Tiered porosity flashback suppressing elements for monopropellant or pre-mixed bipropellant systems

A technology for suppressing components and propellants, applied to engine components, jet propulsion devices, adhesives, etc., can solve problems such as difficult control of flashback failure mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following description, for the purpose of explanation, a large number of specific details are presented to provide a sufficient understanding of the present invention. However, it is obvious that those skilled in the art can implement the present invention without a part of these specific details. For example, although different features belong to a specific embodiment, it should be understood that the features described for one embodiment can also be integrated with other embodiments. However, similarly, no single feature or multiple features of any of the described embodiments are indispensable to the present invention, because other embodiments of the present invention may omit such features.

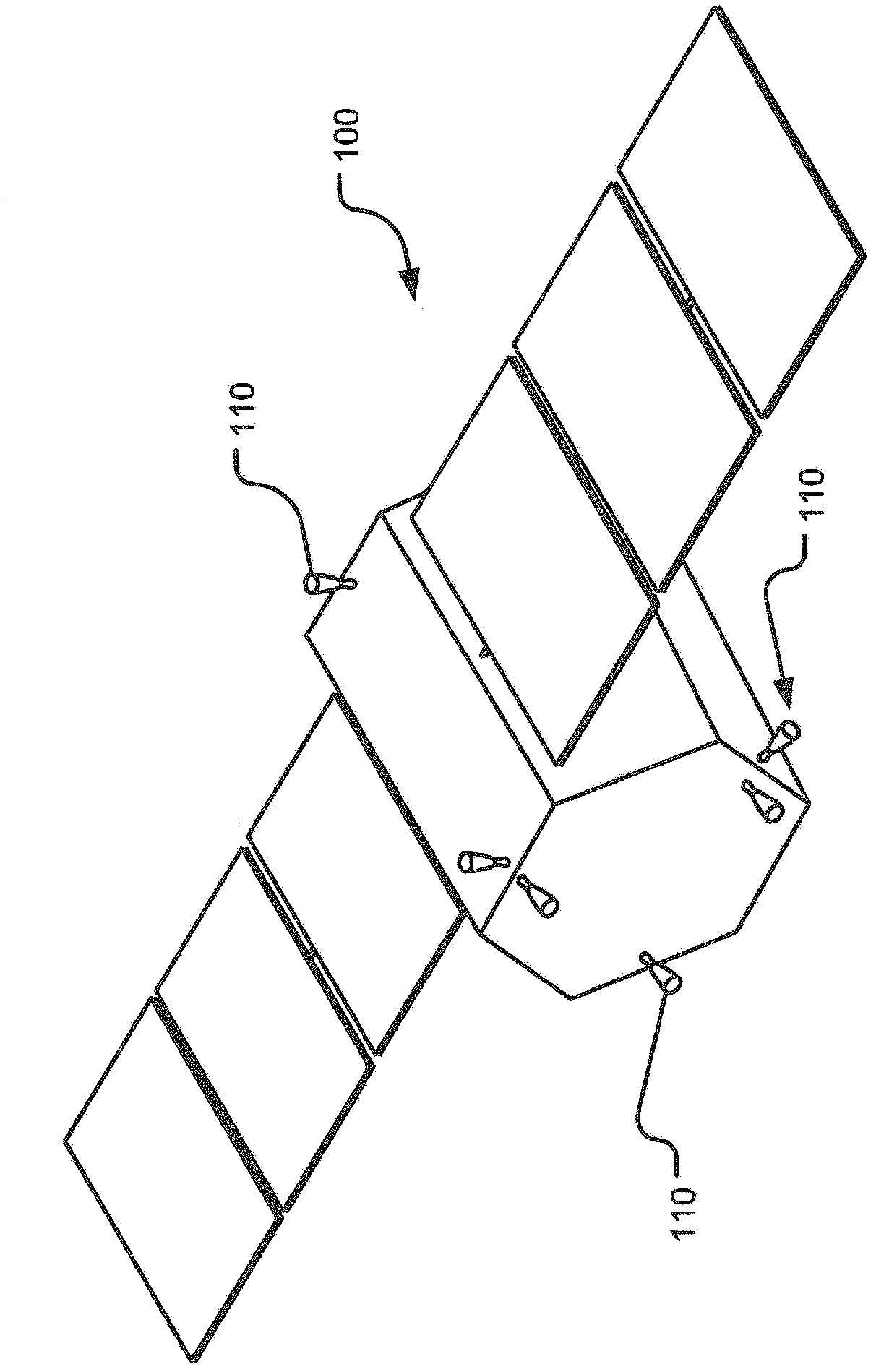

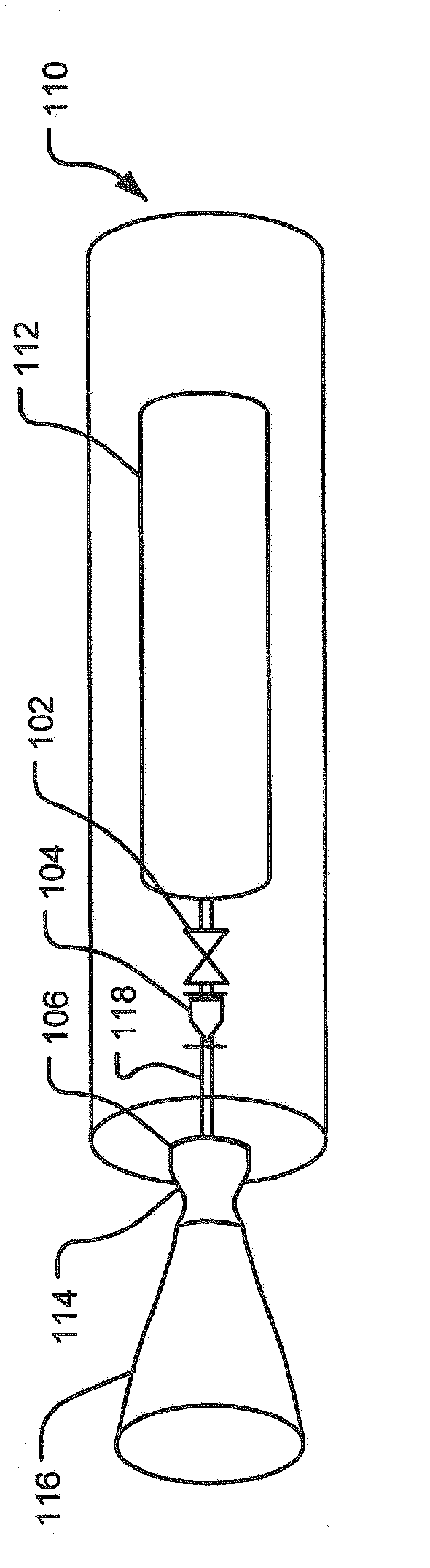

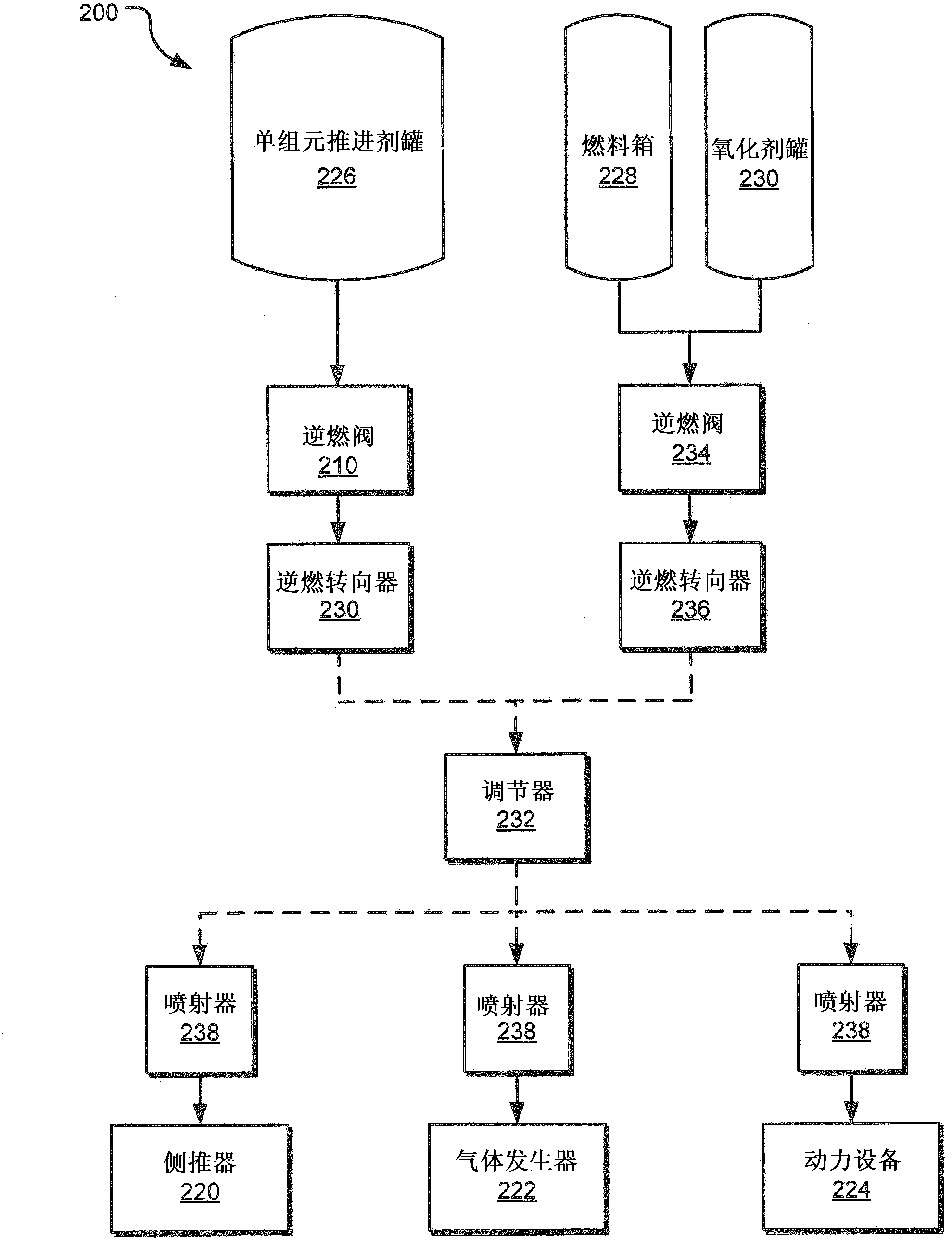

[0039] figure 1 Shows a cross-sectional view of an exemplary single-component propellant propellant system 110 in an orbiter 100 that can utilize flashback suppression devices 102, 104, 106 according to the technology disclosed in the present invention, which includes a si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com