Intensification method and device for continuous banburying process of high polymer materials based on eccentric helix

A spiral and eccentric technology, which is applied in the field of continuous mixing process enhancement and device of polymer materials based on eccentric spiral, can solve the problems of high energy consumption, discontinuous mixing process, low efficiency, etc., and achieve good mixing effect and mixing. The effect of continuous process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

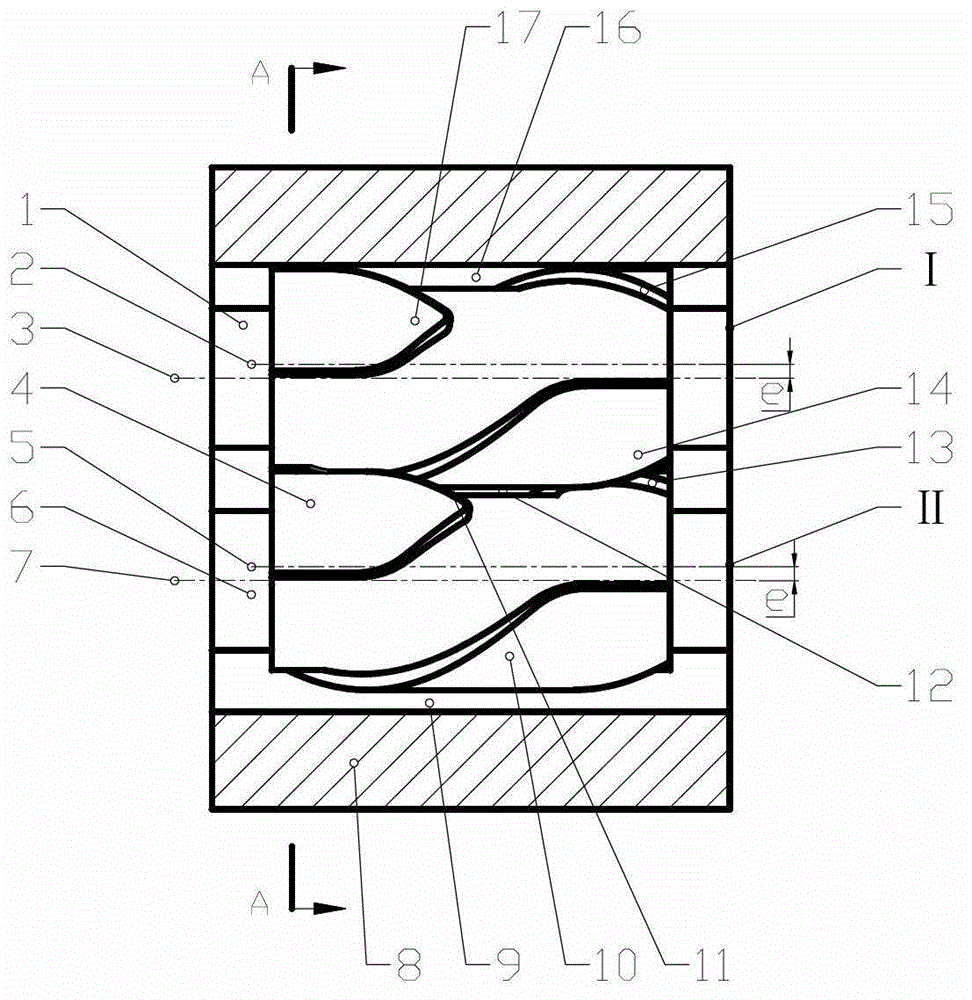

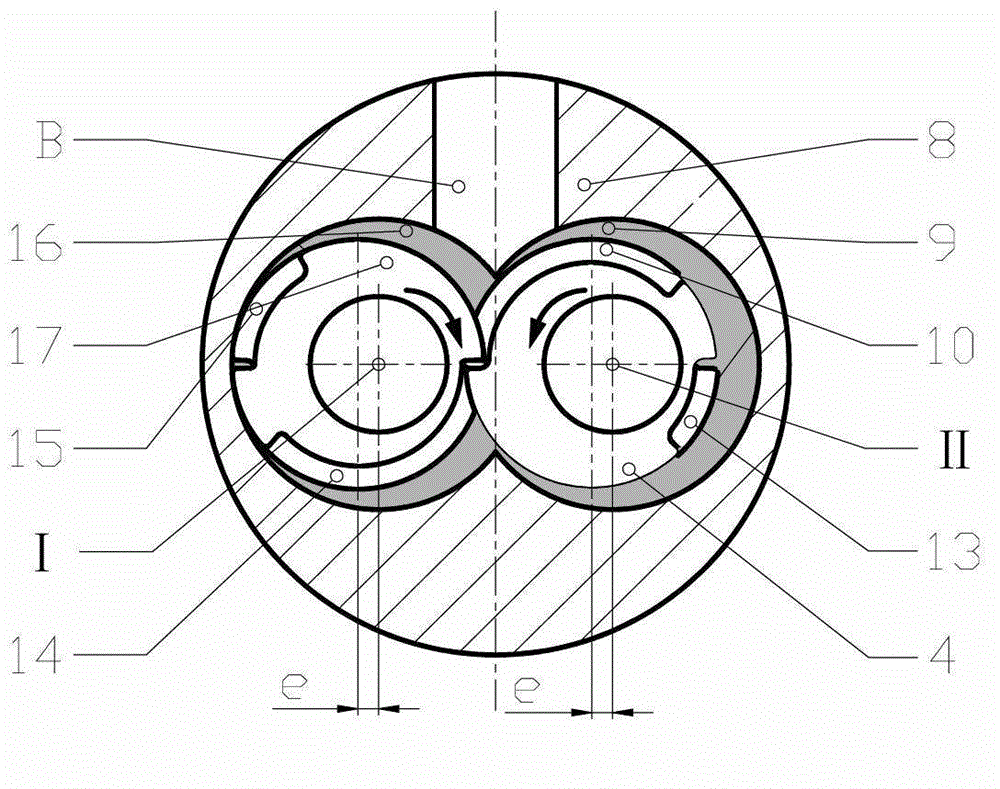

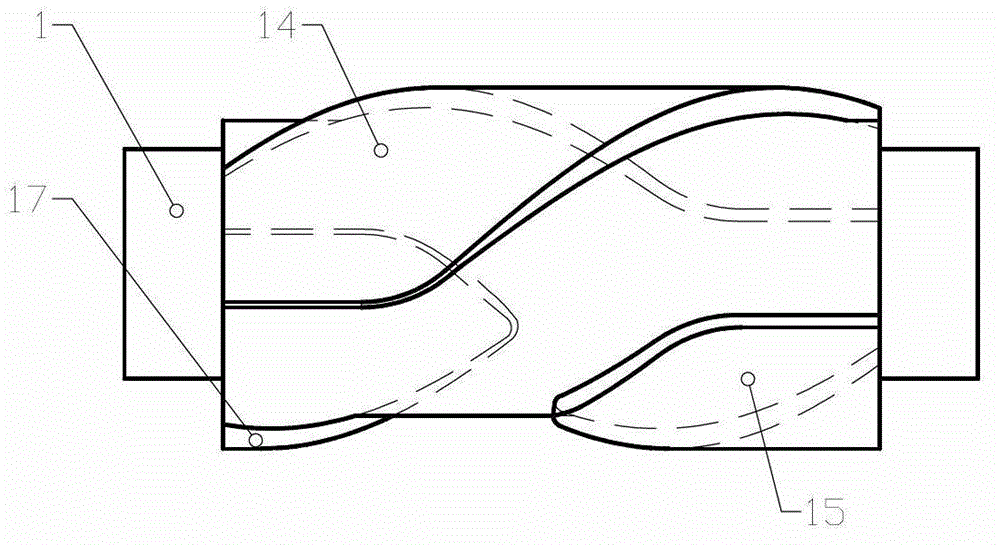

[0023] Such as figure 1 , figure 2 , image 3 As shown, a polymer material continuous mixing process strengthening device based on an eccentric screw is mainly composed of a first screw rotor I, a second screw rotor II and a stator 8 that are eccentric to their respective rotation axes; the first screw rotor I and the second screw rotor The helical rotor II rotates in different directions and engages, and is placed in the hollow stator 8 . The outer surfaces of the first helical rotor I and the second helical rotor II are eccentric meshing rib structures, and the rib structure axis 2 of the first helical rotor I and the rib structure axis 5 of the second helical rotor II are respectively in line with the first The rotor rotation axis 3 of the helical rotor and the rotor rotation axis 7 of the second helical rotor have the same eccentricity e, and the horizontal eccentricity directions of the first helical rotor I and the second helical rotor II are arranged in the same dire...

Embodiment 2

