Pipe communication splice welding pressure-bearing type heat exchanger

A heat exchanger and pressure-bearing technology, which is applied in the field of pipe-connected and welded pressure-bearing heat exchangers, can solve the problems of low water leakage rate of welding seam and high water leakage rate of welding seam, and achieve beautiful weld bead and reduce Welded joints, the effect of reducing welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

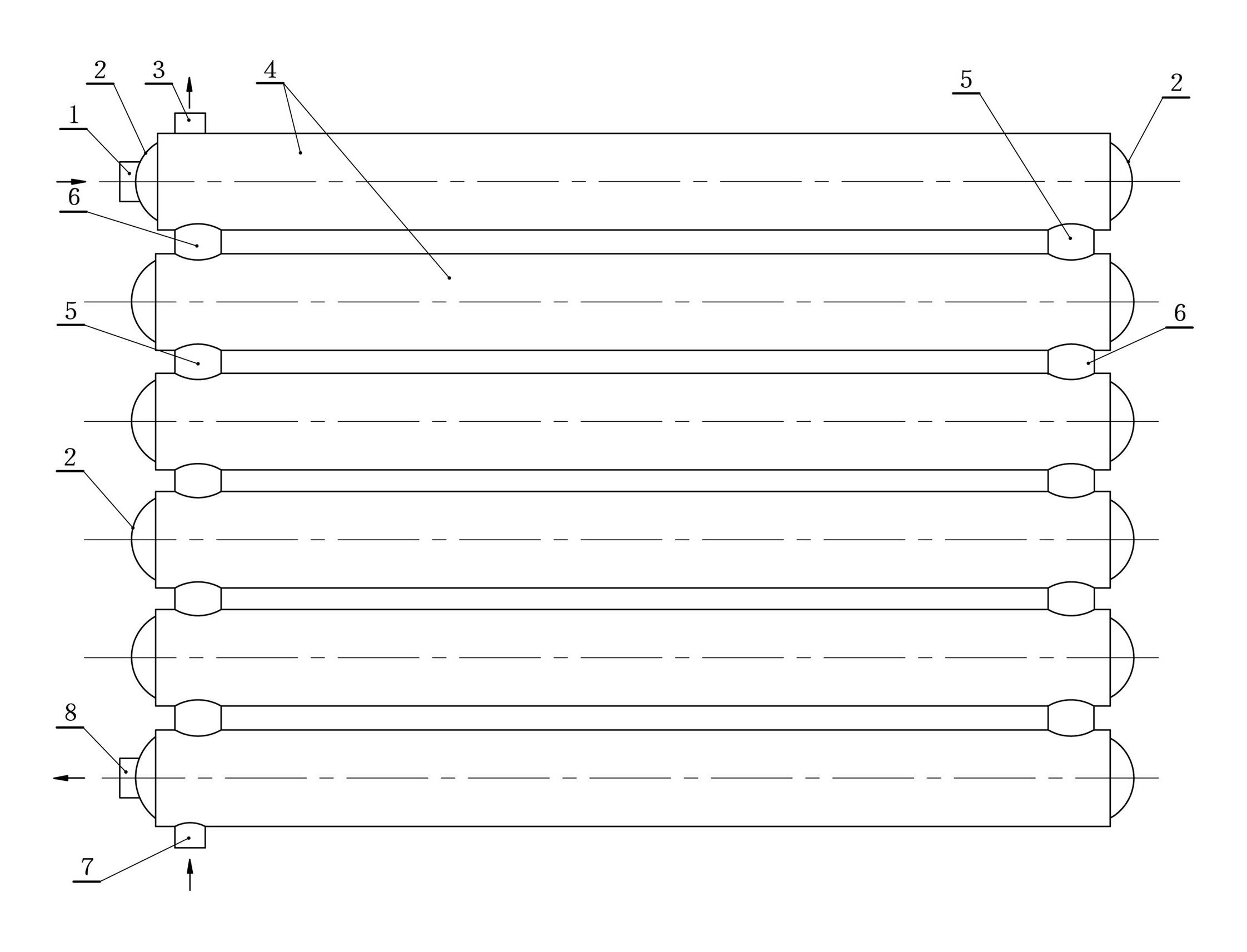

