Catalytic decomposition low-concentration hydrogen peroxide reactor, combustion chamber and application thereof

A hydrogen peroxide, catalytic decomposition technology, applied in the direction of chemical instruments and methods, chemical/physical processes, machines/engines, etc., can solve the problems of high price, insufficient safety, lower decomposition temperature and combustion temperature, etc., to achieve infinite Effects of heat dissipation loss, high safety, and increased life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

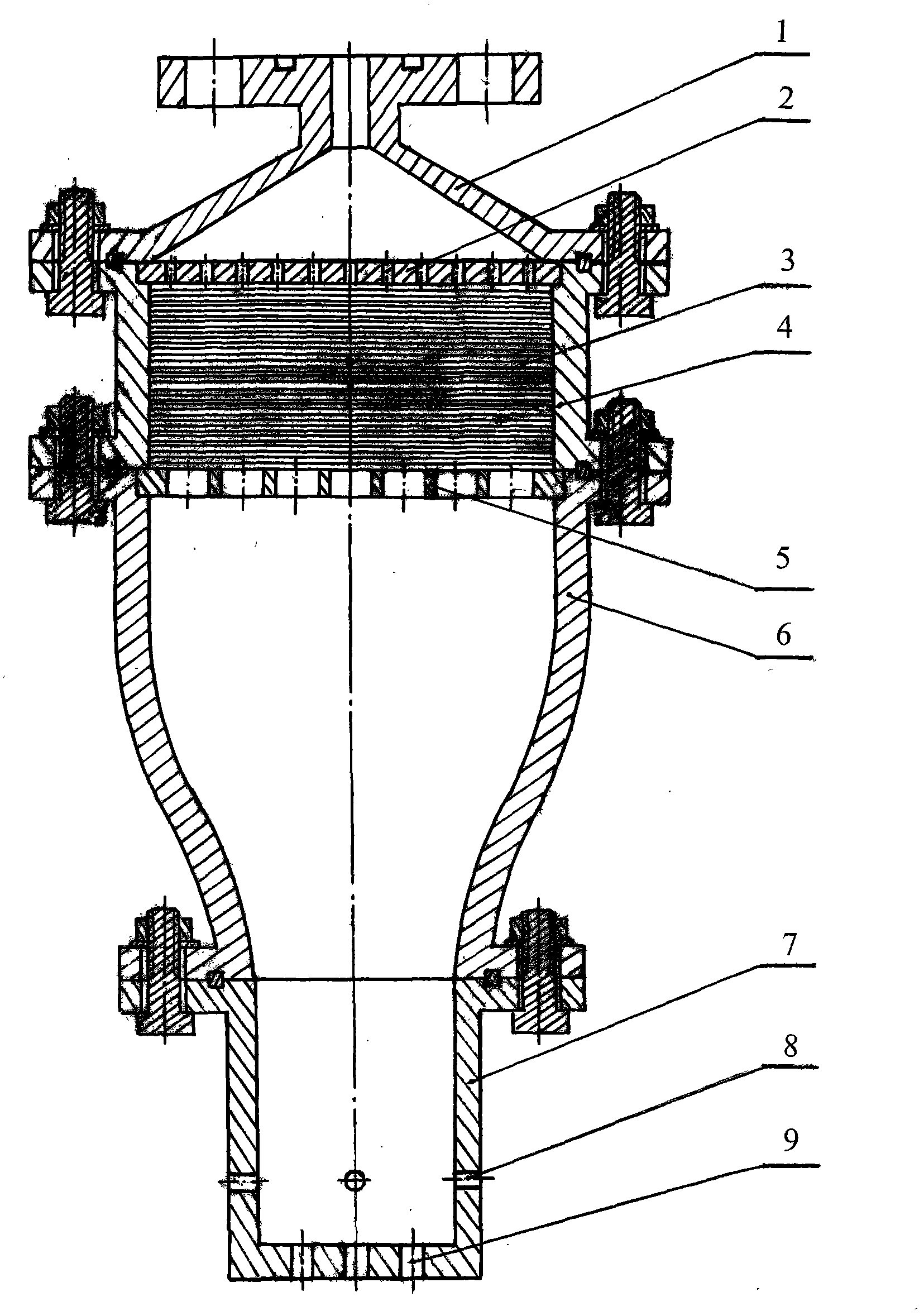

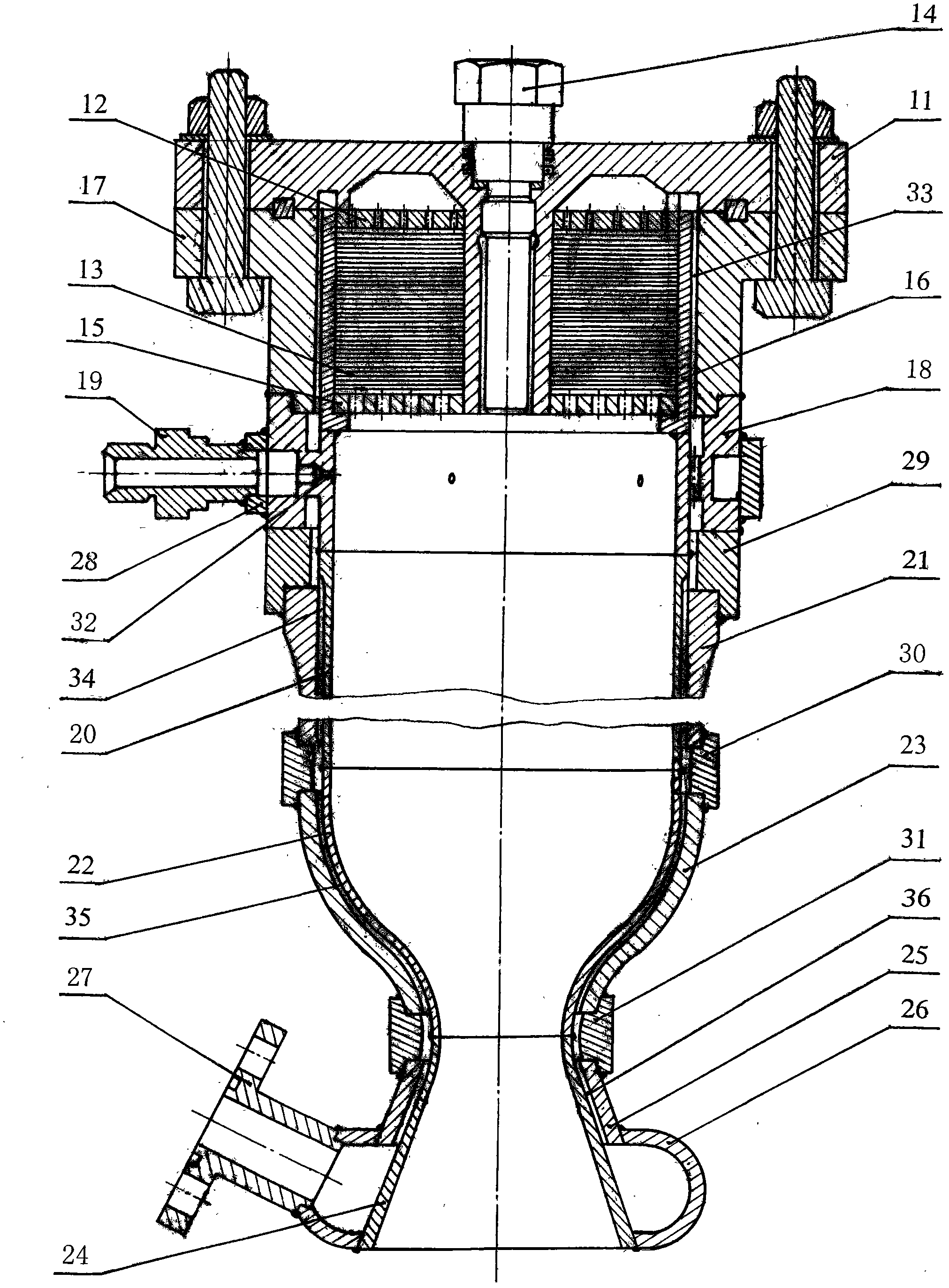

[0022] figure 1 , figure 2 and Figure 3-Figure 6 are three preferred embodiments of the present invention.

[0023] Such as figure 1 As shown, a catalytic decomposition hydrogen peroxide reactor of the present invention comprises a top cover 1, an equalizer plate 2, a catalytic bed 3, a decomposition chamber housing 4, a support plate 5, a collecting chamber housing 6 and a throat housing 7. Screw connection and limit fixation. The reactor adopts a multi-layered, low bed load and pre-contacted cylindrical pure silver mesh catalyst bed 3 for catalytically decomposing 40%-70% hydrogen peroxide, and the throat shell 7 is provided with radial holes 8 or / and shafts. To hole 9.

[0024] The radial holes 8 are a circle of circular holes evenly distributed along the circumference, which eject gas-liquid flow at the speed of sound, and are used for thermal oil recovery of downhole reactors.

[0025] Radial holes 8 are 1-5 circles of circular holes evenly distributed along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com