Magnesium alloy weld joint hot rolling strengthening process

A magnesium alloy, hot rolling technology, applied in the direction of manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., can solve problems as low as 6%, the fracture position is in the heat affected zone, the tensile strength of the joint is low, and the tensile strength is reduced. , to achieve high strength, beautify the appearance and prevent oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

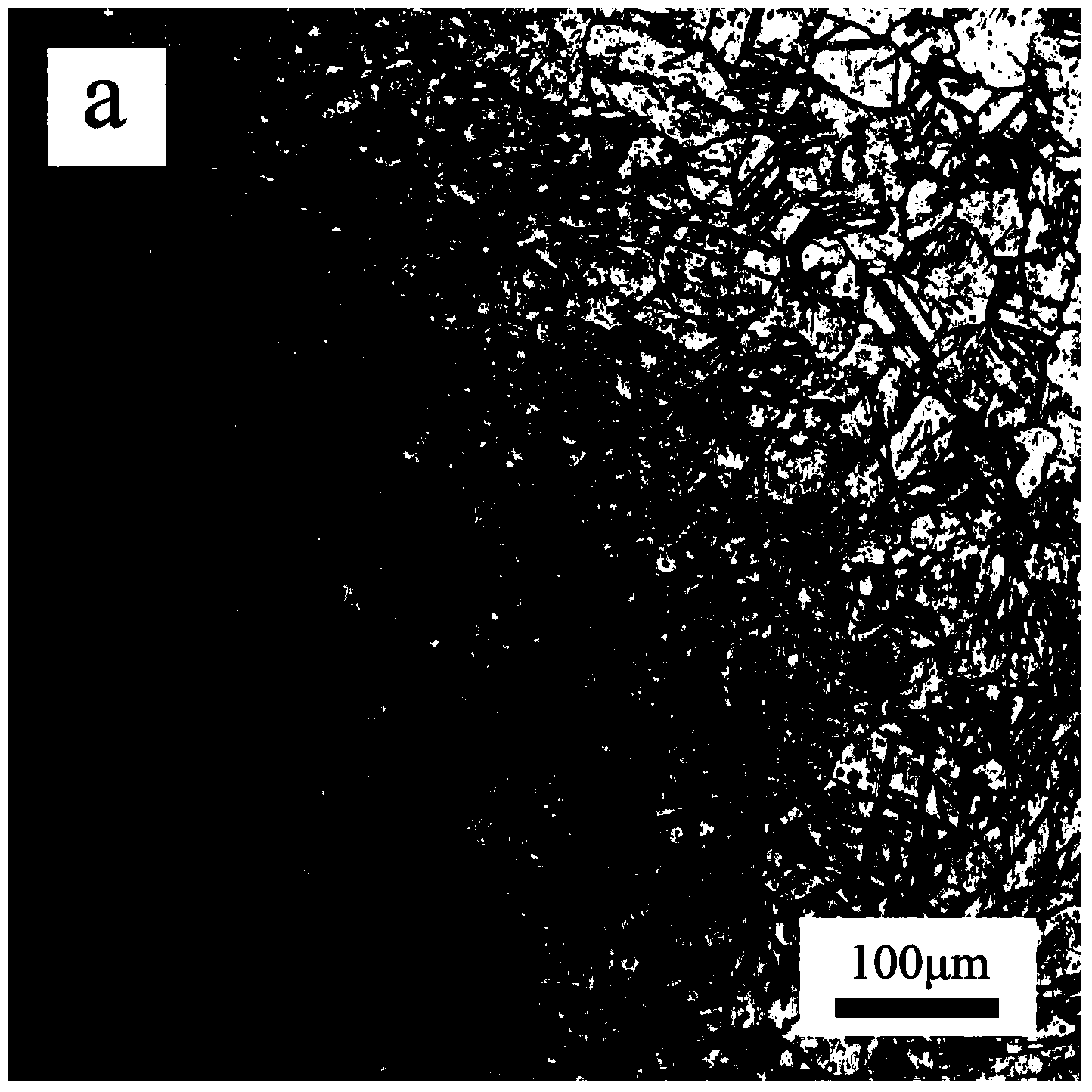

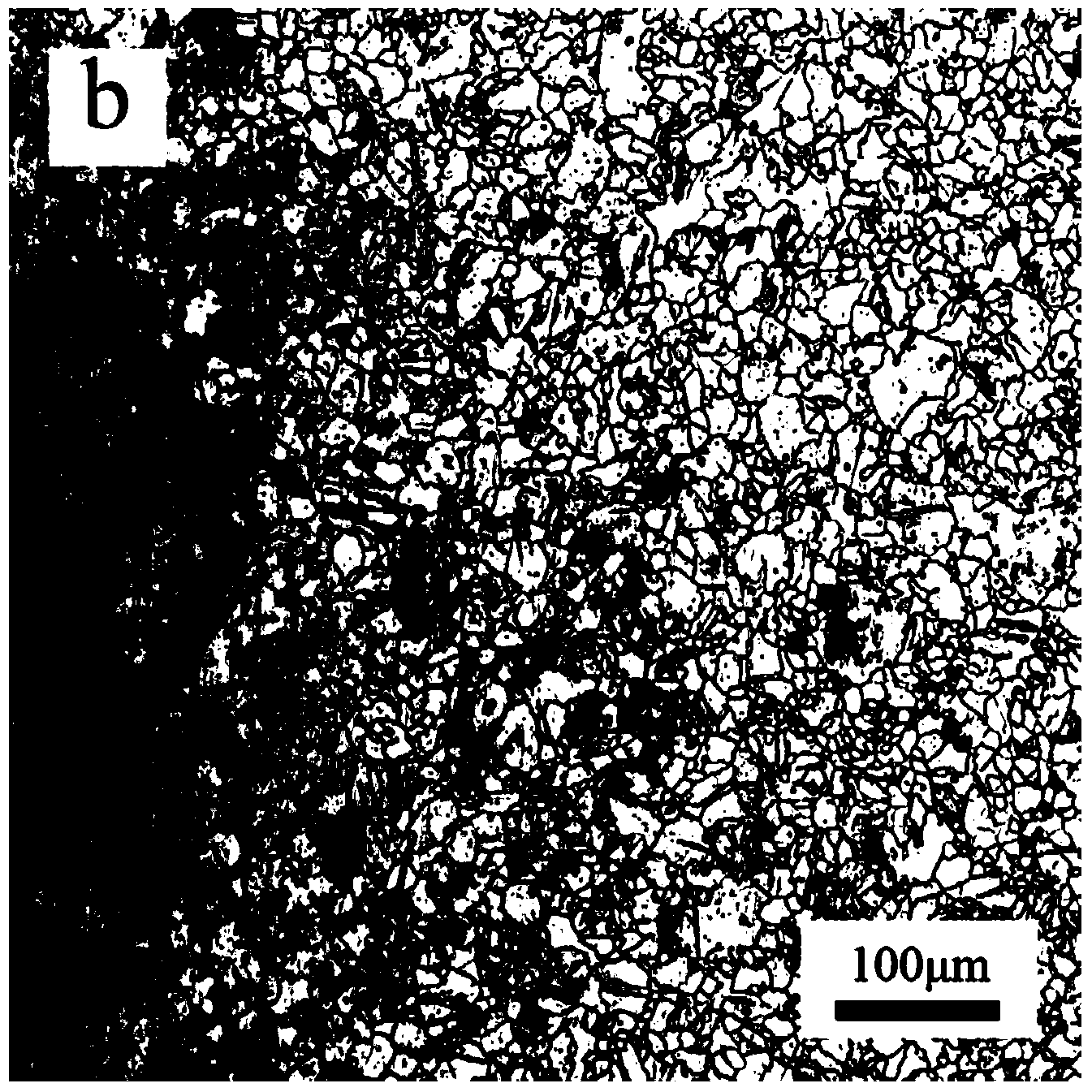

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] The present invention provides a magnesium alloy weld hot rolling strengthening process, which comprises the following steps:

[0027] 1) Inert gas shielded welding is used to weld magnesium alloy parts on both sides;

[0028] 2) Place the magnesium alloy welded parts in a heat treatment furnace at a temperature between 200°C and 350°C, and perform post-weld stress relief annealing for 0.5 to 2 hours;

[0029] 3) The weld reinforcement of the magnesium alloy weldment after annealing shall be subjected to hot rolling for no less than 2 times until the weld seam is flush with the substrate, and the magnesium alloy weldment shall be heated to 350°C to 400°C before each hot rolling. Insulation and preheating for 10min to 0.5h, and hot rolling at 250°C to 350°C.

[0030] Further, in step 1), the weld reinforcement is set to 0.5mm-3.0mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com