Patents

Literature

339results about How to "Reduce welding stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

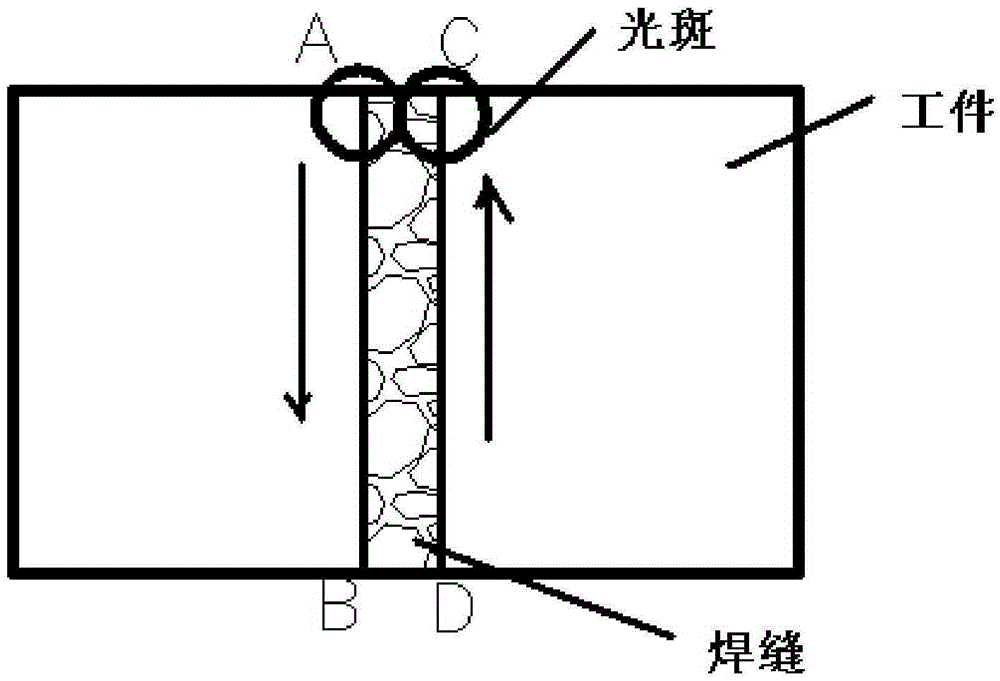

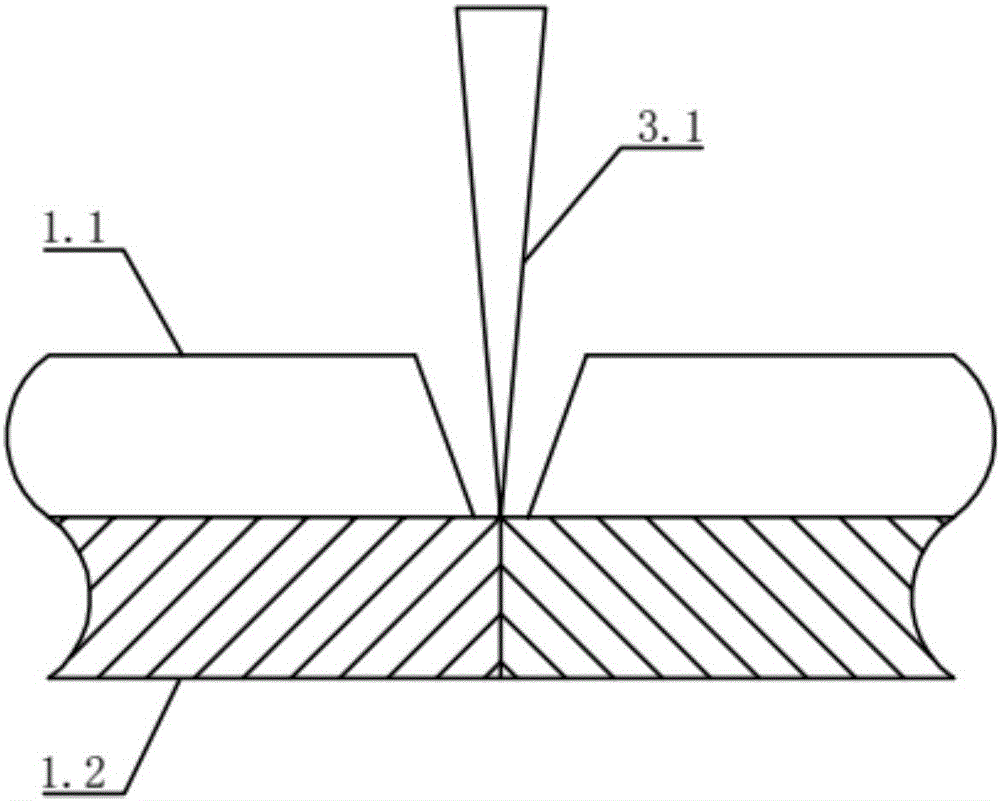

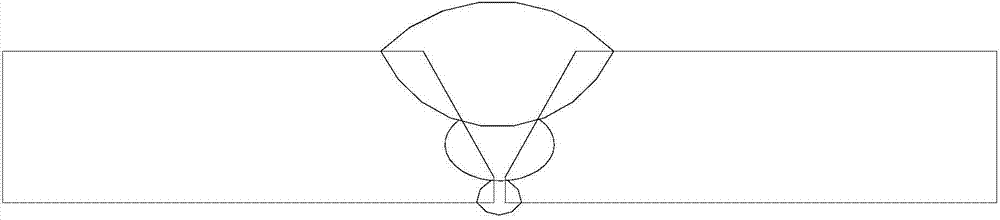

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

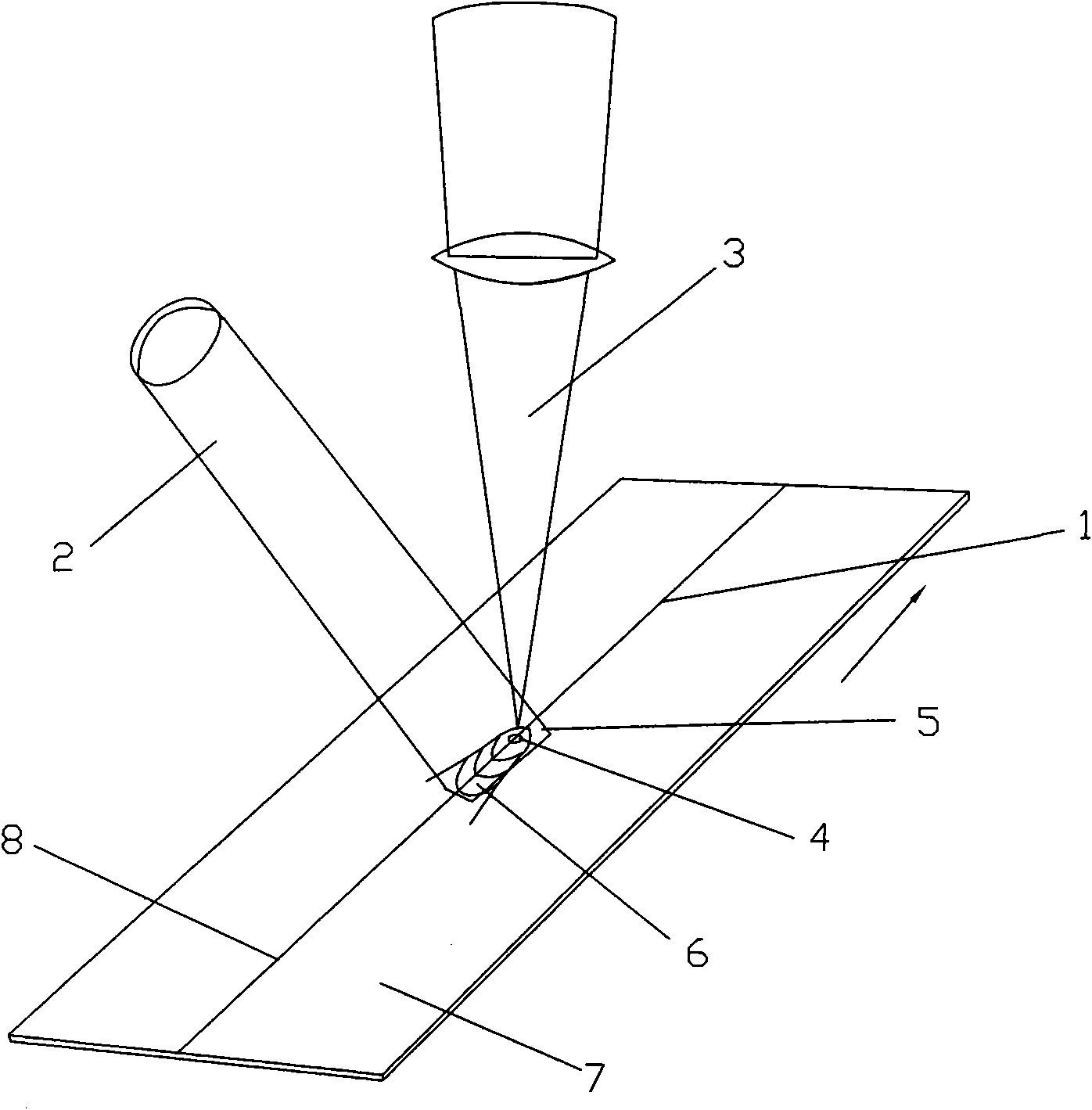

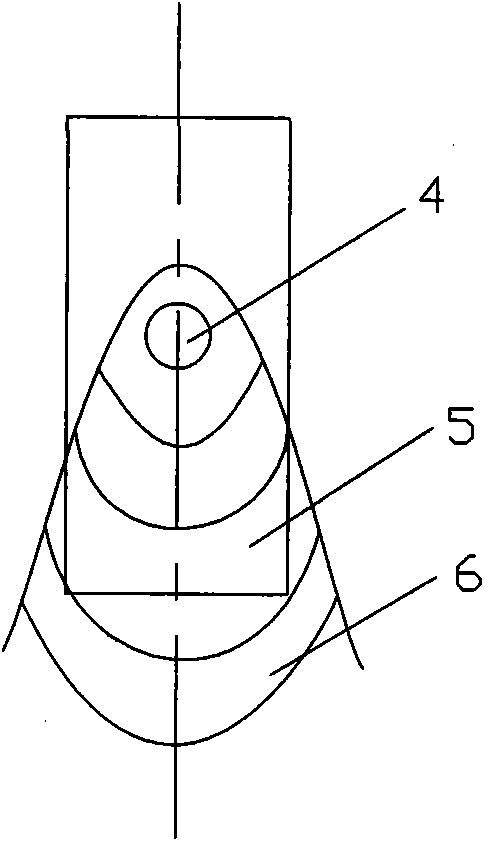

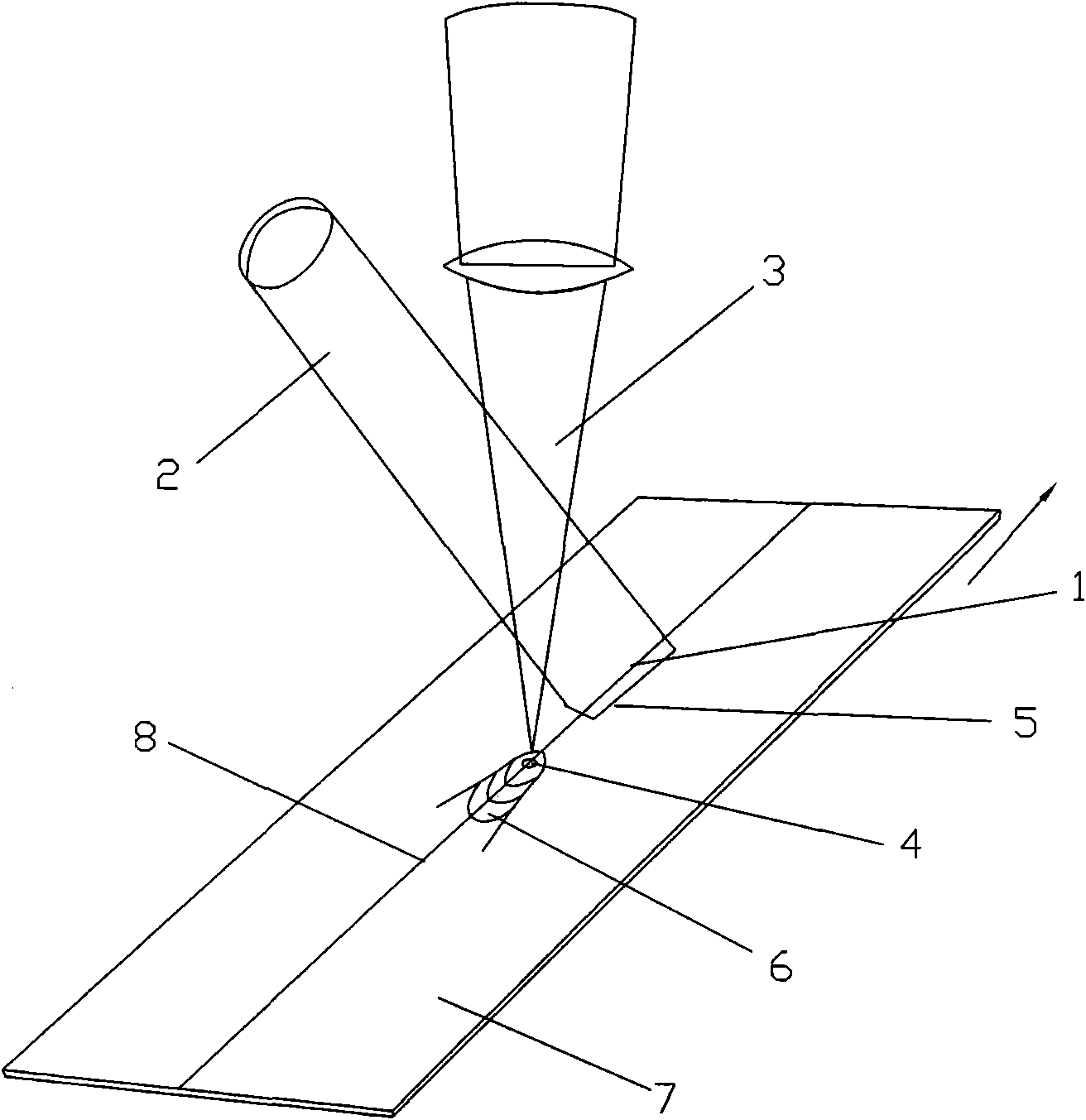

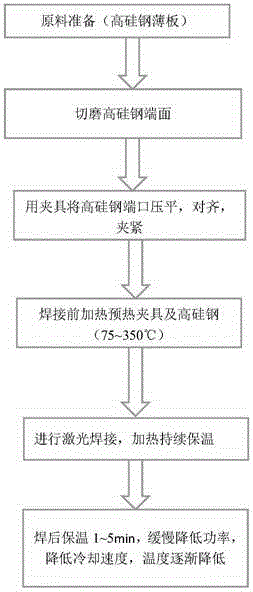

Laser welding method of high silicon steel

ActiveCN106041305ARealize welding formingImprove cooling conditionsWelding/soldering/cutting articlesLaser beam welding apparatusAlloySlow cooling

The invention belongs to the field of the metallurgy technology and material science, and aims at providing a laser welding process method of brittle high silicon steel. Quick welding of strip tension rolling in the rolling preparation process of a high silicon steel thin strip is met. According to the mass ratio, an adopted alloy is prepared from 93%-96.5% of Fe and 3.5%-7% of Si; and the thickness ranges from 0.1 mm to 3.5 mm. According to the method, laser welding and a supplementary heat source are combined, and double-face or single-face welding is adopted; preheating carried out before welding is utilized for controlling the temperature rise speed, and heat preservation during welding and heat preservation carried out after welding are utilized for slow cooling to control the temperature reduction speed; and the temperature gradient and welding stress in the weld joint cooling process are reduced, and welding forming of the brittle high silicon steel is achieved. By means of the adoption of the method, cracks generated by the too high welding stress of the brittle high silicon steel can be avoided well, and the yield and the mechanical performance of the brittle high silicon steel are increased.

Owner:UNIV OF SCI & TECH BEIJING

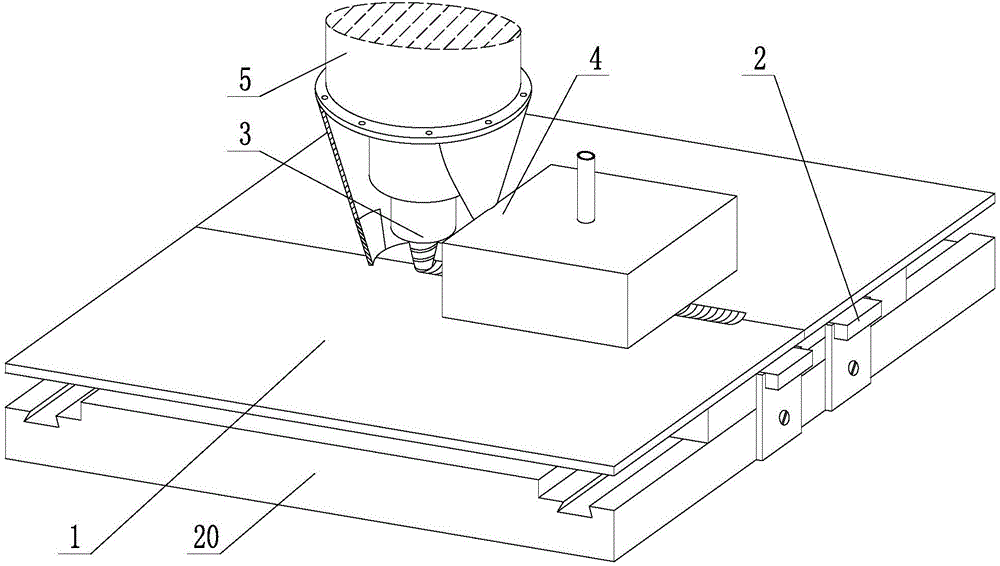

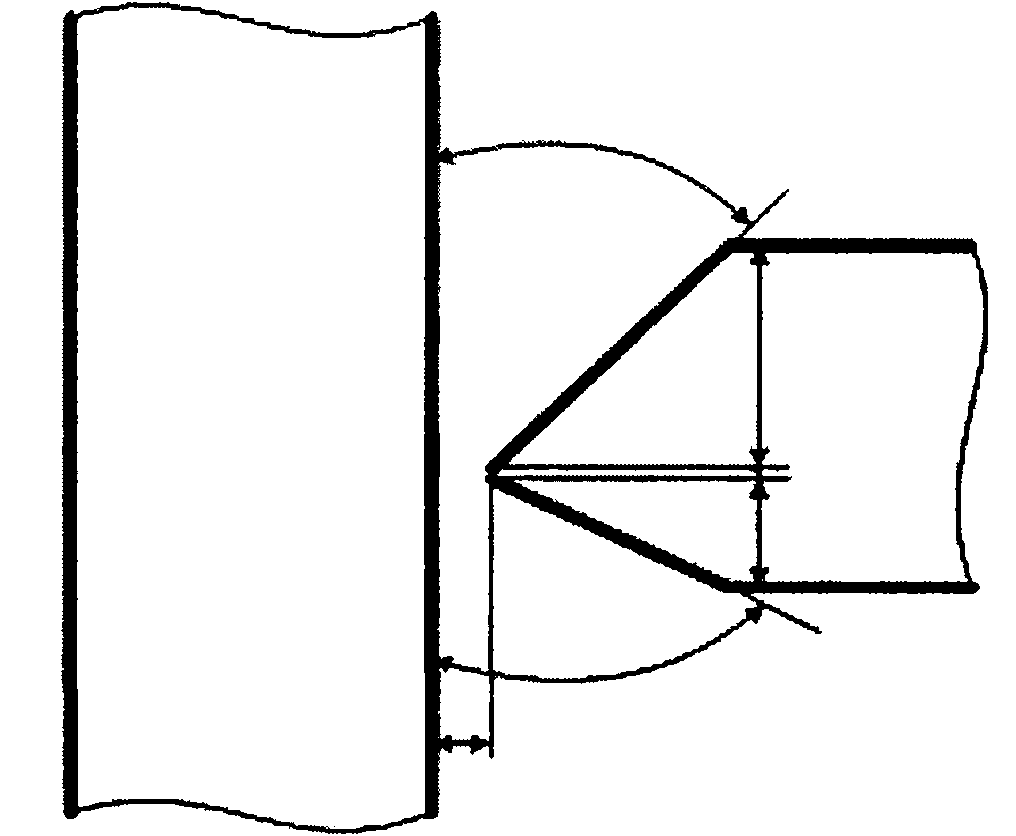

Friction stir welding process for combining back surface heating with frontal surface chilling

ActiveCN106271025AReduce temperature gradientImprove unevennessNon-electric welding apparatusCarbon Dioxide / HeliumShielding gas

The invention discloses a friction stir welding process for combining back surface heating with frontal surface chilling. The friction stir welding process comprises the following steps: a workpiece to be welded is fixedly clamped; heaters are arranged on two sides of a welding line area; a chilling shielding gas protective cover for moving along with a stirring head is arranged on the outer side of the stirring head; the heaters are started to heat the back surface of the workpiece to be welded, so that the temperature of the upper surface of the workpiece to be welded is not higher than 250 DEG C; the chilling shielding gas protective cover is filled with the chilling shielding gas, and the covering range includes the welding line area and the upper surface area of the workpiece to be welded rightly above the heaters; friction stir welding equipment is started, and the rotating stirring head is controlled to insert in the workpiece to be welded; the shaft shoulder end surface of the stirring head is continuously pressed down by a section of distance, and the stirring head is stopped until a set inserting depth is reached; the stirring head is controlled to continuously rotate by a period of time under the set inserting depth, so that the welding line area of the workpiece to be welded is fully preheated to reach an excellent plastic state; and the stirring head is controlled to finish the welding work of the welding line area at a set welding speed.

