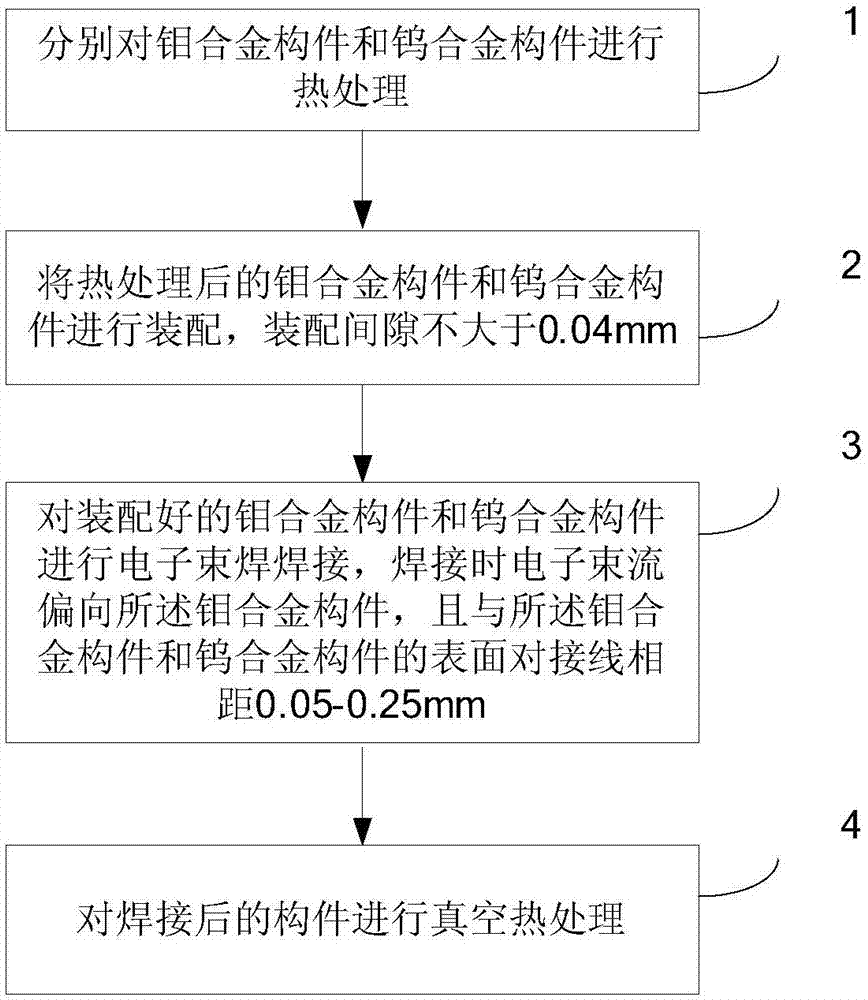

Electron beam welding method for molybdenum alloy and tungsten alloy

A technology of electron beam welding and welding method, applied in electron beam welding equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as cracks and pores, achieve fine grain size of weld seam, reduce material stress, improve The effect of weld performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

