Patents

Literature

44results about How to "Effective deicing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

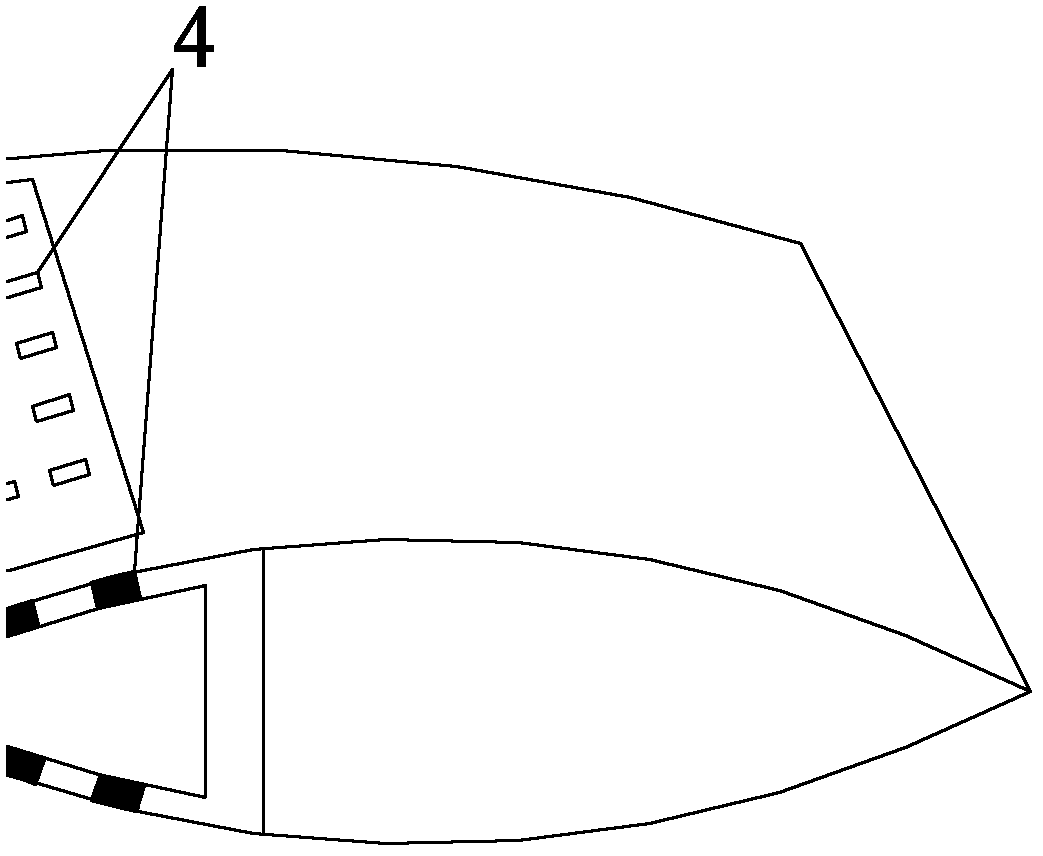

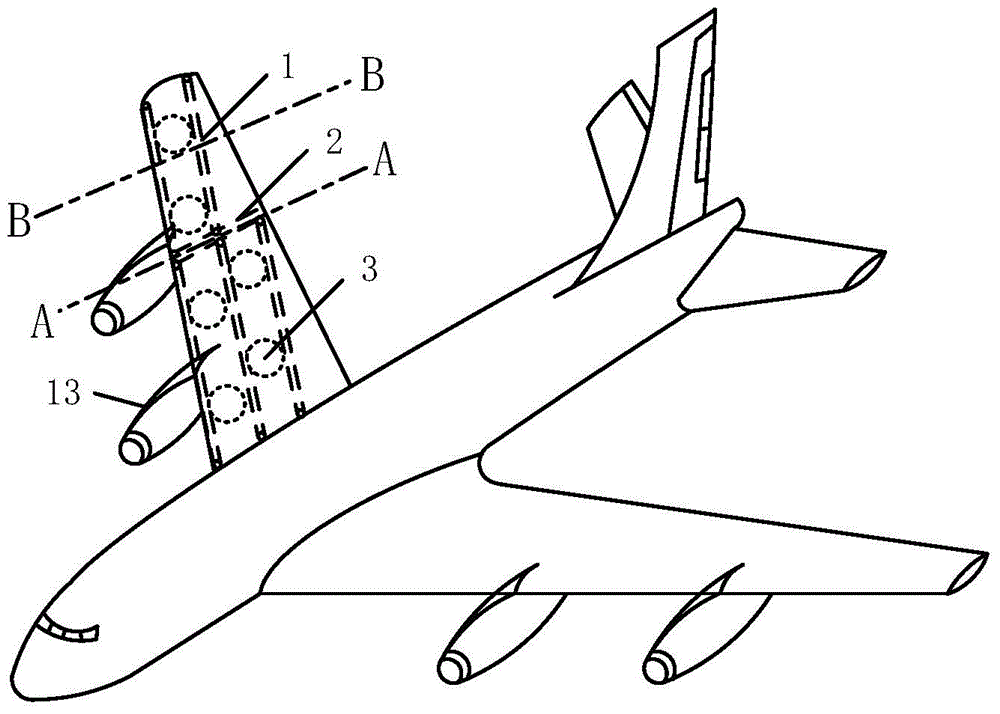

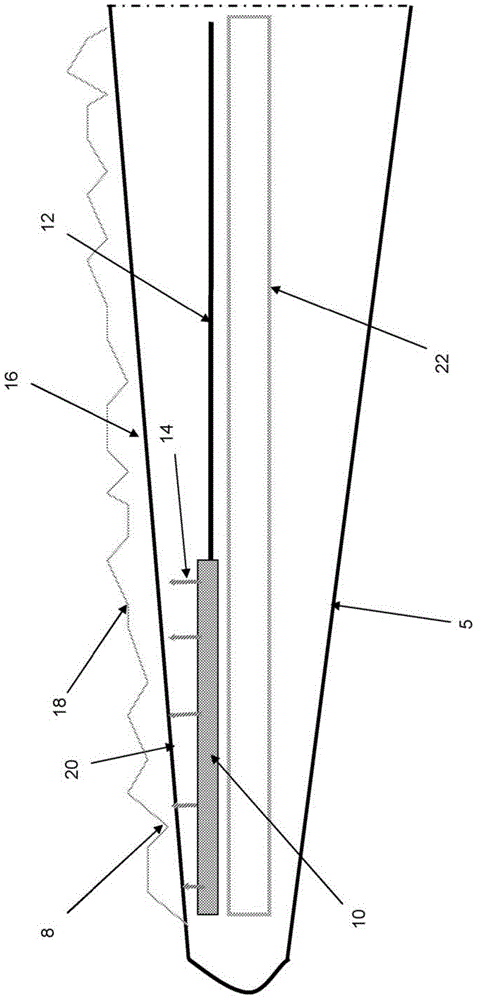

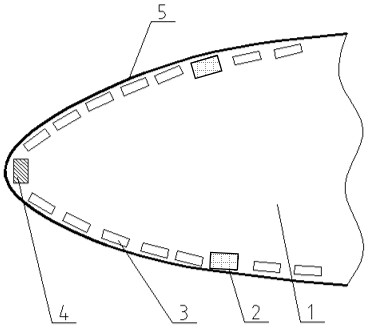

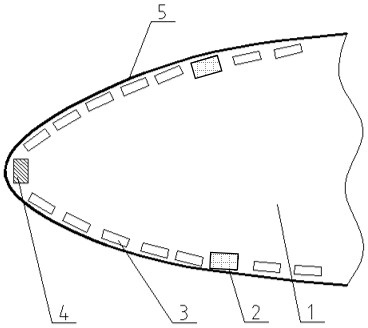

Novel anti-icing and deicing device for airfoils of airplane

InactiveCN102490905AEfficient removalOvercoming Adhesive StrengthDe-icing equipmentsElectricityLeading edge

The invention discloses a novel anti-icing and deicing device for airfoils of an airplane. The device comprises skin, a program controller, an atmospheric temperature sensor and an icing strength annunciator, wherein ultrasonic deicing unit modules are fixedly arranged on the inner surface of the skin, and each ultrasonic deicing unit module comprises a plurality of piezoelectric ceramic transducers; each piezoelectric ceramic transducer is connected with an ultrasonic generator by a connecting cable; the ultrasonic generator is connected with a power supply; and the program controller controls the ultrasonic generator to start and stop according to temperature signals fed back by the atmospheric temperature sensor and controls the power of the ultrasonic generator and the number of the operating ultrasonic deicing unit modules according to ice layer thickness signals fed back by the icing strength annunciator. Therefore, by using the novel anti-icing and deicing device for the airfoils of the airplane, ice layers on the surfaces of the airfoils and the leading edge of an empennage can be effectively removed in real time during the flight of the airplane; the device is efficient, energy-saving, safe and reliable; ice can be thoroughly removed; and the flight safety of the airplane is ensured.

Owner:SOUTHEAST UNIV

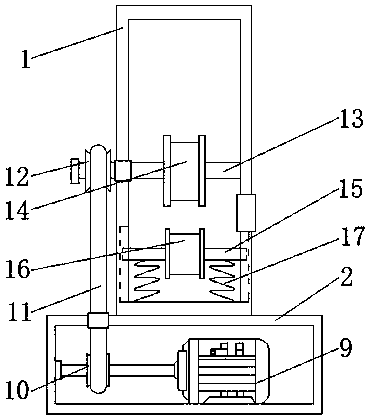

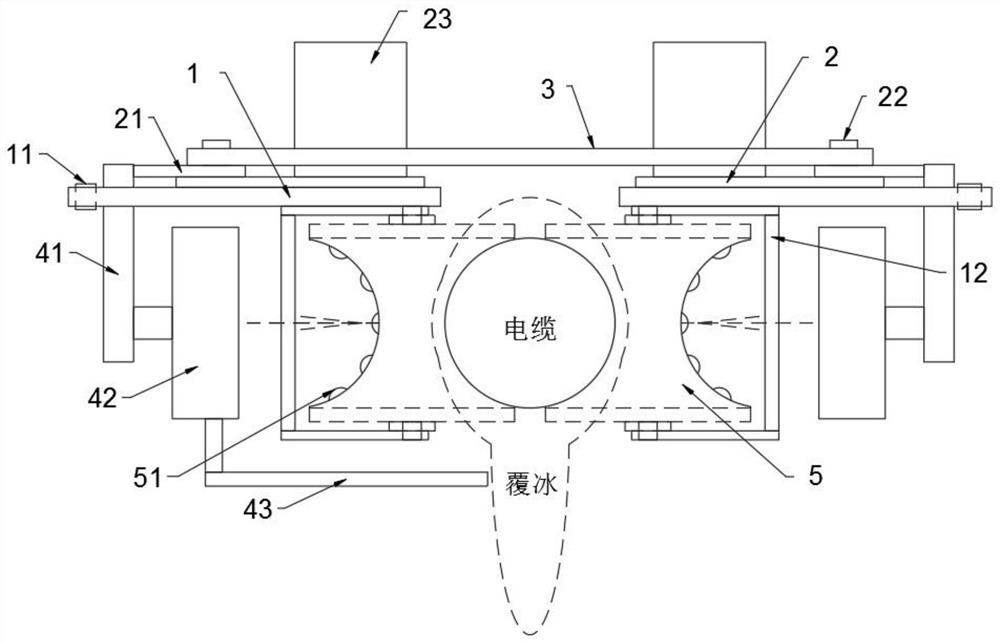

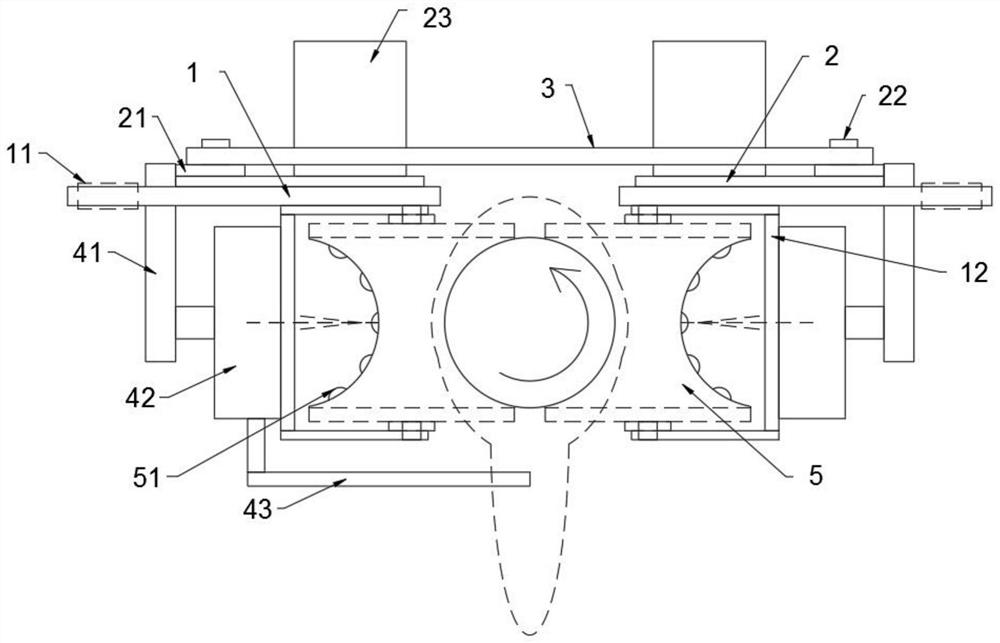

Power cable surface defroster

The invention discloses a power cable surface defroster. The power cable surface defroster comprises a casing, wherein a bottom potion of the casing is fixedly connected with a bottom box, two sides of the bottom box are respectively fixedly connected with a first cross board and a second cross board, a right side of a top portion of the first cross board is fixedly connected with a first heatingboard, a left side of the top portion of the first cross board is fixedly connected with a knocking device, a bottom portion of an inner wall of the bottom box is fixedly connected with a motor, an output shaft of the motor is fixedly connected with a first belt pulley, the surface of the first belt pulley is in transmission connection with a second belt pulley through a belt, and a top portion ofa right side of the casing is in rotation connection with a bottom wheel through an inclined board. The invention relates to the power cable defrosting technology field. The power cable surface defroster is advantaged in that drying processing on cables after defrosting can be effectively carried out, residual water can be prevented from icing to influence use of the cables, unnecessary waste isreduced, cost is saved, the structure is simple, and strong practicality is realized.

Owner:董浩

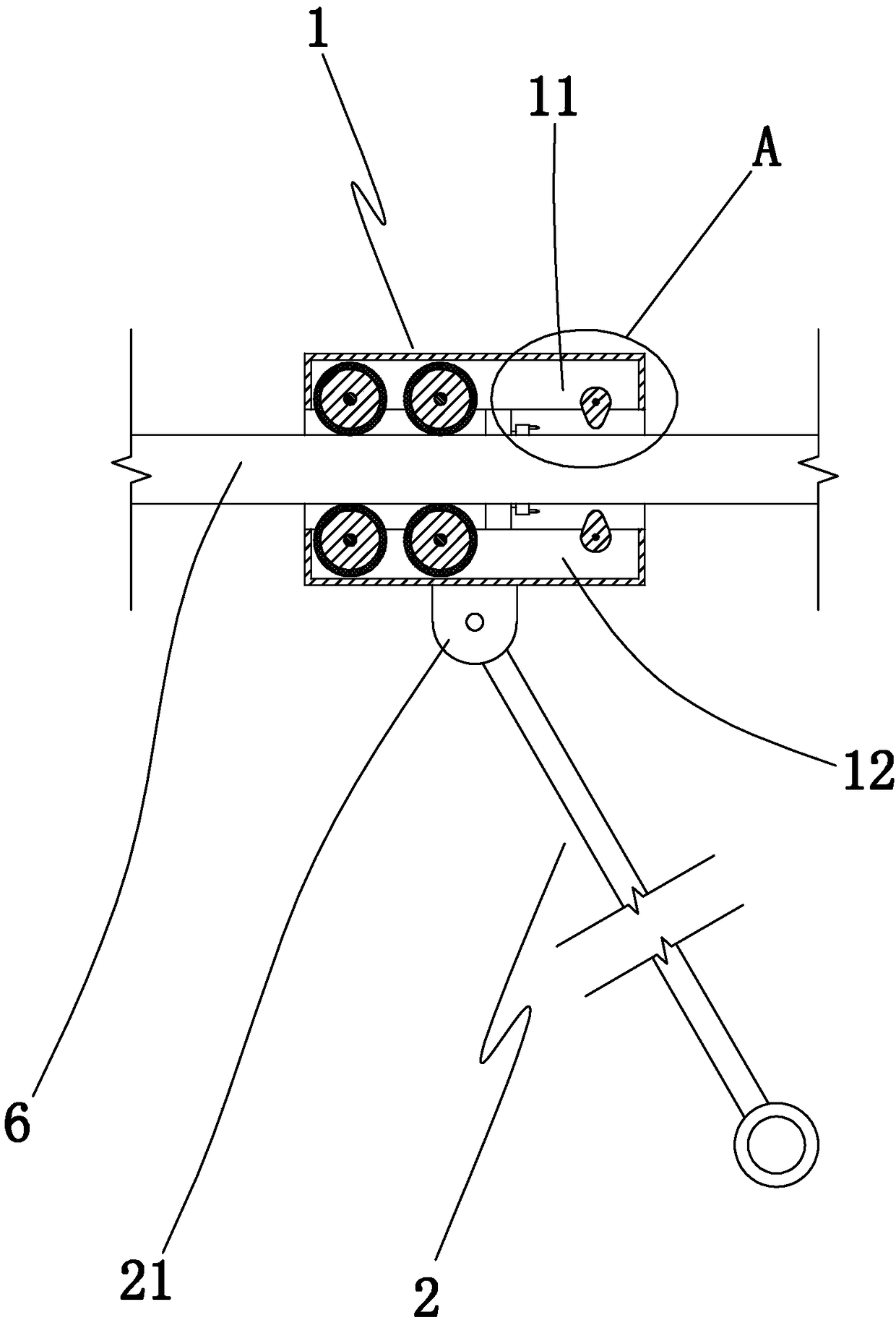

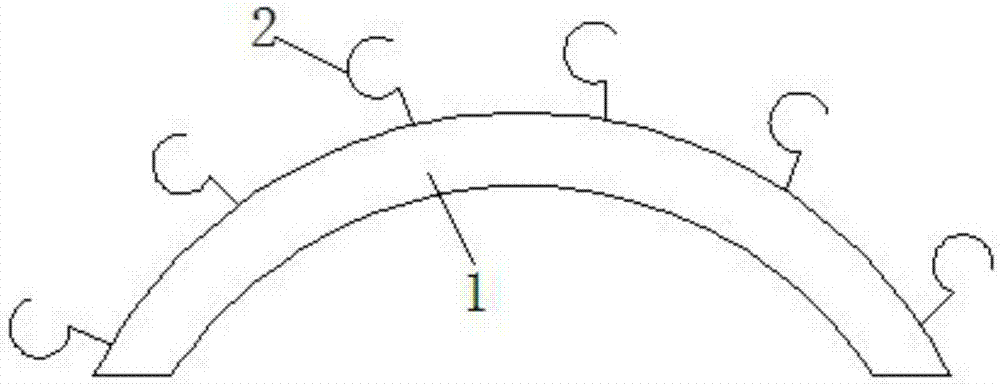

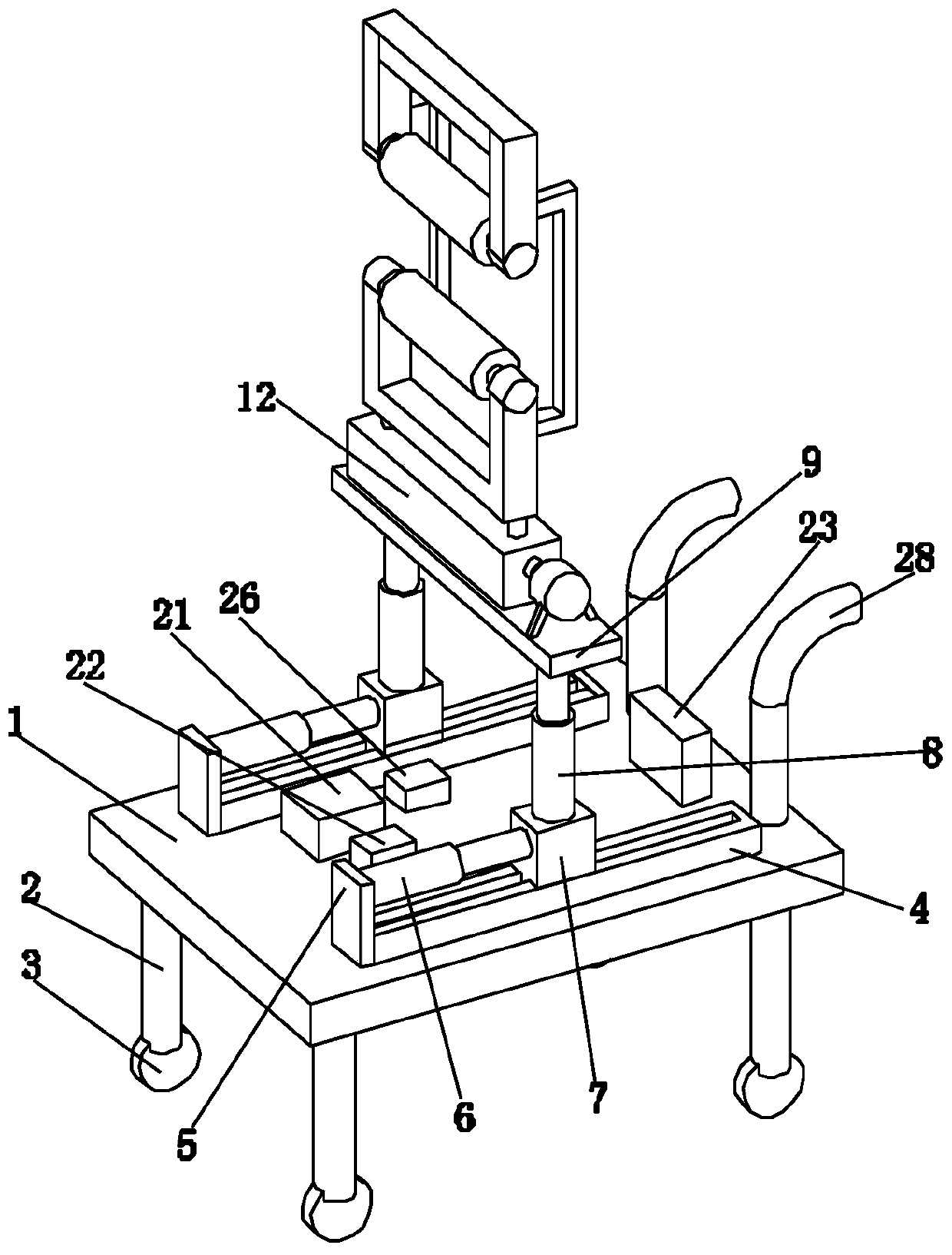

Aerial cable de-icing machine capable of being coated ice-sticking ice resistance agent

The invention provides an ice removing machine for overhead cables which can be applied with ice sticking resistance agent. The ice removing machine is applicable to removing ice for one cable, two cables or four combination cables with a frame for maintaining distance between cables in any adverse weather and geographical environment. The ice removing machine has an applicable type of lever bracket cables and an applicable type of tower cables, wherein the former has an external power source, is small in volume and light in weight and can be conveniently hung to the cables; the latter consists of a dragging device driven by a battery and a motor and a gas ignition assembly with cylinder-shaped fire-jet head, can be conveniently hung to the cables to remove ice rapidly by comprehensive function of thermal force and mechanical force and can stand by on the cables for a long time and operate repeatedly according to the remote instructive of human; and the ice sticking resistance agent can be coated on the cables in advance, thus leading the cables to be not easy to ice up and the ice to be removed easily even if the cables are iced up.

