Patents

Literature

112results about How to "Guarantee the quality of workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In situ deposit-aqueous interface water-quality sampler and sampling method thereof

InactiveCN101608982AStrong maneuverabilityEasy to place and recycleWithdrawing sample devicesMembrane configurationEngineering

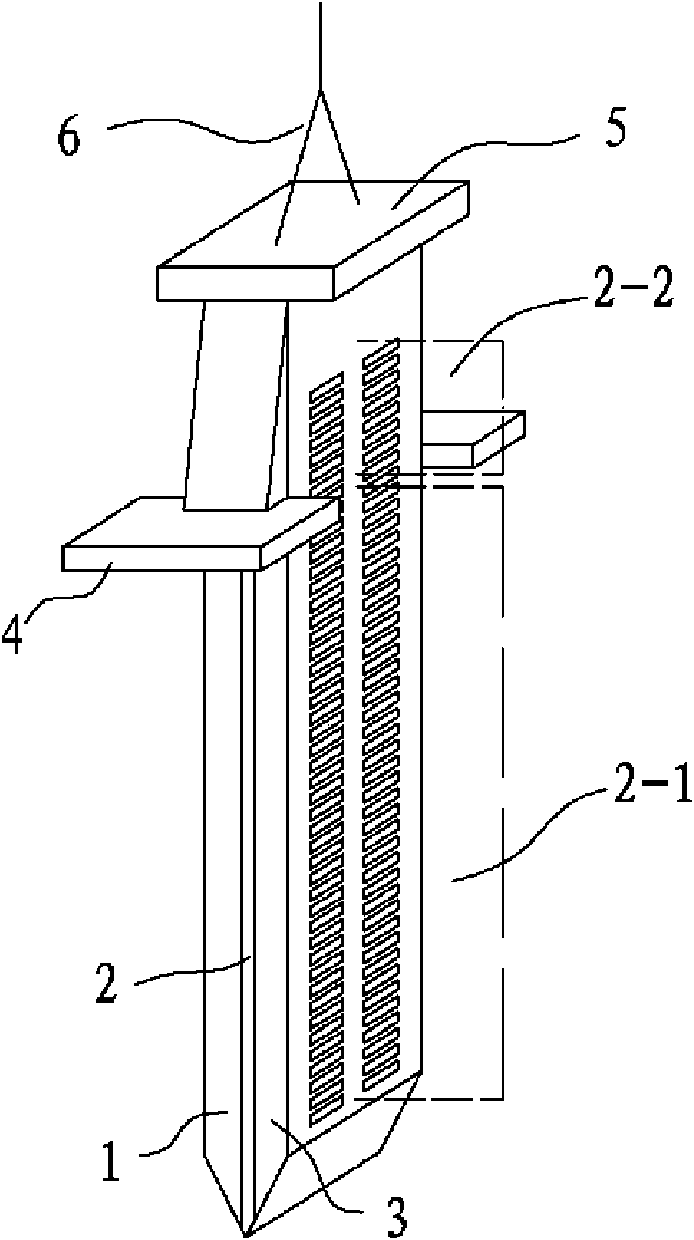

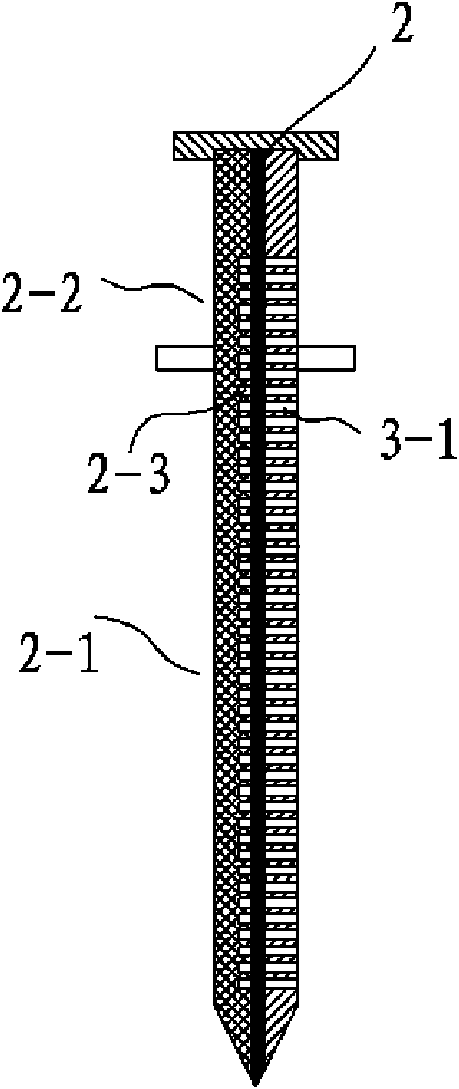

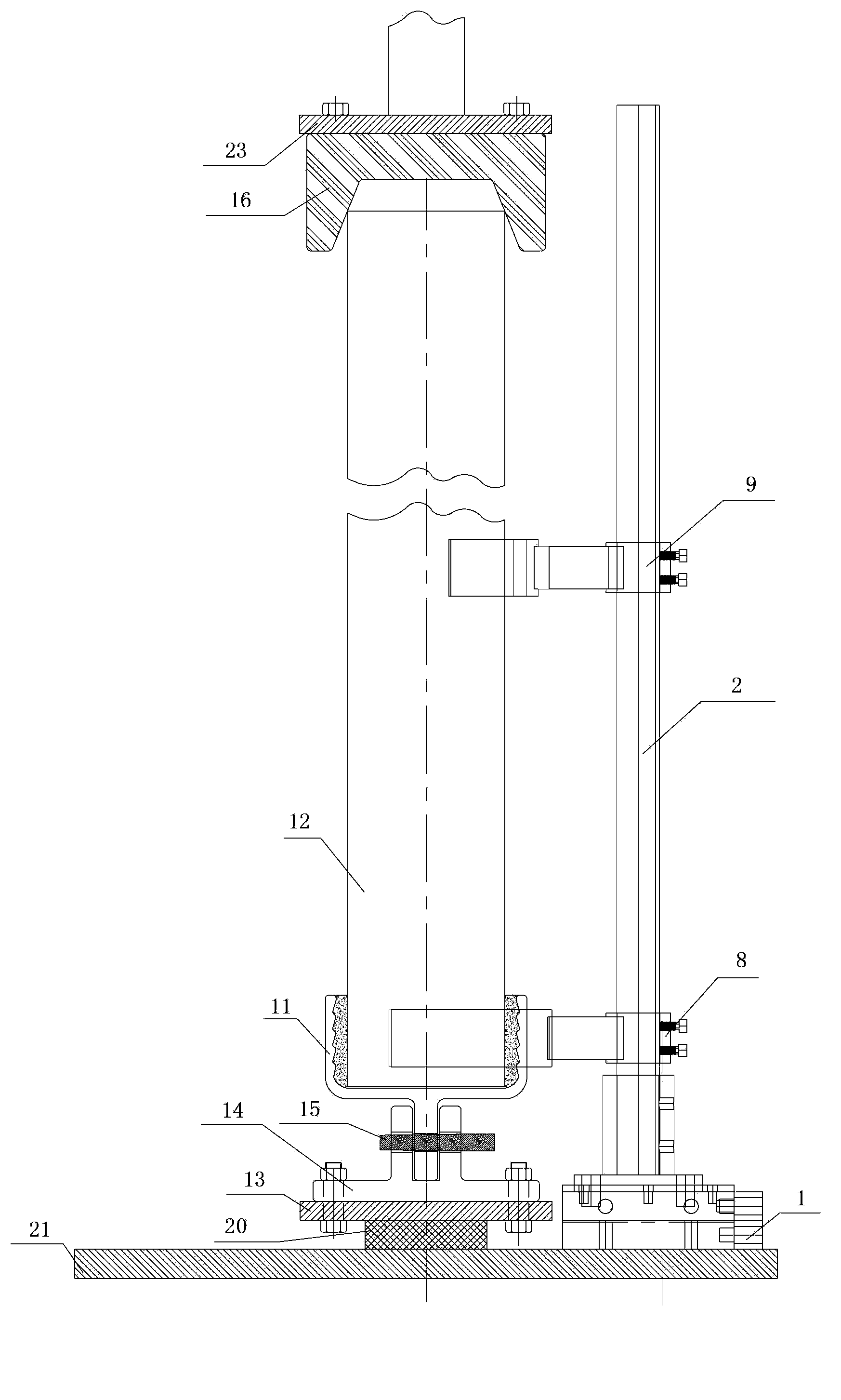

The invention relates to an in situ deposit-aqueous interface water-quality sampler and a sampling method thereof. The sampler adopts a group of sampling plates and a group of protecting plates to clamp osmosis membranes and fix the osmosis membranes together by screws; the sampling plate is divided into an interstitial water sampling section of deposit and an overlying water sampling section of an interface in longitudinal direction; a plurality of transverse grooves which have longitudinal intervals of 2mm to 3mm are arranged on the interstitial water sampling section of deposit and the overlying water sampling section of the interface; the volume of the groove is between 2000microlitre to 4000microlitre; an interfacial limiting plate is arranged between the interstitial water sampling section of deposit and the overlying water sampling section of the interface; the sampler realizes in situ collection of deposit-aqueous interface water-quality samples, adopts an interfacial limiting device, and can accurately determine the deposit-aqueous interface; the sampler is equipped with a weight drop and a retrieve rope, can be used in aquatic deeper lakes, and has operability, site throwing and convenient retrieving; and the volume of each layer of water-quality sampling room reaches to 4000microlitre and can complete more index analysis simultaneously.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

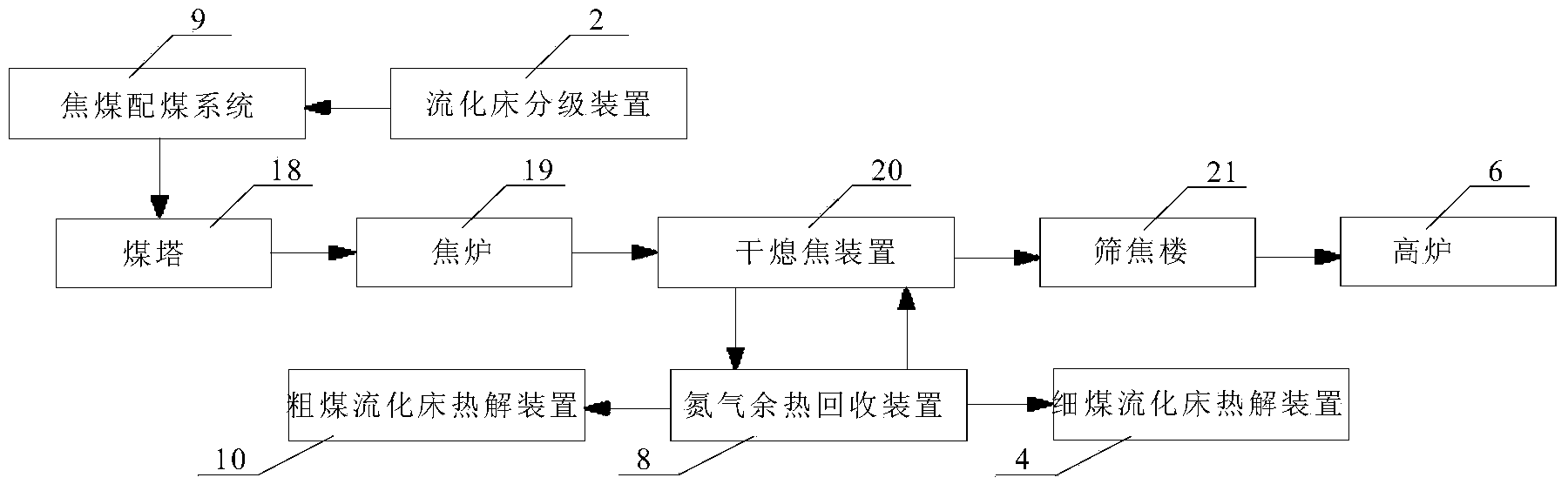

Fluidized-bed low-rank coal upgrading utilization system and method

InactiveCN103710037AAvoid "extensive use" situationsRealize utilization by qualityEnergy inputSpecial form destructive distillationProcess systemsCombustion

