Patents

Literature

178results about How to "Improve the quality of heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot stamping die steel and production method thereof

InactiveCN104928586AImprove the quality of heat treatmentImprove strength and toughnessSolid state diffusion coatingHot stampingHardness

The invention provides hot stamping die steel and a production method thereof. The hot stamping die steel is composed of, by weight, 0.45-0.50% of C, 0.1-0.3% of Si, 0.1-0.3% of Mn, 2.0-2.3% of Cr, 2.3-2.5% of Mo, 0.8-1.0% of V, smaller than or equal to 0.03% of P, smaller than or equal to 0.03% of S and the balance Fe and other inevitable impurities and meets the relational expressions that Mo / Cr=1-1.25 and V / Cr=0.35-0.43. By means of the electroslag remelting process, the ultrafine thermal treatment process, the vacuum thermal treatment process and the plasma nitriding surface treatment process, the produced and obtained hot stamping die steel is low in cost and high in comprehensive performance; the hot stamping die steel has a thermal conductivity coefficient of 34.3 W / m.k, quenching and tempering hardness of 50-53 HRC, ballistic work of 180-210 J, surface hardness of 850-1040 HV0.3 and diffusion thickness of 230-300 microns, and a white bright layer is ceaseless after nitriding.

Owner:BAOSHAN IRON & STEEL CO LTD

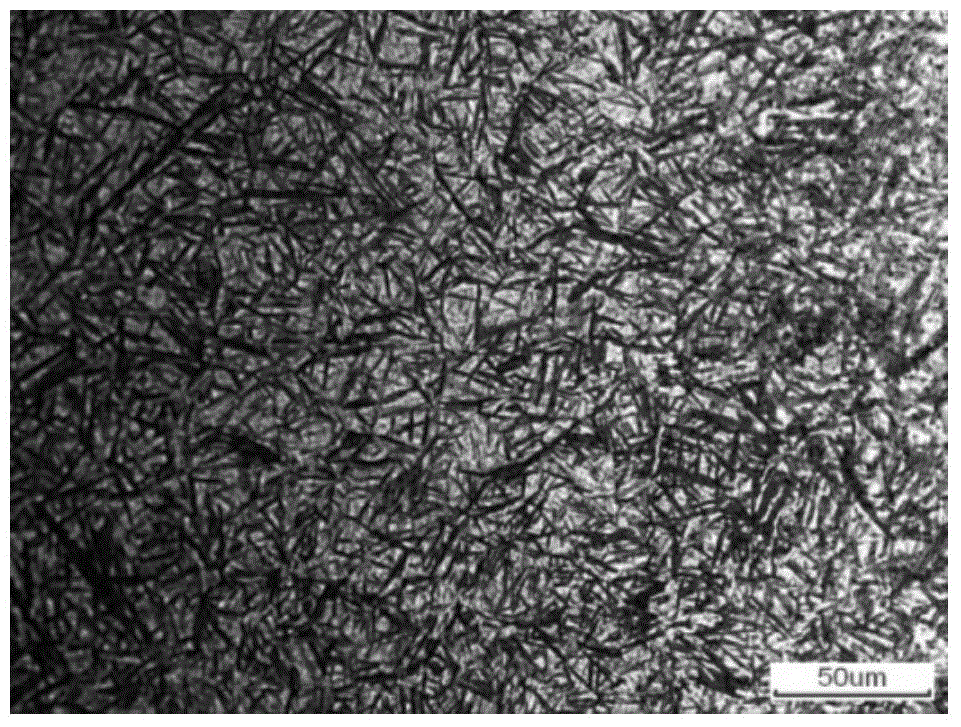

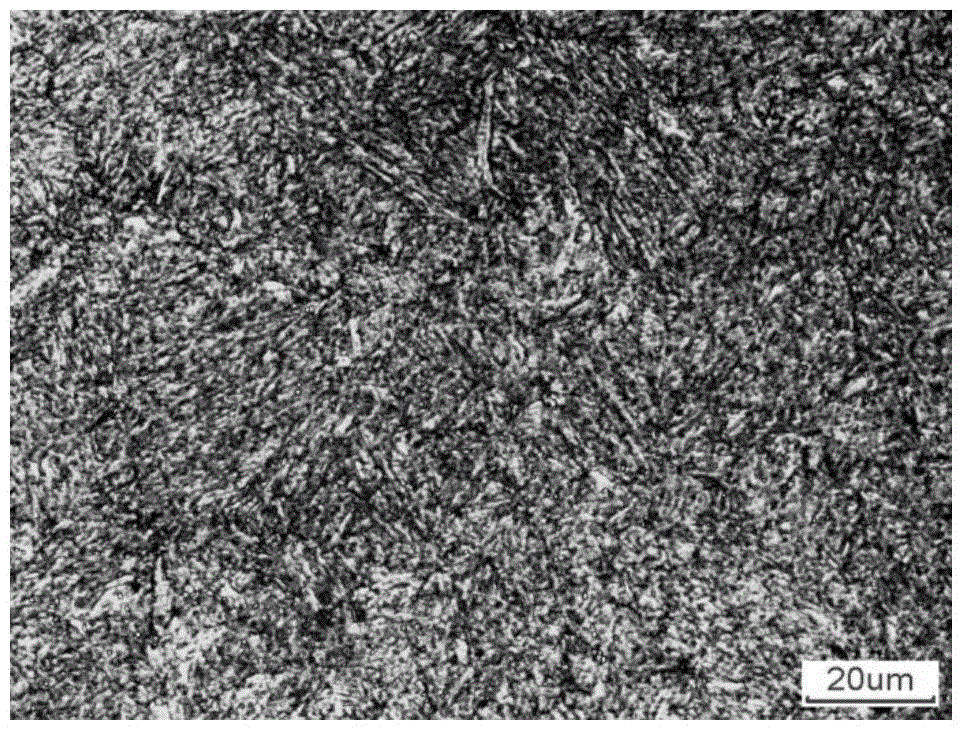

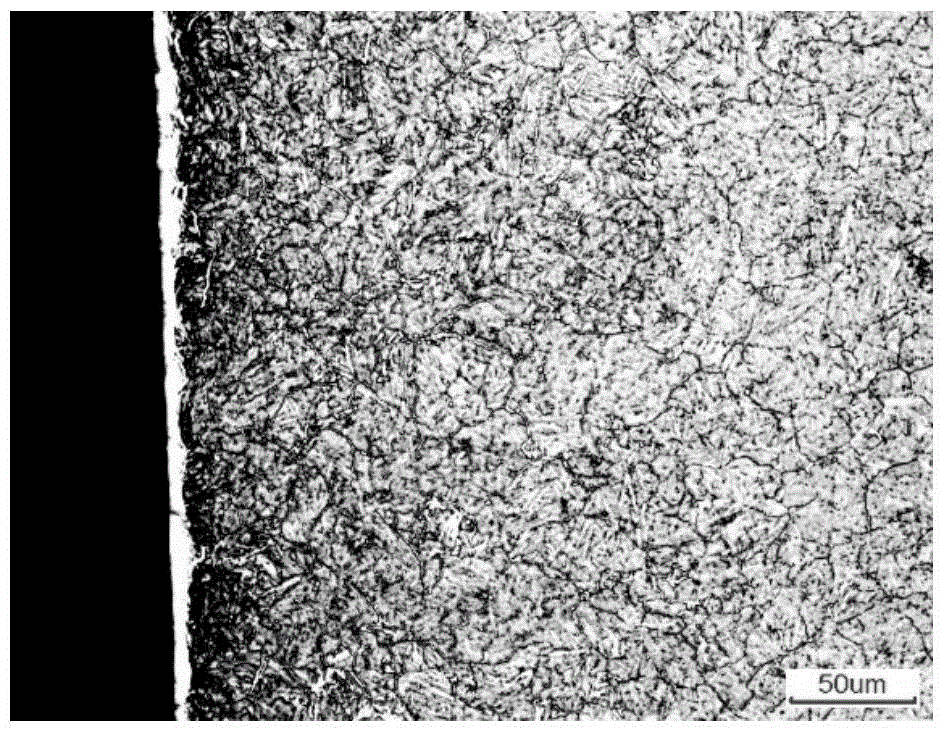

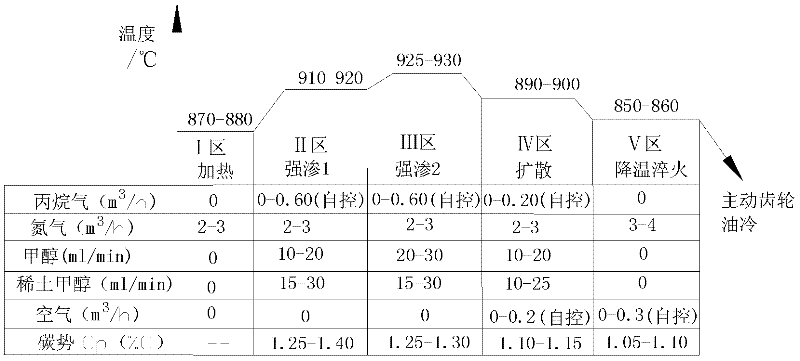

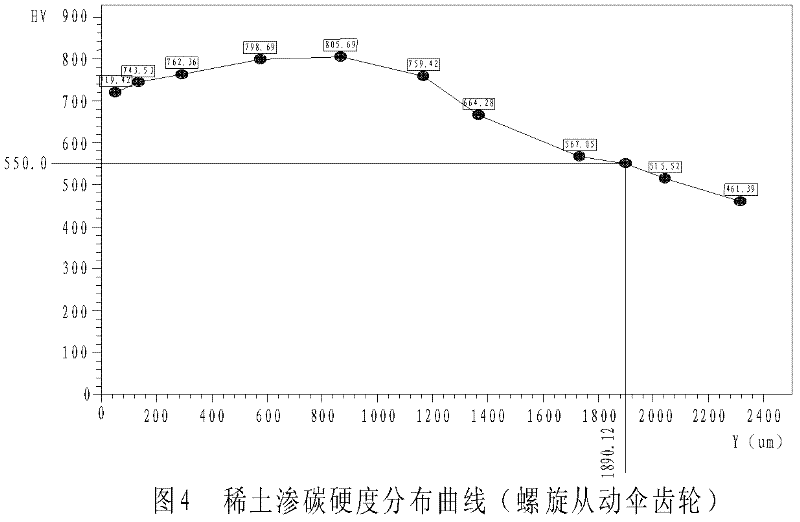

Heat treatment method of spiral bevel gear of cargo truck on double-row rare earth carburization equipment

ActiveCN102373400AEmission reductionIncrease carburizing speedSolid state diffusion coatingCarbon potentialRare earth

The invention provides a heat treatment method of a spiral bevel gear of a cargo truck on double-row rare earth carburization equipment, and relates to a carburization heat treatment technological process of the spiral bevel gear of the cargo truck. The invention solves the problems that energy consumption of carburization heat treatment is high, production cost of a product is high and carburization quenching and gear thermal distortion still exist in a carburization process. The method provided by the invention comprises the following steps of: taking a preheating zone as a strong leakage region 1 and taking a carburizing region as a strong leakage region 2, namely taking a region II and a region III as a carburizing speed main control region and taking a region IV and a region V as a metallographic structure main control region, carrying out temperature control in the regions I, II, III, IV and V, carrying out carbon potential control in the regions II, III, IV and V, and inputtingcarburizing medium propane gas, rare earth methanol penetrating agent, nitrogen, methanol and air into a furnace, thus the heat treatment method is realized. The metallographic structure and surface hardness of the spiral bevel gear subjected to the heat treatment method provided by the invention are all optimized, and heat treatment quality of the spiral bevel gear is improved; meanwhile, capacity is improved by 23%, heat treatment production cost is reduced by 18.9%, and pollution of exhaust emission to the environment is reduced.

Owner:哈尔滨汇隆汽车箱桥有限公司 +3

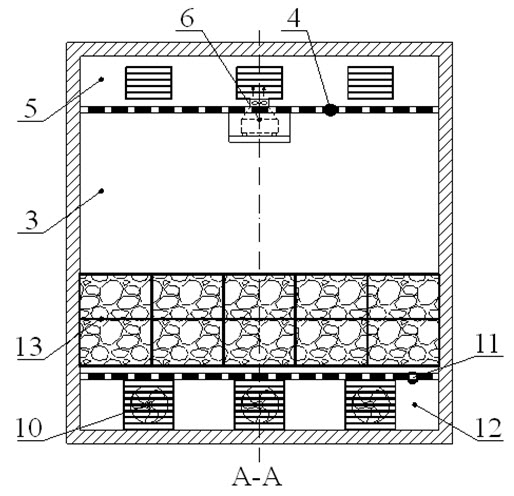

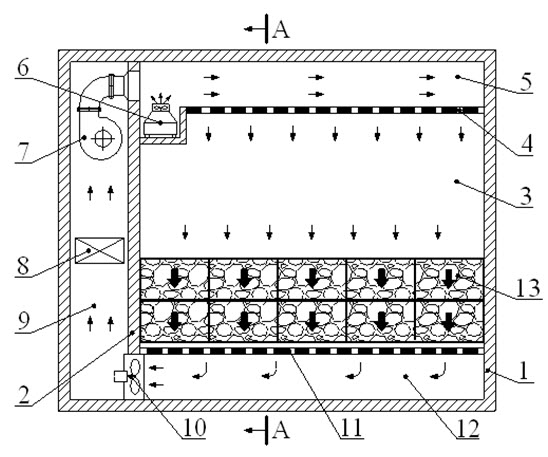

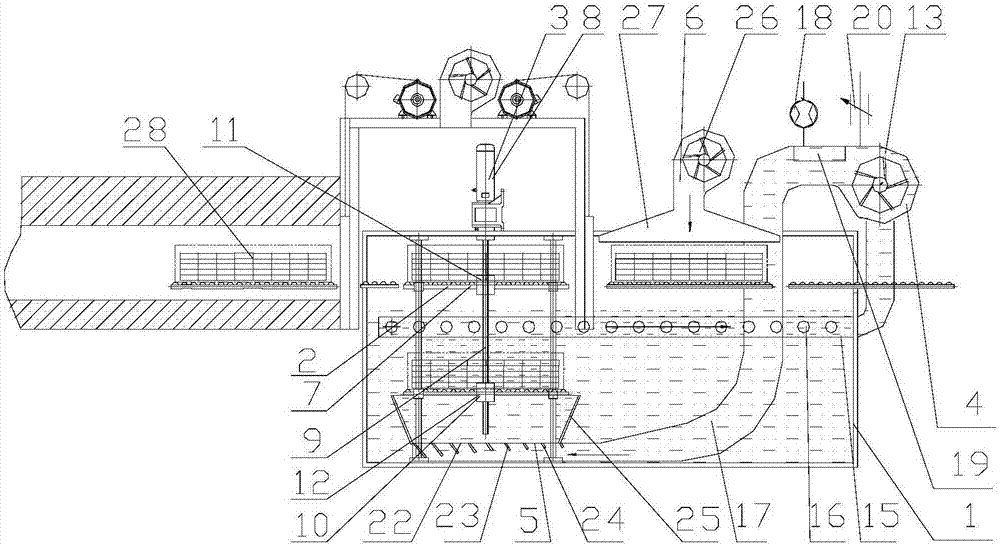

Heat pump type pressure gradient fruit vegetable heat treatment library

ActiveCN101919436AReduce heat treatment energy consumptionShorten the timeFood processingFruits/vegetable preservation by heatingThermodynamicsAir treatment

The invention discloses a heat pump type pressure gradient fruit vegetable heat treatment library. The library is composed of a library entry, a heat pump system, a circulation air system and a humidifying system, the library entry is divided into four parts of air treatment, air supply plenum, fruit vegetable heat treatment and return air plenum. The upper end and the lower end of the clapboard are respectively provided with three centrifugal fans and three pressure gradient fans, an air supply homogenizing plate and a return air floor plate are respectively arranged at the upper part and the lower part in the library, and a fruit vegetable heat treatment chamber is formed between the two plates. An air supply plenum chamber is formed between the air supply homogenizing plate and the upper top wall of the library entry, and a return air plenum chamber is formed between the return air floor plate and the lower bottom of the library entry. The condenser of the heat pump system is arranged in an air treatment chamber, a centrifugal humidifier is arranged above the right side of the clapboard, and the return air floor plate is placed with a fruit vegetable box. Pressure gradient air supply is adopted, so that treatment time can be reduced. The invention adopts heat pump heat source, the heat pump can supply 3-5 units of heat into the library while a compressor consumes every 1 unit electricity; compared with the electric heating method, fruit vegetable heat treatment energy consumption can be obviously reduced, and energy conservation effect of the system is obvious.