Owner:张福生

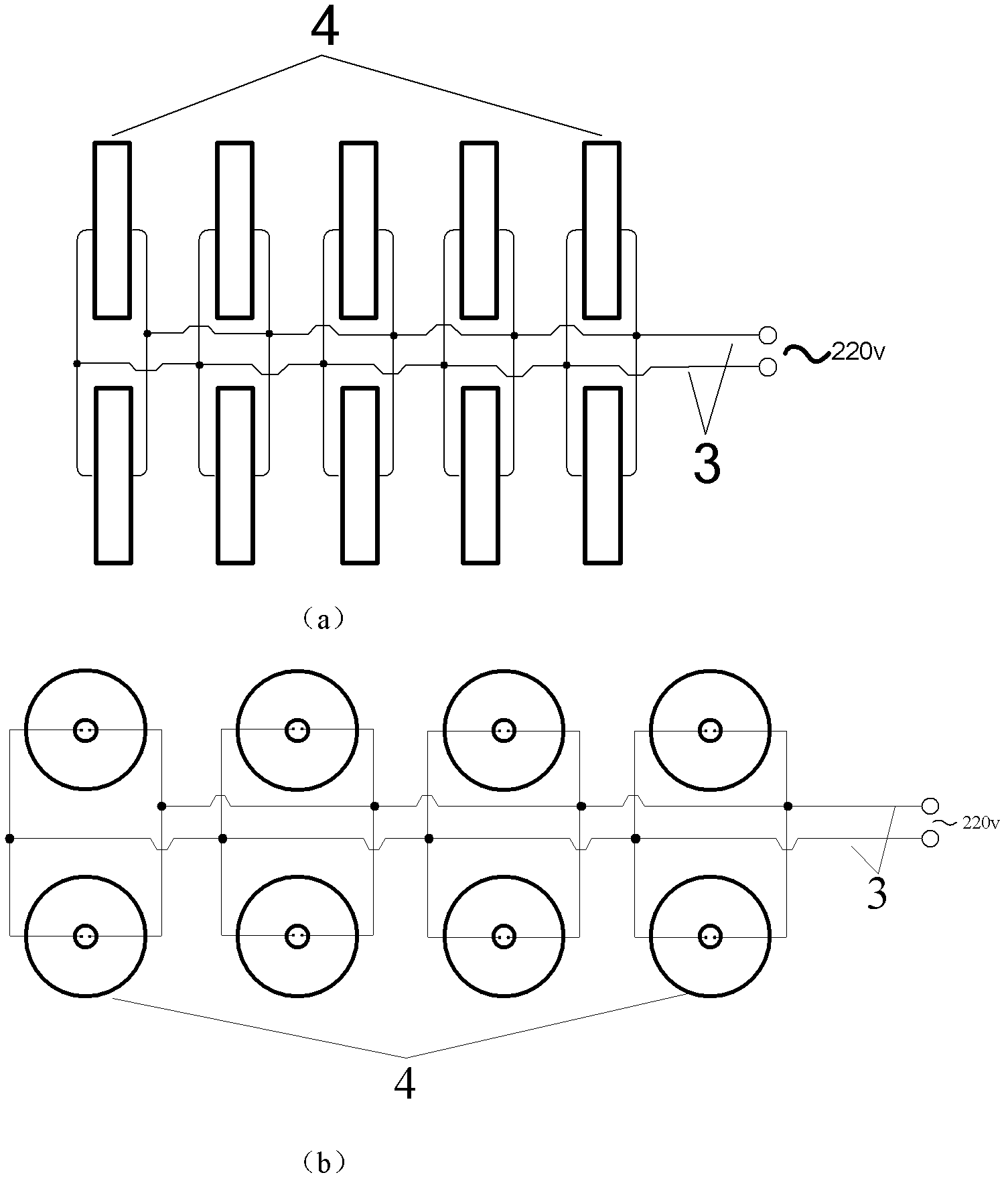

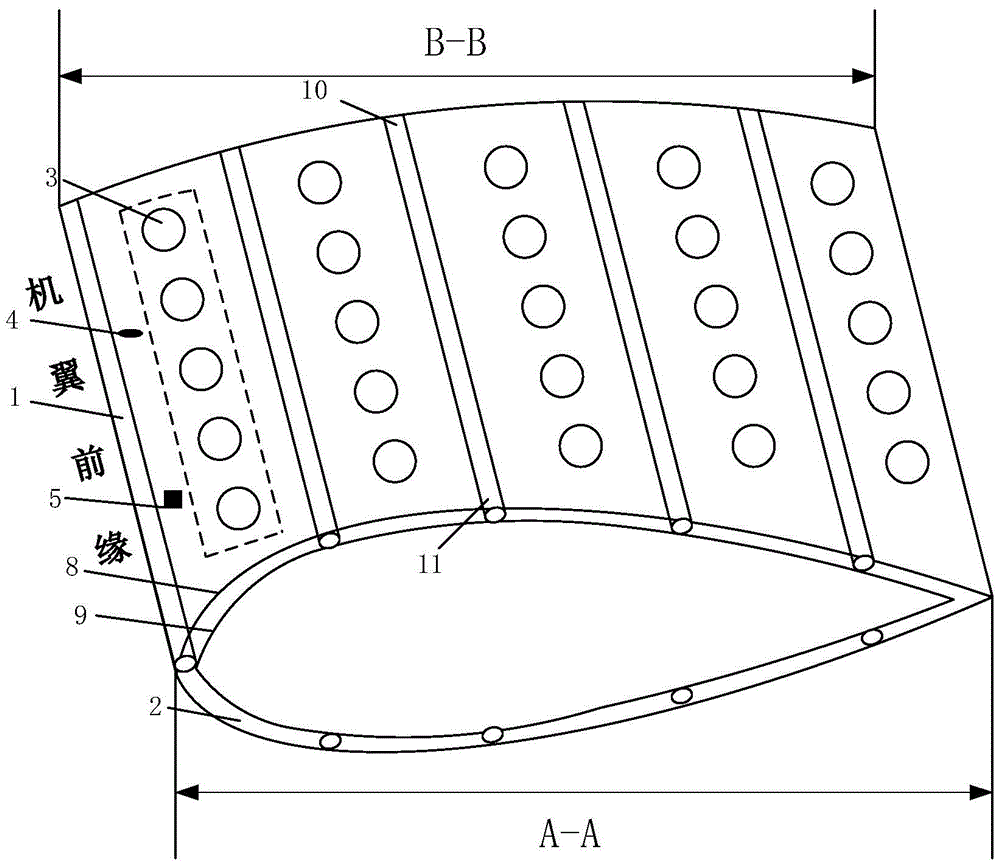

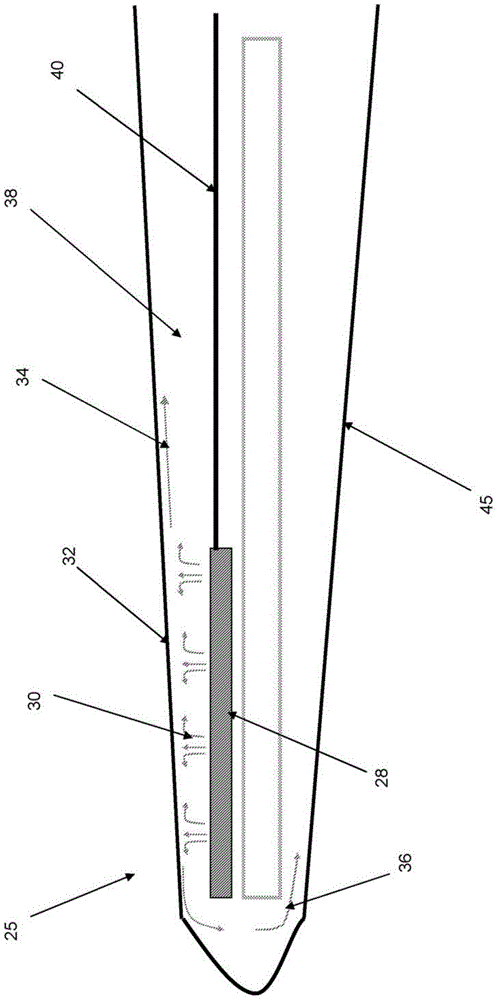

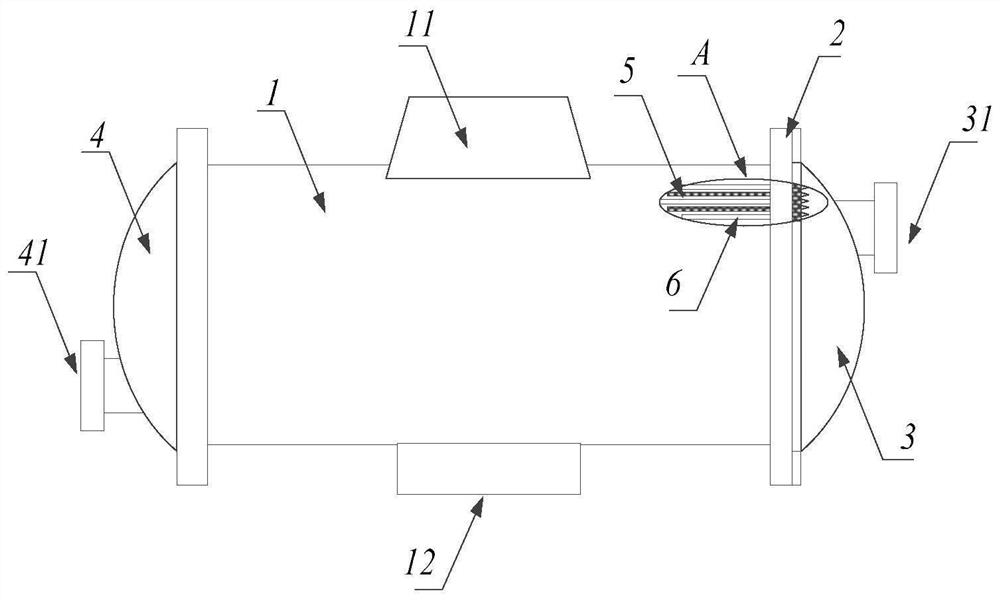

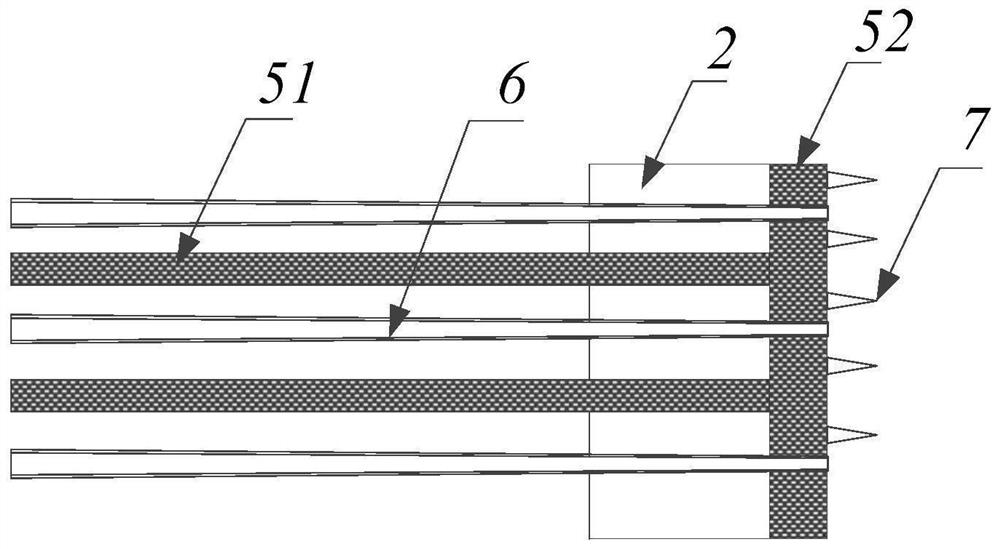

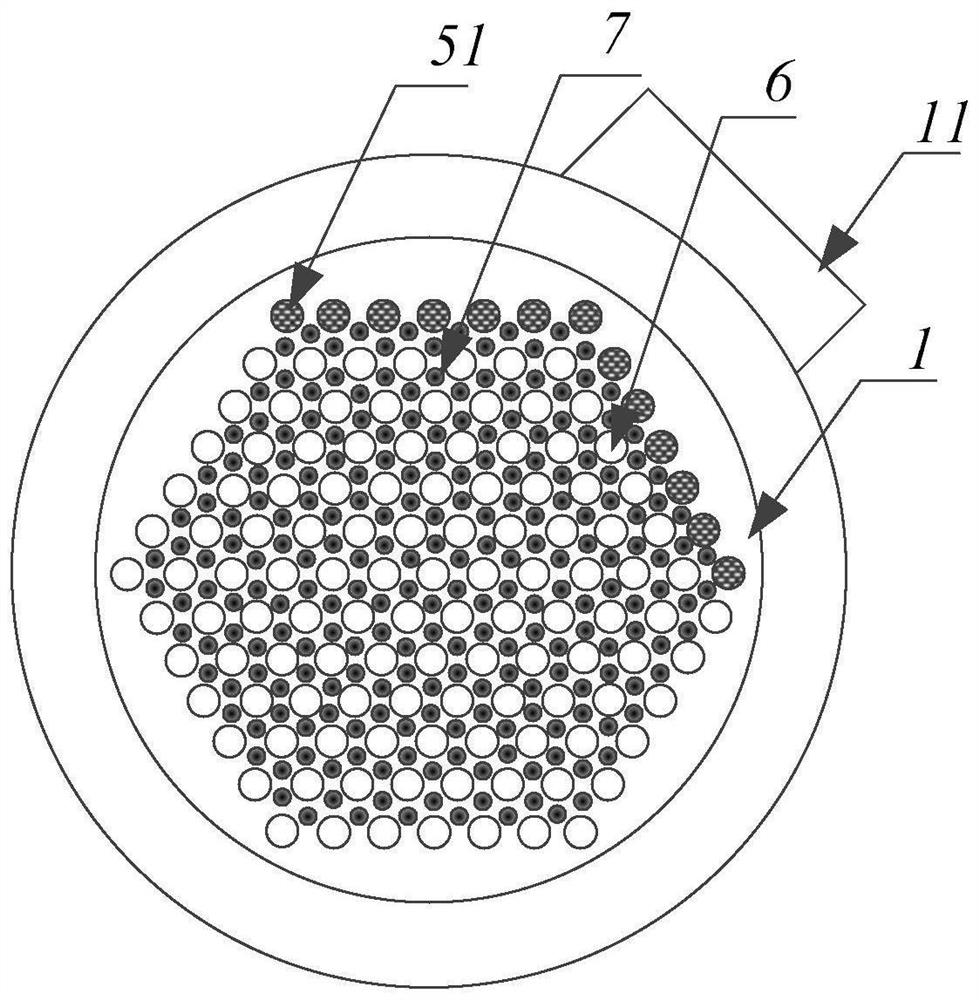

Heat pipe and ultrasonic wave combined ice preventing and removing device and method utilizing waste heat of aircraft engine

InactiveCN105691620APrevent freezingStable anti-icing temperatureDe-icing equipmentsEvaporationAtmospheric temperature

The invention provides a heat pipe and ultrasonic wave combined ice preventing and removing device and method utilizing waste heat of an aircraft engine. The device comprises a heat pipe ice-preventing system, an ultrasonic oscillation ice removing system, a program control system, an atmospheric temperature sensor and an icing strength annunciator. The heat pipe ice-preventing system comprises a communicating pipe installed at the tail portion of the engine to absorb exhaust waste heat and a heat pipe bank bundle with an evaporation section connected with the communicating pipe. The ultrasonic oscillation ice removing system comprises an ultrasonic generator and an ultrasonic transducer unit connected with the output end of the ultrasonic generator through a connecting cable. The program control system automatically controls on and off between the heat pipe bank bundle and the communicating pipe and starting or stopping of the ultrasonic generator according to a temperature signal and an icing strength signal. By means of the synergistic effect of heat pipes and ultrasonic waves, preventing and removing can be combined, compared with a method for removing ice simply through ultrasonic waves, the icing phenomenon of wings is greatly reduced, the flying stability of an aircraft is ensured, and a system is safe and reliable.

Owner:NANJING NORMAL UNIVERSITY

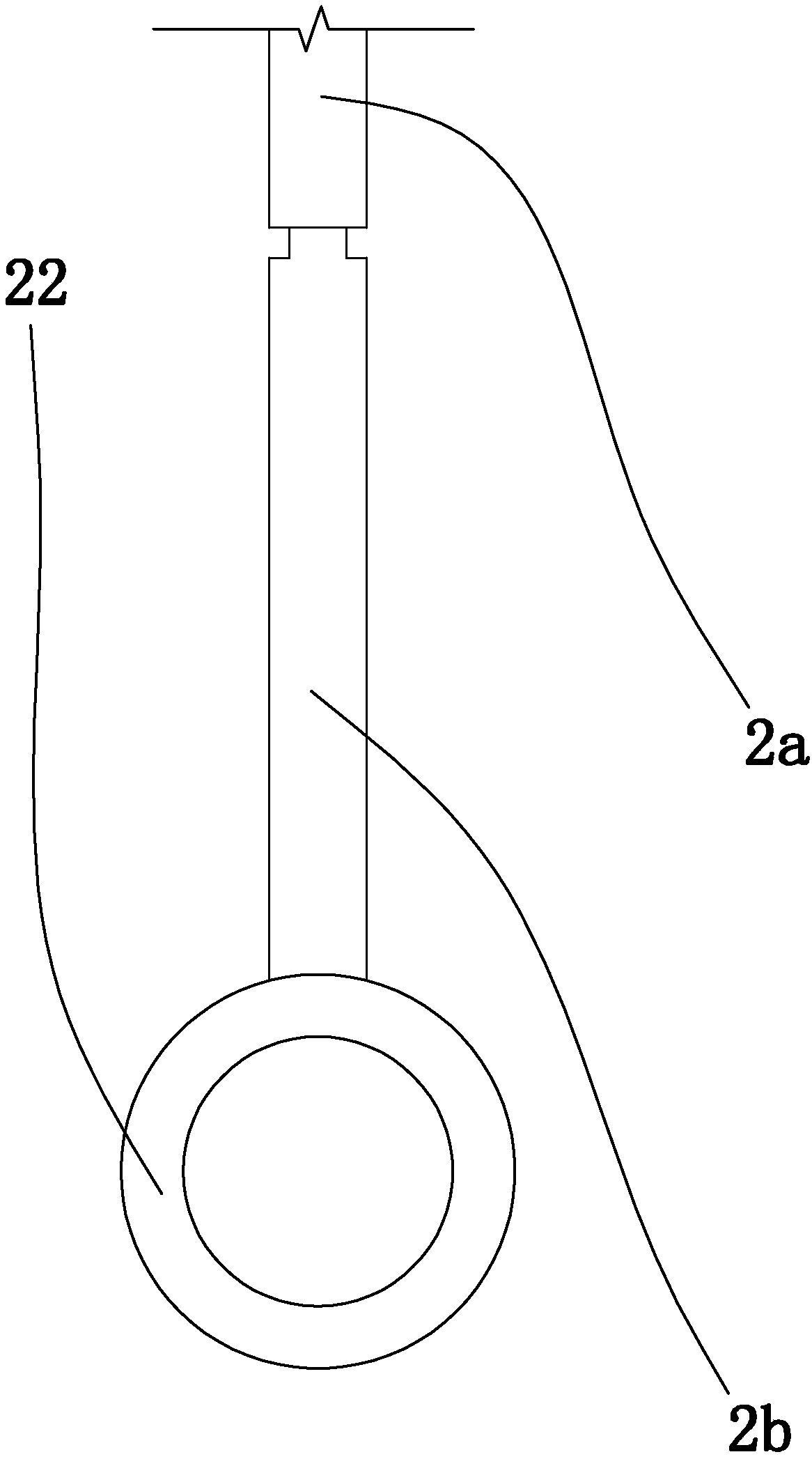

Short-range cable ice removal device

ActiveCN109473932ADeicing continuousEffective deicingOverhead installationEngineeringMechanical engineering

Owner:国网浙江省电力有限公司磐安县供电公司 +1

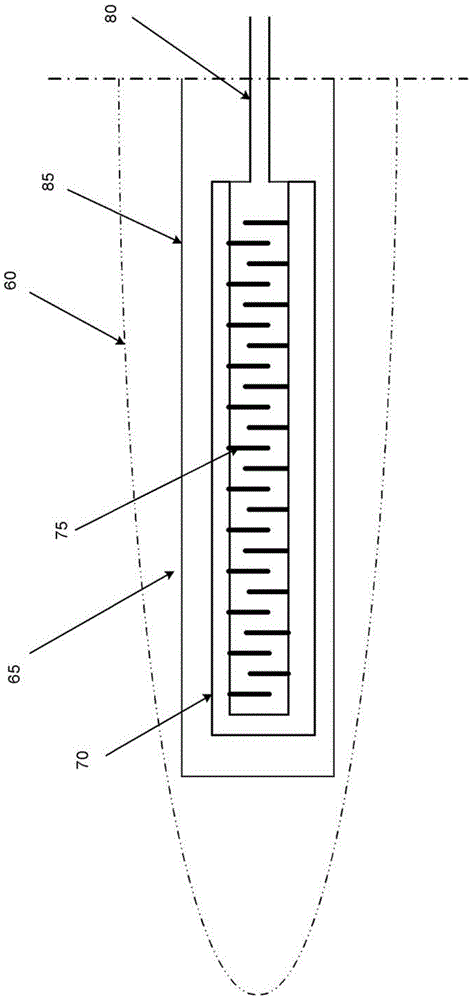

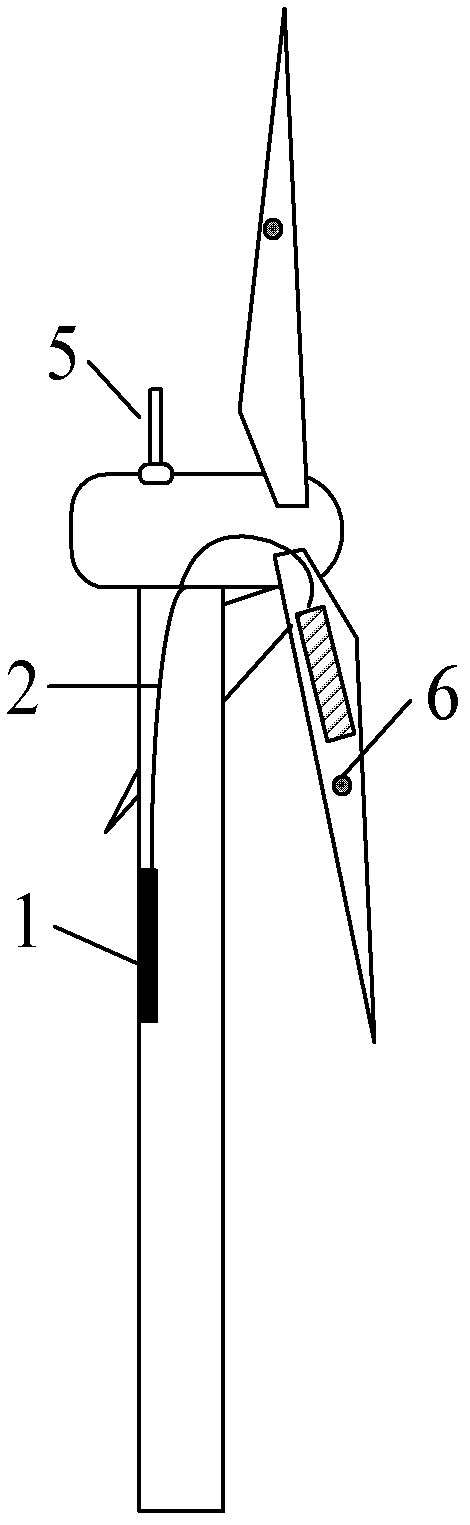

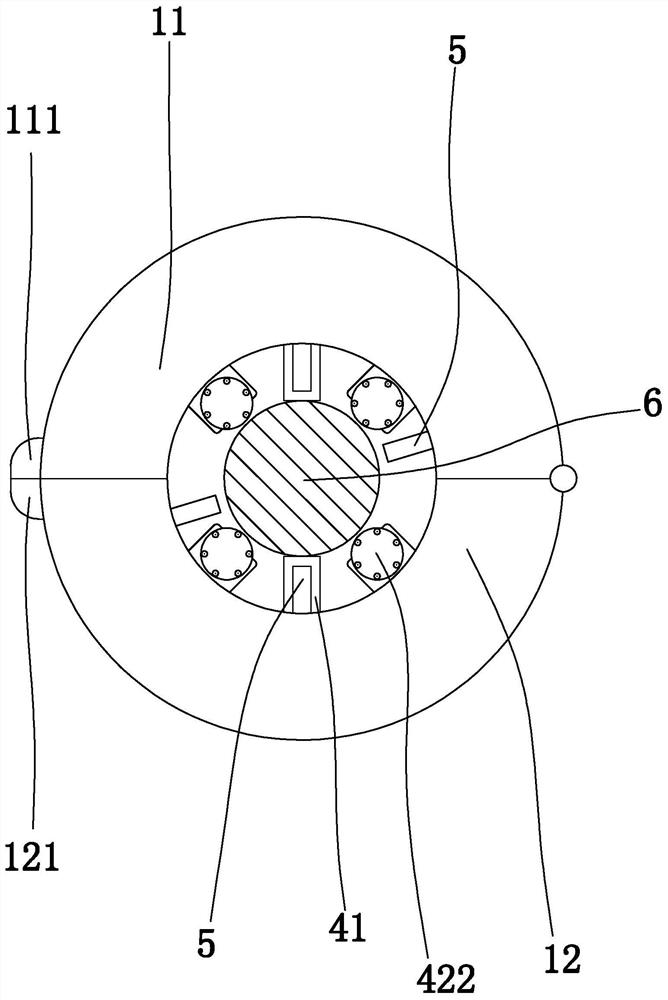

De-icing of a wind turbine blade

ActiveCN104160147AAdditional weight is minimizedEffective deicingEngine fuctionsEfficient propulsion technologiesTurbine bladeEngineering

A heating assembly for a blade of a wind turbine generator, said heating assembly comprising: a heat reservoir positioned within a cavity of said blade, said heat reservoir in communication with a heat source; said heat reservoir including a plurality of orifices for venting hot air from said heat reservoir.

Owner:VESTAS WIND SYST AS

Railway tunnel deicing device

InactiveCN106868955ASimple structureSafe drivingClimate change adaptationRailway tracksRailway tunnelSalt water

The invention discloses a railway tunnel deicing device. The railway tunnel deicing device comprises a deicing device body. Hooks are uniformly fixed to the upper surface of the deicing device body. An inner cavity of the deicing device body is provided with a salt water storage tank. The bottom end of the salt water storage tank is connected with one end of a circulating pump through a connecting pipe, and the other end of the circulating pump is connected with the top end of an atomization device. The left end of the atomization device is connected with a salt water connecting pipe through a connecting pipe. An atomization head is further connected to the salt water connecting pipe through a connecting pipe. The inner cavity of the deicing device body is further provided with a heating device. The heating device is connected with one end of an air blower through a connecting pipe, and the other end of the air blower extends to the outside of the deicing device body through a connecting pipe. A hot air connecting pipe is connected to the right end of the heating device through a connecting pipe. An air outlet nozzle is further connected to the hot air connecting pipe through a connecting pipe. The railway tunnel deicing device is simple in structure and higher in practicability.