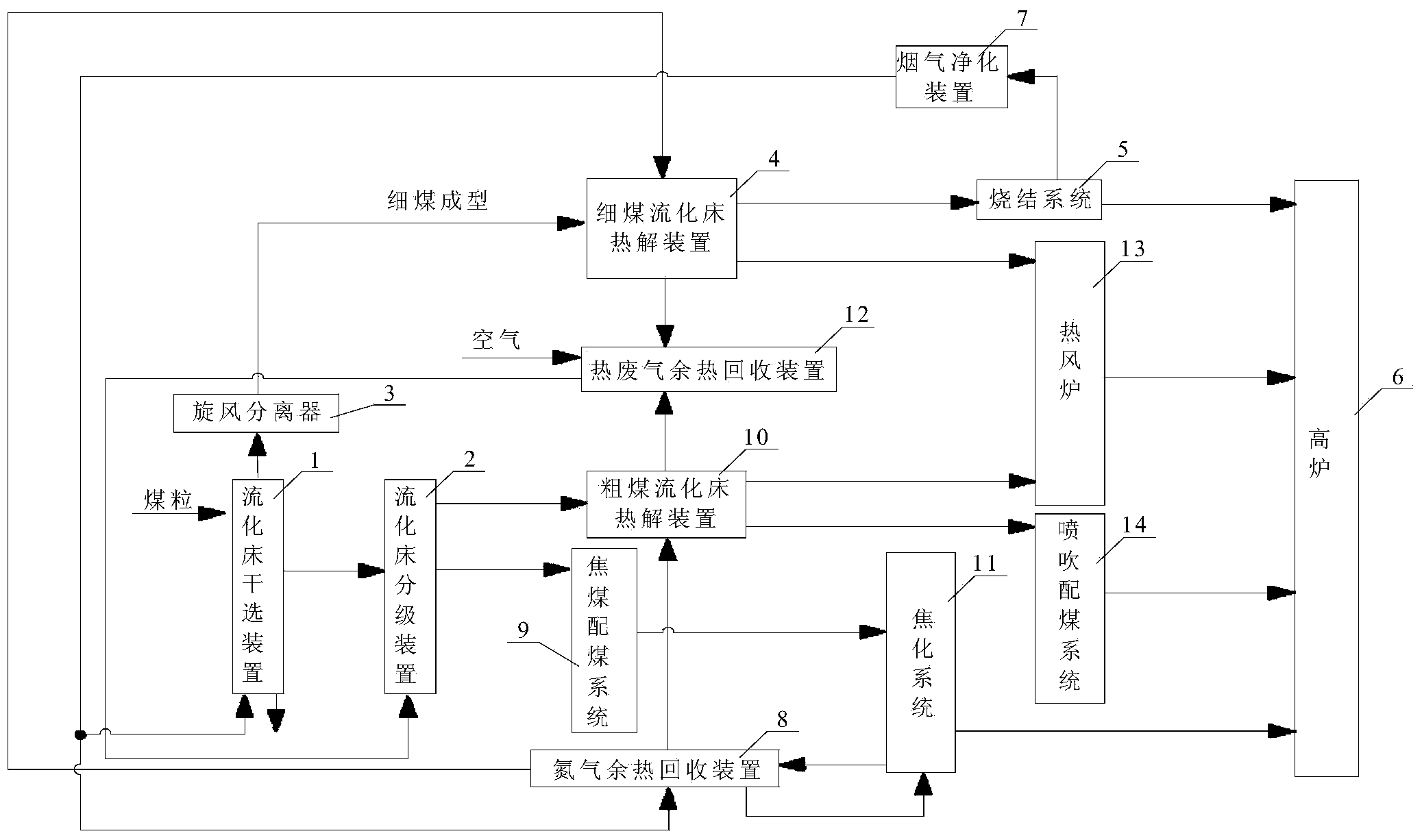

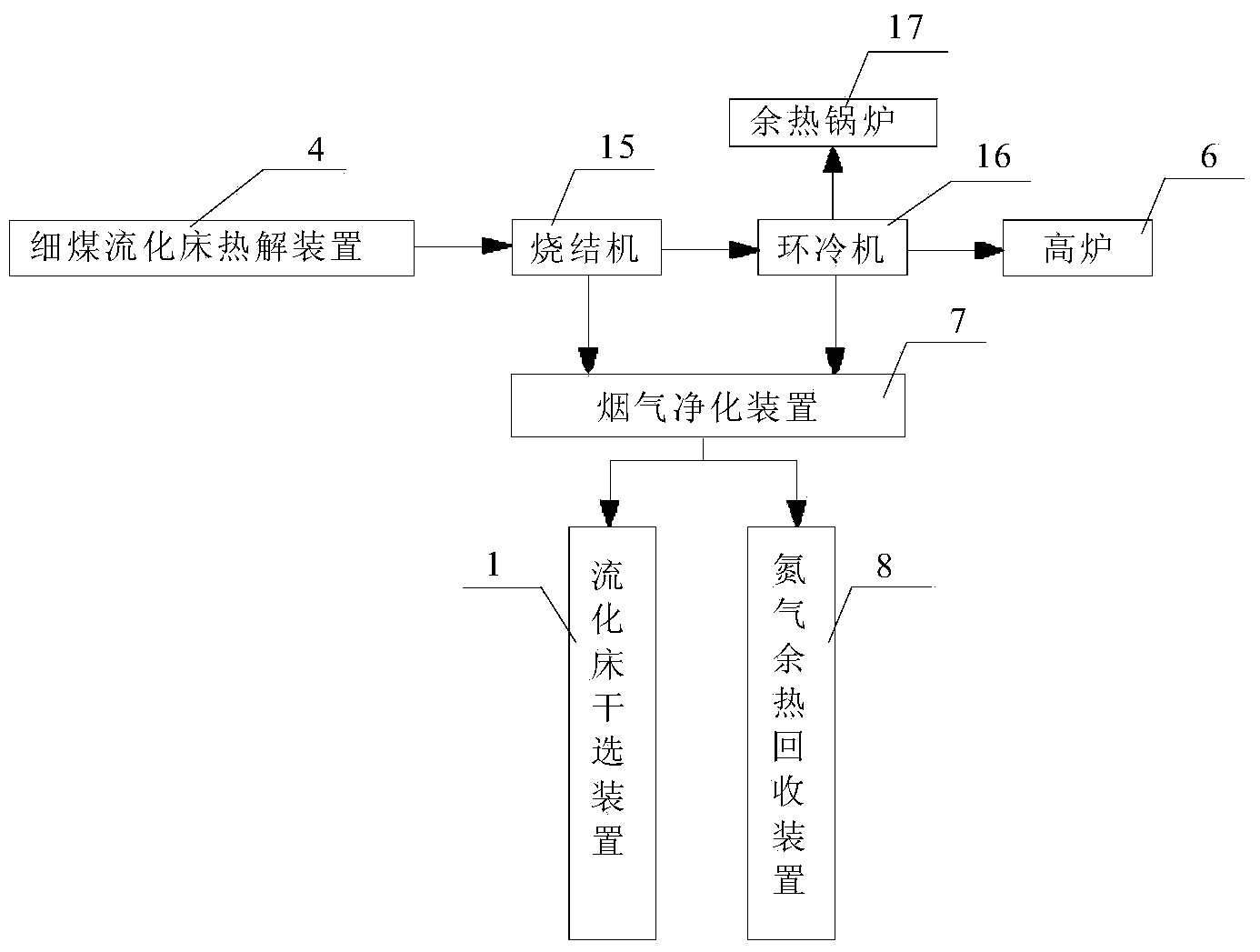

The invention provides a fluidized-bed low-rank coal upgrading utilization system and method, and belongs to the technical field of low-rank coal upgrading utilization. According to the invention, a washing system, a pyrolysis system and an iron-making system of the low-rank coal are coupled together. Firstly, the low-rank coal is subjected to washing treatment so that size grading of the coal is completed while waste stone is exhausted. The coal powder different in particle size is used for a coking system to prepare coke and joins in medium and low temperature pyrolysis to prepare semicoke. The semicoke obtained through pyrolysis is used as coal for sintering and blended coal for injection, respectively; the by-product gas of pyrolysis is fed into a hot blast stove for combustion, wherein waste heat generated by the sintering and coking process systems is recovered for the washing system and the pyrolysis system; and finally, the sinter, the hot air, the injection coal and the coke are fed into a blast furnace for iron-making. According to the invention, the separation, grading, drying and pyrolysis of the low-rank coal are realized; the low-rank coal is utilized after being upgraded in stead of partial high-rank coal; and therefore, the cost of iron per ton can be effectively reduced and the stress of the demand of the iron and steel industry for the high-rank coal can be reduced.

Owner:TSINGHUA UNIV +1

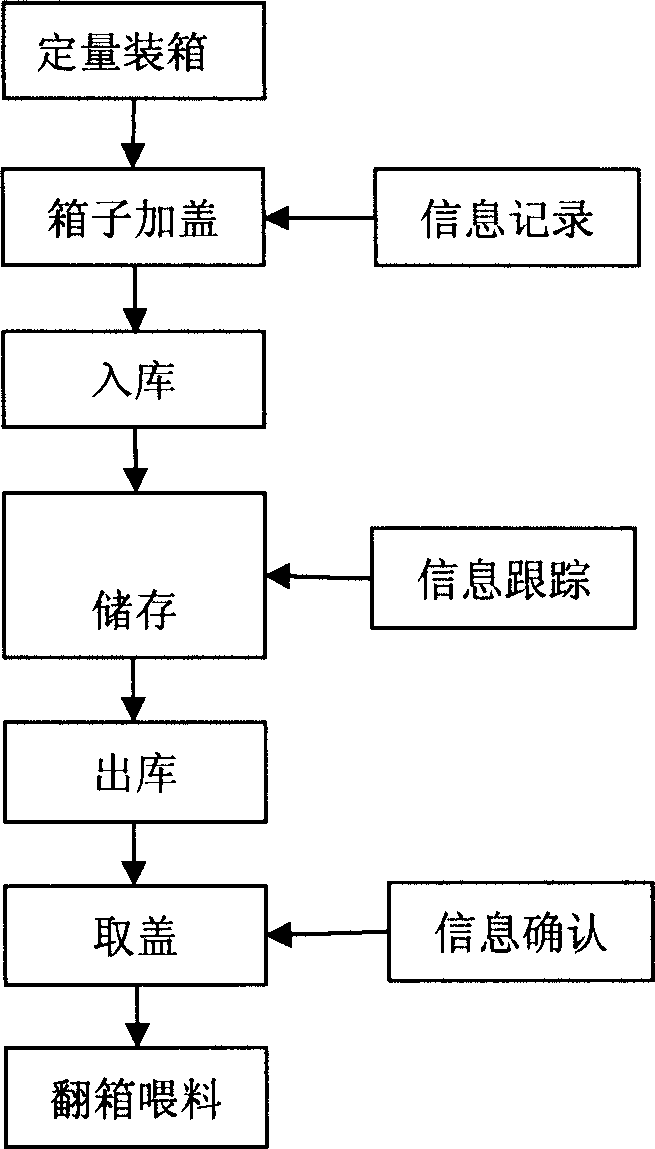

Tobacco leaf automatically boxing storage method

ActiveCN1875793AReduce volumeEliminate the limitation of uneven suction timeTobacco preparationComputer scienceManufacturing line

The invention discloses a storing method of tobacco automate-box, which comprises the following steps: loading quantitative tobacco leaf; adding cover; weighing; recording information; placing in the warehouse; storing and tracing information; taking out after enough reserving time; removing cover to record information; sending the box to subsequent turning-over feeding procedure. The invention guarantees the technological quality of subsequent throwing, which realizes optimum management for entire procedures and equipments.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

Tool special for controlling peeling of cable

ActiveCN103515876AProtection securityImprove efficiencyApparatus for removing/armouring cablesEngineeringBlock structure

The invention discloses a tool special for controlling peeling of a cable. The tool comprises a sleeve, the side wall of the sleeve is provided with a first sliding groove, the inside of the first sliding groove is provided with a movable sliding block structure, the movable sliding block structure is fixedly provided with a movable cable clamp, the upper portion of the movable cable clamp is provided with a corresponding fixed cable clamp, the face, opposite to the movable cable clamp, of the fixed cable clamp is fixedly provided with a sliding bearing, a ball-shaped universal wheel is arranged in a bearing bush of the sliding bearing, and one portion of a ball-shaped wheel of the ball-shaped universal wheel is located outside the sliding bearing. The tool can be used for peeling outer skin of control cables of various models, work efficiency of the cutting process is more than twice than that of a traditional method, cable wire cores and safety of operators can be effectively protected, and good practical value is achieved.

Owner:STATE GRID CORP OF CHINA +1

Biomass fuel forming mold surface powder metallurgy strengthening coating material and process

The invention belongs to the technology for improving biomass fuel forming mold surface hardness (namely improving abrasion resistance of the surface) and particularly relates to a biomass fuel forming mold surface powder metallurgy strengthening coating material and a process which aim at solving the problem of serious abrasion of the biomass fuel forming mold surface. The process includes: weighing appropriate mass of powder according to the area of the portion of a mold needing strengthening and the thickness of a pre-strengthening layer, wherein the powder is composite powder formed by mixing cobalt / nickel-based self-fluxing alloy powder and non-metallic ceramic powder in proportion; adding appropriate amount of bonding forming agents in the composite powder and sufficiently mixing through vacuum stirring to obtain plastic powder bodies; and evenly coating the powder bodies on the biomass fuel forming mold surface, drying and conducting powder metallurgy strengthening in a vacuum furnace according to corresponding temperature rising curves. Hardness of a powder metallurgy strengthening coating can reach rockwell hardness (HRC) 50-70, the thickness is above 2 mm, the coating is smooth, light and free of pore cracks, and a binding interface between the coating and a substrate is fused in metallurgy mode and is even in texture and free of obvious defects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for manufacturing film LED chip device based on gapless plane bonding

ActiveCN101465402AGuaranteed flatnessImprove flatnessSemiconductor devicesOptoelectronicsLaser beams

The invention discloses a preparation method of a film LED chip device based on the gapless plane bonding; the method makes use of the smooth surface of an epitaxial wafer without isolated processing to prepare a permanent or temporary substrate; then laser beams are used for unit isolated processing of devices at the interface position between the epitaxial layer and the substrate so as to ensure the combination yield rate of the substrate and the epitaxial layer, thereby ensuring the film-remaining yield rate of the epitaxial thin film layer after laser stripping and also simplifying the traditional production process.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

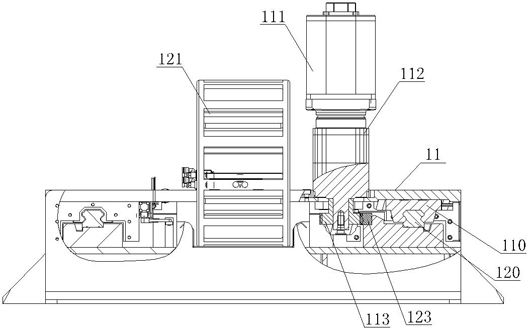

Planar optical waveguide structure and coupling structure and coupling method thereof

ActiveCN105759374AGuarantee the quality of workmanshipShorten the lightCoupling light guidesProcess qualityDirect coupling

The invention relates to the technical field of optical waveguide coupling and provides a planar optical waveguide structure and a coupling structure and a coupling method thereof. The planar optical waveguide structure comprises a single-mode active device and a planar optical waveguide, wherein the planar optical waveguide comprises a silicon dioxide waveguide for transmitting optical signals, the silicon dioxide waveguide is composed of a coupling section and a conduction section, the coupling section is of a trapezoidal structure or a reverse trapezoidal structure, the face, coupled with the single-mode active device, of the coupling section is a trapezoid top, and the face, connected with the conduction section, of the coupling section is a trapezoid bottom. A coupling spacing gap is preformed between the single-mode active device and the planar optical waveguide. Passive beam focusing and direct coupling from a laser device to PLC are completed by adopting the planar optical waveguide structure, the structure can be completed by adopting an automatic device, the process quality can be greatly ensured, the time for beam focusing and welding is shortened, and accordingly the purpose of reducing the costs is achieved.

Owner:WUHAN TELECOMM DEVICES

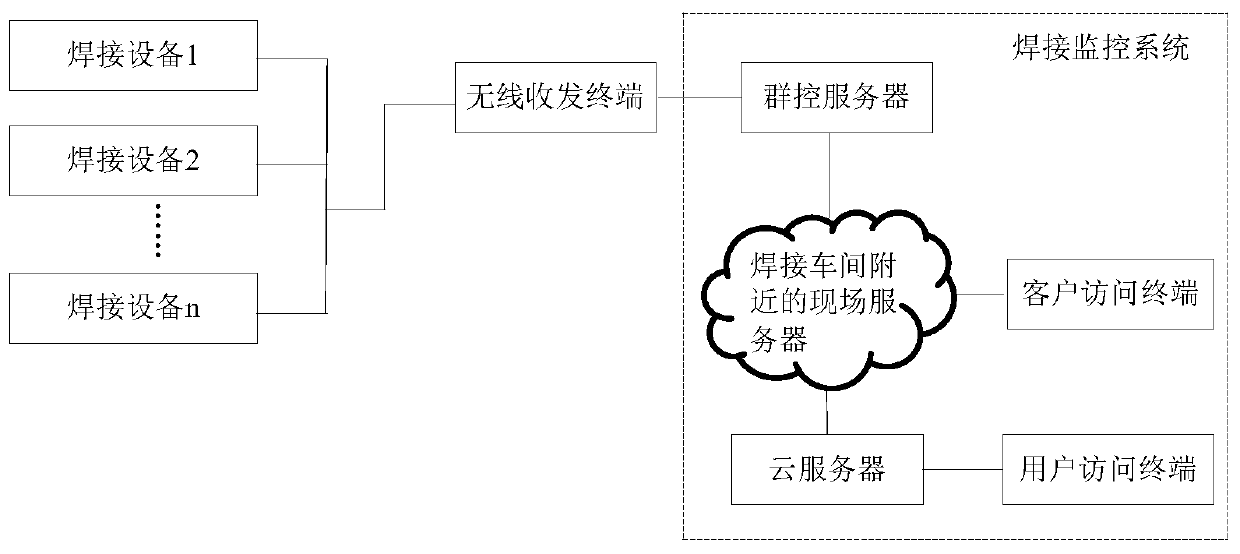

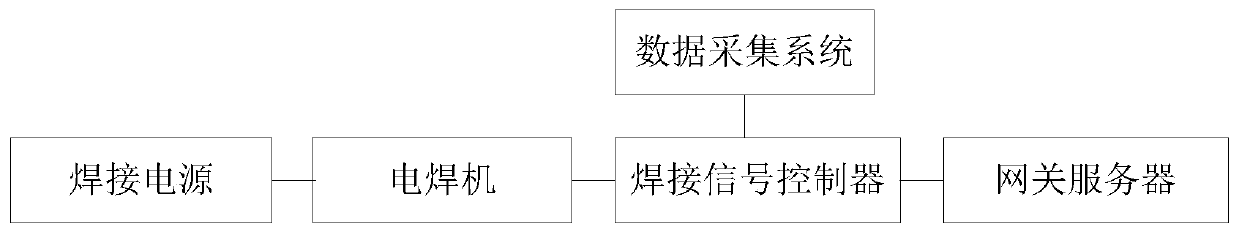

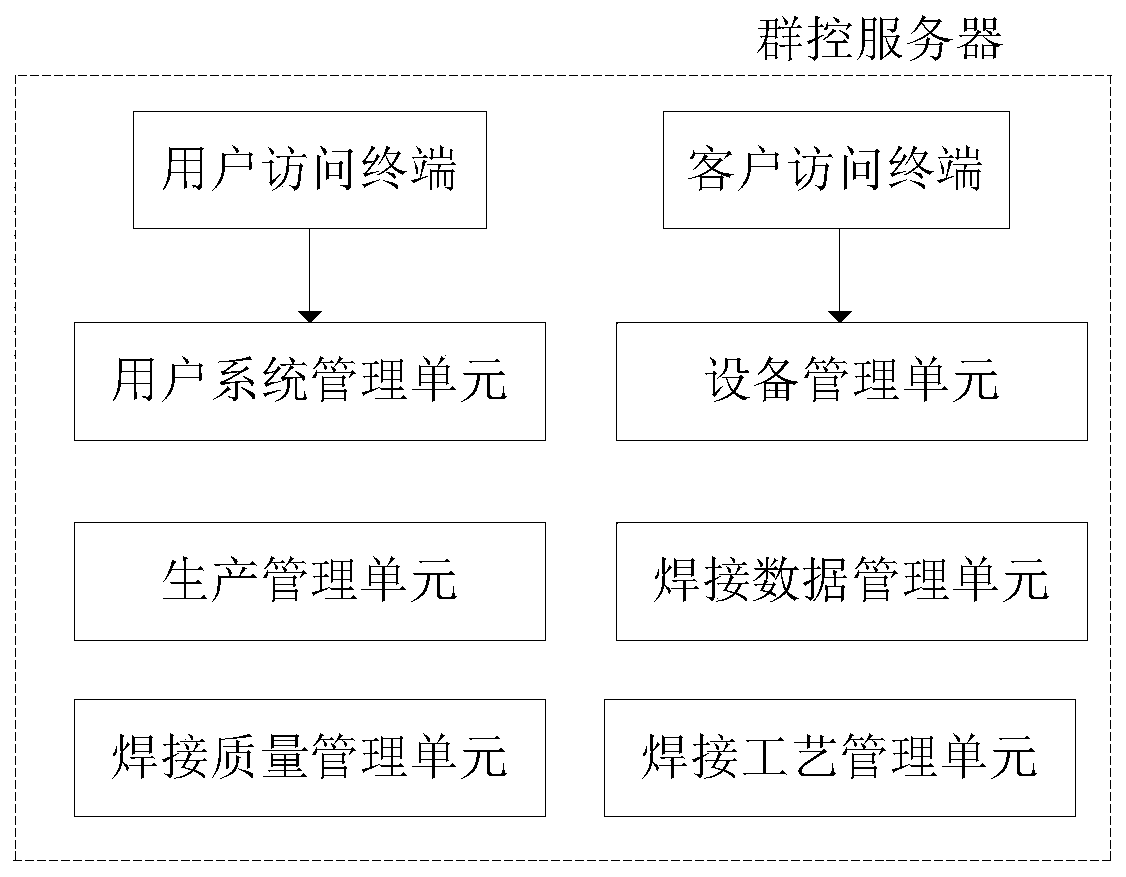

Informationized welding management control system and control method

PendingCN110193686AReal-time monitoring of welding operationsSimple networkingWelding/cutting auxillary devicesAuxillary welding devicesControl systemControl engineering

