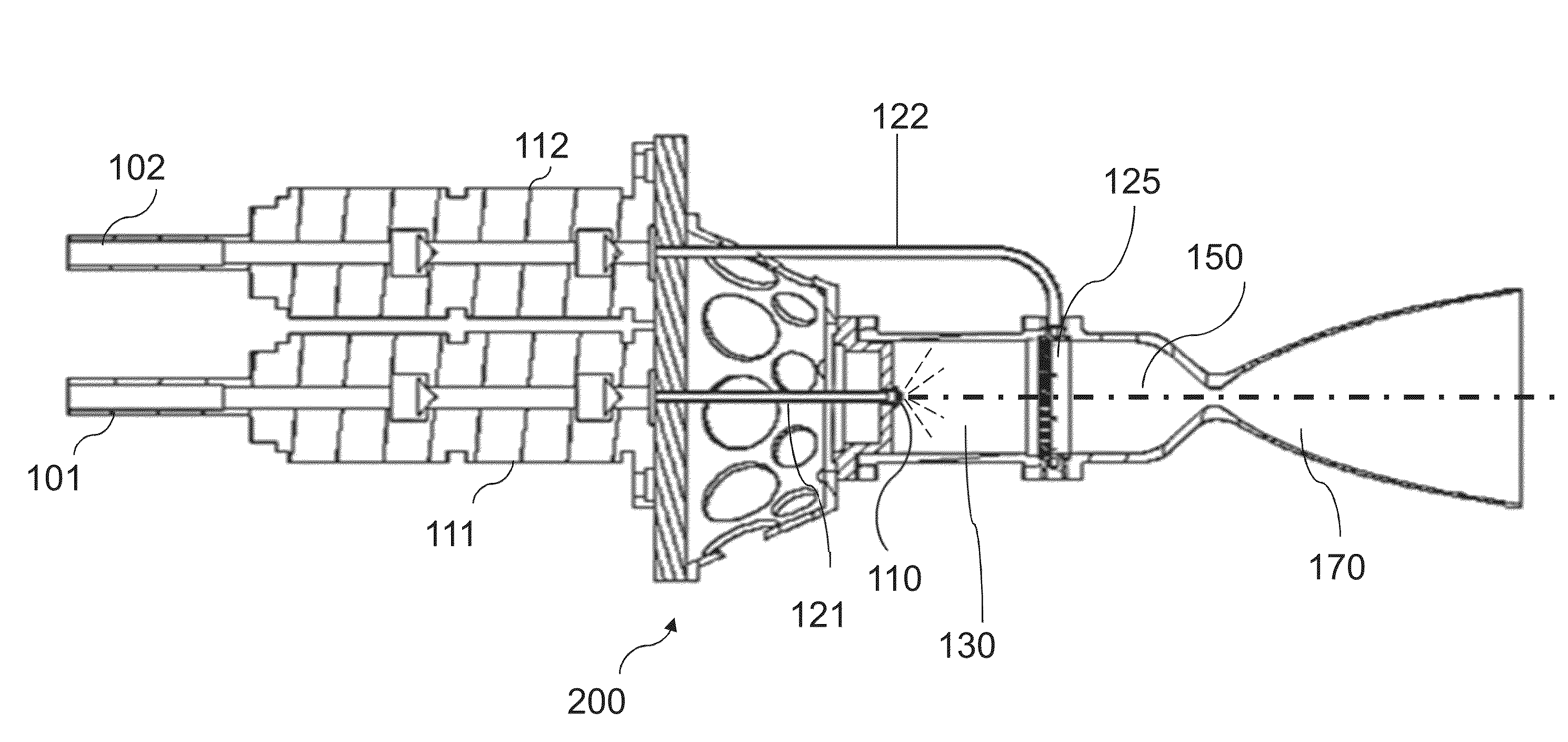

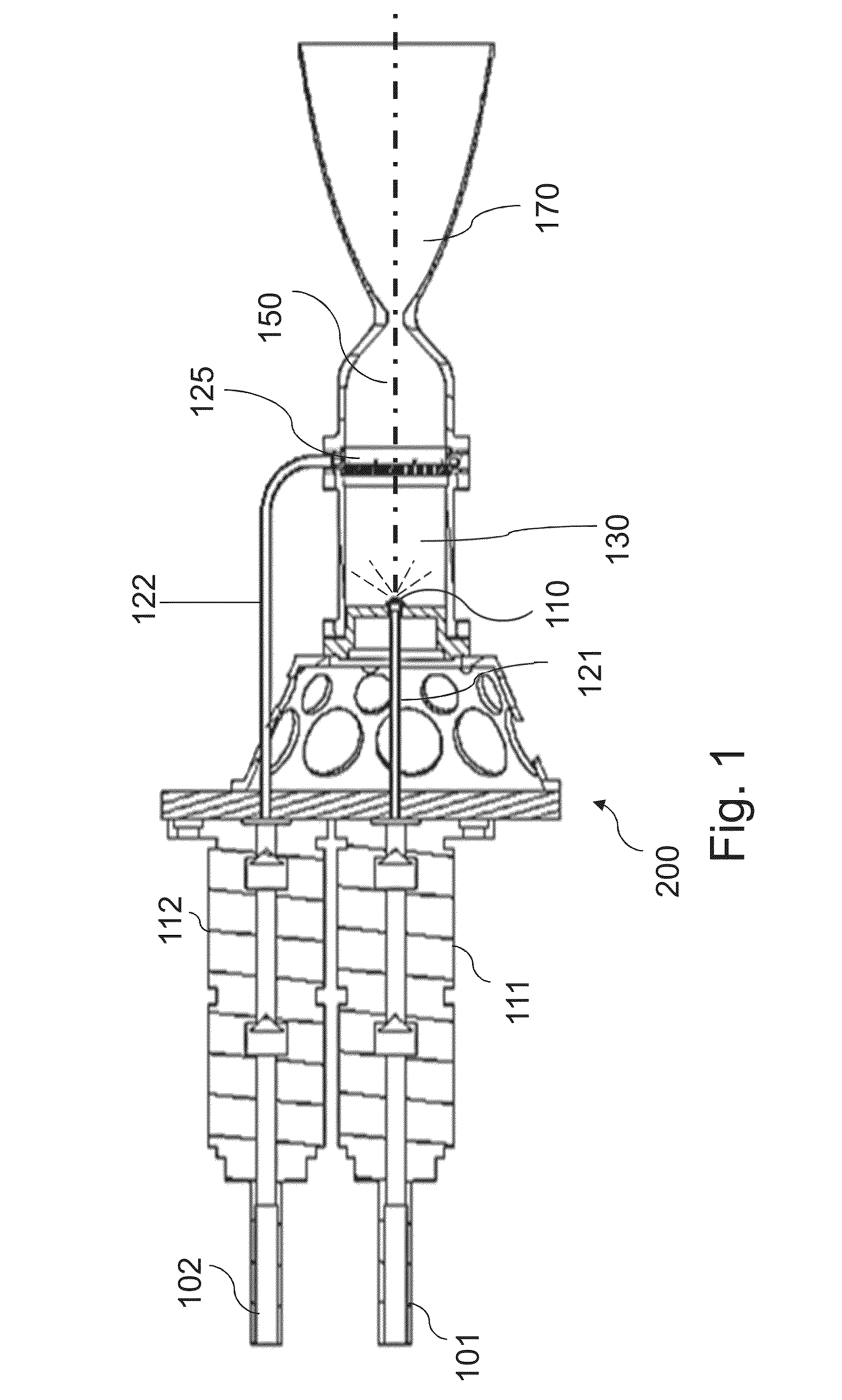

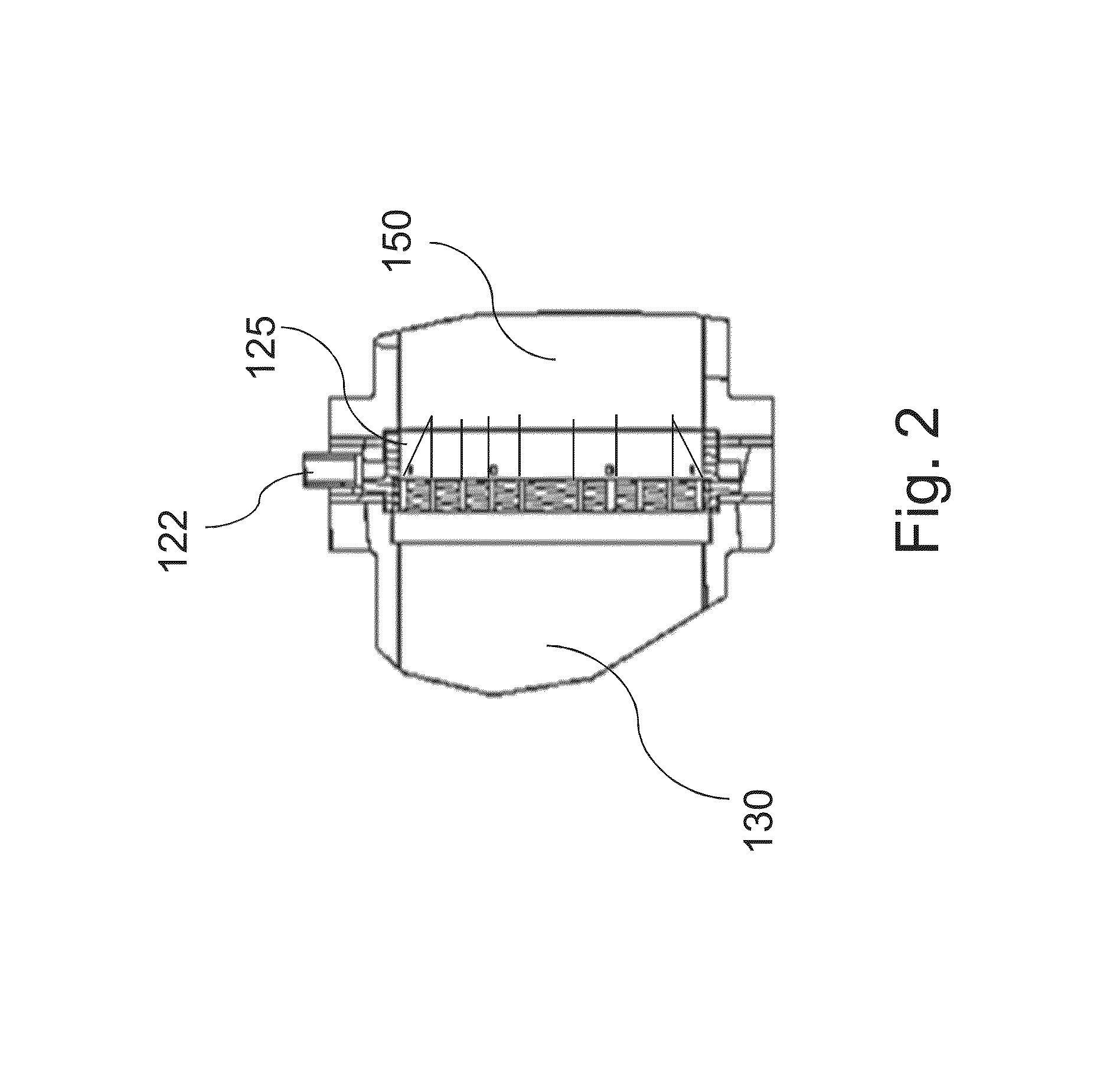

[0025]As illustrated in FIG. 1 a suitable engine capable of operating in bipropellant mode may comprise a primary reaction chamber 130 for a fuel-rich monopropellant, and a secondary reaction chamber 150 for the decomposition of the inventive oxidizer-rich propellant, wherein the primary reaction chamber is connected to the secondary reaction chamber so that fuel-rich gas from the decomposition of the fuel-rich oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| thrust | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com