Owner:CHONGQING DAYANJIE ADVERTISING CO LTD

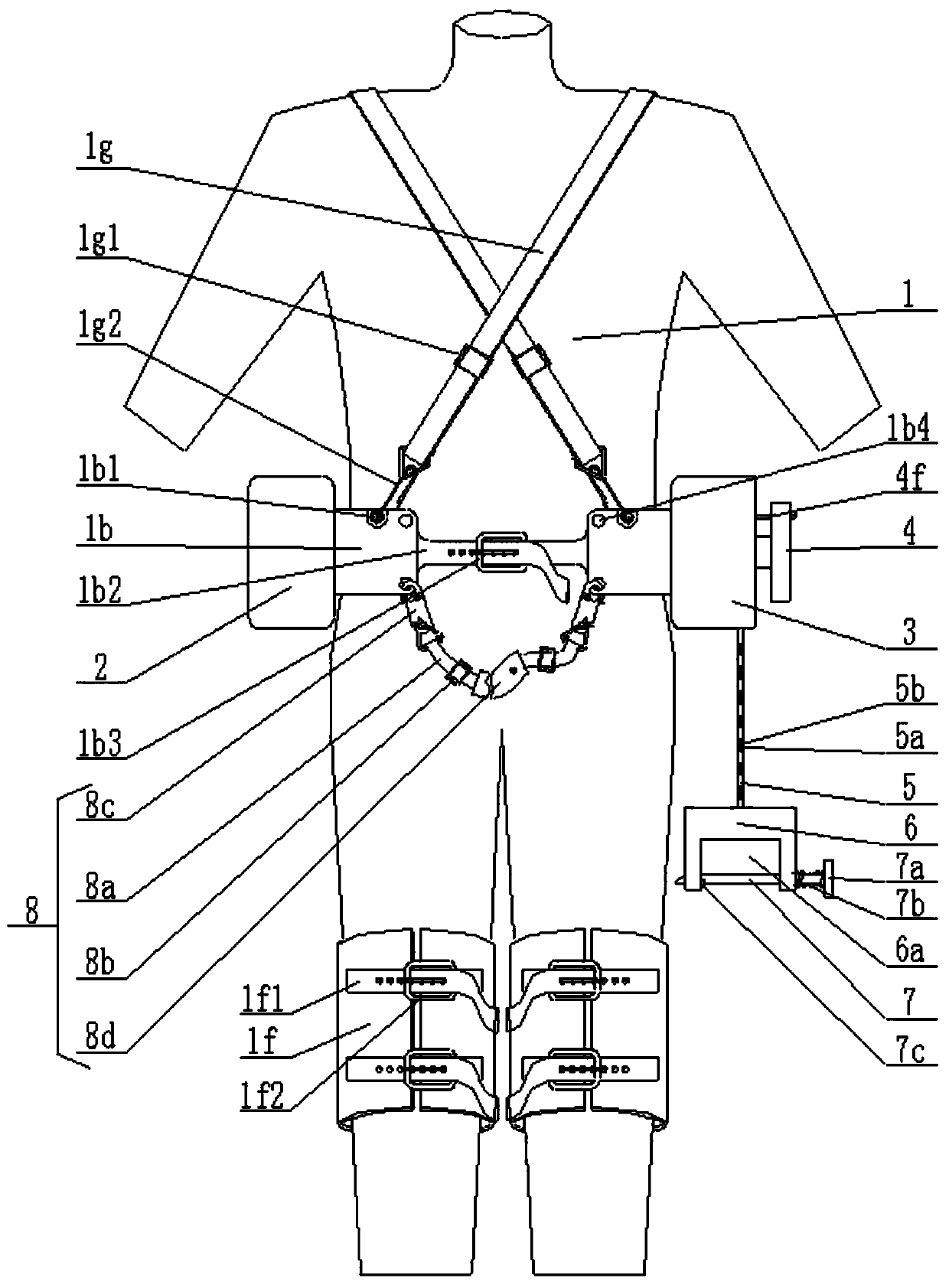

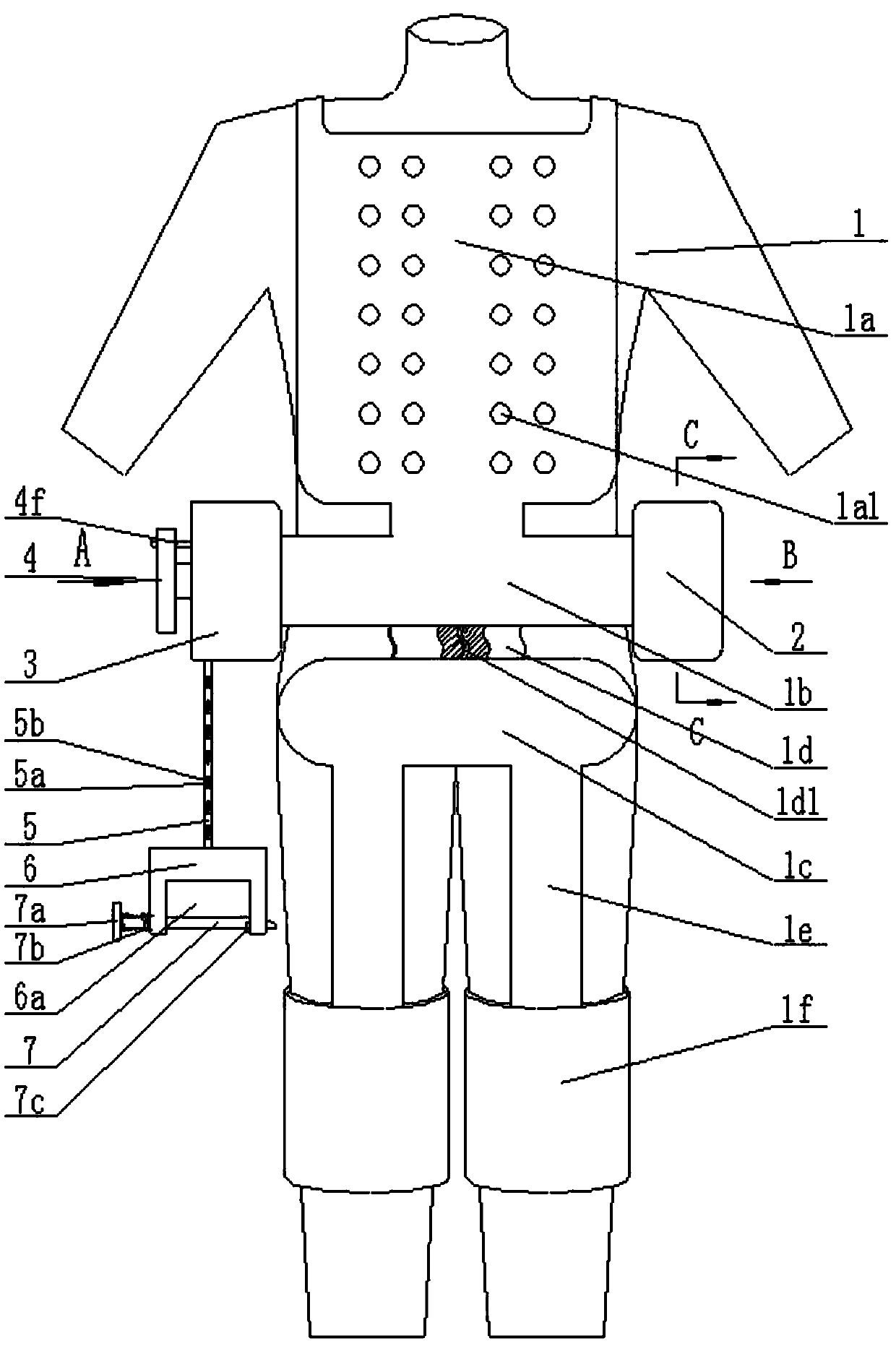

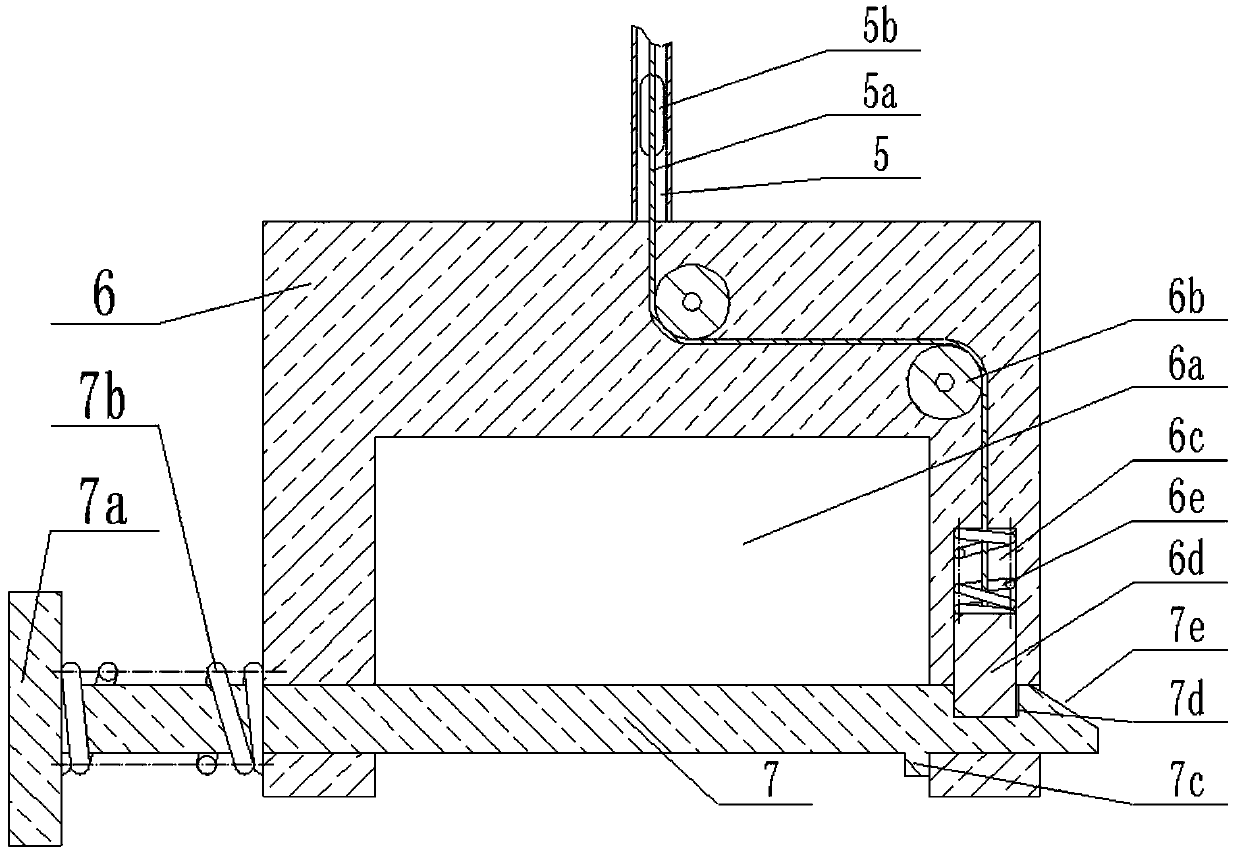

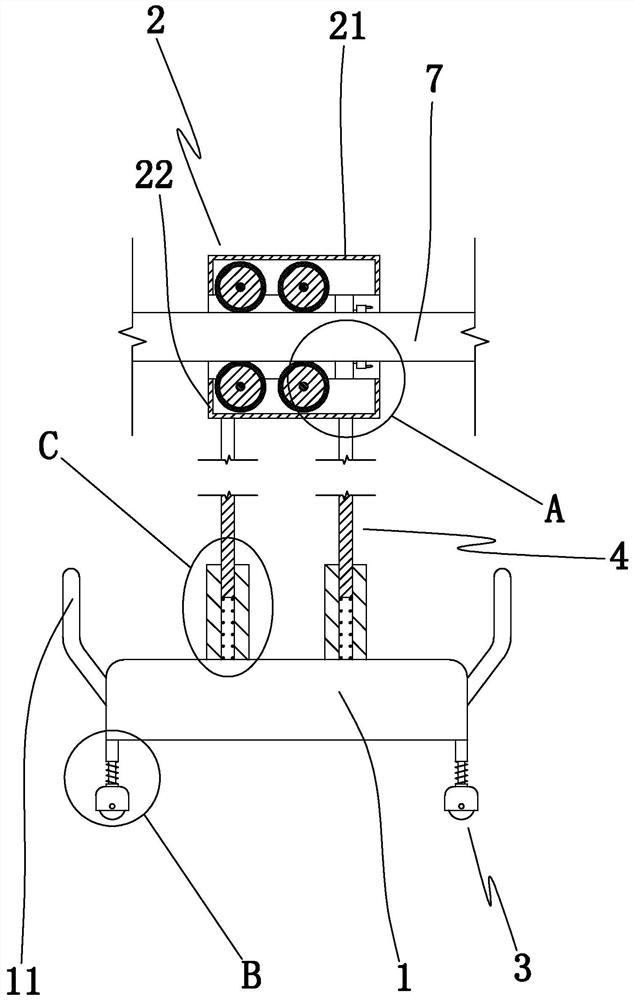

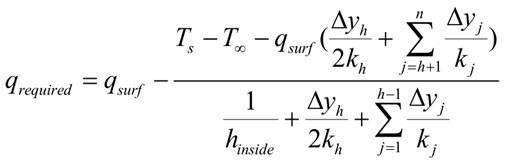

Omni-directional safety belt and application method thereof

The invention relates to an omni-directional safety belt and an application method of the omni-directional safety belt. The omni-directional safety belt comprises a protective coat, a control box, a wire box, a safety rope, a clamping lock, pole encircling belts and the like. The control box and the wire box are fixedly placed on a waist belt, the safety rope is arranged inside the wire box, the clamping lock is arranged at the tail end of the safety rope, and the pole encircling belts are connected with the waist belt. The omni-directional safety belt comprises the two pole encircling belts,when a user encounters an obstacle in the pole climbing process, the situation that the two ends of one pole encircling belt are fixedly connected with the waist belt can be guaranteed, and the safetycoefficient is improved. When an operator falls, the protective coat can be inflated to expand, a stop rod can timely clamp a wire pulley, and multiple protection is provided for the operator. Meanwhile, a manager can see operation data of the operator on the computer, the operation data include the time of working at heights, the operation altitude and the situation whether the falling phenomenon happens or not, and the rescue is timely organized advantageously.

Owner:国网山东省电力公司莱西市供电公司

cable deicer

ActiveCN109473933BEffective deicingReasonable structureOverhead installationElectric machineryStructural engineering

Owner:国网浙江省电力有限公司磐安县供电公司 +1

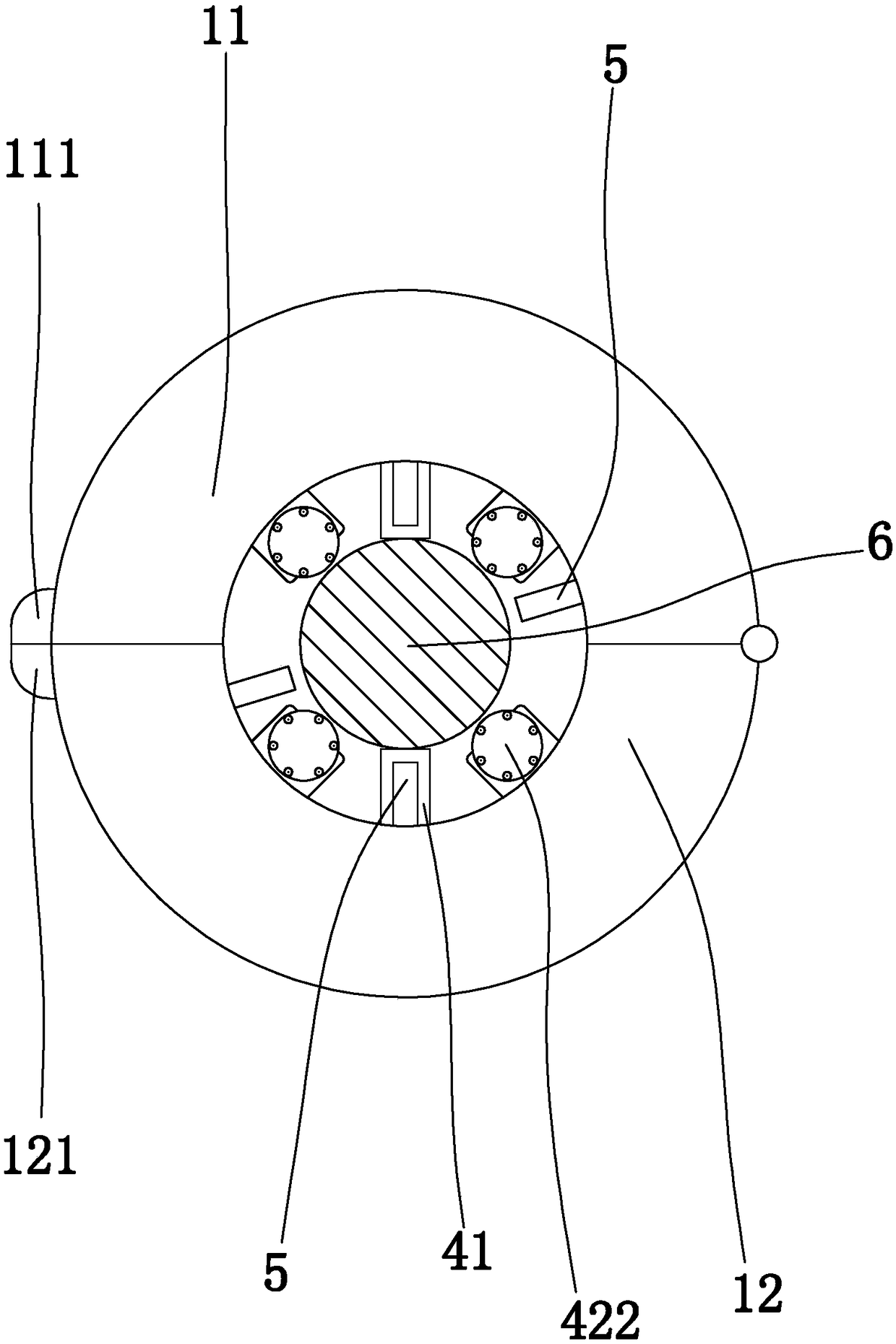

Multiple generator wind turbine

InactiveCN101627208AImprove lightning protectionEasy accessEngine manufactureFinal product manufactureLow speedTurbine

A multiple generator wind turbine employs a single blade arrangement to drive multiple generators. The multiple generators are preferably substantially tubular and can all be mounted on one side of the turbine support structure or can be divided, preferably symmetrically, on opposite sides of the support structure. Preferably, a single drive blade arrangement drives a rotor of a first generator and a shaft connects the first generator to a rotor of a second generator. Additionally, a clutch can be placed in the drive train between two generators to allow turbine operation at lower speeds. The substantially tubular nature of the turbine allows easy access by humans to the interior of the wind turbine and provides ready airflow through the wind turbine to the hub and blades for cooling of equipment therein and / or deicing of the blades.