The invention discloses an informationized welding management control system and control method. The welding management control system involves one or more welding device arranged in a welding workshop and a welding monitoring system in communication connection with the welding device; the welding device comprises a welding machine power supply, a welding machine, a gateway server, a data acquisition system and a welding signal controller, wherein the data acquisition system and the welding signal controller are embedded in the welding machine, the welding machine power supply is electricallyconnected with the welding machine, the data acquisition system and the welding signal controller which are embedded in the welding machine, the gateway server and the data acquisition system are electrically connected with the welding signal controller, and the gateway server is in communication connection with the welding monitoring system so as to realize the management and control of the welding process information. According to the system and the method, the welding device can be controlled and managed, and the running state of the welding device can be monitored, so that the automation level and the management level of the welding workshop are improved, and the control of the product welding quality is improved.

Owner:南宁嘉昌机电设备有限责任公司

Poly blade hard metal drill

InactiveCN101157150ACutting costsAvoid frequent drill changesTransportation and packagingTrepanning drillsMetalworkingHard metal

The invention relates to a multi-edge solidness alloy drill, which belongs to the technical field of metal processing tool. The invention comprises a shank, a chamfer cutting edge arranged at the lower part of the shank, and a thread processing edge arranged at the lower part of the chamfer cutting edge, an aligning edge is arranged at the lower part of the thread processing edge, the chamfer cutting edge is of a spiral shape and can be extended and arranged at the lower part of the shank with equal-interval, and a first plow groove is formed between two adjacent chamfer cutting edges; the thread processing edge is of a spiral shape and can extend downward with equal-interval along a first bottom face of the chamfer cutting edge, a second plow groove connected with the first plow groove is formed between two adjacent chamfer cutting edges, the aligning edges are narrowed and extended serially to the center along the second bottom face of the thread processing edge and merged mutually in the center part, and a third plow groove connected with the second plow groove is formed between every two aligning edges. The invention has the advantages that the frequently drill changing during the processing of the hole shape can be avoided and the technical quality can be ensured; the invention is beneficial for the metal processing company to save the work fixture and the equipment cost; the processing efficiency can be improved above four times.

Owner:CHANGSHU WANKE PRECISION TOOLS CO LTD

Three-dimensional packing machine and sealing system thereof

ActiveCN101624100ACompensation for uneven heatingHeating evenlyWrapper twisting/gatheringPass rateEngineering

The invention discloses a three-dimensional packing machine and a sealing system thereof. Built-in heating pipes of an upper sealing film of a sealing system are in a dislocation distribution mode, thereby effectively compensating the phenomenon of uneven heat generation of a plate surface for the uneven arrangement of heating pipes. In the three-dimensional packing machine, the defective rate of sealing package is greatly reduced, the packing quality of products is greatly increased, the packing pass rate is increased, the unnecessary waste of film materials is avoided in production, and the production cost is reduced.

Owner:AOMEI MEDICAL SUPPLIES CO LTD

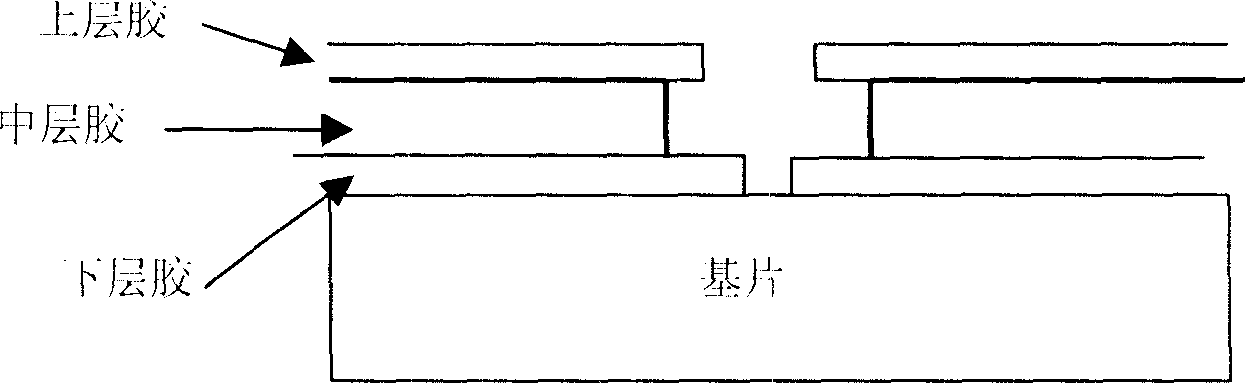

Method for making T-type grating of transistor circuit with high electron mobility

InactiveCN1866472AImprove controllabilityEasy to operateSemiconductor/solid-state device manufacturingSemiconductor devicesCooking & bakingState of art

The invention discloses a circuit-T grid preparing method of high-electron mobility transistor, which comprises the following steps: preparing primitive substrate; cleaning; marking; preparing separation island; evaporating source-drain metal; stripping; alloying; cleaning the substrate; coating PMMA glue; baking; fetching the substrate; exposing the glued substrate through electron beam; developing PMMA glue on the substrate; fixing image; blowing. The method is compatible with advantages of present two T-typed grid preparing method, which avoids each defect simultaneously.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

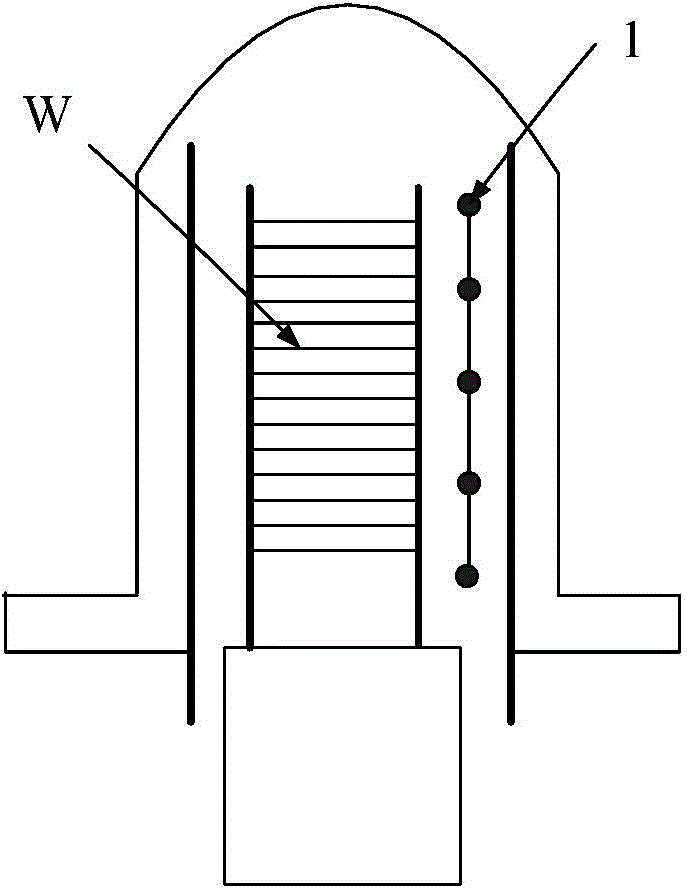

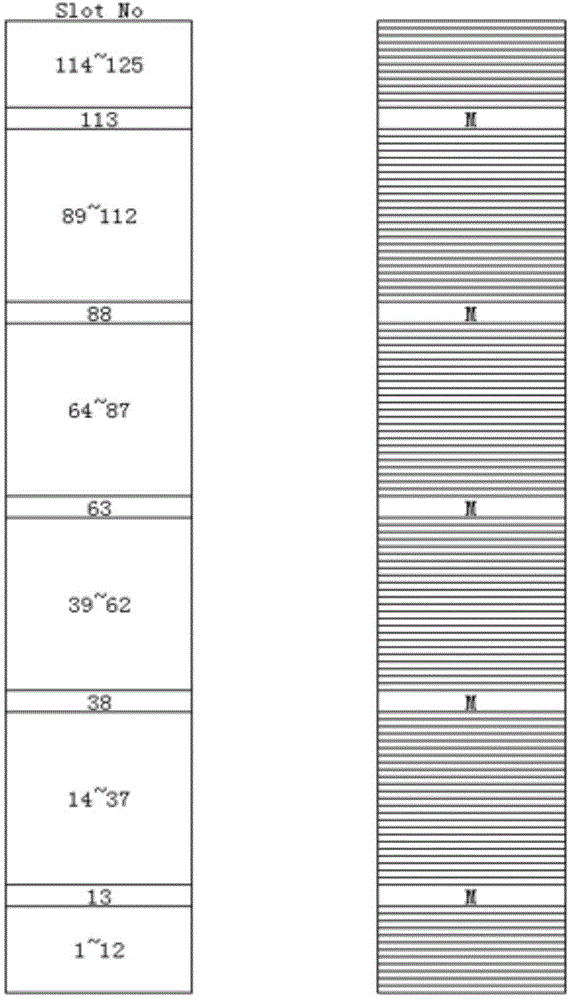

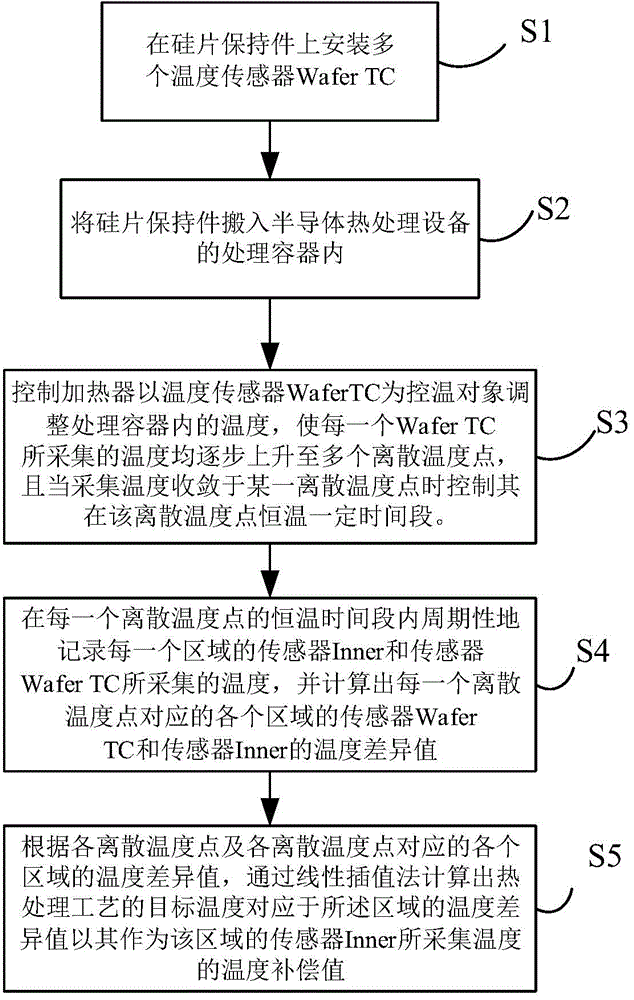

Temperature compensation method and temperature control method and system for heat treatment equipment

ActiveCN104090604AAccurately reflect the real temperatureAdjustable film thicknessAuxillary controllers with auxillary heating devicesTemperature controlEngineering

The invention discloses a temperature compensation method. The method comprises the steps that a plurality of second temperature sensors are installed on a silicon wafer keeping piece; the silicon wafer keeping piece is placed into a treatment container, and the second temperature sensors correspond to a plurality of first temperature sensors in the treatment container in a one-to-one mode; a heater is controlled to take the second temperature sensors as a temperature control object to adjust the temperature inside the treatment container, temperature collected by the second sensors rises to reach a plurality of discrete temperature points, and the collected temperature is controlled to be kept constant for a certain time period at discrete temperature points when converged at the discrete temperature points; the temperature collected by the first temperature sensors and the temperature collected by the second temperature sensors are periodically recorded within the constant temperature time period of each discrete temperature point, and a temperature difference value is calculated; in the actual heat treatment technology, according to the discrete temperature points and the corresponding temperature difference value, the temperature difference value corresponding to target temperature is calculated through a linear interpolation method and used as a temperature compensation value of the temperature collected by the first temperature sensors. The temperature compensation method can truly reflect the silicon wafer temperature.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Loosening moisture regain machine capable of improving stability of leaf moisture content and control method

ActiveCN103919262AImprove stabilityEliminate the effect of moisture contentTobacco preparationFlow control using electric meansEngineeringStreamflow

The invention relates to a loosening moisture regain machine capable of improving the stability of the leaf moisture content and a control method. The control method comprises the following steps that firstly, the water addition is kept unchanged, different steam flows are set through a steam regulating valve, the moisture of leaves discharged from a material discharging port is detected through a moisture detector, and a numerical value of the moisture of the leaves is recorded; secondly, the steam addition is kept unchanged, different water additions are set through a water regulating valve, the moisture of leaves discharged from the material discharging port is detected through the moisture detector, and a numerical value of the moisture of the leaves is recorded; thirdly, a relation of equivalence between influences of steam on the moisture of the leaves and influences of water on the moisture of the leaves is obtained. According to the control method for improving the stability of the leaf moisture content, a total water addition ratio is set, so that the moisture of the tobacco leaves is more even and more stable after the leaves are loosened and the moisture is regained and the technical quality of products is effectively guaranteed.

