Patents

Literature

56results about How to "Construction environment safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method of residual slope wash tunnel with shallow cover and unsymmetrical pressure

ActiveCN104818991ASimple processReasonable processUnderground chambersExcavationsShotcreteEarth surface

The invention relates to a construction method of a residual slope wash tunnel with a shallow cover and the unsymmetrical pressure. The scheme with the step of ground surface grouting and shotcrete anchorage combined supporting, the step of pre-reinforcement of a long pipe shed and the step of correction three-stair four-step excavation construction is adopted, construction is conducted layer by layer from outside to inside, and operation that the deep-cover unsymmetrical pressure side is excavated, supporting is conducted, then the shallow-cover unsymmetrical pressure side is constructed, and an asymmetrical initial supporting structure is used for conducting construction according to the unsymmetrical pressure of surrounding rock is conducted, so that the supporting structure is optimized, the working procedure is more reasonable, and the construction speed is increased.

Owner:中铁二十四局集团福建铁路建设有限公司 +1

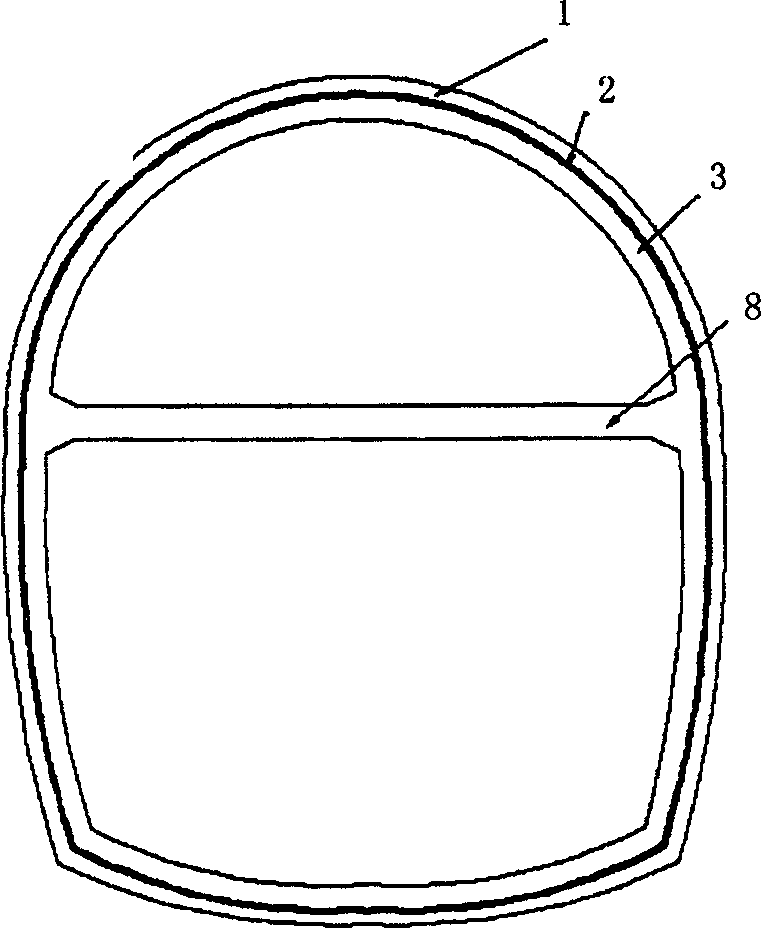

Dormant digging and separating construction method for underground two layers and multilayer composite lining structure

This is an underground hidden digging separated working method it is double layers or multiple layers complex lining brick structure. It contains: Use the existing shallow bury hidden digging technology to finish the lining bricks structure upper parts, and use the routine technology to finish the original support and protection. After finished the original protection and support of vault part, to spread out the water-proof plate and finish the middle separated plate to use the ground model, and pouring cement slurry to make the upper part structure. Under the protected of middle separated plate, then to make the structure under the middle separated plate, to finish the whole working process finally.

Owner:刘昌用

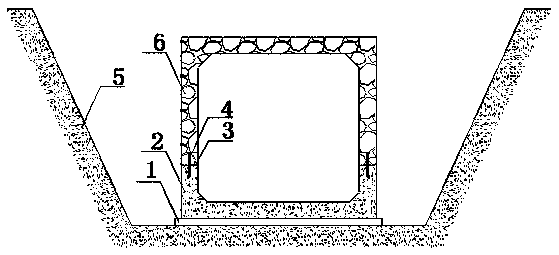

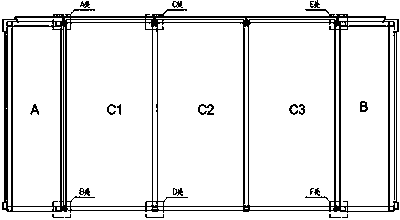

Continuous construction method for aluminum alloy template for comprehensive pipe rack

ActiveCN108914965AFast constructionShorten the construction periodArtificial islandsUnderwater structuresMaterials scienceAluminium alloy

The invention relates to underground comprehensive pipe rack construction, in particular to a continuous construction method for an aluminum alloy template for a comprehensive pipe rack. The continuous construction method comprises the following steps that A, first-time pouring construction of a first-section comprehensive pipe rack body is conducted; B, second-time pouring construction of the first-section comprehensive pipe rack body and first-time pouring construction of a second-section comprehensive pipe rack body are conducted at the same time; C, form removal of the first-section comprehensive pipe rack body is conducted; D, second-time pouring construction of the second-section comprehensive pipe rack body is conducted; and F, first-time pouring construction of a third-section comprehensive pipe rack body is conducted. According to the continuous construction method, the continuous cyclic work is achieved, rapid turnover construction is achieved, the construction speed is increased, the construction period is shortened, construction materials are saved, and the construction environment is safer and more environment-friendly. Meanwhile, a concrete structure formed through the continuous construction method is flat and smooth in surface quality, the requirements of facing and bare concrete are met, secondary plastering is not needed, and the construction cost is saved.

Owner:22MCC GRP PRECISION FORGING

Chemical slip casting strengthening material and preparation method thereof

The invention relates to a chemical slip casting strengthening material and a preparation method thereof. A chemical slip casting strengthening material with two components (component A and component B) is provided, thus effectively solving the problems existing in conventional chemical slip casting materials, such as slow polyurethane polymerization, poor flame retardation and environment pollution. When the chemical slip casting material is used, the component A, i.e. phenolic resin, and the component B, i.e. curing agent, are mixed according to a weight ratio of 1:1. The phenolic resin is obtained by firstly mixing phenol and formaldehyde according to a weight ratio of 1:1.3-1.5, then adding the catalyst NaOH, heating the mixture to a temperature of 90-100 DEG C, causing the reaction to last 4-6 hours, carrying out neutralization and dehydration, cooling the mixture to 25 DEG C and adding foaming agent and surfactant for full mixing. The curing agent consists of 0.6-1.0 part of p-toluenesulfonic acid by weight, 0.8-1.3 parts of phosphoric acid by weight, 0.5-1.0 part of hydrochloric acid by weight and 0.1 part of ethylene glycol by weight. The chemical slip casting material needs a short time for solidification, has an inflaming retarding oxygen index higher than or equal to 54, and is suitable for the slip casting strengthening engineering of a mine, as well as the seepage-proofing, leaking stoppage and strengthening work of an ordinary underground engineering or a water conservancy engineering.

Owner:廊坊鑫美源化工建材有限公司

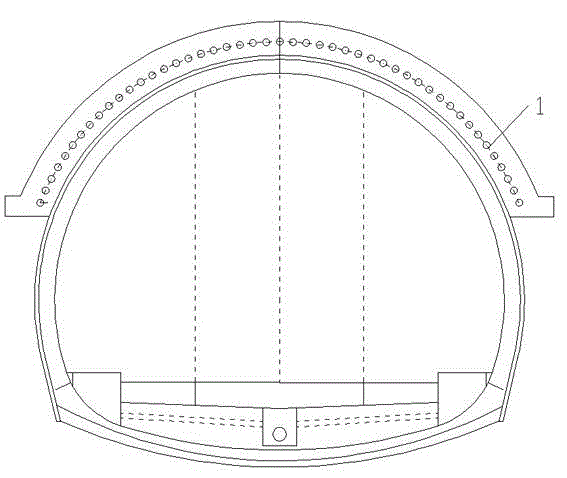

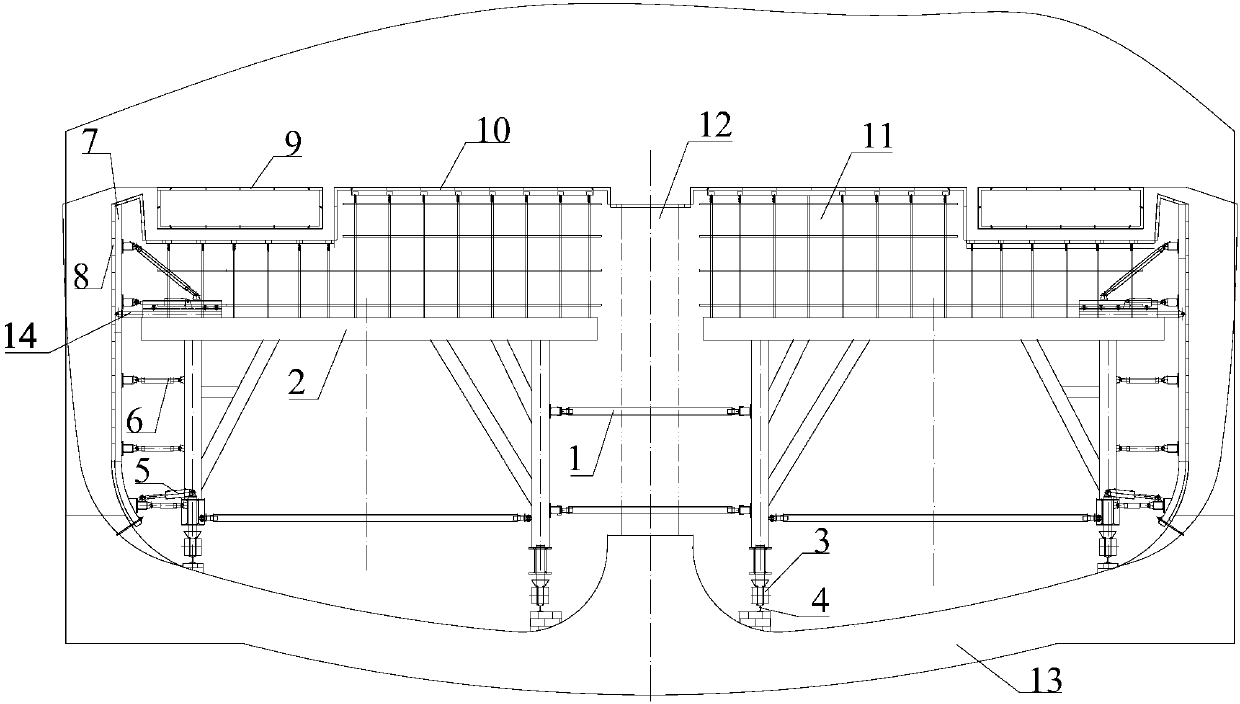

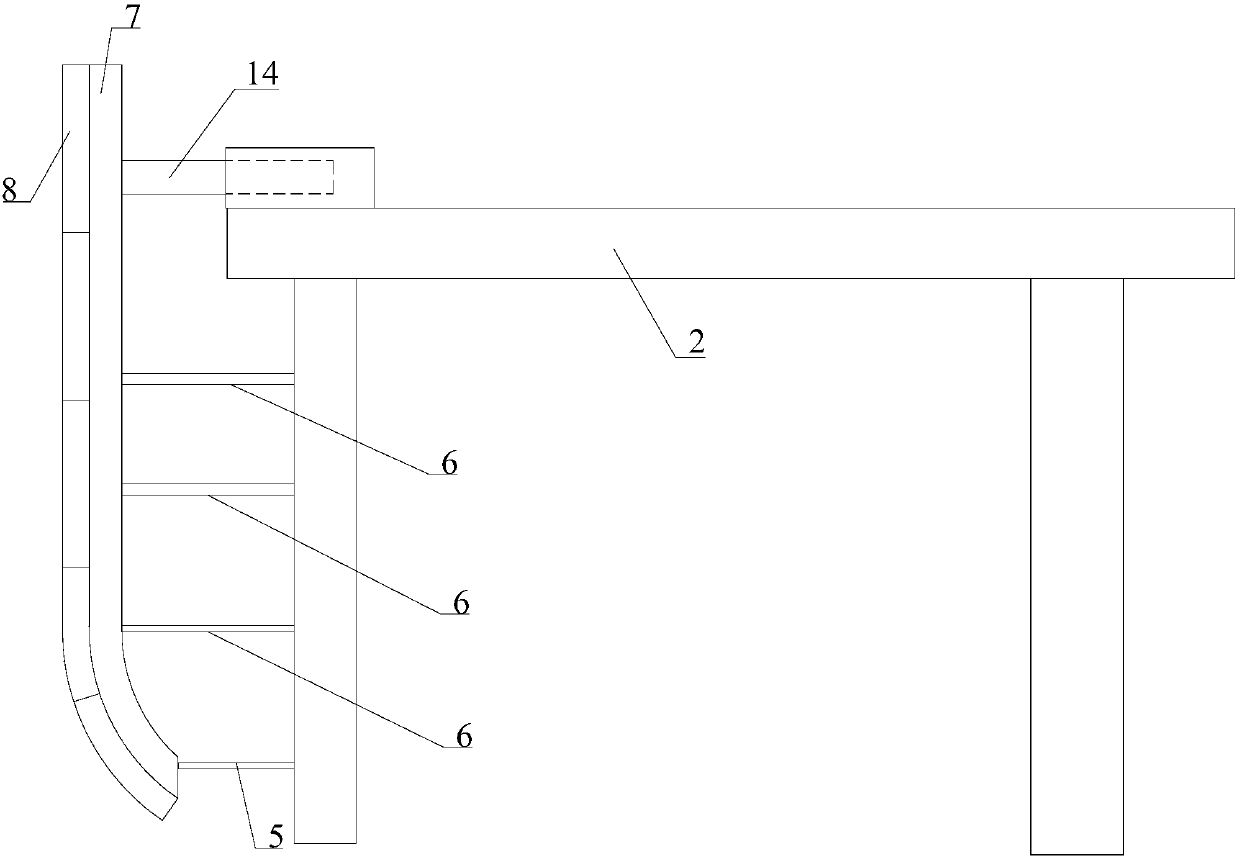

Through type large-section tunnel underground excavation lining trolley and tunnel underground excavation lining construction method

ActiveCN105756687ASolve the problem of temporary empty period when dismantling the temporary support step by stepReduce security risksUnderground chambersTunnel liningSupporting systemArchitectural engineering

The invention discloses a through type large-section tunnel underground excavation lining trolley and a tunnel underground excavation lining construction method, and aims to solve the problem that great risk is caused to tunnel construction as a suspension period is not avoided as the construction engineering of secondary lining is not sufficiently considered in the conventional trolley. The through type large-section tunnel underground excavation lining trolley comprises a trolley support system, a trolley through bracket system and a trolley mold plate system, wherein the systems are all provided with pressure sensors and data acquisition and display devices; the data acquisition and display devices are used for acquiring pressure sensor signals and used for displaying real-time pressure. By adopting the through type large-section tunnel underground excavation lining trolley disclosed by the invention, the problem that the suspension period is caused when temporary supports are dismounted in different steps in a large-section tunnel can be effectively solved, the whole dismounting process is supported by the trolley, stress conversion can be achieved, safety risk can be reduced, a mold can be made at one time in the casting process, the working period can be shortened, and the working intensity can be alleviated.