Owner:WILIC SARL

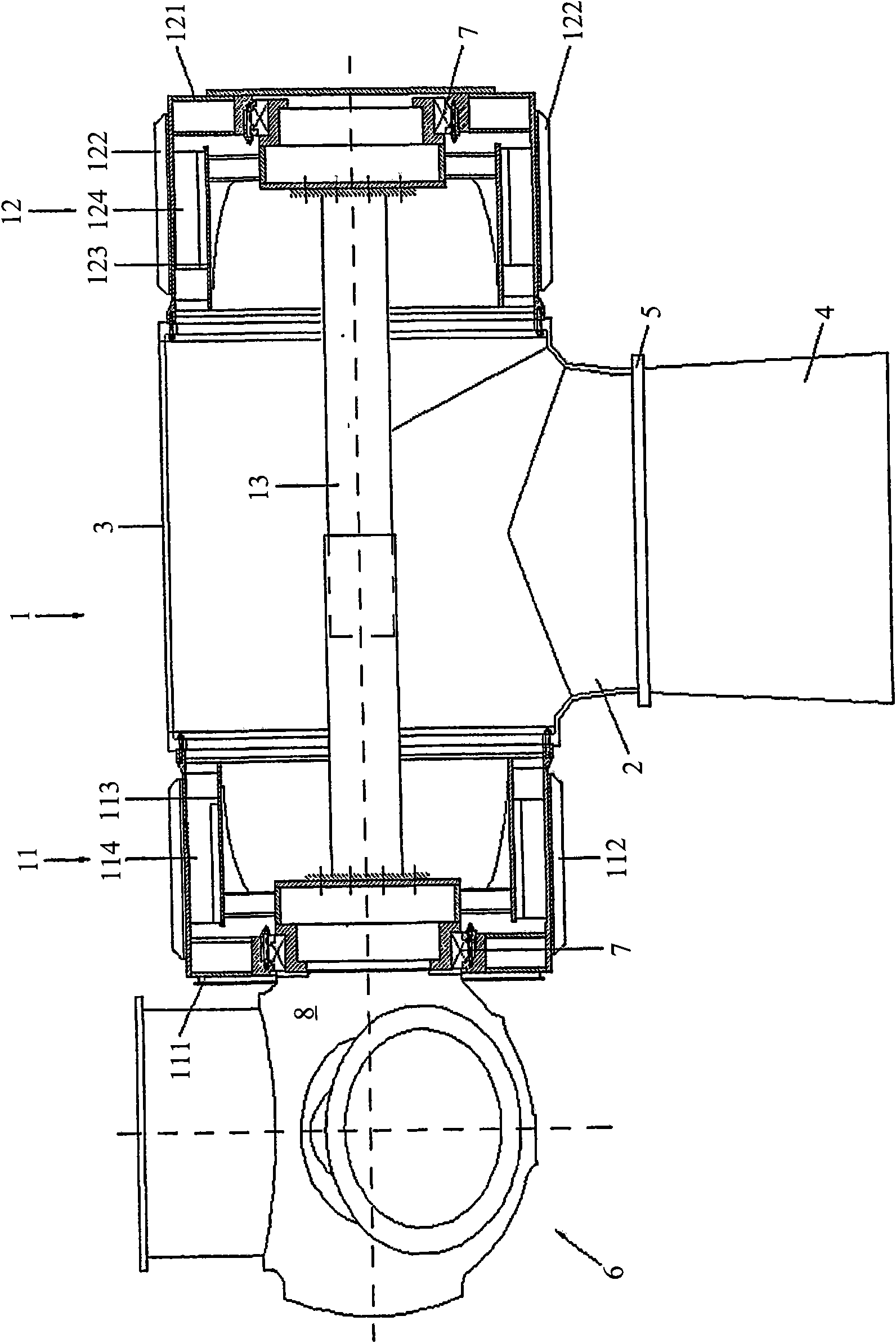

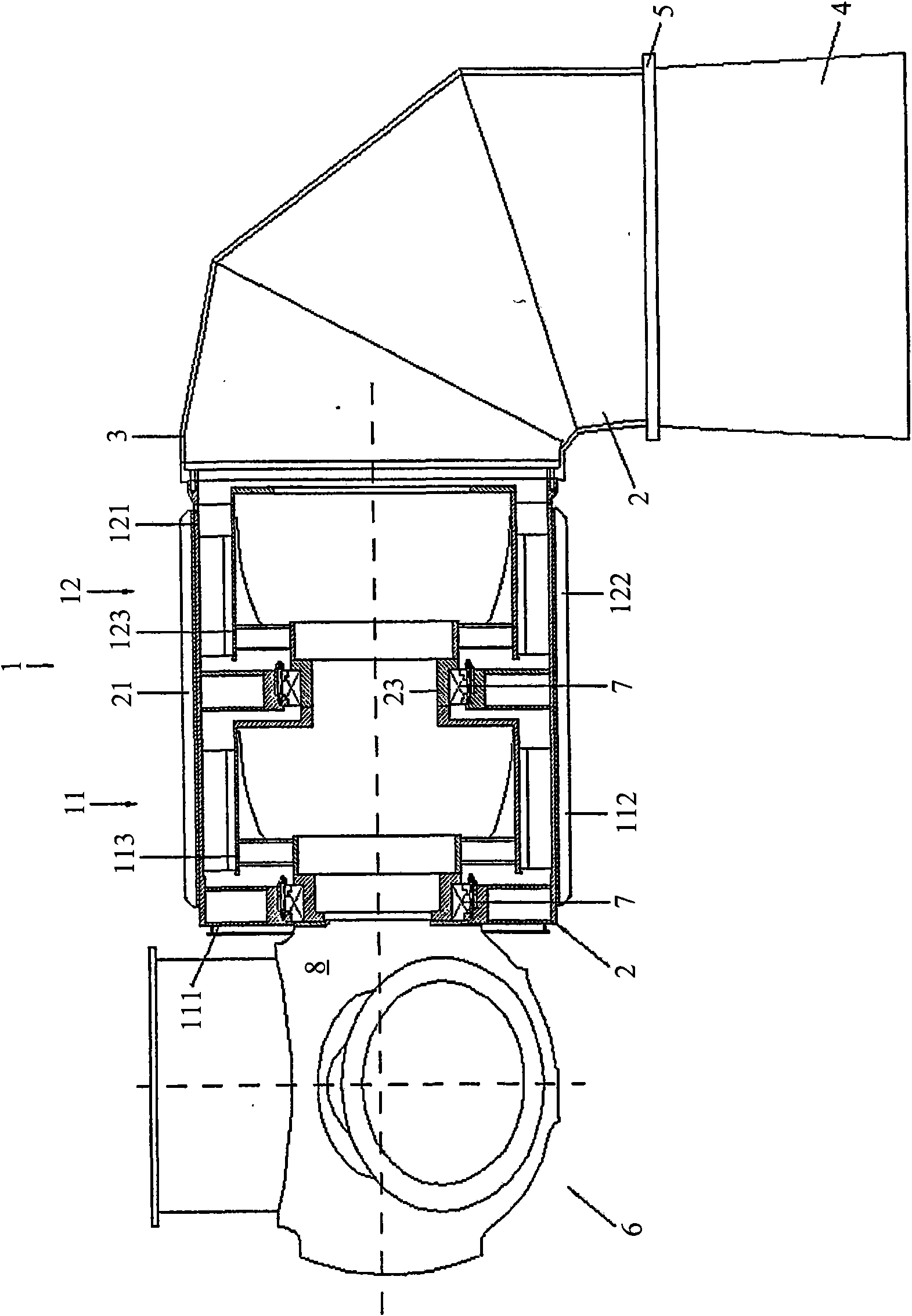

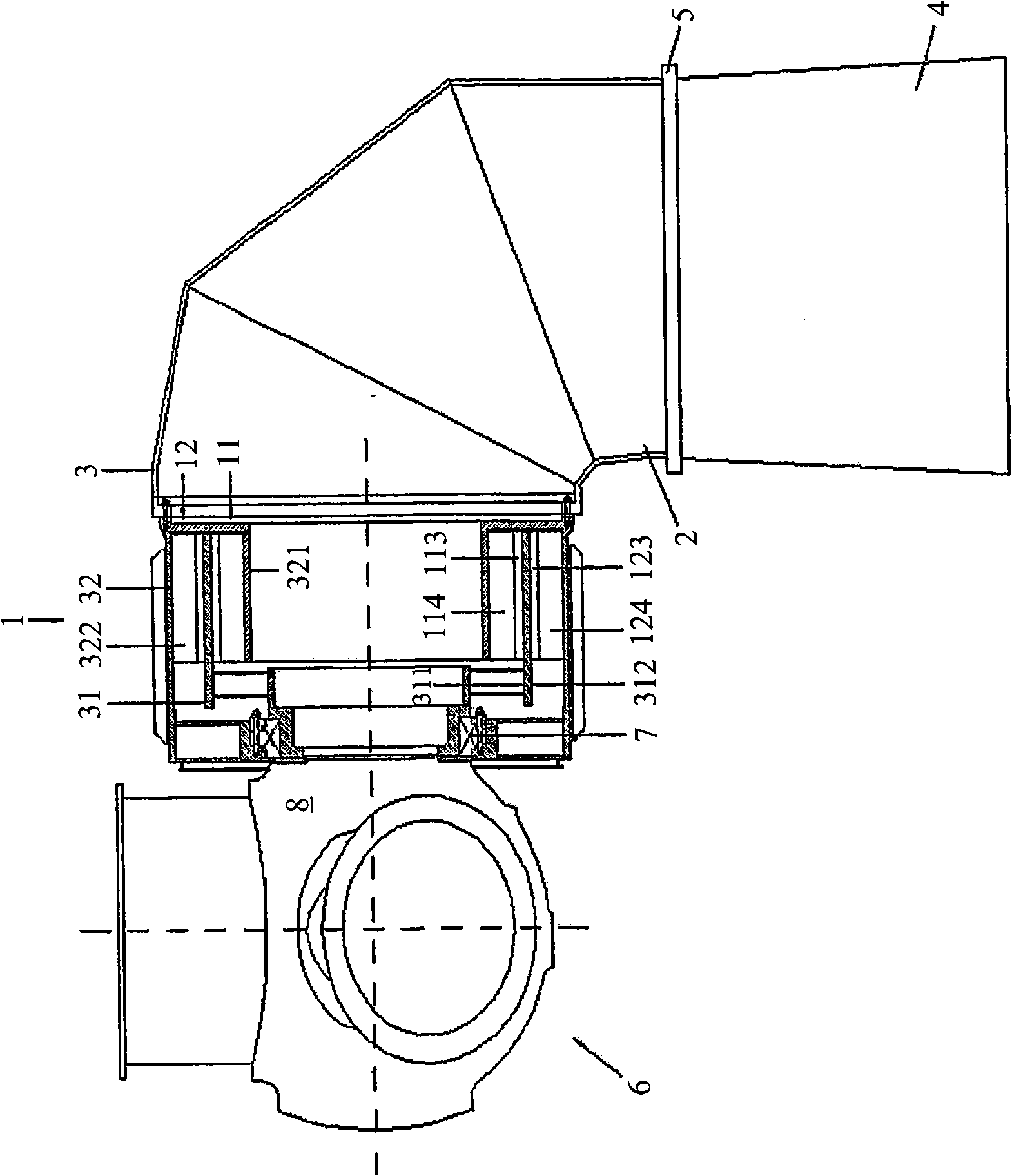

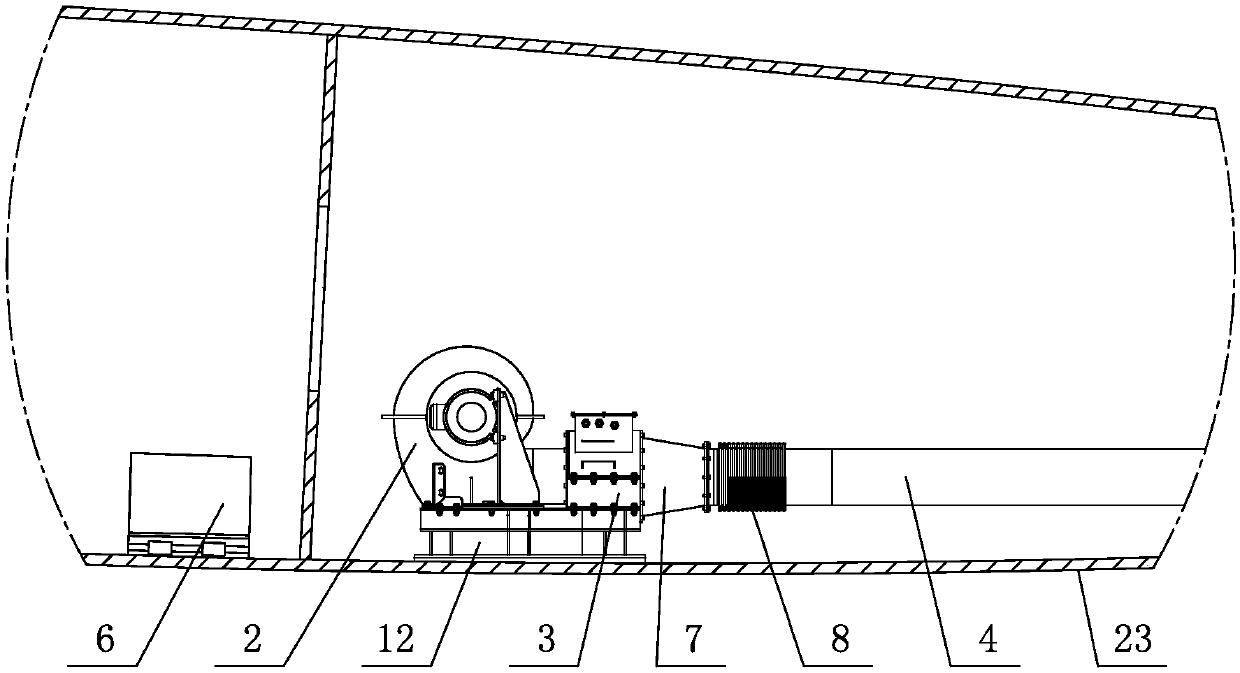

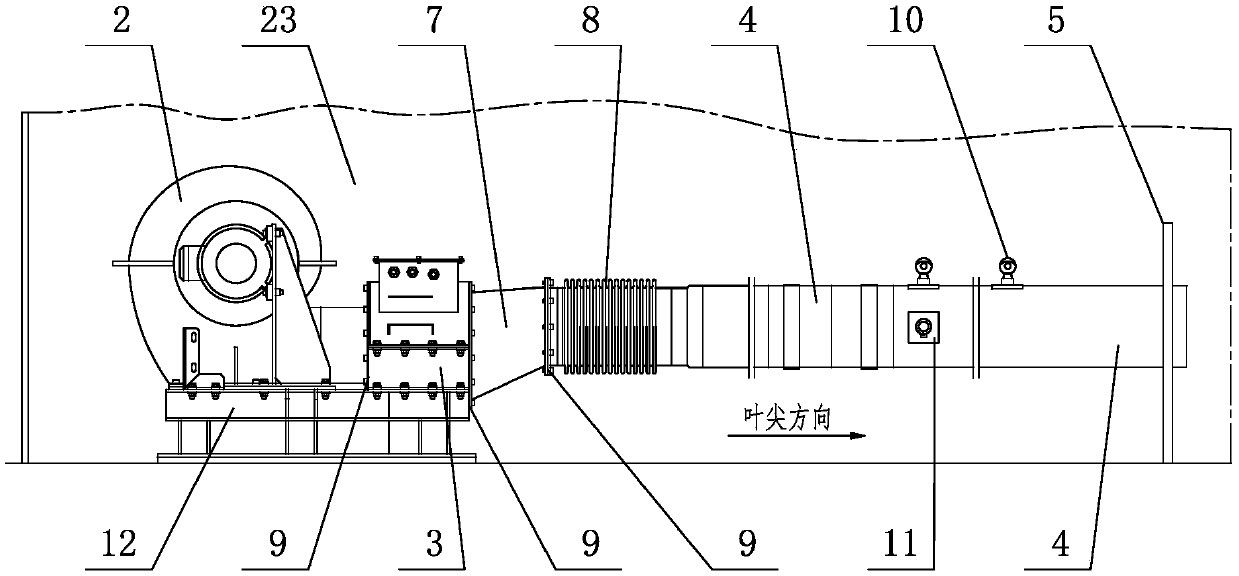

Hot blast type wind power generating set blade deicing device

ActiveCN109611290AEffective deicingSolve crackingMachines/enginesWind motor monitoringElectricityEngineering

The invention discloses a hot blast type wind power generating set blade deicing device. The hot blast type wind power generating set blade deicing device comprises a heating device and a ventilationpipeline. The heating device and the ventilation pipeline are arranged in a blade front edge cavity. The heating device comprises an air blower and a heater. An output end of the heater is connected with an air pipe. An air outlet end of the air pipe penetrates through a wind shield arranged in a blade inner cavity. The blade inner cavity is partitioned into a heating area and a non-heating area by the wind shield. The deicing device further comprises a control cabinet arranged at the root of the blade inner cavity. The heating device is connected with the control cabinet. By means of the hotblast type wind power generating set blade deicing device, blades of a wind power generating set can be effectively deiced, and the running safety and electricity generating capacity of the wind powergenerating set are improved. The hot blast type wind power generating set blade deicing device has a very high practical value.

Owner:ZHEJIANG WINDEY

Cable ice removal vehicle

ActiveCN109473933AReasonable structureGood continuityOverhead installationPositioning systemElectric cables

Owner:国网浙江省电力有限公司磐安县供电公司 +1

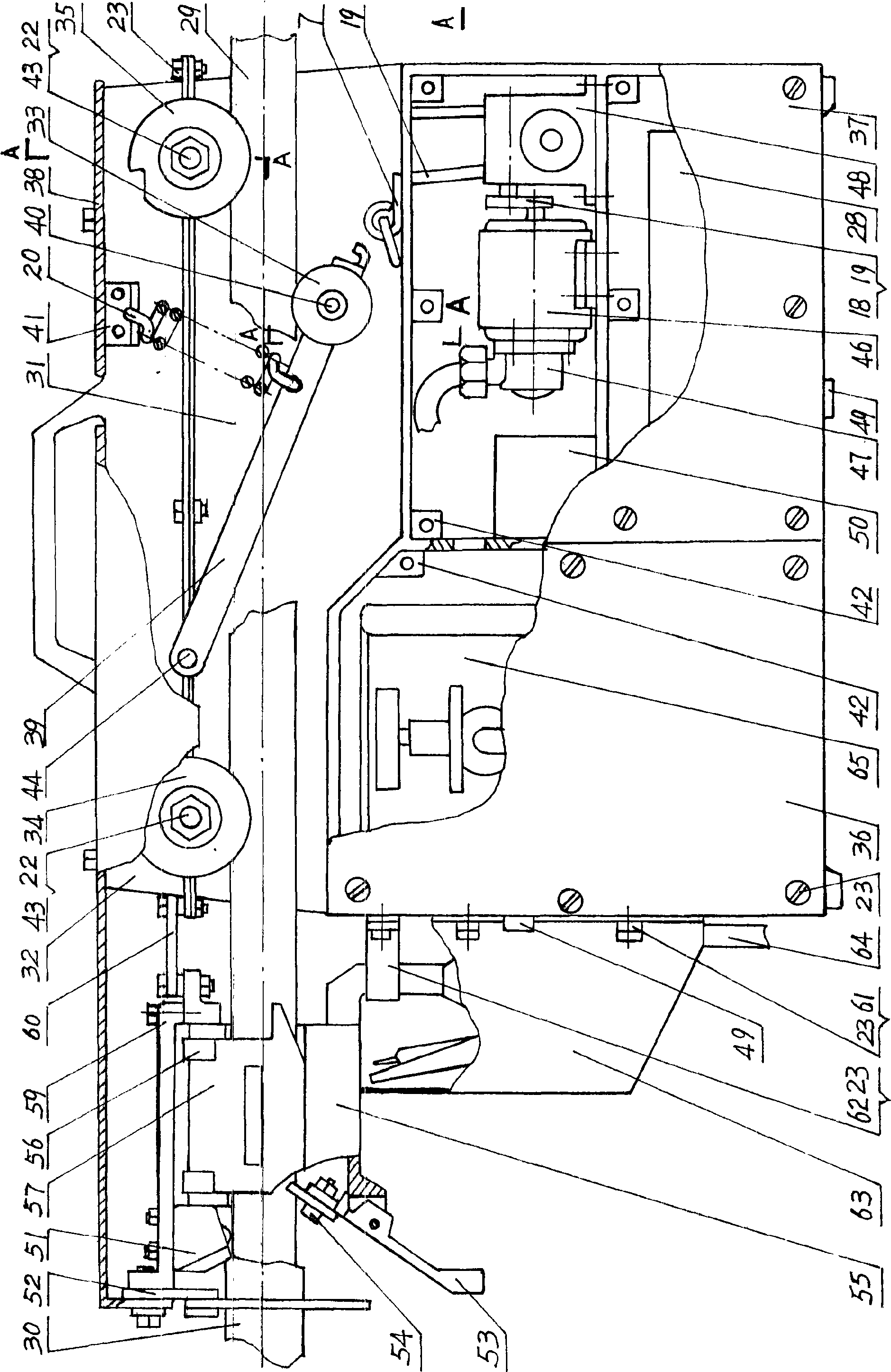

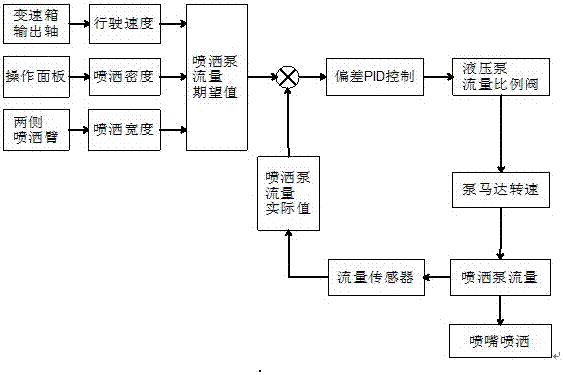

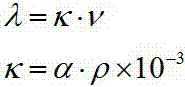

Distributor spraying flow control system

InactiveCN106873650ASpray evenlySimple and fast operationFlow control using electric meansAviationControl objective

The invention relates to a distributor spraying flow control system, and belongs to the field of aviation ground equipment. One key technical parameter of a distributor is to ensure that the spraying volume of deicing fluid per unit area is constant. Through the establishment of mathematical function relationship between the spraying volume of fluid per unit area on one hand and the vehicle speed, the flow of a spray pump and the displacement of a hydraulic pump on the other hand, a control system with the flow of the spray pump as a control objective is formed. The required flow is calculated according to the vehicle speed, the spraying density and the spraying width. The actual flow is detected through an electromagnetic flow meter. After comparison between the actual value and the required value, the displacement of the hydraulic pump is adjusted for the second time, and spraying is carried out again, in order to realize precise control on the flow.

Owner:WEIHAI GUANGTAI AIRPORT EQUIP CO LTD

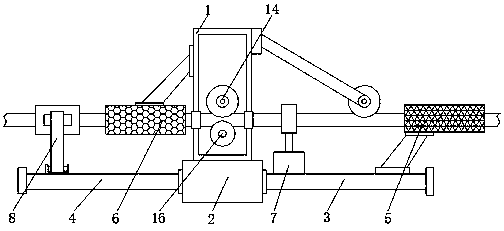

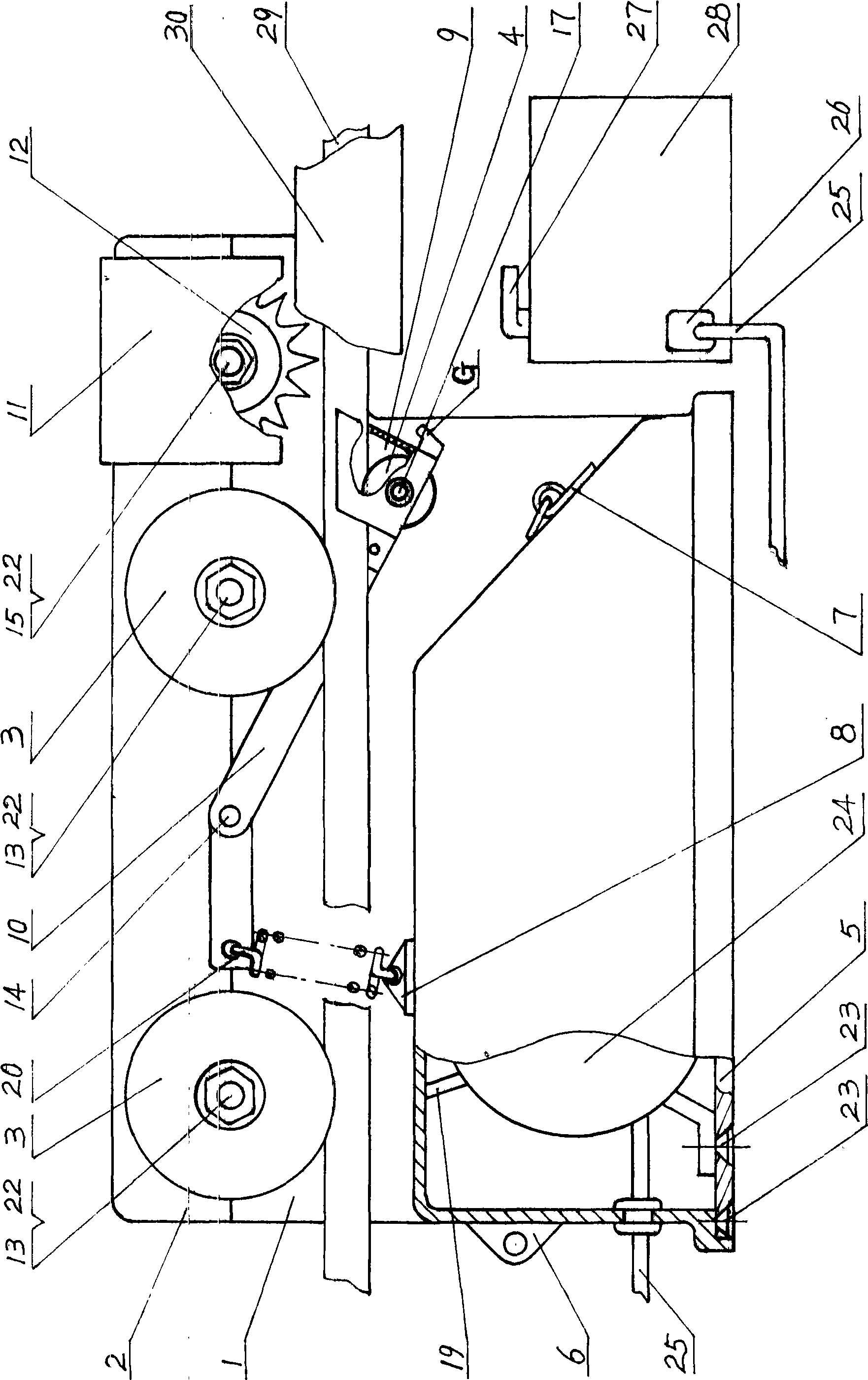

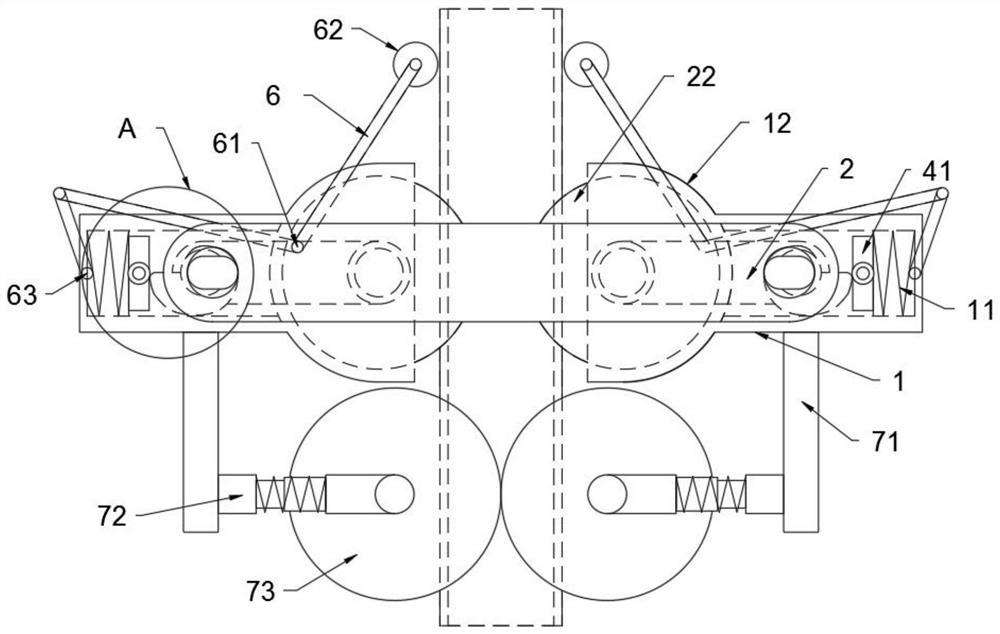

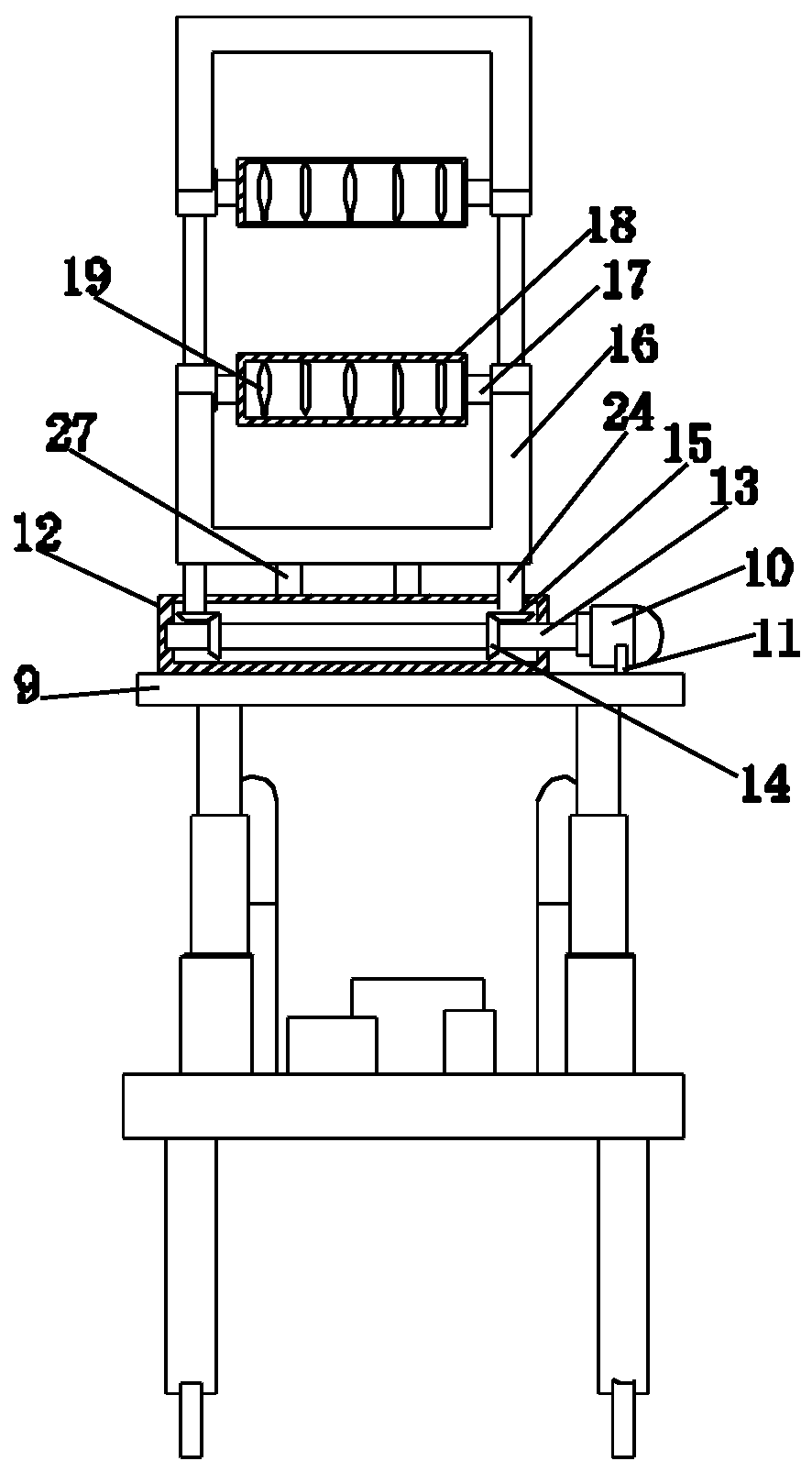

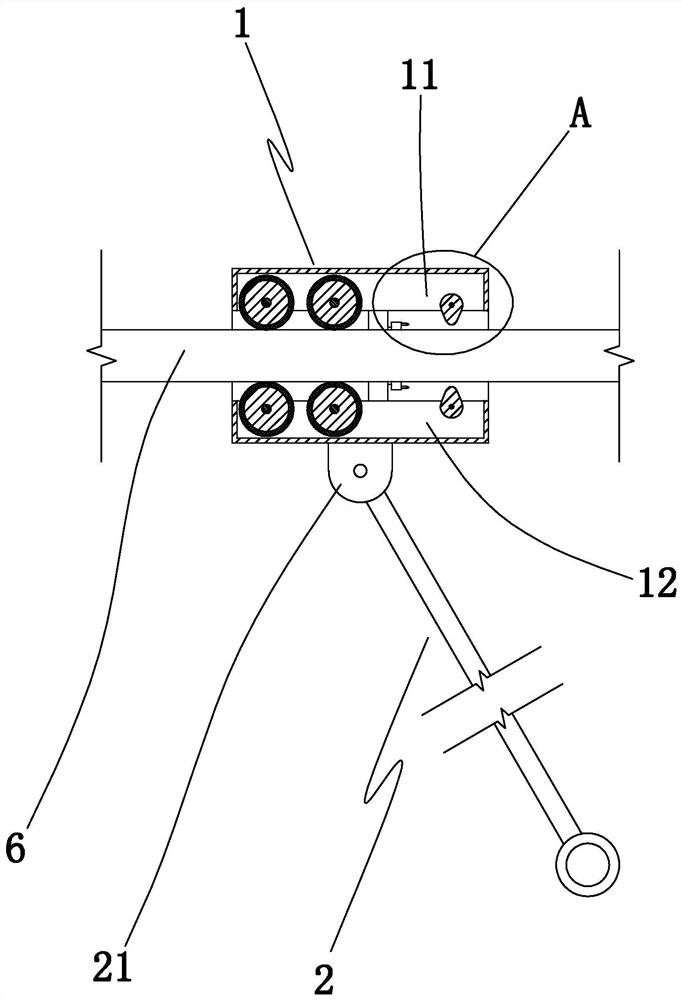

Composite deicing and dewatering cutter for high-voltage transmission line deicing robot

ActiveCN112134241AEffective deicingNatural sheddingOverhead installationElectric machineryElectric power equipment

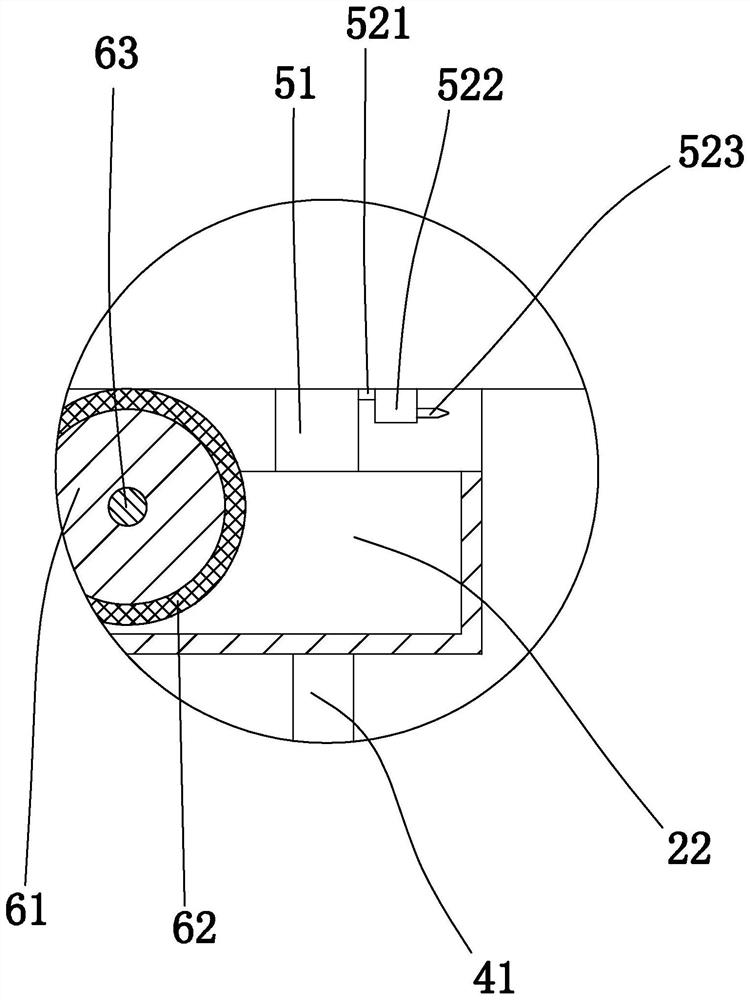

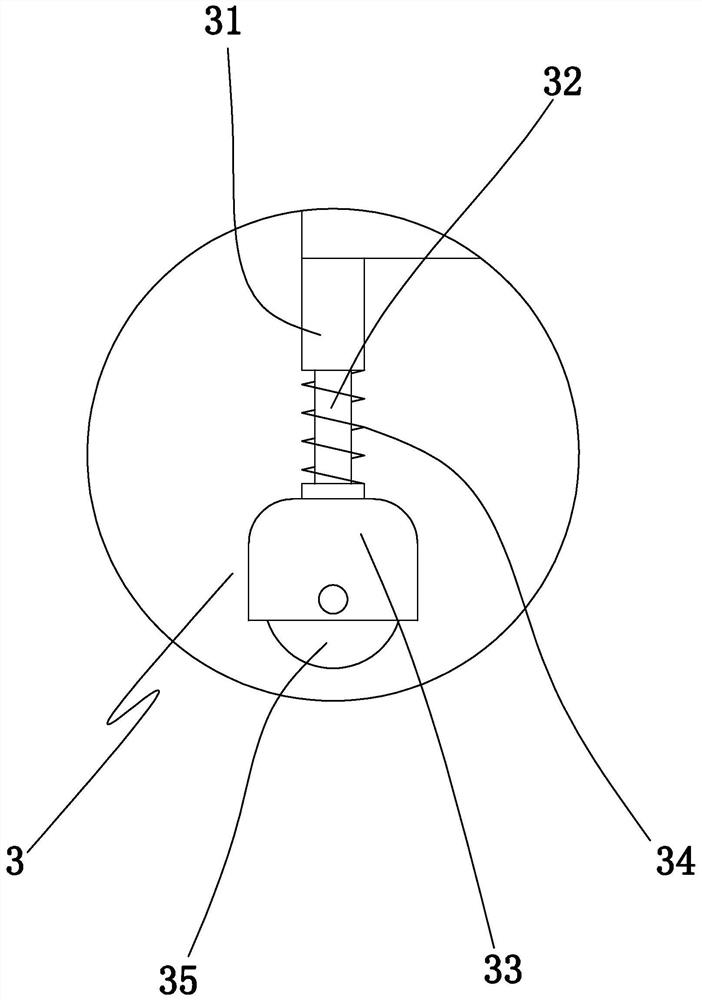

The invention relates to the technical field of power equipment, and particularly relates to a composite deicing and dewatering cutter for a high-voltage transmission line deicing robot. The compositedeicing and dewatering cutter comprises a support, a gear box, a knocking component and a roller which are distributed on the left side and the right side of a cable, wherein the gear box is arrangedon the support, the input end of the gear box is provided with a motor, the roller is connected to the lower portion of the support, the gear box is in transmission connection with the roller, and the output end of the gear box is further provided with a first cam and a second cam. The roller transversely arranged on the two sides of the cable is used for discontinuously extruding ice inwards soas to break the ice on the side surface and separate the upper ice and the lower ice, vibration is brought in cooperation with the knocking component to increase the extrusion force, the separated iceshakes and falls off, and then a sweeping component is used for sweeping away the broken ice. By means of the mode, the sheath of the cable is not damaged, the cutter is not abraded, the cleaning andremoving efficiency is good, and the deicing efficiency is integrally improved.

