Patents

Literature

420 results about "Thermal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tunable frangible battery pack system

ActiveUS7923144B2Minimize the possibilityReduce exposurePrimary cell to battery groupingElectric devicesElectrical conductorThermal force

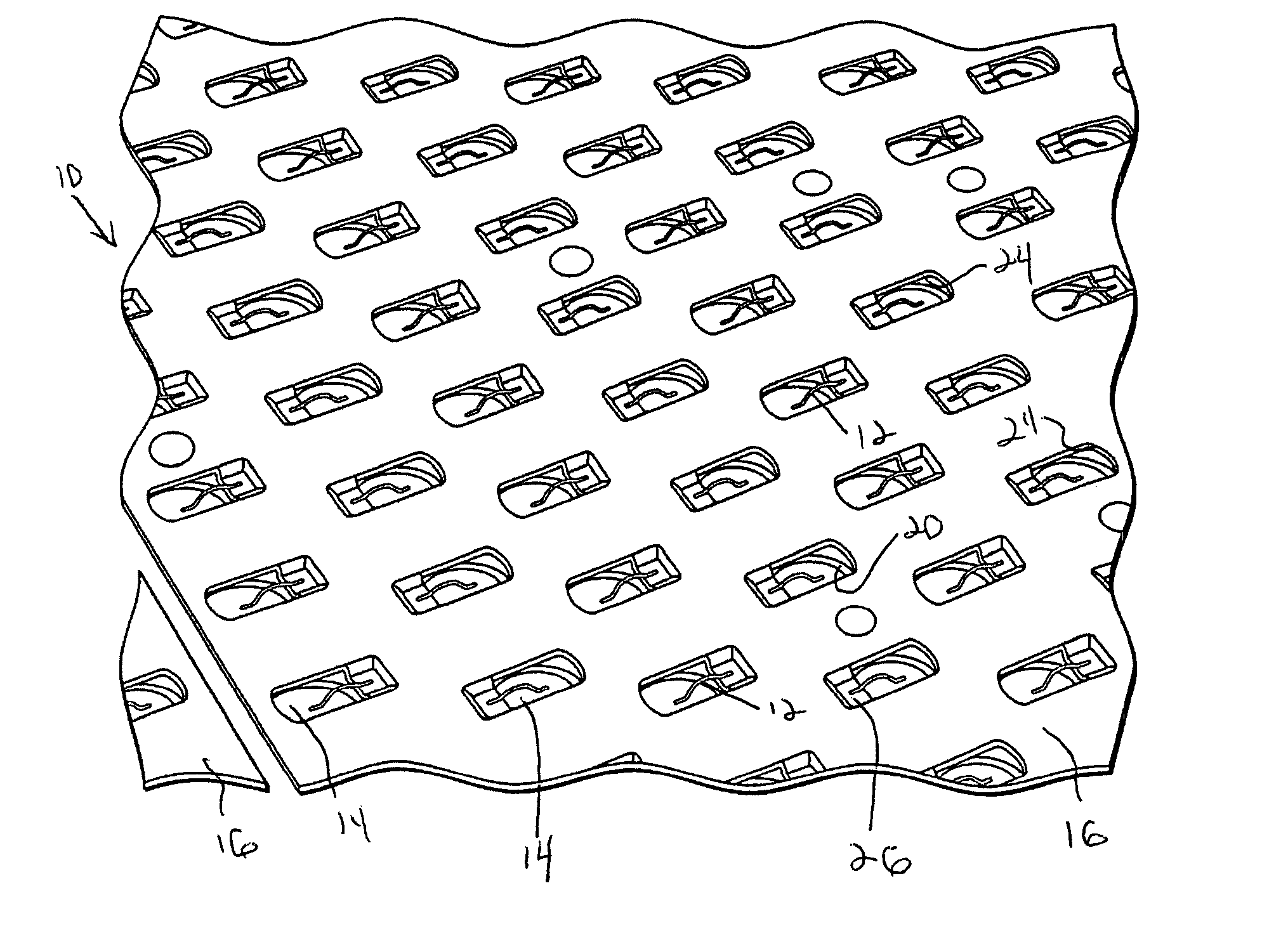

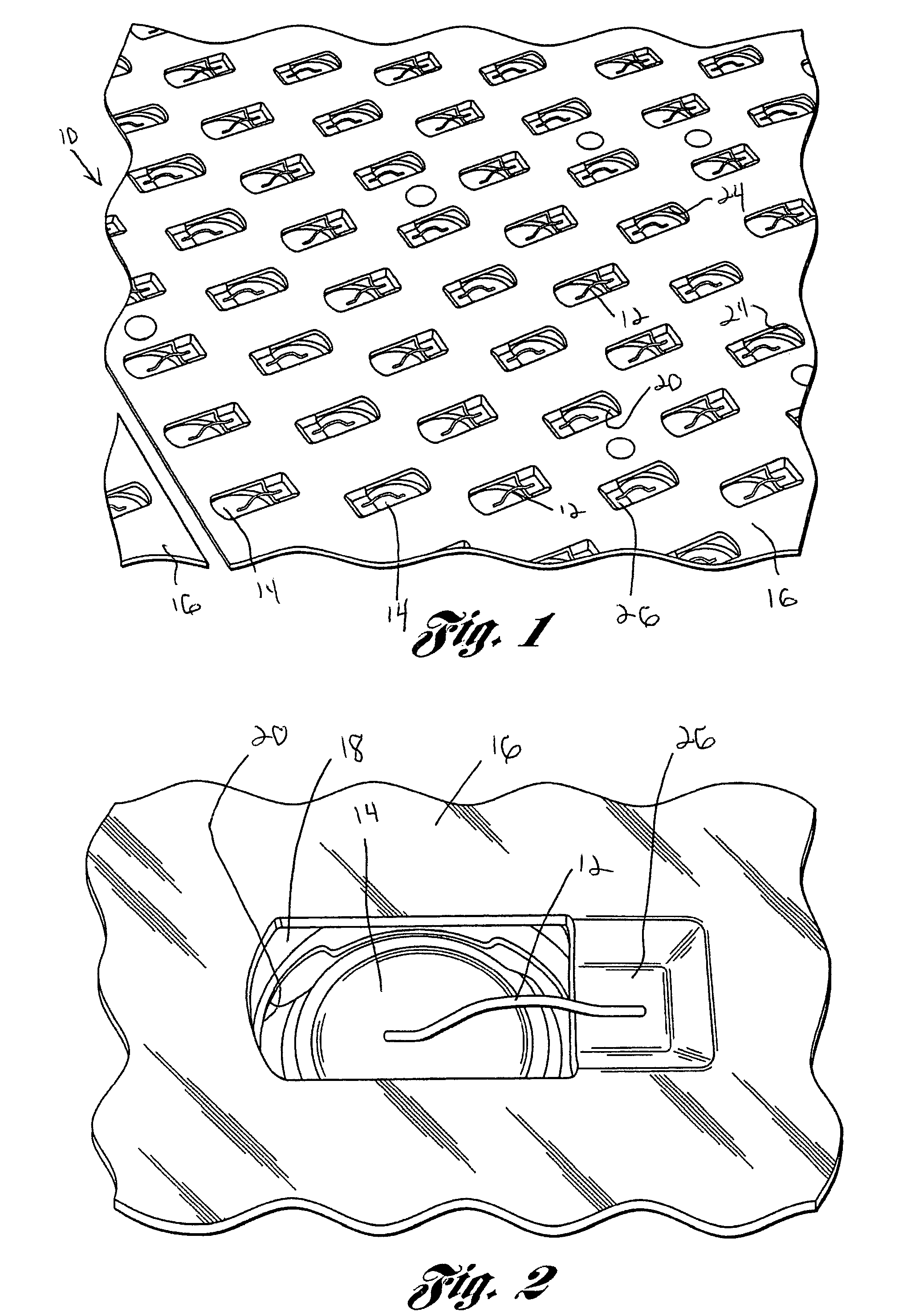

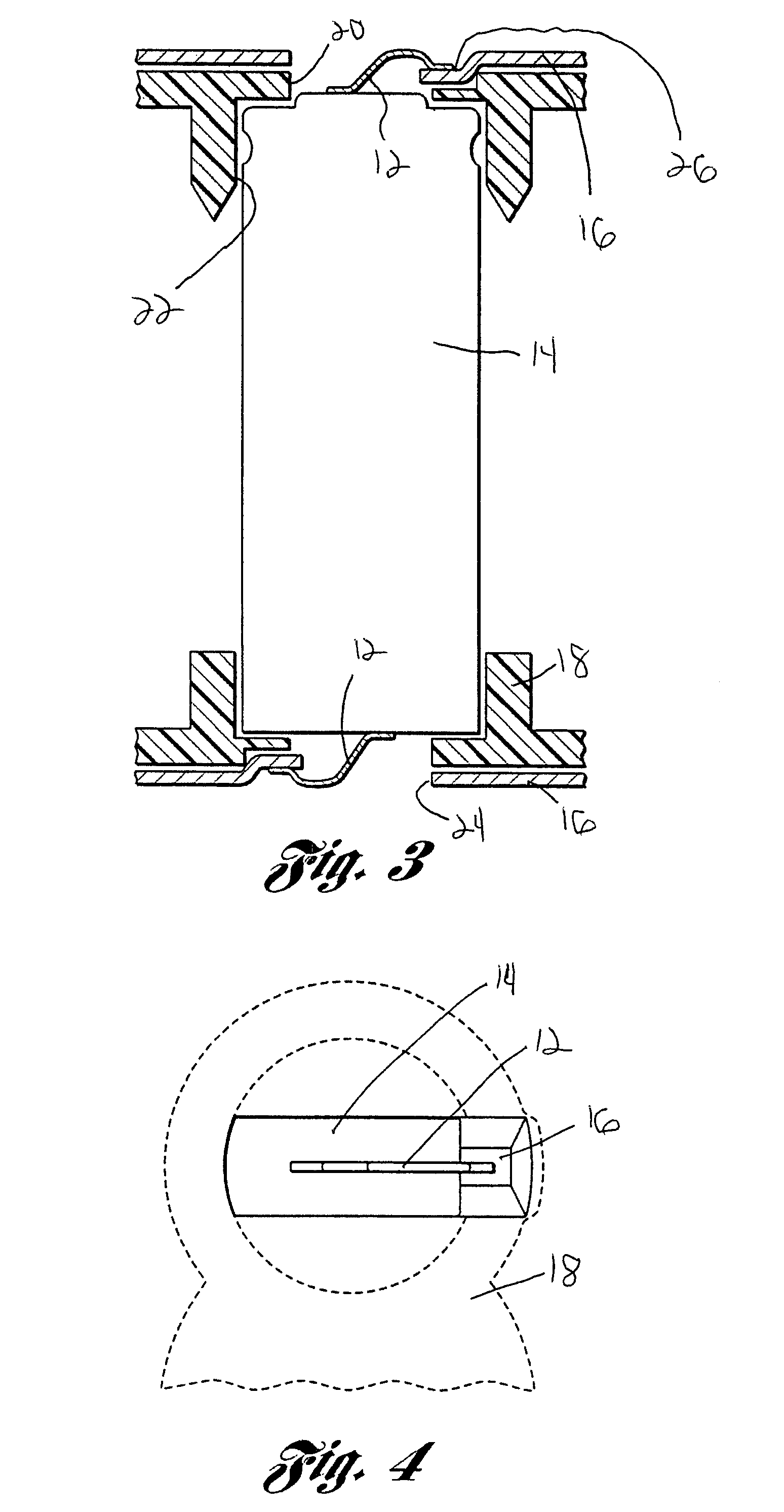

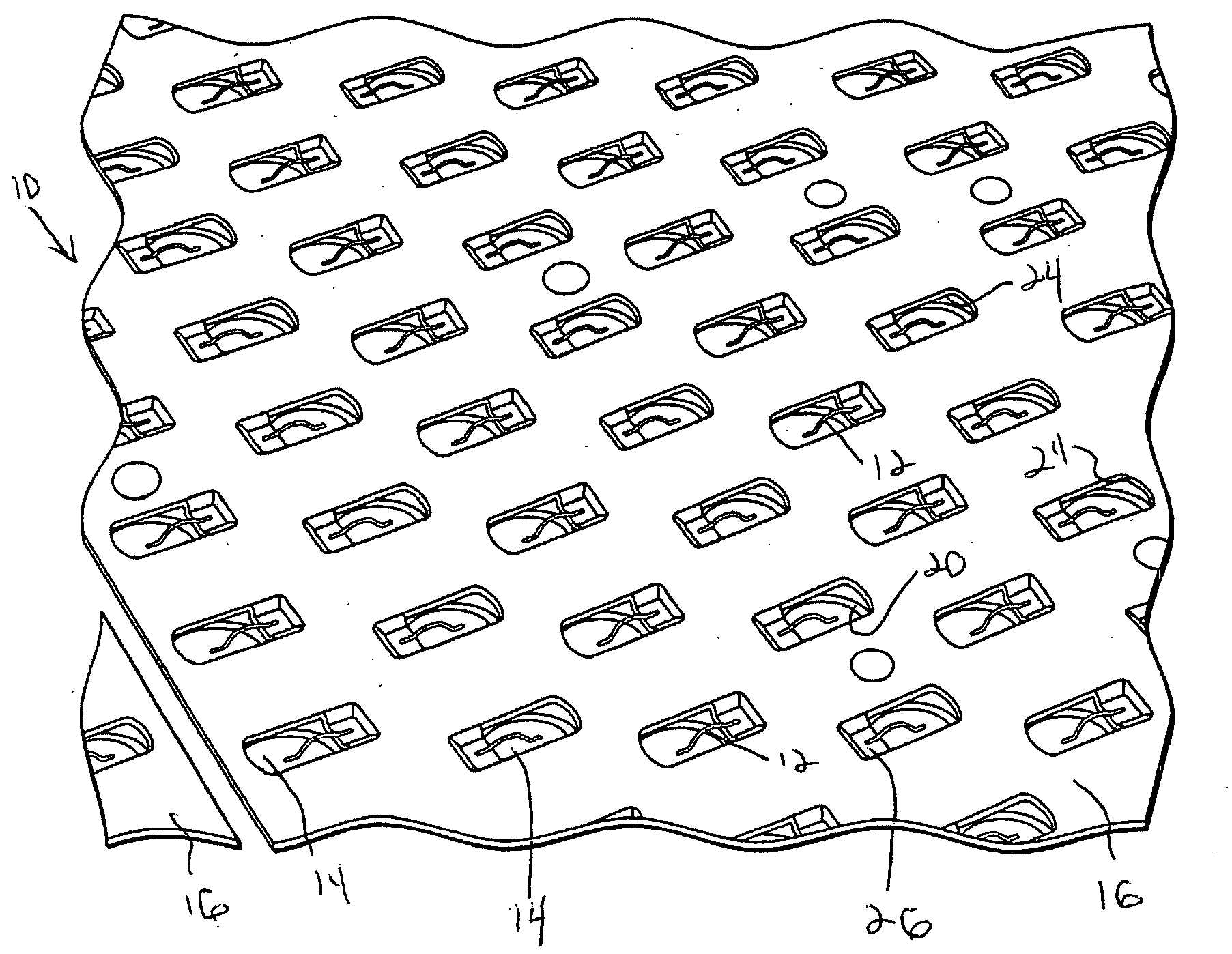

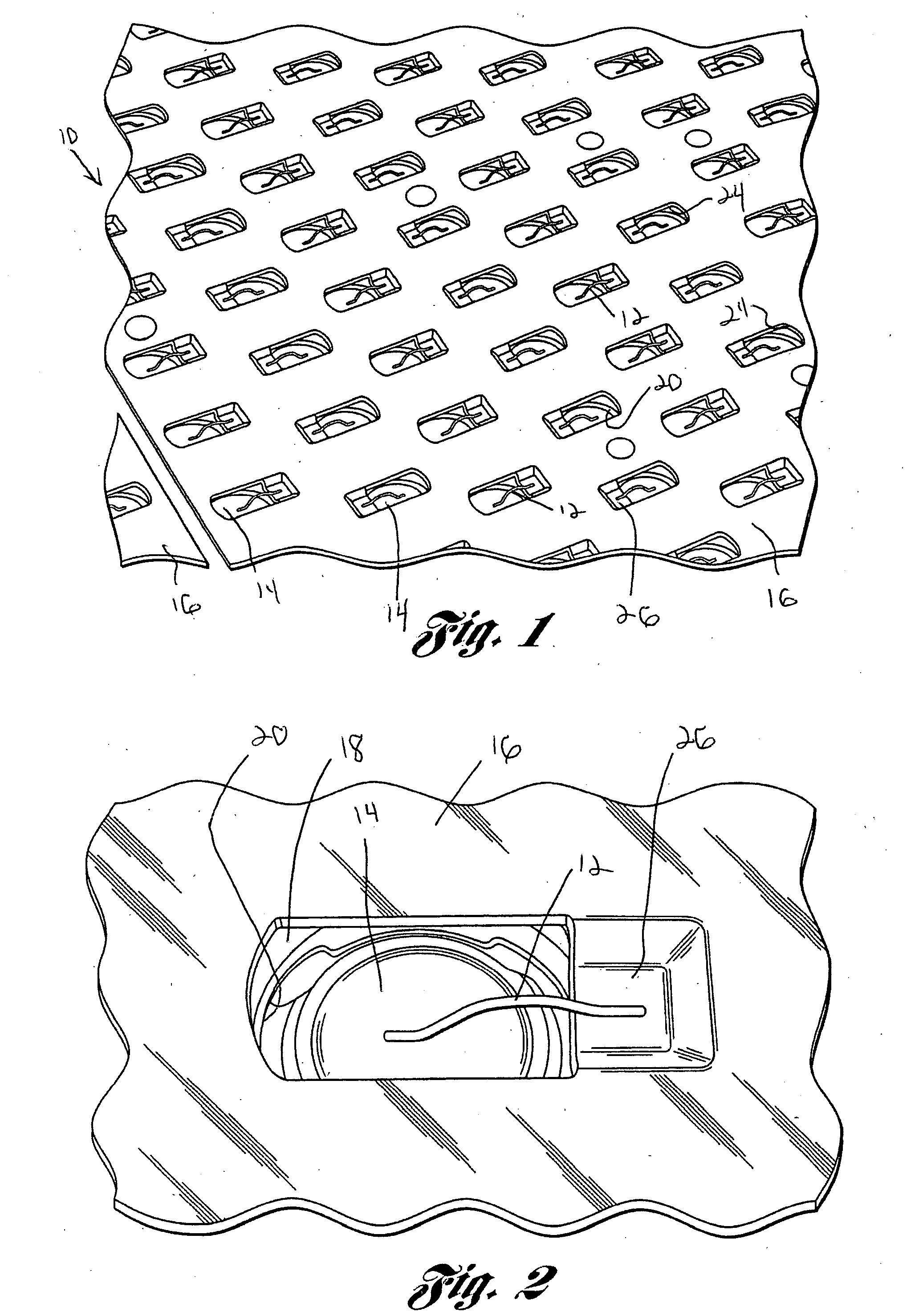

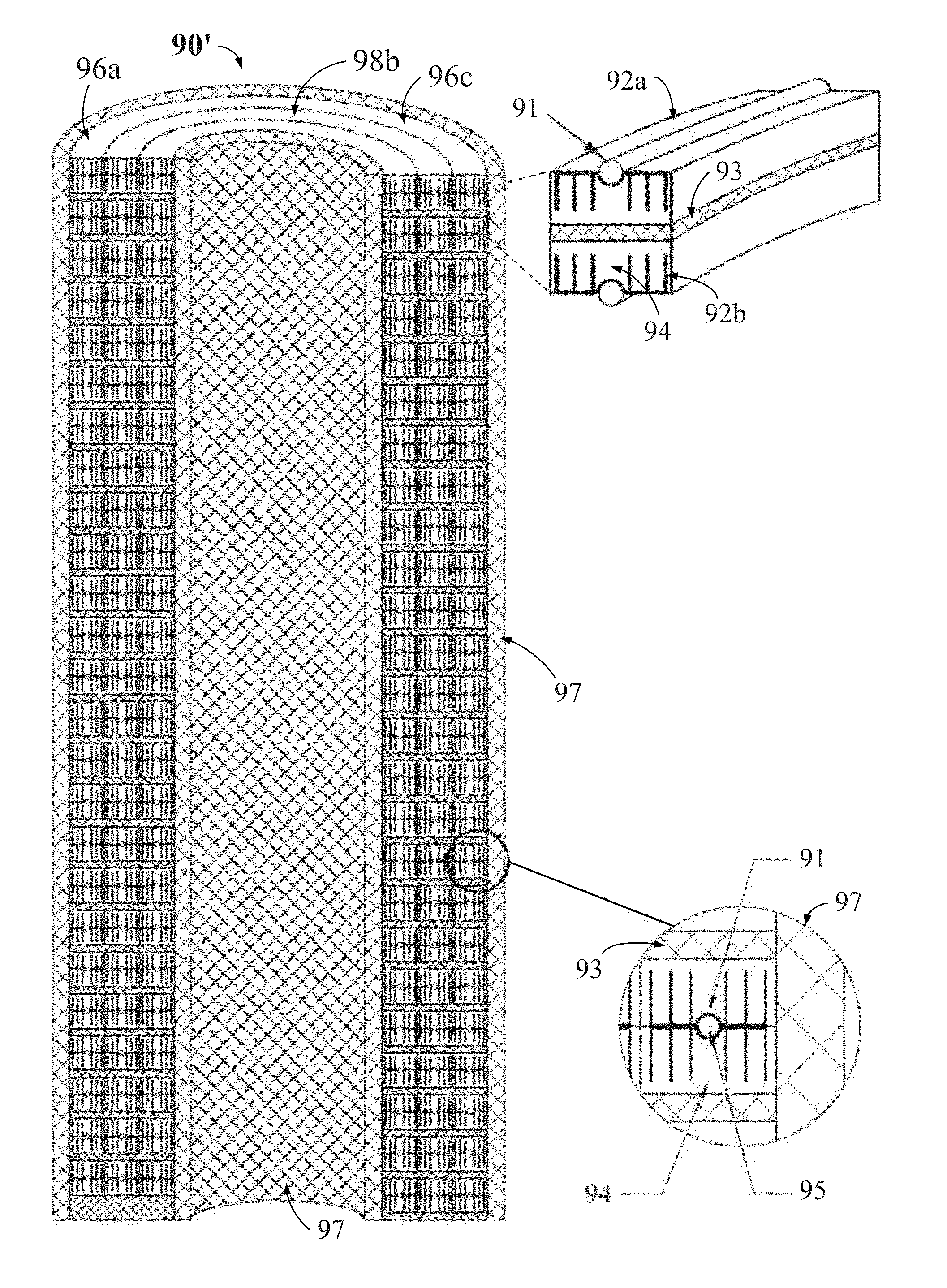

A tunable frangible battery pack system for use in an electric vehicle is disclosed. The tunable frangible battery pack system includes a two piece clamshell housing. The system also includes a plurality of battery cells arranged within the housing and a collector plate secured to each piece of the housing. The system also includes a wire conductor arranged between each of the battery cells and collector plates to create a frangible disconnect system when the battery pack system and electric vehicle are exposed to a predetermined mechanical or thermal force or event.

Owner:TESLA INC

Tunable frangible battery pack system

ActiveUS20080241667A1Allow useMinimize the possibilityPrimary cell to battery groupingElectric devicesElectrical conductorThermal force

A tunable frangible battery pack system for use in an electric vehicle is disclosed. The tunable frangible battery pack system includes a two piece clamshell housing. The system also includes a plurality of battery cells arranged within the housing and a collector plate secured to each piece of the housing. The system also includes a wire conductor arranged between each of the battery cells and collector plates to create a frangible disconnect system when the battery pack system and electric vehicle are exposed to a predetermined mechanical or thermal force or event.

Owner:TESLA INC

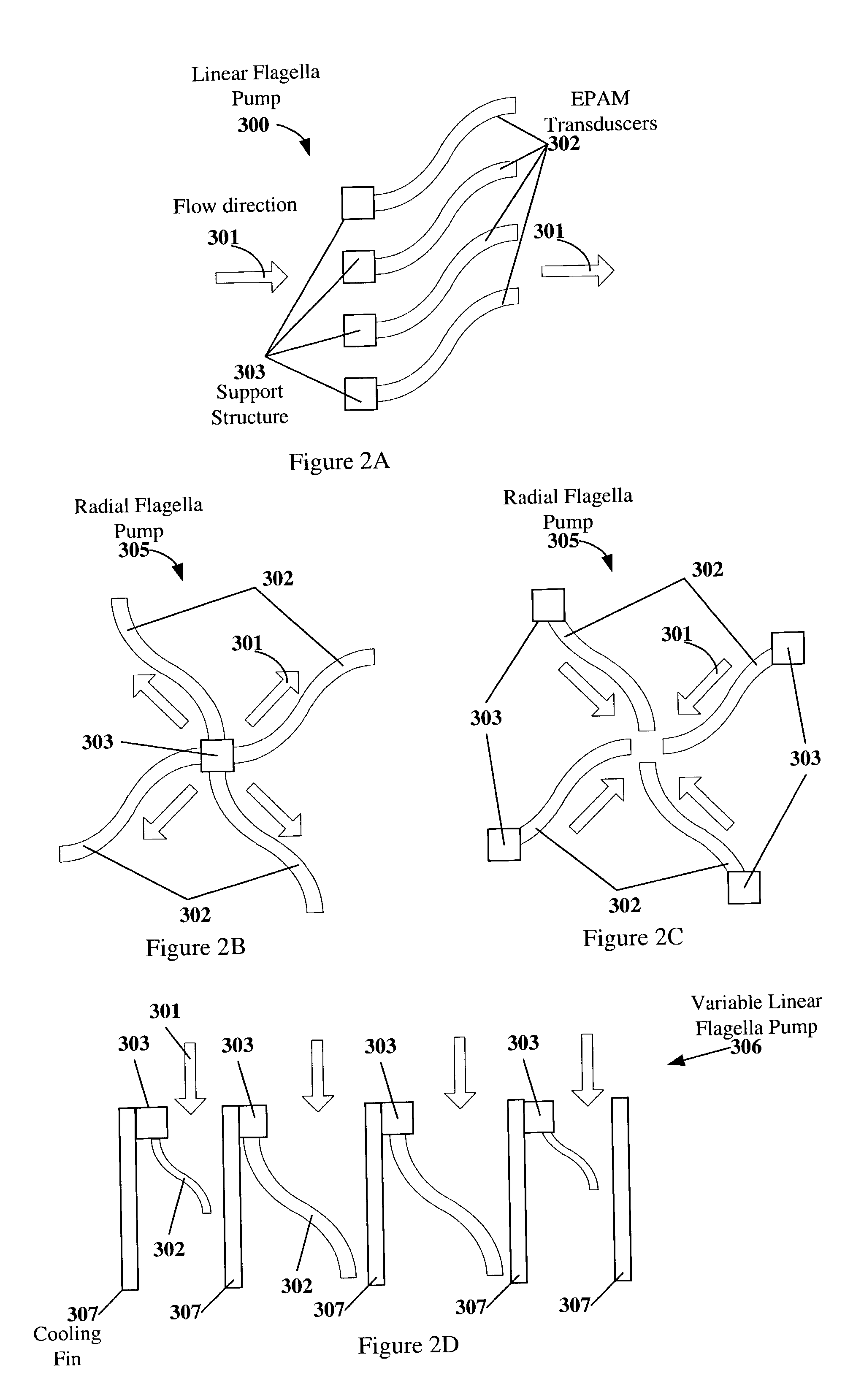

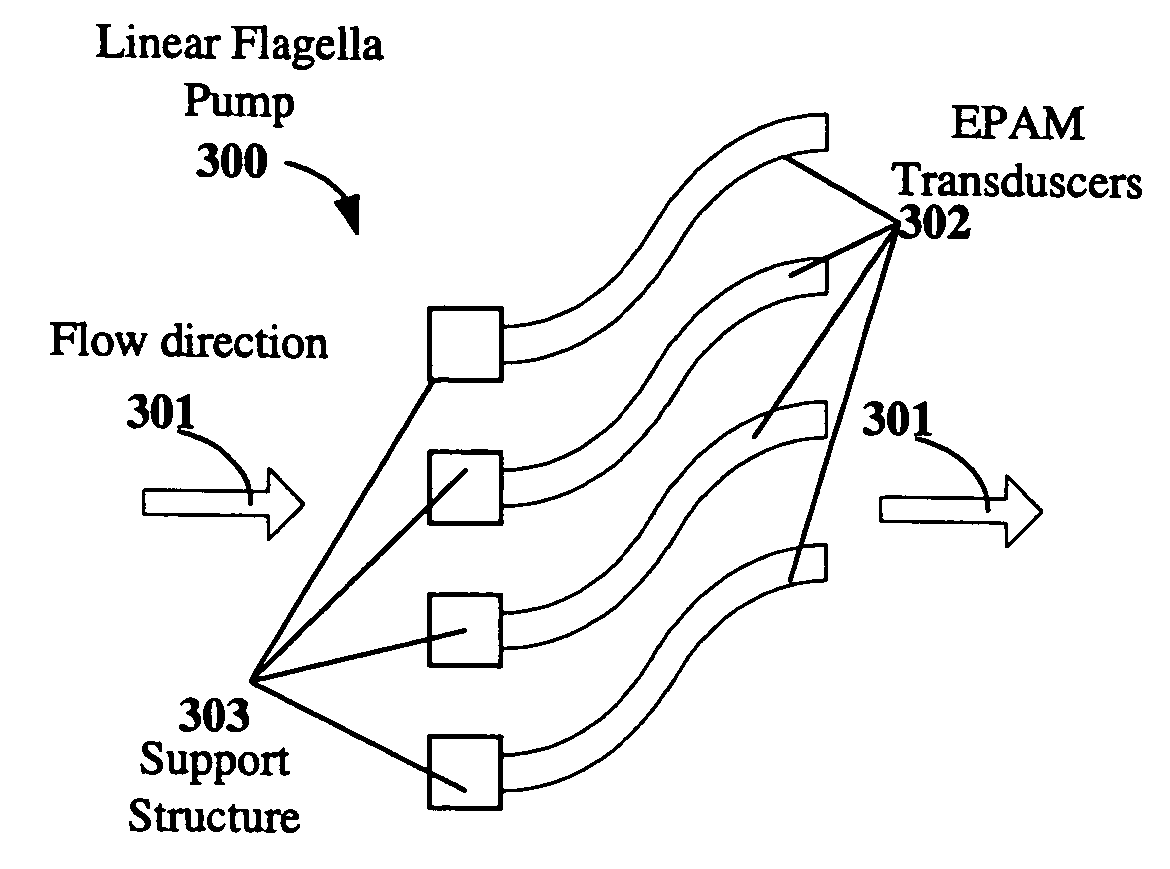

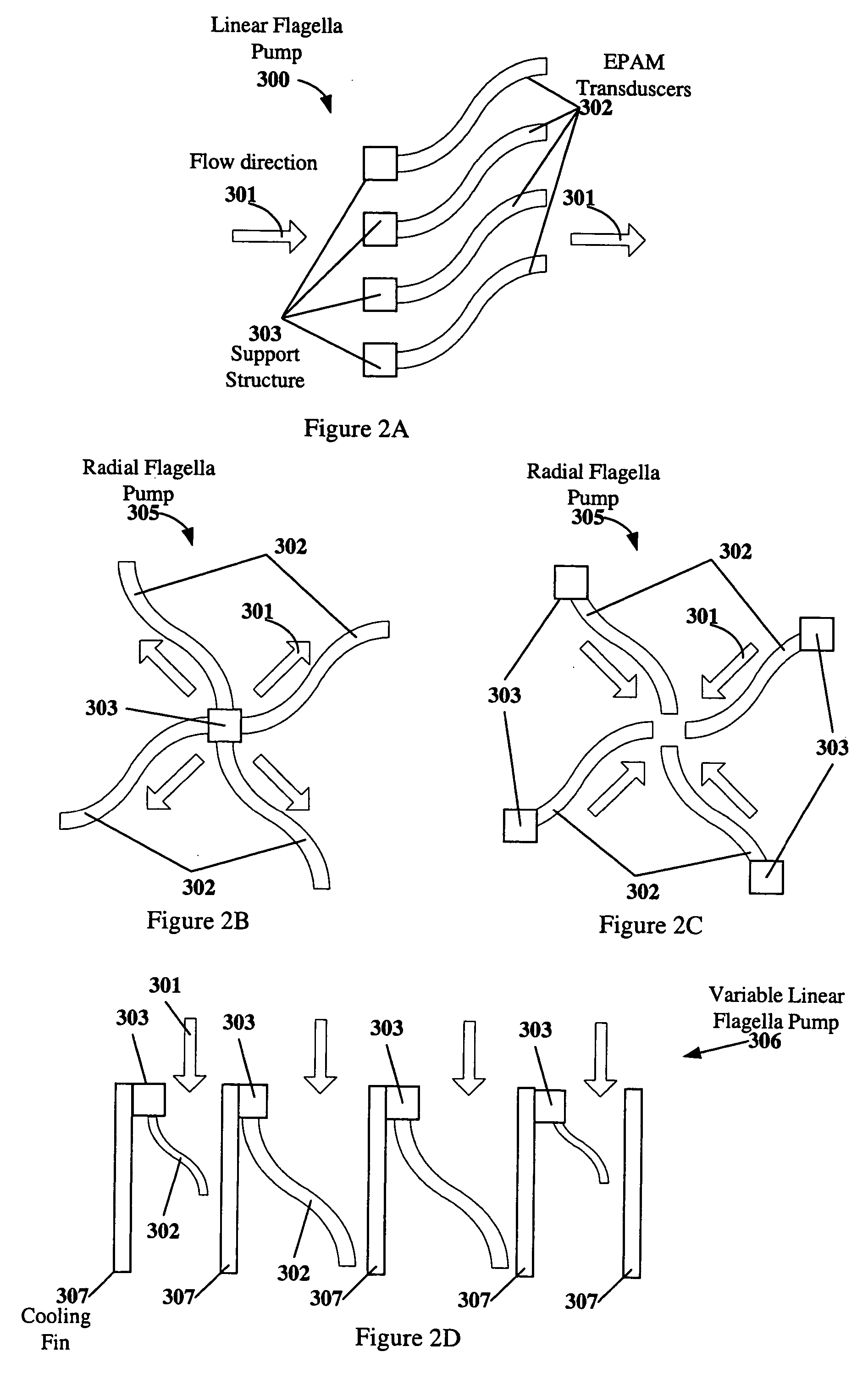

Electroactive polymer devices for moving fluid

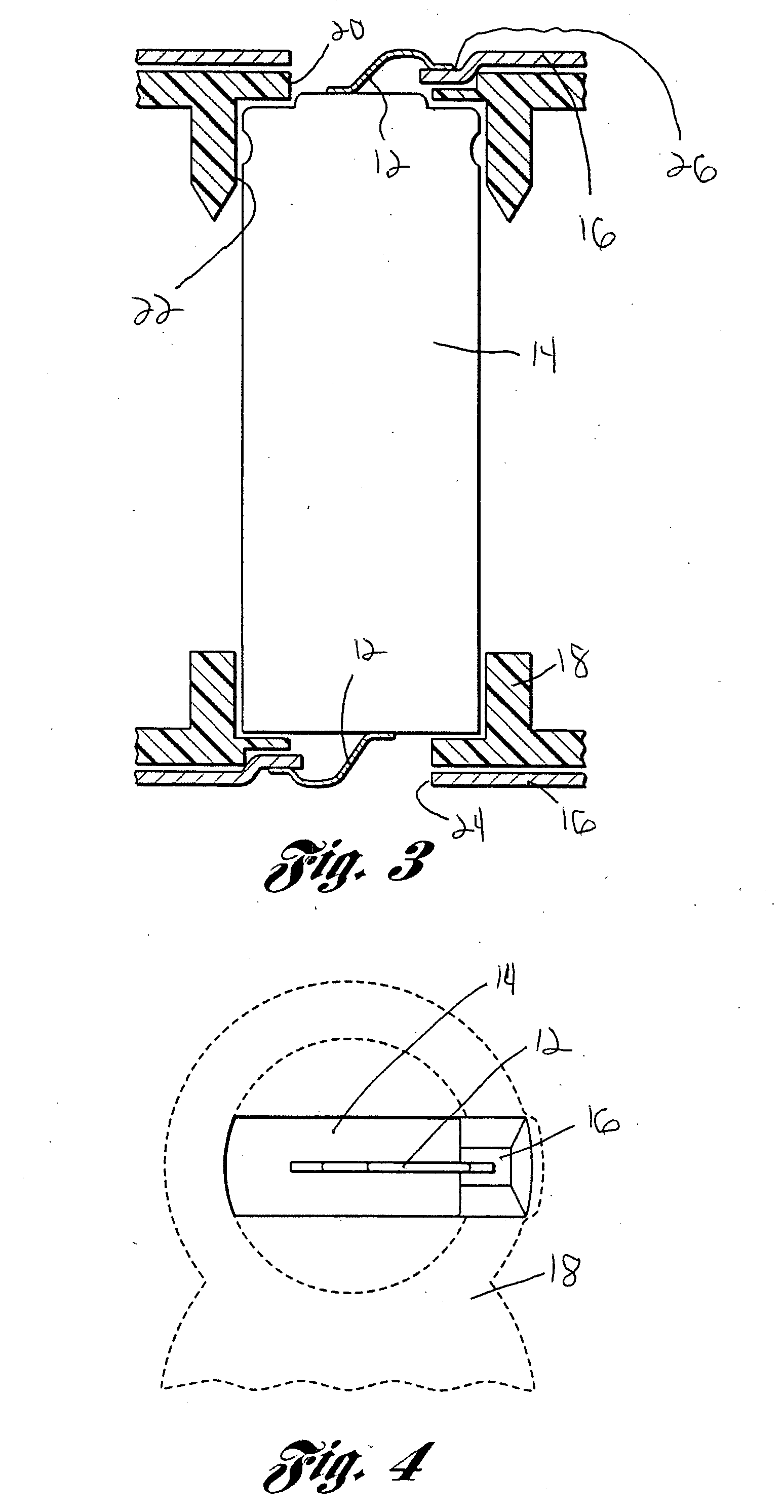

InactiveUS7064472B2Improve mechanical responseImprove responseTransducer detailsFlexible member pumpsHearing rangeThermal force