Owner:SHENYANG AEROSPACE UNIVERSITY

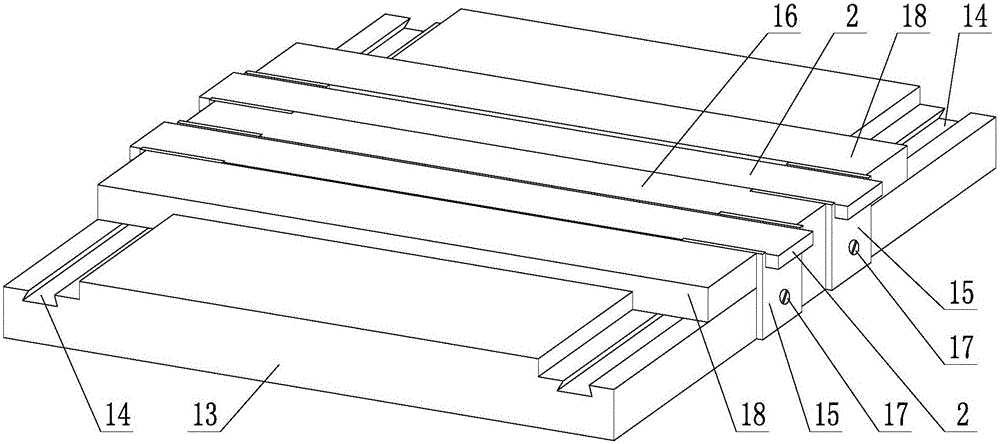

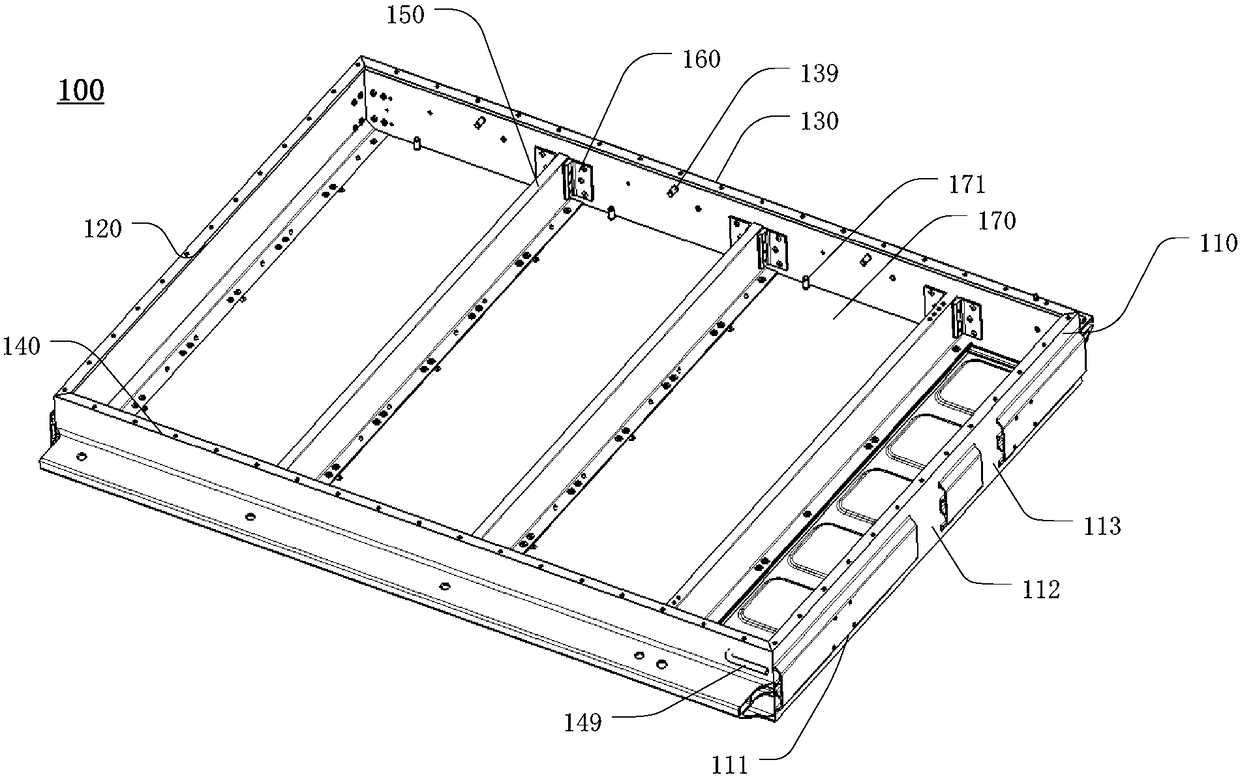

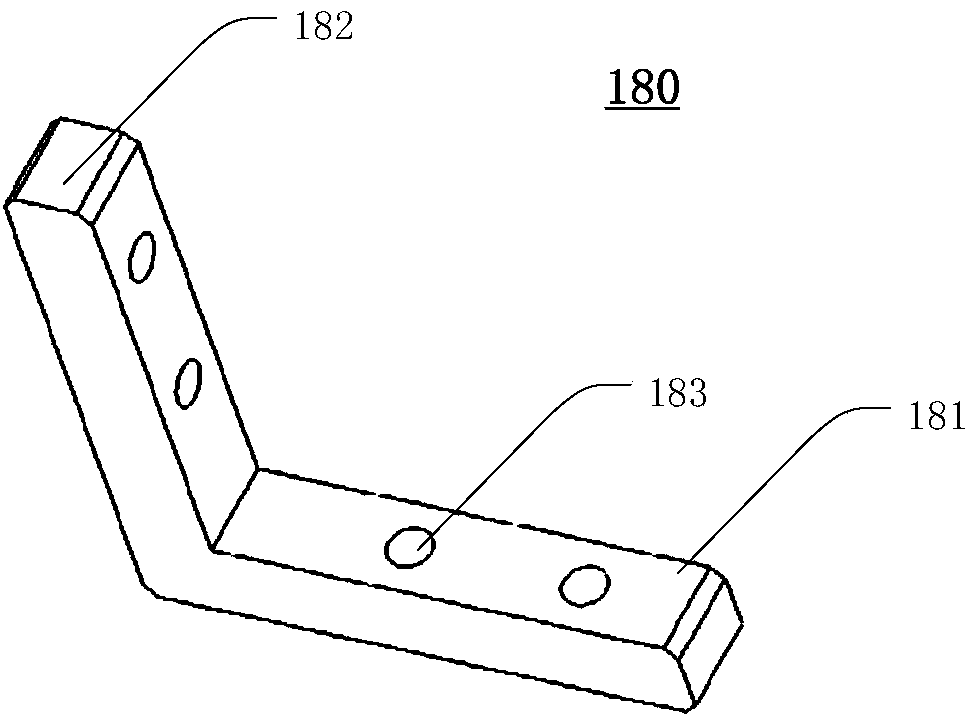

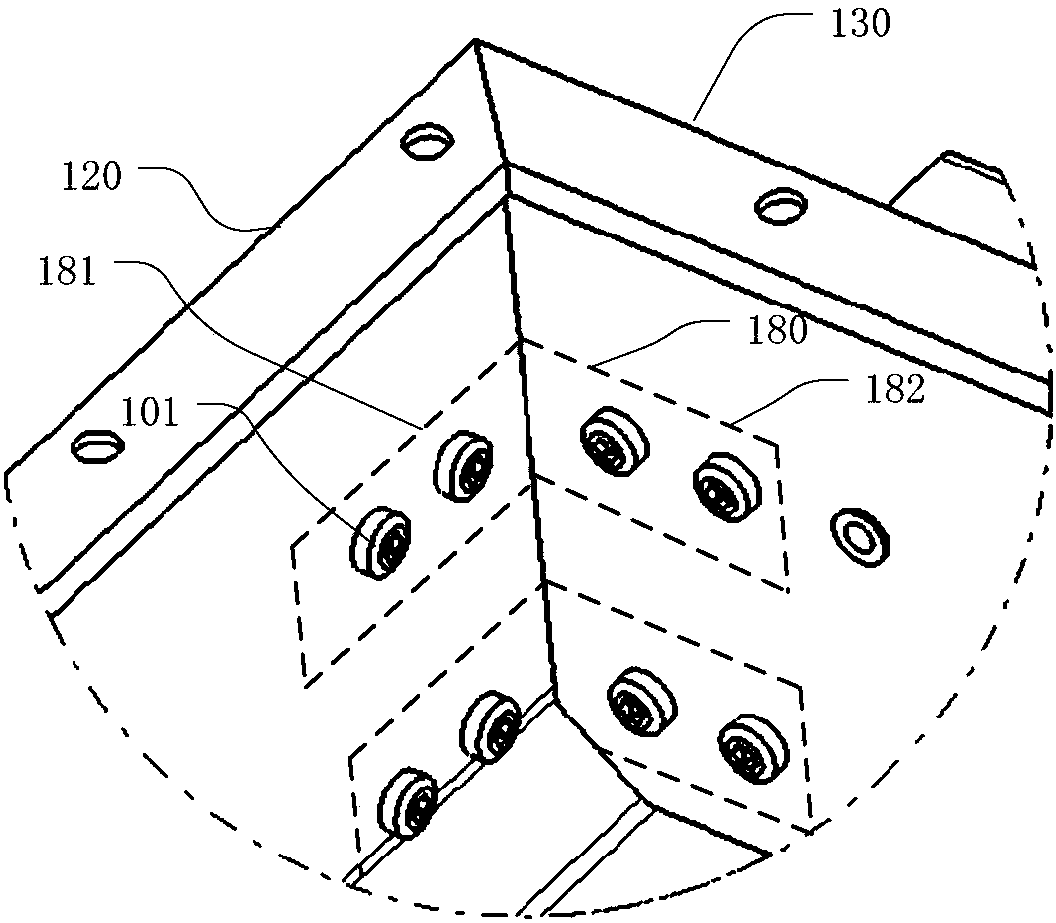

Battery pack and battery case thereof

PendingCN108461685AImprove connection strengthReduce welding stressBattery isolationPropulsion by batteries/cellsElectrical batteryEngineering

The invention provides a battery pack and a battery case thereof. The battery case comprises a bottom plate, a plurality of first beams, a plurality of second beams, a plurality of corner connectors,aplurality of fixed beams, and a plurality of fixed beam connectors, wherein the first and second beams are fixed on the bottom plate to form an accommodating cavity, each first beam is provided witha first cavity, and each second beam is provided with a second cavity; each corner connector is provided with a first connecting portion and a second connecting portion, which form a first angle, thefirst connecting portion of each corner connector islocated in the first cavity of the corresponding first beam and fixedly connected to the first beam, the second connecting portion of each corner connector is located in the second cavity of the corresponding second beam and is fixedly connected to the second beam; the fixed beams are fixed on the bottom plate and are located in the accommodatingcavities., and two ends of each fixed beam are connected with the second beams, respectively; each of the fixed beam connectors is connected with a fixed beam and a second beam. The reliability of the battery case provided by the invention is improved.

Owner:AIWAYS AUTOMOBILE CO LTD

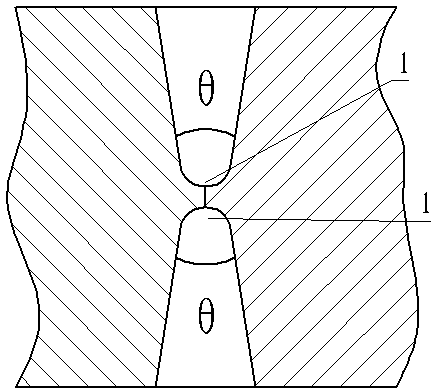

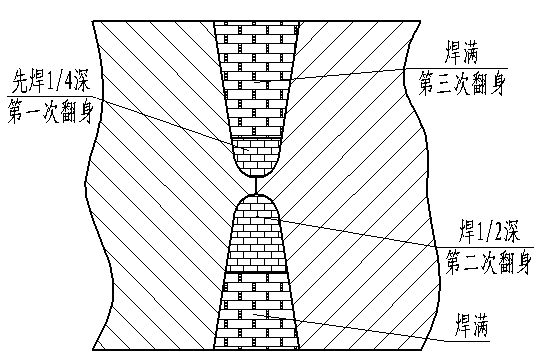

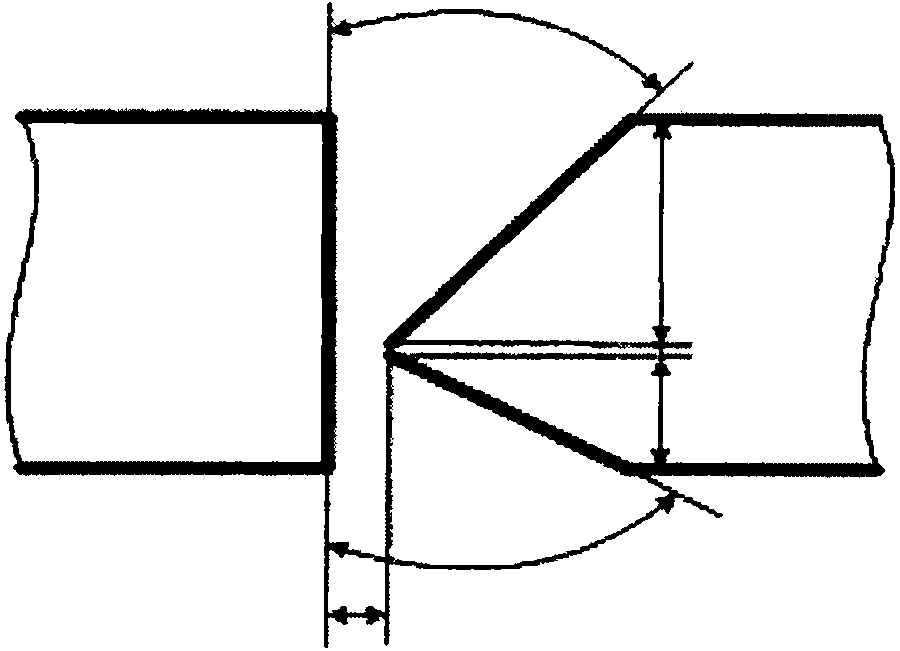

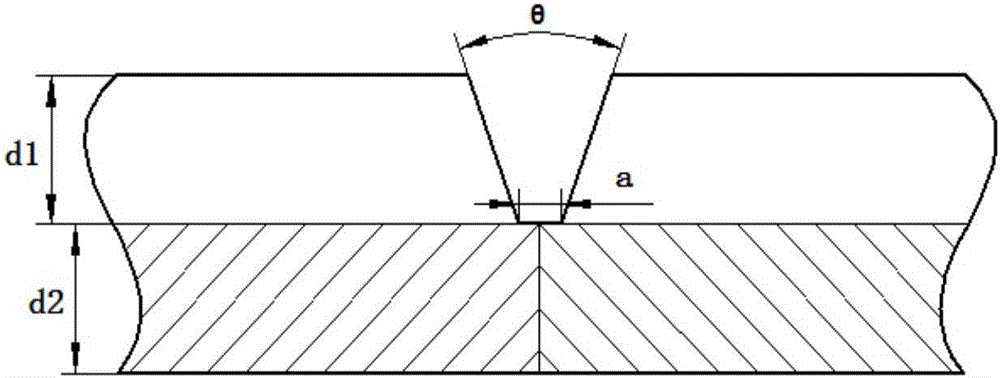

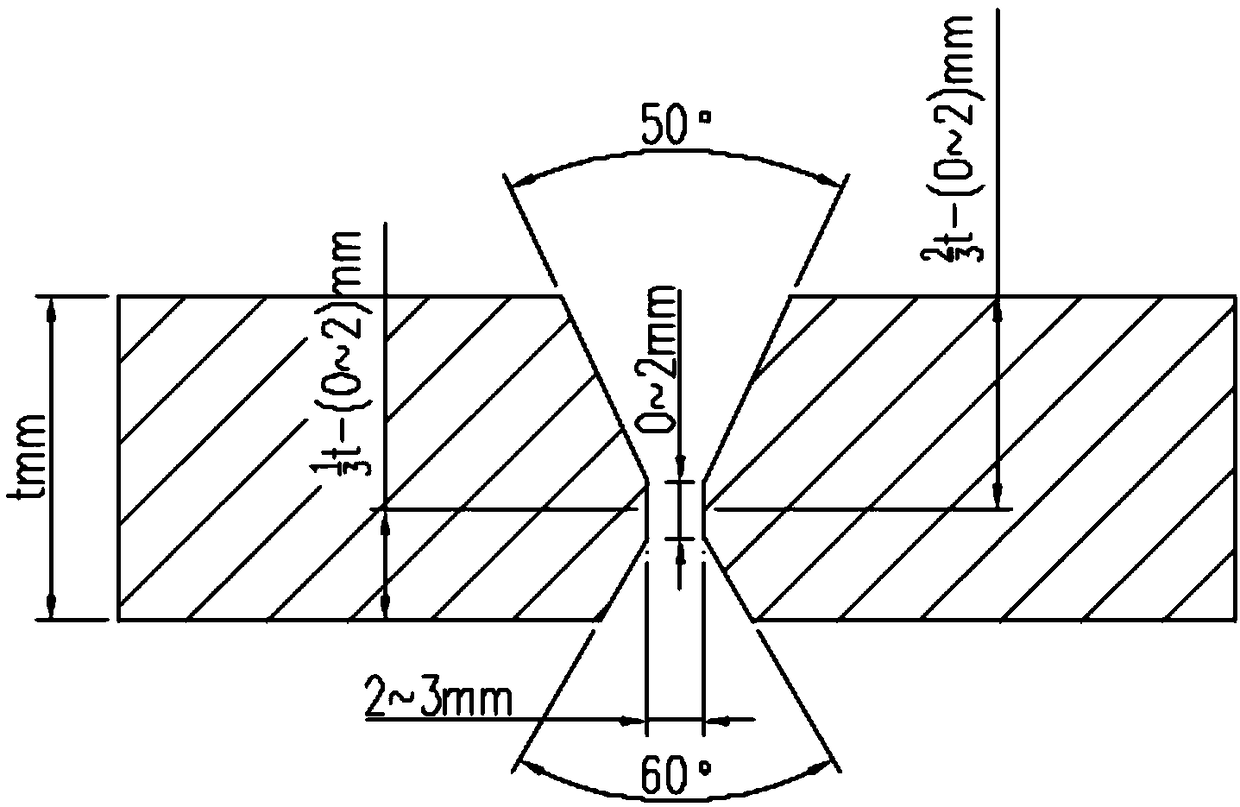

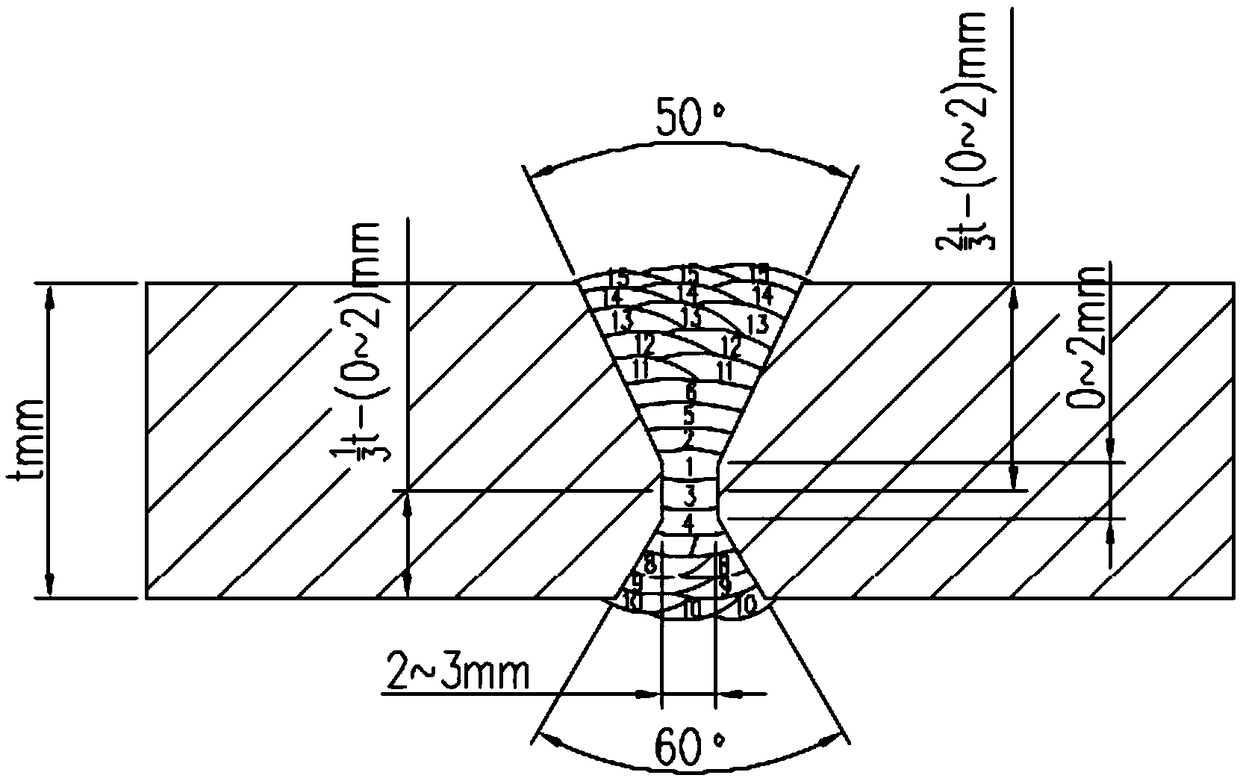

Butt joint method for super-thick steel plates

ActiveCN104002030AShort cooldownHeat dissipation fastWelding/soldering/cutting articlesMetal working apparatusSheet steelButt joint

The invention discloses a butt joint method for super-thick steel plates. The butt joint method for the super-thick steel plates comprises the steps of: machining grooves at butt joint parts of the steel plates, wherein the grooves are U-shaped grooves with symmetrical two surfaces, the angle of each groove is 8-10 degrees, and the radius of the arc at the root of each groove is 9-11mm; pre-heating before welding, wherein the preheating temperature is 40-60 DEG C, and locating welded joints after preheating; alternatively welding the welded joints on two sides by turning over for many times, backstep welding the layers of welding joints; keeping temperature in a welding process to be not more than 200 DEG C; keeping warm after welding, and cooling slowly. Since the U-shaped grooves are employed, the sectional area of the welded joints are greatly reduced, thermal input is reduced, control on welding deformation is facilitated, welding residual stress is reduced by backstep welding, two sides of the welded joint of the steel plate are subjected to uniform force by turning over for many times in welding, deformation in the welding process is corrected, the super-thick steel plate is rapid in heat dissipation after welding, quality of the welded joint is ensured by the method of keeping warm after welding, and stress deformation can be reduced by slowly cooling.

Owner:中铁宝桥(扬州)有限公司

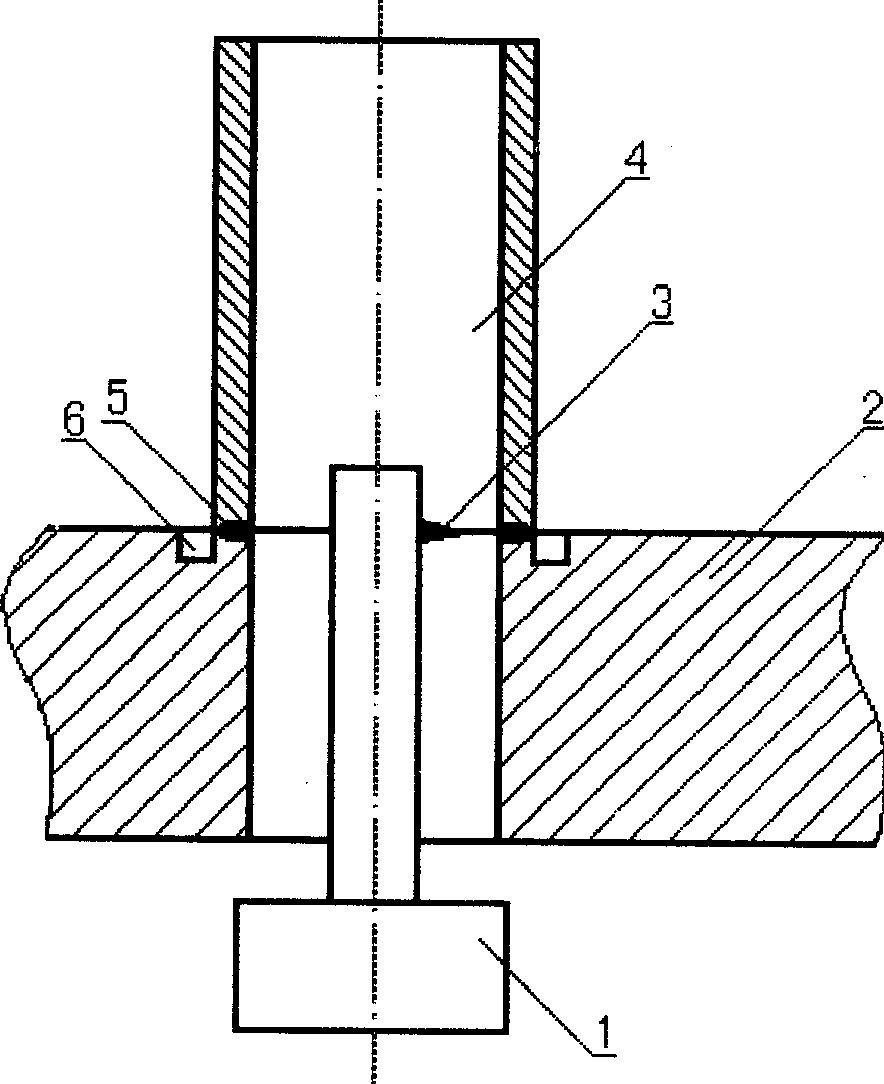

Method for welding inner hole of heat exchanger

ActiveCN1792532AExtended service lifeReduce welding stressArc welding apparatusHeat exchange apparatusPlate heat exchangerTorch

An internal hole welding method for heat exchanger includes such steps as machining circular hole on tube plate, machining a circular slot around the circular hole for releasing stress, butt connection between heat exchanging tube and the boss between slot and hole, inserting the argon arc welding torch in the hole, and welding.