Owner:SONGYUAN POWER SUPPLY COMPANY OF STATE GRID JILINSHENG ELECTRIC POWER SUPPLY

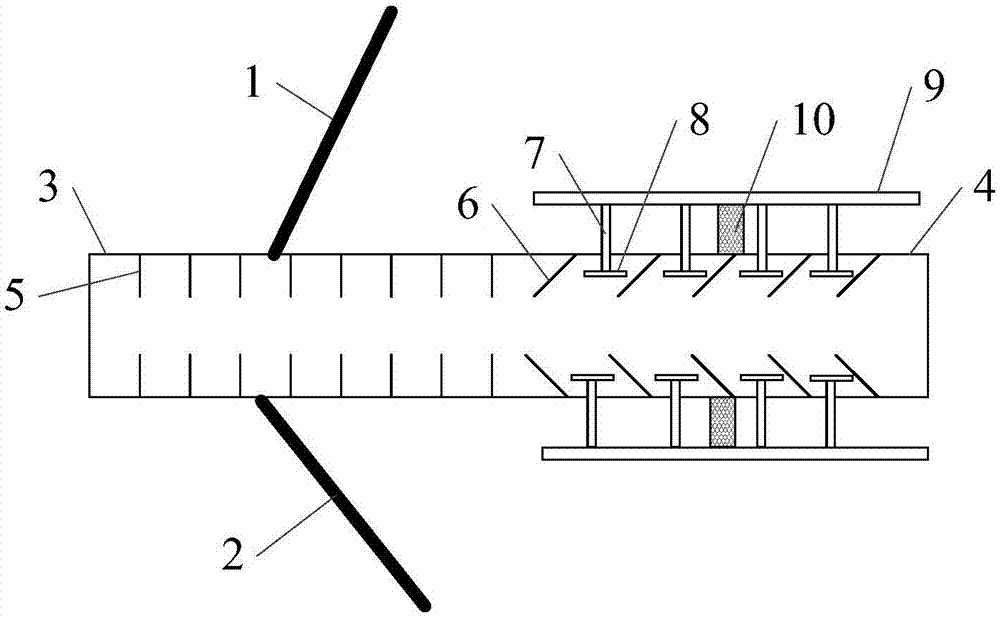

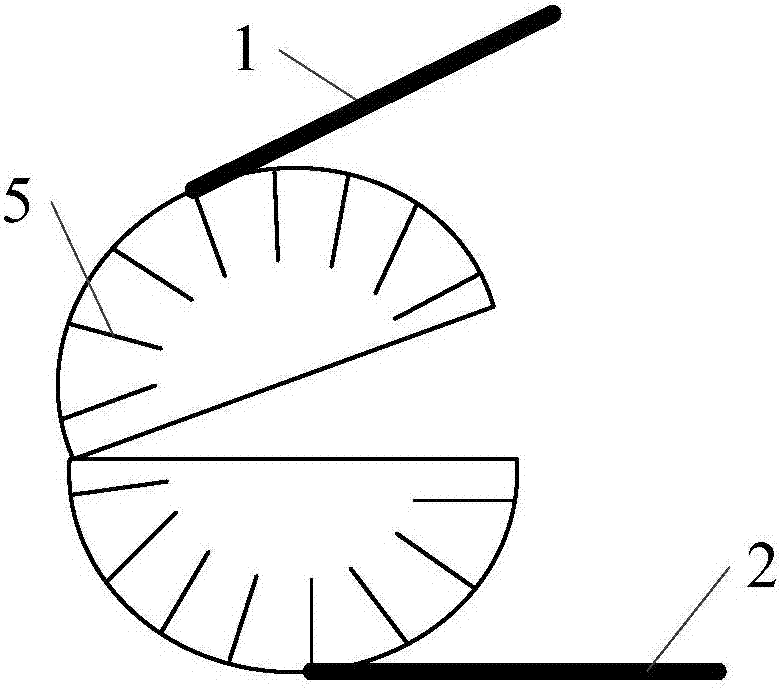

Transmission line deicer

The present invention discloses a transmission line deicer. The device comprises: a first operation rod, a second operation rod, a third operation rod, a fourth operation rod, a sheet metal, a return spring and a cylinder, the two ends of the cylinder are open, the cylinder comprises a left half cylinder and a right half cylinder which are connected, the left half cylinder comprises a first upper half cylinder and a first lower half cylinder which are in hinged connection, and a plurality of deicing nails are uniformly distributed at the inner walls of the first upper half cylinder and the first lower half cylinder; and a plurality of ice shovel sheets are uniformly distributed in the right half cylinder, and the right half cylinder comprises a second upper half cylinder and a second lower half cylinder. The technical problem is solved that current deicing of a transmission power is high in cost, difficult to realize or bad in deicing effect; the device provided by the invention can rapidly and effectively perform deicing, the cost is low, and the realization is easy.

Owner:NANCHONG POWER SUPPLY COMPANY STATE GRID SICHUANELECTRIC POWER

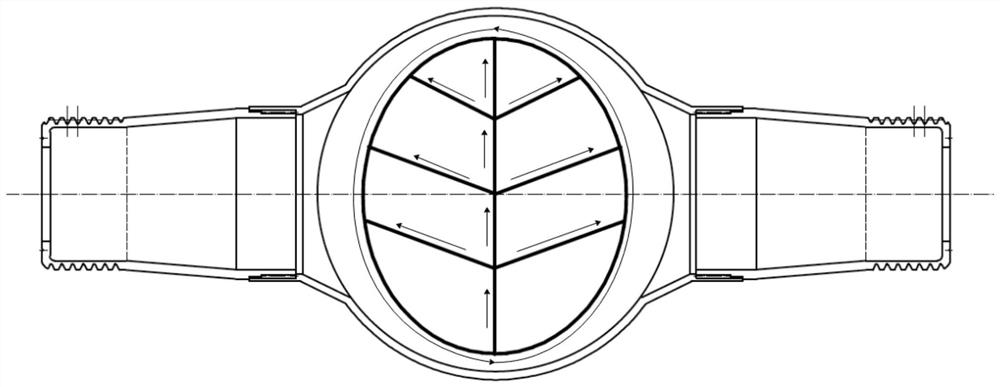

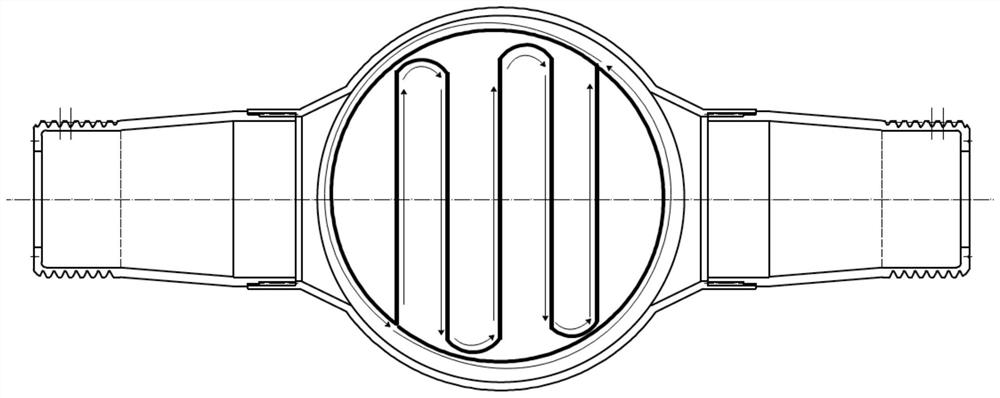

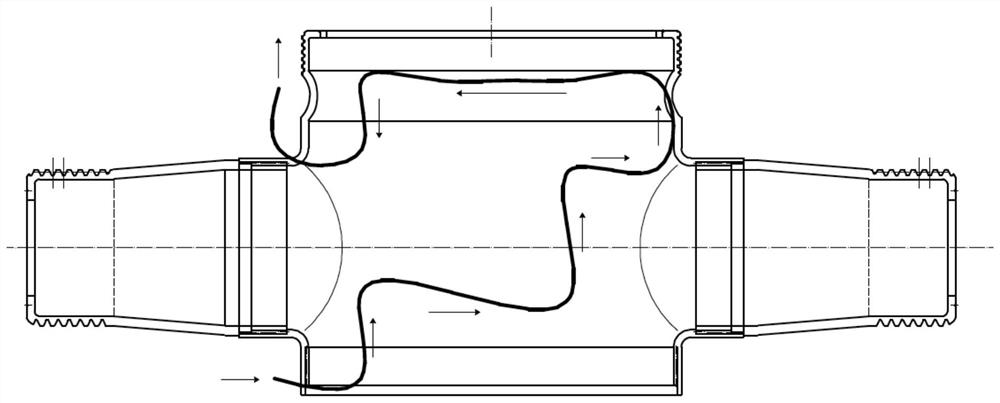

Water meter with deicing device

InactiveCN111854879ARemove freezeReduce difficultyVolumetric apparatus damage preventionEnvironmental engineeringMechanical engineering

The invention discloses a water meter with a deicing device. The water meter is characterized in that a device used for fluid flowing and a device used for controlling fluid flowing are arranged outside the water meter shell, the device used for controlling fluid flowing executes a deicing algorithm, that is, whether freezing is formed in the water meter or not is detected, and if yes, fluid is heated and controlled to flow for deicing. The method and the system solve the technical problem of how to effectively deice the outer surface of the water meter.

Owner:HANGZHOU QIANBO TECH CO LTD

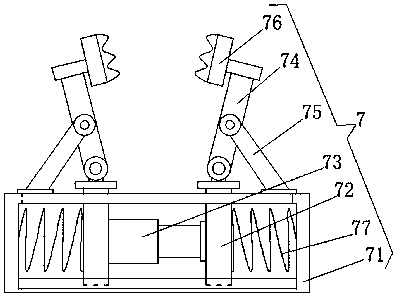

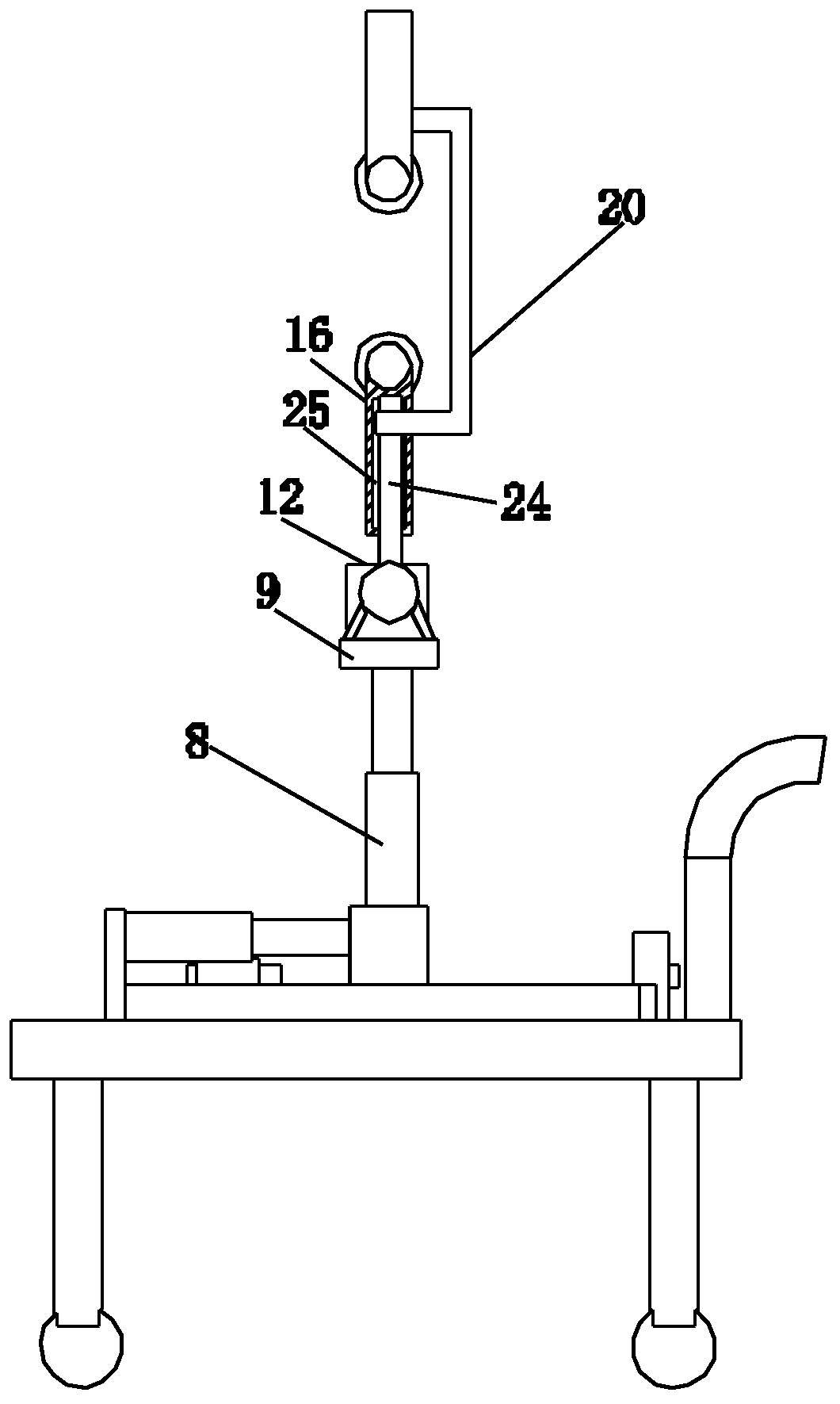

Deicing device for power transmission line

PendingCN110620365ACompact structureEasy to operateOverhead installationEngineeringPower transmission

The invention discloses a deicing device for a power transmission line. The device comprises a bottom plate, and at least one sliding table is arranged on the upper surface of the bottom plate. A sliding block is slidably connected into the sliding table. A fixed plate is arranged at one end of the upper surface of the sliding table; the fixed plate is connected with the sliding block through a hydraulic telescopic rod; the upper end of the sliding table is fixedly connected with a supporting plate through a hydraulic lifting column. A fixed box is arranged on the upper surface of the supporting plate; a first rotating shaft is arranged in the fixed box; one end of the first rotating shaft passes through the fixed box and is connected with the output end of a motor; two U-shaped frames arearranged at the upper end of the fixed box; the two U-shaped frames are oppositely arranged; a fixed shaft is arranged in the U-shaped frames; the outer side surface of the fixed shaft is rotatinglyconnected with a roller, and the interior of the roller is provided with an annular heating wire. According to the invention, a deicing operation can be carried out on power transmission lines of different heights, and the damage to the power transmission lines during deicing is avoided; meanwhile, ice blocks between the power transmission lines can be effectively removed, and the deicing convenience is greatly improved.

Owner:国网河南省电力公司新安县供电公司 +1

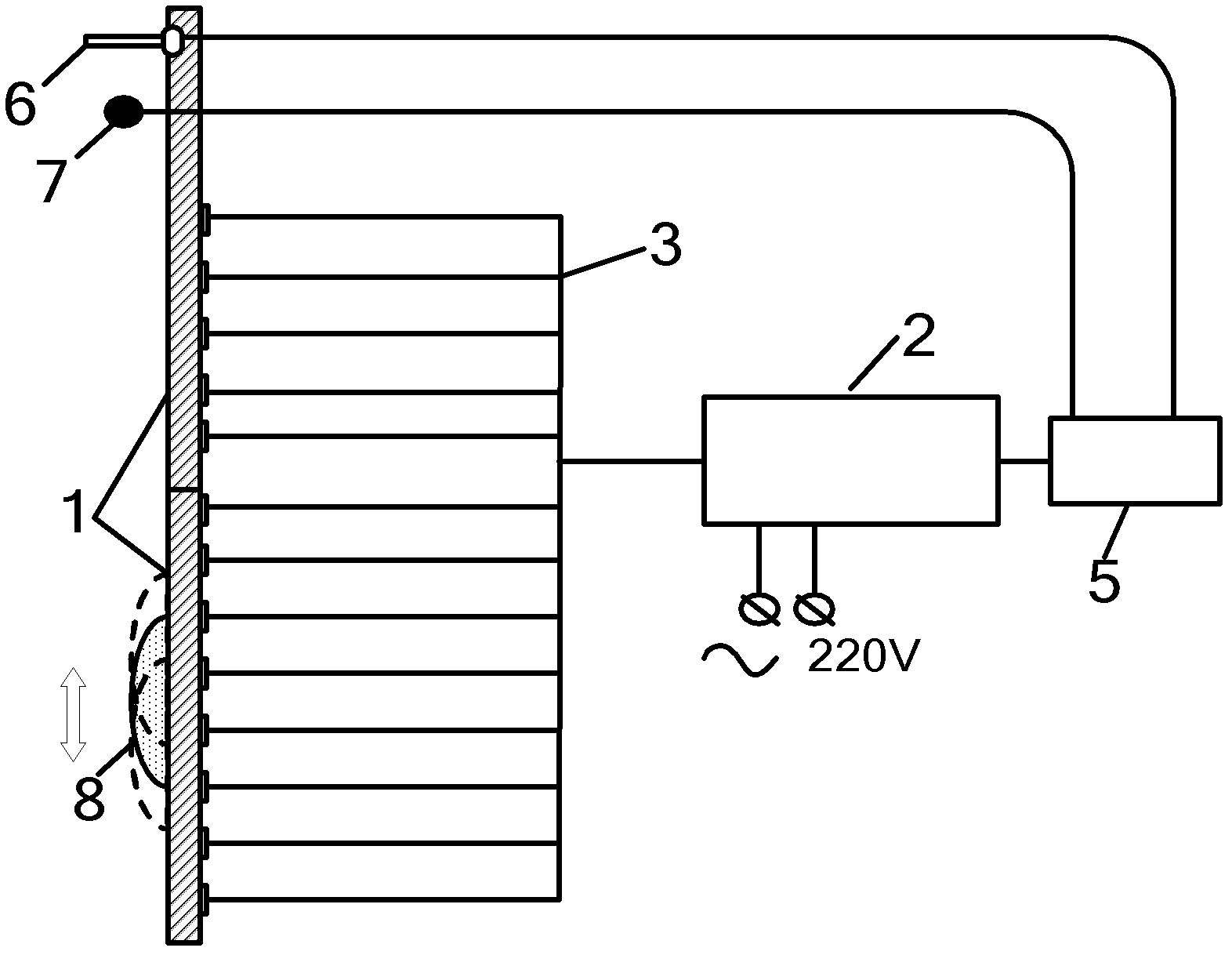

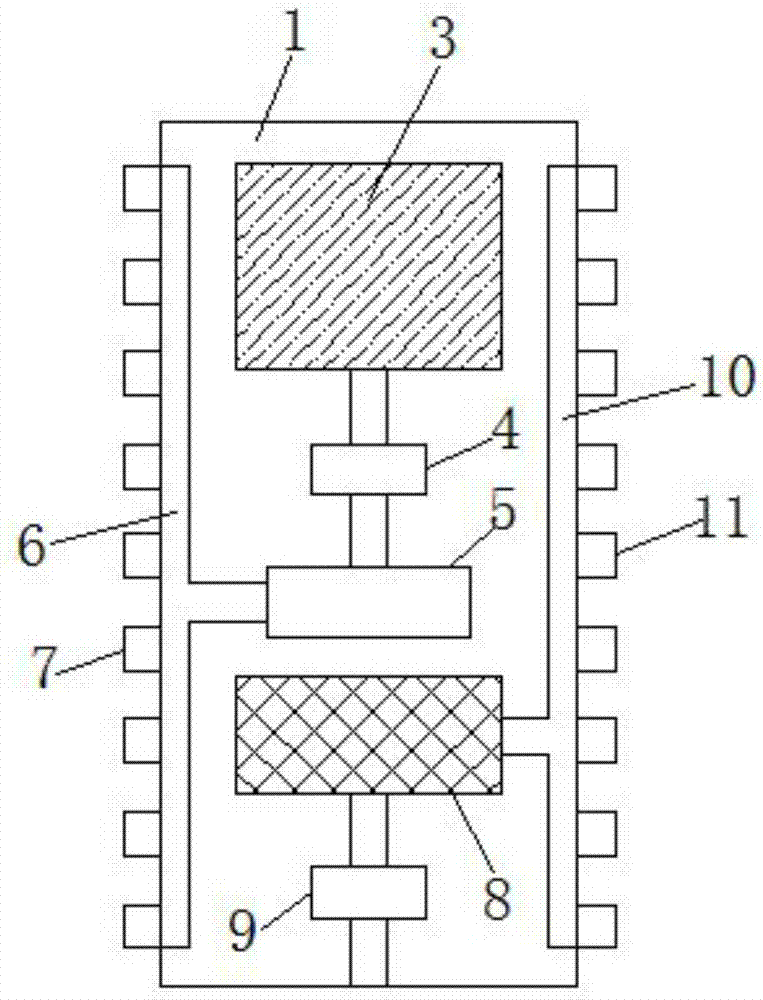

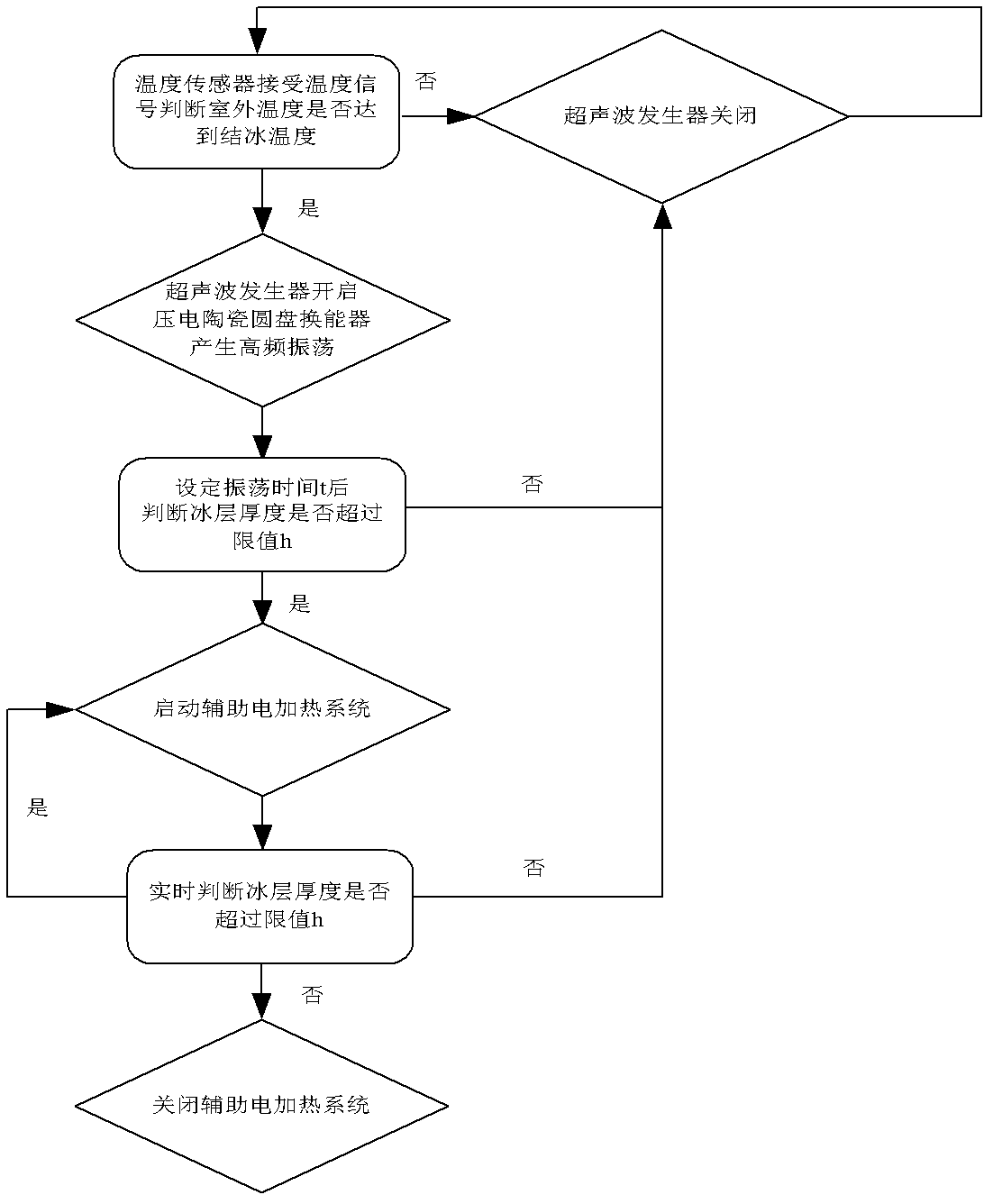

Heat-assistant ultrasonic combined ice-removing device and control method thereof

InactiveCN102434405BGuaranteed uptimeOvercoming Adhesive StrengthWind energy generationWind motor componentsAutomatic controlEngineering

The invention discloses a heat-assistant ultrasonic combined ice-removing device and a control method thereof. The heat-assistant ultrasonic combined ice-removing device comprises a wind driven generator blade, an automatic controlling device, an assistant electrical heating device, an ultrasonic high-frequency oscillation device, an outdoor ambient temperature sensor and a blade surface ice layer thickness tester, wherein the assistant electrical heating device comprises an electrical heating power source and an electrical heating band; the ultrasonic high-frequency oscillation device comprises an ultrasonic generator and an ultrasonic energy converter; the automatic controlling device controls the ultrasonic generator to work according to a temperature signal fed back by the outdoor ambient temperature sensor and an ice layer thickness signal fed back by the blade surface ice layer thickness tester, and controls the assistant electrical heating device to work according to the ice layer thickness signal fed back by the blade surface ice layer thickness tester and a continuous working period of the ultrasonic generator. The invention has the capacities of effectively removing the ice layer on the surface of the blade, ensuring safety operation of the wind generating set in winter and increasing operational efficiency of the wind generating set in winter, and is simple and efficient, safe and reliable.