Owner:LONGYAN CIGARETTE FACTORY

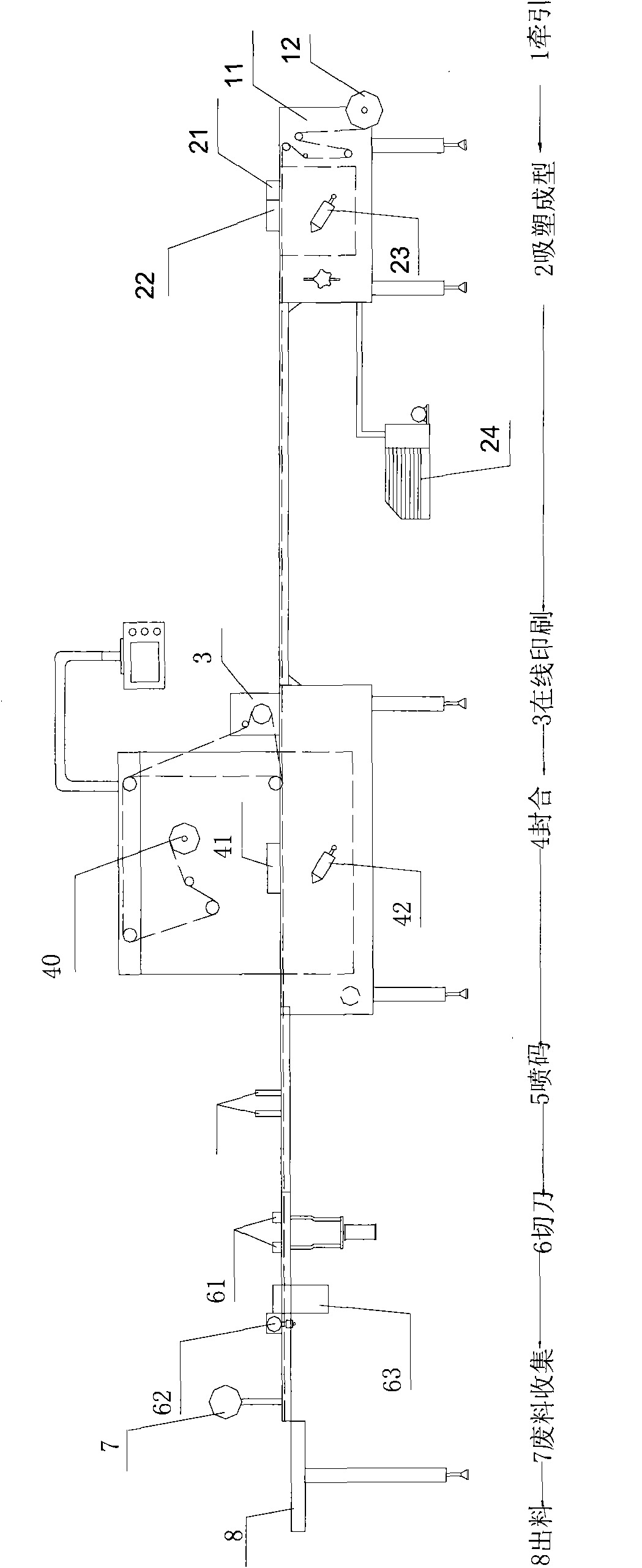

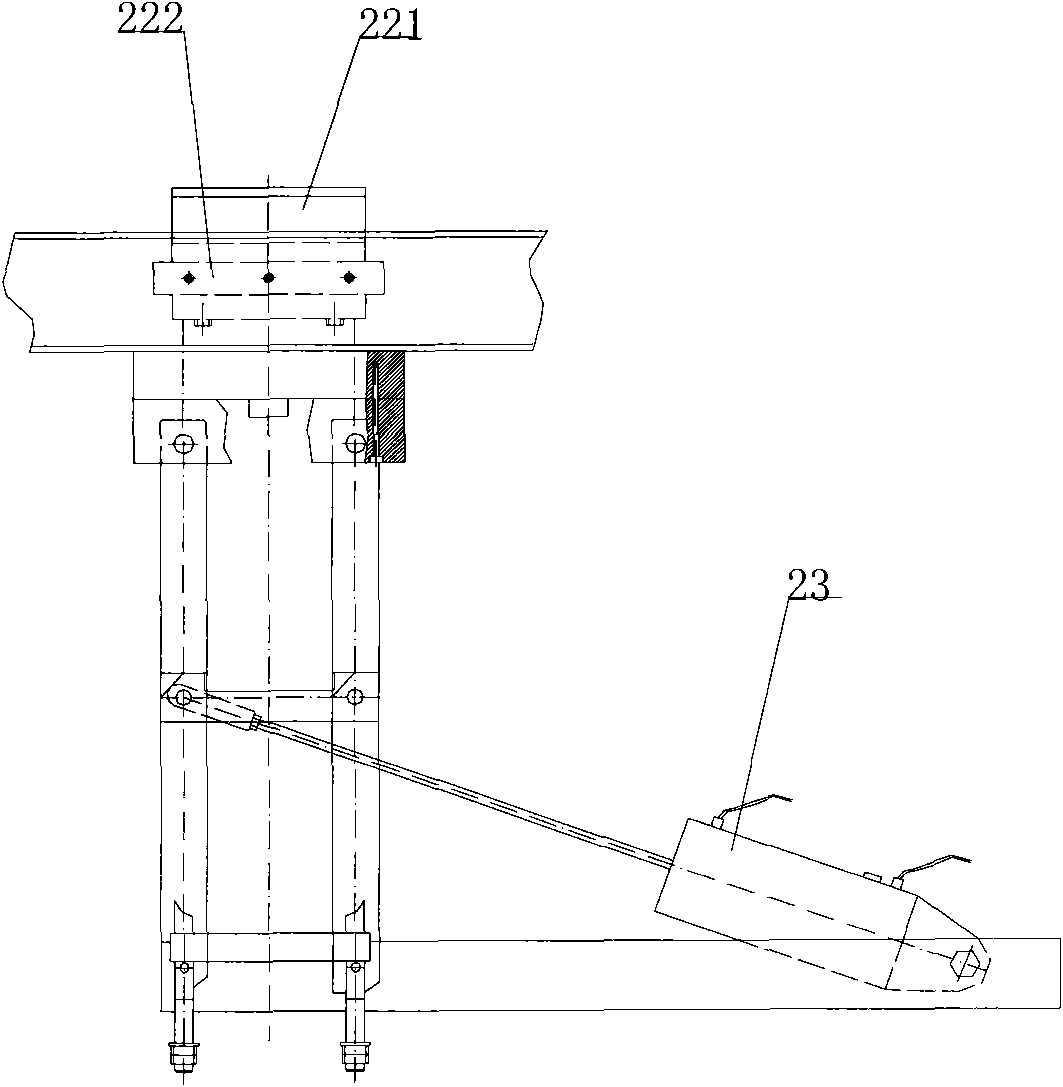

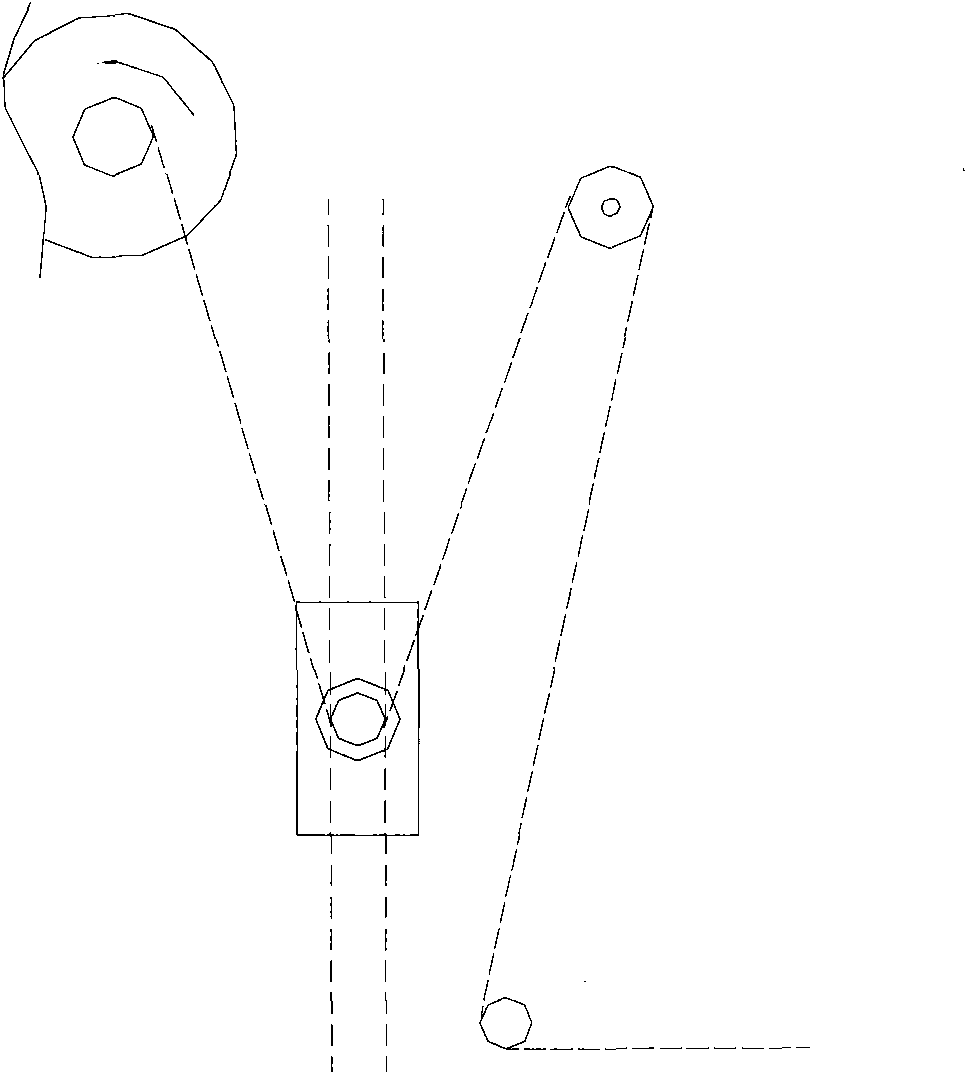

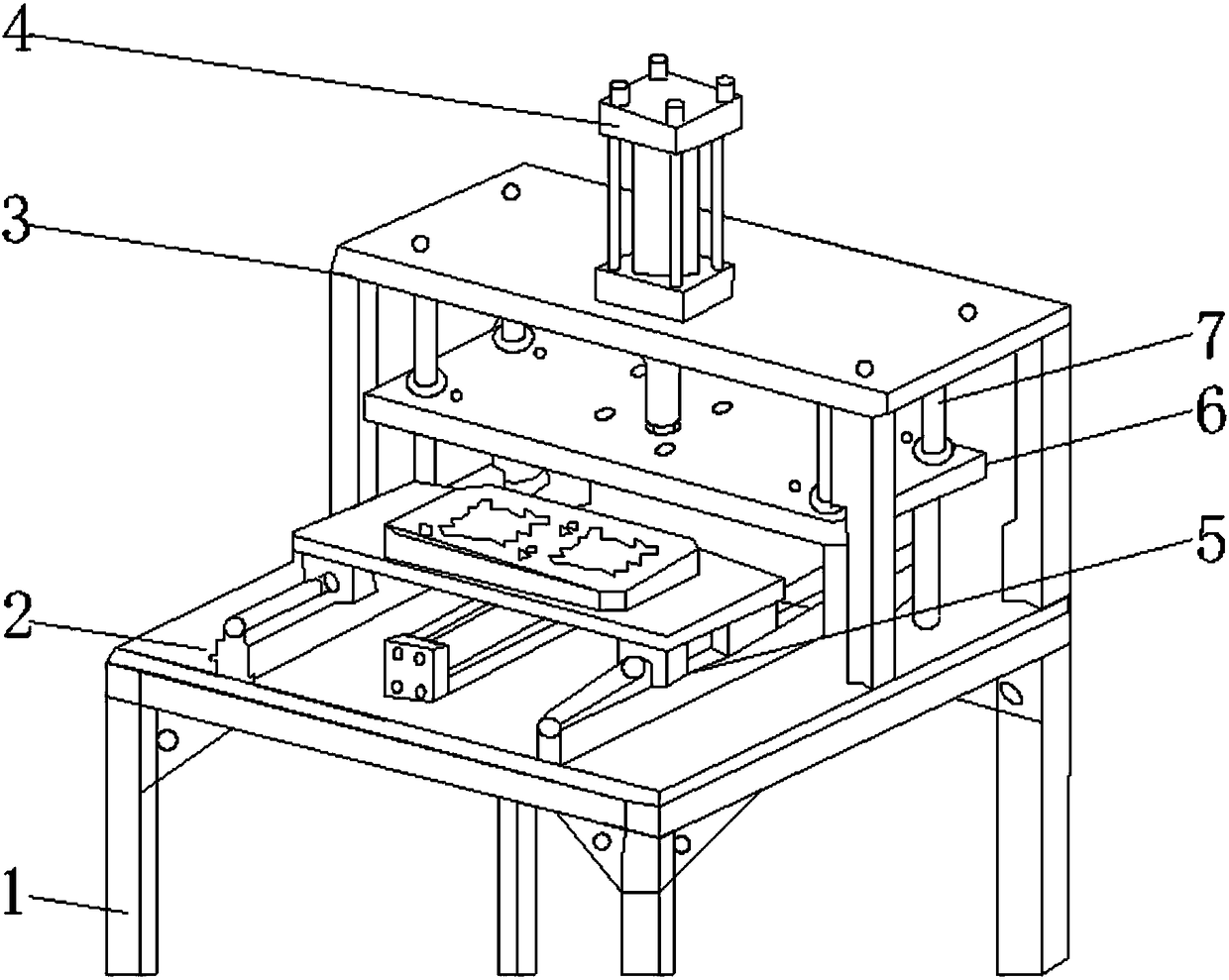

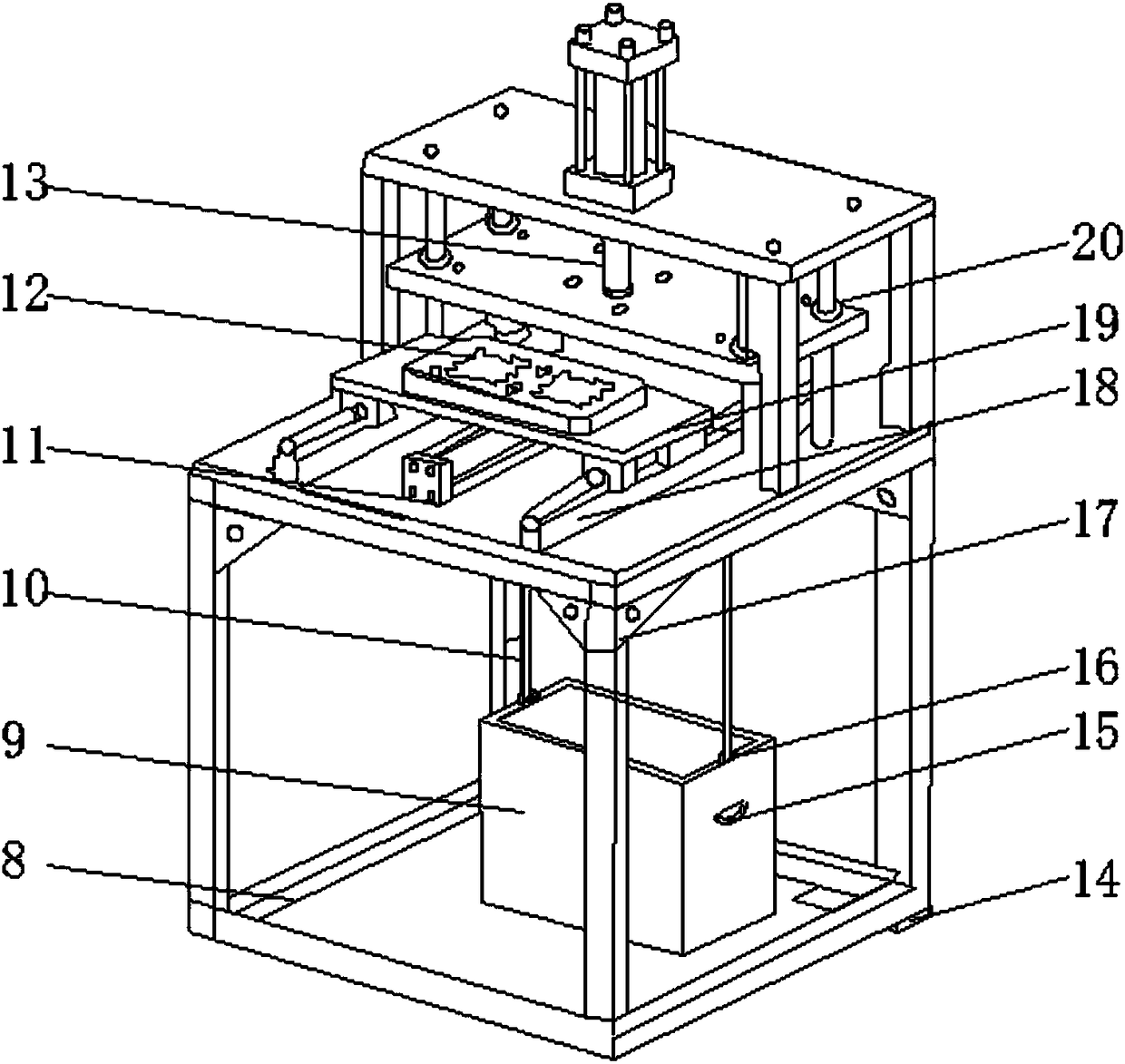

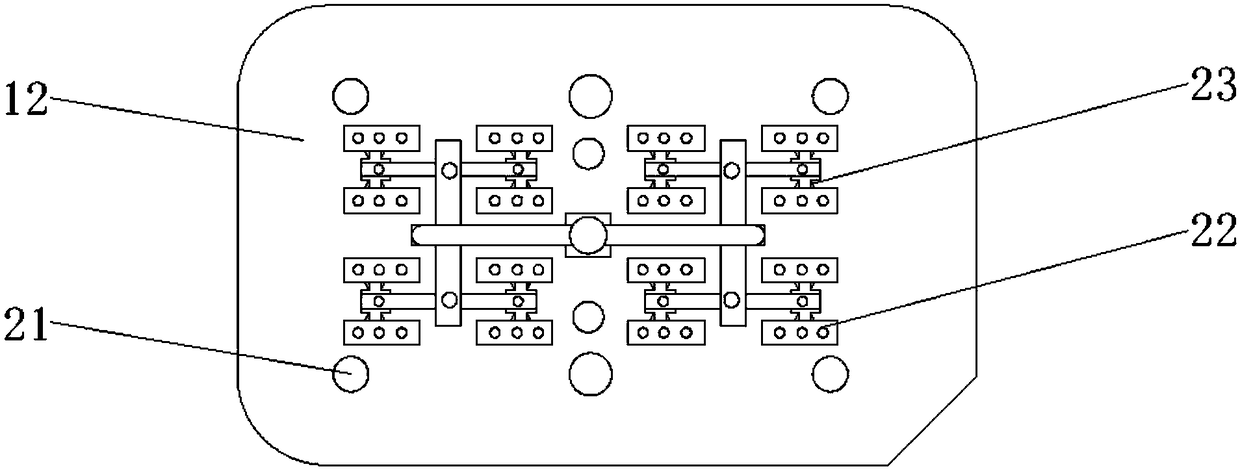

Method for manufacturing automotive equipment capable of automatically punching plastic nozzles