Owner:TIANJIN UNIV

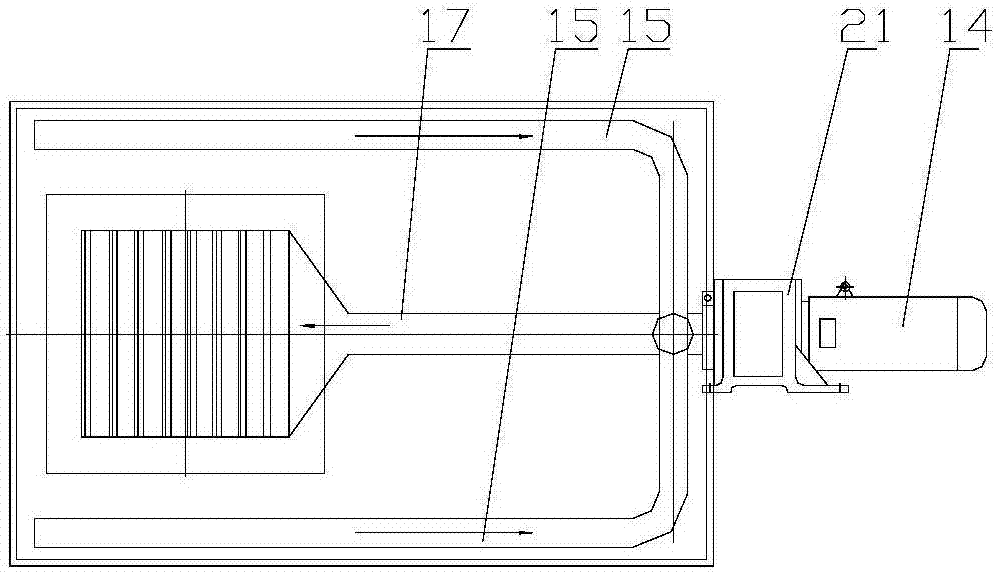

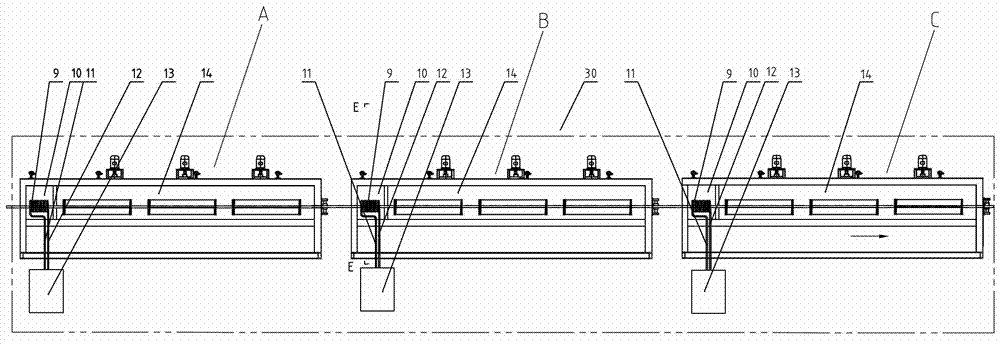

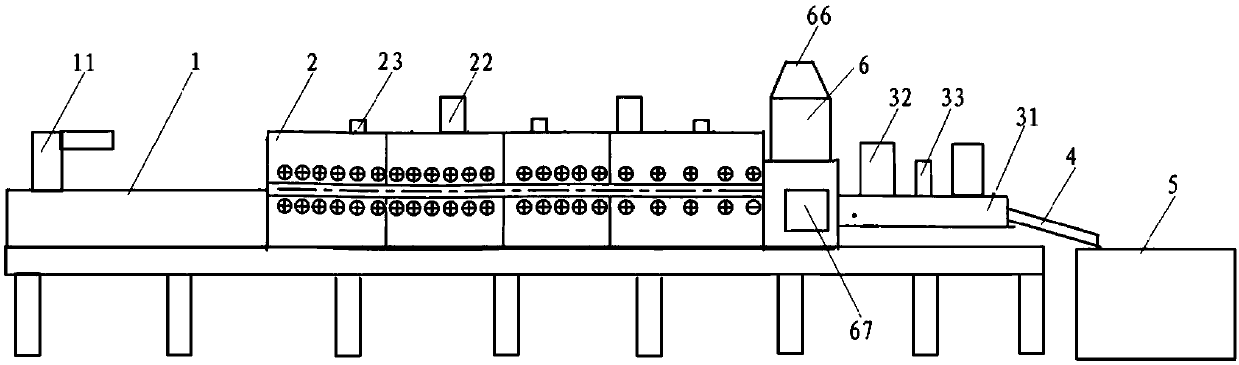

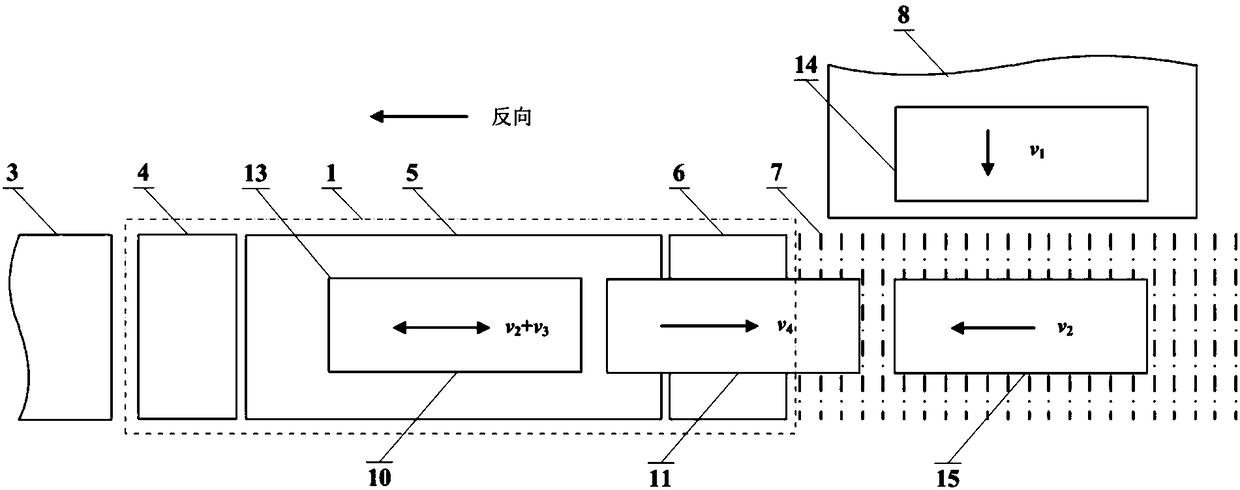

Stepped quenching process and its apparatus suitable for bainite and martensite quenching

InactiveCN1884592ASimple processing methodImprove the quality of heat treatmentQuenching agentsQuenching devicesProduction lineHearth

This invention involves a kind of step quenching process which is suitable for Bainitic and Martensite quenching and the equipment utilizing this step quenching process. The workflow includes: heating, quenching in low-temperature nitrate groove and isothermal; turn to oil grooves to cool down, wash and dry; turn to air furnace for isothermal temper. The above step quenching is performed in roller hearth furnace production line. After adjusting the technology parameter, this production line can undergo Bainitic step quenching and Martensite step quenching. This production line is composed mainly by roller hearth heating furnace, nitrate groove, oil groove, cleaner, dryer and temper furnace. This invention can improve the heat treatment quality; reduce the amount of nitrate and pollution. This production line can undergo normal Martensite quenching, Martensite step quenching and Bainitic step quenching, so to reduce investiment and increase the effeiciency.

Owner:北京时代新人轴承有限公司 +1

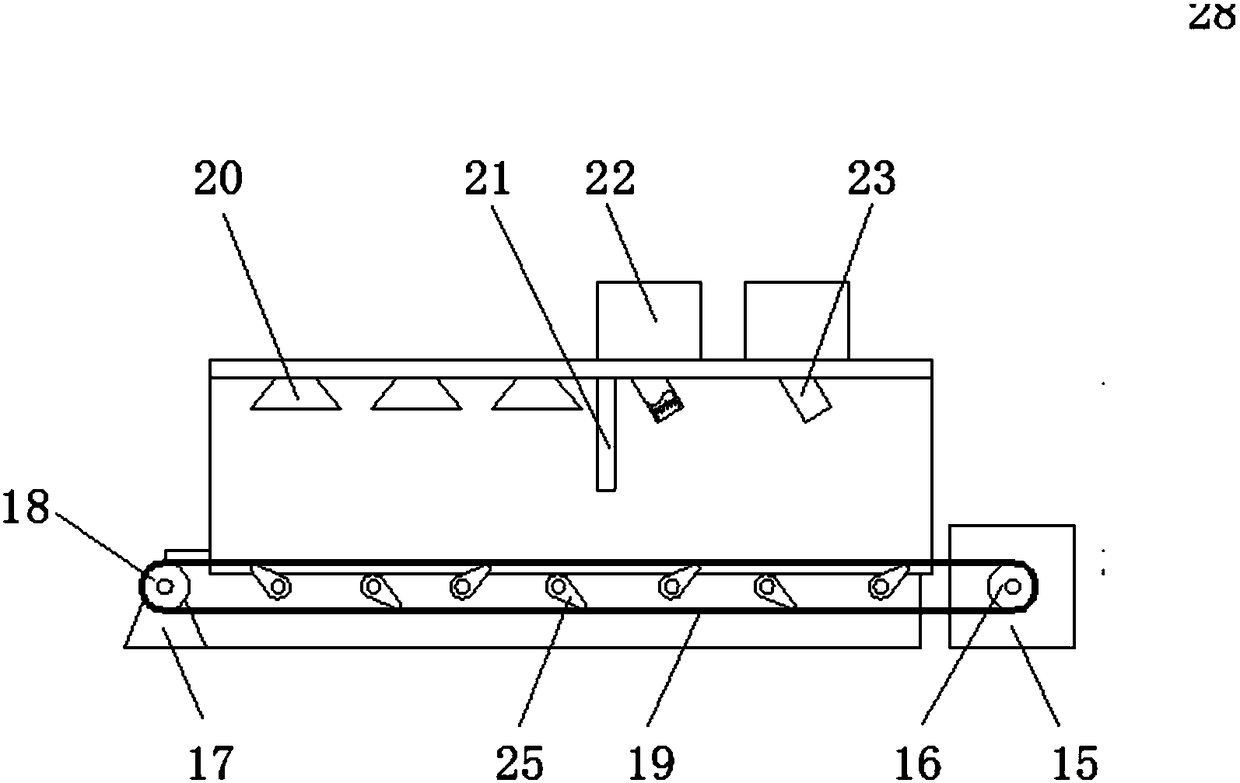

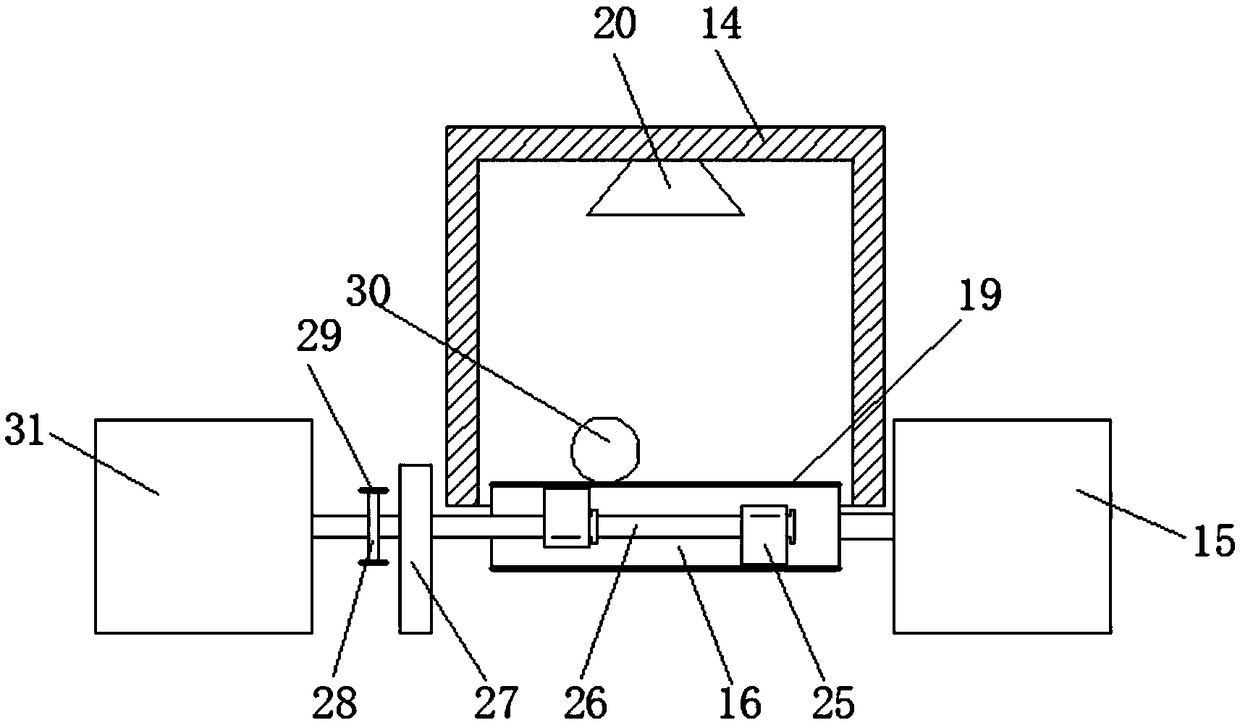

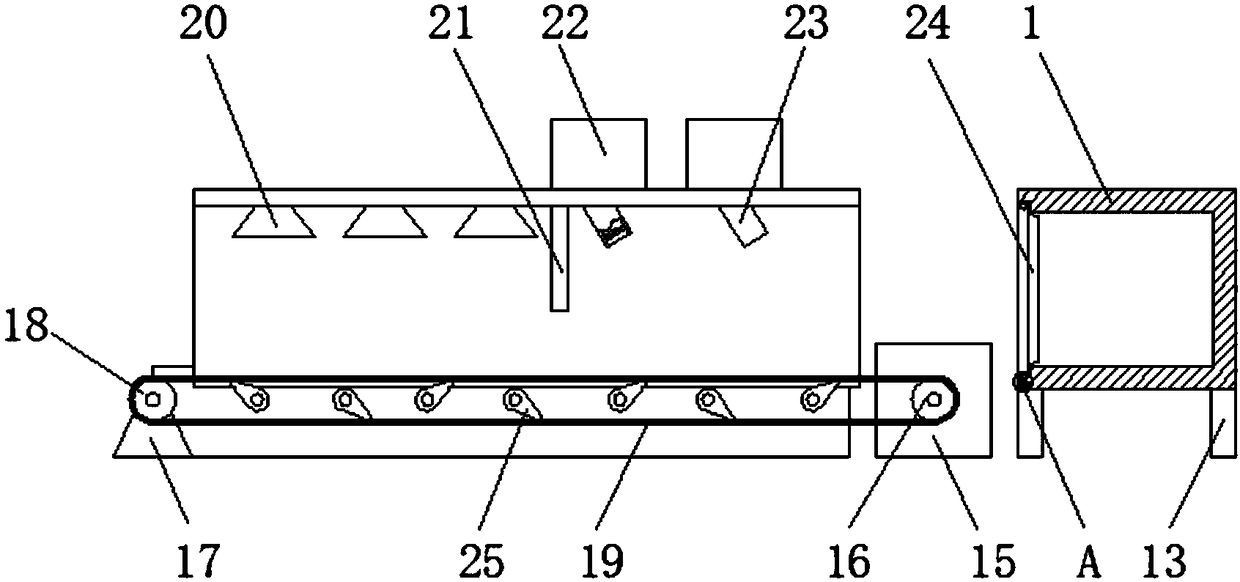

Hardware cleaning device

InactiveCN108057669ASimple structureEasy to implementDrying gas arrangementsDrying machines with progressive movementsTreatment qualityHeat treated

The invention discloses a hardware cleaning device. The hardware cleaning device comprises a cleaning dryer, a transmission motor is installed on one side of the bottom end of the cleaning dryer, anda drive roll is installed at the driving end of the transmission motor; an installing rack is arranged at the end, far away from the transmission motor, of the cleaning dryer, a rotation shaft is installed on the installing rack and sleeved with a driven roll, the drive roll and the driven roll are jointly provided with a conveyer belt in a winding mode, and the upper section of the conveyer beltis located in the cleaning dryer; and multiple water nozzles are arranged on the top wall of the cleaning dryer, two blowing pipes are installed on one side of the water nozzles, and a partition plateis installed between the blowing pipes and the water nozzles. The hardware cleaning device is simple in structure and easy to implement, the heat treatment quality is improved by cleaning hardware before heat treatment, and therefore the hardware cleaning device is worthy of popularization.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

Processing method of positioning hook forge piece

InactiveCN102989940AUniform deformationLess prone to dead zonesMetal-working apparatusTemperingIndustrial engineering

The invention discloses a processing method of a positioning hook forge piece. The processing method of the positioning hook forge piece comprises the following steps: 1), selectively using 35mm round steel and cutting by using a shearing machine, wherein the length of a sheared rough blank piece is 172mm; 2) putting the rough blank piece obtained in the step 1 into an intermediate frequency heating furnace for heating at a heating temperature of 1120 to 1180 DEG C and keeping the heating for 2-3min; 3) drawing out two ends of the workpiece obtained in the step 2 by utilizing an air hammer till the arrival of 20+ / -2mm diameter, wherein the hammer drawing is performed for 8-14 times; 4) putting the drawn-out workpiece into a bending die of a punching machine for bending; 5), putting the bent workpiece into a shaping die in an electric screw press for hot forging by using the shaping die, wherein the temperature is 900 DEG C and the pressure is 630T; and 6) putting the hot forged workpiece into the punching machine for side cutting and punching. With the adoption of a quenching and tempering heat treatment technology for a positioning hook provided by the invention, the high temperature normalizing and the forging are caused to organically form a continuous production line; and therefore, the defects of the prior art are overcome, the energy resource is saved, the heat treatment quality is improved, the production period is shortened, the production cost is lowered and the radiation pollution to a workshop environment is reduced.

Owner:CHANGLI FORGING

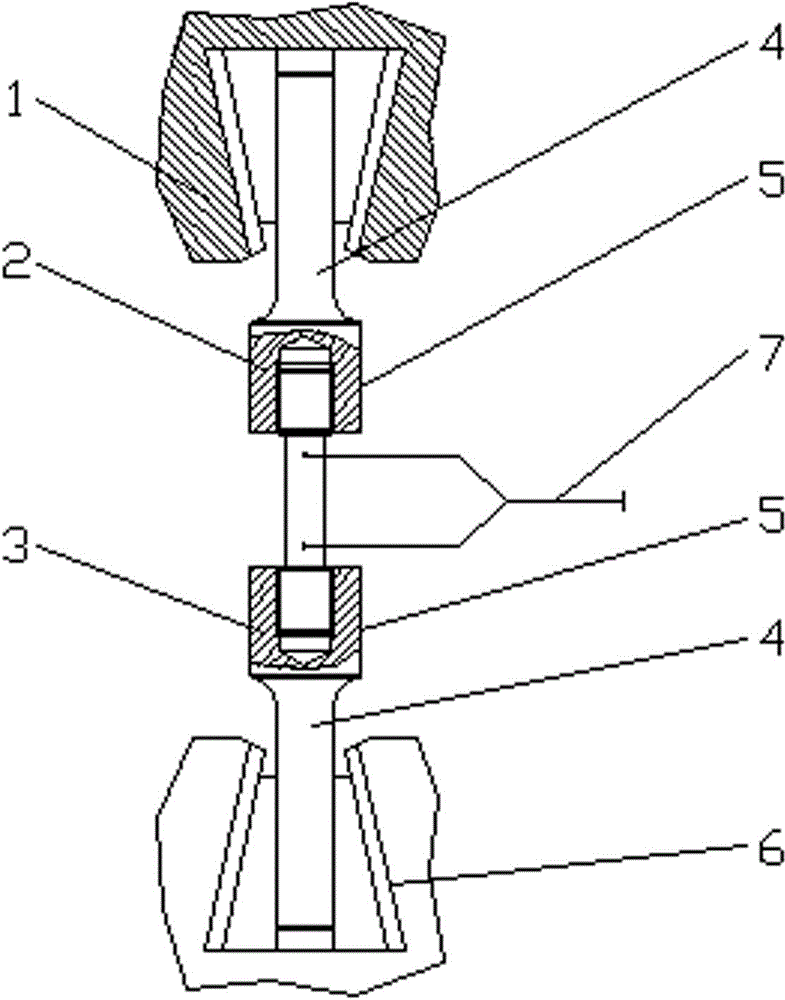

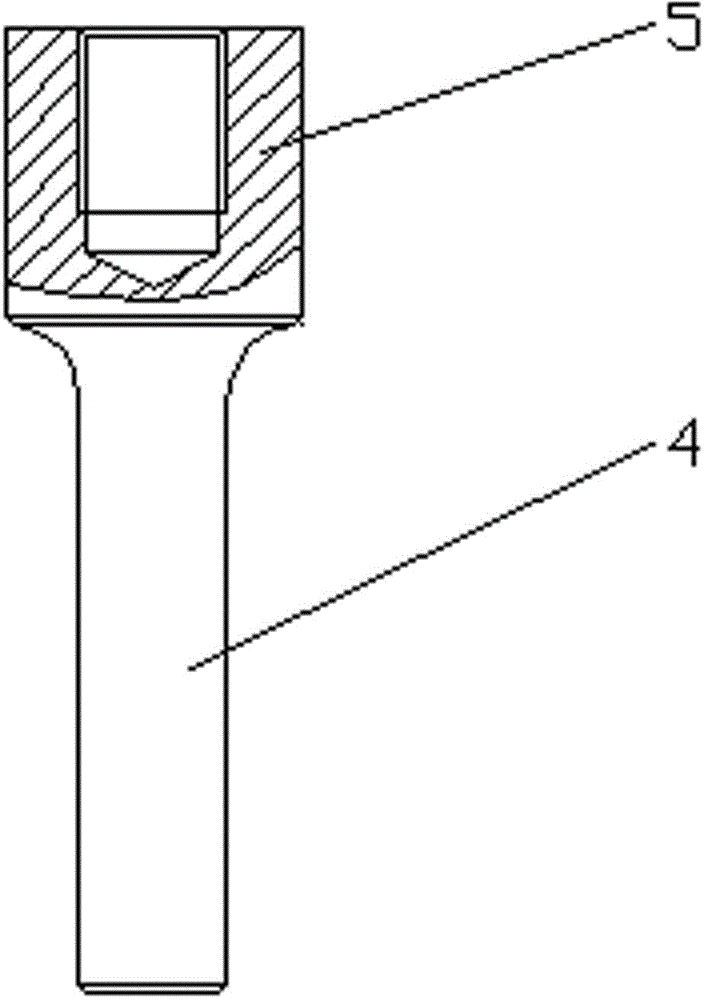

Processing inspection fixture for special steel tensile sample and inspection method

InactiveCN104865121AReduce consumptionReduce lossMaterial strength using tensile/compressive forcesEngineeringTower

The invention relates to a processing inspection fixture of a special steel tensile sample and an inspection method. The processing inspection fixture comprises an upper fixture and a lower fixture, wherein each of the upper fixture and the lower fixture is of a tower-shaped threaded sleeve structure, and is composed of clamping ends and threaded sleeves; the other ends of the upper and lower clamping ends are respectively mounted in a upper tester jaw and a lower tester jaw; the upper fixture and the lower fixture respectively fix one end of a tensile finished product sample with a threaded head; meanwhile, a tester extensometer is clamped on the tensile finished product sample with the threaded head. According to the invention, the technical problems that the short special steel tensile sample cannot clamp the extensometer and the clamp slipping affects the accuracy of inspection results are solved; the fixture is convenient and rapid to replace, can be recycled, and has long service life; the tensile batch inspection of the special steel products can be completed at low cost by using the processing inspection fixture for the special steel tensile sample and the inspection method.

