Patents

Literature

35 results about "Thermal oil recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

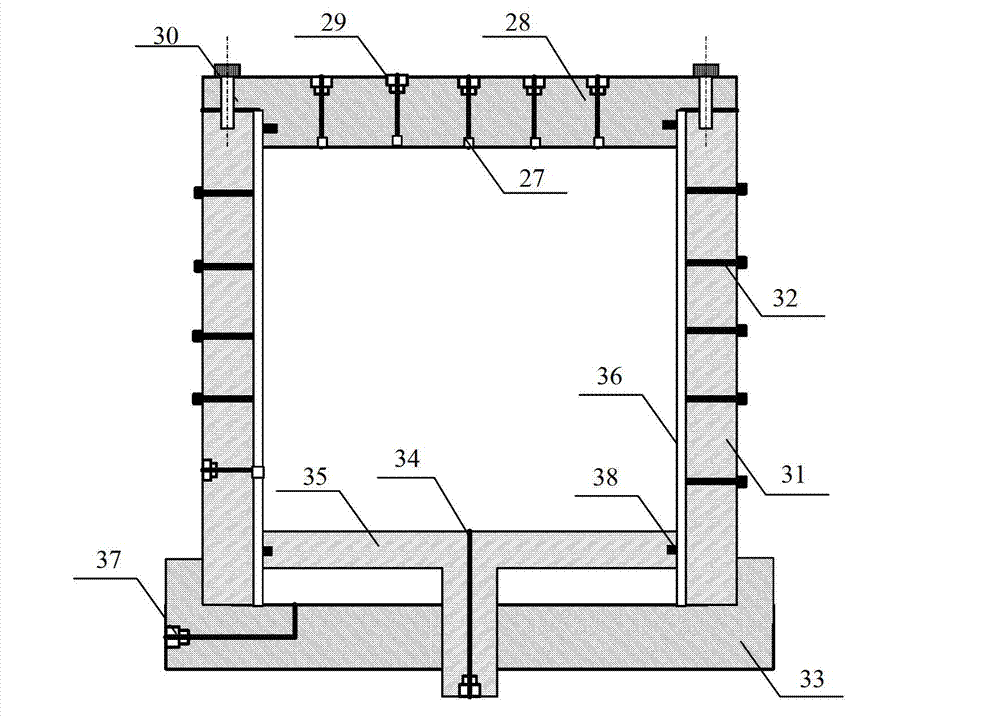

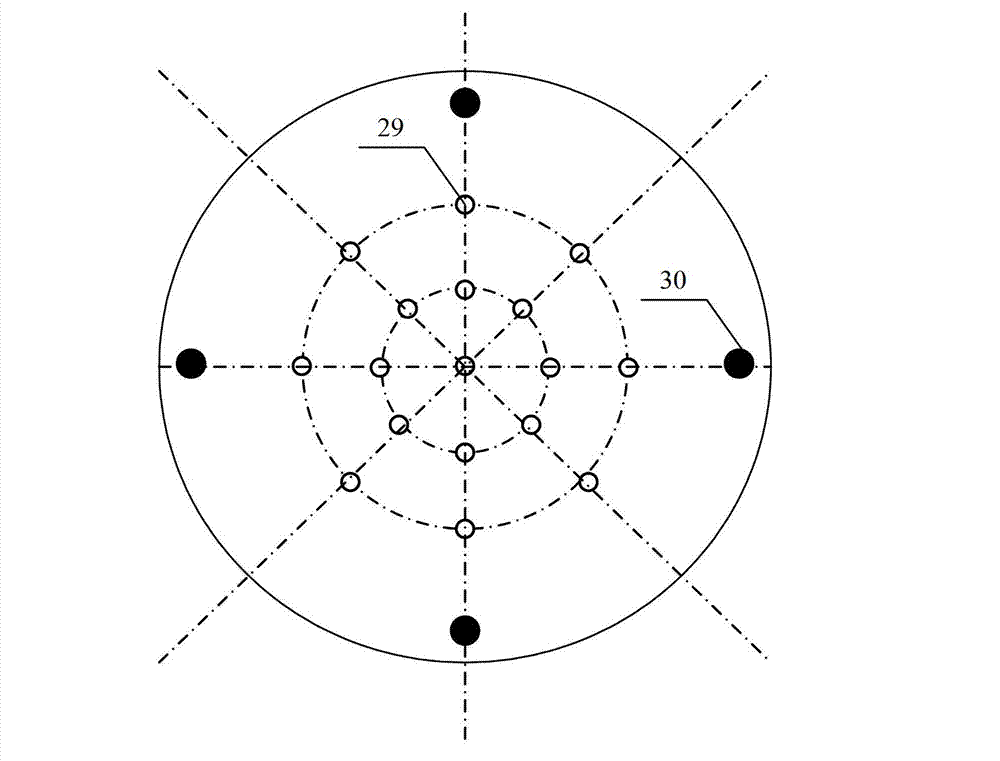

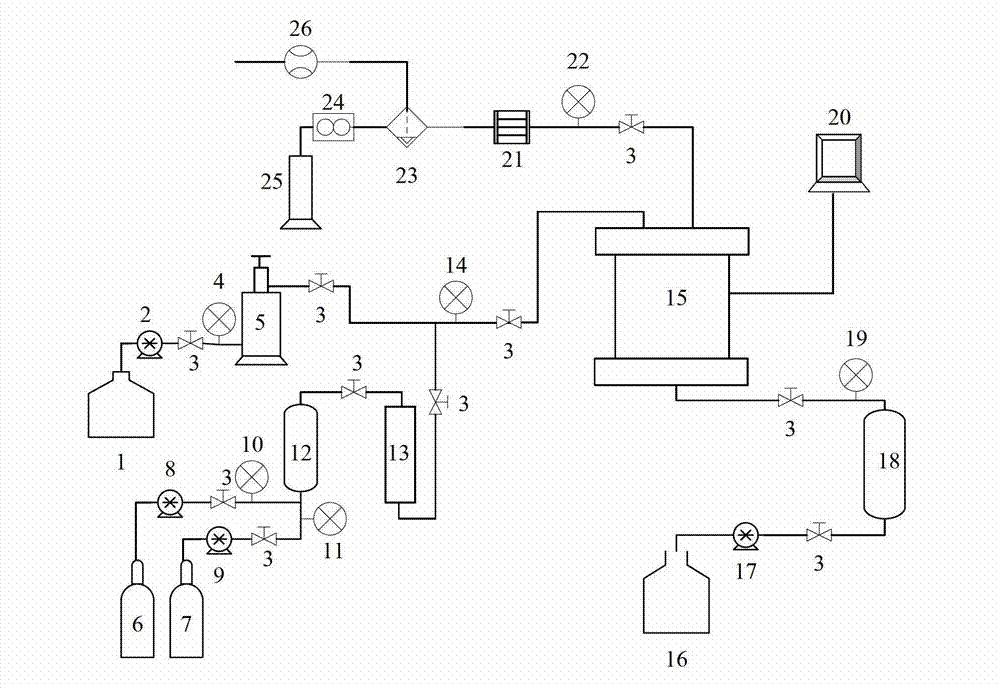

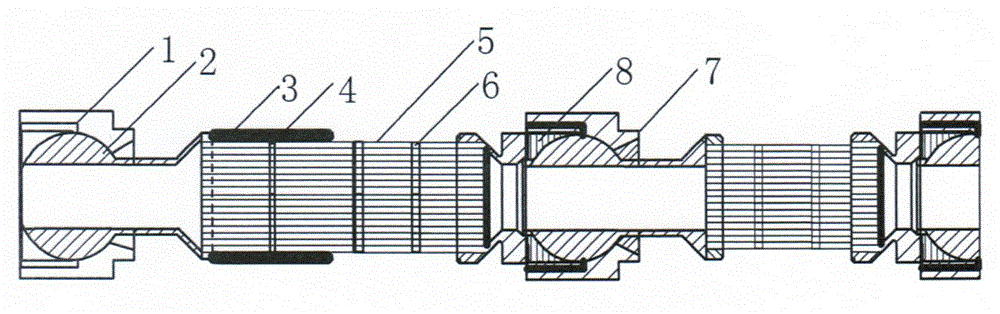

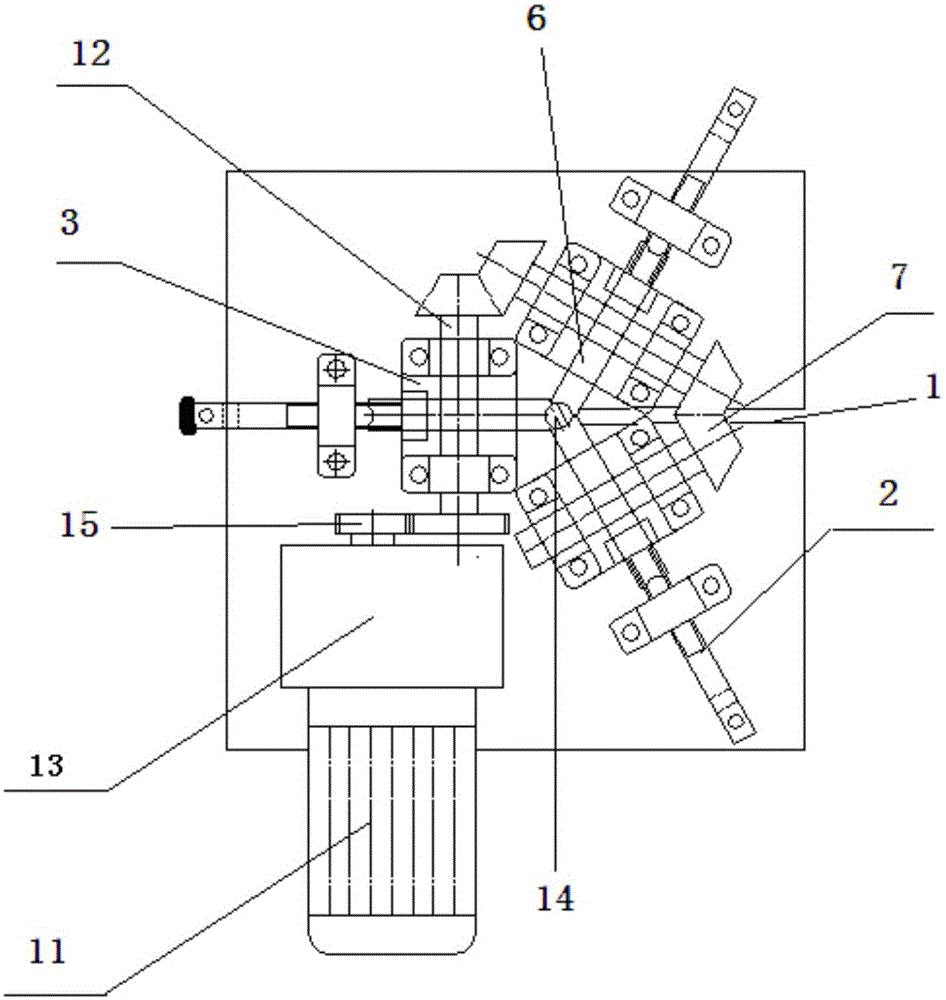

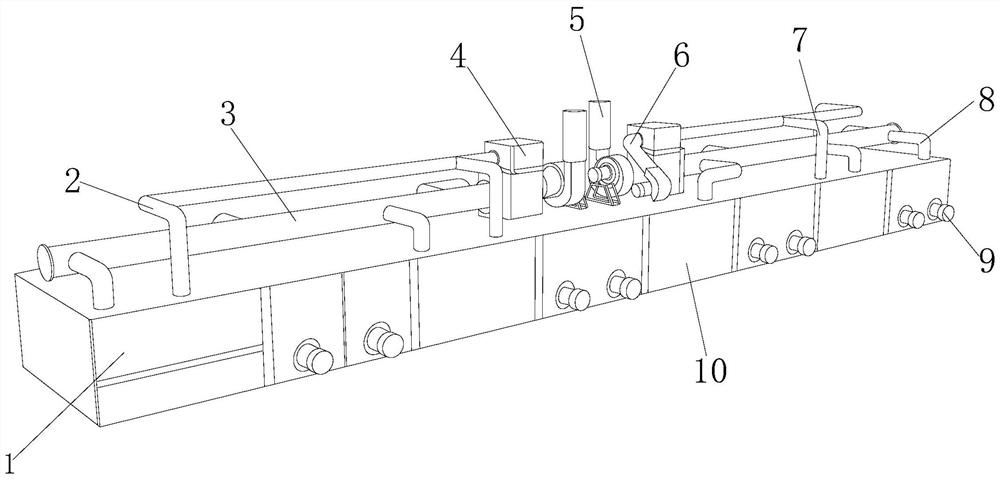

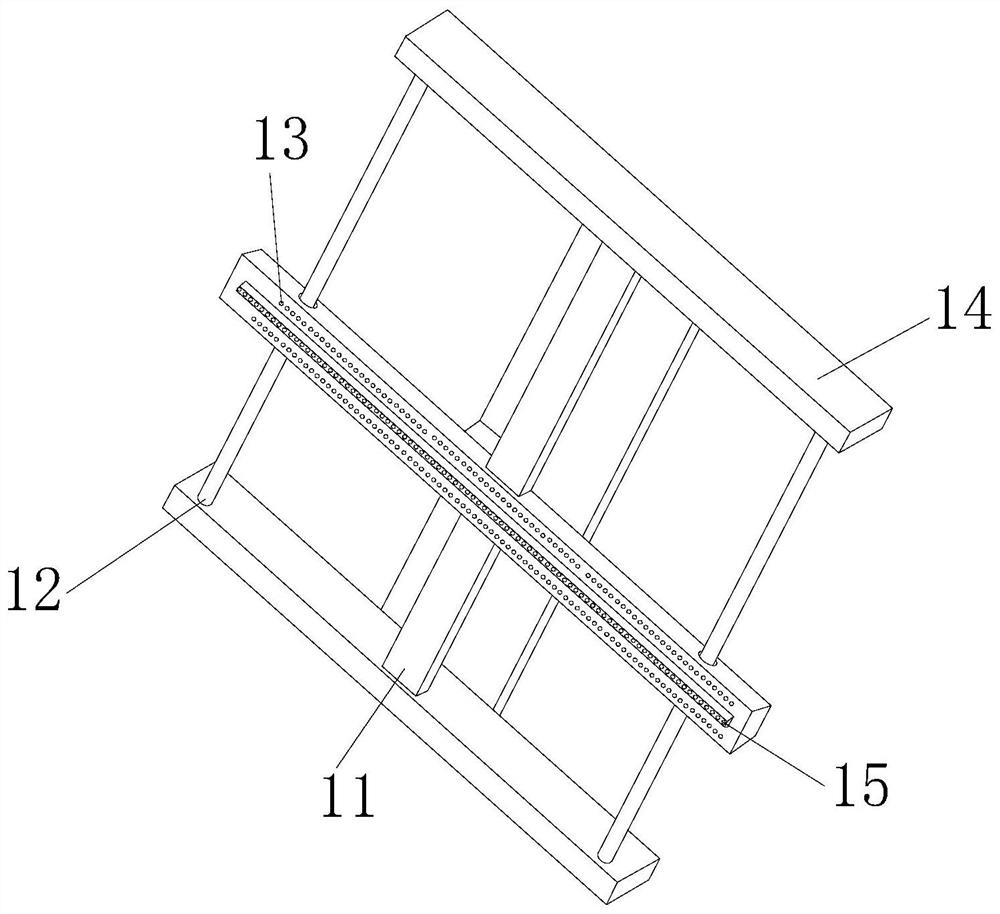

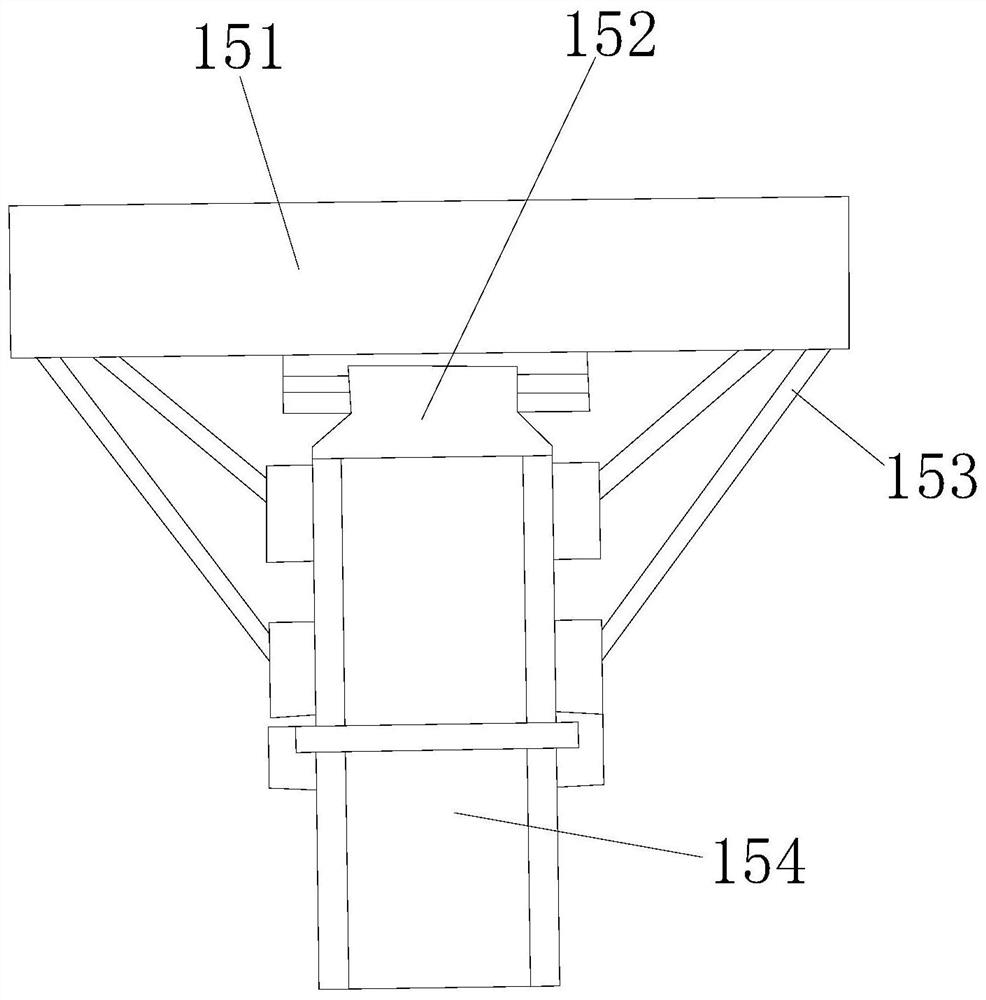

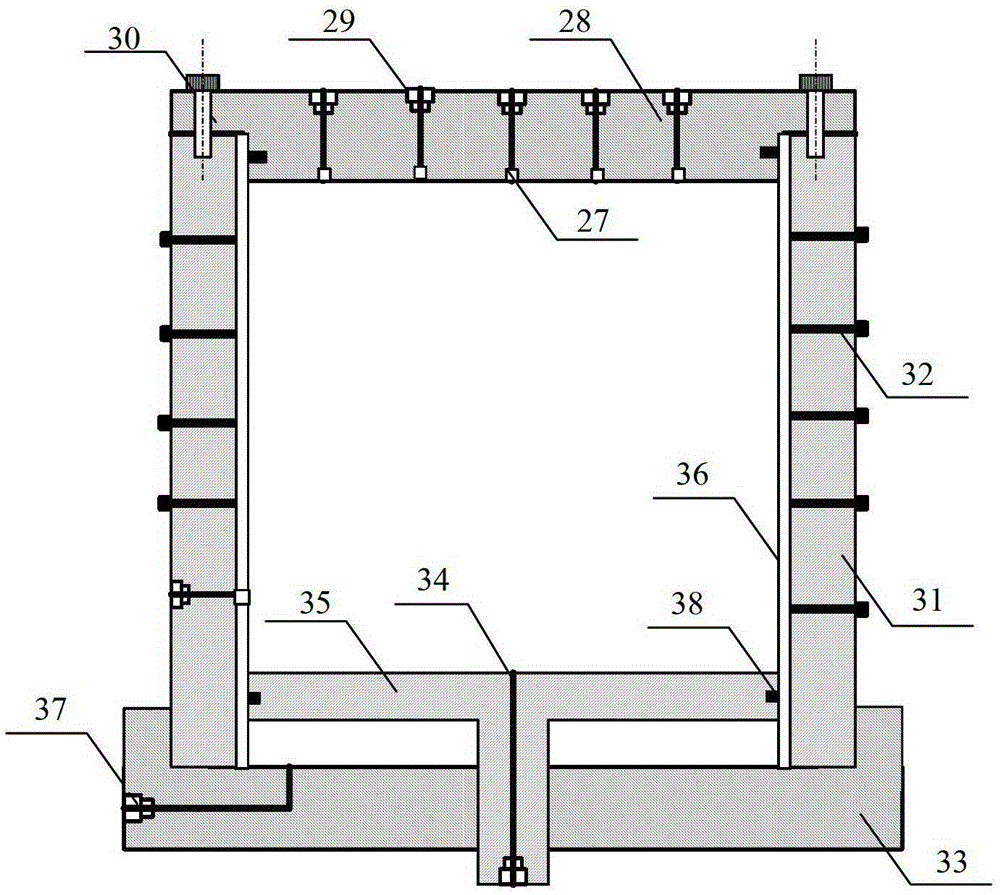

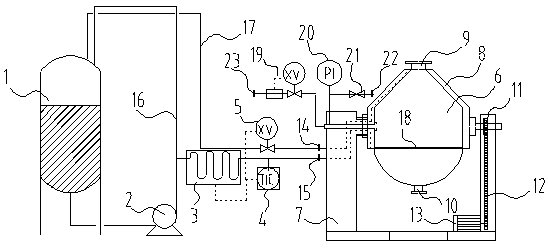

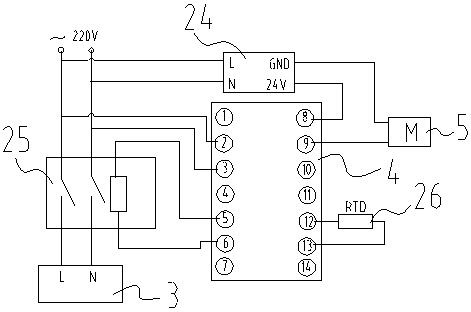

Experimental device for simulating heavy oil reservoir gas auxiliary steam thermal oil recovery and special model system thereof

