Patents

Literature

450 results about "Thrust chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

These have either two throats or two thrust chambers (with corresponding throats). The central throat is of a standard design and is surrounded by an annular throat, which exhausts gases from the same (dual-throat) or a separate (dual-expander) thrust chamber. Both throats would, in either case, discharge into a bell nozzle.

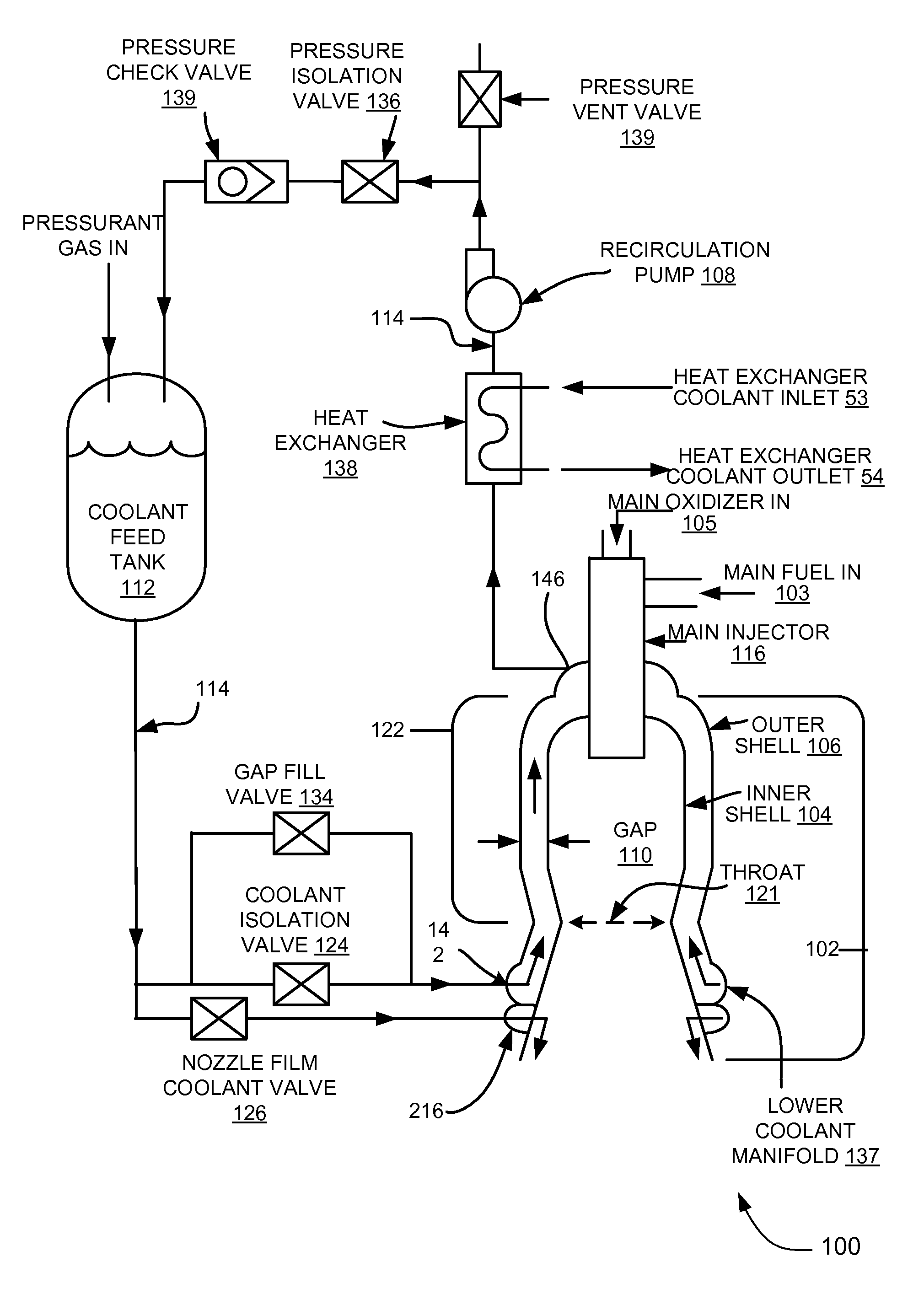

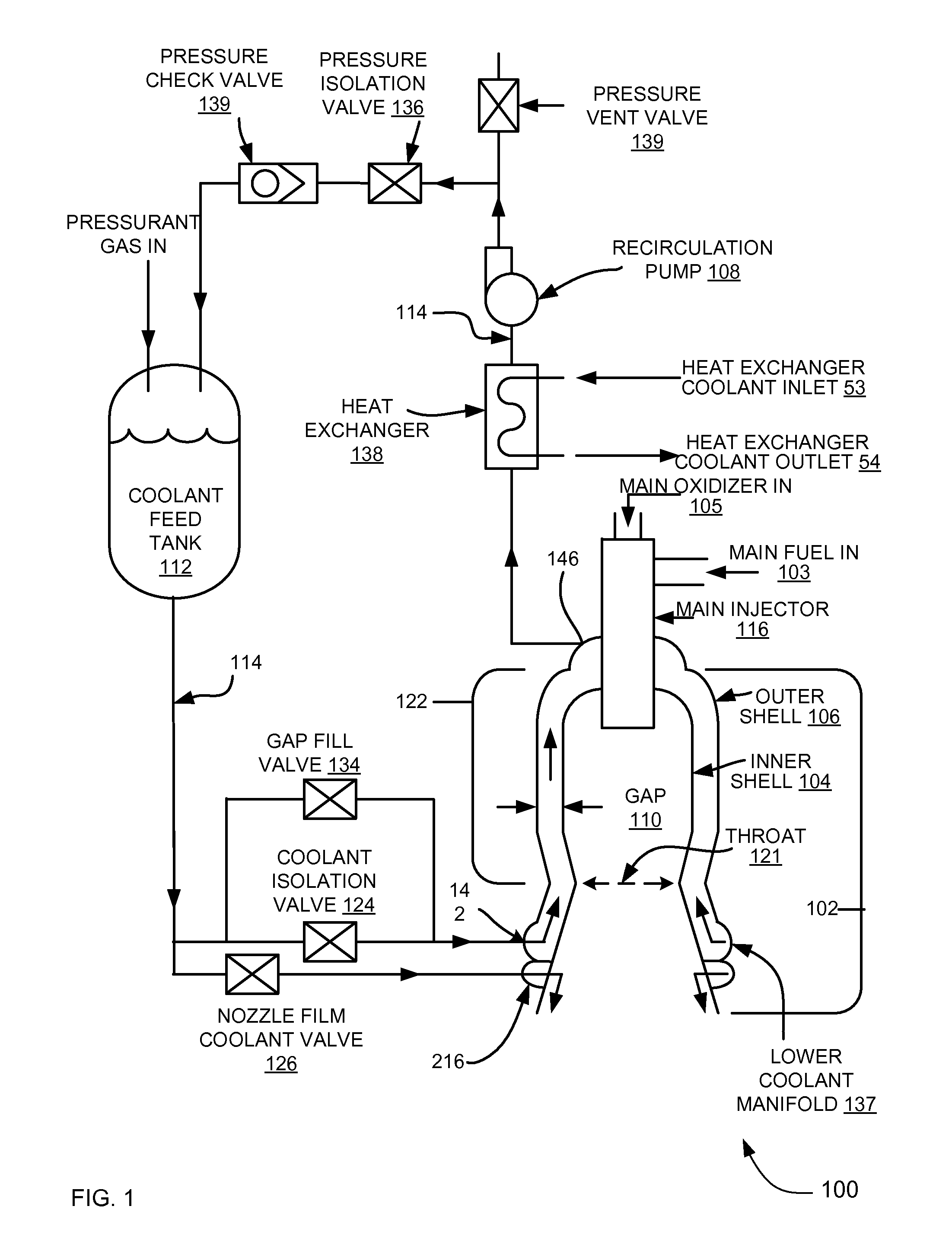

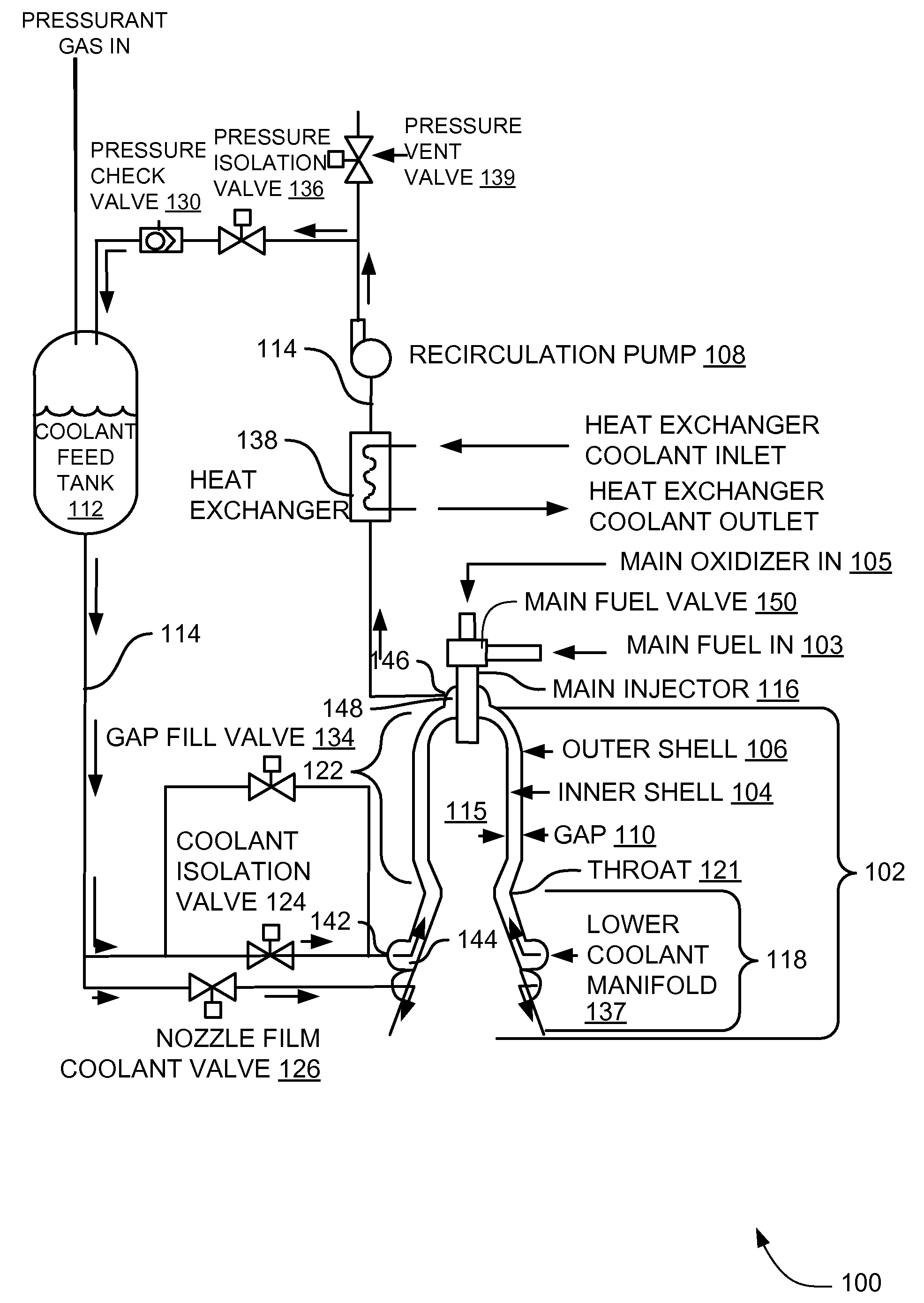

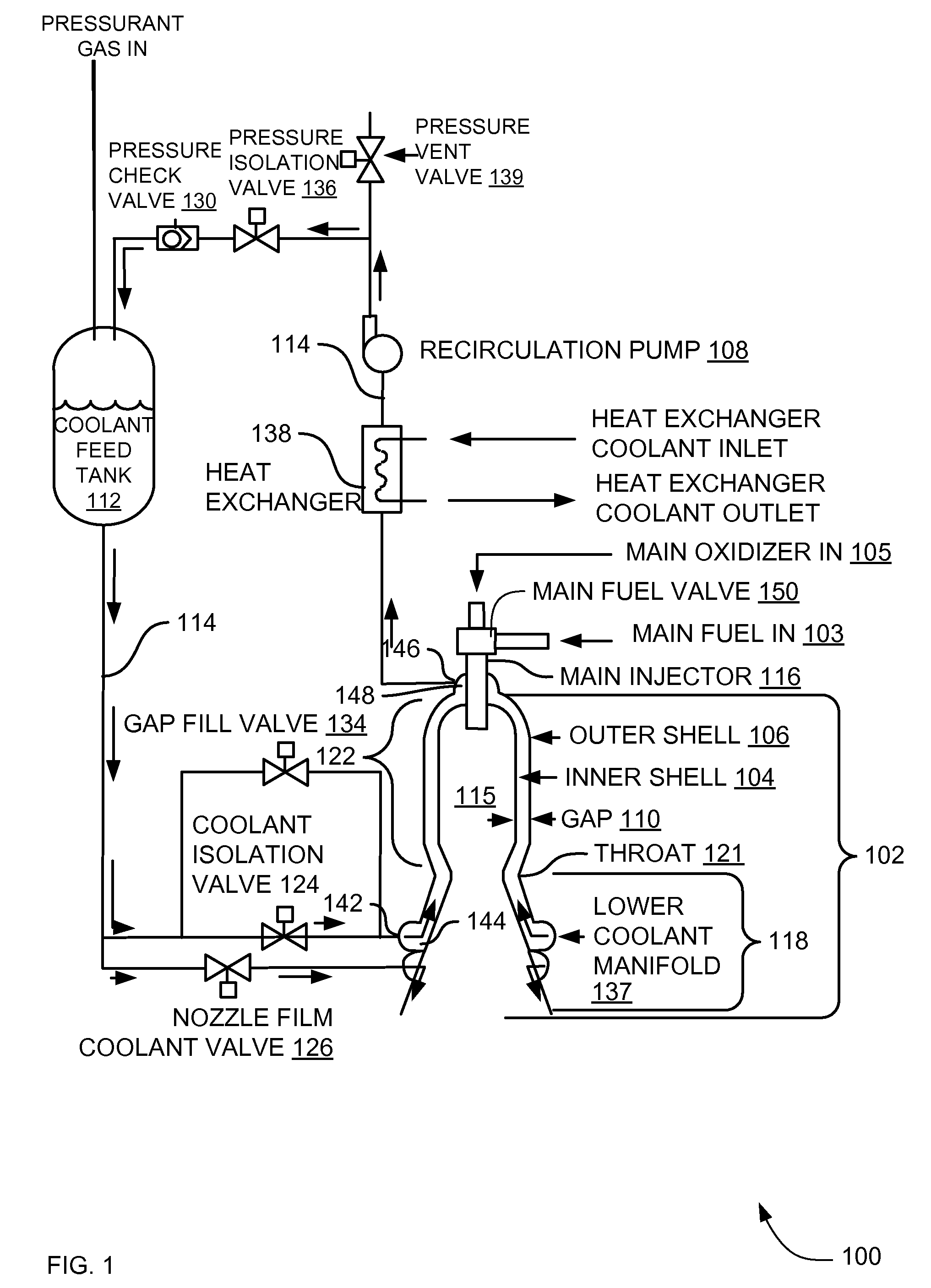

Simplified thrust chamber recirculating cooling system

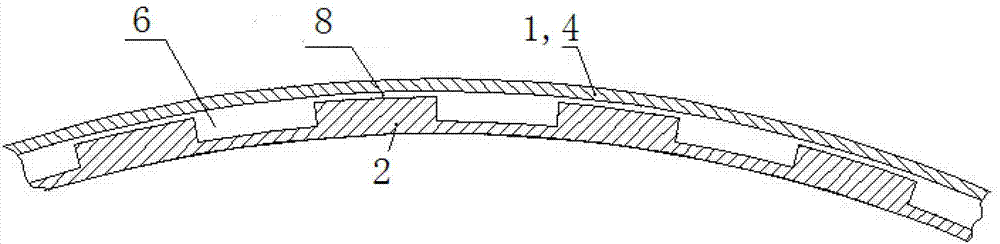

In some implementations a propulsion system includes a thrust chamber having a gap between an inner shell and an outer shell, the inner shell and the outer shell being attached together to form the thrust chamber. In some implementations, the rocket engine also includes a recirculating cooling system operably coupled to the gap in at least two locations and operable to recirculate a convective coolant through the gap.

Owner:PAVIA THOMAS CLAYTON +1

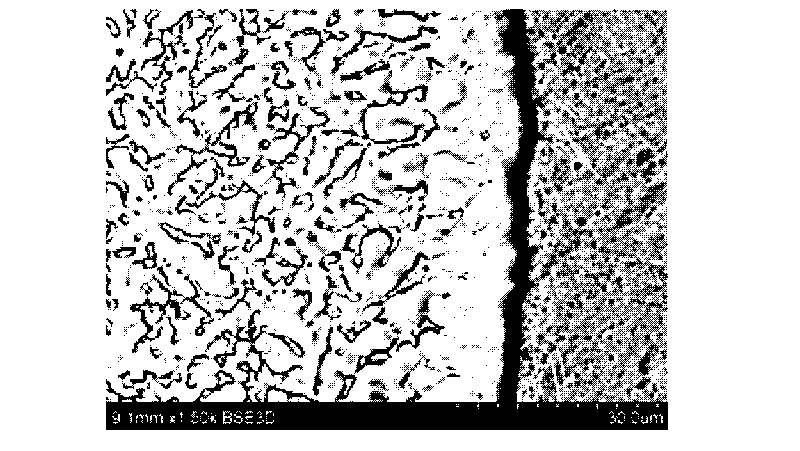

Method for controlling brittle phases of titanium and stainless steel electronic beam welding joints adopting composite intermediate layers

InactiveCN101722356AElectron beam welding apparatusWelding/soldering/cutting articlesAcid washingTitanium alloy

The invention relates to a method for controlling the brittle phases of titanium and stainless steel electronic beam welding joints adopting composite intermediate layers, belonging to the welding field of heterogeneous difficult-welding metal. The invention solves the problem that the tradition metal and stainless steel welding method can not avoid the generation of the brittle phases. The method comprises the following steps of: using pure copper and pure vanadium as the intermediate layers to form members to be welded, wherein the members to be welded consist of stainless steel, pure copper, pure vanadium and titanium, ultrasonically cleaning the members to be welded by acetone, drying the members to be welded after acid washing and water washing, and then performing secondary electronic beam welding in vacuum. The joints obtained by the method have no brittle phases, the tensile strength of the joints is greater than 299 MPa, and the yield strength is greater than 260 MPa. The method is suitable for manufacturing thrust chamber bodies of aircraft engines, nuclear fuel processing equipment in nuclear industry, and titanium / steel composite members and titanium alloy / steel composite members in chemical and medical equipment.

Owner:HARBIN INST OF TECH

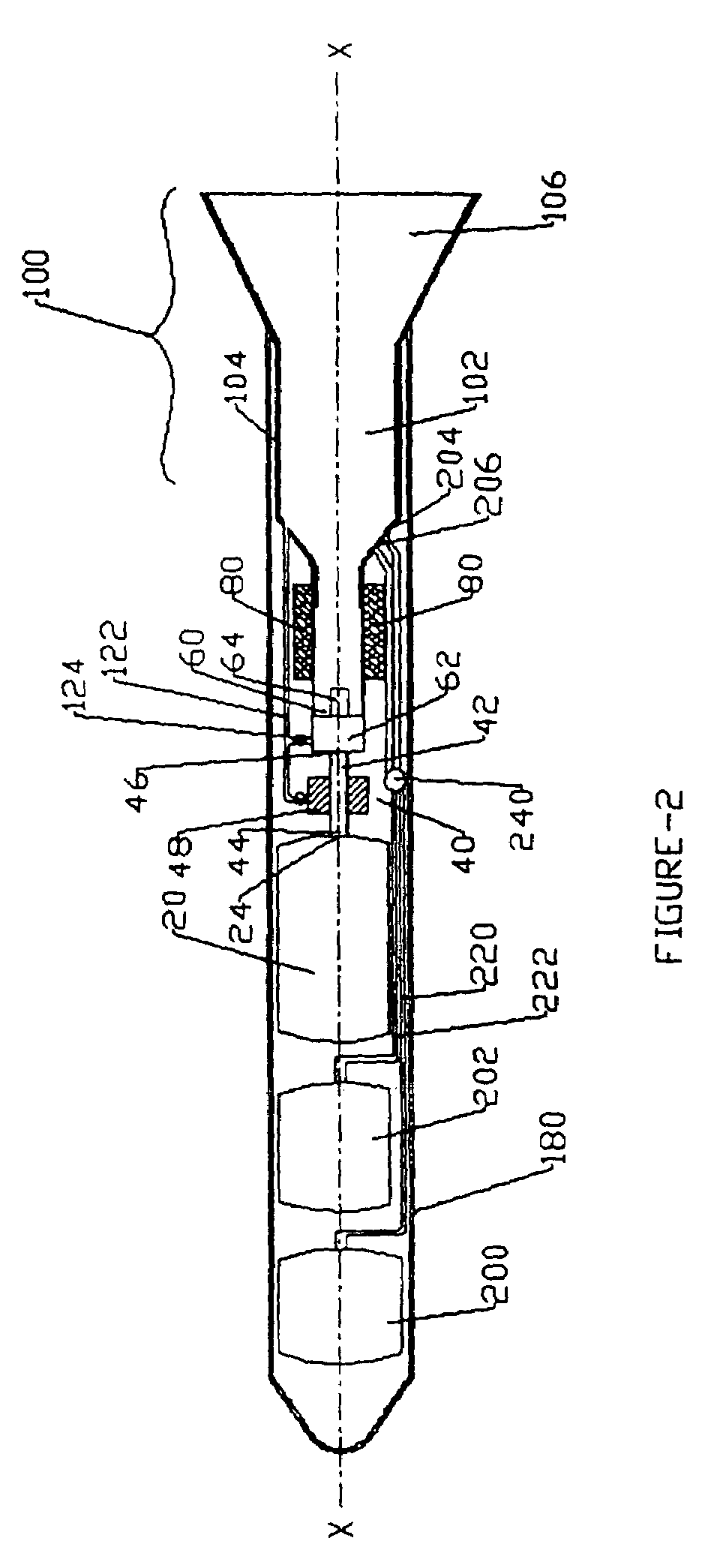

Propulsion from combustion of solid propellant pellet-projectiles

InactiveUS7194852B1High volume loadAbility to throttleGas turbine plantsContinuous jet plantsRamjetCombustion chamber