Owner:SOUTHEAST UNIV

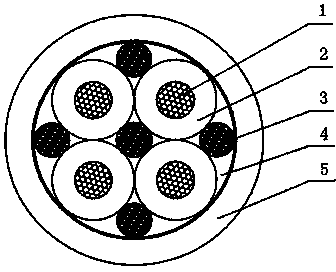

Deicing cable

InactiveCN103426540AReduce weightHigh power transmission efficiencyClimate change adaptationFlexible cablesWeather resistanceFrost

The invention belongs to the technical field of cable manufacturing, and provides a deicing cable. The deicing cable is composed of inner cable cores, an insulation protective layer, outer cable cores, fillers and a frost-proof layer. The peripheries of the inner cable cores are covered with the insulation protective layer, the outer cable cores are distributed in gaps among the inner cable cores, heat generated after the outer cable cores are charged with electricity can deice effectively, and the frost-proof layer can effectively prevent the outer portion of the cables from being frozen. The deicing cable is reasonable in structural design, weight of the cable is reduced, and the deicing cable can deice and keep warm in normal electricity transmission, is good in frost-proof effect, can fast and effectively remove ice layers on the outer portion of the cable, is good in electric current transmission effect, good in weather ability and high in electric energy transmission efficiency, has certain rigidity, is good in torsional property, improves flexibility, can meet various requirements for electrical property and mechanical property, is simple in structure and good in practicability, and has good popularization and application value.

Owner:HENAN KOSEN CABLE

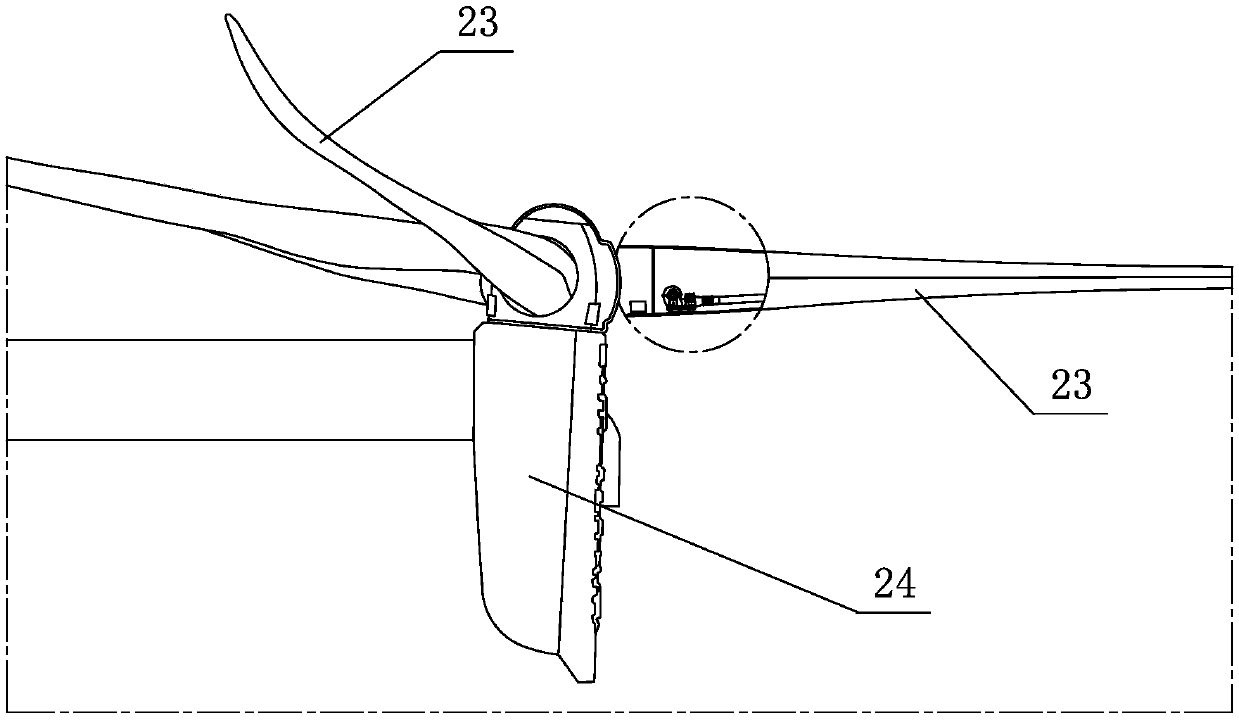

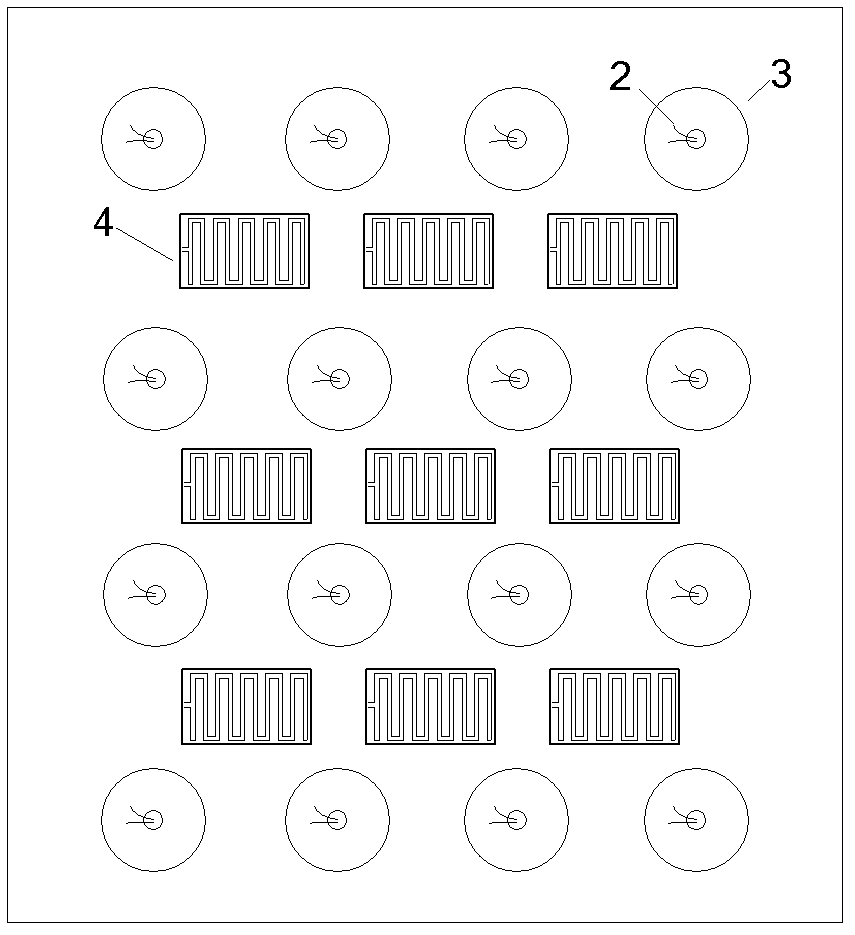

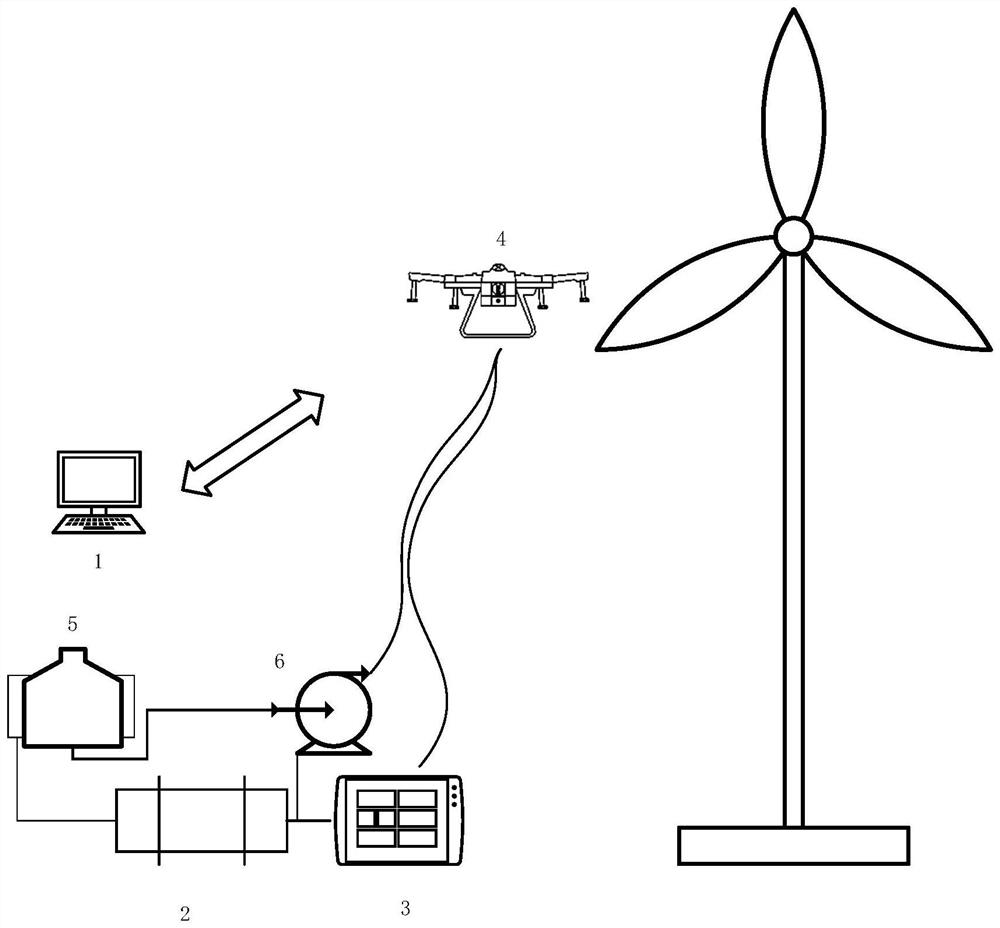

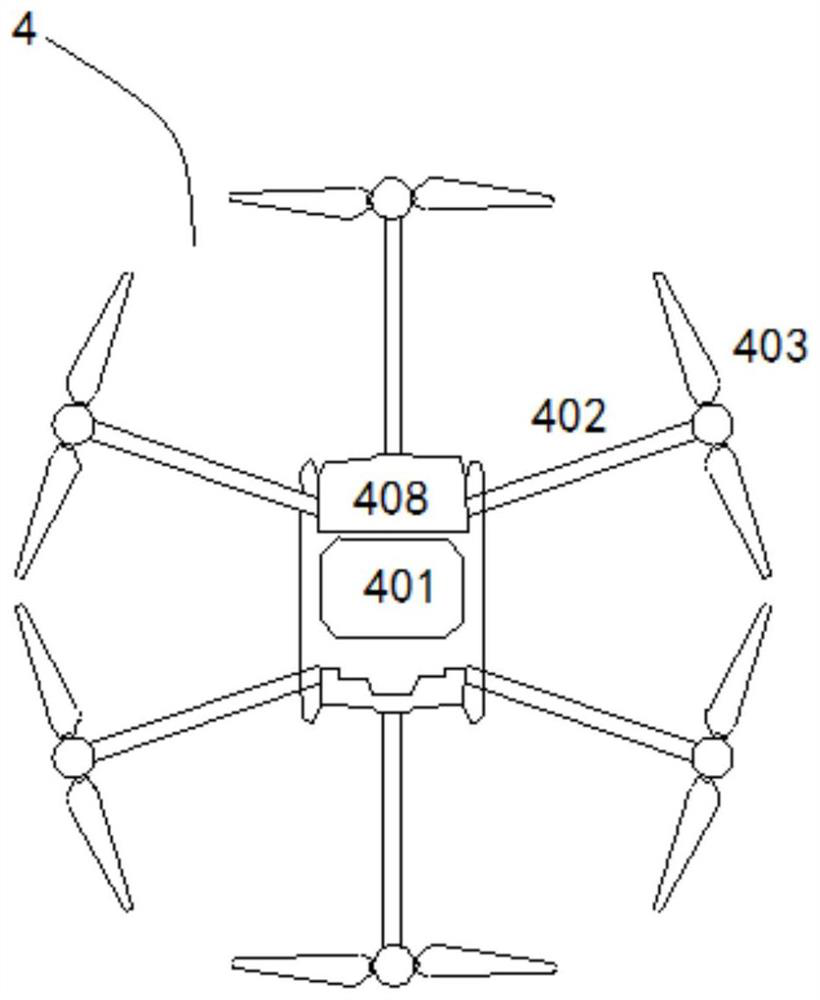

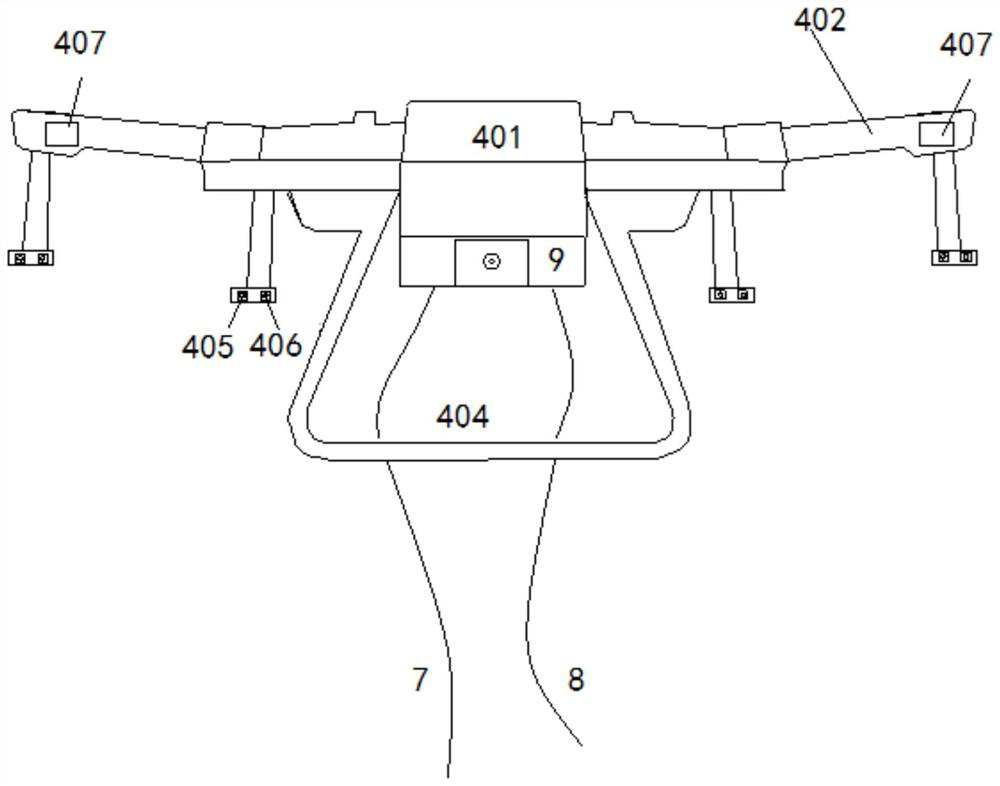

Wind power blade deicing system and method based on unmanned aerial vehicle

PendingCN114056569ANo secondary pollutionAvoid secondary pollutionMachines/enginesWind energy generationRadar systemsSprayer

The invention discloses a wind power blade deicing system and method based on an unmanned aerial vehicle. The unmanned aerial vehicle can be flexibly operated, and the wind power blade is comprehensively shot through the infrared camera, so that the freezing point is found. An RTK positioning system accurately positions and records coordinate information of a freezing point of the wind power blade, the omnidirectional radar system can control the unmanned aerial vehicle to hover near the freezing point, the safe distance between the unmanned aerial vehicle and the wind power blade is 2.5 m, and damage to the wind power blade due to shaking of the unmanned aerial vehicle is avoided; the steering engine can adjust the directions of the sprayer and the nozzle to ensure the spraying accuracy; An FPV camera shoots the ice melting and removing process in the whole process and transmits the image to the operating handle screen in real time, so that the ice removing and cleaning process is timely and efficient; A ground system can provide power guarantee and signal guarantee for the mooring unmanned aerial vehicle, and the unmanned aerial vehicle can execute a deicing task in a high-altitude long-endurance and high-response mode.

Owner:XIAN THERMAL POWER RES INST CO LTD

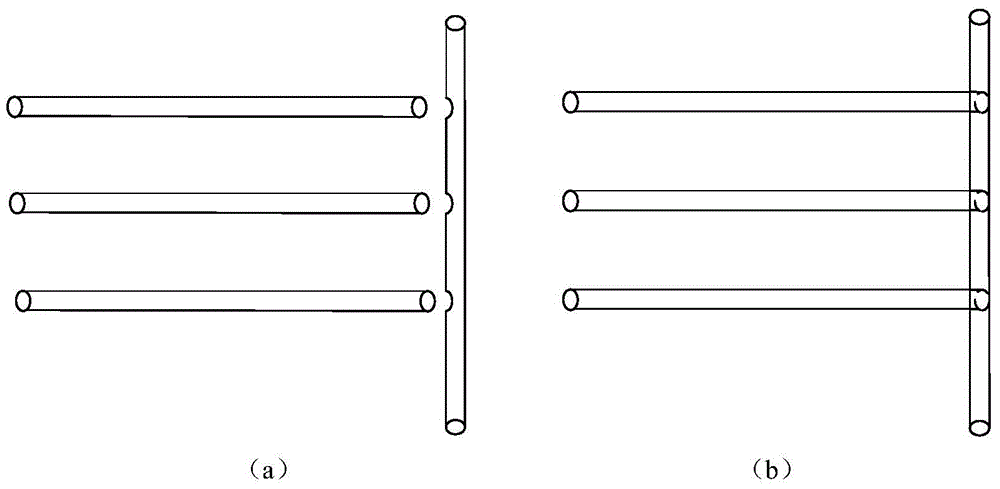

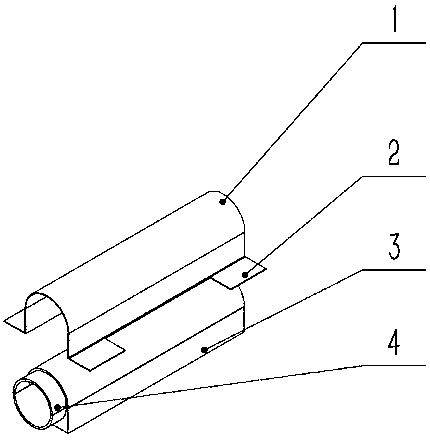

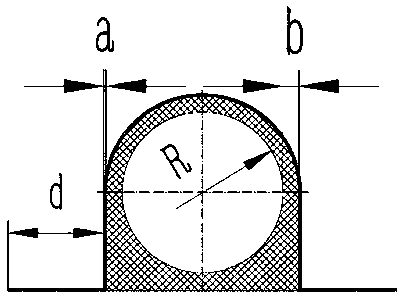

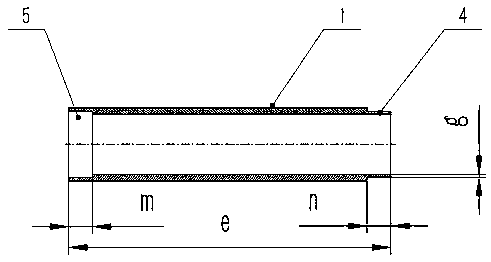

Wind power blade gas-heat anti-icing and deicing air guide pipeline and installation method thereof

InactiveCN111536325AEasy to fixReduce quality problemsThermal insulationMachines/enginesInsulation layerStructural engineering

The invention discloses a wind power blade gas-heat anti-icing and deicing air guide pipeline and an installation method thereof. The wind power blade gas-heat anti-icing and deicing air guide pipeline comprises a plurality of construction units which are spliced, each construction unit comprises an outer protection layer and an inner heat insulation layer, the inner heat insulation layer is madeof a material with a low heat conductivity coefficient, the inner heat insulation layer is provided with a cylindrical air guide channel, and the two ends of the cylindrical air guide channel are respectively provided with a socket convex head and a socket concave part which are used for mutual connection of the construction units; the inner surface of the outer protection layer is attached to theouter surface of the inner heat insulation layer, and the outer protection layer is also provided with a fixed installation wing. The inner wall of the cylindrical air guide pipeline has small wind resistance, thereby facilitating hot wind transfer; meanwhile, the fixed installation wing is arranged, thereby greatly facilitating mounting and fixation and saving the installation time and the laborcost of installation; and the inner heat insulation layer reduces heat loss in the air guide process, thereby improving the anti-icing and deicing power of the system.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