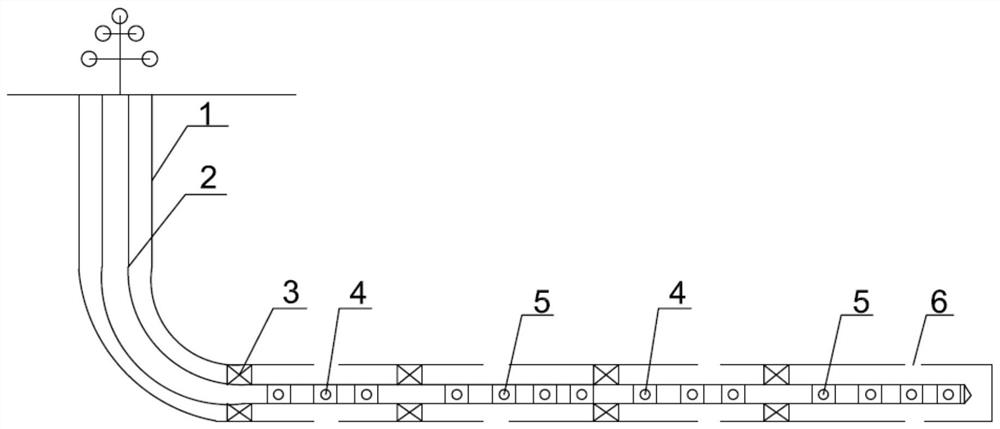

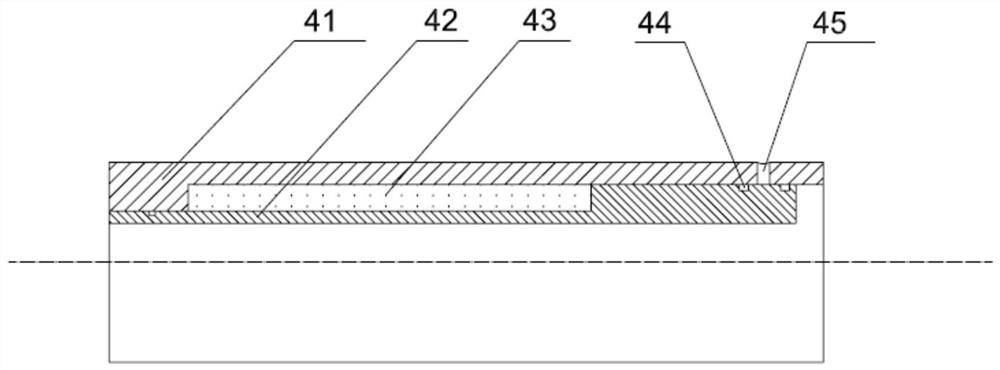

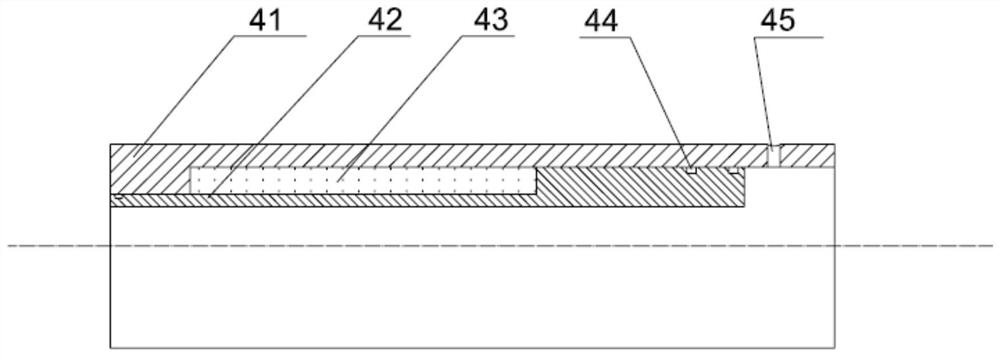

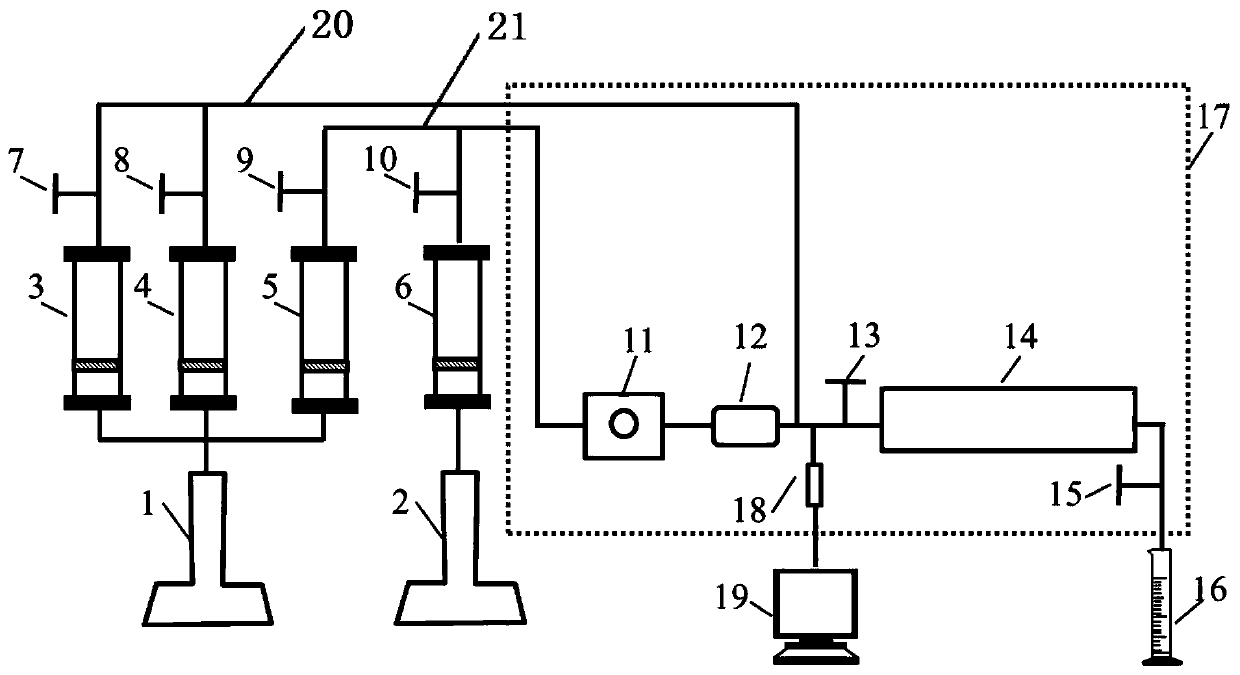

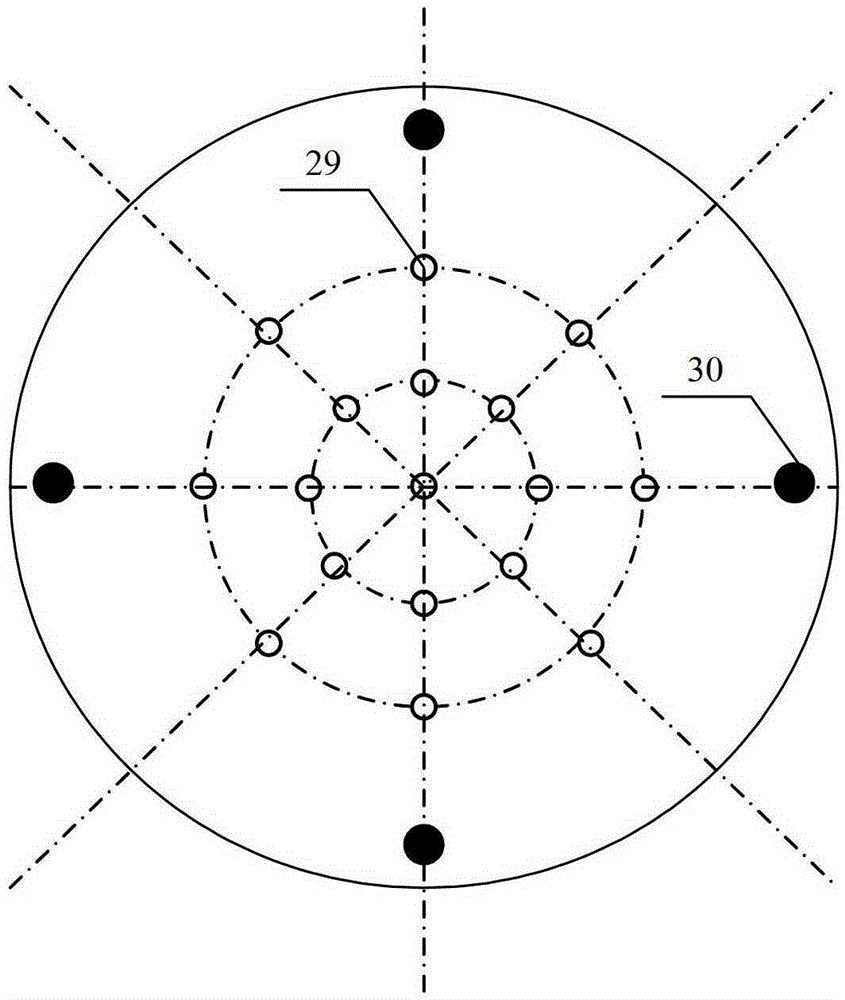

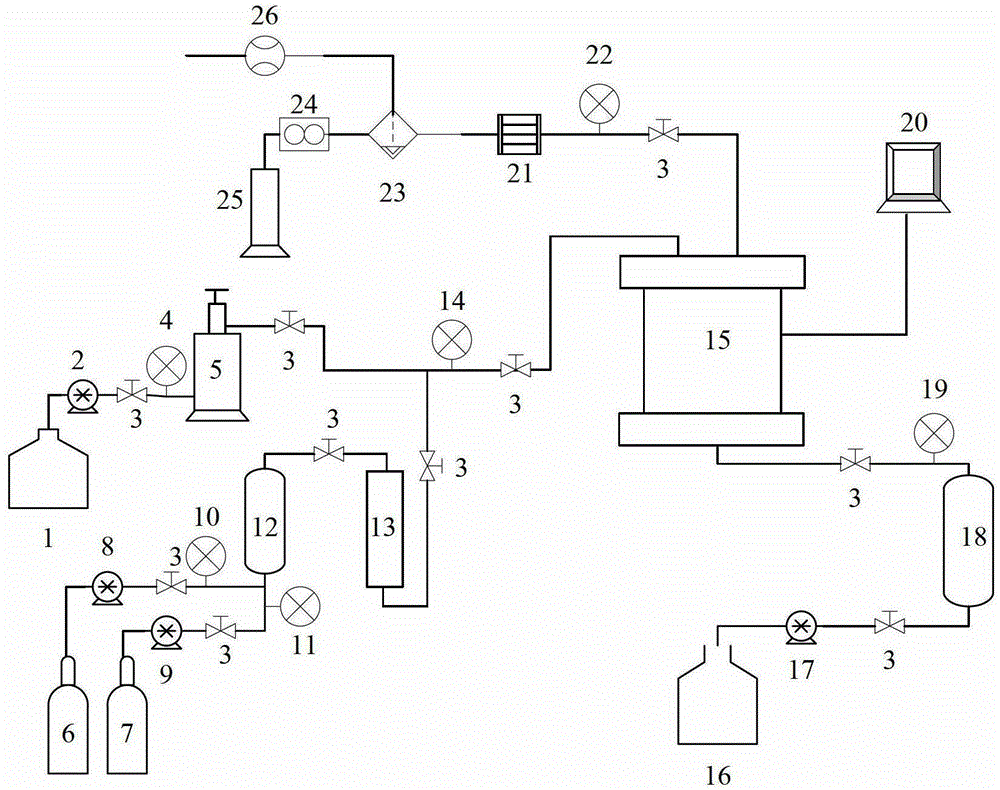

The invention discloses an experimental device for simulating heavy oil reservoir gas auxiliary steam thermal oil recovery and a special model system of the experimental device. The model system consists of a cylinder body. Openings at both ends of the cylinder body are respectively matched with an upper cover and a piston in a sealing mode. The piston is fixed on the cylinder body through a piston fixed pressing cap. At least one fluid in-out hole is formed in the upper cover, and the fluid in-out hole extends to a cavity of the cylinder body and connected with a well model connecting port. The well model connecting port is used for connecting well models. At least one data acquisition port is arranged on the cylinder body. The data acquisition port extends to the cavity of the cylinder body, the piston fixed pressing cap is provided with a liquid inlet, and the liquid inlet extends to a cavity between the piston and the piston fixed pressing cap. The experimental device can carry out precise experiments over a production increasing mechanism and an effect of gas improving steam stimulation and steam drive, the experimental results are genuine and believable, and the device has an important significance for gas auxiliary steam thermal oil recovery and development.

