Pulse pendulum type monopropellant engine

A pendulum engine, single-component technology, applied in the direction of swing piston engine, rotary or swing piston engine, engine components, etc., can solve the problem of system energy density and power density reduction, system energy and power density reduction, chemical battery energy Low density and other problems, to achieve the effect of reducing friction loss, easy starting and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

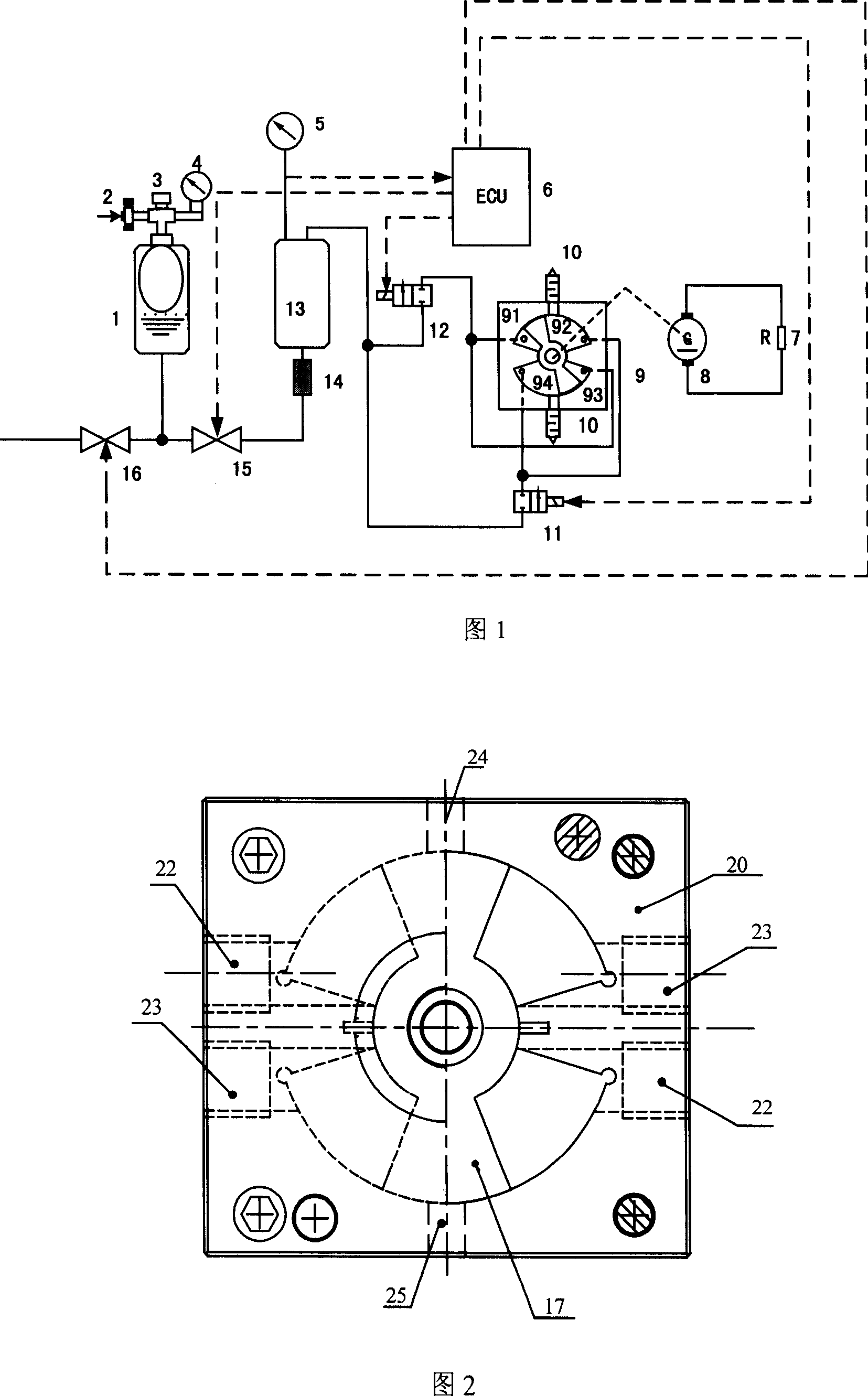