Owner:KRISHNAN VINU B

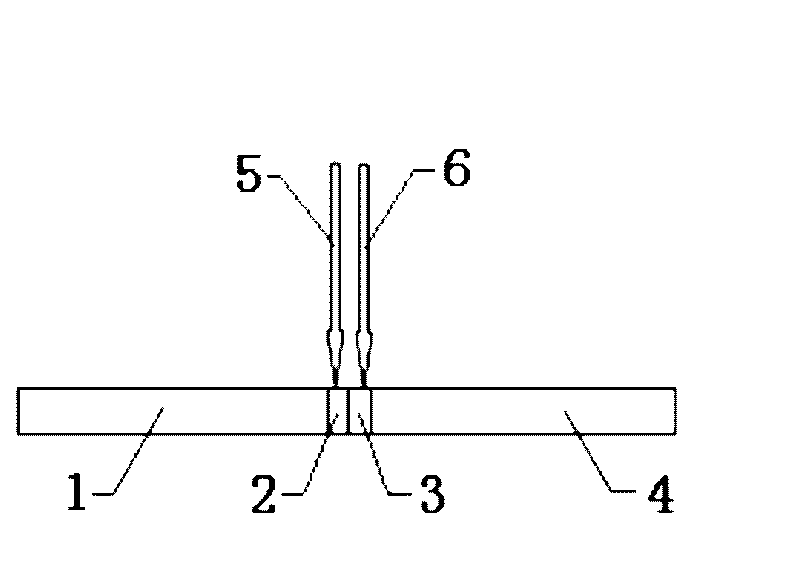

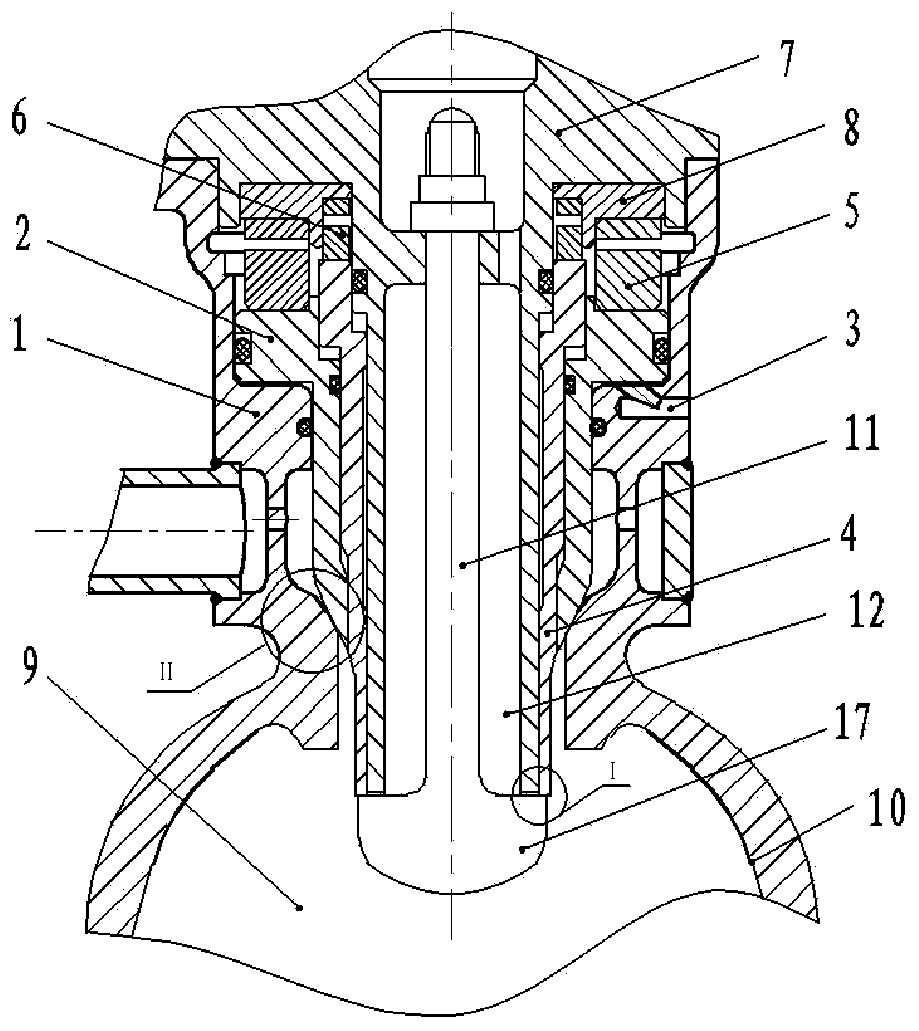

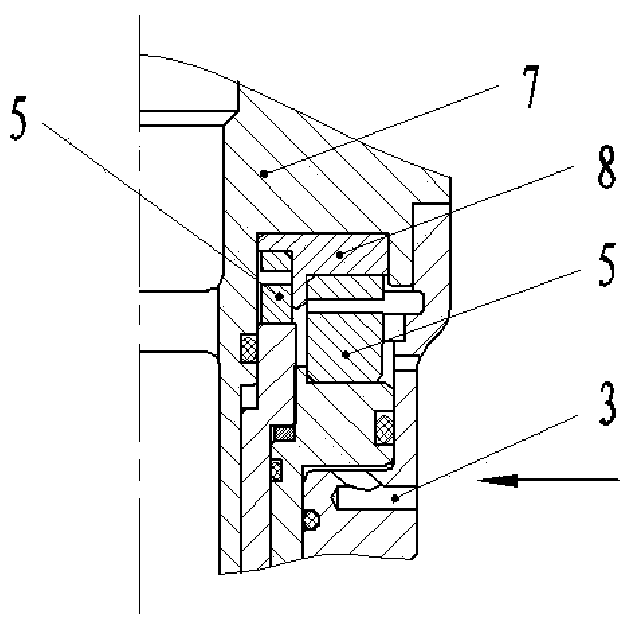

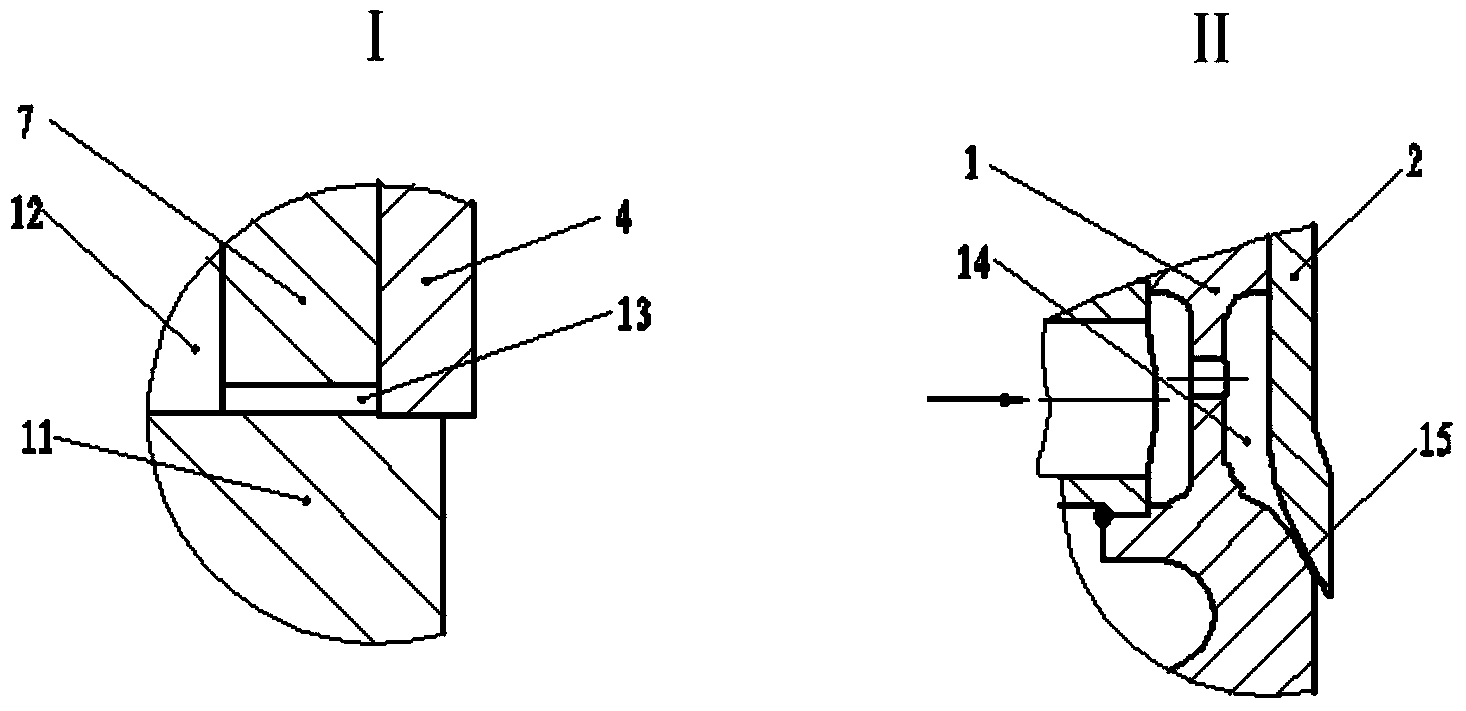

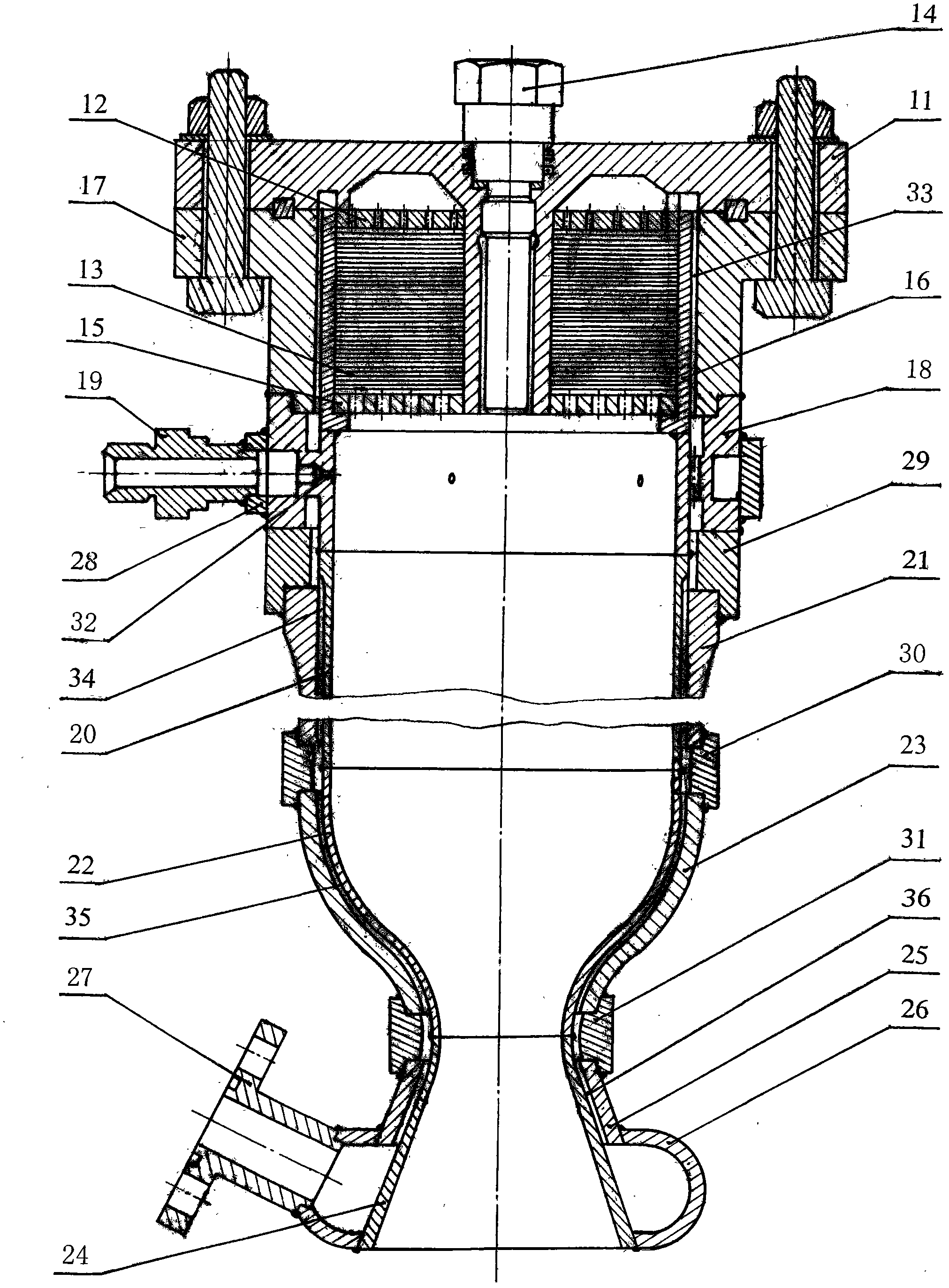

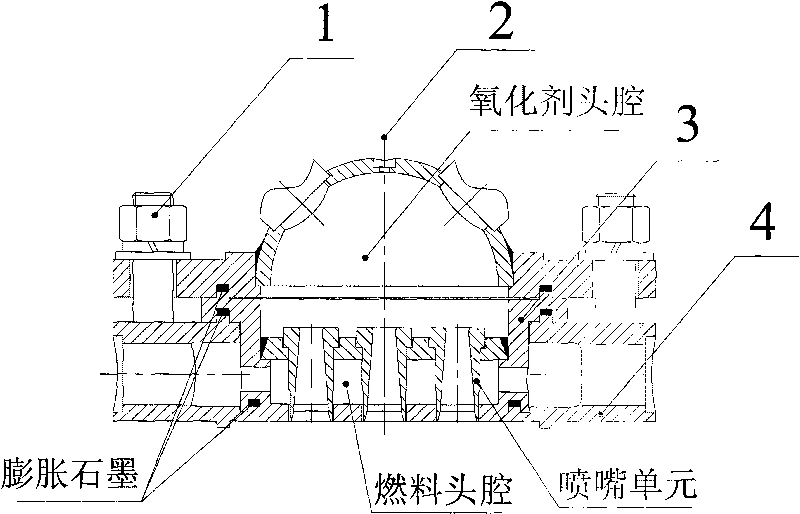

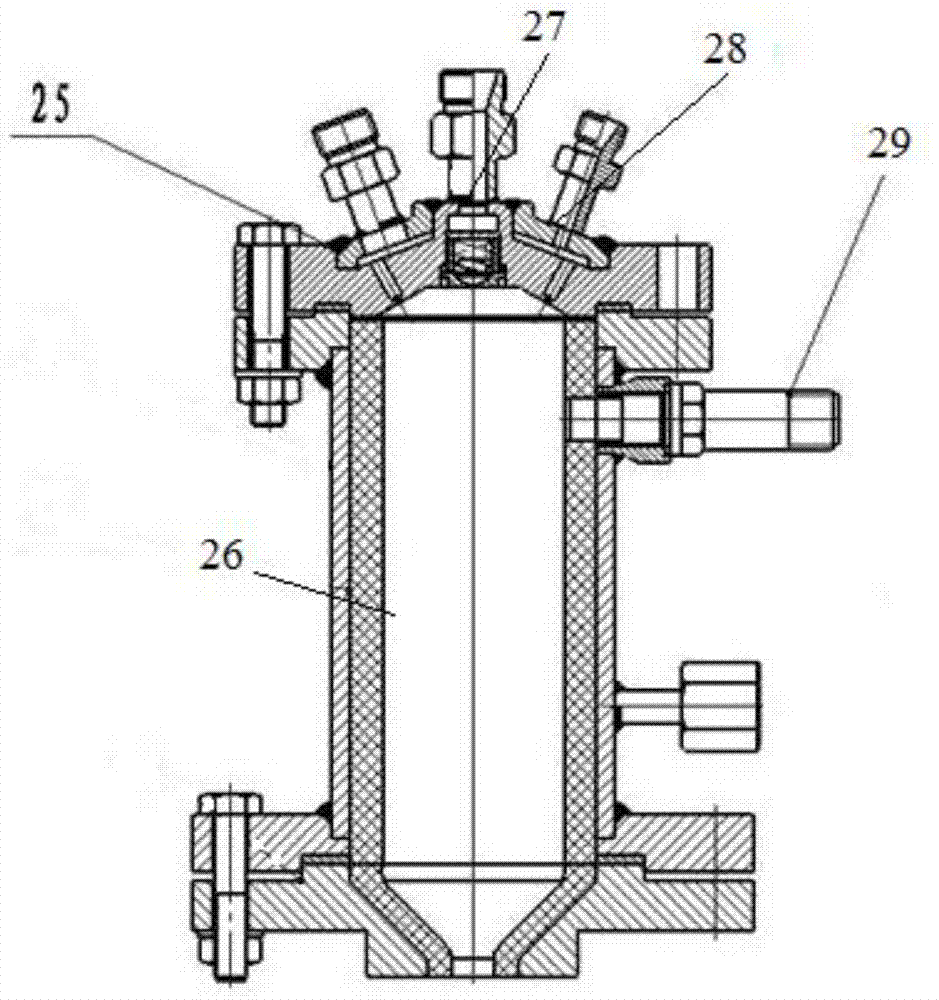

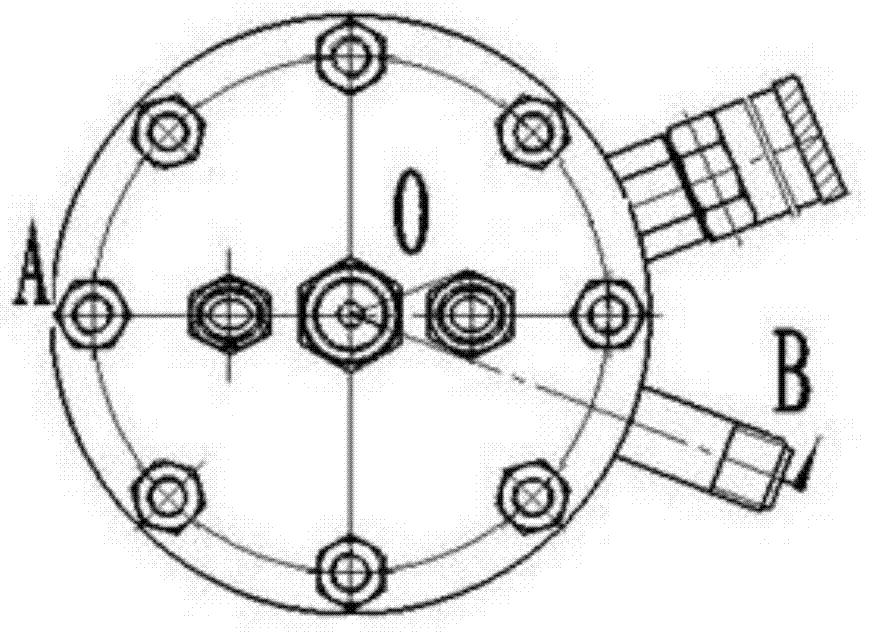

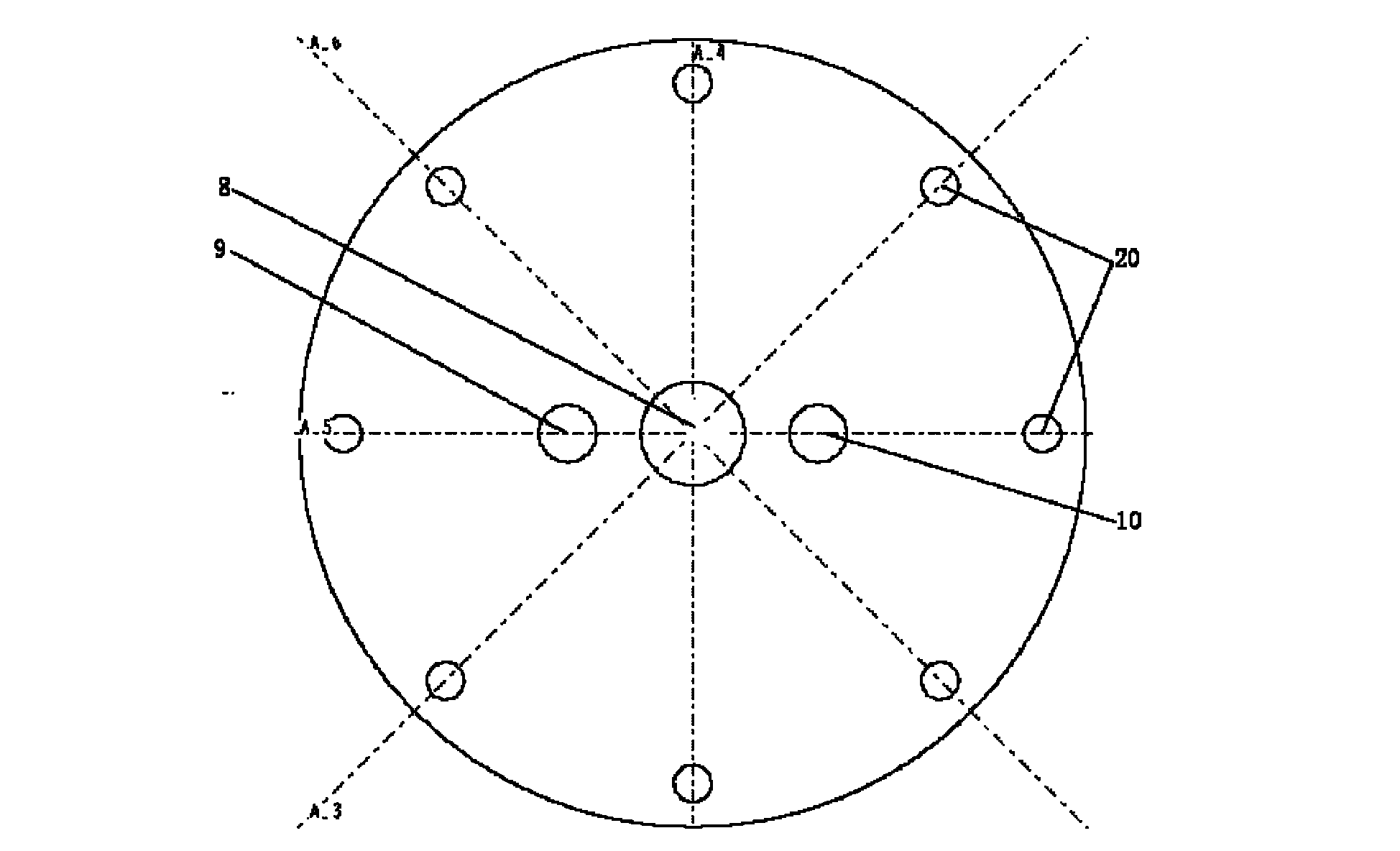

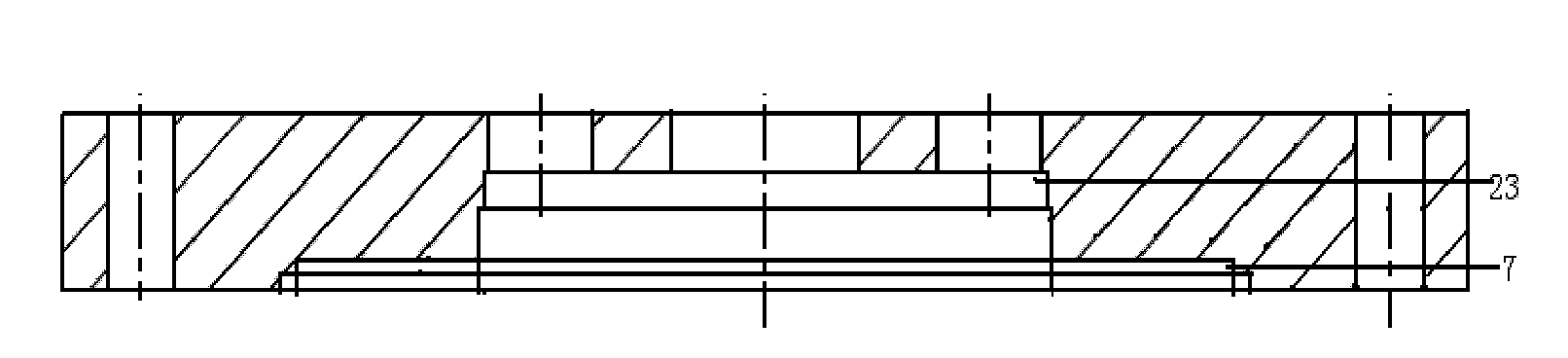

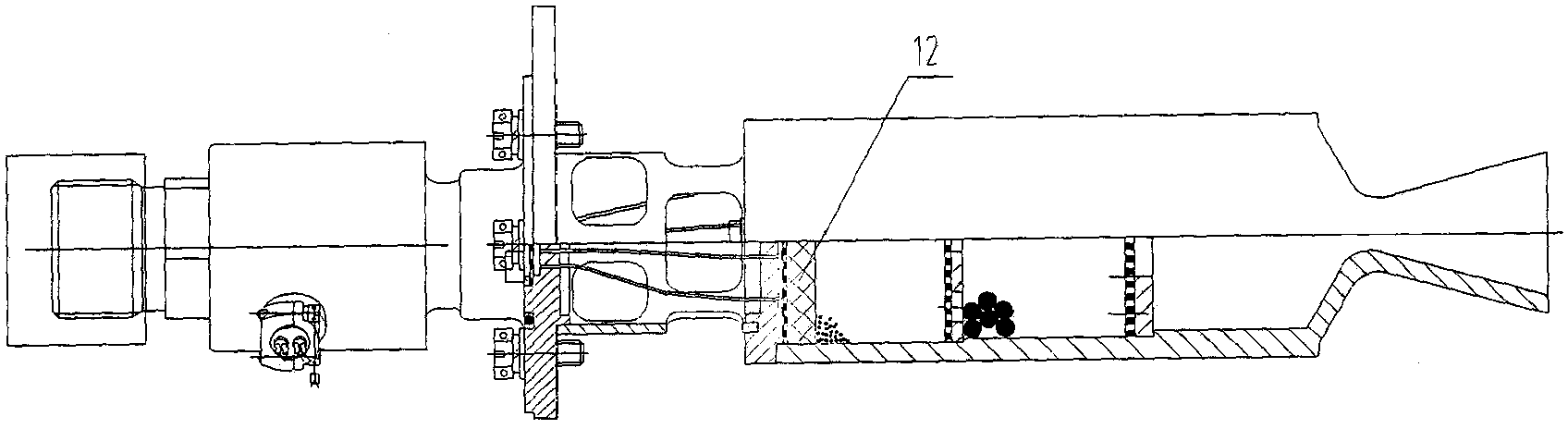

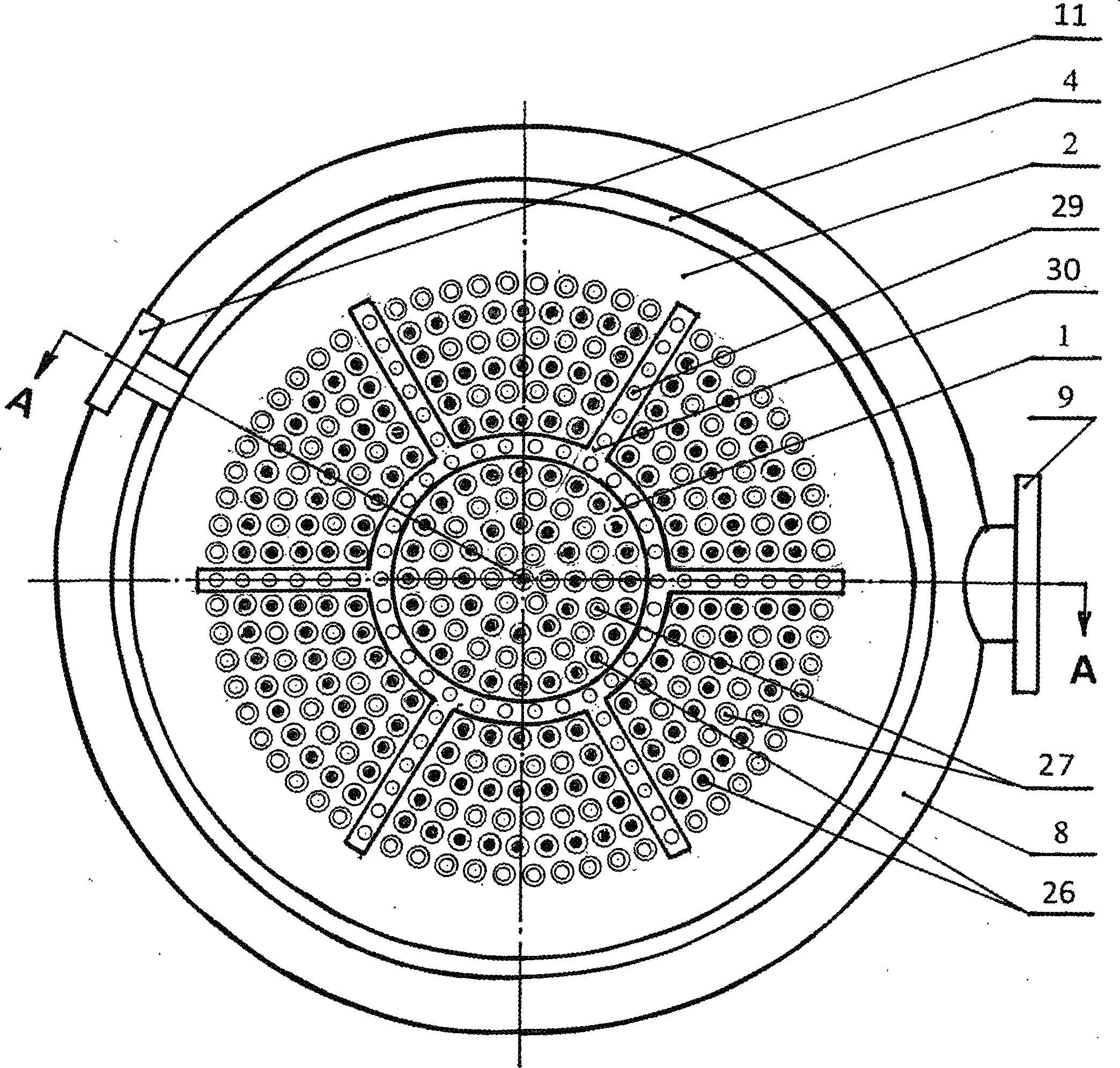

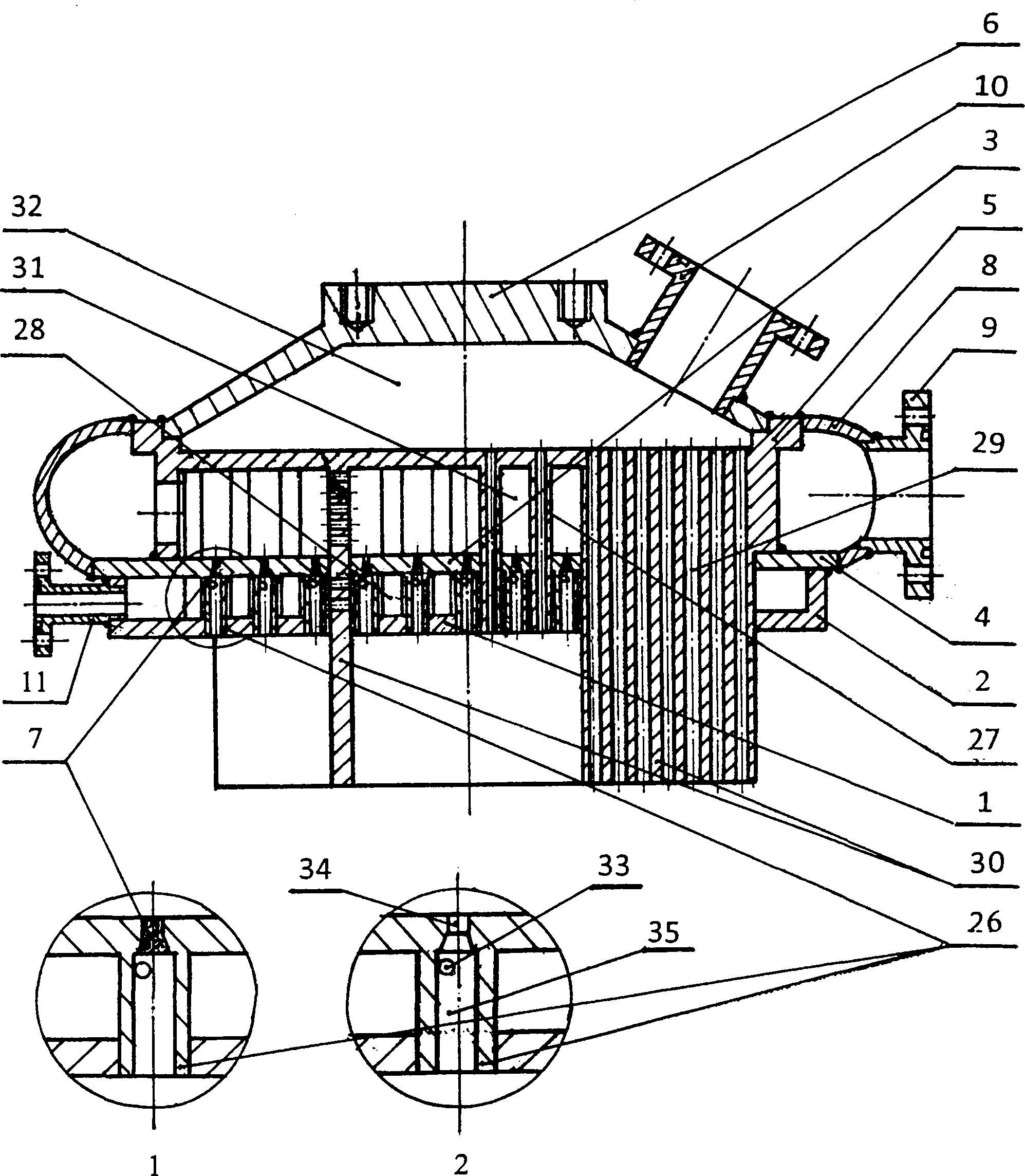

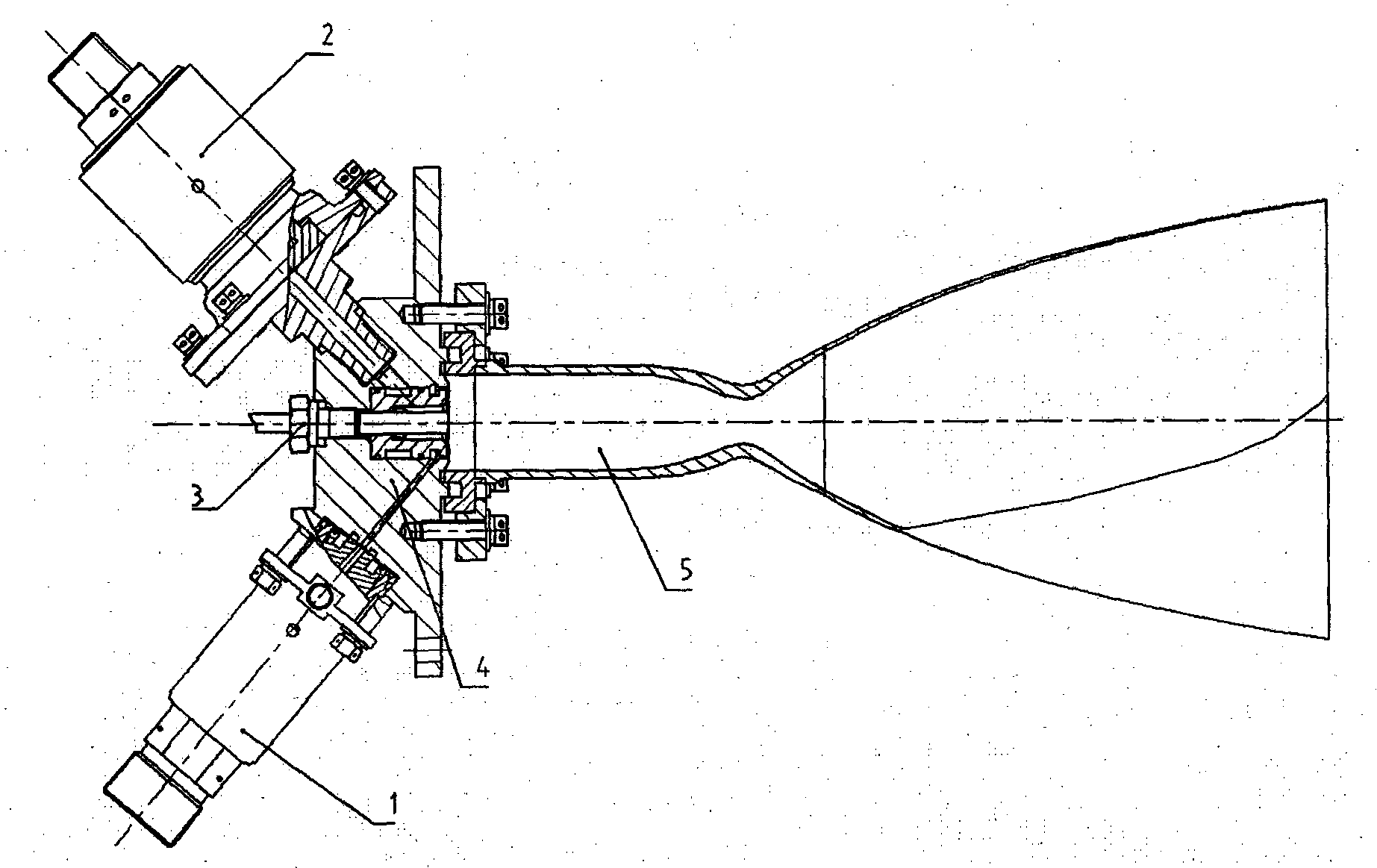

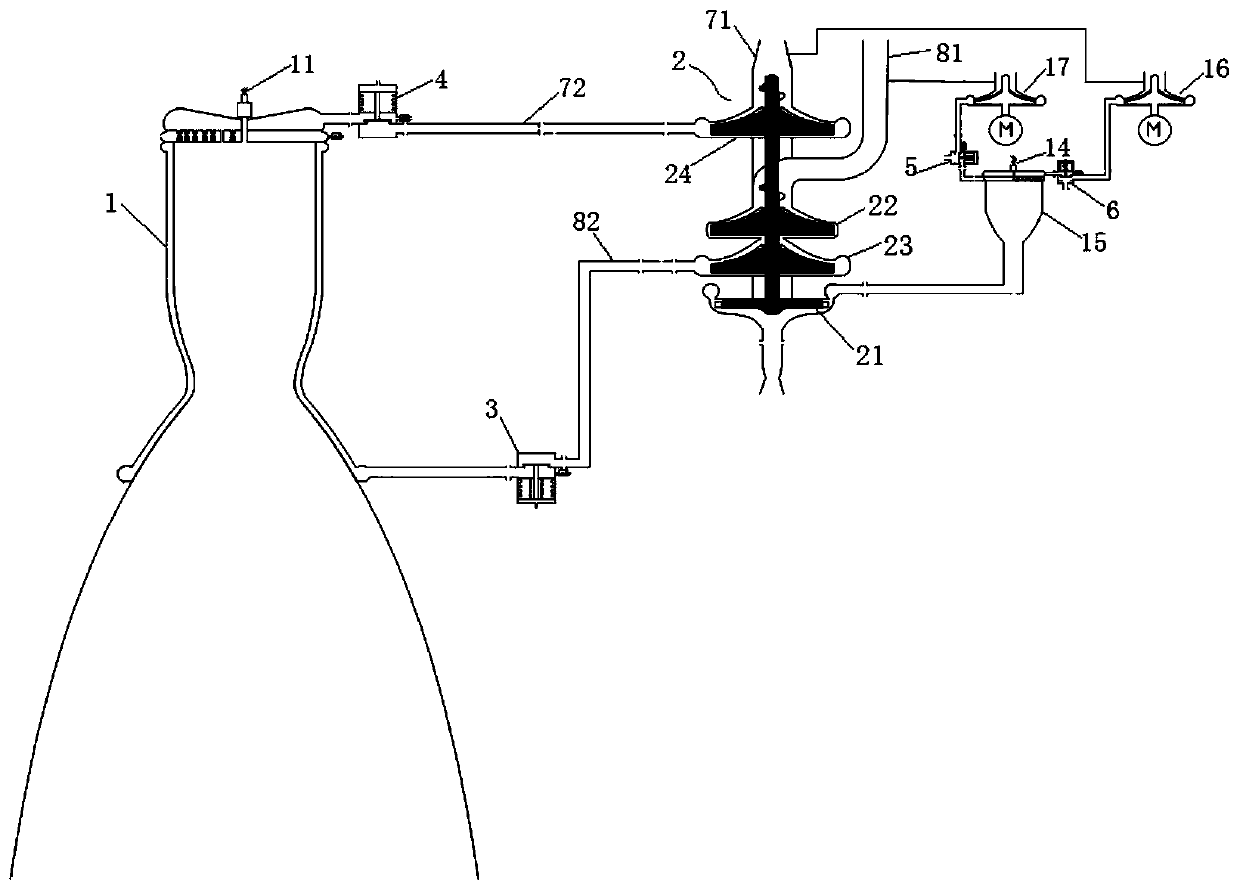

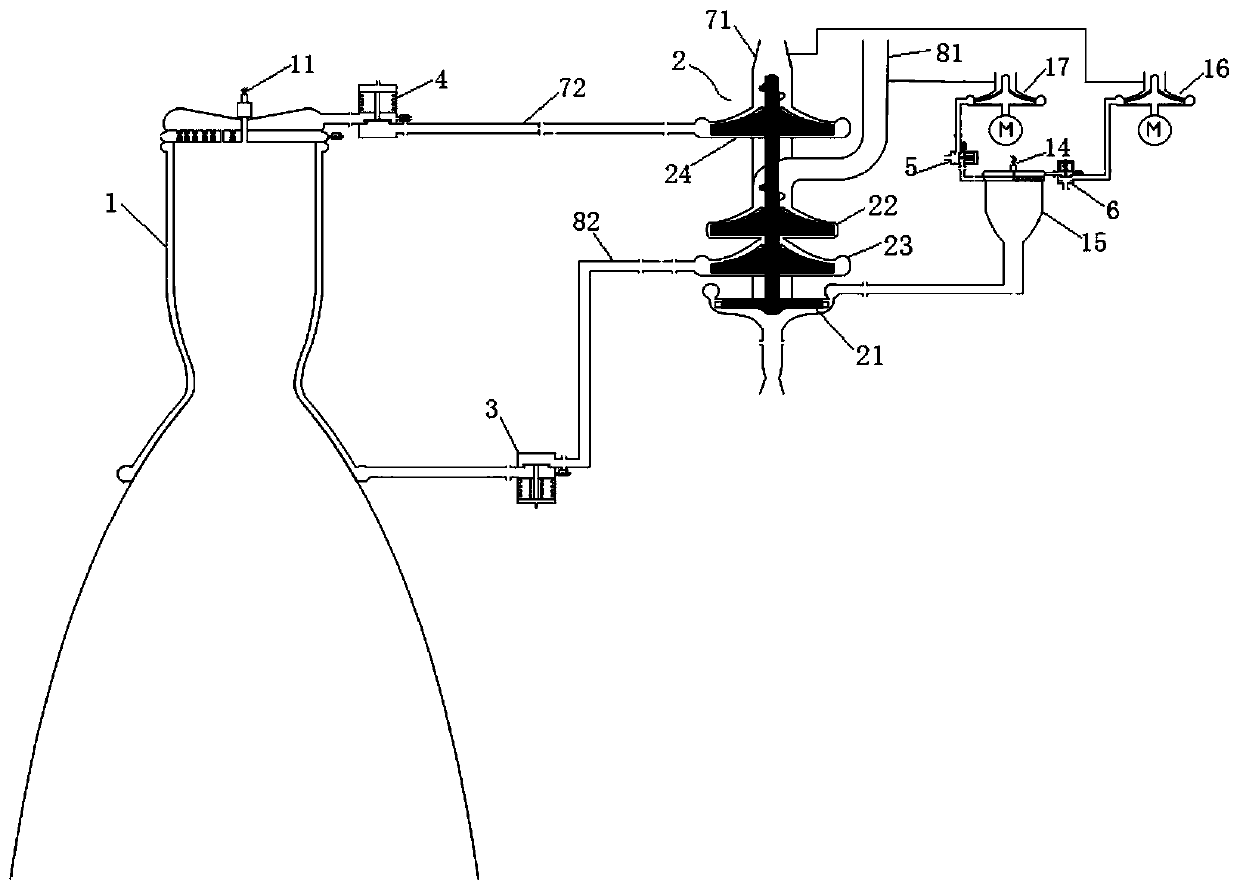

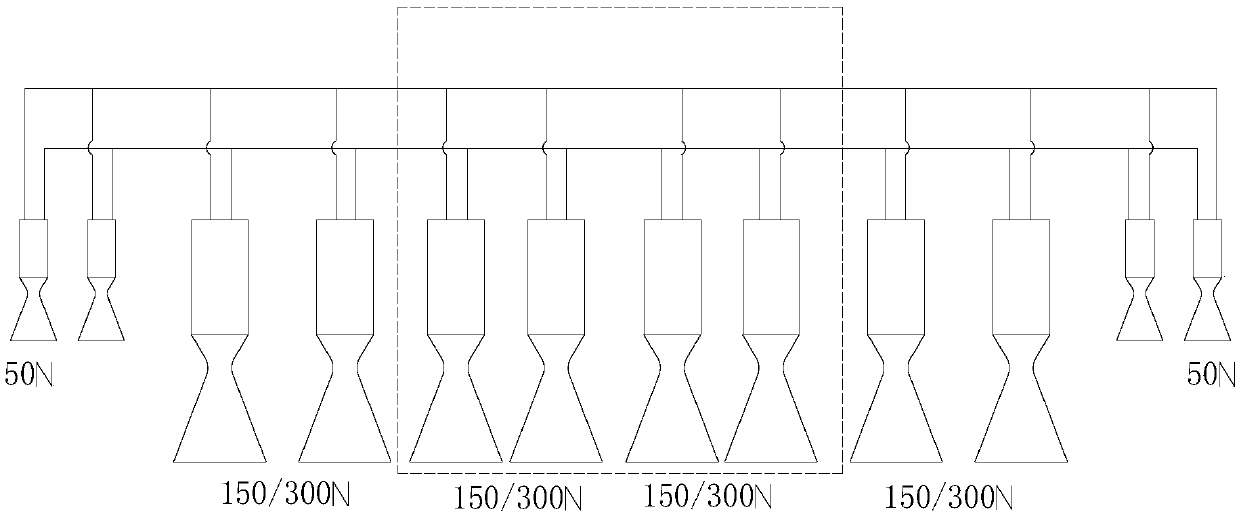

Slotted coaxial pintle type injector thrust chamber

ActiveCN104234870AOvercome the problem of poor response characteristics and low performanceQuick responseRocket engine plantsThrust chamberInjector