Owner:CHINA NAT OFFSHORE OIL CORP +1

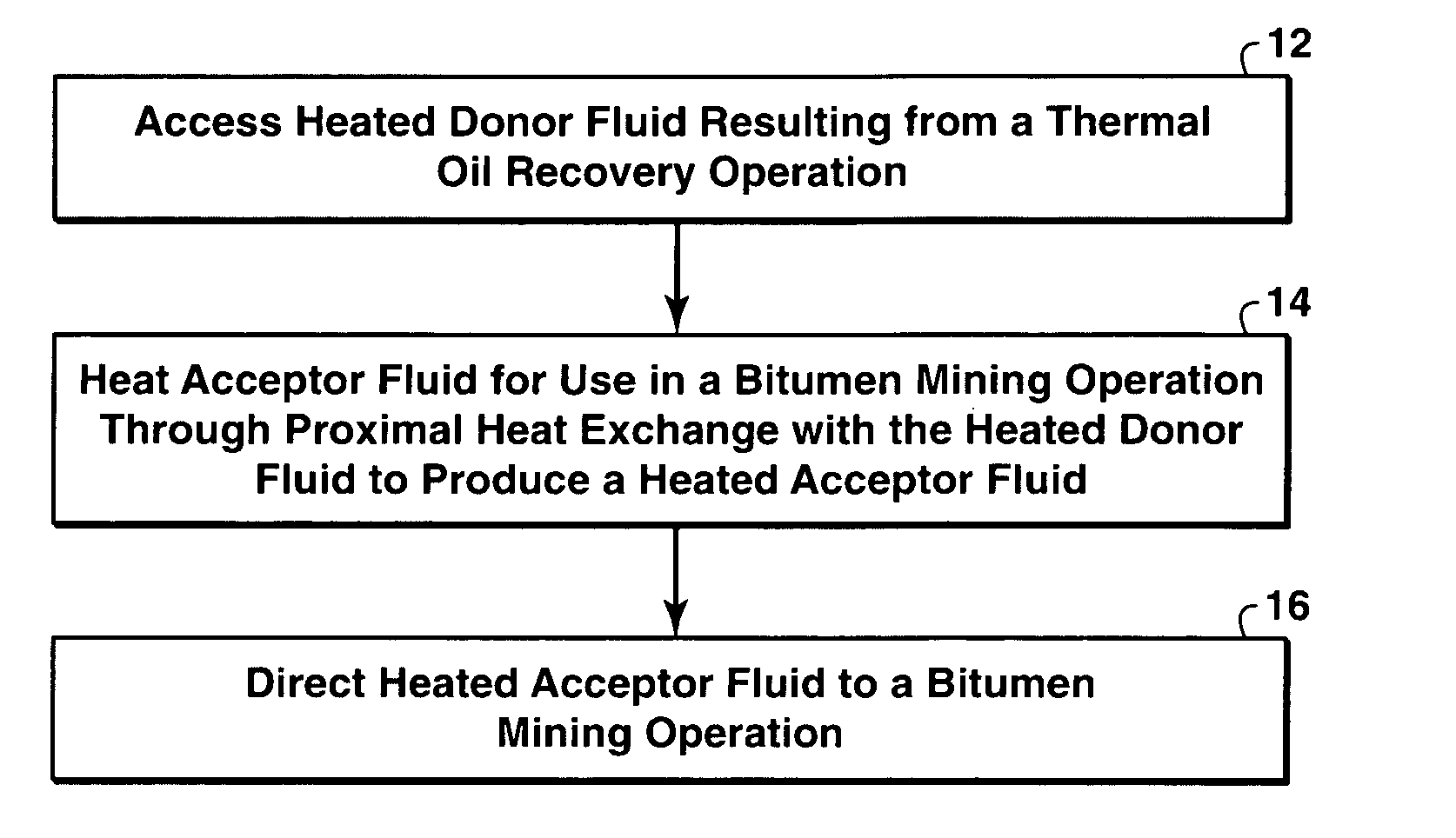

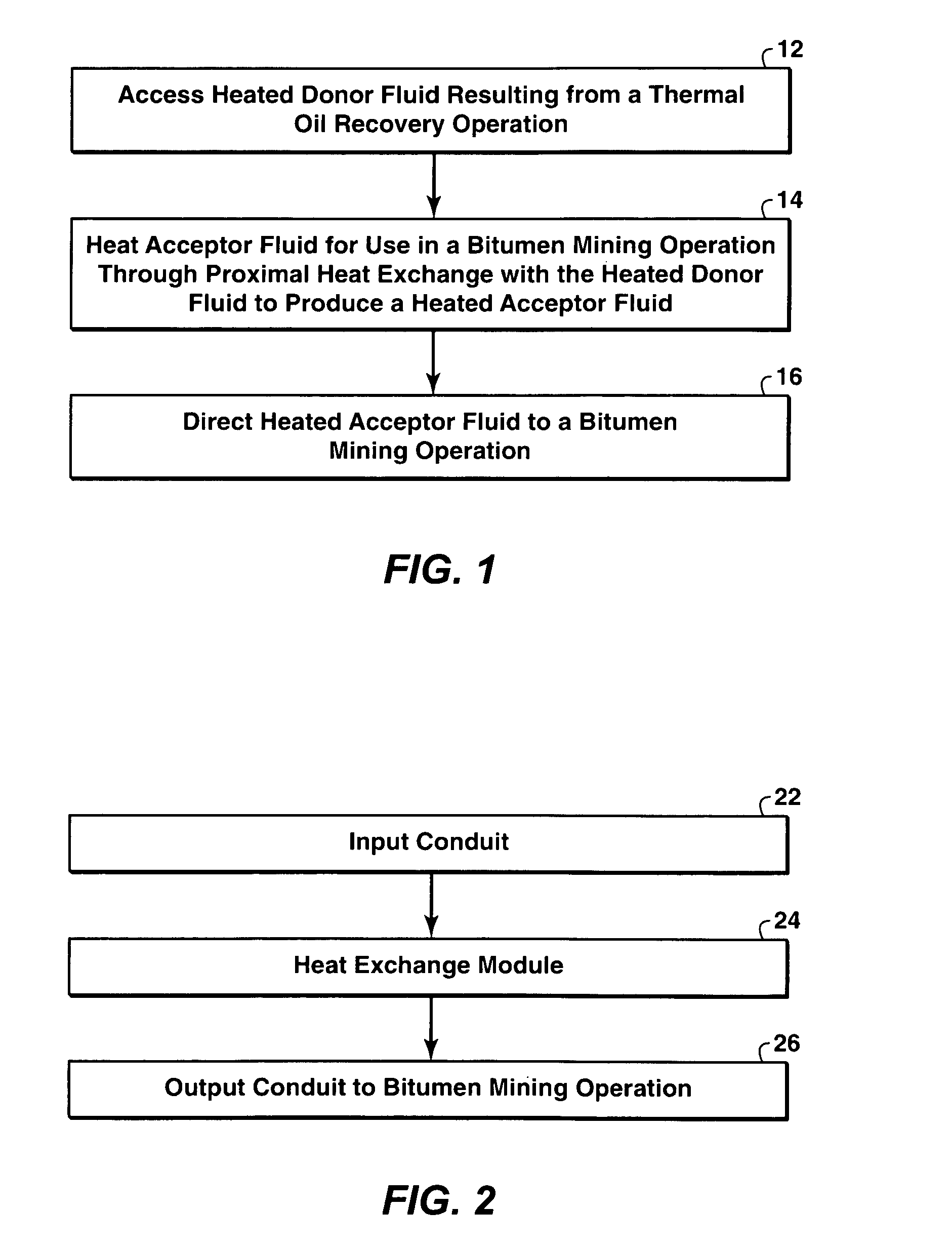

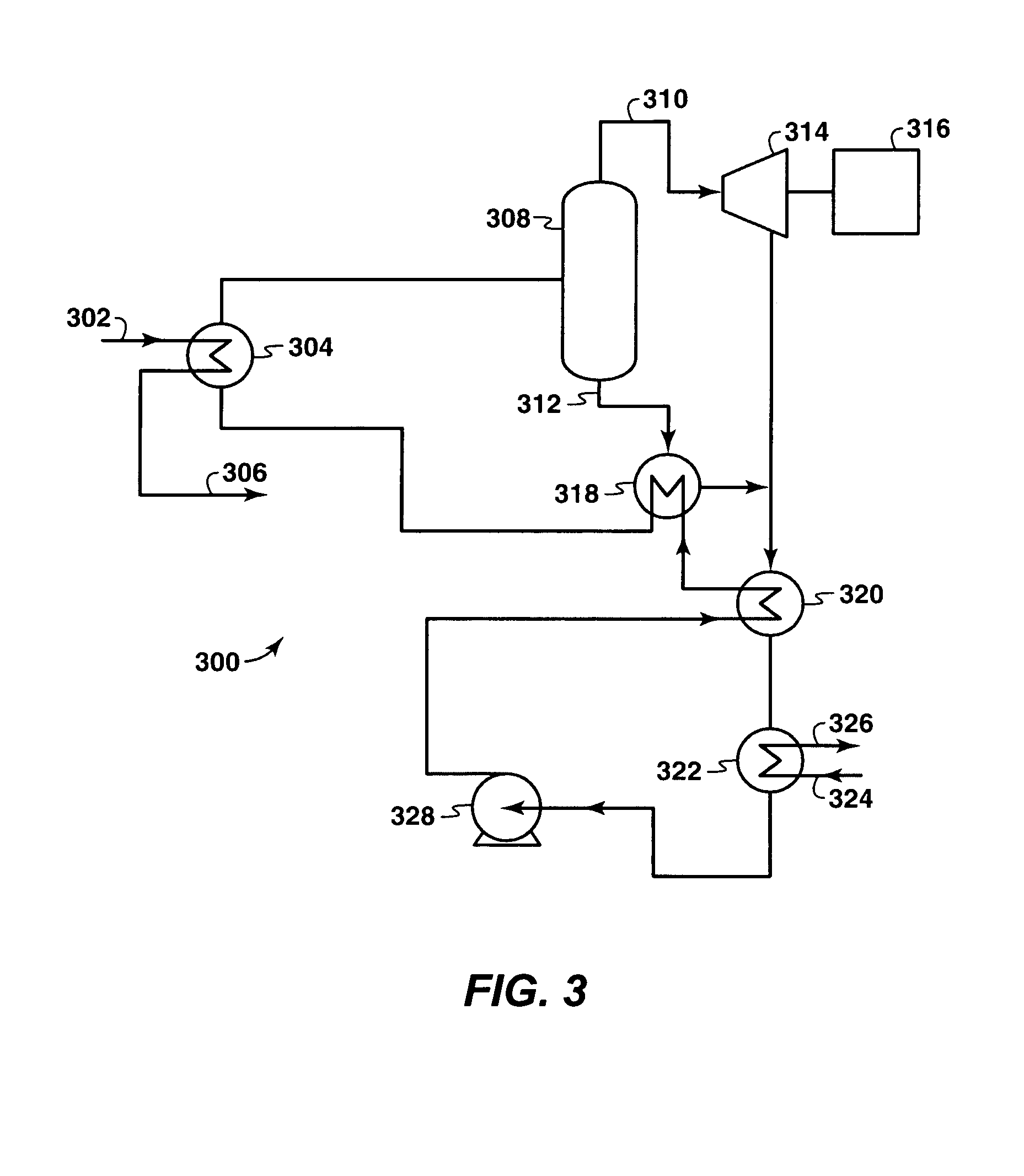

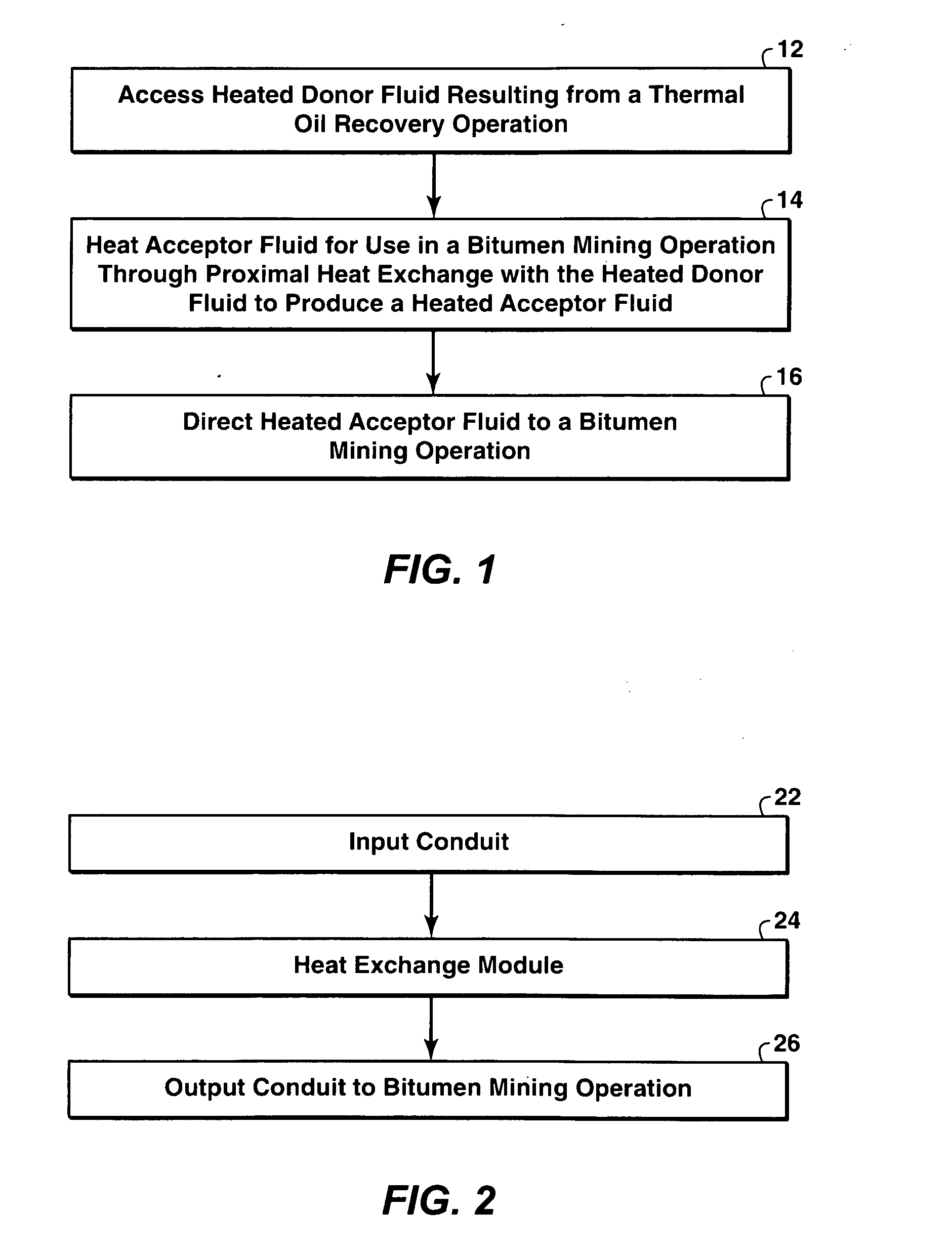

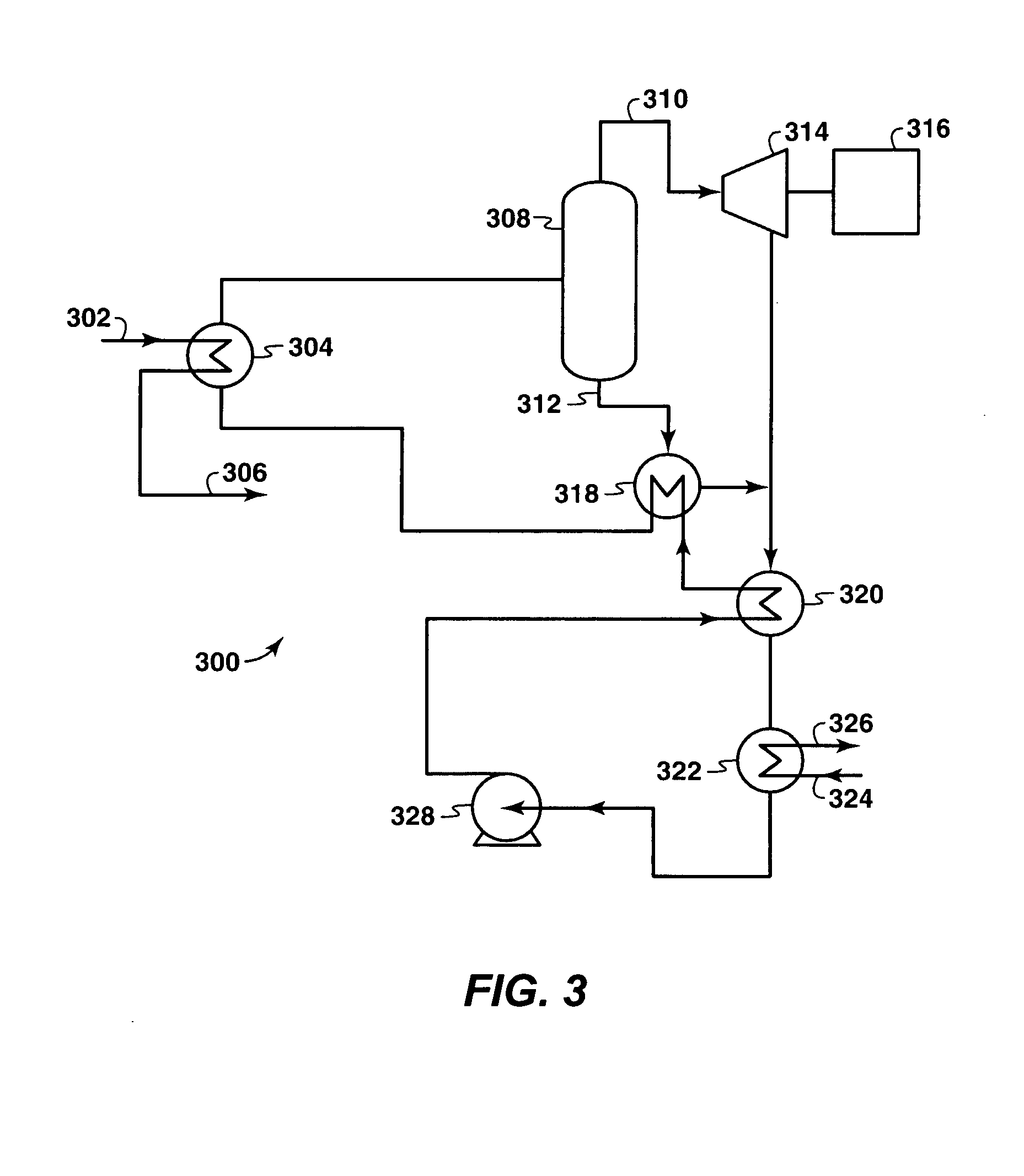

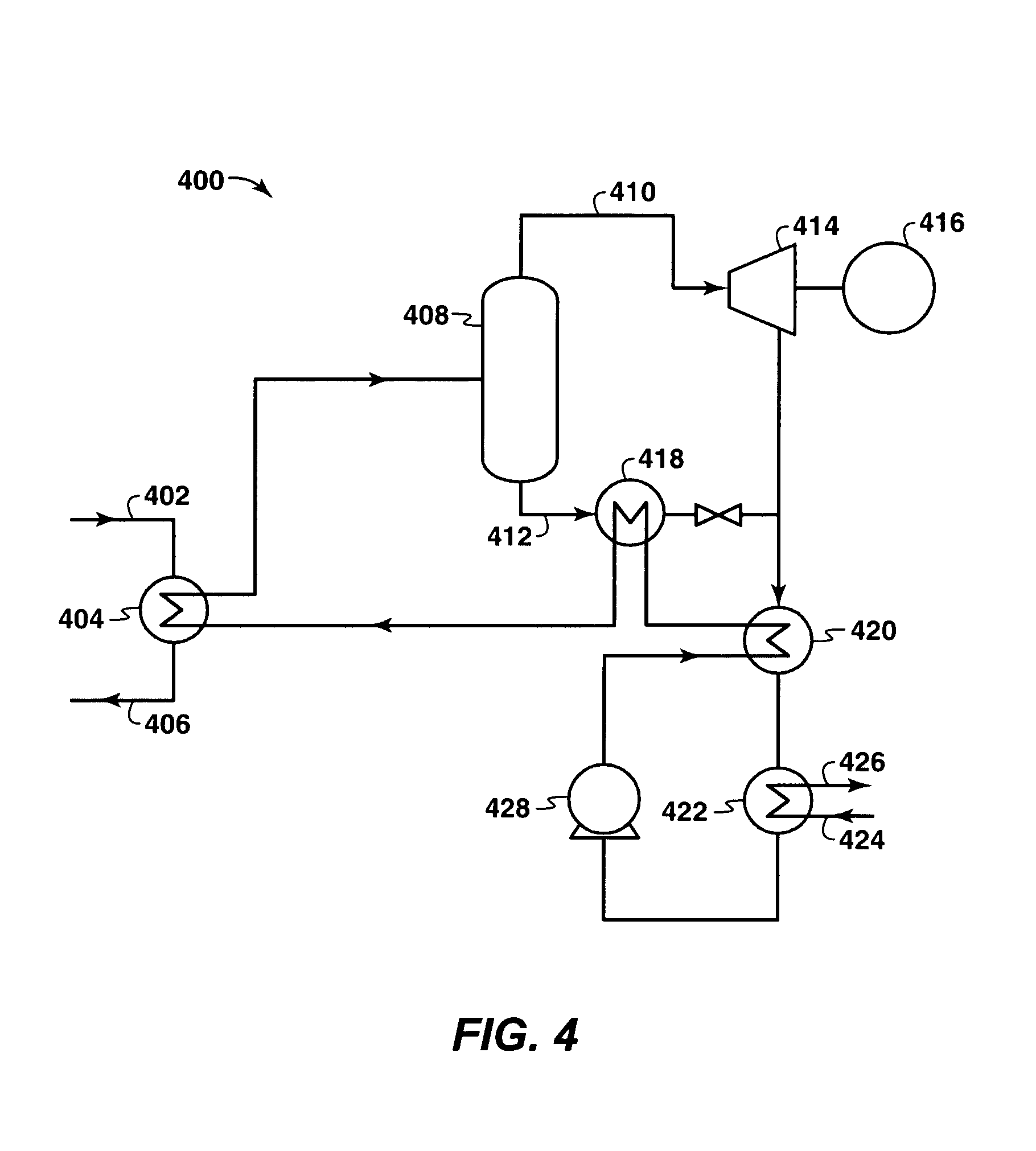

Method and system integrating thermal oil recovery and bitumen mining for thermal efficiency

Thermal oil recovery operations, such as SAGD, result in waste heat that is typically released to the environment. Bitumen mining operations require heat input for heating fluids used in the mining process. A method and system of recovering heat from a thermal recovery operation for use in bitumen mining operation may include a heated donor fluid from a thermal recovery operation which heats an acceptor fluid for use in bitumen mining via proximal heat exchange using a power cycle or heat exchange module, such as an ammonia and water based Kalina® Cycle.

Owner:EXXONMOBIL UPSTREAM RES CO

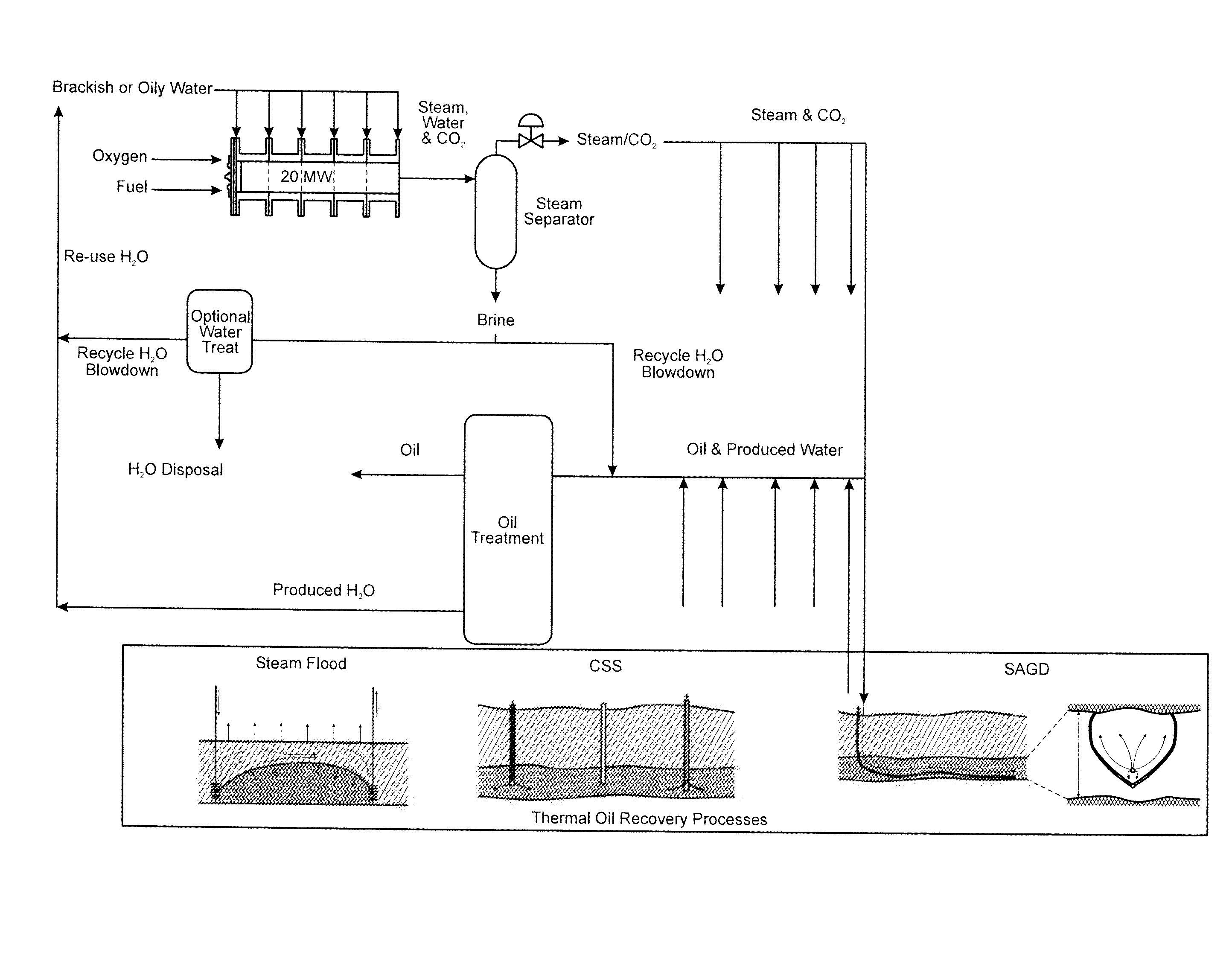

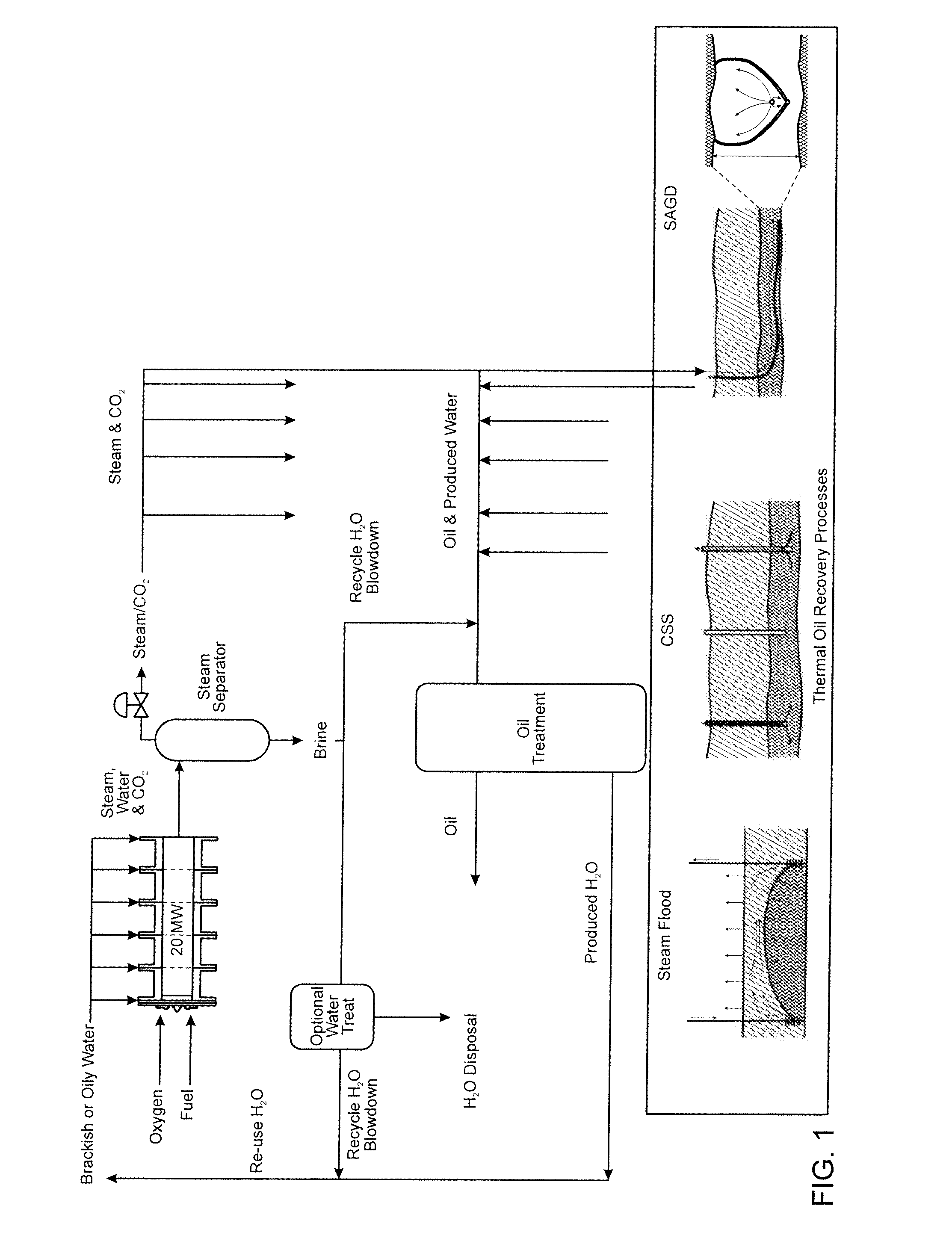

Zero emission steam generation process

InactiveUS20120160187A1Eliminate requirementsImprove thermal efficiencySteam generation using pressureSubmerged flame steam boilersWater requirementProduced water