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

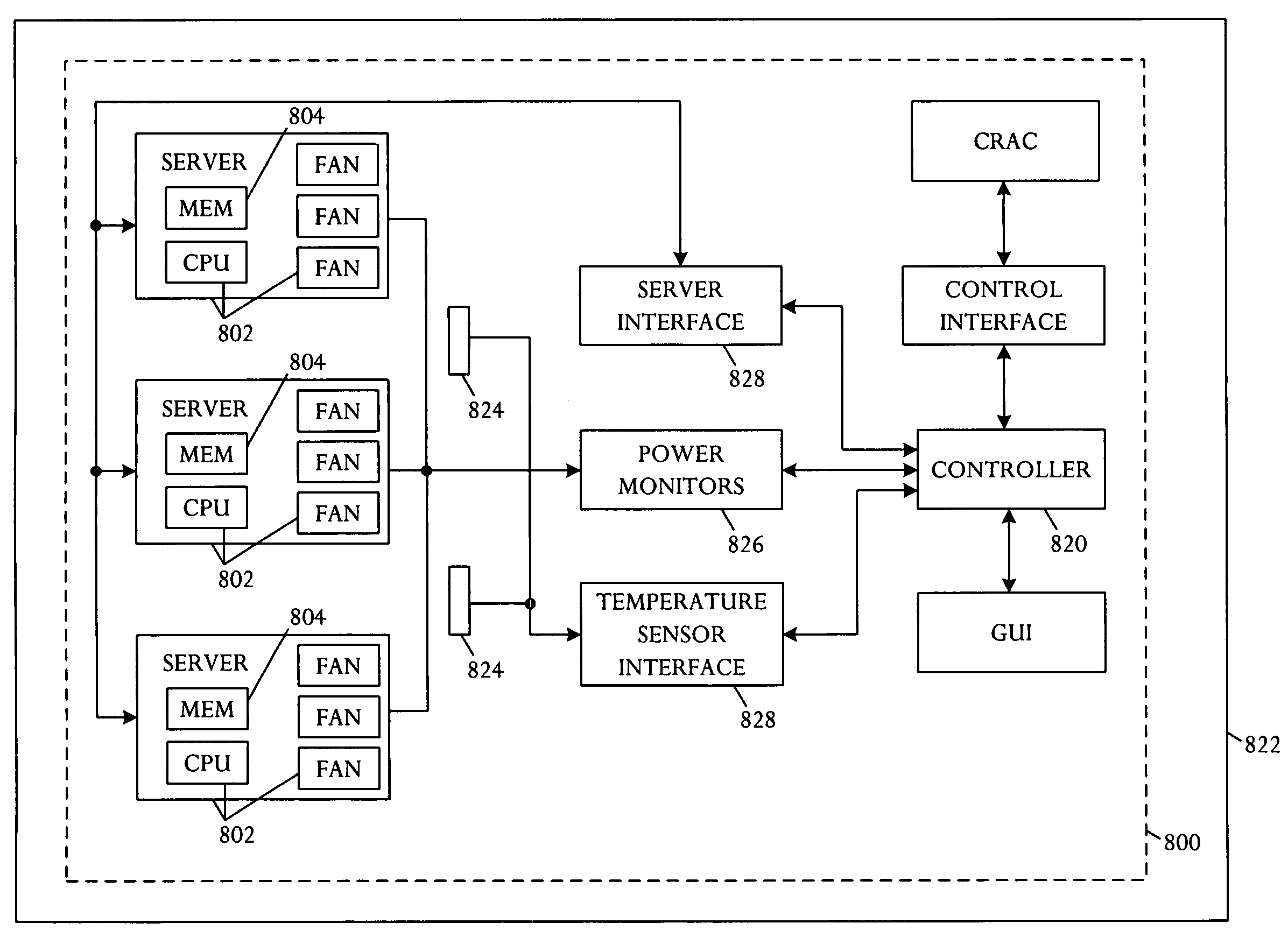

Thermal management using stored field replaceable unit thermal information

A method of managing conditions in a data center comprises storing information relating to field replaceable unit thermal properties in at least one field replaceable unit non-volatile memory and generating information for real-time dynamic temperature mapping of the data center based on the field replaceable unit thermal property information.

Owner:HEWLETT PACKARD DEV CO LP

Electroactive polymer devices for moving fluid

InactiveUS20060158065A1Improve responseTransducer detailsFlexible member pumpsHearing rangeThermal force

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

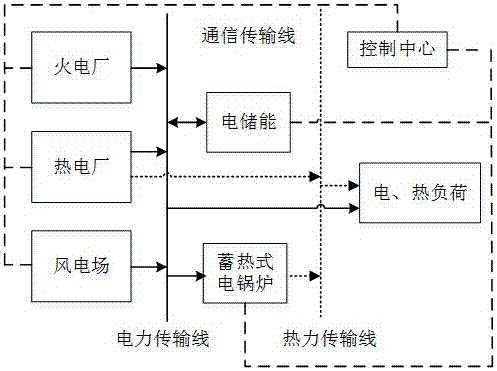

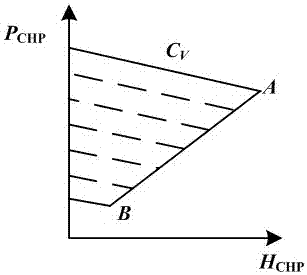

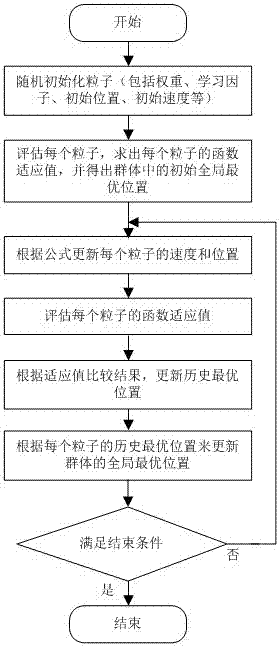

Combined system energy optimization method with consideration of wind power consumption

InactiveCN107508328APromote development and utilizationImprove wind power absorption capacitySingle network parallel feeding arrangementsEnergy storageNew energyElectric power system

The invention, which belongs to the grid-connected optimization operation field of the new energy, relates to a combined system energy optimization method with consideration of wind power consumption; and thus in order to solve a wind curtailment problem, the combined system energy optimization method uses a cogeneration system based on combined operation of a wind power-electric energy storage-heat accumulating type electric boiler and takes economic optimum as an objective to reduce the wind-curtailment power effectively by increasing the load space. To be specific, the method comprises the following steps: (1), establishing an overall system framework including a conventional thermal power generating unit, a cogeneration unit, a wind turbine generator, an electric energy storage and heat accumulating type electric boiler; (2), carrying out comprehensive modeling of a cogeneration system; (3), establishing an optimal economic objective function; (4), establishing a power and heating power balancing relationship and operational constraints of all units during the operation period of the cogeneration cooperation system; and (5), carrying out optimization for active power outputs of all units. Therefore, development and utilization of the wind power are promoted; and power supply reliability of the power system is improved. The method can be applied to large-scale-wind-power-included provincial companies of all stages and has the broad application prospects.

Owner:NORTHEAST DIANLI UNIVERSITY +2

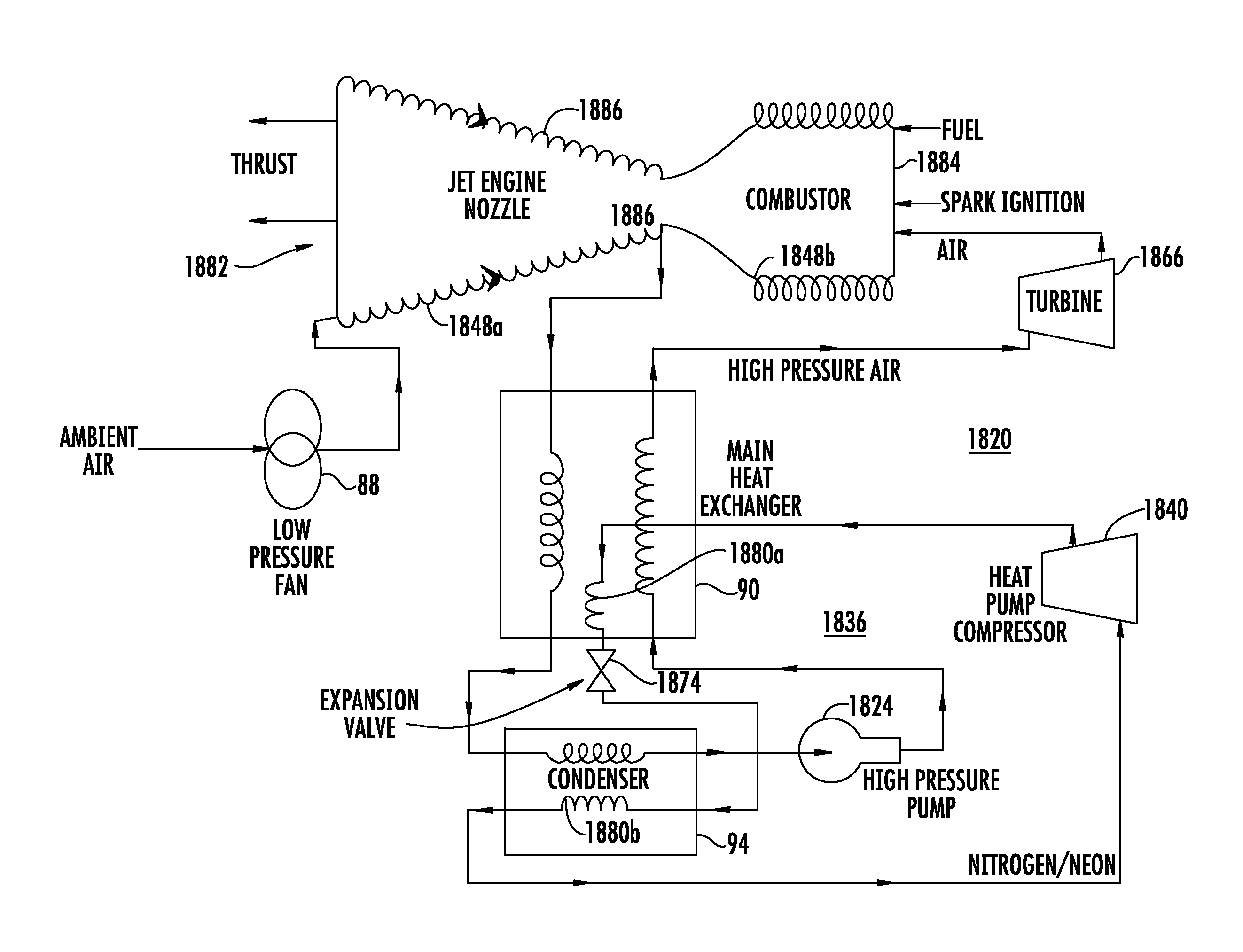

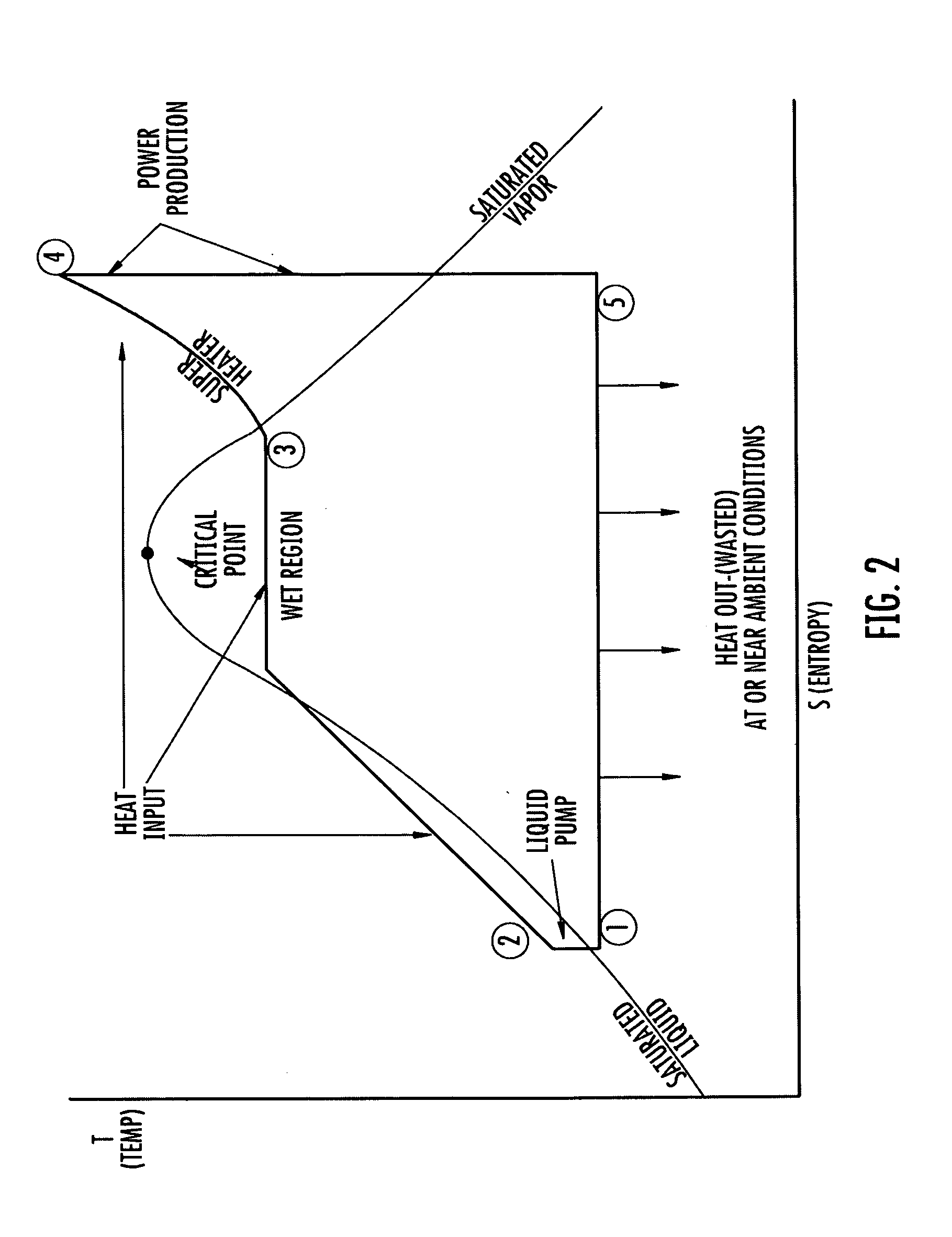

Ultra-high-efficiency engines and corresponding thermodynamic system

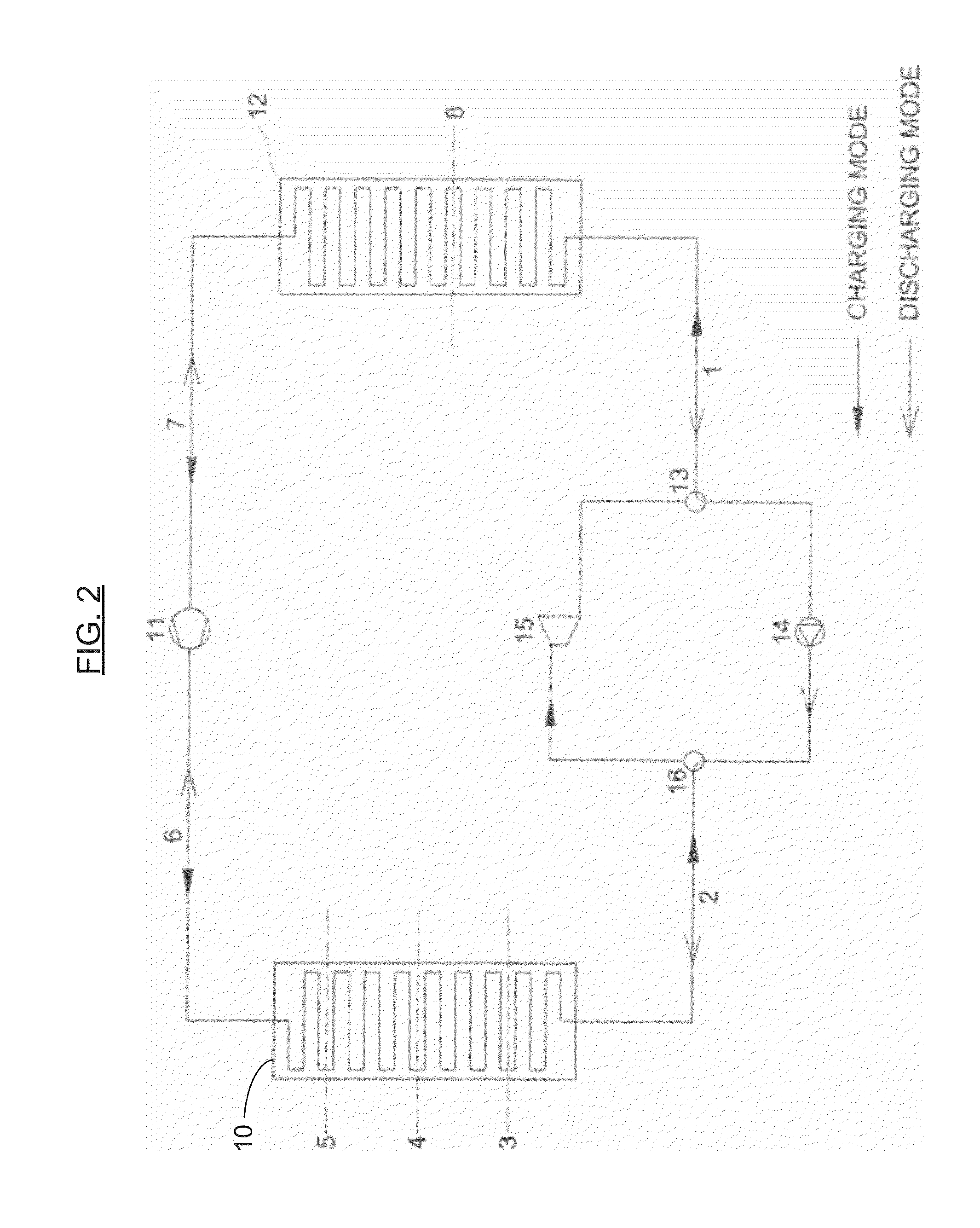

ActiveUS20110252796A1Improving the thermodynamic efficiency of a number of enginesImprove engine efficiencyGas turbine plantsEfficient propulsion technologiesWorking fluidEngineering

A thermodynamic system and method of producing useful work includes providing a working fluid and a fluid pump, or compressor, for pumping the working fluid in a cycle. A thermal input is provided for supplying heat to the working fluid. An expansion device downstream of the thermal input converts motion of the working fluid to useful work. A heat pump is provided. A number of different means of implementing the heat pump are presented, including direct transfer of working fluid mass flow. The heat pump pumps heat from one portion of the working fluid to another portion of the working fluid. For some applications, a regenerator, or recuperator, may be used to transfer heat from a high temperature portion of the working fluid to a lower temperature portion.