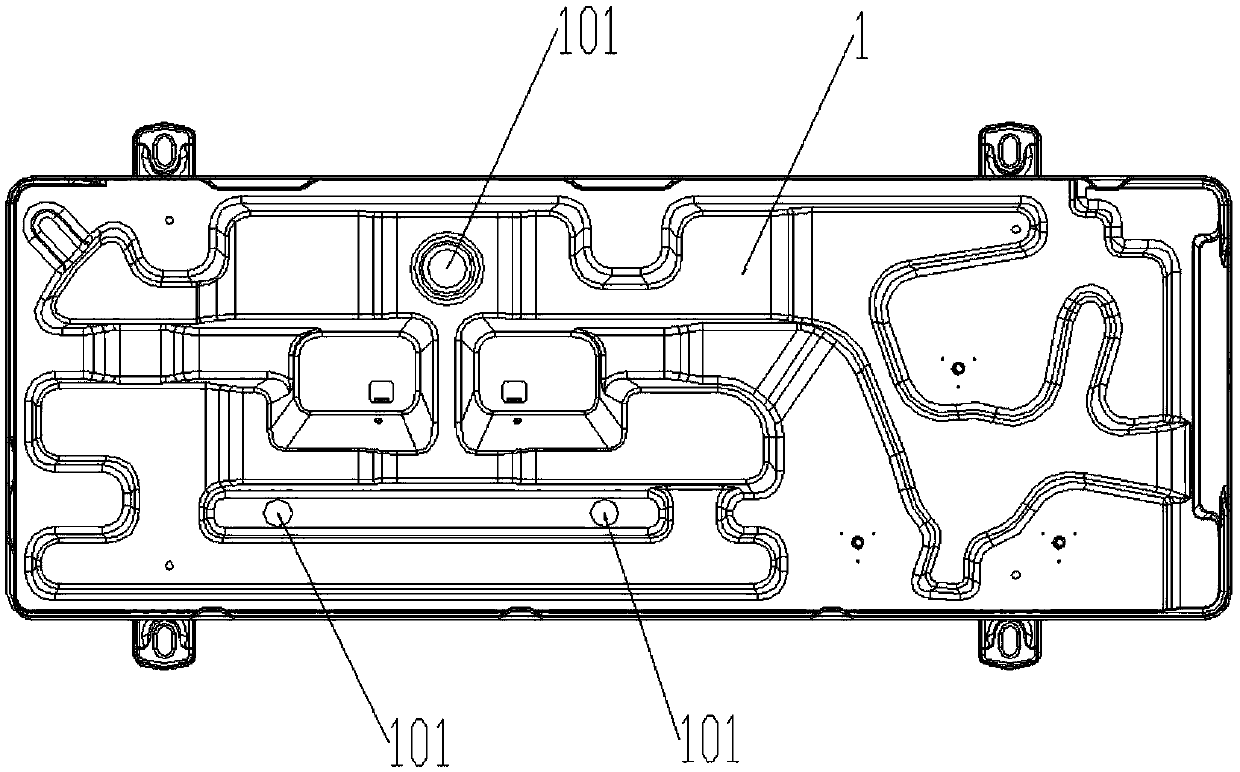

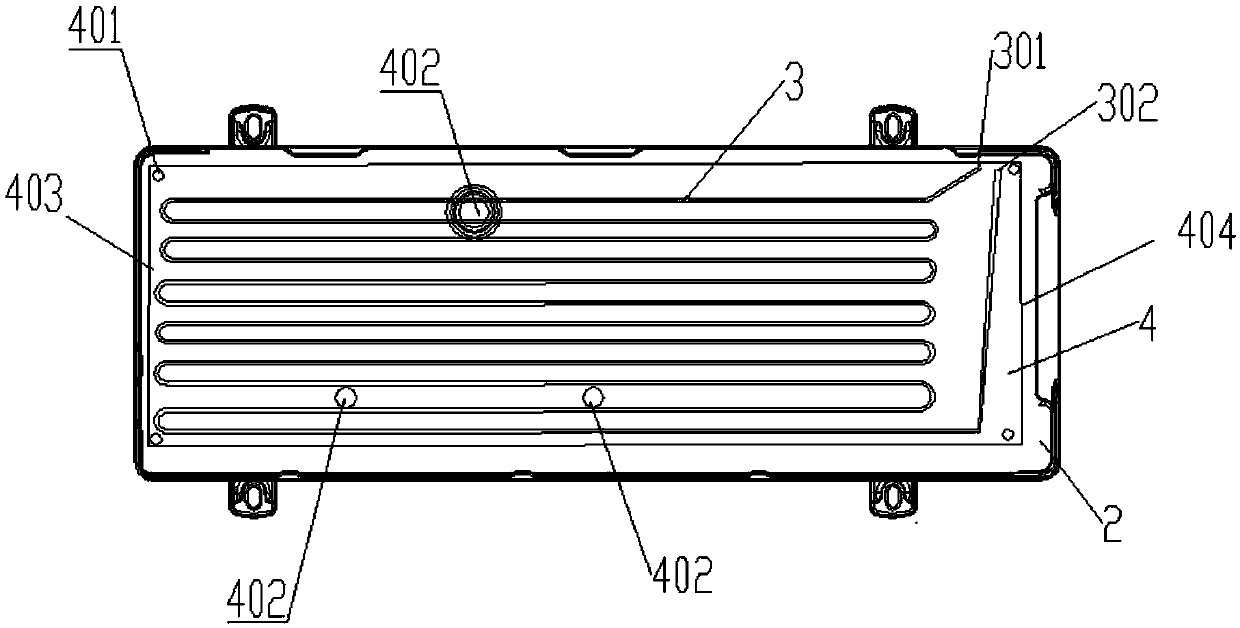

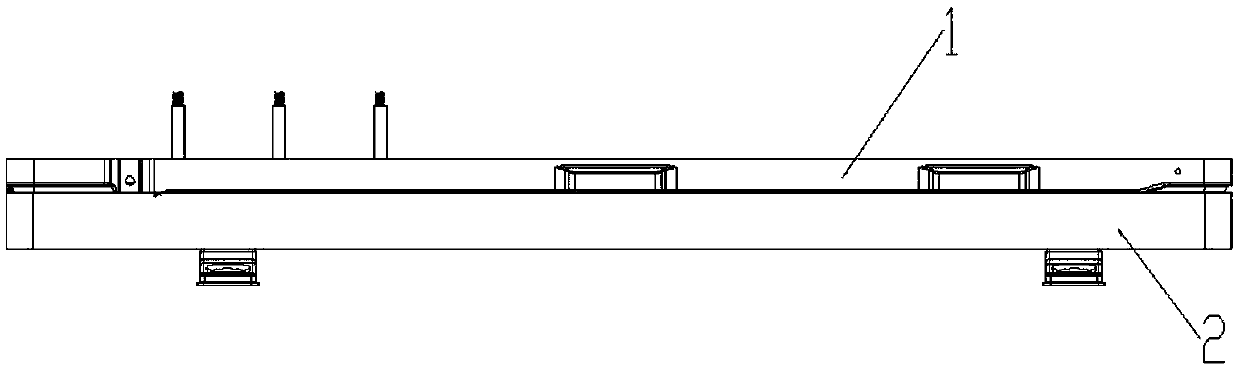

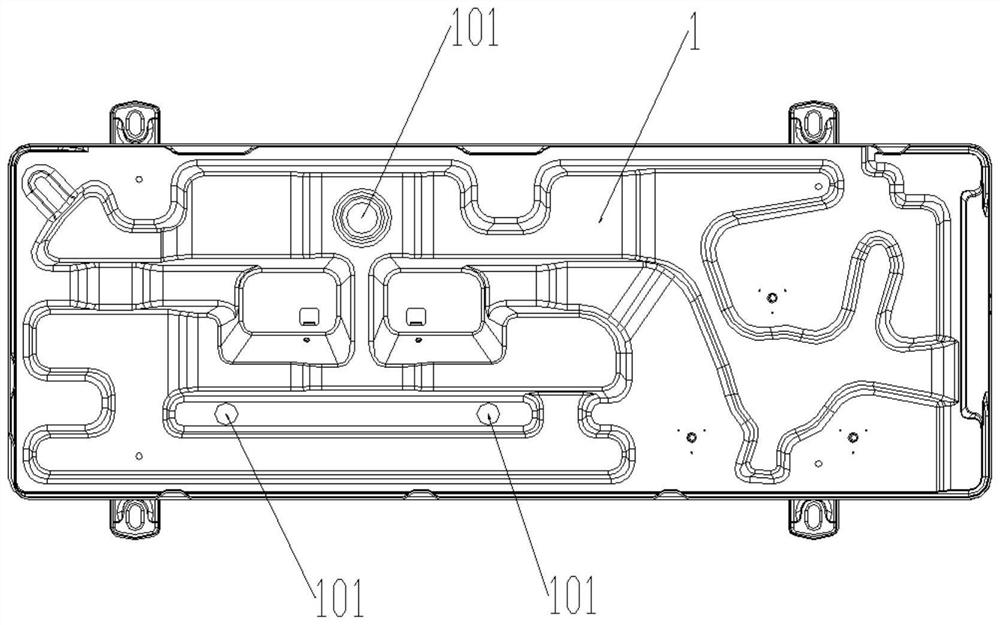

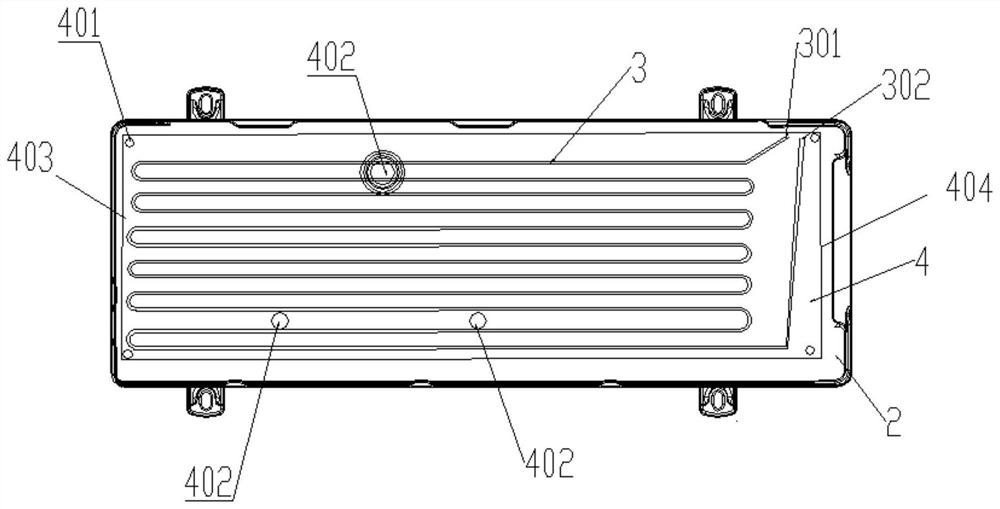

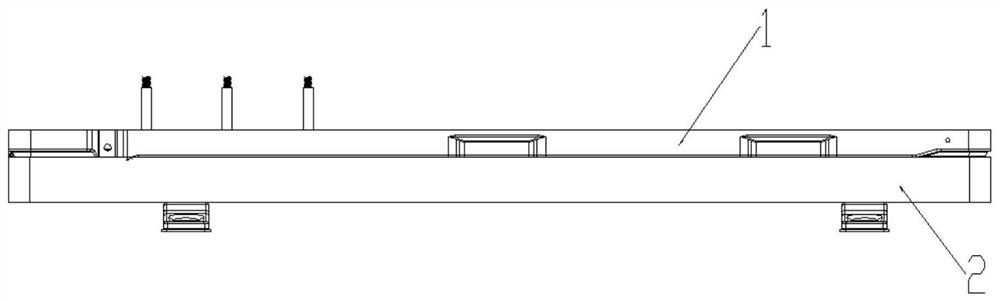

Air conditioning outdoor unit, air conditioner and air conditioner control method

ActiveCN111197819ASimple structureEasy to implementCorrosion preventionRefrigeration componentsAutomotive engineeringRolling chassis

The invention provides an air conditioning outdoor unit, an air conditioner and an air conditioner control method. The air conditioning outdoor unit comprises a compressor, an outdoor heat exchanger and a chassis, wherein the chassis comprises a chassis upper bottom and a chassis lower bottom arranged from top to bottom; an interlayer is arranged between the chassis upper bottom and the chassis lower bottom; and a refrigerant pipeline is arranged in the interlayer and is connected with the outdoor heat exchanger in parallel. The air conditioning outdoor unit, the air conditioner and the air conditioner control method have the advantages of being thorough in deicing, high in long-term operating stability, simple in structure and easy to implement, and improving the refrigerating and heatingeffect of the air conditioner.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

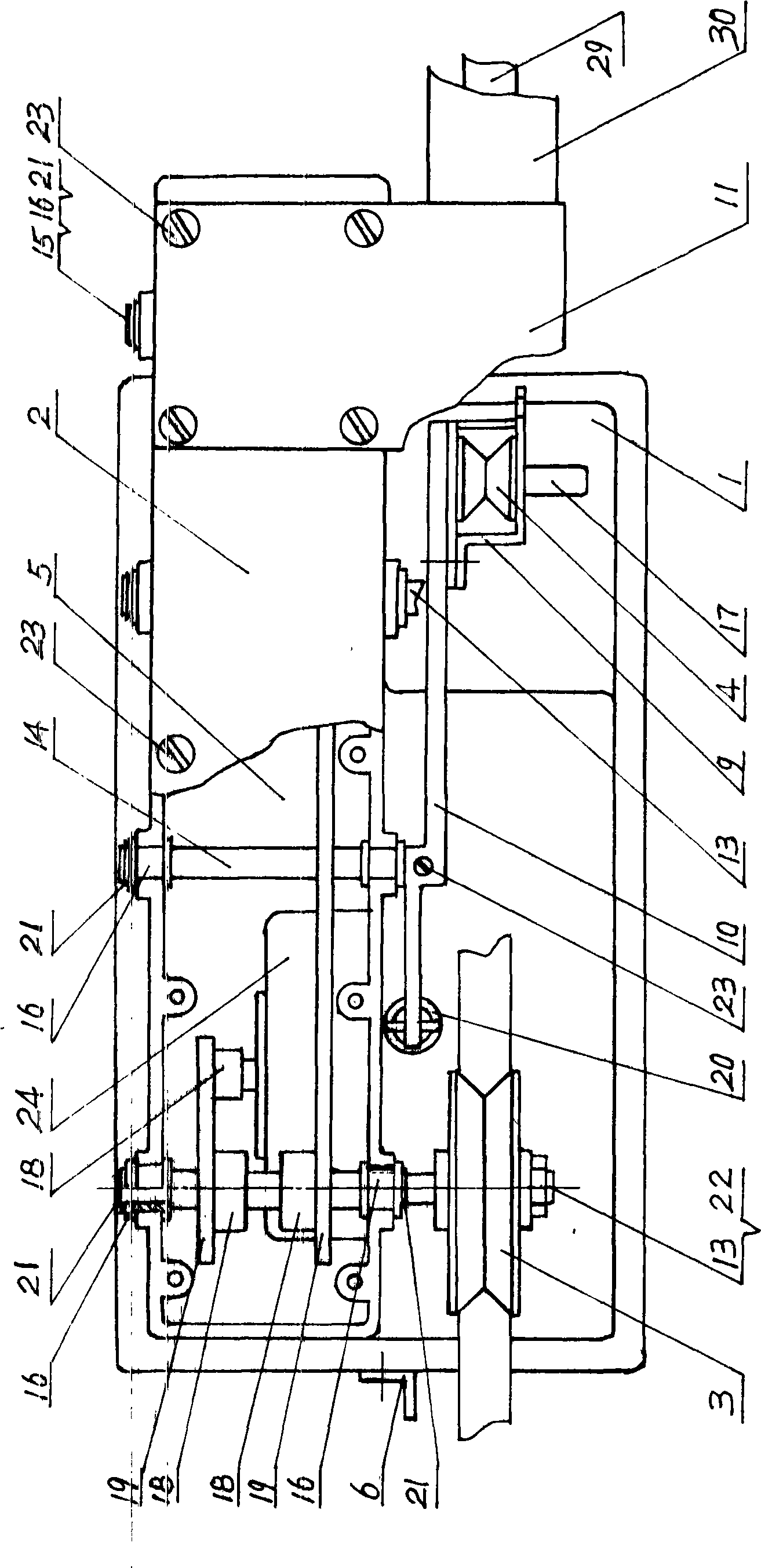

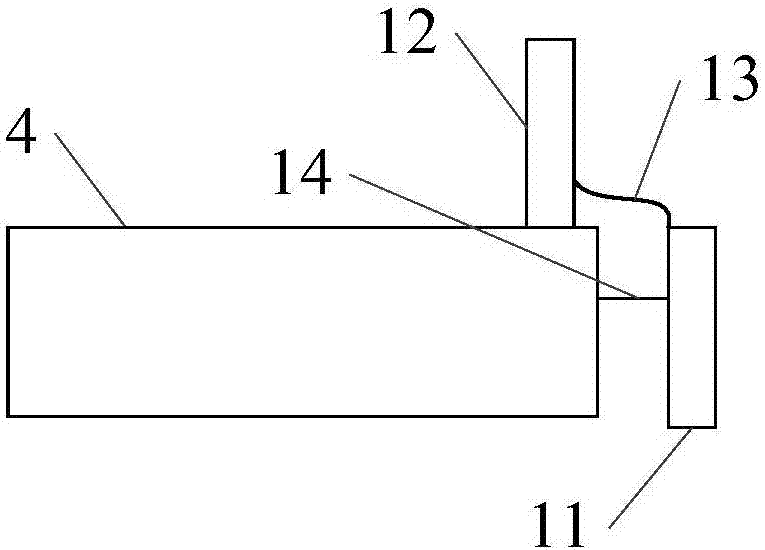

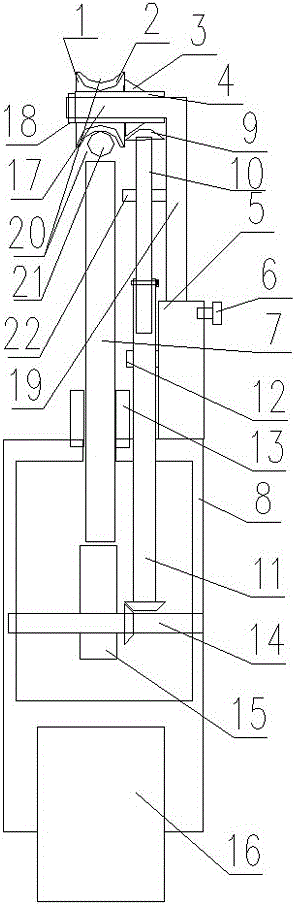

Online deicing device for 10KV loop closing circuit of distribution network

ActiveCN106058772AEffective deicingSo as not to damageOverhead installationApparatus for overhead lines/cablesElectricityLoop closing

The invention discloses an online deicing device for a 10KV loop closing circuit of a distribution network. The online deicing device comprises an insulating rod and a shell arranged on the insulating rod; a driving shaft is arranged in the shell; a deicing shovel stretching out of the shell and capable of vertically moving is arranged on the shell; an eccentric wheel for driving the deicing shovel to vertically move is arranged on the driving shaft; a deicing guide circuit protection mechanism is arranged on the shell; the deicing guide circuit protection mechanism comprises a connecting rod and a rotating shaft, wherein the connecting rod is arranged on the shell; the rotating shaft is arranged at the free end of the connecting rod; a rotary drum sleeves the rotating shaft; an idler wheel sleeves a sleeve; a groove matched with a frozen conductor wire is arranged at the circumferential side of the idler wheel; and the rotary drum and the driving shaft are connected through a driving mechanism. Power failure is unnecessary in a deicing process; and operators cannot be injured by high-voltage electricity.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

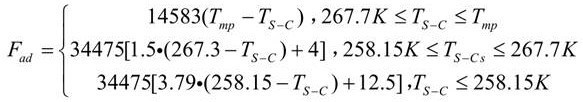

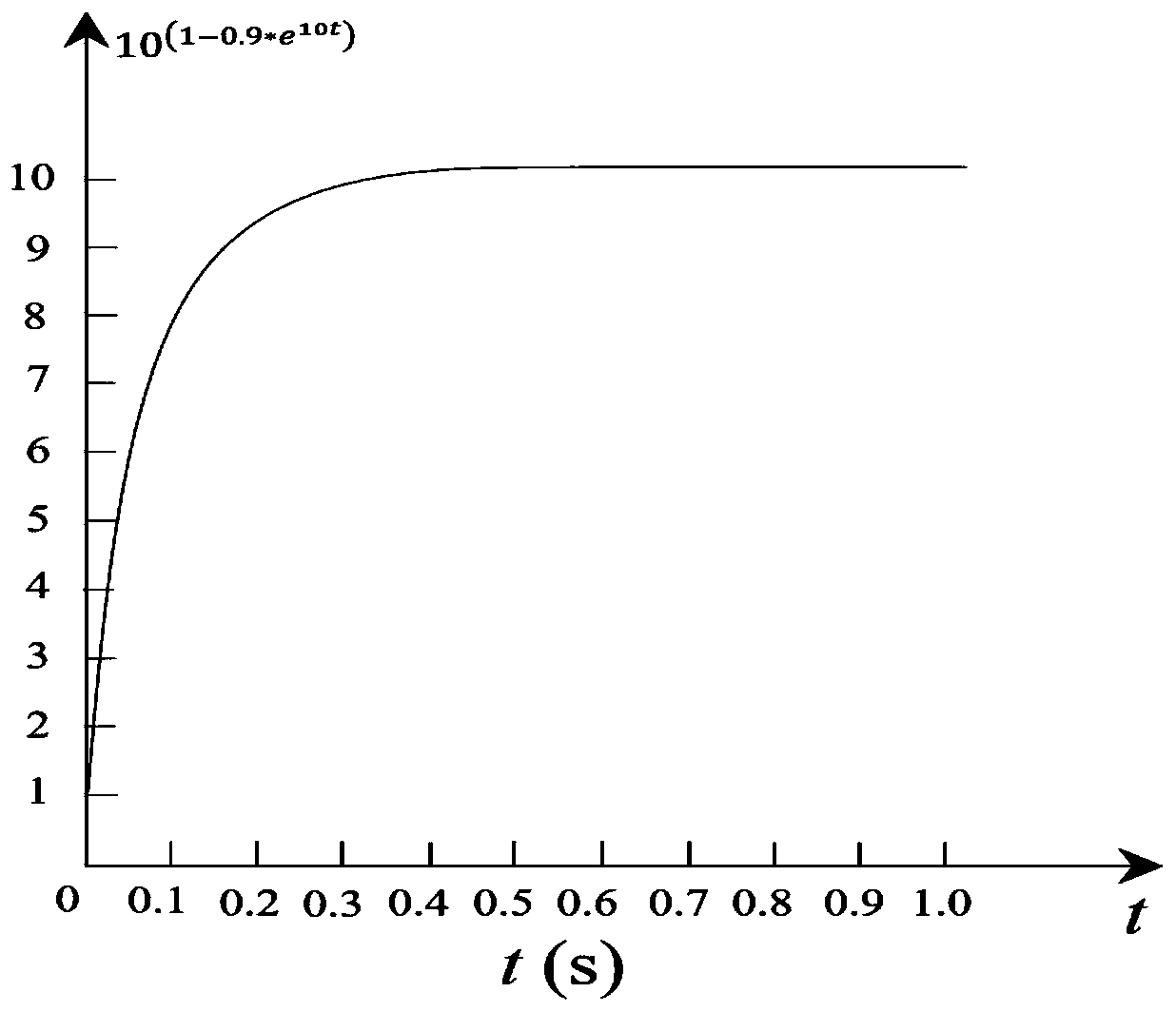

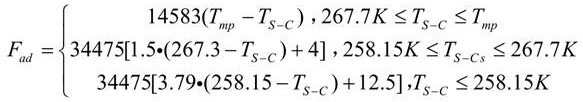

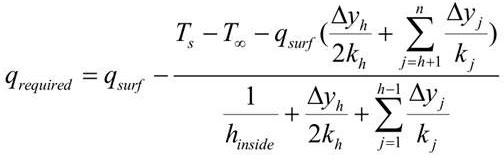

An optimized wind turbine blade deicing method

ActiveCN113236512BReduce energy consumptionIncrease economic benefitsMachines/enginesWind energy generationHeat flowTurbine blade

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

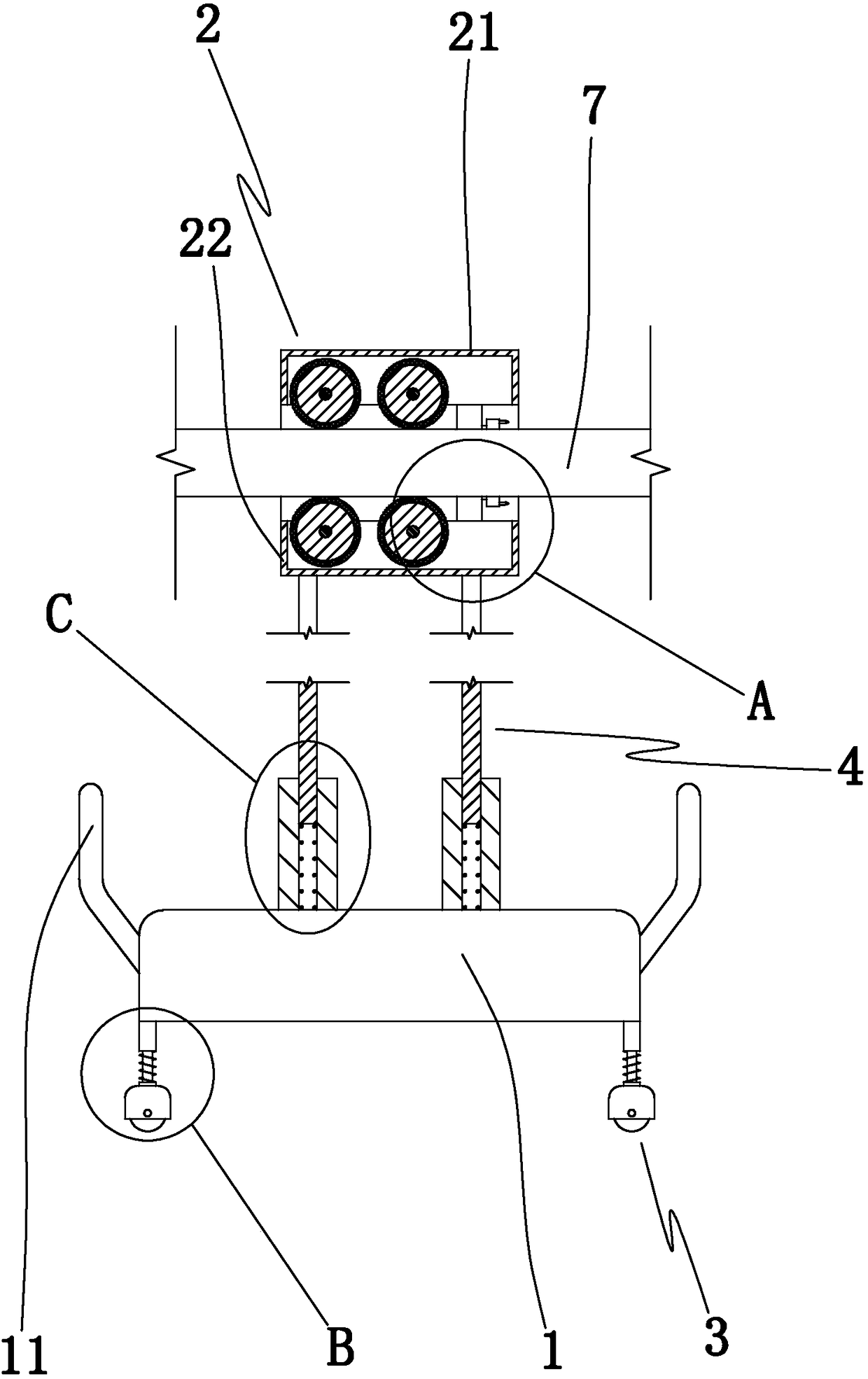

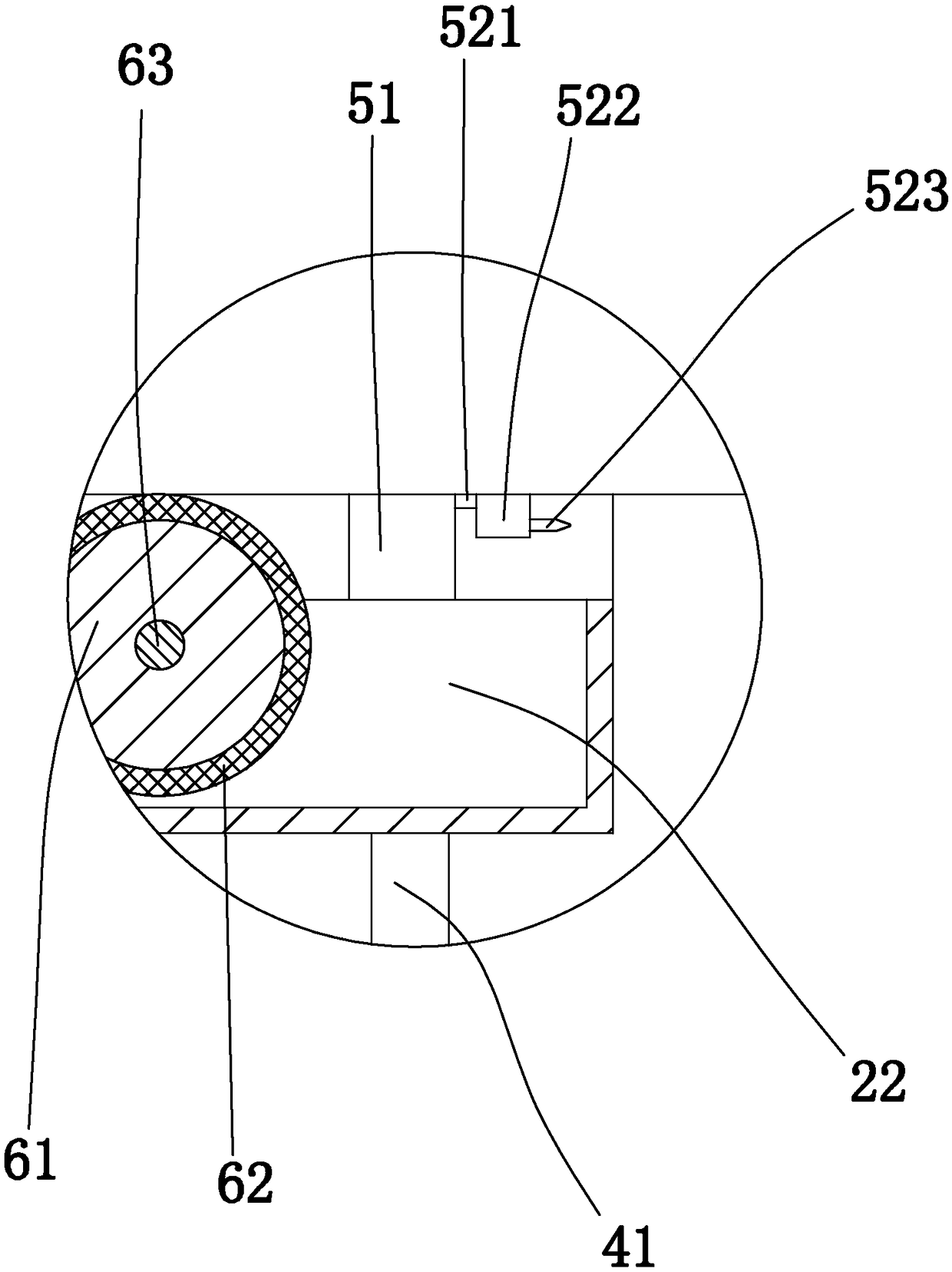

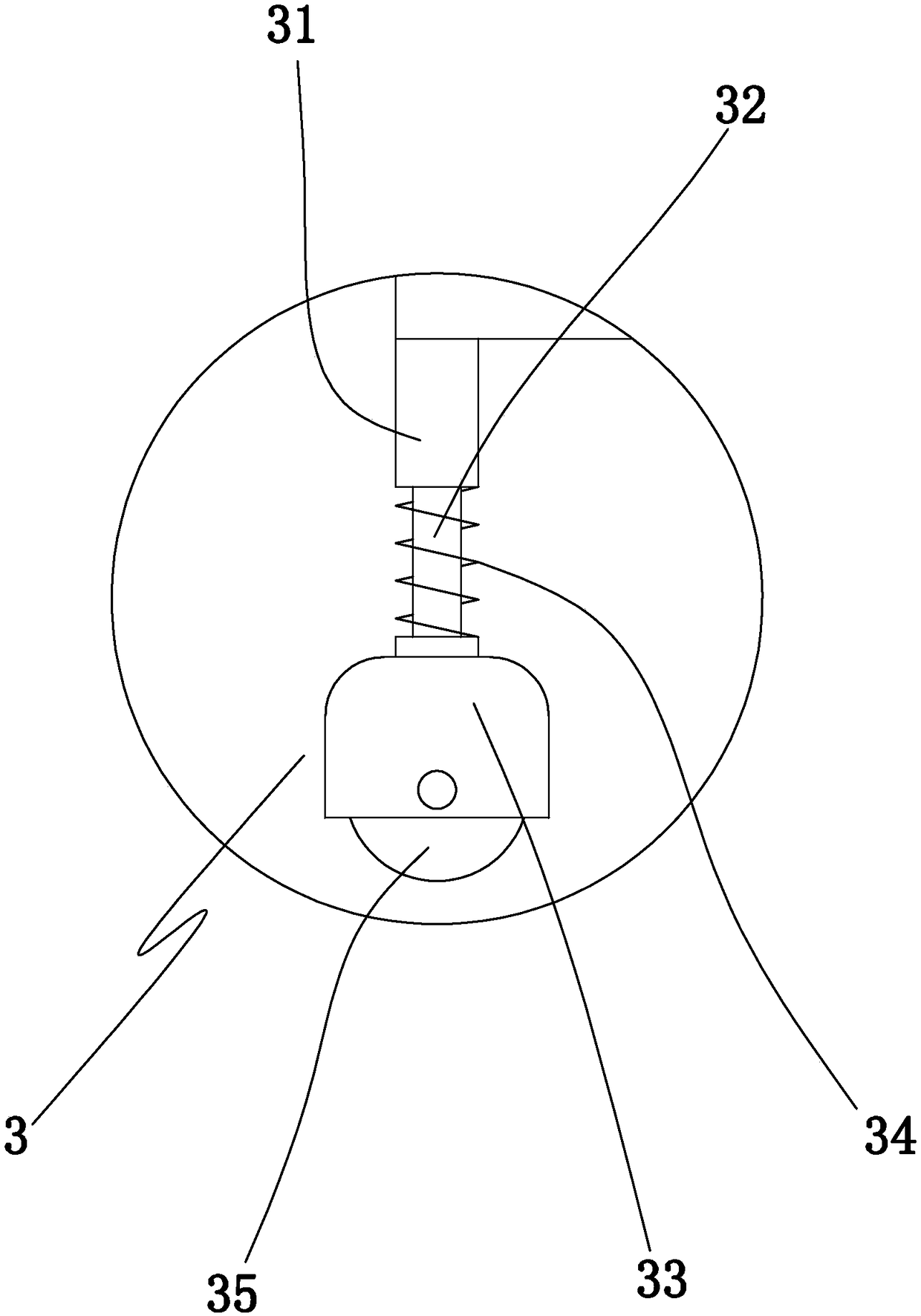

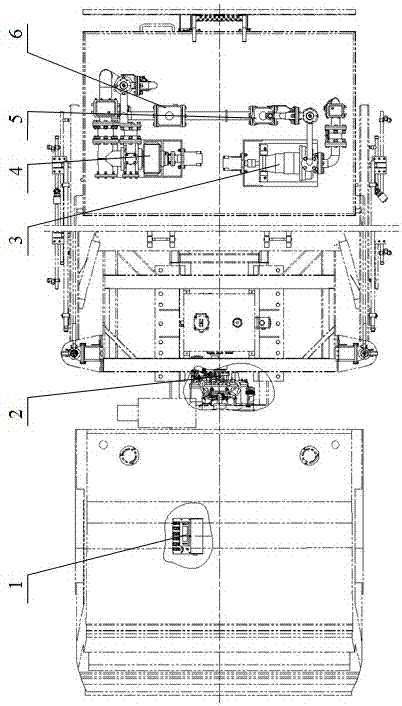

A cable short-range deicer

ActiveCN109473932BEffective deicingReasonable structureOverhead installationElectric machineryStructural engineering