InactiveCN108177308AEasy to slide up and downHigh precisionDomestic articlesEngineeringSurface mounting

The invention discloses a method for manufacturing automotive equipment capable of automatically punching plastic nozzles. The equipment comprises a process table, a mechanical propping plate, a prepressing plate and a nozzle collecting box, wherein a conveying air cylinder is arranged on the surface of the process table; a lower die plate is arranged on the top of a moving plate; fixing columns are arranged on the surface, at two sides of guide rails, of a process table; the mechanical propping plate is arranged on the tops of the fixing columns; a punching cylinder is arranged on the top ofthe mechanical propping plate; a pressure bearing column is arranged at the output end of the punching cylinder; an upper die fixing plate is arranged at the bottom of the pressure bearing column; theprepressing plate is arranged at the bottom end of the upper die fixing plate; pillars are uniformly arranged at the bottom of the process table; a supporting bottom plate is arranged at the bottomsof the support columns; and the nozzle collecting box is arranged below the process table inside the supporting bottom plate. The equipment disclosed by the invention has the beneficial effects that through a series of structures, plastic products can be accurately placed in the process of punching the plastic nozzles; the punching accuracy and the punching efficiency are increased; and the subsequent processing is facilitated.

Owner:苏州胜利高睿智能汽车制造有限公司

Scheduling control method for wafer loading device of semiconductor heat treatment equipment, and system

InactiveCN105205585ARealize loading and unloading scheduling managementEnsure safetyResourcesManufacturing computing systemsDiffusionControl flow

The invention relates to a scheduling control method for a wafer loading device of semiconductor heat treatment equipment, and a system. The method comprises steps that, a management configuration file of a management and control flow is pre-set or set in real time; a take and put mapping relation between a wafer box and wafers is established according to configuration items in the configuration file, distribution situations of all wafers in the wafer box before loading operation are respectively recorded in a file according to a wafer quantity check mode before displacement; during wafer take and put operation, the wafer management and control flow is established according to the take and put mapping relation and the recorded file, loading and unloading of the wafers relative to the wafer box are carried out through a manipulator, the recorded file is updated in real time according to wafer distribution situations after loading and unloading operation, finally, the recorded file after update is contrasted to determine whether parameters reach or surpass corresponding parameters in the configuration file. According to the method, through software and hardware combination design for the semiconductor equipment, the wafer scheduling management function of the semiconductor diffusion equipment in a non-configured wafer loading device storage bin is realized.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

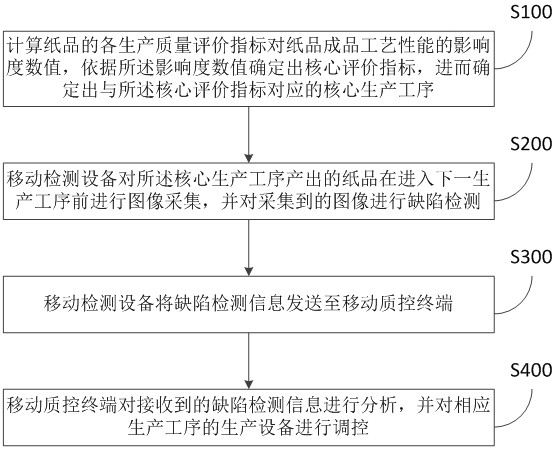

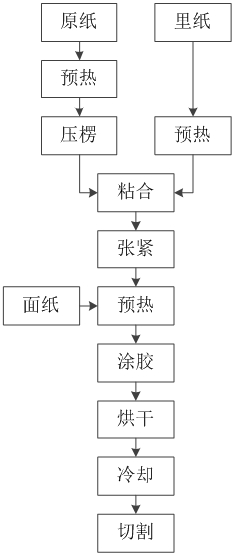

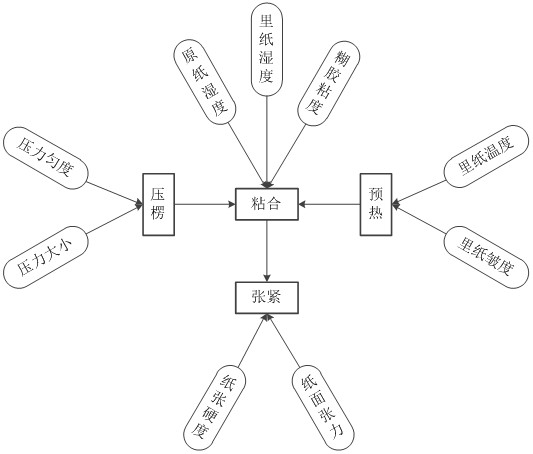

Paper product production quality intelligent inspection method and system

ActiveCN112557406AGuarantee the quality of workmanshipImprove accuracyOptically investigating flaws/contaminationQuality controlManufacturing line

The invention discloses a paper product production quality intelligent inspection method and a system, and the method comprises the steps: firstly calculating the impact degree values of all production quality evaluation indexes of a paper product on the technological performances of a paper product finished product, determining a core evaluation index according to the impact degree values, and determining a core production process corresponding to the core evaluation index; moving detection equipment to perform image acquisition on paper products produced in the core production process beforeentering a next production process, carrying out defect detection on the collected images, then moving the detection equipment to send defect detection information to a mobile quality control terminal, and finally adopting the mobile quality control terminal to analyze the received defect detection information; and regulating and controlling the production equipment of the corresponding production process. According to the method, on the premise of ensuring the process quality of paper products, the process processing capacity, the defect monitoring capacity and the equipment control capacityof a production line are balanced and optimized, and the limited defect monitoring capacity is applied to the most critical detection point.

Owner:ZHEJIANG GREAT SHENGDA PACKING CO LTD

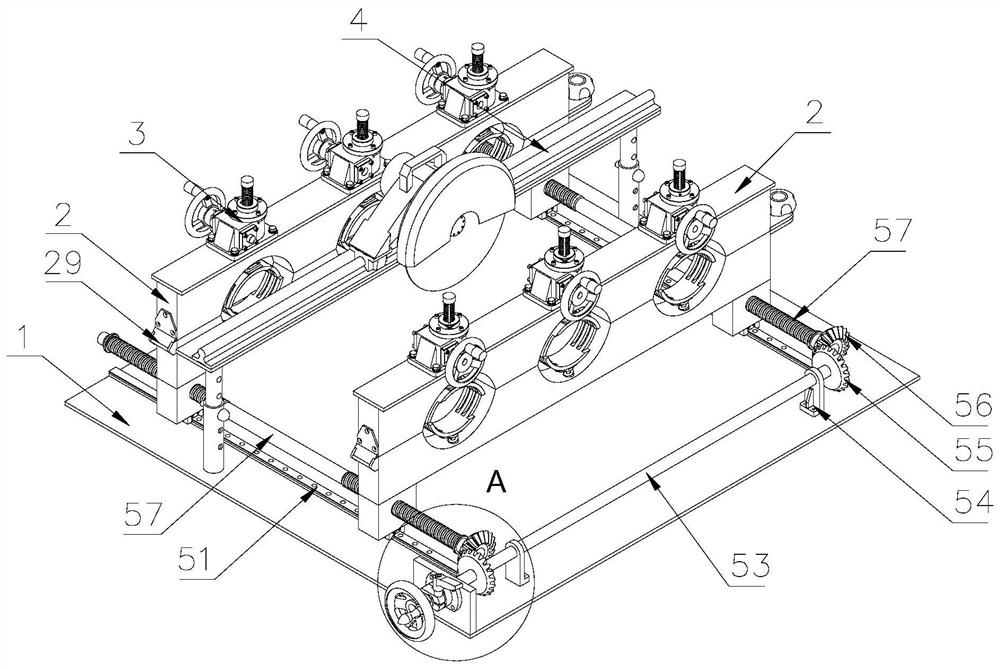

Coaxiality control tool and coaxiality control method

ActiveCN103440939AUniform thicknessImprove electromechanical performanceInsulatorsCeramic compositeComposite insulators

The invention discloses a coaxiality control tool and a coaxiality control method. The coaxiality control tool comprises a base and a screw rod. A first sliding block and a tensioning device are arranged on the base, a second sliding block is arranged on the first sliding block, and baffles are arranged on the left side and the right side of the second sliding block respectively. A stand column is arranged on the second sliding block, and an accessory limiting and clamping device and a ceramic part limiting and clamping device are arranged on the stand column. A second baffle is arranged on one side of the base, and one end of the screw rod penetrates through the second baffle and is connected with the first sliding block. The first sliding block moves on the base in a left-and-right and back-and-forth mode through the screw rod and is firmly fixed on the base through the tensioning device after moving to a proper position. The coaxiality control tool is used for controlling the vibration adhesive binding geometric tolerance of a bar type ceramic composite insulator so that the coaxiality of an adhesive binding ceramic part and an accessory can be 1mm and the coaxiality of the upper accessory and the lower accessory can be 0.5mm. Following forming process quality can be ensured, core shift of a whole product will not exist, the insulation thickness is even, the electromechanical property of the product is greatly improved, and long-term operation of the product can be stable and reliable.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