Owner:北京住总集团有限责任公司

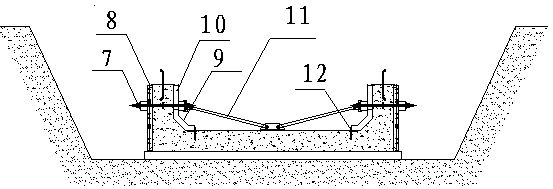

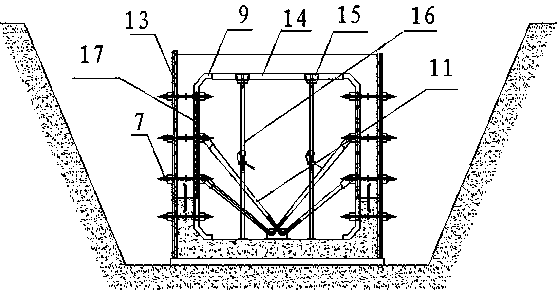

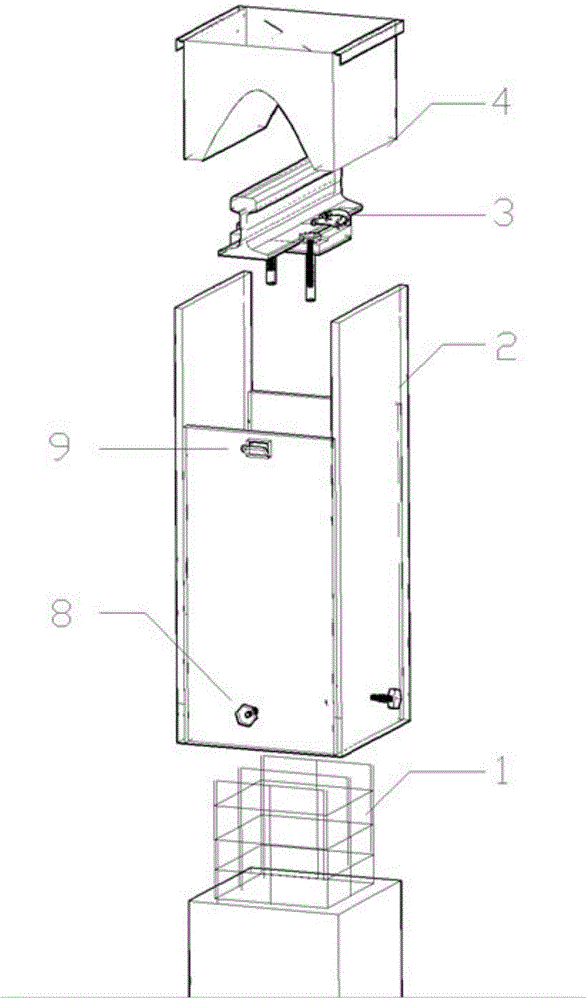

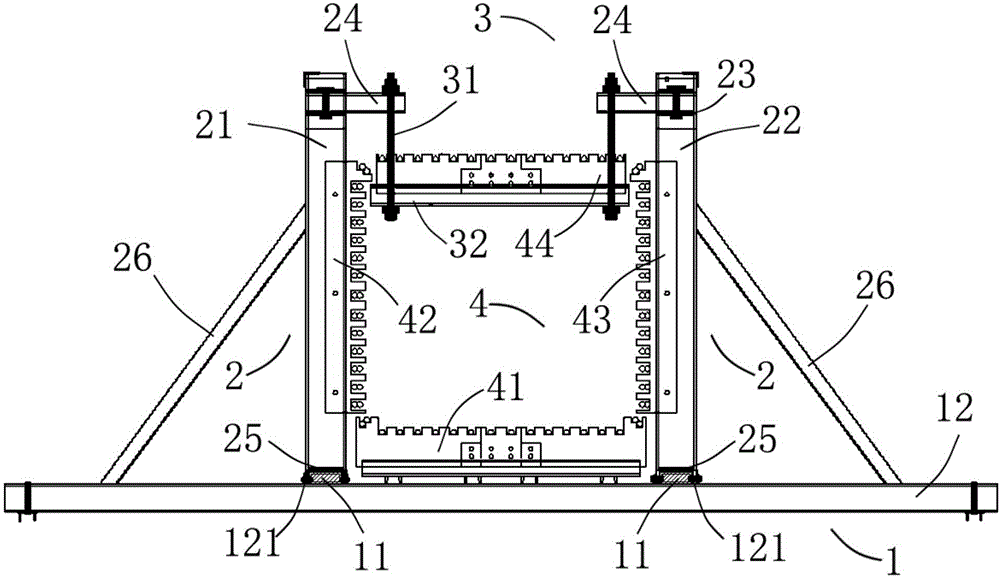

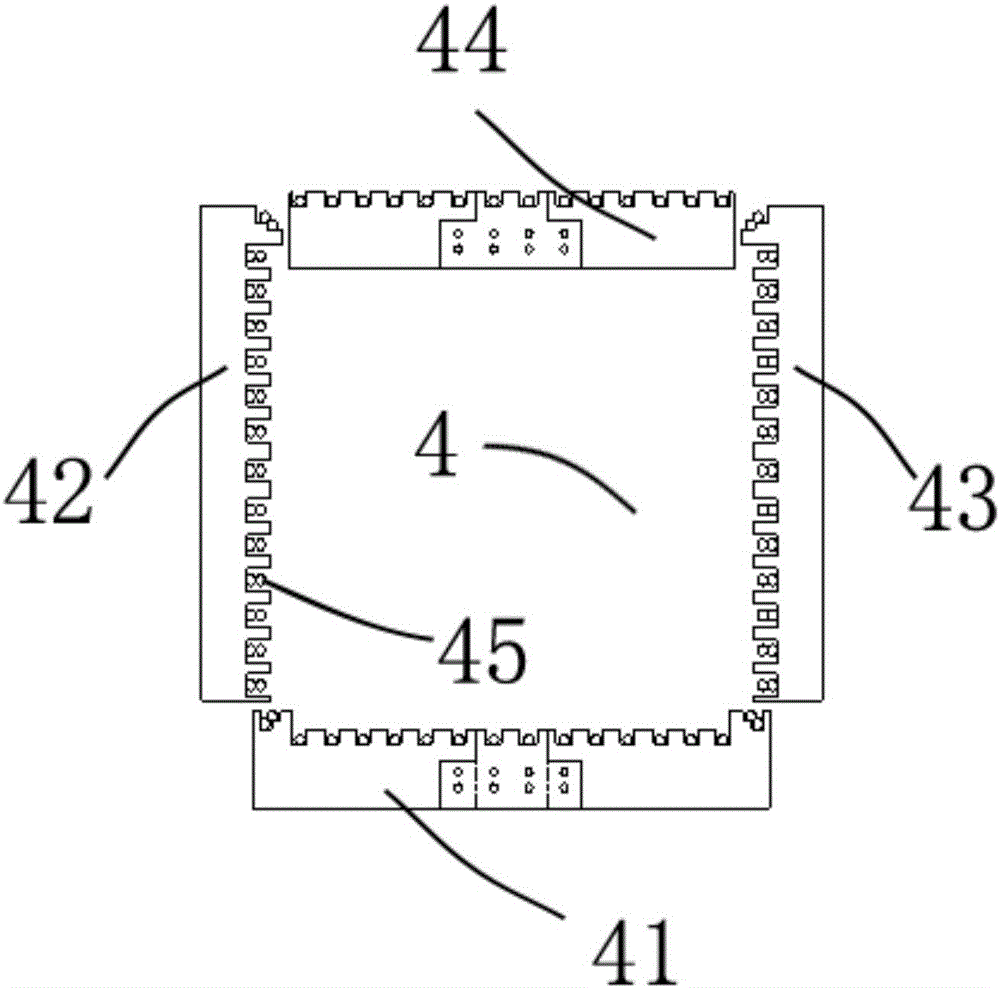

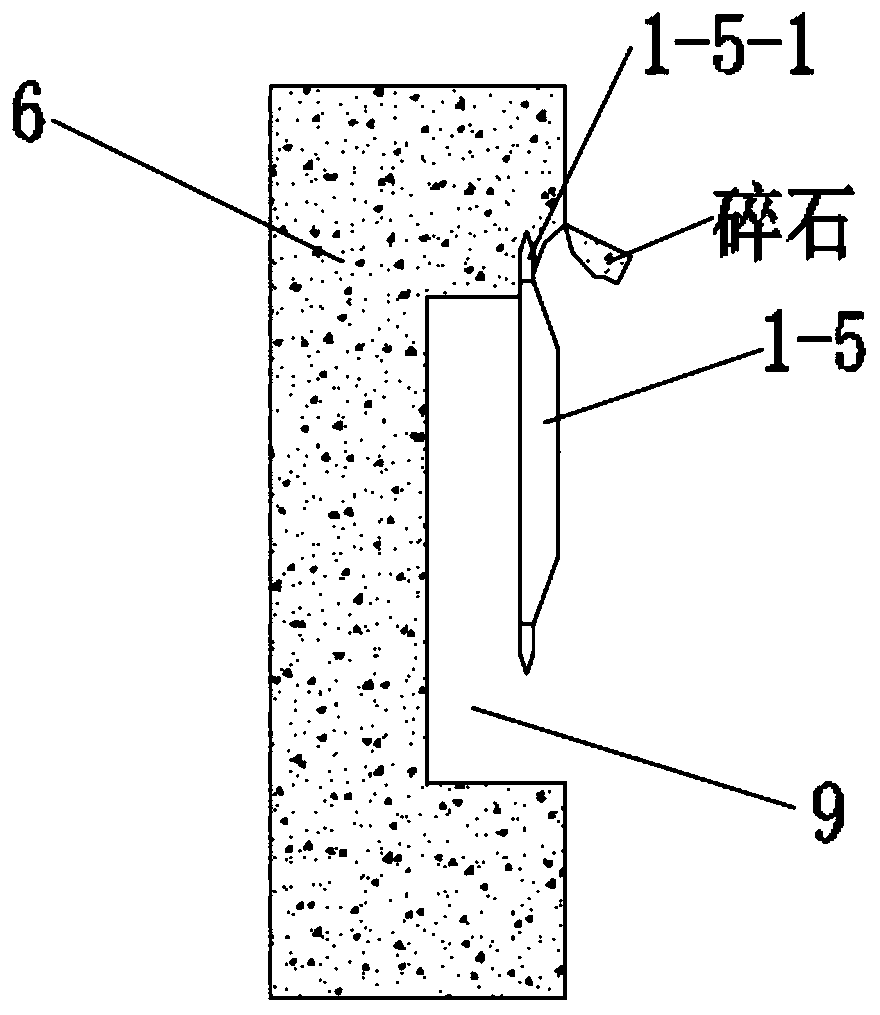

Integrated pouring device for installation of rail column type inspection pit fastening system

InactiveCN104631232AOvercome the problem of easy pollutionAvoid spillingRailway track constructionIndustrial buildingsEngineeringRebar

The invention discloses an integrated pouring device for installation of a rail column type inspection pit fastening system. The periphery of a stand column reserved steel bar is wrapped by shaping aluminum formworks, wherein the two shaping aluminum formworks parallel to a steel rail above the reserved steel bar are higher than the other two shaping aluminum formworks at the positions perpendicular to the steel rail, and the shaping aluminum formworks are used for fixing a matched pouring funnel. The invention further discloses a laying method of the integrated pouring device. The integrated pouring device replaces traditional woodworking operation wasting time and materials, solves the problems that the formwork supporting effect is slow and parts are prone to contamination in the pouring process, and is short in construction period, low in use cost, convenient to construct, high in efficiency, good in stability and wide in application range.

