Slotted coaxial pintle type injector thrust chamber

A technology of injectors and thrust chambers, which is applied in the field of liquid rocket engines, can solve problems such as technical difficulties, achieve broad application prospects, improve combustion performance, and reduce the effect of splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

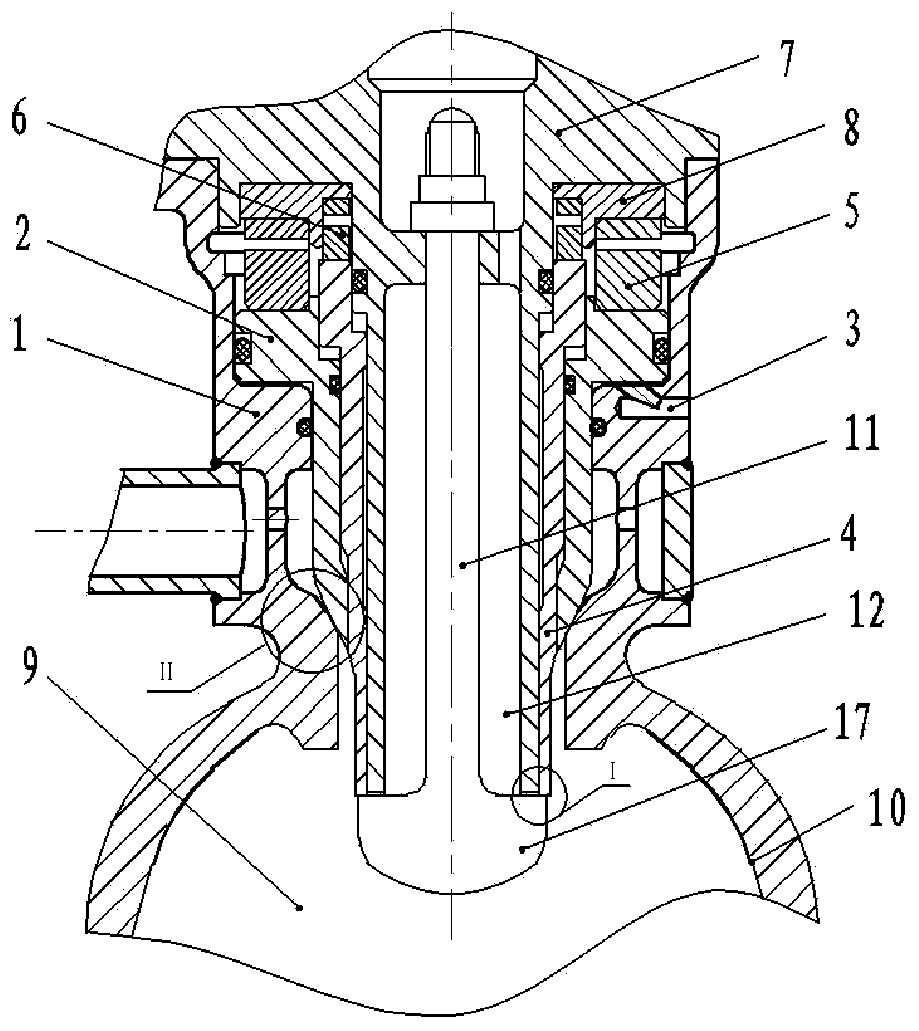

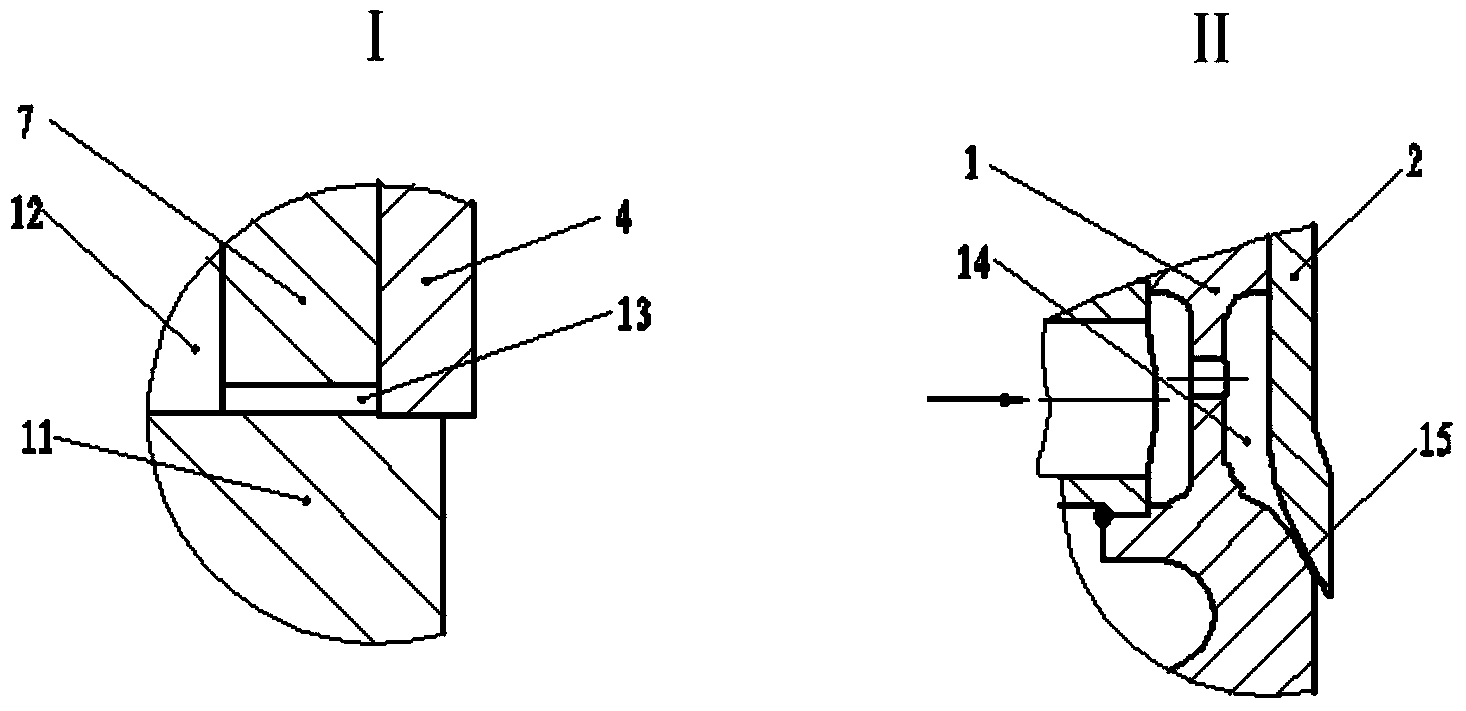

[0033] Such as figure 1 , Figure 4 The central cylinder 7 shown is one of the key parts of the embodiment. The end notches 16 of the central cylinder 7 are evenly spaced, different in size, and staggered T-shaped grooves and rectangular grooves. The T-shaped groove 13 is the main groove. The rectangular groove 14 is an auxiliary groove, and the impact of multiple radial jets ejected from the radial nozzle 13 and the annular liquid film of the axial outer ring ejected from the annular nozzle 15 ensures that the two propellants are collided to form a good friction The large-gradient radial mixing ratio distribution not only improves the efficiency but also realizes the penetration of part of the fuel to fully cool the body. Part of the jet flows along the surface of the splash plate 9 after hitting the click wall. The notch design is optimized according to the blocking rate, the proportion of auxiliary grooves and the number of grooves, the injection pressure drop ratio (or m...