The invention relates to a slotted coaxial pintle type injector thrust chamber. The slotted coaxial pintle type injector thrust chamber comprises a center barrel and a shell, an inner sleeve and an outer sleeve are arranged between the center barrel and the shell, an outer passage and an annular nozzle are formed by the outer sleeve and the shell, a center passage and a radial nozzle are formed by the inner sleeve and the center barrel, the upper end of the outer sleeve is connected with the center barrel through a main spring and a washer, and the upper end of the inner sleeve is connected with the center barrel through an auxiliary spring and the washer. The slotted coaxial pintle type injector thrust chamber is high in efficiency and low in cost.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

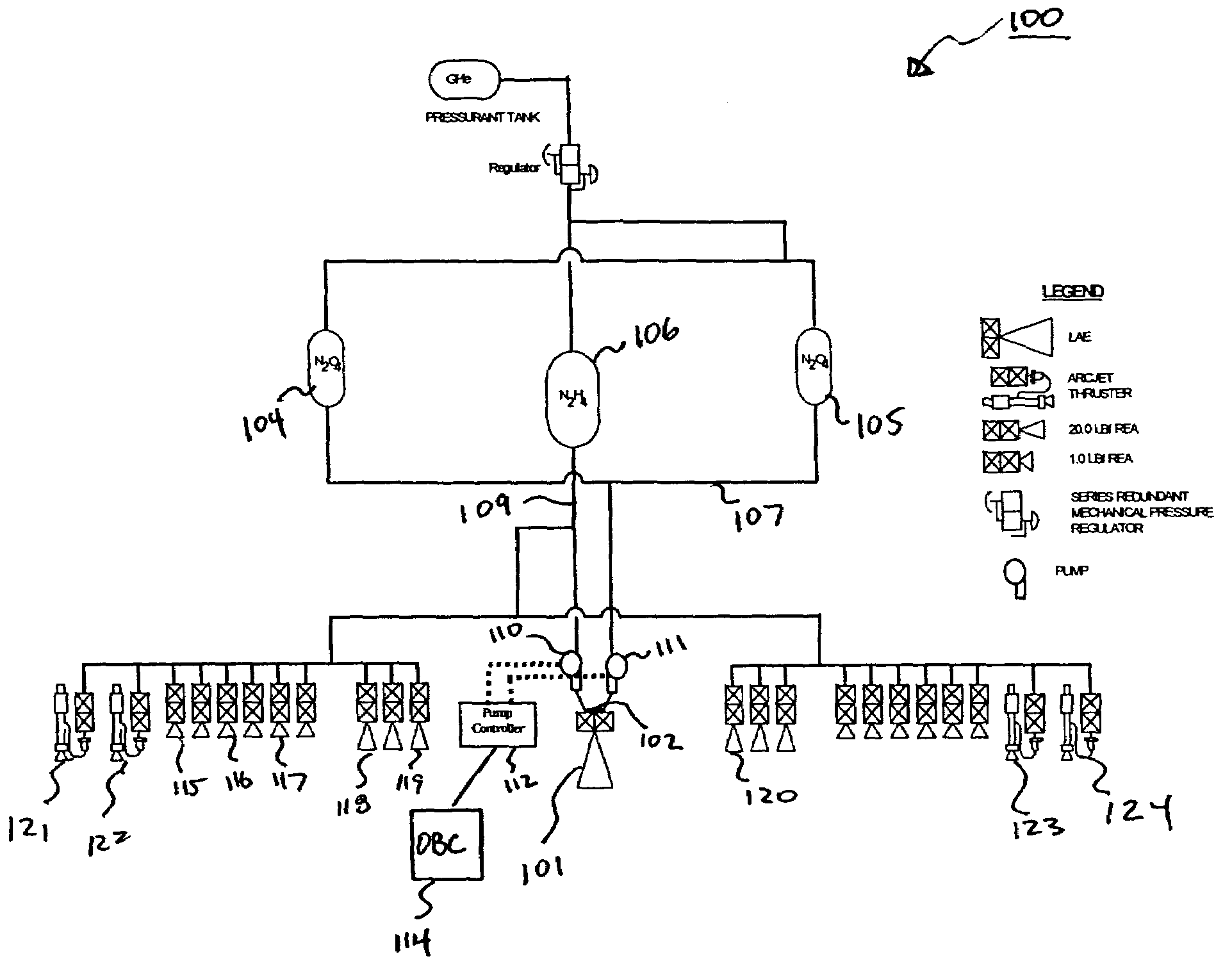

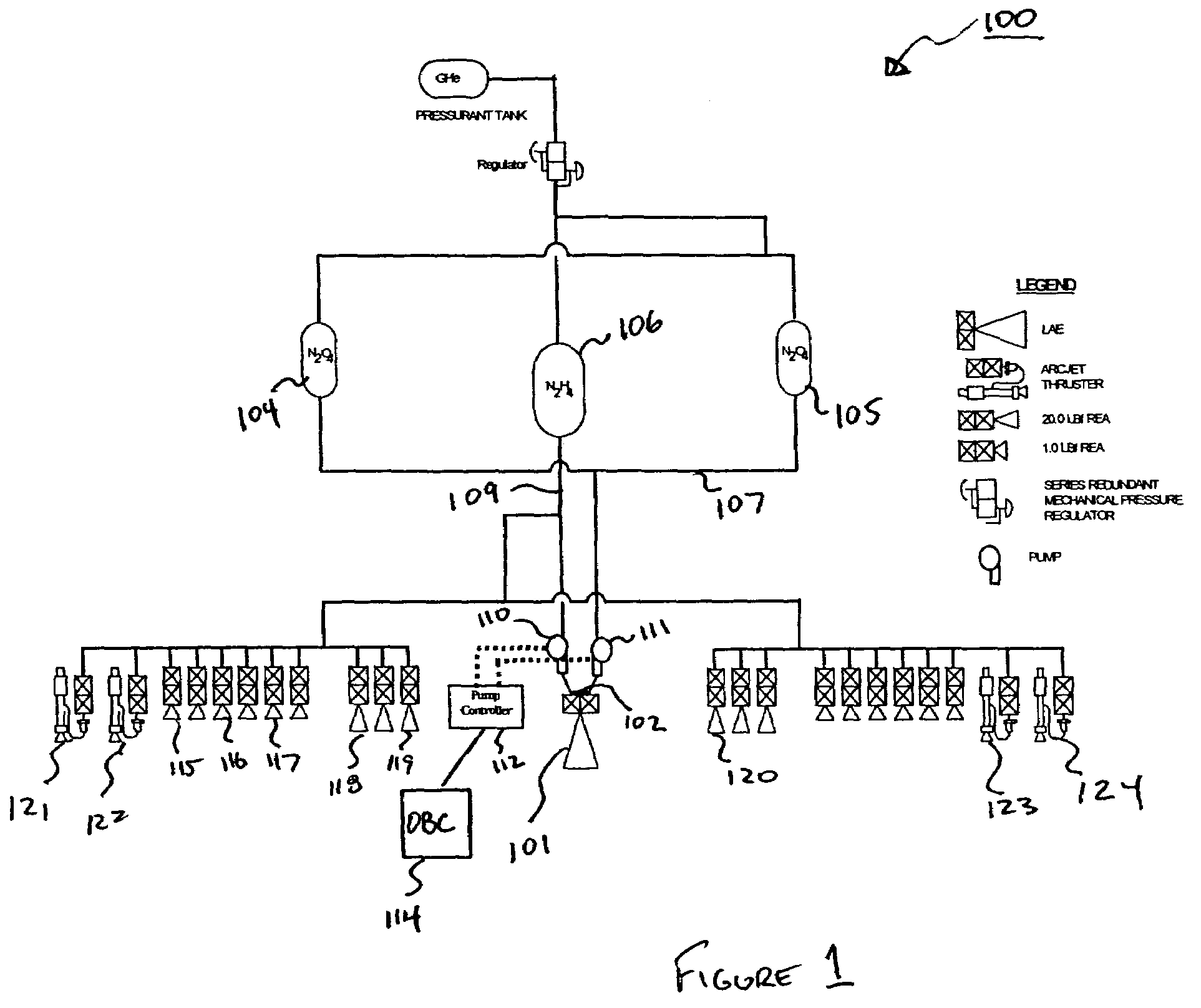

Enhanced high-efficiency spacecraft propulsion system

InactiveUS7762498B1Improving seal materialImproving geometry selectionLaunch systemsCosmonautic propulsion system apparatusSpacecraft propulsionOn board

A high-efficiency spacecraft propulsion system, including includes electric pumps inserted in the oxidizer and fuel lines that increase liquid apogee engine (“LAE”) operating pressure and reduce tank-operating pressure. An on-board computer generates pump drive signals, in response to measured oxidizer and fuel line pressures, that are input to the pump controller electronics. The controller electronics provides current drives to the pump motors. The system uses an LAE that can operate at higher thrust chamber pressures (e.g., 500 psia) than standard LAEs, where pump-fed rocket motors have integrated turbopumps that are fuel operated. The turbopump increases LAE complexity and cost, reduces fuel efficiency, and is not compatible with active thrust and mixture ratio control.

Owner:LOCKHEED MARTIN CORP

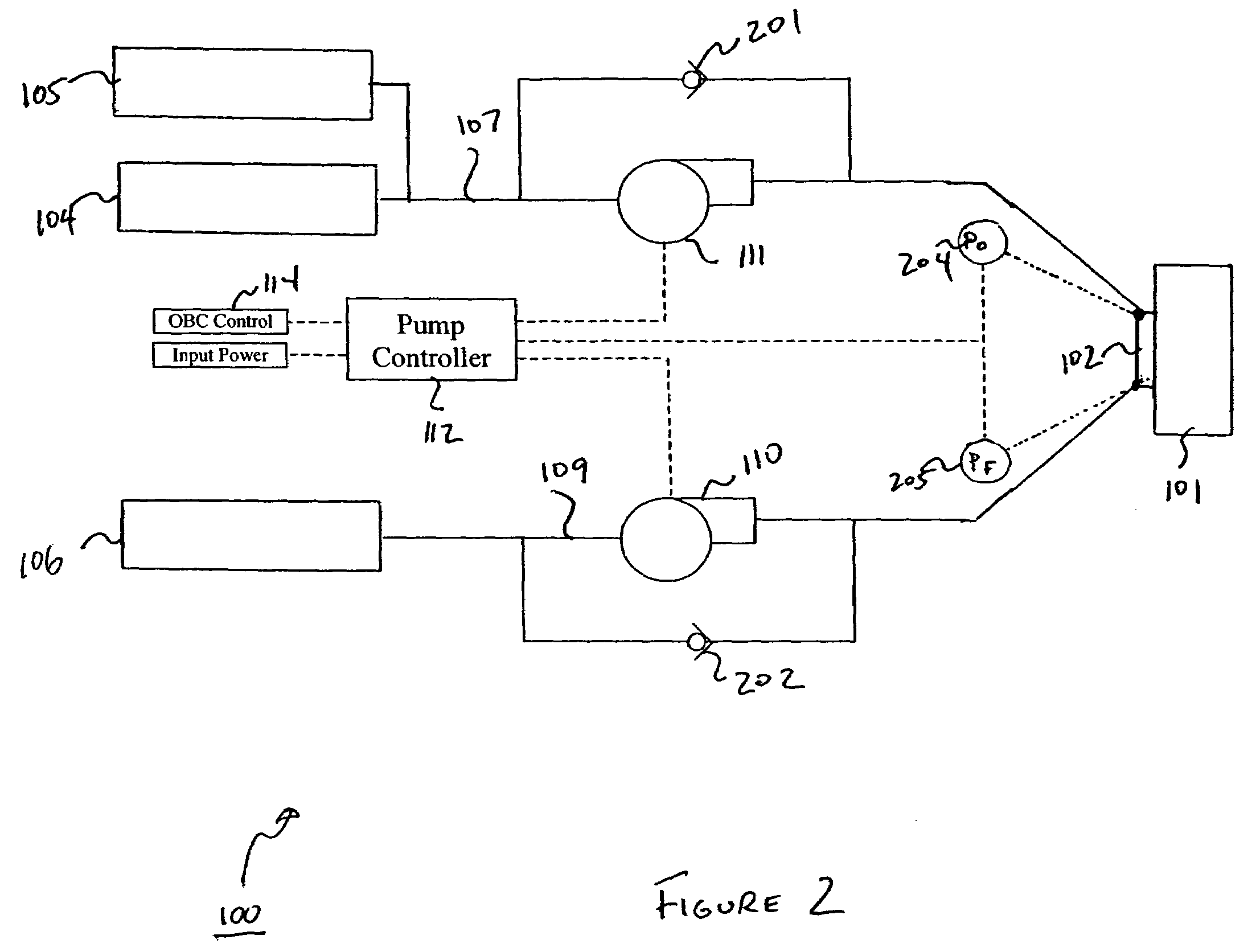

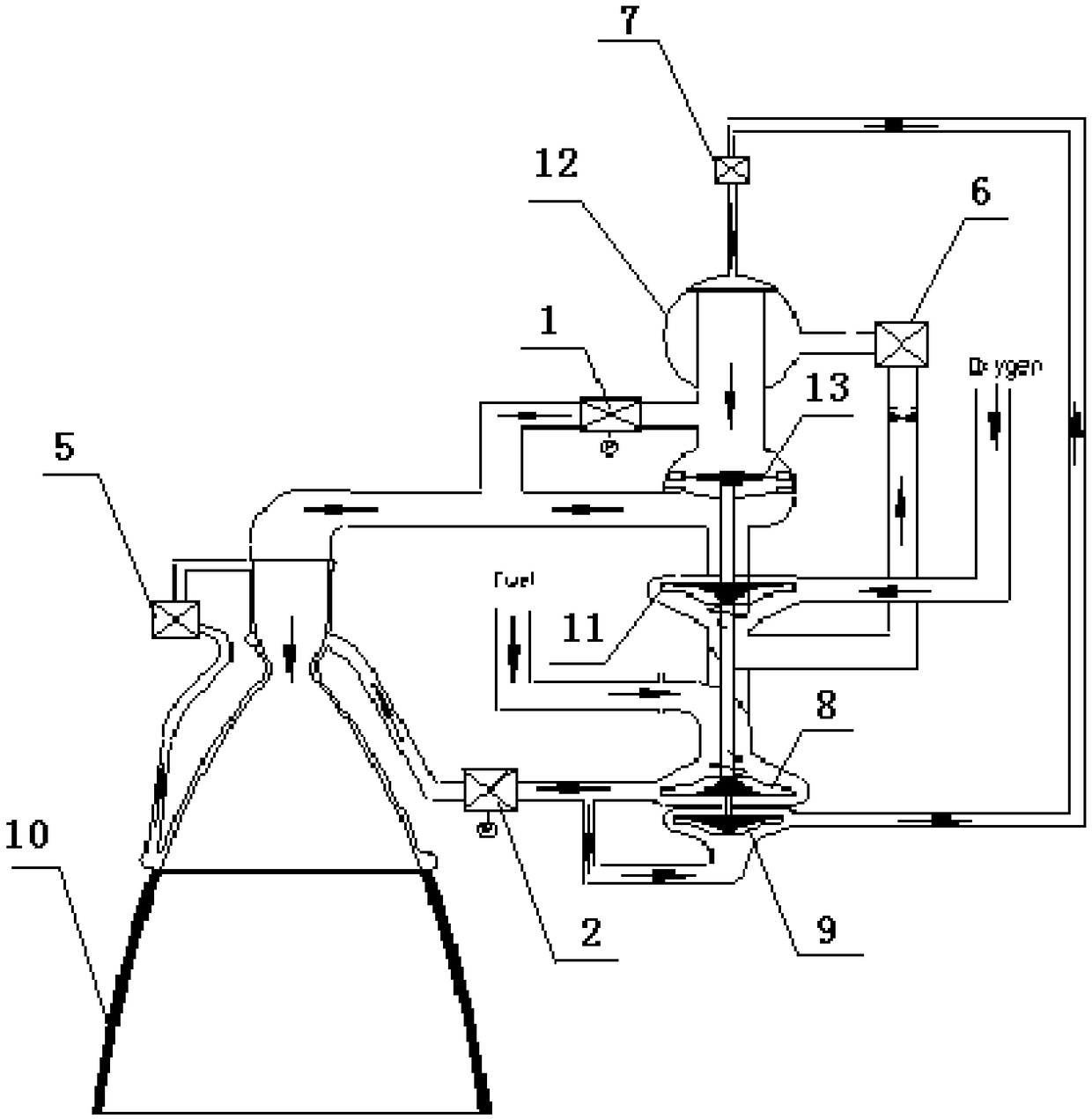

Oxygen-enriched fuel gas propelling achieved supplementary fired cyclic engine system and thrust deep adjusting method

ActiveCN108953003AImproved Thrust AdjustabilityEfficient injectionRocket engine plantsThrust chamberTurbine

The invention relates to a thrust deep adjusting method of an oxygen-enriched fuel gas propelling achieved supplementary fired cyclic engine. When a supplementary fired cyclic engine works, a fuel entering into a fuel gas generator through a fuel path of the fuel gas generator and an oxidant entering into the fuel gas generator through an oxidant supply path combust, generated oxygen-enriched fuelgas drives a main turbine to work to drive the main turbine to rotate and work, and the fuel gas enters a thrust chamber through a fuel gas supply path of the thrust chamber to generate a thrust; theengine stays in an oxygen-enriched fuel gas independent propelling state and keeps a low thrust working condition, a fuel main valve of the thrust chamber is opened when the engine needs to enter into a primary working condition to work, and the fuel enters the thrust chamber for supplementary firing, so that the engine is converted into a rated thrust to work. The thrust deep adjusting method ofthe supplementary fired cyclic engine provided by the invention is simple in system, has no special demands on combustion device and can achieve deep adjustment of the engine thrust.

Owner:XIAN AEROSPACE PROPULSION INST

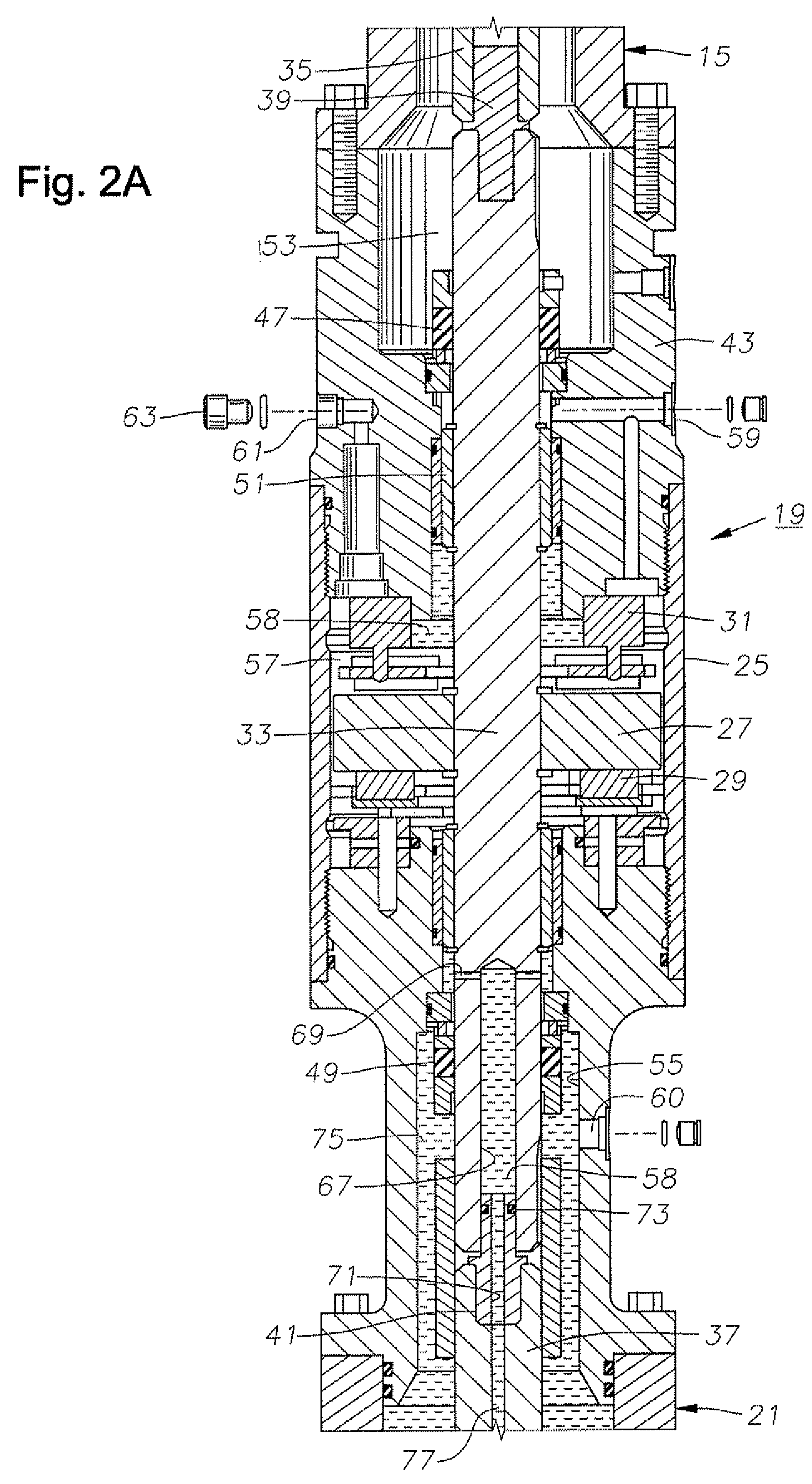

Motor seal

A method and apparatus for stabilizing a thrust chamber and circulating fluids within a motor seal is described herein. The apparatus includes a thrust chamber having a thrust runner and a radial bearing. A flow path exists through the radial bearing which stabilizes the thrust runner and circulates fluids in the thrust chamber. The flow path may consist of a plurality of grooves located adjacent to the radial bearing.