Owner:邵冠慧

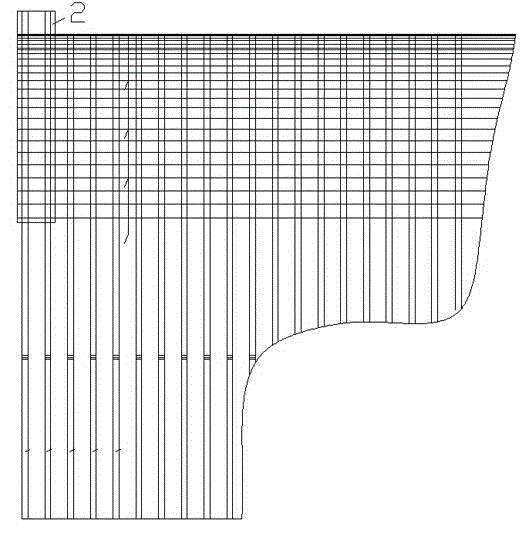

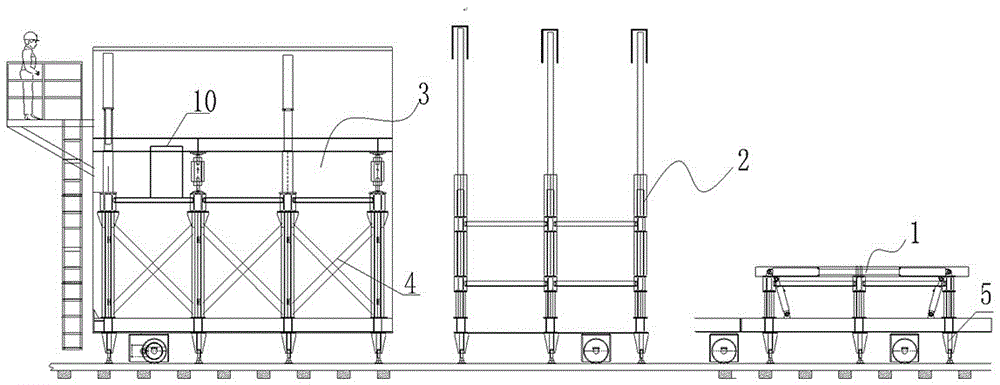

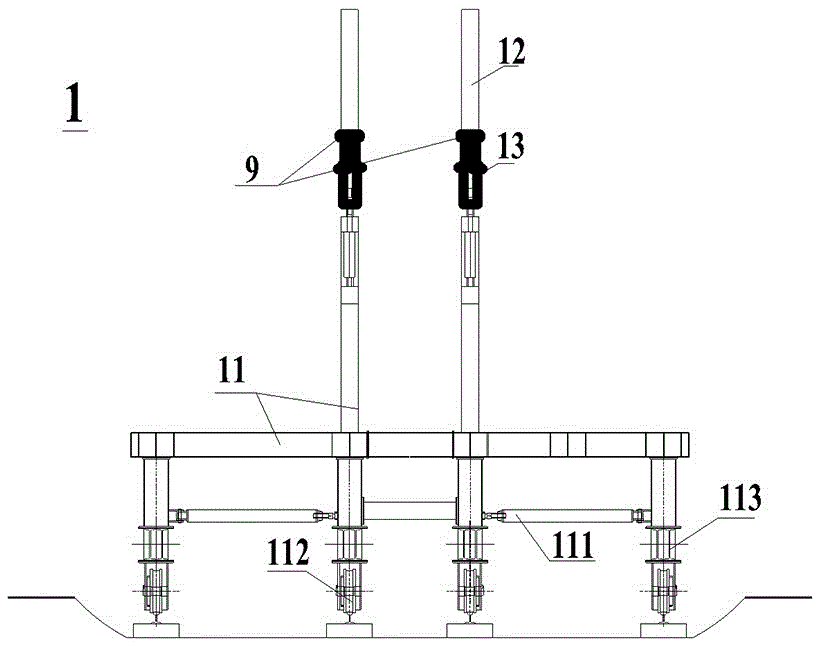

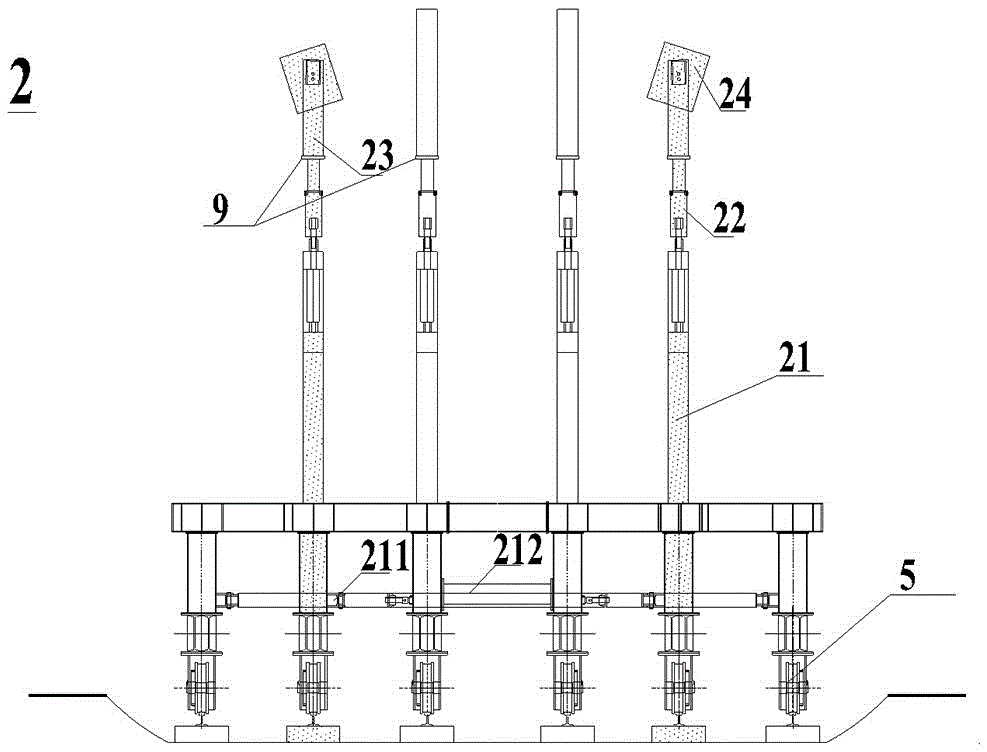

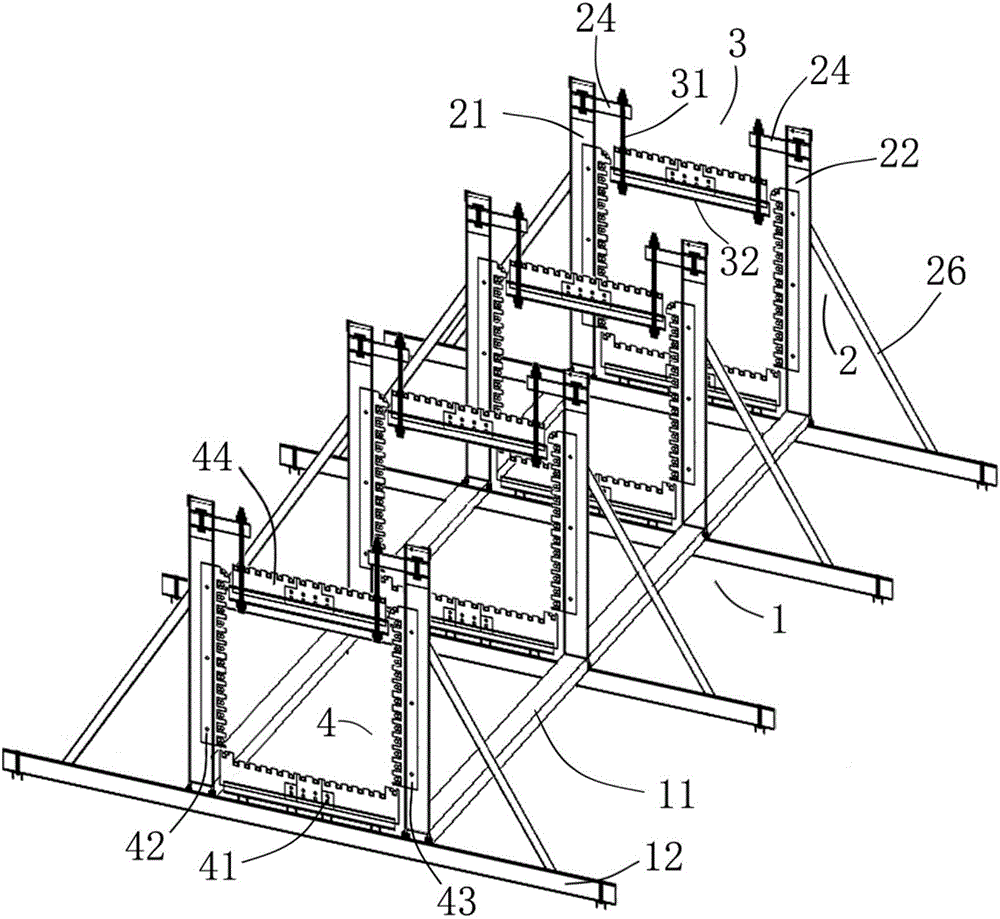

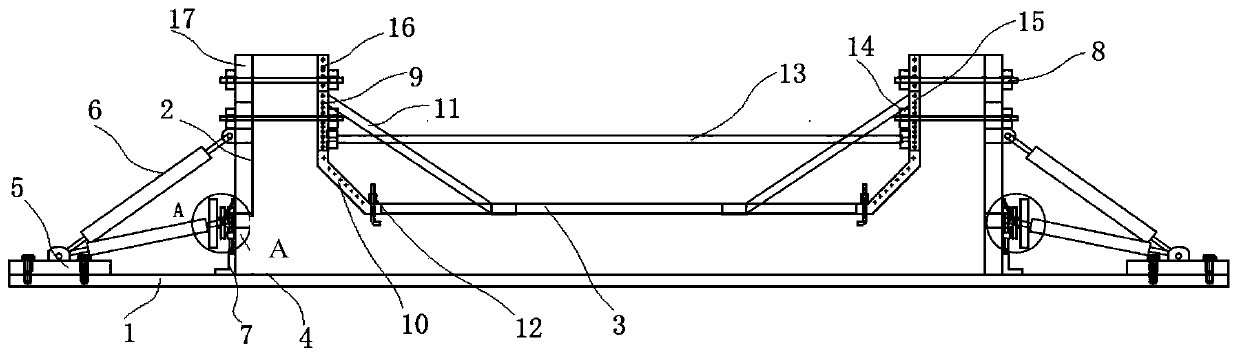

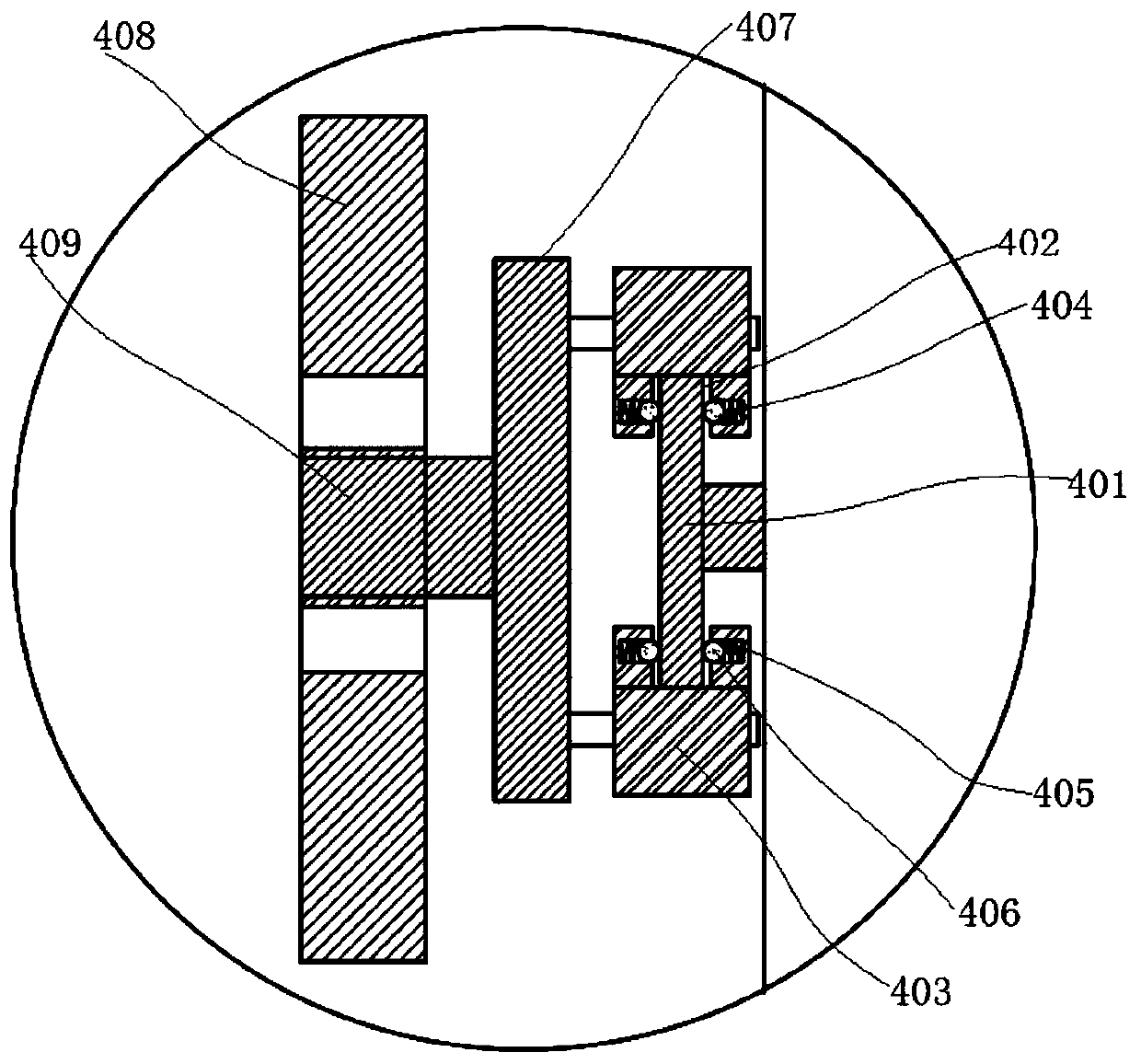

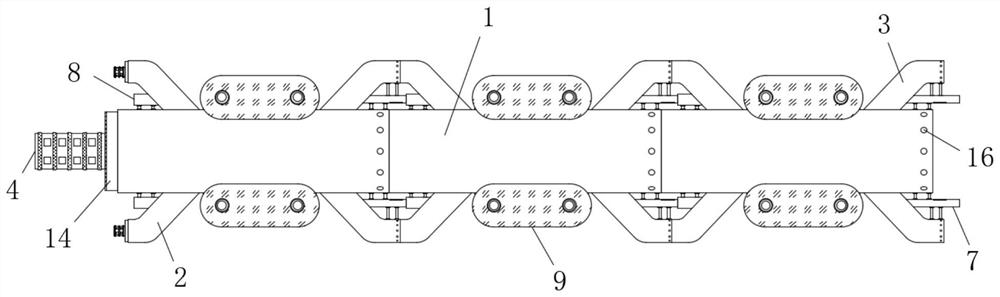

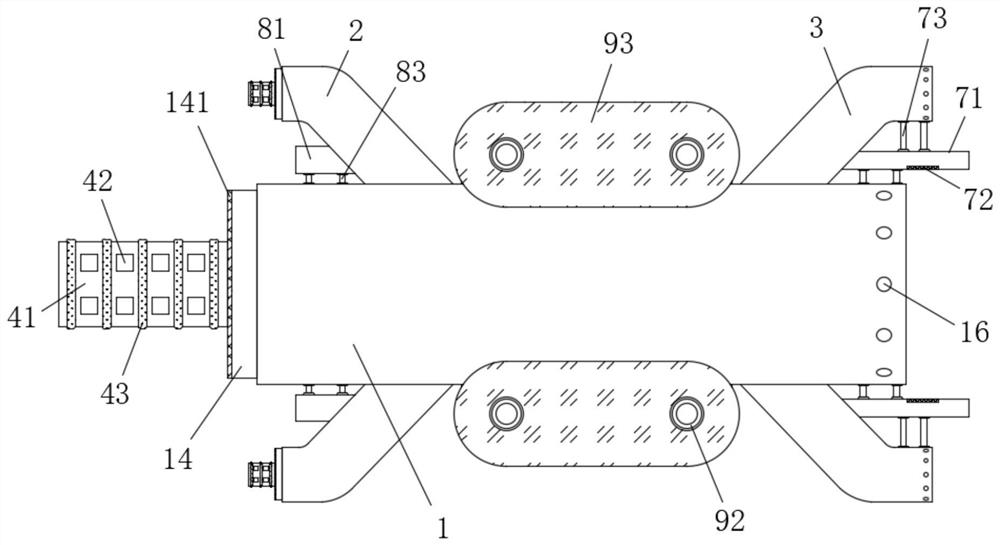

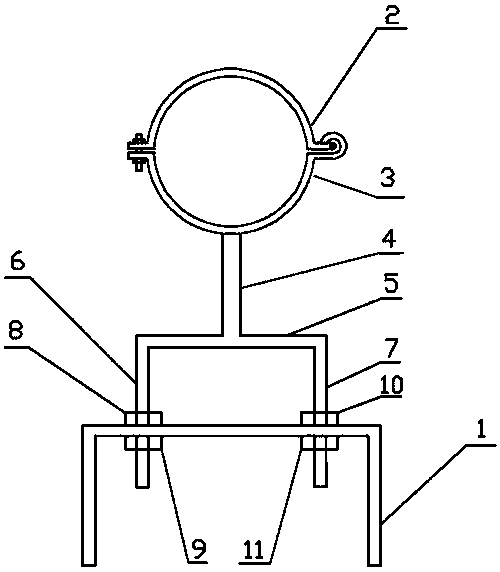

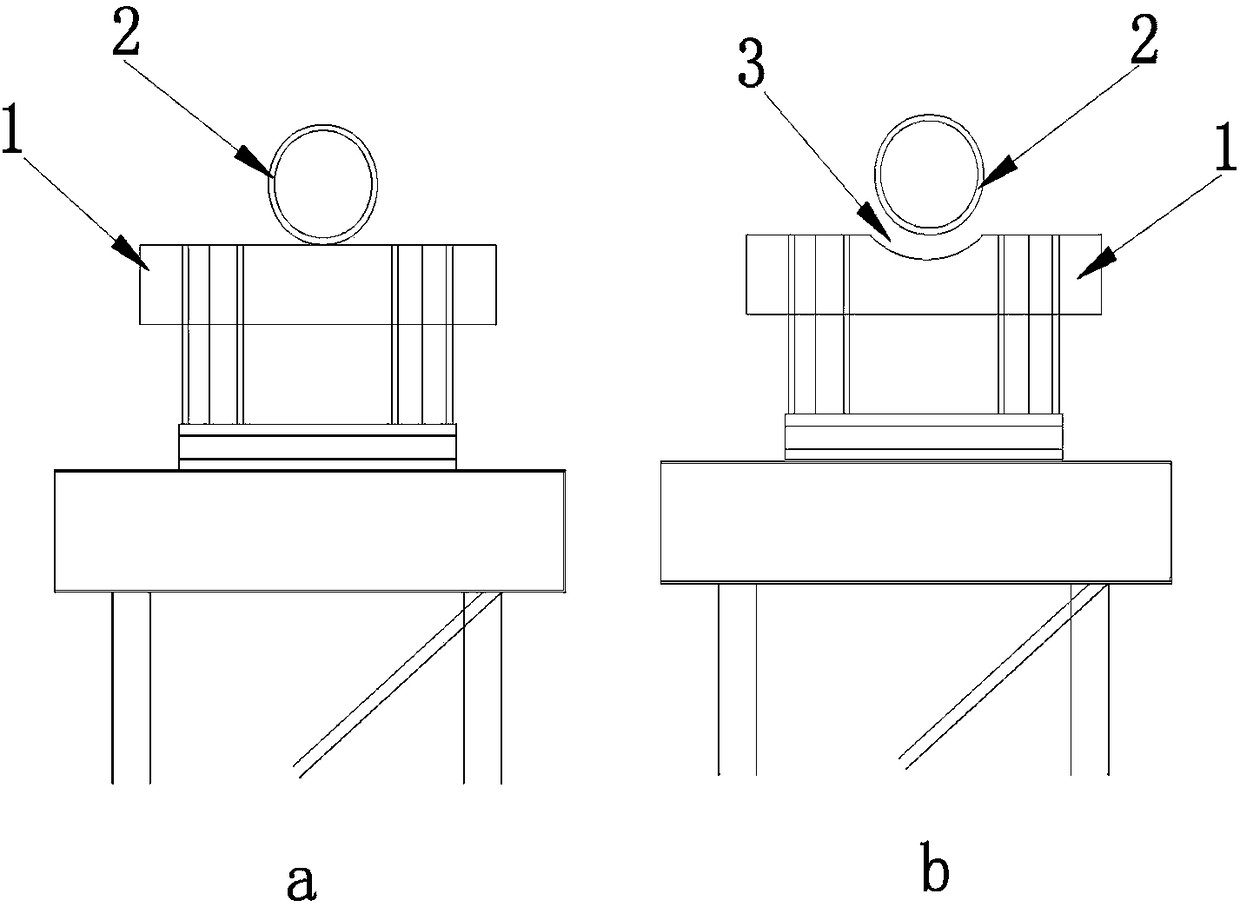

Manufacturing method of reinforcing steel bar section and adjustable reinforcing steel bar section splitting jig frame thereof

ActiveCN106400690AOperational securityConstruction environment safetyBridge erection/assemblyRebarSupport plane

The invention discloses a manufacturing method of a reinforcing steel bar section and an adjustable reinforcing steel bar section splitting jig frame thereof. The adjustable reinforcing steel bar section splitting jig frame comprises a bearing platform, a vertical supporting frame, a suspension frame and a toothed plate set, wherein the bearing platform comprises a pair of longitudinal bearing steels, and a plurality of transverse bearing steels which are orthogonally connected below the longitudinal bearing steels; the vertical supporting frame comprises a plurality of pairs of left supports and right supports; the left supports and the right supports are vertically arranged on the transverse bearing steels; the suspension frame comprises hoisting ribs, and suspension plates which are connected with the left supports and the right supports through the hoisting ribs in a suspension manner; the toothed plate set comprises lower toothed plates which are connected with the corresponding transverse bearing steels, left toothed plates which are connected with the corresponding left supports, right toothed plates connected with the corresponding right supports, and upper toothed plates connected with the corresponding suspension plates. With the adoption of the adjustable reinforcing steel bar section splitting jig frame, a safe and reliable construction environment is provided; in addition, the adjustable reinforcing steel bar section splitting jig frame can be transferred to use and has the characteristics of being fast to bind and manufacture, high in reinforcing steel bar mounting accuracy, and small in workload of aloft work.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