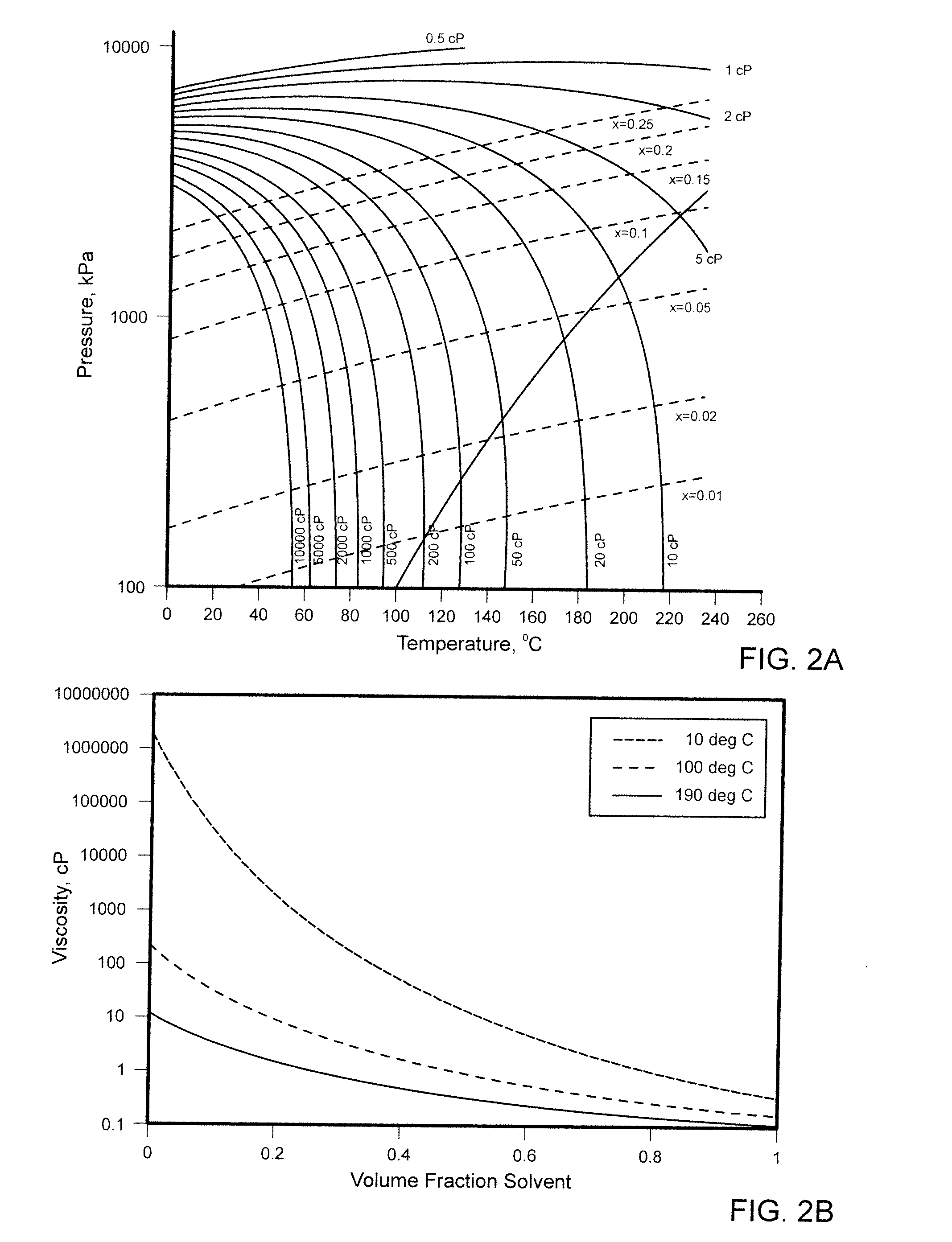

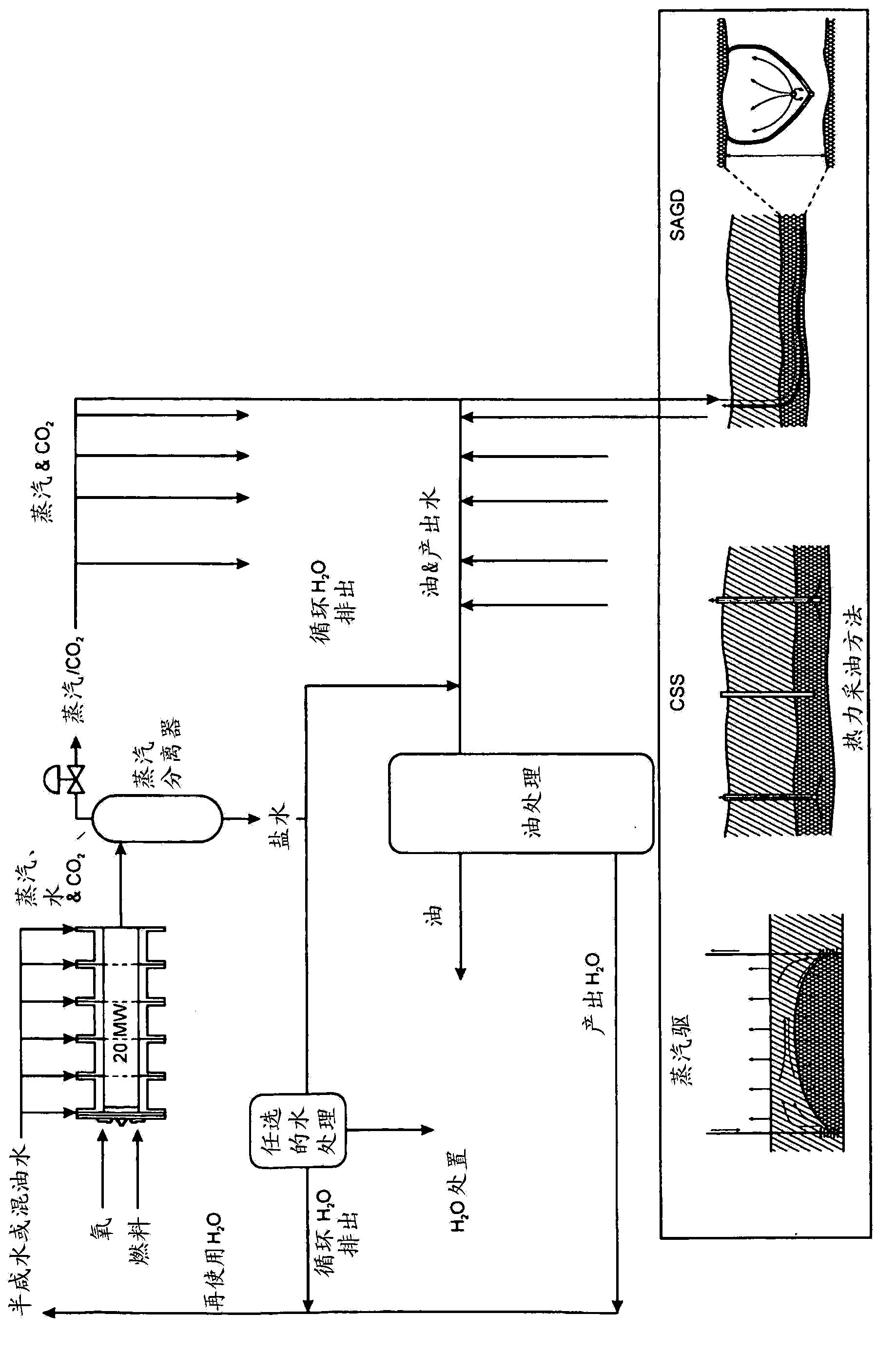

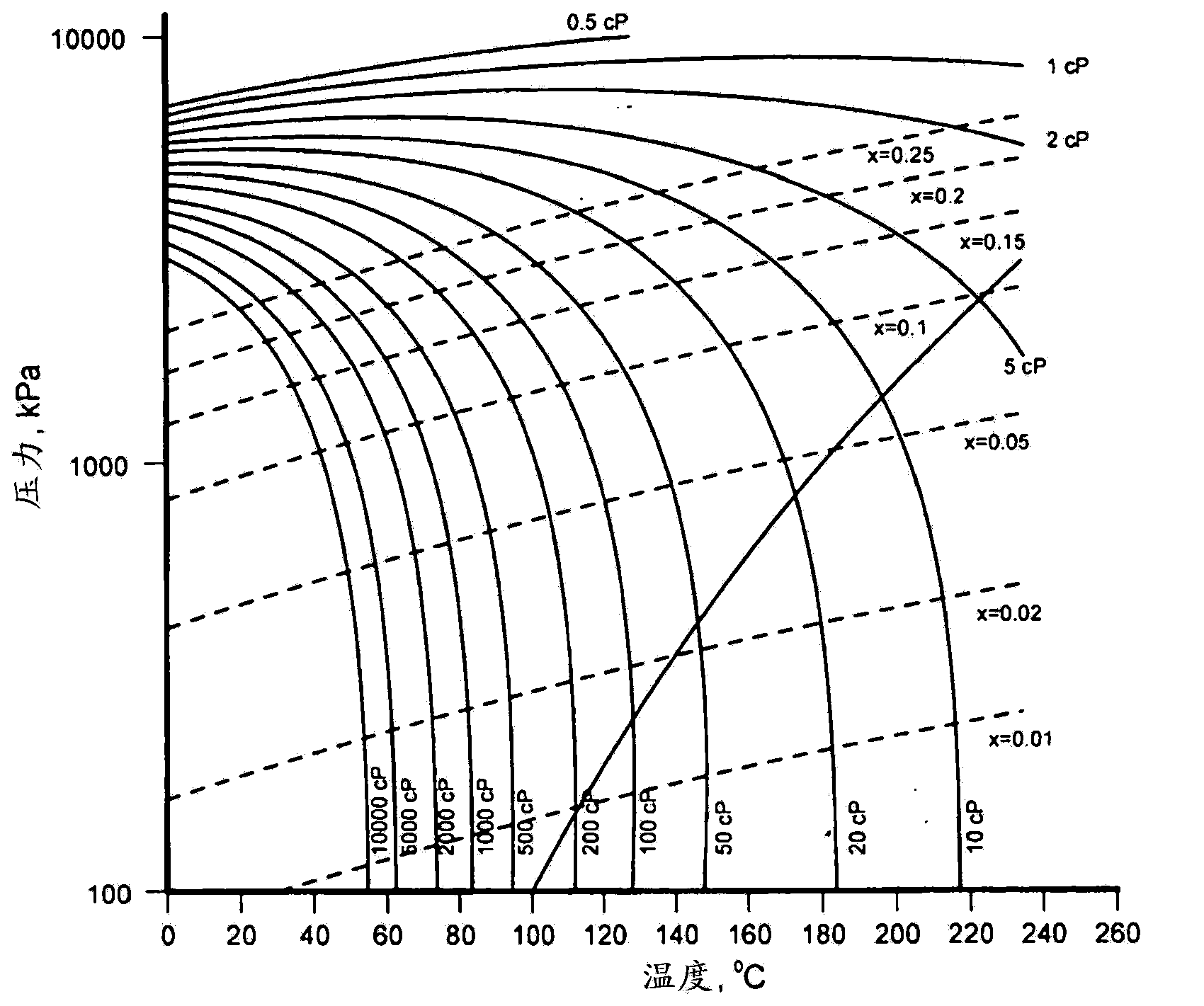

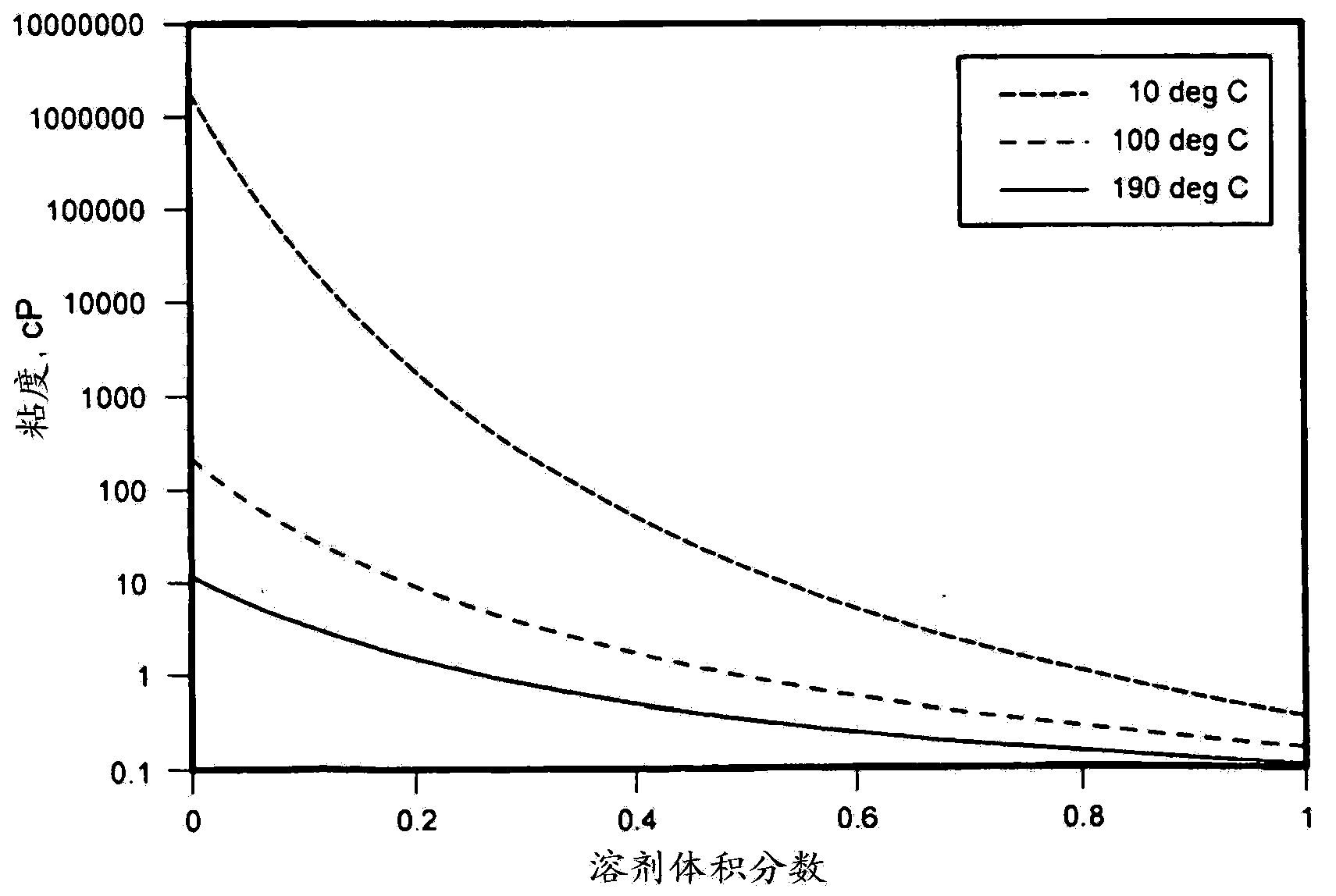

This invention provides a new process to generate steam directly from untreated water produced simultaneously with thermally recovered crude oil, and to inject the steam and combustion products into a hydrocarbon reservoir to recover hydrocarbons and to sequester a portion of the carbon dioxide produced during the creation of steam. The invention removes the ongoing additional water requirements for thermal oil recovery and the need for surface treating of produced water for re-use, yielding improved process efficiencies, reduced environmental impact, and improved economic value.

Owner:PAXTON CORP +2

Zero emission steam generation process

InactiveCN103403291AHigh thermal efficiencySteam generation heating methodsInsulationThermal oil recoveryProcess engineering

This invention provides a new process to generate steam directly from untreated water produced simultaneously with thermally recovered crude oil, and to inject the steam and combustion products into a hydrocarbon reservoir to recover hydrocarbons and to sequester a portion of the carbon dioxide produced during the creation of steam. The invention removes the ongoing additional water requirements for thermal oil recovery and the need for surface treating of produced water for re-use, yielding improved process efficiencies, reduced environmental impact, and improved economic value.

Owner:CLEAN ENERGY SYST +2

Method and System Integrating Thermal Oil Recovery And Bitumen Mining For Thermal Efficiency

Thermal oil recovery operations, such as SAGD, result in waste heat that is typically released to the environment. Bitumen mining operations require heat input for heating fluids used in the mining process. A method and system of recovering heat from a thermal recovery operation for use in bitumen mining operation is described. A heated donor fluid from a thermal recovery operation is used to heat an acceptor fluid for use in bitumen mining via proximal heat exchange using a power cycle or heat exchange module, such as an ammonia and water based Kalina® Cycle. By utilizing waste heat from thermal recovery operations to heat fluids used in bitumen mining, thermal efficiencies are realized.

Owner:EXXONMOBIL UPSTREAM RES CO

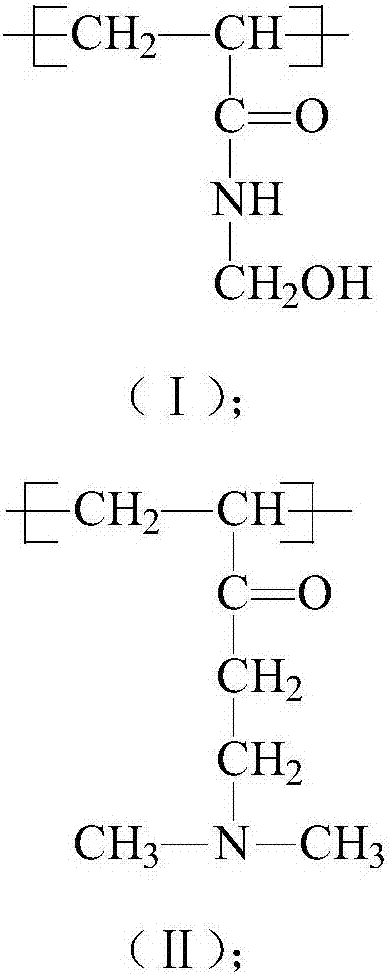

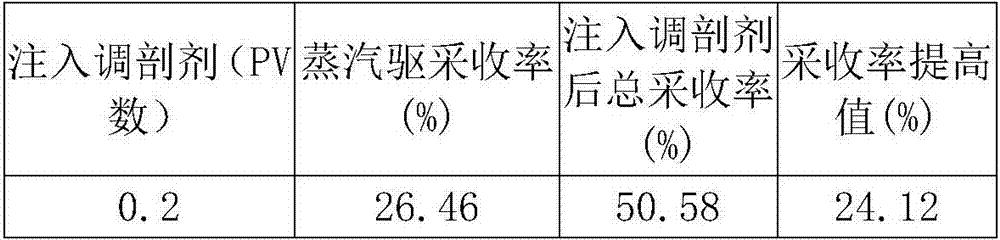

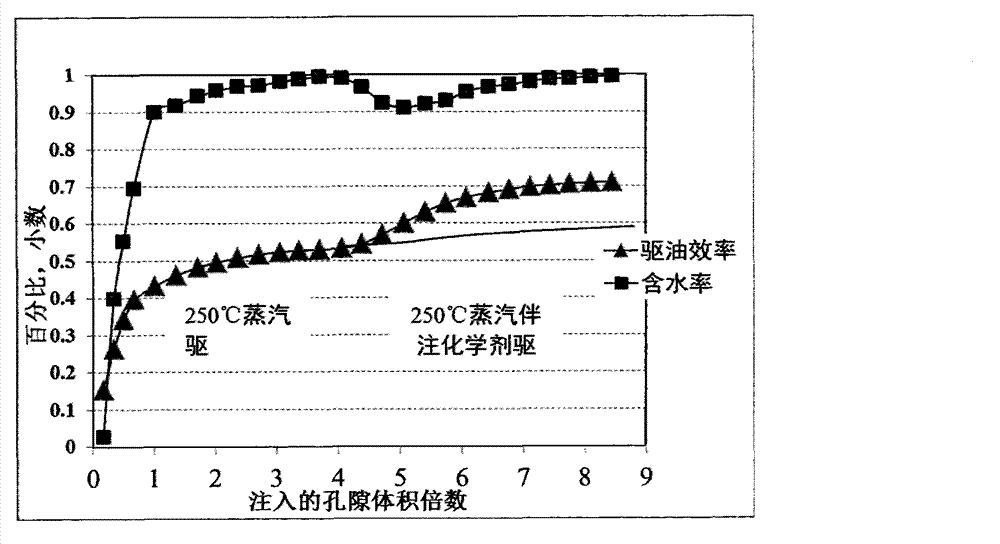

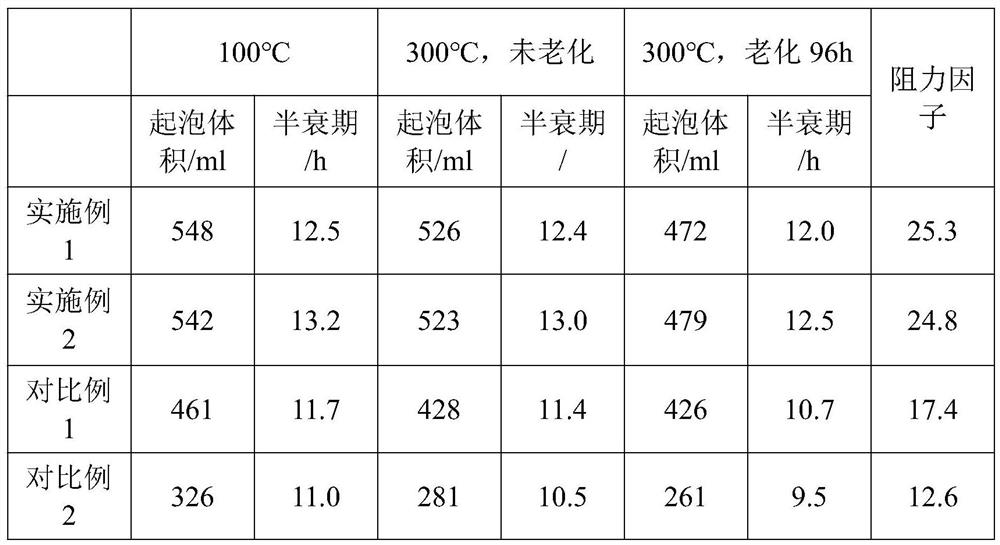

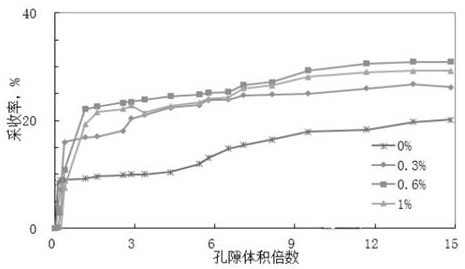

High-temperature-resistant auxiliary steam-driven oil-displacing agent for thermal oil recovery and application thereof