Owner:WEATHERFORDLAMB

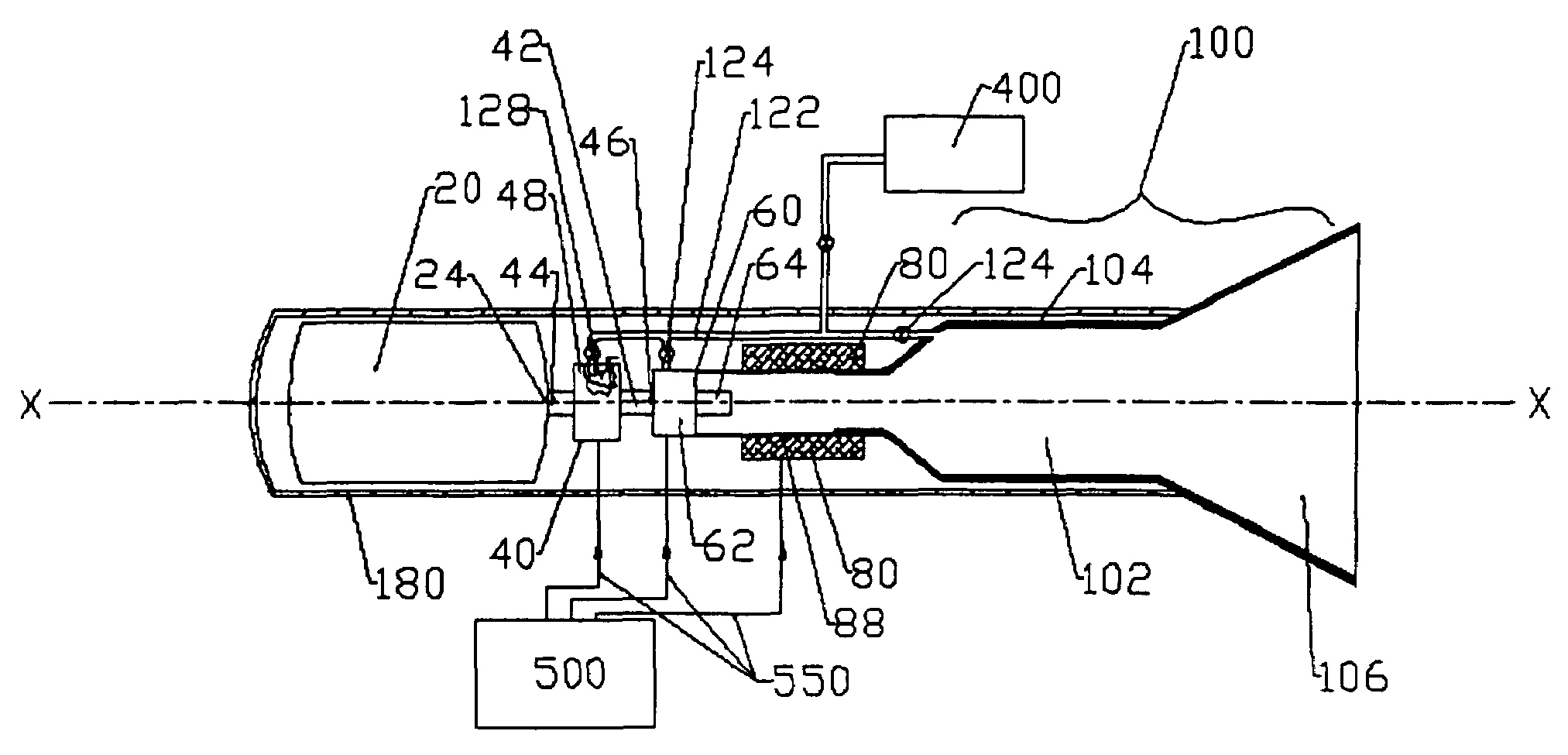

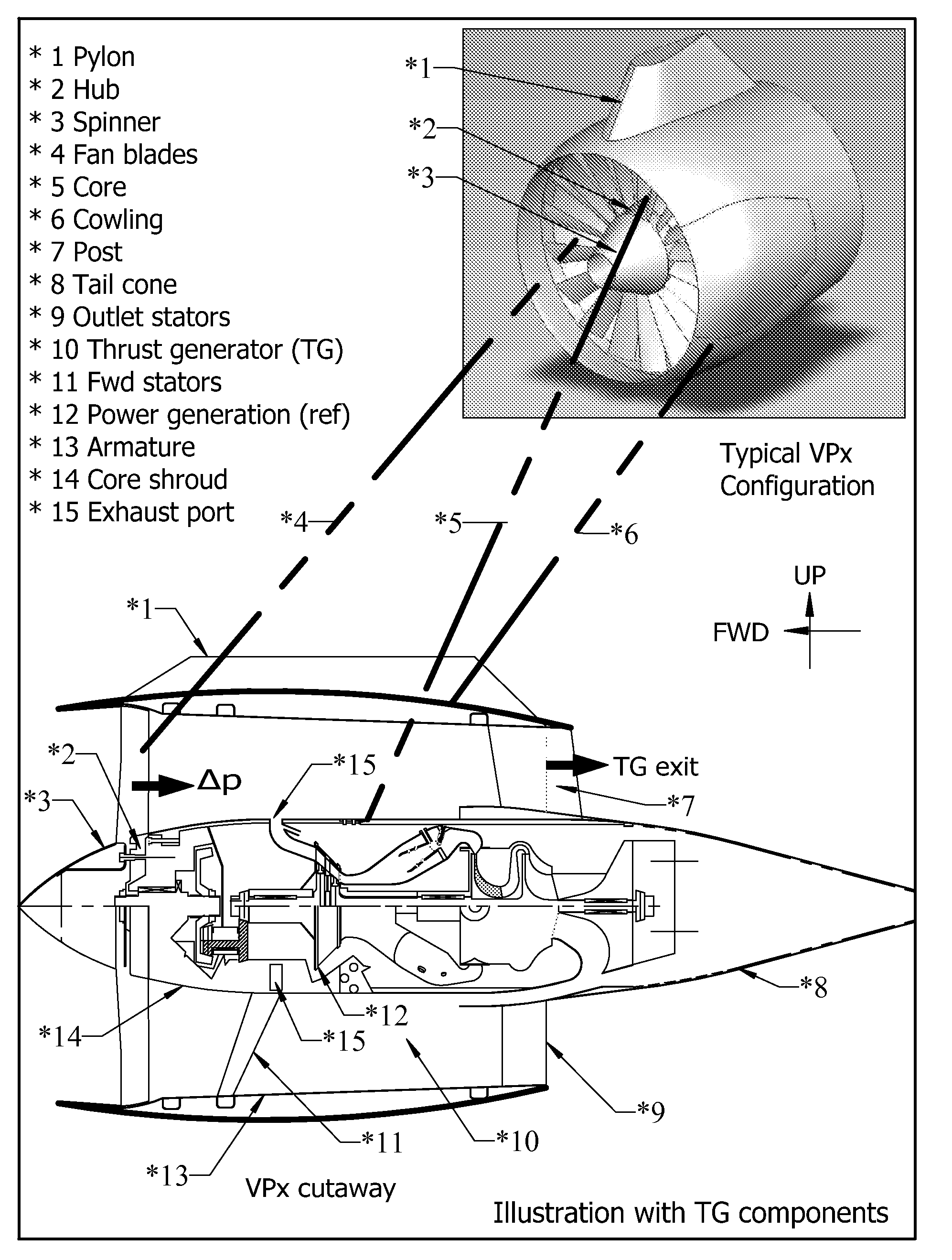

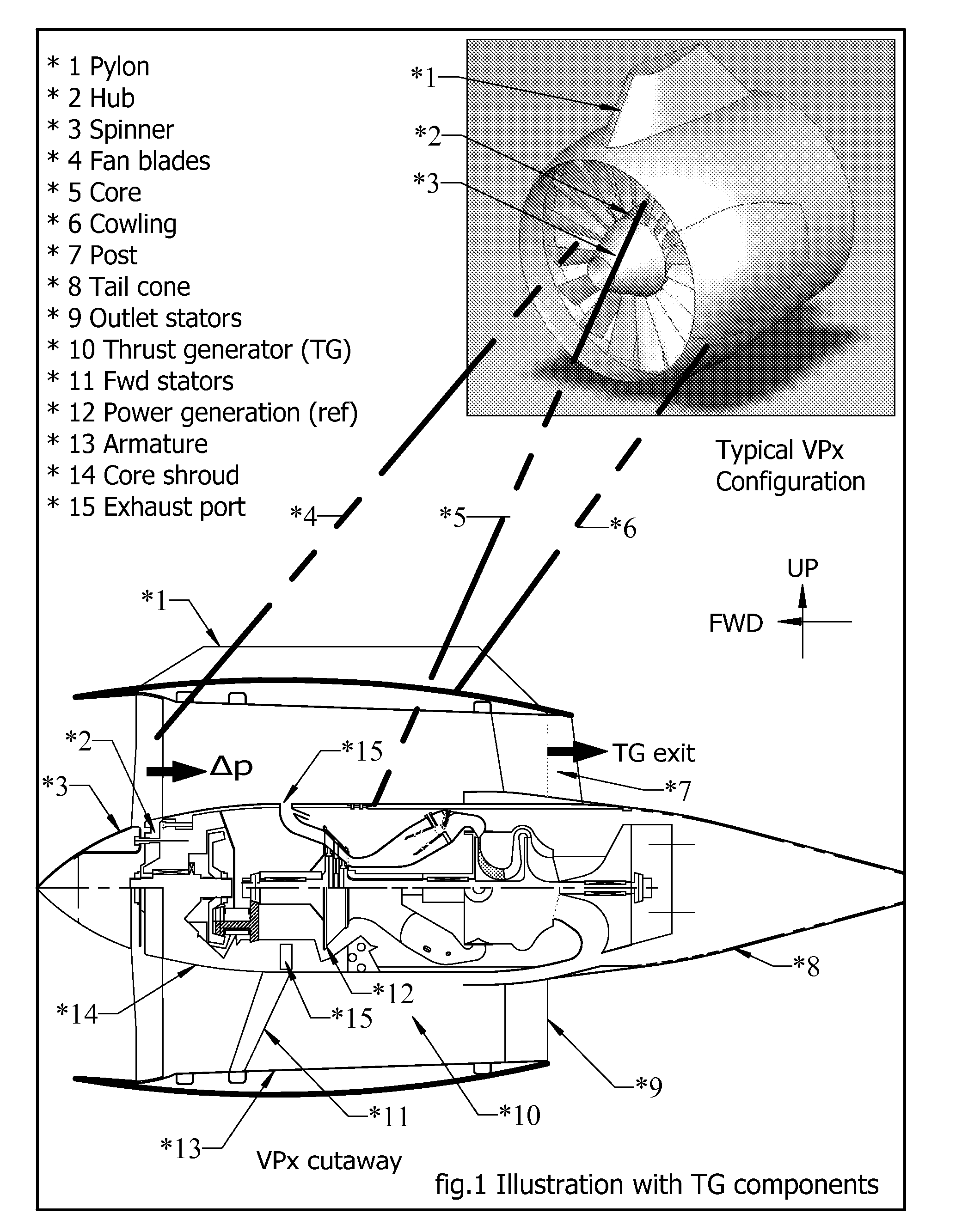

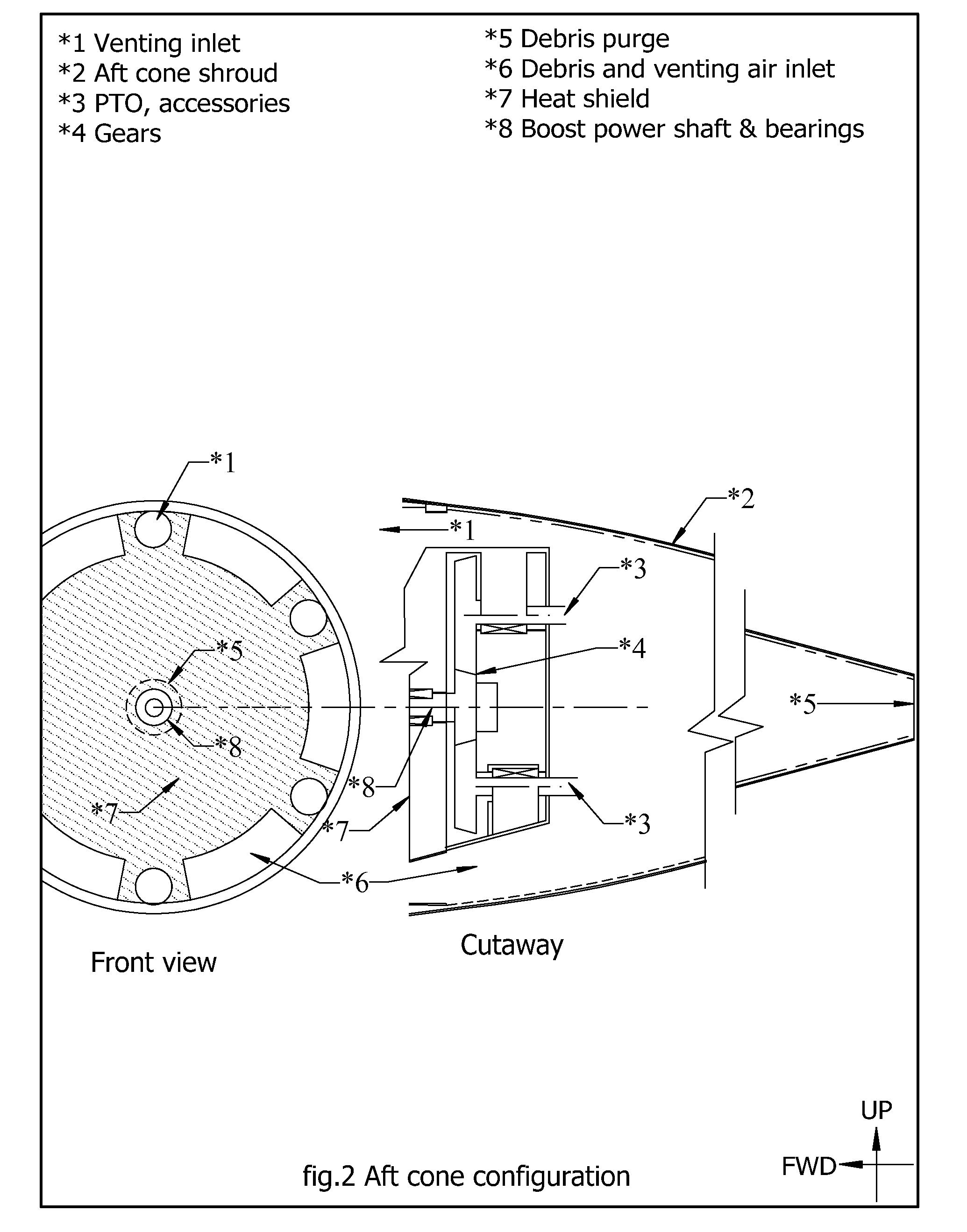

Heat regeneration for a turbofan, a Velarus Propulsion

InactiveUS20100180568A1Extend your lifeEasy to manufactureContinuous combustion chamberGas turbine plantsCombustion chamberFan blade

The invention adds details and alternate design supplementing the concept established with my patent application Ser. No. 12 / 013,431, Aircraft Propulsion System (APS). The APS ultimate fuel economy objectives requires long term design development, and this invention compromises some fuel economy for the expediency of short term implementation of a heat regeneration for turbofans via the re-arrangement of existing components and a few unique items readily designed. While this Velarus Propulsion (VPx) attains only 42% fuel economy, it retains the original APS fundamental architecture implementing heat regeneration for a turbofan engine, as well as the additional benefits of noise and emission abatement. This invention consists of the three APS technologies as follows:a) A novel arrangement of the power generation core features the turbine exhaust entering directly into the thrust chamber, thus providing heat regeneration with an appropriate configuration of the thrust chamber.b) The design of a modified combustor introduces the concept of a supersonic nozzle driving the turbines which allows for greater combustor's chamber temperature while injecting the gases at temperatures acceptable to current turbine blade metallurgy. This feature increases the engine thermal efficiency.c) The hub design allows for two options, a simpler fixed fanblade design or an advanced controllable pitch fan blade, increasing the mission and performance flexibility of a given turbofan size.In addition, this invention adds functionality to the aft cone, such as debris purge, accessories installation, and thrust reversers free from hot gases.

Owner:SACHS HUMBERTO W

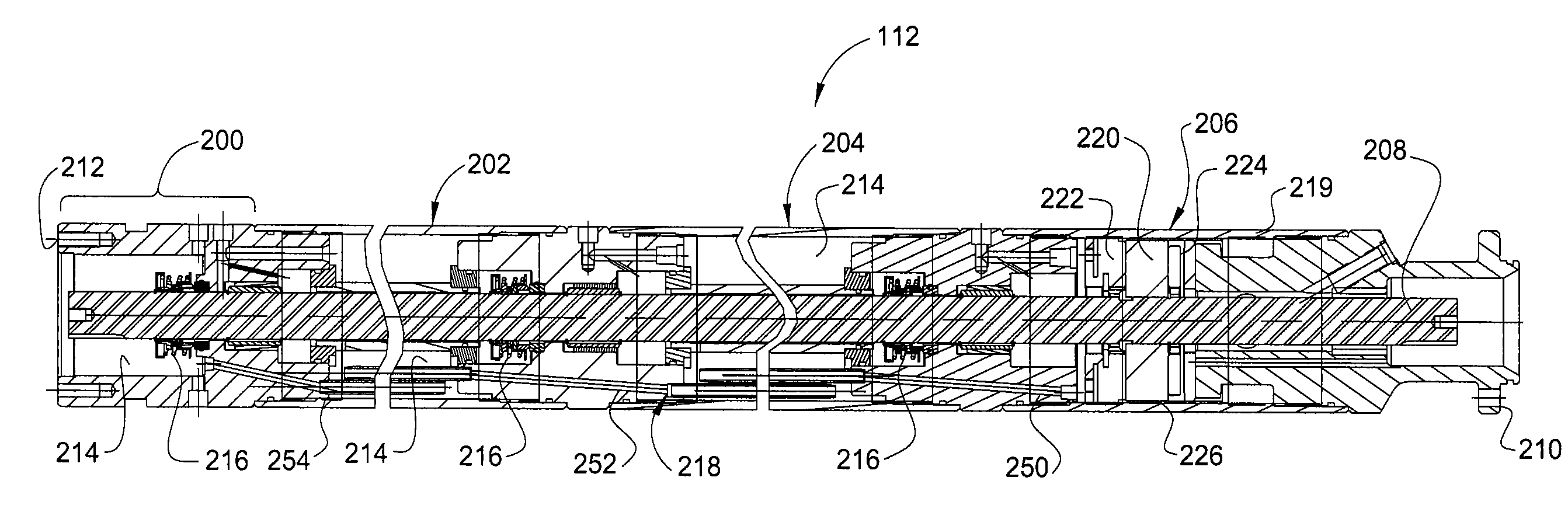

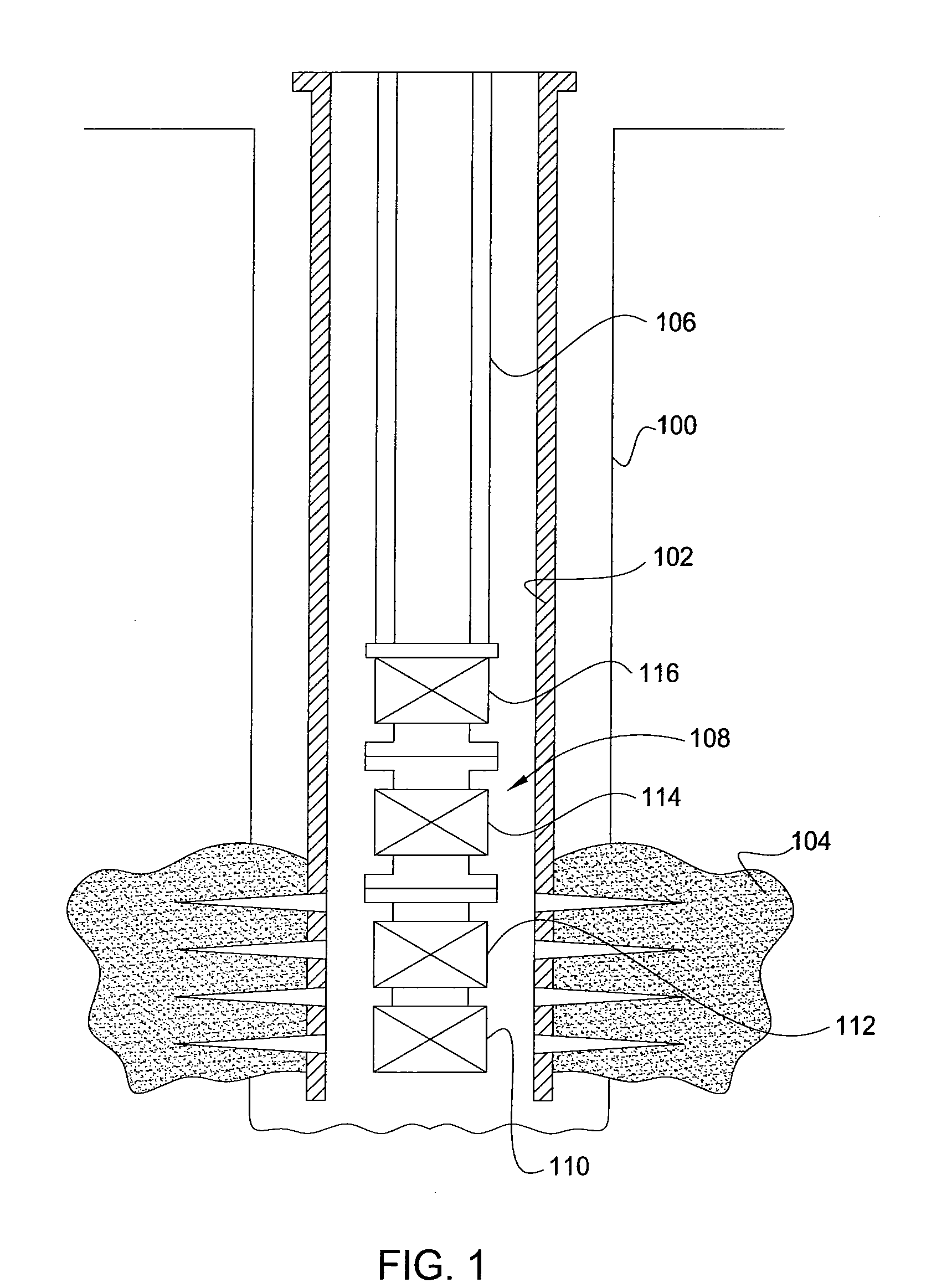

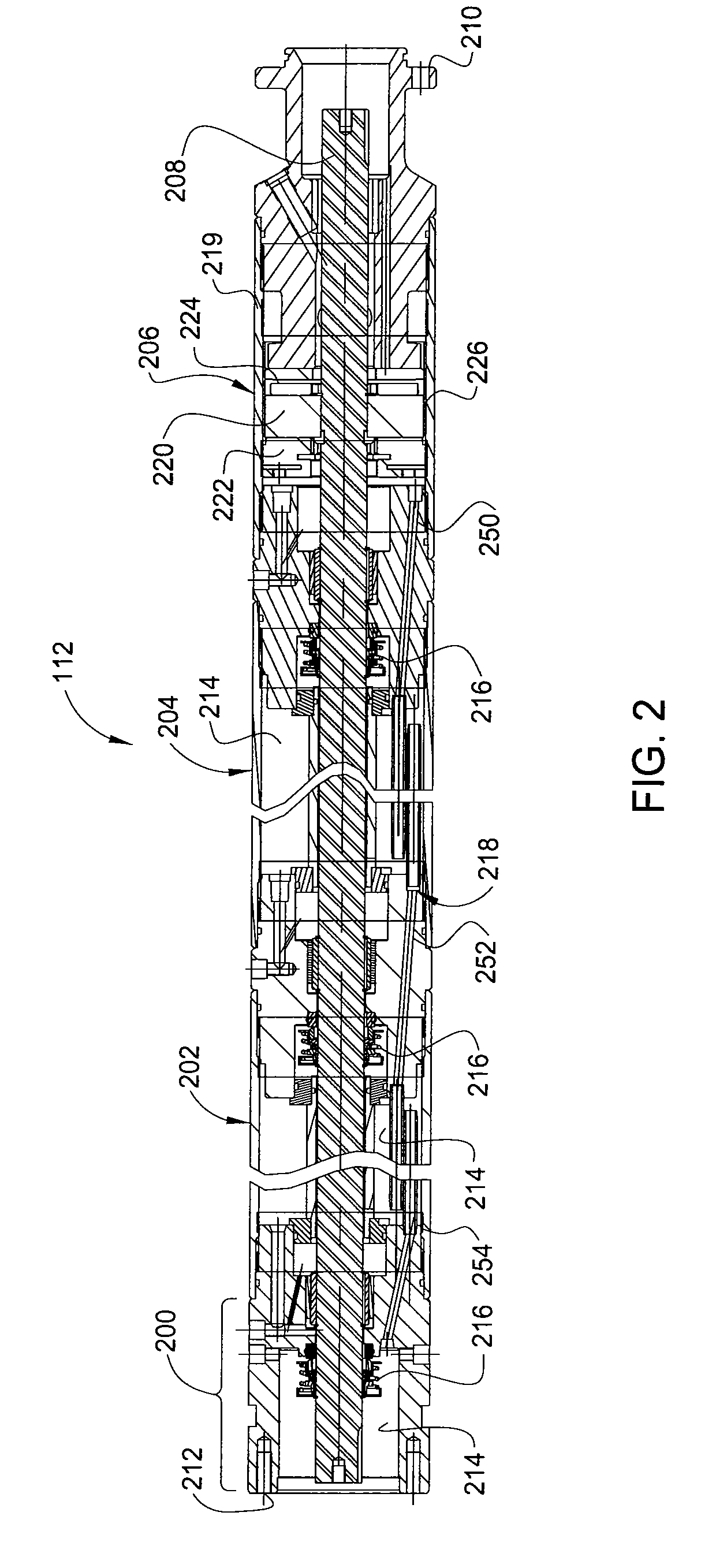

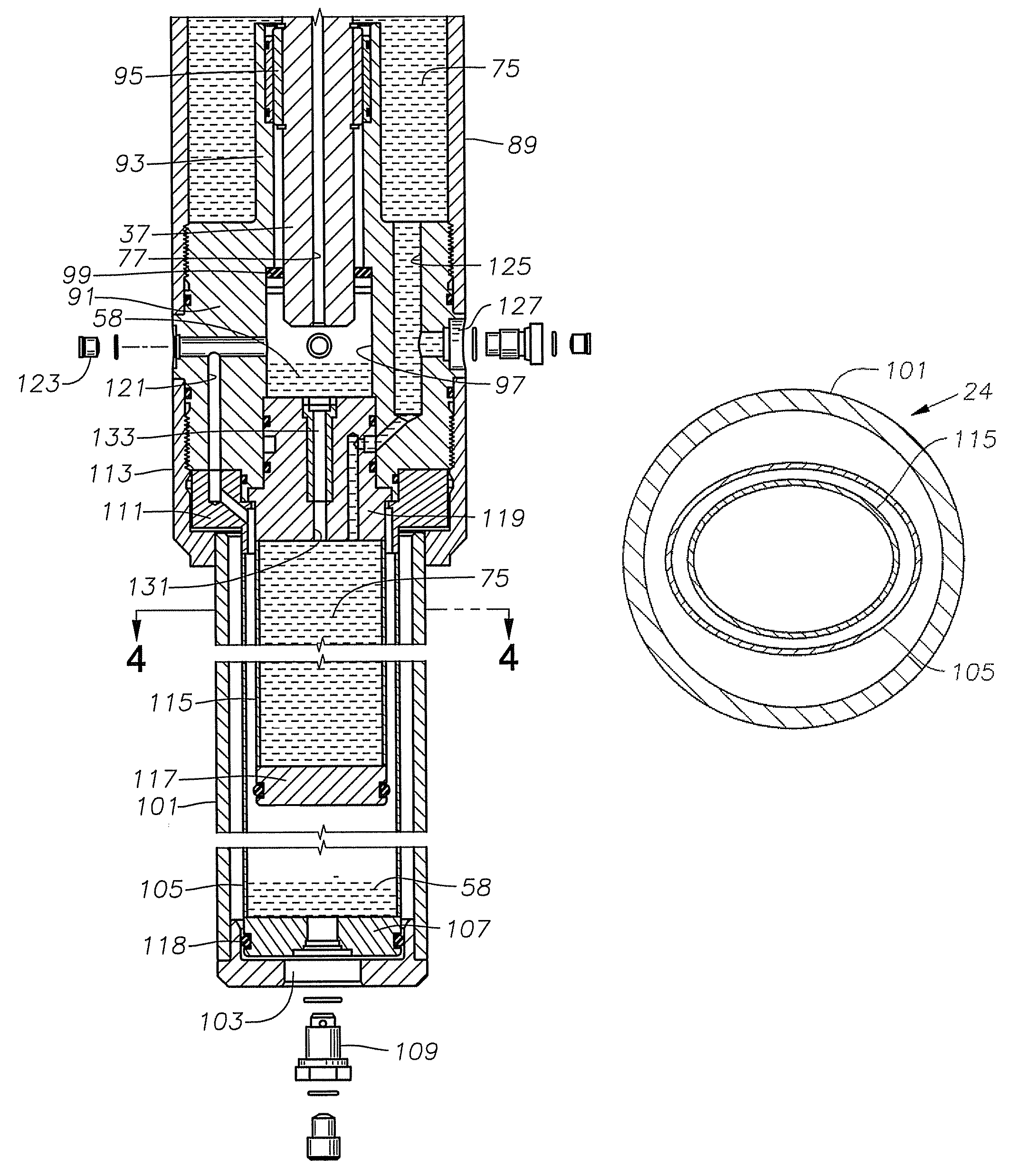

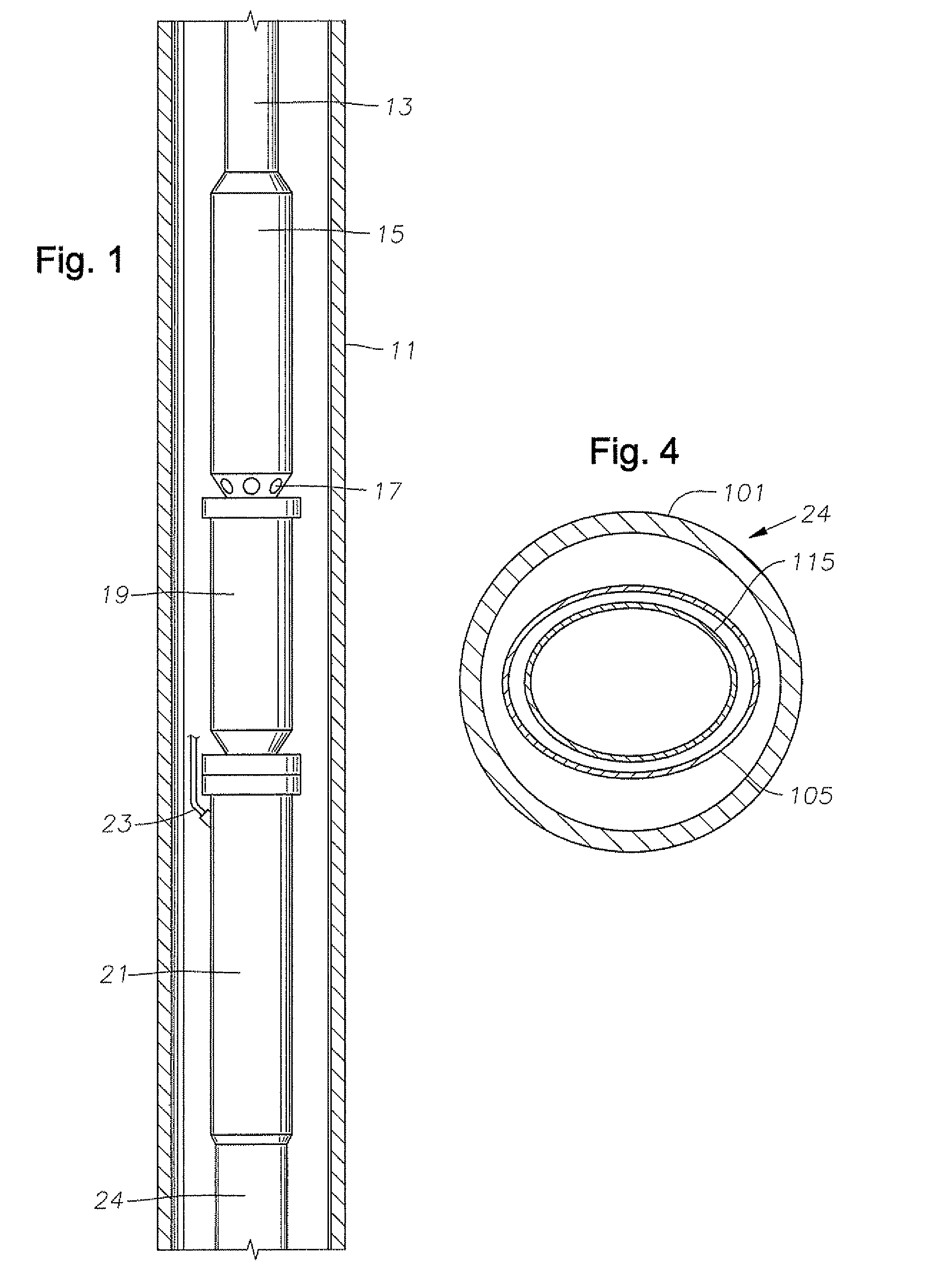

Pressure equalizer in thrust chamber electrical submersible pump assembly having dual pressure barriers

A well pump assembly has a rotary pump with an electrical motor that contains a motor lubricant. A thrust chamber is mounted between the motor and the pump, the thrust chamber containing a thrust chamber lubricant. Seals prevent the entry of thrust chamber lubricant into the motor chamber. A pressure equalizing chamber is mounted to the motor for admitting well fluid. A first pressure barrier in the equalizing chamber equalizes the pressure of the thrust chamber lubricant with that of the well fluid. A second pressure barrier contained within the first pressure barrier equalizes the pressure of the motor lubricant with thrust chamber lubricant.

Owner:BAKER HUGHES HLDG LLC

Catalytic decomposition low-concentration hydrogen peroxide reactor, combustion chamber and application thereof

InactiveCN102658066ALow priceImprove securityRocket engine plantsChemical/physical processesCombustion chamberKerosene

The invention relates to a catalytic decomposition low-concentration hydrogen peroxide reactor and a combustion chamber, which solve the problem that in the prior art, price is expensive, safety is not high, freezing point is high, decomposition temperature and ignition temperature are high, purpose is single and the like. A multilayer low-bed-load and pre-contact fine silver net catalysis bed for catalytic decomposition of 40%-70% of hydrogen peroxide is adopted, and service life is greatly prolonged. Radial holes or / and axial holes are arranged on a laryngeal casing of the catalytic decomposition low-concentration hydrogen peroxide reactor for using in underground reactor oil recovery by heating, mining and marine accident self rescuing and a life support system of spaceships and rocket oxidizer storage tank supercharging. The catalytic decomposition low-concentration hydrogen peroxide combustion chamber is provided with a plurality of radial spraying holes for spraying diesel oil or kerosene, an electronic spark plug for ignition, a combustion chamber body with the 40%-70% of hydrogen peroxide serving as a regeneration cooling agent and two kinds of spraying tubes, and the catalytic decomposition low-concentration hydrogen peroxide combustion chamber can be used for thrust chamber gas spraying thrust of a plurality of military projects and road ice and snow removal by heat and crude oil pollution.

Owner:葛明龙

Propulsion from combustion of solid propellant pellet-projectiles

InactiveUS7506500B1High volume loadAbility to throttleGas turbine plantsRocket engine plantsRamjetCombustion chamber

Propulsion from combustion of solid propellant pellet-projectiles for providing a useful propulsion that has the advantages of both solid and liquid propulsion engines, and also can make use of either solid chemical propellants or fissionable nuclear material as the fuel. Preferred methods and systems can include a storage chamber for storing solid propellant pellets, a feeding system having a pellet feeding channel and a pellet feeding mechanism connected to the storage chamber and to a gun assembly, which is positioned along a longitudinal axis to eject the pellets at a certain velocity. A triggering system positioned between gun assembly and thrust chamber can initiate the propellant pellet-projectile, and a thrust chamber having a combustion chamber for combustion of propellant pellet-projectile with an exhaust nozzle. Additionally, an auxiliary power system can be used to power the components and various electrical and electronic systems that may be present in the invention for controlling the engine components. The gun assembly may include an ejector mechanism for ejecting the propellant pellets through at least one barrel. The triggering system can produce a medium creating an ambience for the initiation of propellant pellet-projectiles. Methods and systems can be used for space and rocket crafts, turbojets and ramjets.

Owner:KRISHNAN VINU B

Free piston engine and self-actuated fuel injector therefor

InactiveUS20020092485A1Fuel injection apparatusFree piston enginesFree-piston engineCombustion chamber

