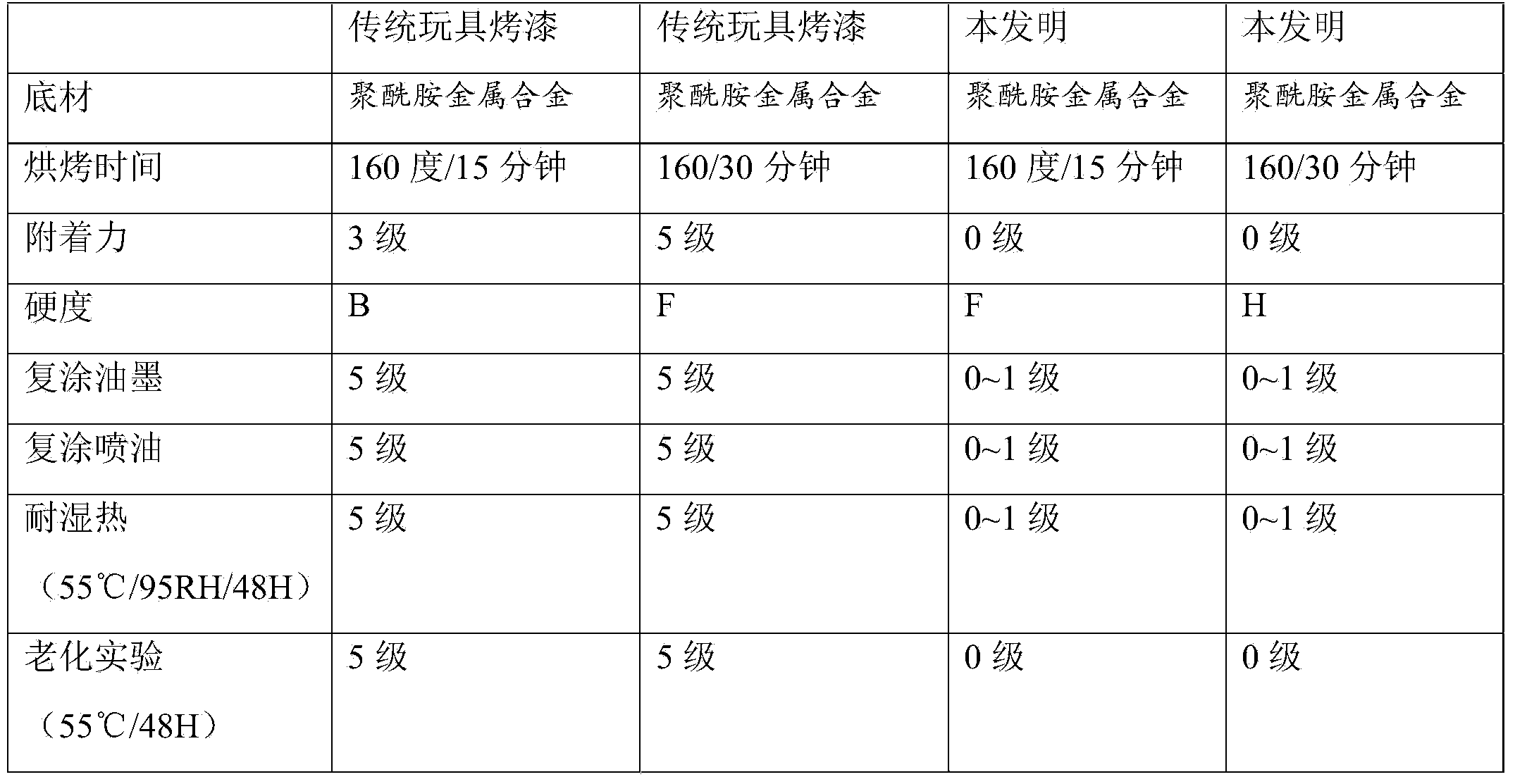

Paint composition applied to polyamide metal alloy toys

A metal alloy and polyamide technology, applied in polyester coatings, coatings, epoxy resin coatings, etc., can solve the problems of poor surface activity and slow thermal conductivity of polyamide metal alloys, and achieve wide adhesion and excellent physical and chemical properties. , the effect of increasing profits and market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following description will be made with reference to preferred embodiments of the present invention.

[0038] The embodiment of the present invention provides a kind of baking varnish that is used for polyamide metal alloy toy, comprises following component by weight ratio:

[0039] Hydroxy acrylic resin: 20-40%

[0040] Polyester resin: 20-30%

[0041] Amino resin A: 10-20%

[0042] Amino resin B: 10-20%

[0043] Epoxy resin: 2-4%

[0044] Silicone additives: 2 to 4%

[0045] Adhesion promoter: 2~4%

[0046] Pigment / dye: 5~20%.

[0047] Describe below the effect of each component in the formula among the present invention:

[0048] Among them, hydroxyacrylic resin is characterized by fast drying and wide adhesion. After the screening of acrylic acid commonly used in coatings, this resin has good adhesion, gloss, haze and fullness on polyamide metal alloys, and the price is moderate. It is suitable as a raw material for polyamide metal alloy toy coatings, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com