Q460C steel welding process

A welding process and welding zone technology, which is applied in the welding process field of Q460C steel in GB1591-2008, can solve the problems of reduced toughness, long residence time at high temperature, and weakened effect of microstructure, so as to reduce welding deformation and welding stress , the effect of preventing excessive grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

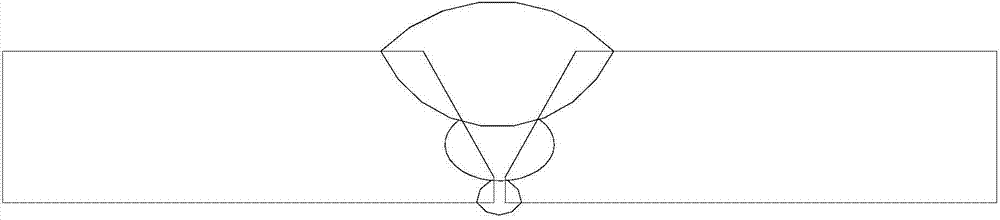

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0039] The welding process of a kind of Q460C steel described in the present invention adopts argon / carbon dioxide fine mixed gas shielded welding to carry out bottom welding, adopts argon / carbon dioxide mixed gas shielded welding to carry out filling and cover welding, and operates according to the following steps:

[0040] The present invention carries out rigorous and detailed design on the process, and provides normative process operation guidance for the welding of Q460C steel.

[0041] (1) Determination of welding process parameters

[0042] Since Q460C contains more alloying elements, the hardening of this type of steel increases. As the carbon equivalent and plate thickness of the steel increase, the tendency of hardening and cold cracking increases, and under the action of high stress, The tendency to produce welding cracks is also greatly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com