Owner:ALEXIUS RICHARD C +1

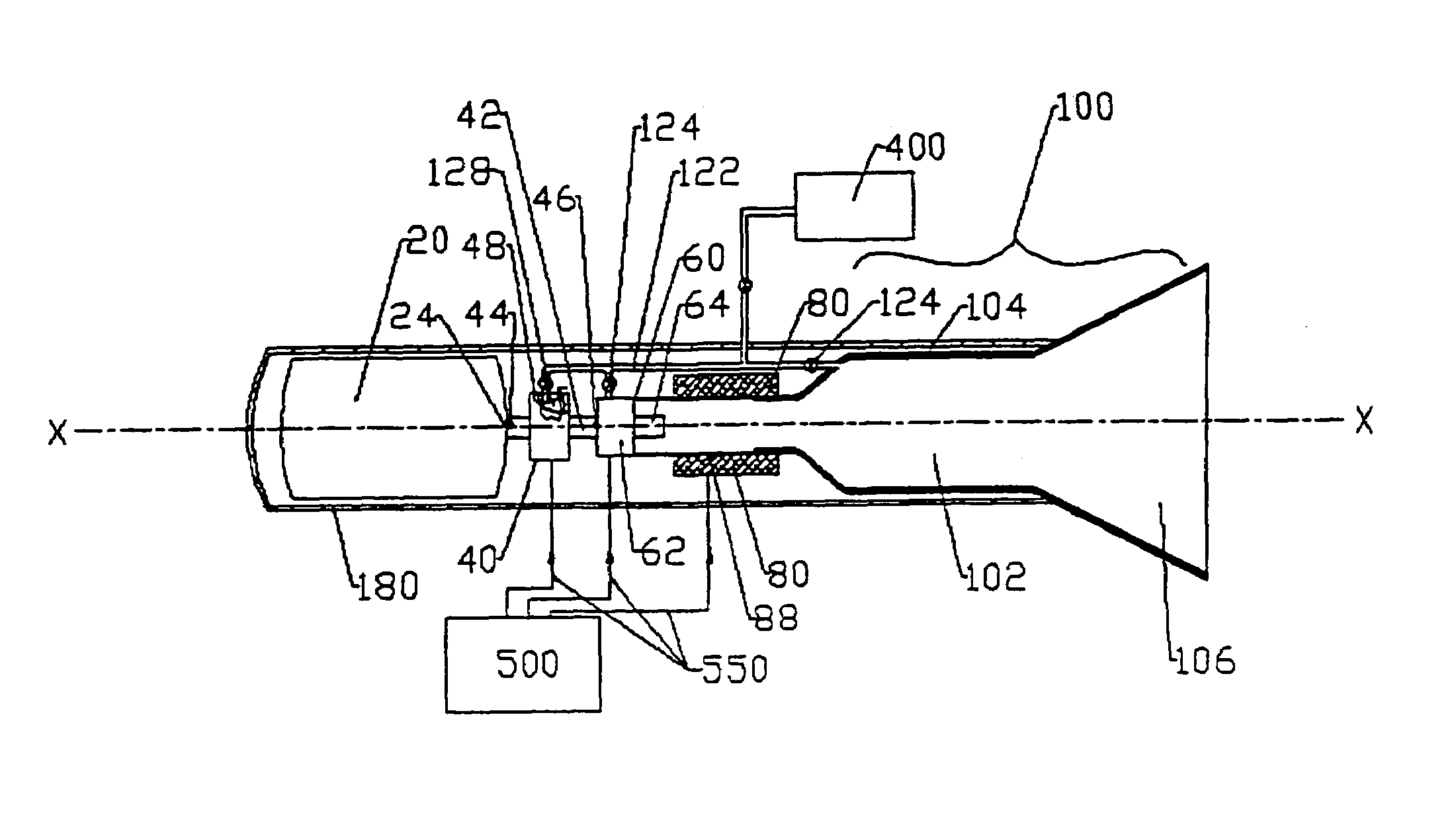

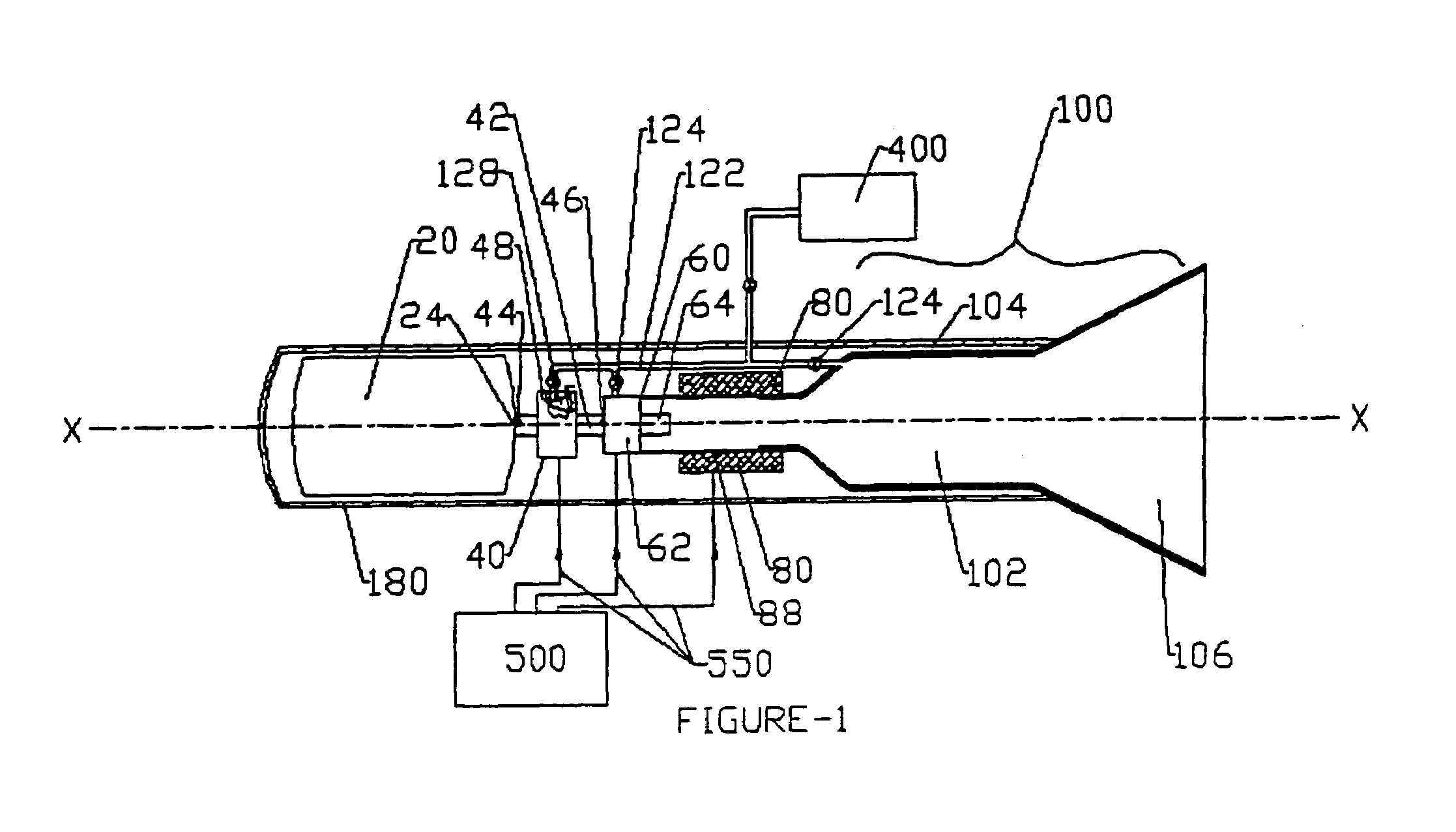

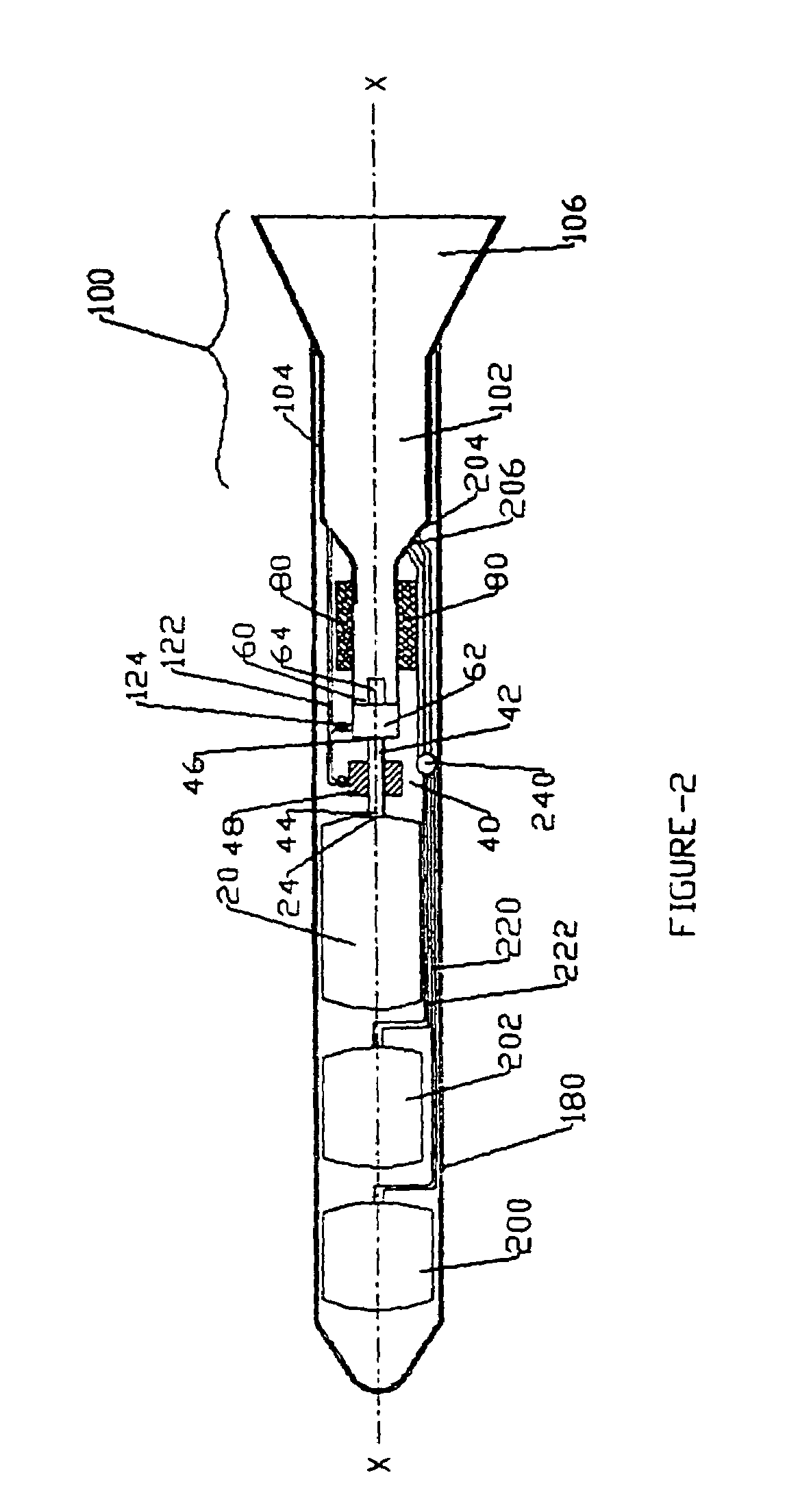

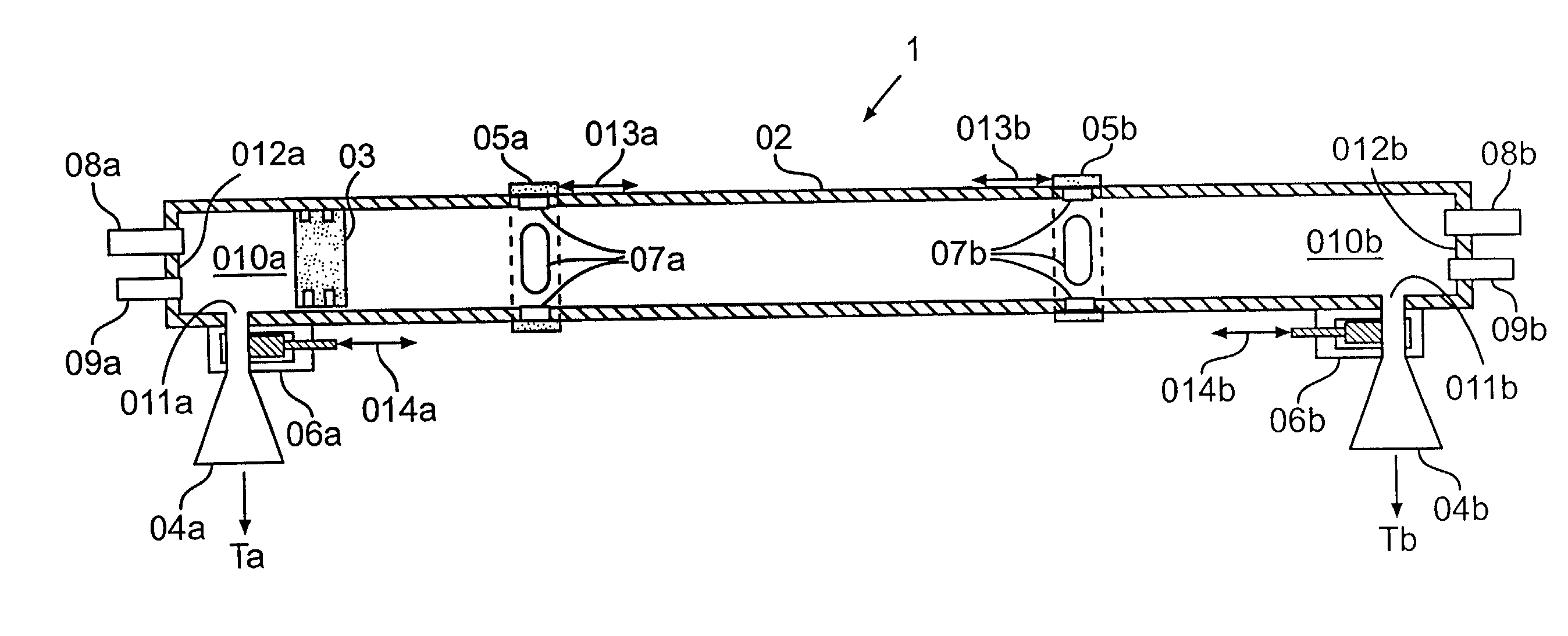

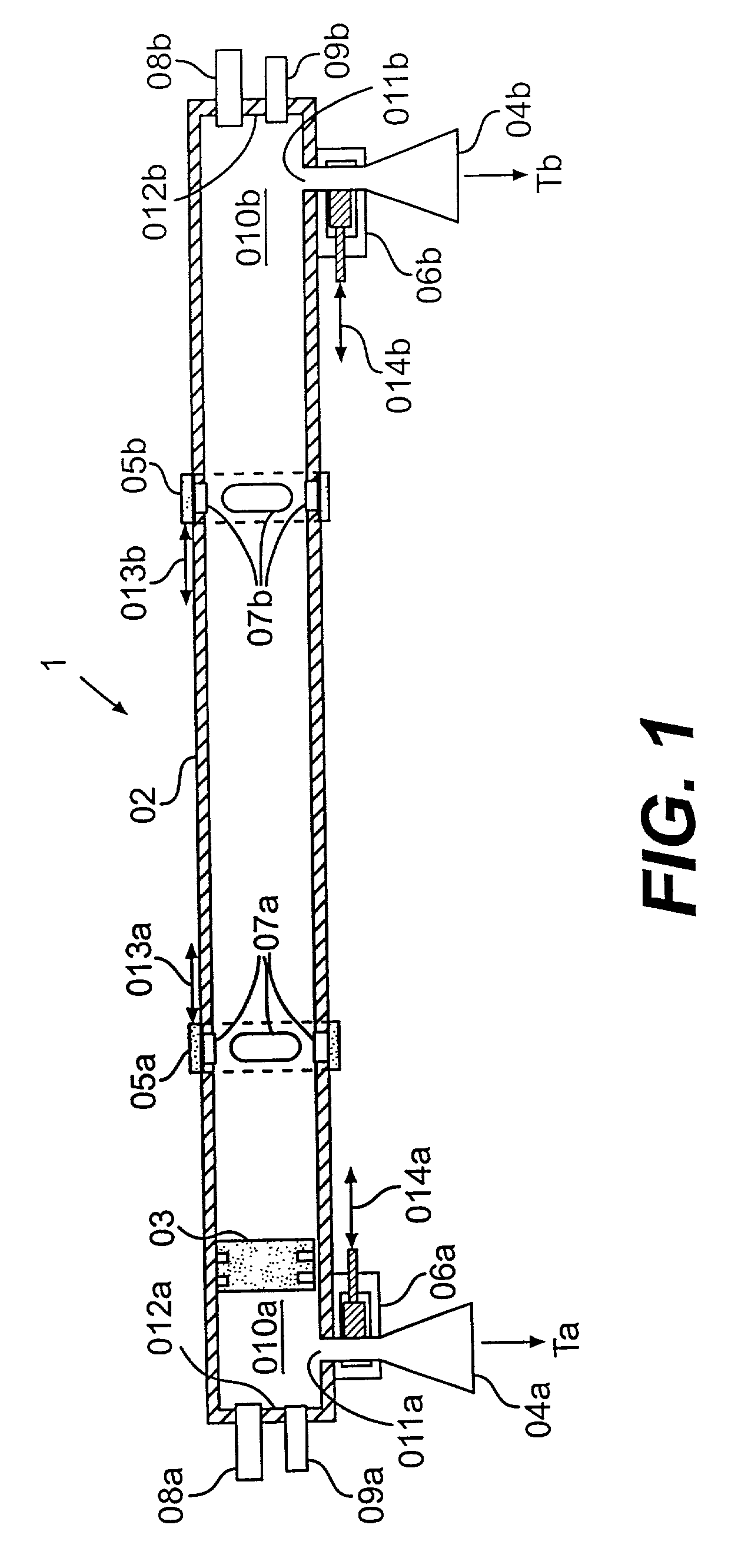

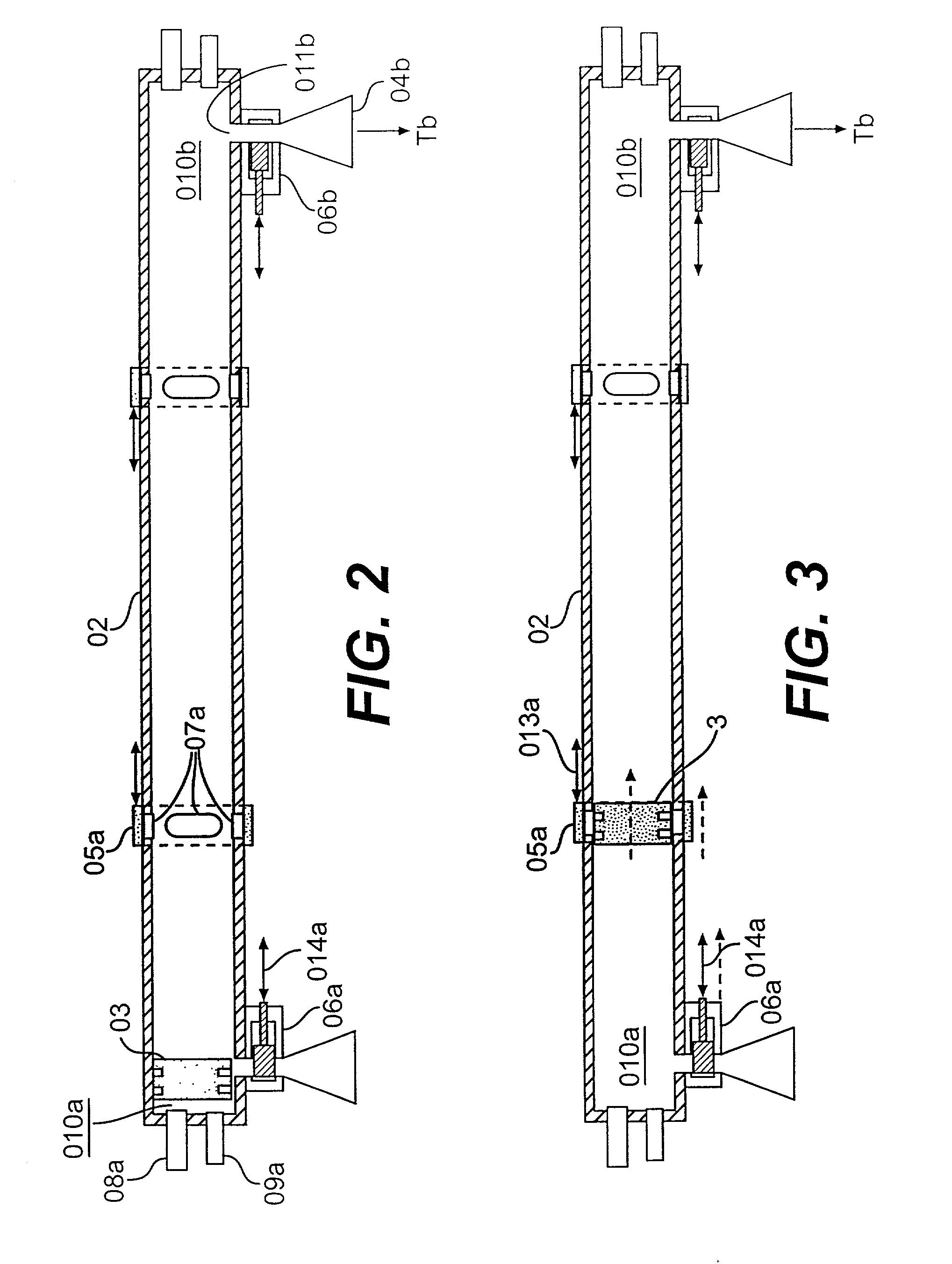

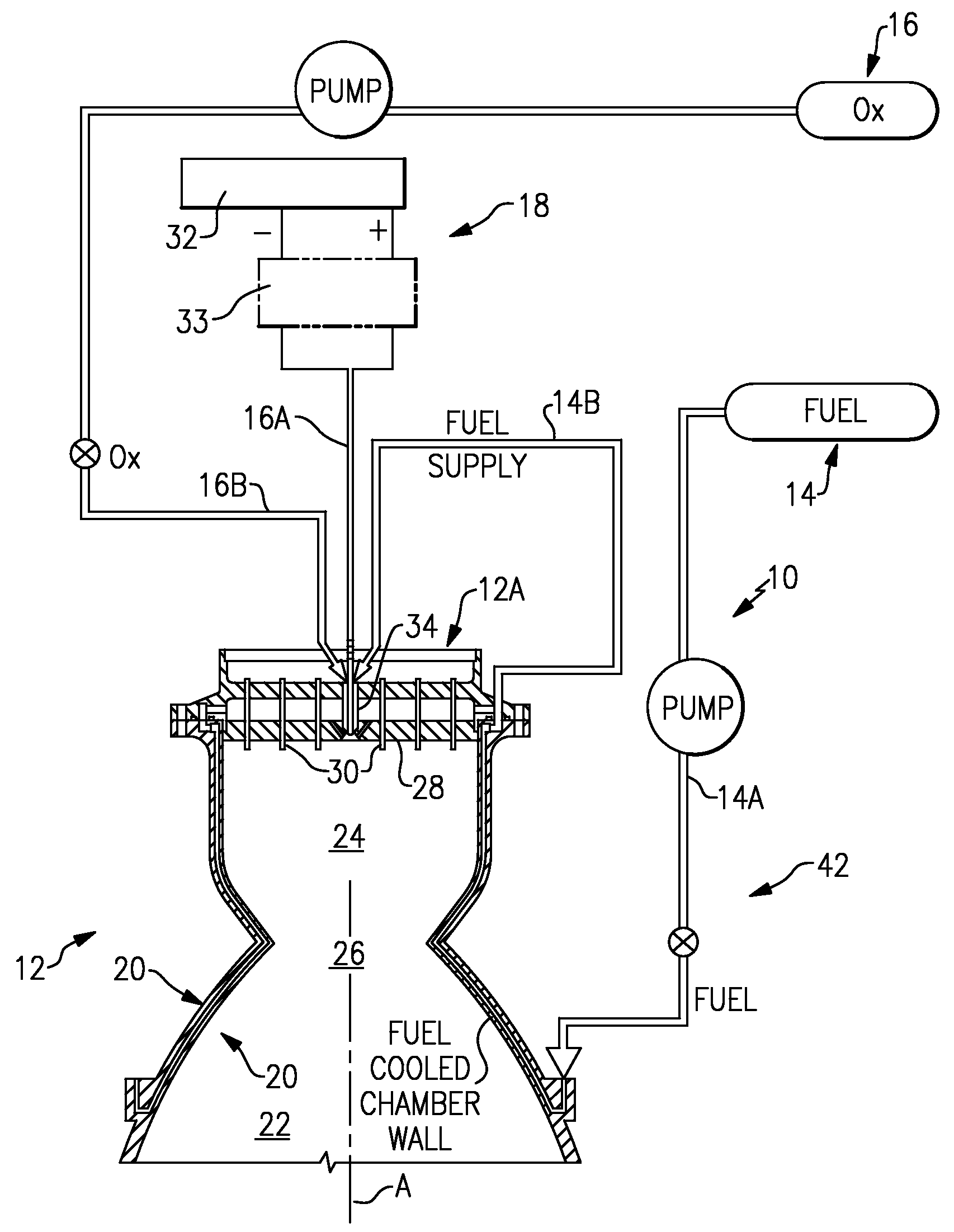

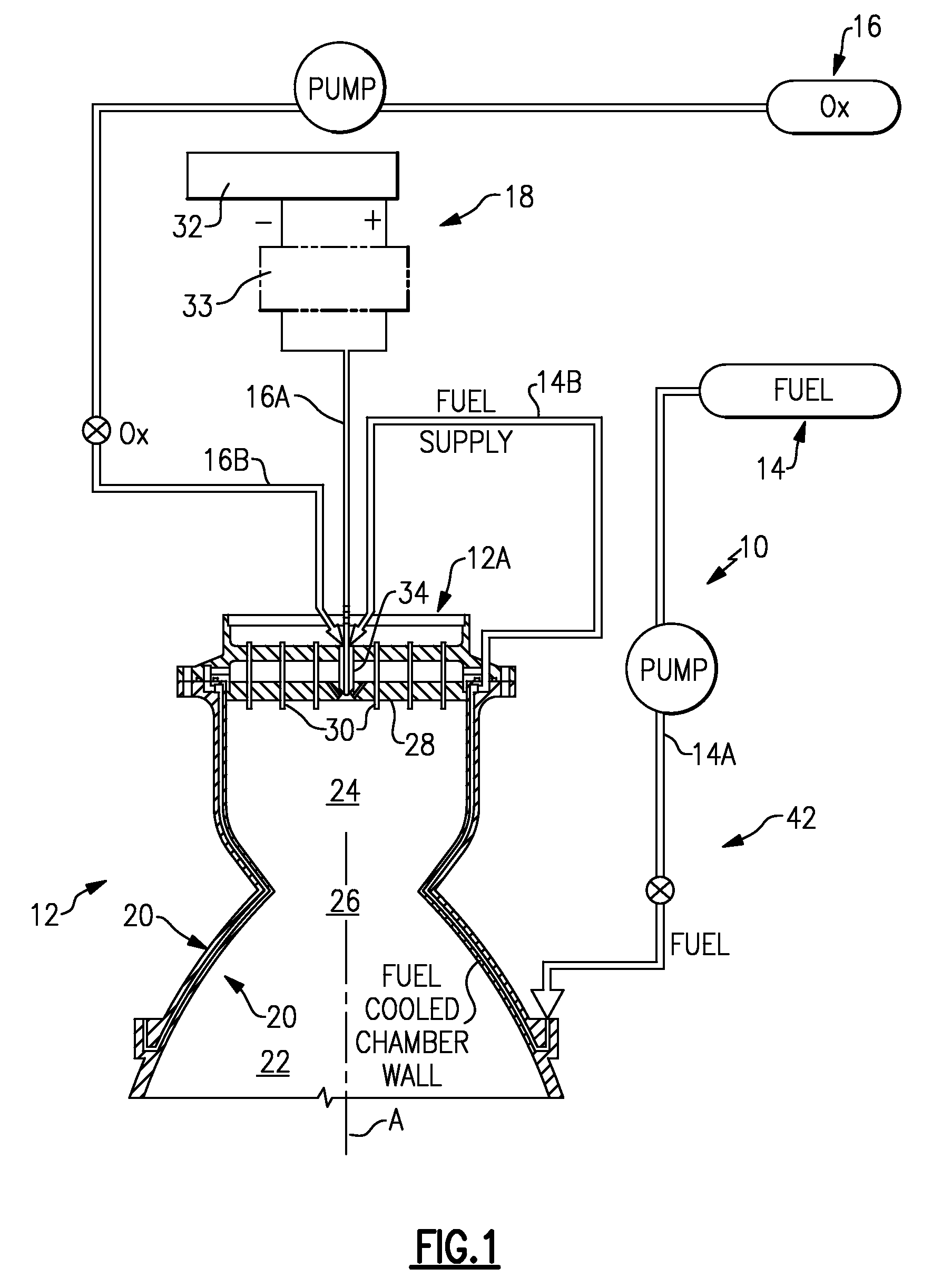

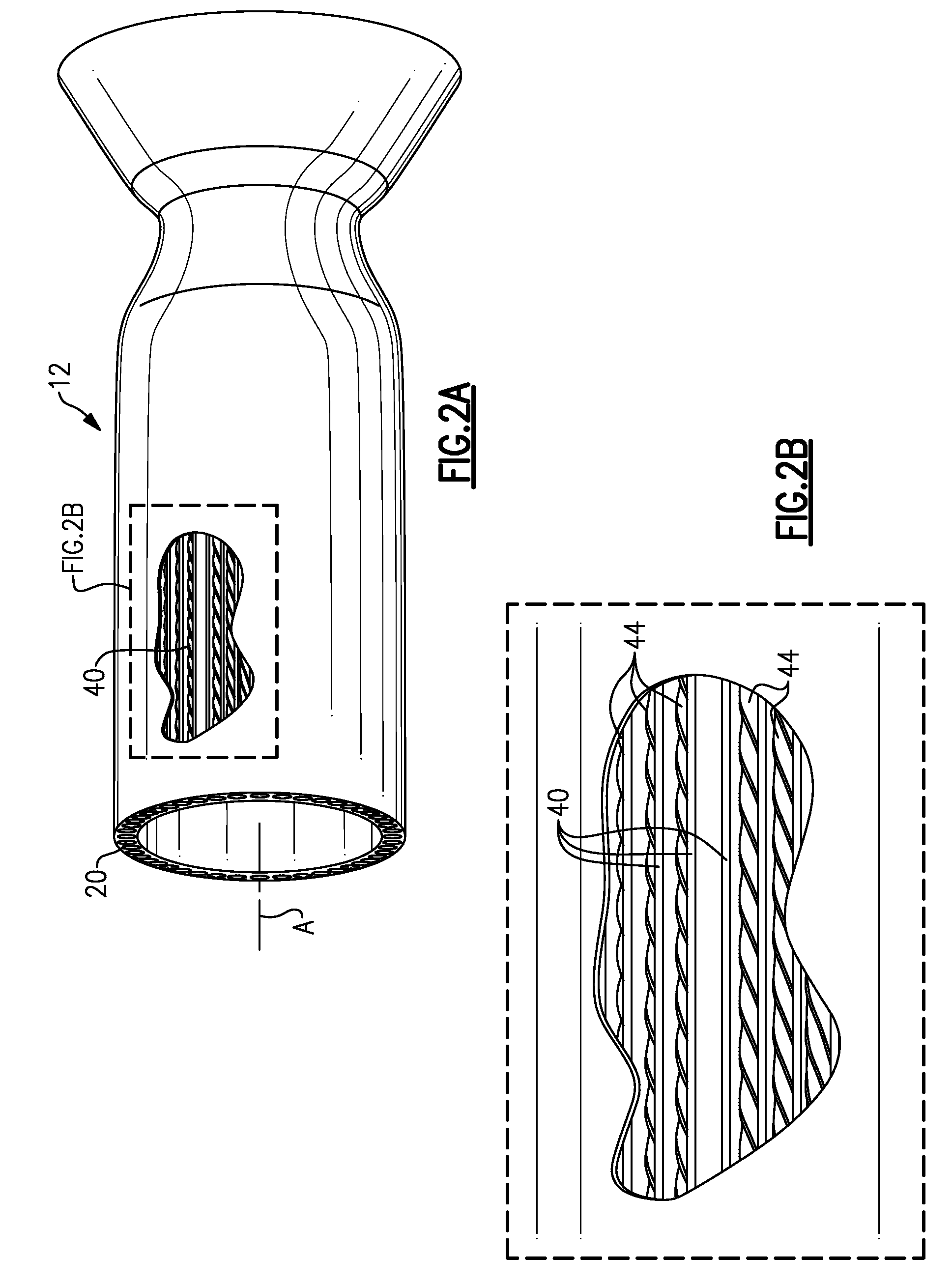

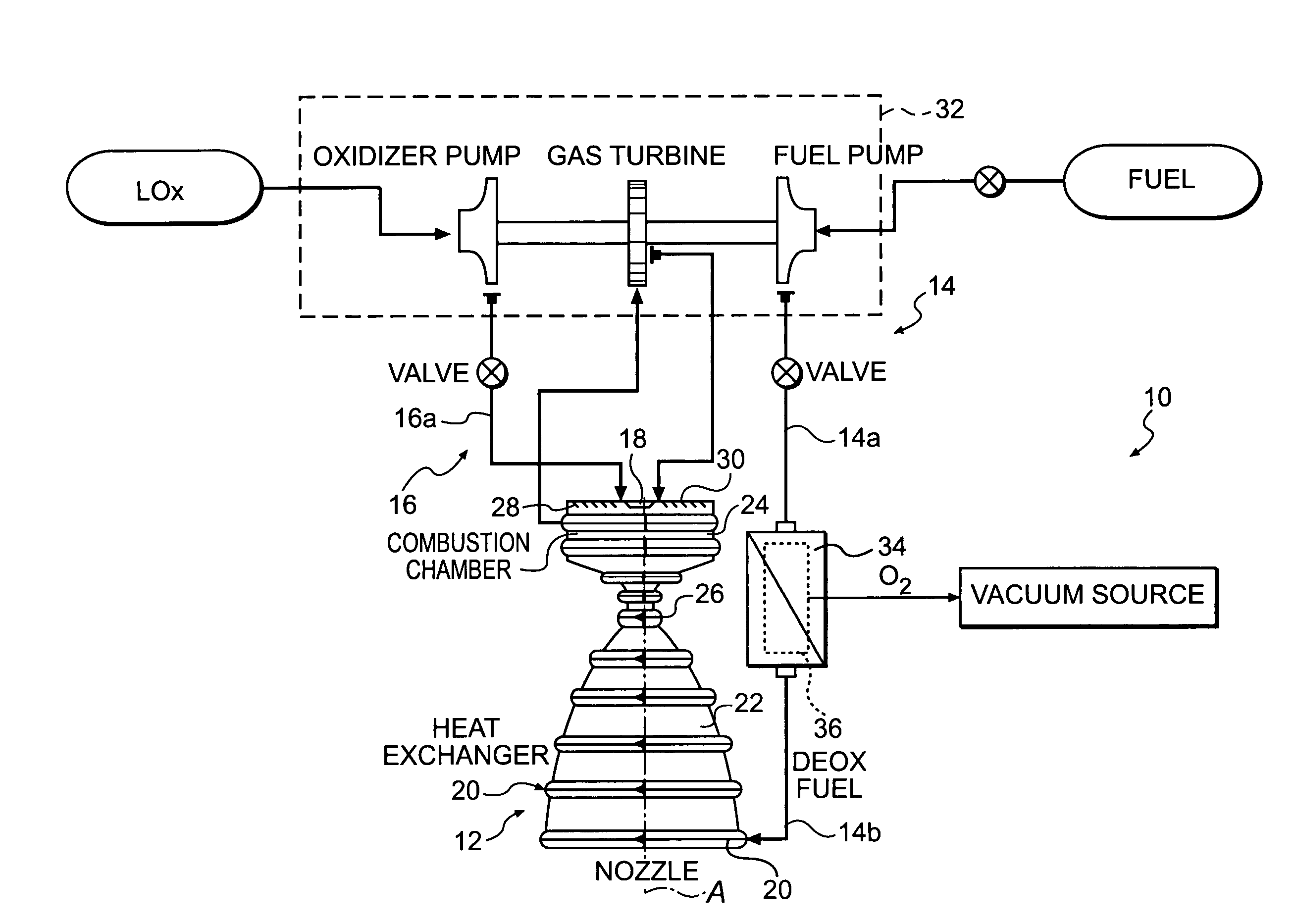

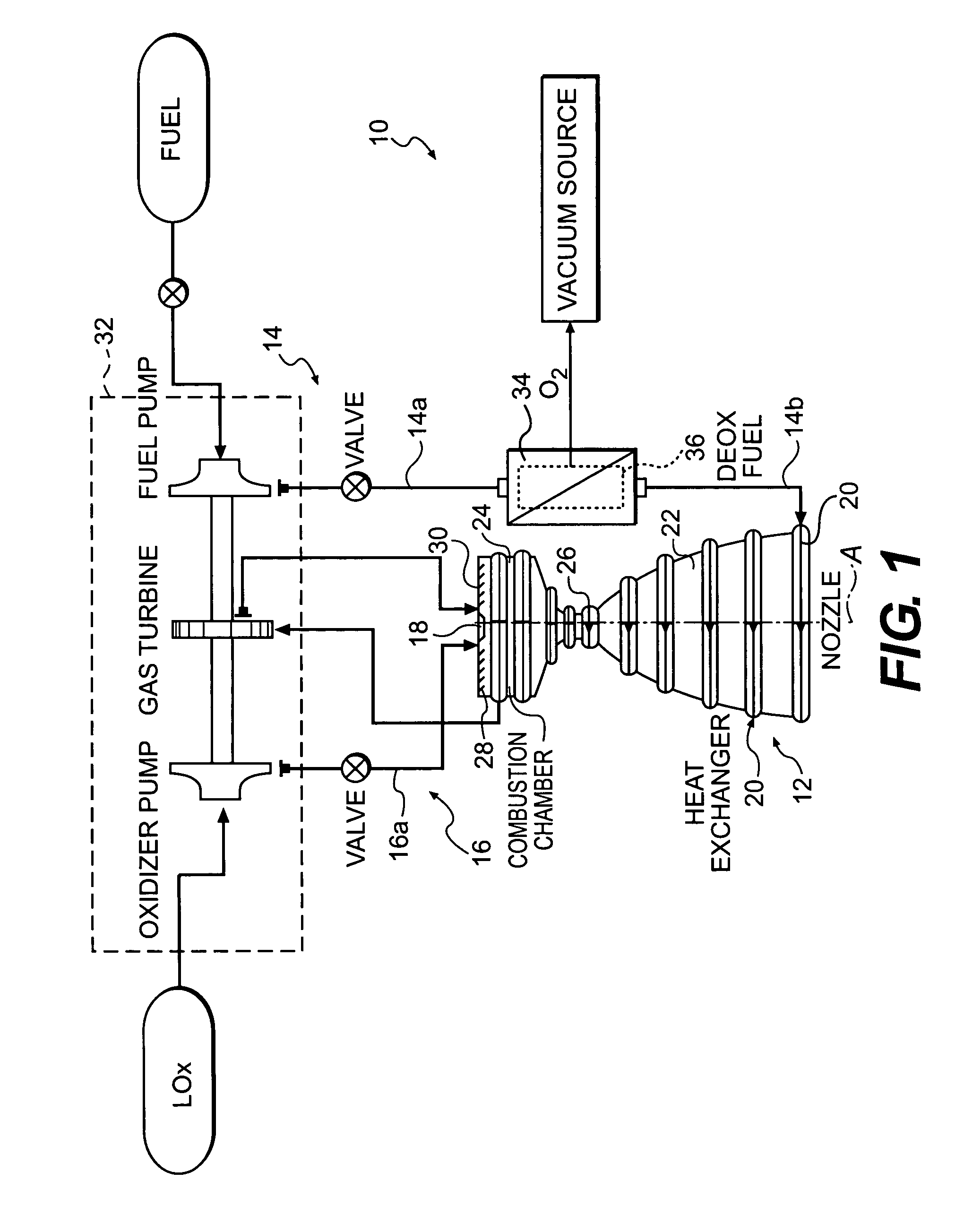

Simplified thrust chamber recirculating cooling system

InactiveUS20090293448A1Simple structureCosmonautic vehiclesCosmonautic propulsion system apparatusThrust chamberCoolant

In some aspects a propulsion system includes a thrust chamber having a gap between an inner shell and an outer shell, the inner shell and the outer shell being attached together to form the thrust chamber. The rocket engine also includes a recirculating cooling system operably coupled to the gap in at least two locations and operable to recirculate a convective coolant through the gap.