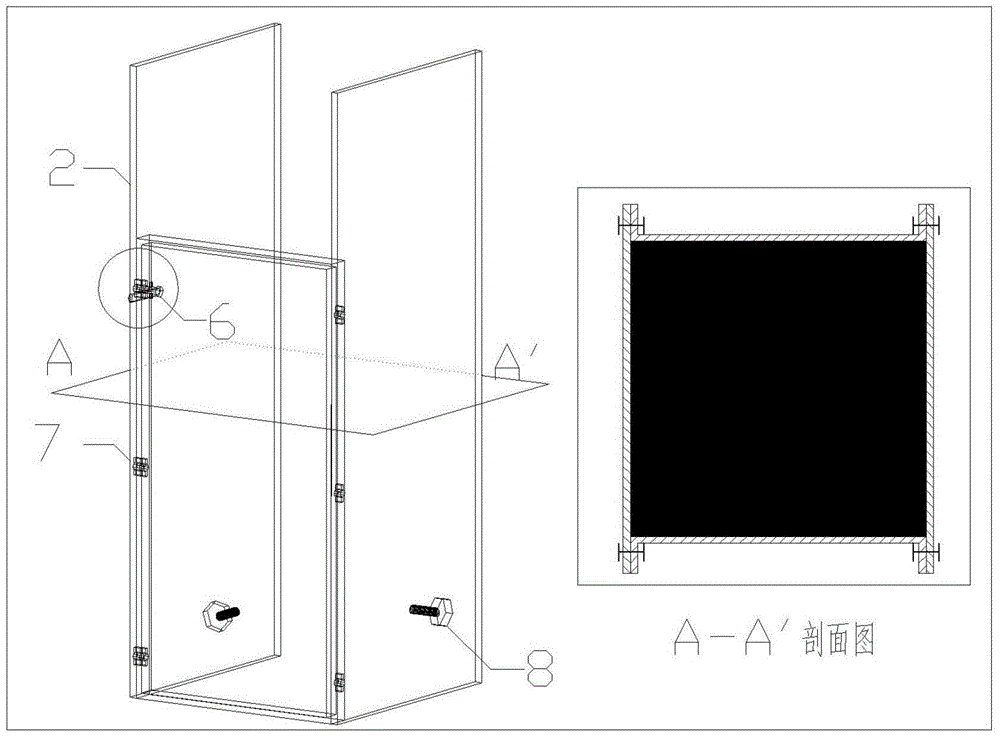

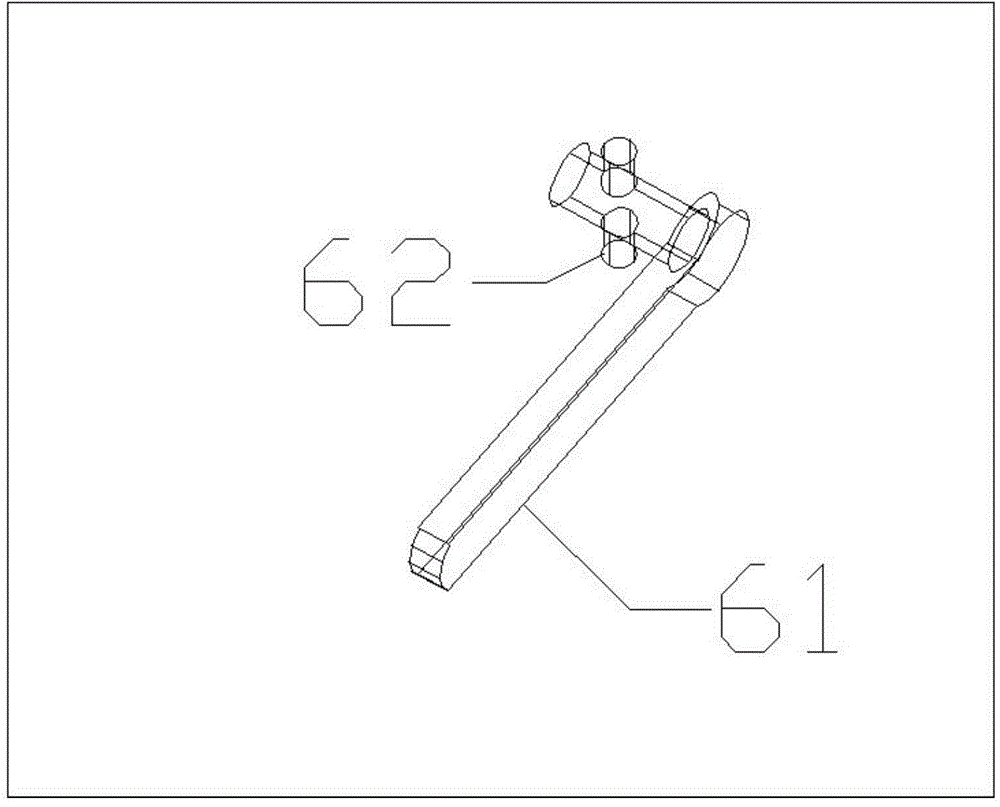

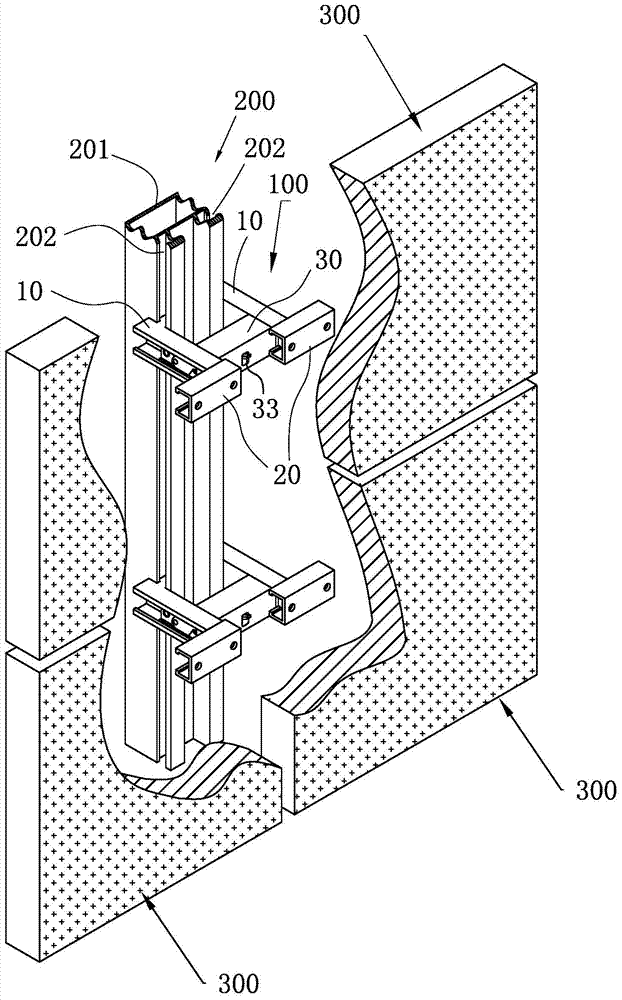

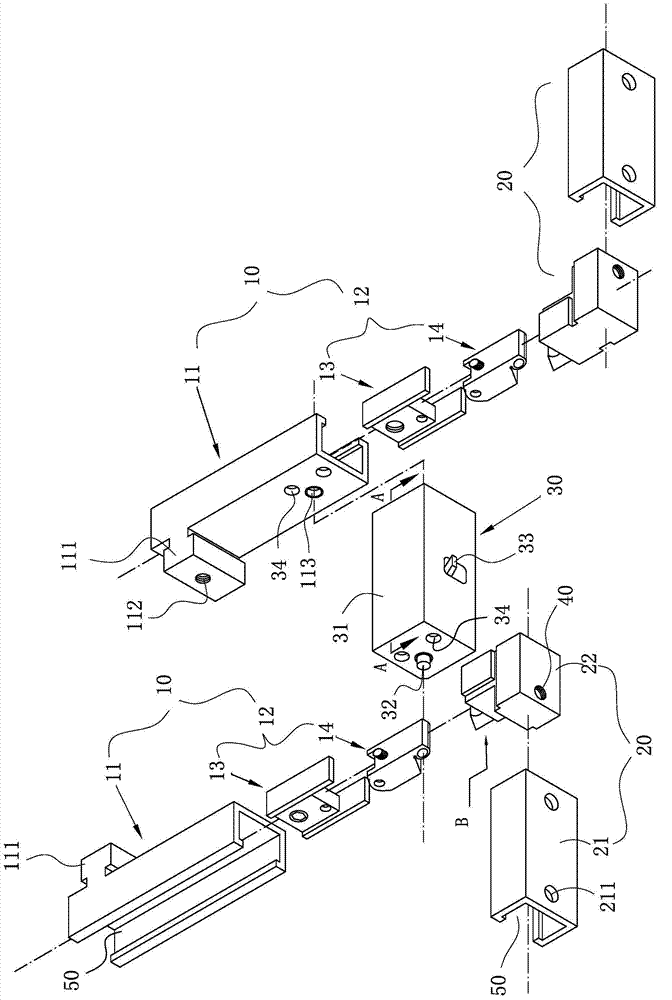

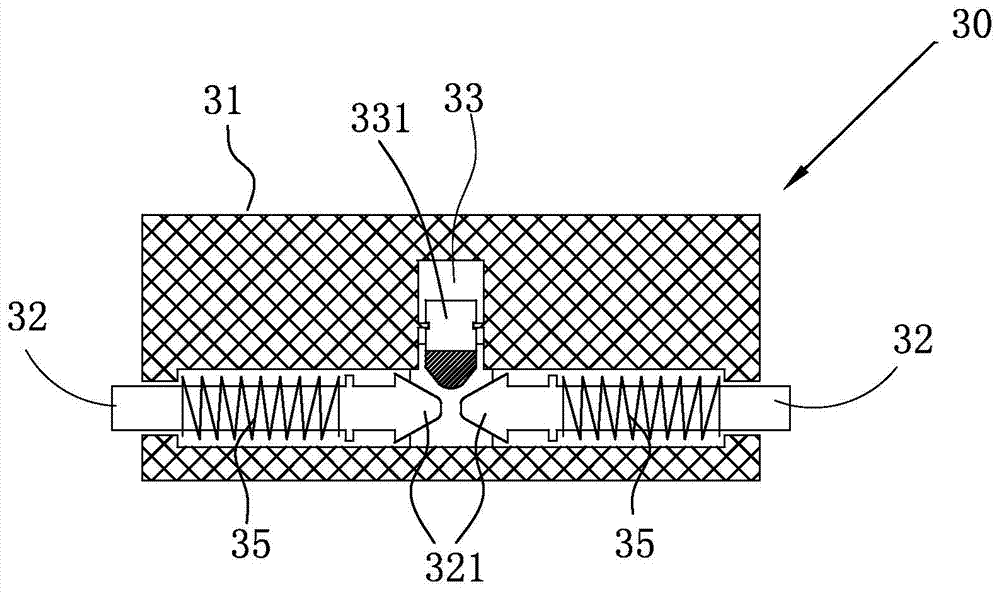

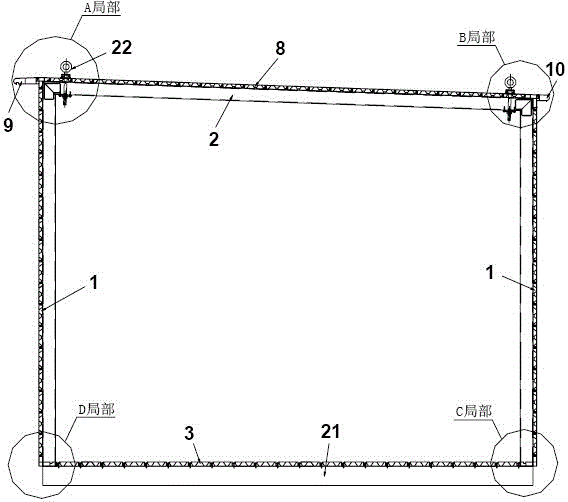

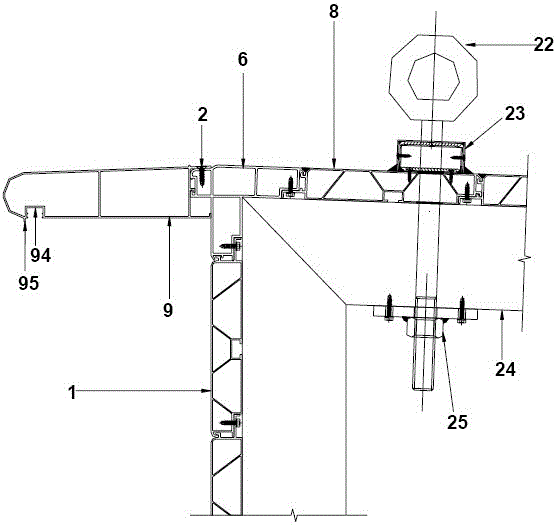

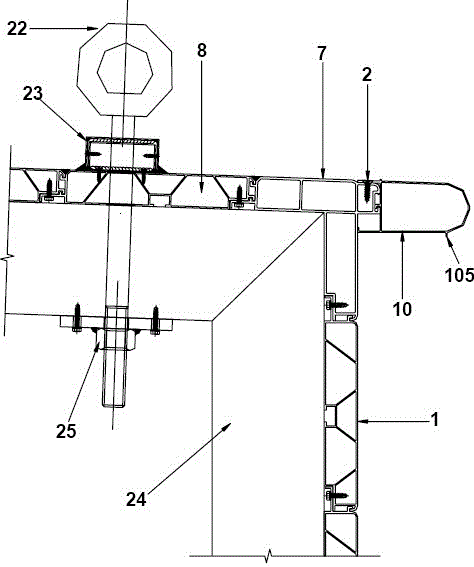

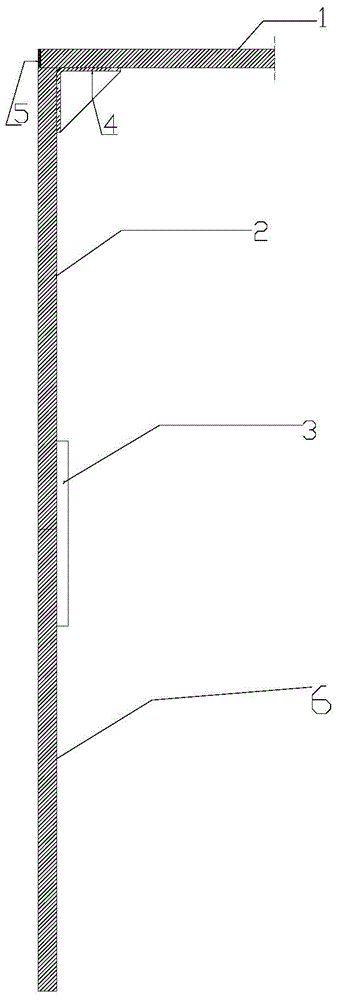

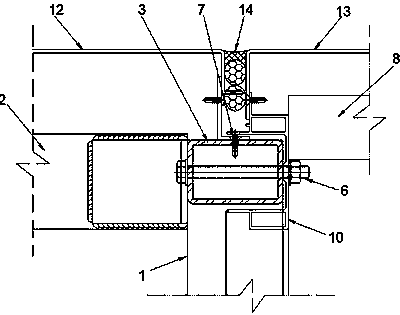

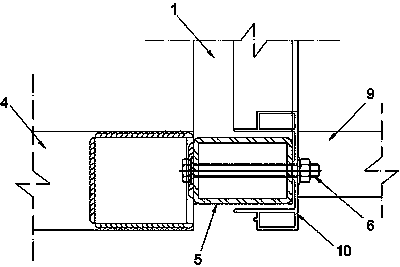

Mounting system of decoration panel, connecting component and mounting method of decoration panel

The invention discloses a mounting system of a decoration panel, a connecting component and a mounting method of the decoration panel. According to mounting system of the decoration panel, the connecting component and the mounting method of the decoration panel, the decoration panel can be mounted and dismantled rapidly through locking and unlocking and can be replaced freely at any time. The mounting system of the decoration panel comprises a stand column, the decoration panel and the connecting component which fixes the decoration panel on the stand column, wherein the connecting component comprises a longitudinal fastening assembly and a horizontal fastening assembly, the longitudinal fastening assembly is connected to the lateral side of the stand column in a detachable mode and can reciprocate vertically on the lateral side of the stand column, the horizontal fastening assembly is connected with the decoration panel in a detachable mode, and the longitudinal fastening assembly is connected with the horizontal fastening assembly in a fast assembling and disassembling mode through a locking mechanism. According to the mounting system of the decoration panel, the connecting component and the mounting method of the decoration panel, horizontal keels and a basic cushion board are not needed, the decoration panel mounting method which is novel, accurate, reliable, efficient, high in quality, standard and industrialized is provided, and the decoration panel can be replaced and updated freely and conveniently at any time by an owner or a user or decoration panels which are the same as the decoration panel which is mounted on the wall can be mounted according to the requirements of the owner or the user for the decoration panel after the decoration panel is mounted or when the decoration panel is in use. The mounting system of the decoration panel, the connecting component and the mounting method of the decoration panel are suitable for public decoration and home decoration, the mounting speed is high, cost is low, and needed labor is little.

Owner:深圳广田高科新材料有限公司

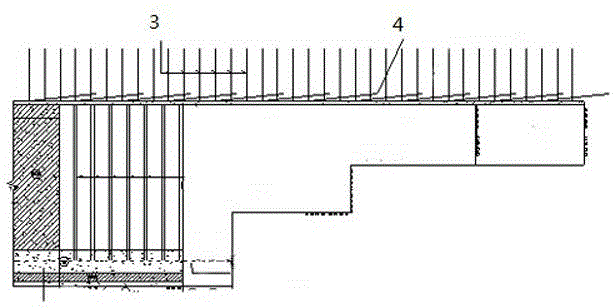

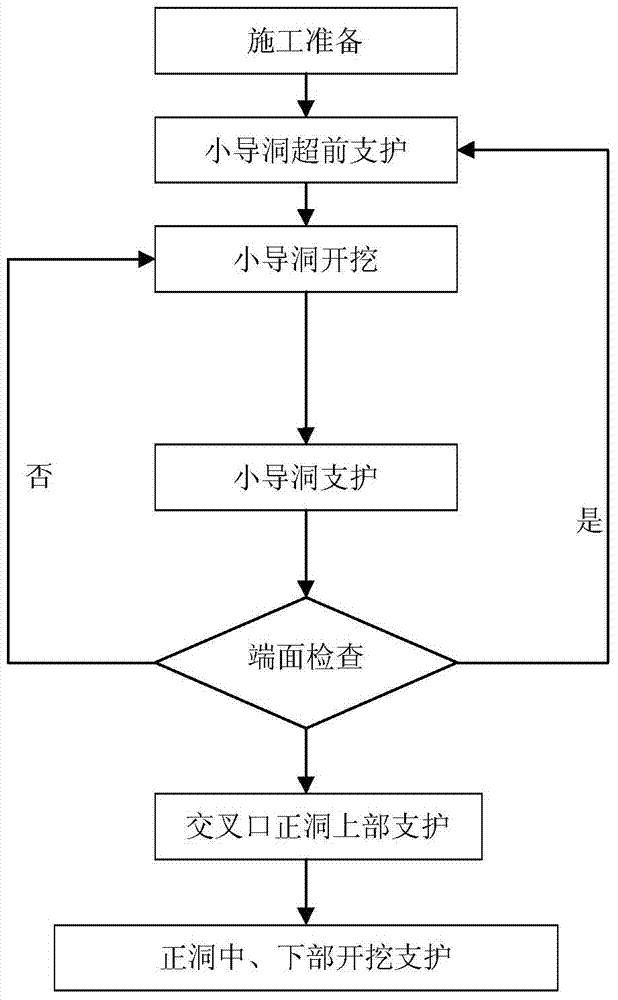

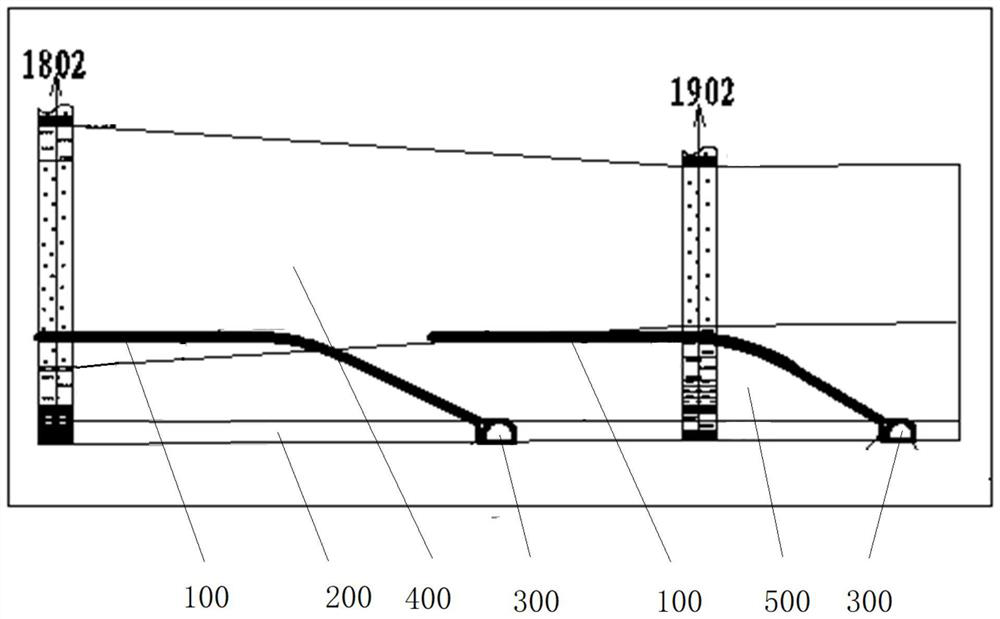

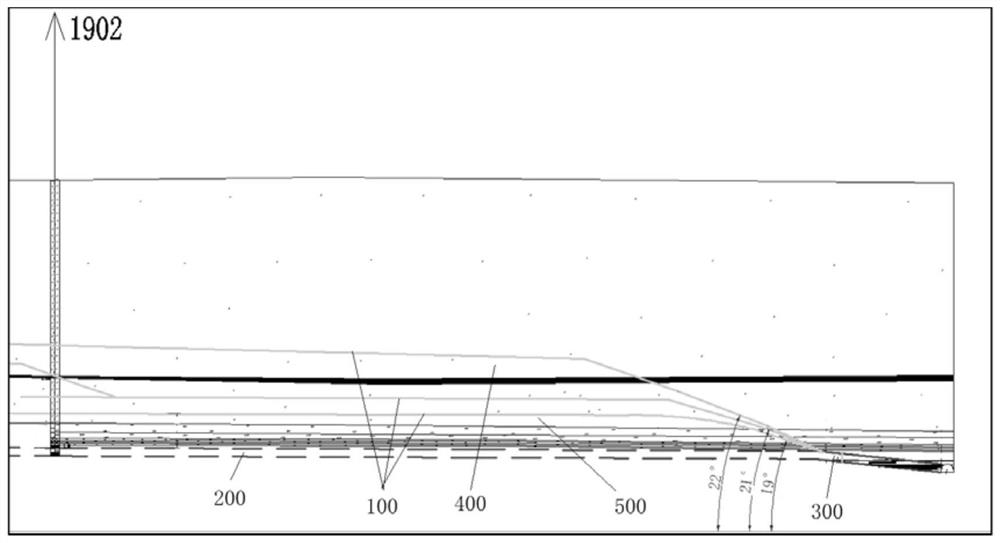

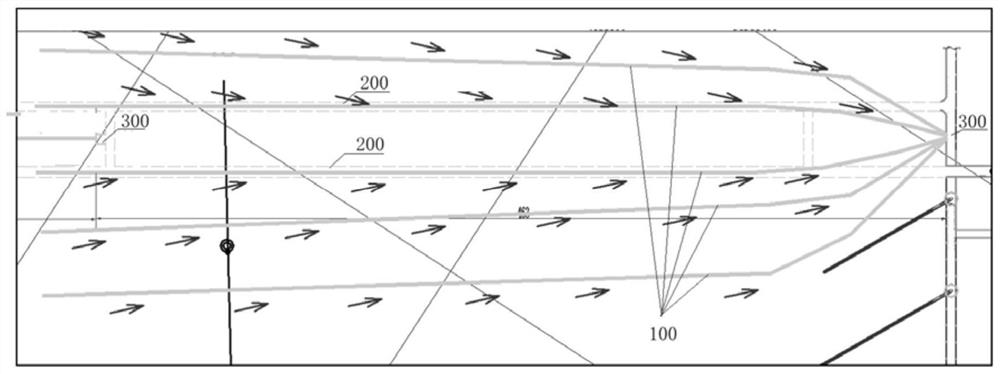

Weak surrounding rock auxiliary gallery small pilot tunnel crossing main tunnel roof brushing construction method

InactiveCN104329098AImprove construction progressConstruction environment safetyUnderground chambersTunnel liningHigh probabilitySteel frame

The invention discloses a weak surrounding rock auxiliary gallery small pilot tunnel crossing main tunnel roof brushing construction method. The method comprises the following steps: (1) preparing for construction; (2) constructing an advance support of the small pilot tunnel; (3) excavating the small pilot tunnel in two steps after the advance support of the small pilot tunnel is finished; (4) performing combined support by using a steel frame, a system anchor rod, a reinforcement mesh and concrete after the excavation of the small pilot tunnel is finished; (5) timely constructing an upper primary support of the main tunnel when the small pilot tunnel is constructed to an arch springing outer side line on the other side of the main tunnel; (6) performing excavation support on the middle part and the lower part of the main tunnel. The method has the beneficial effects that the safety of an auxiliary gallery and fast entry into the main tunnel are guaranteed, the risk of high probability of collapse on the top of the tunnel during intersection construction at a weak surrounding rock geological section is reduced and avoided, the temporary support cost is saved and the construction progress is quickened.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD

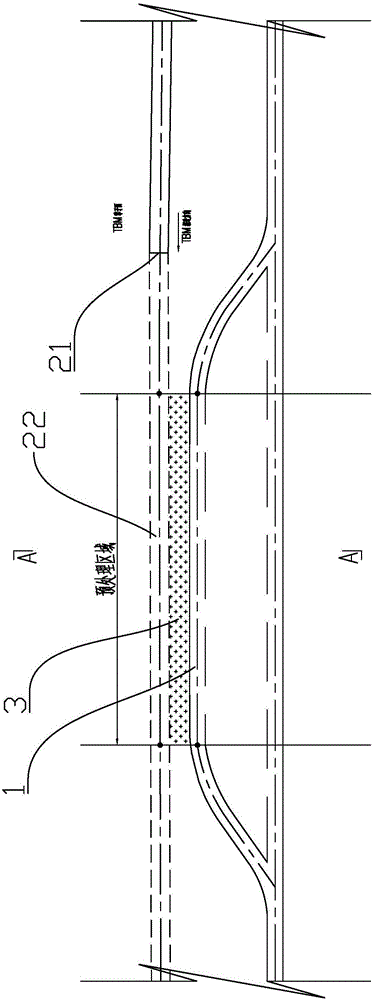

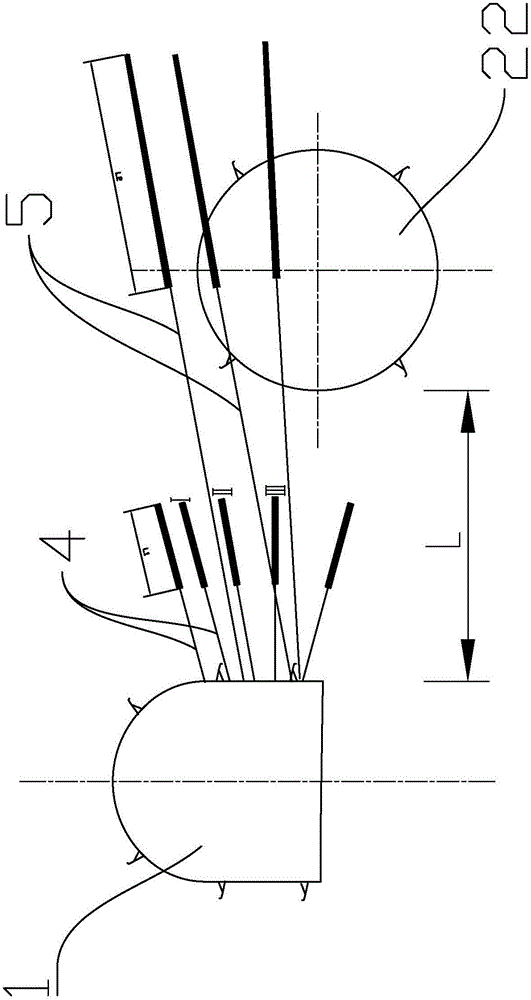

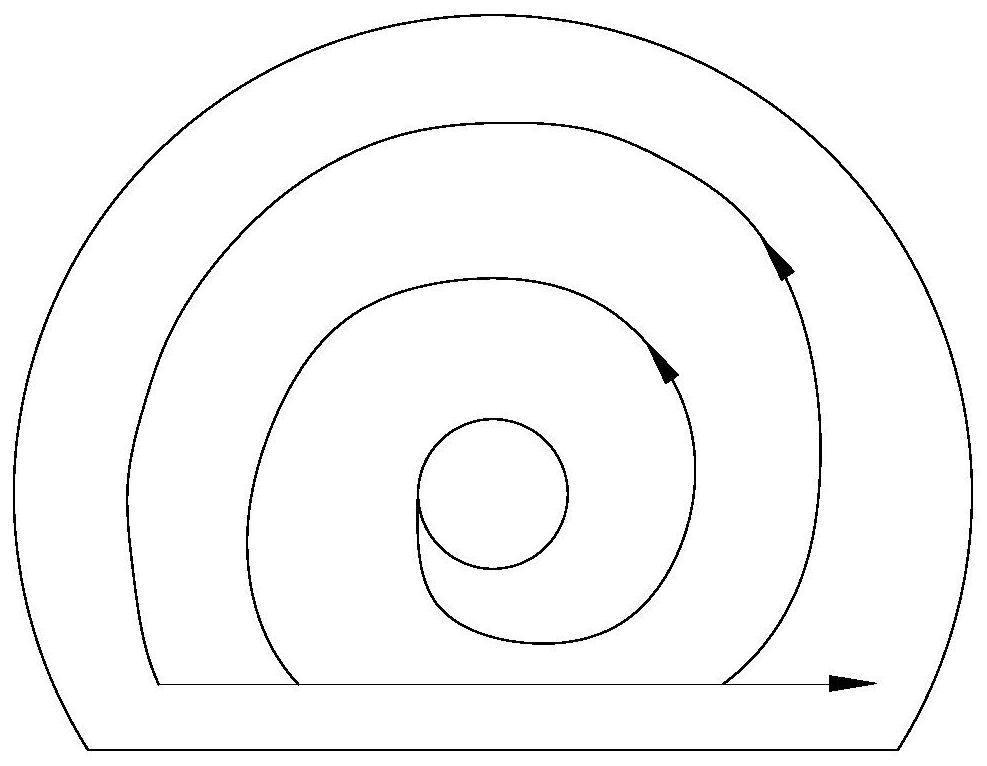

Surrounding rock pre-treatment method for TBM passing through round-tunnel section with strong rockburst risk

ActiveCN106014428AEliminate the risk of strong rockburstsReduce stress concentrationMining devicesBlastingBurstingHigh pressure water

The invention relates to a surround rock pre-treatment method for TBM passing through a round-tunnel section with a strong rockburst risk, and aims at eliminating the rockburst risk since a high-stress region cannot be formed in the surround rock between two tunnels when TBM passes through the region. According to the technical scheme, the method comprises the following steps of: 1, determining a pre-treatment region of which the clear spacing between a to-be-constructed tunnel and an adjacent existing tunnel in the TBM tunnelling direction is less than twice to-be-constructed tunnel diameter of TBM; 2, performing controlled bursting; 2.1, distributing multiple rows of bursting holes I in the to-be-treated region and the rock pillar region between the existing tunnel and the to-be-constructed tunnel through the existing tunnel; 2.2, distributing multiple rows of bursting holes II in the arch crown of the to-be-constructed tunnel and the spandrel part, far from the existing tunnel side, of the to-be-constructed tunnel through the existing tunnel; 2.3, bursting the bursting holes I, then bursting the bursting hole II; 3, injecting high-pressure water, selecting partial bursting holes I to carry out circulating water injection and pressurization; and 4, carrying out normal tunnelling of the TBM.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

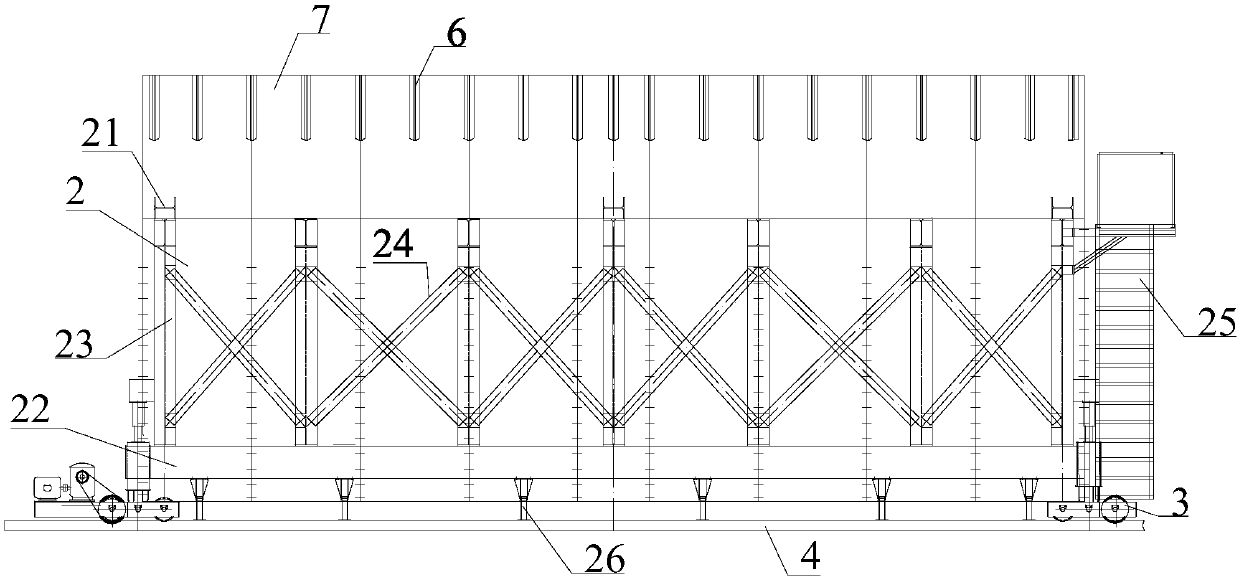

Movable type trolley for bored tunnel construction and construction method of movable type trolley

ActiveCN107630709AImprove work efficiencyReduce loss rateUnderground chambersTunnel liningTunnel constructionMovable type

The invention discloses a movable type trolley for bored tunnel construction. The movable type trolley comprises a trolley portal frame, walking wheels mounted on the lower portion of the trolley portal frame and matched rails adaptive with the walking wheels. Suspension arms extend out of the left side and the right side of the trolley portal frame correspondingly, the suspension arms are connected with a formwork skeleton, and a hydraulic supporting rod is further arranged between the trolley portal frame and the formwork skeleton. In the bored tunnel construction process, if the movable type trolley is adopted to conduct construction, the formwork skeleton can be suspended on the trolley directly through the suspension arms, after the position of the formwork skeleton is adjusted and positioned through the hydraulic supporting rod, a formwork for construction can be directly mounted on the outer side of the formwork skeleton, after that, concrete is poured on the formwork and maintenance is conducted, construction is convenient and rapid, and thus the construction progress can be accelerated greatly. After construction is completed, the formwork is separated from the concrete, the trolley can directly walk to a next construction section to conduct construction after the formwork is taken back, the utilization rate of the device is high, and thus the construction cost is lowered greatly.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Hard rock roadway tunneling method capable of integrating drilling, water exploitation and milling

The invention discloses a hard rock roadway tunneling method capable of integrating drilling, water detecting and milling. The hard rock roadway tunneling method capable of integrating the drilling, the water detecting and the milling includes the steps: arranging a milling tunneling machine on a tunneling working face, installing a movable mechanical arm on the milling tunneling machine, and installing an integrated drilling machine at the front end of the movable mechanical arm; before using the milling tunneling machine to mill a hard rock body, using the movable mechanical arm for adjusting space positions and postures of the integrated drilling machine so as to enable the integrated drilling machine to drill several long straight deep holes in a part of the hard rock body for detecting water; on the premise of confirming that no water burst dangerous situation exists, filling the long straight deep holes of the rock body with an appropriate amount of explosive for deep hole blasting, and forming large diameter deep holes so as to enabling disc cutters to conveniently penetrate into a certain depth in the rock body; and finally using the milling tunneling machine for milling and smashing the hard rock body. The hard rock roadway tunneling method capable of integrating the drilling, the water detecting and the milling uses the disc cutters for milling and smashing the hard rock body on the basis of fully utilizing the theory that rock is low in tensile strength, is strong in rock breaking ability and high in efficiency, and has an advanced water detecting function.

Owner:CHINA UNIV OF MINING & TECH

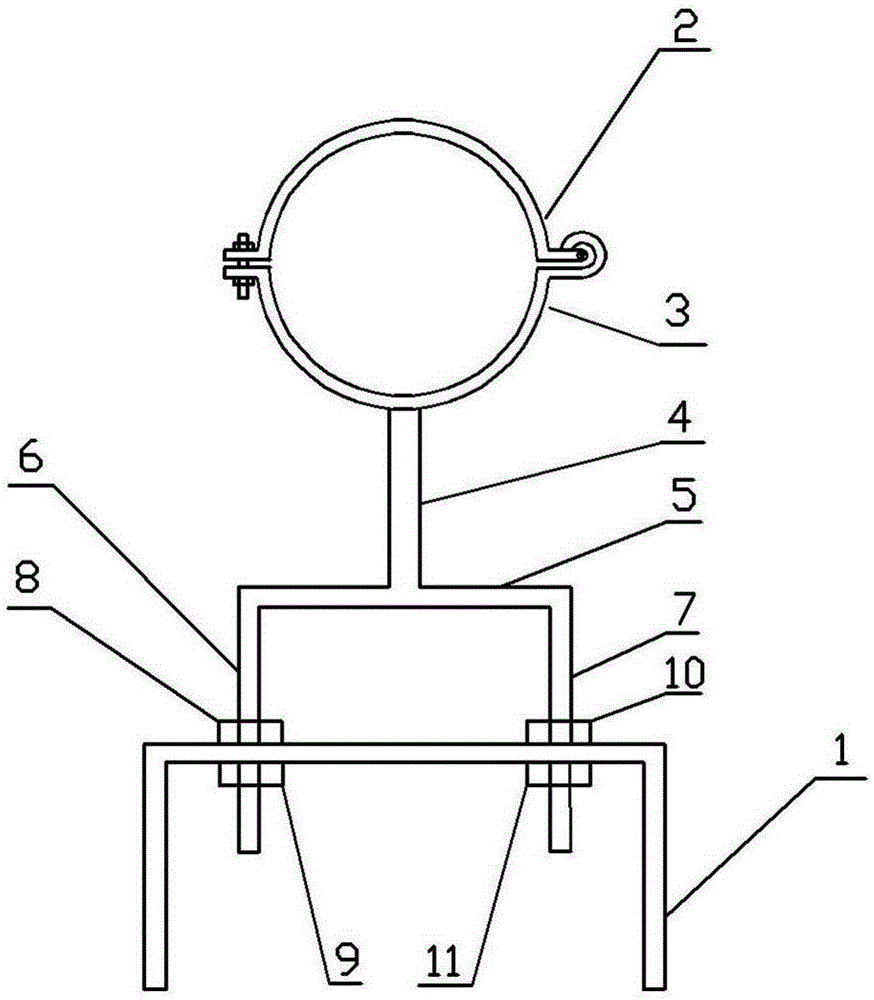

Chemical equipment pipe supporting frame

InactiveCN106704711AEffective support and fixationGuarantee the quality of workmanshipPipe supportsPipeline systemsProcess qualityEngineering

The invention relates to a chemical equipment pipe supporting frame which comprises a support, a supporting rod and a pipe clamp. The pipe clamp comprises an upper hoop and a lower hoop which are both in semicircular ring shapes, one end of the upper hoop is hinged to one end of the lower hoop, and the other end of the upper hoop is in bolt connection with the other end of the lower hoop; an adjusting rod comprises a first vertical rod connected with the lower hoop, a first transverse rod connected with the bottom end of the first vertical rod, a first screw rod and a second screw rod, and the first screw rod and the second screw rod are connected with the two ends of the first transverse rod, and are correspondingly embedded into through holes in the support; and the first screw rod is in clamped connection with the support through a first upper nut and a first lower nut, and the second screw rod is in clamped connection with the support through a second upper nut and a second lower nut. By means of the above structure, a chemical equipment pipe can be effectively supported and fixed, the vibration influences on the pipe can be effectively prevented or greatly reduced, and therefore the process quality and the construction safety of chemical equipment are further guaranteed.

Owner:天津希瓦科技发展有限公司

Stratum settlement-preventing shield shell filling material and preparation method thereof

ActiveCN107459324AReduced risk of stuckReduce construction costsFilling materialsUltimate tensile strength

The invention discloses a stratum settlement-preventing shield shell filling material and a preparation method thereof. The stratum settlement-preventing shield shell filling material is prepared by mixing comprises a material A and a material B, wherein the material A comprises the following components: 25-30% of bentonite, 3-5% of a thickener, 3-5% of a colloidal stabilizer, 1-6% of a water-proofing agent and the balance of water; the material B comprises the following components: 45-55% of water glass and the balance of water; the volume ratio of the material A to the material B is 1:(0.8-1.2). In the filling material, the material A and the material B can be pumped according to equal volume, and after the material A and the material B meet each other and are mixed, a mixture can be quickly viscosified and has high viscosity and certain supporting strength, so that even if the material A and the material B are pumped out of a shield shell, the stratum settlement-preventing shield shell filling material can still effectively fill a gap above the shield shell and can effectively prevent the stratum settlement.

Owner:SHANDONG UNIV

Continuous construction method for aluminum alloy template used for comprehensive pipe rack

ActiveCN111305261AFast Turnaround ConstructionFast constructionArtificial islandsUnderwater structuresStructural engineeringPipe

The invention specifically provides a continuous construction method for an aluminum alloy template used for a comprehensive pipe rack. Second-time pouring construction of a first-section comprehensive pipe rack and first-time pouring construction of a second-joint comprehensive pipe rack are conducted at the same time, the construction speed is increased, the construction period is shortened, anda bottom die structure demounted from the first-section comprehensive pipe rack is used for conducting construction of a bottom plate and a guide wall of the second-joint comprehensive pipe rack while a wall body and a top plate aluminum alloy template of the first-section comprehensive pipe rack are installed; when the strength of concrete reaches 1.2 Mpa, an inner wall template and an outer wall template are demounted and are conveyed to a next construction section; and when concrete pouring is completed and the strength reaches 50%-75%, a top face template is demounted, a top support and longitudinal supporting rods are reserved, after the strength of the concrete reaches 100%, demounting is conducted, meanwhile, construction of a bottom plate and a guide wall of the second-joint comprehensive pipe rack is completed, the demounted wall body and the top plate aluminum alloy template are used for continuously conducting construction of a wall body and a top plate of the second-section comprehensive pipe rack, and therefore continuous cyclic work is achieved.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE +1