Owner:SGIS SONGSHAN CO LTD

Induction heating furnace provided with half-split panel induction coils

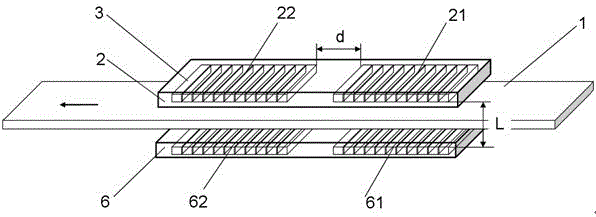

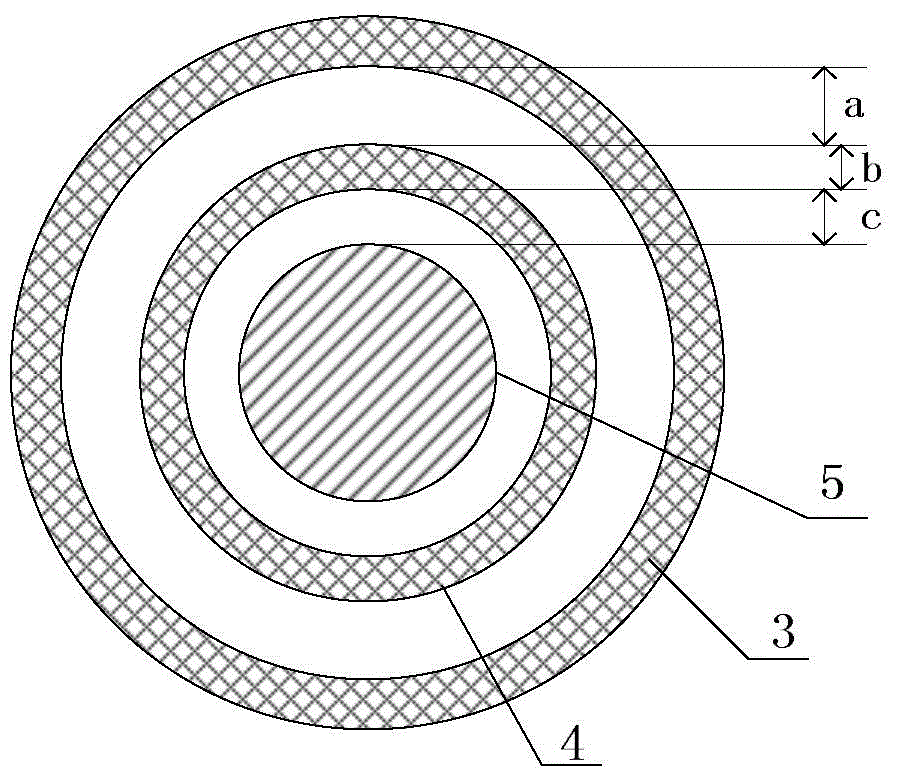

ActiveCN105698525ADoes not affect normal productionMeet temperature distribution requirementsCoil arrangementsFurnace typesHeating furnaceCopper

The invention relates to an online induction heating technology for steel plates. An induction heating furnace with split flat induction coils, comprising an upper set of flat induction coils (2) and a lower set of flat induction coils (6), the lower set of flat induction coils is fixedly installed on the induction furnace support, and the upper set of flat induction coils The coil is installed on the frame that can move up and down. The upper group of flat induction coils and the lower group of flat induction coils form a pair of flat induction coils. The heated plate (1) passes between the upper and lower two groups of flat induction coils; the flat induction coil includes copper tubes (3) and yoke (4), the yoke is E-shaped, and the two working sections of the multi-turn copper tube coil are respectively placed in two inner grooves of the E-shaped yoke and placed in parallel, and placed in front of the E-shaped groove of the yoke The copper tube inside is the front copper tube, and the copper tube placed at the back of the E-shaped groove of the yoke is the rear copper tube. The current direction flowing through the front copper tube and the rear copper tube is opposite. When encountering a severely warped steel plate during production, the upper set of plate induction coils can be lifted quickly.

Owner:BAOSHAN IRON & STEEL CO LTD

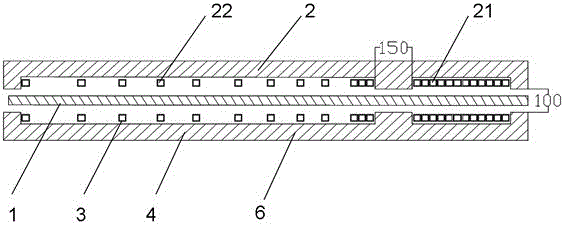

Induction heating method and device with self-adaptive distance adjusting function

ActiveCN105648164ABroaden and enhance processing capabilitiesIncrease productivityFurnace typesIncreasing energy efficiencyControl systemEngineering

The invention discloses an induction heating method suitable for steel plates with any warping degree. Firstly, a steel plate (2) is moved to an inlet of inductors (8) of an induction heating furnace through a roller bed system (1), displacement sensors (5) located on the upper portion of the front end of each upper inductor (3) are used for detecting the distance between the surface of the steel plate and the sensors and sending a measurement result to an intelligent processing unit; secondly, the intelligent processing unit works out the warping degree of the steel plate and an upper inductor position adjusting mode and sends the warping degree of the steel plate and the upper inductor position adjusting mode to a PLC control system; thirdly, the PLC control system sends adjustment commands to an upper inductor position adjusting system (4), so that the distance between the steel plate and the upper inductors is kept relatively constant; and fourthly, when the steel plate enters the inductors, infrared temperature measuring units (6) mounted at the inlet ends of the upper inductors are used for detecting the temperature of the steel plate, power needed for heating the steel plate to a target temperature is worked out, and an inductor heating system is started to heat the steel plate, so that when the steel plate leaves the induction heating furnace, the temperature of the steel plate reaches the target temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

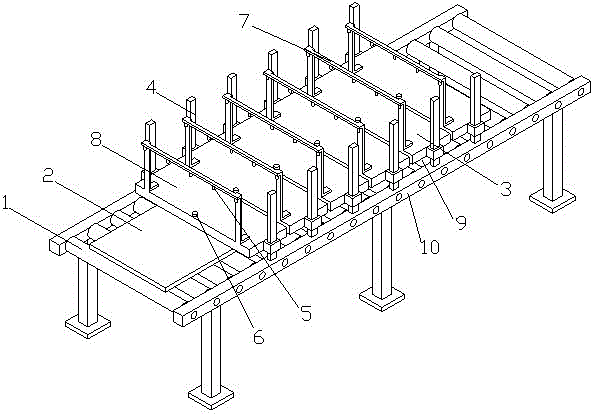

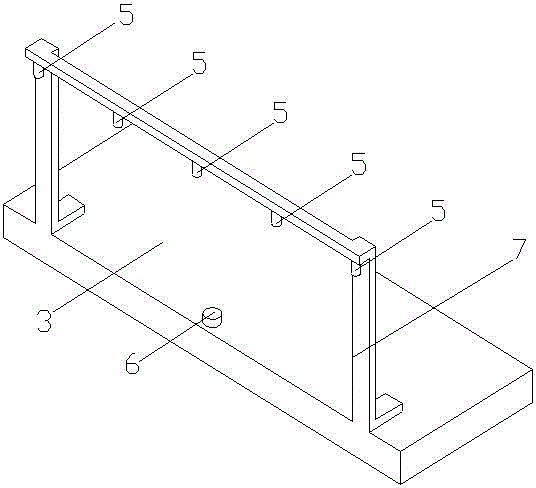

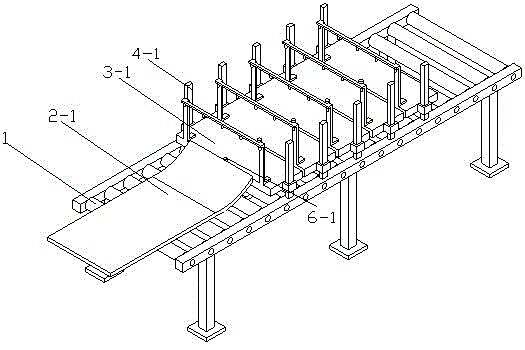

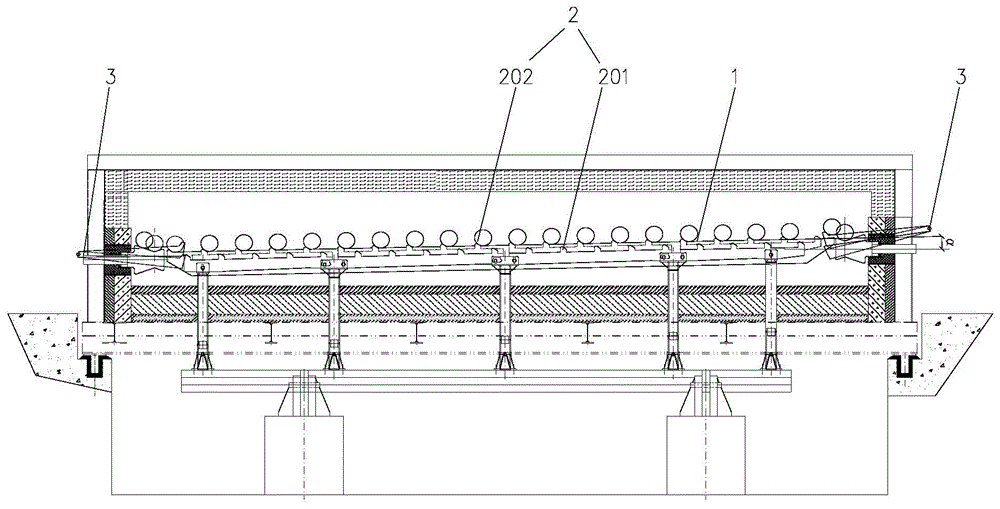

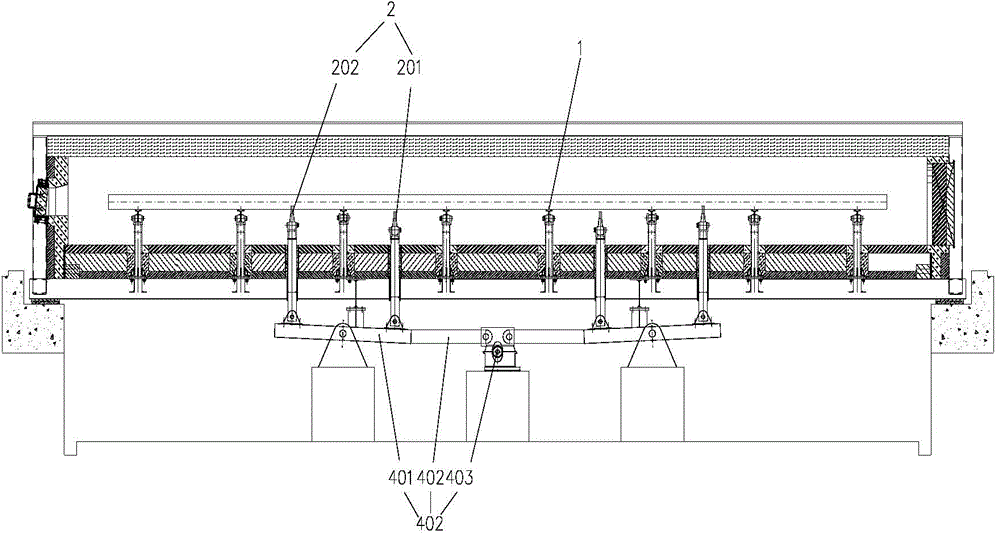

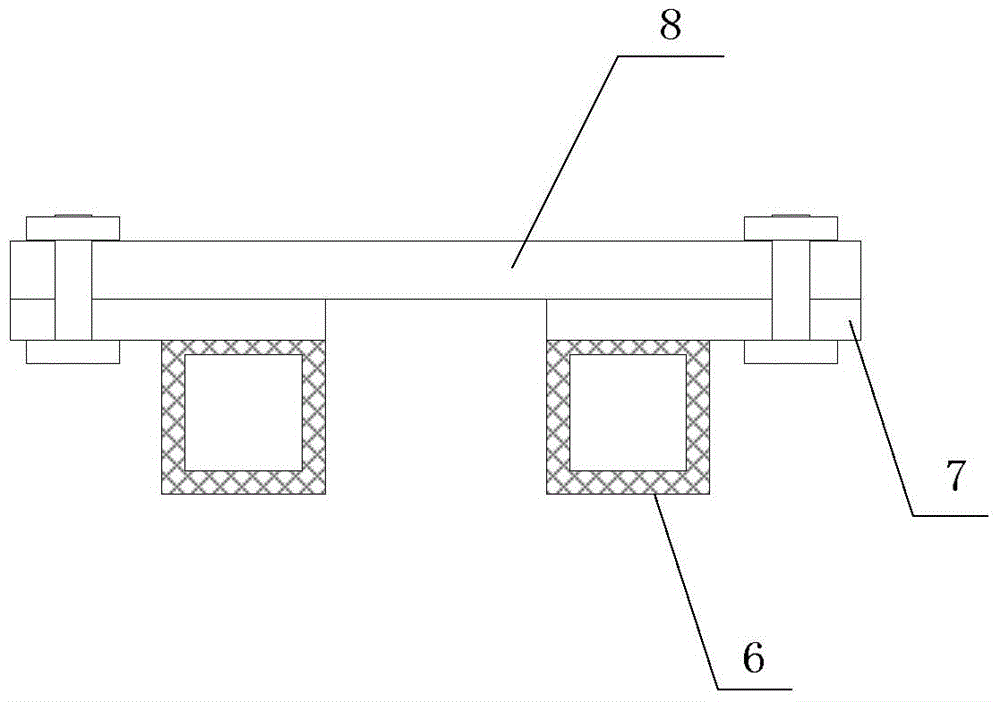

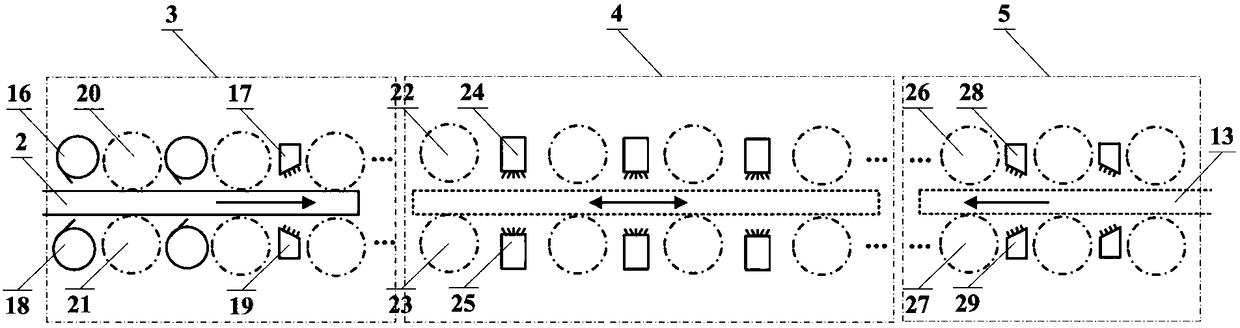

Intra-furnace conveying system for cylindrical workpiece and conveying method of intra-furnace conveying system

ActiveCN104596240AAvoid squeezing each otherReduce mutual shadowingFurnace typesHeat treatment furnacesEngineeringFront and back ends

The invention discloses an intra-furnace conveying system for a cylindrical workpiece and a conveying method of the intra-furnace conveying system and belongs to the technical field of furnace body fittings. The conveying system comprises a micro-inclined rail unit, workpiece positioning units, steel pushing machine units and driving devices, which are arranged in a furnace; the driving devices correspond to the workpiece positioning units one by one; the steel pushing machine units are arranged at the front and back ends of the micro-inclined rail unit; the workpiece positioning units are arranged beside the micro-inclined rail unit at equal intervals; each workpiece positioning unit comprises at least two odd positioning units and at least two even positioning units; the odd positioning units and the even positioning units are respectively in parallel with the workpiece in a row and are arranged in a staggered manner; each driving device is arranged between the corresponding odd positioning unit and the corresponding even positioning unit; the conveying method comprises a furnace entering process, a conveying process, a separating and positioning process, and a furnace discharging process. With the intra-furnace conveying system for the cylindrical workpiece and the conveying method, a thermal processing furnace system is simplified substantially, the cost is greatly reduced, and the thermal efficiency of the furnace body and the thermal processing quality of the workpiece are improved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

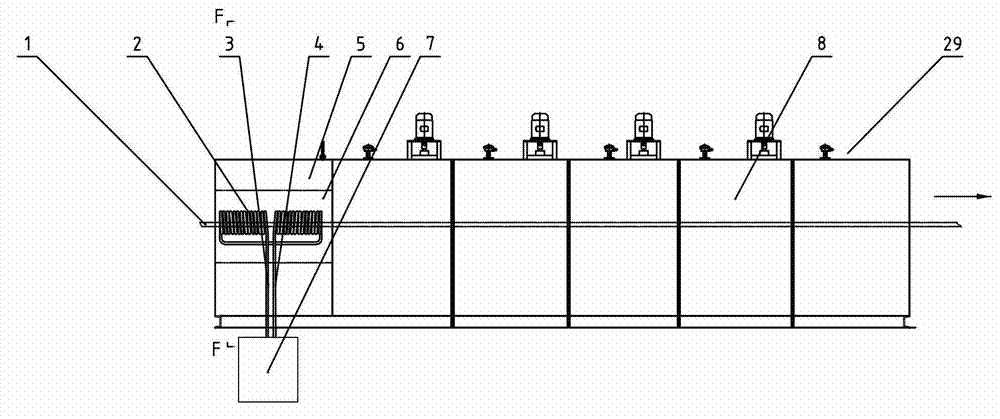

Heat treatment device of rod-like material

InactiveCN103484648ACompact structureSave human effortFurnace typesHeat treatment furnacesCombustorFlue gas

The invention relates to a heat treatment device of rod-like materials. The device comprises a heating furnace, a combustor for combusting fuel, a loading module, a feeding module, a charging module and a slip pipe. The loading module automatically screen the rod-like materials in a bunker, adjust the state of the materials and push the materials to a conveyor belt of the feeding module; a material moving device sequentially move the rod-like materials on the conveyor belt into a feed chute one by one; a pneumatic material pushing device pushes the rod-like materials in the feed chute into a heating furnace; once one rod-like material is pushed into a feed inlet, one rod-like material is discharged from a discharge port of the discharging module; a heat supply source in the heating furnace is employed to heat the rod-like materials from the outside of tubes; and the heat laden in the flue gas is treated by a heat exchanger and a high pressure blower fan to realize recovery of flue gas waste heat. The device provided by the invention has high degree of automation, is suitable for batch heat treatment of rod-like materials and has the advantages of high efficiency, low cost, energy saving and environmental protection.