Owner:TIANJI COAL CHEM IND GROUP +1

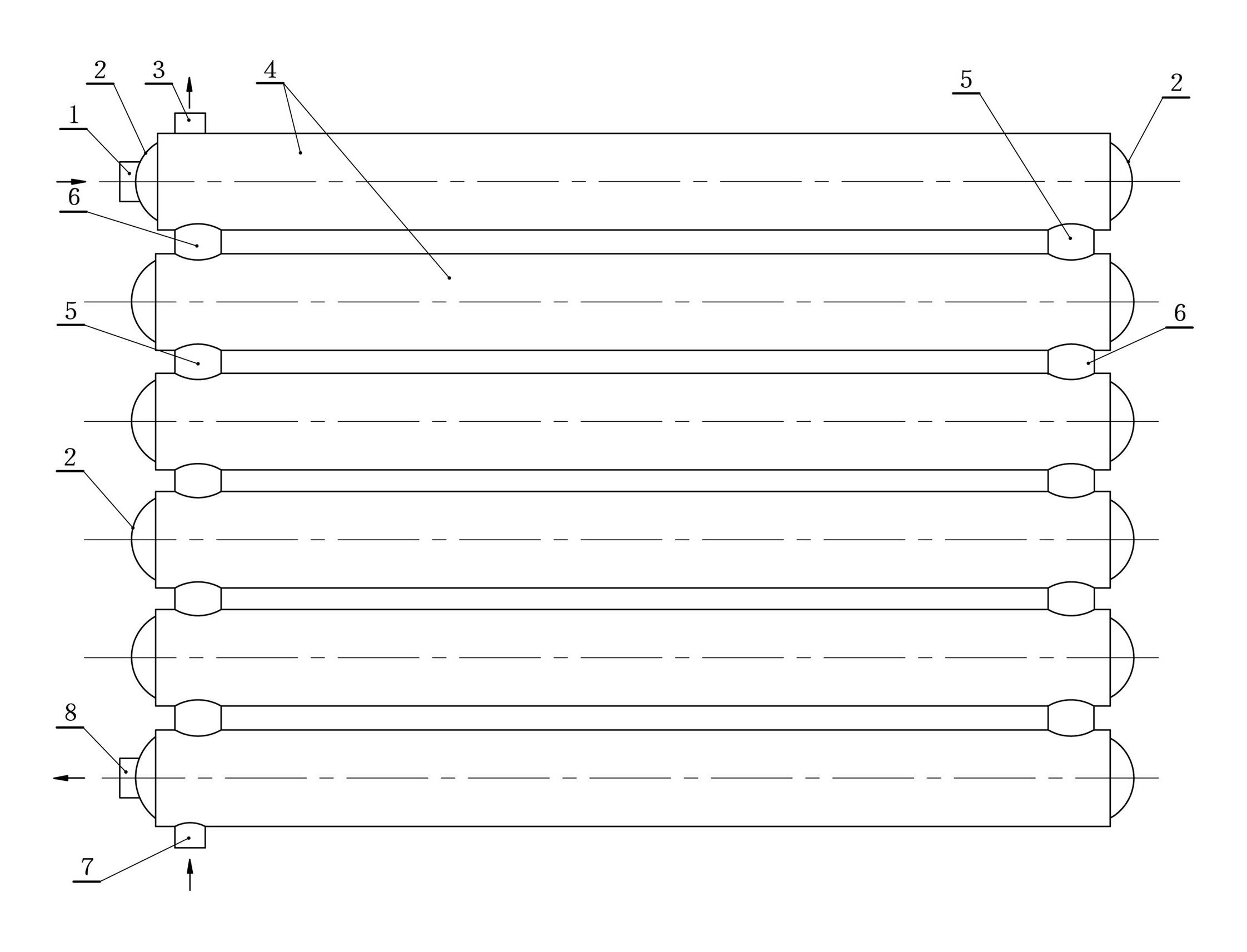

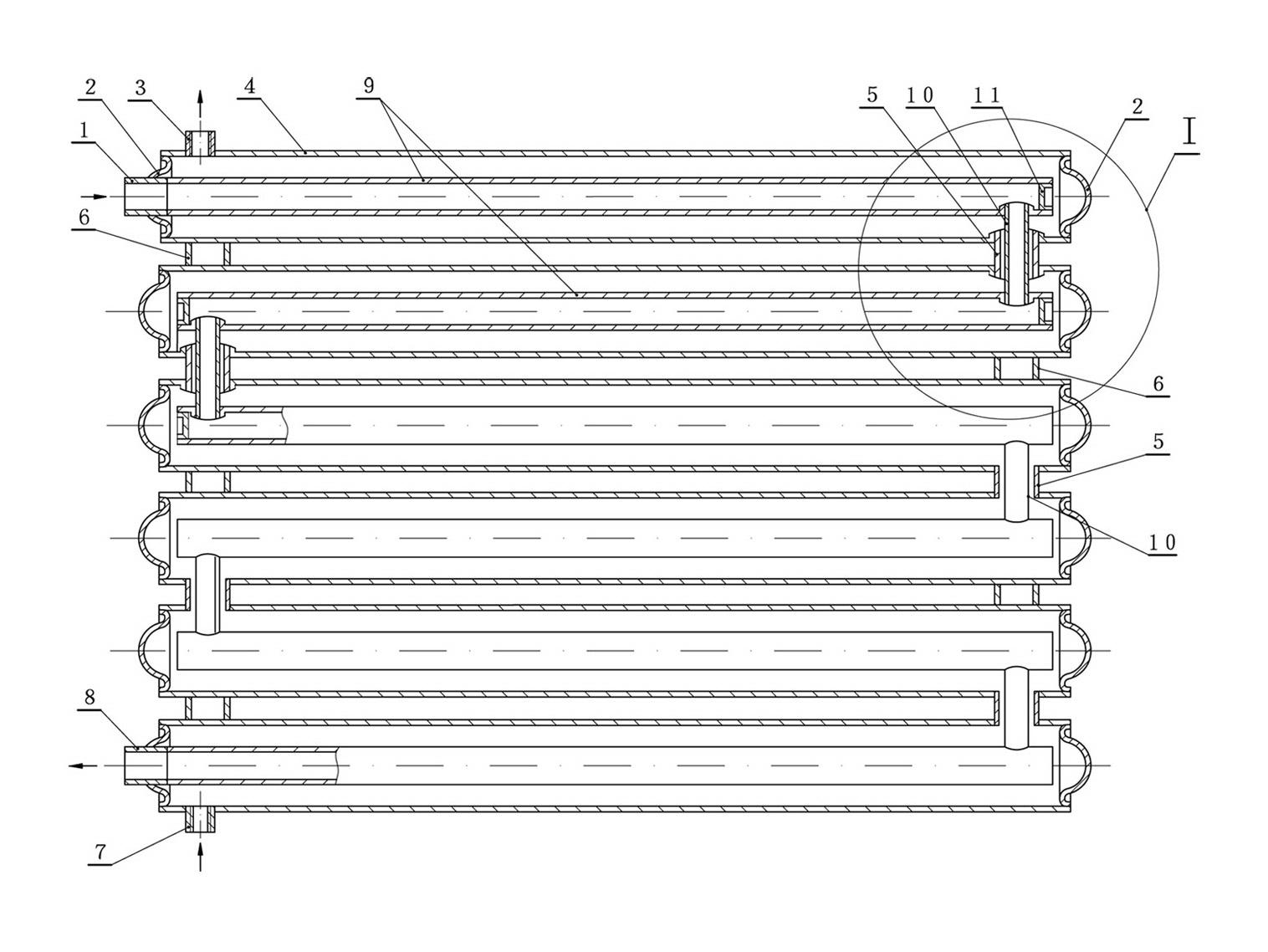

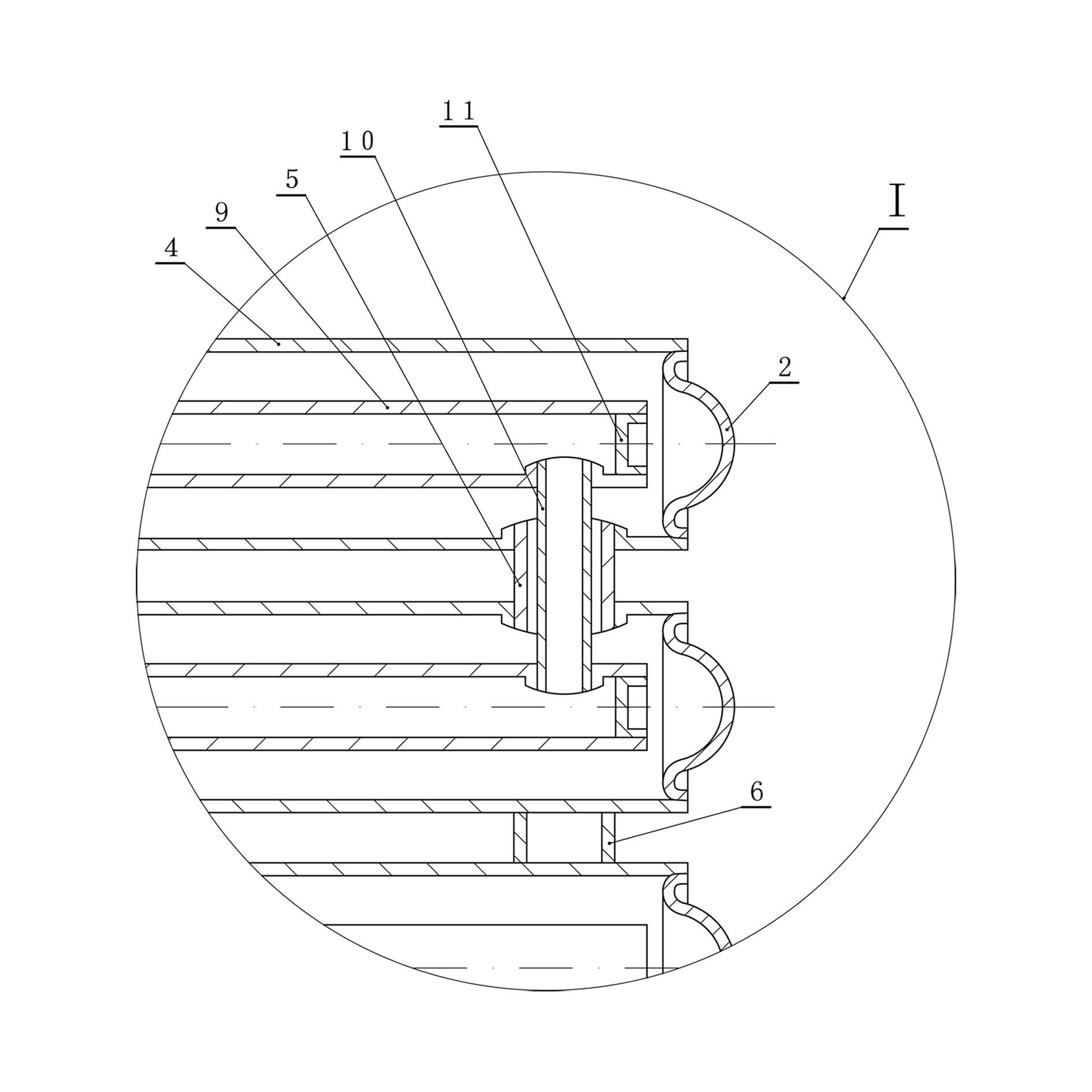

Pipe communication splice welding pressure-bearing type heat exchanger

InactiveCN102322754AIncrease heat transfer areaSolve the welding seam leakage rate is too highHeat exhanger sealing arrangementHeat exchanger casingsWater leakagePlate heat exchanger

The invention relates to a pipe communication splice welding pressure-bearing type heat exchanger, which comprises tap water heat absorption pipes. Heat supply pipes are arranged in the tap water heat absorption pipes. The tap water heat absorption pipes are communicated through tap water communication pipes. The heat supply pipes are communicated through heat supply pipe communication pipes. The seal heads of the tap water heat absorption pipes are outwardly flanged and embedded in the ports of the tap water heat absorption pipes. The flanges of the seal heads of the tap water heat absorption pipes and the port edges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. The walls of the tap water heat absorption pipes are punched and inwardly flanged. The tap water communication pipes are inserted in the punches of the tap water heat absorption pipes. The port edges of the tap water communication pipes and the punched inward flanges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. Heat supply pipe blocking plates are embedded in the ports of the heat supply pipes. The heat supply pipe blocking plates are outwardly flanged. The outward flanges of the heat supply pipe blocking plates and the port edges of the tap water heat absorption pipes are in splice alignment edge-kneading welding connection. According to the pipe communication splice welding pressure-bearing type heat exchanger disclosed by the invention, two technical defects of higher water leakage ratio of the welding line and incapability of continuously producing hot water of the original patent product can be solved; and the heat exchanger has the advantages of no leakage and continuous hot water production.

Owner:张伟

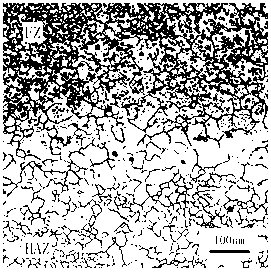

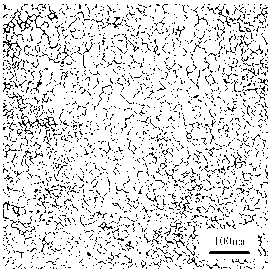

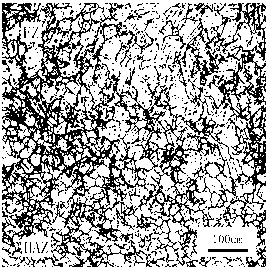

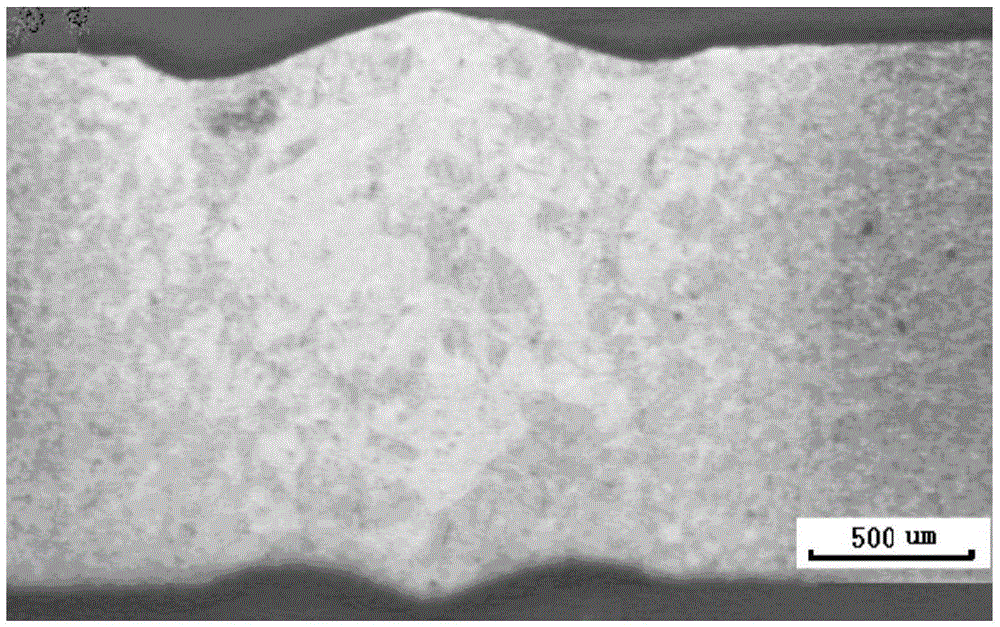

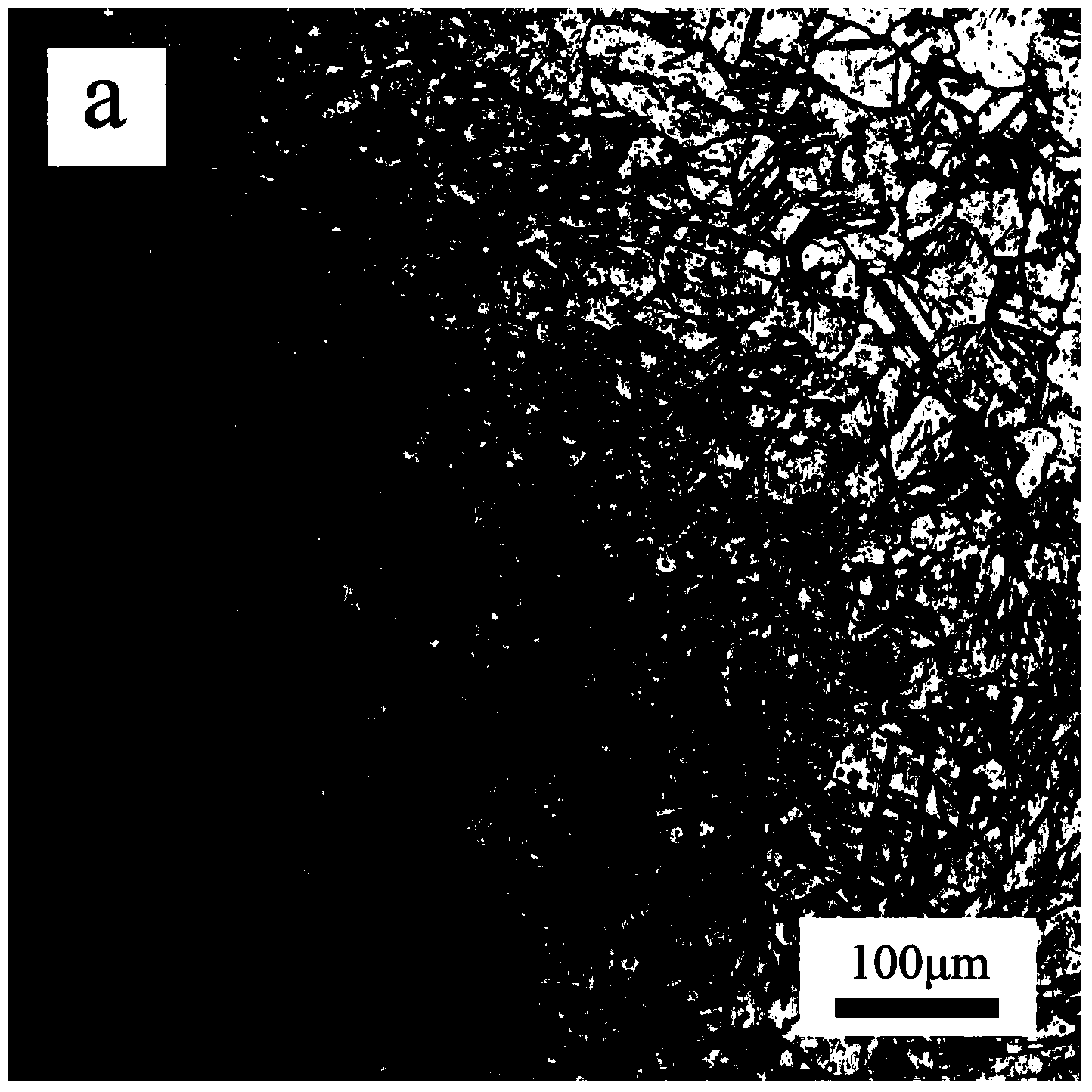

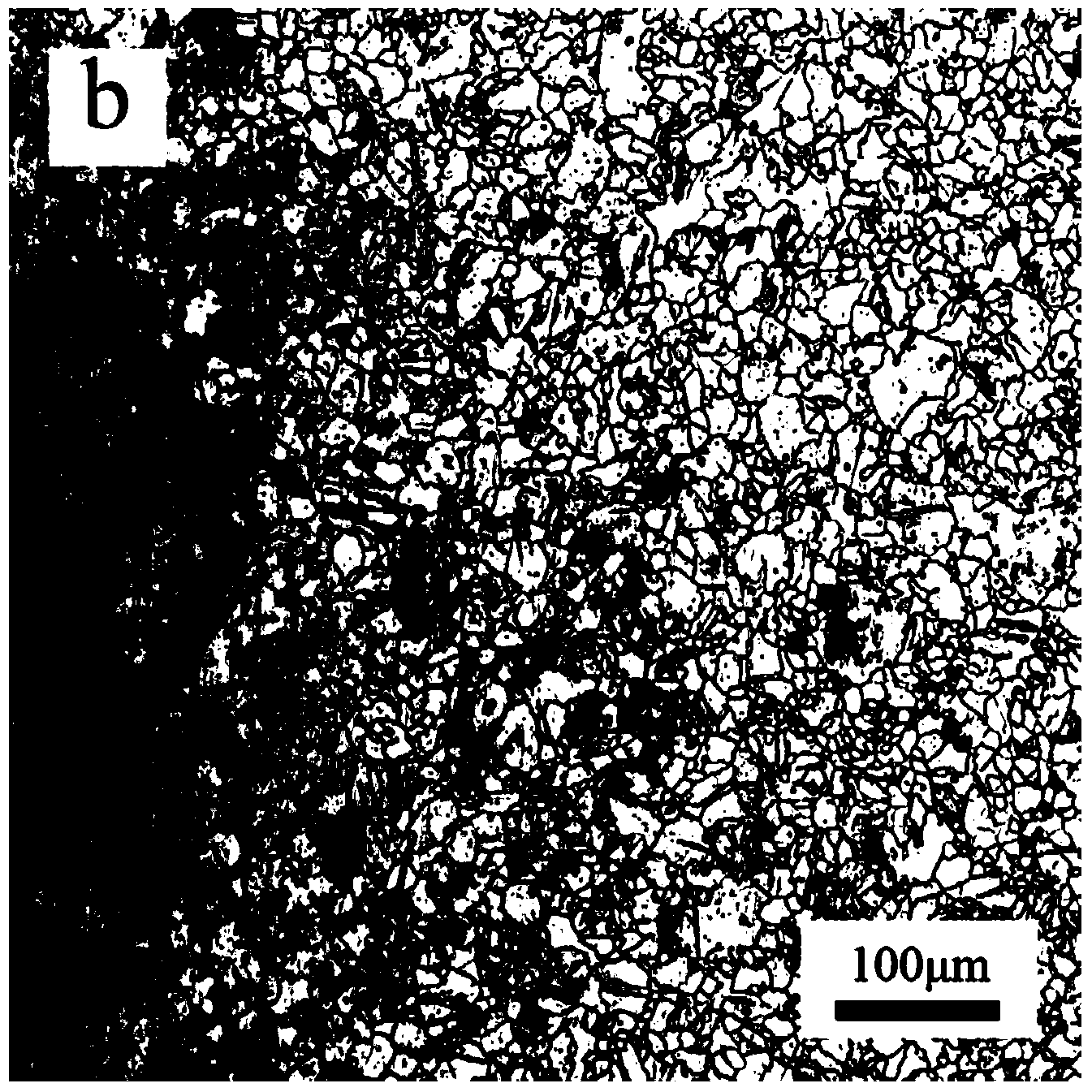

Method for improving weld structure and performance of magnesium alloy

The invention provides a method for improving a weld structure and performance of a magnesium alloy, which comprises the following steps: firstly, placing an magnesium alloy welding plate in a heat treatment furnace to carry out stress relief annealing for a certain time at a temperature of 250 DEG C to 350 DEG C; then, polishing and flattening a weld joint by adopting abrasive paper for metallograph to enable the magnesium alloy welding plate to be at the same height with a base material; and heating the magnesium alloy to a certain temperature higher than a recrystallization temperature and carrying out hot rolling after carrying out heat preservation for a certain time. The method is generally suitable for weld penetration magnesium alloy plates such as an AZ31 magnesium alloy plate, an AZ61 magnesium alloy plate, an AZ80 magnesium alloy plate and the like. Intensity of the weld joint and a heat affected zone of the welded magnesium alloy plate is obviously lower than that of the base material. By a means of carrying out hot rolling after carrying out heat preservation at a certain temperature, the method can effectively improve intensity of a magnesium alloy welding part and enables tissues and performance of the weld joint, the heat affected zone and a base metal to be consistent.