ActiveCN107955594AEnhanced overall recoveryOil displacement effect is goodDrilling compositionThermal oil recoveryCarboxylic salt

The invention belongs to the technical field of thermal oil recovery and particularly relates to a high-temperature-resistant auxiliary steam-driven oil-displacing agent for thermal oil recovery and application thereof. The oil-displacing agent is a copolymer comprising a hydroxyl-containing acrylamide derivative unit, an acrylate derivative unit and a carboxylate-containing acrylamide derivativeunit. The oil-displacing agent is injected while the steam is injected into the stratum, so that the rheological property of thick oil can be improved, the oil-water interfacial tension can be reduced, the colloid stability can be enhanced, and the oil-displacing effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

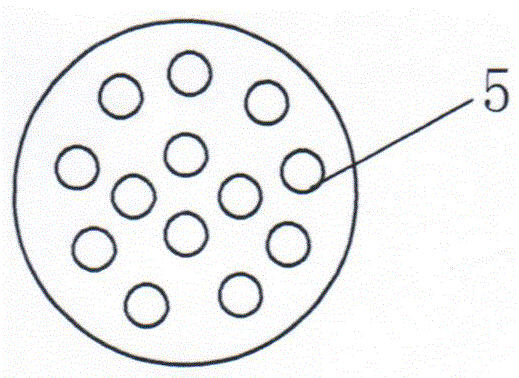

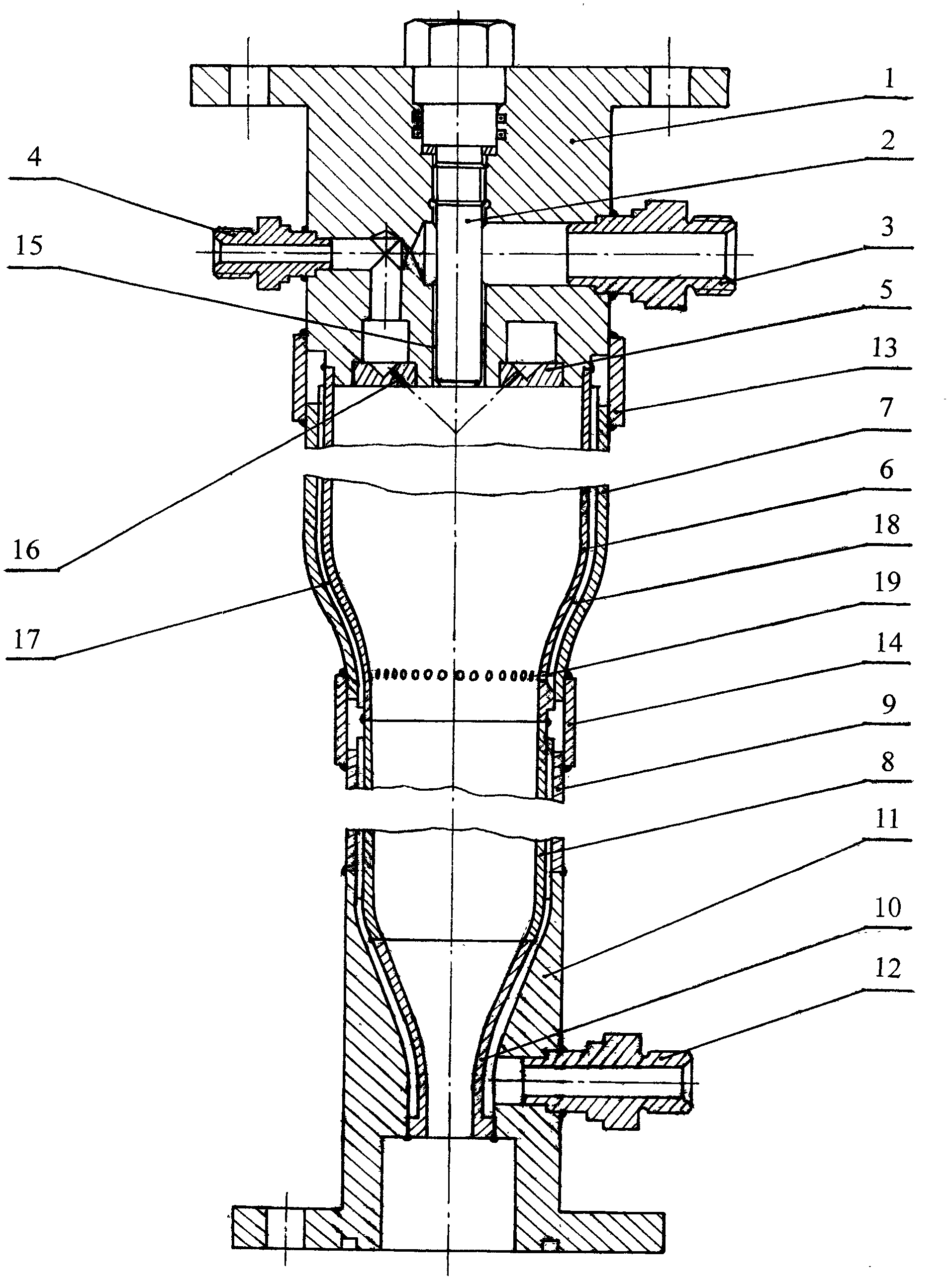

Offshore thermal oil recovery steam transport pipe

InactiveCN104832723AFlexibleDelivery normalThermal insulationPipe elementsThermal oil recoveryLine tubing

The invention provides an offshore thermal oil recovery steam transport pipe. A plurality of pipe bodies with connecting caps and threaded joints are connected with one another so as to form the transport pipe. A spherical head is arranged in each connecting cap; a spherical sealing gasket is installed in each threaded joint; a plurality of gas guide thin pipes are connected between the connecting cap and the threaded joint through mobile rings; the outer side of the gas guide thin pipe group is wrapped with a thermal insulation mineral blanket; the outer side of the thermal insulation mineral blanket is wrapped with a steel wire protective net; and the gas guide thin pipes are distributed annularly at intervals. Since the transport pipe of the invention is formed through combining a plurality of thin pipes, the transport pipe can be stressed and deformed with the action of an external force, and the transport pipe can be flexible, so that the pipe can absorb impact of sea waves and normally transport high-temperature and high-pressure steam. The transport pipe can be adaptive to the free bending of a steam transport pipeline. The transport pipe has the advantages of convenient connection, long service life, safety and environmental protection. The transport pipe can be suitable for be applied to offshore thermal oil recovery steam transport pipelines, and is suitable for pipeline compensation and corner-turning application of various kinds of pipelines on the ground.

Owner:辽宁锦兴石油机械有限公司

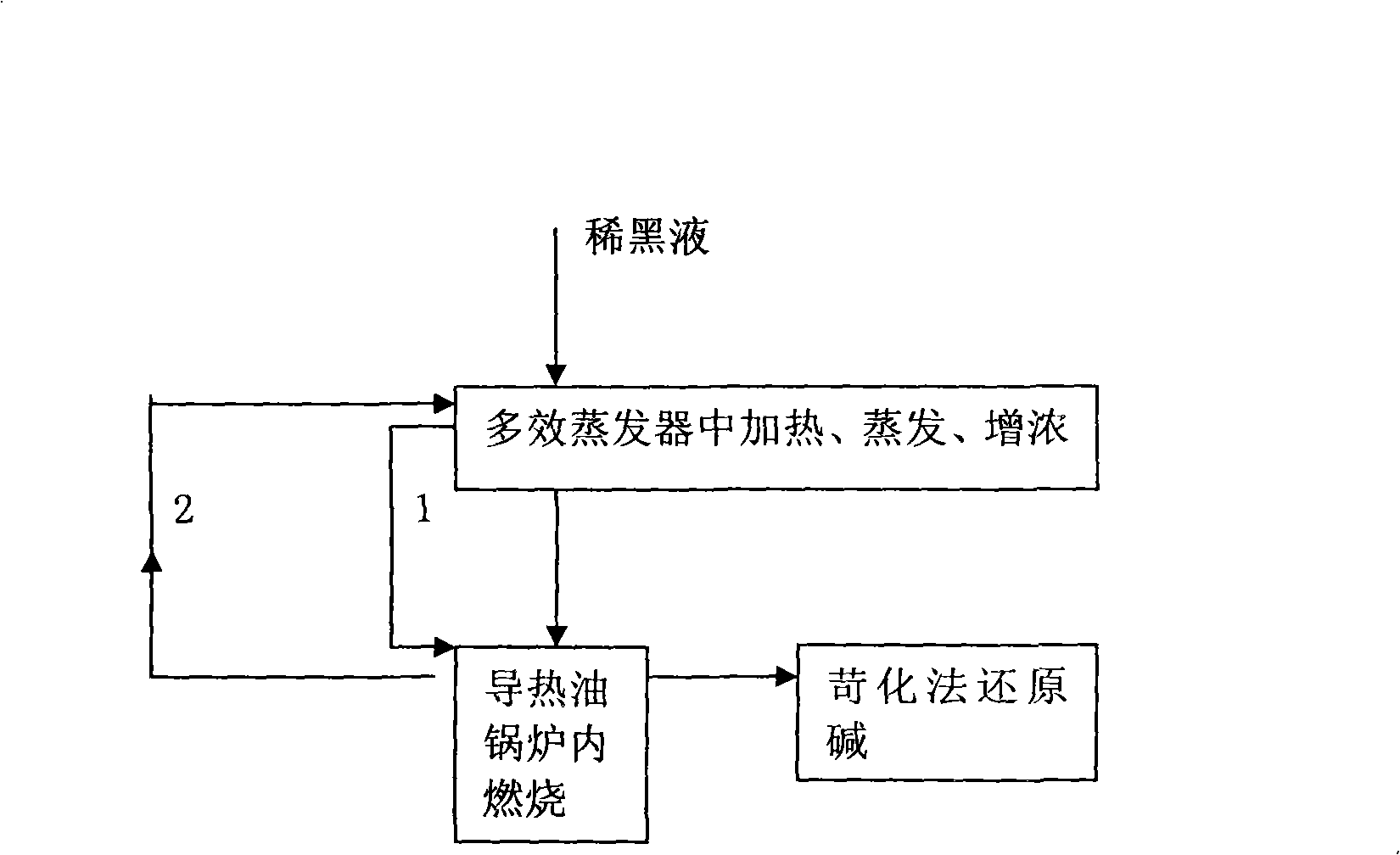

Process for incinerating cotton linter black liquor and recycling alkaline by utilizing heat conduction oil boiler

InactiveCN101526221AConducive to emission reductionSave resourcesChemical industryStorage heatersThermal energyCarbon dioxide binding

The invention discloses a process for incinerating cotton linter black liquor and recycling alkaline by utilizing a heat conduction oil boiler, which belongs to the technical field of pulping waste water treatment. The process comprises the following steps: (a) cotton linter pumping black liquor with the mass concentration of about 6 percent from an extracting workshop section is heated, evaporated and thickened by a multiple-effect evaporator which takes cyclic heat conduction oil as a heat source till the mass concentration of the black liquor reaches 40-50 percent; (b) the thickened black liquor is sprayed into the heat conduction oil boiler for combustion, the heat energy is recovered by the heat conduction oil in a heating surface, and sodium carbonate generated by the combination of sodium hydroxide and carbon dioxide in the waste water is discharged out of the boiler; (c) the generated sodium carbonate is reduced into alkaline by adopting a hydrated lime causticizing method, and the alkaline resources are recycled for productive cycle and utilization. The process saves the construction funds by one third, saves energy by 30 percent and reduces the operation cost by 25 percent compared with the general alkaline recovery process, has high heat energy utilization ratio and zero CODcr index of discharged waste water and can thoroughly and effectively solve the pollution of cotton linter black liquor.

Owner:程好军

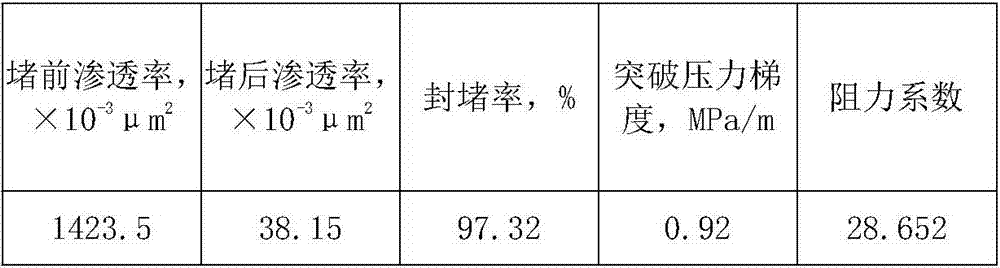

Inorganic gel profile control agent suitable for thermal oil recovery and use method thereof

InactiveCN107118751AEffective blockingWater-swellableFluid removalDrilling compositionMass ratioSealant

The invention discloses an inorganic gel profile control agent suitable for thermal oil recovery and a use method thereof, and relates to the chemical field of oil field application. The inorganic gel profile control agent is prepared from gel emulsion and inorganic matter formation sealant, wherein the mass ratio of weak gel emulsion is 85-90%, and the mass ratio of the inorganic matter formation sealant is 10-15%; the weak gel emulsion is prepared from parts of HPAM (hydrolytic polyacrylamide) with a relative molecular weight of 1000*10<4>, an organic chromium system, aluminum citrate, sodium fluosilicate and prepared water, and the inorganic matter formation sealant is montmorillonite. The use method comprises the following steps: combining with oil field production data to design a profile control agent injection amount; after the profile control agent finishes being prepared, injecting into a stratum via an oil field injection well; after a preset range is achieved, standing for 2-3 days to cure the profile control agent; after curing, carrying out a subsequent injection production operation. According to the profile control agent, the high-temperature stratum can be effectively sealed, the profile control agent can be applied to thermal force oil extraction ways including in-situ combustion, steam flooding, SAGD (Steam Assisted Gravity Drainage), mixed-phase thermal fluid flooding and the like; before the weak gel emulsion is cured, viscosity is low, and the weak gel emulsion can be easily injected, can be suitable for a mineralization degree below 100000mg, is cheap and easy to obtain.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

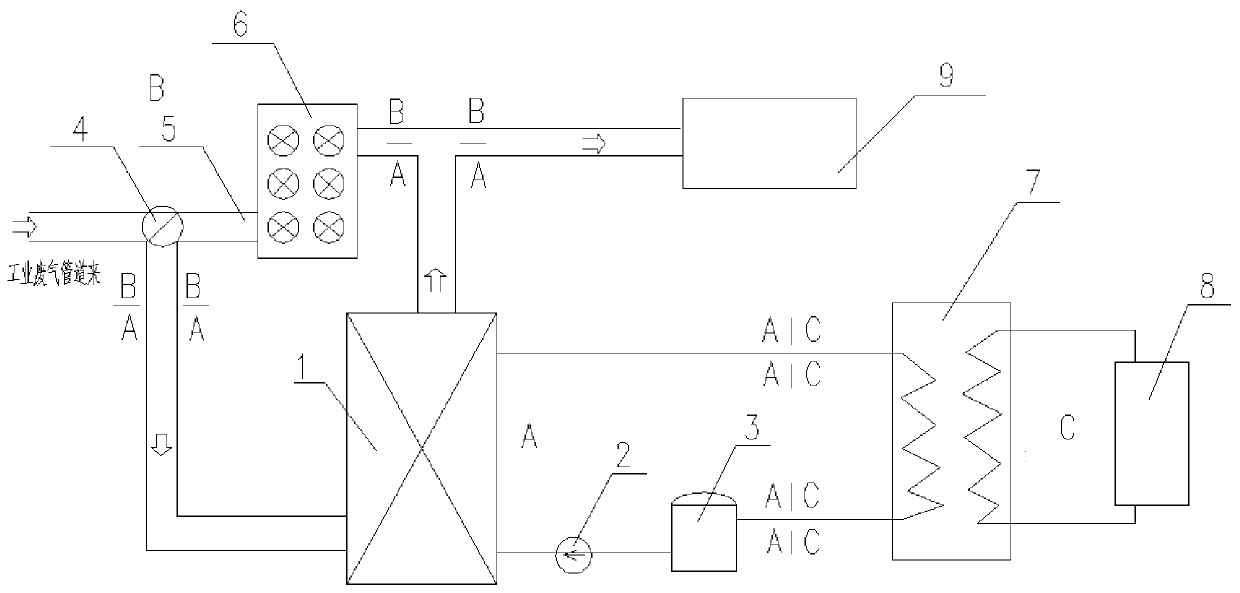

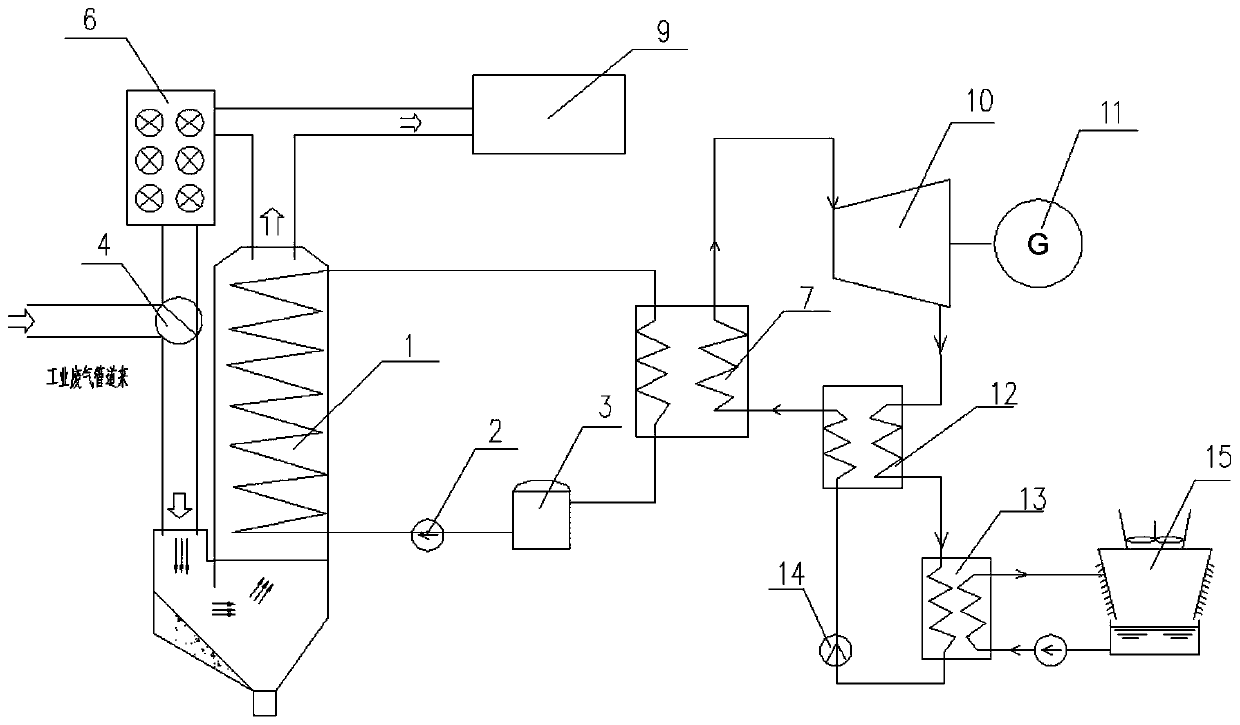

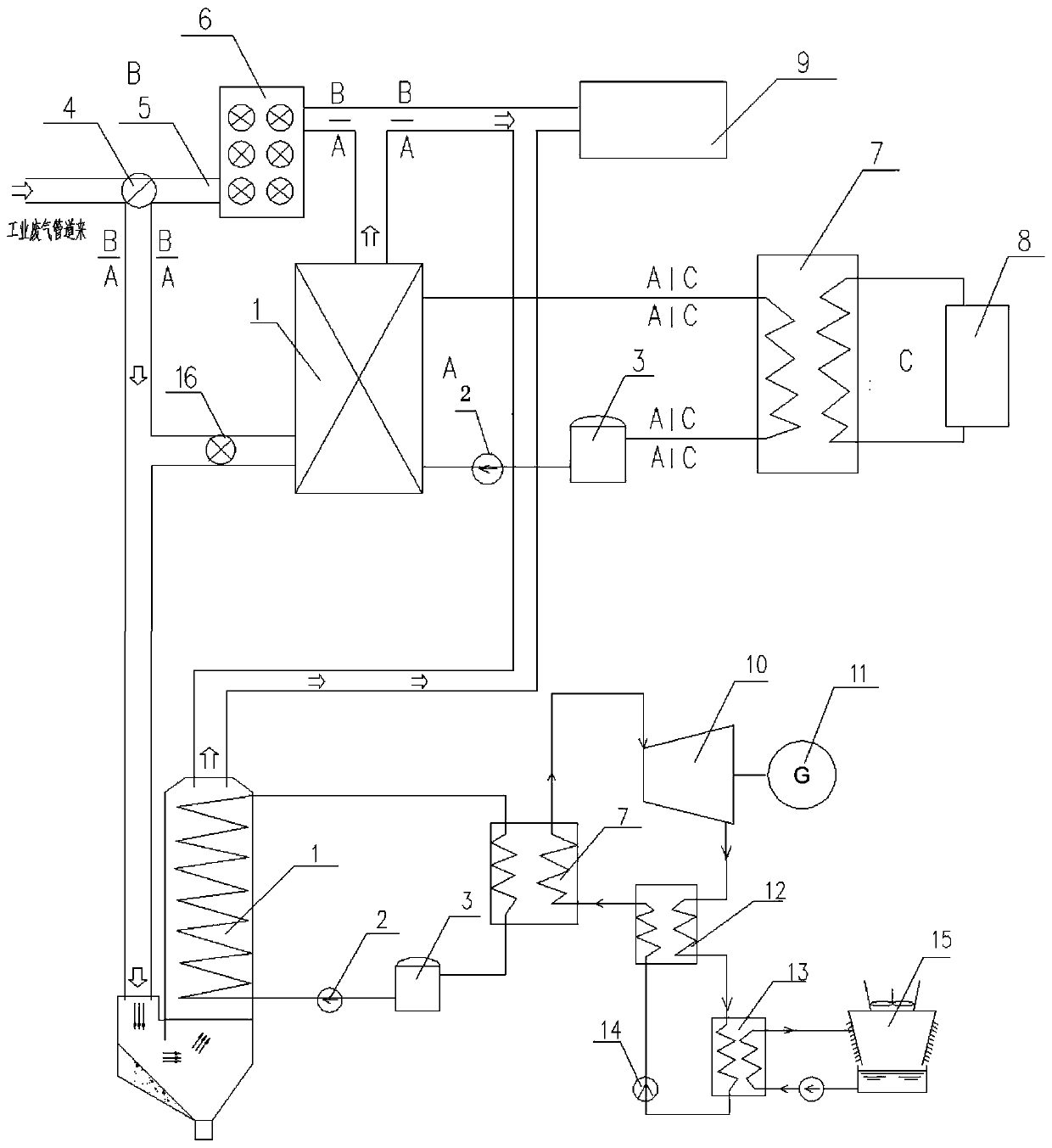

System for recycling industrial waste gas waste heat by means of heat transfer oil