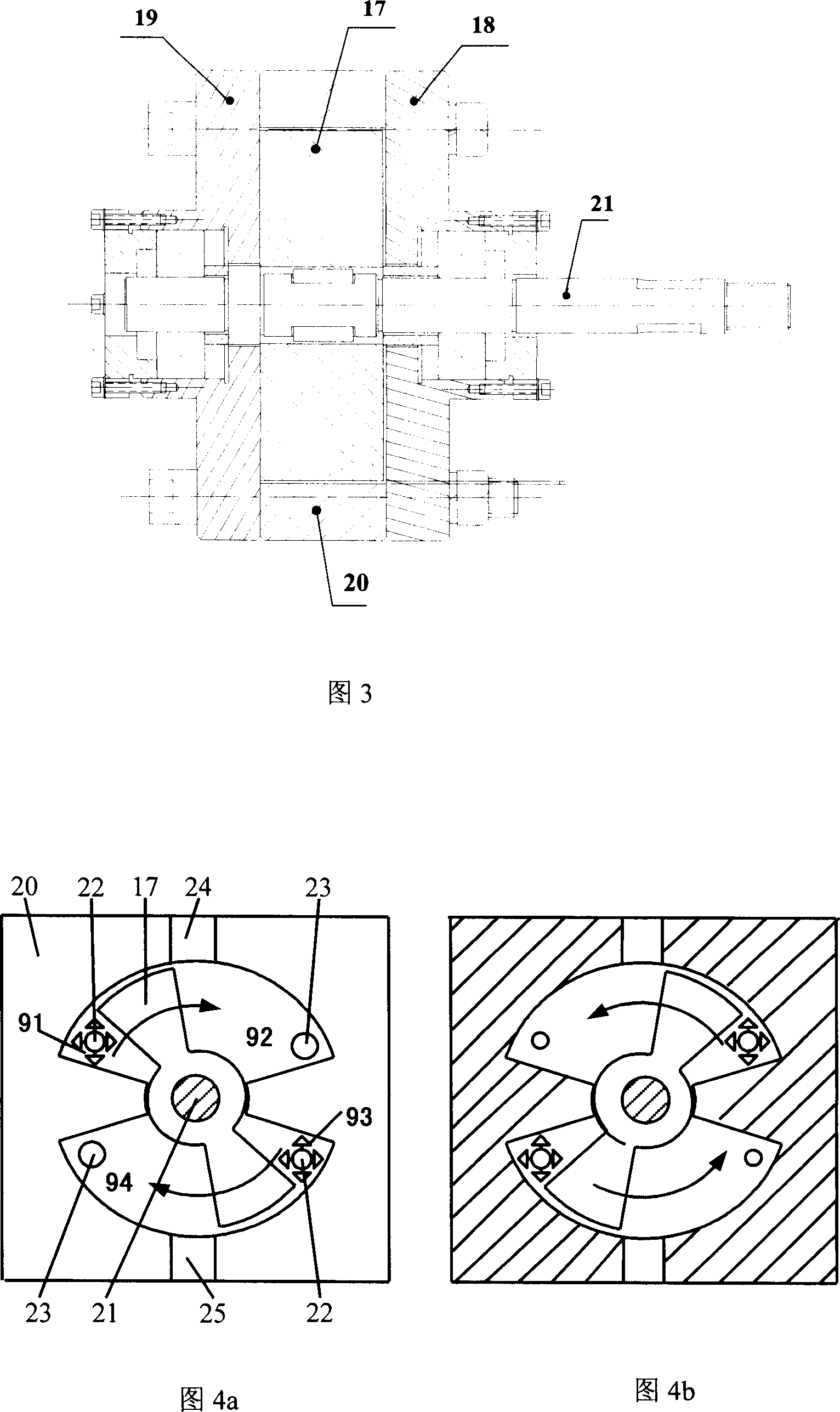

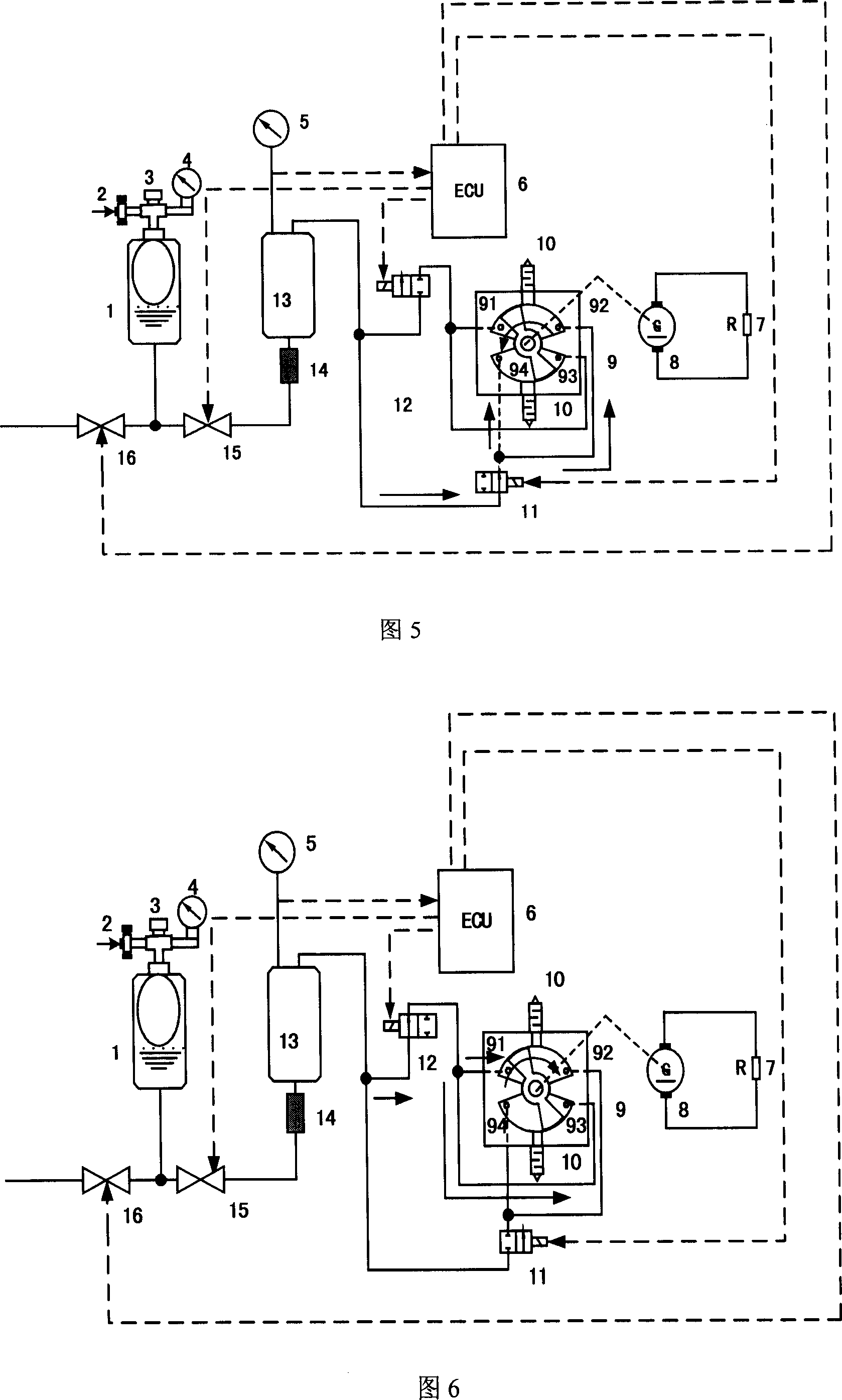

[0019] The pulse pendulum monocomponent engine of the present invention uses a monocomponent propellant such as a mixture of high-concentration hydrogen peroxide and diesel oil as fuel, and decomposes the above-mentioned mixed monocomponent fuel into high-temperature and high-pressure mixed gas through a catalytic reaction and stores it in the gas storage In the tank; when the pressure of the mixed gas in the gas storage tank reaches the set pressure value, the electronic control unit (ECU) controls the engine to work through two pneumatic switch valves, so as to realize the direct output of the swing power or the electric energy output through the generator. The operating frequency of the pendulum engine is equal to the switching frequency of the two pneumatic switching valves. The invention has the characteristics of small volume, light weight, high energy density, few moving parts, reliable operation and wide application range, etc. A power supply device ranging from watts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com