Variable working condition type primary rocket system of rocket based combined cycle engine

A rocket engine and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of complex servo mechanisms or power devices, poor controllability, low precision, etc., to achieve accurate flow and meet the needs of flow regulation , the effect of quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

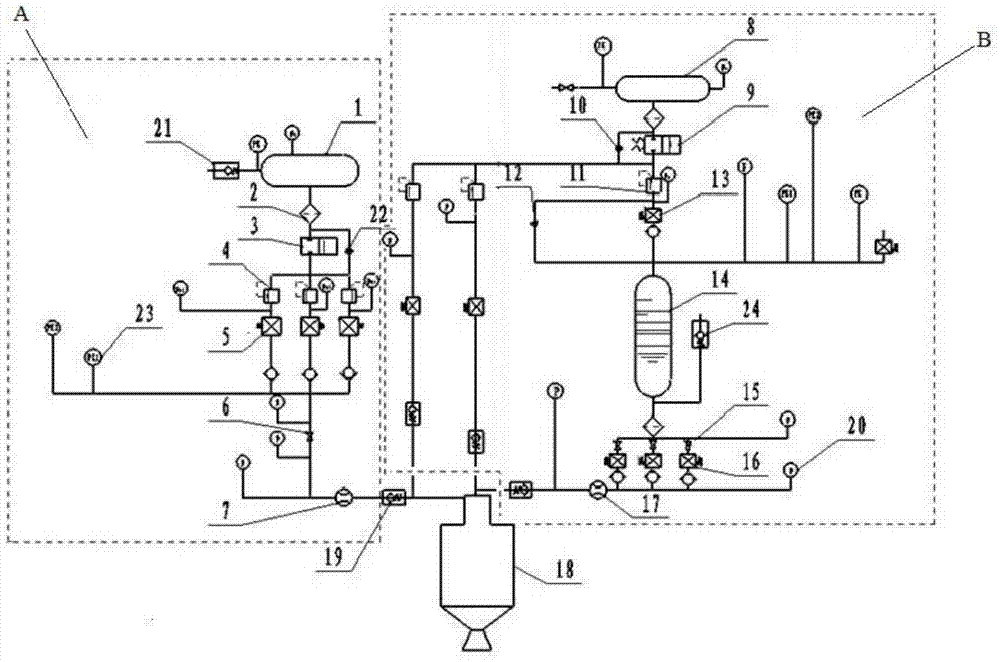

[0022] like figure 1 As shown, a primary rocket system of a rocket-based combined cycle engine with variable operating conditions includes a propellant supply system connected by pipelines and a primary rocket engine thrust chamber 18, and the propellant supply system includes an oxidant supply system A and a fuel supply system B The oxidant supply system A includes an oxygen flow control system, the oxygen flow control system includes a plurality of oxygen delivery pipelines, each oxygen delivery pipeline is provided with an oxygen pressure reducing valve 4 for opening and closing, and the outlet of the oxygen delivery pipeline is connected to Oxygen orifice 6 is arranged; fuel supply system B comprises pressure control system, and pressure control system comprises a plurality of fuel delivery pipelines, and the outlet of each described fuel delivery pipeline is all provided with cavitation venturi 15, and fuel delivery pipeline The inlet of is connected with the nitrogen pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com