Owner:GROTE JAMES ROBERT +1

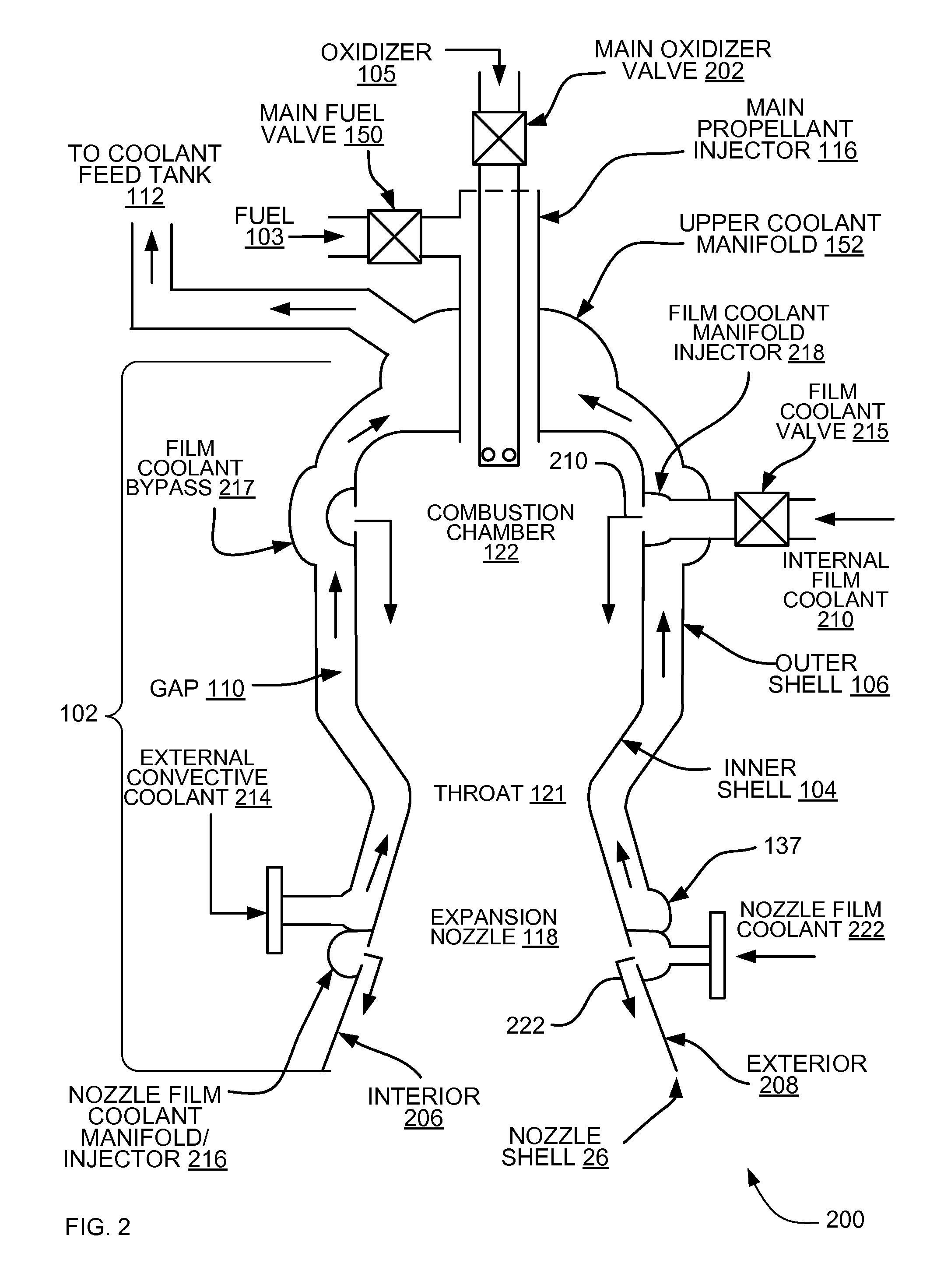

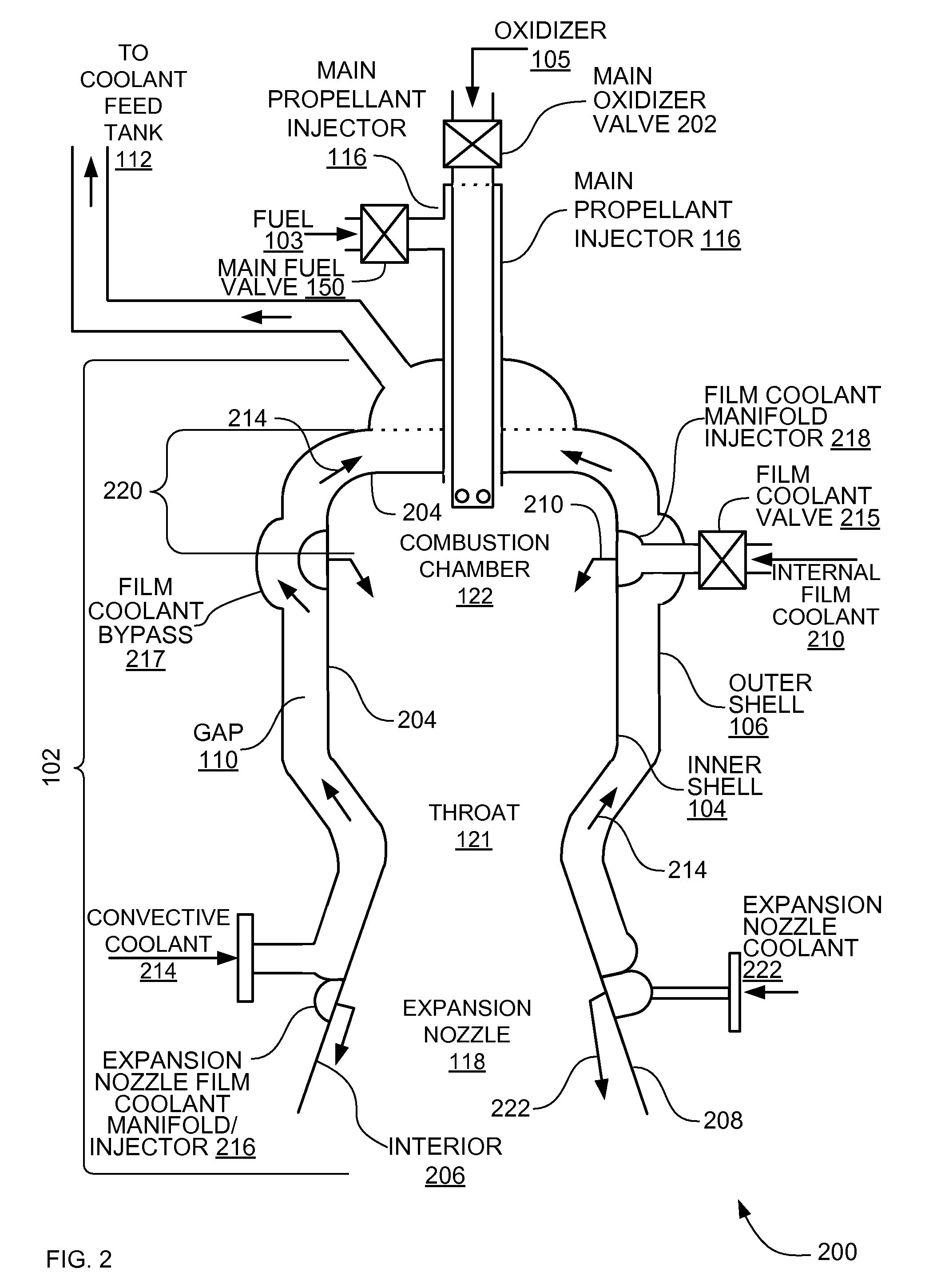

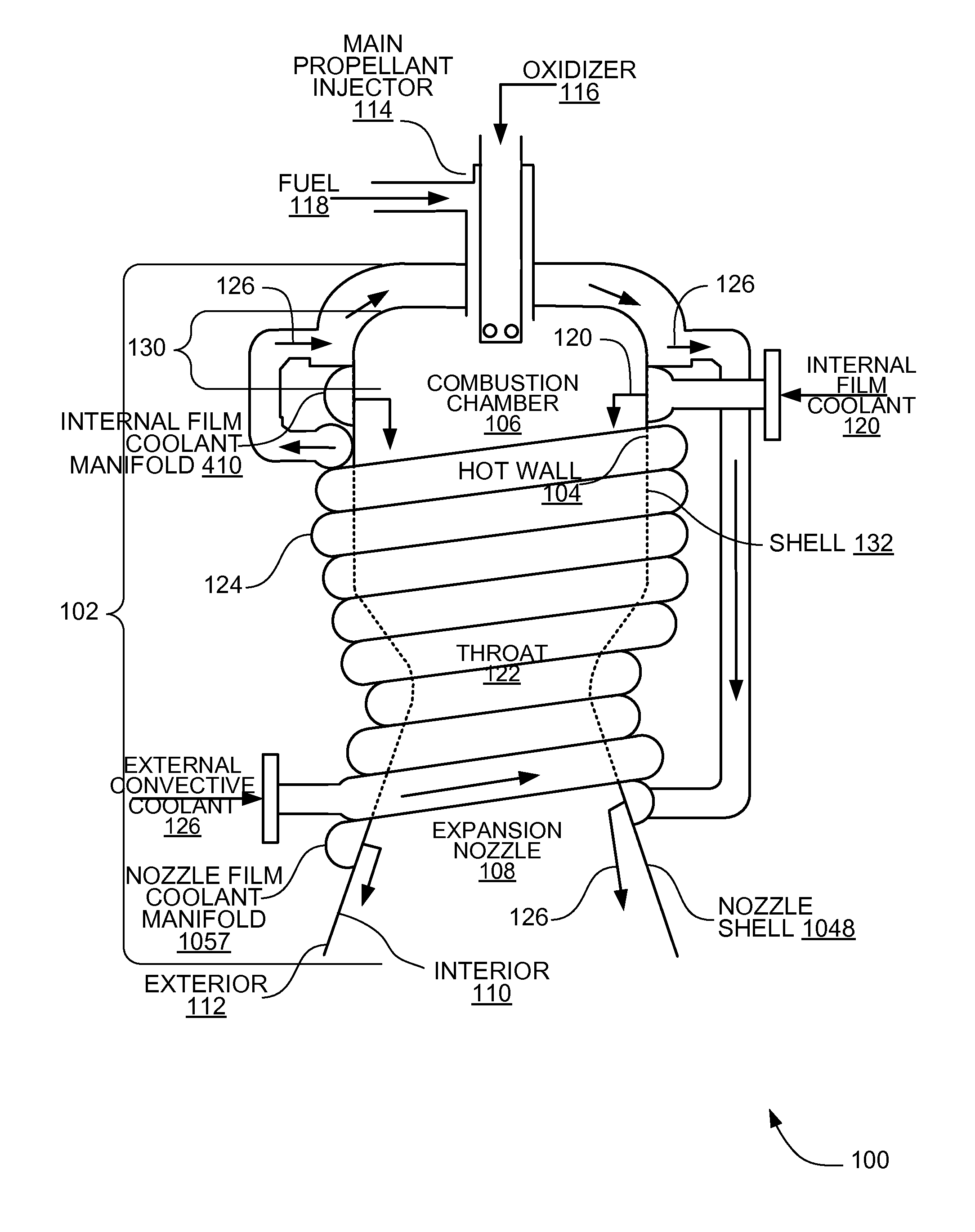

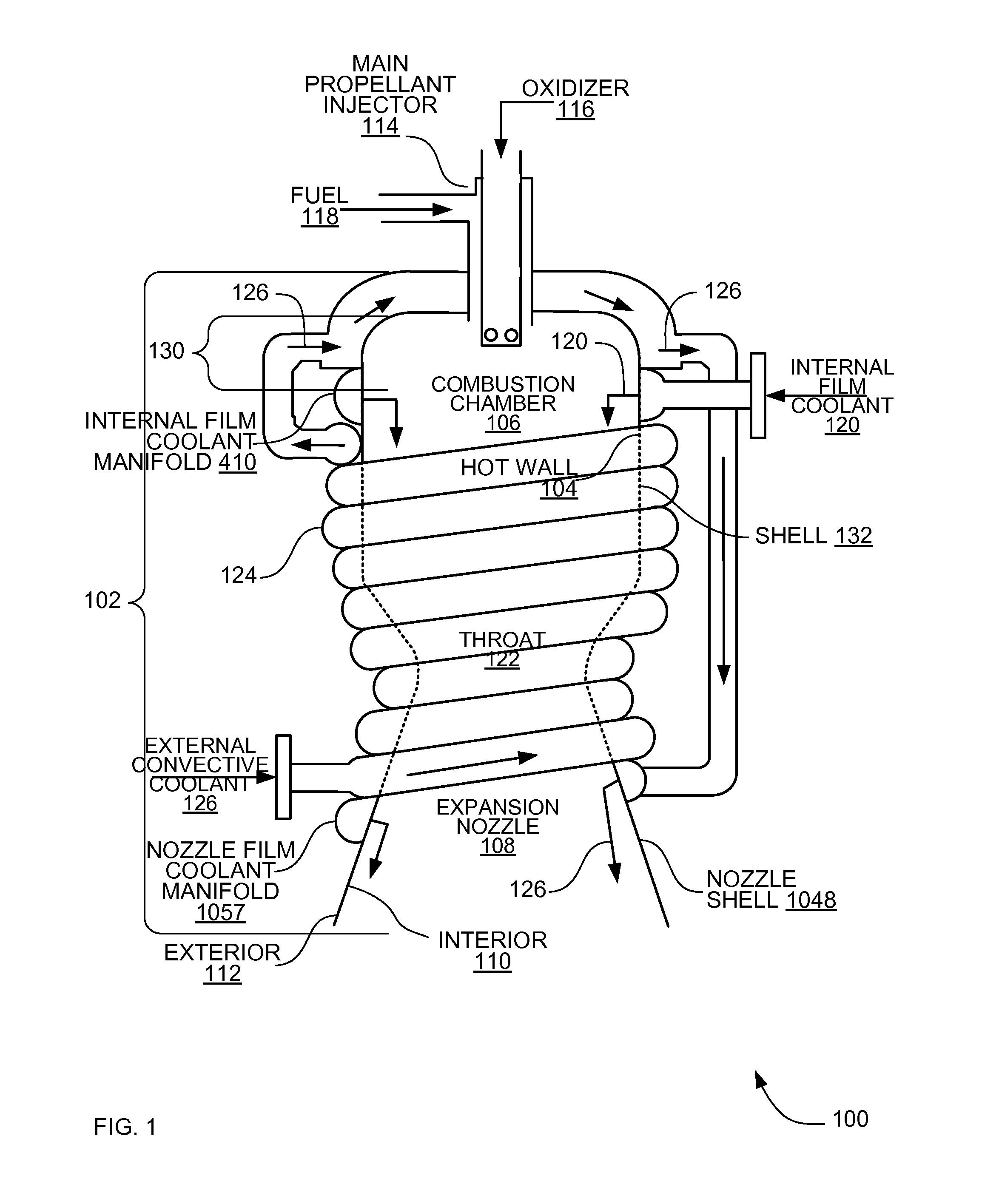

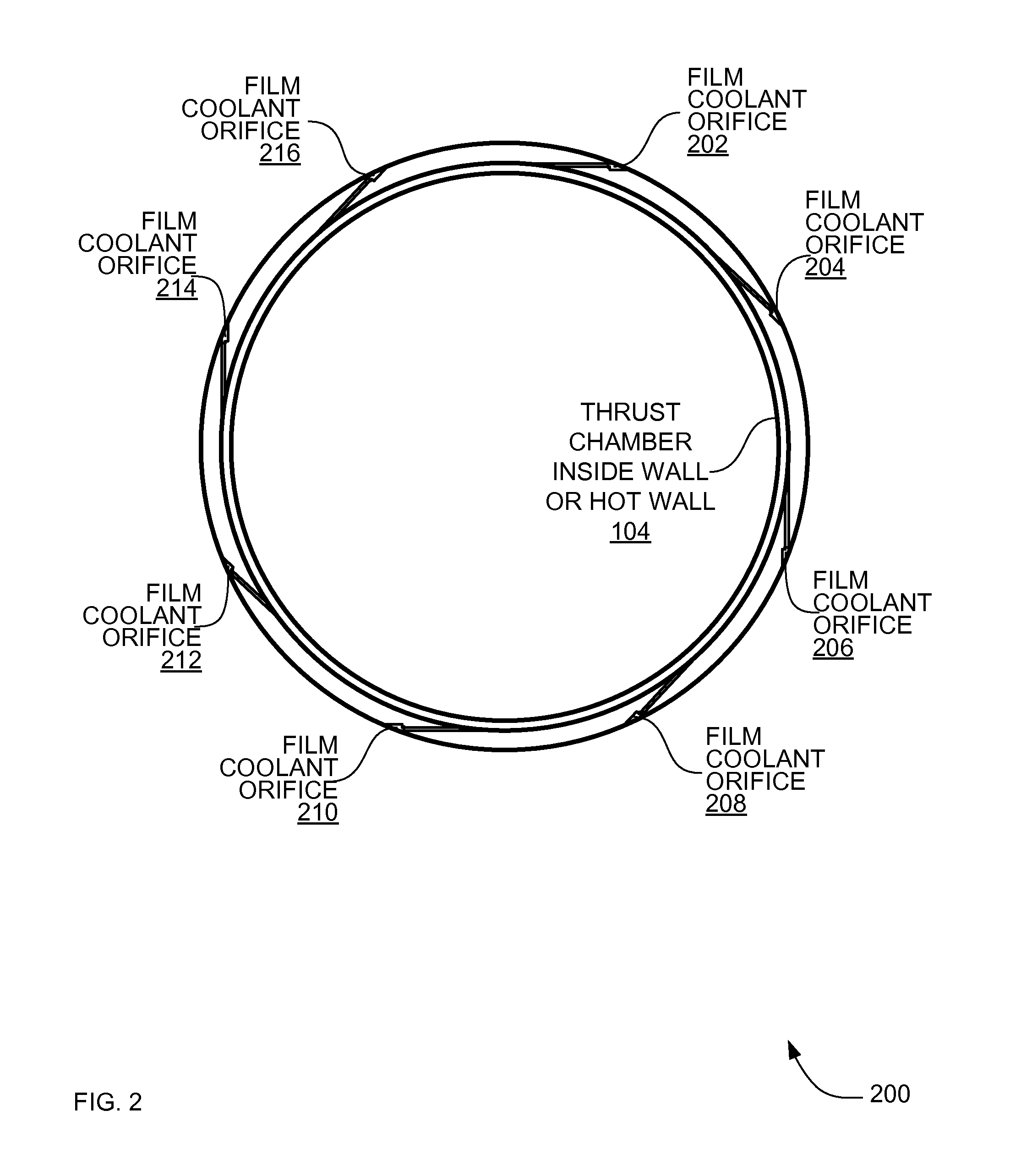

Systems, methods and apparatus for propulsion

In some implementations a propulsion system includes a thrust chamber comprised of a combustion chamber and an expansion nozzle. The thrust chamber has an interior and exterior surfaces and a main propellant injector mounted to the thrust chamber to inject an oxidizer and a fuel into the interior of the thrust chamber. The total fluid flowing to the rocket engine is compromised of oxidizer, fuel, internal film coolant, and external convective coolant. The internal film coolant ranges from about 1% to about 10% of the total fluid. Reduced coolant tubing circumscribes the exterior of the thrust chamber to circulate an external convective coolant, and a nozzle film coolant manifold mounted to the expansion nozzle injects the external convective coolant onto the interior wall of the expansion nozzle, the external convective coolant being about 1% to about 10% of the total fluid flow to the thrust chamber.

Owner:GROTE JAMES ROBERT +1

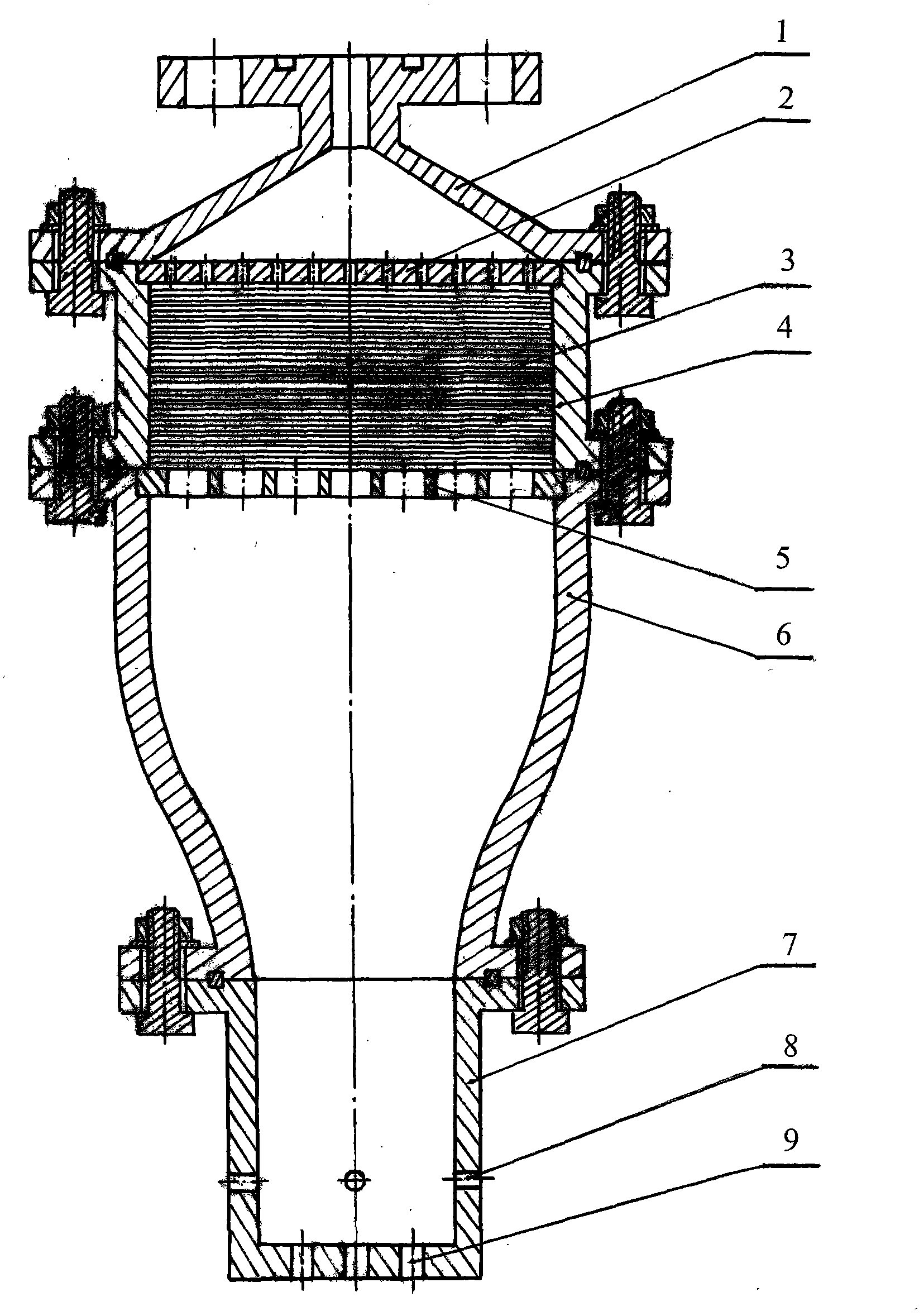

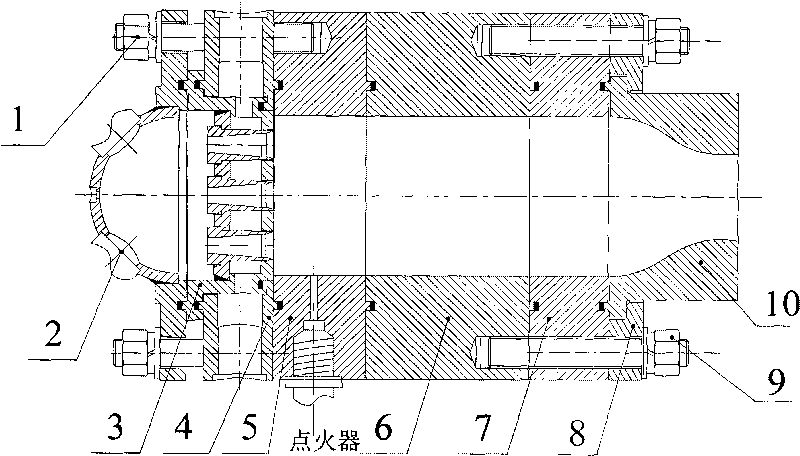

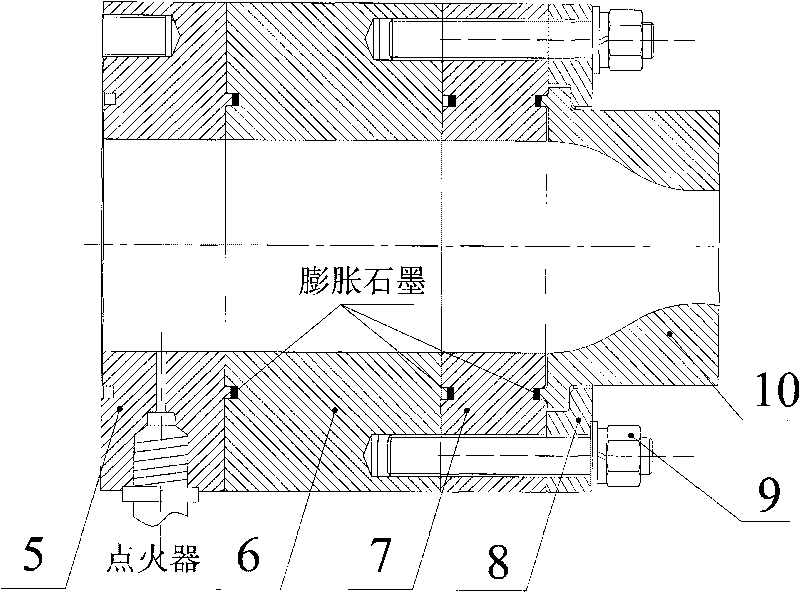

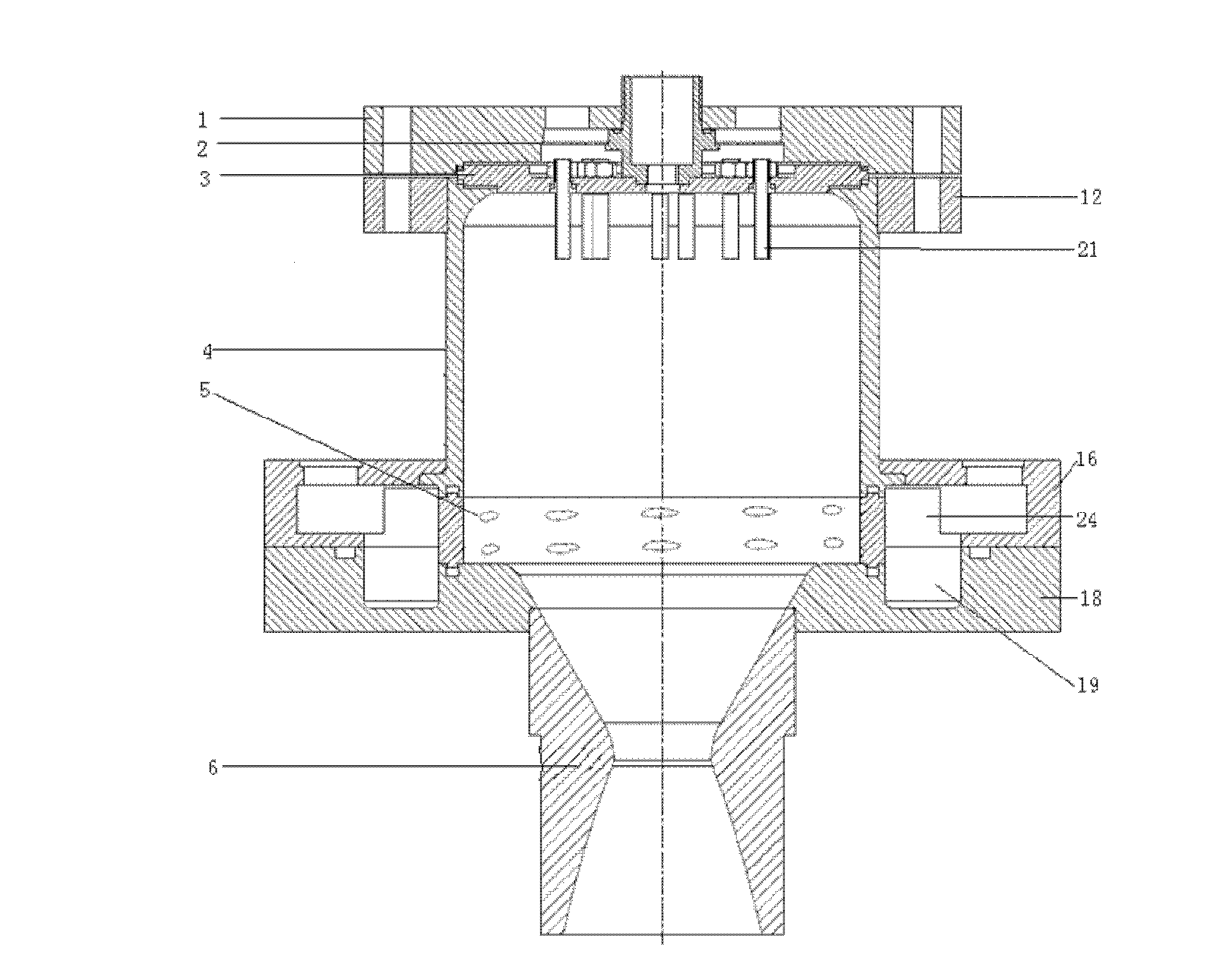

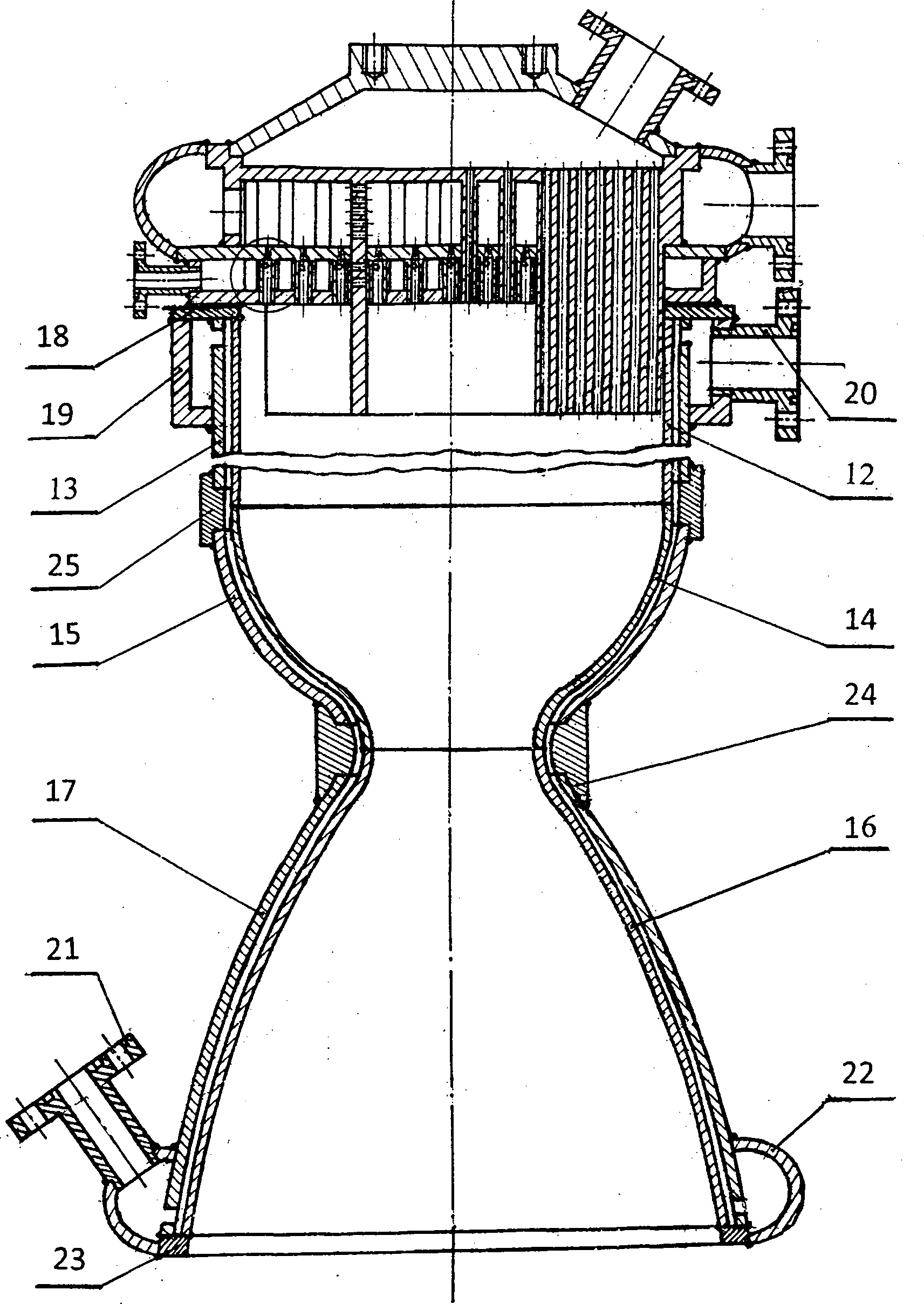

Modularized heat-capacity type thrust chamber

The invention relates to a modularized heat-capacity type thrust chamber comprising an injector assembly, a head top cap, a head bottom cap, a body cylinder section and a tail spray pipe, wherein the injector assembly, the head top cap and the head bottom cap are connected by adopting bolts to form the head of the thrust chamber; the body cylinder section is in a sectional type structure; and each section of the cylinder section, the tail spray pipe and the head of the thrust chamber are connected by adopting bolts. The head and the body of the thrust chamber, and the cylinder section and the spray pipe section are sealed in the mode of compacting expanded graphite sealing rings between a boss and a groove. The head can be made of a stainless steel material, the body cylinder section is made of red copper, and the spray pipe section is made of a high temperature-resistant material. By adopting the invention, when performing the experimental study on a rocket engine, experimenters can conveniently replace the module of the engine to change the studied parameter for carrying out comparative analysis, therefore, the cost is obviously reduced.