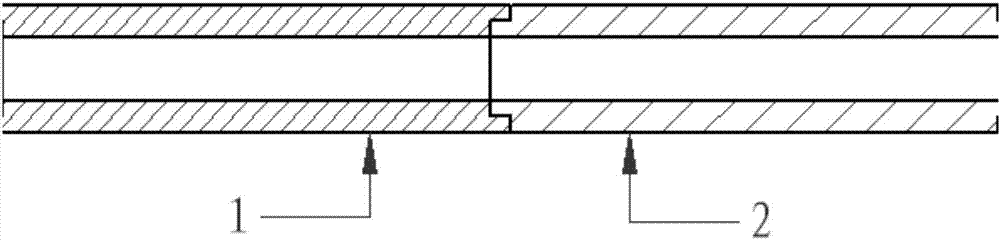

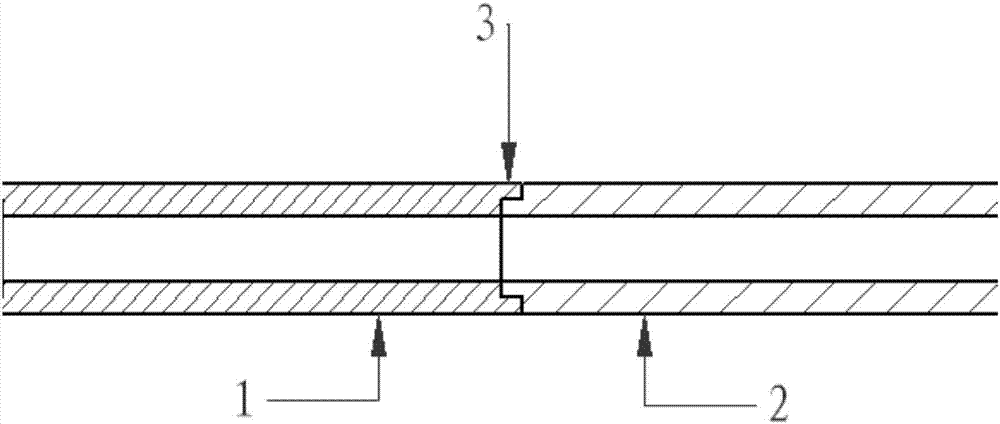

[0063] components to be welded such as figure 2 As shown, the molybdenum alloy component 1 is a hollow cylindrical structure, and the right end surface is provided with a mounting groove. The side end surface is provided with a protrusion matching the installation groove. Molybdenum alloy component 1 is TZM alloy, which is made by powder metallurgy forging method, and tungsten alloy component 2 is WRe25 alloy, which is made by vacuum arc melting method.

[0064] Electron beam welding is carried out on the molybdenum alloy component 1 and the tungsten alloy component 2, comprising the following steps:

[0065] Step (1): Soak the molybdenum alloy component 1 and the tungsten alloy component 2 in aqua regia for 1 minute, take them out, clean them with alcohol, and then dry them with nitrogen at a pressure of 0.4 MPa;

[0066] Step (2): Put the molybdenum alloy component 1 into a vacuum heating furnace, and the vacuum degree in the furnace is 1X10 -3 Pa, raise the temperature ...

Embodiment 2

[0071] components to be welded such as figure 2 As shown, the molybdenum alloy component 1 is a hollow cylindrical structure, and the right end surface is provided with a mounting groove. The side end surface is provided with a protrusion matching the installation groove. The molybdenum alloy component 1 is a TZC alloy prepared by powder metallurgy followed by forging, and the tungsten alloy component 2 is WRe3 alloy prepared by powder metallurgy followed by forging.

[0072] Electron beam welding is carried out on the molybdenum alloy component 1 and the tungsten alloy component 2, comprising the following steps:

[0073] Step (1): Soak the molybdenum alloy component 1 and the tungsten alloy component in aqua regia for 4 minutes, take them out, wash them with acetone, and then dry them with nitrogen at a pressure of 0.5 MPa;

[0074] Step (2): Put the molybdenum alloy component 1 into a vacuum heating furnace, and the vacuum degree in the furnace is 2X10 -4 Pa, heat up to...

Embodiment 3

[0079] components to be welded such as figure 2 As shown, the molybdenum alloy component 1 is a hollow cylindrical structure, and the right end surface is provided with a mounting groove. The side end surface is provided with a protrusion matching the installation groove. The molybdenum alloy component 1 is a TZC alloy, which is made by vacuum arc melting, and the tungsten alloy component 2 is a WRe3 alloy, which is made by forging after powder metallurgy preparation.

[0080] Electron beam welding is carried out on the molybdenum alloy component 1 and the tungsten alloy component 2, comprising the following steps:

[0081] Step (1): Soak the molybdenum alloy component 1 and the tungsten alloy component in aqua regia for 1 minute, take them out, clean them with alcohol, and then dry them with nitrogen at a pressure of 0.3 MPa;

[0082] Step (2): Put the molybdenum alloy component 1 into a vacuum heating furnace, and the vacuum degree in the furnace is 5X10 -4 Pa, raise the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com