Owner:BURKHART TECH

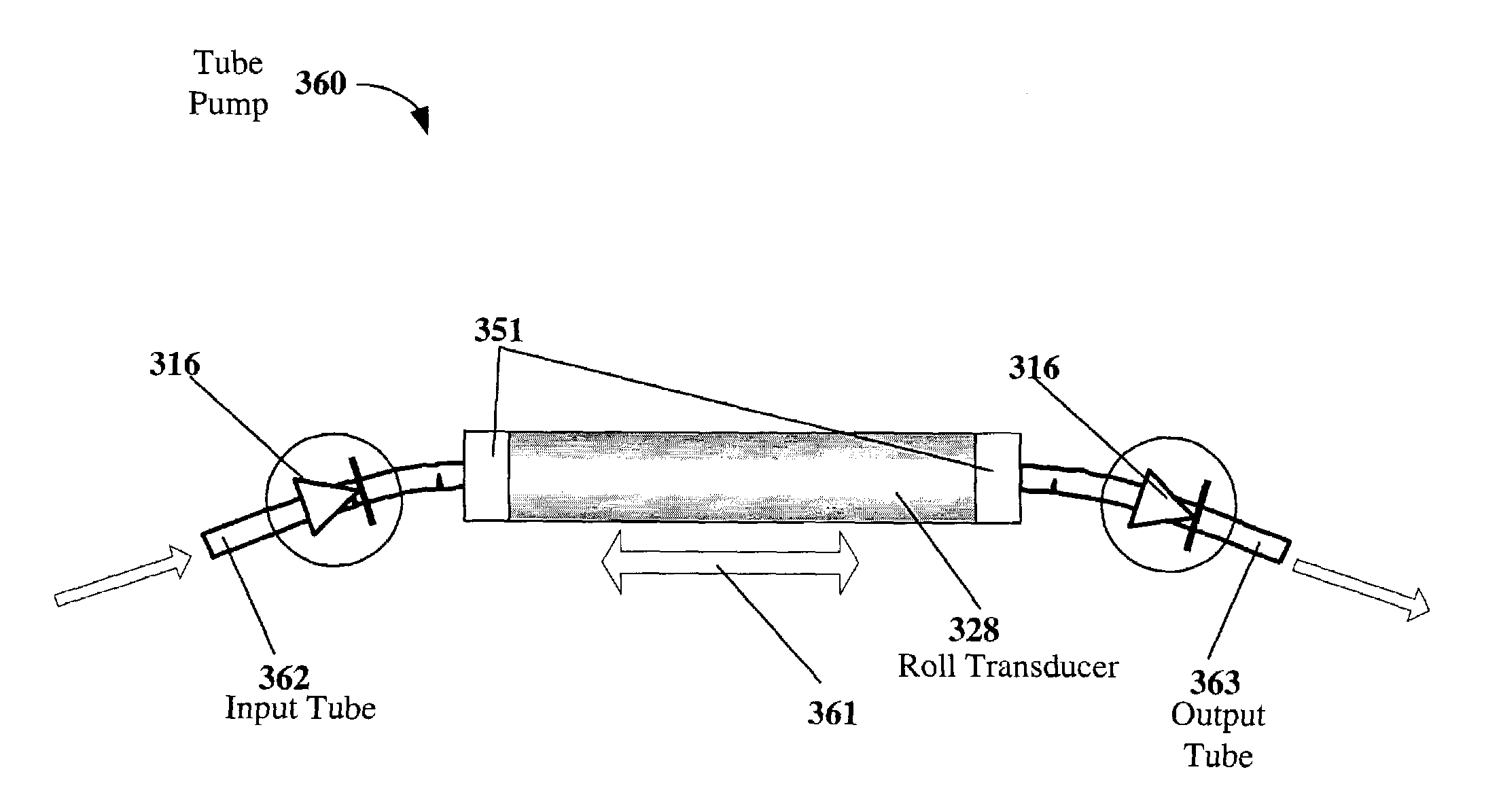

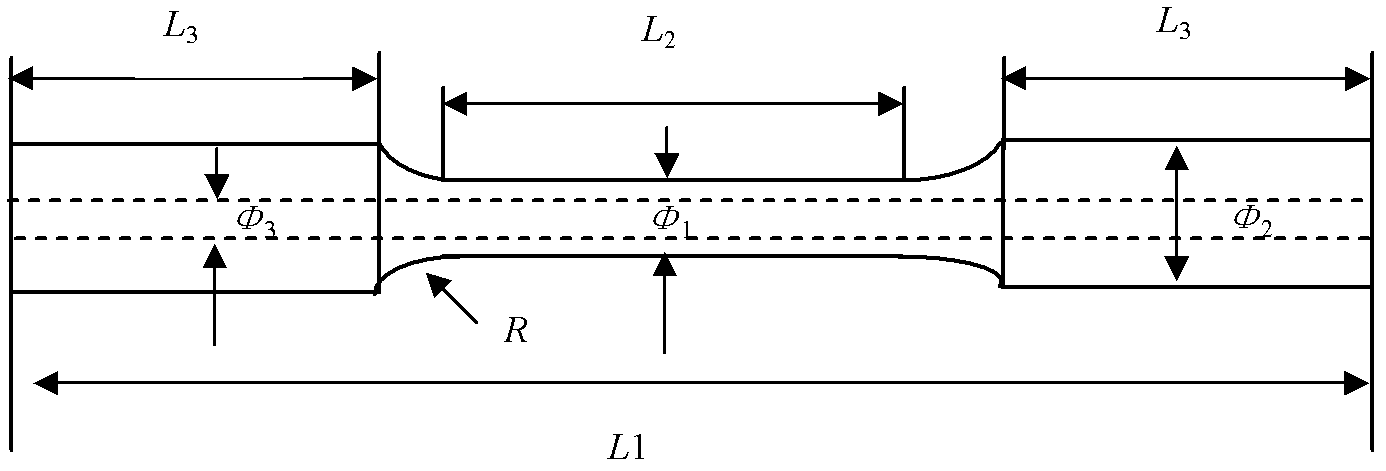

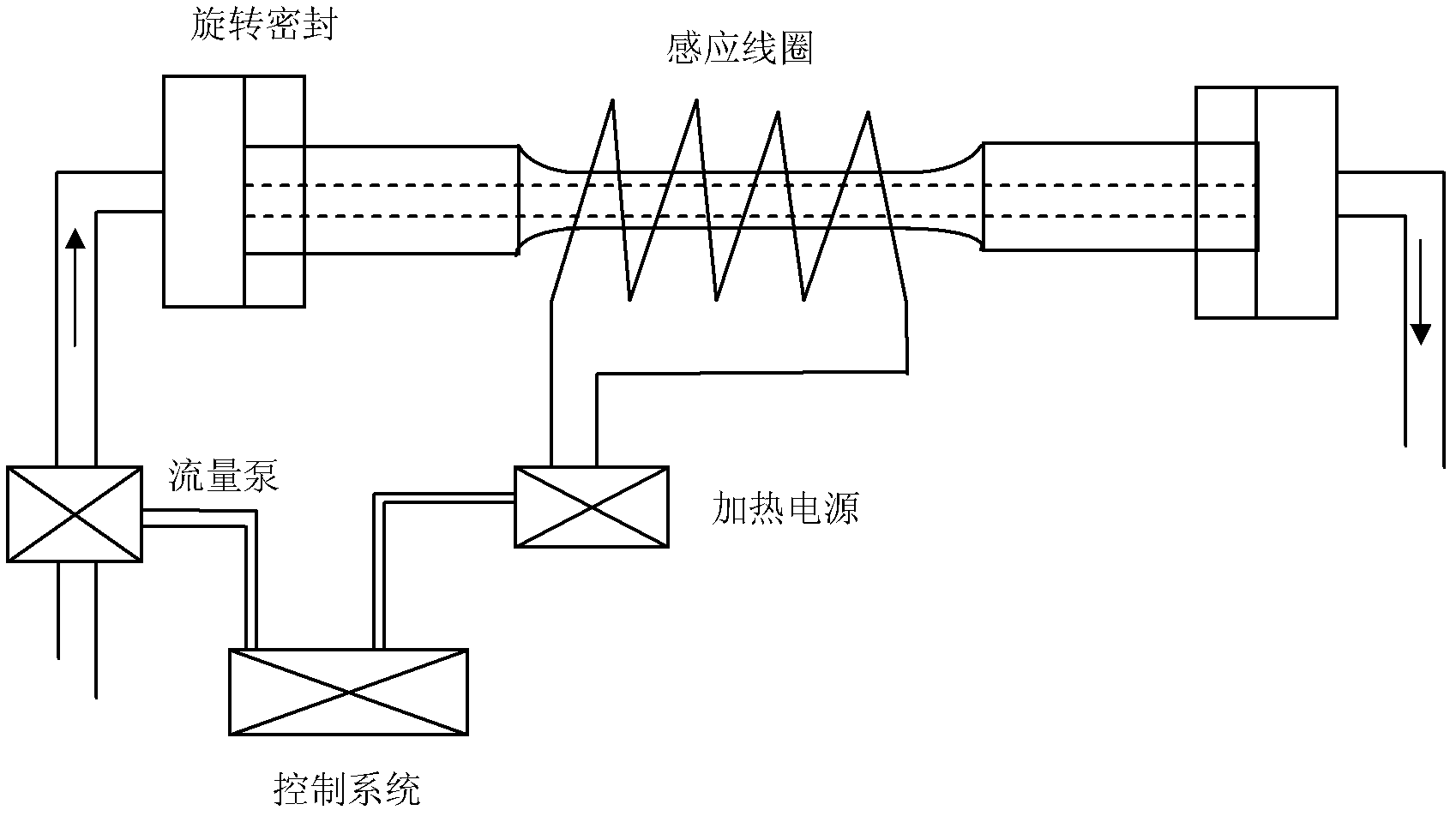

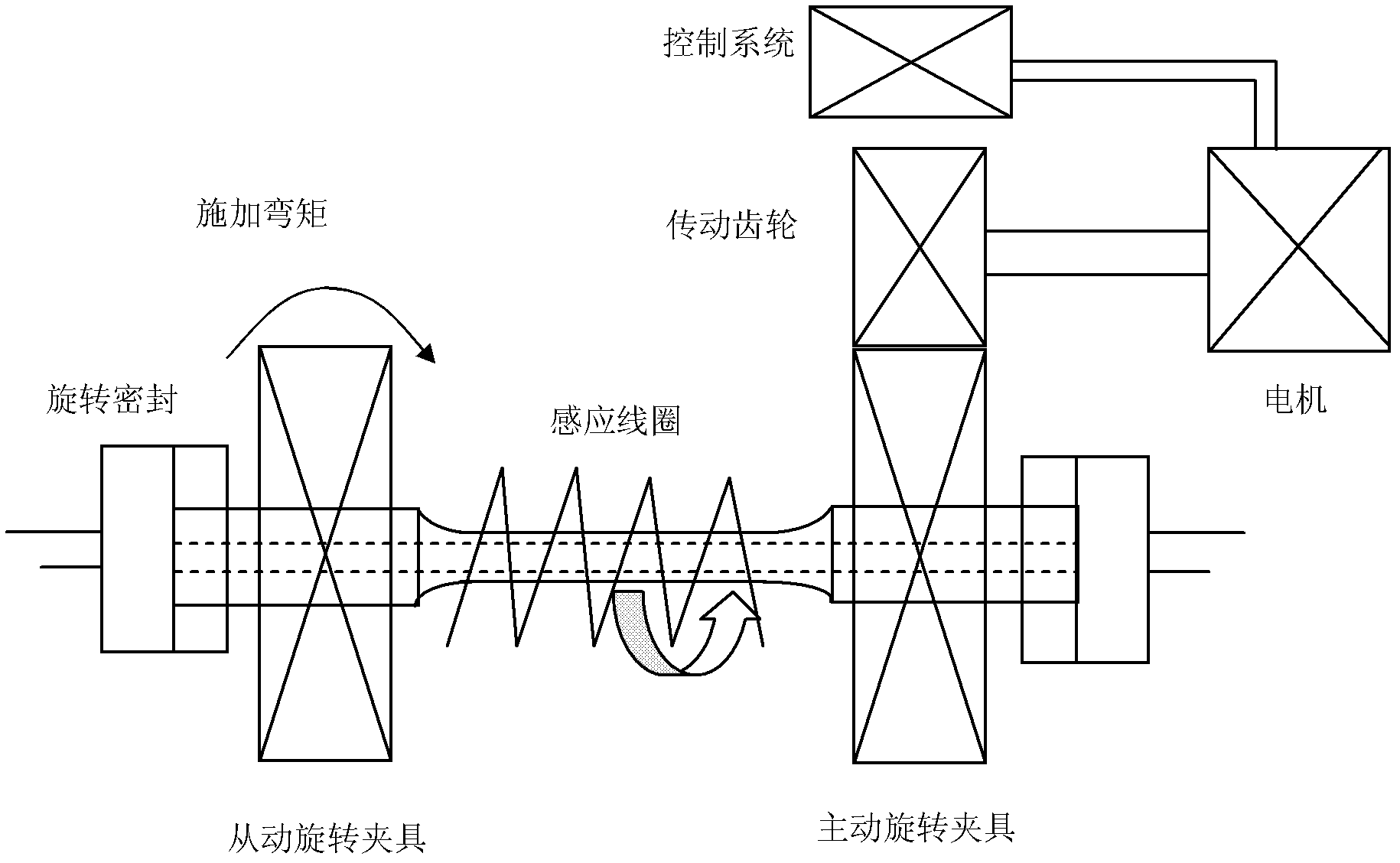

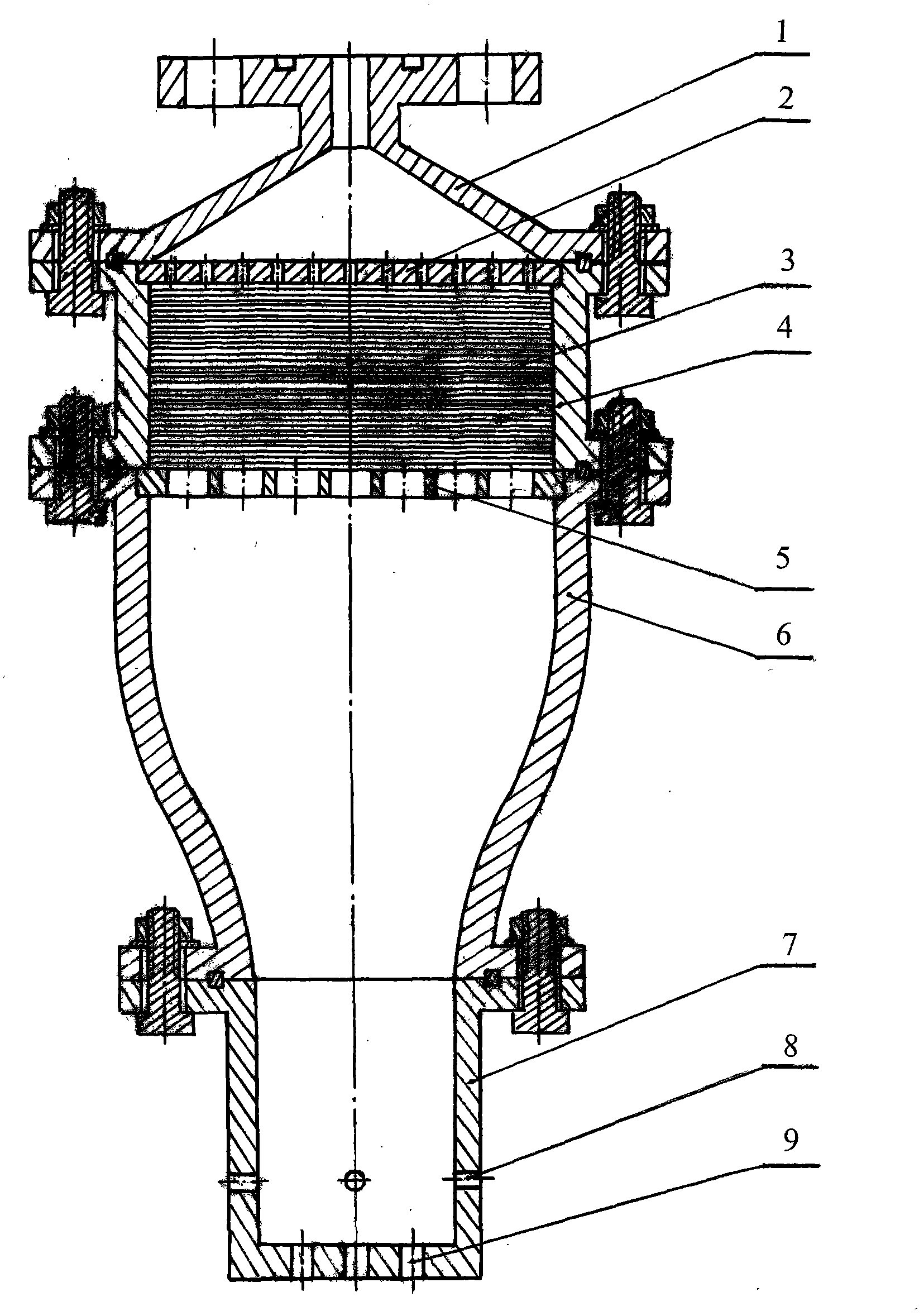

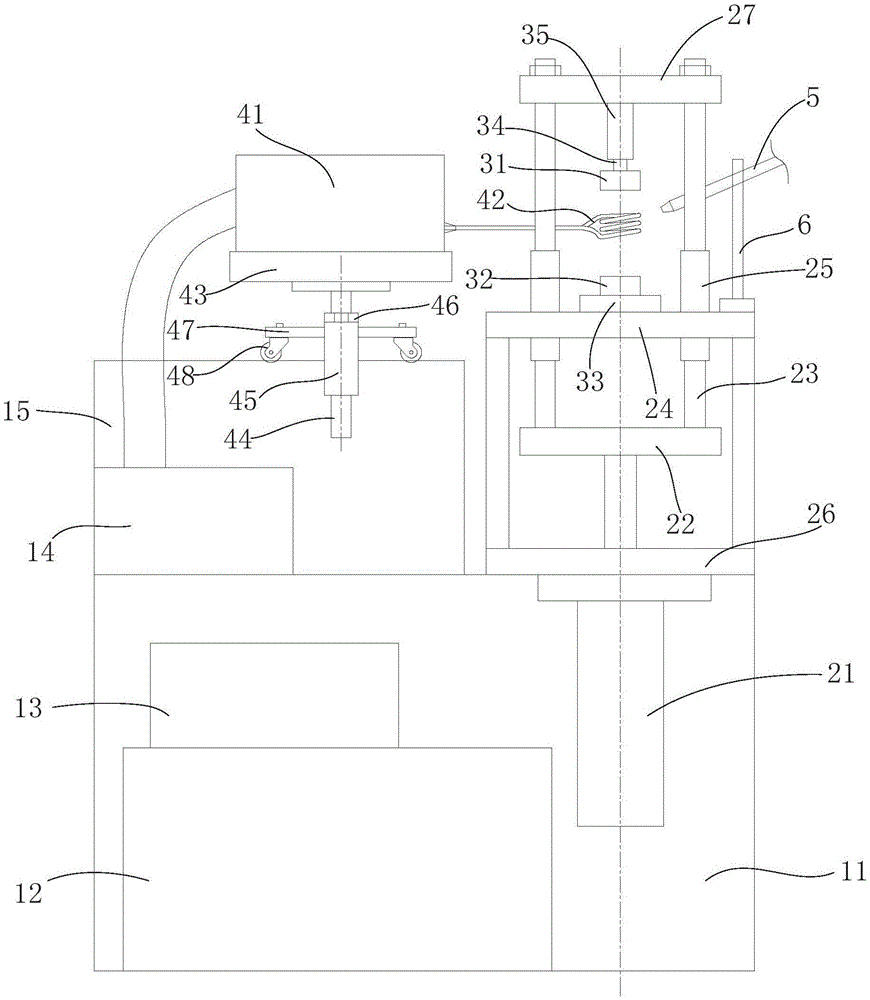

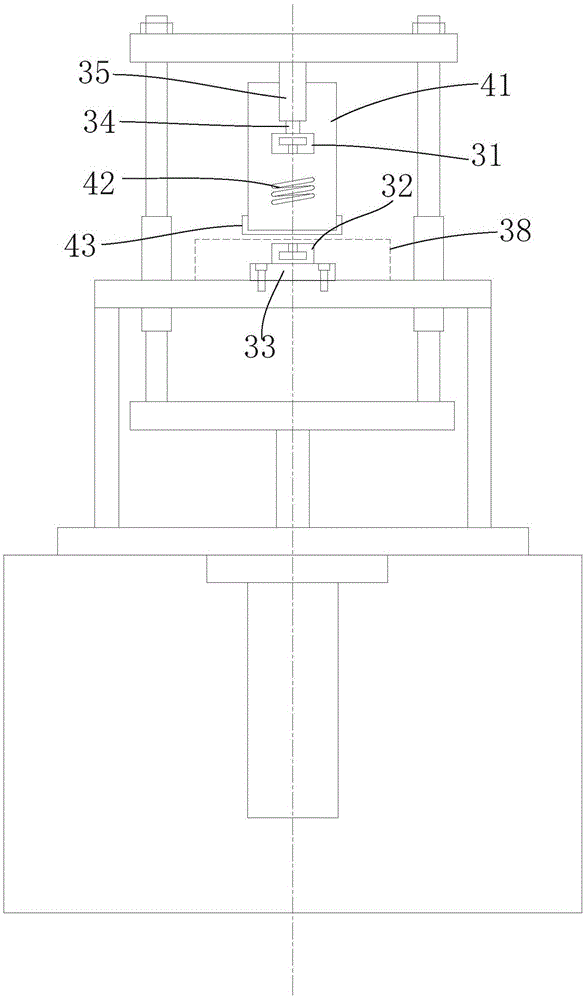

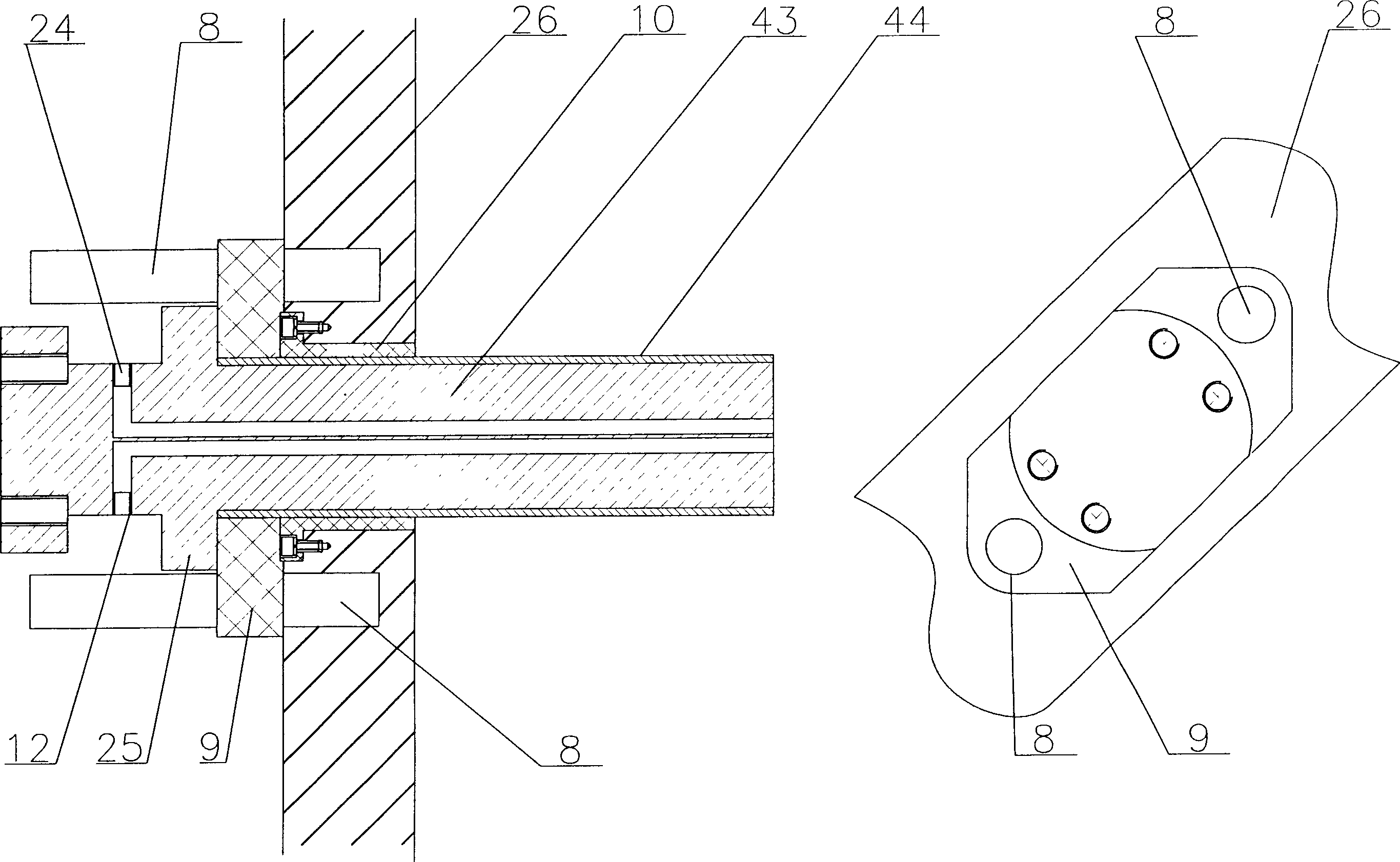

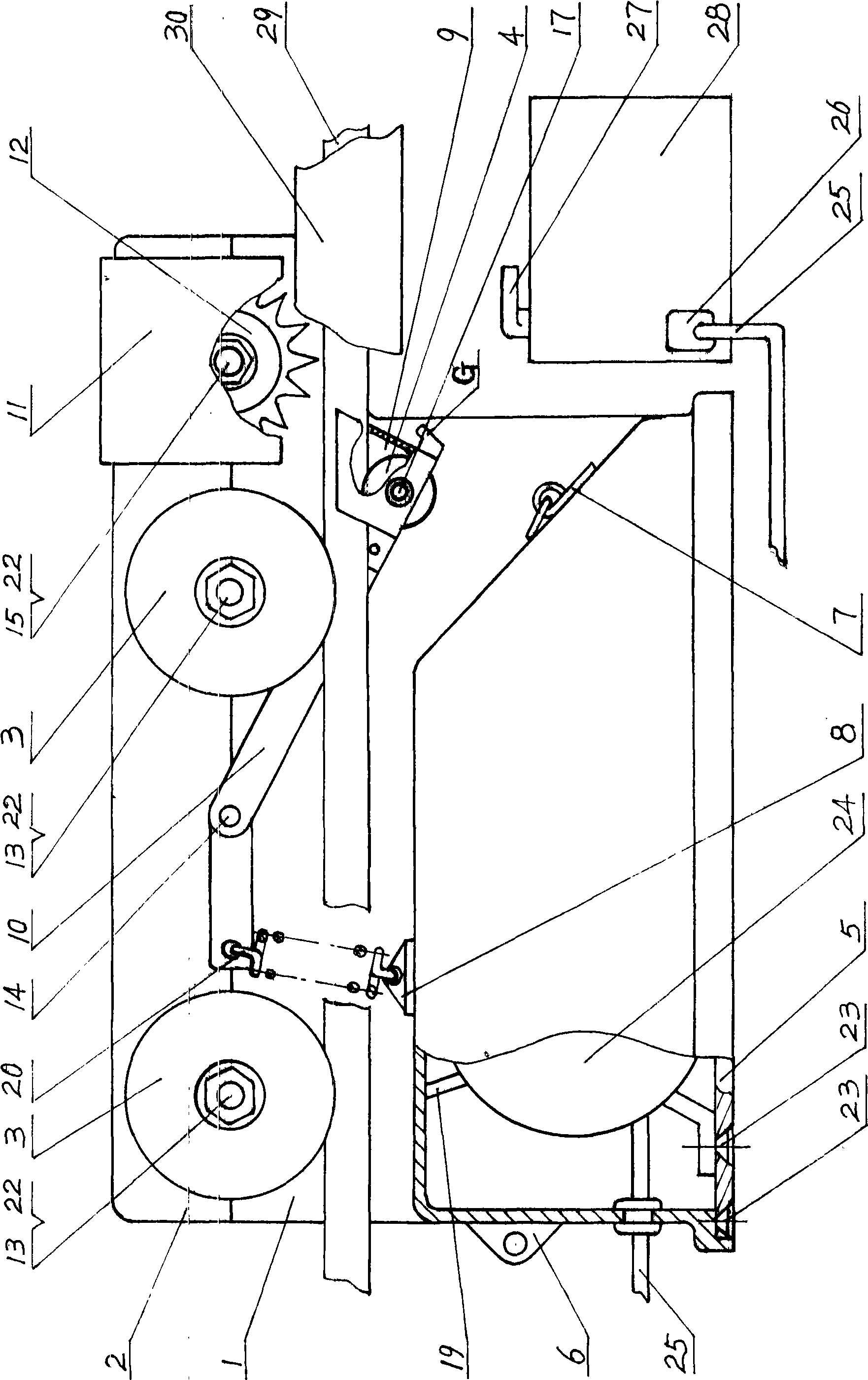

Thermal-force coupling fatigue test device and method

The invention relates to a thermal-force coupling fatigue test device and method, belonging to the field of metal material performance test and analysis. The device comprises a tested material test sample, a cold-thermal fatigue system and a stress fatigue system, wherein the test sample comprises a clamping section, a test section and a transition section; the cold-thermal fatigue system comprises a high frequency induction coil, a rotary seal device, a flow pump, a temperature sensor, a heating power supply, a cooling medium pipeline and a control system; and the stress fatigue system mainly comprises a driving rotating fixture, a driven rotating fixture, a transmission gear, a motor and a motor control system. The method comprises the following steps of: connecting and fixing the test sample with the cold-thermal fatigue system and the stress fatigue system, and carrying out cold-thermal fatigue while stress fatigues under different stresses are carried out to obtain a curve which shows variation of stress fatigue life along with cyclic stress; and adjusting parameters of the cold-thermal fatigue, thus influence of cold-thermal fatigue temperature to fatigue limit can be obtained.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing micro nano-crystalline cellulose with mechanical force chemical method

ActiveCN102433786AShort reaction timeReduce energy consumptionPaper material treatmentMicro nanoCellulose

The invention discloses a method for preparing micro nano-crystalline cellulose with a mechanical force chemical method. The micro nano-crystalline cellulose is obtained by mixing and grinding cellulose and a chemical aid. The method has the advantages of small using amount of chemical aid, easiness for operating and low energy consumption. Due to the adoption of the mechanical force chemical method for preparing the micro nano-crystalline cellulose, the synergistic effect of mechanical force, thermal force and chemical force generated in the process can be fully utilized by the cellulose under the multiple actions of mechanical force, thermal force and chemical force, a system is in the chemical active state, the reaction activation energy is reduced, and the occurrence and performance of a chemical reaction are catalyzed and excited. The aim of well preparing a large amount of micro nano-crystalline cellulose quickly in a saving way is fulfilled.

Owner:FUJIAN AGRI & FORESTRY UNIV

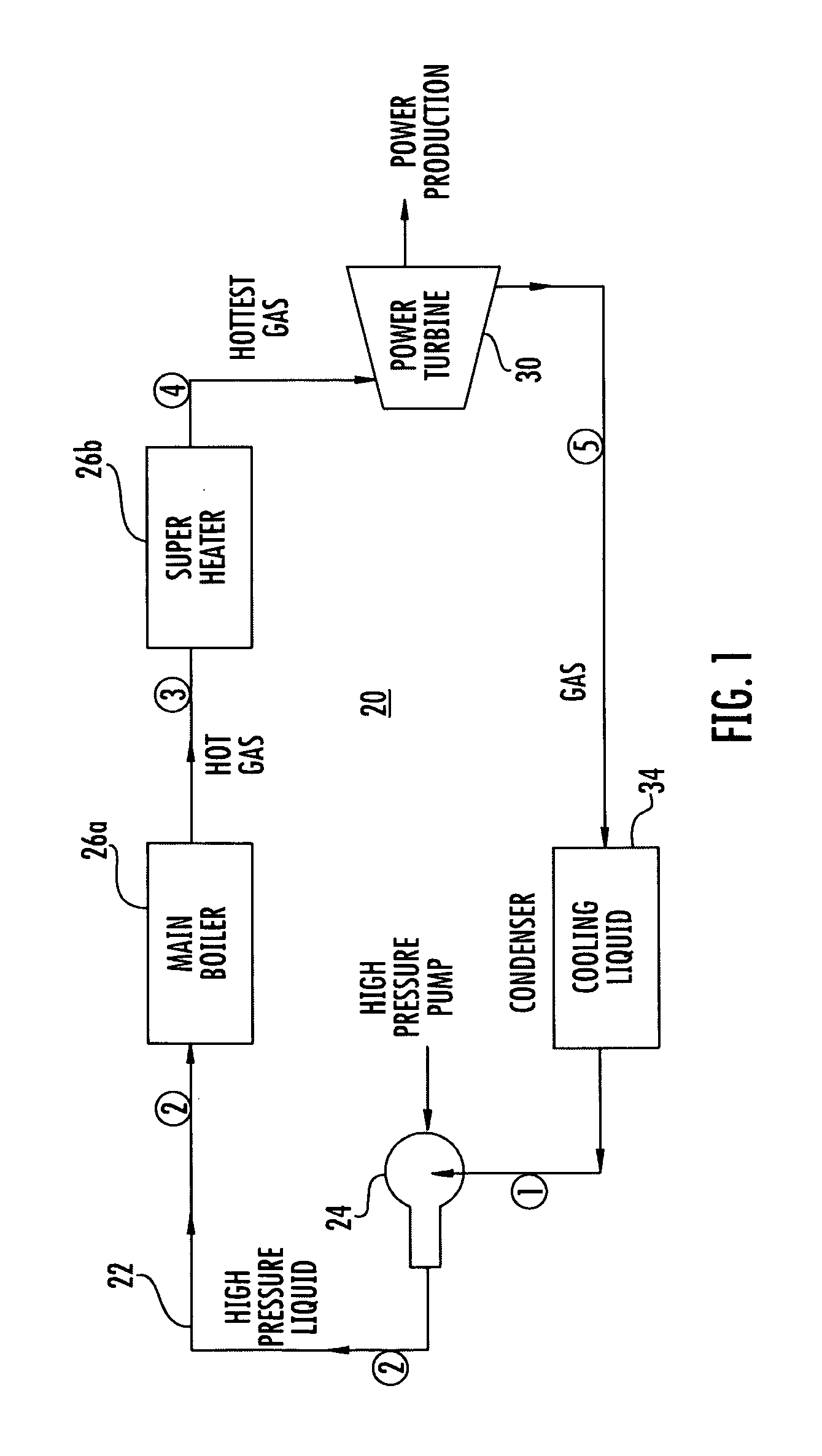

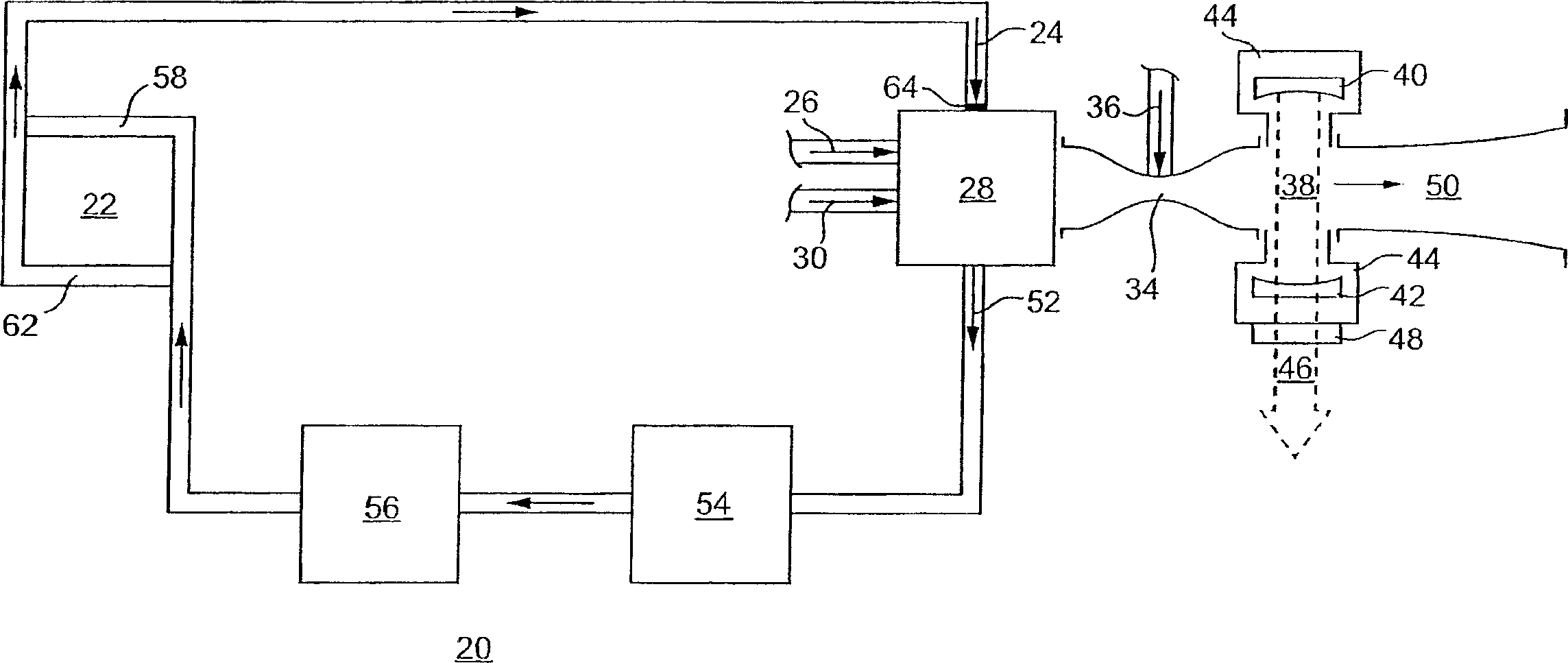

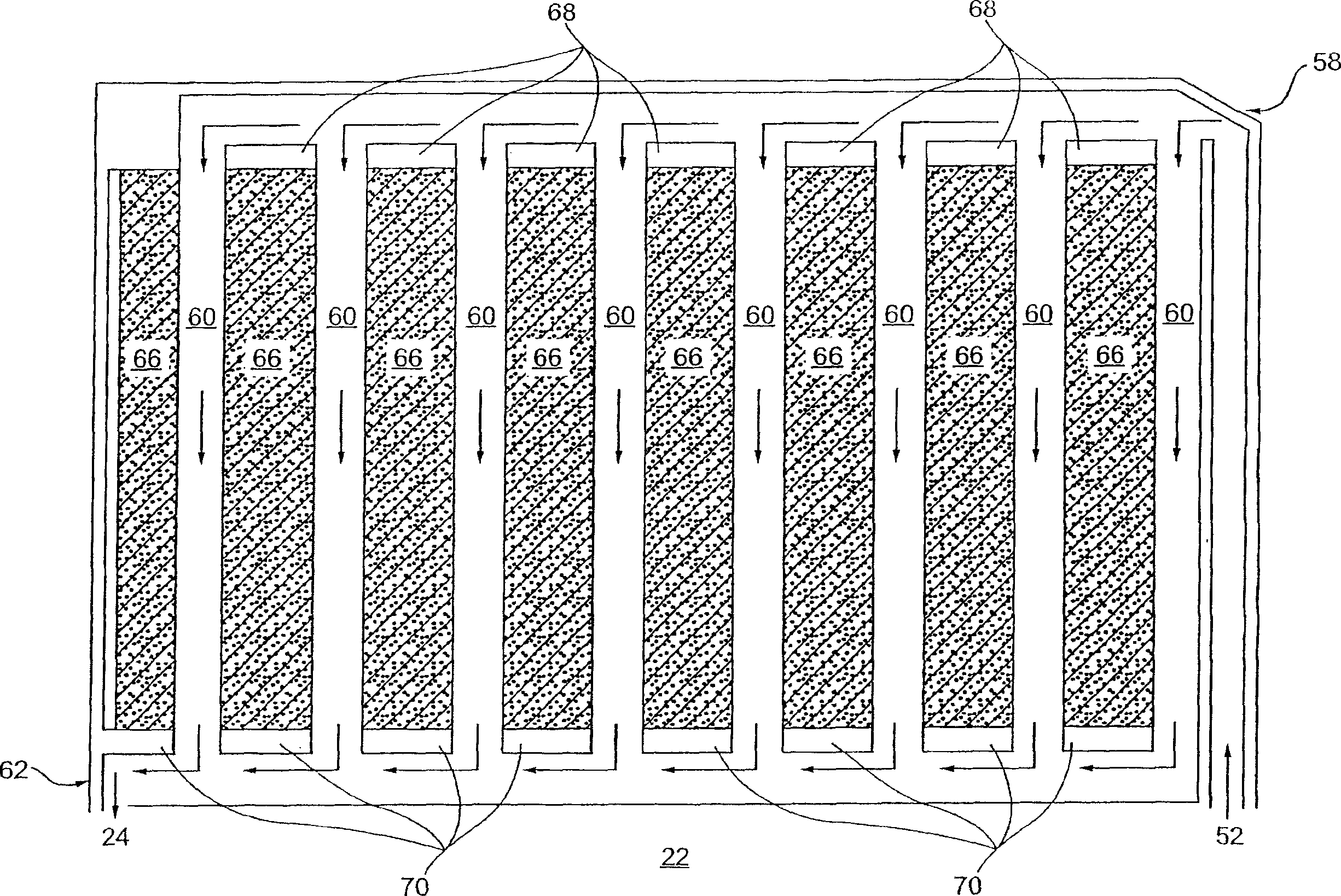

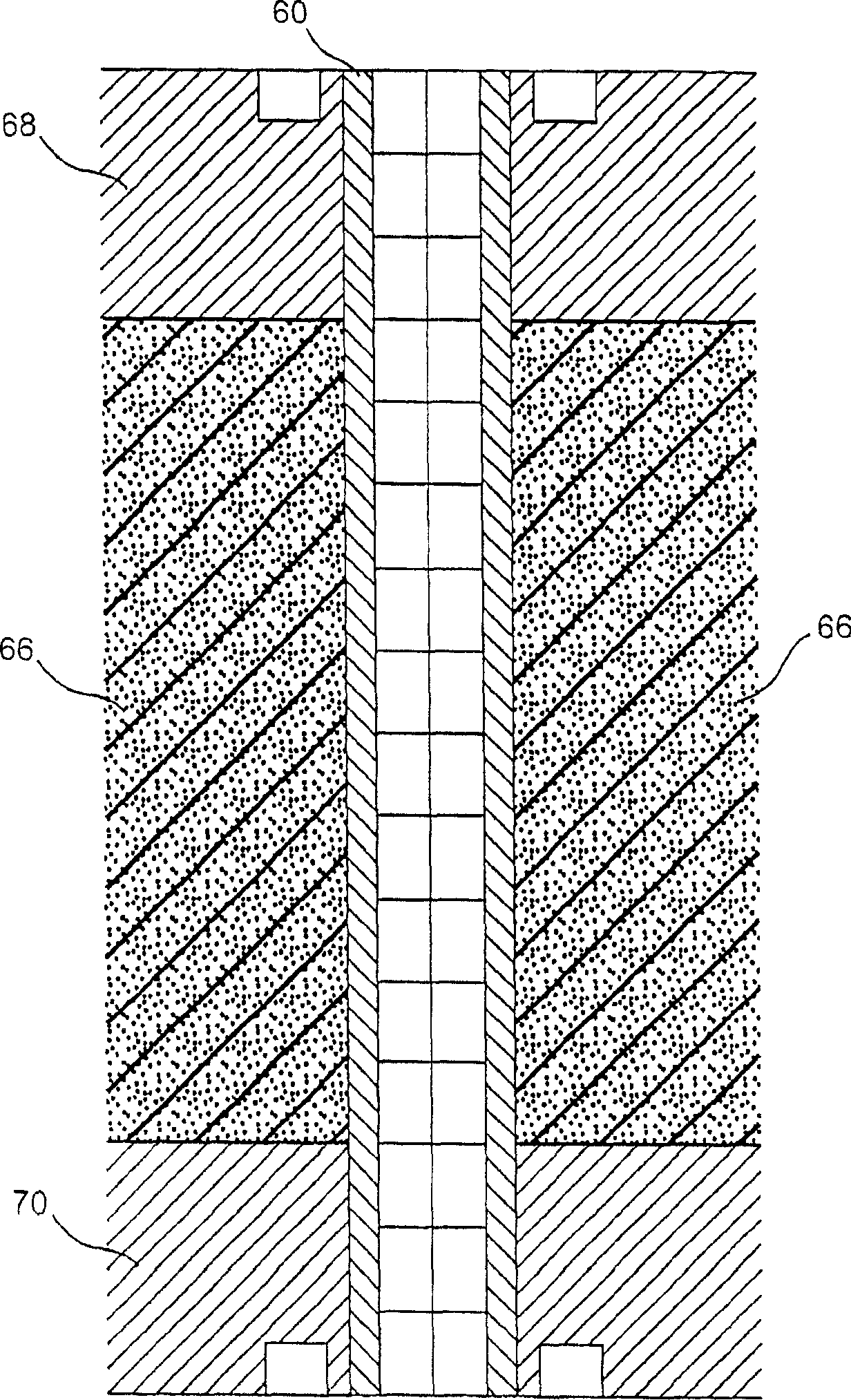

Apparatus, system, and methods for mechanical energy regeneration

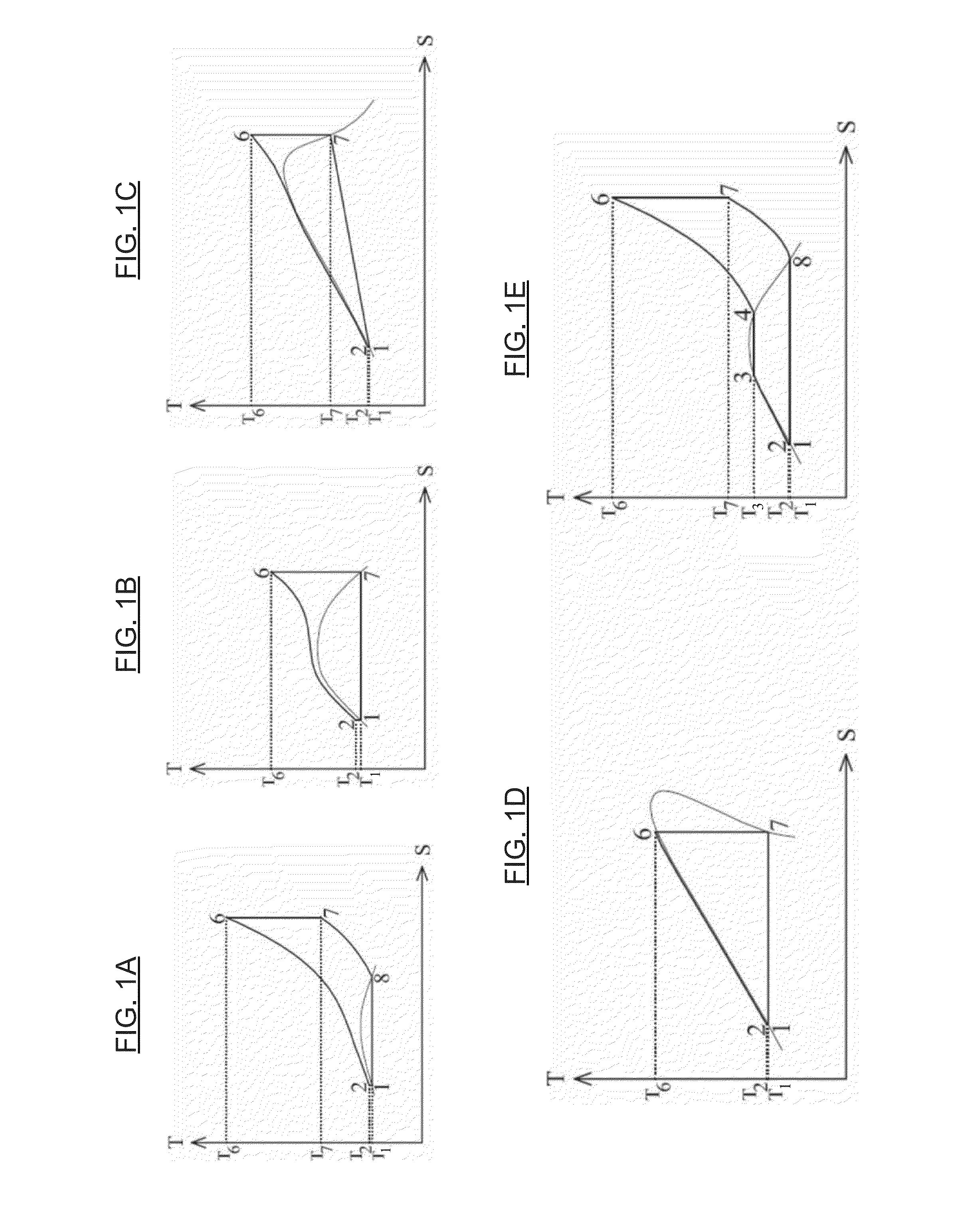

ActiveUS9394807B1Small second law lossPresent inventionHeat storage plantsSteam useWorking fluidThermal force

Systems and methods for storing and retrieving thermo-mechanical energy are disclosed. The systems and methods generally include a thermodynamic loop or cycle (e.g., a reversible transcritical, trilateral, or Rankine / vapor compression cycle) that works as a heat pump in a charging mode and as a heat engine in a discharging mode. The thermodynamic loop or cycle includes a gas pressure changing device, a liquid pressure changing device, and a working fluid. The system further includes one or more heat storage devices with solid heat storage material(s). Heat is transferred between the working fluid and the solid heat storage material(s) in the high and low pressure sides of the thermodynamic cycle, respectively.