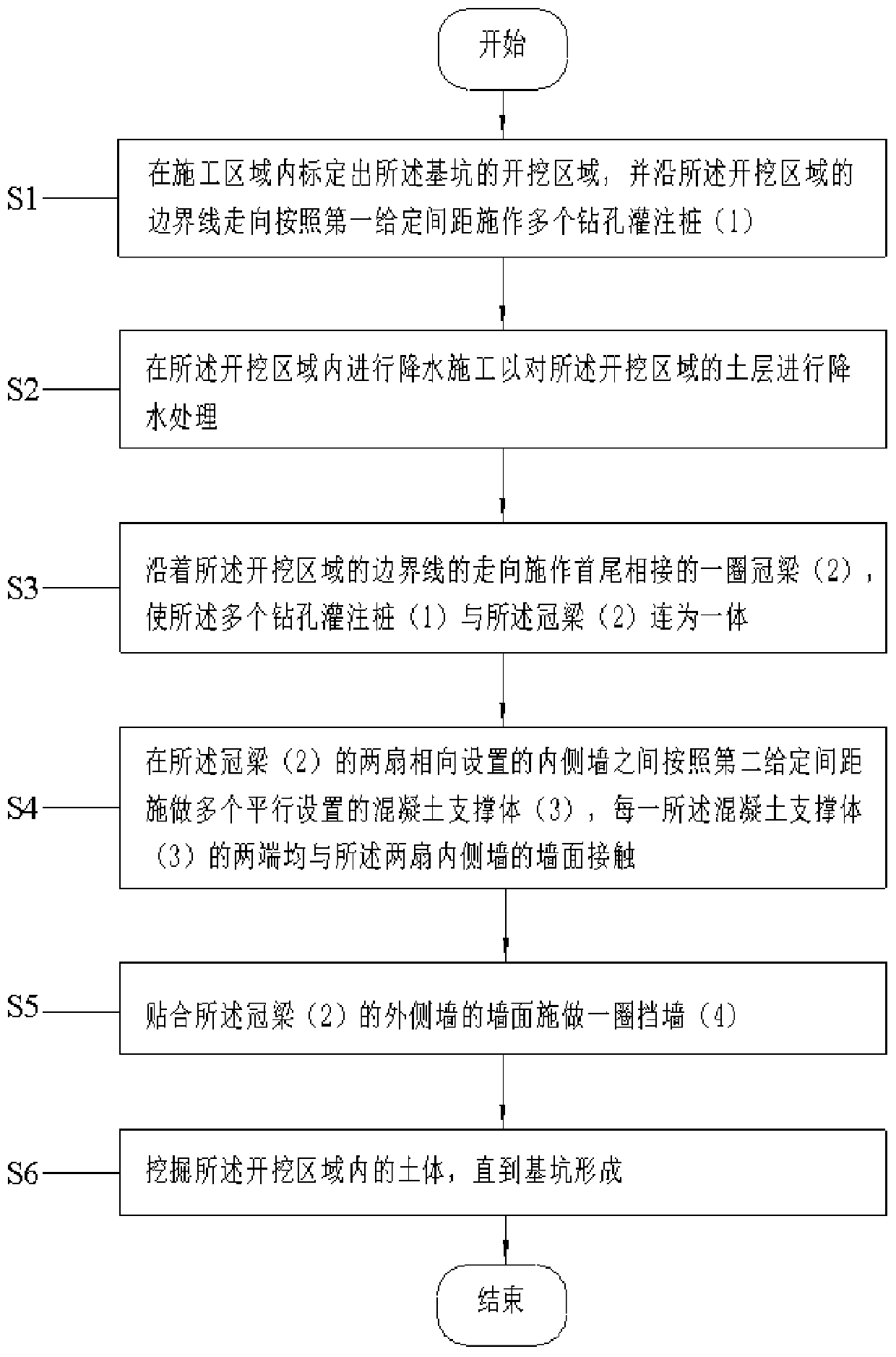

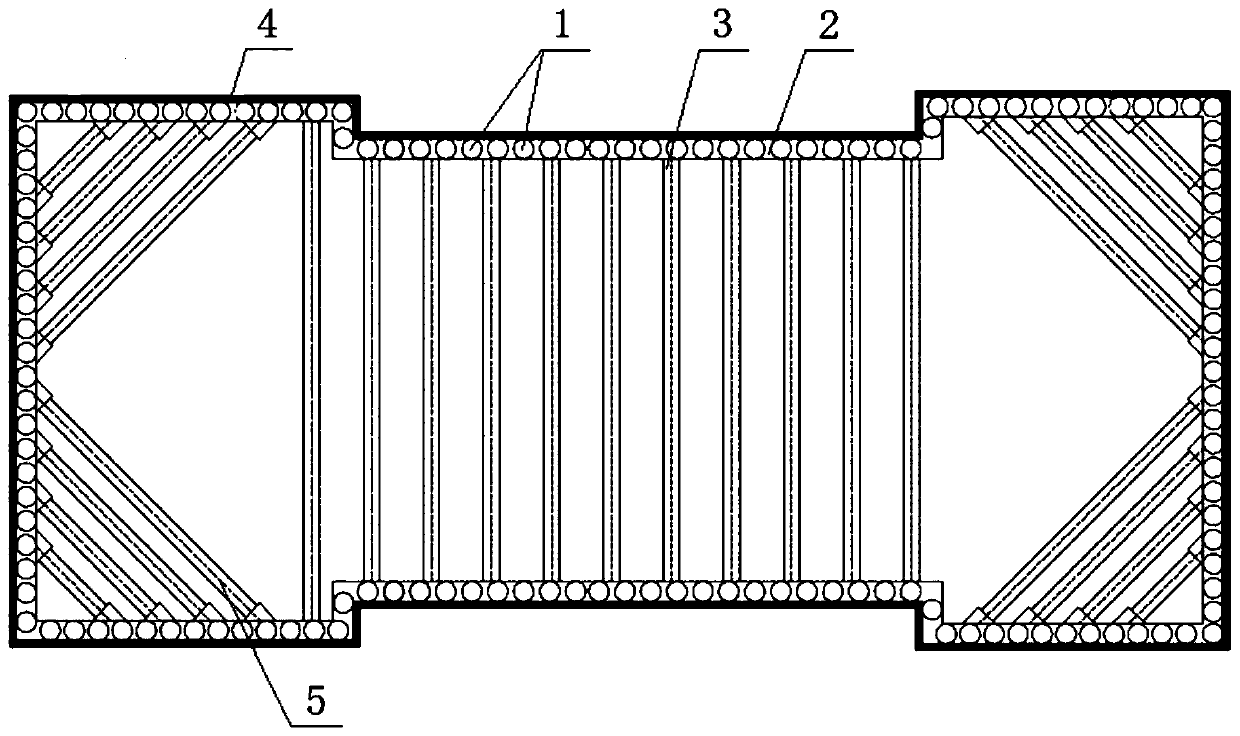

Excavation method of foundation pit

InactiveCN110453688ASolve the problem of insufficient supportAvoid displacementExcavationsBulkheads/pilesLandslideSubway station

The invention provides an excavation method of a foundation pit. The excavation method comprises the following steps that, (S1), an excavation area of the foundation pit in a construction area is marked, and a plurality of drilling pouring piles are constructed according to a first given distance along a boundary line of the excavation area; (S2), precipitation construction is conducted in the excavation area so that soil layers of the excavation area are subjected to precipitation treatment; (S3), a circle of crown beams connecting from heads to tails are arranged along a boundary trend of the excavation area, so that the multiple drilling pouring piles and the crown beams are connected as a whole; (S4), a plurality of concrete support bodies arranged in parallel are arranged between thetwo inner side walls, arranged opposite to each other, of the crown beams according to a second given distance; (S5), a circle of retaining walls are arranged on the wall surface of the external sidewalls fitted with the crown beams; and (S6), soil bodies of the excavation area are excavated to form the foundation pit. According to the excavation method, the foundation pit is supported and protected before the excavation of the foundation pit, the overall support structure of the foundation pit is strengthened, the problem that the support and protection to the foundation pit is insufficientis solved, and occurrences of landslide, collapse and other accidents in subway stations after completion are avoided.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Aluminium alloy structural house

ActiveCN106801473AReduce the use effectImprove bending abilityRoof coveringConstruction materialMaterials scienceWall plate

The invention relates to an aluminium alloy structural house. The aluminium alloy structural house is provided with aluminium wall plates, aluminium roof panels, aluminium floor plates, and mounting connecting structures of the aluminium floor plates and corner connecting materials; convex-concave buckle groove shapes are formed at the connecting positions between each aluminium wall plate, each aluminium roof panel as well as each aluminium floor plate and the corresponding corner connecting material; the aluminium wall plates, the aluminium roof panels as well as the aluminium floor plates and the corner connecting materials are embedded into one another and are fixed via bolts or screws, so that the connection is firmer and safer. The overall structure formed by connecting various components has good bending resistance, torsion resistance, impact resistance and overall stability; the use of bottom cross beams, upright posts and ring beams is used, or the bottom cross beams, the upright posts and the ring beams are not used, so that the utilization space of the house is increased; the waterproof property of a wall surface of the house is also reinforced by designed left and right aluminium edges, and the attractiveness of the house is also improved. The aluminium alloy structural house has the characteristics of waterproof property and high convenience in mounting without using a sealing material.

Owner:ALUHOUSE TECHGD CO LTD

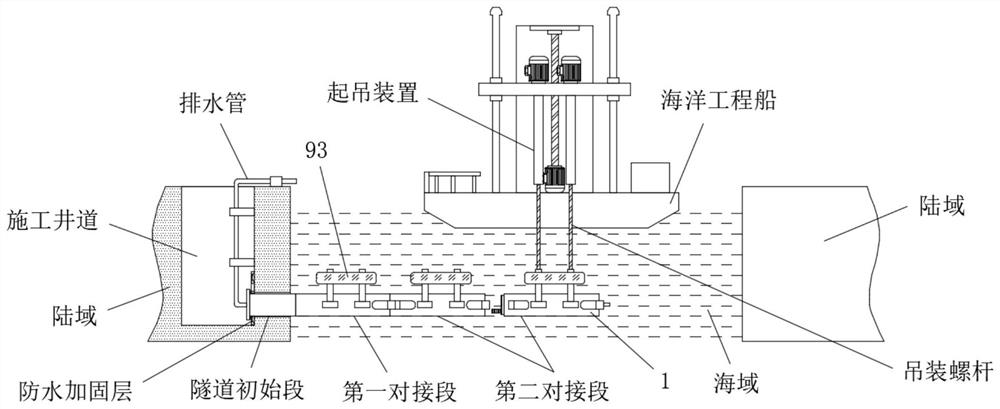

Seabed submerged floating tunnel structure and construction method thereof

InactiveCN113216262APlay the effect of positioning dockingPlay a sealing effectArtificial islandsUnderwater structuresStructural engineeringSeabed

The invention relates to a seabed submerged floating tunnel structure, and belongs to the technical field of tunnels. The seabed submerged floating tunnel structure comprises a tunnel body, the tunnel body comprises a tunnel main body section, two first tunnel branch sections and two second tunnel branch sections, wherein the two first tunnel branch sections and the two second tunnel branch sections are symmetrically arranged on the two sides of the tunnel main body section correspondingly; the two first tunnel branch sections and the two second tunnel branch sections communicate with the interior of the tunnel main body section; and a bearing mechanism located right below a portal is arranged at one end of the tunnel main body section. The invention further discloses a construction method. The seabed submerged floating tunnel structure and the construction method thereof have the advantages that the structure design is reasonable, in addition, the butt joint mode is simple and effective, tunnel butt joint is realized in a pouring connection mode, the stability of tunnel butt joint is improved, the functions of seabed observation and sealing performance test are added in the construction process, in this way, seabed construction is easy to operate, the accuracy and efficiency of tunnel butt joint are improved, in addition, a very safe construction environment is provided, meanwhile, an escape emergency channel is designed in a whole tunnel, and the overall safety performance of the tunnel is improved.

Owner:温州凯胜瑞恒科技有限公司

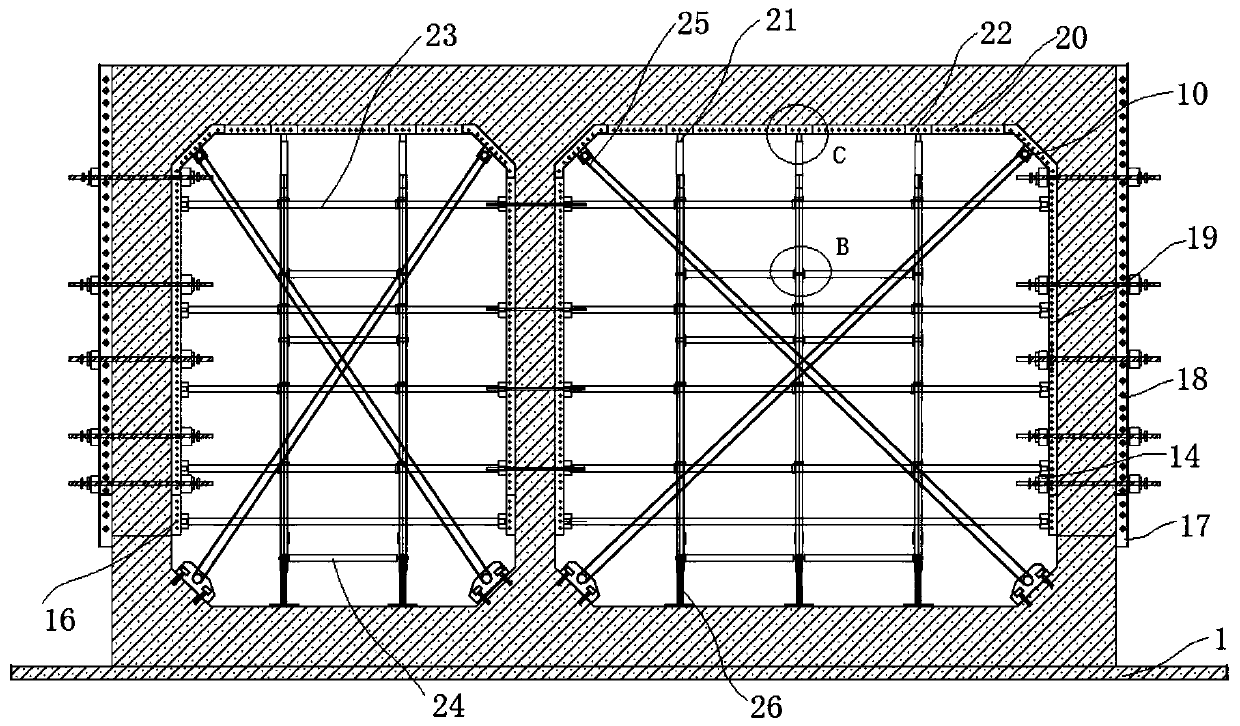

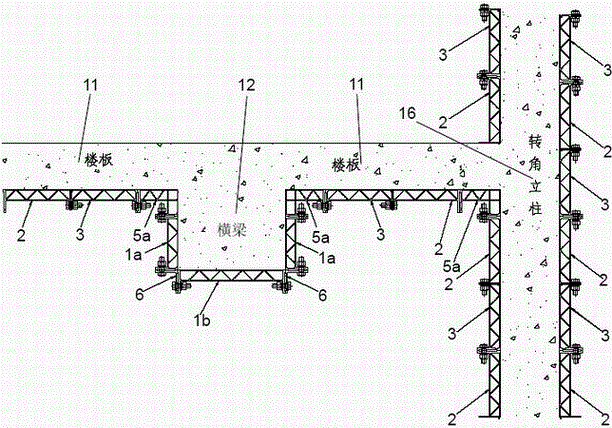

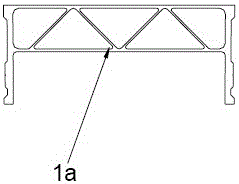

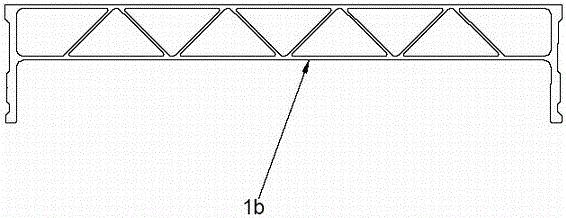

Beam, floor and corner uptight column composite structure of building aluminium alloy templates

PendingCN106677520ALarge operating spaceSave man hoursForms/shuttering/falseworksForming/stuttering elementsSupporting systemMaterials science

The invention relates to a beam, floor and corner uptight column composite structure of building aluminium alloy templates. Edge plates used for connecting of fastening pieces are arranged on all the aluminium templates. The aluminium templates are connected and combined through the fastening pieces, subjected to concreting and then constitute the beam, floor and corner uptight column composite structure. The sixth aluminium template, the first aluminium template A, the fifth corner template aluminium template A, the third aluminium template and the second aluminium template are connected and arranged on the left side and the right side of a beam correspondingly. Concreting is conducted on the first aluminium template B, and the first aluminium template B and the aluminium templates on the two sides of the first aluminium template B constitute the beam. Concreting is conducted on the multiple aluminium templates, and a floor is constituted. The floor and the beam are combined into a whole. A corner upright column is arranged on one side of the beam, and concreting is conducted between the vertical inner faces of the aluminium templates and the vertical outer faces of the aluminium templates. Concreting construction is conducted by using the aluminium alloy building templates, so that the beam, floor and corner uptight column composite structure has the advantages that the quality of the surface of poured concrete is high, the average using cost is low, carbon is low, emission is reduced, formaldehyde emission does not exist, and a supporting system is simplified.

Owner:肇庆南亚金属研制有限公司

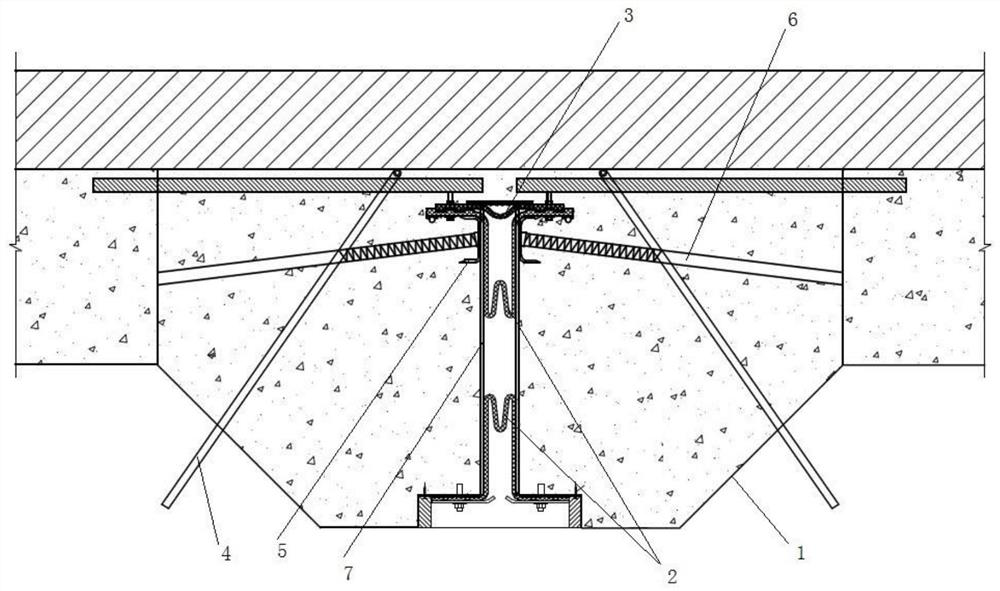

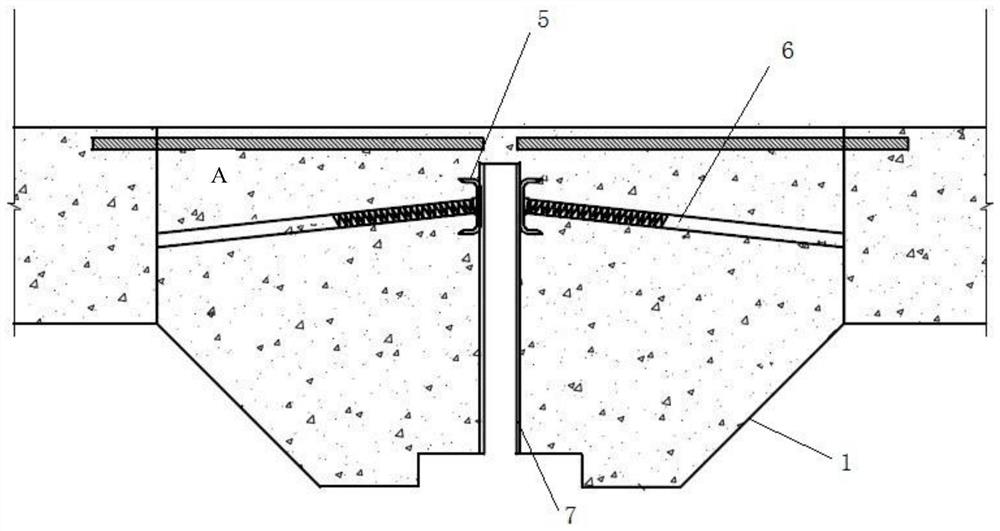

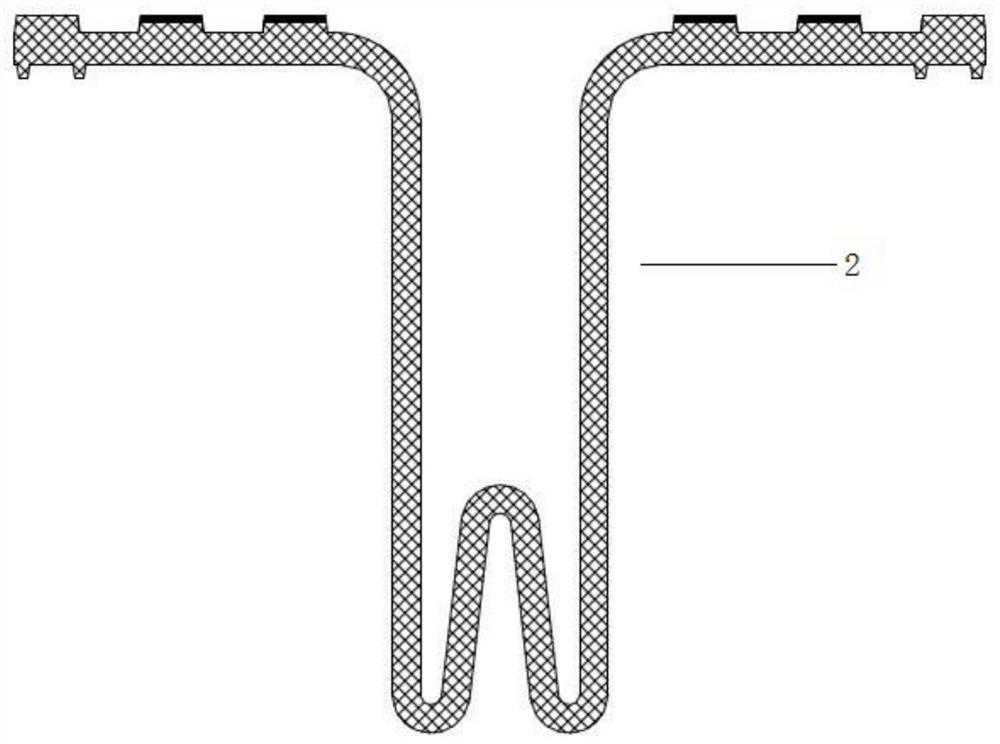

Large-section special deformation joint building method based on earthquake fracture zone