Owner:ZHEJIANG SHANGDING IND FURNACE

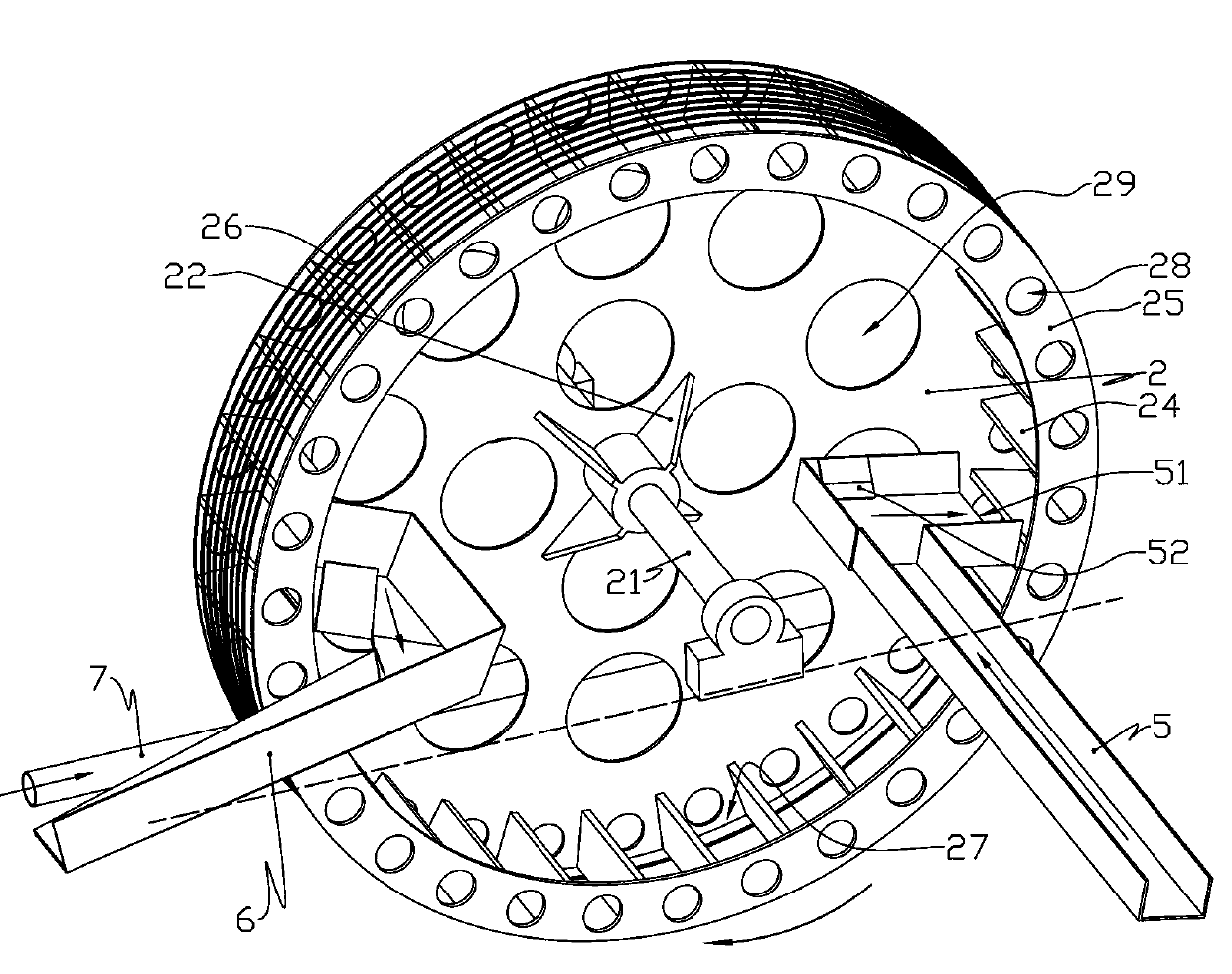

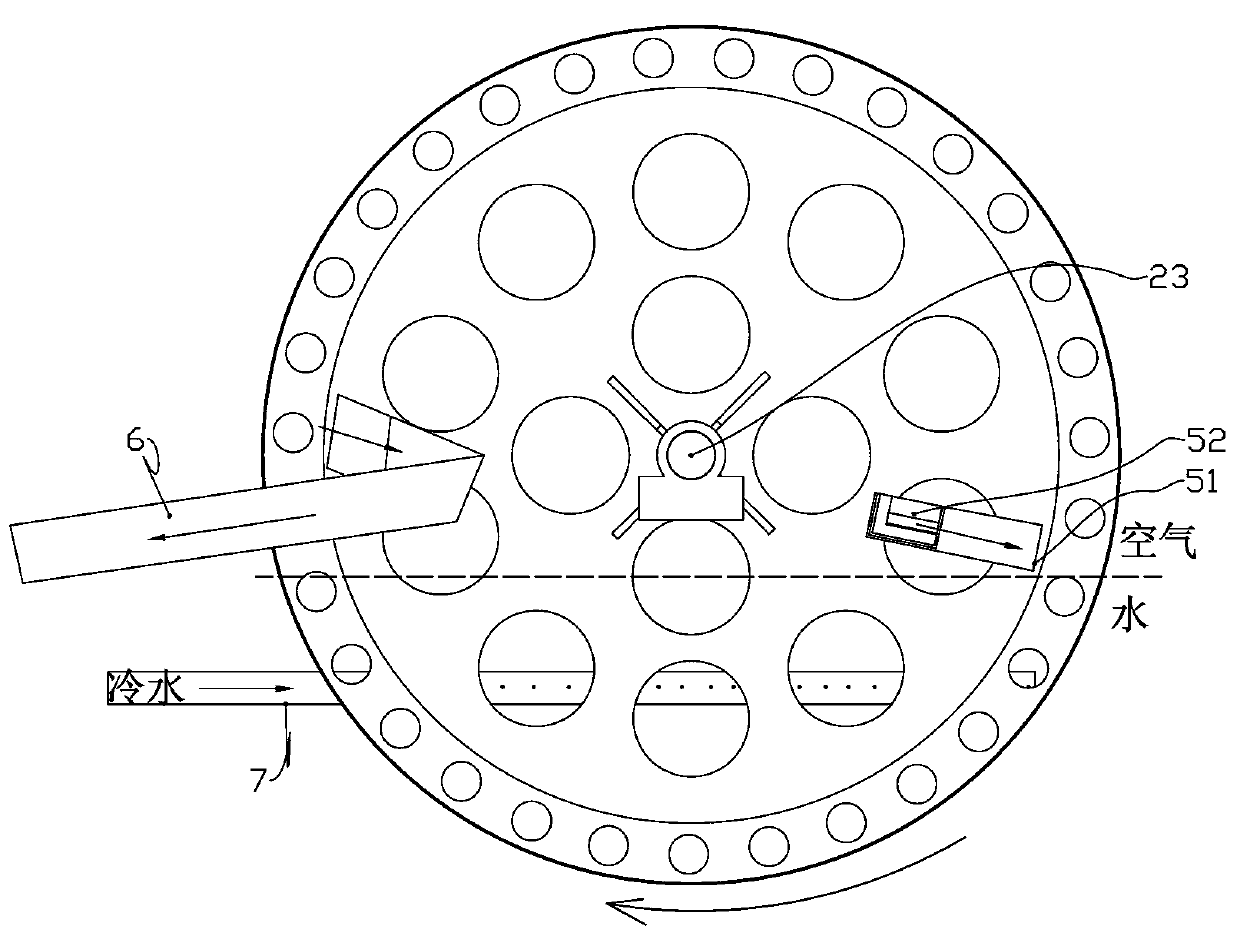

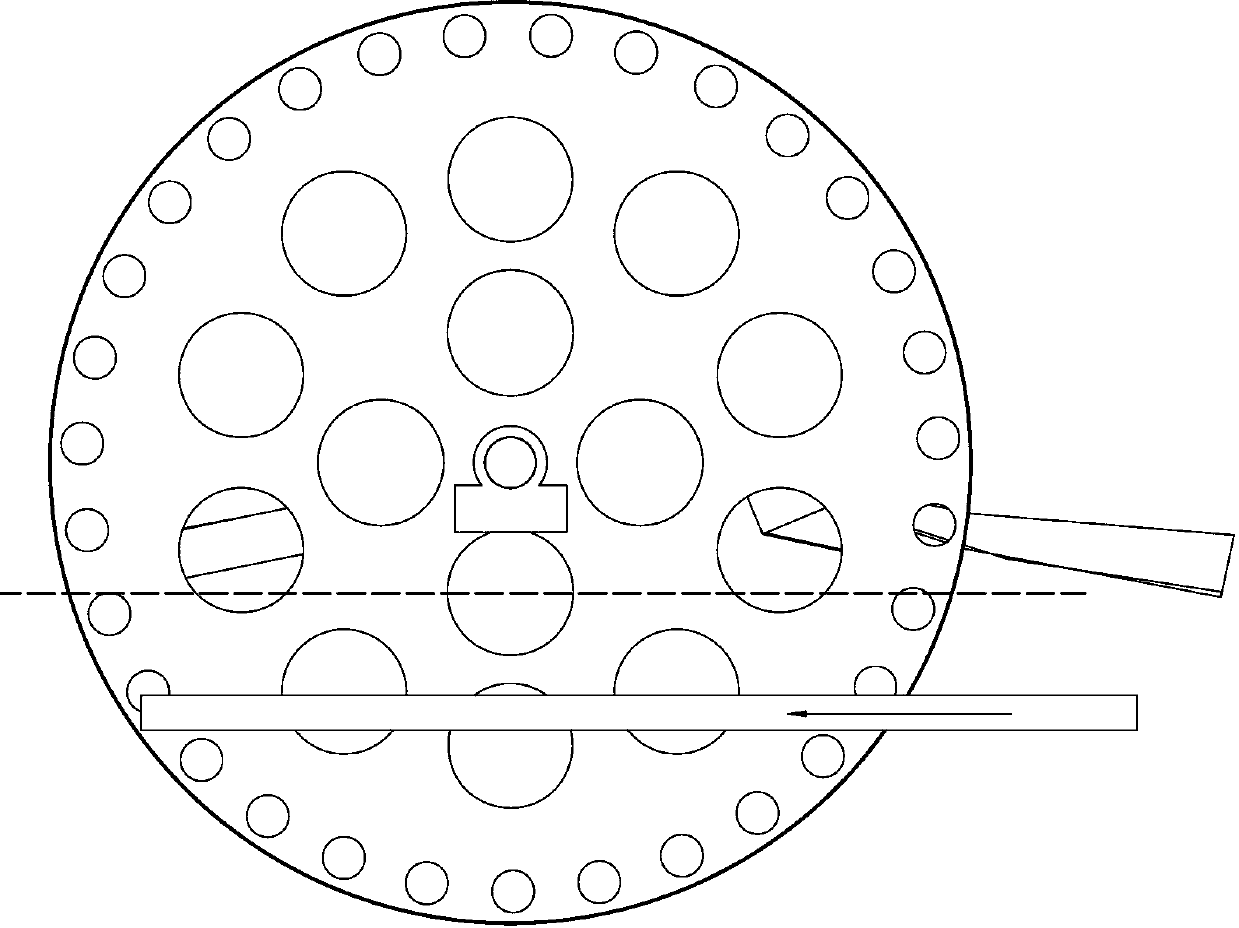

Heat treatment quenching apparatus used for steel ball with minor diameter

InactiveCN103589849ASimple structureReduce volumeFurnace typesProcess efficiency improvementSteel ballQuenching

The invention relates to a heat treatment quenching apparatus used for a steel ball with minor diameter, which comprises a pool, a rotating disk, a cold water supply pipe, a speed regulation motor, and a steel ball supply long groove and a steel ball recovery long groove, a rotating shaft is fixed at the center of the rotating disk, the rotating shaft crosses over the rotating shaft, thereby the bottom half of the rotating disk is placed in the pool, a plurality of container-like cavities which are opened inwards used for accommodating steel balls are circumferentially and uniformly arranged along the outer edge of the rotating disk, the steel ball supply long groove stretches into one cavity at one side of the bottom half of the rotating disk and supplies the steel ball, the steel ball recovery long groove extends to one cavity at other side of the top half of the rotating disk and is used for carrying the steel ball after quenching; the cold water supply pipe is the spray pipe which is placed in the pool, and the bottom half of the rotating disk supplies cold water, and the setting of a spiracle on the spray pipe is gradual decrease from a water inputting end. The heat treatment quenching apparatus aims at the quenching apparatus used for forging steel ball with diameter between 20-30 millimeters, and can satisfy large-batch quenching requirement.

Owner:JINAN HUIXIN IND

Steel wire induction-heating device

InactiveCN104694732AReduce distanceIncrease productivityFurnace typesIncreasing energy efficiencyTreatment qualityHeating efficiency

The invention discloses a steel wire induction-heating device. The steel wire induction-heating device comprises a worktable, and a plurality of cylindrical induction coil formed by winding hollow copper pipes; a plurality of supporting plates are detachably mounted on the worktable; each induction coil is fixedly mounted on one supporting plate; the induction coils are coaxially connected in series; an insulating tube is arranged inside each induction coil, and a round steel wire to be heated is put into the insulating tube; the wall thickness of each insulating tube is 2-3mm, the distance between the inner wall of each induction coil and the outer wall of each insulating tube is 3-4mm, and the distance between the inner wall of each insulating tube and the outer wall of each steel wire to be heated is 2-3mm. Compared with the prior art, the steel wire induction-heating device is reasonable in design, flexible in use, safe and reliable, and capable of meeting a plurality of processing requirements; in addition, the dimensions of the diameter of each steel wire and the inner diameter of each induction coil are reasonably matched, so that the distance between the steel wire and the induction coil can be reduced, and furthermore, the heating efficiency and the heat treatment quality of the steel wire can be improved.

Owner:江苏金基特钢有限公司

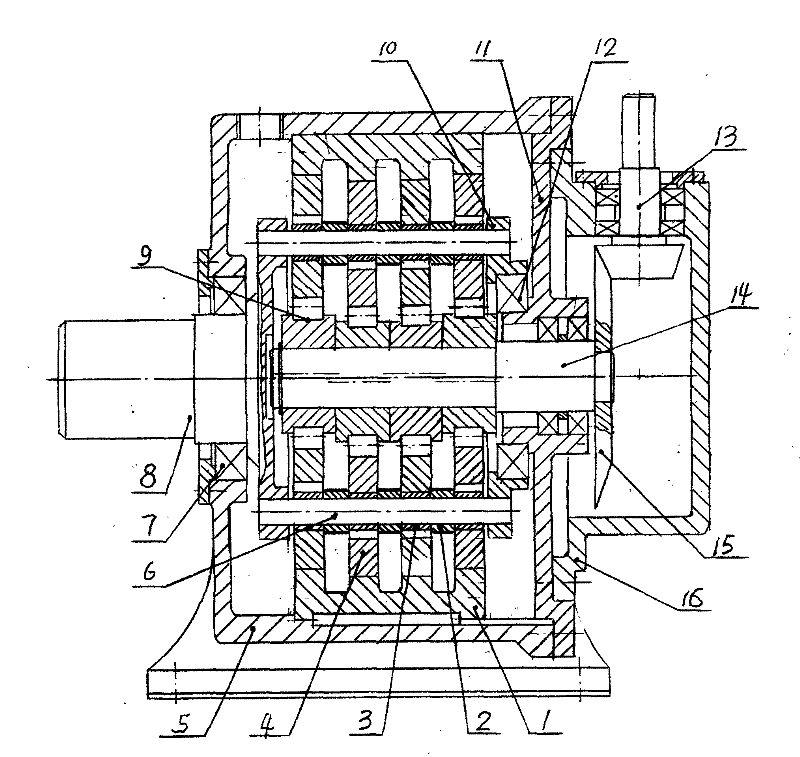

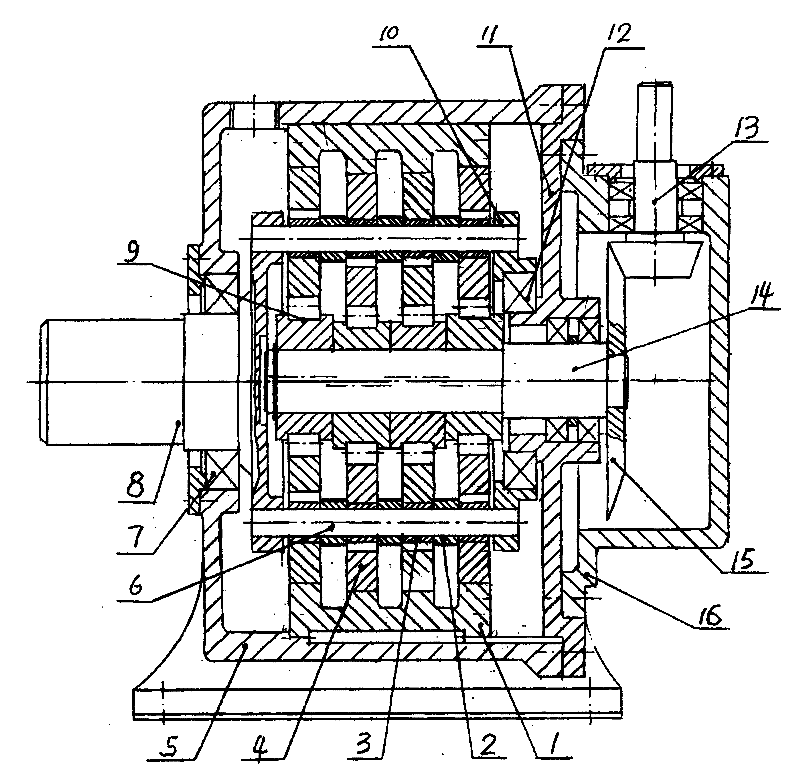

Reducer with bevel gear and hypocycloid in large transmission ratio for ore grinding machine

InactiveCN102192280ASmall radius of curvatureImprove contact strengthToothed gearingsReduction drivePhase difference

The invention relates to the technical field of reducing the speed of an ore grinding machine. A reducer with a bevel gear and a hypocycloid in large transmission ratio for an ore grinding machine is characterized by comprising a bevel gear pair and a cycloid transmission part; the bevel gear pair comprises driving and driven bevel gears and the cycloid transmission part is composed of a machine body, an input shaft, eccentric bearings, a cycloid gear, an inner cycloid gear ring, a W mechanism and bearings; the W mechanism comprises an output shaft, a column pin, a uniform loading disc and an annular plate; in the W mechanism, the output shaft is supported on an inner hole of the machine body through utilizing the bearing and an inner hole of the uniform loading disc is supported on the outer circle of a flange of an end cover through utilizing the bearing; in four single-eccentric bearings: the phase difference between the first bearing and the second bearing and the phase difference between the third bearing and the fourth bearing are 180 DEG and the phase of the second bearing is same as that of the third bearing. In the invention, the reducer has the beneficial effects as follows: (1) the hypocycloid gear is engaged by purely rolling, so that the bearing capability is improved by 2-3 times; (2) the length of the axial direction is reduced by 45-55% and the cost is reduced by 40-50%; (3) the reversed installation service life of the cycloid gear is doubled; and (4) the inertia force and the inertia moment are completely balanced in theory when the reducer is operated.