Owner:国网浙江省电力有限公司磐安县供电公司 +1

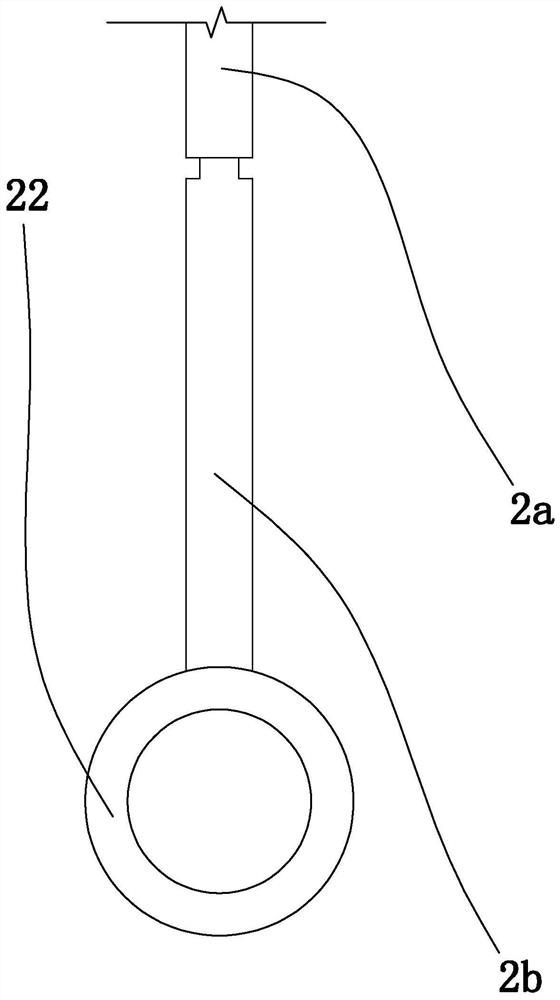

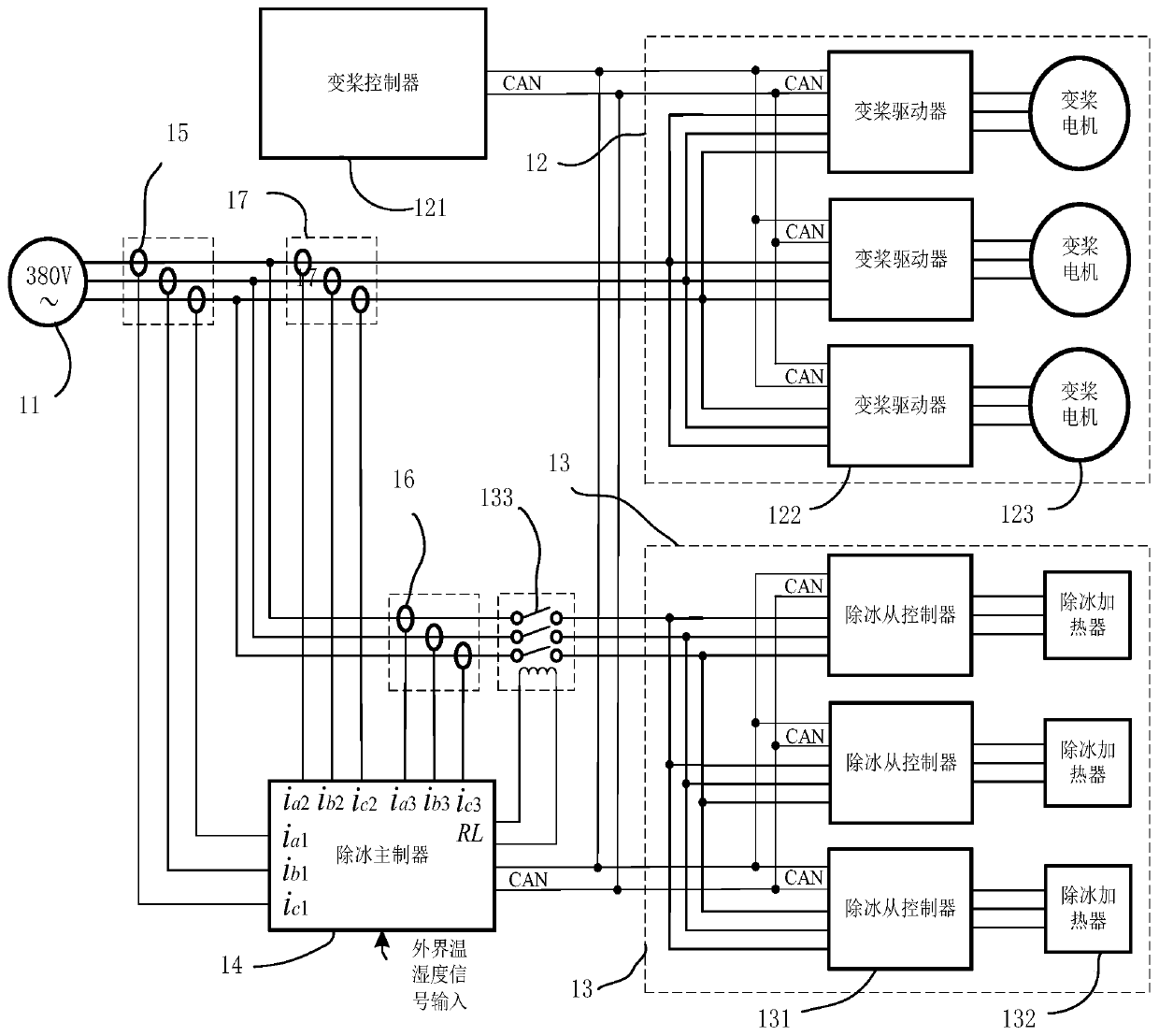

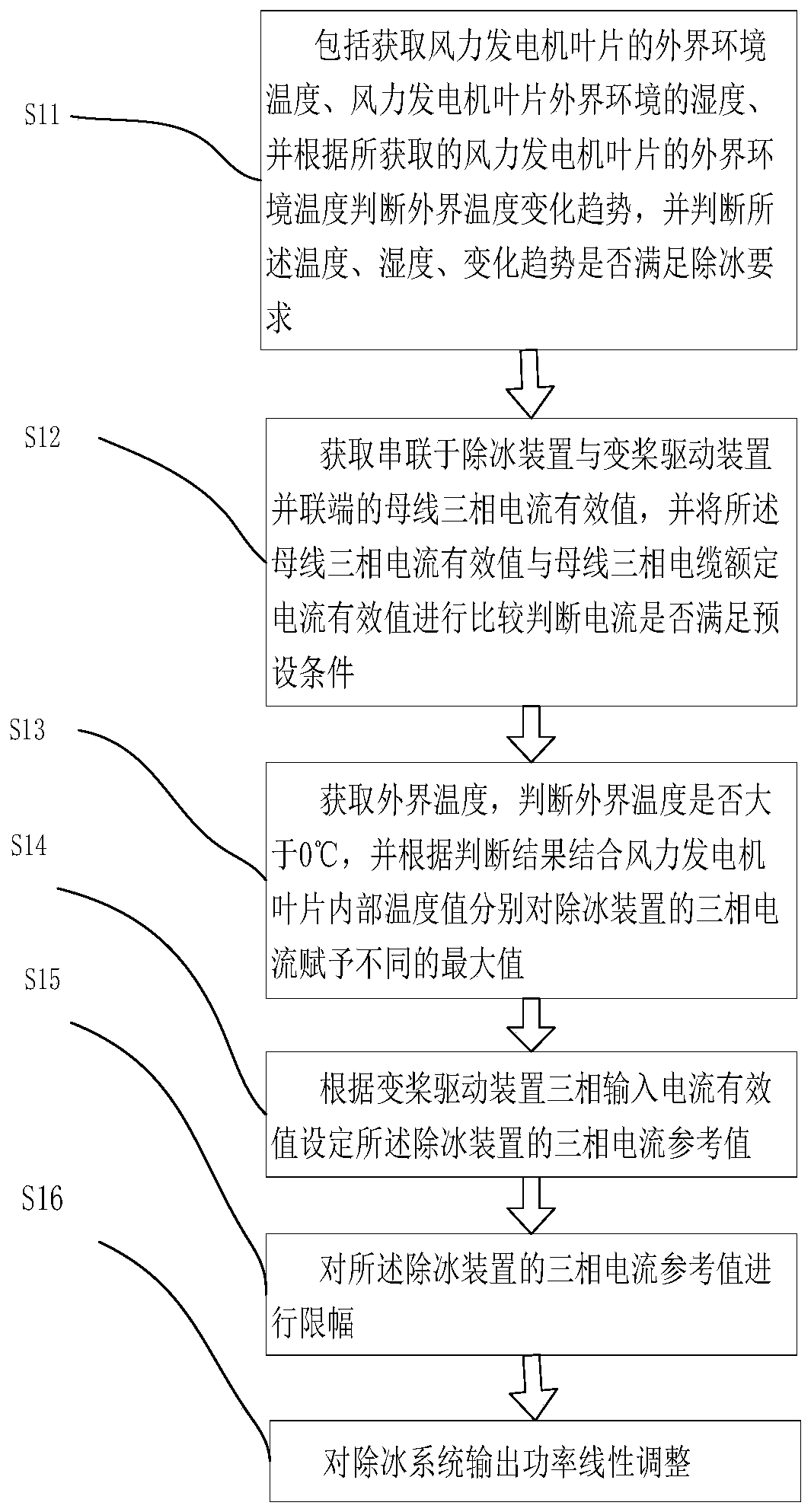

Wind turbine blade deicing method, deicing system and terminal equipment

ActiveCN110285027BReduce use costImprove production efficiencyWind motor controlFinal product manufactureWind drivenElectric cables

Owner:湖南风创能源科技有限公司

Optimized wind turbine blade deicing method

ActiveCN113236512AReduce energy consumptionIncrease economic benefitsMachines/enginesWind energy generationThermodynamicsHeat flow

The invention belongs to the field of wind turbine blade ice prevention and removal, and particularly relates to an optimized wind turbine blade deicing method. The optimized wind turbine blade deicing method comprises the following steps that a wind turbine blade is divided into a high / low-power continuous heating area and a periodic heating area; the required current heat is calculated by setting the initial value of the surface temperature of the blade; the current heat rate is adopted for testing, the current heat rate value is adjusted, and the optimal electric heat flow rate needed by the low / high-power continuous heating area is obtained; the accumulated ice shape of the periodic heating area is obtained through tests of the two optimal values, the icing resultant force is obtained through simulation calculation according to the accumulated ice shape, the icing adhesion force is made to be equal to the icing resultant force, the surface temperature of the periodic heating area is obtained through calculation, and then the electric heating flow rate needed by the periodic heating area is obtained; and finally, the optimal heat flow rate values, obtained through tests and simulation, of all the areas are used for controlling all the areas for deicing. According to the optimized wind turbine blade deicing method, energy consumption can be reduced on the basis of effective deicing, and economic benefits of a wind power plant can be improved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

Anti-blocking condenser

PendingCN114111366AImprove practicalityAvoid accumulationSteam/vapor condensersIndirect heat exchangersThermodynamicsEngineering

The invention relates to the technical field of ship condensers, in particular to an anti-blocking condenser which comprises a heat exchange cavity, the heat exchange cavity is provided with a heat source inlet and a heat source outlet, a heat exchange pipe is arranged in the heat exchange cavity and penetrates through the heat exchange cavity, and an inlet and an outlet are formed in the outer portion of the heat exchange cavity. A heat conduction structure is arranged at the position, close to the heat source inlet, in the heat exchange cavity and penetrates through the heat exchange cavity to extend to the heat exchange pipe inlet. The heat conduction structure is arranged at the heat source inside the condenser, the heat conduction structure conducts steam heat to the heat exchange pipe inlet on the outer side of the heat exchange cavity to heat crushed ice at the heat exchange pipe inlet, the heat of the condenser is fully utilized, crushed ice accumulation is effectively prevented, and the service life of the condenser is prolonged. The defect that cooling water supply is cut off due to the fact that crushed ice blocks an inlet of the heat exchange pipe is overcome, effective deicing is achieved, smooth operation in the heat exchange pipe is further guaranteed, normal work of the condenser in the crushed ice environment is guaranteed, and the practicability of the condenser is improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

An air conditioner outdoor unit, an air conditioner and a control method for the air conditioner

ActiveCN111197819BSimple structureEasy to implementCorrosion preventionRefrigeration componentsProcess engineeringHeating effect

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

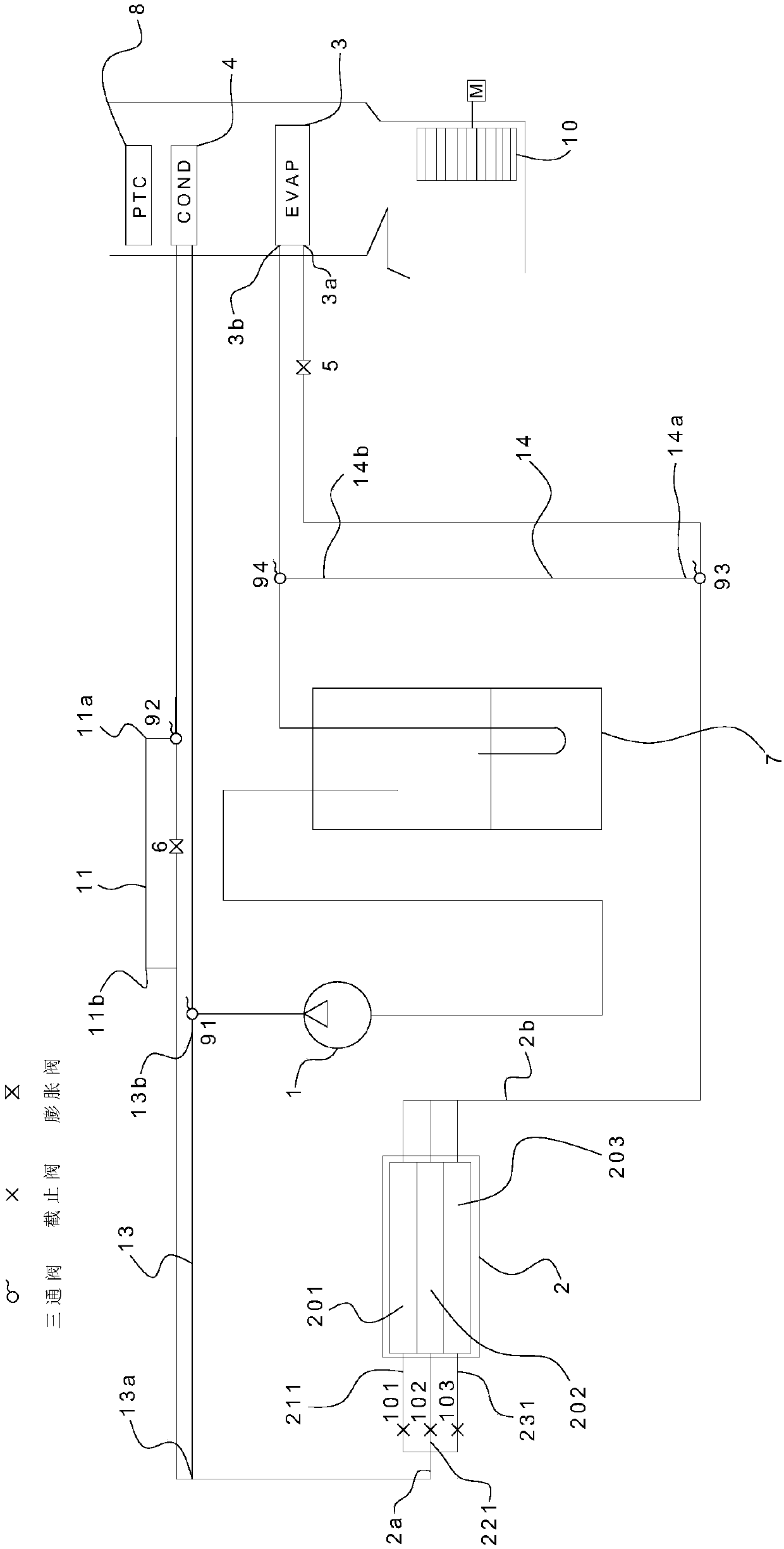

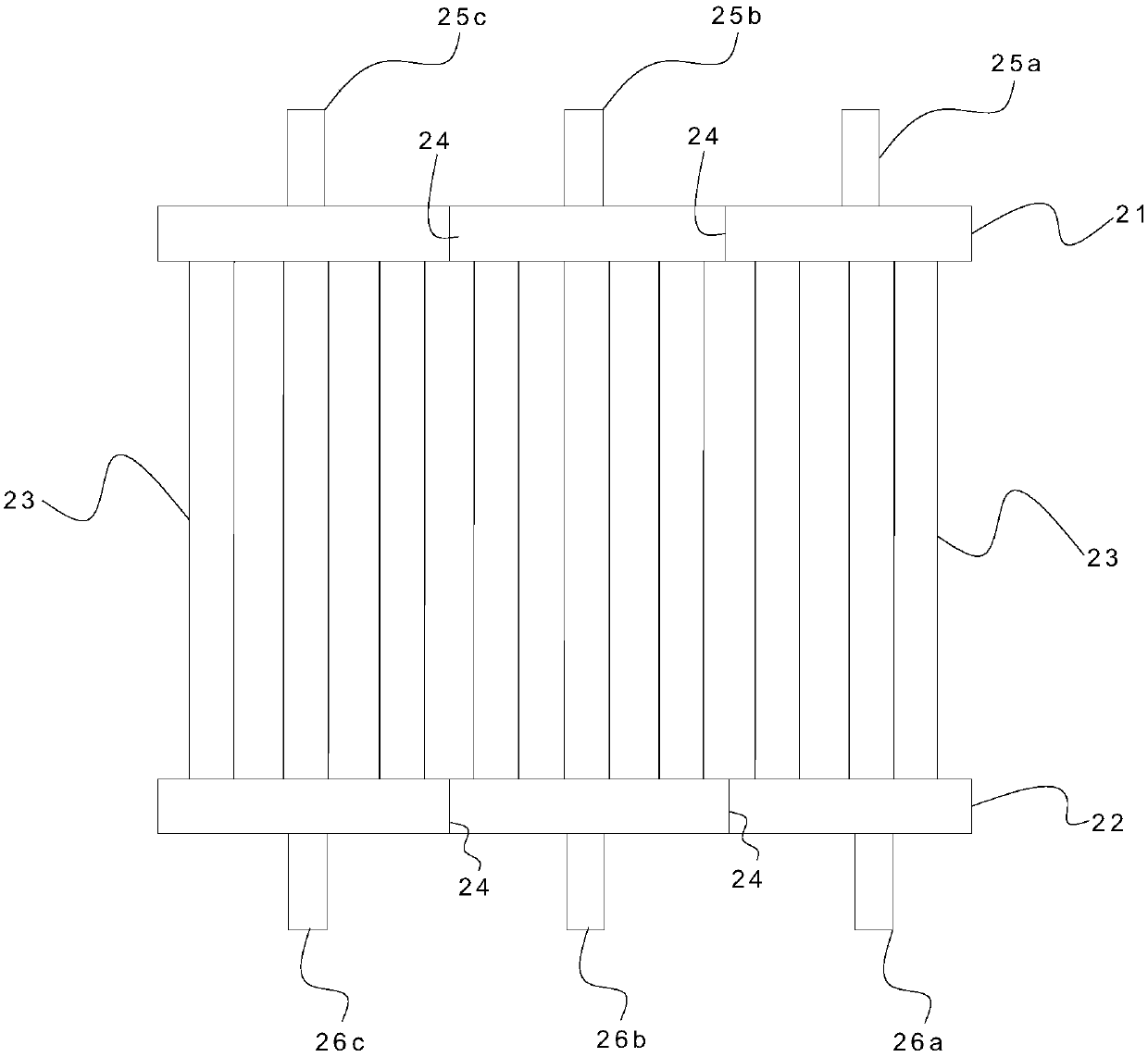

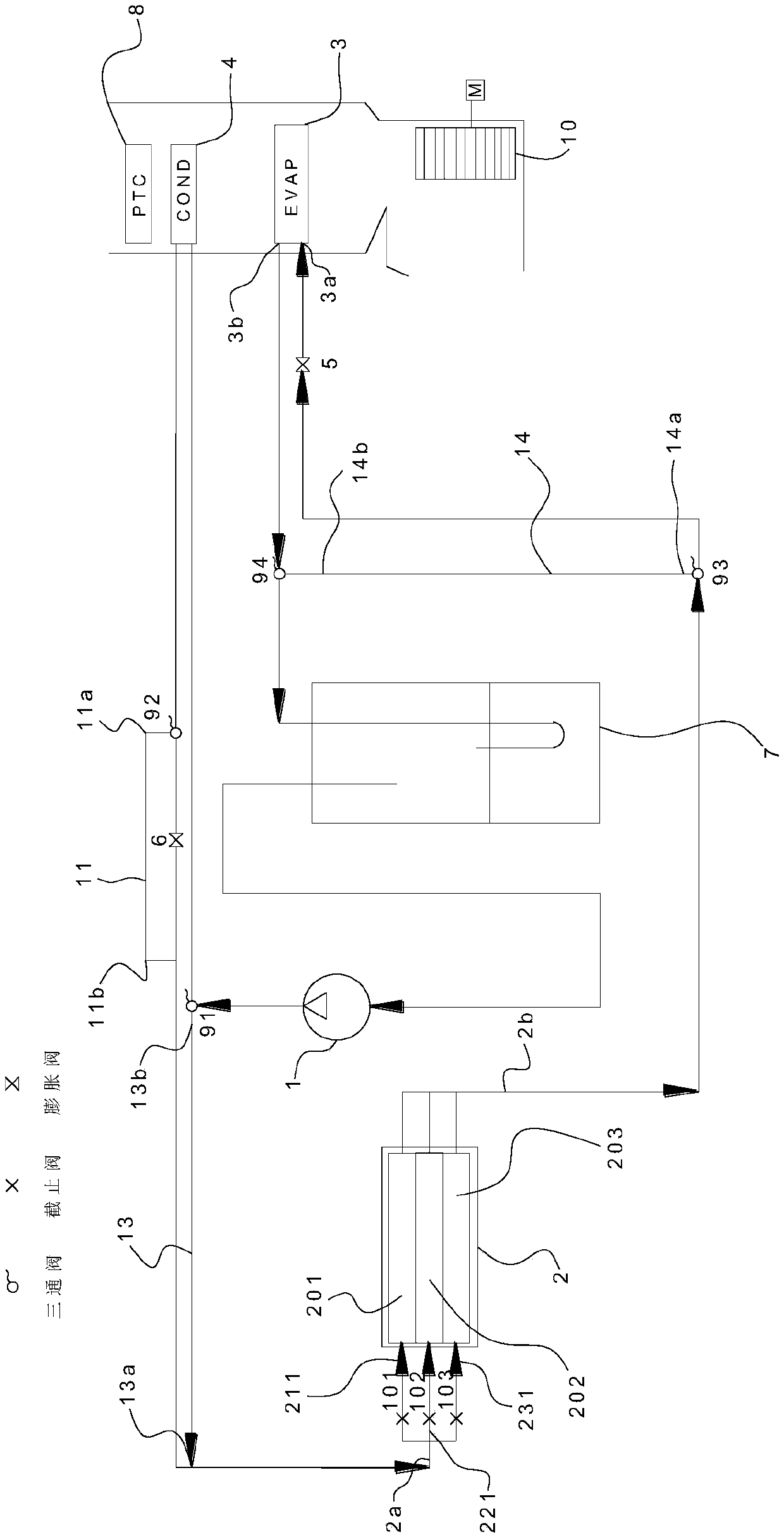

Automobile air-conditioning system

ActiveCN109572352ALess total deicing timeReduced Power RequirementsAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningEngineering

The invention discloses an automobile air-conditioning system. The air-conditioning system includes a compressor, an outdoor heat exchanger, an indoor heat exchanger, an indoor condenser and a first expansion device; the outlet of the compressor communicates with the inlet of the indoor condenser; the outlet of the indoor condenser can communicate with the outdoor heat exchanger; the first expansion device communicates with the first connection port of the indoor heat exchanger; the air-conditioning system includes a deicing mode, a heating mode and a refrigeration mode; the outdoor heat exchanger includes N outdoor heat exchanging parts, and the outdoor heat exchanging parts do not communicate with each other, wherein N >= 2; and in the deicing mode, the indoor condenser is in a bypass state, the outlet of the compressor communicates with N-1 outdoor heat exchanging parts at the most, and the N-1 outdoor heat exchanging parts communicate with the indoor heat exchanger through the first expansion device. The air-conditioning system can rapidly and effectively deice the outdoor heat exchanger.

Owner:HANGZHOU SANHUA RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com