Owner:KREUGER STEN

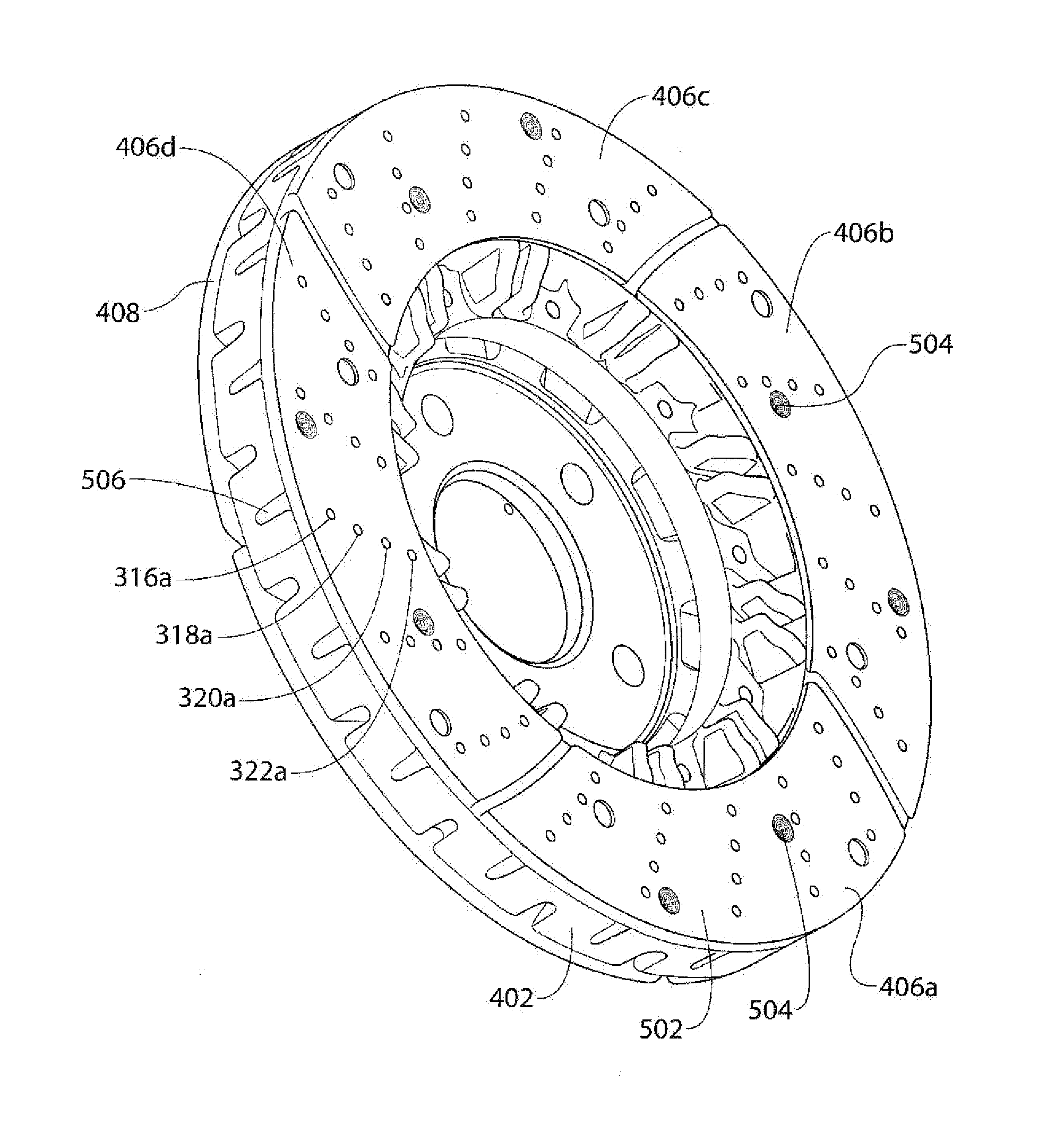

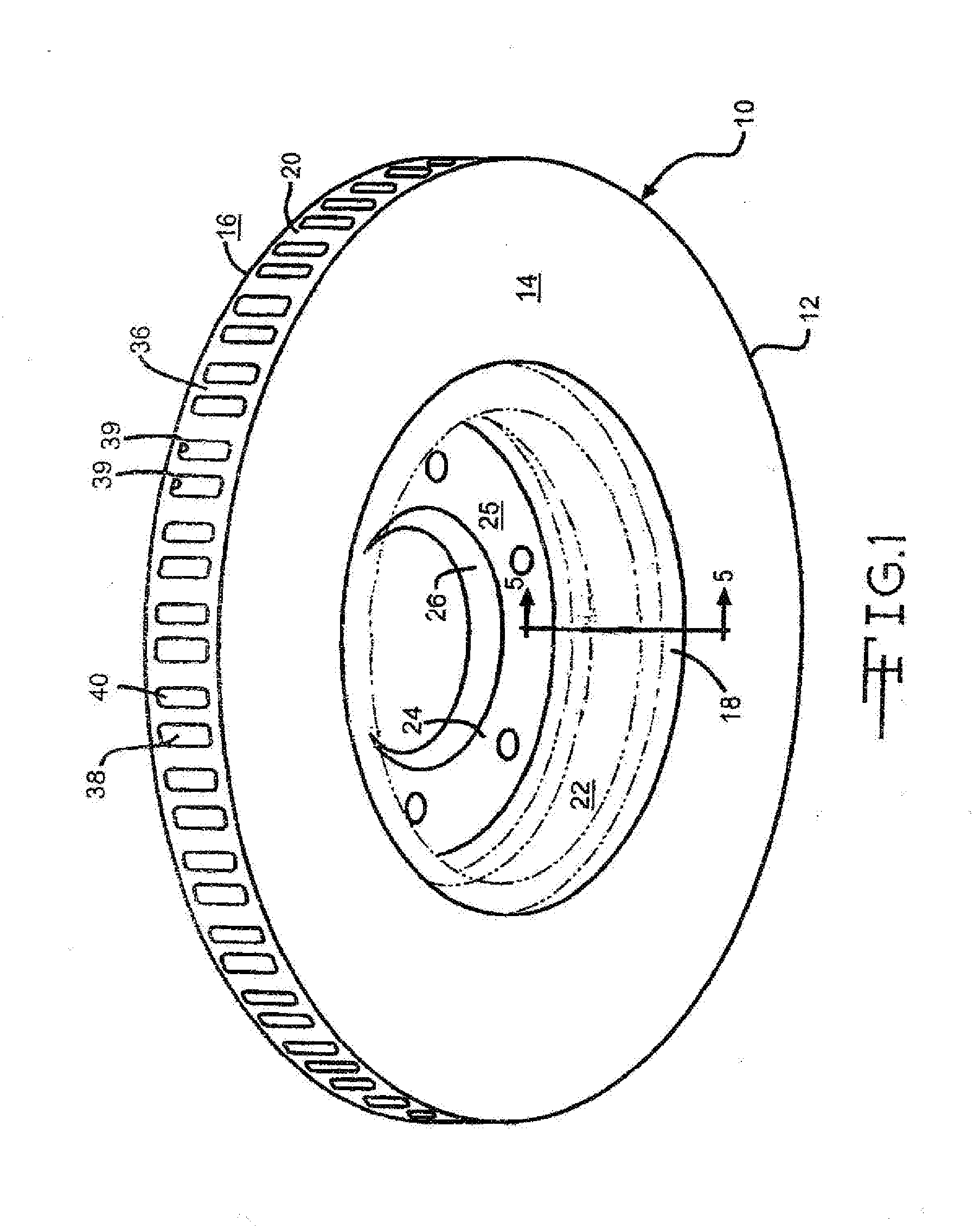

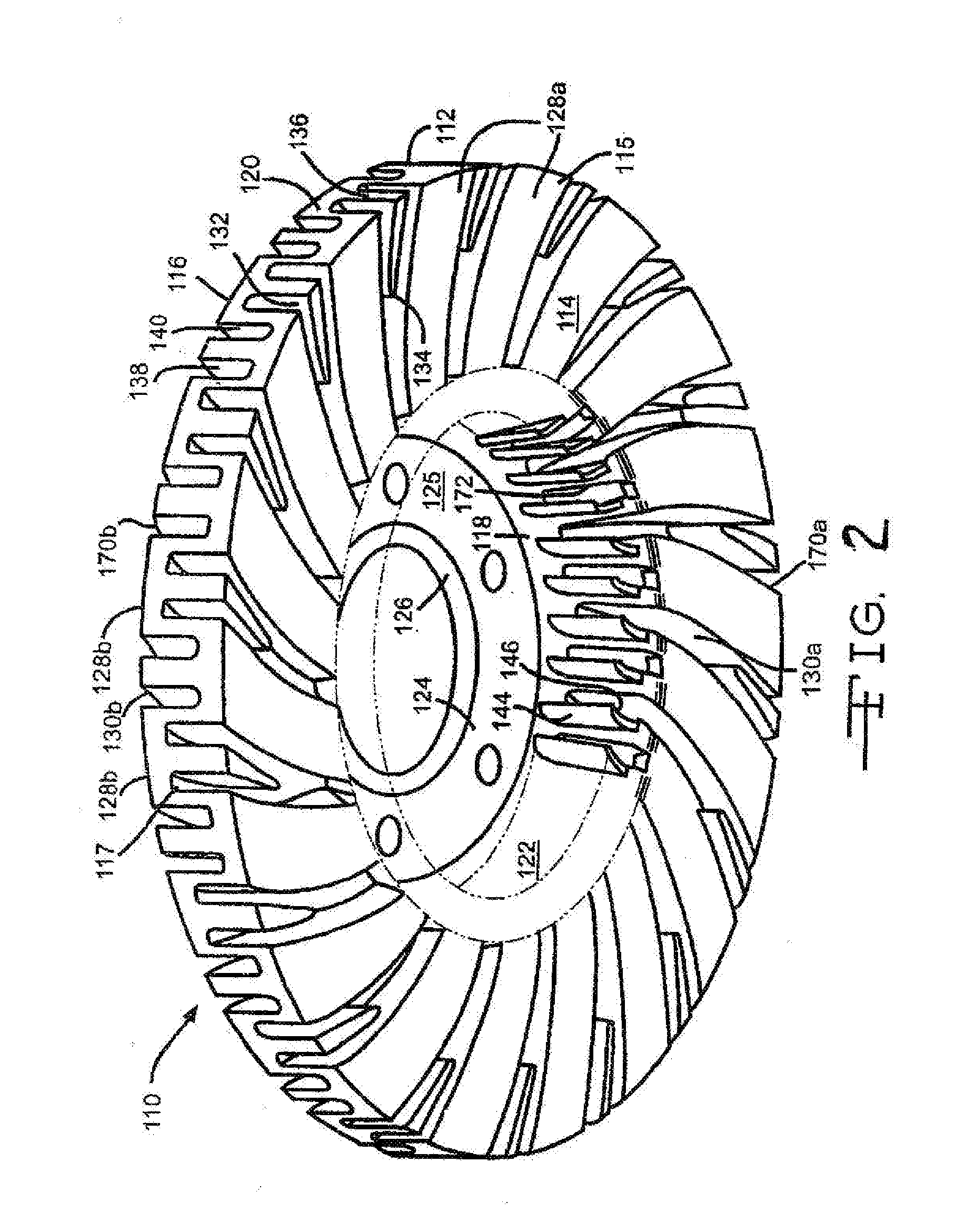

Segmented brake rotor with externally vented carrier

InactiveUS20120255820A1Improve effectivenessFunction increaseBraking discsFriction liningBrakeThermal force

An externally vented brake rotor (EVR) core design, such as exemplified by U.S. Pat. No. 6,536,564, is being used to improve the function and effectiveness of a segmented brake rotor (SBR) through more efficient management of the thermal forces created in the segmented rotor. Specifically, segmented friction plates are attached to the EVR core to form friction surfaces. Air flow through the vents contacts the back side of the friction plates. At least one segmented friction plate may be provided with a tab or protrusion that engages a corresponding receiving recess in the carrier surface of the EVR core, thereby relieving lateral stress forces.

Owner:MCCORD GEOFFREY K +1

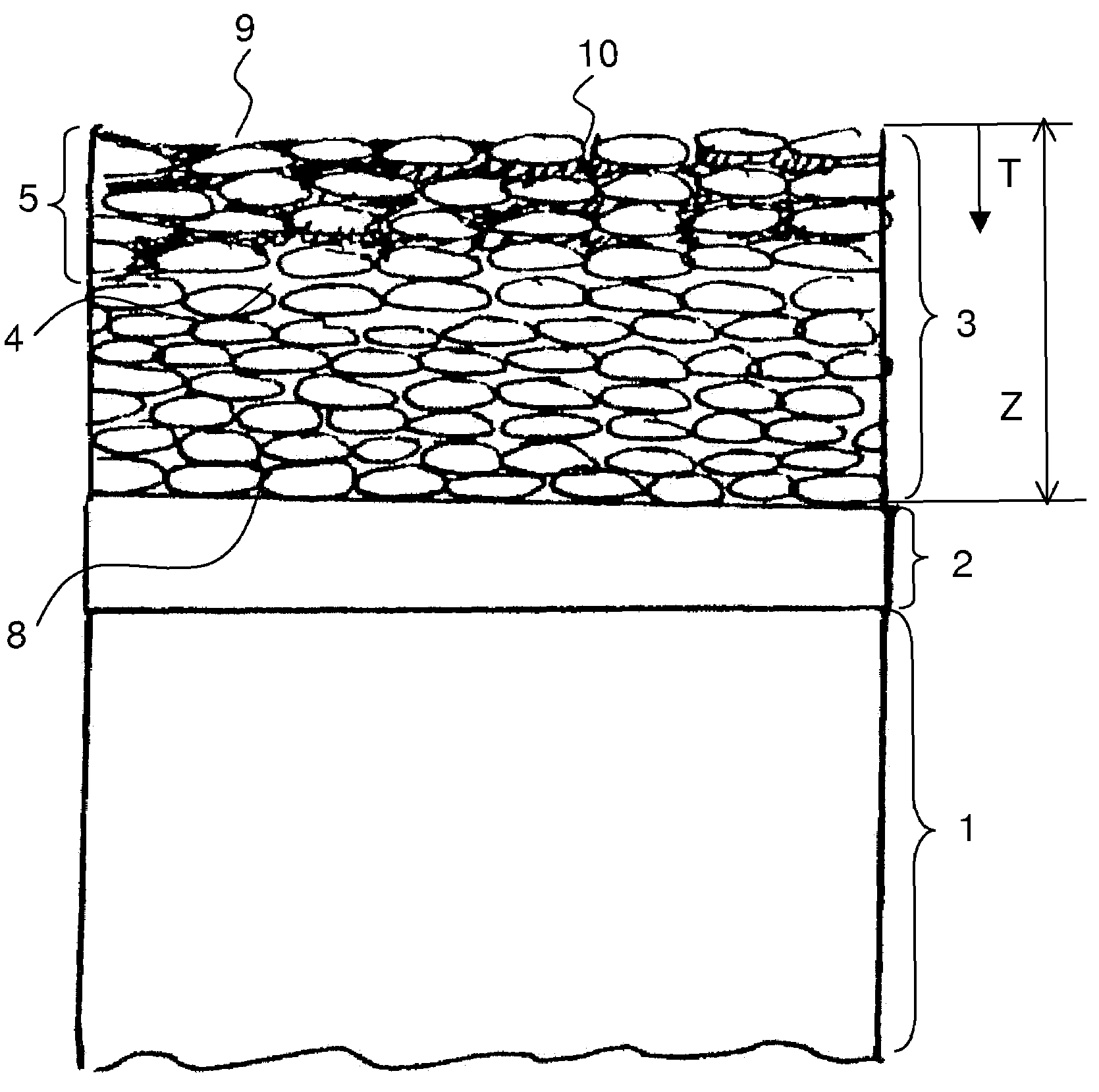

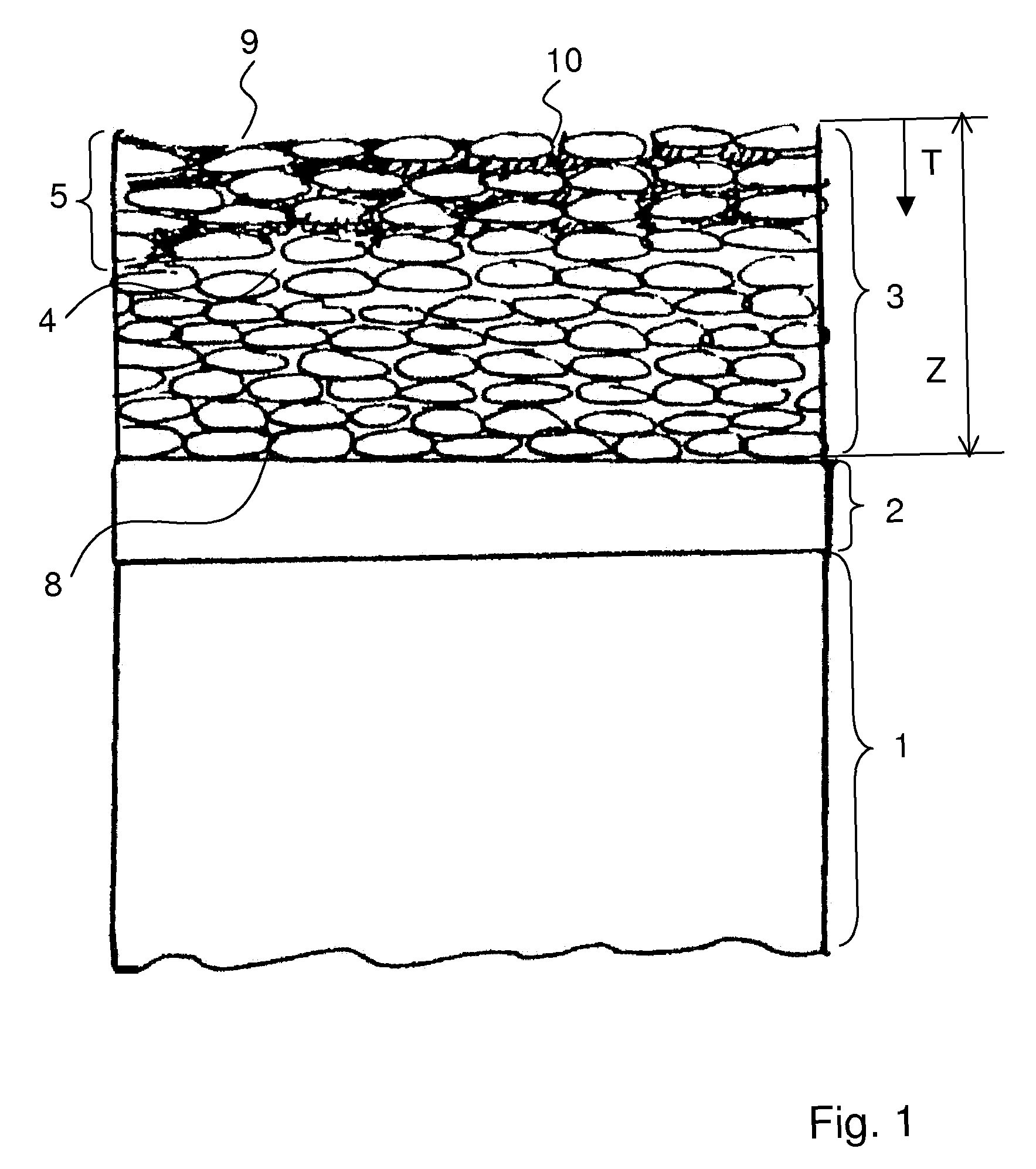

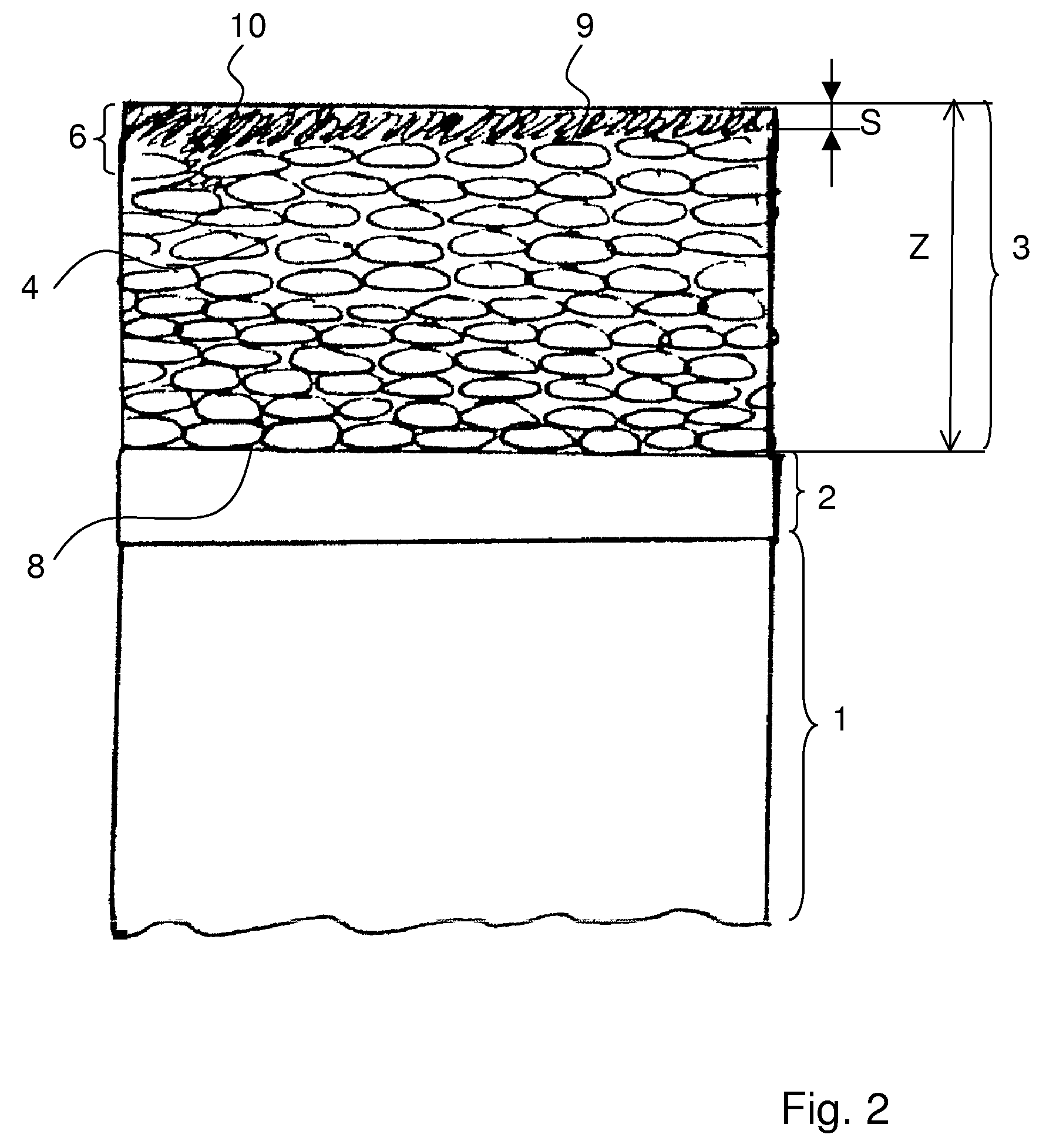

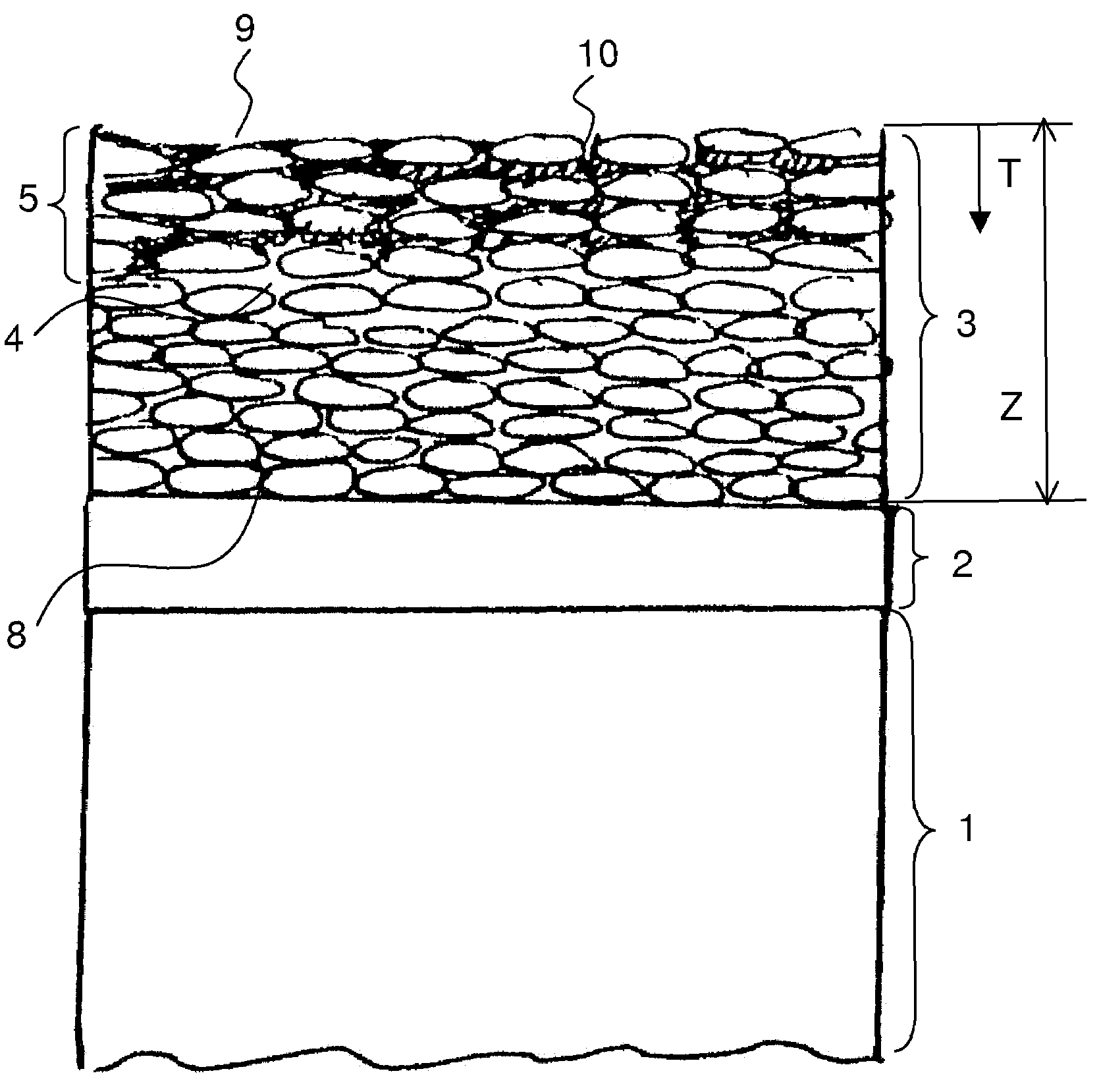

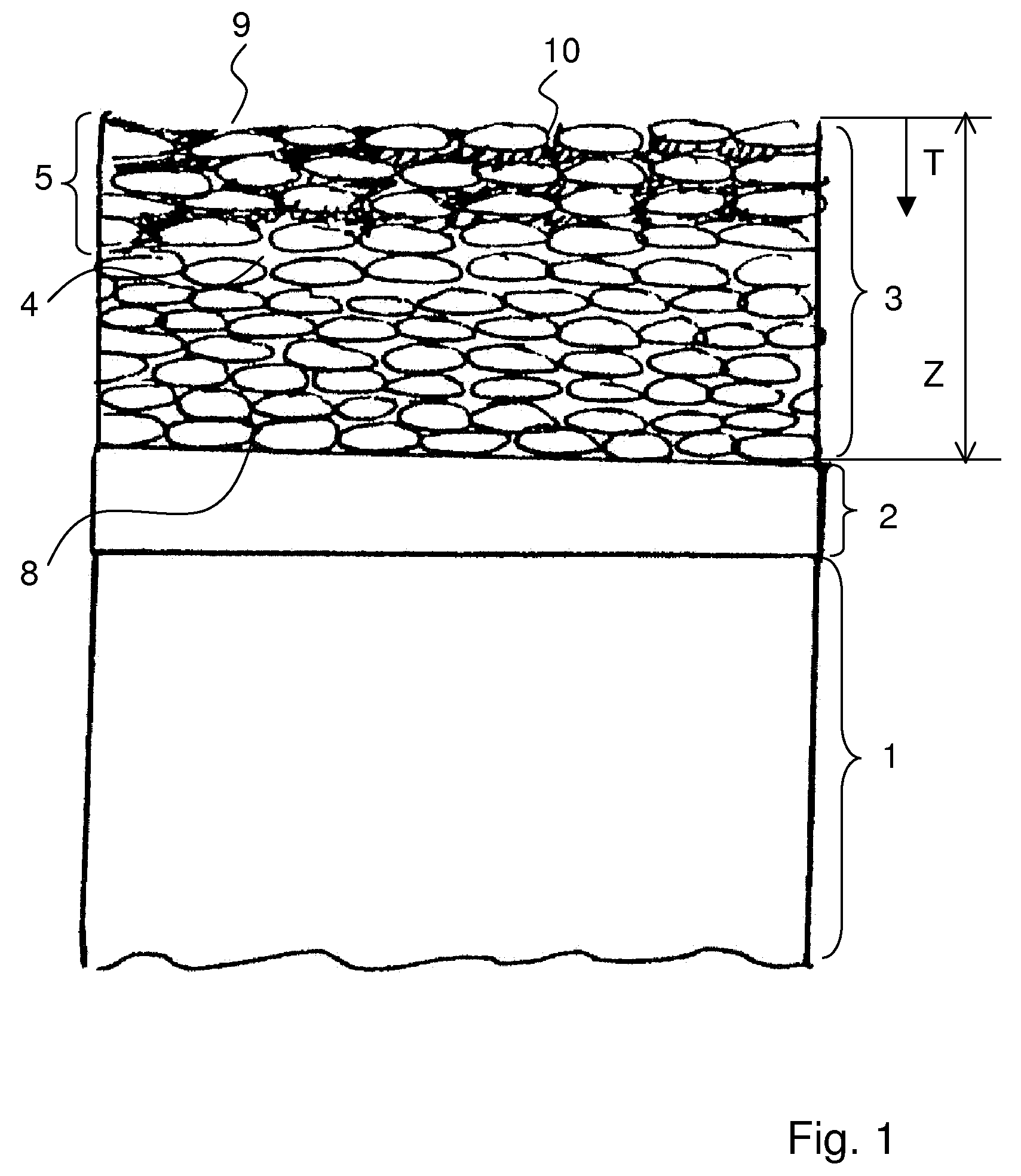

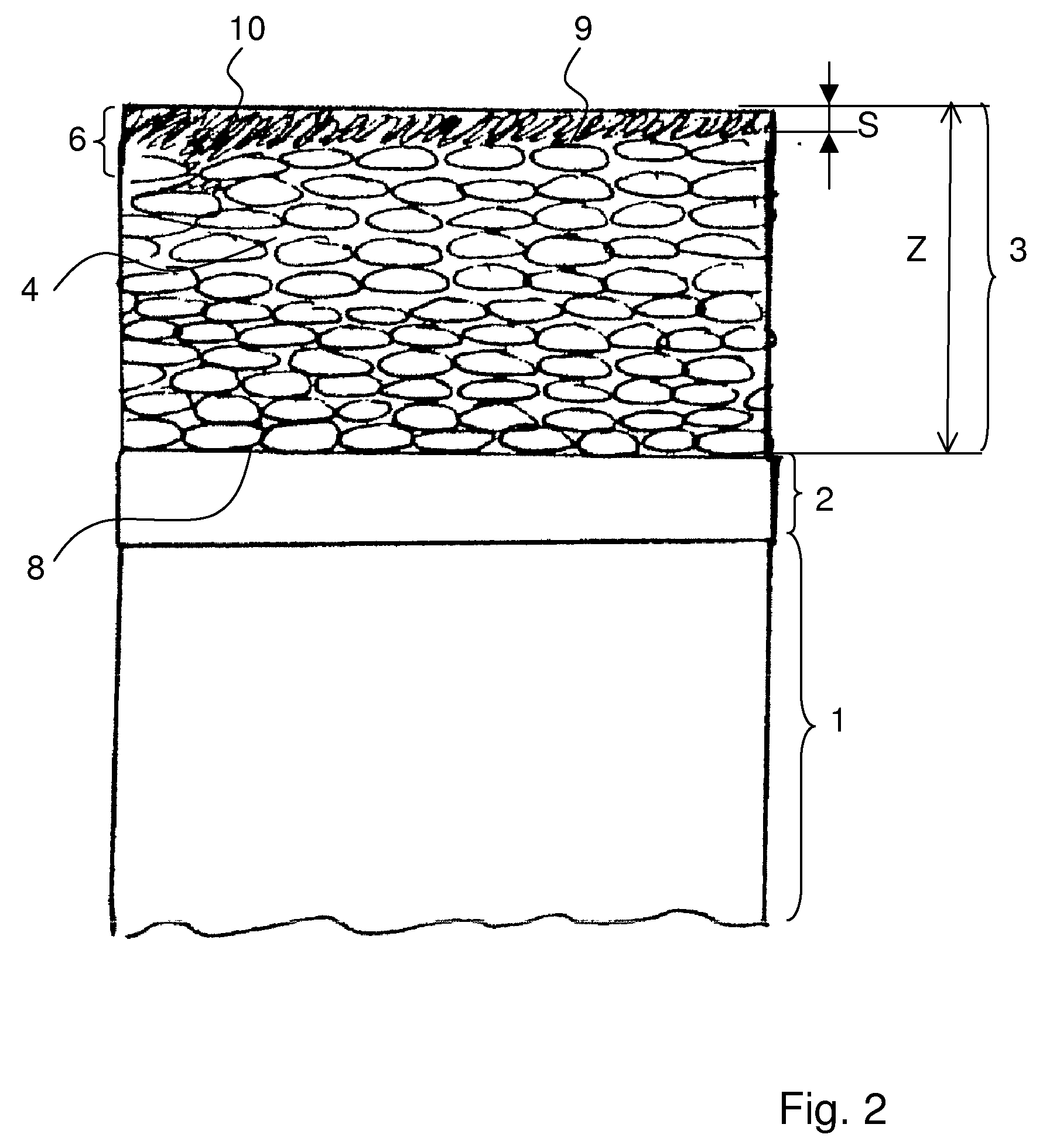

Methods for the protection of a thermal barrier coating system and methods for the renewal of such a protection

ActiveUS8356482B2Improve protectionLiquid degasificationMolten spray coatingCoating systemProduct gas

A method for the application and / or renewal of a protection for a thermal barrier coating system of a heat engine involves a thermal barrier coating system that includes a bond coat layer (2) and a thermal barrier coating layer (3) of porous structure (4), wherein the bond coat layer (2) is located between and in contact with a base metal (1) of a heat engine component and with the thermal barrier coating layer (3) and bonds the thermal barrier coating layer (3) to the base metal (1). At least one substance is applied inside the engine as a liquid or carried by a liquid by spraying and / or by flowing it across a hot gas exposed surface (9) of the barrier coating layer (3) of the heat engine component mounted within the heat engine in the assembled state prior to the initial start-up of the engine, before the first operation interval, or during a washing cycle of the thermal engine and / or at the end of an operation interval, before a subsequent operation interval, wherein the substance covers and / or at least partly penetrates into the porous structure (4), and concomitantly or subsequently hardens to remain within the pores (4) and / or on the upper surface (9) of the thermal barrier coating layer. Preferably, but not necessarily, for the application, the turbine washing equipment of the engine is used.