Owner:吴小杰

Resistance pit annealing furnace

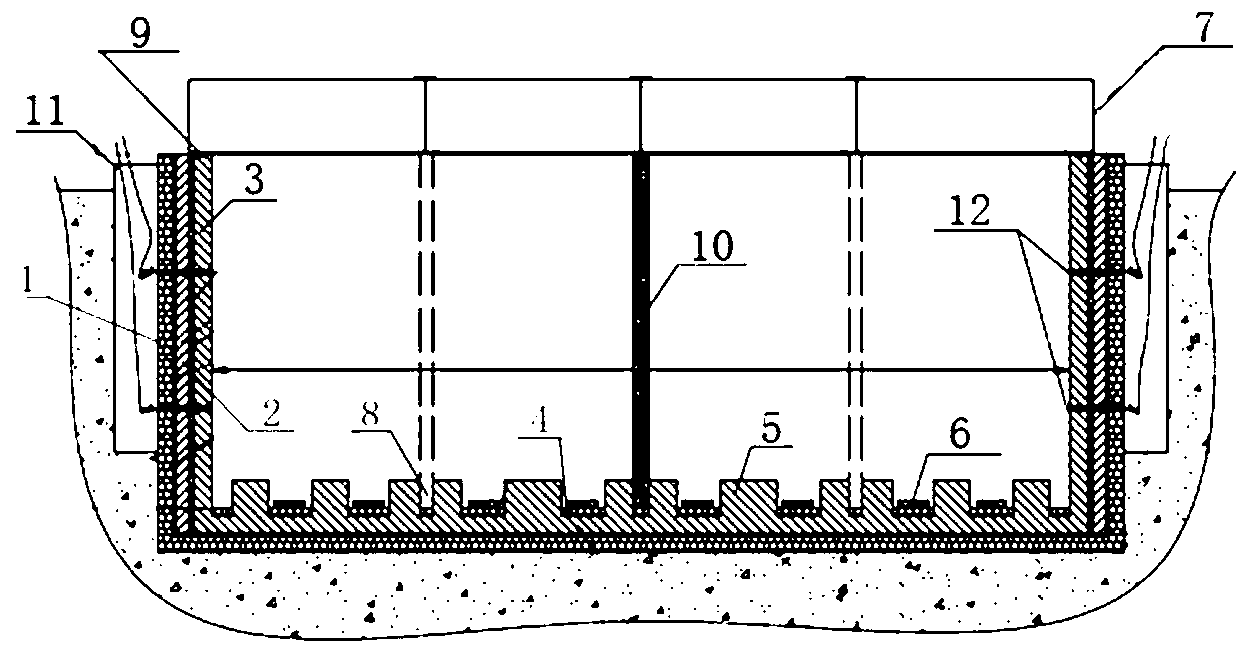

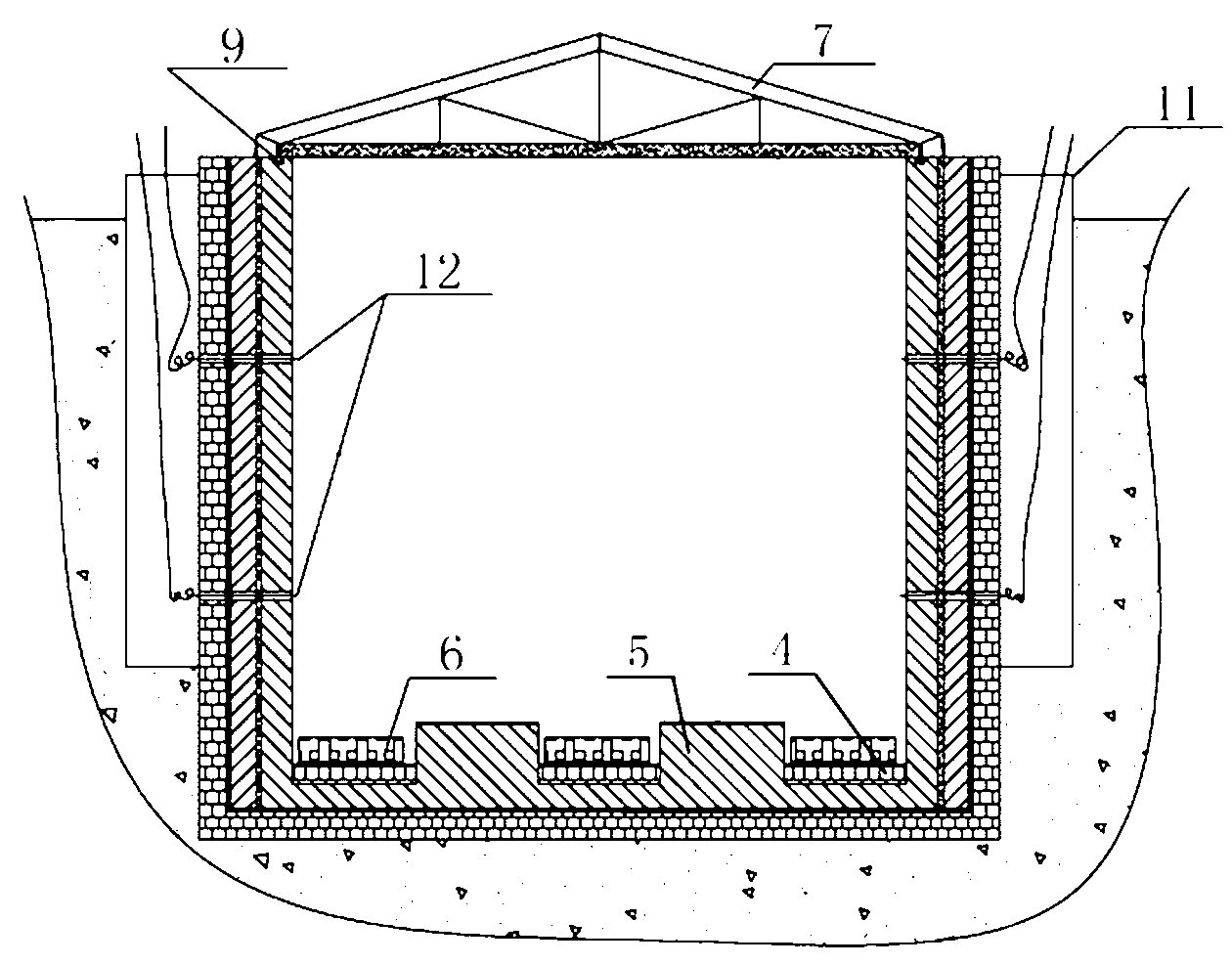

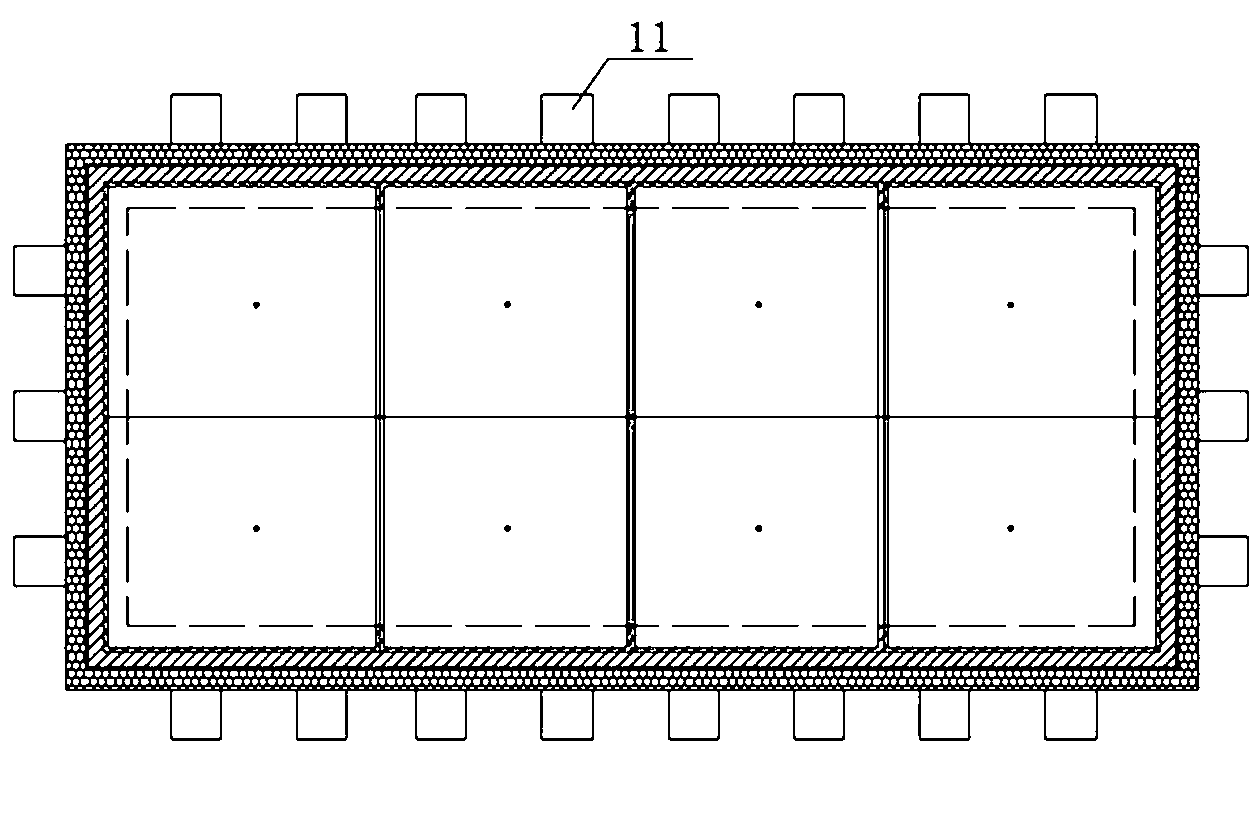

The invention provides a resistance pit annealing furnace, which comprises a furnace body and a furnace cover, wherein the furnace body is embedded in a pit; the furnace cover covers on the top opening of the furnace body; buttresses are spread all over on the bottom face of the interior of the furnace body; an electric heating plate is arranged on a furnace bottom between each two buttresses; the furnace wall of the furnace body is provided with a plurality of temperature detectors; the electric heating plates and the temperature detectors are respectively and electrically connected onto a controller arranged outside the pit; a plurality of side walls for conducting wires and / or data lines to pass through are arranged between the outer wall of the furnace body and the wall of the pit; the wall of the furnace body consists of a brick wall, a plaster layer, a waterproof layer, a reinforced concrete furnace wall, a flame-retardant fiber board thermal insulation layer and a heat-resistance reinforced refractory castable furnace wall; and the furnace bottom of the furnace body consists of the brick wall, the plaster layer and the waterproof layer. According to the resistance pit annealing furnace provided by the invention, the furnace body is embedded in the pit, and the furnace bottom and the furnace wall can be integrally poured, so that the integral structure is simple in design; and the furnace bottom and the furnace wall respectively consist of the brick wall, the plaster layer and the waterproof layer, so that the cost can be saved, and the investment can be reduced.

Owner:河北二十冶建设有限公司

Hot forging machining method of positioning hook for train

InactiveCN103071742AEnergy savingImprove the quality of heat treatmentMetal-working apparatusHeating furnaceForging

The invention discloses a hot forging machining method of a positioning hook for a train, comprising the following steps of: 1) selecting circular steel with the diameter of 35 mm; utilizing a cutting machine to carry out blanking, wherein the length of a blank piece is 172 mm after cutting; 2) putting the blank piece obtained by the step 1 into an intermediate-frequency heating furnace to be heated, wherein the heating temperature is 1120-1180 DEG C and the heating time is kept for 2-3 min; 3) utilizing an air hammer to stretch two ends of a workpiece obtained by the step 2 and stretching the diameter to 20+ / -2 mm, wherein the hammer is used for stretching for 8-14 times; 4) placing the stretched workpiece into a bending die of a punching machine to carry out bending work; 5) putting the bent workpiece into a molding die in an electric spiral pressing machine; utilizing the molding die to carry out hot forging on the workpiece, wherein the temperature is 900 DEG C and the pressure is 630 T; and 6) putting the workpiece which is subjected to the hot forging into the punching machine to be subjected to edge cutting and punching treatment. According to the hot forging machining method disclosed by the invention, a tempering heat treatment process of the positioning hook of a continuous production line is organically formed by high-temperature normalizing and forging, and the defects of the prior art are overcome; the energy source is saved and the heat treatment quality is improved; the production period is shortened and the production cost is reduced; and the radiation pollution to a workshop environment is reduced.

Owner:CHANGLI FORGING

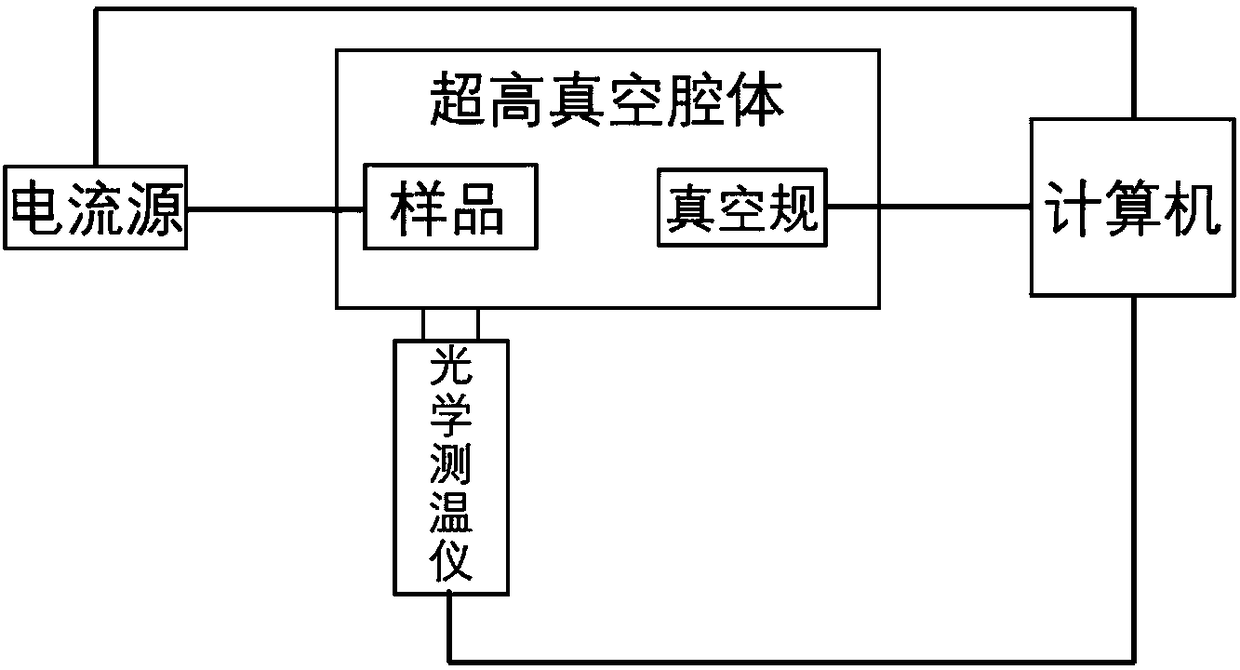

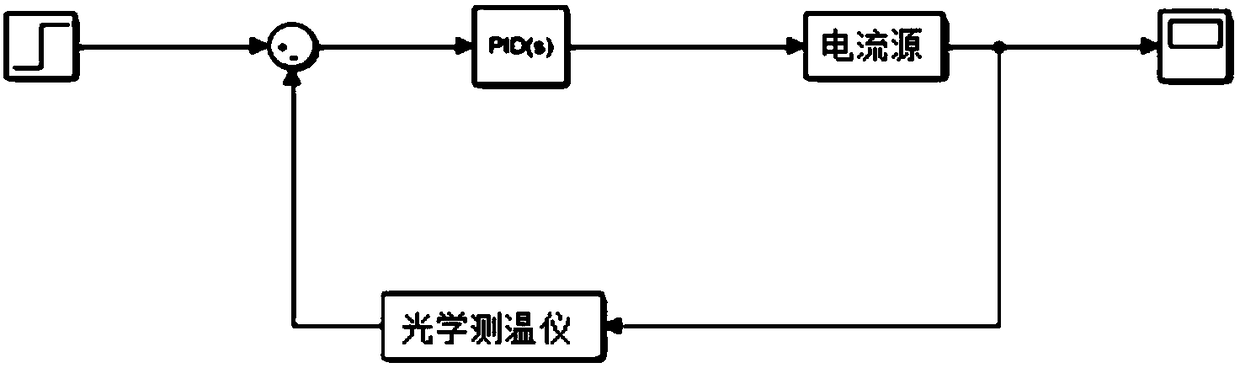

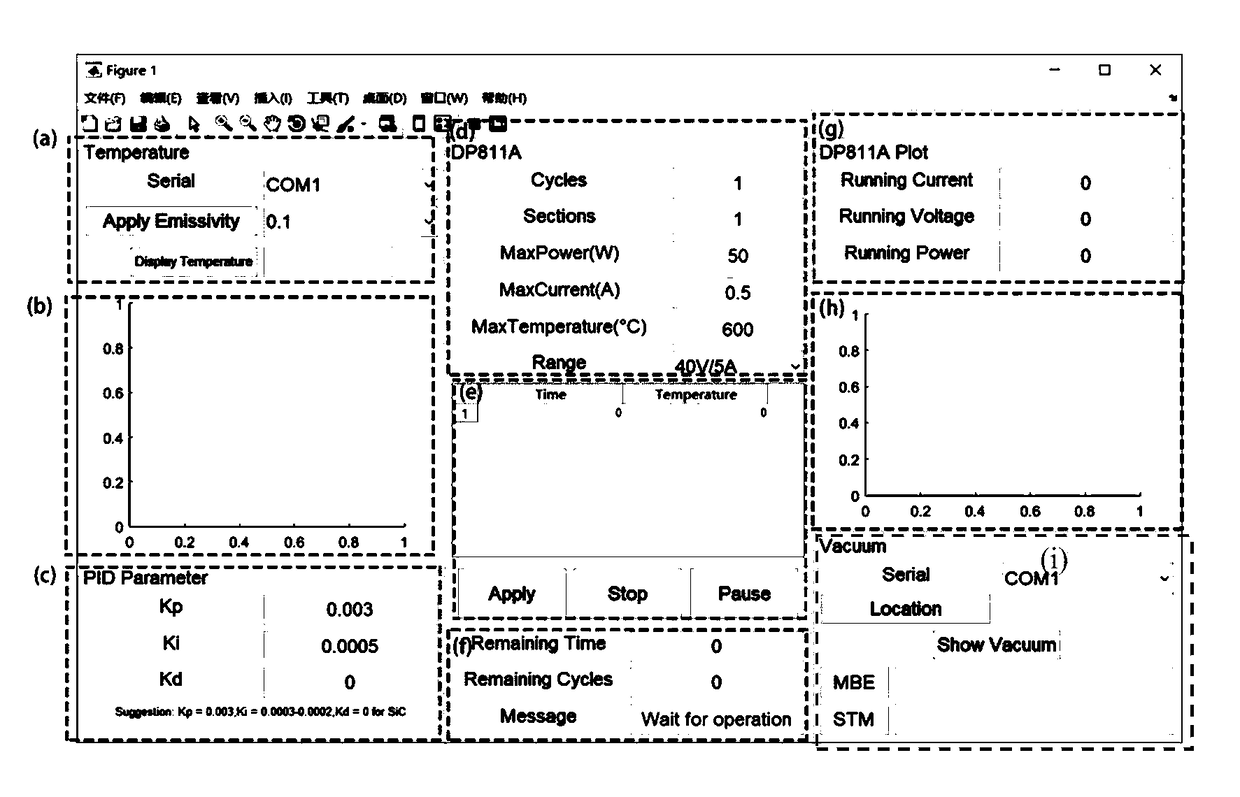

Automatic temperature control system and method for sample heat treatment process under ultrahigh vacuum

PendingCN108427453AImprove experimental efficiencyImprove experimental accuracyTemperatue controlControllers with particular characteristicsTemperature controlAutomatic train control

The invention discloses an automatic temperature control system and method for a sample heat treatment process under ultrahigh vacuum, and belongs to the field of temperature control. The system comprises an optics thermodetector, a vacuum gauge, a computer and a current source, the optics thermodetector and the vacuum gauge are located in ultrahigh vacuum sampling heating equipment, an infrared thermodetector and the vacuum gauge are connected with the computer, the computer is connected with the current source, and the current source is connected with a sample. Temperature negative feedbackto current of the heated sample is utilized, thereby achieving simple, quick and accurate temperature control, an RS232 serial port is used for connecting various instruments, a temperature differencevalue between a sample temperature measured by the optics thermodetector and a preset sample temperature is calculated, and a PID algorithm is used for feeding back and setting the applied current onthe sample by the current source. Although different types of current is required for heating samples due to sizes, manufacture and the like, the system can accurately control the sample temperatureto a set temperature within 1 DEG C in half a minute.