[0025] refer to Figure 4, The eccentric rotor and screw combined continuous mixing equipment is mainly composed of twin-screw feeding device I, eccentric screw-based continuous mixing process strengthening device II, and conveying and shaping device III. Among them, the feeding device I mainly realizes the addition and transportation of materials, the continuous mixing process strengthening device II based on the eccentric screw mainly realizes the mixing strengthening effect of materials, and the conveying and setting device III realizes material output and product molding. The feeding device I is composed of a twin-screw component 11 and a feeding device 8 arranged on the first rotating shaft 9 and the second rotating shaft 10. The continuous mixing process strengthening device II based on the eccentric screw mainly consists of the first eccentric screw rotor 7 and the second eccentric screw rotor. The screw rotor 12 is composed, and the conveying and shaping device III is ...

Embodiment 3

[0027] refer to Figure 5 , the injection equipment of the polymer material continuous mixing process strengthening device based on the eccentric screw is mainly composed of the polymer material plasticizing conveying unit I, the plunger injection unit II and the collector 5. Polymer material plasticizing conveying unit I mainly includes hopper 1, first screw conveying part 2, second screw conveying part 4 and continuous mixing process strengthening device 3 and other components; plunger injection unit II mainly includes injection cylinder 6, injection The plunger 7, the injection barrel 8, the cavity 9, the collecting pipe 10 and the nozzle 11 and other components; The discharge end face of the transitional sleeve of the delivery unit I is fixedly connected, and its discharge end face is fixedly connected with the feed end face of the injection cylinder 8 of the plunger injection unit II, and the cavity 9 communicates with the collecting pipe 10 . The material is added from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com