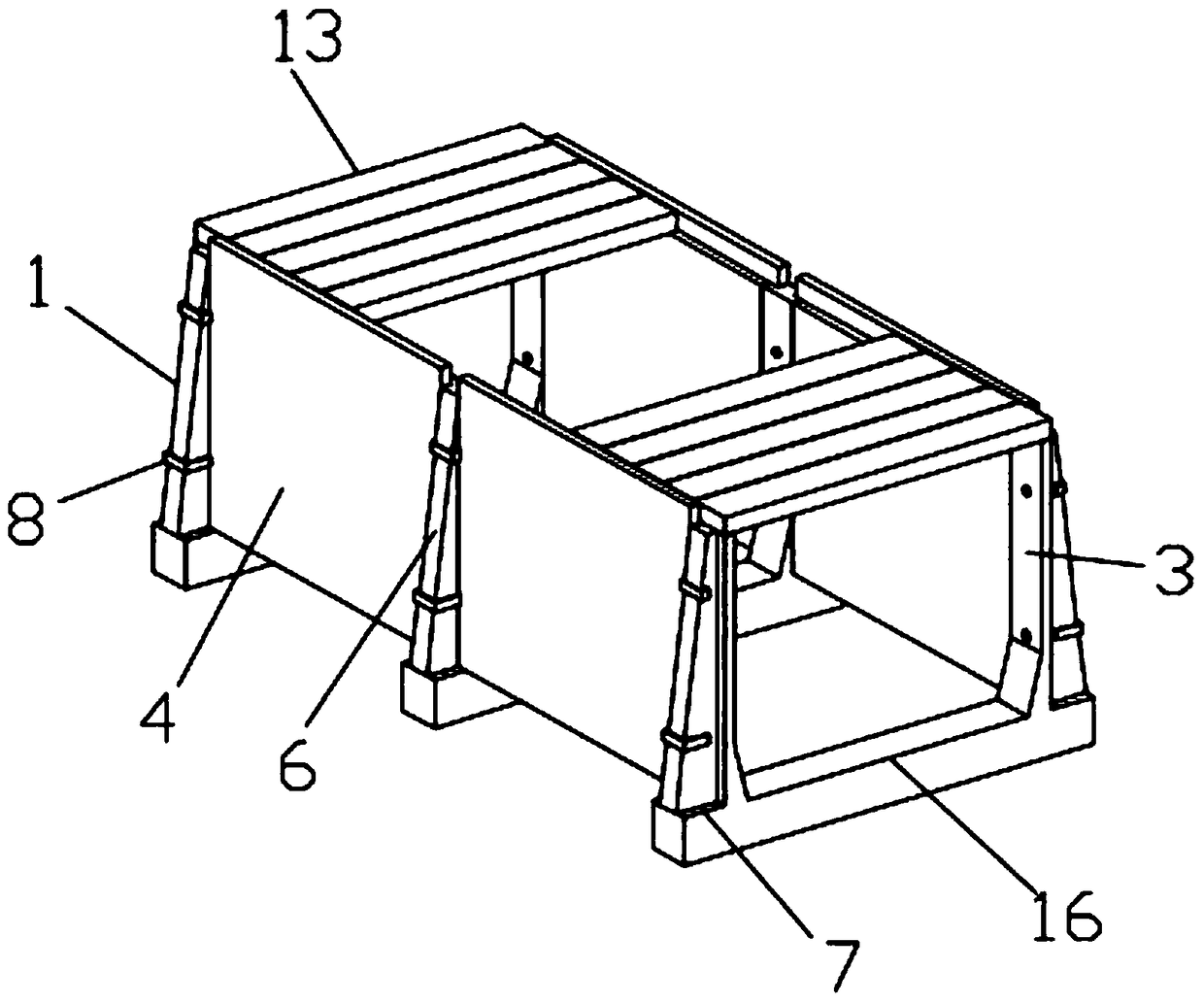

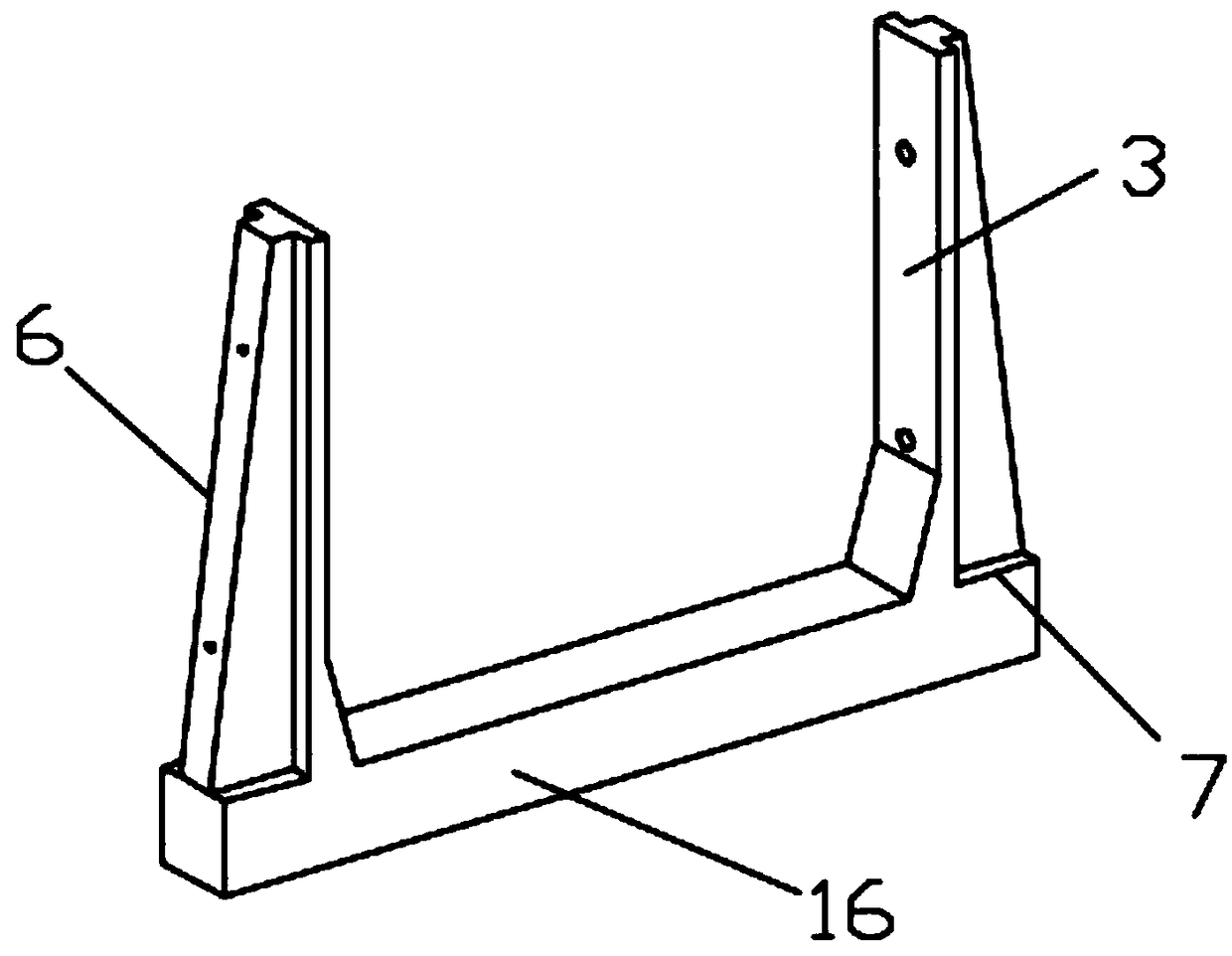

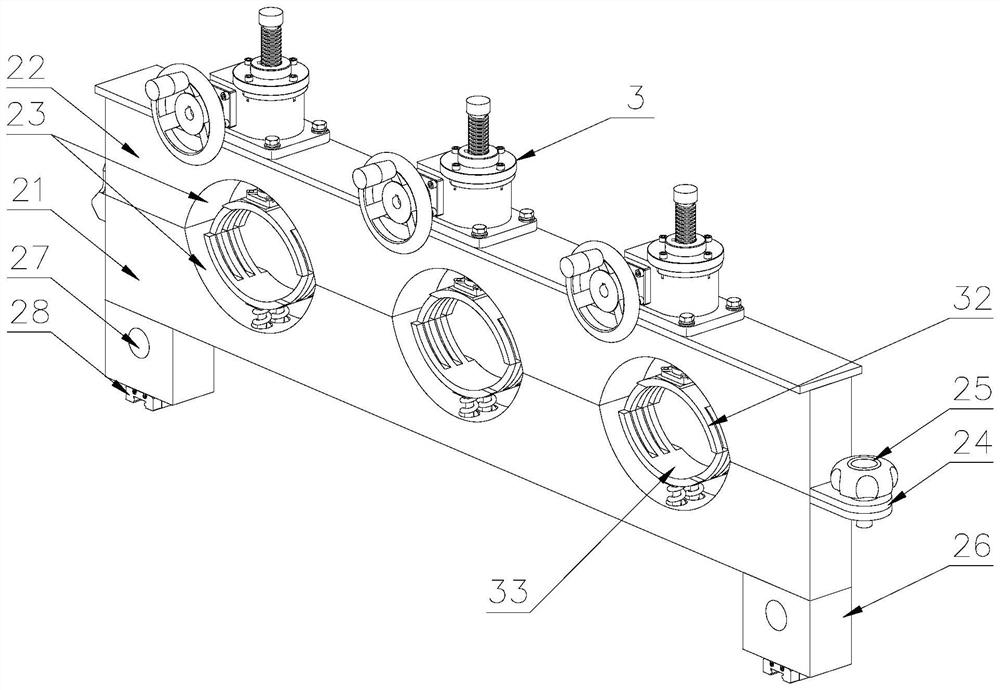

Chemical equipment pipe supporting frame

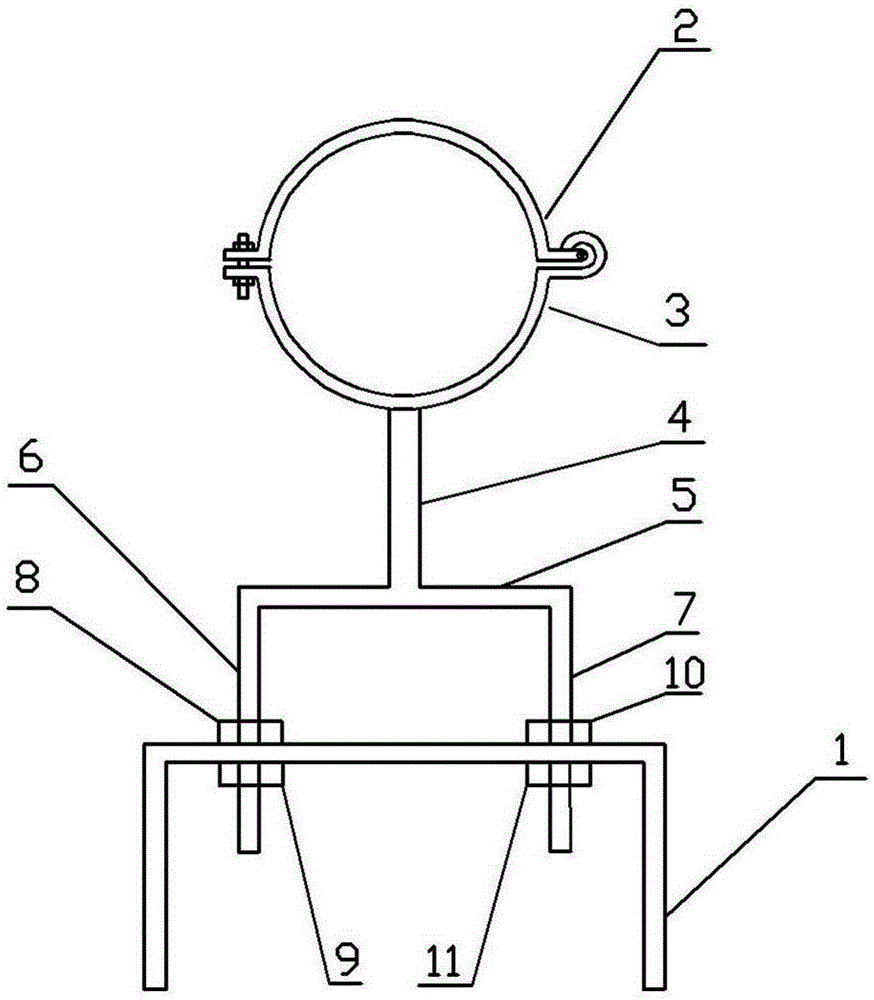

InactiveCN106704711AEffective support and fixationGuarantee the quality of workmanshipPipe supportsPipeline systemsProcess qualityEngineering

The invention relates to a chemical equipment pipe supporting frame which comprises a support, a supporting rod and a pipe clamp. The pipe clamp comprises an upper hoop and a lower hoop which are both in semicircular ring shapes, one end of the upper hoop is hinged to one end of the lower hoop, and the other end of the upper hoop is in bolt connection with the other end of the lower hoop; an adjusting rod comprises a first vertical rod connected with the lower hoop, a first transverse rod connected with the bottom end of the first vertical rod, a first screw rod and a second screw rod, and the first screw rod and the second screw rod are connected with the two ends of the first transverse rod, and are correspondingly embedded into through holes in the support; and the first screw rod is in clamped connection with the support through a first upper nut and a first lower nut, and the second screw rod is in clamped connection with the support through a second upper nut and a second lower nut. By means of the above structure, a chemical equipment pipe can be effectively supported and fixed, the vibration influences on the pipe can be effectively prevented or greatly reduced, and therefore the process quality and the construction safety of chemical equipment are further guaranteed.

Owner:天津希瓦科技发展有限公司

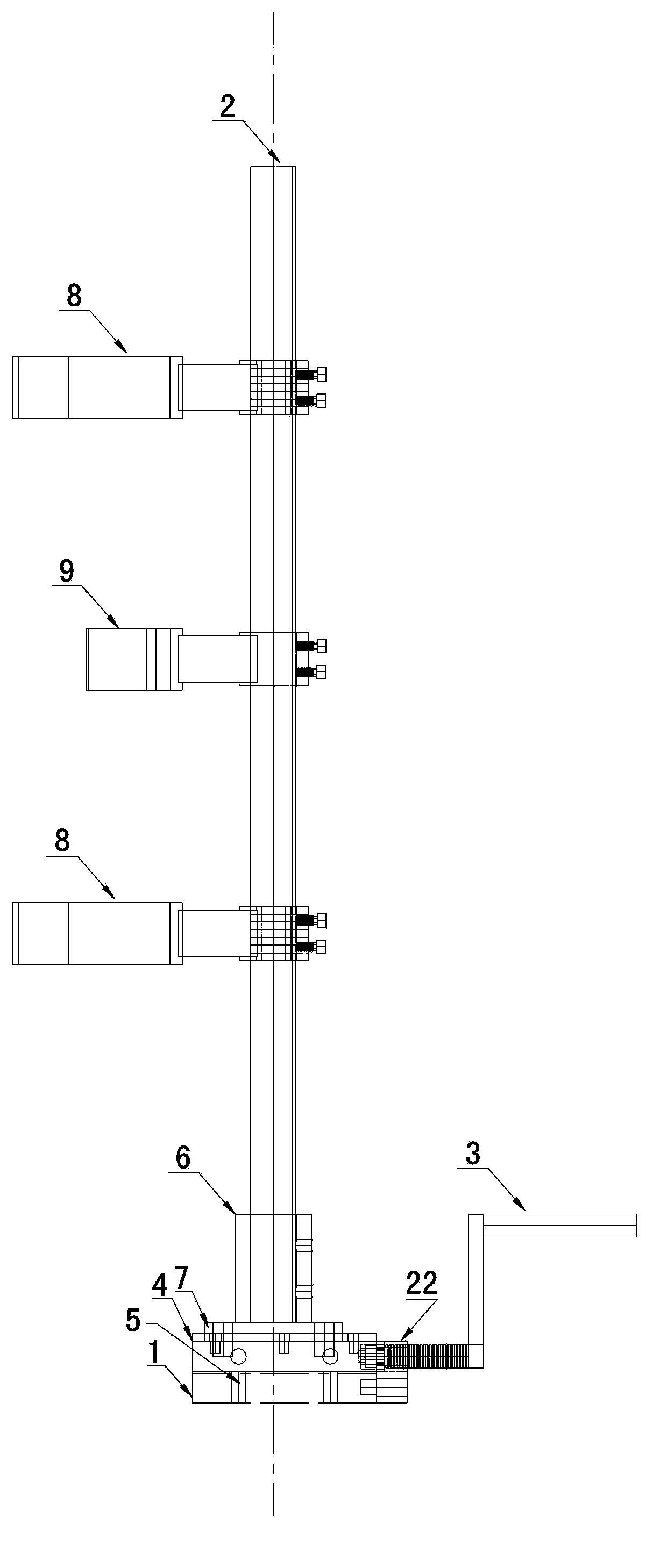

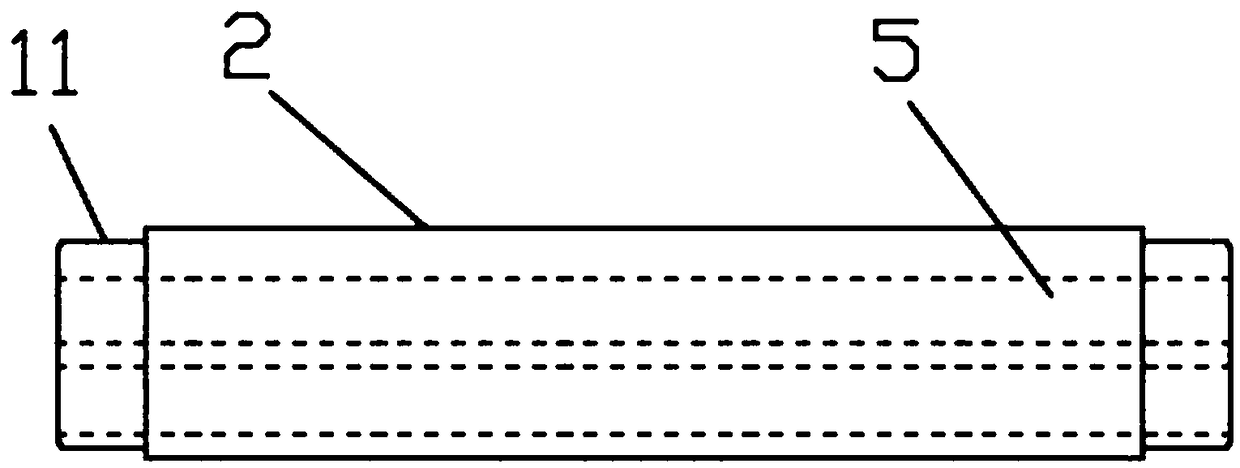

Solar energy high-temperature heat collecting pipe exhaust method used for generating electricity and horizontal-type exhaust platform

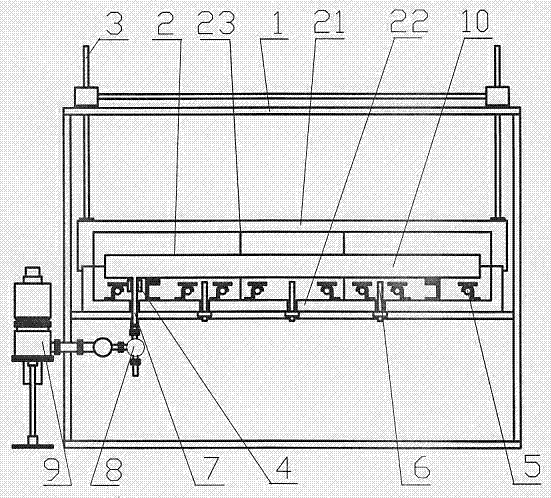

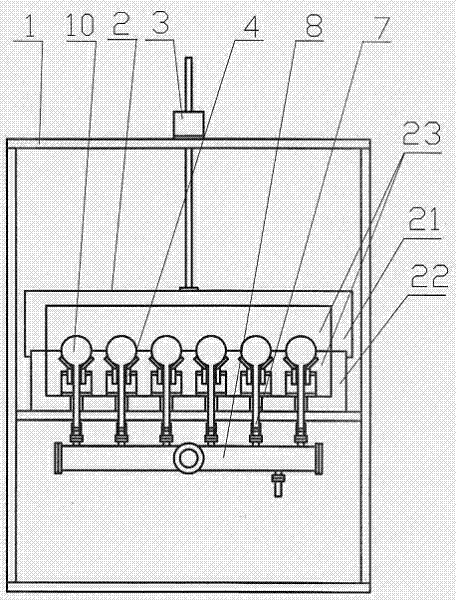

InactiveCN102162689ASolve the difficult problem of loading and unloadingEasy to openSolar heat devicesGlass reforming apparatusTemperature controlVacuum pumping

The invention discloses a solar energy high-temperature heat collecting pipe horizontal-type exhaust platform, comprising a rack (1), a heat preservation box (2), a lifting mechanism (3), an electric heating sealing furnace (4), an electric heating pipe (5), a thermocouple (6), a vacuum plastic tube (7), an exhaust header pipe (8) and a molecular pump vacuum air suction system (9), wherein, a horizontal-type square box body structure is adopted for the heat preservation box (2) which is divided into an upper box body (21) and a lower box body (22); the box body is separated into three temperature control areas by a clapboard (23); the electric heating sealing furnace (4) and a stainless steel vertical-tube electric heating pipe (5) are arranged on the base plate of the lower box body (22); an armoured thermocouple (6) is arranged in the heat preservation box (2) for detecting the temperature in the box; the molecular pump vacuum air suction system (9) is connected with the tail end of a high-temperature heat collecting pipe (10) through the exhaust header pipe (8) and the vacuum plastic tube (7), so as to carry out roasting and exhausting. In the invention, the existing heat collecting pipe exhaust platform vertical structure is changed into a horizontal-type structure, thus the difficulties that the equipment and the workshop are ultrahigh, as well as the use, the maintenance, the assembling and the disassembling of the workpieces are difficult caused by exhausting by a ultralong pipe are solved, thus creating condition for automation implementing.