Owner:NANJING UNIV

Quenching and cooling device

The invention belongs to the technical field of quenching and cooling, and relates to a quenching and cooling device. The quenching and cooling device includes a quenching tank, a quenching bench, a quenching bench lifting system, a medium circulating system, a medium outlet system, a medium blowdown system, a cooling zone carrier roller, a power motor, a leading screw, a nut, a guiding sleeve, a guide rail, a circulating pump, a variable frequency motor, a liquid suction pipeline, a liquid suction port, a liquid discharging pipeline, an electronic flow meter, a cooler, an electric regulating valve, a flow controller, a medium outlet, a flow guiding plate, blades, a coaming plate, a fan and a fan cover, and the quenching bench lifting system includes the power motor, the leading screw, the quenching bench, a guide sleeve and the guide rail. The quenching and cooling device has the advantages of high automation degree, fast cooling speed, controllable cooling process, controllable flow, pressure and flowing direction of a cooling medium, uniform cooling, improvement of the product heat treatment quality, reduction of the loss of the cooling medium, reduction of the cleaning workload, increase of the working efficiency, ingenious and reasonable design of the overall structure, scientific principle, convenience in operation, convenience in use, good safety and reliability, and friendliness to application environment.

Owner:QINGDAO TAIDE AUTOMOBILE BEARING

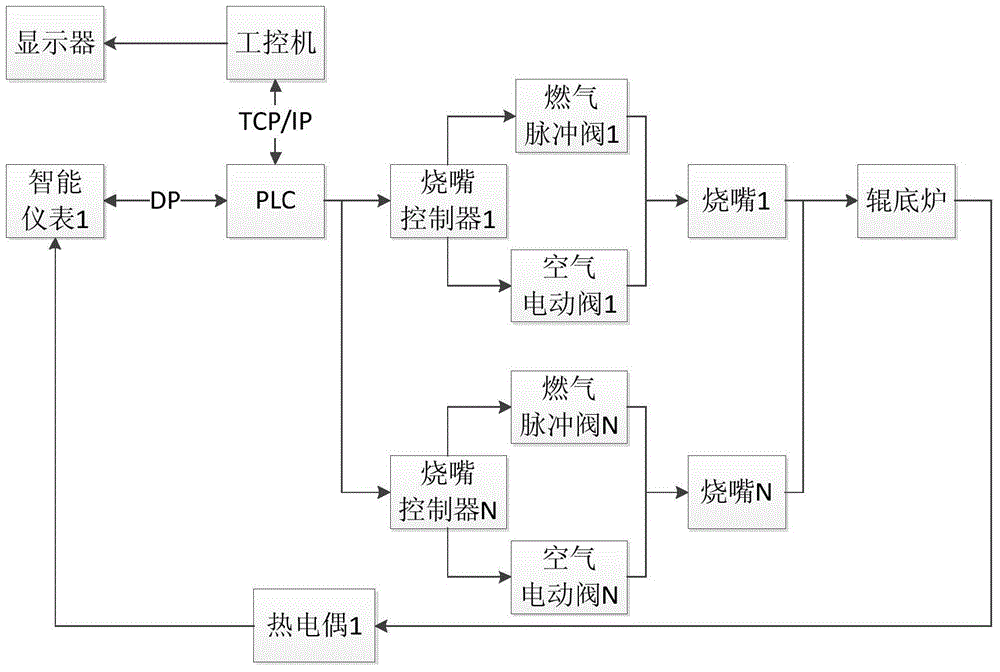

Gas type roller hearth furnace temperature control method and device

InactiveCN104911330AImprove qualityThe control method is simple and smartFurnace typesHeat treatment process controlTemperature controlFurnace temperature

The present invention discloses a gas type roller hearth furnace temperature control method and device, belongs to the field of roller hearth furnace temperature control method and device, and aims to solve the problems of poor controlling accuracy and the like of the method in the prior art; the gas type roller hearth furnace temperature control method is as follows: using a control unit for unified control of combustion, extinguishing, and the combustion duration time of all burners; and the gas type roller hearth furnace temperature control device includes a plurality of temperature sensors distributed in a fired gas roller hearth furnace, intelligent temperature control instruments connected with the temperature sensors, a PLC connected with the intelligent temperature control instruments, and an industrial personal computer connected with the PLC, and also includes burner control units arranged between each burner and the PLC. The gas type roller hearth furnace temperature control method and device innovatively bring forward the idea of overall control of the burners, the control method is simpler and smarter, temperature control precision is higher, and the gas type roller hearth furnace temperature control method and device are more saving energy, improve the quality of the gas roller hearth furnace, and are more universal.

Owner:CHINA NORTH IND NEW TECH PROMOTION INST +1

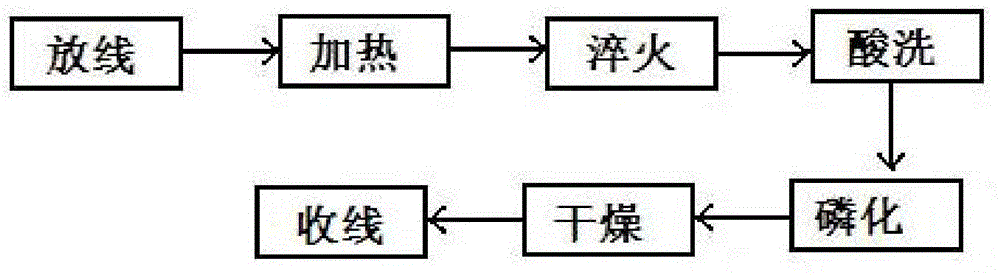

Thermal treatment technique of steel wire

ActiveCN102912109AImprove heat utilizationNo pollution in the processFurnace typesMetallic material coating processesThermal treatmentQuenching

The invention discloses a thermal treatment technique of a steel wire, comprising the following steps of: paying-off the steel wire by a pay-off rack; heating the steel wire by natural gas; putting the heated steel wire in a quenching bath for quenching; washing by water; putting the steel wire a pickling tank and then a phosphating tank; drying in a drying baker; and finally taking up. According to the invention, the whole thermal treatment line is free of pollution, clean and environment-friendly, the utilization rate of the thermal treatment heat is high, and energy is saved.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