Owner:ANSALDO ENERGIA SWITZERLAND AG

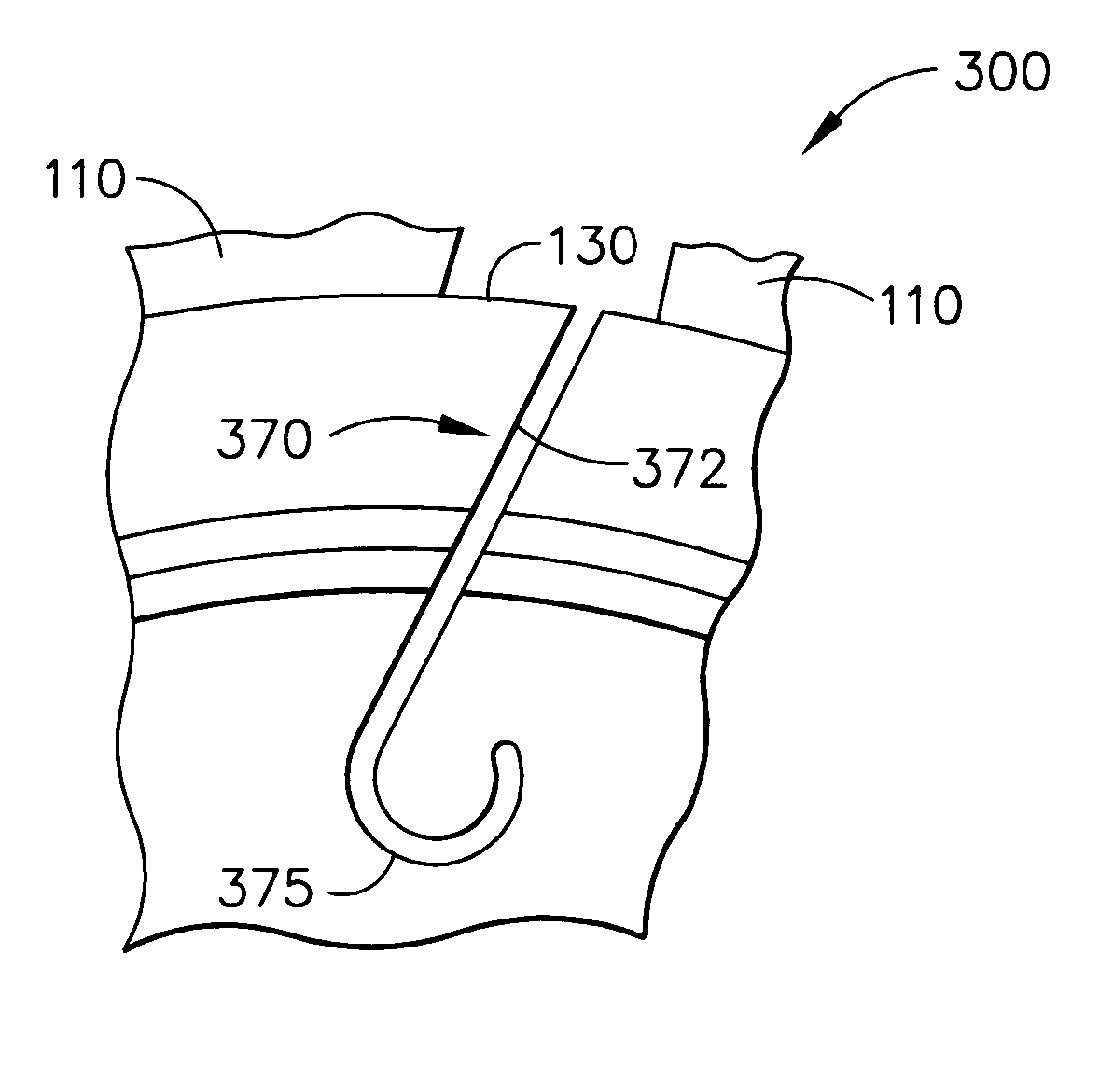

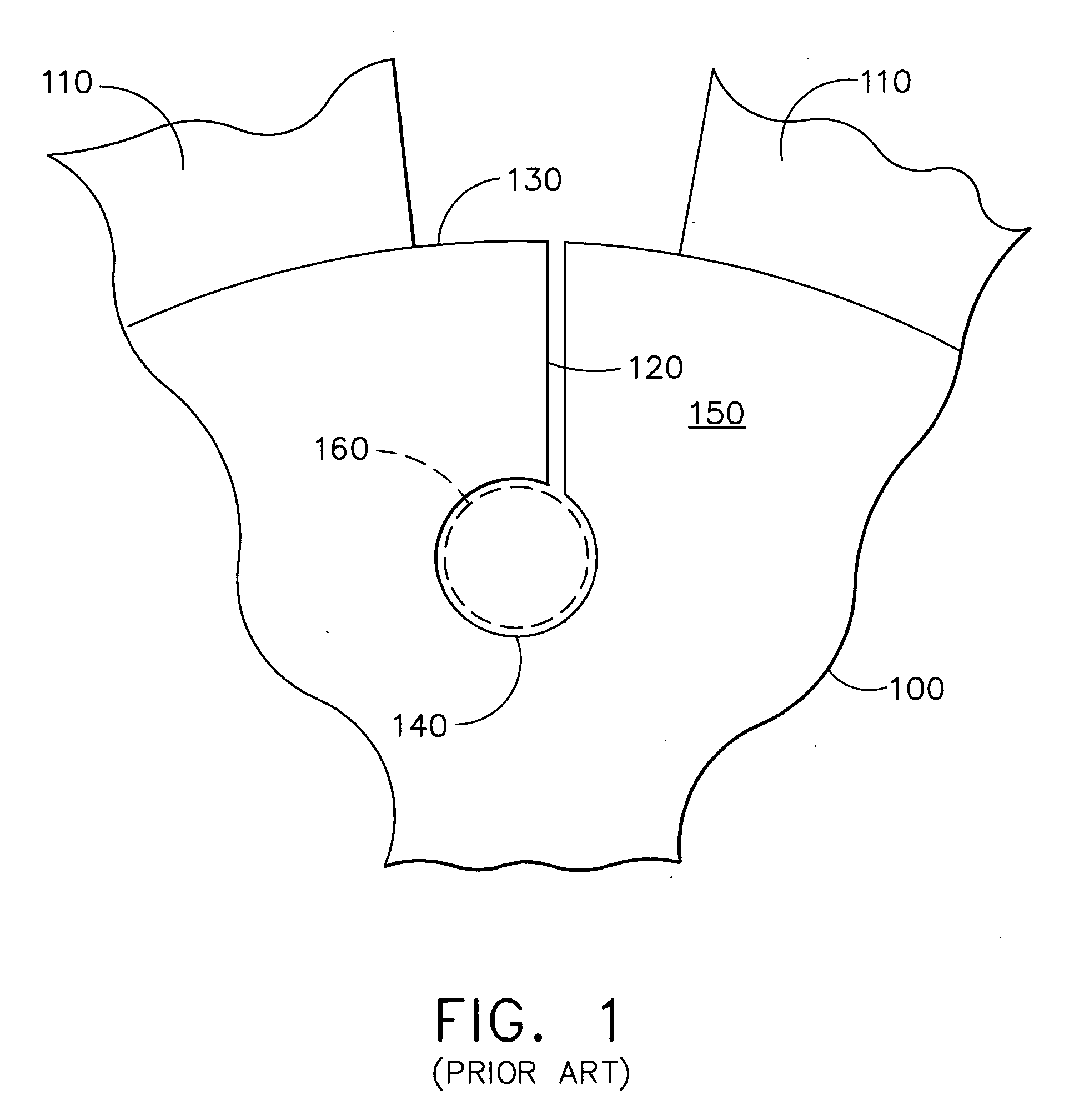

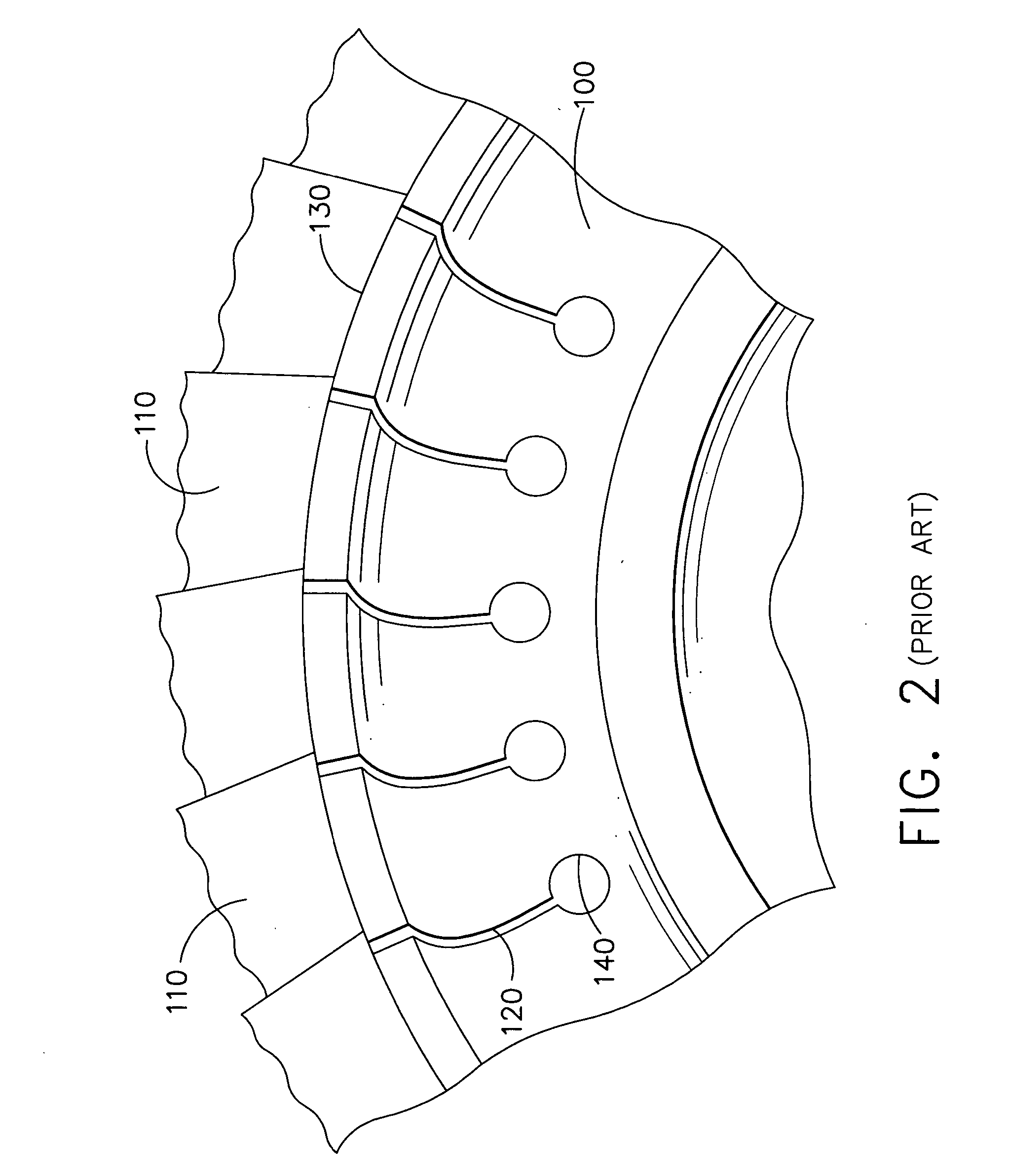

Hoop stress relief mechanism for gas turbine engines

A hoop stress relief mechanism is disclosed for use on a rotary body to relieve stress caused by both thermal and centrifugal forces. The mechanism may consist of a J-shaped slot cut from the outer rim of the rotary body a distance inwardly toward the axis of rotation, the slot having a curve in its inward end that curves back towards the outer rim. The J-shaped slot may extend through the rotary body to join its two faces. The J-shaped slot may be fabricated by an electric discharge wire machine. The electric discharge wire machine may make multiple passes in order to smooth the bottom surface of the curved slot portion.

Owner:HONEYWELL INT INC

Catalytic decomposition low-concentration hydrogen peroxide reactor, combustion chamber and application thereof

InactiveCN102658066ALow priceImprove securityRocket engine plantsChemical/physical processesCombustion chamberKerosene

The invention relates to a catalytic decomposition low-concentration hydrogen peroxide reactor and a combustion chamber, which solve the problem that in the prior art, price is expensive, safety is not high, freezing point is high, decomposition temperature and ignition temperature are high, purpose is single and the like. A multilayer low-bed-load and pre-contact fine silver net catalysis bed for catalytic decomposition of 40%-70% of hydrogen peroxide is adopted, and service life is greatly prolonged. Radial holes or / and axial holes are arranged on a laryngeal casing of the catalytic decomposition low-concentration hydrogen peroxide reactor for using in underground reactor oil recovery by heating, mining and marine accident self rescuing and a life support system of spaceships and rocket oxidizer storage tank supercharging. The catalytic decomposition low-concentration hydrogen peroxide combustion chamber is provided with a plurality of radial spraying holes for spraying diesel oil or kerosene, an electronic spark plug for ignition, a combustion chamber body with the 40%-70% of hydrogen peroxide serving as a regeneration cooling agent and two kinds of spraying tubes, and the catalytic decomposition low-concentration hydrogen peroxide combustion chamber can be used for thrust chamber gas spraying thrust of a plurality of military projects and road ice and snow removal by heat and crude oil pollution.

Owner:葛明龙

Methods for the protection of a thermal barrier coating system and methods for the renewal of such a protection

ActiveUS20100242477A1Improve protectionMolten spray coatingLiquid degasificationCoating systemTurbine

A method for the application and / or renewal of a protection for a thermal barrier coating system of a heat engine involves a thermal barrier coating system that includes a bond coat layer (2) and a thermal barrier coating layer (3) of porous structure (4), wherein the bond coat layer (2) is located between and in contact with a base metal (1) of a heat engine component and with the thermal barrier coating layer (3) and bonds the thermal barrier coating layer (3) to the base metal (1). At least one substance is applied inside the engine as a liquid or carried by a liquid by spraying and / or by flowing it across a hot gas exposed surface (9) of the barrier coating layer (3) of the heat engine component mounted within the heat engine in the assembled state prior to the initial start-up of the engine, before the first operation interval, or during a washing cycle of the thermal engine and / or at the end of an operation interval, before a subsequent operation interval, wherein the substance covers and / or at least partly penetrates into the porous structure (4), and concomitantly or subsequently hardens to remain within the pores (4) and / or on the upper surface (9) of the thermal barrier coating layer. Preferably, but not necessarily, for the application, the turbine washing equipment of the engine is used.

Owner:ANSALDO ENERGIA SWITZERLAND AG

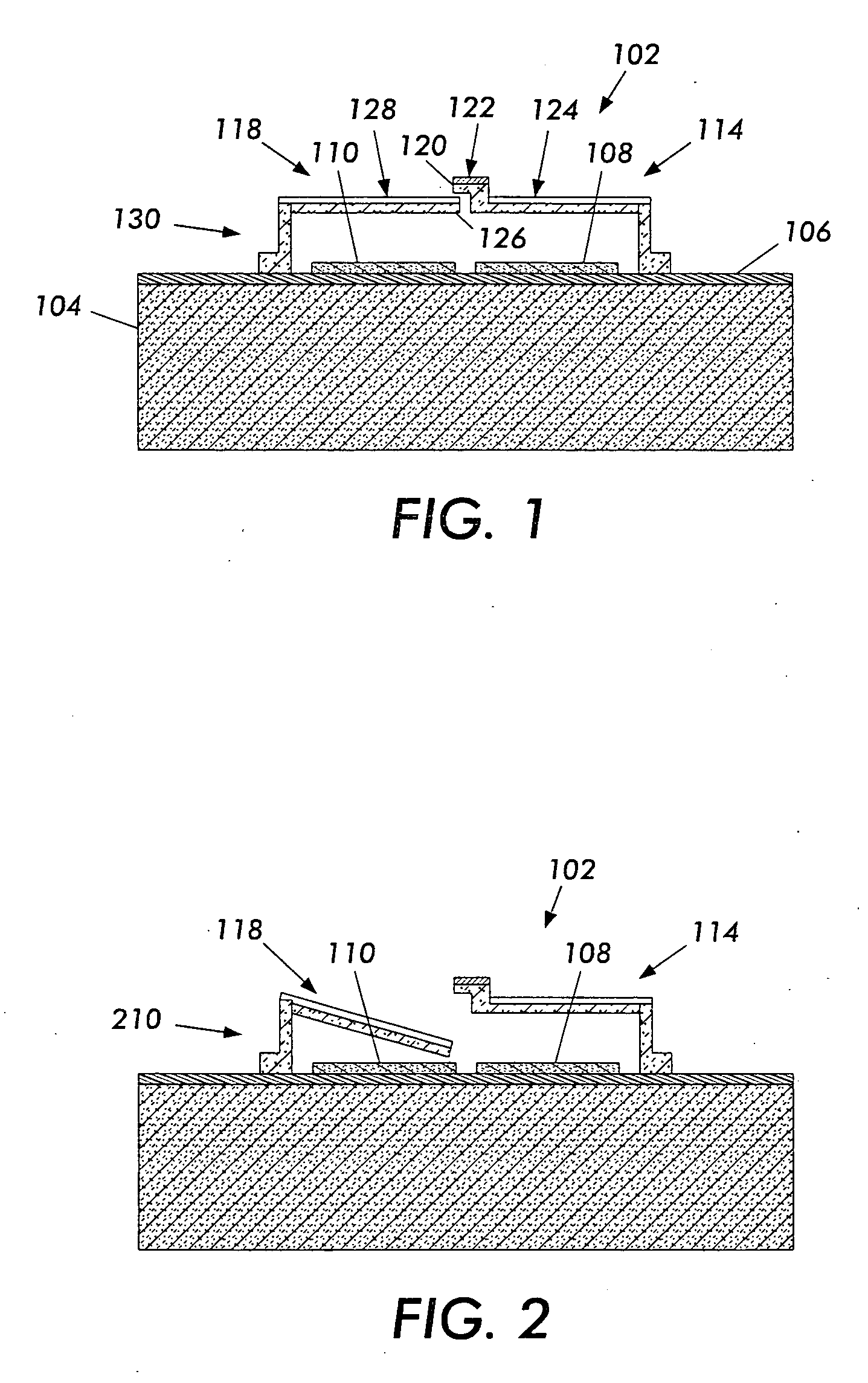

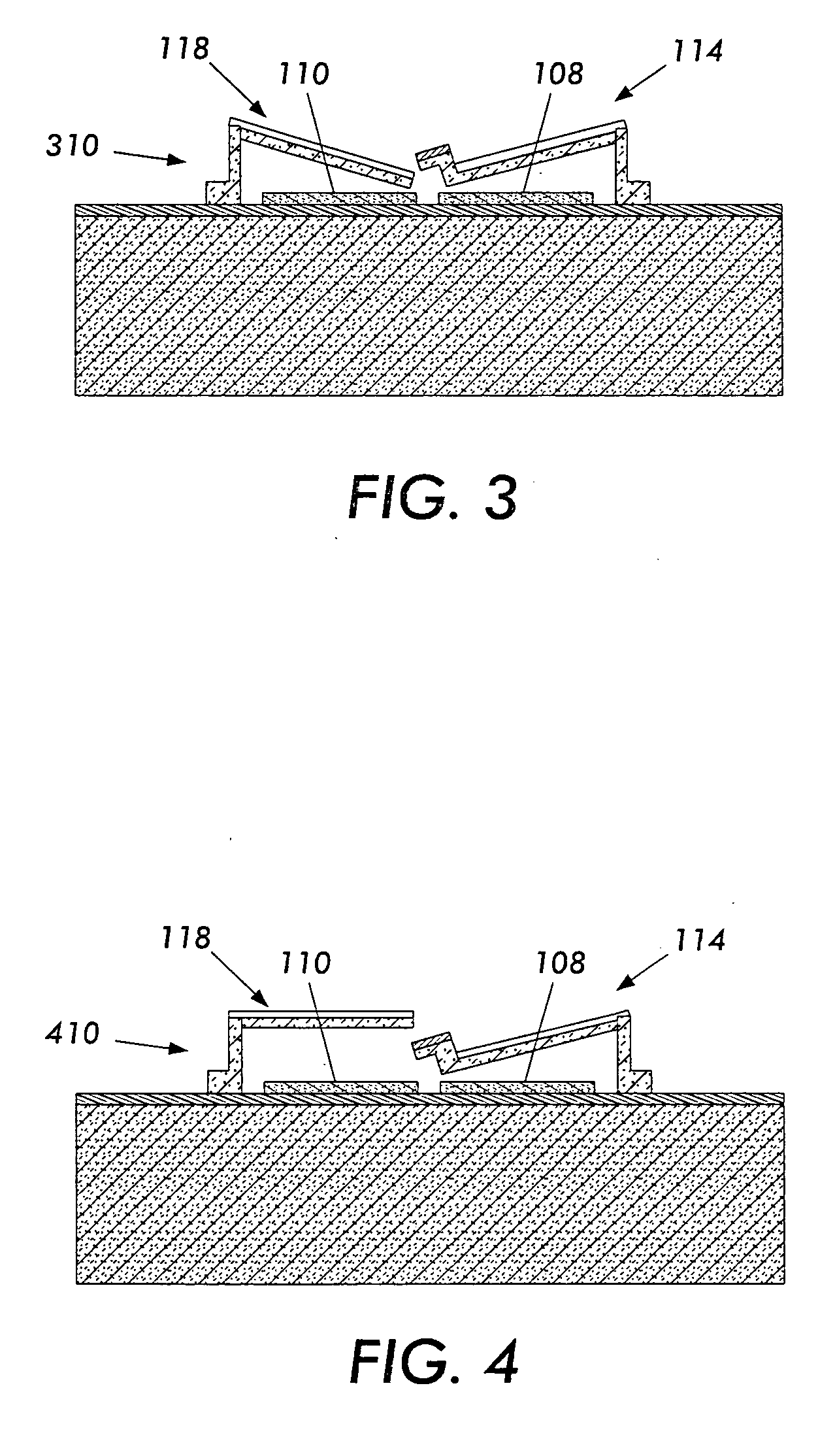

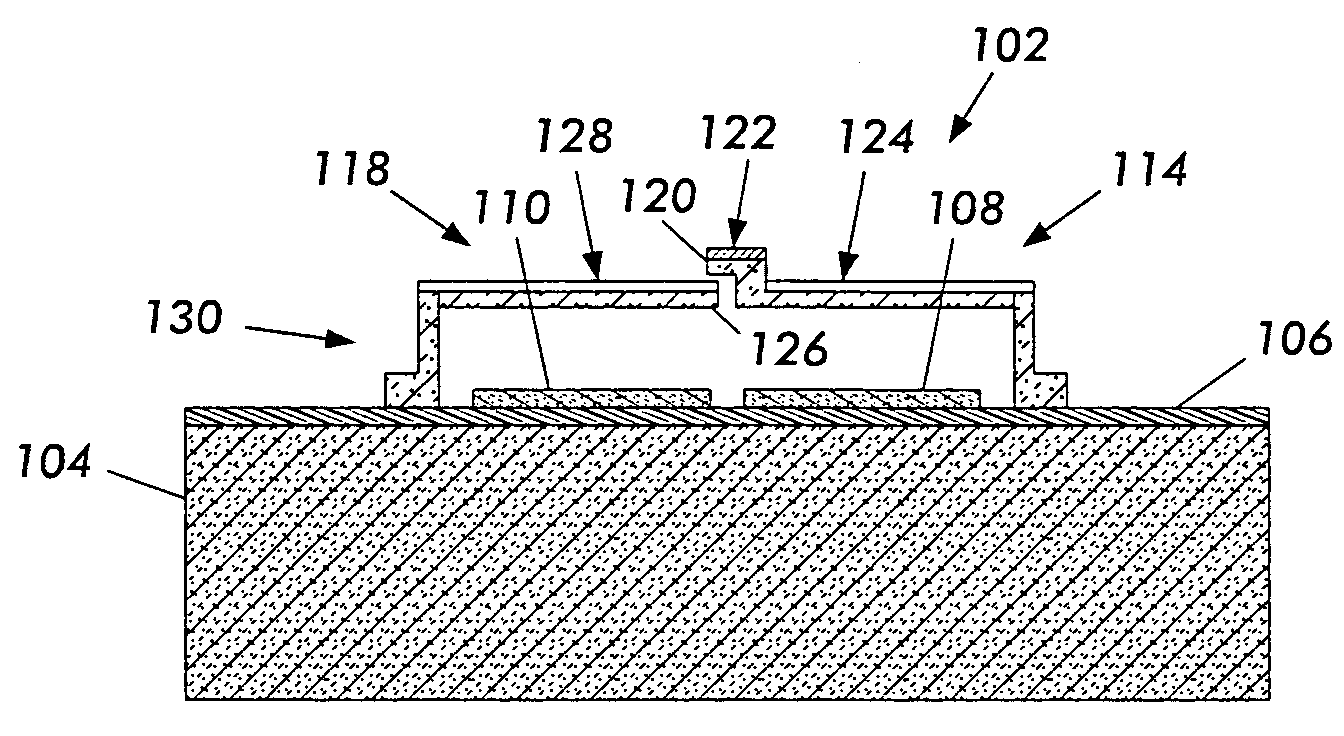

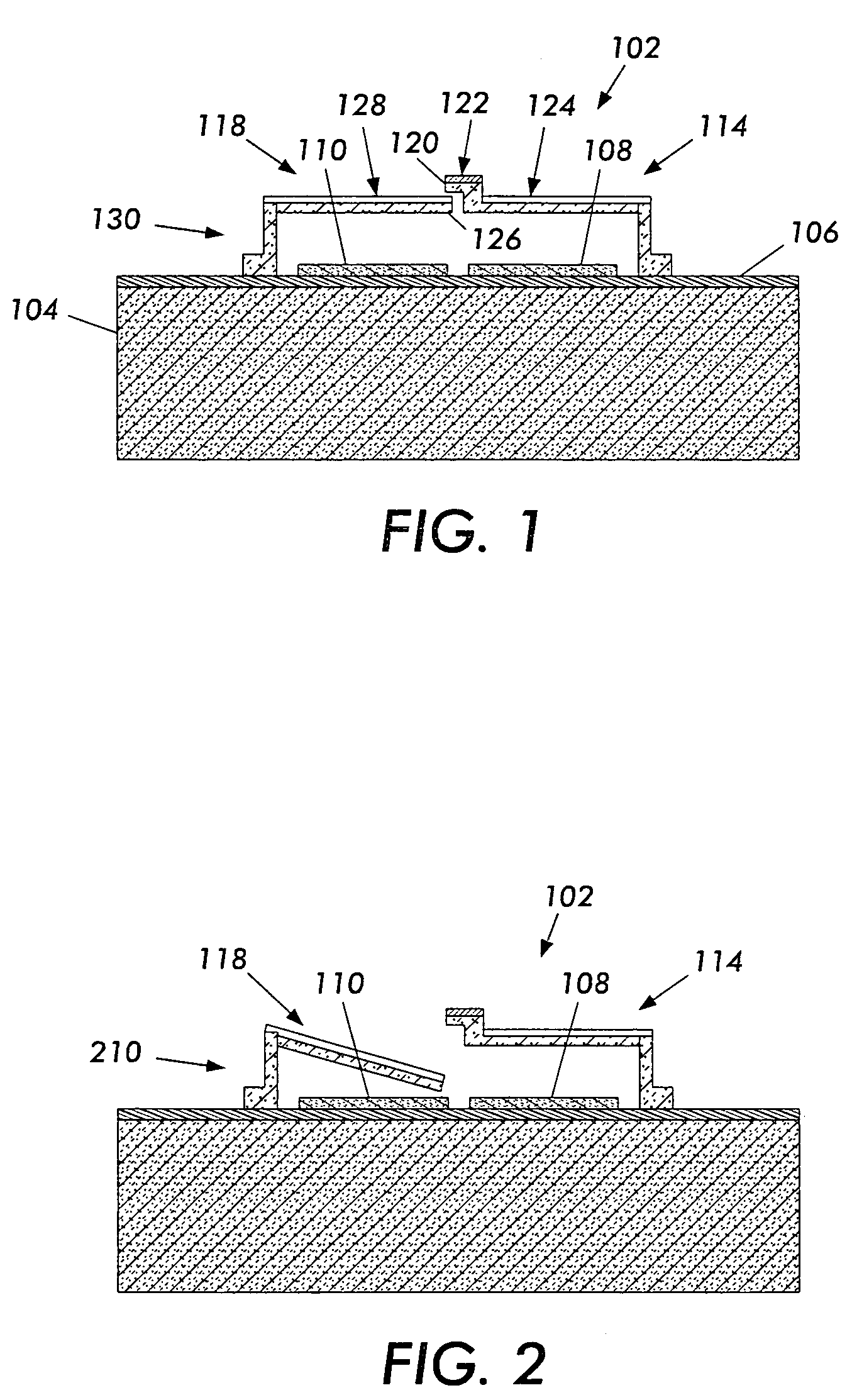

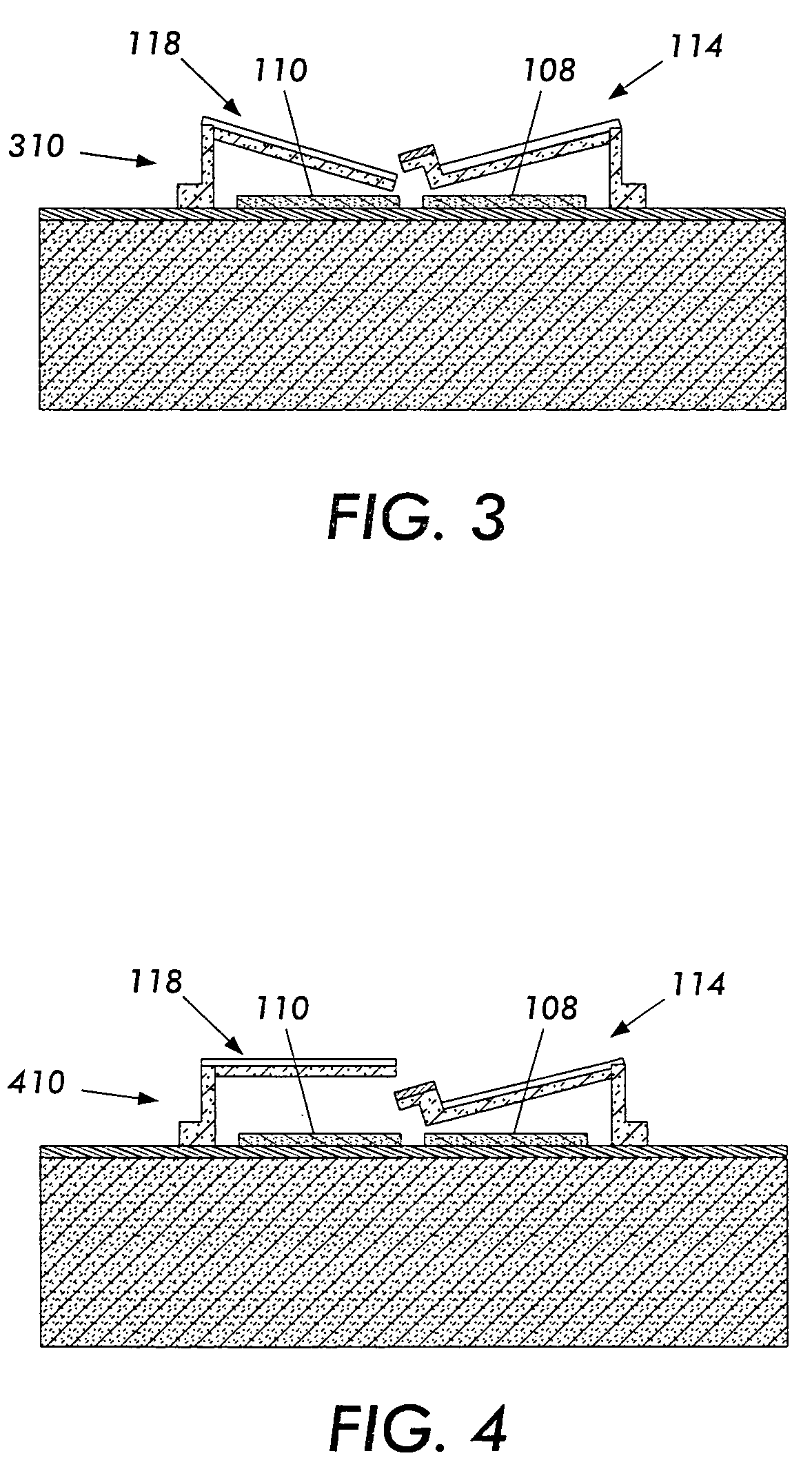

Electromechanical memory cell with torsional movement

InactiveUS20070002604A1Variable resistance carrier recordingVariable capacitance carrier recordingElectricityThermal force

A memory cell uses a pair of cantilevers to store a bit of information. Changing the relative position of the cantilevers determines whether they are electrically conducting or not. The on and off state of this mechanical latch is switched by using, for example, electrostatic, electromagnetic or thermal forces applied sequentially on the two cantilevers to change their relative position. The amount of power required to change the state of the cell is reduced by supporting at least one of the cantilevers with at least one lateral projection that is placed in torsion during cantilever displacement. After a bit of data is written, the cantilevers are locked by mechanical forces inherent in the cantilevers and will not change state unless a sequential electrical writing signal is applied. The sequential nature of the required writing signal makes inadvertent, radiation or noise related data corruption unlikely.