Owner:衡阳市真空机电设备有限公司

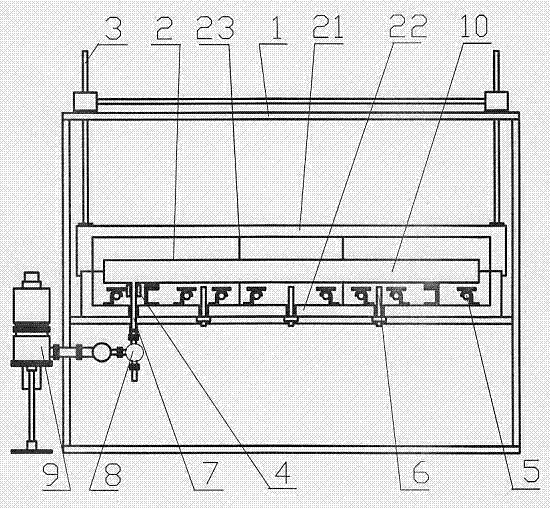

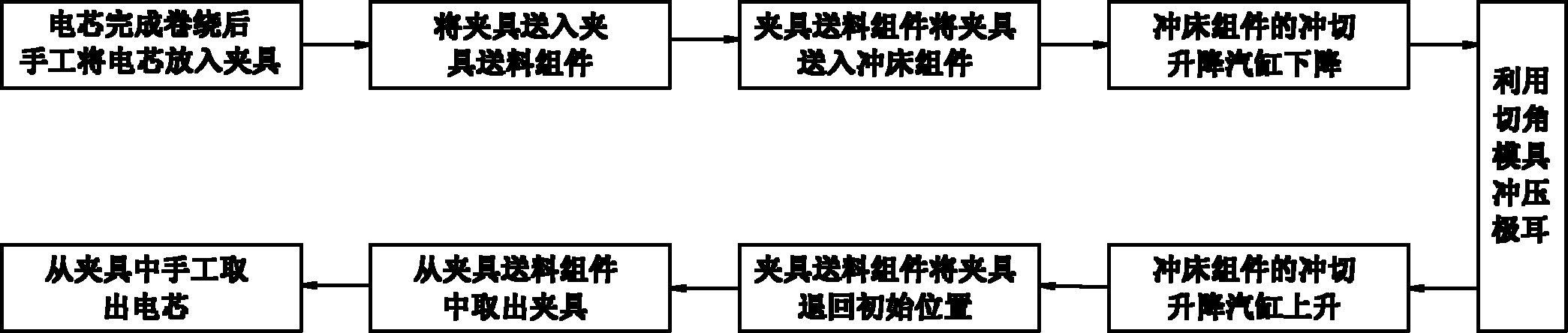

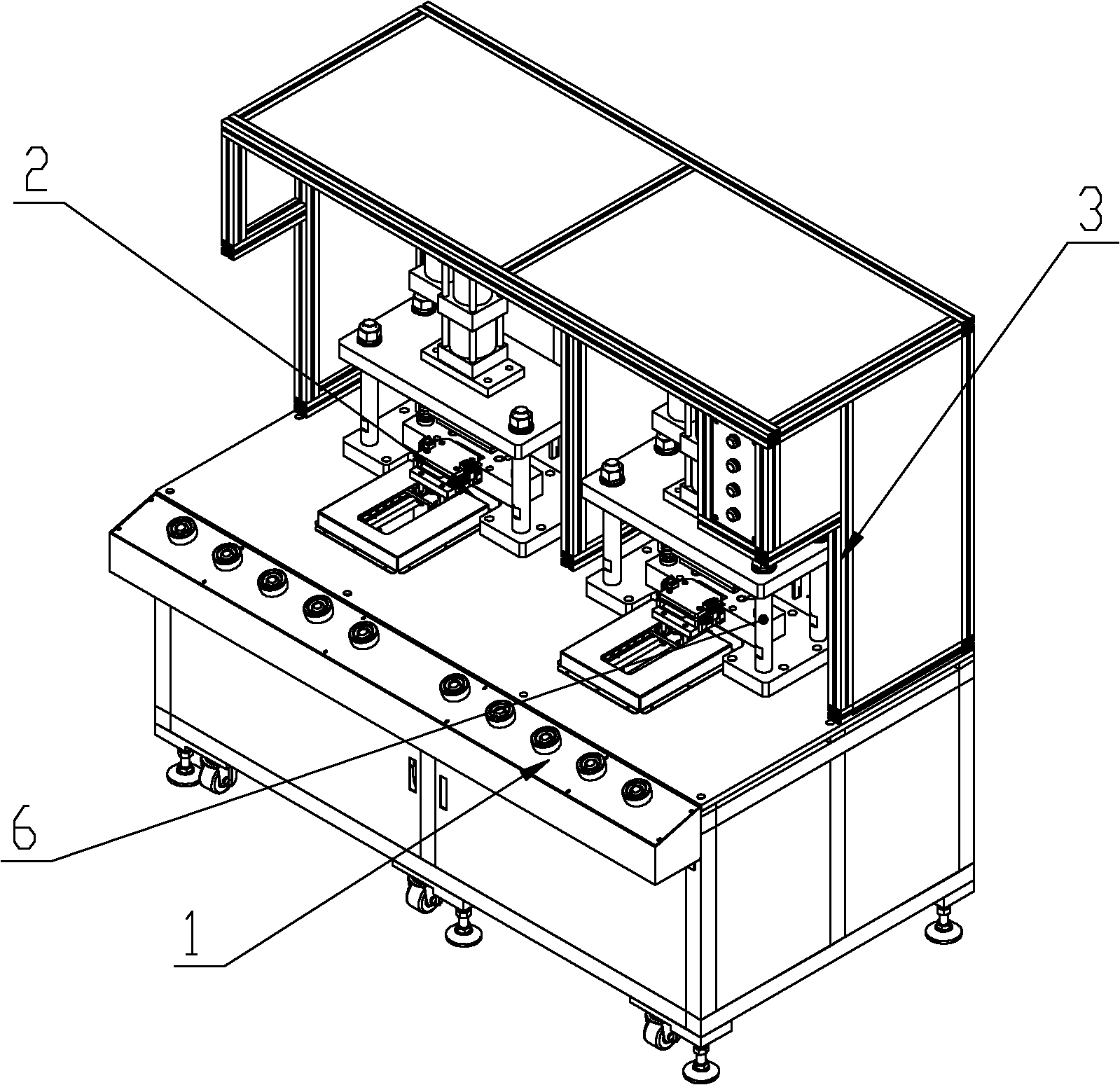

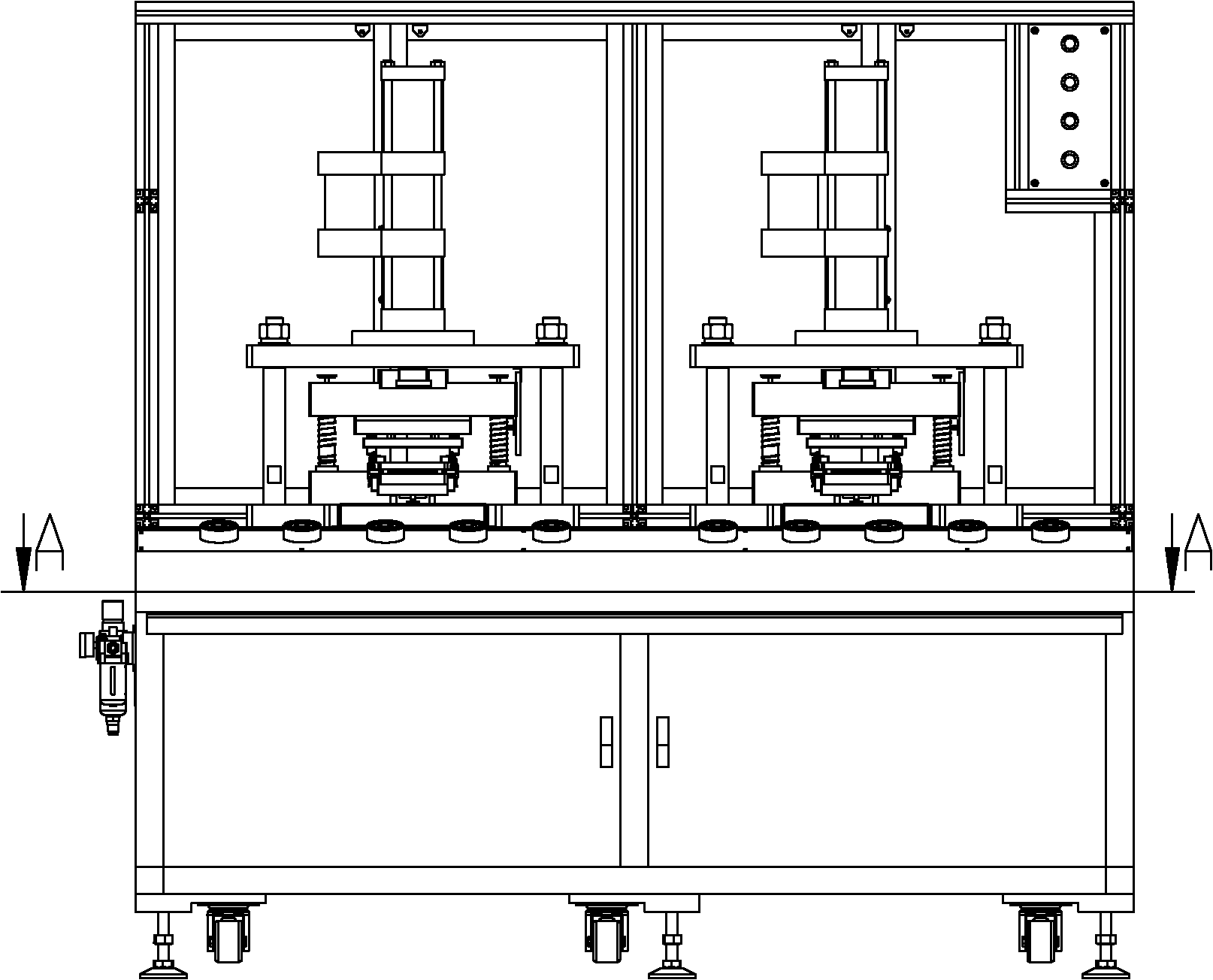

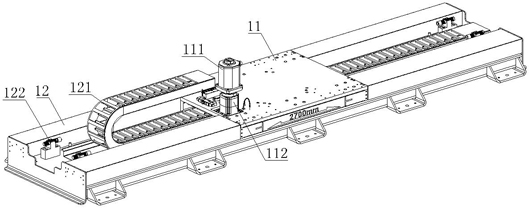

Method and equipment for forming electric core tab

ActiveCN102842697AGuarantee the quality of workmanshipWind evenlyCell component detailsWinding machinePunching

The invention discloses a method and equipment for forming an electric core tab. The method comprises the following steps: winding an electric core on a winding machine by a tab in an initial shape; and after finishing the winding operation, carrying out punch forming on the tab on the wound electric core. The equipment comprises a machine frame assembly, a punch assembly and a clamp feeding assembly, wherein the punch assembly comprises a corner cutting mould with a punching head and a corner cutting position, and a punching and cutting drive part; the punch assembly is mounted on the machine frame assembly; the clamp feeding assembly comprises a linear guide rail pair, a movable sliding table, a feeding drive part and a clamp; the linear guide rail pair is mounted on the machine frame assembly and extends to the corner cutting position of the corner cutting mould; and the clamp is mounted on the movable sliding table. Compared with the conventional mode that the tab on a single pole piece is formed and wound into the electric core in the prior art, the complicated processes are reduced, the process efficiency is improved, the tab is more stable to form, and the process quality of the electric core winding operation is easily guaranteed by accurately controlling the position and the shape of the tab.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Automobile steel plate trimming device

ActiveCN108500769AGuarantee the quality of workmanshipWon't clogEdge grinding machinesGrinding carriagesMagnetic polesEngineering

The invention relates to the technical field of automobile accessory production equipment and particularly discloses an automobile steel plate trimming device which comprises a telescopic shaft. A positioning part is arranged on the telescopic shaft, a supporting table is arranged on the top of the telescopic shaft, a first rotating shaft is arranged on one side of the telescopic shaft, and a polishing wheel is arranged on the first rotating shaft; a first decelerating mechanism and a second rotating shaft are arranged between the first rotating shaft and the telescopic shaft, a second decelerating mechanism is arranged between the first rotating shaft and the second rotating shaft, a transmission roller is arranged on the second rotating shaft and connected with a tensioning roller through a conveying belt, and an electromagnet is arranged in the polishing wheel; airbags are arranged on the conveying belt, liquid inlets are formed in the tops of the airbags, liquid outlet pipes are arranged at the bottoms of the airbags, and movable blocks are arranged in the airbags; and magnetic poles on the sides, close to the liquid outlets, of the movable blocks are the same as a magnetic pole of the electromagnet, and the concave parts of the airbags are provided with attracting nets coated with magnetic layers. When the automobile steel plate trimming device is adopted to trim a steel plate, cooling and metal debris attracting treatment are conducted on the polishing wheel, and the quality of the steel plate is improved.