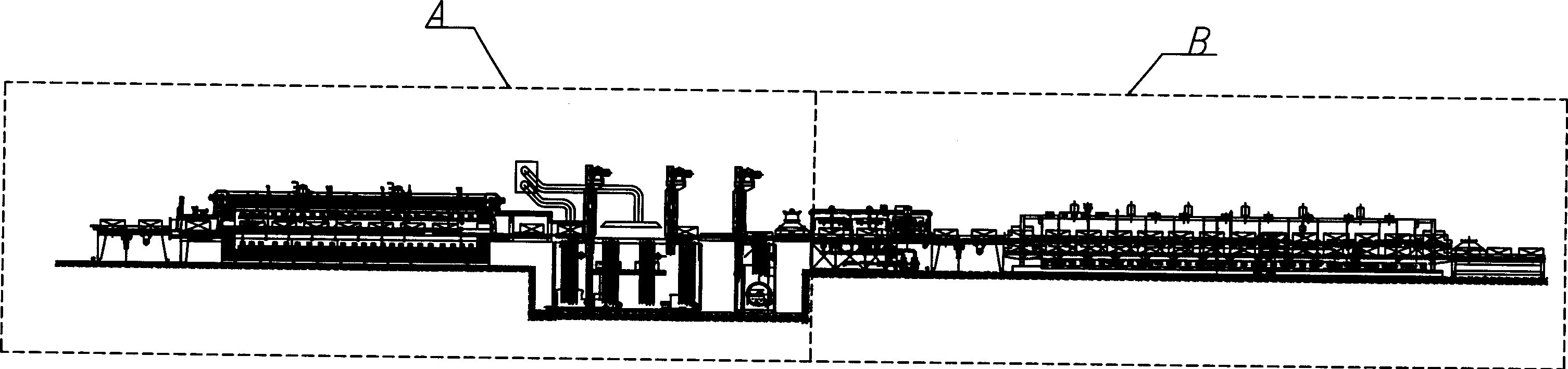

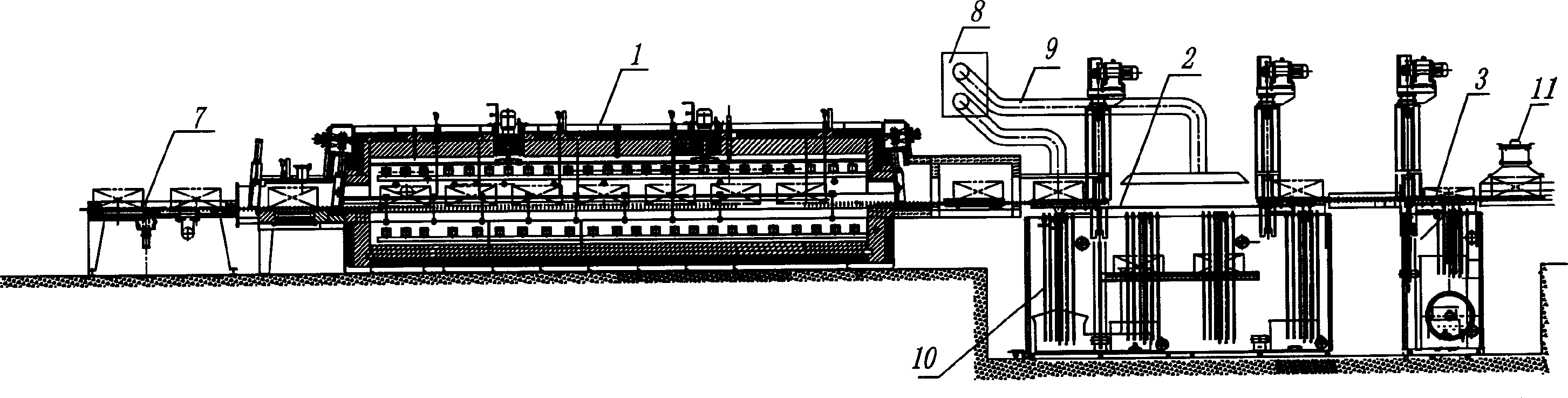

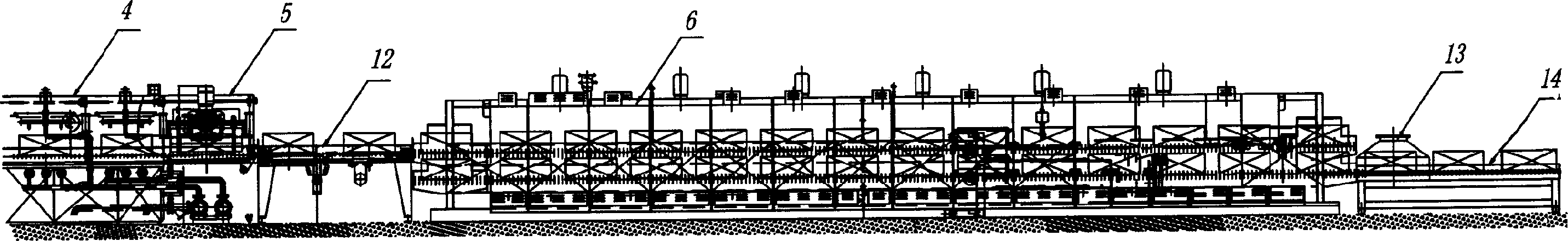

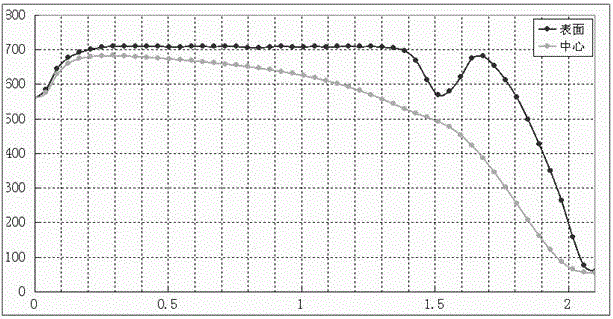

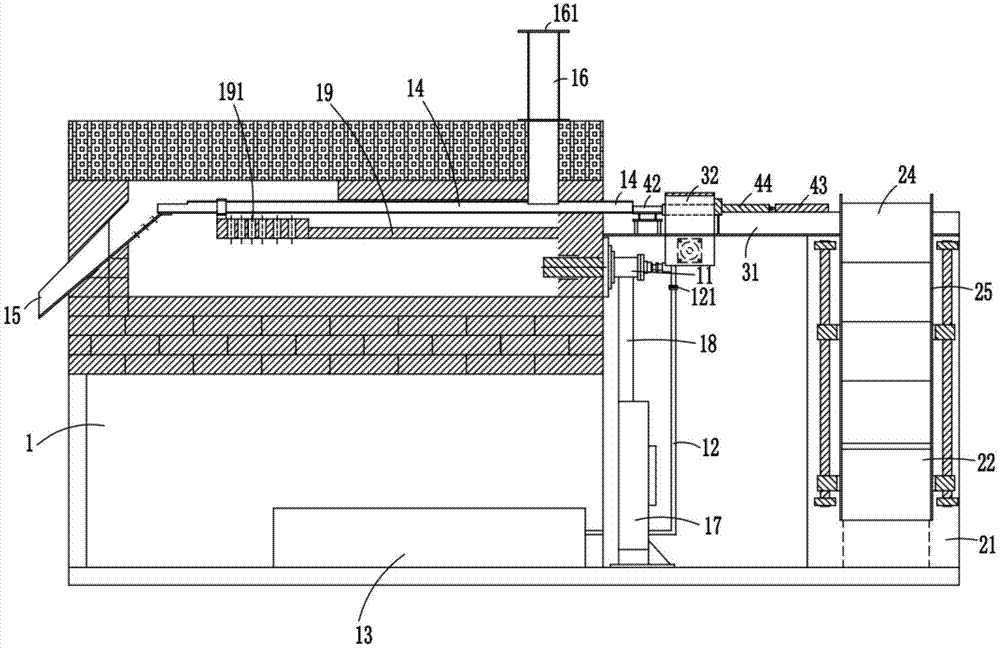

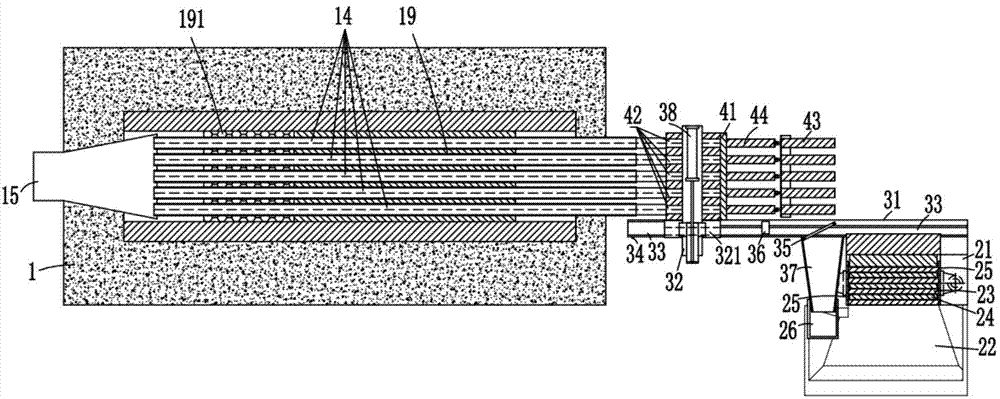

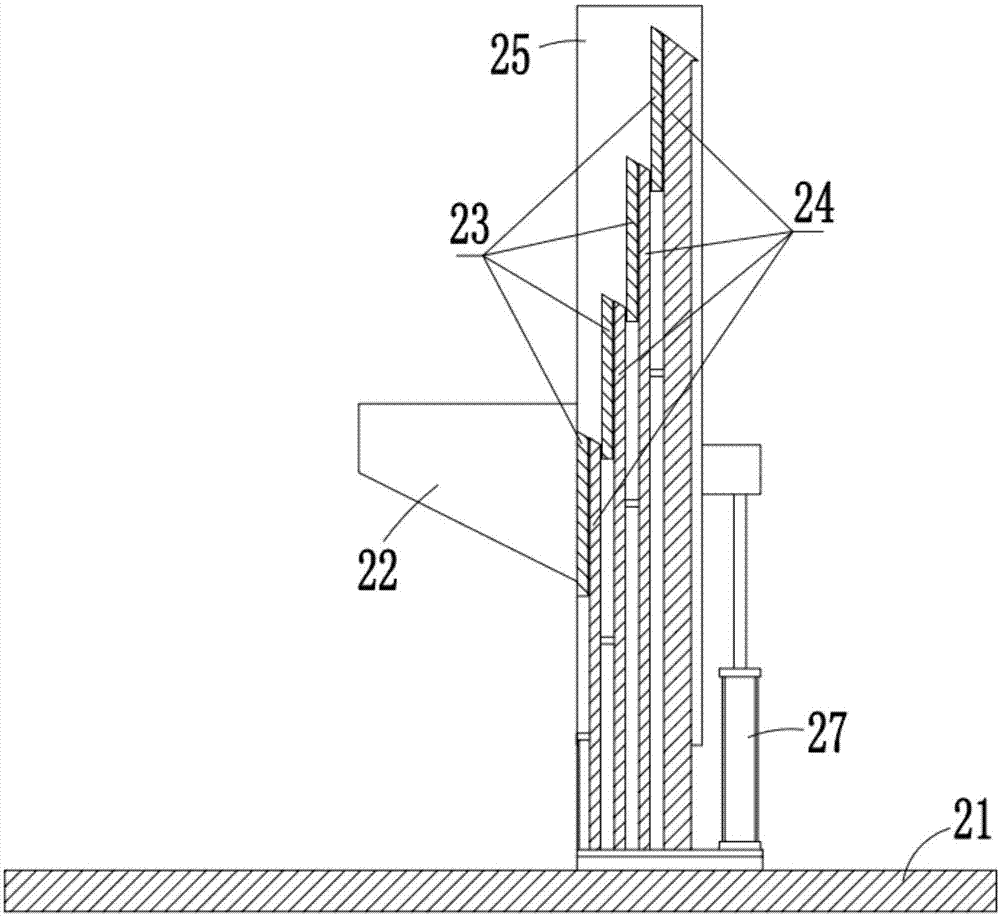

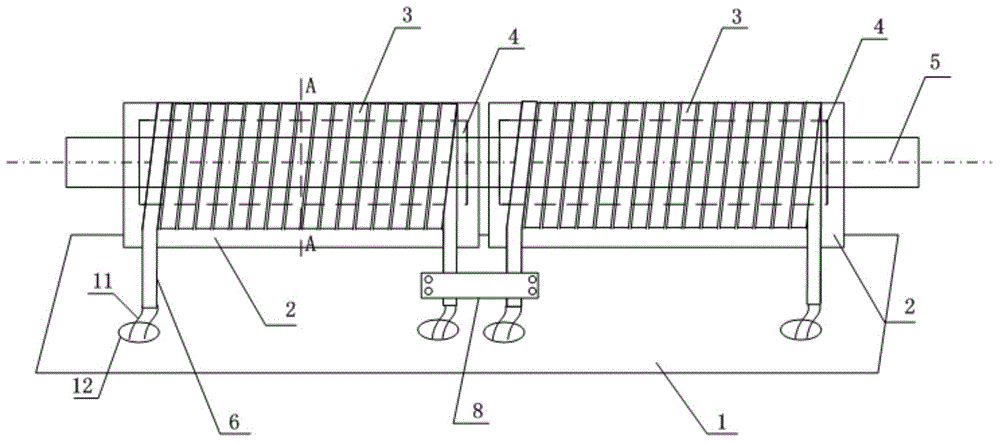

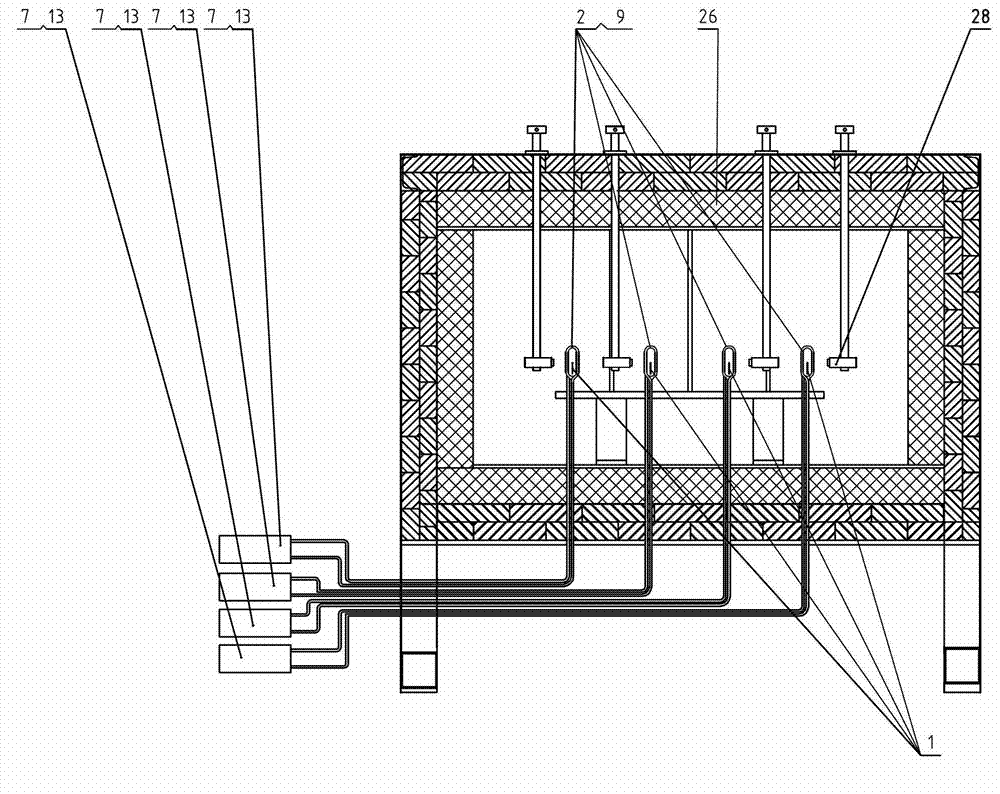

Quenching-tempering sensing rapid heating equipment and technology of heat treatment production line of bimetal strip sawblade

InactiveCN103045839AImprove the quality of heat treatmentEfficient heatingIncreasing energy efficiencyFurnace typesProduction lineHeating furnace

The invention provides quenching-tempering sensing rapid heating equipment and a quenching-tempering sensing rapid heating technology of a heat treatment production line of a bimetal strip sawblade, and relates to the field of production and processing of the bimetal strip sawblades. The quenching-tempering sensing rapid heating equipment comprises quenching heating equipment and tempering heating equipment which are sequentially arranged from the input direction to the output direction of the sawblade; three heating units of the tempering heating equipment are sequentially arranged from the input direction to the output direction of the sawblade; the quenching sensing heater is arranged in a quenching sensing heating furnace and is used for rapidly heating the sawblade; the quenching-tempering sensing heater is arranged in the tempering sensing heating furnace; the sawblade passes through a heating cavity of the tempering sensing heater; and the tempering sensing heater is used for rapidly heating the sawblade. The sawblade is rapidly sensed and heated at 700 to 1180 DEG C in the quenching sensing heating furnace and is then sequentially and rapidly sensed and heated at 300 to 550 DEG C in the tempering sensing heating furnace of the three heating units. The quenching-tempering sensing rapid heating equipment and the quenching-tempering sensing rapid heating technology are applied to online dynamic quick bright quenching and online quick tempering heat treatment of the bimetal strip sawblade.

Owner:曹玉贵

Thermal treatment device for metal

PendingCN108676968ACompact structureIngenious structureFurnace typesHeat treatment process controlEngineeringHeat losses

The invention discloses a thermal treatment device for a metal. The device comprises a heating area, a discharging buffering area and a cooling area which are sequentially arranged, wherein the heating area comprises a heating furnace; the cooling area comprises a cooling device; the discharging buffering area comprises a discharging buffering device, and the discharging buffering device comprisesa protecting cover, and a guide mechanism which is arranged in the protecting cover; a buffering area feeding port and a buffering area discharging port are formed in the outer side of the protectingcover; the buffering area feeding port communicates with a discharging port of the heating furnace; the buffering area discharging port communicates with a feeding port of the cooling device; one endof the guide mechanism is connected to the buffering area feeding port, and the other end of the guide mechanism is connected to the buffering area discharging port. The thermal treatment device forthe metal is compact and ingenious in structure, high in reliability, and high in automation degree; the discharging buffering device is additionally arranged, so that outside cold air can be effectively prevented from directly entering the heating area, and as a result, the heat loss is decreased; the heat transfer between the heating area and the cooling area is avoided; the heating efficiency and the thermal treatment quality are improved; and moreover, the workpiece damage is reduced; and the product quality is improved.

Owner:海安金锻工业有限公司

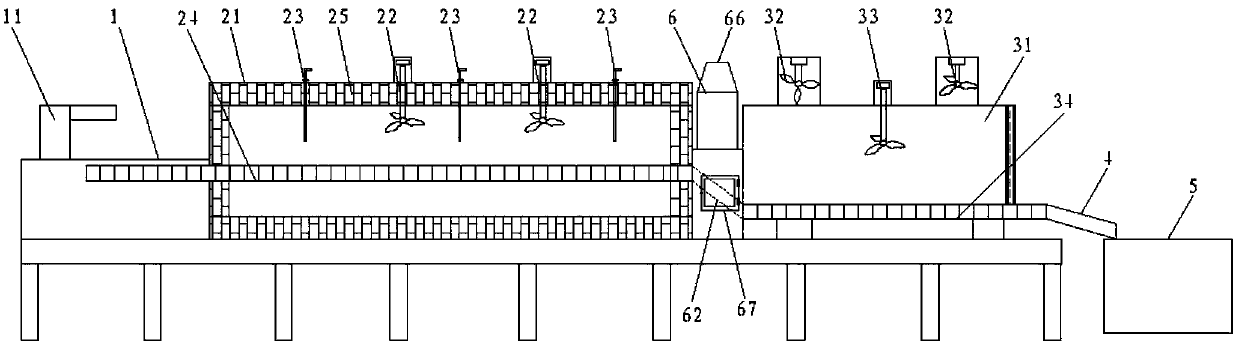

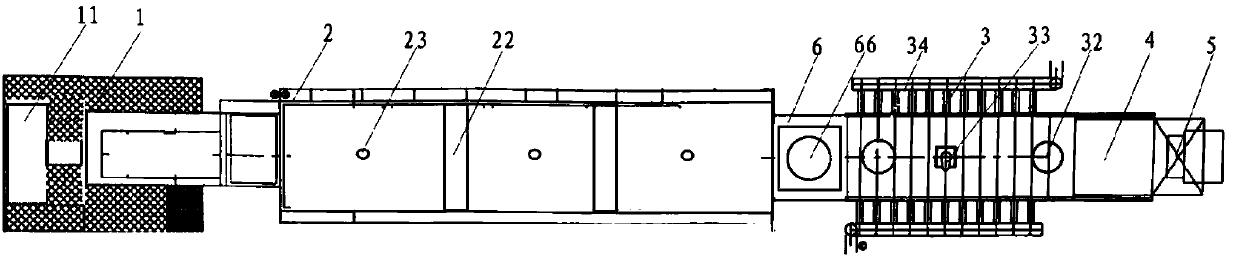

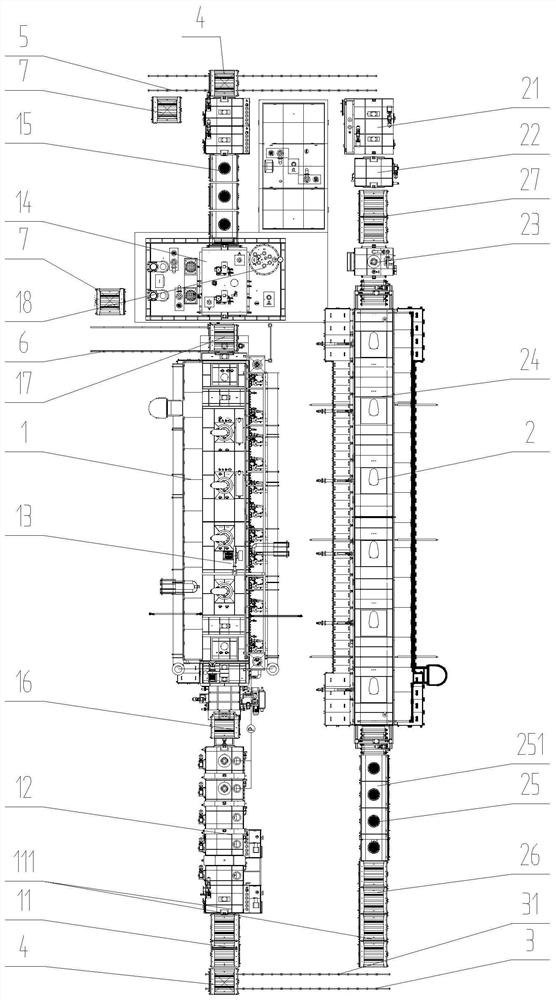

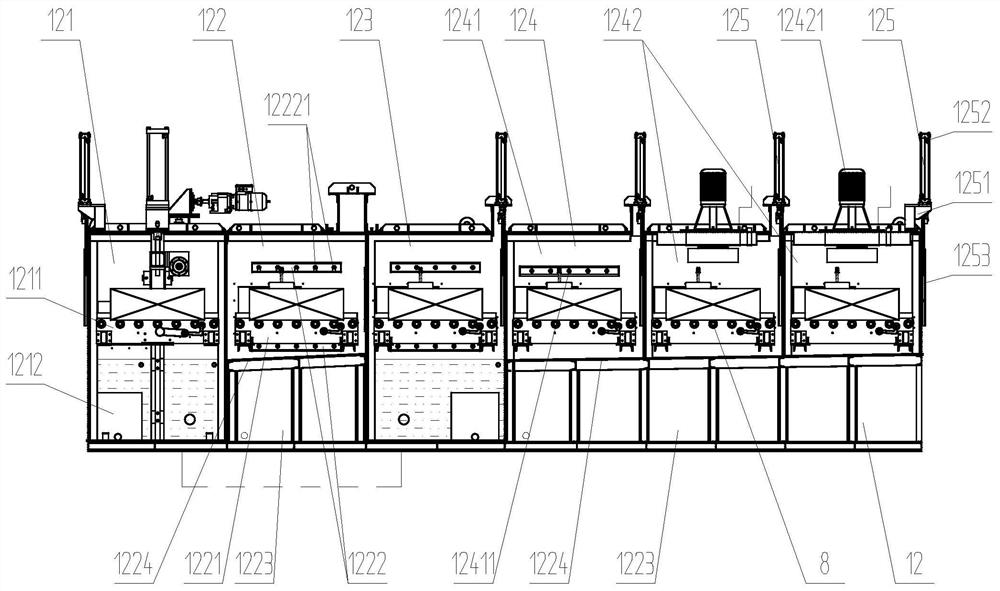

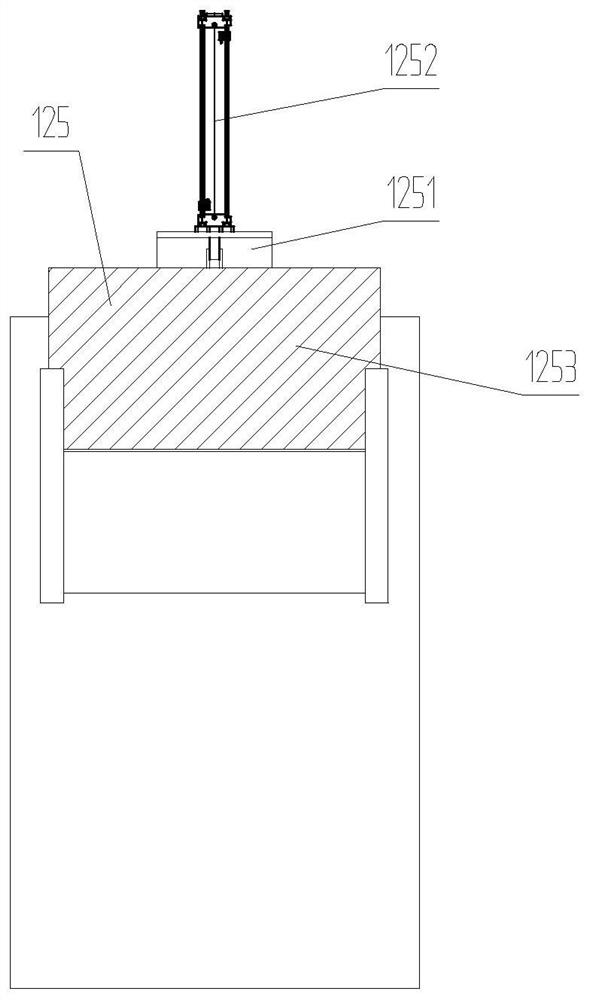

Heat treatment production line for bearing parts

ActiveCN113512640AImprove heat treatment efficiencyImprove the quality of heat treatmentFurnace typesHeat treatment furnacesTemperingEngineering

The invention discloses a heat treatment production line for bearing parts. The heat treatment production line comprises a quenching line and a tempering line, a feeding transition material table set, a front cleaning device, a quenching heating furnace, a salt bath quenching device and a quenching rear air cooling cleaning system are linearly arranged on the quenching line in sequence from left to right, a cold cleaning device, a draining chamber, a drying chamber, a tempering furnace, a tempering rear air cooling device and a discharging transition material table set are sequentially and linearly arranged on the tempering line from right to left, a first rail set is installed on the ground on the left side of the quenching line and the tempering line, a second rail set is installed on the ground on the right side of the quenching line and the tempering line, and the first rail set and second rail set are each provided with a lifting conveying material table. The heat treatment production line is specially designed and arranged according to a bearing part heat treatment process, is reasonable in layout and small in occupied area, is divided into the quenching line and the tempering line, can complete the whole heat treatment process of the bearing parts through one-time circulation, has the functions of cleaning, drying and the like, and is high in bearing part heat treatment efficiency and stable in heat treatment quality.