PendingCN110388832ARespond to failures in timeTimely response to maintenanceRecuperative heat exchangersIncreasing energy efficiencyCustomer requirementsEngineering

The invention relates to the technical field of waste gas waste heat recovery, in particular to a system for recycling industrial waste gas waste heat by means of heat transfer oil. The system comprises a three-way valve which communicates with an industrial waste gas source pipeline, wherein one outlet of the three-way valve communicates with an air cooler through a bypass flue, and the air cooler communicates with a flue gas ultralow emission system; and the other outlet of the three-way valve communicates with a flue gas inlet of a heating module or / and a flue gas inlet of a power generation module through a waste gas inlet flue, and a flue gas outlet of the heating module or / and a flue gas outlet of the power generation module communicates with the flue gas ultralow emission system. The bypass flue is arranged and used as an emergency bypass device during system accidents or overhauling, and therefore sudden faults and maintenance of the system can be timely carried out; by utilizing waste heat of industrial waste gas, the system can selectively recycle heat or power generation, the waste heat of the waste gas can be fully utilized, reasonable arrangement can be carried out according to different regions and customer requirements, and the system has good applicability.

Owner:广东东实开能能源有限公司 +4

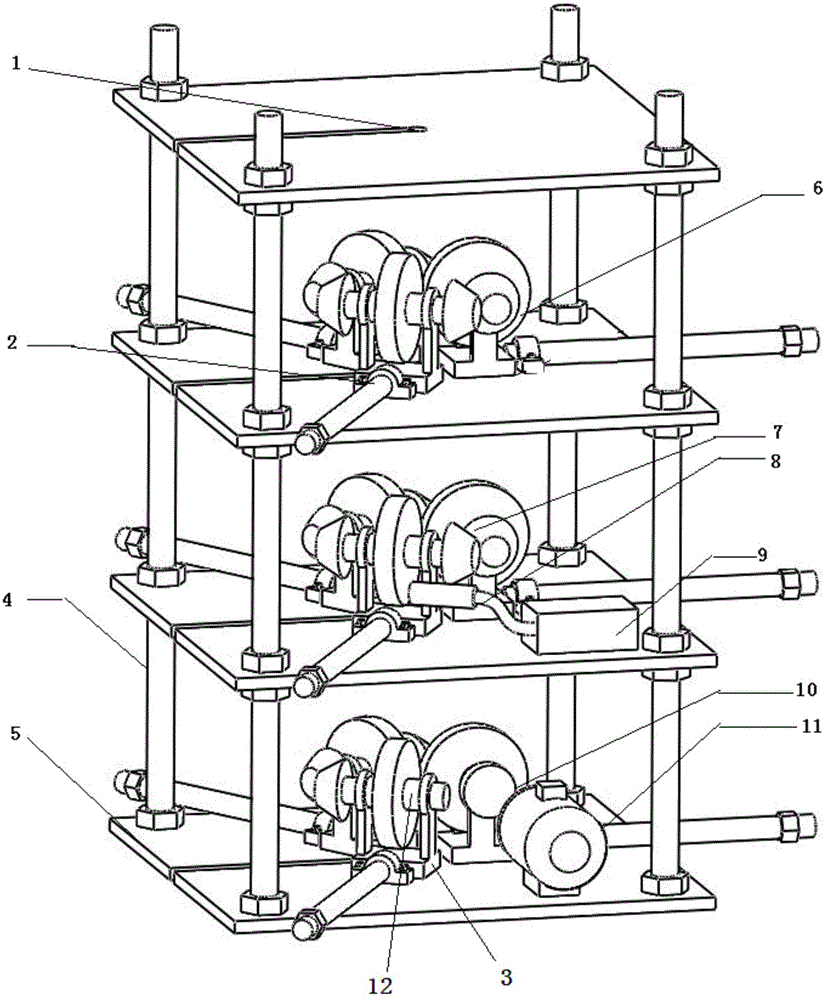

Automatic running device for on-line testing cable

InactiveCN105024311AHigh precisionImprove working conditionsApparatus for laying cablesThermal oil recoveryGear wheel

The invention discloses an automatic running device for an on-line testing cable which is particularly suitable for online running construction of a downhole testing cable of a thermal oil recovery steam injection well. The device comprises bottom boards and straightening running mechanisms. Each straightening running mechanism is provided with three cable tight pulleys which are in 120-degree uniform arrangement, and wheel faces of the cable tight pulleys are used for clamping the cable. Each cable tight pulley is fixed on a transmission shaft provided with bevel gears and is supported by a fixed holder. The rotation of the cable tight pulleys is achieved by the bevel gears. The fixed holders are fixed on the bottom boards. The cable enters the abutting surfaces of the cable tight pulleys via the cable entrance of the bottom boards and runs into the downhole. A reduction gearbox is connected with a motor. A main drive gear is installed on the output shaft of the reduction gearbox and is meshed with a transmission gear on the transmission shaft. The motor is connected with a power supply control cabinet of a well site via a power line. The use of automatic running device solves the problems that the manual running construction has high labor intensity, has difficulties in cable running and is prone to damage the cable. The automatic running device can improve the running speed, running quality and depth precision of the on-line testing cable in site.

Owner:CHINA PETROLEUM & CHEM CORP +1

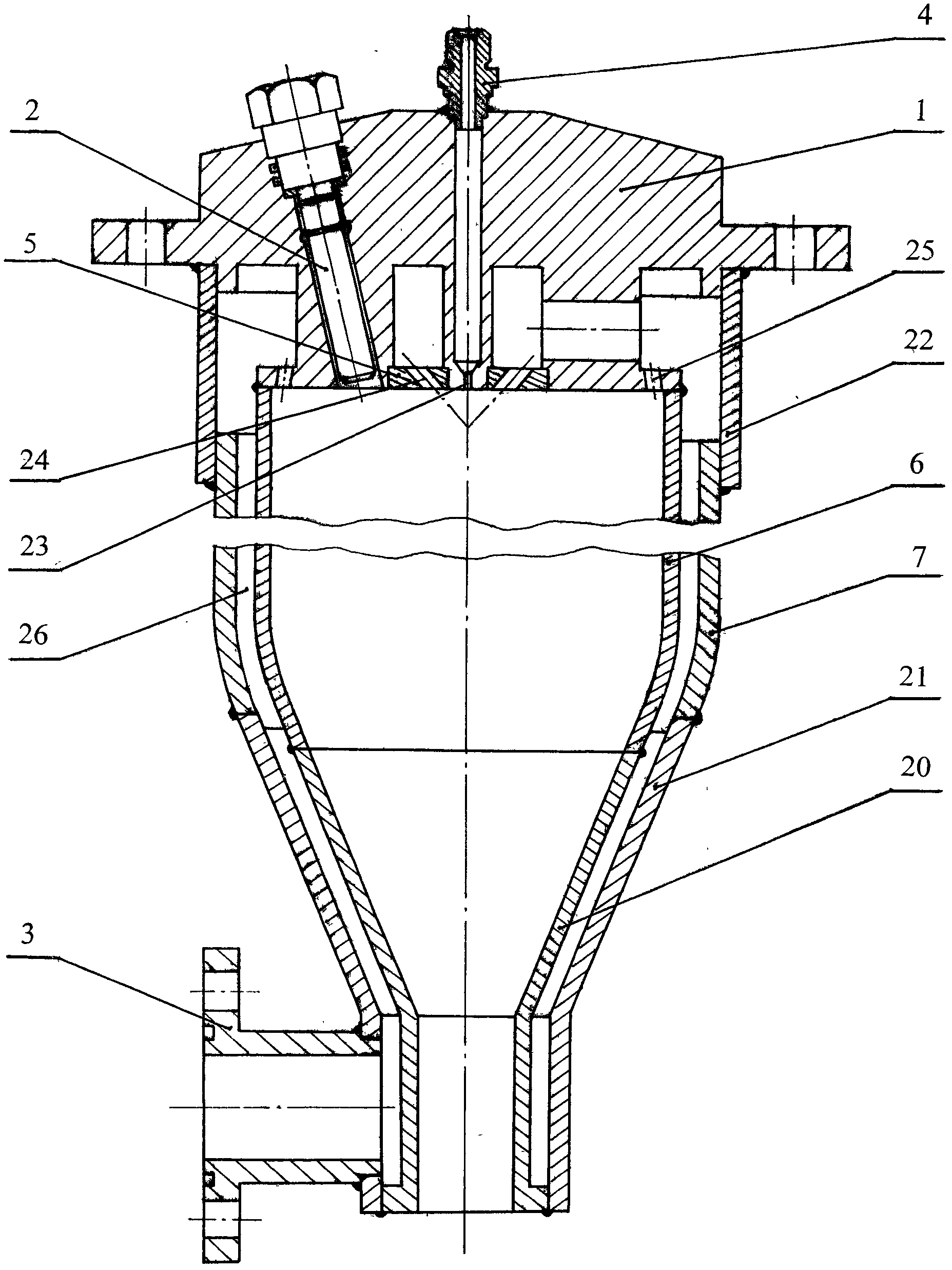

Liquid-cooling and gas-cooling air-diesel gas generators and application thereof

InactiveCN102661138AExtended Exhaust Scattering SurfaceUnique structureWater cleaningGeneral water supply conservationRadiation lossCombustion chamber

The invention relates to liquid-cooling and gas-cooling air-diesel gas generators, and provides a liquid-cooling air-diesel gas generator, which aims to prevent an inner wall of a combustion chamber from being burnt out and eliminate the heat radiation loss of the combustion chamber and is used for combining thermal oil recovery with air injection and expanding the application of the thermal oil recovery and the air injection. An annular inclined-hole jetting unit and a short combustion chamber body which has a small combustion chamber diameter and is provided with coolant uplink and downlink straight groove channels are adopted, and softened water serving as a regenerative coolant is applied to the thermal oil recovery, so that hot gas flow, hot liquid flow and cold air can be alternately injected, and the application can be expanded by taking 25 to 50 percent hydrogen peroxide as the regenerative coolant. The invention also provides a gas-cooling air-diesel gas generator, and a five-strike jetting unit, an internal cooling air hole and an external cooling air uplink straight groove channel are adopted. The two air generators are provided with two jetting pipes and mainly applied to the thermal oil recovery and the thermal cleaning of wellhead ground oil stains, sea floating oil, beach oil stains and road surface ice and snow.

Owner:葛明龙

Efficient pour inhibitor for thermal oil recovery process

InactiveCN104694097AImprove applicabilityStrong pouring capacityDrilling compositionWater basedParaffin wax

The invention relates to an efficient pour inhibitor for a thermal oil recovery process. The efficient pour inhibitor comprises the following ingredients including (1) biphenyl, condensed aromatics or polycyclic aromatic hydrocarbon derivatives not containing an oxygen element and a sulfur element, (2) liquid petroleum type products with the aromatic content exceeding 5 percent, petroleum resin being in a liquid state at normal temperature, or hydrocarbon natural aggregates being in a particle state at the normal temperature. (3) surfactants; (4) fusel oil. (5) alcohol anhydride with a closed-cup flash point greater than 20 DEG C. and (6) oil-soluble or water-soluble polymers, each of which is provided with a nonpolar part co-crystallized with paraffin moleculars and a polar part capable of warping a wax crystal form, on a main chain and / or a branched chain. The efficient pour inhibitor has the advantages that all functions of water-based pour inhibitors and oil-based pour inhibitors are integrated, the existing various thermal exploitation processes can be effectively assisted for exploiting high condensation oil and heavy oil reservoirs, the exploitation cost is greatly reduced, the production period of an oil well is prolonged, the oil well yield is increased, the final recovery ratio of the oil reservoirs is improved, and the economic benefit is obvious.

Owner:QINGDAO HUICHENG PETROCHEM TECH

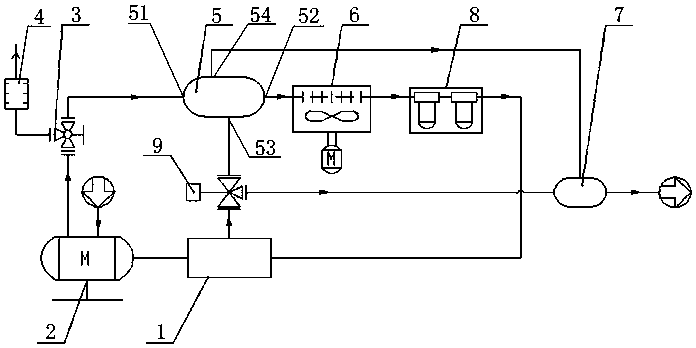

Novel flue gas thermal oil recovery equipment

PendingCN110219628AAchieve storageReasonable structureCleaning apparatusFluid removalOil productionZero emission

The invention discloses novel flue gas thermal oil recovery equipment. The novel flue gas thermal oil recovery equipment comprises a waste heat recovery heat-exchange system, a flue gas pressurizing system, a cooling system, a purification filtering system, a gas mixing system and a flow adjusting and control system; an inlet of the waste heat recovery heat-exchange system communicates with a fluegas outlet of an engine; the flue gas pressurizing system is connected with the engine and connected with the waste heat recovery heat-exchange system; an outlet of the waste heat recovery heat-exchange system is sequentially connected with the cooling system and the purification filtering system; and an inlet of the gas mixing system is connected with a second flow path outlet of the waste heatrecovery heat-exchange system and the outlet of the flue gas pressurizing system, an inlet of the flow adjusting and control system is connected with the flue gas pressurizing system, and an outlet ofthe flow adjusting and control system is connected with the waste heat recovery heat-exchange system and the gas mixing system. The novel flue gas thermal oil recovery equipment utilizes flue gas generated by the engine in a power system of the novel flue gas thermal oil recovery equipment to be recovered for incremental oil production operation, a flue gas generation device is omitted, and energy reutilizing and zero emission of exhaust gas are achieved.

Owner:新疆科瑞石油工程技术服务有限公司

Friction setting sand prevention pipe column, friction setting packer and method

PendingCN114482891AEffective settingGuaranteed reliabilitySealing/packingThermal oil recoveryWorking fluid

The invention discloses a friction setting sand prevention pipe column, a friction setting packer and a friction setting method. The friction setting sand prevention pipe column comprises the packer, a blind pipe, a safety connector, a sand prevention device, a centralizer and a screwed plug which are sequentially connected from top to bottom. The packer is a friction setting packer; the friction setting packer comprises a setting releasing system and a hanging packing system, and the lower end of the setting releasing system and the upper end of the hanging packing system are connected and fixed through a hanging pin. The setting releasing system comprises a releasing inner pipe, a friction assembly and a limiting ring, and the friction assembly is installed on the outer wall of the releasing inner pipe. Through the action of the friction assembly, the functions of setting, hanging, packing and the like can be completed without pressing of a pump truck, the setting cost of the pump truck can be saved, the time for waiting for the pump truck and a tank truck in construction can also be saved, meanwhile, the damage of working fluid to a reservoir is reduced, and the energy loss of thermal oil recovery is reduced. Conical holes are uniformly distributed in the sand prevention device, so that the validity period is prolonged while sand prevention is met.