Owner:宁波高新区新柯保汽车科技有限公司

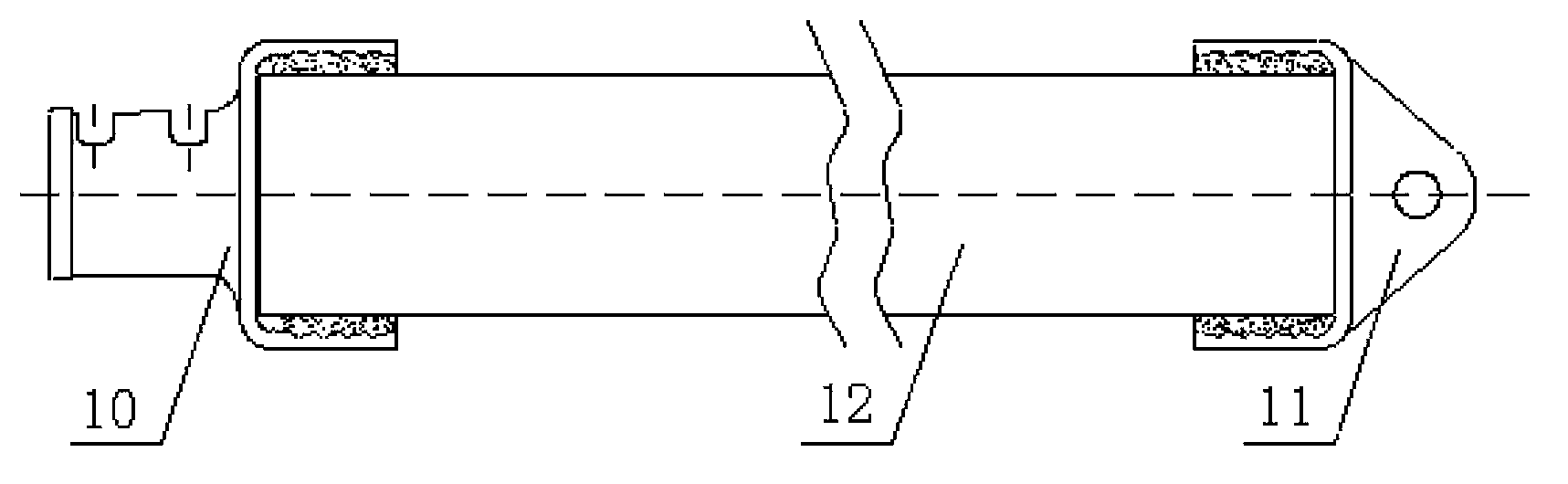

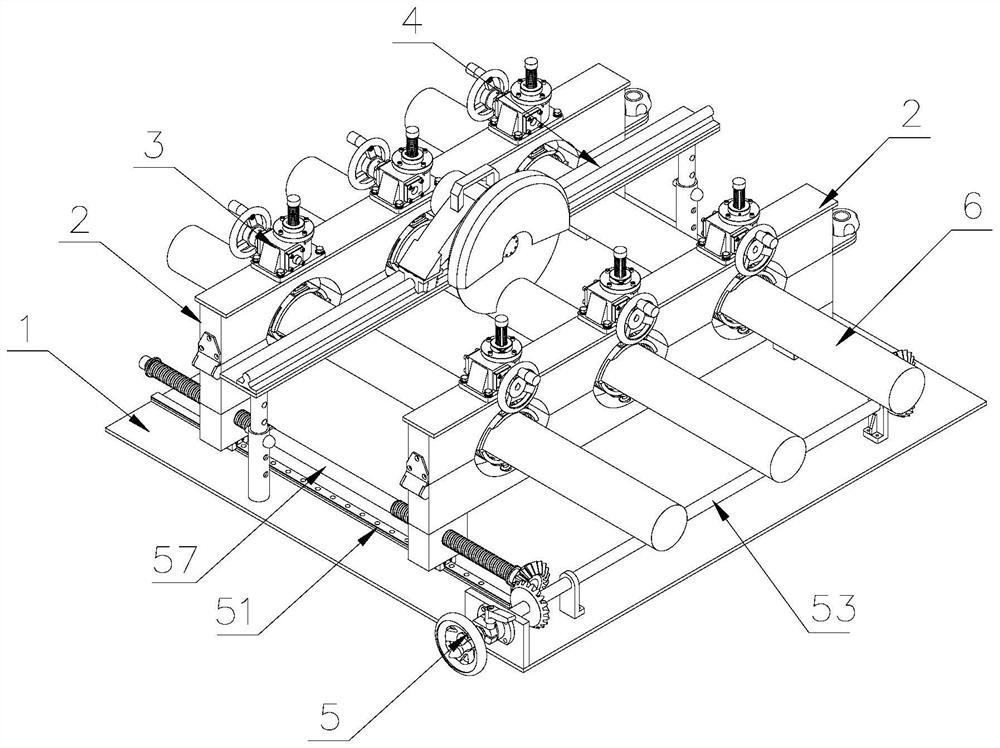

Device for winding rubber strip on inner wall of roller

The invention relates to a device for winding a rubber strip on the inner wall of a roller, comprising a roller, a roller wheel bracket, a limit rod, a stand, a rubber strip feeding mechanism, a movable platform mechanism, a rubber strip turning mechanism, a rubber strip guiding mechanism and a winding arm. The roller is arranged above the roller wheel bracket; the rubber strip feeding mechanism and the movable platform mechanism are respectively fixed above the stand; the rubber strip turning mechanism is fixed above the movable platform mechanism and on the side surface of the movable platform; and the winding arm is fixed under the movable platform. The invention realizes automatic winding of the rubber strip, furthest decreases the influence on winding effect caused by rotation sideslip of the roller, protrusion of welding joint on the inner wall of the roller, and the like, replaces manual winding working mode of an operator to reduce the labor intensity of the technical personnel, improves the efficiency of the winding process, and ensures the processing quality. The invention can be applied to the production of molding processes of rubber layers on the inner wall of rollers with different diameters, thereby having wide application prospect.

Owner:XI AN JIAOTONG UNIV

Dust collecting device for leather product engraving machine

InactiveCN108127253ASimple structureAvoid flying aroundLaser beam welding apparatusIsolation effectLaser transmitter

The invention discloses a dust collecting device for a leather product engraving machine. The device comprises a base, circular side plates are fixed to the left and right end faces of the base respectively, and a PLC is installed on the side surface of one side plate. The dust collecting device for the leather product engraving machine has a simple structure, a dust cover is matched with a laseremitter for installation, the dust cover moves with the laser emitter to isolate an engraving area, and dust generated during engraving by the laser emitter can be effectively prevented from flying everywhere. A protective cover is matched with the base to seal a working space, the external dust is prevented from entering, and the normal operation of electrical components is ensured. the dust in the dust cover is removed through negative pressure of a dust box, a brush rotates with the dust cover relative to the laser emitter and can sweep the dust adhered to the surface of a leather product,and negative pressure absorption is facilitated. The overall operation is convenient, the isolation effect is good, the dust is removed thoroughly, and the quality of the leather product engraving process is ensured.

Owner:平阳县云海皮件有限公司

Oblique crossing circular pipe intersection face inner insertion plate turning connection structure

InactiveCN105625575ARelieve force dependenceStrong engineering reliabilityWelding/cutting auxillary devicesBuilding constructionsButt jointClassical mechanics

The invention relates to a welding method for steel pipe intersection in the construction industry and is suitable for multi-limb steel pipe bearing column vertical intersection connection and stiffness enhancing, assembly welding, butt joint and construction. An oblique crossing circular pipe intersection face inner insertion plate turning connection structure comprises oblique crossing circular pipes and a pier connected with the oblique crossing circular pipes, a longitudinal turning connection plate is axially inserted in an intersection face of the oblique crossing circular pipes in a through mode, the longitudinal turning connection plate extends out of the intersection face in the radial direction and axially extends into the pier, limb pipes of the oblique crossing circular pipes are fixed to the longitudinal turning connection plate in a welded mode, and the longitudinal turning connection plate is fixed to the pier in a welded mode. The limb pipes and turning connection plates inserted in the intersection face are independently welded through a multi-limb steel pipe column intersection technology, stress dependence of the limb pipes to limb pipe connection is eliminated, engineering reliability is high, and welding technological quality is guaranteed. By means of the intersection face inner insertion plate turning connection structure, machining problems are solved, layer-to-layer section tearing resistance of crossing portions is enhanced, and the safety coefficient is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Prefabricated distribution network civil engineering cable well assembly combination

InactiveCN109457727ALittle life impactHigh precisionCable installations on groundArtificial islandsProcess qualityOperation safety

The invention relates to the technical field of cable assembly equipment, and discloses a prefabricated distribution network civil engineering cable well assembly combination. The combination comprises joint clamping pillows and prefabricated ducts, wherein each joint clamping pillow comprises a pillow block at the bottom and pillow arms which are arranged at the two sides and perpendicular to thepillow block, the two ends of the prefabricated ducts are clamped and fixed by the joint clamping pillows, prefabricated side plates on the two sides of every two adjacent joint clamping pillows areconnected and fixed, a plurality of cable ducts are arranged inside the prefabricated ducts, and the joint clamping pillows, the prefabricated ducts and the prefabricated side plates are all prefabricated into standard pieces in a unified specification by a factory. The prefabricated distribution network civil engineering cable well assembly combination has the beneficial effects that the assemblytype prefabricated pieces are produced through modern machinery of the factory, the product precision is high, the quality is stable, the construction schedule duration is greatly shortened, the process quality is guaranteed, on-site complex conditions can be avoided, the application range is wide, the operation safety risk is greatly reduced, and the influence on the life of surrounding people is greatly reduced.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD

Multi-cable cutting device for cable erection

ActiveCN112542797AImprove cutting efficiencyAvoid hand pullingApparatus for cutting/splicing cablesElectric machineryStructural engineering

The invention discloses a multi-cable cutting device for cable erection. Two sets of clamping devices are arranged. In each clamping device, a lower clamping plate is arranged at the upper part of a base, one side of the lower clamping plate is movably connected with one side of an upper clamping plate through a hinge, a plurality of cable clamping grooves are formed in the upper clamping plate and the lower clamping plate, and cables are placed in the cable clamping grooves. A cutter rest is installed between the two sets of clamping devices and comprises stand columns arranged at the two ends of the base, a supporting plate connected with the upper ends of the stand columns, and a first guide rail installed on the upper portion of the supporting plate; a cutting machine is arranged on one side of the upper portion of the supporting plate; supporting legs are arranged on the two sides of a motor of the cutting machine; first sliding blocks are arranged on one sides of the lower portions of the supporting legs; and handles are arranged on the upper portions of the supporting legs on the two sides. According to the multi-cable cutting device for cable erection of the invention, themultiple wire clamping grooves are formed in the upper clamping plates and the lower clamping plates; when cables are to be cut, the wire clamping grooves are used for clamping the cables, so that themultiple cables are cut at a time; and therefore, the cutting precision of the cables is guaranteed, the process quality of cable cutting is improved, and the working efficiency is improved.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

PETG thermal shrinkage film gassho glue suitable for high speed gassho machines

ActiveCN109897567AGuarantee the quality of workmanshipWell mixedAdhesivesShrinkage rateEthyl acetate

The invention discloses a PETG thermal shrinkage film gassho glue suitable for high speed gassho machines. The PETG thermal shrinkage film gassho glue suitable for high speed gassho machines is prepared from, by volume, 52 to 58% of 1,4-dioxane, 32 to 38% of 1,3-Dioxolane, and 8 to 12% of ethyl acetate through mixing. The operation speed of the high speed gassho machines is controlled to be 300 to450m / min; the transverse shrinkage rate of the PETG thermal shrinkage film is 55 to 65%; mixng is convenient; gassho effect is obvious; and gassho technology quality can be ensured.

Owner:SONGYU PRINTING & PACKING CO LTD

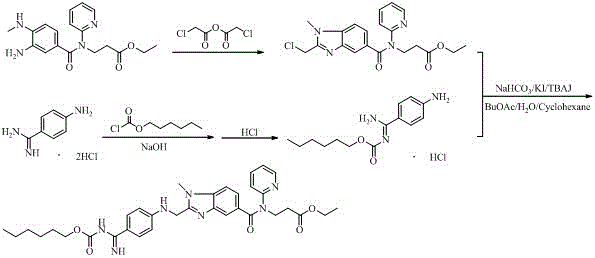

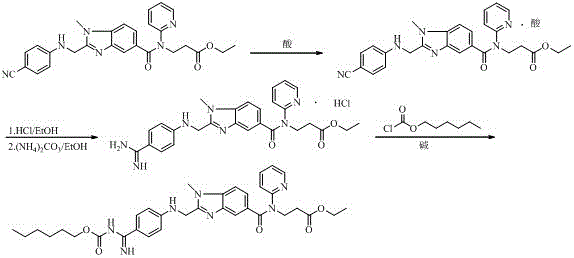

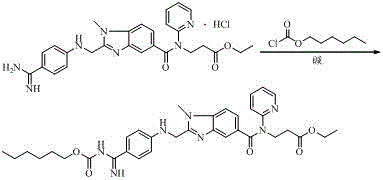

Industrial preparation method of dabigatran

ActiveCN106543144AReduce recrystallizationSimple processOrganic chemistryPurification methodsDistillation

The invention discloses an industrial preparation method of dabigatran, and belongs to the field of medicinal chemistry, wherein the preparation method sequentially comprises a condensation reaction, a closed cyclization reaction, a Pinner reaction, and other steps. According to the present invention, the hydrogen chloride / alcohol / ester solution is prepared by using acyl chloride and alcohol as raw materials, such that the problems of corrosion on equipment, high hidden safety danger, environmental pollution and the like caused by the use of hydrogen chloride gas in the prior art are solved; and the reactions in various steps are subjected to the industrial-scale-based optimization, the unnecessary distillation, extraction and re-crystallization process is reduced, the process is simplified, the purification method of the final product dabigatran is improved, the purification efficiency is increased in the case of the ensuring of the process yield and the product quality, the process reproducibility is good, the preparation cost is low, and the method is the ideal industrial preparation method of the dabigatran.

Owner:CHENGDU LIKAI CHIRAL TECH

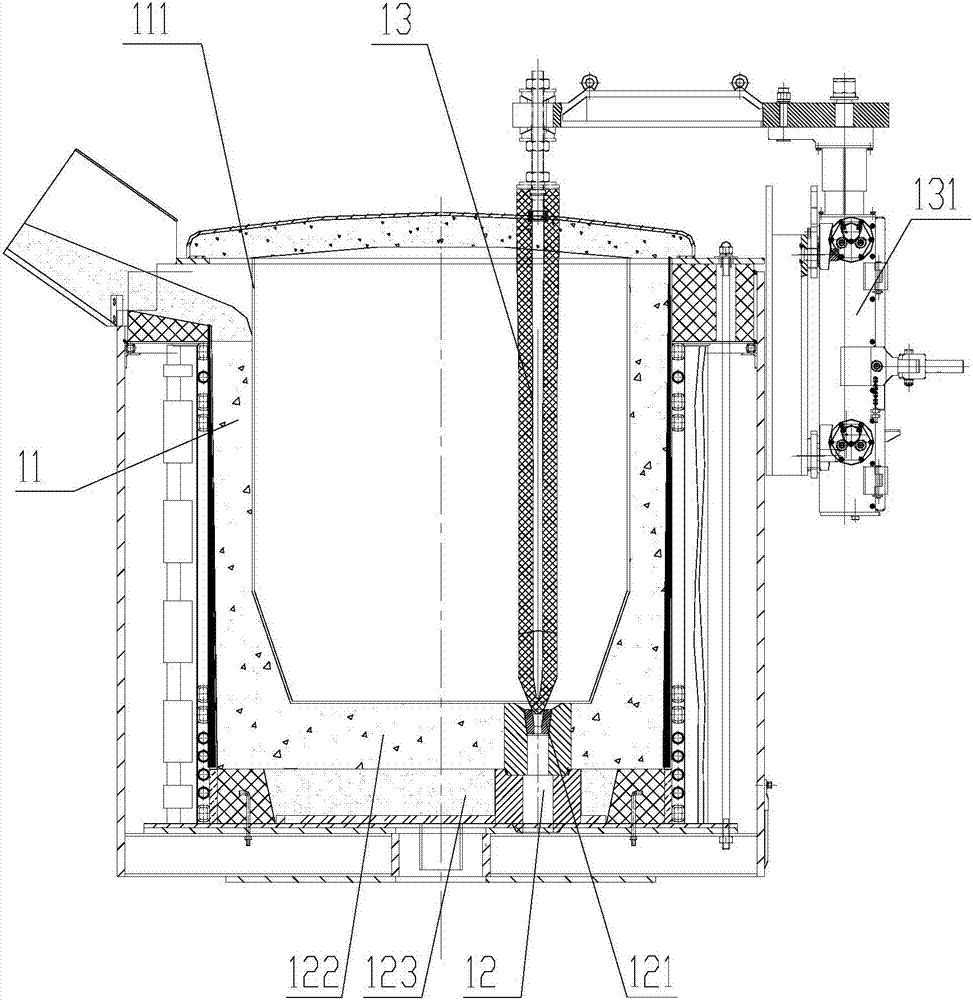

Pouring equipment and bottom pouring furnace thereof

PendingCN107052318AEfficient work is goodImprove workabilityMolten metal conveying equipmentsEquipment useEngineering

The invention discloses a bottom pouring furnace which comprises a furnace body. A furnace base is arranged at the bottom of the furnace body. A sprue gate penetrates through the furnace base in the vertical direction. A plug rod is arranged inside the furnace body. The bottom end of the plug rod aligns the sprue gate to be matched, and the diameter of the plug rod is larger than that of the sprue gate. The furnace body is provided with a driving device capable of driving the plug rod to move in the vertical direction. By the adoption of the bottom pouring furnace, the small-flow pouring operation effect can be effectively improved, and the pouring quality is guaranteed. The invention further discloses pouring equipment using the bottom pouring furnace.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

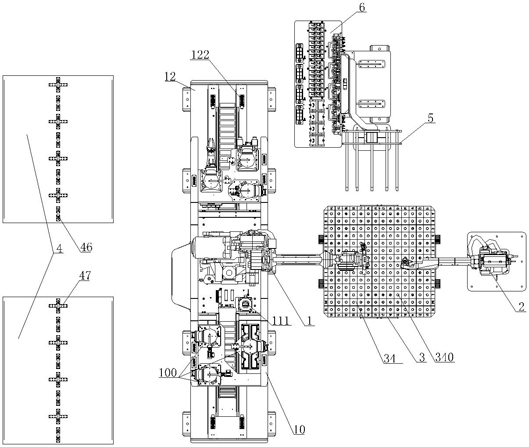

Flexible assembling and welding system for standard parts and non-standard parts and method

ActiveCN112404783AAvoid flawsReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringIndustrial engineering

The invention relates to a flexible assembling and welding system for standard parts and non-standard parts and a method. The flexible assembling and welding system comprises at least one carrying robot used for carrying positioning bodies and workpieces, at least one welding robot used for tailor-welding and / or welding the standard parts and the non-standard parts, and at least one self-locking rotary positioning platform arranged between the carrying robots and the welding robots and used for splicing, fixing, tailor-welding and welding the workpieces. Double-station flexible positioning rotary platforms for positioning the workpieces are arranged on the outer sides of the carrying robots. Positioning fixture repositories suitable for the self-locking rotary positioning platforms and thedouble-station flexible positioning rotary platforms are arranged at the side parts of the self-locking rotary positioning platforms. The flexible assembling and welding system for standard parts andnon-standard parts and the method have the advantages of being wide in welding object range, low in operation labor intensity, high in splicing and welding efficiency, consistent in fusion depth of workpiece products and capable of effectively guaranteeing the later-period assembling process and the servicing quality.

Owner:HENAN WINNER VIBRATING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com