A monocomponent engine with non-toxic unit propellant

A technology of propellant and engine, which is applied in the direction of machine/engine, rocket engine device, jet propulsion device, etc., to achieve the effect of reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

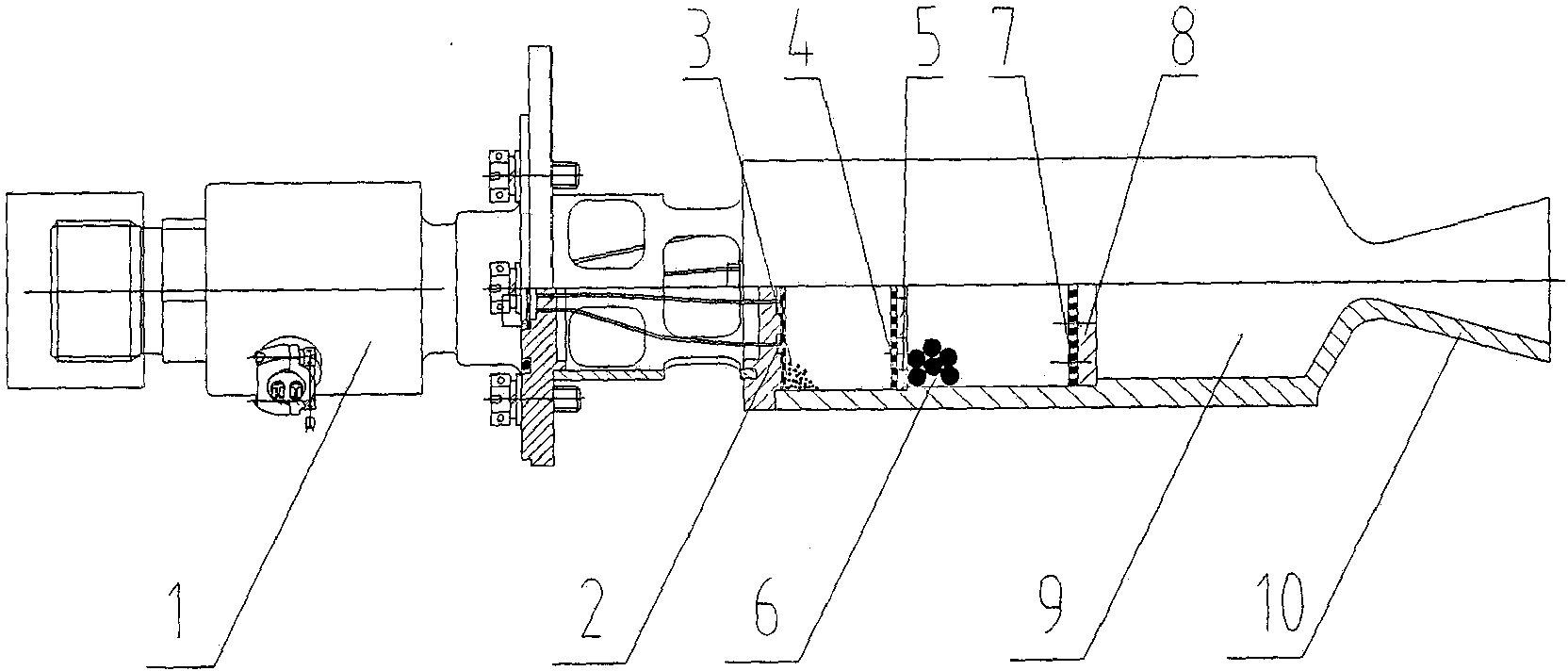

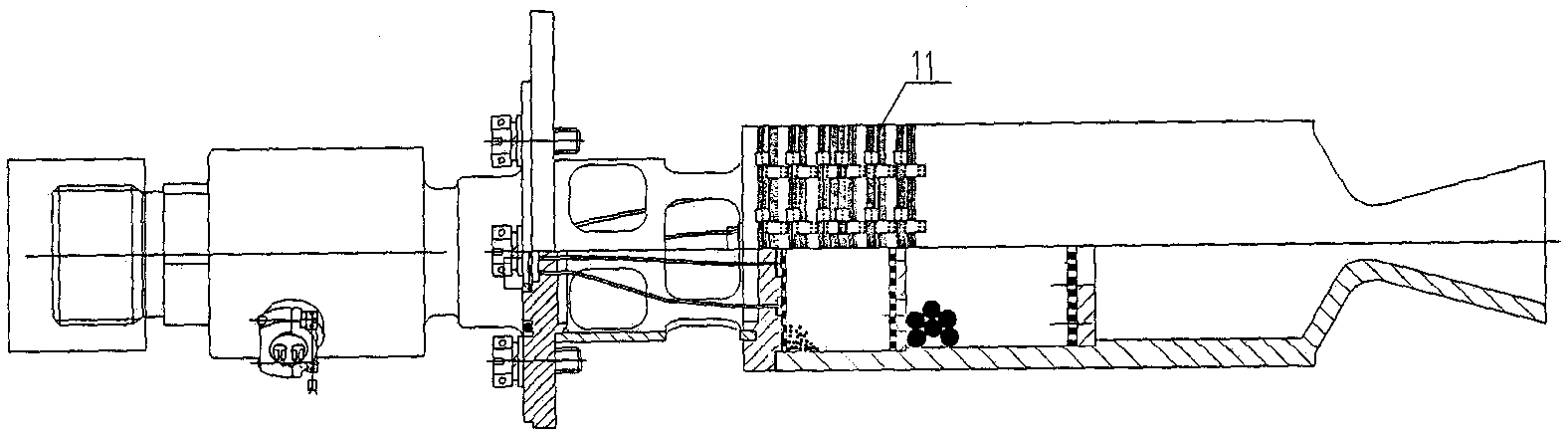

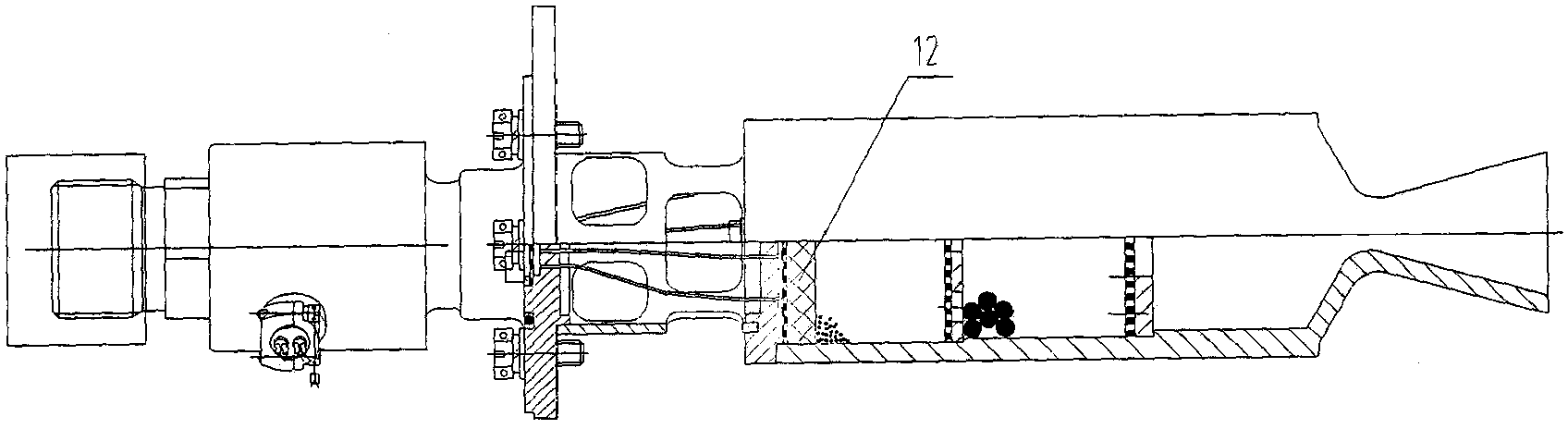

[0015] figure 1 It is the engine structure schematic diagram without heater of the present invention, by electromagnetic valve (1), injector (2), catalytic front bed (3), screen (4), dividing plate (5), catalyst back bed (6) ), baffle (7), baffle (8), combustion chamber (9), nozzle (10) form.

[0016] The solenoid valve (1) controls the start and shutdown of the engine, and the non-toxic liquid propellant enters the injector (2) for atomization through the solenoid valve (1). The hot back-leaching of the catalyst bed (3) and the catalyst rear bed (6) are mainly used to decompose the oxidant in the propellant after atomization, and the active component of the catalytic bed is metal iridium, and the iridium content is between 5% and 35%. In between, the front bed of the catalyst adopts fine particle 20 mesh ~ 30 mesh catalyst to ensure the rapid decompositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com