Owner:XEROX CORP

Electromechanical memory cell with torsional movement

InactiveUS7349236B2Variable resistance carrier recordingVariable capacitance carrier recordingElectricityThermal force

A memory cell uses a pair of cantilevers to store a bit of information. Changing the relative position of the cantilevers determines whether they are electrically conducting or not. The on and off state of this mechanical latch is switched by using, for example, electrostatic, electromagnetic or thermal forces applied sequentially on the two cantilevers to change their relative position. The amount of power required to change the state of the cell is reduced by supporting at least one of the cantilevers with at least one lateral projection that is placed in torsion during cantilever displacement. After a bit of data is written, the cantilevers are locked by mechanical forces inherent in the cantilevers and will not change state unless a sequential electrical writing signal is applied. The sequential nature of the required writing signal makes inadvertent, radiation or noise related data corruption unlikely.

Owner:XEROX CORP

Technique for processing engine valve spring

InactiveCN101642867AHigh thermal relaxation resistanceReasonable process designThermal forceEngineering

The invention relates to the field of spring processing technique, in particular to a technique for processing an engine valve spring. The technique includes inspection of raw materials, self inspection of cold forming flaw detection length, 25 to 60 minutes of annealing under the temperature from 250 to 480 DEG C and cross section grinding; the mode of automatic working of the grinding head of apower drive grinding wheel is used for internal and external chamfering grinding, the secondary shot peening technology with the gradual upgrade from thickness to thinness is adopted, 100 percent of demagnetization is carried out, and the thermal forced compression technology is carried out at the temperature from 100 to 300 DEG C under the pressure from 2 to 20 Mpa; loading selection is carried out according to the requirements of different loading sections; and FUCHS rust-preventative oil immersion is carried out, and finally finished products are packed and then are stored.

Owner:QIANJIANG SPRING HANGZHOU CO LTD

Technic for processing suspension spring

The invention relates to the technical field of spring manufacturing, in particular to a technic for processing a suspension spring. The technic includes the whole processes of feeding inspection of raw materials of steel wire rods, molding, heat treatment, preliminary treatment, packaging and storage. The technic is characterized in that after being molded, the raw materials are processed by theheat treatment, cooling and temperature preservation and then are processed by the thermal forced compression technology, cooling means that the temperature of the spring is lowered to range from roomtemperature to 200 DEG C by cooling, and temperature preservation means that the temperature of the spring is maintained to range from the room temperature to 300 DEG C; the thermal forced compression technology adopts temperature compression, the temperature ranges from the room temperature to 290 DEG C, and heat shot blasting is carried out after the thermal forced compression technology is carried out; and the preliminary treatment includes deoiling, degreasing, parkerising, cleaning and passivation.

Owner:QIANJIANG SPRING HANGZHOU CO LTD

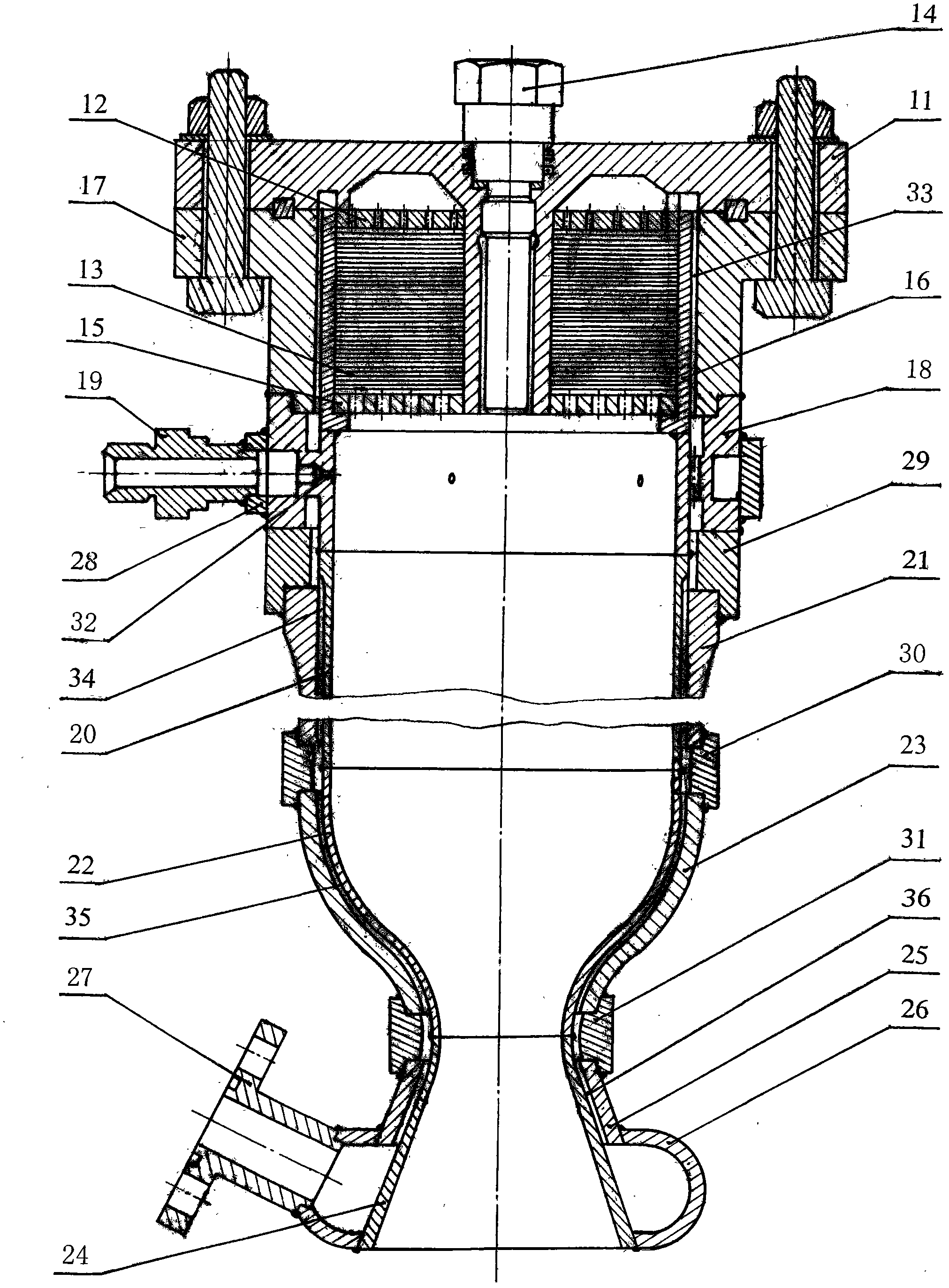

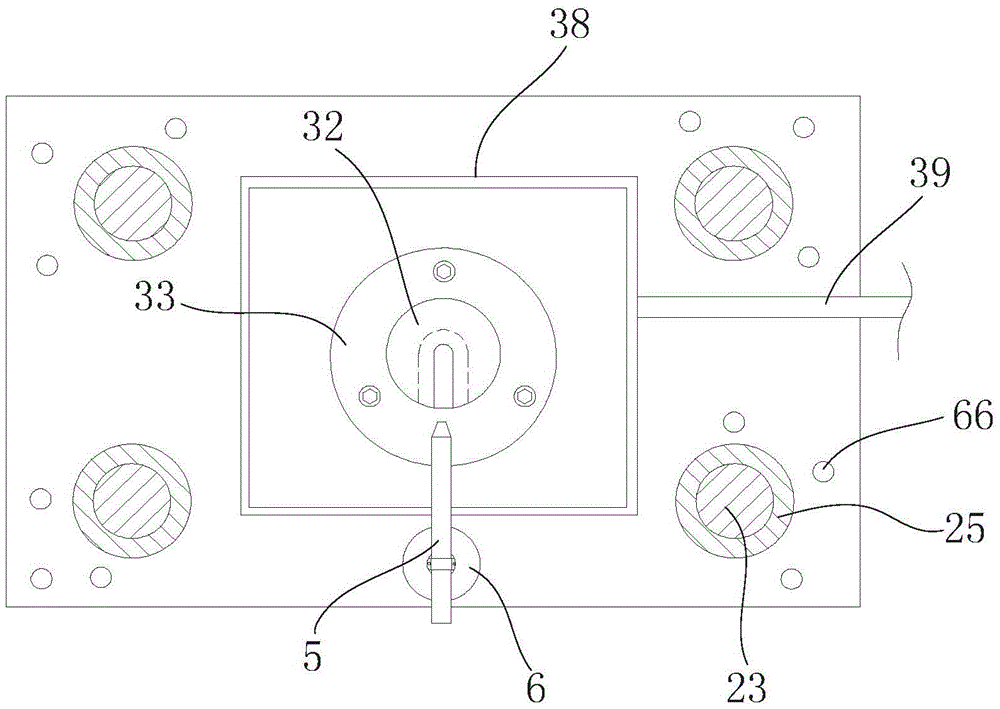

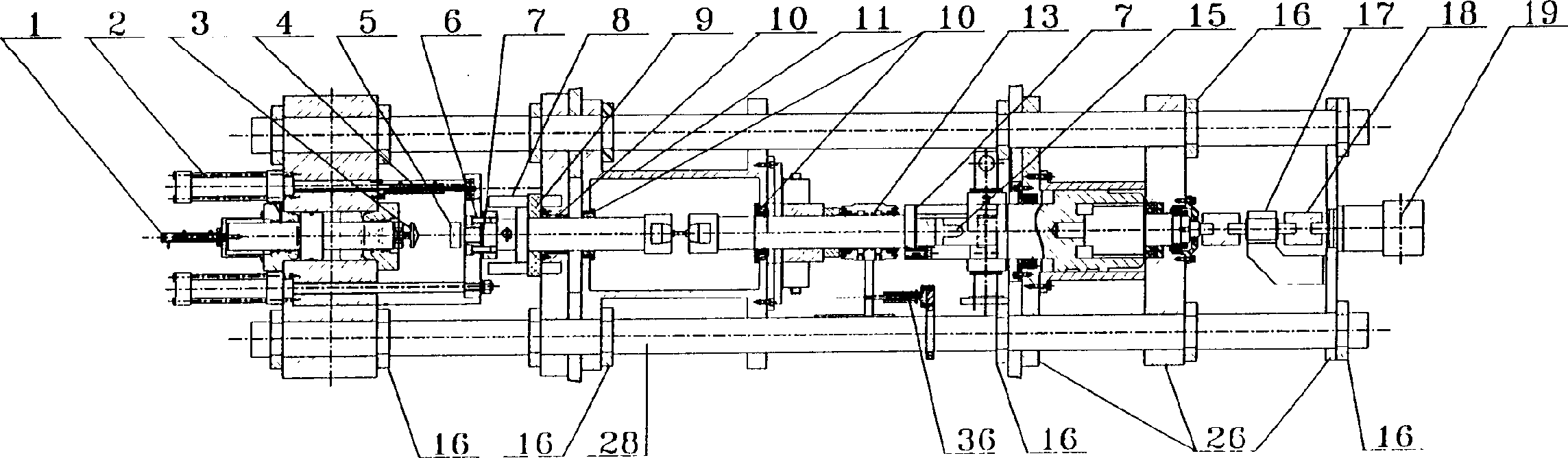

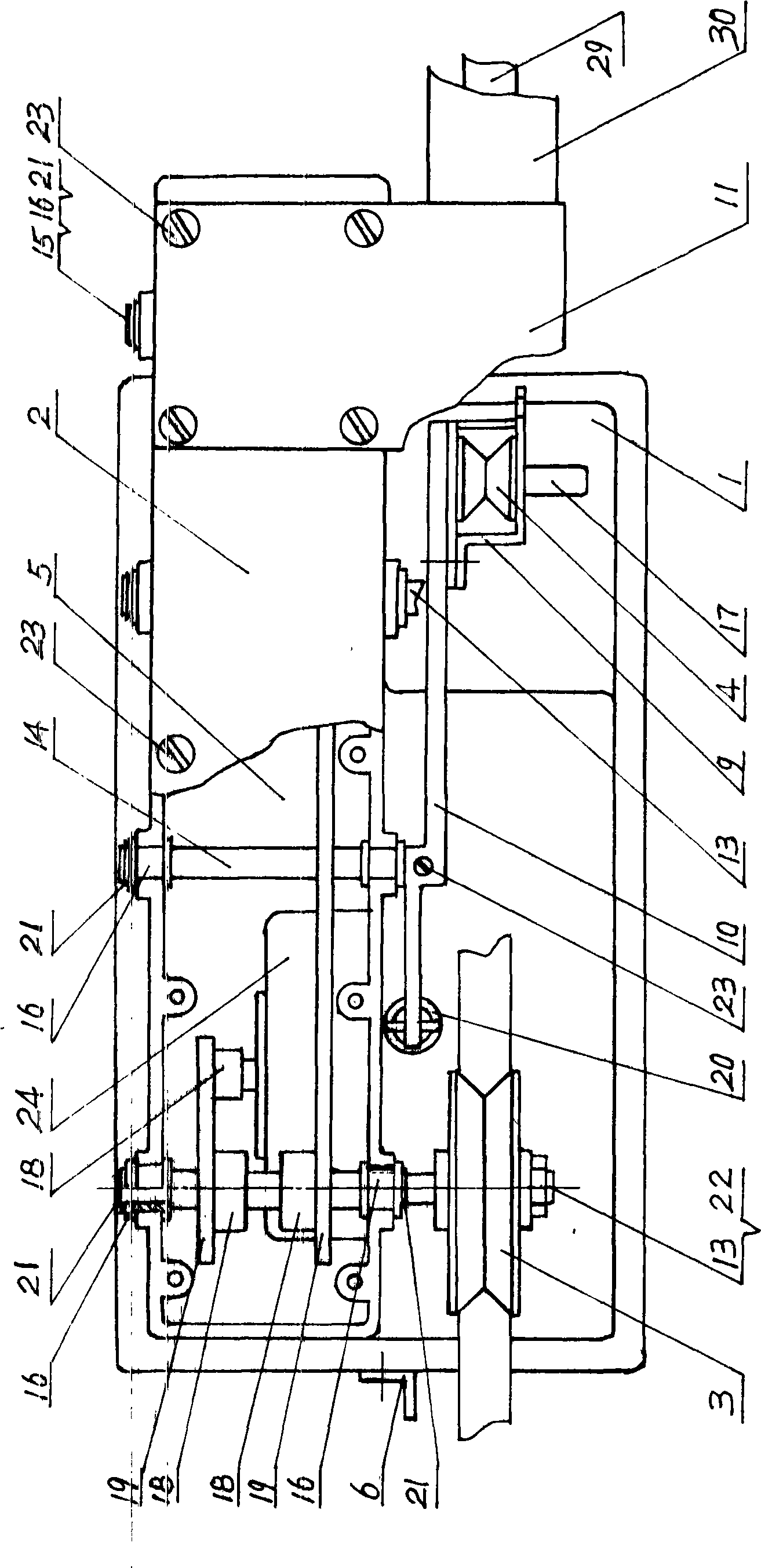

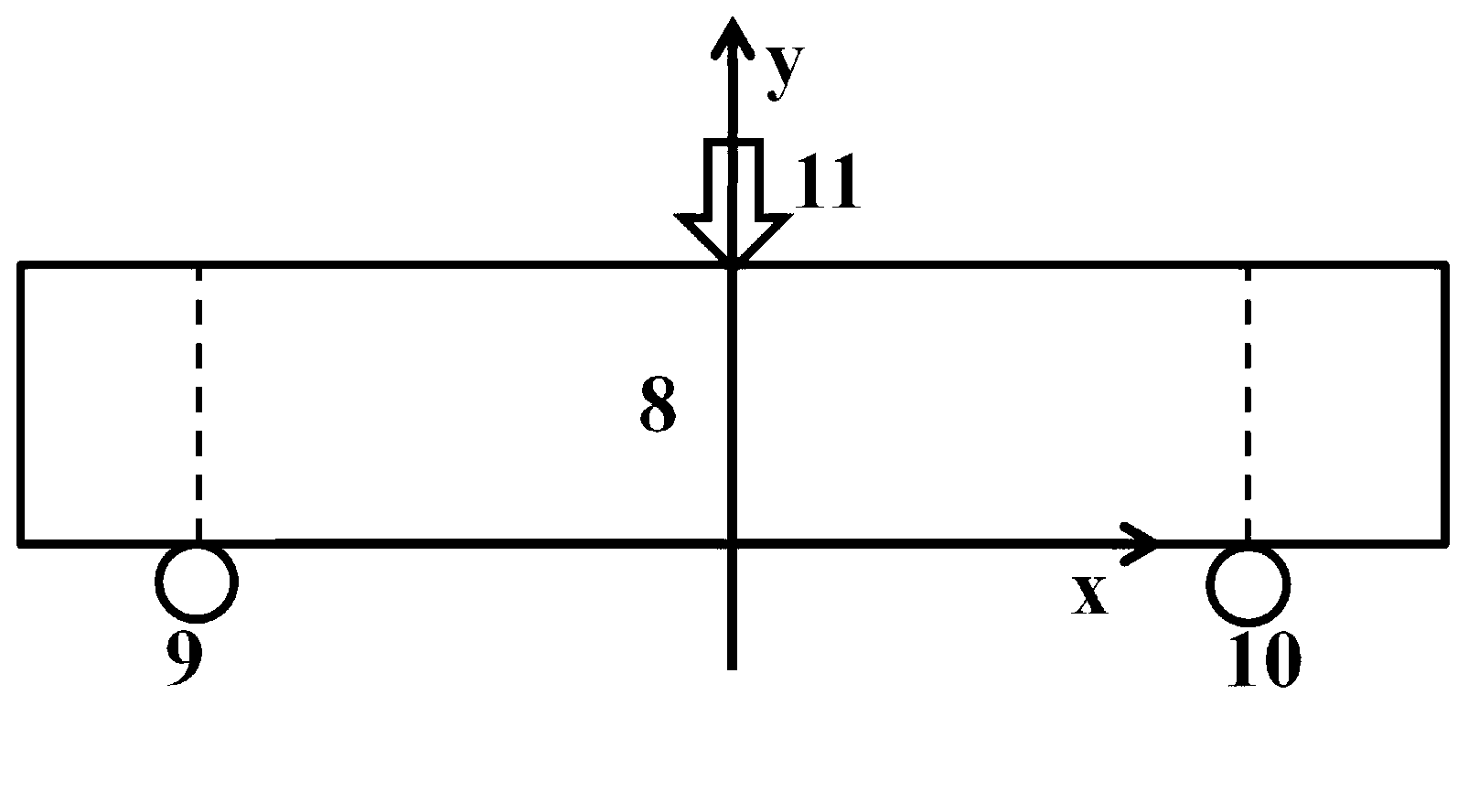

Fatigue testing device of material under thermal-mechanical coupling effect

InactiveCN105651638AAccurate predictionPredict fatigue lifeMaterial strength using tensile/compressive forcesTest efficiencyThermal force

The invention provides a fatigue testing device of a material under a thermal-mechanical coupling effect. The fatigue testing device comprises a loading device used for supplying single-axis tension load or compression load to a sample, an induction heating coil used for quickly heating and a cooling device used for quickly cooling the sample, wherein the loading device comprises two clamp bases and a driving mechanism used for driving the two clamp bases to be close to each other or far from each other; the induction heating coil is located in a sample loading area formed between the two clamp bases; the cooling device is close to the sample loading area and can adopt an air-cooling manner or a water-cooling manner; clamp heads corresponding to the sample are arranged on the two clamp bases; the induction heating coil can rotate horizontally and vertically to adjust the position. The fatigue testing device provides a reasonable test environment for testing the fatigue life of the material or a product under the thermal-mechanical coupling effect, can implement the thermal-mechanical coupling fatigue test under the tension and compression states so as to more accurately predict the fatigue life of the material or the product, and is capable of quickly increasing the temperature, shortening the test period and improving the test efficiency.

Owner:安徽微世特机电设备有限公司

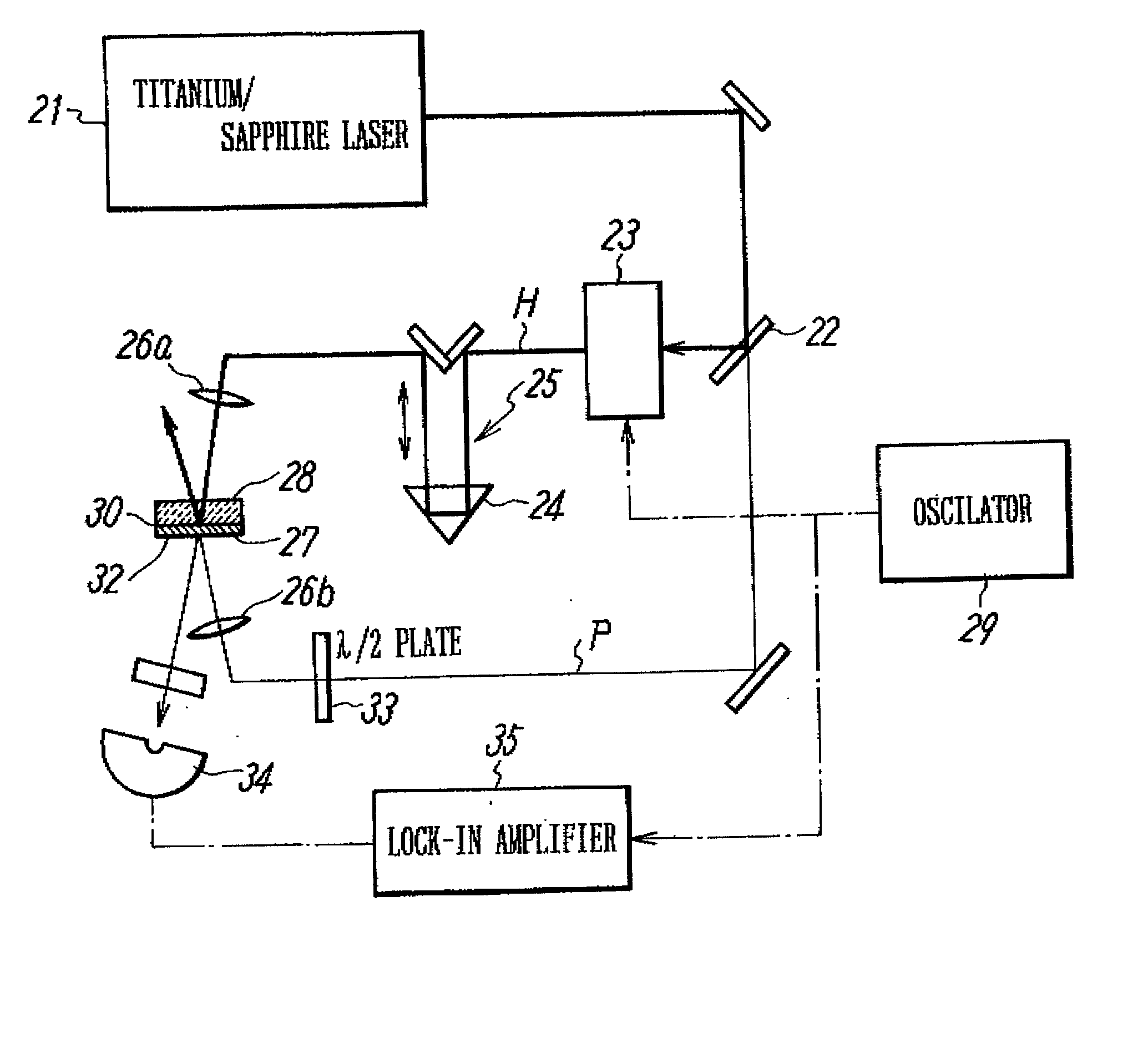

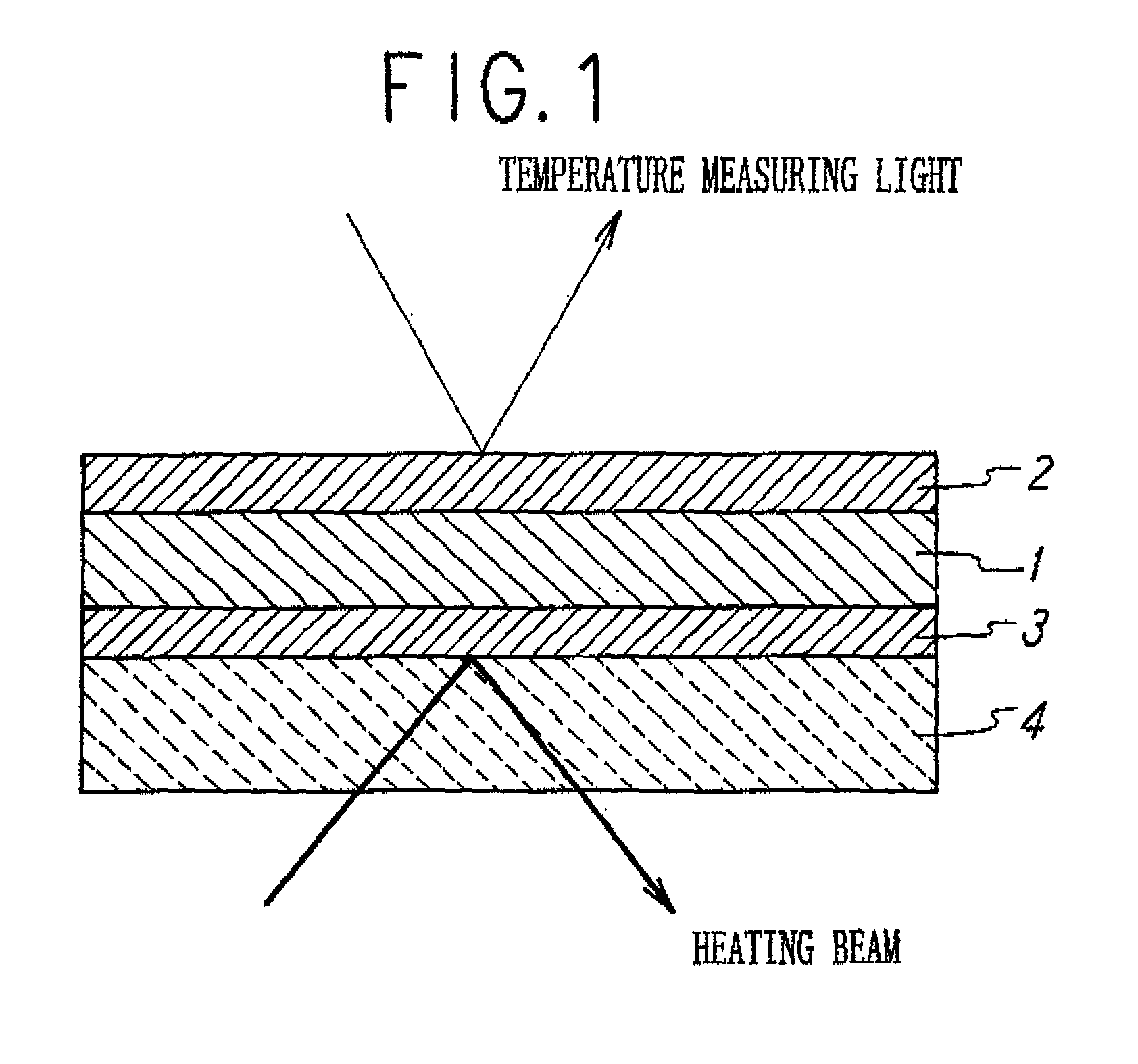

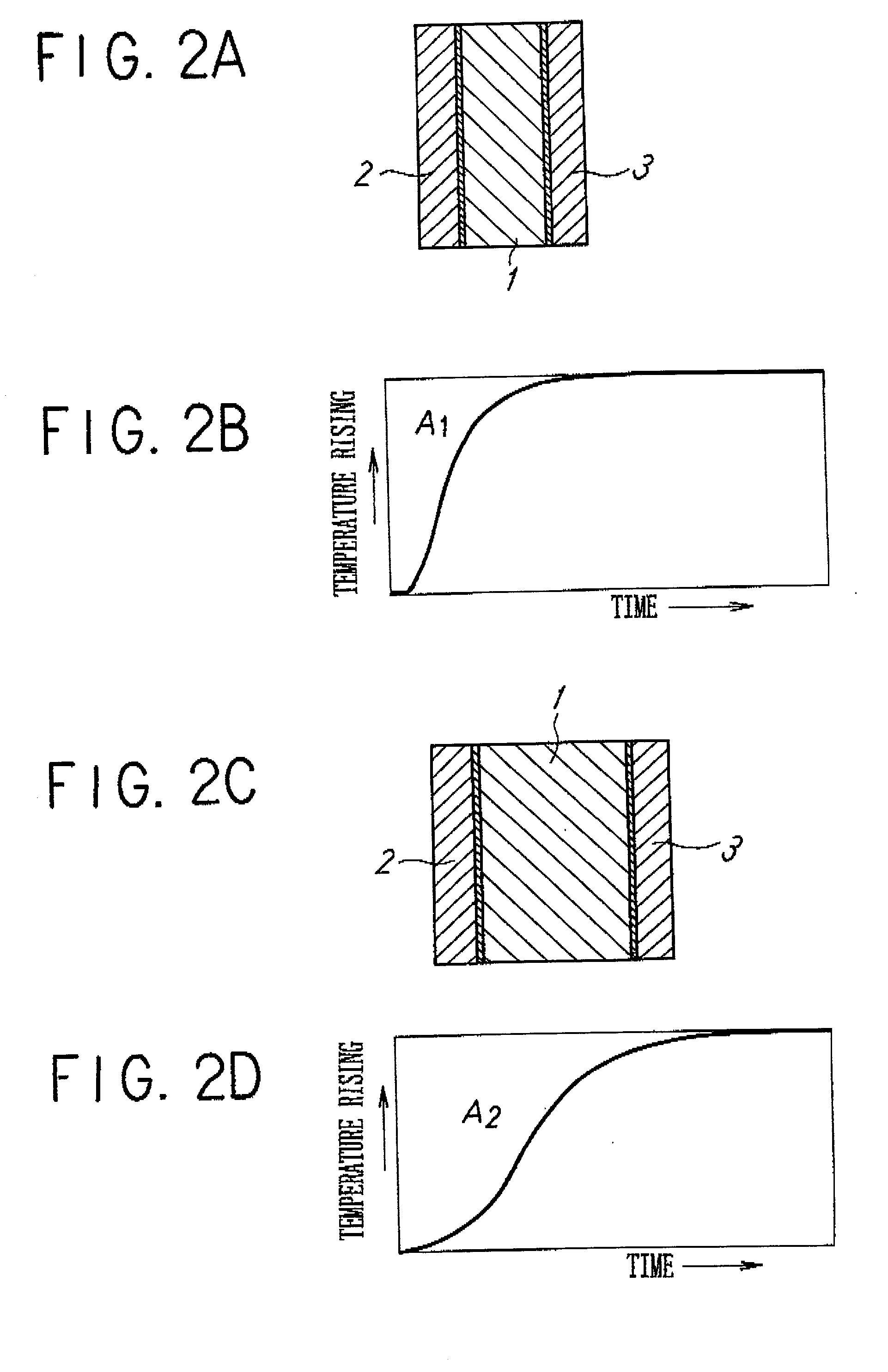

Method for measuring thermal diffusivity and interface thermal resistance

InactiveUS20020080850A1Material thermal conductivityMaterial heat developmentThermal forceThermal diffusivity

An object of the invention is to make it possible to correctly and easily measure a thermal diffusivity within a three-layer substance containing an non-metal substance. A non-metal film 1 whose thermophsical properties are unknown is disposed between a first metal film 2 and a second metal film 3, thereby forming a sample having a three-layer structure. The metal films 2 and 3 have predetermined known thermophsical properties, belong to the same sort of substance and have the same thickness. The three-layer substance is disposed on a transparent substrate 4 and is heated from below the second metal film 3, using a picosecond light pulse coming from below and passing through the transparent substrate 4. The light pulse used in the irradiation is converted into a heat in the second metal film 3 during only one picosecond, with such heat diffusing through interface / non-metal film layer / interface and thus arriving at the first metal film 2. By measuring a temperature change on the surface of the first metal film 2, it is possible to perform correct measurement by using the thermoreflectance method formerly suggested in a patent application by the inventors of the present invention.

