Method for welding Q420 steel for power grid iron tower

A welding method and iron tower technology, applied in the field of steel welding, can solve the problems of inability to meet the high-quality and high-efficiency requirements of power grid iron towers, difficult welding joint test parameters, uneven welding quality, etc. Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

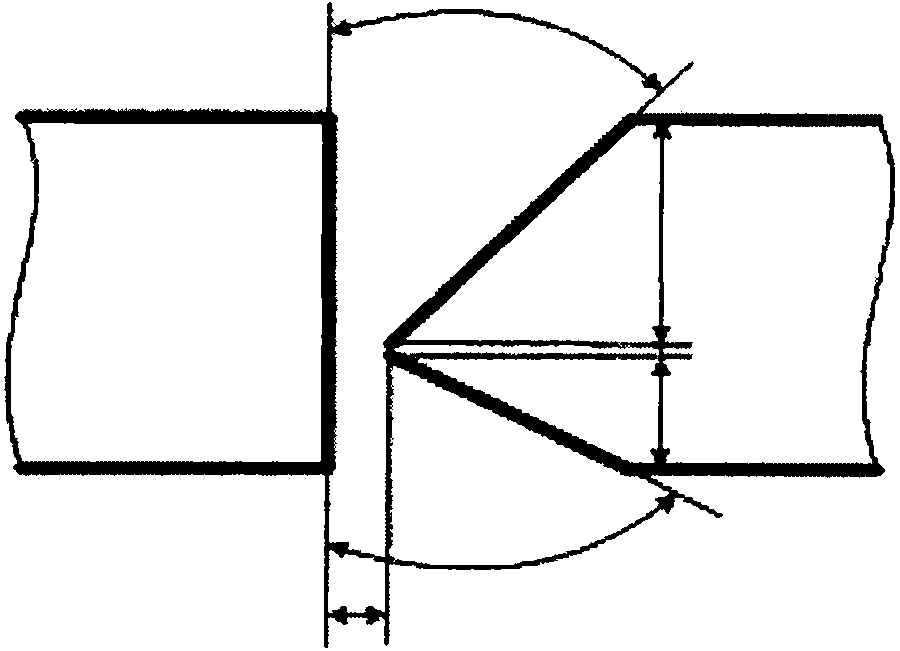

[0028] A welding method for Q420 steel for power grid iron towers, used for welding Q420 steel plates with a thickness of 12mm or 16mm, and suitable for welding in the form of butt joints. 2 NBC-350 welding machine with Ar welding power source, welding consumables use Atlantic brand J557ф3.2 welding rod or Atlantic brand J557ф4.0 welding rod, or Atlantic brand ER55-G welding wire, using 80% Ar+20% CO 2 The semi-automatic solid wire mixed gas shielded welding process welds at room temperature without preheating, see the attached figure 1 , the butt joint adopts an asymmetric K-shaped groove, the groove angles on both sides are 45-50° and 58-62° respectively, the width of the blunt side of the groove is 0-2.5mm, the gap between the welding counterparts is 0-4mm, and the welding process adopts flat Three spatial positions of welding, vertical welding and horizontal welding, welding speed = 12-29cm / min, heat input = 123-296kj / min.

Embodiment 2

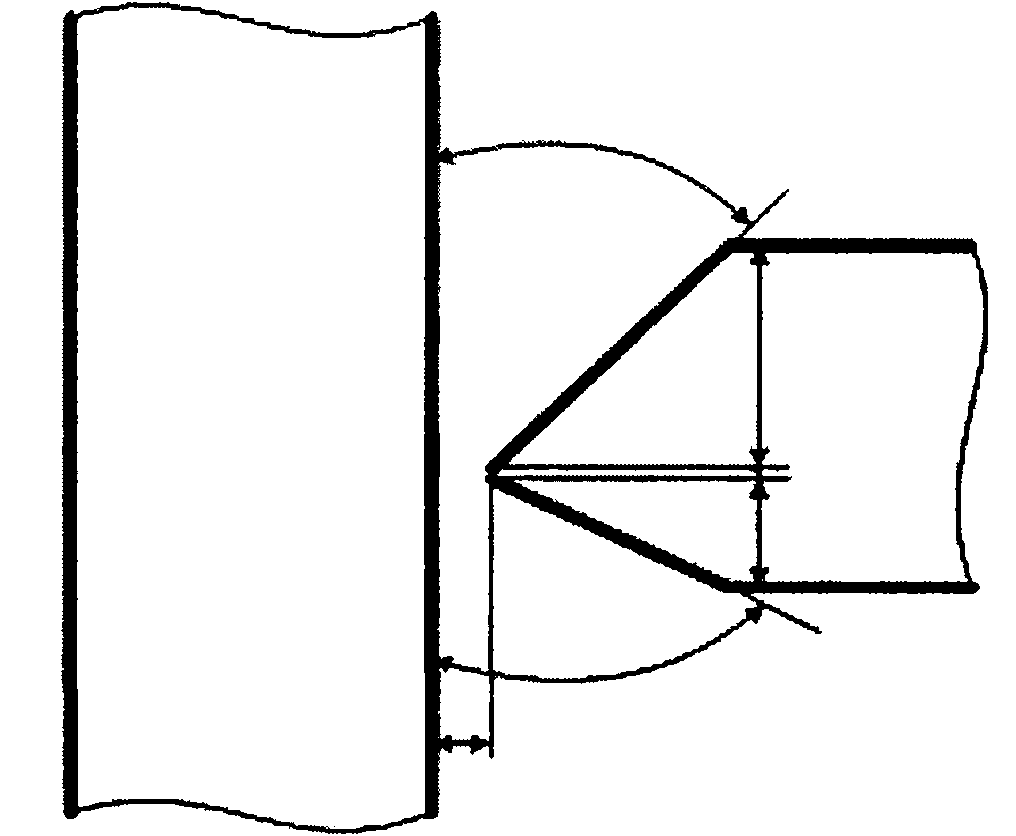

[0030] A welding method for Q420 steel for power grid iron towers, which is used for welding Q420 steel plates with a thickness of 12mm or 16mm, and is suitable for welding in the form of T-shaped joints with full penetration. 2 NBC-350 welding machine with Ar welding power source, welding consumables use Atlantic brand J557ф3.2 welding rod or Atlantic brand J557ф4.0 welding rod, or Atlantic brand ER55-G welding wire, using 80% Ar+20% CO 2 The semi-automatic solid wire mixed gas shielded welding process is welded at 0°C, and the Q420 steel is preheated to 150°C before welding. figure 2 , the T-shaped joint with gold penetration adopts an asymmetric K-shaped groove, the angles of the grooves on both sides are 45-50° and 58-62° respectively, the width of the blunt edge of the groove is 0-3mm, and the gap between the welding counterparts is 0-3mm. The welding process adopts three spatial positions of flat welding, vertical welding and horizontal welding, welding speed = 16-44cm / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com