Embodiment 2

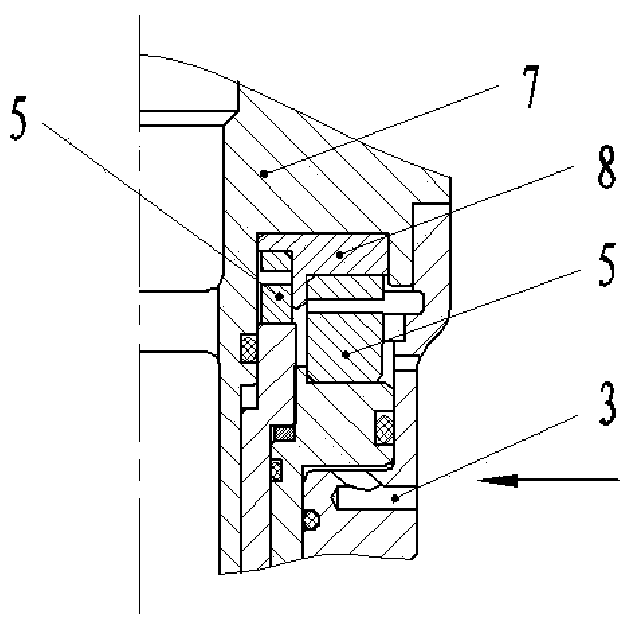

[0035]The main spring 5 and the auxiliary spring 6 are one of the key parts of the implementation plan. They are made of 65Mn spring steel through heat treatment, wire cutting, surface treatment and pressure treatment to meet the high spring stiffness and large compression required by the design. When shutting down, the outer sleeve 2 and the inner sleeve 4 are in a sealed state by relying on the pre-compression pre-tightening force.

Embodiment 3

[0037] Such as figure 1 , Figure 4 As shown, the end notches 16 of the central cylinder 7 are T-shaped slots and rectangular slots with uniform intervals, different sizes, and staggered arrangements. The T-shaped slots 13 are the main slots, and the rectangular slots 14 are auxiliary slots. The impact of multiple radiated radial jets and the annular liquid film of the axial outer ring ejected from the annular nozzle 15 ensures that the two propellants collide to form a good radial mixing ratio distribution with a large gradient, which not only improves the efficiency The partial fuel that can realize penetration again fully cools down the body. Part of the jet flows along the surface of the splash plate 9 after hitting the click wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com