Owner:CHONGQING UNIV

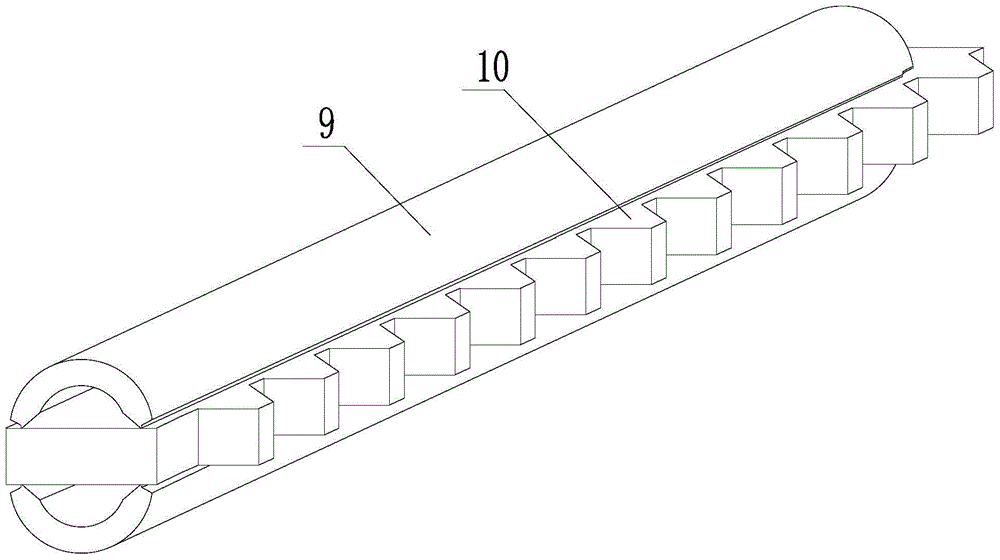

Efficient photovoltaic isomerism solder strip

ActiveCN103985775AWhen the combination is applicableReduce welding stressPhotovoltaic energy generationSemiconductor devicesCouplingAlloy

The invention relates to an efficient photovoltaic isomerism solder strip. The solder strip comprises an electric conduction base strip made of metal simple substances or alloy material, and the base strip is provided with an upper wide surface and a lower wide surface. V-shaped grooves and a coupling platform are distributed on at least one wide surface of the electric conduction base strip. The depth h of the V-shaped grooves is 0.055 mm<h<0.15 mm. The diameter of the maximum inscribed circle of the coupling platform is larger than or equal to 0.10 mm. The maximum length of the platform in the length direction of the electric conduction base strip is smaller than 50 mm. The optimally designed V-shaped grooves and the coupling platform are manufactured on the surface of the electric conduction base strip, and a high-cost-performance custom design scheme is provided for partial reuse of reflected light on the surfaces of the solder strip, reduction of soldering stress, a guarantee of soldering strength and current collecting electrical loss caused by equalization grooving.

Owner:FUNDANT JIANGSU ADVANCED MATERIALS CO LTD

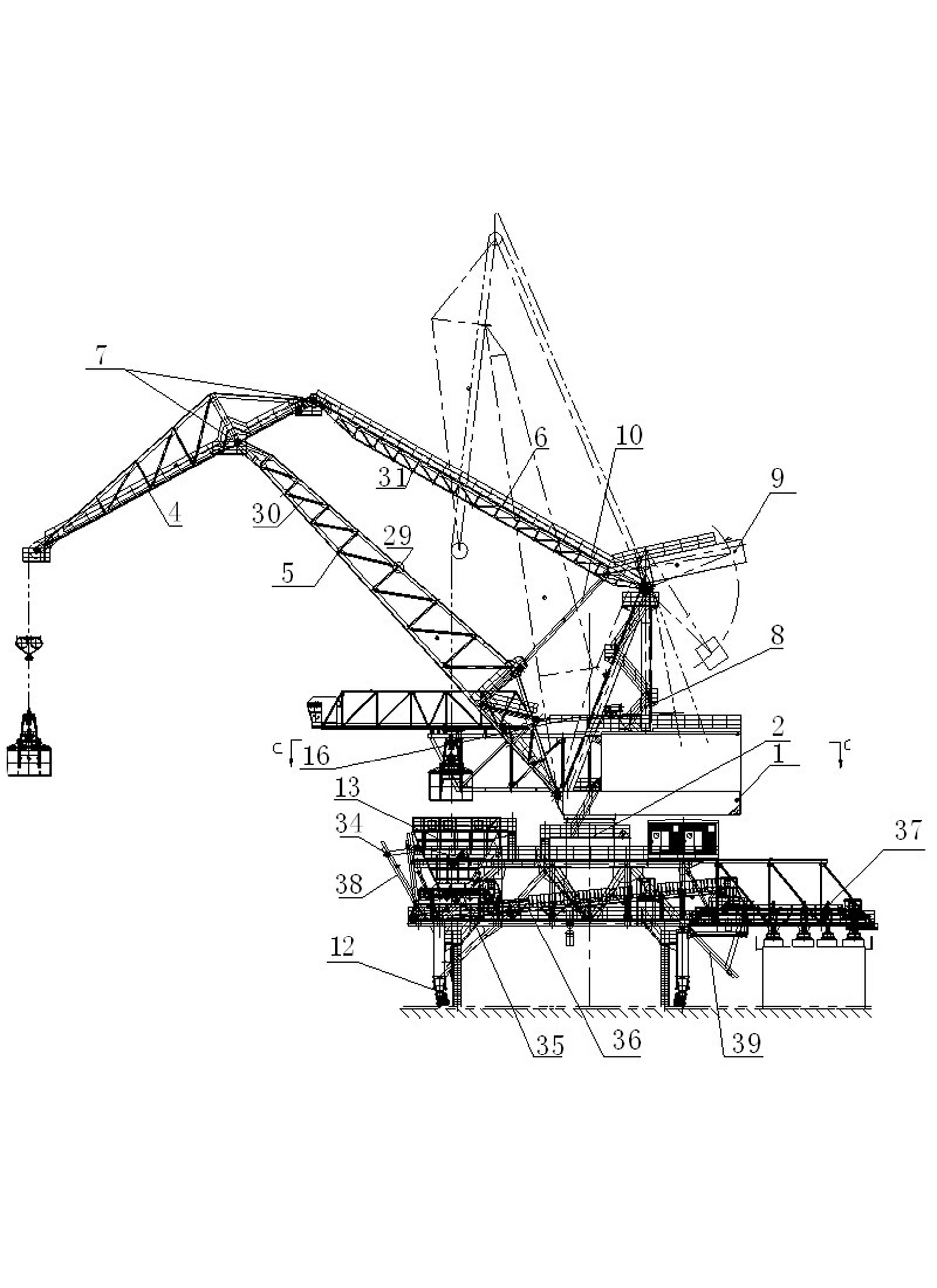

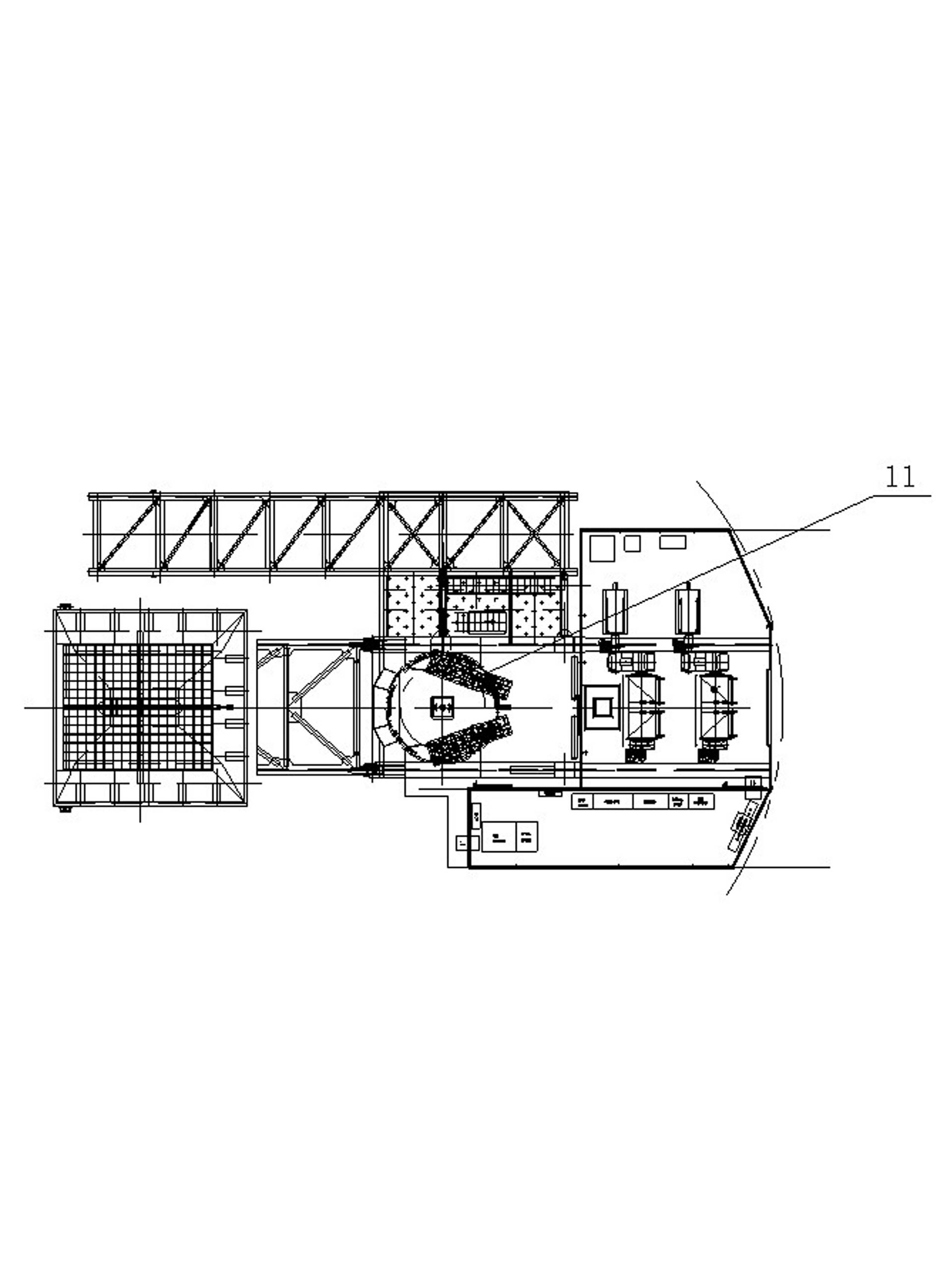

Horizontal luffing grab portal crane

InactiveCN102229412AImprove transmission efficiencyHigh transmission efficiency and high telescoping speedCranesNumerical controlGusset plate

The invention relates to a horizontal luffing grab portal crane, including a four-bar linkage level luffing boom system, a travelling mechanism and a gantry structure. The crane is characterized in that: a luffing mechanism comprises a triple screw, a screw pedestal and an electric transmission mechanism. The outside of the triple screw is provided with a telescopic cover, the inside of the screw pedestal is equipped with a sleeve with nuts, and two ends outside the sleeve are provided with bearings in the screw pedestal. The electric transmission mechanism comprises a motor, a driving gear and a brake apparatus. The end of the triple screw is hinged to a boom, and the luffing mechanism is equipped with a speed adjustable control system. The four-bar linkage boom system and a gantry beam are both girder construction which employs a T-shaped structure and a rectangular pipe. The T-shaped structure is a main chord member, and the rectangular pipe as a web member is welded on a web member gusset plate. In the blanking process, the T-shaped structure and the web member gusset plate are integrated through numerical control cutting. The crane of the invention has high operating cycle frequency which can reach 6 million times, high luffing speed, smooth running of grab bucket, high operating efficiency and long service life.

Owner:江苏海隆重机有限公司

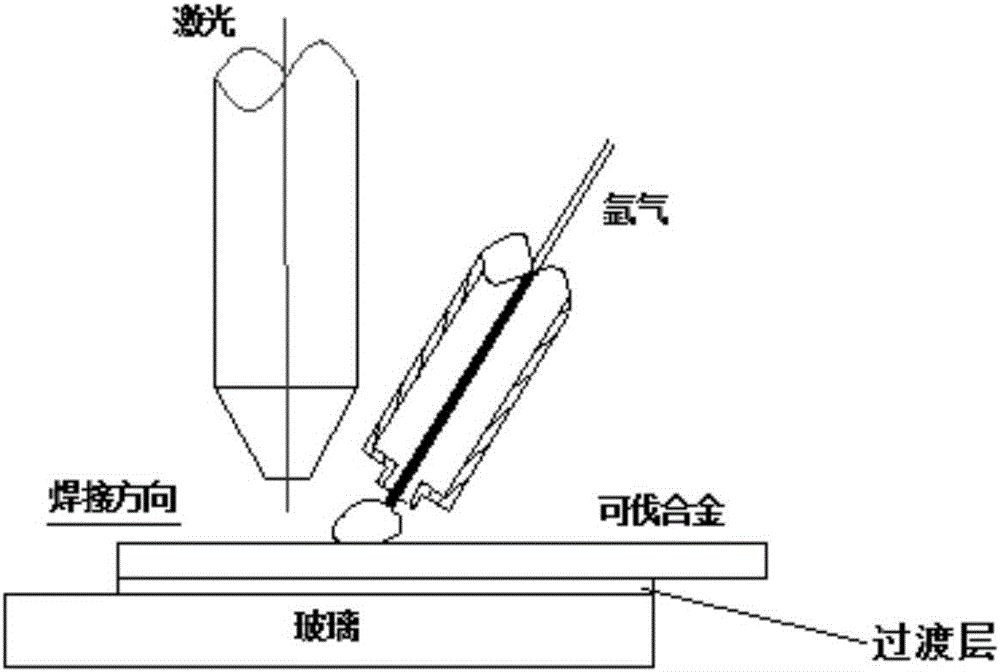

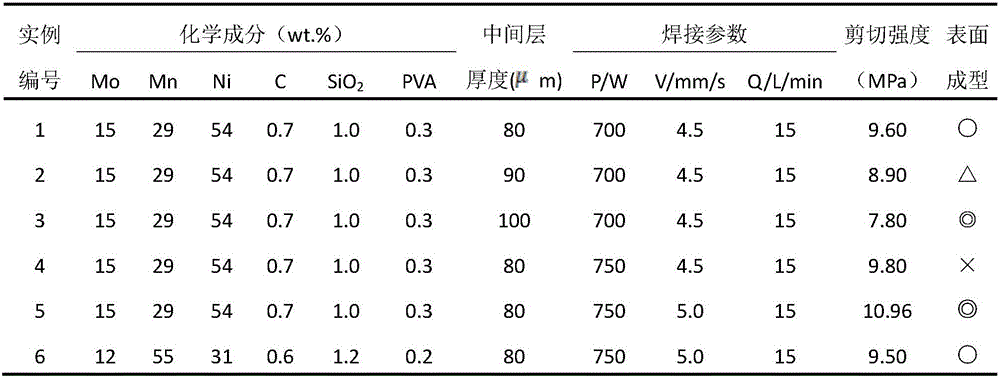

Laser welding method for connecting molybdenum-group glass/kovar alloy by adding Mo-Mn-Ni metal interlayer

The invention relates to a laser welding method for connecting molybdenum-group glass / kovar alloy by adding a Mo-Mn-Ni metal interlayer, and belongs to the technical field of connection of non-metal and metal materials. The method comprises the following steps: cleaning glass, removing a surface oxidation film from kovar alloy, and performing degreasing and deoiling treatment; preparing an oxidation film on the kovar alloy in an oxidizing furnace; preparing a Mo-Mn-Ni interlayer metal powder layer through a tabletting machine; arranging the glass at the bottom layer, the Mo-Mn-Ni interlayer metal powder at the middle layer and the kovar alloy at the top layer to form a sandwich welded structure, enabling the three to be in close contact, putting into a furnace, and preheating; radiating a laser beam onto the surface of the kovar alloy to perform laser welding; and after the welding is finished, quickly transferring the weldment into the heating furnace, performing stress-relief annealing, and cooling to room temperature in the furnace. The method provided by the invention promotes interface wetting, reduces postwelding stress, improves joint strength, lowers production cost and prolongs product service life.