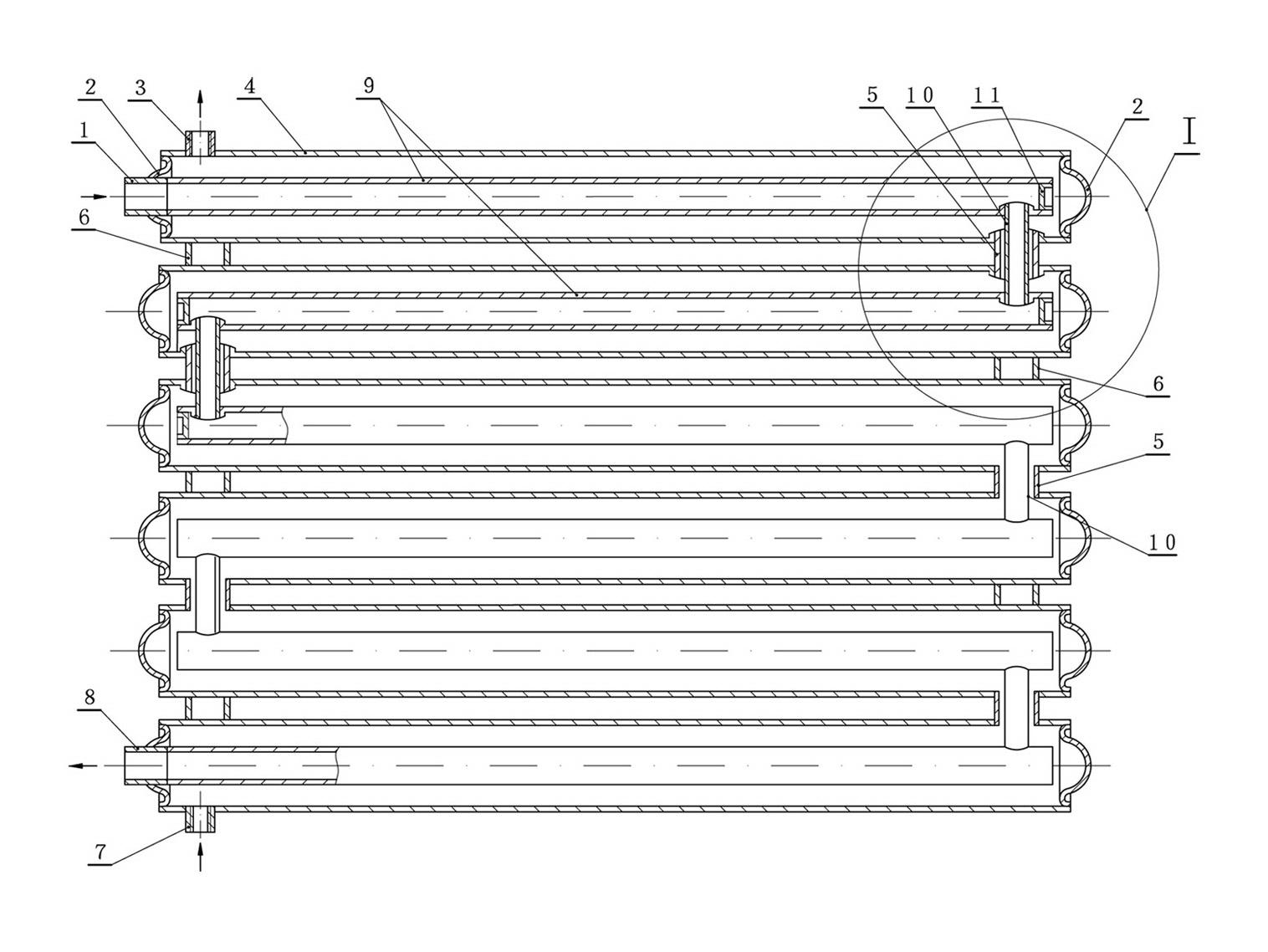

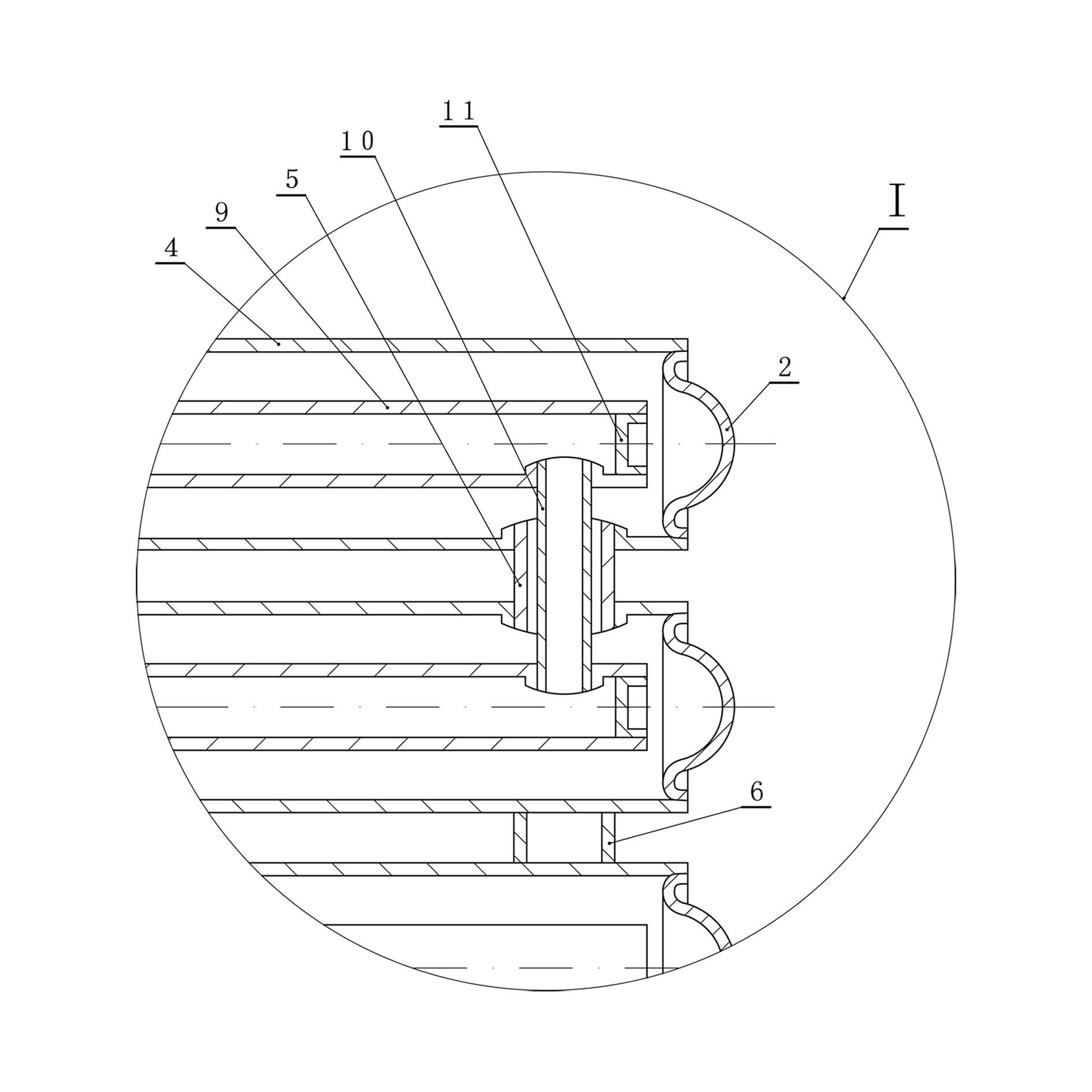

[0033] The tube Unicom and welded pressure-bearing heat exchanger of the present invention is as figure 1 , figure 2 , image 3 As shown, it includes: two or more tap water heat-absorbing pipes 4, the tap water heat-absorbing pipes 4 are provided with heat supply pipes 9, the tap water heat-absorbing pipes 4 are connected through tap water connecting pipes 5, and the heat supply pipes 9 The heating pipe connecting pipe 10 communicates between them; the heating inlet 1 and the heating outlet 8 are fixedly connected with the inlet and outlet of the heating pipe 9 respectively, and the tap water inlet 7 and the tap water outlet 3 are connected with the inlet and outlet of the tap water heat-absorbing pipe 4 respectively. The outlet end is fixedly connected; it is characterized in that: the end of the tap water heat-absorbing pipe 4 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com