Owner:CHINA PETROLEUM & CHEM CORP +1

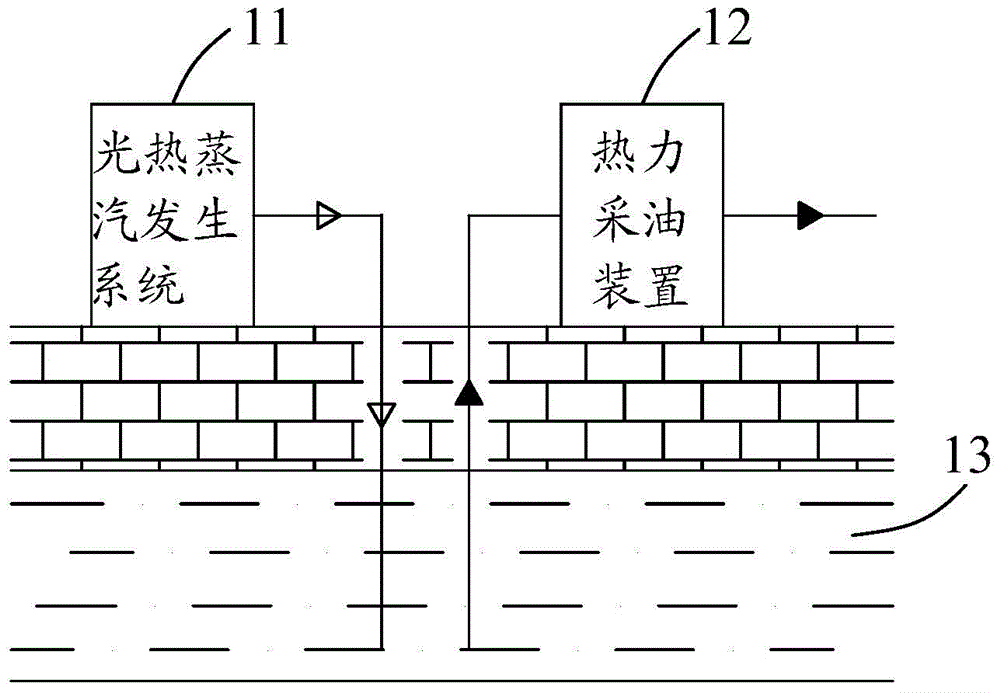

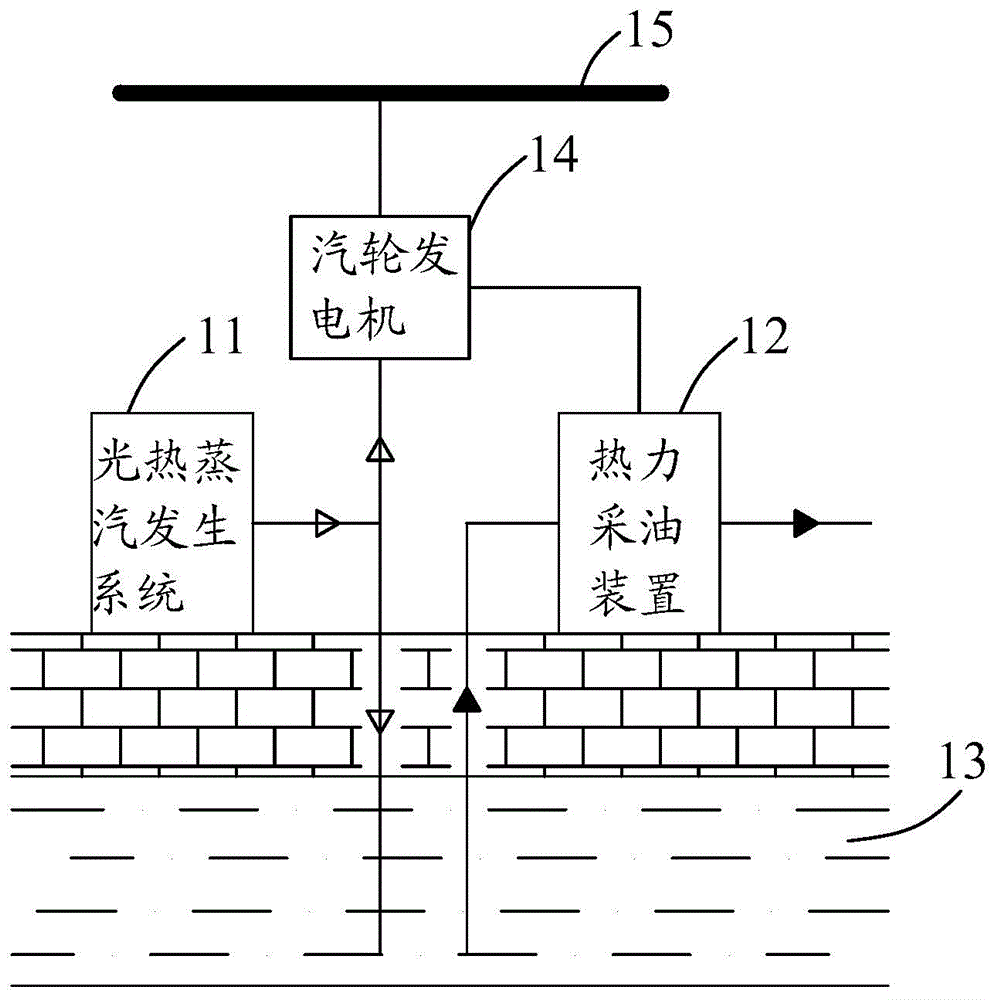

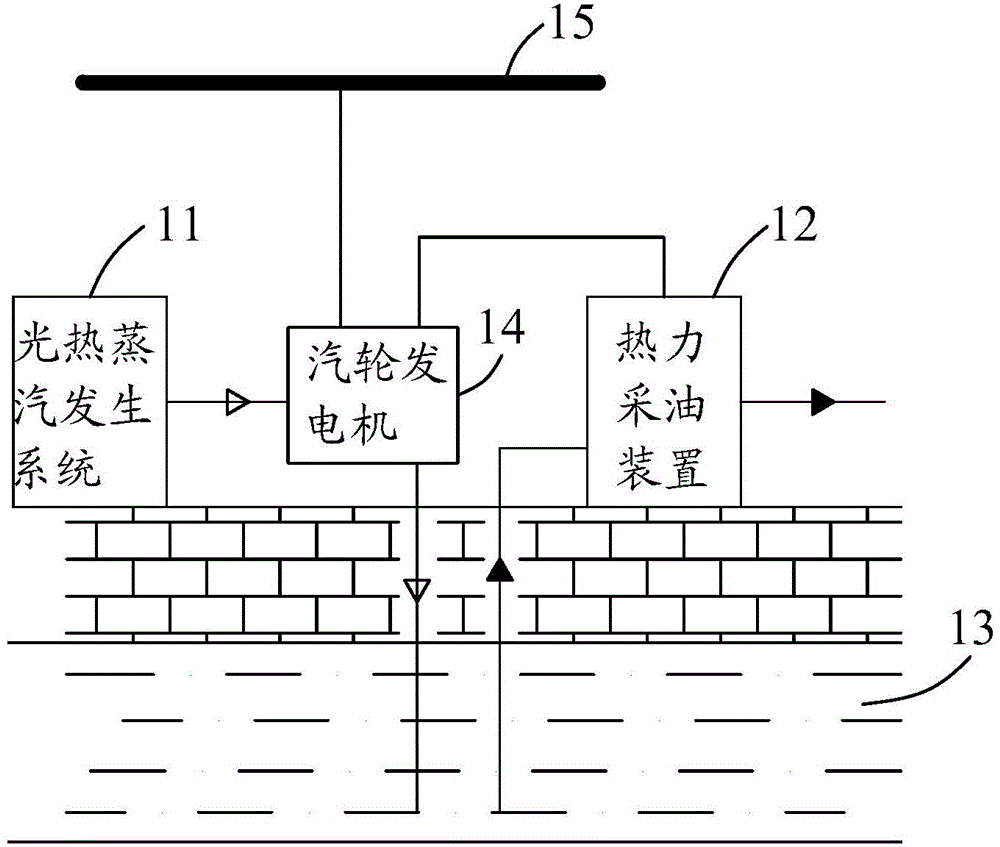

Oil recovery system utilizing light thermal energy

InactiveCN104153748AContinuous and stable supplyReduce mining costsFrom solar energySteam useThermal oil recoveryThermal energy

The invention provides an oil recovery system utilizing light thermal energy. The oil recovery system comprises a light thermal steam generation system and a thermal oil recovery device, wherein the light thermal steam generation system is used for generating steam by making use of thermal energy of sunlight and injecting the steam into an oil reservoir, and the thermal oil recovery device is used for collecting oil, heated by steam and diluted, in the oil reservoir. By the oil recover system utilizing the light thermal energy, energy conservation and emission reduction can be realized, utilization rate of solar energy is increased, and cost of oil exploitation is lowered.

Owner:北京特瑞邦新能源技术有限公司

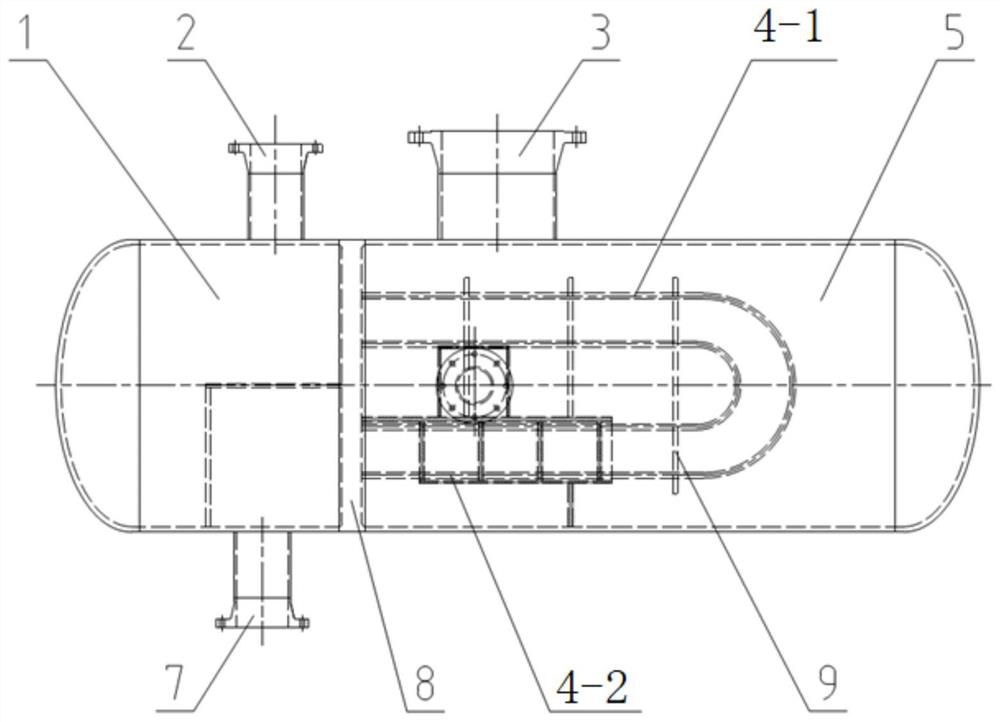

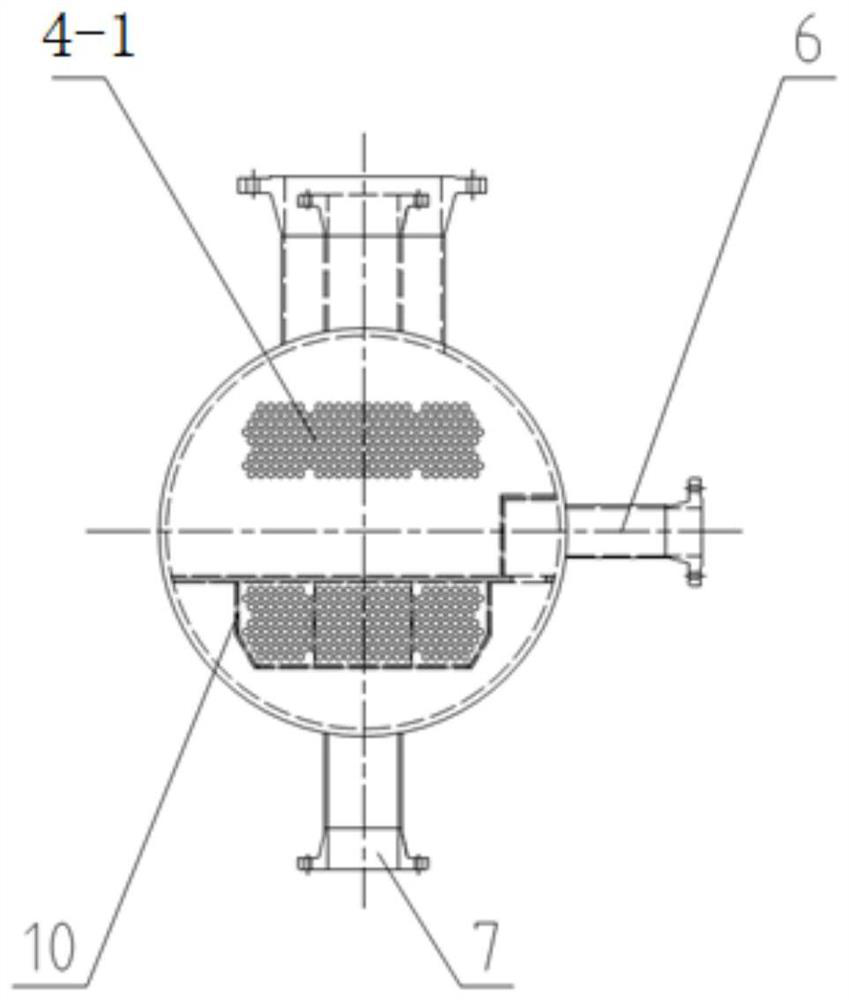

Two-section type conduction oil recovery heat exchanger for trough type photo-thermal power plant

The invention provides a two-section type conduction oil recovery heat exchanger for a trough type photo-thermal power plant. The two-section type conduction oil recovery heat exchanger comprises a shell, wherein a shell side inlet and a shell side outlet are formed in the shell, a heat exchange pipe structure is arranged in the shell and respectively communicates with a pipe side inlet and a pipeside outlet, and a heat exchange medium enters the heat exchange pipe structure through the pipe side inlet and leaves through the pipe side outlet. The heat exchanger is characterized in that the heat exchange pipe structure is divided into a condensation section and a supercooling section, conduction oil mist entering the shell from the shell side inlet firstly passes through the condensation section to be condensed into saturated liquid conduction oil, then the saturated liquid conduction oil passes through the supercooling section to be continuously cooled into supercooled liquid conduction oil, and the supercooled liquid conduction oil flows out of the shell through the shell side outlet. According to the heat exchanger provided by the invention, two functions of condensation and supercooling are realized through one heat exchanger. Compared with an existing conduction oil recovery heat exchanger, one supercooling heat exchanger is omitted, and the arrangement space and the investment cost of the equipment are correspondingly reduced.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

High-temperature resistant steam chemical auxiliary agent for thermal oil recovery

ActiveCN102925132AEnhanced overall recoveryHigh activityFluid removalDrilling compositionThermal oil recoverySurface-active agents

The invention provides a novel high-temperature resistant steam chemical auxiliary agent for thermal oil recovery. The novel high-temperature resistant steam chemical auxiliary agent comprises 65-85% a high-temperature resistant poly fatty acid acylamino alkyl dimethyl tertiary amine non-ionic surface active agent and 15-35%a mutual solvent in terms of percentage by weight. The technical bottleneck that the chemical oil displacing agent in the prior art cannot be used at high temperature is overcome; the steam chemical auxiliary agent disclosed by the invention can have high stability and oil displacing performance in the steam atmosphere being up to 350 DEG C; therefore, chemical displacement and steam displacement are combined perfectly and organically; the oil recovery cost is favorably reduced; and the thermal oil displacing recovery rate is increased.

Owner:DONGYING HUALI PETROLEUM TECH

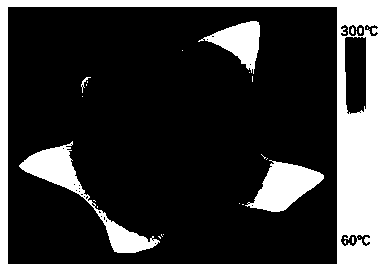

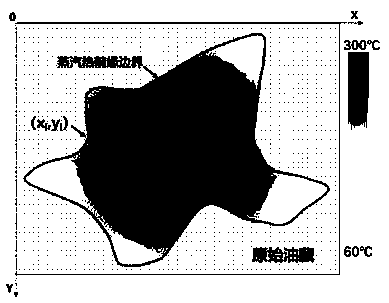

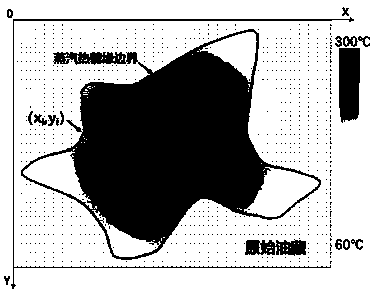

Method for quantitatively evaluating thermal recovery reservoir steam thermal leading edge balance based on Gini coefficient

PendingCN110705026ARealize quantitative evaluationFluid removalDesign optimisation/simulationThermal oil recoveryThermodynamics

The invention provides a method for quantitatively evaluating the steam thermal front edge balance of a thermal oil recovery reservoir based on a Gini coefficient. The method comprises the steps thata steam injection development temperature field is calculated through numerical simulation of the thermal oil recovery reservoir; taking the temperature higher than the initial oil reservoir temperature as a steam hot leading edge boundary, and drawing the boundary in a temperature field diagram; sequentially reading the grid coordinates of the steam injection well and the numerical simulation grid coordinates passed by the boundary of the steam hot leading edge; sequentially calculating the distances between the steam injection well and the boundary coordinates of the steam hot front edge according to a formula of the distance between the two planar points; solving the minimum distance between the steam injection well and the boundary of the steam hot leading edge; solving the distance between the circular boundary and the steam hot leading edge boundary respectively; drawing a Lorentz curve of the distance between the circular boundary and the hot leading edge boundary; solving a Gini coefficient G; according to the method for quantitatively evaluating the steam thermal front edge balance of the thermal oil reservoir based on the Gini coefficient, the defects of traditional qualitative evaluation of the steam thermal front edge can be effectively overcome, and quantitative evaluation of the steam thermal front edge balance is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A thermal recovery string and oil recovery method thereof

ActiveCN111255424BInject evenlyFull heat exchangeFluid removalWell/borehole valve arrangementsThermal oil recoveryThermodynamics

The invention proposes a thermal recovery string and an oil recovery method thereof. The thermal recovery string includes: oil pipes arranged in the wellbore; Both sides of holes or screen seams; heat-sensitive oil production valves, which are set on the tubing for oil production, corresponding to the casing perforations or screen seams on the wellbore; and heat-sensitive injection valves, which are used to inject steam, The heat-sensitive injection valve is arranged behind the heat-sensitive oil production valve and arranged alternately with the heat-sensitive oil production valve in the horizontal section of the tubing, corresponding to the area of casing perforation or screen seam. The thermal recovery string can improve the development degree of heavy oil reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

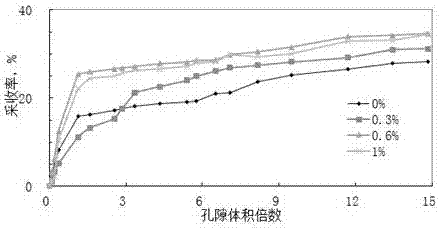

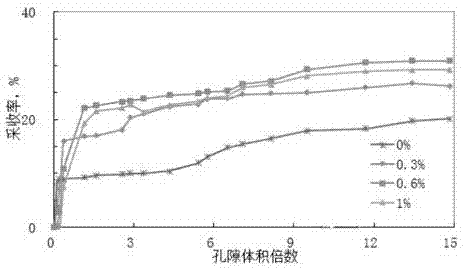

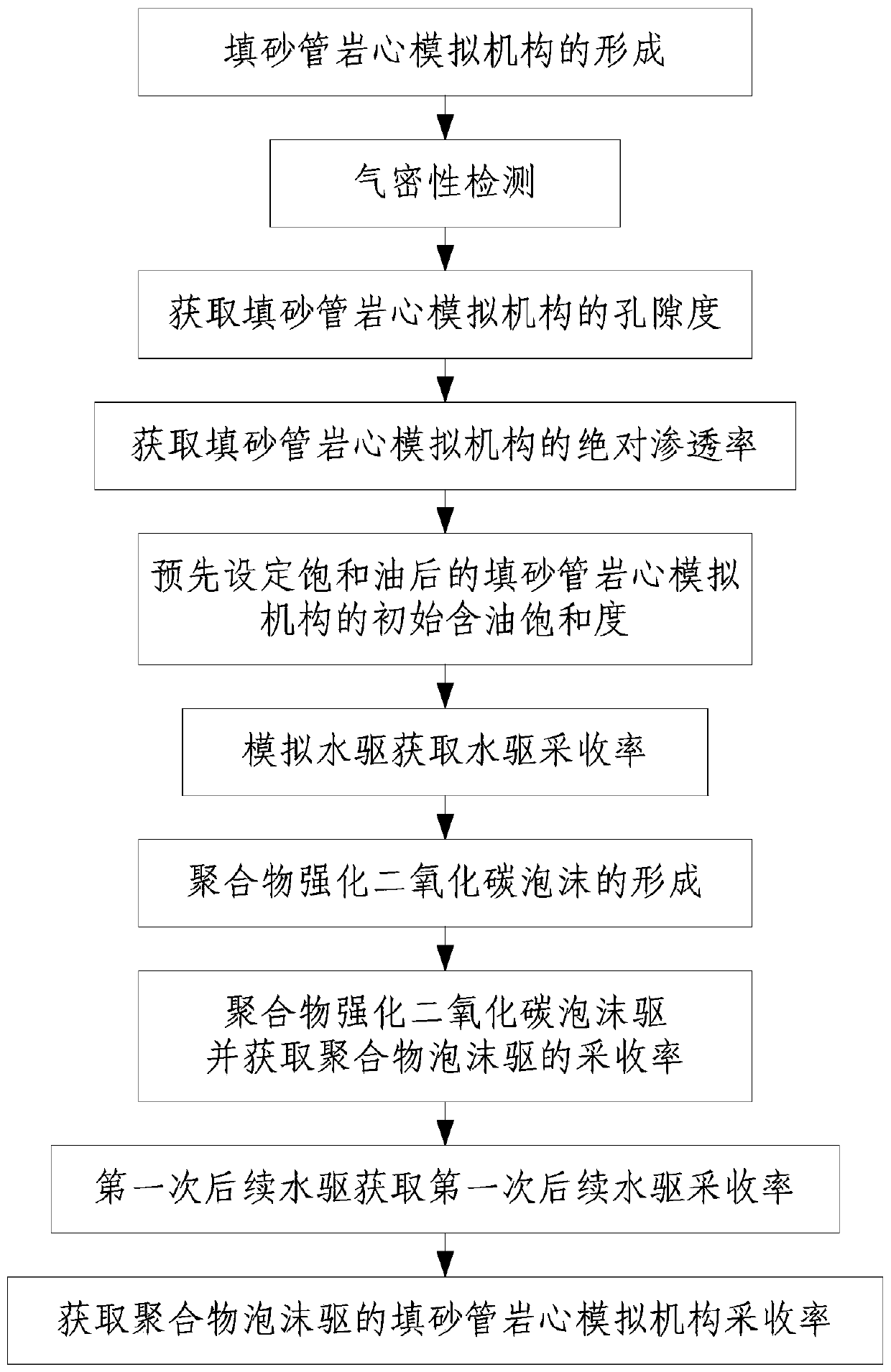

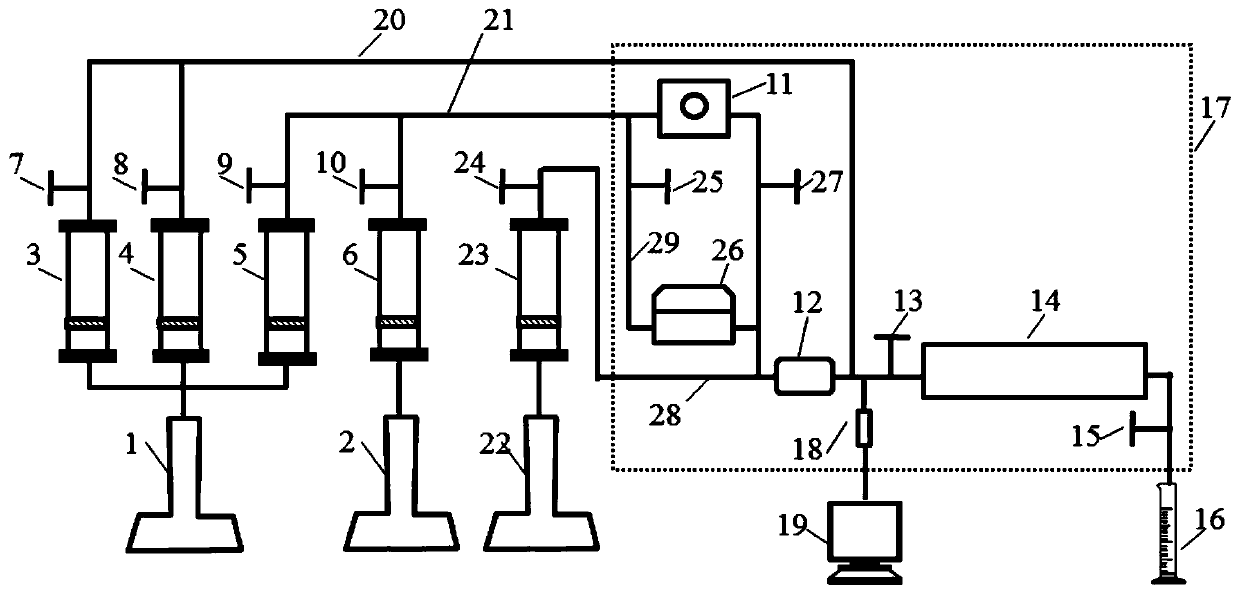

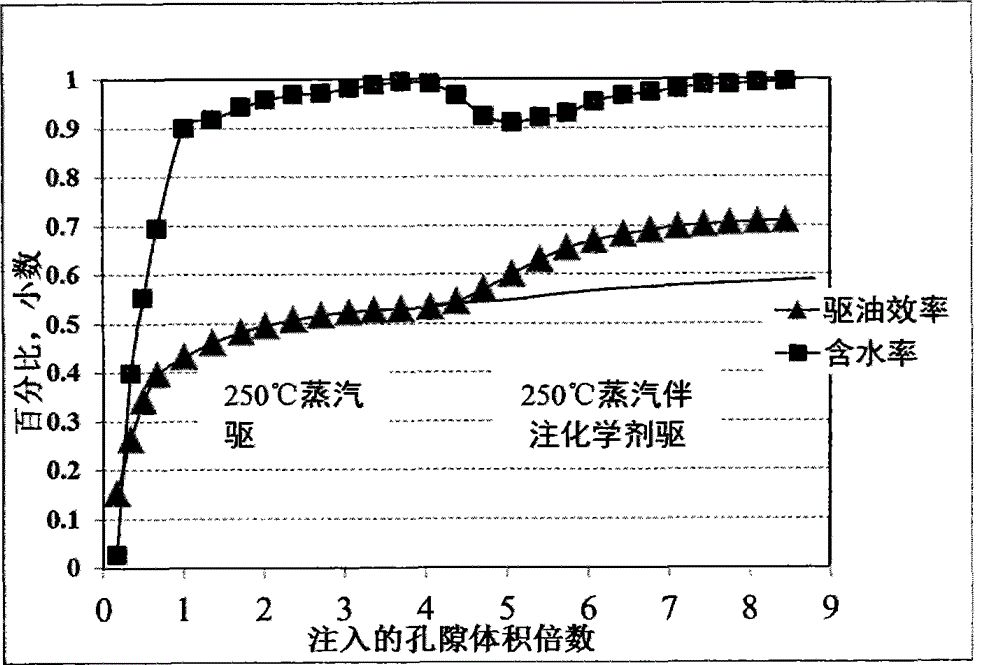

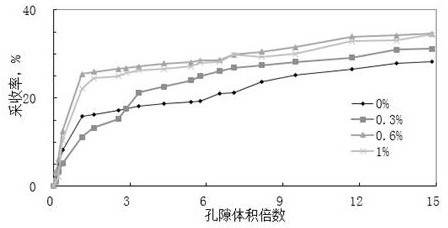

Device and method for improving recovery of thin-bed heavy oil reservoirs based on foam flooding