Owner:BEIJING UNIV OF TECH

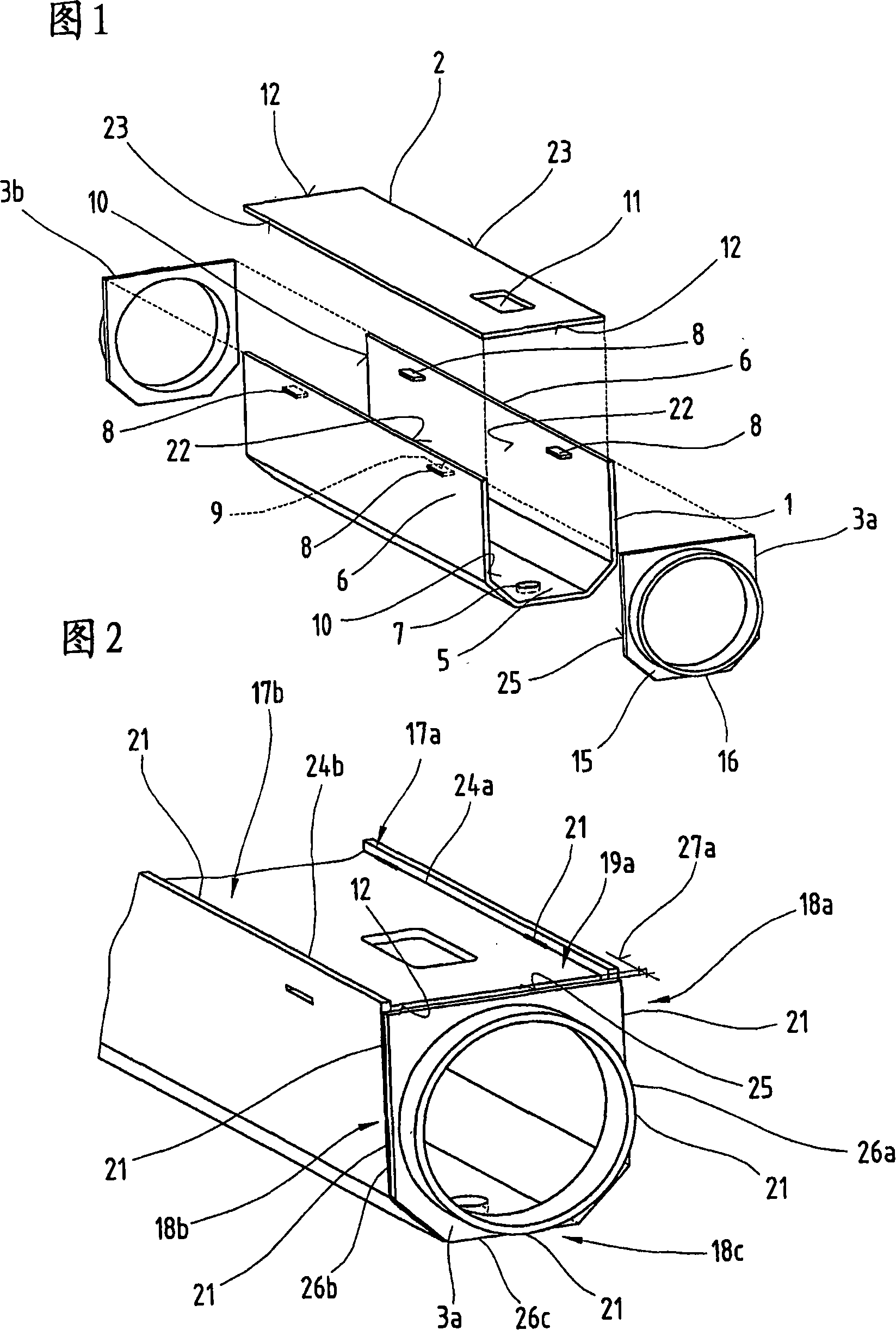

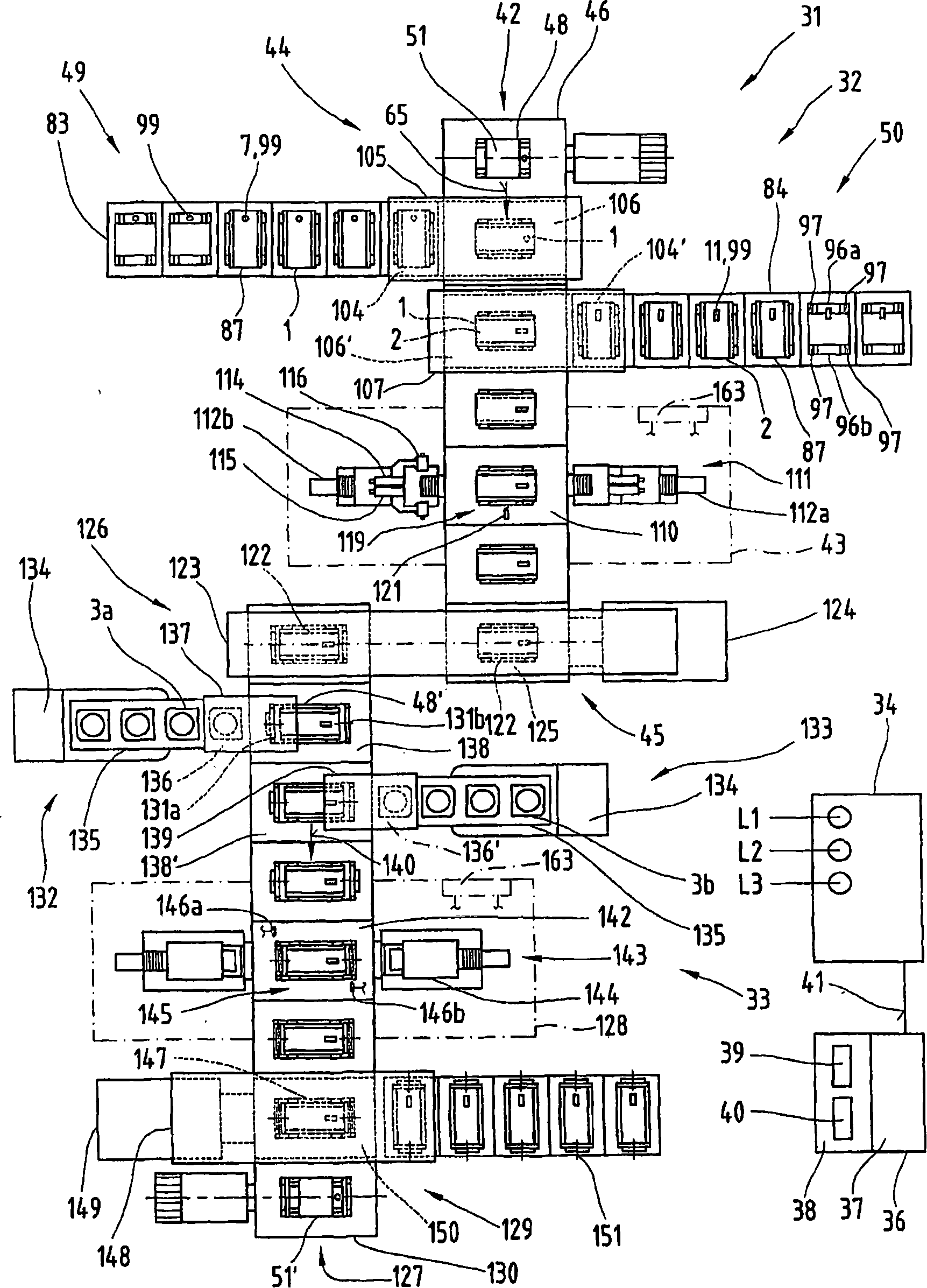

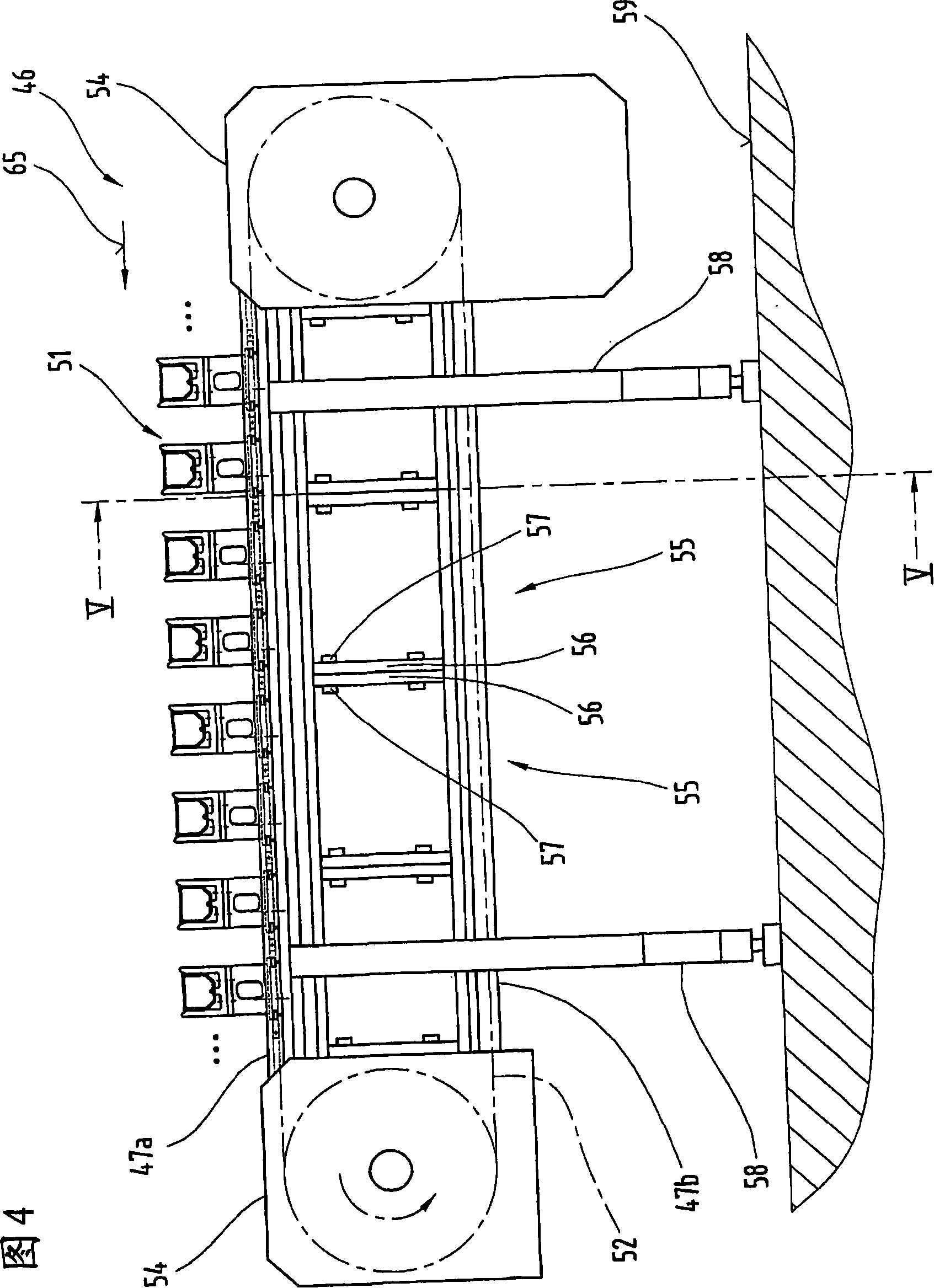

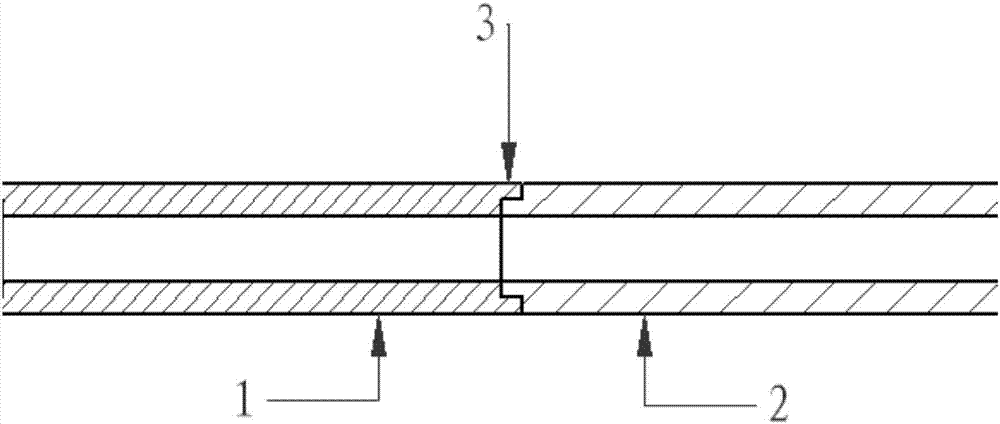

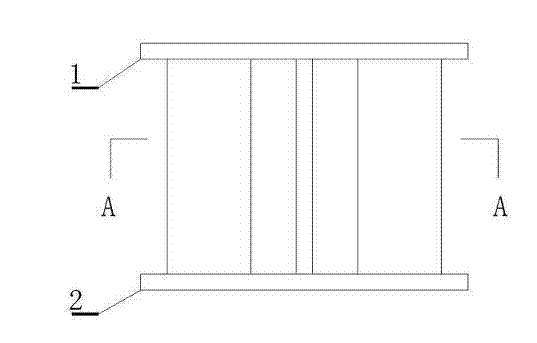

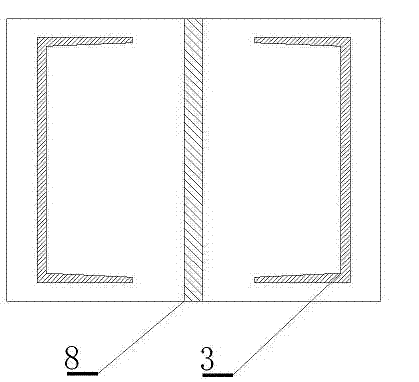

Installation for producing and method for assembling parts

InactiveCN101163567ATakt time optimizationEasy to controlConveyorsWelding/cutting auxillary devicesLocation EquipmentSupport surface

The invention concerns a method and an installation for producing a component consisting of several assembled parts. The first part (1) and the second part (2) are taken from a part delivery site proximate the conveying device and set in mutually oriented position on part conveying supports of the conveying device then conveyed with the part conveying supports to an assembling station. The part conveying device is maintained in a retaining position in the assembling station, the mutually oriented parts (1, 2) are moved by means of a heightwise positioning device (200a, 200b) and simultaneously moved from a conveying position on the part conveying support to a delivering position. Then the parts are positioned relative to each other, fixed and finally assembled to form the component. The assembled component is then set on a part conveying support and carried with said support. The part conveying supports comprise a housing exclusively provided with positioning means for holding a part (1) during its transport and, in the advancing direction of this positioning means, spaced apart supporting lateral guiding surfaces as well as support surfaces for one part (1) resting on the preceding surfaces.

Owner:STIWA HLDG

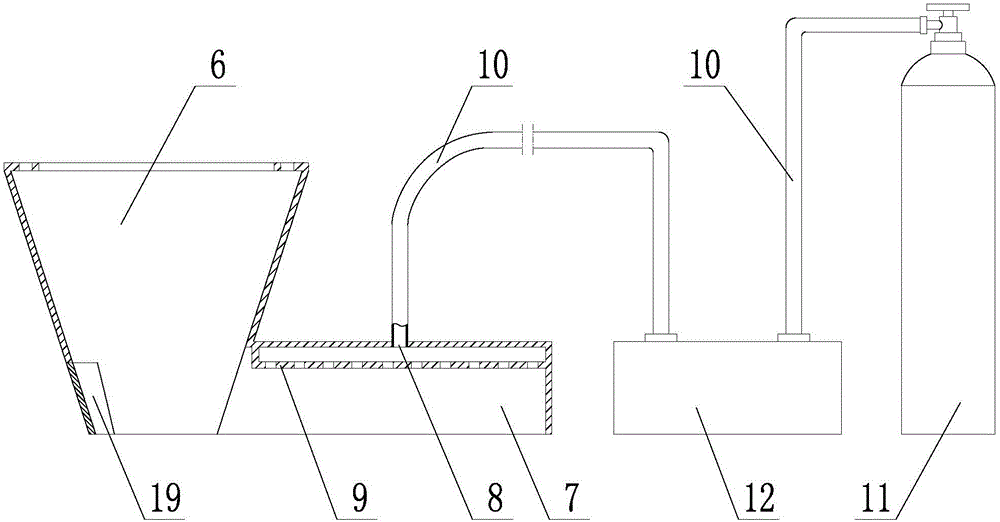

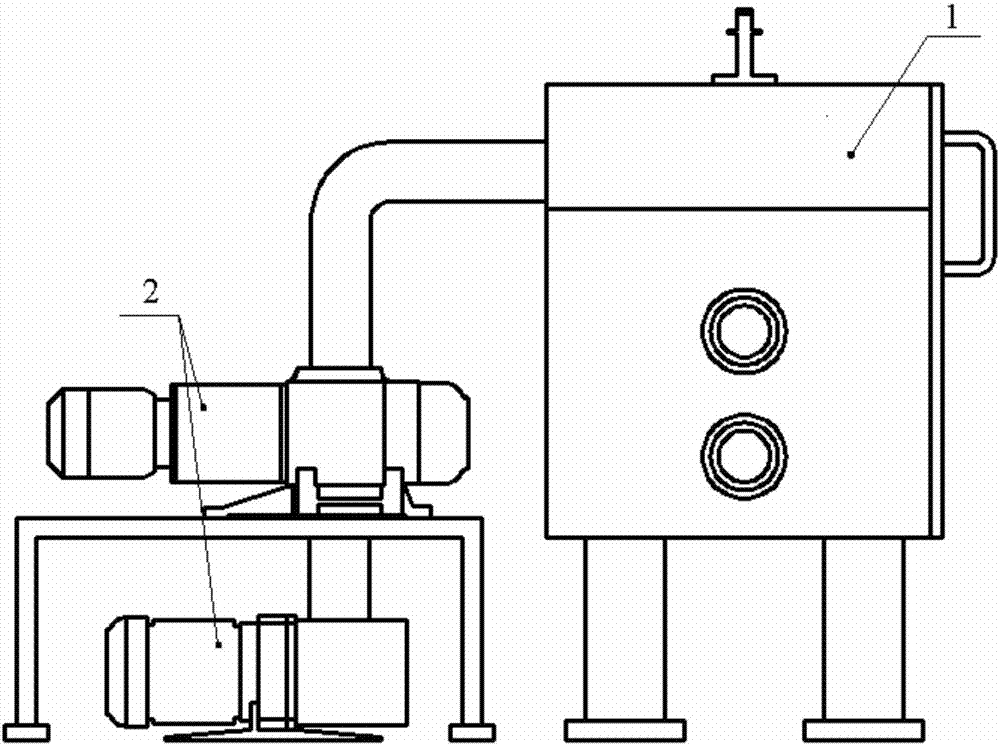

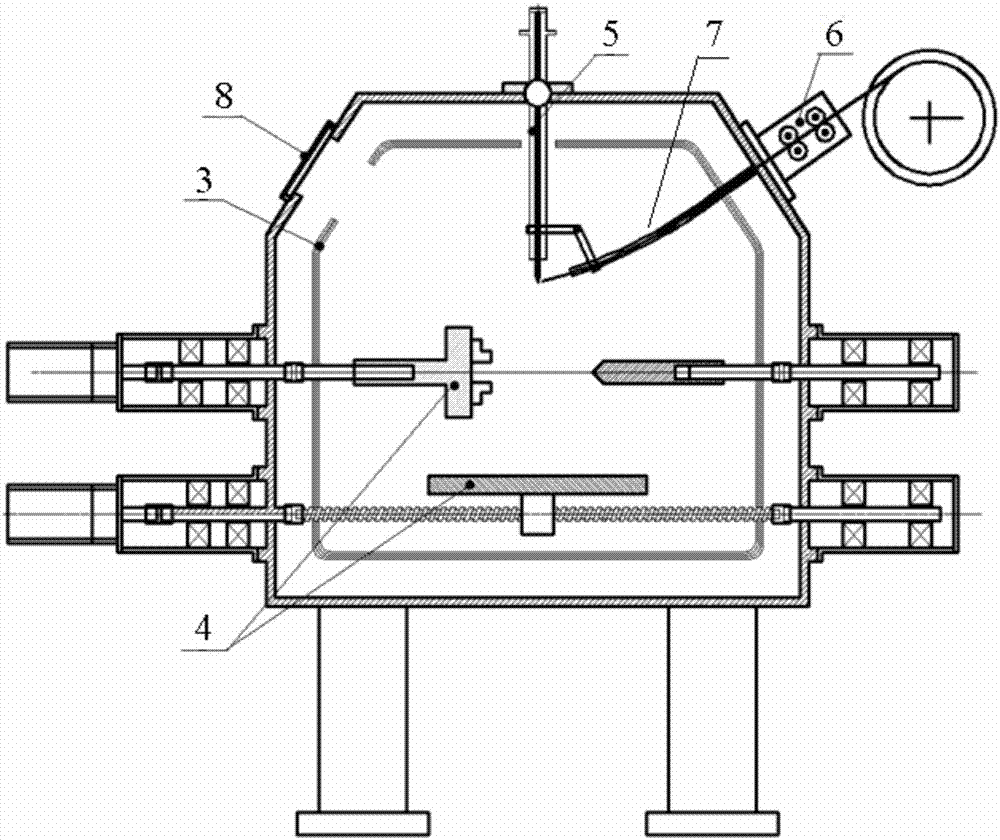

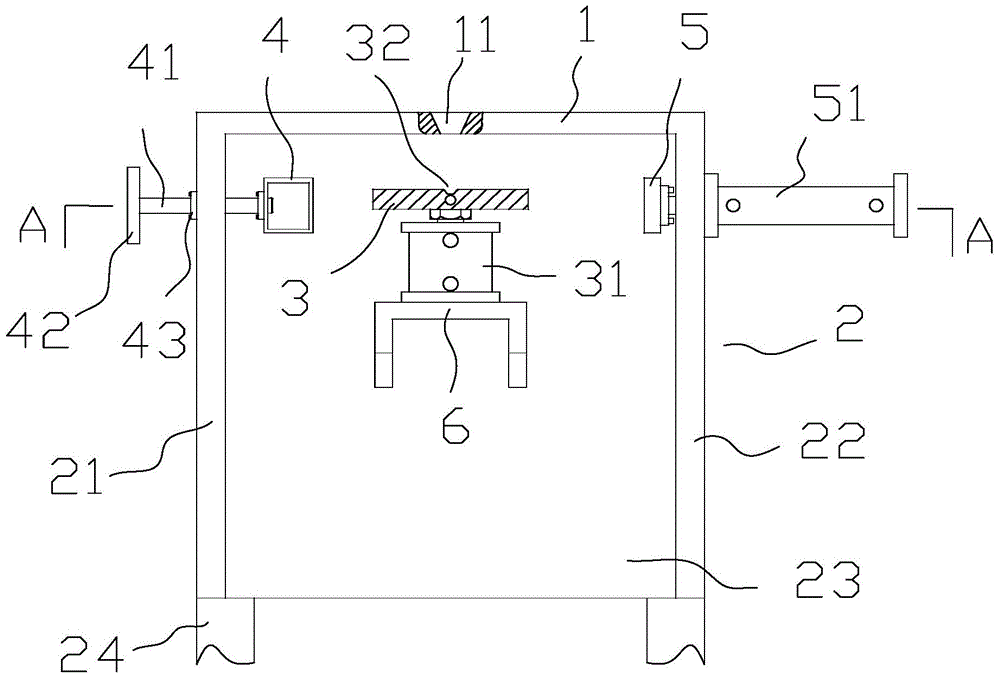

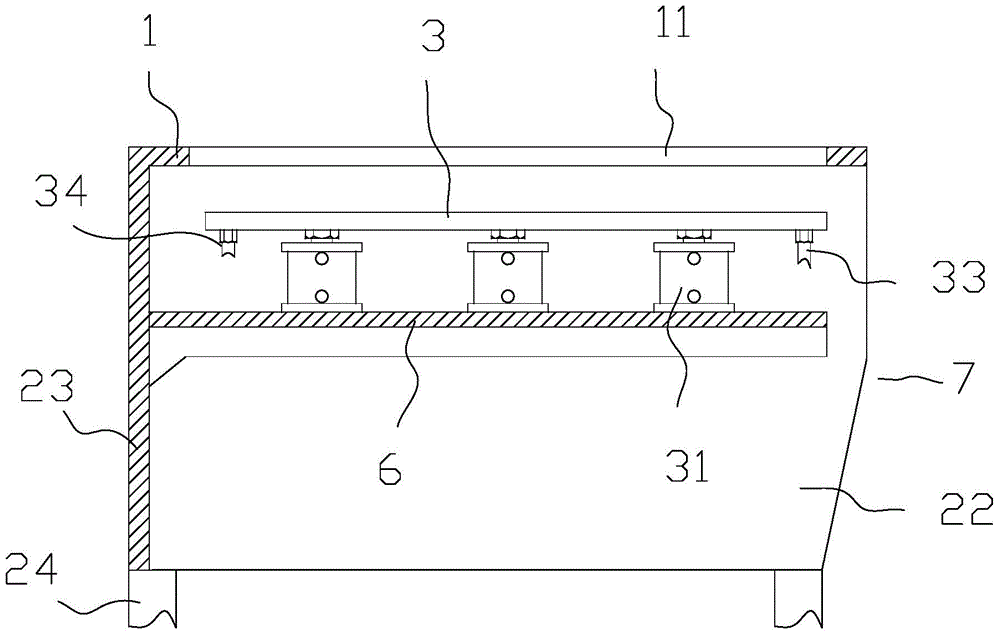

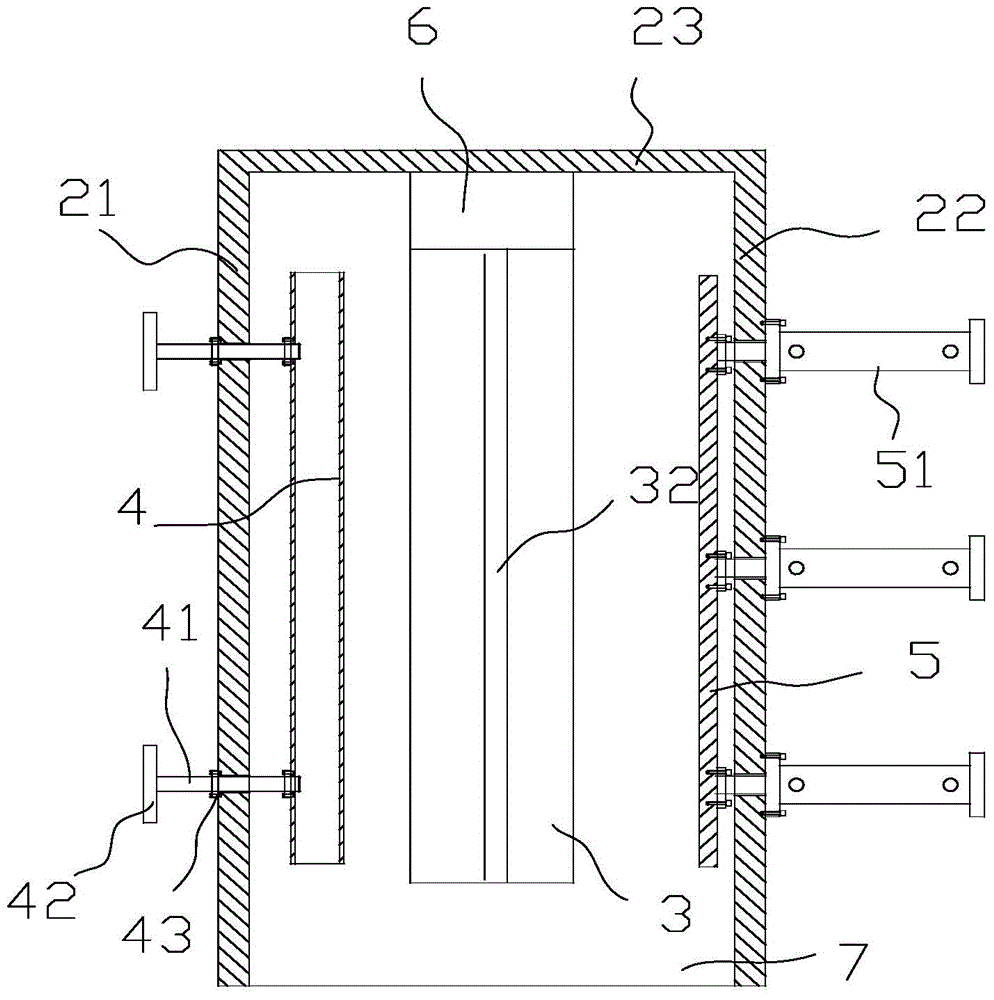

Combined heat source welding method and device in vacuum/ in protective atmosphere

ActiveCN106903398AEasy control of thermal cyclingReduce welding stressWelding accessoriesNumerical controlWelding power supply

The invention discloses a combined heat source welding method and device in vacuum / in a protective atmosphere. The combined heat source welding method in vacuum / in the protective atmosphere comprises the steps that in vacuum / in the protective atmosphere, a heating furnace used as a basic heat source conducts overall heating on a welded piece to heat the welded piece to the high temperature of 600-1200 DEG C, and the temperature is kept; then, a welding gun used as a local heating heat source is used for heating and melting the area to be welded, and a weld joint is formed after cooling and solidification; the welded piece is cooled to the indoor temperature at a set cooling speed under the action of the basic heat source, and then the welding process is completed. The combined heat source welding device in vacuum / in the protective atmosphere is composed of a vacuum pump group, the furnace, a heating chamber, a welding power source, a basic heating power source, a control cabinet, a high-temperature-resistant numerical control moving mechanism, the welding gun and a wire feeding mechanism. By the adoption of the combined heat source welding method in vacuum / in the protective atmosphere, welding cracks of low-plasticity metal materials at the indoor temperature can be effectively avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for conducting laser modification welding on titanium alloy weld joint through wave absorbing coating

ActiveCN105397337AEffective control of undercut defectsReduce welding stressWelding/cutting media/materialsWelding/soldering/cutting articlesTitanium alloyLaser

The invention provides a method for conducting laser modification welding on a titanium alloy weld joint through a wave absorbing coating. The method includes the steps that firstly, the weld joint is preprocessed; secondly, the weld joint is coated with the wave absorbing coating; thirdly, the weld joint is scanned through a defocusing laser spot, and the laser modification welding operation conducted on titanium alloy is completed, wherein the wave absorbing coating is prepared from, by mass, 40-70% of NaF2, 10-20% of Y2O3, 10-20% of Cr2O3 and 10-20% of La2O3. By means of the technical scheme, the undercut defects on the surface of the titanium alloy weld joint can be effectively eliminated, and residual stress of welding can be remarkably reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Method for welding Q420 steel for power grid iron tower

ActiveCN101913017AReduce splashBeautiful shapeWorkpiece edge portionsWelding accessoriesSheet steelButt joint

The invention discloses a method for welding Q420 steel for a power grid iron tower, which is used for welding Q420 steel plates with the thickness of 12mm or 16mm and is suitable for two joint forms of a butt joint and a full penetration weld T-shaped joint. The process comprises the following steps of: welding by adopting a mixed gas arc welding process of 80% Ar plus 20% CO2 semiautomatic solidwire; by adopting a multi-layer welding method, welding a first layer in a horizontal welding position and welding other layers in a downward welding position after the back chipping, wherein the butt joint uses asymmetric K-shaped grooves, and groove angles at both sides of the butt joint are 45-50 degrees and 58-62 degrees respectively, the width of truncated edge of the groove is 0-3mm ,and the welding interface-gap is 0-3mm. In the invention, the welding process is optimally designed by aiming at the peculiarity of the Q420 steel for the power grid iron tower. The whole process saves time, labor and energy, and various test parameters of the welding joints all exceed national standards, thereby providing the technical support for the power grid iron tower production and construction.

