Reactive powder concrete containing waste steel fibers, and a preparation method thereof

A technology of active powder and steel fiber, which is applied to the field of active powder concrete containing waste steel fiber and its preparation, and achieves the effects of reducing production cost, reducing resource utilization, good economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

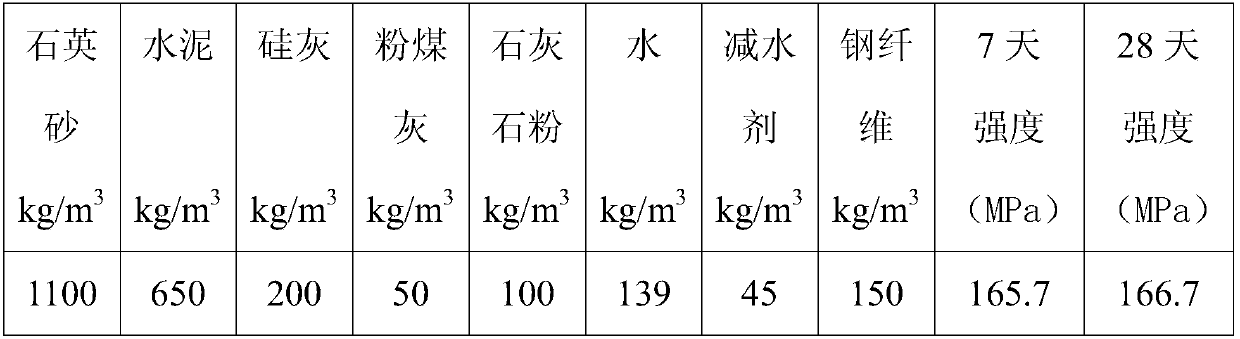

[0028] Reactive powder concrete is prepared from waste tire steel fibers. The mix ratio design scheme, preparation method and strength test results are as follows:

[0029]

[0030] Prepare all the raw materials according to the mixing ratio, first stir the quartz sand and steel fiber for 1min, then add cement, silica fume, fly ash, limestone powder, mix and stir for 1min, mix the water and water reducing agent evenly, then add it to the stirring pot and stir After 5 minutes, pouring and molding was carried out according to the standard of mortar molding. After one day, the mold was removed and placed in water vapor at 80°C for 48 hours, and then naturally cured to the corresponding age to test the strength results.

Embodiment 2

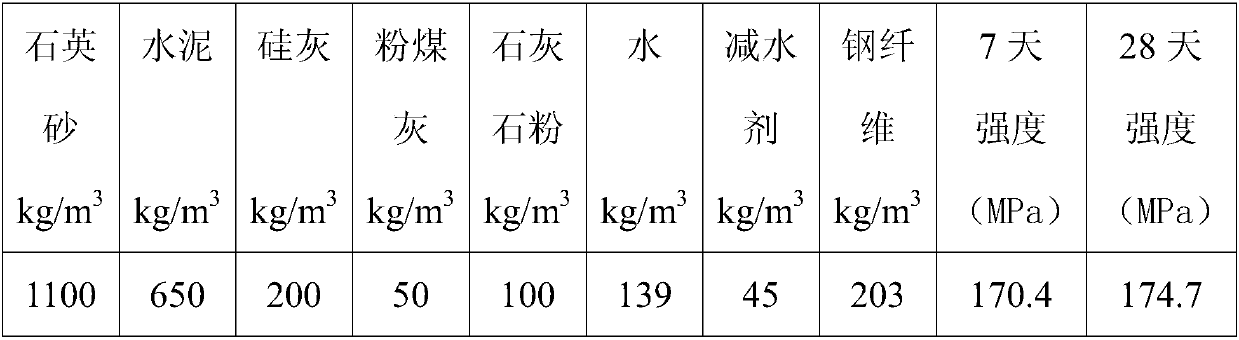

[0032] Reactive powder concrete is prepared from waste tire steel fibers. The mix ratio design scheme, preparation method and strength test results are as follows:

[0033]

[0034] Prepare all the raw materials according to the mixing ratio, first stir the quartz sand and steel fiber for 1min, then add cement, silica fume, fly ash, limestone powder, mix and stir for 1min, mix the water and water reducing agent evenly, then add it to the stirring pot and stir After 5 minutes, pouring and molding was carried out according to the standard of mortar molding. After one day, the mold was removed and put into water at 80 °C for 48 hours, and then naturally cured to the corresponding age to test the strength results.

Embodiment 3

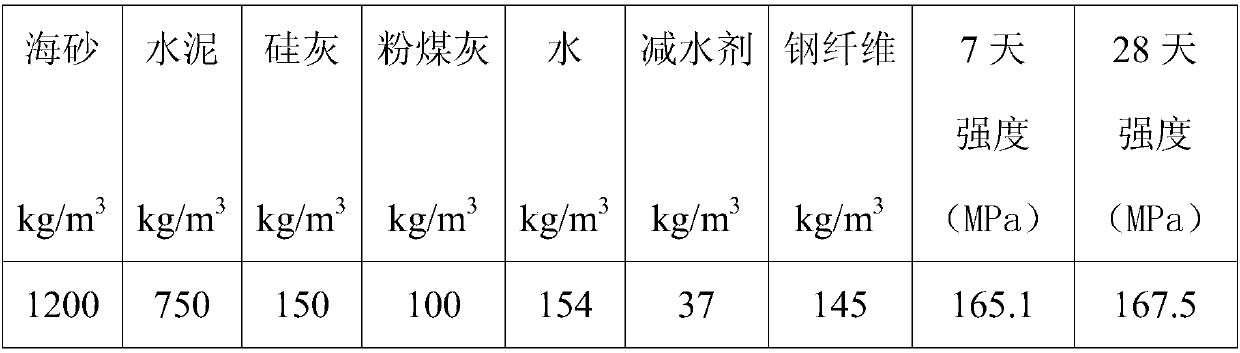

[0036] Reactive powder concrete is prepared from waste tire steel fibers. The mix ratio design scheme, preparation method and strength test results are as follows:

[0037]

[0038] Prepare all the raw materials according to the mixing ratio, first stir sea sand and steel fiber for 2 minutes, then add cement, silica fume, fly ash and mix and stir for 2 minutes, mix water and water reducer evenly, add them to the mixing pot and stir for 6 minutes, then Cast and form according to the standard of mortar molding. After one day, remove the mold and put it in water vapor at 80°C for 48 hours, and then naturally cure to the corresponding age to test the strength results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com