Owner:BEIHANG UNIV

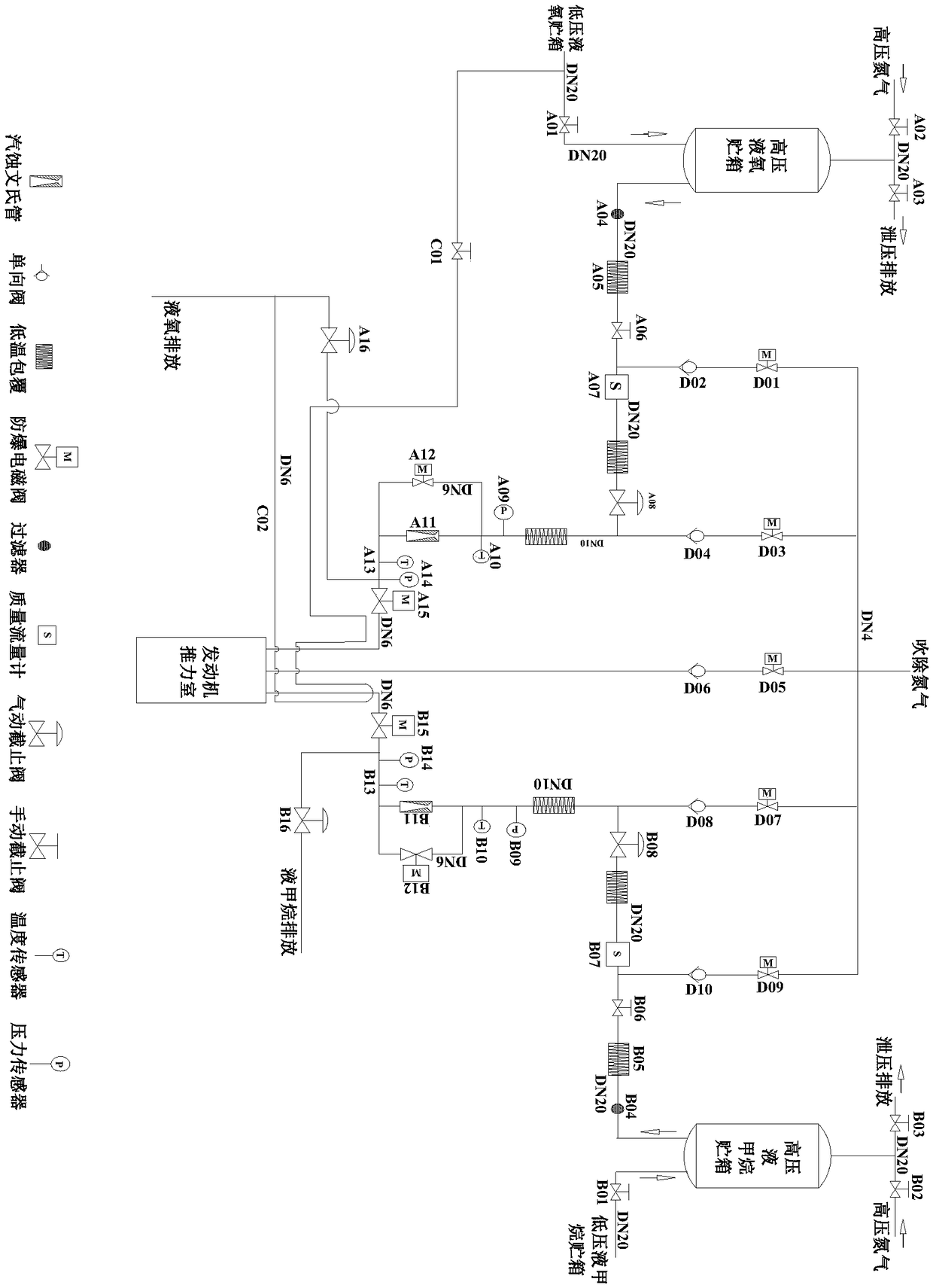

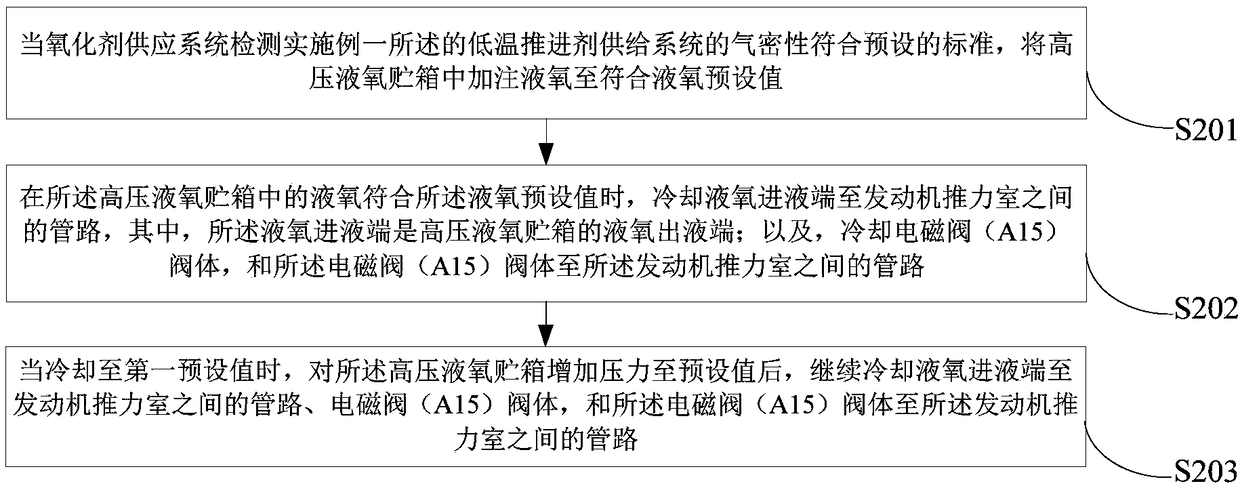

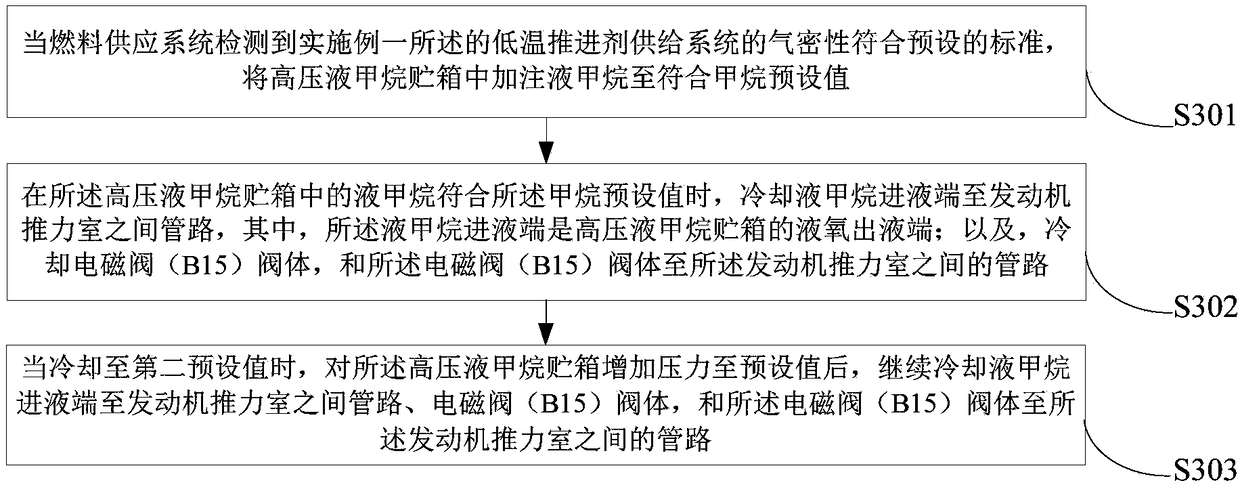

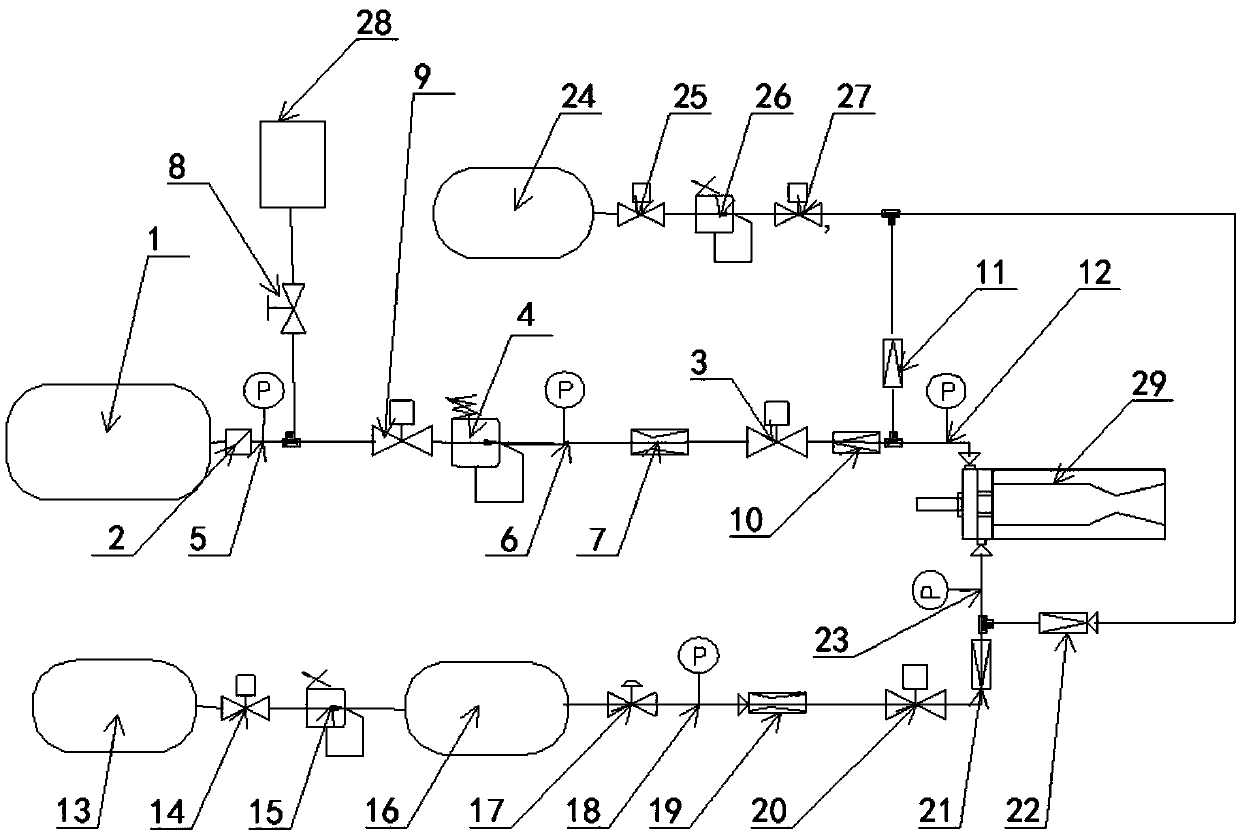

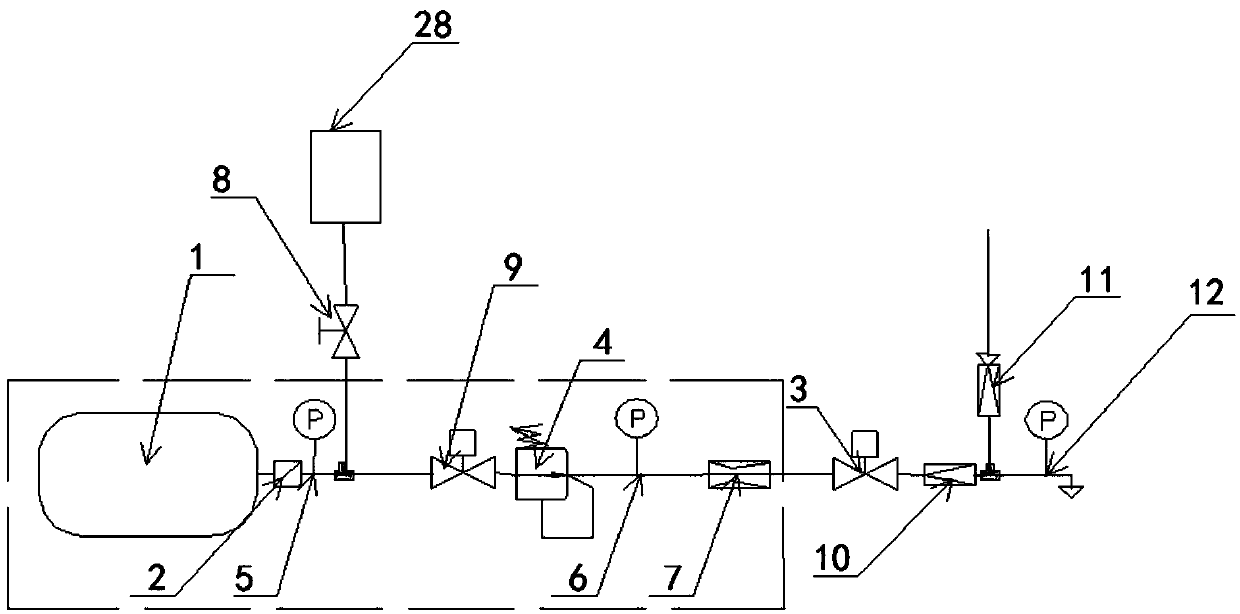

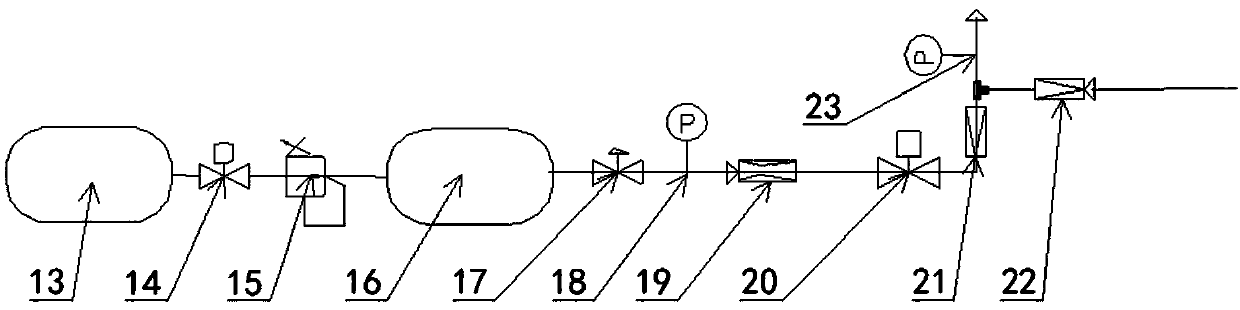

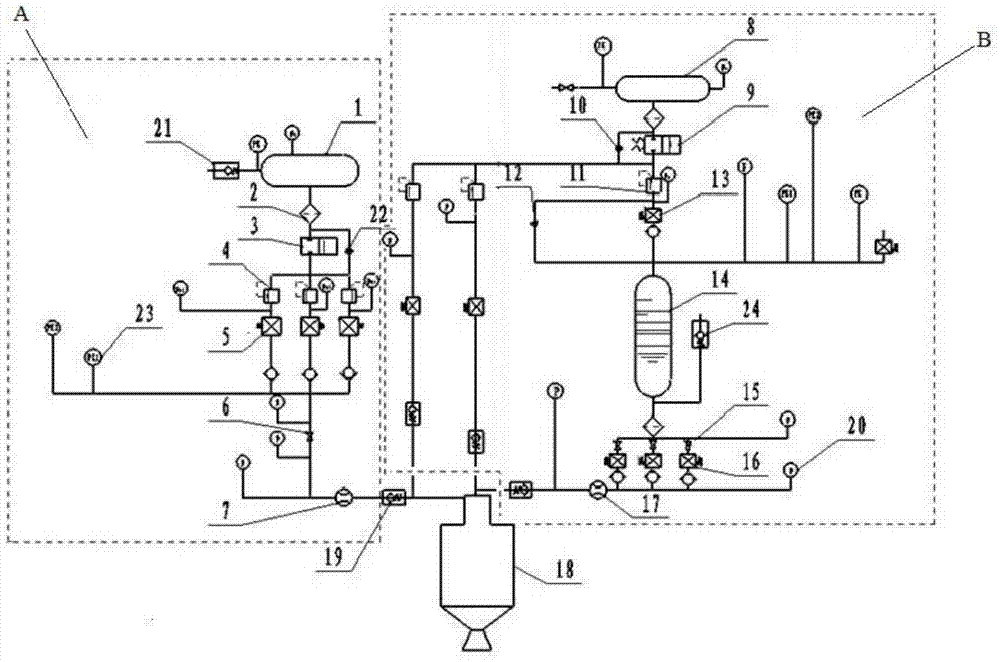

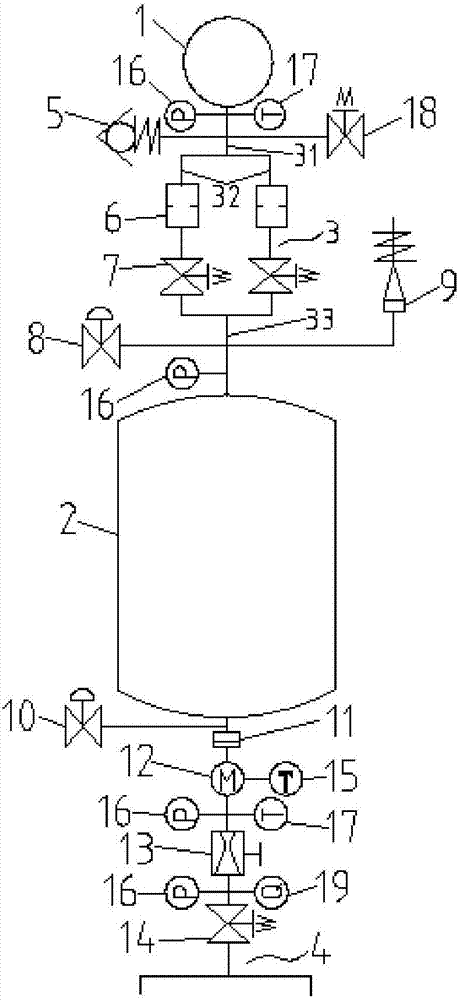

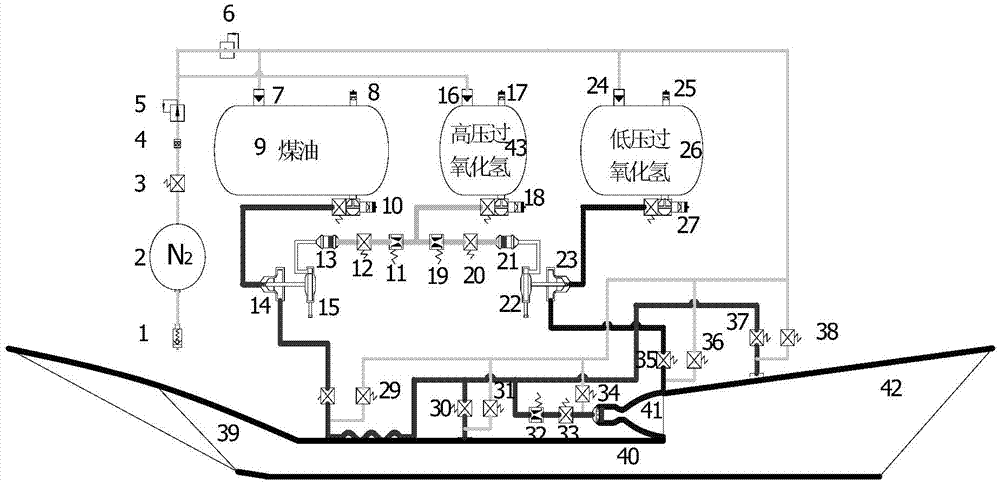

Low-temperature propellant supplying system, method and device

ActiveCN109469558AStable adjustment of delivery volumeControl flowGas-turbine engine testingRocket engine plantsThrust chamberNitrogen

The invention provides a low-temperature propellant supplying system, a method and a device. The low-temperature propellant supplying system comprises a nitrogen blowing away system, an oxidant supplying system, a fuel supplying system and a low-pressure liquid oxygen cooling system; the nitrogen blowing away system is used for carrying out purging operation on a system pipeline before and after an experiment and detecting the air tightness of the low-temperature propellant supplying system; under the condition that the air tightness of the low-temperature propellant supplying system is qualified, the oxidant supplying system is used for conveying liquid oxygen to an engine thrust chamber; the fuel supplying system is used for conveying liquid methane to the engine thrust chamber; the low-pressure liquid oxygen cooling system is used for cooling a pipeline, wherein partial pipeline is located between an electromagnetic valve (A15) and the engine thrust chamber and partial pipeline is located between an electromagnetic valve (B15) and the engine thrust chamber. According to the embodiment of the supplying system, the method and the device, the required preset temperature can be achieved before the test, the low-pressure liquid oxygen cooling system adopts low-pressure liquid oxygen to cool the environment so as to ensure the safety, the propellant conveying amount can be stablyadjusted, and simplicity and reliability are achieved.

Owner:BEIHANG UNIV

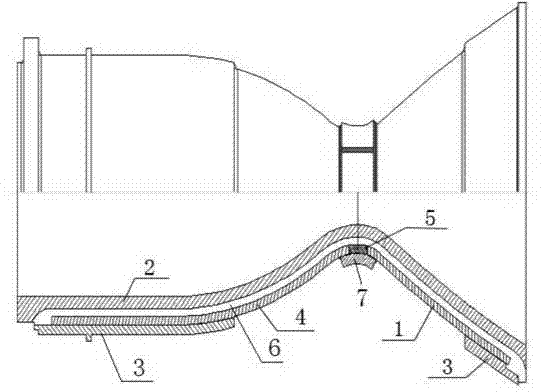

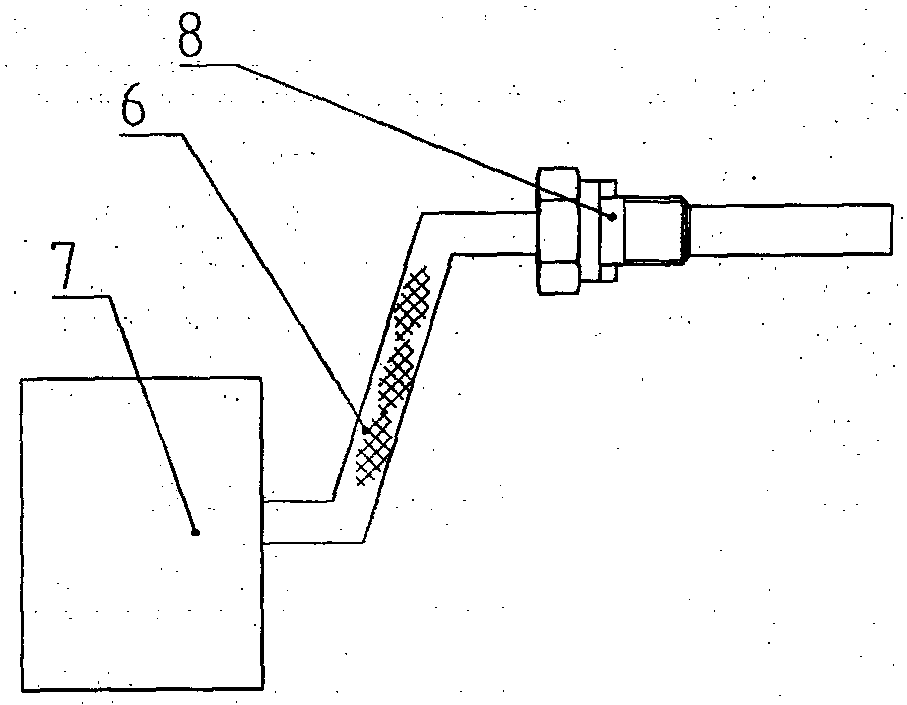

Diffusion brazing manufacture method for hydrogen peroxide thrust chamber body

ActiveCN102950351AIncrease productivityImprove product qualitySoldering apparatusArc welding apparatusPositive pressureThrust chamber

The invention provides a diffusion brazing manufacture method for a hydrogen peroxide thrust chamber body. The method specifically comprises the following steps that (a), an assembling clearance between the outer surface of the inner wall of a thrust chamber and the inner surfaces of a spray pipe outer wall and a middle section outer wall is controlled between 0.04 and 0.9mm; (b), 0.01 to 0.5mm nickel-base brazing filler metal is spot-welded on the outer surface of the inner wall of the thrust chamber, and the spray pipe outer wall and the middle section outer wall are respectively sleeved outside the inner wall of the thrust chamber; (c), the spray pipe outer wall and the middle section outer wall are respectively circumferentially located and welded with connecting semi-rings in an argon arc way, and then thrust chamber collectors are welded at the two ends of a connecting piece for the spray pipe outer wall and the middle section outer wall in an argon arc way; and (d) diffusion brazing is carried out on the outer surface of the inner wall of the thrust chamber and the inner surfaces of the spray pipe outer wall and the middle section outer wall by a positive pressure brazing furnace. The method has the advantages of simple welding technology, high reliability, stable product quality and high production efficiency.

Owner:CAPITAL AEROSPACE MACHINERY +1

Gas-oxygen-kerosene rocket-engine pressurizing delivery system and small-rocket-engine propellant supplying system

The invention relates to the field of rocket-engine propellant delivery systems, in particular to a gas-oxygen-kerosene rocket-engine pressurizing delivery system and a small-rocket-engine propellantsupplying system. The pressurizing delivery system comprises an oxygen supplying system, a fuel oil supplying system and a blowing-off system; the oxygen supplying system comprises an oxygen storage tank valve assembly, a first stop valve, a first one-way valve and a second one-way valve; the oxygen storage tank valve assembly, the first stop valve and the first one-way valve are sequentially communicated through a pipe, the second one-way valve is communicated with the blowing-off system, and an outlet of the first one-way valve and an outlet of the second one-way valve are connected with a thrust chamber through the same pipe; the fuel oil supplying system is connected with the blowing-off system to enter the thrust chamber through the pipe. The gas-oxygen-kerosene rocket-engine pressurizing delivery system in the technical scheme is compared with a liquid-oxygen-kerosene rocket propellant delivery system, complex design such as pressurization-system gas-liquid phase transition, delivery-system low-temperature two-phase flow and engine pre-cooling are not required to be considered, and the complex degree and the quality of the system structure are also greatly reduced.

Owner:BEIHANG UNIV

Variable working condition type primary rocket system of rocket based combined cycle engine

The invention discloses a variable working condition type primary rocket system of a rocket based combined cycle engine. The variable working condition type primary rocket system comprises a propellant supply system and a primary rocket engine thrust chamber which are connected through a pipeline, wherein the propellant supply system comprises an oxidant supply system and a fuel supply system, the oxidant supply system comprises an oxygen flow rate control system, the oxygen flow rate control system comprises a plurality of oxygen conveying pipelines, each oxygen conveying pipeline is provided with an oxygen pressure relief valve for opening and closing the corresponding oxygen conveying pipeline, an outlet of each oxygen conveying pipeline is connected with an oxygen perforating plate, the fuel supply system comprises a plurality of fuel conveying pipelines, an outlet of each fuel conveying pipeline is provided with a cavitation venturi pipe, and an inlet of each fuel conveying pipeline is connected with a nitrogen pressure relief device. The variable working condition type primary rocket system of the rocket based combined cycle engine has the advantages that the flow rate of a propellant can be accurately, controllably, stably and quickly adjusted, the complexity is low, and the operation is simple.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Gaseous hydrogen/gaseous oxygen eddy current cooling thrust chamber injector

InactiveCN102207043AImprove stabilityImprove cooling effectRocket engine plantsCombustion chamberThrust chamber

The invention provides a gaseous hydrogen / gaseous oxygen eddy current cooling thrust chamber injector, which comprises an injector head, a turbulent flow disc, an injection panel, a combustion chamber, a gaseous oxygen injection ring and an injection pipe. The injector has a simple structure, and a gaseous oxygen nozzle inclines upwards along the inner wall surface of the combustion chamber, so that the stability of external eddy current and the cooling effect are improved; the problem that the cooling effect is unsatisfactory because the wall surface temperature of the combustion chamber is high is solved; and the gaseous hydrogen / gaseous oxygen eddy current cooling thrust chamber injector can be applied to a thrust chamber with the thrust of 3,000N and the pressure of the combustion chamber of 2MPa.

Owner:BEIHANG UNIV

A monocomponent engine with non-toxic unit propellant

The invention proposes a non-toxic unit propellant single component engine, the engine is composed of a thrust chamber and a solenoid valve, and the thrust chamber is composed of an injector and a body. The body consists of two layers of catalytic beds and combustion chambers. The catalytic bed uses fine-grained catalysts for the front bed and coarse-grained catalysts for the rear bed. The active component of the catalyst used is metal iridium, and the iridium content is between 5% and 35%. There is a combustion chamber behind the catalytic bed. A coated refractory metal mesh and a coated refractory metal porous plate exist between the front and rear catalytic beds and between the catalytic bed and the combustion chamber. The solenoid valve is opened, and the non-toxic unit propellant is ejected from the injector, and is catalytically decomposed by the catalytic bed, and the decomposition product and the fuel of the propellant are burned in the combustion chamber, and then enter the nozzle to generate thrust. The problem of the combustion temperature and engine structure layout of the non-toxic unit propellant in the single-unit engine propellant is solved, and the expected effect of stable and reliable decomposition and combustion of the non-toxic unit structure propellant is achieved.

Owner:SHANGHAI INST OF SPACE PROPULSION

Coolant flow swirler for a rocket engine

InactiveUS20080264035A1Enhanced convective heat transferImprove cooling effectEngine fuctionsRocket engine plantsThrust chamberCoolant flow

Owner:ROCKETDYNE

Rocket thrust chamber with fuel switching function and supply system of rocket thrust chamber

The invention relates to a rocket thrust chamber with the fuel switching function and a supply system of the rocket thrust chamber and belongs to an afterburning type rocket engine capable of switching hydrogen peroxide / kerosene into liquid hydrogen. The rocket thrust chamber aims at integrating a hydrogen peroxide / liquid hydrogen engine with a hydrogen peroxide / kerosene engine and achieving the fuel switching function. The technical schemes of a head four-bottom three-cavity structure suitable for switching fuel, a combined fuel nozzle shared by hydrogen rich gas, hydrogen ultra-rich gas and kerosene, a straight-hole type oxidizing agent nozzle continuously injecting oxygen rich gas before and after fuel is switched, a body where an oxidizing agent flows through uninterruptedly for cooling, a hydrogen peroxide system used before and after fuel is switched, a kerosene system used before fuel is switched, a liquid hydrogen system used after fuel is switched and the like are adopted. The rocket thrust chamber with the fuel switching function is suitable for engines of a single-stage-to-orbit rocket, a core-stage rocket and a reusable aerospace craft and the rocket thrust chamber also can be applied to an engine of a hydrogen peroxide / liquid hydrogen upper-stage rocket when fuel is not switched.