Owner:STATE GRID CORP OF CHINA +1

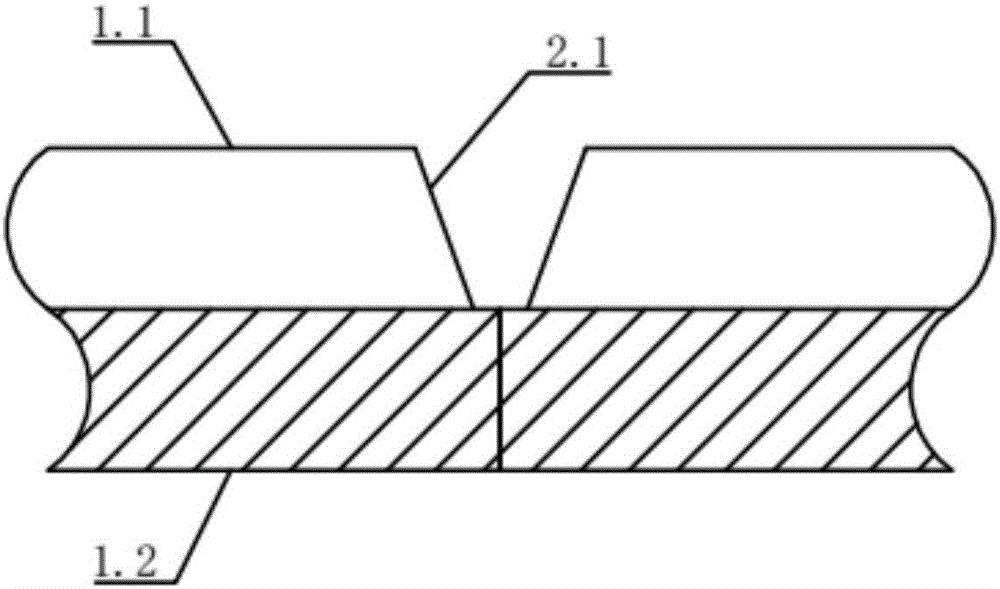

One-sided welding double-sided molding welding method for titanium steel composite pipe

ActiveCN106425104AGood for fusion transitionLow costWelding/cutting media/materialsWelding/soldering/cutting articlesAlloyTitanium

The invention provides a one-sided welding double-sided molding welding method which is suitable for welding a titanium steel composite pipe. The one-sided welding double-sided molding welding method aims at solving the problems that in existing titanium steel composite pipe welding, operation of the welding process is complicated, the accumulated heat input is large, it is necessary to prepare special welding consumables, and the welding efficiency is low. The one-sided welding double-sided molding welding method for the titanium steel composite pipe comprises the following steps that (1), a flat bottom groove with a blunt edge is machined at the pipe end of the titanium steel composite pipe to be welded; (2), a welding area is cleaned; (3), a titanium alloy layer of the titanium steel composite pipe is welded through a laser welding method; (4), acetone is used as a binder so that evenly-mixed transition layer metal powder can be made into paste, the groove bottom is evenly welded, pressing is conducted, and drying is conducted; and (5), transition layer metal is molten through laser energy, the transition layer is formed firstly, and then filling of the steel metal layer is conducted through electric arc welding. By the adoption of the method, one-sided welding double-sided molding welding of the titanium steel composite pipe is achieved, and the welding quality of the titanium steel composite pipe is improved.

Owner:SOUTHWEST JIAOTONG UNIV

Q460C steel welding process

InactiveCN104708170AAvoid it happening againLarge grainArc welding apparatusWelding/soldering/cutting articlesEngineeringPipe welding

The invention relates to a Q460C steel welding process. Argon / carbon dioxide refined mixed gas shielded welding serves as bottom welding, and argon / carbon dioxide mixed gas shielded welding serves as filling cosmetic welding. By the adoption of the Q460C steel welding process, a quenched structure can be prevented from being produced during steel pipe welding, structural grains can be prevented from being too large, welding stress can be reduced, and welding deformation can be decreased.

Owner:JIANGSU HONGGUANG STEEL POLE

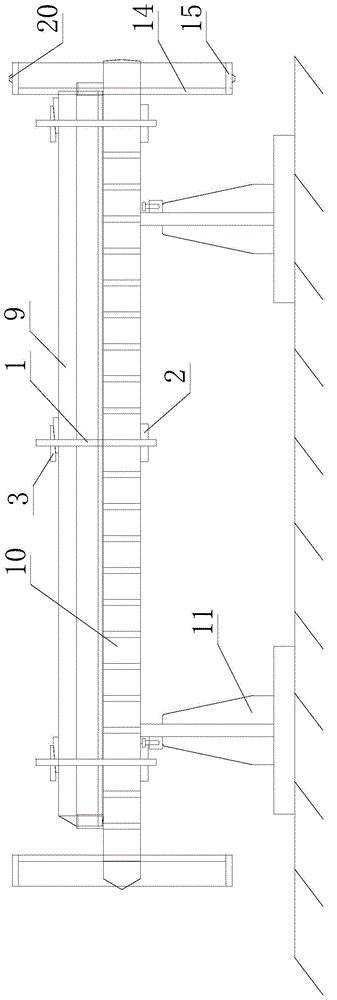

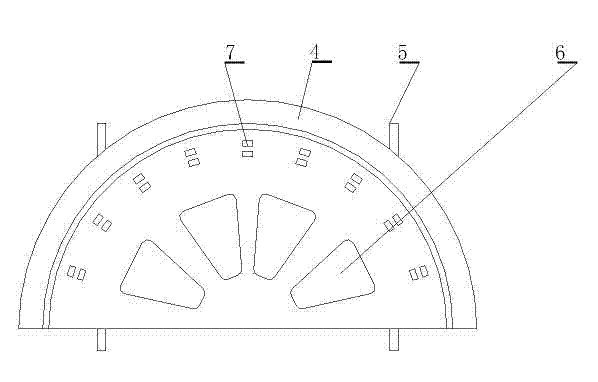

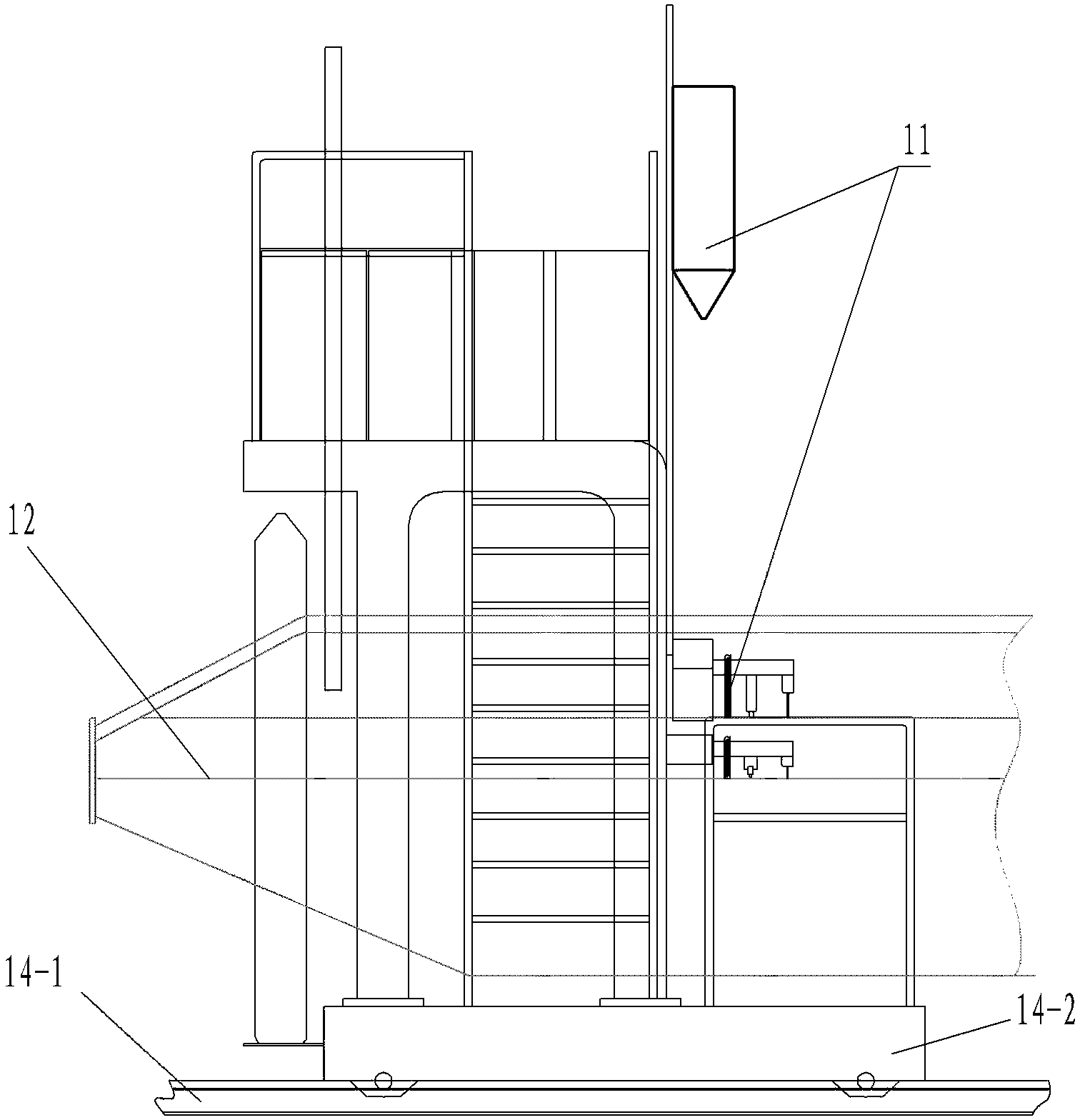

Process method for assembling and welding pile leg of ocean platform

InactiveCN105057857AWelding quality is easy to controlDimensional accuracy is easy to controlArc welding apparatusProduction lineEngineering

The invention discloses a process method for assembling and welding a pile leg of an ocean platform. According to the method, the production speed is high, and the percent of pass of products is high. A pile leg assembly is composed of a rack and two semicircular pipes. Coming cargo examination should be carried out on the rack and the semicircular pipes carefully, and the rack and the semicircular pipes are installed through a tool. The rack is turned over through a turnover device. The assembled pile leg examined to be qualified is lifted to an electric heating furnace stage trolley, conveyed into a furnace and heated, wherein the temperature ranges from 150 DEG C to 200 DEG C. The temperature in a hearth should be kept even. The heated pile leg is placed on the ground. Two welding joints are in the horizontal state. Manual welding rods are used for backing welding. Welding is performed on the pile leg by four welding workers from the middle position. The two sides are simultaneously and symmetrically welded. After welding is finished, the pile leg is turned over and welded continuously. After the welding joints are backed for 1 to 2 layers, the pile leg is lifted to roller carriers on a submerged arc welding production line and then formally welded. The welded pile leg is conveyed into a thermal treatment furnace, the heating temperature ranges from 200 DEG C to 280 DEG C and maintained for 2 to 3 hours, and then the pile leg is delivered out of the thermal treatment furnace.

Owner:张家港润通海洋工程科技有限公司

GMAW-Ar welding method for Q420B steel plate

InactiveCN109352142AAvoid cold cracksReduce hardnessArc welding apparatusWelding/cutting media/materialsSheet steelSlag

The invention provides a GMAW-Ar welding method for a Q420B steel plate. The GMAW-Ar welding method for the Q420B steel plate comprises the following steps: S1: making asymmetric X-shaped grooves in specimens, S2: grinding the groove surface and the periphery of the grooves within 20 mm with a grinding wheel machine, S3: assembling the ground specimens, S4: position welding the assembled specimens, S5: preheating the specimens by a flame heating method before welding, S6: welding the bottom by adopting the GMAW-Ar method, S7: carrying out welding through the GMAW-Ar method, S8: cleaning root of a bottom welding pass by carbon arc air gouging, S9: controlling the interlayer temperature between 150 and 200 DEG C by the flame heating method, S10: cleaning up slag and spatter during welding, and S11: detecting flaw. The GMAW-Ar welding method for the Q420B steel plate can effectively control the cold crack and the laminar tearing tendency and improve the welding quality.

Owner:GUANGZHOU ZENGLI STEEL STRUCTURE

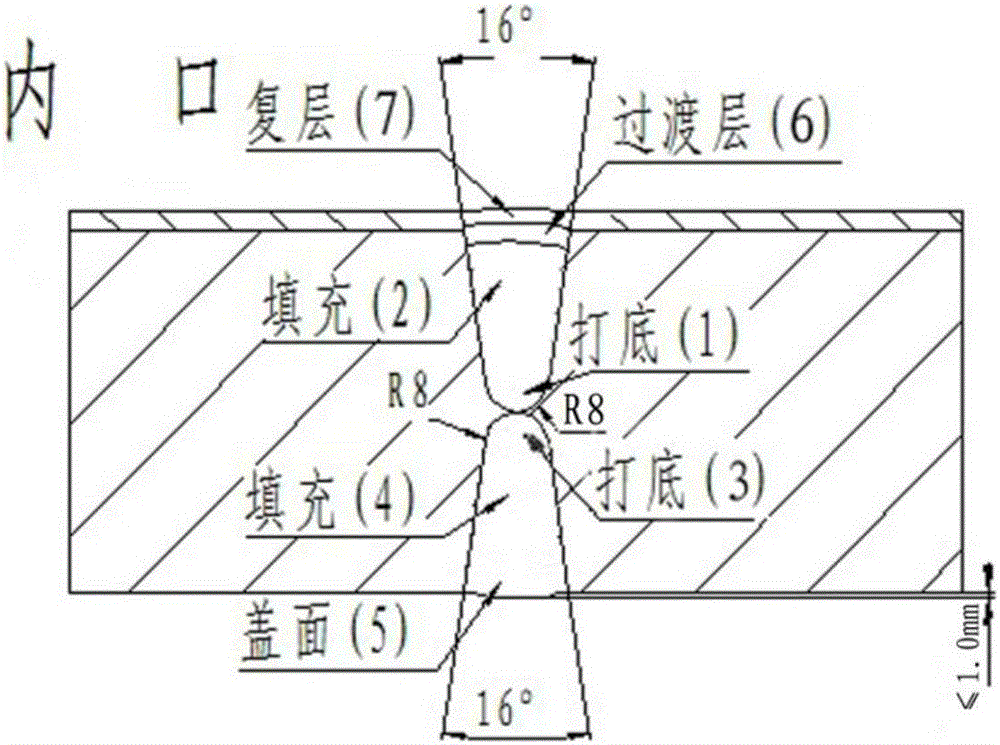

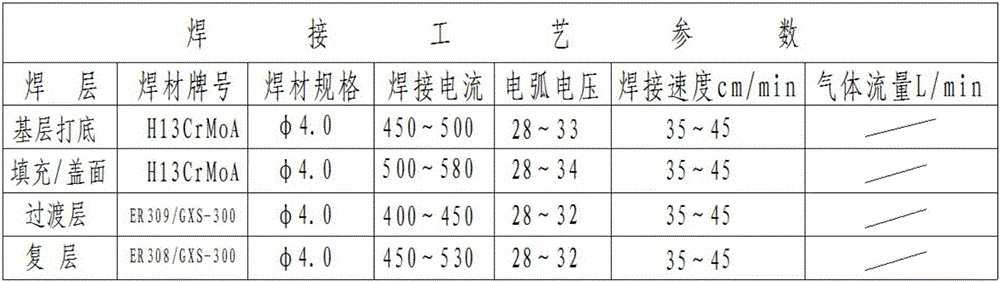

Automatic submerged arc welding method for pearlitic heat-resistant steel composite board

ActiveCN105665898AReduce fillingReduce the amount of weldingArc welding apparatusWelding/soldering/cutting articlesWeld seamEngineering

The invention discloses an automatic submerged arc welding method for a pearlitic heat-resistant steel composite board. The significant advantages are achieved by changing the welding method and the groove type and adjusting the welding sequence. The automatic submerged arc welding method has the significant advantages that by optimizing the groove type, the welding material filling quantity is reduced, and the welding efficiency is improved; a mechanical mode is adopted to conduct groove machining and welding seam back chipping, parent metal hardening caused by rapid heating and rapid cooling of thermal cutting or carbon arc air gouging is effectively avoided, and the rolling machining and welding quality of a barrel is improved; outer edge back chipping is conducted immediately after inner edge base layer welding is completed, welding stagnation and reheating in the middle can be effectively avoided, and the welding quality is guaranteed; transition layer welding is conducted immediately after base layer welding is completed, composited layer welding is conducted after crack detection is qualified, repeated preheating and transition layer welding which are conducted after nondestructive detection of previous base layer welding is completed and qualified can be effectively avoided, and the composited layer welding quality is improved.

Owner:LUXI IND EQUIP

Low-alloy steel pipe welding process

InactiveCN105983752AParameters are strictly and reasonably controlledProcess specificationArc welding apparatusNondestructive testingPipe welding

The invention discloses a low-alloy steel pipe welding process, characterized by comprising a welding process including the following steps: confirming a groove, clearing two sides of the groove, group seaming, tack welding, back welding, clearing welding splatters, fill welding in layers, cosmetically welding, clearing weld roots, cosmetically welding, clearing welding splatters, auto-checking appearance for qualification, stamping numbers and clearing, nondestructively detecting and clearing, repairing, and nondestructively detecting and clearing; the low-alloy steel pipe welding process of the invention enables strict and reasonable control for parameters of various process stages, the flow is standardized, welding stress and deformation are decreased, and therefore mechanical properties of a welded pipe are improved.

Owner:重庆金亚模具制造有限公司

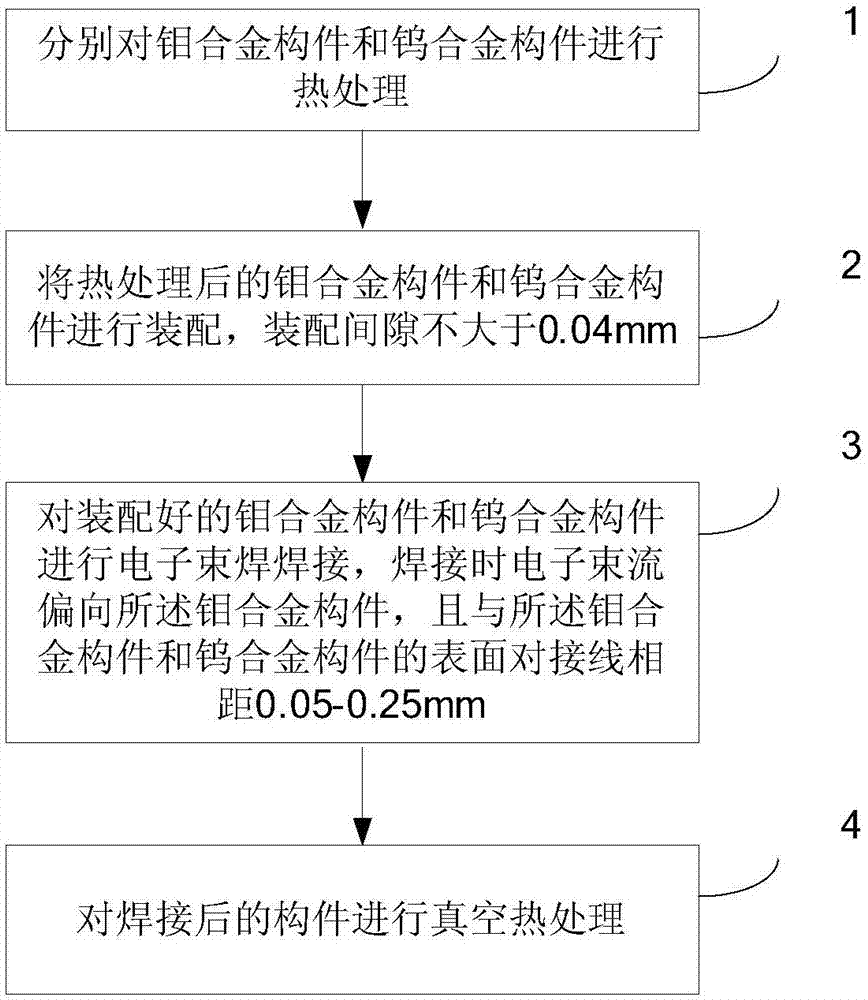

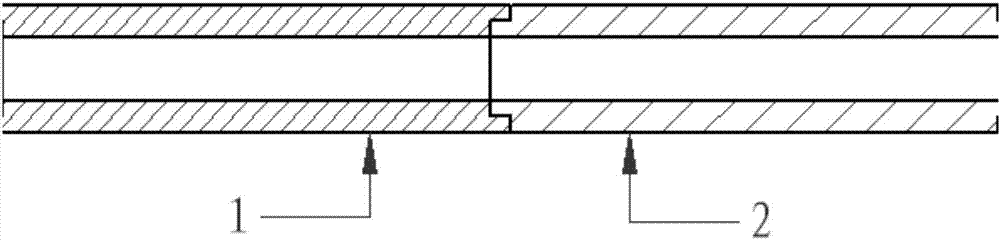

Electron beam welding method for molybdenum alloy and tungsten alloy

ActiveCN107186329AFast coolingWeld grain fineElectron beam welding apparatusWelding/soldering/cutting articlesMechanical propertyElectron

The invention relates to an electron beam welding method for a molybdenum alloy and a tungsten alloy, and belongs to the technical field of welding processes. The method comprises the following steps of: separately performing thermal treatment on a molybdenum alloy component and a tungsten alloy component, and assembling the molybdenum alloy component and the tungsten alloy component subjected to thermal treatment with an assembly gap not greater than 0.04 mm; performing electron beam welding on the assembled molybdenum alloy component and the assembled tungsten alloy component, deflecting electron beam current to the molybdenum alloy component during welding, and enabling distance between a surface butt-joint line of the molybdenum alloy component and a surface butt-joint line of the tungsten alloy component to be 0.05-0.25 mm; and performing vacuum thermal treatment on the welded components. The welding method provided by the invention is high in cooling speed, is small in welding seam crystalline grain, is relatively small in dimension of a second phase, is beneficial for improving welding seam performances, is good in welding seam surface forming, is relatively high in welding seam internal quality, is high in mechanical property, has welding seam strength greater than 250 MPa, is high in sealing performance, is small in welding seam width and is high in reliability.