ActiveCN111828019AShorten the construction periodReduce damageUnderground chambersHydro energy generationSupporting systemJoint (building)

The invention particularly provides a large-section special deformation joint building method based on an earthquake fracture zone. A tunnel structure is enlarged according to design requirements, a 550 mm later-period damage reinforcing space is reserved, the thickness of a second lining is improved according to the enveloping performance, the thickness of the improved second lining is 600 m, thewidth of the special deformation joint in a ground fracture affection area is designed to be 150 mm, fault movement is achieved, and the damage degree generated by fault movement is reduced. An end formwork is designed before construction, the end formwork, a special-shaped formwork and a special-shaped formwork supporting system are machined in advance to be subjected to trial splicing, end formworks, special-shaped formworks and arch frame formworks are allowed to be produced in a batched manner when errors are in the allowed range, the deformation joint construction period is shortened, the construction speed is increased, the construction period is shortened, construction materials are saved, and the construction environment is safer.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE +1

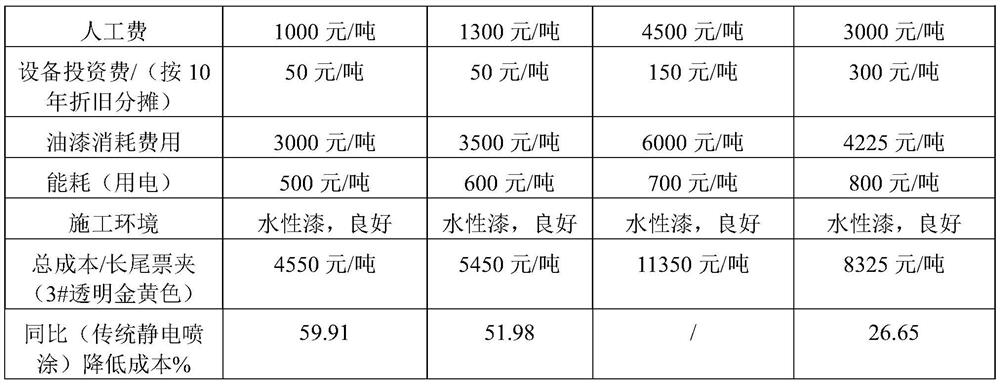

Surface coating process for binder clip

PendingCN114505211ASimple coating processSmall footprintPretreated surfacesMetallic material coating processesProcess engineeringSmall footprint

The invention discloses a binder clip surface coating process which is carried out by adopting an automatic rolling spraying machine and comprises the following steps: S1, carrying out surface pretreatment on a binder clip; s2, a charging stage; s3, a preheating stage; s4, a spraying stage; s5, a cooling stage; and S6, an unloading stage. According to the surface coating process for the long-tail ticket holder, the labor cost of a long-tail ticket holder coating line can be reduced, the coating process is simple, the occupied area is small, the equipment investment is low, the paint loss is small, the construction environment is safe, and the comprehensive cost is optimal; and the requirement of greatly reducing the cost of an enterprise can also be met.

Owner:宁波长发涂料有限公司

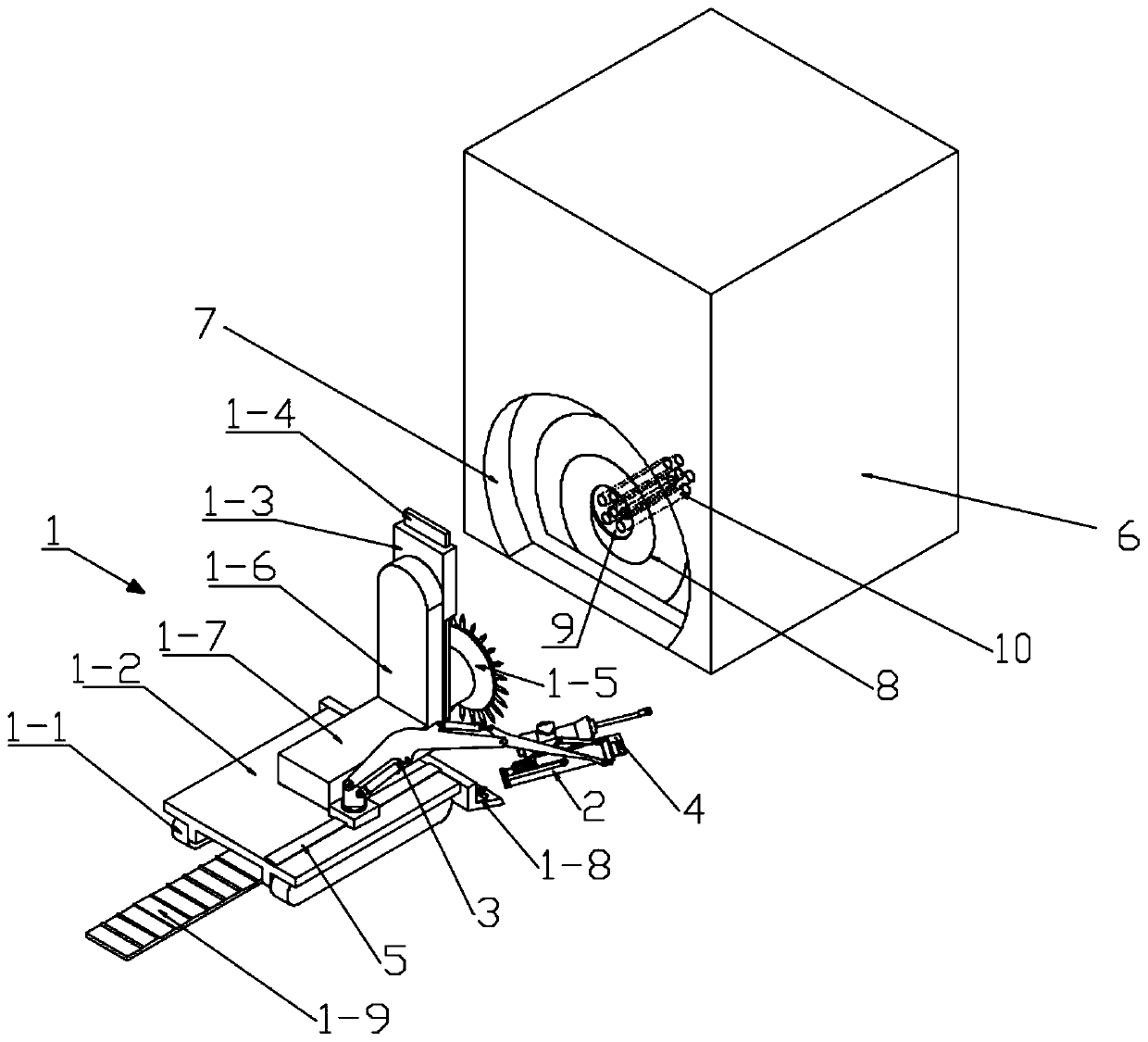

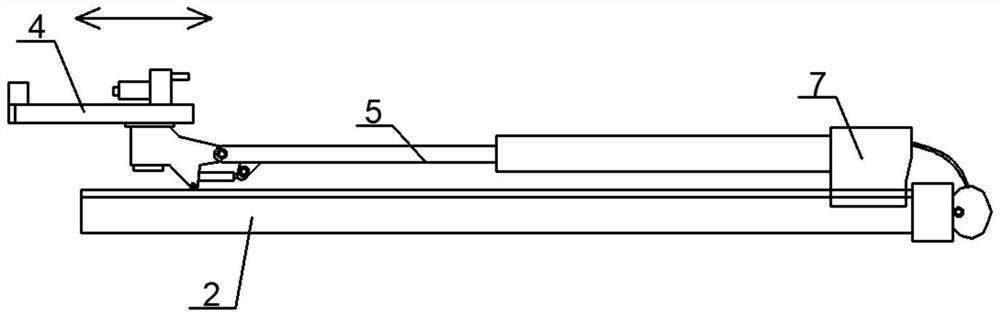

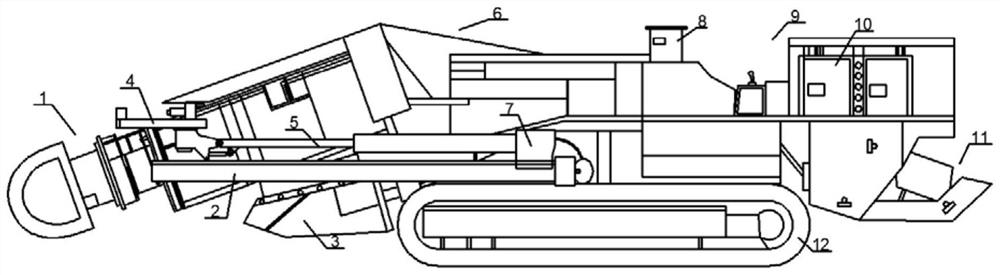

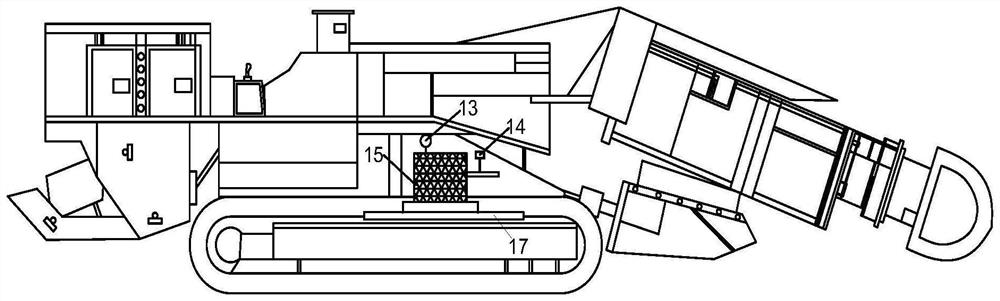

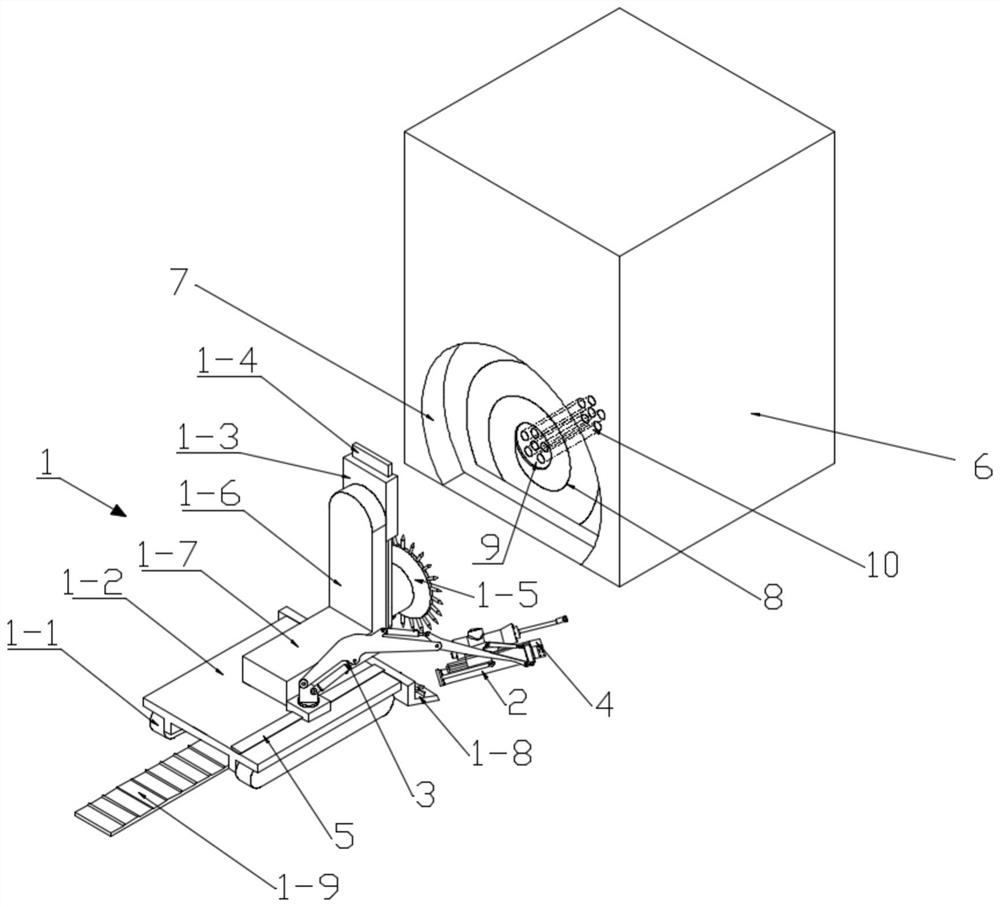

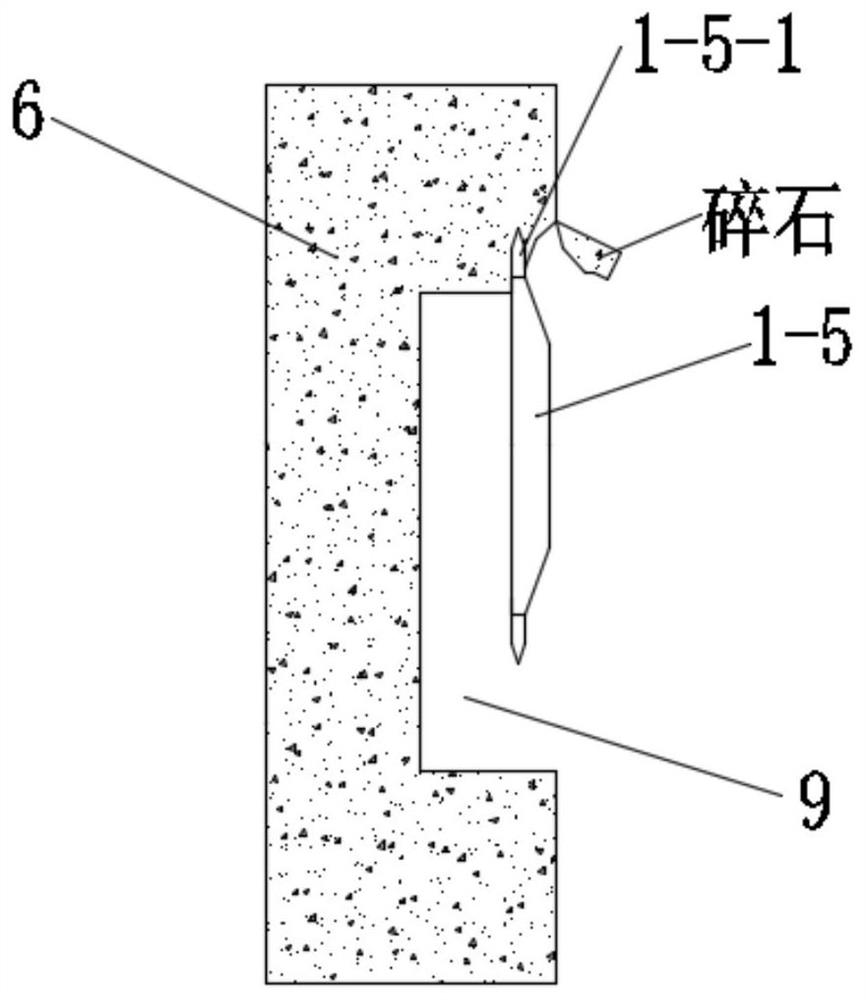

Drilling-pressing-digging integrated hard rock tunneling equipment

PendingCN114645711AExcellent performanceReduce labor intensityDisloding machinesDerricks/mastsTunnel engineeringWater tanks

The invention discloses drilling-pressing-tunneling integrated hard rock tunneling equipment, relates to the field of hard rock roadway (tunnel) tunneling, and can reduce potential safety hazards of tunneling work to the minimum and greatly improve the tunneling efficiency. The hard rock tunneling equipment comprises a tunneling machine, a drilling machine system and a hydraulic fracturing system, wherein the drilling machine system and the hydraulic fracturing system are mounted on the tunneling machine; the drilling machine system comprises a drilling machine, a drilling machine mounting table, a drilling arm, a sliding rail and a base; the sliding rail is connected to a rack of the heading machine; the hydraulic fracturing system comprises a water tank, a high-pressure pump, a pressure gauge, a water pressure monitor, a high-pressure pipe and a hole packer, and the high-pressure pump is fixedly connected to a rack of the heading machine. Not only is harmful gas not required to be discharged, but also integrated equipment is not influenced by working face space, so that the maneuverability of a drilling machine and hydraulic fracturing equipment is remarkably improved, and the purpose of improving the working efficiency of tunneling engineering is finally achieved.