Owner:葛明龙

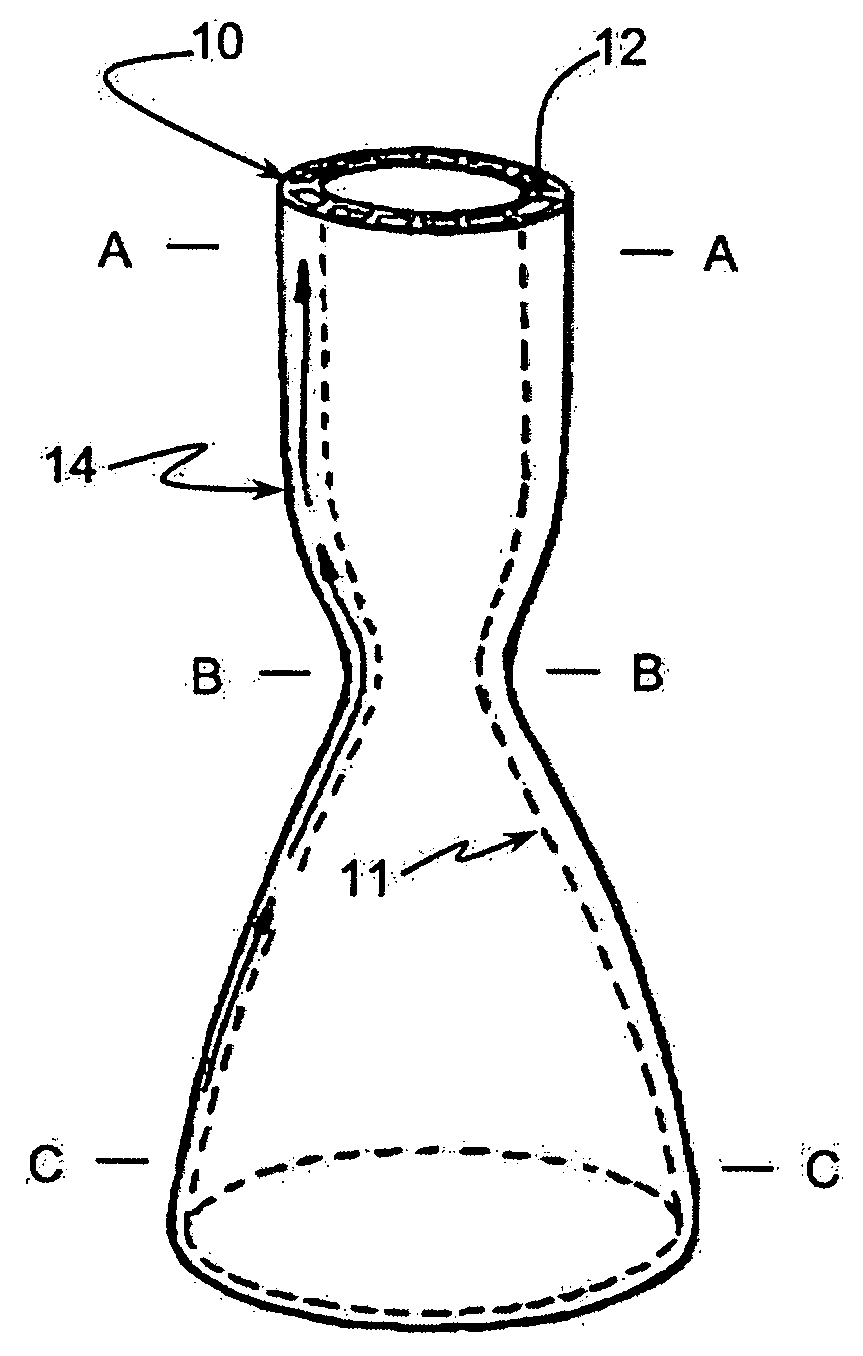

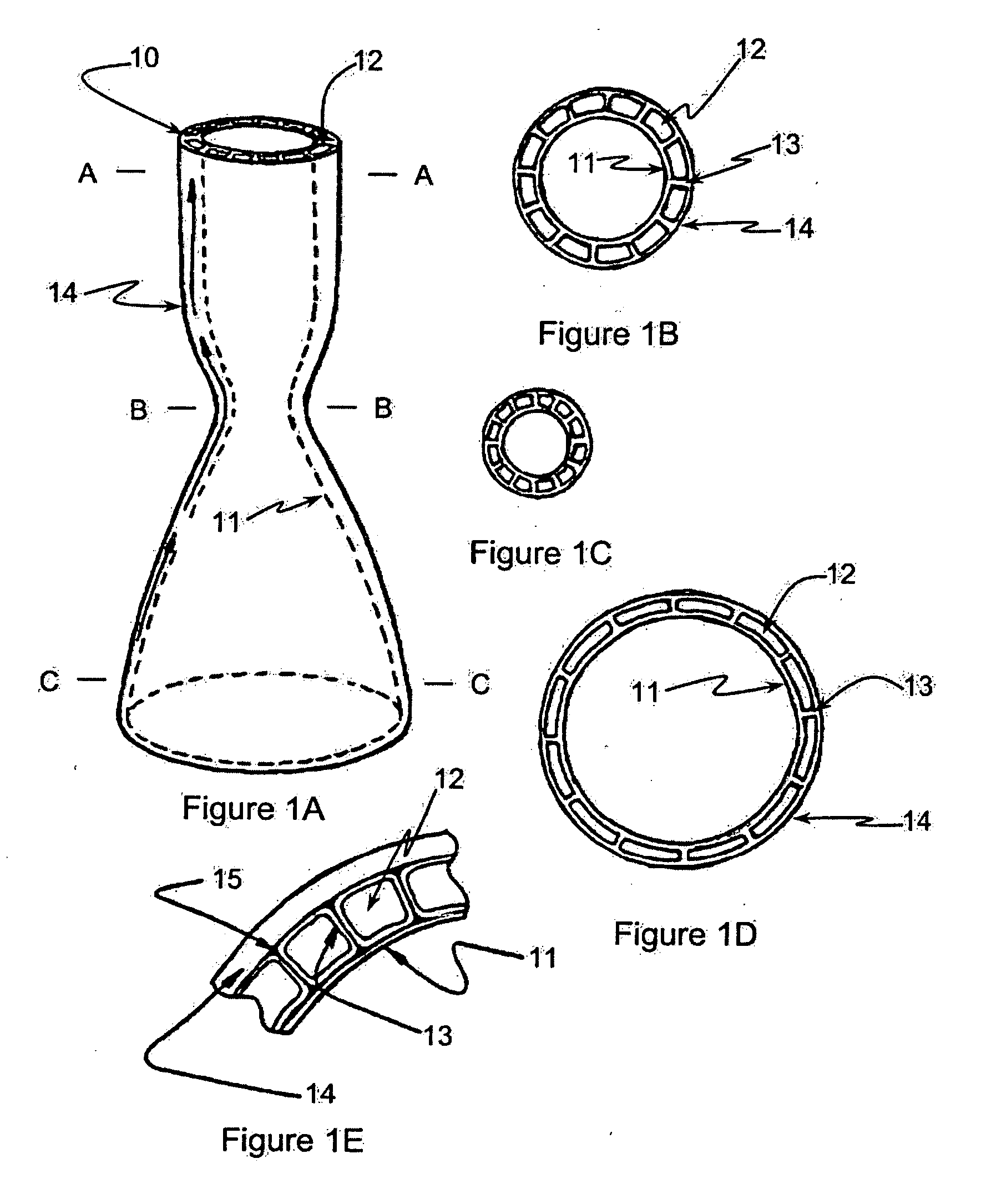

Actively-cooled fiber-reinforced ceramic matrix composite rocket propulsion thrust chamber and method of producing the same

InactiveUS20040222571A1Ceramic shaping apparatusStationary tubular conduit assembliesThrust chamberActive cooling

An actively-cooled, fiber-reinforced ceramic matrix composite thrust chamber for liquid rocket propulsion systems is designed and produced with internal cooling channels. The monocoque tubular structure consists of an inner wall, which is fully integrated to an outer wall via radial coupling webs. Segmented annular void spaces between the inner wall, outer wall and adjoining radial webs form the internal trapezoidal-shaped cooling channel passages of the tubular heat exchanger. The manufacturing method enables producing any general tubular shell geometry ranging from simple cylindrical heat exchanger tubes to complex converging-diverging, Delaval-type nozzle structures with an annular array of internal cooling channels. The manufacturing method allows for transitioning the tubular shell structure from a two-dimensional circular geometry to a three-dimensional rectangular geometry. The method offers the flexibility of producing internal cooling channels of either constant or continuously variable cross-sectional area, in addition to orienting the cooling channels either axially, helically or sinusoidally (e.g., undulating) with respect to the longitudinal axis of the tubular shell structure with without significant added manufacturing complication.

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

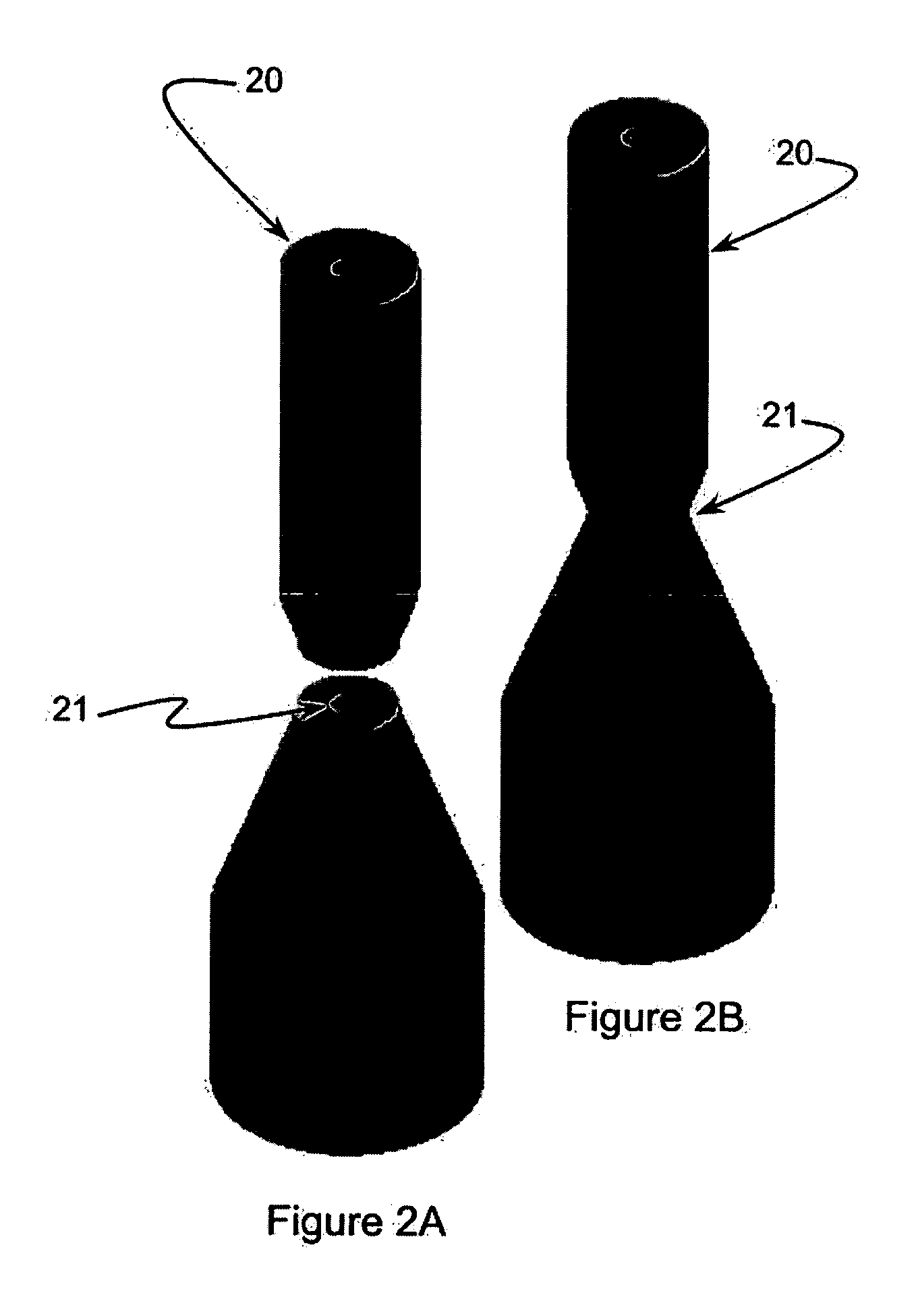

Hydrocarbon-fueled rocket engine with endothermic fuel cooling

InactiveUS20100257839A1Improve combustion stabilityImprove mixing efficiencyCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberKerosene

A rocket engine utilizes a kerosene-based fuel in a supercritical state which is catalytically converted to lighter hydrocarbons with heat from a thrust chamber assembly which operates as a heat exchanger. This process is facilitated by a fuel stabilization deoxygenator system which removes dissolved oxygen and / or by inerting the internal surfaces of the fuel-cooled combustion chamber wall passages by applying a zeolite-based catalyst coating to permit the fuel to be heated beyond normal temperature ranges. The supercritical kerosene-based fuel is passed through a turbine and injected into the combustion chamber to burn with the gaseous oxidizer. An increased mixing efficiency between the gaseous components results in an increase in combustion efficiency and increased stability of combustion.

Owner:UNITED TECH CORP

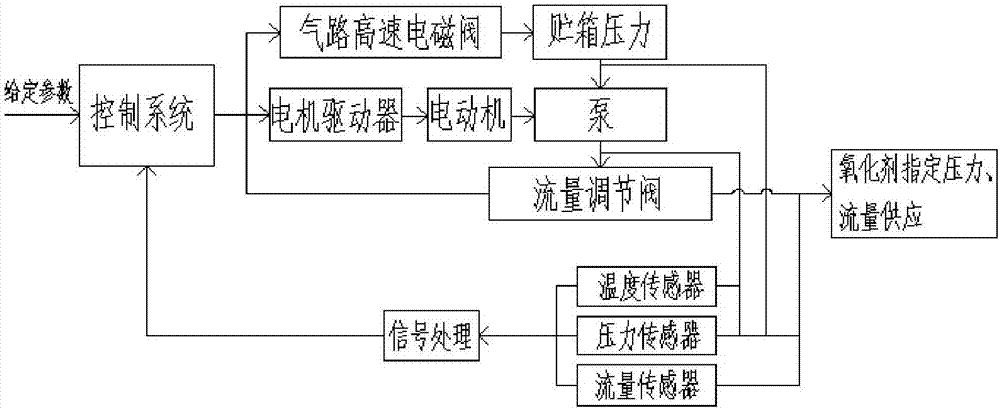

Electric pump conveying system for solid-liquid rocket engine

ActiveCN107237703ASatisfy flow pressureSatisfy delivery pressureRocket engine plantsGas cylinderSolenoid valve

The invention discloses an electric pump conveying system for a solid-liquid rocket engine. The electric pump conveying system comprises a high-pressure gas bottle and a storage box. The high-pressure gas bottle is connected with a storage box through a first pipeline. The storage box is connected with a thrust chamber through a second pipeline. A pressurizing one-way valve, pore plates, gas path high-speed electromagnetic valves, a storage box exhaust hand valve and a safety valve are mounted on the first pipeline. A filling-discharging hand valve, a diaphragm valve, a pump, a flow adjusting valve and a liquid path high-speed electromagnetic valve are mounted on the second pipeline, wherein the pump is connected with a motor. By controlling opening and closing of the gas path electromagnetic valves, the pressure of the storage box is adjusted to meet the task requirement; when the pressure of the storage box exceeds the break valve of the diaphragm valve, the diaphragm valve breaks; and oxidizing agents in the storage box are pressurized through the pump driven by the motor after passing through the diaphragm valve, and then the flow of the oxidizing agents is controlled through the flow adjusting valve, after the liquid path high-speed electromagnetic valve is opened, the oxidizing agents are supplied to the thrust chamber according to the flow and pressure of task requirements. The electric pump conveying system is especially suitable for a solid-liquid rocket engine on a small carrier rocket.

Owner:BEIHANG UNIV

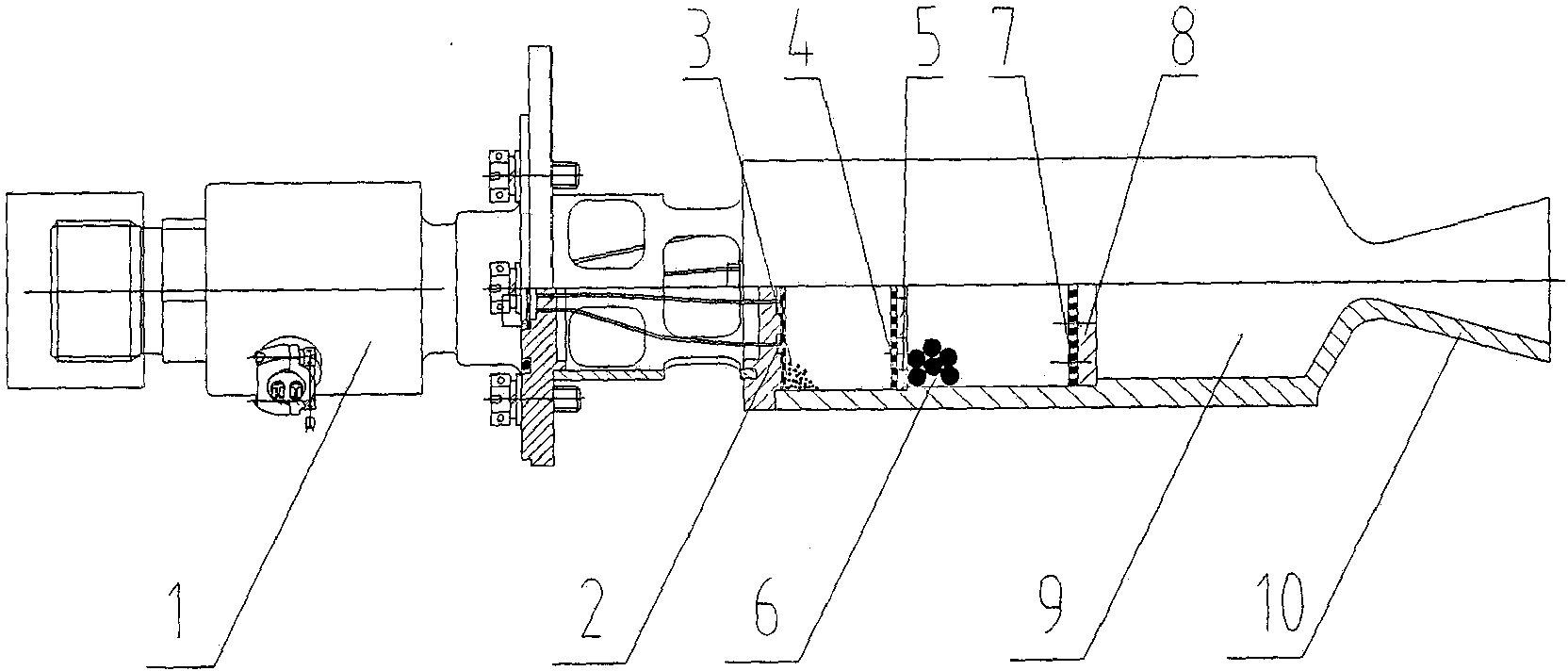

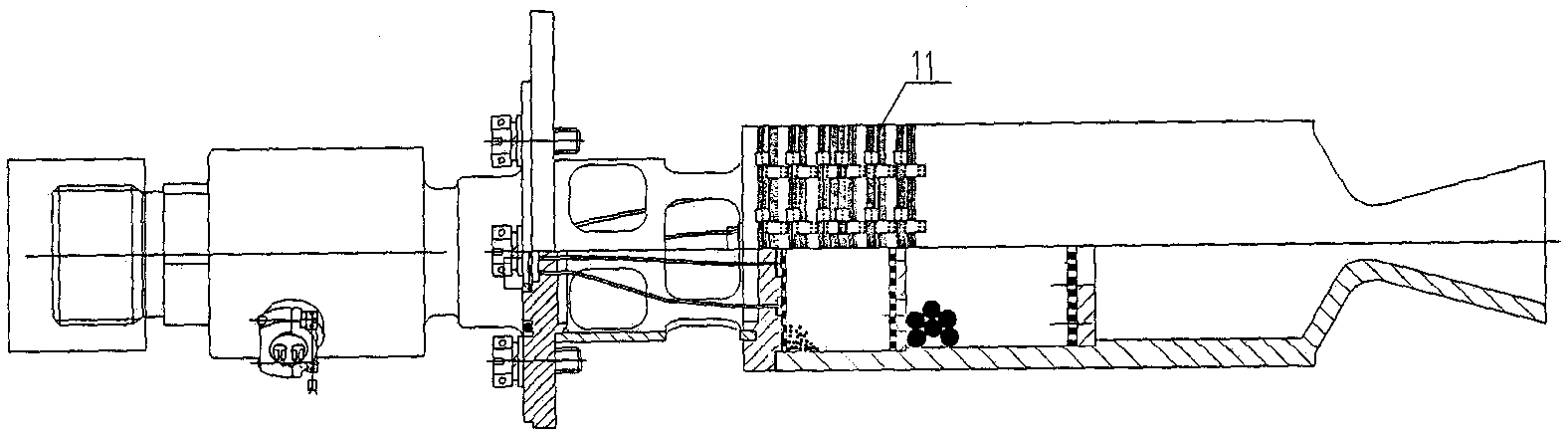

small thrust rocket engine

ActiveCN106134417BTo achieve non-toxicImprove performanceElectric spark ignitersRocket engine plantsCombustion chamberKerosene

The invention discloses a small-thrust rocket engine applied to aerospace vehicles, which comprises a fuel valve (1), an oxygen valve (2) connected with an injector (4), and transports kerosene and gaseous oxygen to the injector (4) respectively ; The tail of the injector (4) is provided with an electric igniter (3); the injector (4) is connected with the thrust chamber body (5); the thrust chamber body (5) is composed of a combustion chamber and a nozzle The electric spark generated by the igniter (3) directly ignites the propellant gas mixture near the injection surface of the injector (4), and the gas is discharged from the nozzle to generate thrust. The invention uses gas-oxygen / kerosene as a propellant, solves the environmental pollution problem of the existing toxic spontaneous combustion propellant engine, and achieves beneficial effects such as non-toxic, non-polluting, high performance, fast response, and adaptation to steady-state / pulse dual working modes. .

Owner:SHANGHAI INST OF SPACE PROPULSION

Variable-thrust rocket engine and rocket with same

The invention relates to the technical field of spaceflight propulsion, in particular to a variable-thrust rocket engine and a rocket with the same. The variable-thrust rocket engine drives a first electric pump and a second electric pump through a motor so as to provide an oxidant and a fuel for a gas generator respectively, due to the fact that the rotating speed of the motor is adjustable, theflow of the oxidant and the fuel entering the fuel gas generator can be changed, fuel gas generated by the fuel gas generator drives a pressurizing device, and the power of the pressurizing device ischanged; and the pressurizing device is used for changing the flow of the fuel and the oxidant which are injected into a thrust chamber, so that the pushing force of the rocket engine is adjusted. Moreover, the first electric pump and the second electric pump are also used as a starting device of the rocket engine, so that multiple starting of the engine is realized, and the structure of the variable-thrust rocket engine is simplified.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

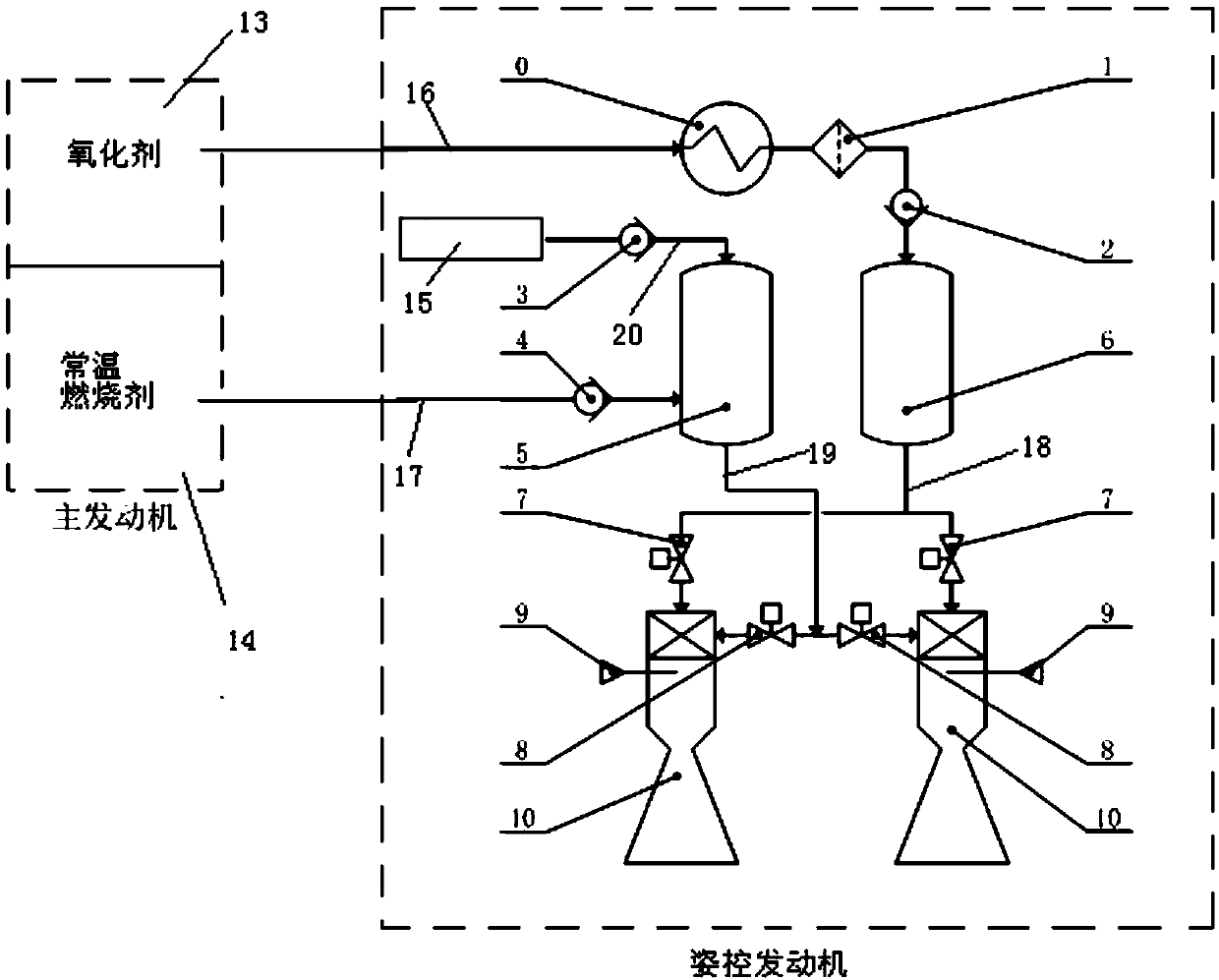

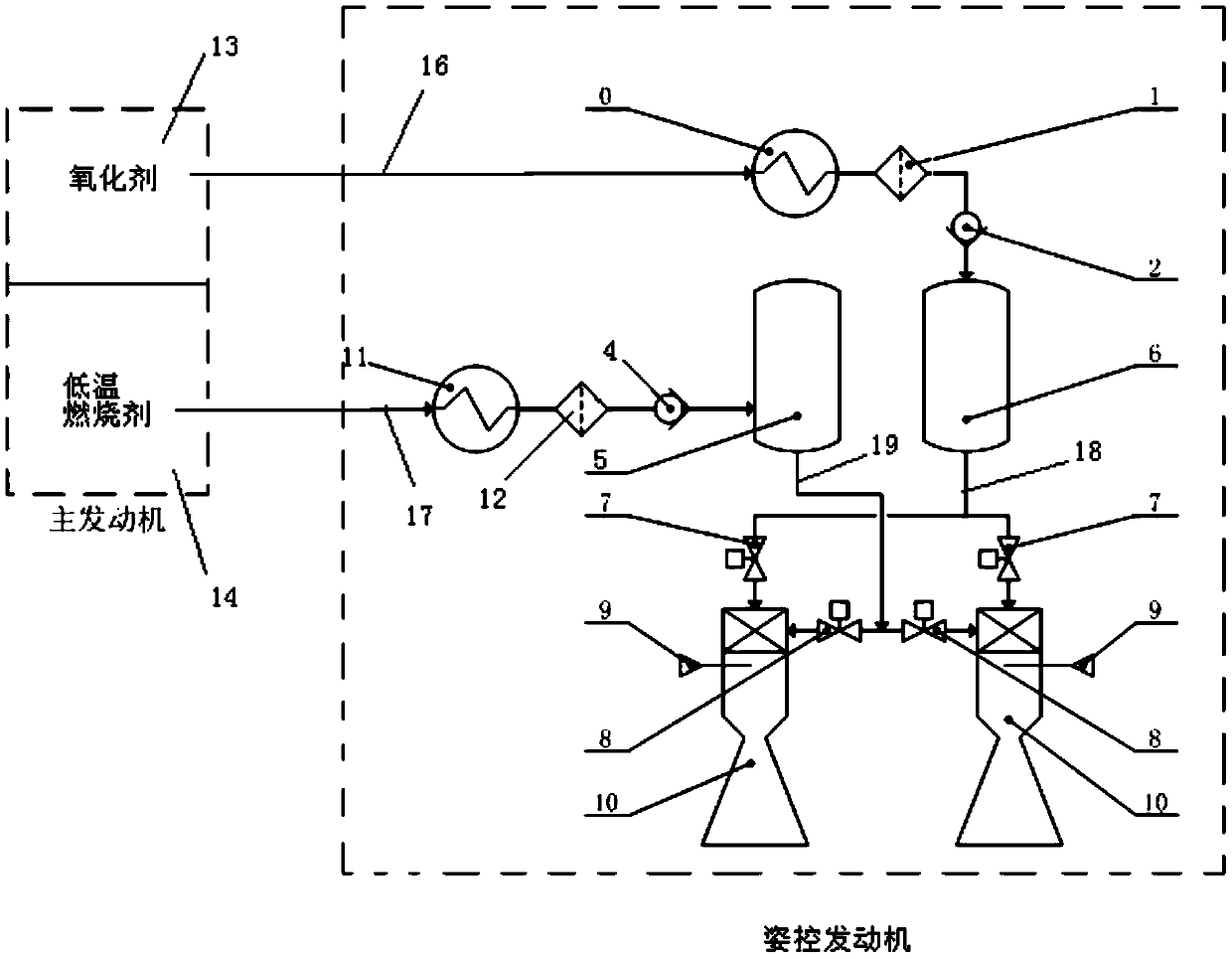

Power system for carrier rocket upper stage and orbit transfer vehicle

The invention discloses a power system for a carrier rocket upper stage and an orbit transfer vehicle. The power system for the carrier rocket upper stage and the orbit transfer vehicle solves the existing problems that a main engine and an attitude control engine are relatively independent, the carrying burden is relatively heavy,a propellant used in the attitude control engine is rather toxic,and the environment and safety of a human body are seriously threatened. The power system for the carrier rocket upper stage and the orbit transfer vehicle comprises the main engine and the attitude control engine; a propellant tank of the main engine can simultaneously deliver a propellant to a thrust chamber of the main engine and a thrust chamber of the attitude control engine under the action ofa propellant supply system of the propellant tank, and liquid oxygen is used as an oxidant of the propellant; kerosene, or liquid hydrogen or liquid methane is used as an incendiary agent; the detoxication of the attitude control engine is achieved, and integration of the homologous propellant of the main engine and the attitude control engine is achieved; a propellant tank of the attitude control engine can be supplemented after operation through the main engine; and the propellant dosage carried by the attitude control engine during flight can be reduced, thus the weight of the overall system is lowered, and the payload of a carrier is greatly increased.

Owner:XIAN AEROSPACE PROPULSION INST

Hydrogen-peroxide-based RBCC (Rocket Based Combined Cycle) engine pressure pumping and squeezing integrated fuel system

ActiveCN103696883AOvercoming complexityOvercome the huge disadvantageRocket engine plantsCombustion chamberKerosene

The invention provides a hydrogen-peroxide-based RBCC (Rocket Based Combined Cycle) engine pressure pumping and squeezing integrated fuel system. The hydrogen-peroxide-based RBCC engine pressure pumping and squeezing integrated fuel system comprises a pressurization unit, a supplying unit, an engine body and a connecting pipeline unit; the pressurization unit is used for performing pressurization on the supplying unit; the supplying unit which is connected with the engine body through the connecting pipeline unit supplies propellant to the engine body. The hydrogen-peroxide-based RBCC engine pressure pumping and squeezing integrated fuel system has the advantages of overcoming disadvantages of a complex and huge system due to the fact that a rocket thrust chamber and a stamping combustion chamber separately supply fuel, synthesizing respective advantages of the hydrogen peroxide and kerosene propellant, being high in density specific impulse, satisfying combination engine design requirements for integrated fuel supplying and an integrated cooling structure and being mature in utilization and maintenance technology, relatively simple in system composition and easy to achieve.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com