Owner:BEIJING INST OF CONTROL ENG

Method for preventing deformation of large-size thin-wall annular casting during welding process

ActiveCN102528218ANo mouth opening/neck deformationNo distortionWelding accessoriesLarge sizeMaterials science

The invention relates to a method for preventing deformation during a welding process, in particular to a method for preventing the deformation of a large-size thin-wall annular casting during the welding process. The method is characterized in that the method comprises the following steps of: preparation before welding: preparing a shim plate used for supporting at least five points of the casting so as to ensure that the casting is padded flatly and cannot be deformed by external forces during the welding, and an anti-deformation welding tooling, and then fixing the casting on the tooling; pre-heating before welding; selection of parameters of the welding process; and control of the welding process. The method provided by the invention is unique; the quality of the casting can be ensured; the production cycle can be shortened; the working efficiency can be improved; and the production cost can be saved.

Owner:KOCEL STEEL

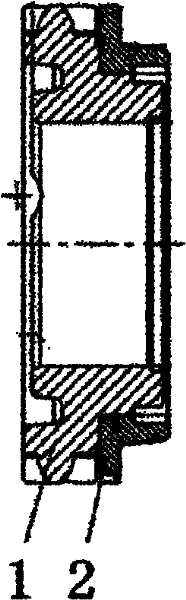

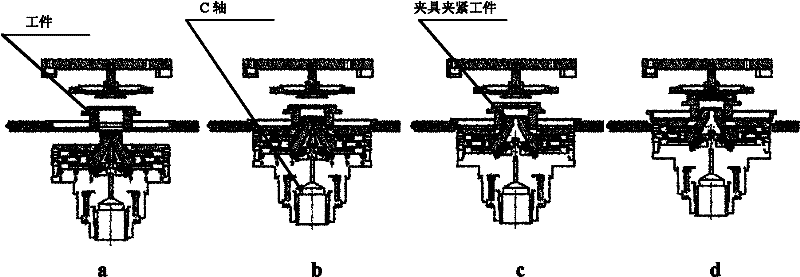

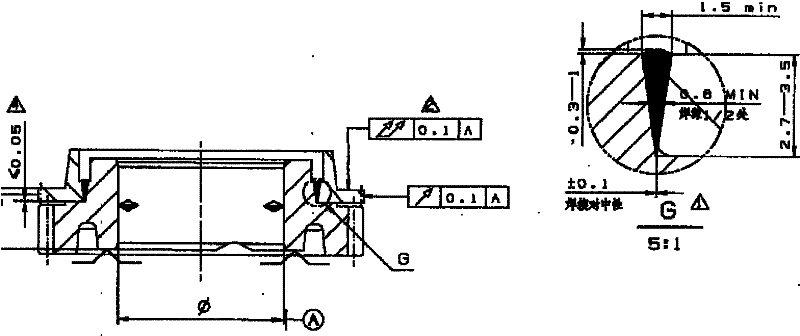

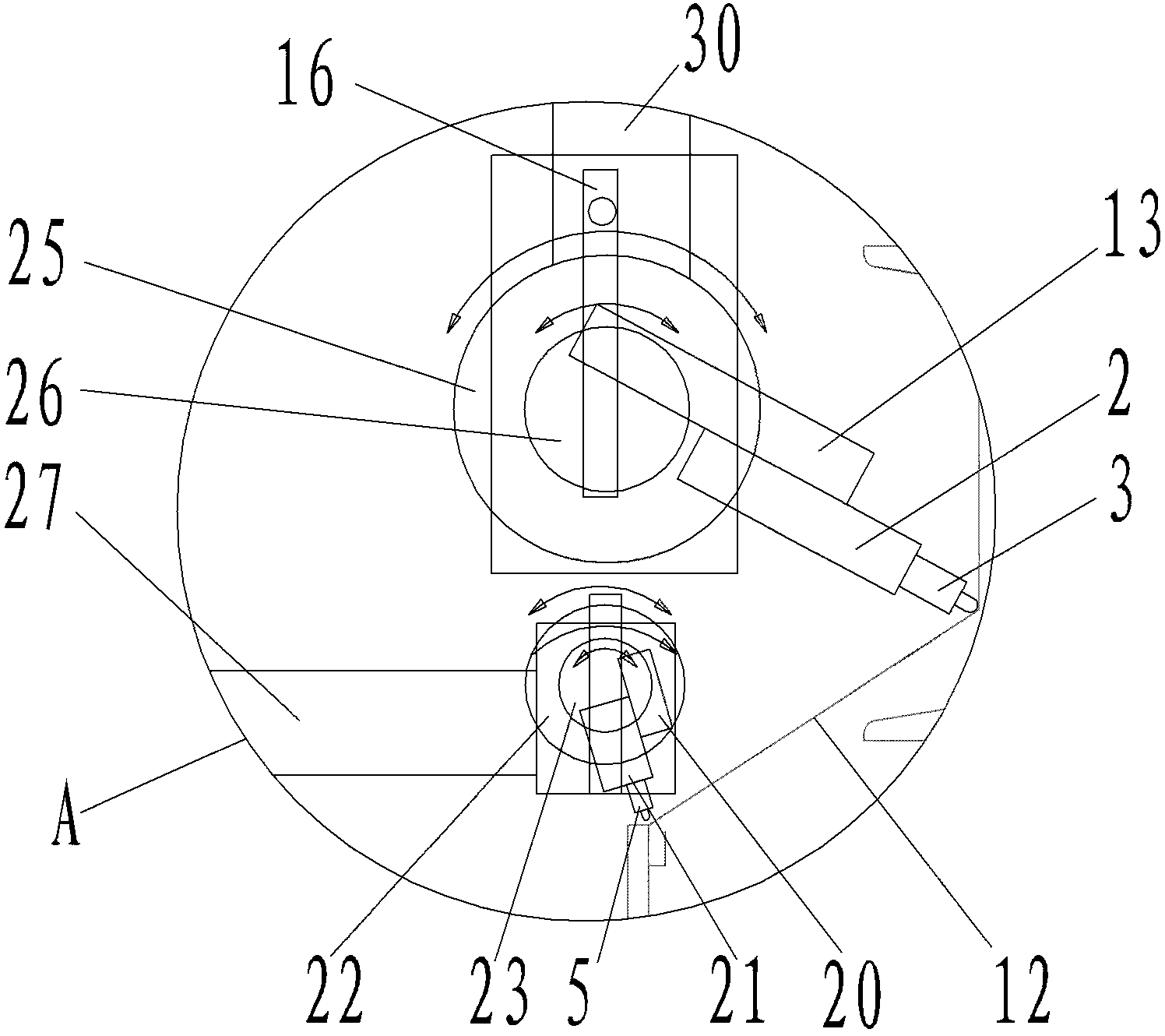

After-heating laser welding method for jointed gear ring and gear

ActiveCN102476241AReduce welding stressShallow weld depthLaser beam welding apparatusThrust bearingSpot welding

The invention relates to an after-heating laser welding method for a jointed gear ring and a gear and belongs to the technical field of a vehicle transmission. The after-heating laser welding method comprises the following steps: respectively preprocessing a jointed bevel gear and the gear; performing after-heating processing pressing and electromagnetic preheating treatment for a welding area; and lastly, placing the gear on a turntable, rotating the turntable for 180 degrees, jacking the gear out of a platform by a vertical shaft under the turntable, clamping the gear from an inner hole, pressing downward under the action of a reverse thrust bearing, and performing spot welding, pre-welding and deep fusion welding in turn according to an initial position for welding. According to the after-heating laser welding method, the problem that a gear assembly is subjected to welding deformation and crack generation during an after-heating laser welding processing process of the jointed bevel gear and the gear is solved, and a set of after-heating laser welding technical parameters suitable for bath production is formed.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

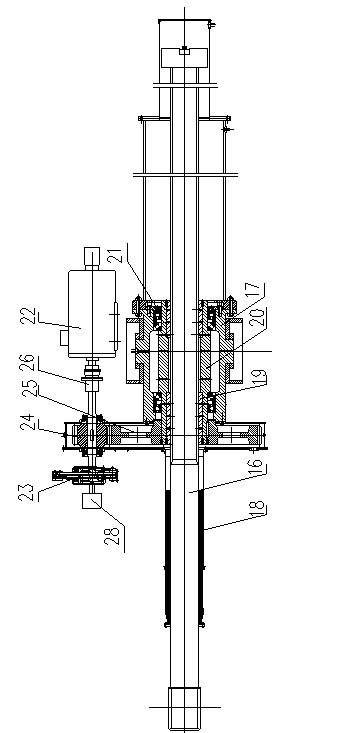

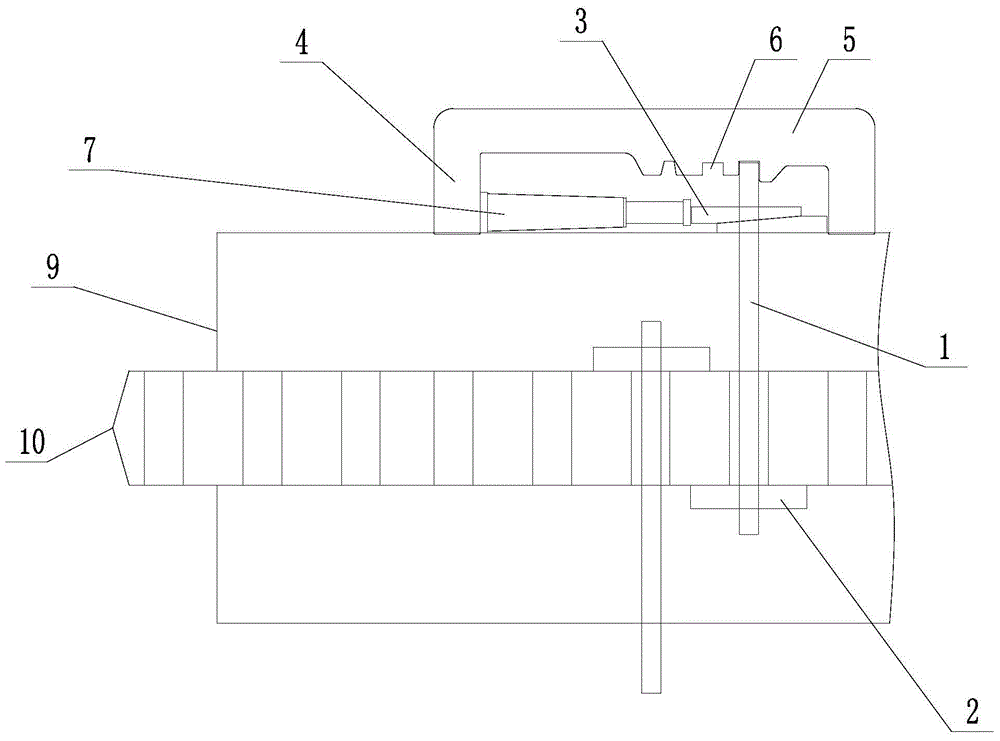

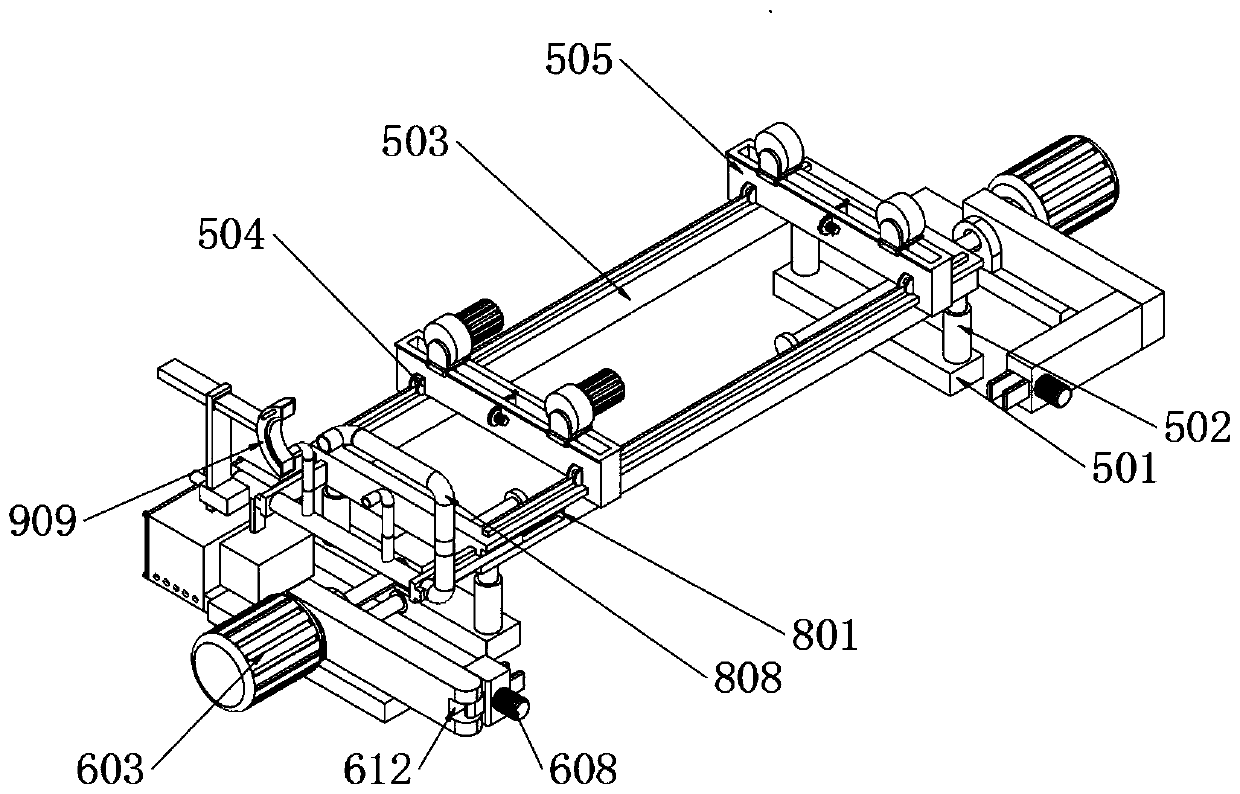

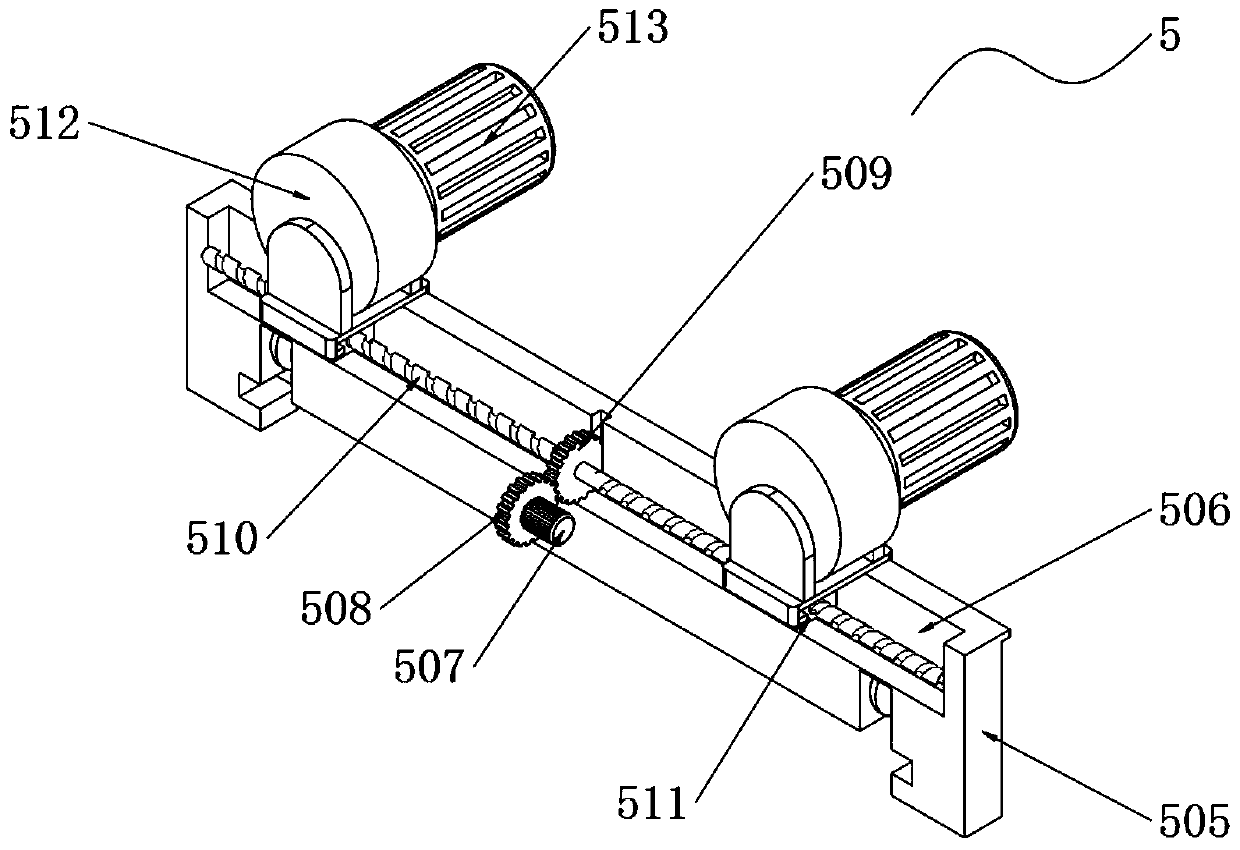

Crane main beam welding machine

InactiveCN102699497AReduce labor intensityReasonable welding distanceElectrode supporting devicesReciprocating motionWelding

The invention relates to a crane main beam welding machine. The crane main beam welding machine comprises a fixed mount, a movable frame which is arranged on the fixed mount along horizontal direction in a guiding manner, the crane main beam welding machine further comprises a movable frame driving device which is in transmission connection with the movable frame and drives the movable frame to do reciprocating motion along the horizontal direction, and the movable frame is provided with a welding fun which is used for conducting welding construction on a position to be welded of a crane main beam. The invention provides a crane main beam welding machine which can lighten the labor intensity of workers in welding and manufacturing of the crane main beam.

Owner:HENAN MINE CRANE

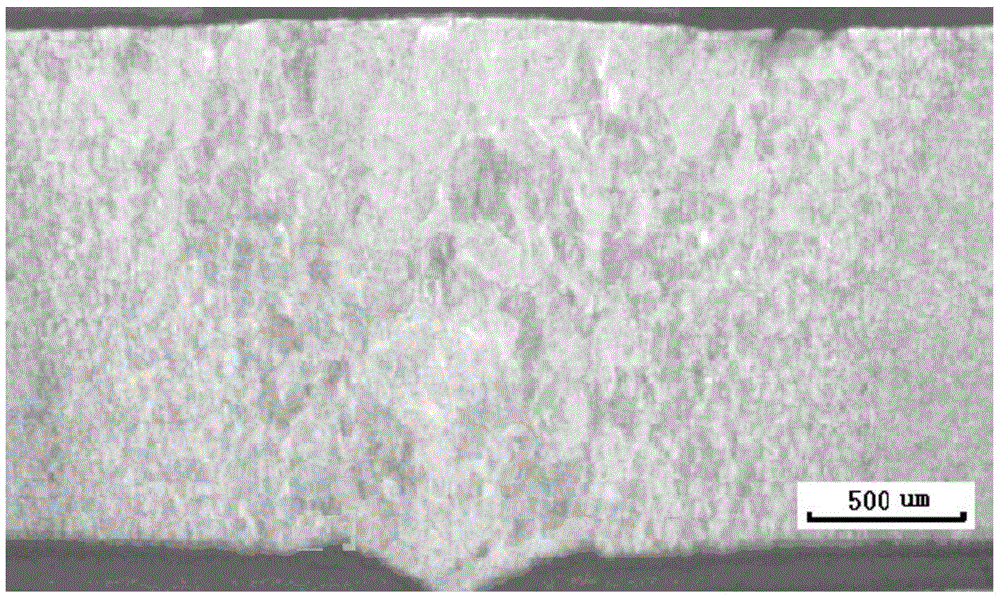

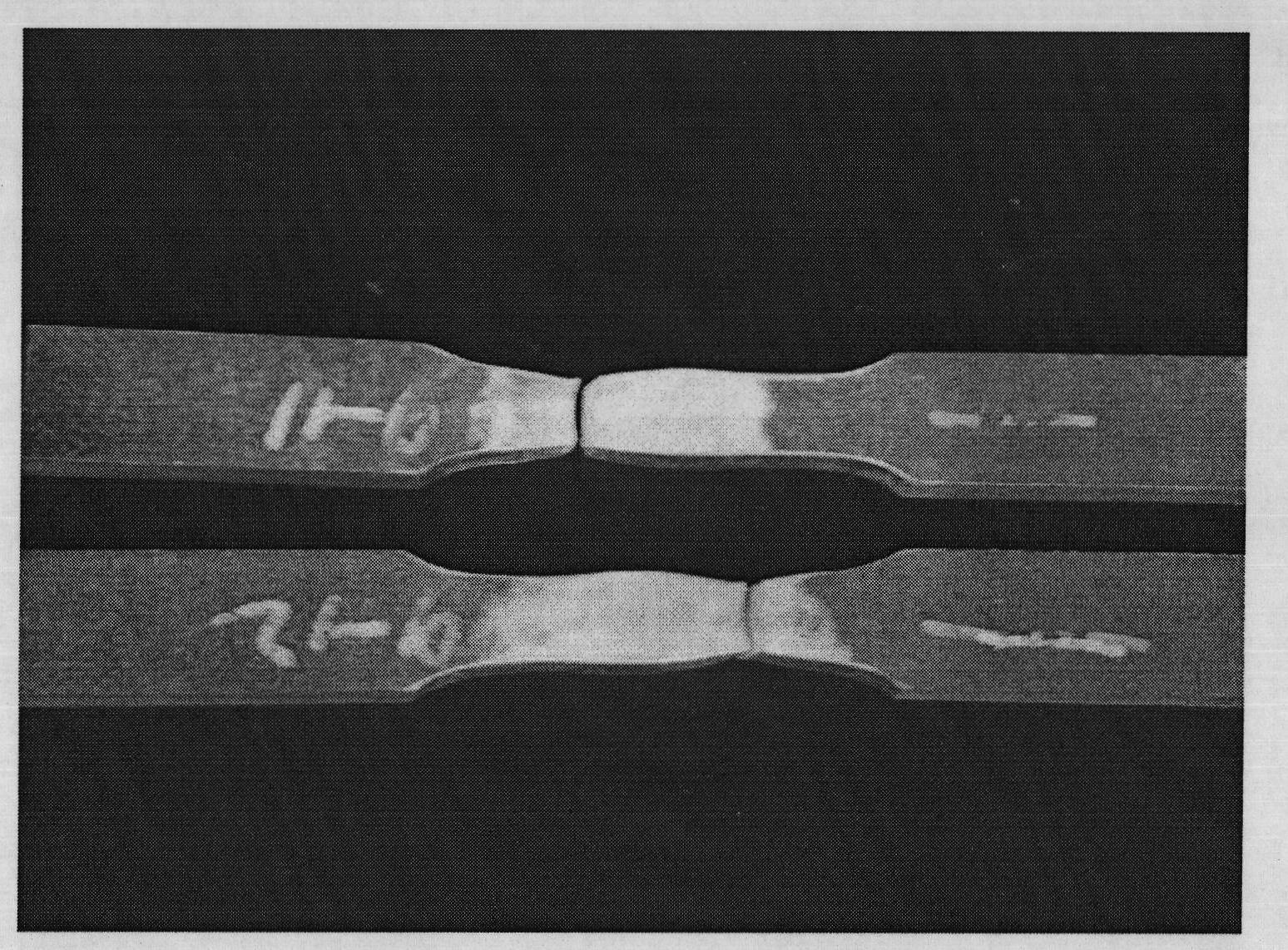

Magnesium alloy weld joint hot rolling strengthening process

ActiveCN103526142AHigh strengthHigh hardnessFurnace typesHeat treatment furnacesStress reliefUltimate tensile strength

The invention discloses a magnesium alloy weld joint hot rolling strengthening process, which comprises the following steps: 1) welding magnesium alloy pieces on both sides by adopting insert gas arc welding; 2) placing the magnesium alloy welding piece into a heat treatment furnace, and performing postwelding stress relief annealing at 200 to 350 DEG C for 0.5 to 2 hours; and 3) performing hot rolling on the surplus height of the weld joint of the magnesium alloy welding piece for at least two times until the weld joint is in level with a base body, wherein the magnesium alloy welding piece is heated to 350 to 400 DEG C before hot rolling at each time, heat preservation and preheating are performed for 10 minutes to 0.5 hour and hot rolling is performed at 250 to 350 DEG C. According to the process, the operation process is simple, the processing period is short, the weld joint strength is higher than the tensile strength of the base material, the tissue is refined, and the appearance of the welding piece is beautified. The process has a certain straightening effect on the magnesium alloy plate which is deformed after being welded, and is applicable to the complete-penetration magnesium alloy materials such as AZ31, AZ61 and AZ80.

