Wind power blade gas-heat anti-icing and deicing air guide pipeline and installation method thereof

A technology for wind power blades and air ducts, which is applied in the direction of heat insulation protection of ducts, wind power generation, and duct protection. It can solve the problems of excessive contact heat dissipation of air guide ducts, difficulty in installing air guide ducts, and large heat dissipation of air guide ducts. , to prevent heat loss, improve power utilization, and reduce downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

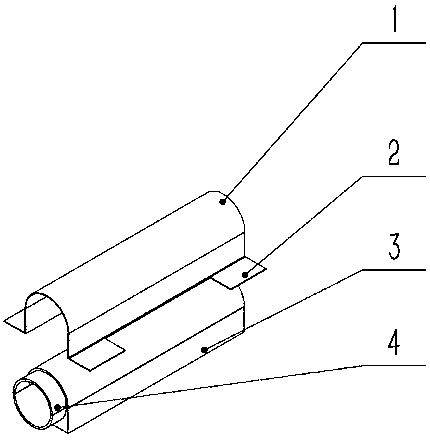

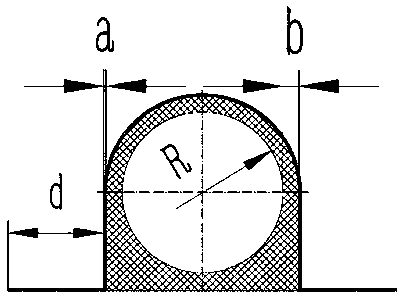

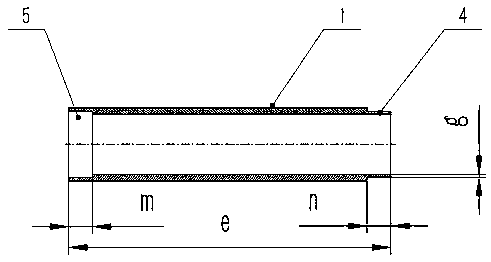

[0036] Such as Figures 1 to 3 As shown, this embodiment provides an air-heat anti-icing anti-icing air duct for wind power blades, which is formed by splicing a plurality of structural units, and the number of structural units can be determined according to the system design. In this embodiment, the structural unit is Ω-shaped, the upper part of the outer protective layer 1 is arc-shaped, and the arc-shaped inner surface is rough; the inner surface is rough to facilitate fixing with the inner layer of insulation; The inner surface of the layer should be pasted with release cloth to ensure the roughness of the inner surface of the outer protective layer.

[0037] Such as figure 1As shown, the structural unit includes an outer protective layer 1 and an inner thermal insulation layer 3. The inner thermal insulation layer 3 is made of a material with low thermal conductivity. In this embodiment, polyurethane is used, which can play a better role in thermal insulation and preven...

Embodiment 2

[0048] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that, in this embodiment, the inner layer insulation layer also includes an embedded glass fiber reinforced plastic layer 6; the middle and inner layer insulation layer of this embodiment is not integrally formed, and the specific preparation method is include:

[0049] S1. prepare a thinner layer of embedded FRP layer 6 by winding molding or pultrusion molding process, the thickness of FRP layer 6 is less than 1mm; the embedded FRP layer 6 ensures the flatness and smoothness of the inner surface of FRP of the inner layer, and another On the one hand, the upper inner protective layer and the lower inner protective layer play a connecting role;

[0050] S2. Prepare a mold for foam foaming, the mold includes an upper half mold and a lower half mold, and the upper half mold and the lower half mold are respectively foamed and filled with polyurethane foam to form an upper inner layer ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com