ActiveCN109209315BProduce quicklyContinuous productionFluid removalDrilling compositionThermal oil recoveryPolymer

The invention discloses a device for improving the recovery rate of thin-bed heavy oil reservoirs based on polymer foam flooding. The invention also discloses a device for improving the recovery rate of thin-layer heavy oil reservoirs based on the combination of polymer foam flooding and jelly foam flooding. The invention also discloses a method for improving the recovery rate of the thin layer heavy oil reservoir based on polymer foam flooding. The invention discloses a method for improving the recovery rate of thin-bed heavy oil reservoirs based on the combination of polymer foam flooding and jelly foam flooding. The invention solves the problem that the foaming liquid easily enters the foam generator while the gas is difficult to enter during foam production, and at the same time solves the problem of low primary and secondary recovery of thin-layer heavy oil reservoirs and the inapplicability of thermal oil recovery through the cold oil recovery method It provides an important theoretical basis for the scientific use of foam flooding to enhance the recovery of thin-layer heavy oil reservoirs and its specific on-site construction.

Owner:CHANGAN UNIV

High-temperature resistant steam chemical auxiliary agent for thermal oil recovery

ActiveCN102925132BEnhanced overall recoveryImprove stabilityFluid removalDrilling compositionThermal oil recoverySurface-active agents

The invention provides a novel high-temperature resistant steam chemical auxiliary agent for thermal oil recovery. The novel high-temperature resistant steam chemical auxiliary agent comprises 65-85% a high-temperature resistant poly fatty acid acylamino alkyl dimethyl tertiary amine non-ionic surface active agent and 15-35%a mutual solvent in terms of percentage by weight. The technical bottleneck that the chemical oil displacing agent in the prior art cannot be used at high temperature is overcome; the steam chemical auxiliary agent disclosed by the invention can have high stability and oil displacing performance in the steam atmosphere being up to 350 DEG C; therefore, chemical displacement and steam displacement are combined perfectly and organically; the oil recovery cost is favorably reduced; and the thermal oil displacing recovery rate is increased.

Owner:DONGYING HUALI PETROLEUM TECH

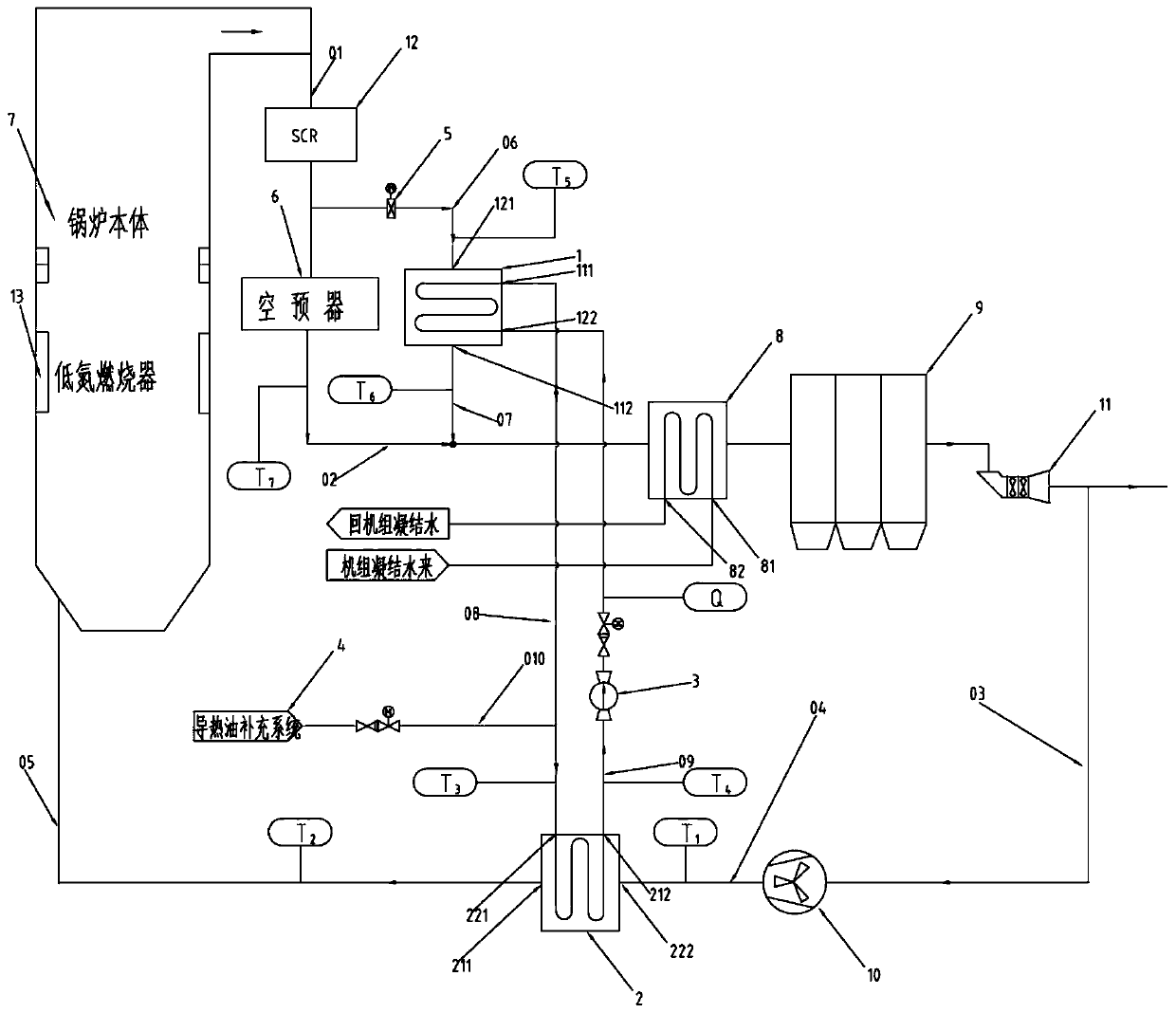

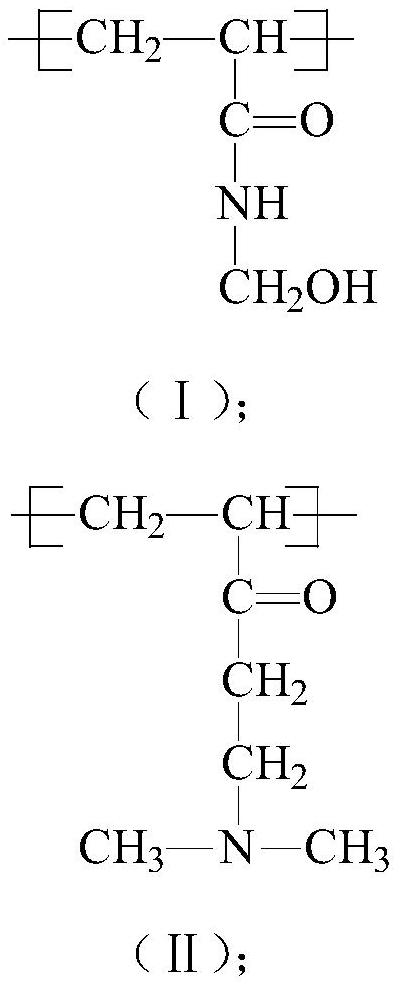

Cold smoke recirculating unit heat conduction oil recovery bypass smoke heat system and control method

ActiveCN110925744AReduce design pressure ratingImprove heat transfer coefficientSolid fuel combustionCombustion technology mitigationAir preheaterThermal oil recovery

The invention discloses a cold smoke recirculating unit heat conduction oil recovery bypass smoke heat system. The cold smoke recirculating unit heat conduction oil recovery bypass smoke heat system comprises a bypass smoke cooling device, a recirculating cold smoke heating device, a closed circulating oil pump, a heat conduction oil replenishing system, an adjusting baffle door, an air preheaterand a boiler body. A first inlet of the bypass smoke cooling device communicates with a smoke exhaust port through the adjusting baffle door, and a first outlet of the bypass smoke cooling device communicates with a smoke outlet of the air preheater. The bypass smoke cooling device communicates with the recirculating cold smoke heating device in a circulating manner. The recirculating cold smoke heating device communicates with a cold smoke recirculating draught fan and a hearth dry bottom hopper of the boiler body. The input end of the closed circulating oil pump communicates with a second outlet of the recirculating cold smoke heating device, and the output end of the closed circulating oil pump communicates with a second inlet of the bypass smoke cooling device. The output end of the heat conduction oil replenishing system communicates with an eighth pipeline and is used for replenishing a heat conduction oil circulating medium. A smoke inlet of the air preheater communicates with the smoke exhaust port of the boiler body.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

System capable of utilizing heat conducting oil to recycle waste heat of industrial waste gas

ActiveCN111609752AImprove cleanlinessQuick scrapeCleaning processes and apparatusRotary device cleaningHeat conductingCollector device

The invention discloses a system capable of utilizing heat conducting oil to recycle waste heat of industrial waste gas. The system structurally comprises a deashing device, a water intake pipe, an air intake pipe, a preheater, a heat exchanger, a blowing device, a water-out pipe, a connecting pipe, a circulating pump and a heat collector. When the system is used after improvement, a scraper and ascraping and sweeping rod are matched on a support rod to slide left and right so as to rapidly scrape impurities in a waste heat recycling device and prevent the impurities from blocking a waste heat recycling pipeline, and a sliding plate helps the scraping and sweeping rod to move, so that the heat exchanging effect of the waste heat is improved; the blowing component purges viscous dust and very fine dust to blow away dust, so that plenty of dust are prevented from being adsorbed to a heat exchanging pipe; a rotary screw rod drives a disc body to rotate, so that a sweeping brush can rapidly sweep viscous dust and very fine dust in the waste heat recycling device, and then, an adsorption plate adsorbs swept dust, so that the waste heat recycling device can continuously operate to improve the heat conversion rate of the heat exchanging pipe.

Owner:四川中电福溪电力开发有限公司

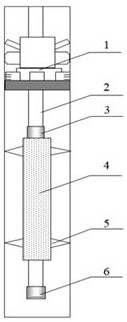

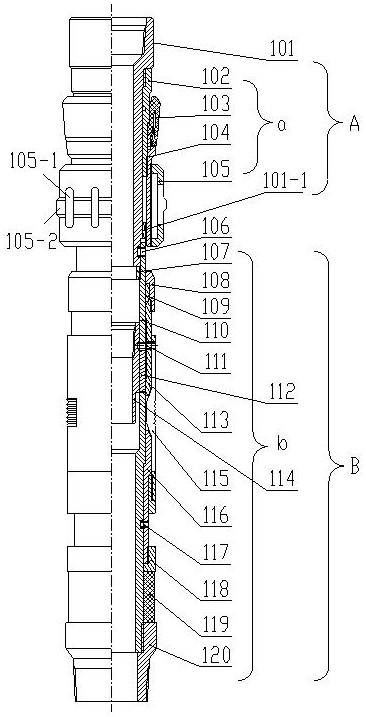

Experimental device and special model system for simulating gas-assisted steam thermal oil recovery in heavy oil reservoirs

The invention discloses an experimental device for simulating heavy oil reservoir gas auxiliary steam thermal oil recovery and a special model system of the experimental device. The model system consists of a cylinder body. Openings at both ends of the cylinder body are respectively matched with an upper cover and a piston in a sealing mode. The piston is fixed on the cylinder body through a piston fixed pressing cap. At least one fluid in-out hole is formed in the upper cover, and the fluid in-out hole extends to a cavity of the cylinder body and connected with a well model connecting port. The well model connecting port is used for connecting well models. At least one data acquisition port is arranged on the cylinder body. The data acquisition port extends to the cavity of the cylinder body, the piston fixed pressing cap is provided with a liquid inlet, and the liquid inlet extends to a cavity between the piston and the piston fixed pressing cap. The experimental device can carry out precise experiments over a production increasing mechanism and an effect of gas improving steam stimulation and steam drive, the experimental results are genuine and believable, and the device has an important significance for gas auxiliary steam thermal oil recovery and development.

Owner:CHINA NAT OFFSHORE OIL CORP +1

High-temperature foaming agent for thickened oil steam huff and puff and preparation method thereof

The invention belongs to the technical field of thermal oil recovery, and particularly relates to a high-temperature foaming agent for thickened oil steam huff and puff and a preparation method thereof. The preparation method comprises the following steps of preparing CeO2 by taking sodium alginate as a template and Ce(NO3)3.6H2O as a raw material, and then dispersing a product obtained by copolymerization of alpha-olefin sodium sulfonate, sodium acrylate and 1-vinyl-2-pyrrolidone in water by taking ammonium persulfate as an initiator to prepare the high-temperature foaming agent. The high-temperature foaming agent provided by the invention has a good foaming effect at high temperature, and can effectively prevent a steam channeling phenomenon.

Owner:洪益民

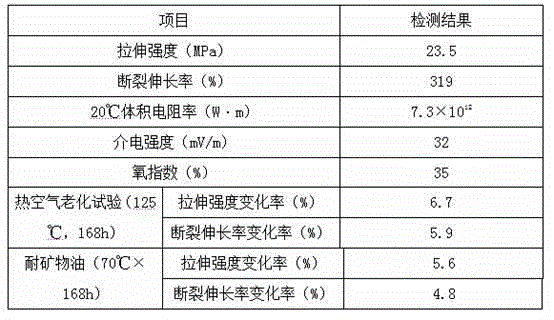

Heat tracing cable sheath material for thermal oil recovery and preparation method of heat tracing cable sheath material

InactiveCN104448798AImprove heat resistanceGood oil resistancePlastic/resin/waxes insulatorsEthyl laurateAntimony

The invention discloses a heat tracing cable sheath material for thermal oil recovery and a preparation method of the heat tracing cable sheath material. The heat tracing cable sheath material is prepared from the following raw materials in parts by weight: 40-60 parts of nylon 6, 25-35 parts of polyphenylene sulfide, 16-22 parts of a perfluoro(ethylene-propylene) copolymer, 10-15 parts of ash calcium powder, 8-12 parts of nano titanium phosphate, 10-15 parts of volcanic rock powder, 3-6 parts of basic lead carbonate, 5-10 parts of dibutyl fumarate, 2-3 parts of tri(ethyl laurate thiol) antimony, 1.5-2.5 parts of triphenyl phosphite, 3-5 parts of trimethylolpropane, 4-8 parts of sasol wax, 1-2 parts of tetraphenyl bisphenol-A-diphosphate, 10-15 parts of diethylene glycol dibenzoate, 8-14 parts of aluminum hypophosphite, 1-2 parts of 2,3,4-trihydroxybenzophenone and 2-4 parts of auxiliary agents. The sheath material disclosed by the invention has excellent heat resistance and oil resistance and good wear resistance, fatigue resistance and aging resistance, is safe and reliable, is long in service life, and ensures that the requirements for working environments of thermal oil recovery can be completely met.

Owner:ANHUI KEYANG THERMAL CONTROL

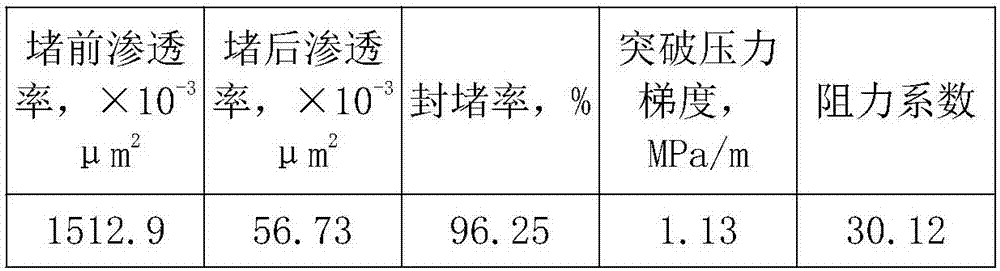

A high temperature resistant auxiliary steam flooding oil displacement agent for thermal oil recovery and its application

ActiveCN107955594BEnhanced overall recoveryOil displacement effect is goodDrilling compositionThermal oil recoveryThermodynamics

The invention belongs to the technical field of thermal oil recovery and particularly relates to a high-temperature-resistant auxiliary steam-driven oil-displacing agent for thermal oil recovery and application thereof. The oil-displacing agent is a copolymer comprising a hydroxyl-containing acrylamide derivative unit, an acrylate derivative unit and a carboxylate-containing acrylamide derivativeunit. The oil-displacing agent is injected while the steam is injected into the stratum, so that the rheological property of thick oil can be improved, the oil-water interfacial tension can be reduced, the colloid stability can be enhanced, and the oil-displacing effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cold smoke recirculation unit heat transfer oil recovery bypass flue gas heat system and control method

ActiveCN110925744BReduce coal consumption for power generationImprove recycling efficiencySolid fuel combustionCombustion technology mitigationAir preheaterThermal oil recovery

The invention discloses a heat conduction oil recovery bypass flue gas heat system of a cold smoke recirculation unit, comprising a bypass flue gas cooling device, a recirculation cold smoke heating device, a closed circulation oil pump, a heat conduction oil replenishment system, and an adjustment baffle door , the air preheater and the boiler body; the first inlet of the bypass flue gas cooling device communicates with the exhaust port through the adjustment baffle door, and the first outlet of the bypass flue gas cooling device communicates with the smoke outlet of the air preheater ;The bypass flue gas cooling device is in circulation communication with the recirculation cold smoke heating device; The second outlet of the smoke heating device is connected, the output end of the closed circulation oil pump is connected with the second inlet of the bypass flue gas cooling device; the output end of the heat transfer oil replenishment system is connected with the eighth pipeline, which is used to provide supplementary heat transfer oil circulation medium ; The smoke inlet of the air preheater communicates with the smoke outlet of the boiler body.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Solid-liquid separation and purification integration equipment for lithium hexafluorophate preparation

PendingCN109879300AThe production cycle is shortenedShorten the production cycleLithium compoundsLithiumHydrogen fluoride

The invention discloses solid-liquid separation and purification integration equipment for lithium hexafluorophate preparation. The solid-liquid separation and purification integration equipment comprises a heat conduction oil tank, a heat conduction oil pump, a heater, a container, a bracket, a jacket, a material outlet, a liquid discharging hole, a gear, a chain, a motor, a heat conduction oil inlet, a heat conduction oil outlet, a heat conduction oil circulating pipe, a heat conduction oil recovery pipe and a filter screen. According to the equipment, lithium hexafluorophate crystals and lithium hexafluorophate hydrogen fluoride solution are separated and further purified, an amount of equipment for realizing the process is reduced, an integration degree is higher, and the problems of quality risk, long production period and manpower waste in a middle link when multiple pieces of equipment are used for realizing solid-liquid separation and purification process in the prior art are solved.

Owner:青海聚之源新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com