Owner:CHONGQING UNIV

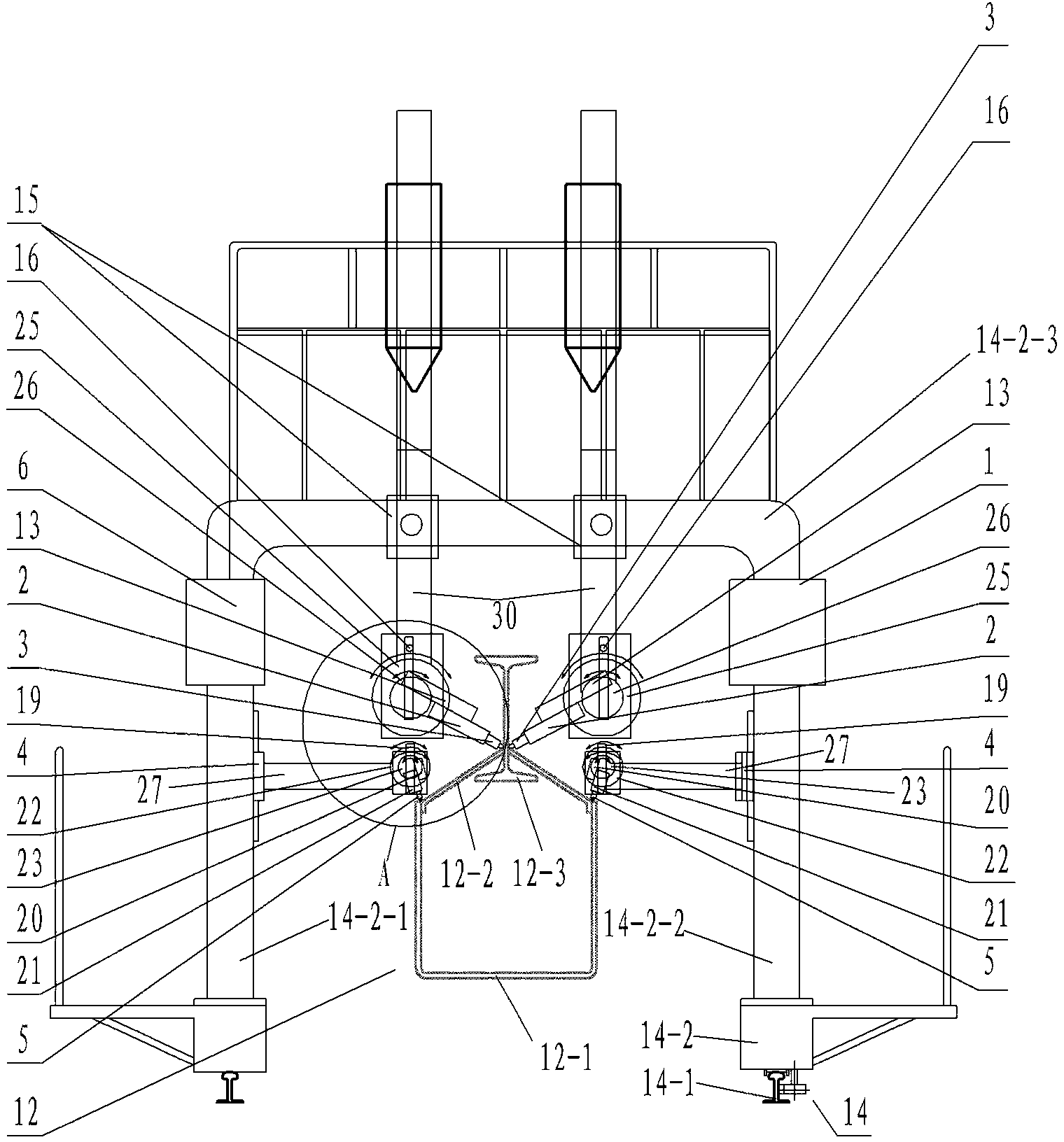

Seam welding device for locomotive capacitor square housing

ActiveCN103600194AEasy to fixPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Classical mechanics

The invention relates to a seam welding device for a locomotive capacitor square housing. The seam welding device comprises a welding platform, a rack, a suspension, a jacking plate, a positioning plate and a clamping plate. An elongated welding groove is arranged in the center of the welding platform. The rack is provided with an opening end for the capacitor housing entering and exiting. The suspension is arranged below the welding platform and parallel to the welding groove, and is located at the rack opening end in a suspended manner. The jacking plate is fixed at the upper end of the suspension through a jacking cylinder. The positioning plate is arranged on one side of the jacking plate and is fixed on the rack through a horizontal displacement adjusting device. The clamping plate is arranged on the other side of the jacking plate and is fixed on the rack through the jacking cylinder. The capacitor housing can be mounted and fixed conveniently, a center seam and the welding groove can be positioned accurately, the welding seam can be uniform and straight, welding slag can be discharged downwardly timely, welding stress is small, and welding quality is good.

Owner:ANHUI TONGFENG ELECTRONICS

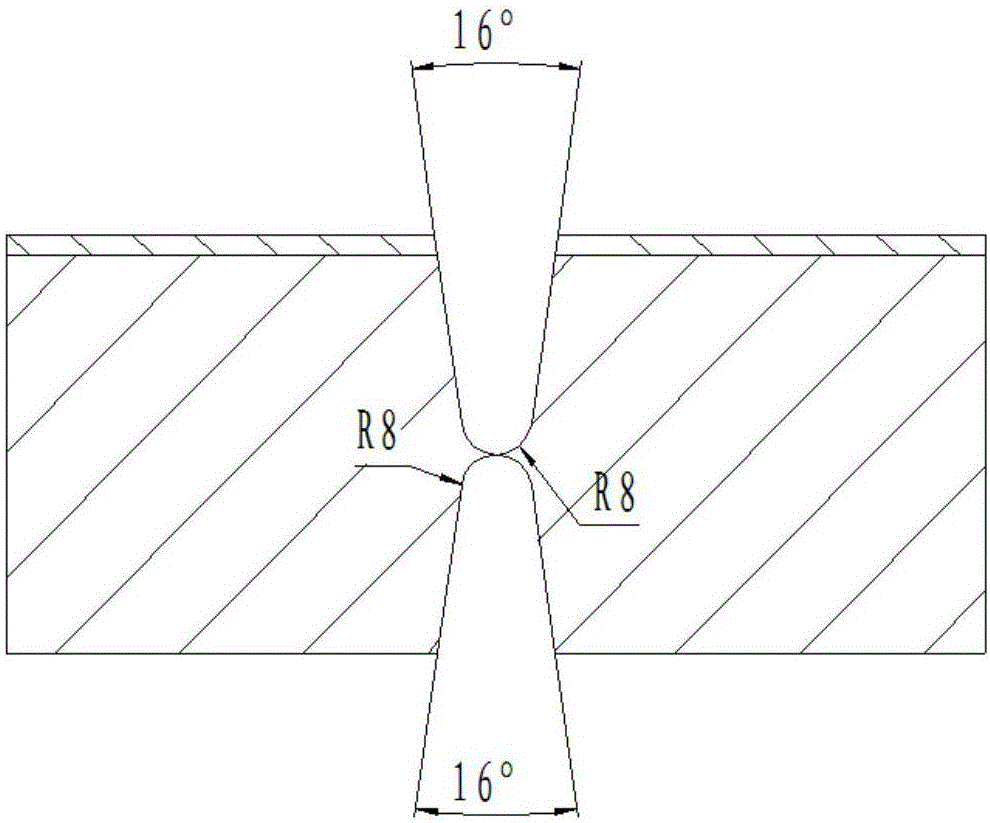

Welding method of super-thick steel casting

InactiveCN109108431AEliminate welding residual stressReduces the chance of weld cracksArc welding apparatusFurnace typesLayer removalWelding deformation

The invention discloses a welding method of a super-thick steel casting. Process steps include S1, preparing a joint: an asymmetric X-type groove is adopted; S2, preheating: the front side and the reverse side are uniformly heated, the preheating temperature is set within the range of 150-160 DEG C, and the heating rate does not exceed 100 DEG C / h; S3, back welding: gas shielded welding backingis carried out on flux-cored welding wires for three layers, and fire warming is carried out to remove stress after each weld seam is welded; S4, reverse side air gouging: air gouging back chipping and carburized layer removal are carried out; S5, reverse side back welding: back welding is carried out by three layers after the temperature of the steel casting reaches a preheating temperature according to the method described in the step 2, and fire warming is performed on each weld seam to remove stress; S6, filling and cover surface welding: the front side and the reverse side are welded respectively by one welder simultaneously and symmetrically, and hammering is carried out layer by layer after each layer of weld beads of each weld seam is welded; and S7, 550 DEG C *2h heat treatment after stress removal is carried out immediately after the completion of welding. By means of the method, welding stress and welding deformation can be significantly reduced, and the probability of generating steel casting welding cracks is greatly reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

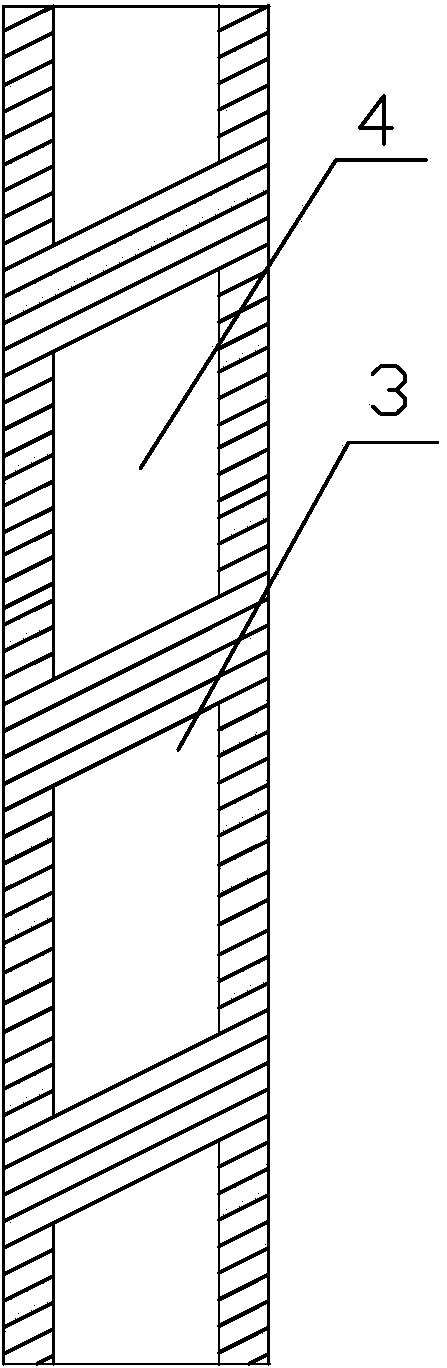

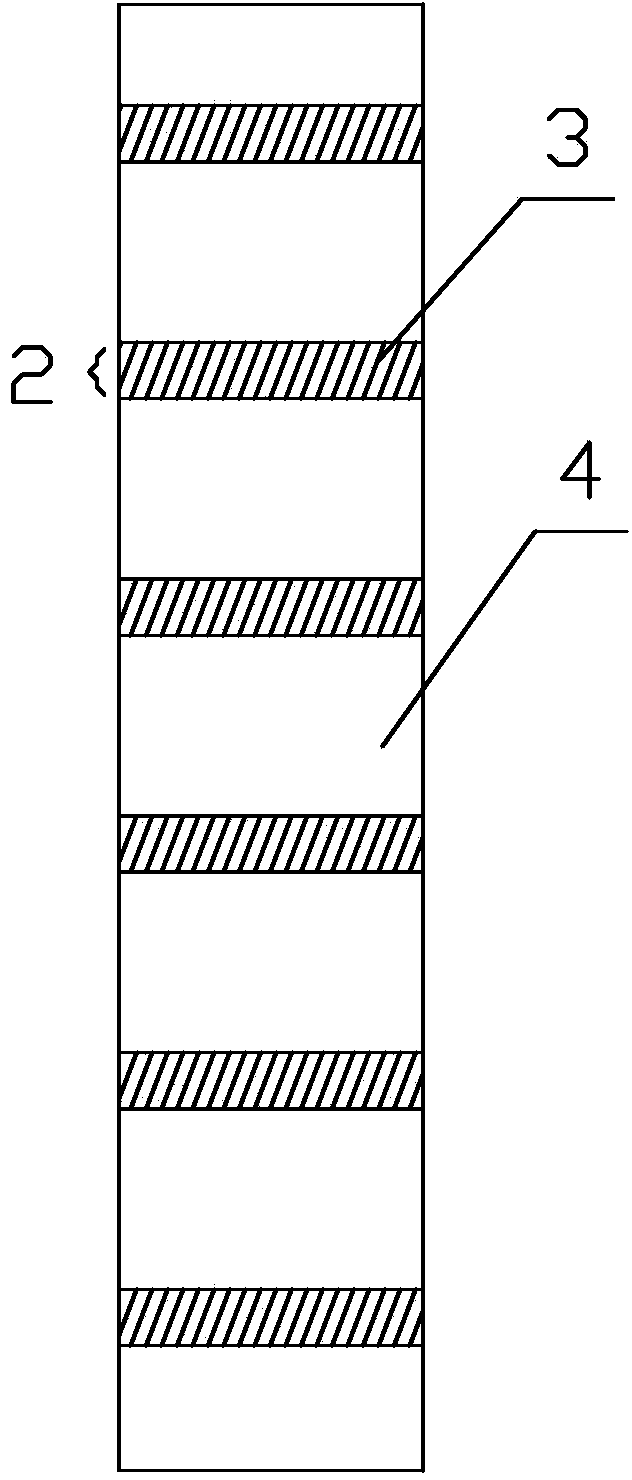

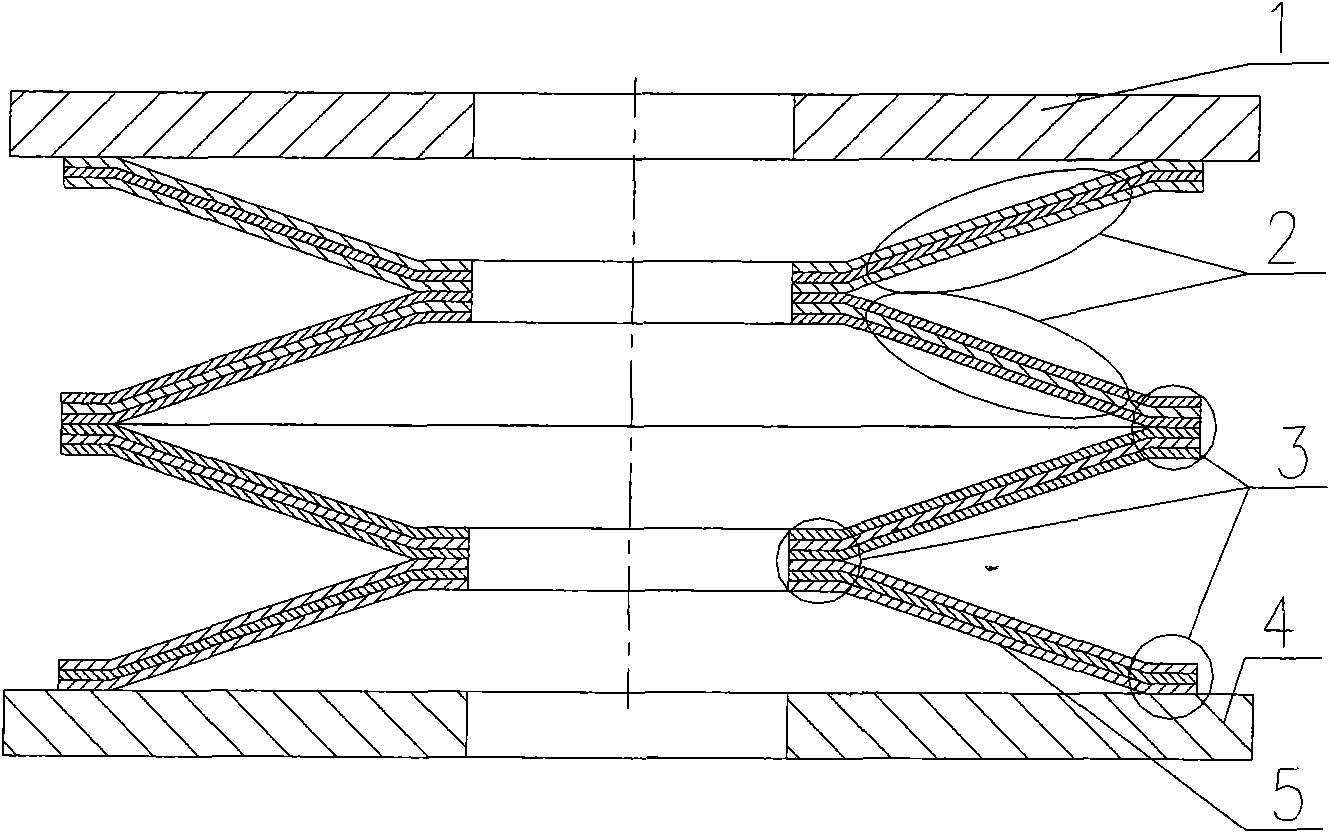

Diffusion welding multilayer structure diaphragm capsule

The invention is a diffusion welding multilayer structure diaphragm capsule, belonging to the field of diaphragm capsule manufacturing. By adopting the methods of diffusion welding, machining and shaping, the manufacturing of diaphragm capsule in the invention can be realized. The main procedures include thin wall blank preparation, surface cleaning, surface modified treatment, welding-stopping treatment, diffusion welding, machining, shaping and the like. Compared with the multilayer structure diaphragm capsule manufactured by other methods, the multilayer structure diaphragm capsule manufactured by the invention has the advantages of fine fatigue property (above 1 million times), strong pressurization performance, adjustable rigidity, high compression ratio (higher than 80%), capability of micromation of inner holes, high precision of geometric dimensions, strong destabilization resistance, precise and controllable weldingline profile, adjustable width of weldingline and the like. By using the invention, the diaphragm capsule in the shape of circle, square and other shapes can be manufactured, and can serve as a compensation element of displacement and angle in hydraulic, barometric, transferring pipeline installation, an elastic compensation element and a pore damping element as well as a measuring element for a manometer and an altimeter; besides, the diaphragm capsule can be also used as a heat transferring finned tube for air conditioning, refrigeration and other devices as well as a metal capsule of separating gas or liquid for an accumulator and a storage box. The invention can provide multilayer structure diaphragm capsule products with fine performance for related industries.

Owner:北京智创联合科技股份有限公司

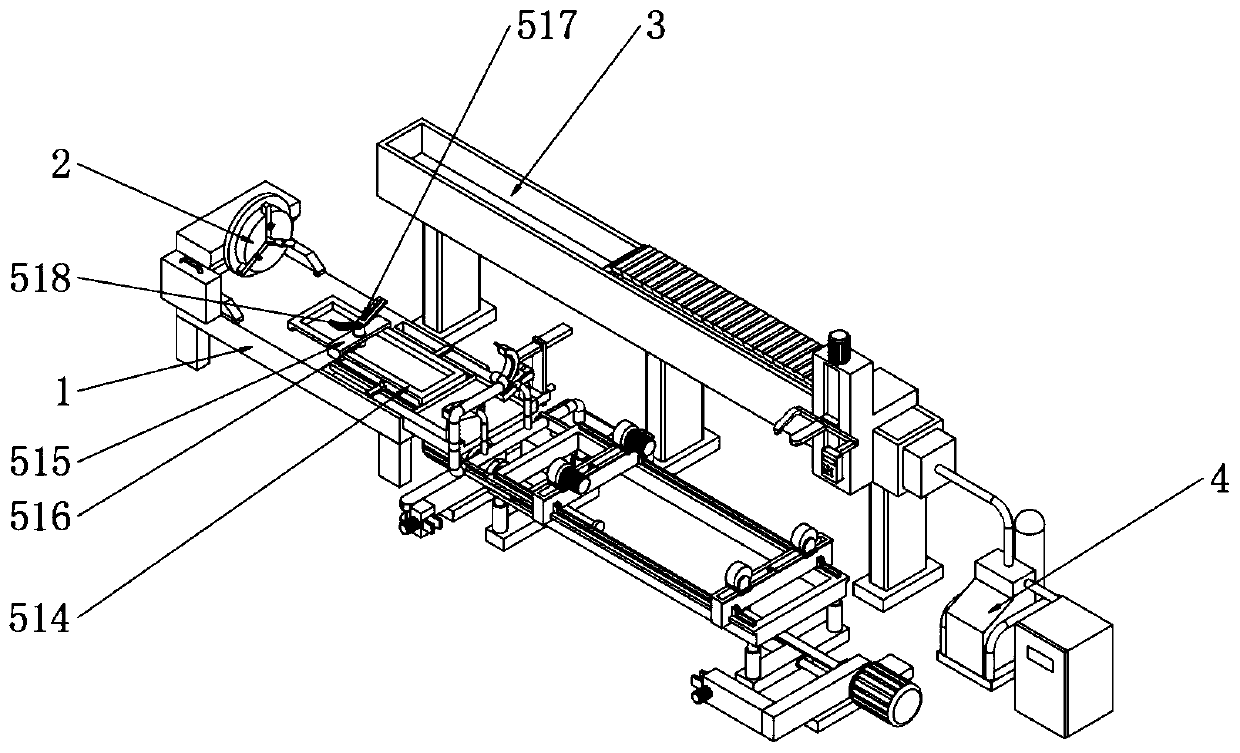

On-site automatic welding device and welding method for large pipelines

InactiveCN111347215AScientific and reasonable structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesElectric machineSupport plane

The invention discloses a one-site automatic welding device and welding method for large pipelines. The automatic welding device comprises a welding supporting frame, wherein two horizontal supportingplates are placed on one side of the welding supporting frame, flush electric pushing rods are installed at the two ends of the top surfaces of the two horizontal supporting plates correspondingly, the four flush electric pushing rods are installed at the four corners of the bottom surface of a flush supporting frame correspondingly, material supporting rods are installed in the two ends of the top surface of the flush supporting frame in an embedded mode, supporting rolling wheels are installed at the bottom ends of the material supporting rods, the bottom surfaces of the supporting rollingwheels make contact with the top surface of the flush supporting frame, lead screw installing grooves are formed in the middles of the top surfaces of the material supporting rods, rotating motors areinstalled in the middles of one ends of the material supporting rods, friction wheels are movably installed at the top ends of sliding frames, and a movable supporting plate is installed at one end of the outer side of the fixing supporting frame in an embedded mode. Through the cooperative use of the flush electric pushing rods, an inclined rolling wheel frame, a welding positioner and a corresponding electric pushing rod, the center lines of the two pipelines are located on the same straight line conveniently, the pipelines can be adjusted and supported, and the working efficiency is improved.

Owner:林进卓

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com