Chemical equipment pipe supporting frame

A technology of chemical equipment and support frame, applied in the field of support, can solve problems such as vibration, pipeline breakage, endangering the environmental safety of chemical equipment, etc., and achieve the effect of ensuring process quality and reducing the impact of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

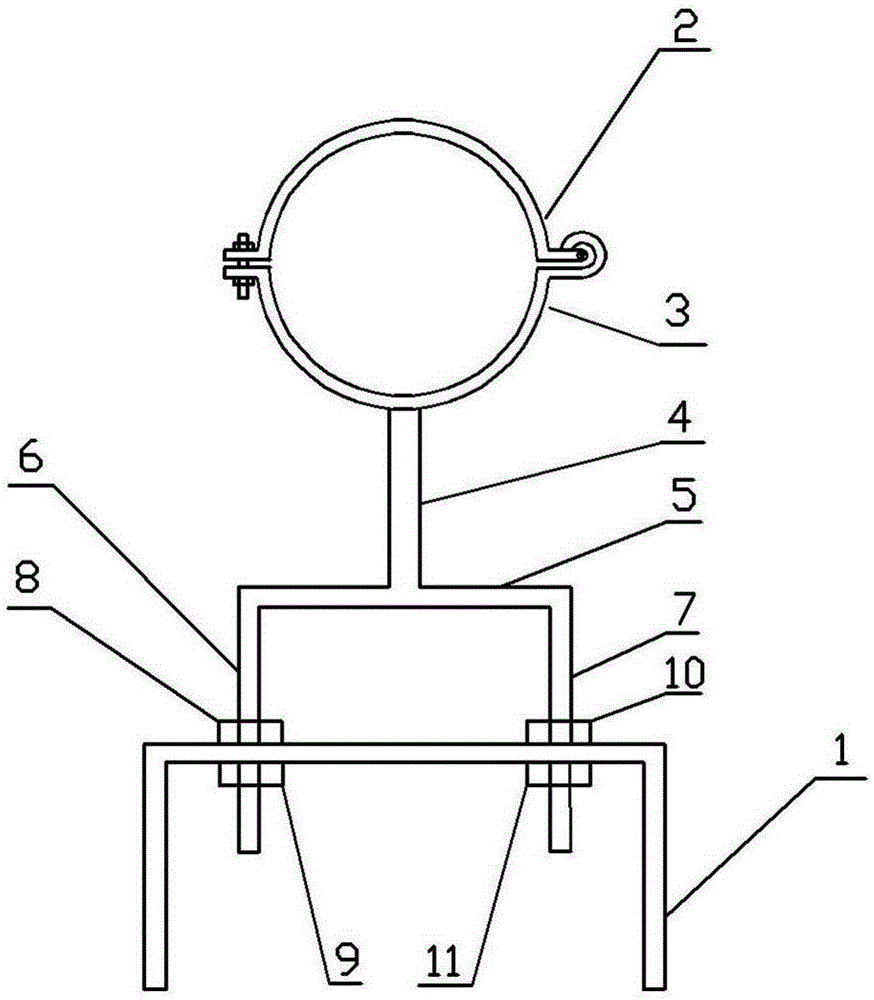

[0013] Such as figure 1 As shown, the present invention discloses a chemical equipment pipeline support frame, which comprises a bracket 1, a support rod arranged on An upper clamp 2 and a lower clamp 3, one end of the upper clamp 2 and one end of the lower clamp 3 are hinged, and the other end of the upper clamp 2 and the other end of the lower clamp 3 are Bolt connection; the adjusting rod includes the first vertical bar 4 connecting the lower clamp, the first cross bar 5 connecting the bottom end of the first vertical bar 4 and the first cross bar 5 connecting the two ends of the first cross bar 5 respectively. The screw rod 6 and the second screw rod 7, the first screw rod 6 and the second screw rod 7 are correspondingly embedded in the through holes provided on the bracket 1, and the first screw rod 6 passes through the first upper nut 8 and the second screw rod. The lower nut 9 and the second screw rod 7 are clamped and connected to the bracket 1 through the second uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com