Dormant digging and separating construction method for underground two layers and multilayer composite lining structure

A multi-layer composite, construction method technology, applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of slow construction, stratum disturbance, adverse structural effects, etc., to simplify the construction process, reduce construction costs, reduce The effect of ground disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

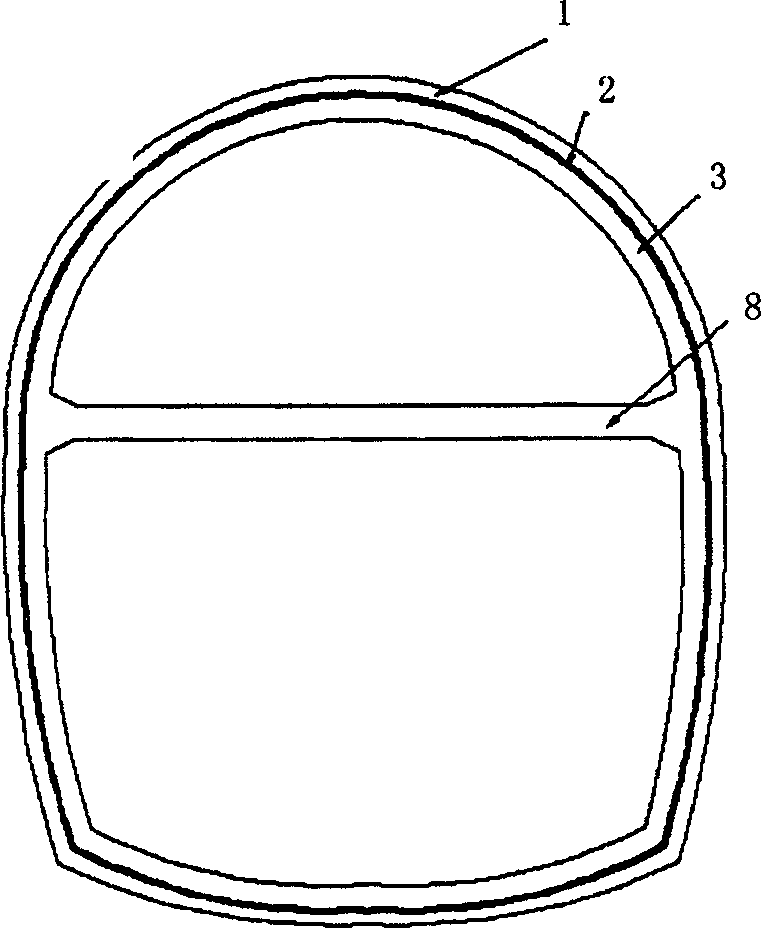

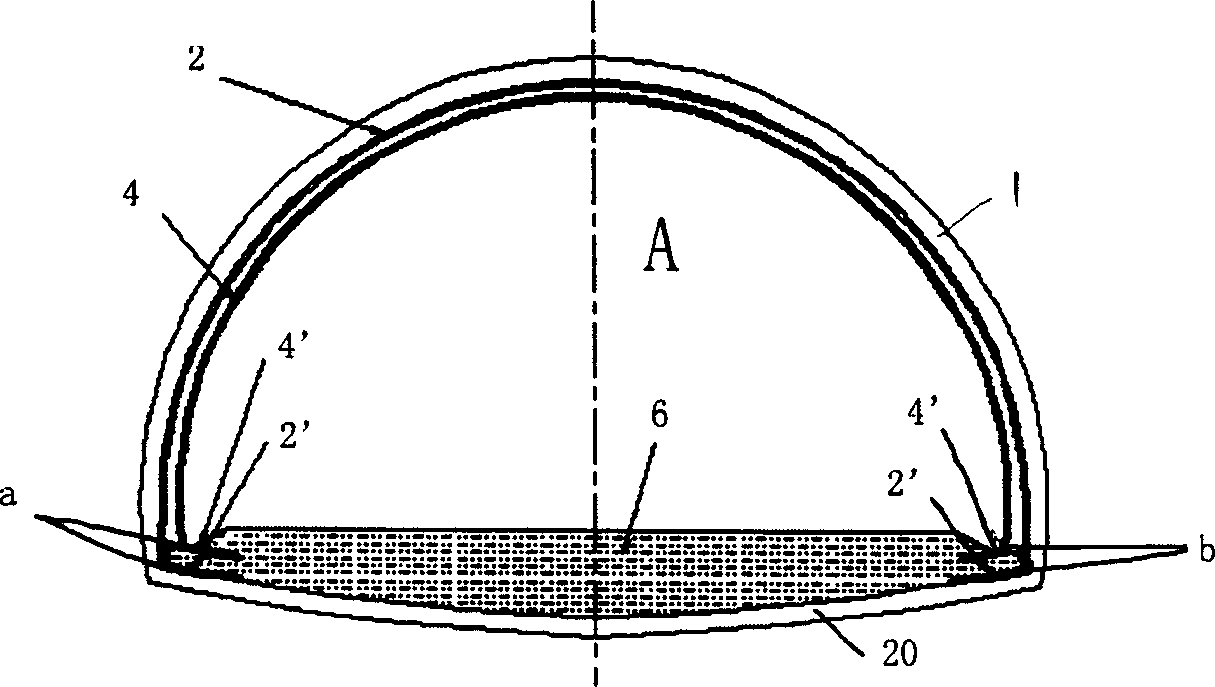

[0027] see figure 1 , using the excavation separation construction method of the present invention, the main body double-layer composite lining structure for urban subway separation stations is completed. The underground double-layer composite lining structure includes