Owner:CHINA UNIV OF MINING & TECH

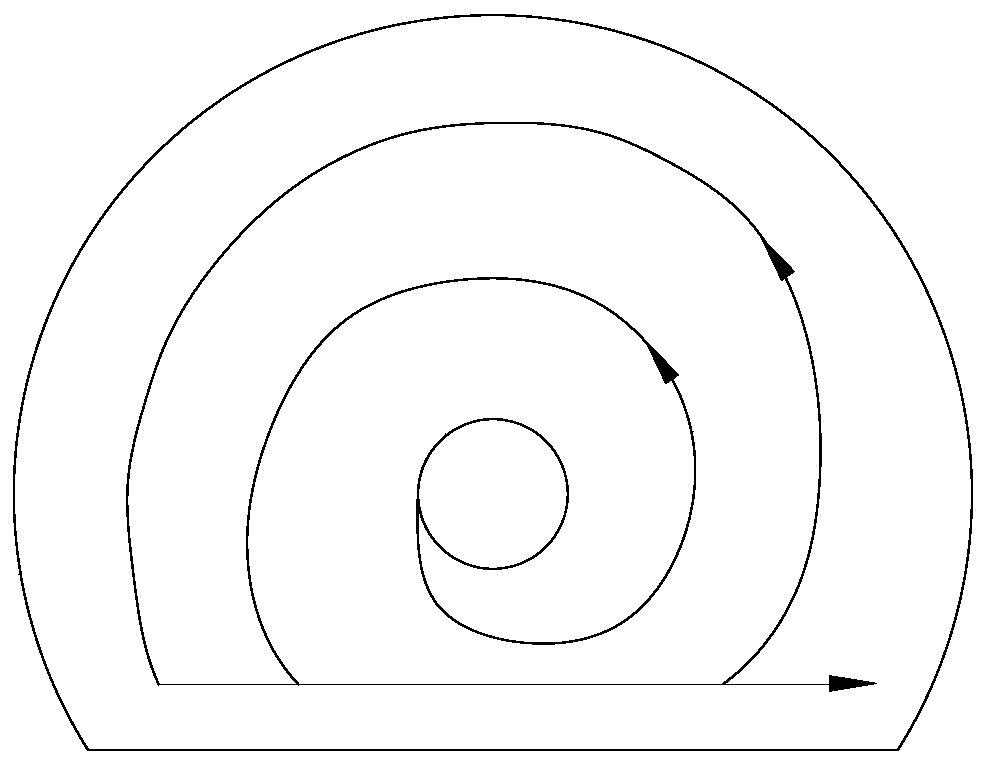

Pressurizing and spring protection recharge well and method

ActiveCN104594326ASolve wasteImprove recharge efficiencySoil preservationGround subsidenceWater filter

The invention discloses a pressurizing and spring protection recharge well and method. The pressurizing and spring protection recharge well comprises a push rod pressure device, wherein the push rod pressure device is used for transmitting pressure to recharged water of a well pipe by a pressure conduction device; the pressure conduction device is arranged on the well pipe; a water filtering pipe is arranged under the well pipe; a water inlet channel is arranged on one side of the well pipe; a check valve is arranged at the connection part of the water inlet channel and the well pipe; the upper part of the water filtering pipe is connected with a pressure sensor; the pressure sensor is connected with a pressure control system by a steel pipe; the pressure control system is connected with a push rod pressurizing device by a pressure control connection device. According to the pressurizing and spring protection recharge well, the problems of ground subsidence caused by consolidation deformation of a ground layer adjacent to a construction region, which is caused by foundation pit dewatering, and waste of underground water resources in hydrogeological units of the construction region, which is caused by the foundation pit dewatering are solved; a series of problems that equipment and procedures are complicated, the occupying area is large, citizens are disturbed by construction and the like in a popularization process of an underground water recharge technology are solved, so that the recharge efficiency is improved and the recharge cost is reduced.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Supporting frame for chemical equipment pipeline

InactiveCN109282086AEffective support and fixationGuarantee the quality of workmanshipPipe supportsPipe elementsProcess qualityEngineering

The invention relates to a supporting frame for a chemical equipment pipeline. The supporting frame comprises a support, a supporting rod and a pipeline clamp, wherein the pipeline clamp comprises anupper hoop and a lower hoop which are both in a semi-circular ring shape, one end of the upper hoop is hinged to one end of the lower hoop, and the other end of the upper hoop is connected with the other end of the lower hoop in a bolt mode; and an adjusting rod comprises a first vertical rod, a cross rod, a first screw and a second screw, wherein the first vertical rod is connected with the lowerhoop, the first cross rod is connected with the bottom end of the first vertical rod, the first screw and the second screw are connected with the two ends of the first cross rod respectively, the first screw and the second screw are correspondingly embedded in through holes formed in the support, the first screw is connected with the first screw rod through a first upper nut and a first lower nutin a clamped mode, and the second screw is connected with the support through a second upper nut and a second lower nut. By the adoption of the structure, the chemical equipment pipeline can be effectively supported and fixed, so that the vibration influence of the pipeline can be effectively prevented or greatly reduced, and the process quality and construction safety of chemical equipment are guaranteed.

Owner:吕小宝

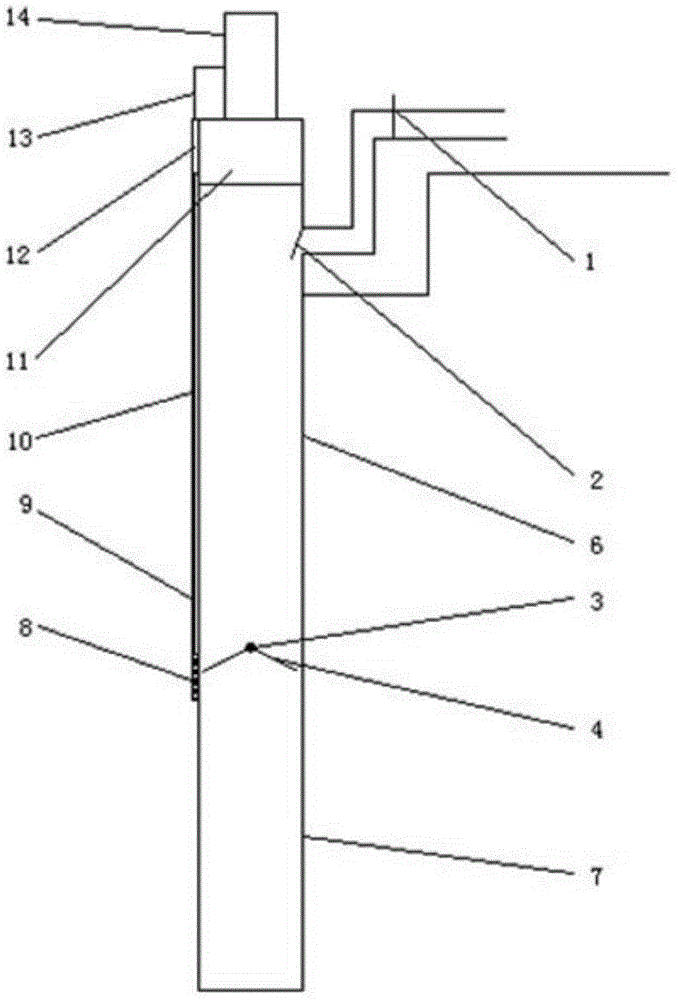

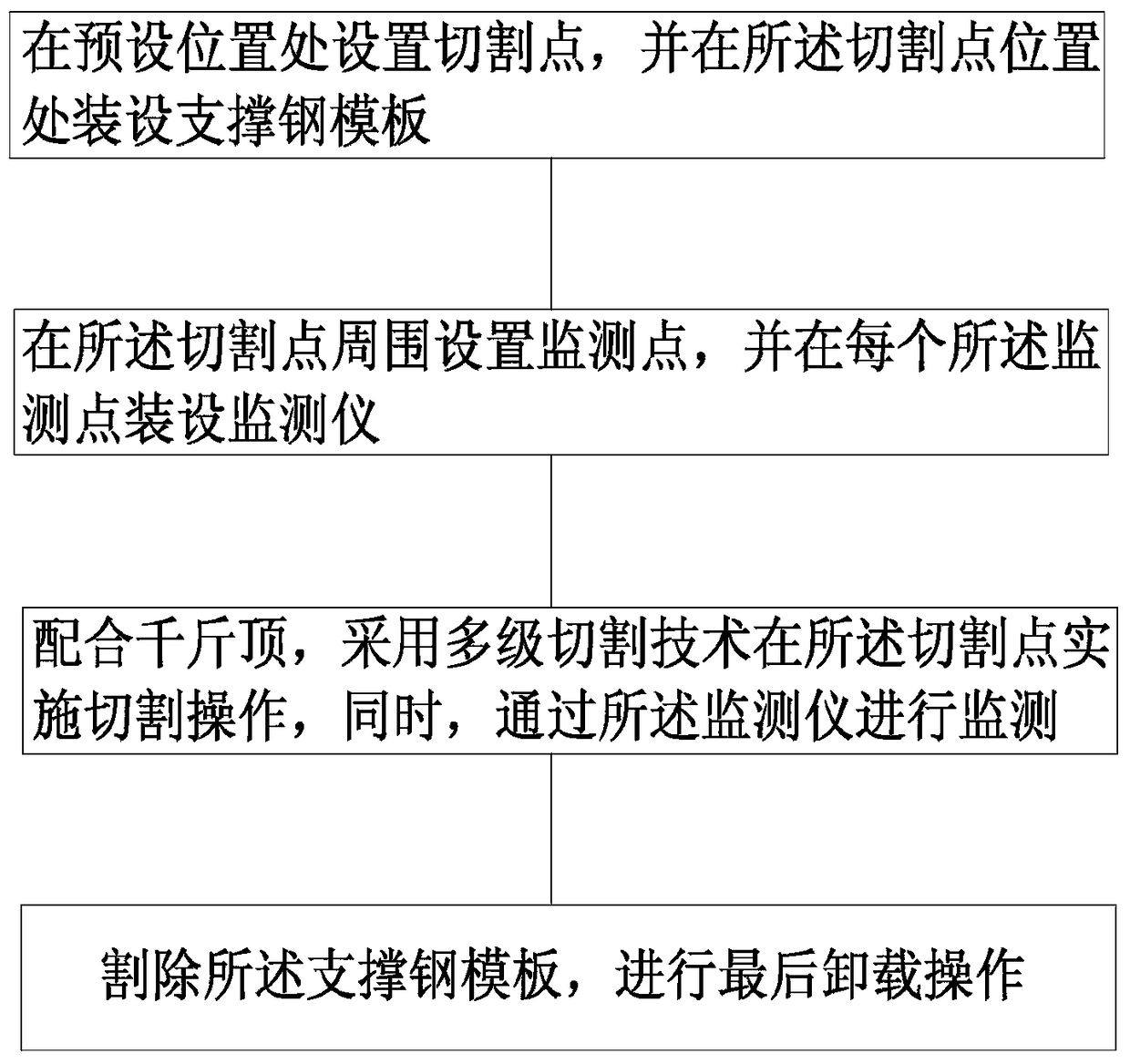

Support frame unloading method for truss structure

The invention discloses a support frame unloading method for a truss structure. The method comprises the steps that a cutting point is set at a preset position, and a support steel template is installed at the position of the cutting point; monitoring points are set around the cutting point, and a monitor is installed at each monitoring point; in cooperation with a jack, a multi-stage cutting technique is adopted for conducting cutting operation at the cutting point, and meanwhile monitoring is conducted through the monitors; the support steel template is cut off, and final unloading operationis conducted. By means of the method, the stability performance of the truss structure after the support frame is unloaded can be effectively known, the safety performance of the entire truss structure is ensured, a safe construction environment is created, and the method is worthy of wide popularization.

Owner:JIANGSU PERMANENT STEEL STRUCTURE

Novel composite bio-based building template material and system

ActiveCN105670164AWide variety of sourcesLow priceForming/stuttering elementsHigh turnoverPolyvinyl chloride

The invention relates to a novel composite bio-based building template material.The novel composite bio-based building template material comprises chemical components including, by weight, 43.63-47.41% of PVC (polyvinyl chloride), 33.06-36.67% of light calcium carbonate, 10.57-11.54% of wood meal, 0.52-0.71% of stearic acid, 0.52-0.61% of PE (polyethylene) wax, 2.18-2.55% of stabilizers, 2.61-2.75% of CPE (chlorinated polyethylene), 0.86-1.09% of ACR and 1.3-1.43% of DOP (dioctyl phthalate).The novel composite bio-based building template material has the advantages of saving of a great quantity of wood, excellent physical and mechanical performances, light weight, high impact strength, high turnover rate, high flatness, convenience and quickness in mounting and demounting, excellent heat insulation performance, good sound absorption effects, avoidance of use of release agents, avoidance of onsite construction wastes, high standard and universality and evident price superiority.

Owner:南京施瓦乐新材料科技有限公司

A hard rock roadway excavation method integrating drilling, water exploration and milling

The invention discloses a hard rock roadway tunneling method capable of integrating drilling, water detecting and milling. The hard rock roadway tunneling method capable of integrating the drilling, the water detecting and the milling includes the steps: arranging a milling tunneling machine on a tunneling working face, installing a movable mechanical arm on the milling tunneling machine, and installing an integrated drilling machine at the front end of the movable mechanical arm; before using the milling tunneling machine to mill a hard rock body, using the movable mechanical arm for adjusting space positions and postures of the integrated drilling machine so as to enable the integrated drilling machine to drill several long straight deep holes in a part of the hard rock body for detecting water; on the premise of confirming that no water burst dangerous situation exists, filling the long straight deep holes of the rock body with an appropriate amount of explosive for deep hole blasting, and forming large diameter deep holes so as to enabling disc cutters to conveniently penetrate into a certain depth in the rock body; and finally using the milling tunneling machine for milling and smashing the hard rock body. The hard rock roadway tunneling method capable of integrating the drilling, the water detecting and the milling uses the disc cutters for milling and smashing the hard rock body on the basis of fully utilizing the theory that rock is low in tensile strength, is strong in rock breaking ability and high in efficiency, and has an advanced water detecting function.

Owner:CHINA UNIV OF MINING & TECH

A kind of ground subsidence shell filling material for shield tunneling and its preparation method

ActiveCN107459324BReduced risk of stuckReduce construction costsFilling materialsUltimate tensile strength

The invention discloses a stratum settlement-preventing shield shell filling material and a preparation method thereof. The stratum settlement-preventing shield shell filling material is prepared by mixing comprises a material A and a material B, wherein the material A comprises the following components: 25-30% of bentonite, 3-5% of a thickener, 3-5% of a colloidal stabilizer, 1-6% of a water-proofing agent and the balance of water; the material B comprises the following components: 45-55% of water glass and the balance of water; the volume ratio of the material A to the material B is 1:(0.8-1.2). In the filling material, the material A and the material B can be pumped according to equal volume, and after the material A and the material B meet each other and are mixed, a mixture can be quickly viscosified and has high viscosity and certain supporting strength, so that even if the material A and the material B are pumped out of a shield shell, the stratum settlement-preventing shield shell filling material can still effectively fill a gap above the shield shell and can effectively prevent the stratum settlement.

Owner:SHANDONG UNIV

Shield type well digging method and drainage device

PendingCN114856426AConstruction environment safetyDirectional drillingHydro energy generationDirectional boringGeotechnical engineering

The invention provides a shield type well digging method and a water drainage device, and the shield type well digging method comprises the following steps: S01, segmenting a roadway according to a preset length in the designed length direction of the roadway; s02, construction operation is conducted on the divided sections in sequence, and the construction operation of each section comprises the following sub-steps that S021, drilling detection is conducted on a roadway top plate so that advanced detection work can be conducted, and S022, roadway well digging is conducted after advanced detection work is completed, in the sub-step S021, drilling detection is conducted through a directional drill, and in the advanced detection work process, drilling detection is conducted through a directional drill; according to a detection result, the top plate is treated firstly when the top plate needs to be treated, the safety of roadway well digging in the step S022 is guaranteed, advanced detection is adopted in the shield type well digging method, the roadway tunneling area is detected through directional drilling, and a safer construction environment is provided for later tunneling.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD

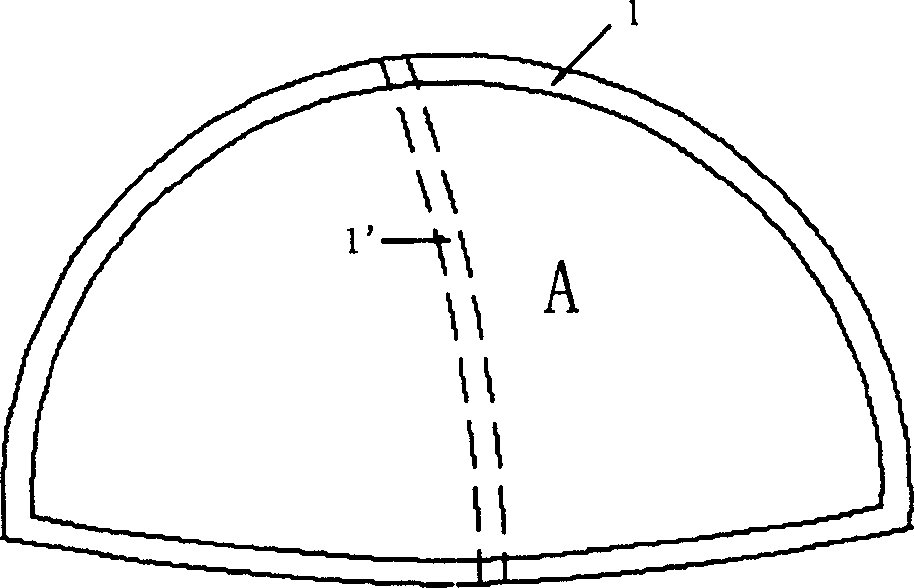

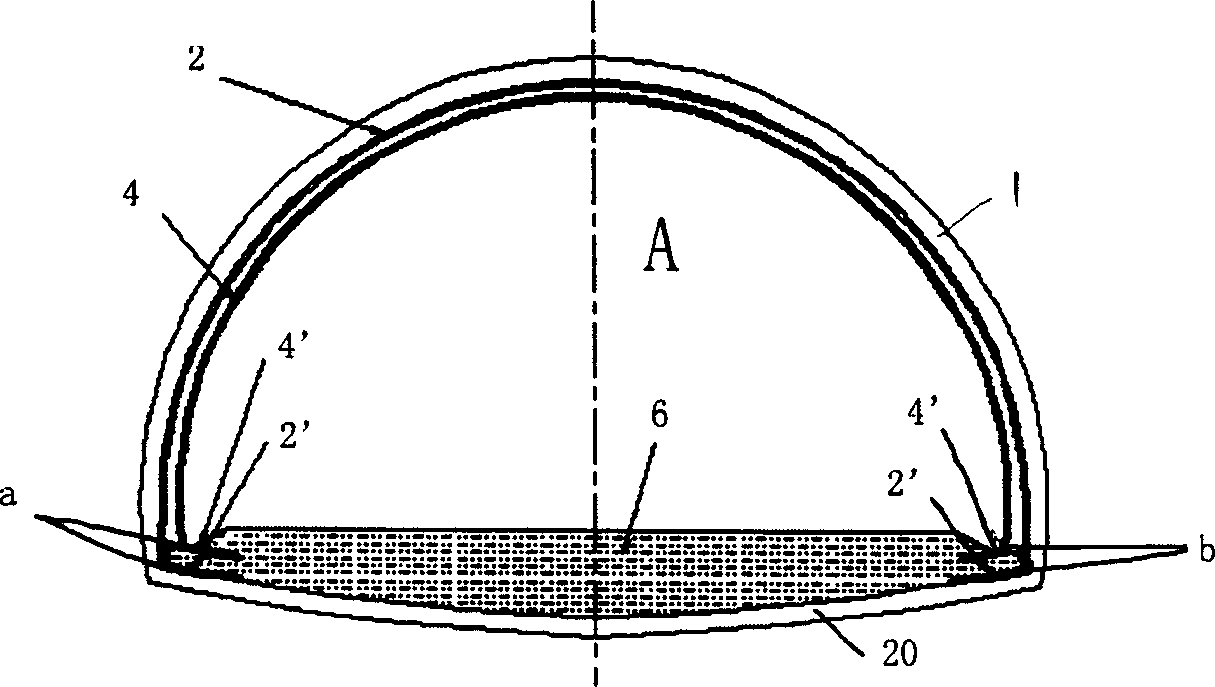

Aluminum alloy modular house quick installation structure

PendingCN109024923AConstruction environment safetyThe construction environment is cleanBuilding roofsBuilding insulationsArcuate shapeMechanical engineering

The invention relates to an aluminum alloy modular house quick installation structure comprising a module A, a module B and more than one intermediate module C that are interconnected via splicing material. The splicing material is an arc-shaped body; upper and lower sides of the arc-shaped body are respectively provided with an upper locking rib and a lower locking rib, and the upper locking ribis provided with an upper connecting rib; a part, positioned close to the upper locking rib, of the upper connecting rib is provided with a resisting and abutting block; rear parts of the upper and lower sides of the arc-shaped body are provided with reinforcement ribs, and a middle part of the arc-shaped body is provided with a screw bolt hole. Top and bottom connection parts between the module Aand the intermediate module C are connected via the splicing material, and aluminum roof panels are mounted above the splicing material. Top and bottom connection parts between the intermediate module C and the module B are connected via the splicing material, and aluminum roof panels are mounted above the splicing material. In the structure disclosed in the invention, an aluminum alloy house with a large area is divided into a plurality of module houses, the size of house modules is controlled in a transportable range, and a problem of overall transportation of large aluminum alloy houses can be solved.

Owner:ALUHOUSE TECHGD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com