Owner:NAT INST OF ADVANCED IND SCI & TECH

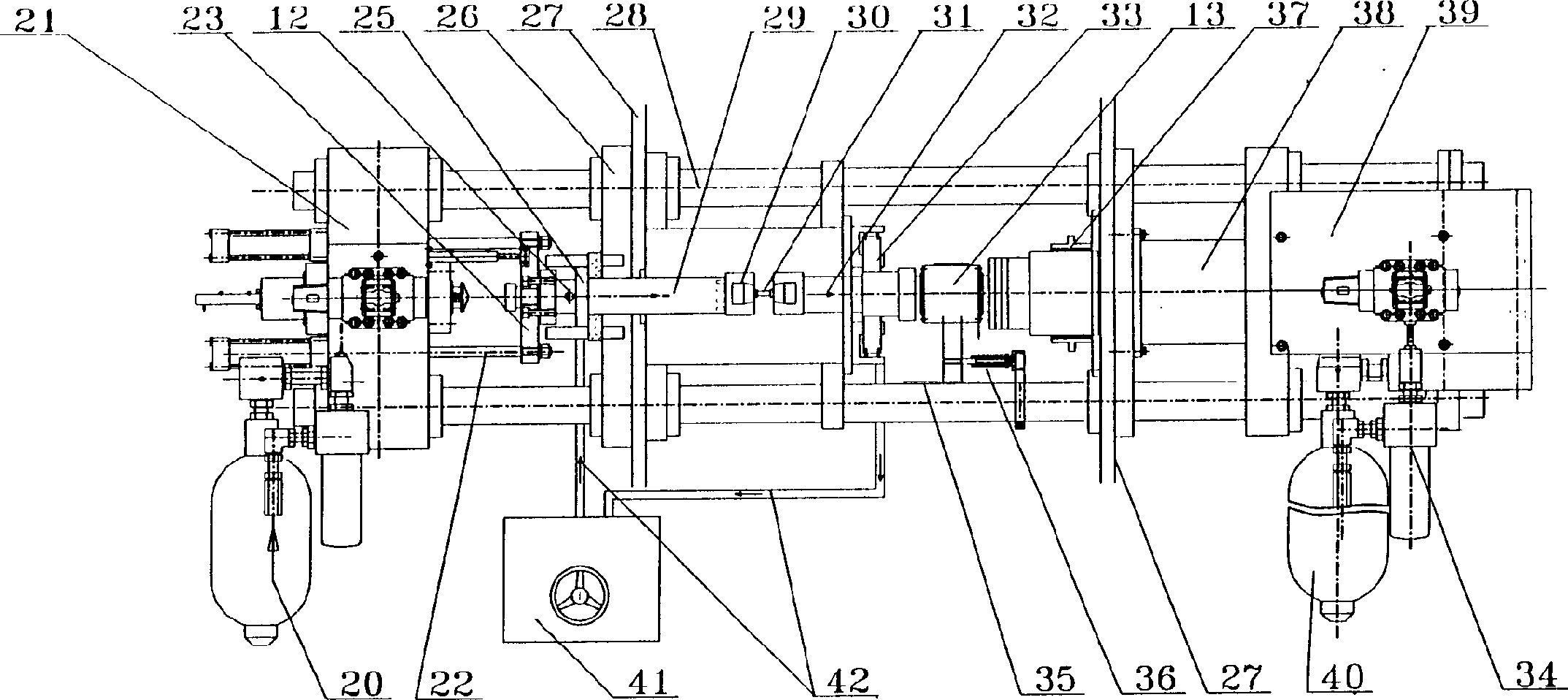

Multifunctional thermodynamic simulated experiment machine

InactiveCN1412727AImprove rigidityReduce distortionEducational modelsThermodynamic simulationHydraulic cylinder

The multifunctional thermodynamic simulation experiment equipment is formed from cross beams, main and auxiliary hydraulic cylinders, shaft, operation box, test conversion device, force measuring device, electric conducting device, turning connector, hydraulic brake, positioning beam and supporting beam. Under the condition of no changing any component said invention can implement tension, compression and torsion experiments, and also can make tension-torsion composite stress deformation experiment.

Owner:NORTHEASTERN UNIV

Phase-change heat exchanger

Owner:THE BOEING CO

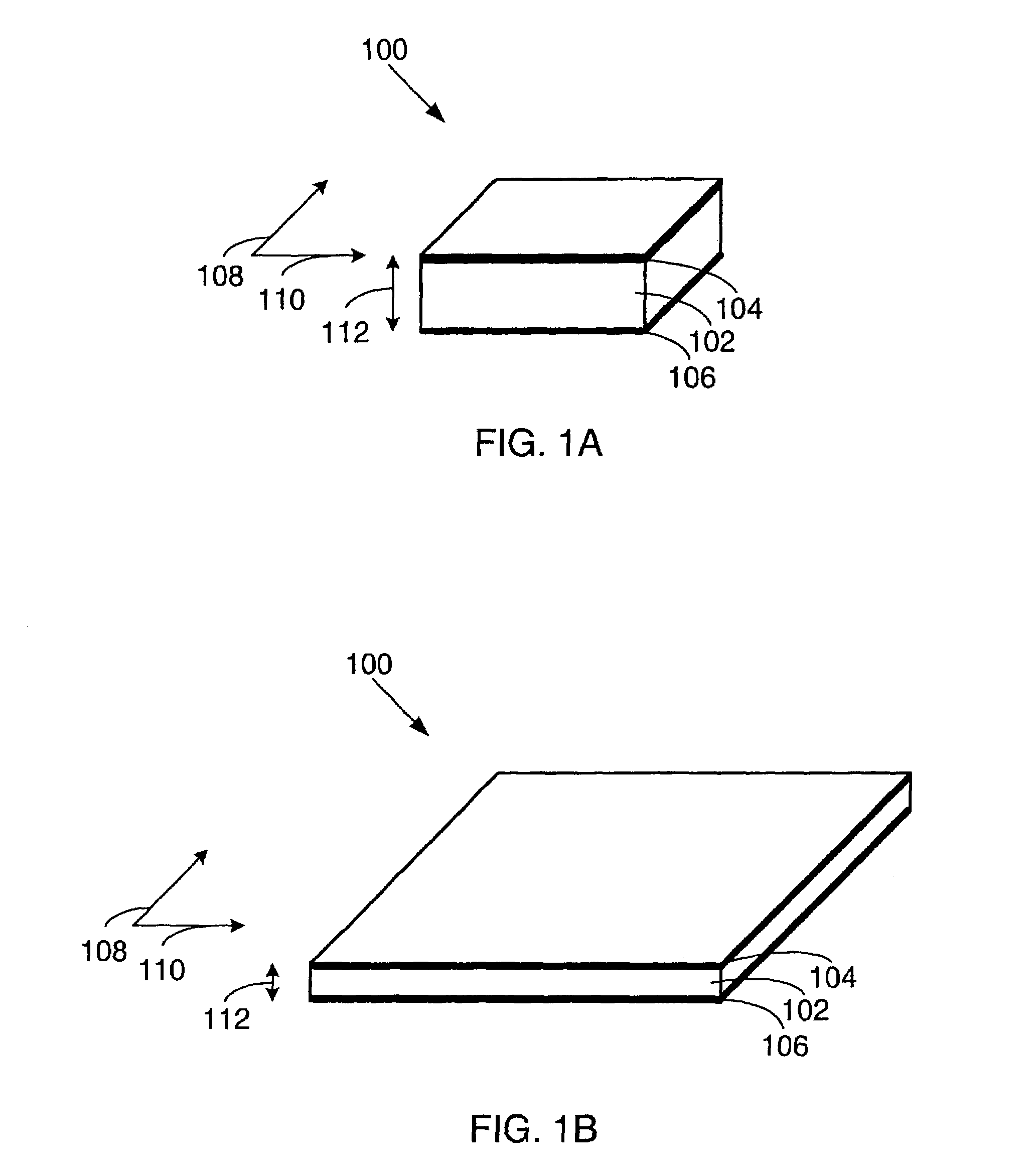

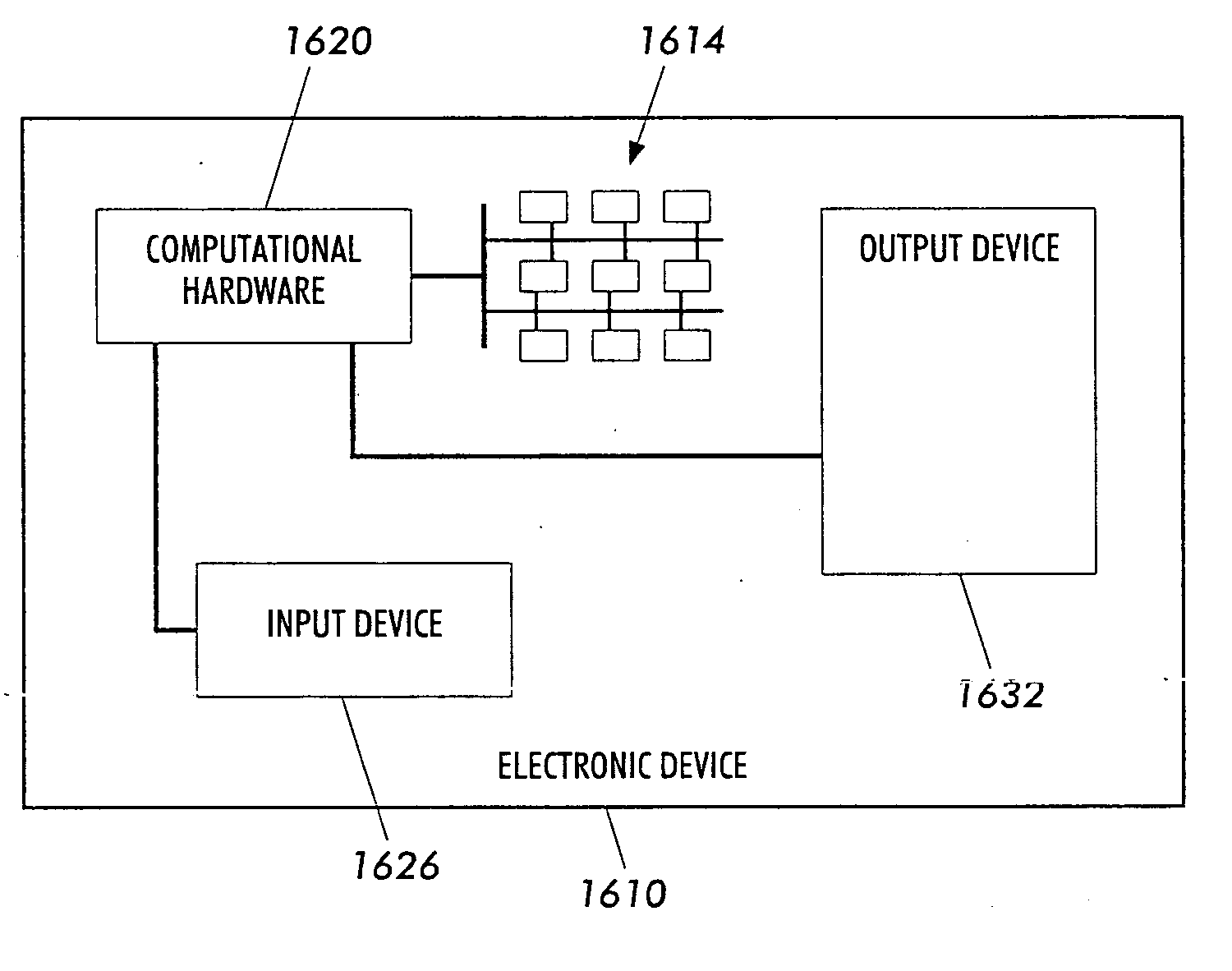

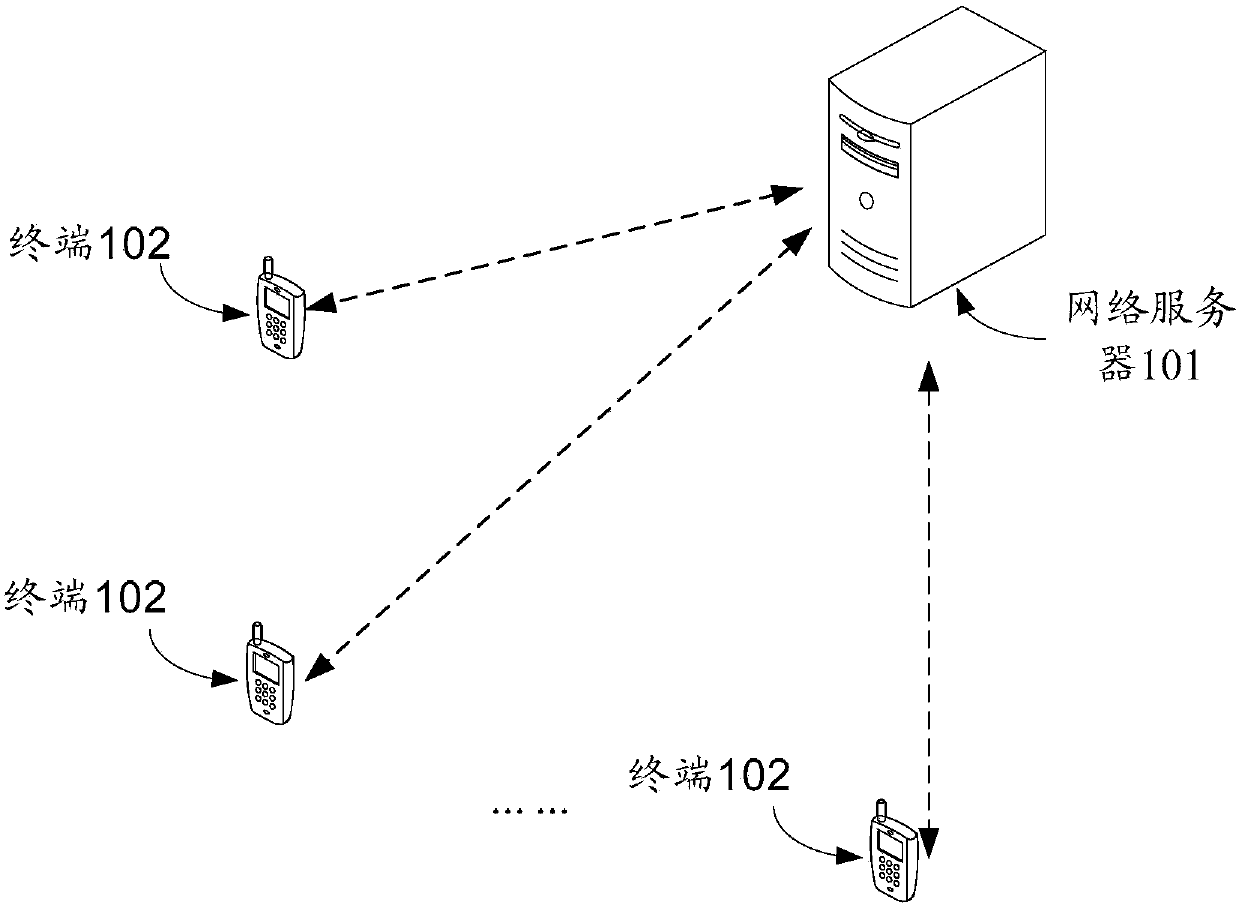

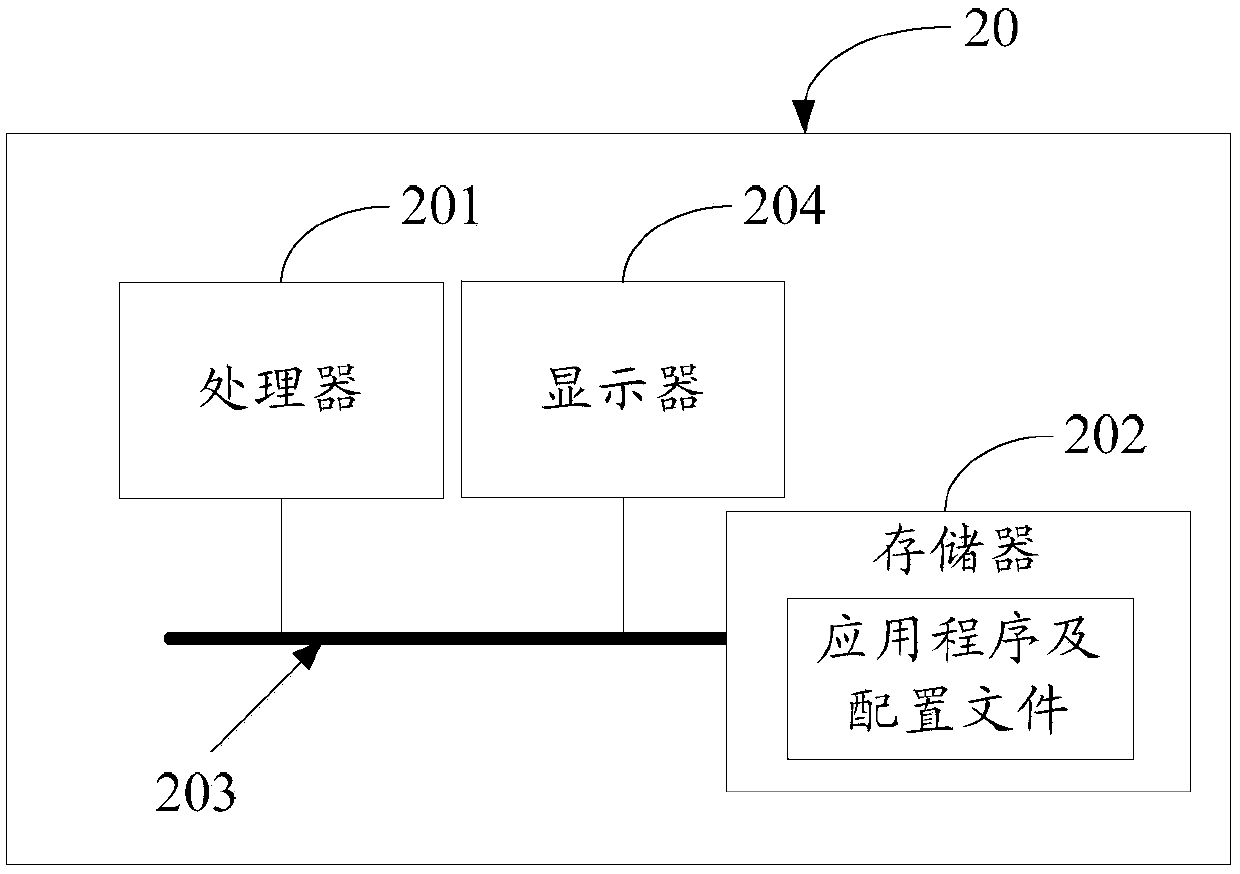

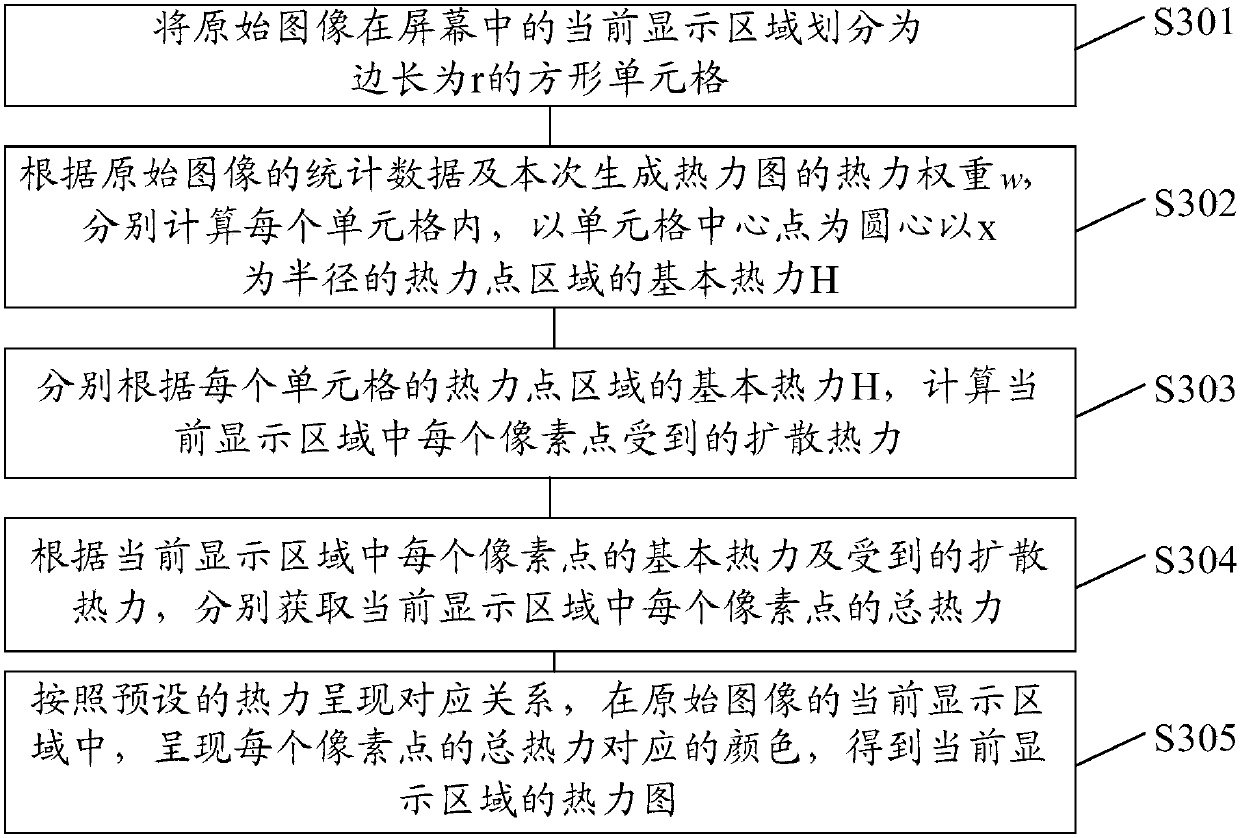

Thermodynamic diagram generation method and device

Embodiments of the invention provide a thermodynamic diagram generation method and device, relates to the field of image processing, and aims at enabling thermodynamic diagrams to continuously and correctly reflect features of areas and enabling changes of image scaling not to influence the continuity and correctness of the thermodynamic diagrams. The method comprises the following steps of: dividing an original image into cells in the current display area of a screen; calculating basic thermal force of a thermodynamic point area of each cell according to statistical data and a thermodynamic weight for generating a thermodynamic diagram; calculating diffusion thermal force suffered by each pixel point in the current display area according to the basic thermal force of the thermodynamic point areas of the cells; obtaining total thermal force of each pixel point in the current display area; and displaying a color corresponding to the total thermal force of each pixel point in the currentdisplay area in the current display area of the original image according to a preset thermodynamic display corresponding relationship, so as to obtain a thermodynamic diagram of the current display area. The method and device are used for generating thermodynamic diagrams.

Owner:XFUSION DIGITAL TECH CO LTD

Impact and thermal force composite testing device of explosive

InactiveCN103323491AGet impact sensitivityTest crash safetyMaterial exposibilityUsing mechanical meansThermal forceShock sensitivity

The invention discloses an impact and thermal force composite testing device of an explosive. The device comprises a base, a strike anvil, a strike rod, a drop hammer and a heating device, wherein the bottom of the strike anvil is embedded in the base, and the strike anvil is used for placing an explosive piece, the strike rod is arranged above the strike anvil, the drop hammer is arranged above the strike rod, and the heating device can be used for heating the base. According to the device disclosed by the invention, the heating device used for heating the base is arranged, and can transfer heat to the explosive piece, the temperature of the explosive piece can be set, and impact tests at different heights can be carried out by utilizing the drop hammer to impact, so that impact sensitivities of the explosive piece under different temperatures are achieved, and evaluation means are provided for the safety of the explosive under a high-temperature condition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Aerial cable de-icing machine capable of being coated ice-sticking ice resistance agent

The invention provides an ice removing machine for overhead cables which can be applied with ice sticking resistance agent. The ice removing machine is applicable to removing ice for one cable, two cables or four combination cables with a frame for maintaining distance between cables in any adverse weather and geographical environment. The ice removing machine has an applicable type of lever bracket cables and an applicable type of tower cables, wherein the former has an external power source, is small in volume and light in weight and can be conveniently hung to the cables; the latter consists of a dragging device driven by a battery and a motor and a gas ignition assembly with cylinder-shaped fire-jet head, can be conveniently hung to the cables to remove ice rapidly by comprehensive function of thermal force and mechanical force and can stand by on the cables for a long time and operate repeatedly according to the remote instructive of human; and the ice sticking resistance agent can be coated on the cables in advance, thus leading the cables to be not easy to ice up and the ice to be removed easily even if the cables are iced up.