primary support shotcrete layer 1, ECB (conventional polyethylene-vinyl acetate and asphalt copolymer) or other waterproof sheet waterproof layer 2, secondary lining C30 (concrete) reinforced concrete layer 3 and partition plate 8.

[0028] The construction technique of the present embodiment comprises concrete steps as follows:

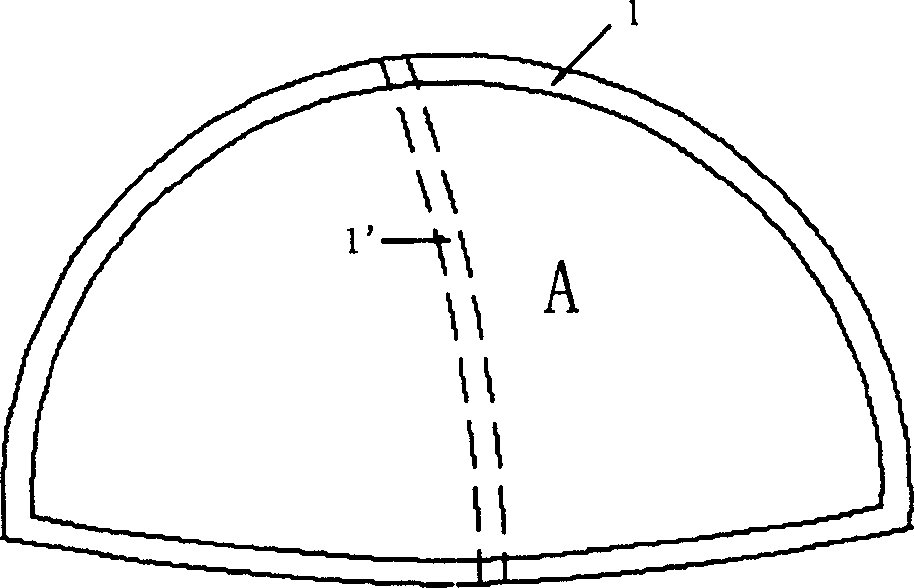

[0029] see figure 2 , use the existing shallow buried excavation technology to complete the excavation and initial support of the upper half of the structure, including the completion of the initial support through conventional precipitation, advance ground reinforcement and shotcrete existing construction technology; at the same time, strictly follow the "pipe advance, The constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com