Owner:张福生

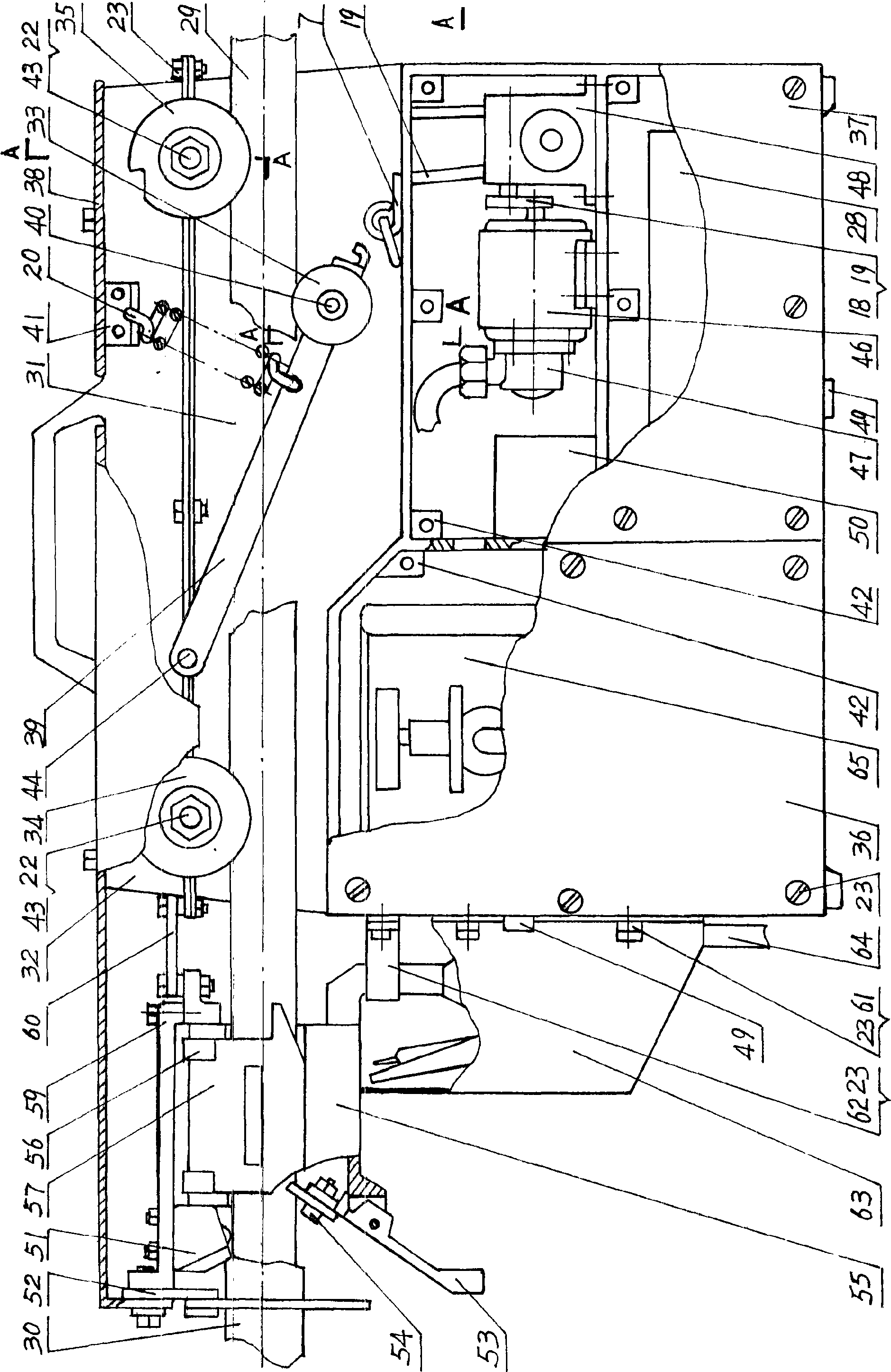

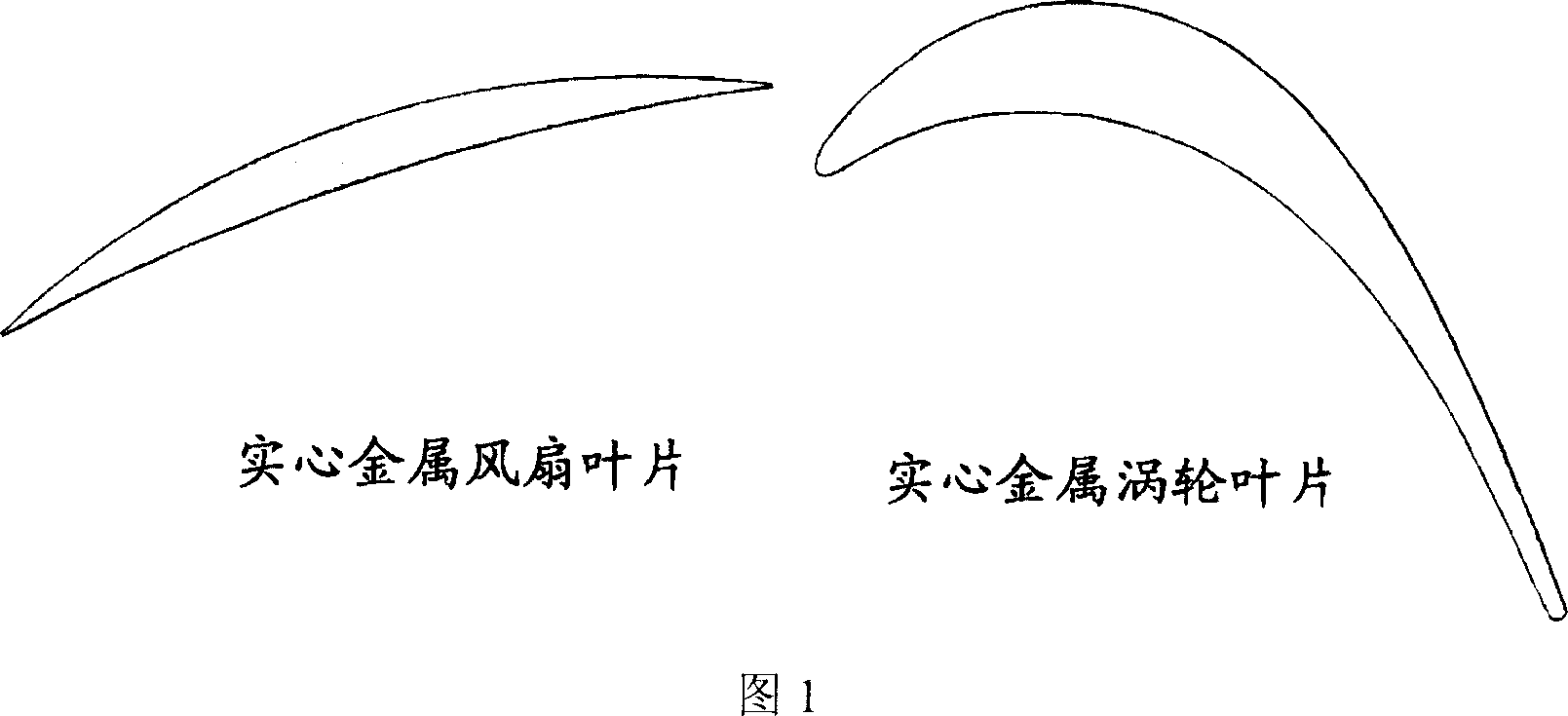

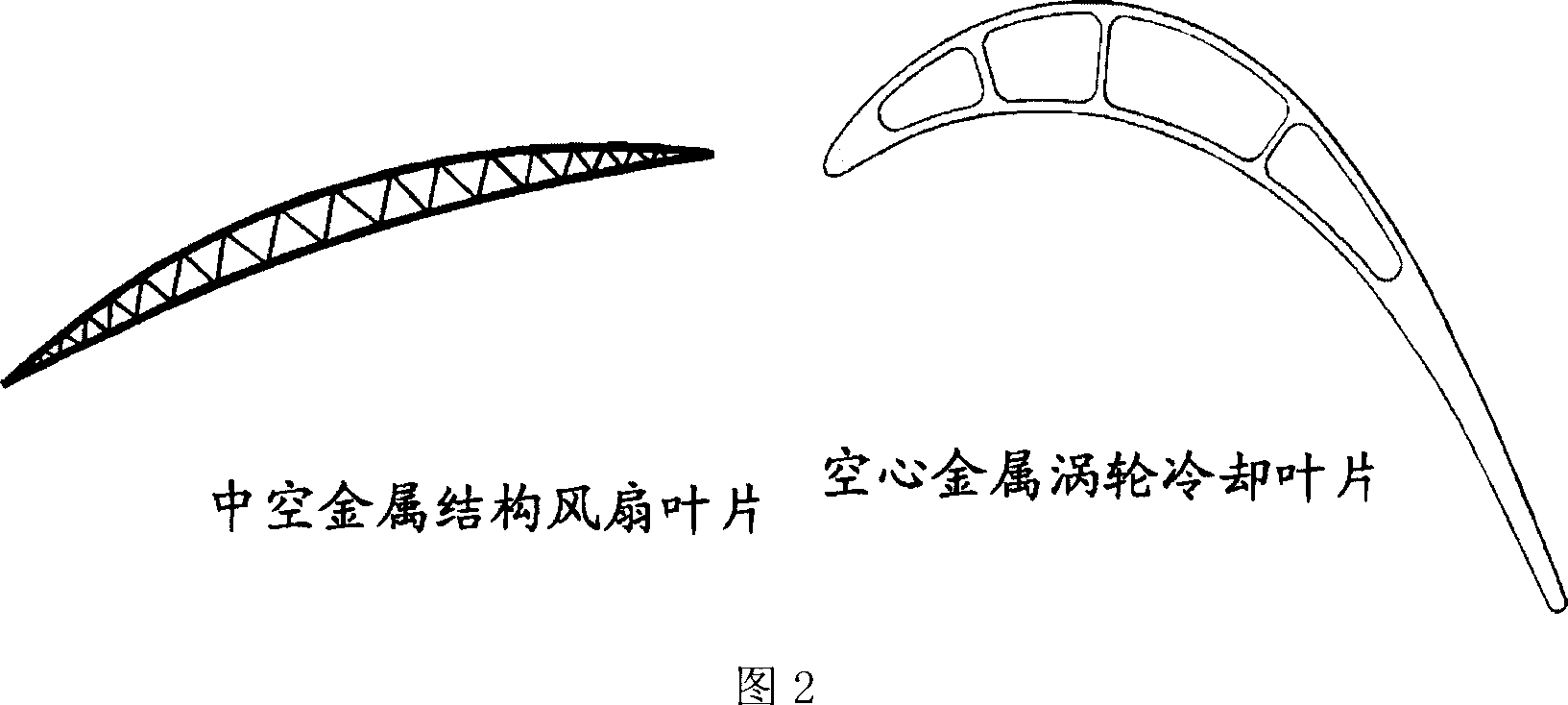

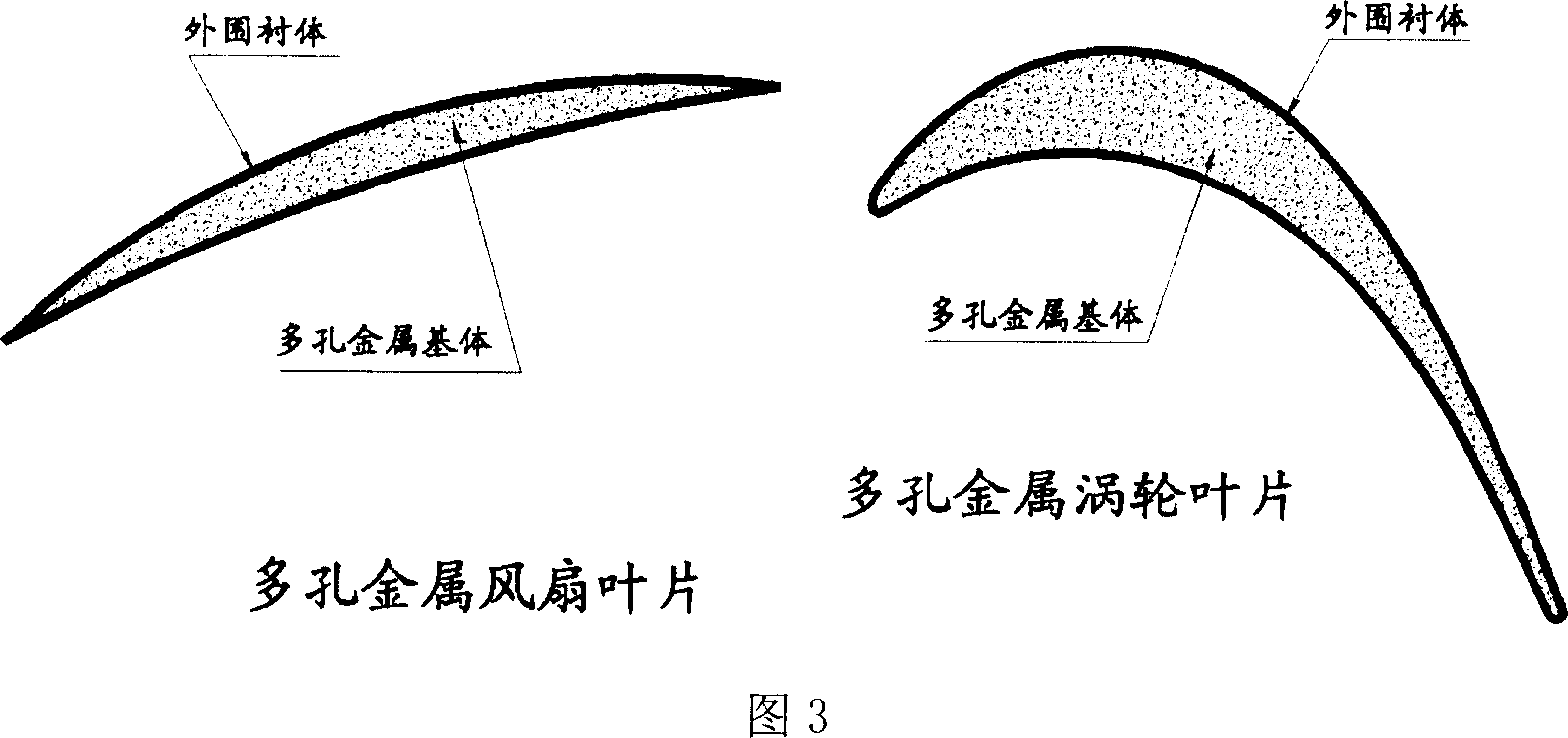

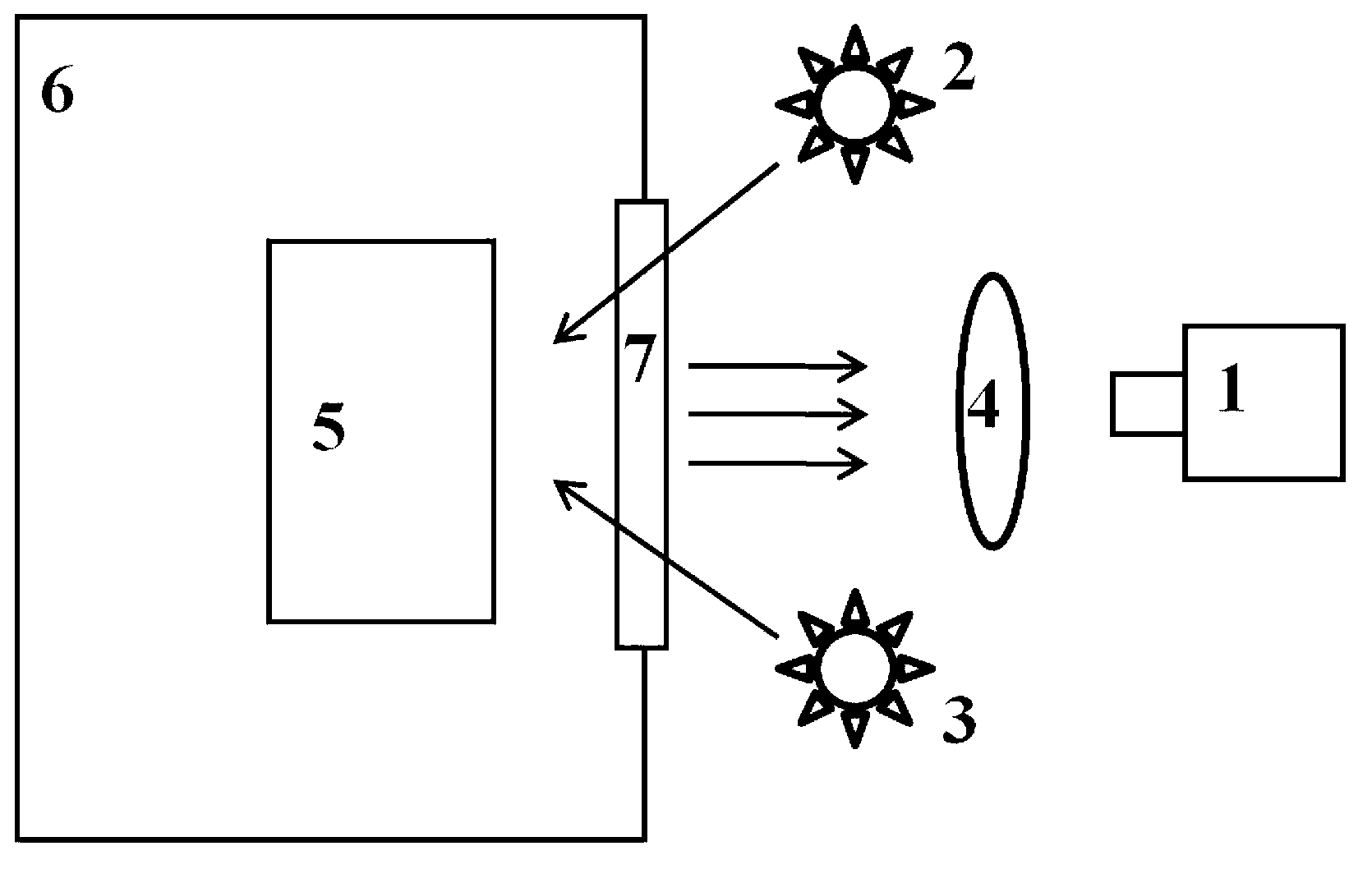

Porous metal vane coupling design method

InactiveCN101078354AImprove performanceExtended service lifePump componentsBlade accessoriesState of artImpeller

The invention relates to a design method for porous metal blade. The method combines porous metal material with design of blade and the manufacturing process. By the high specific strength characteristic of porous metal material and adjusting porosity of said material, blade coupling design of process, strength, vibration, and pneumatic thermal force is carried out so as to improve the specific strength of blade and satisfy the flow control demand of blade boundary layer. The method conquers the lack of solid or hollow blade in prior technology. The good performance of porous metal material is used. Blade material characteristic, strength, vibration and pneumatic thermal force performance are considered in synthesis. The coupling design method for blade process, strength, vibration, pneumatic thermal force of porous metal is provided and part performance of aeroengine and gas turbine can be improved greatly. At the same time the invention provides a blade designed by the method, aeroengine and gas turbine comprising blade mentioned above.

Owner:BEIHANG UNIV

Non-contact experimental method for measuring heat constant of high-temperature material

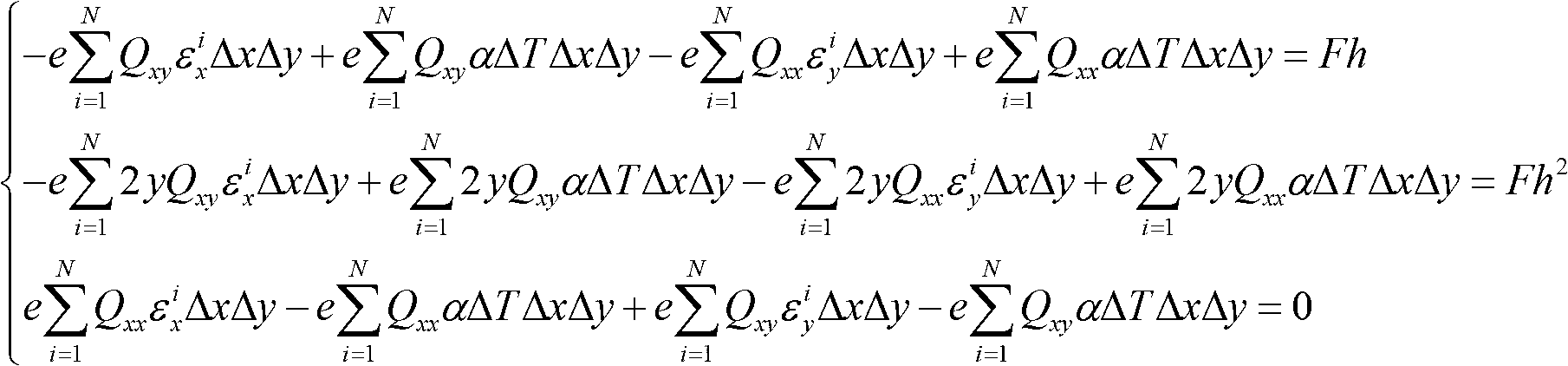

InactiveCN103018111ALabor savingEasy to operateMaterial thermal coefficient of expansionMaterial strength using steady bending forcesVirtual fieldFull field

The invention discloses a non-contact experimental method for measuring a heat constant of a high-temperature material, and belongs to the technical field of experimental mechanics and high-temperature test. An elastic modulus, a poisson ratio and a thermal expansion coefficient of the material under a high temperature are measured by combining a high-temperature digital speckle technology, a three-point bending technology and a virtual field technology. By the method, a charge coupled device (CCD) is used for recording speckle maps of a three-point bent test sample before and after thermal load; a full-field strain before and after the thermal load is calculated by a digital speckle method; the elastic modulus, the poisson ratio and the thermal expansion coefficient of the material under high temperature are calculated; and the elastic modulus, the poisson ratio and the thermal expansion coefficient of the material under high temperature can be measured at the same time.

Owner:TSINGHUA UNIV

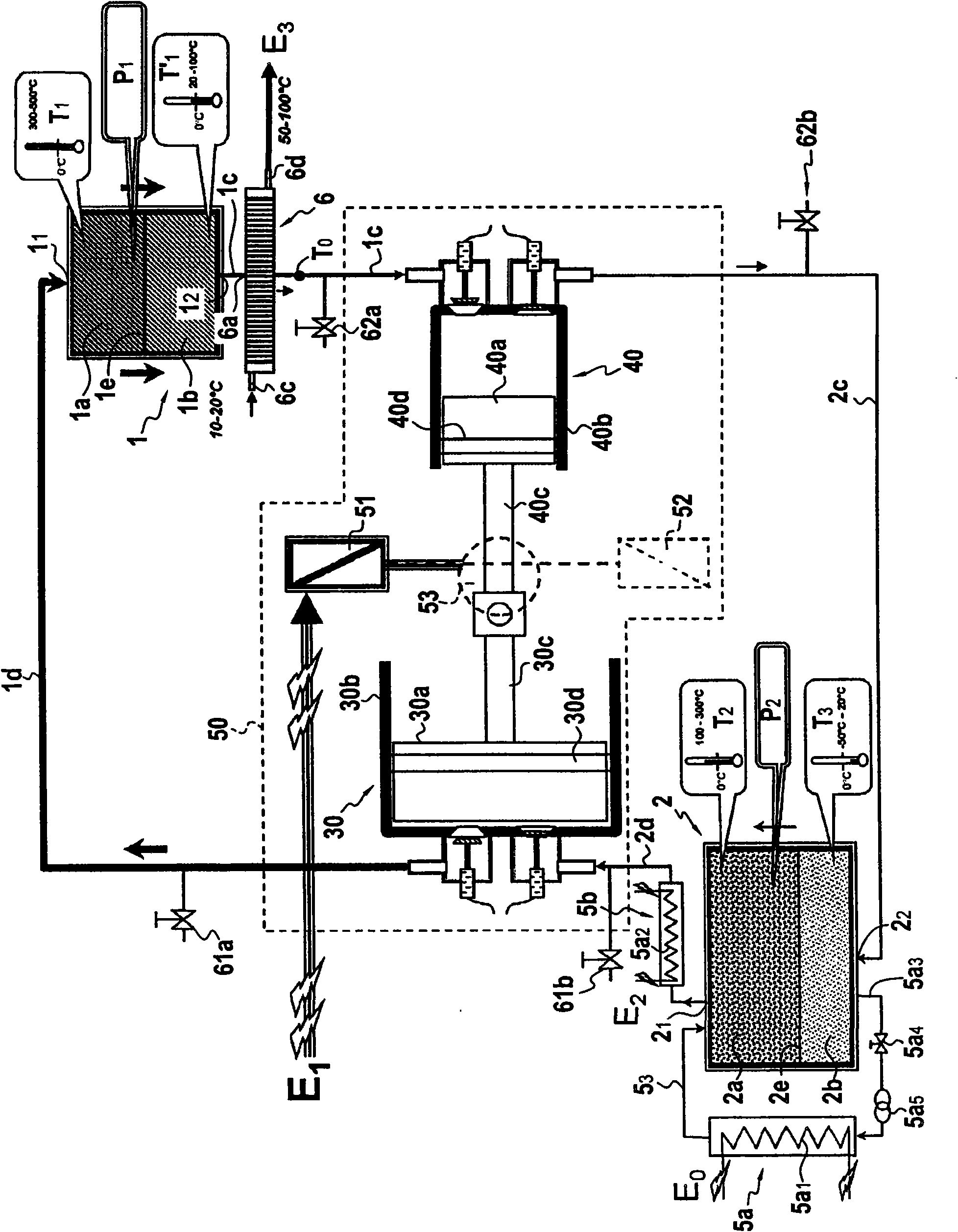

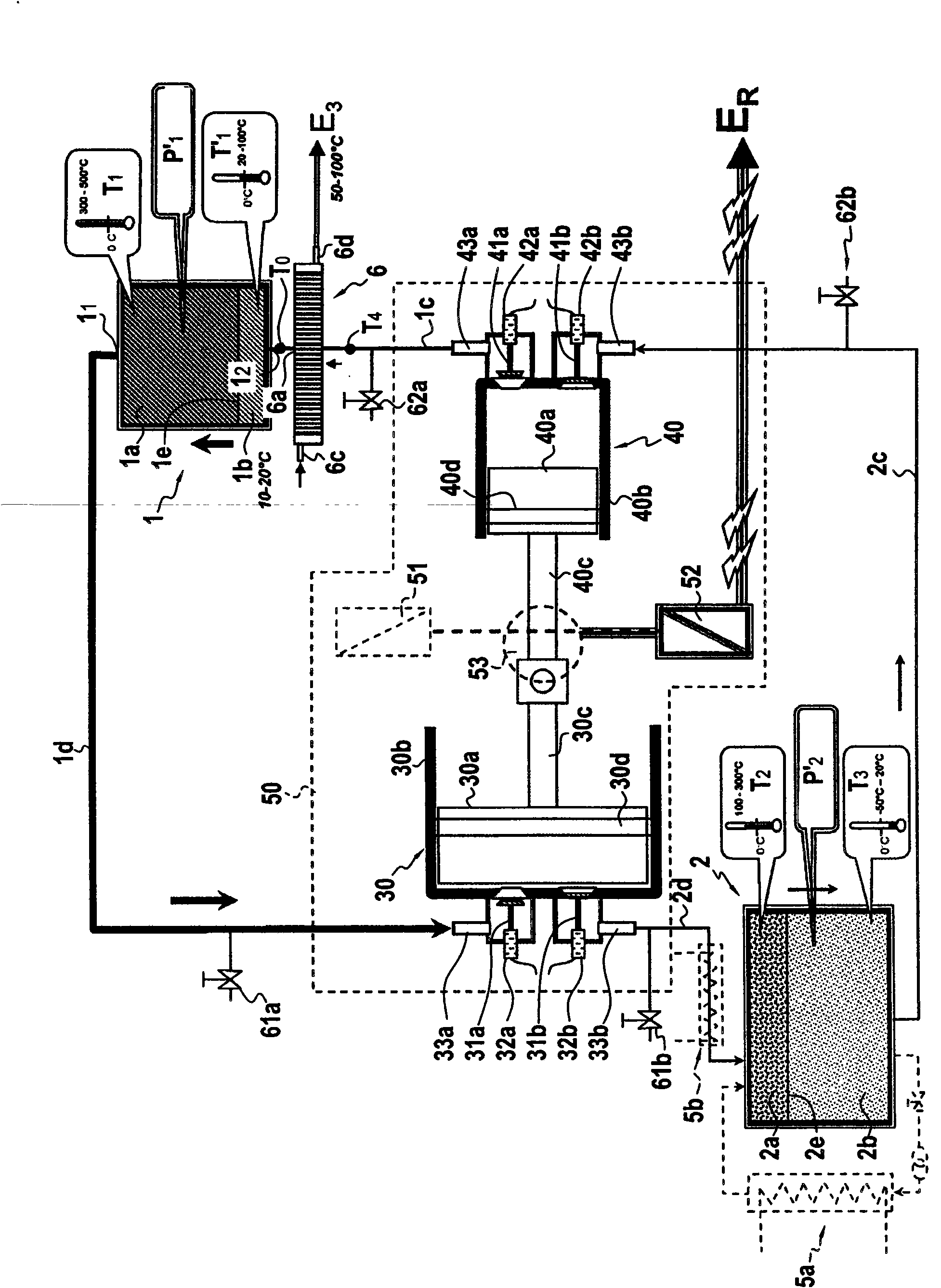

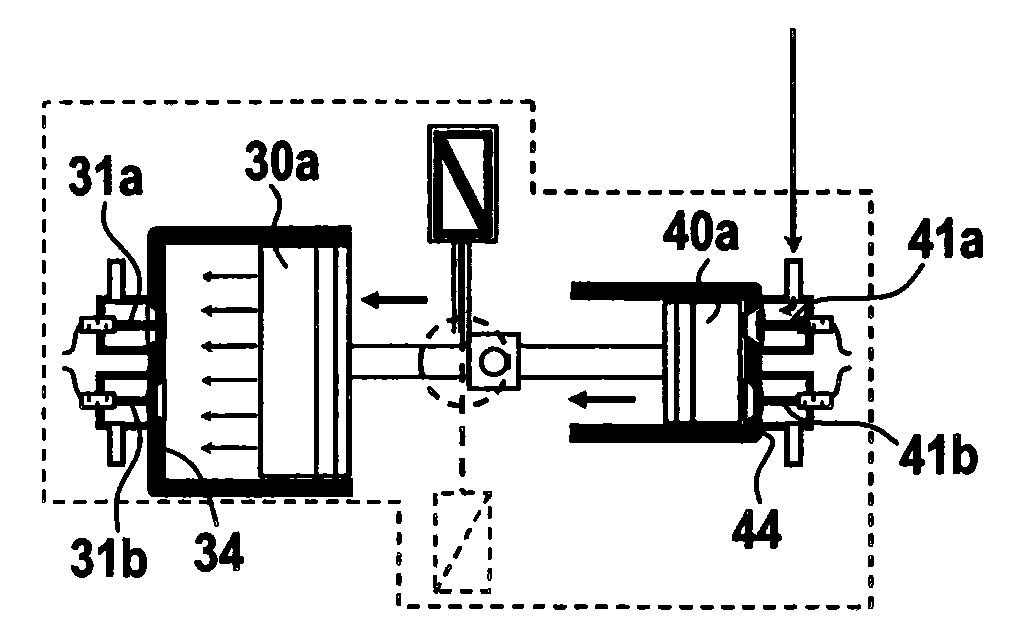

Installation and methods for storing and restoring electrical energy using a piston-type gas compression and expansion unit

The present invention relates to installations and methods for storing and restoring electrical energy comprising two, a first and a second, lagged chambers (1,2) containing porous refractory materials (11) through and between which a gas is circulated by causing the gas to circulate through two, a first and a second, compression / expansion sets (30, 40) interposed in the circuit of pipework (1c, 1d, 2c, 2d) between the upper ends (11, 21) and, respectively, lower ends (12, 22) of said first and second chambers, each compression / expansion set comprising a piston (30a, 40a) to which there is imparted a translational movement in a cylinder (30b, 40b), each set operating in a different mode, either in compression mode or in expansion mode, one of the two compression / expansion sets receiving a gas at a higher temperature than the other set such that, in compression mode, it is operated by an electric motor (41) which consumes electrical energy that is to be stored E1, and in thermodynamic engine mode it operates an electric generator (52) able to restore electrical energy (ER). The electrical energy is stored in the form of heat in masses of refractory products, and this stored thermal potential energy is restored in the form of electrical energy.

Owner:SAIPEM SPA

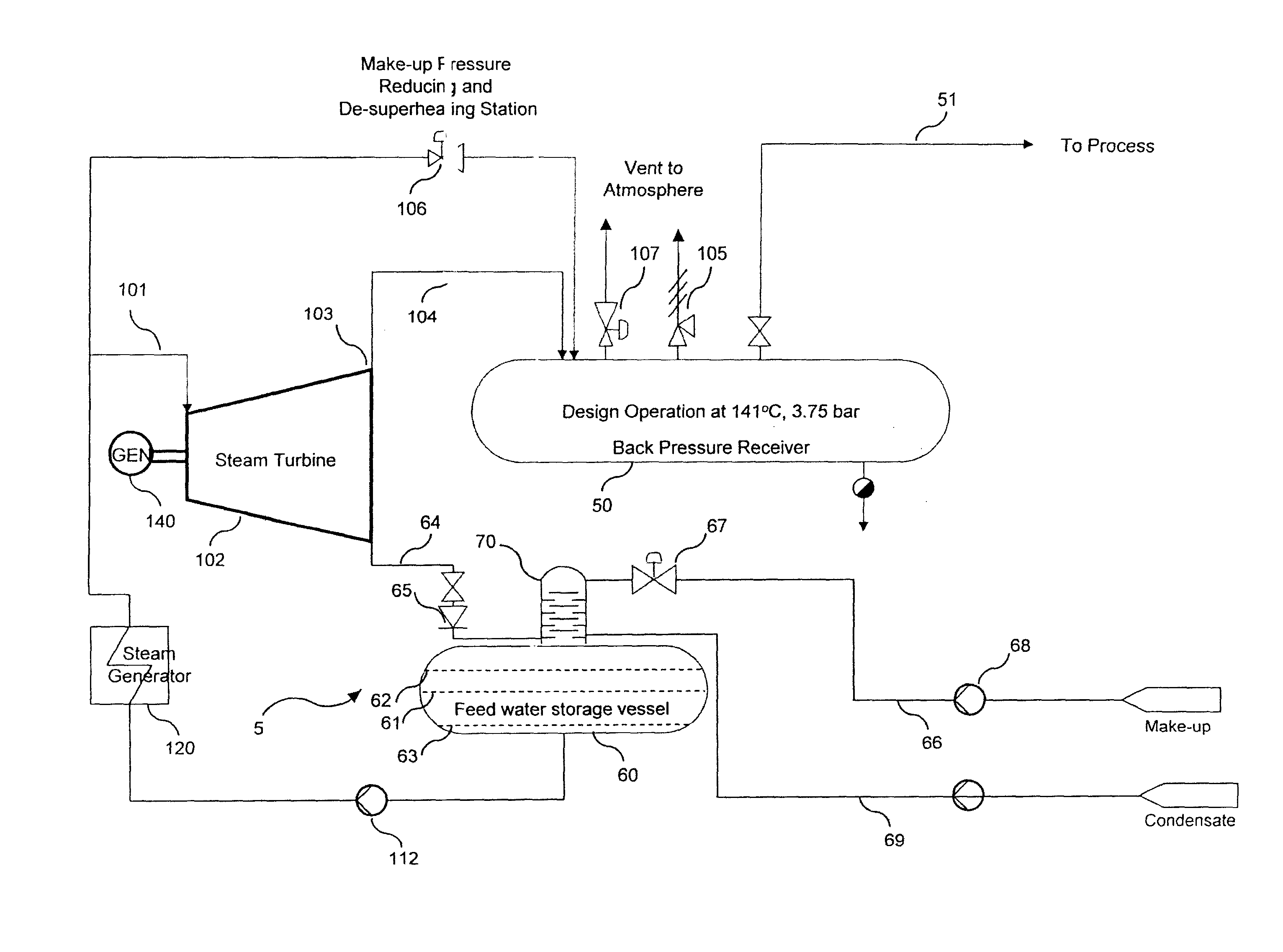

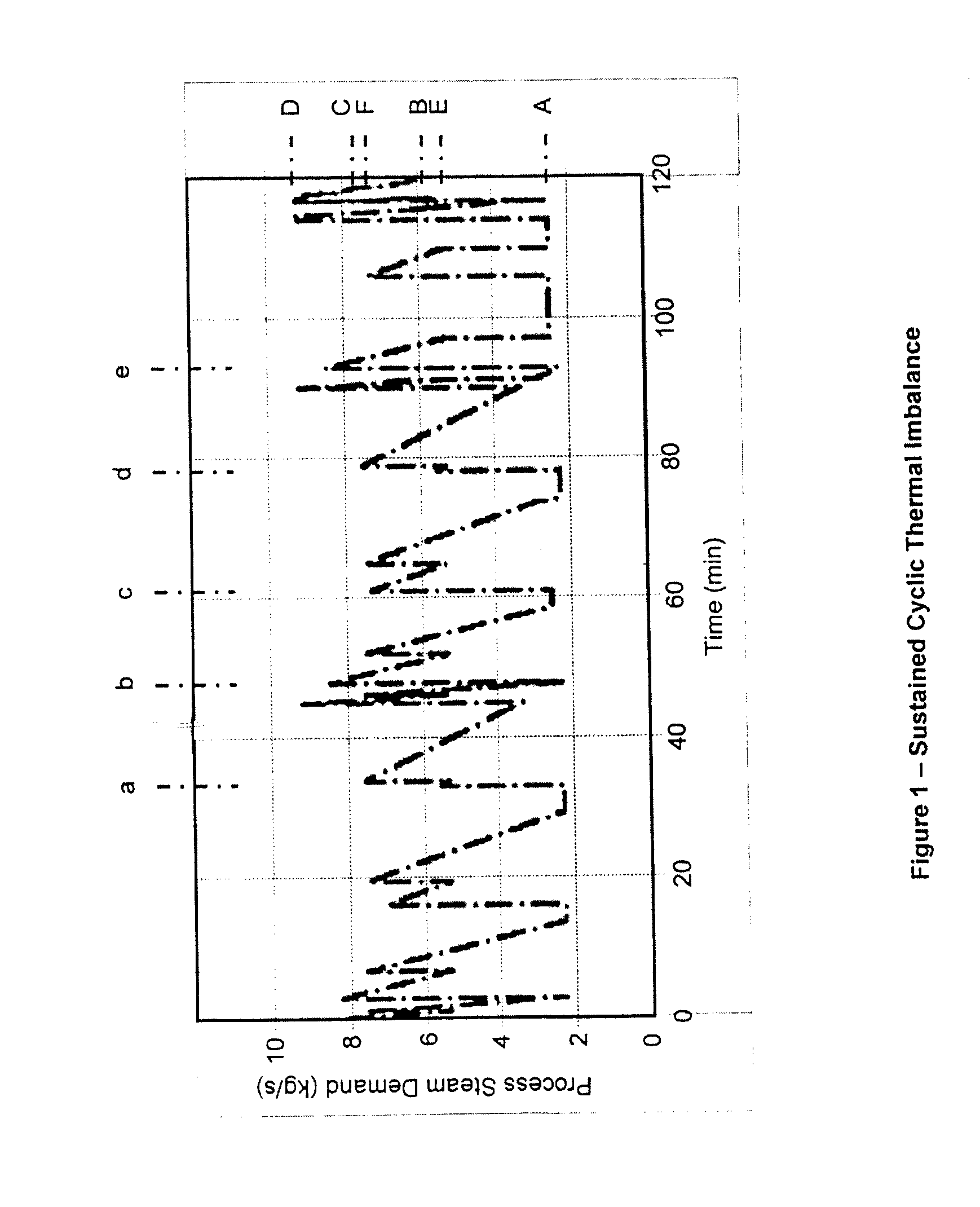

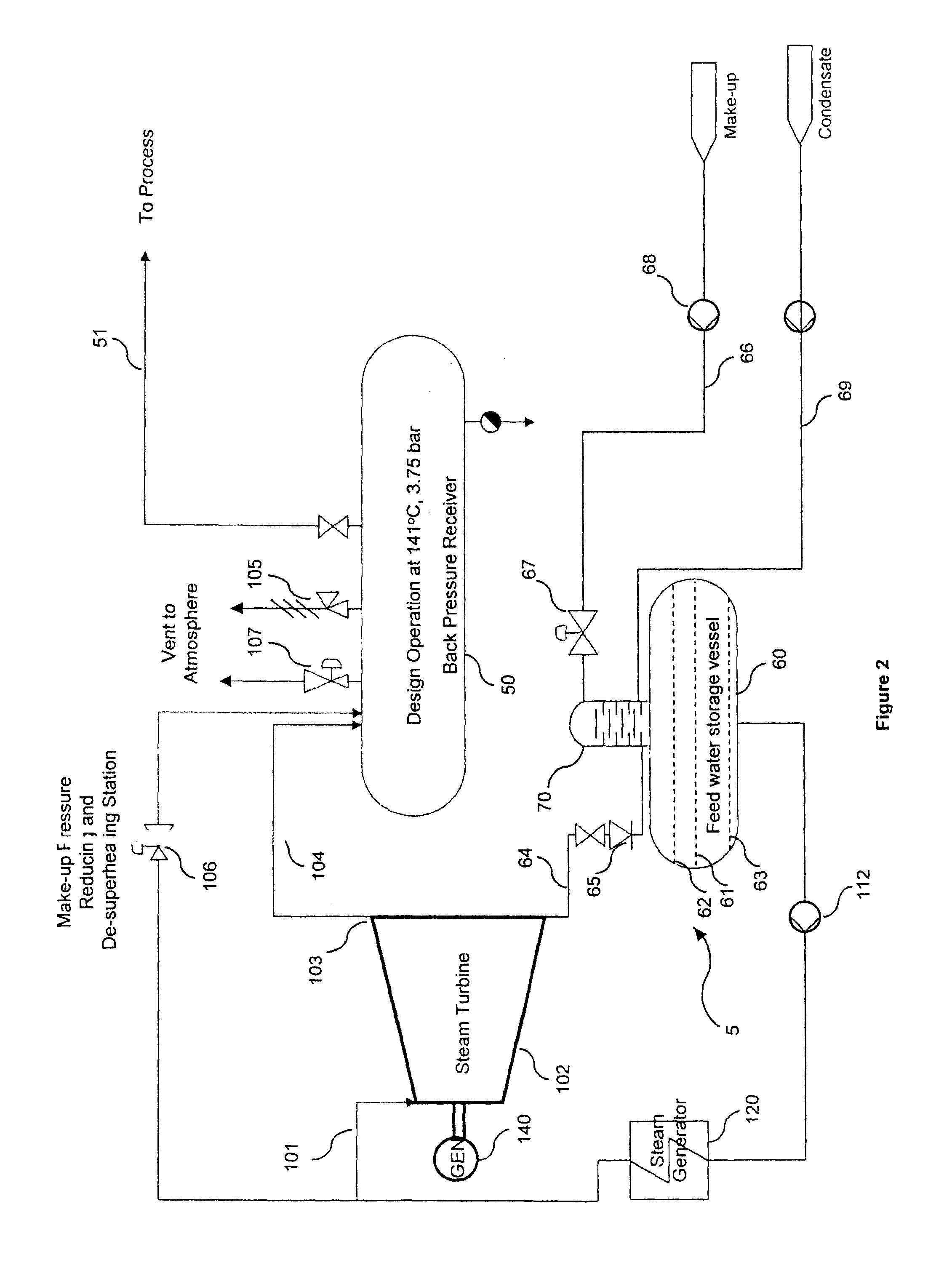

Method and apparatus of producing and utilizing thermal energy in a combined heat and power plant

ActiveUS20140208752A1Reduce flow rateIncrease flow rateSteam useSteam accumulatorsThermal energyThermal force

Method and apparatus for operating a combined heat and power system with greater flexibility, reliability, control and stability, for providing operational flexibility and energy efficiency in operating a combined heat and power plant which includes a backpressure steam engine that expands a high temperature heat source of a thermodynamic fluid to generate mechanical power and discharge its spent heat for a beneficial use comprises a vessel subsystem for the spent heat, said vessel subsystem including: at least one main indirect heat exchange device or vessel (7) in heat exchange communication between its primary space (10) and its secondary space (11). The present invention also discloses the use of a method and apparatus to operate a combined heat and power system.

Owner:PALANISAMY KRISHNA MOORTHY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com