Owner:ZHEJIANG XCC GRP CO LTD

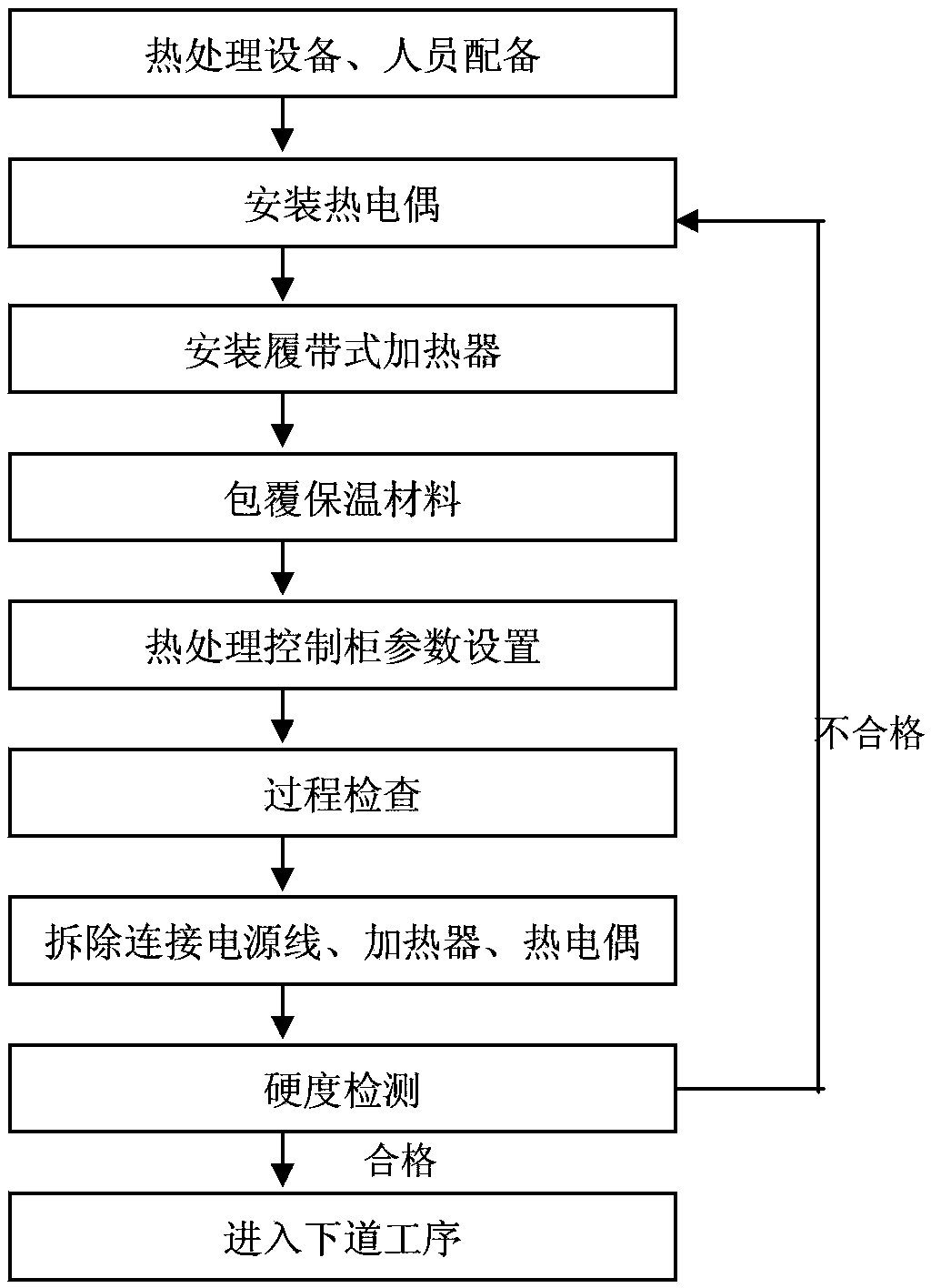

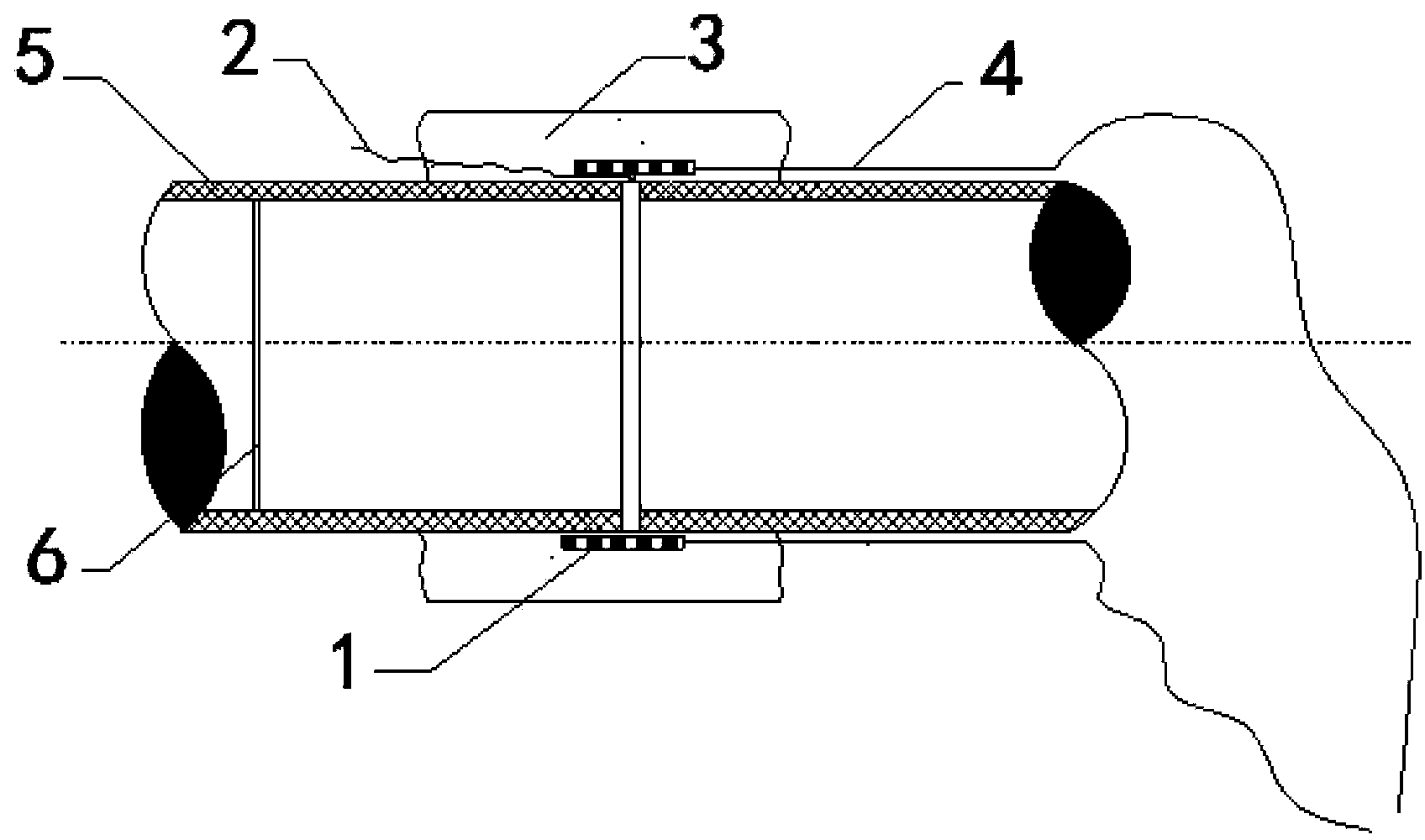

Anti-sulfur acid-resistant long conveying pipeline heat treatment process

ActiveCN104212966AEasy to operateImprove ergonomicsFurnace typesHeat treatment furnacesTemperature controlInfrared

The invention relates to an anti-sulfur acid-resistant long conveying pipeline heat treatment process, which belongs to the technical field of a pipe-line system. According to the invention, Jiangsu Yineng heat treatment equipment is selected, an infrared ray high-temperature ceramic crawler type electric heater is employed, a set of complete heat treatment equipment comprises a lorry (transportation), a generator with 200KW, two temperature control cabinets (six crossings can be simultaneously controlled by each temperature control cabinet, each technical curve parameter can be respectively set, and each temperature control cabinet can be independently operated) and a corresponding secondary power line; a forklift is specially equipped for the heat treatment, temporary road can be build, and heat treatment equipment can be ensured to reach the assigned field. The heat treatment process has the advantages of strong operationality, high work efficiency and simple process. The heat treatment construction problem of the non fixed place pipeline weld can be effectively solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

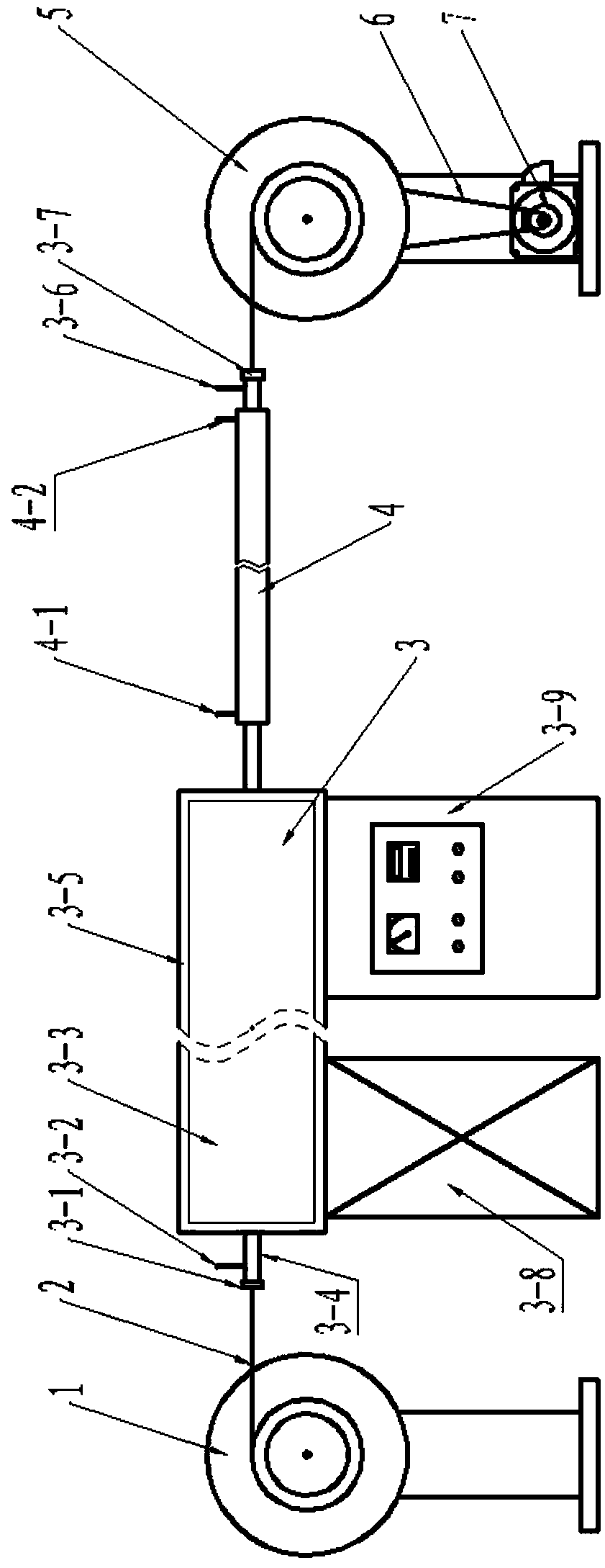

Continuous thermal processing device and thermal processing method of MgB2 superconduction wire/strip

ActiveCN107799235AReduce temperature differenceRapid heating and coolingApparatus for heat treatmentSuperconductor device manufacture/treatmentTransmission beltEngineering

The invention discloses a continuous thermal processing device. In the device, a take-up wheel is driven to rotate through a transmission belt by a motor, a lead is driven to pull a material to be thermally processed to sequentially pass through a heating region and a cooling region of the thermal processing device, dynamic continuous thermal processing and cooling processing are performed, rapidtemperature rising and reduction of the material is achieved in one step, the temperature difference of the material at different positions during the thermal processing process is reduced, the thermal processing quality is improved, and the application range of the device is expanded. The invention also discloses a thermal processing method of an MgB2 superconduction wire / strip. By the method, the MgB2 superconduction wire / strip is placed in the thermal processing device, continuous and rapid temperature rising and reduction thermal processing under inert gas production is performed, a non-super conduction impurity phase is prevented from being generated from an MgB2 superconduction core wire, an adhesion phenomenon among MgB2 lines / strips is prevented, and the continuous thermal processing device is flexible, controllable, convenient and efficient.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

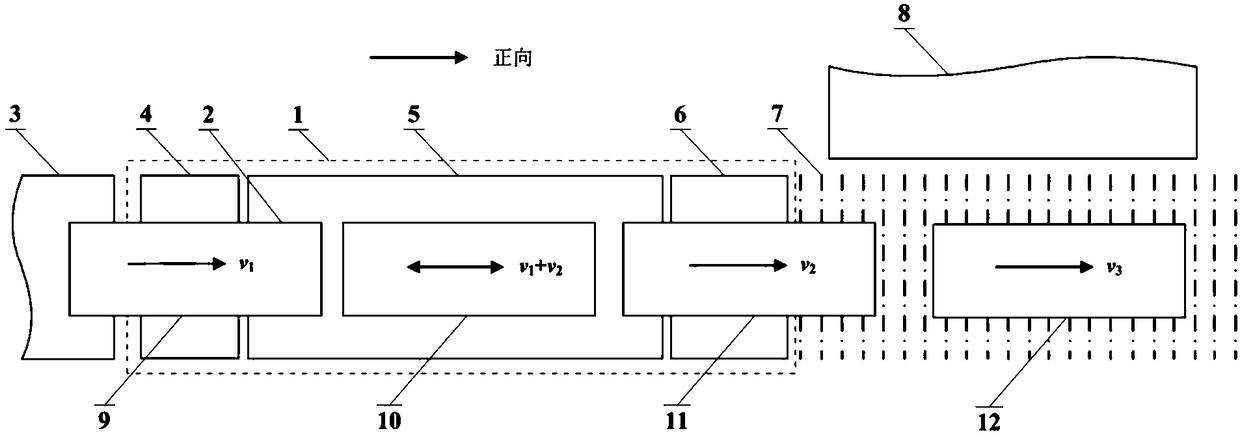

Plate-strip roller type quenching device and method capable of realizing reverse quenching

InactiveCN108486332AIncrease productivityIncrease profitFurnace typesHeat treatment furnacesHigh pressureQuenching

The invention belongs to the technical field of metal plate-strip heat treatment devices, and provides a plate-strip roller type quenching device and a plate-strip roller type quenching method capableof realizing reverse quenching. The device is formed by a front high-pressure cooling area, a rear high-pressure cooling area and a middle low-pressure cooling area; when a plate-strip enters from the front high-pressure cooling area, a forward quenching method is implemented; and when the plate-strip enters from the rear high-pressure cooling area, a reverse quenching method is implemented. According to the device and the method, the utilization rate of the quenching device can be greatly improved; and a special cooling device and a special cooling strategy are adopted for the thin and thickplates-strips, so that the heat treatment plate shapes and the uniformity of the plates-strips are improved at the same time, and multiple purposes are realized through one machine.

Owner:NORTHEASTERN UNIV

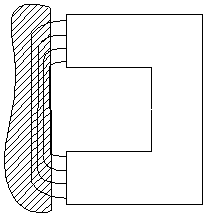

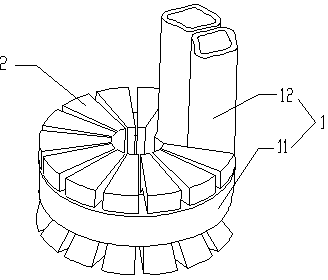

Internal-hole high-frequency quenching induction coil

InactiveCN102796857AReduce distanceQuality improvementIncreasing energy efficiencyQuenching devicesQuenchingWater pipe

The invention relates to an internal-hole high-frequency quenching induction coil. The internal-hole high-frequency quenching induction coil is characterized in that the internal-hole high-frequency quenching induction coil comprises a cooling water pipe (1) and multiple magnetizer pieces (2); the cooling water pipe (1) comprises a C-shaped water pipe section (11) and two linear water pipe sections (12); the two linear water pipe sections (12) are located at the same side of the C-shaped water pipe section (11); the two linear water pipe sections (12) are vertically connected to two ends of the C-shaped water pipe section (11); a longitudinal section of each one of the multiple magnetizer pieces (2) has a C-shaped structure and the C-shaped structure comprises an upper horizontal section (21), a vertical section (22) and a lower horizontal section (23); an outer end of the lower horizontal section (23) is provided with a downward inclined plane and an inclination angle of the downward inclined plane is in a range of 40 to 45 degrees; a cross section of each one of the multiple magnetizer pieces (2) has a sector structure; the multiple magnetizer pieces (2) are sleeved on the C-shaped water pipe section (11); and openings of the C-shaped structures face outward. The internal-hole high-frequency quenching induction coil has the advantages that efficiency and quality of internal-hole high-frequency quenching are high.

Owner:WUXI YINGBEI PRECISION BEARING

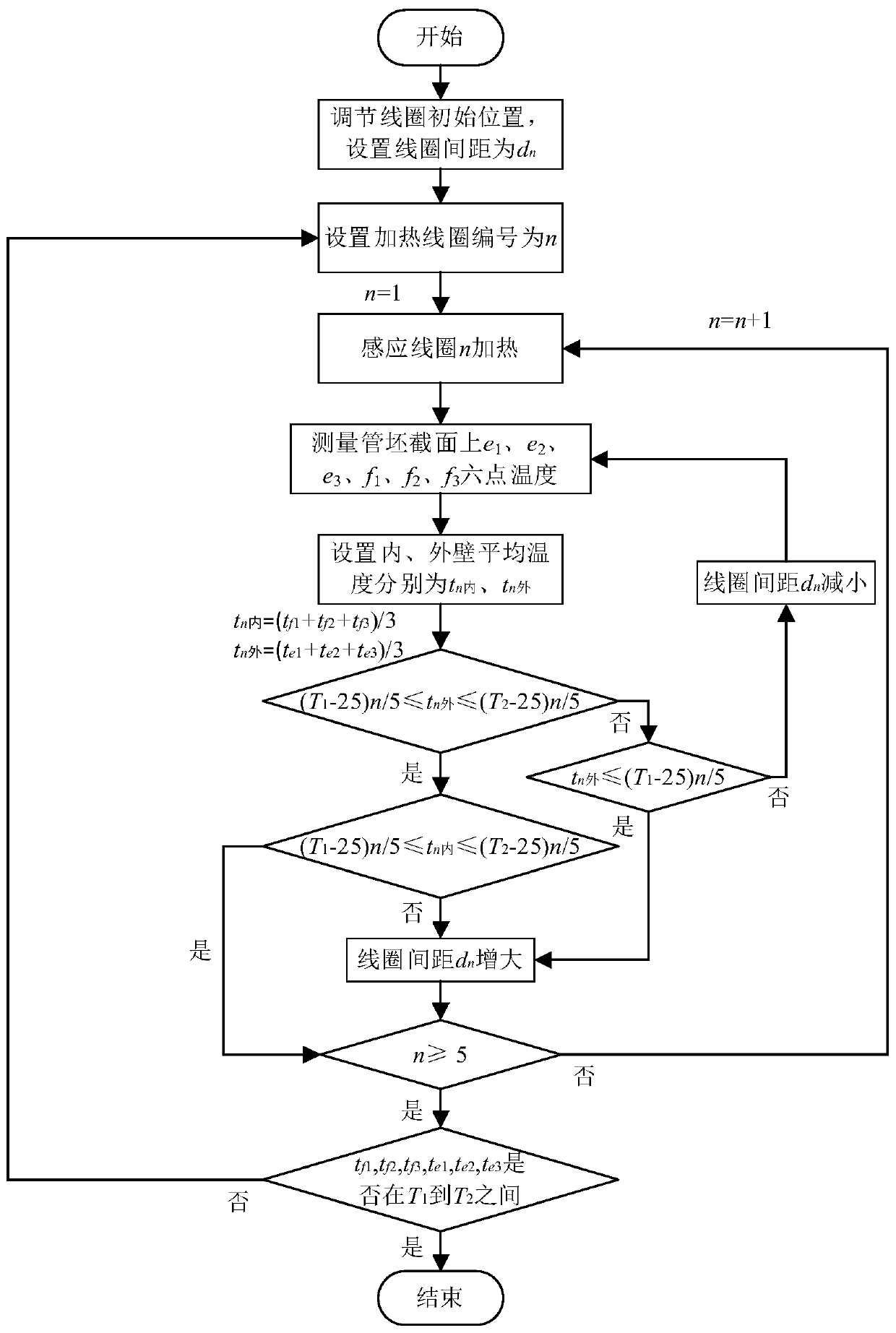

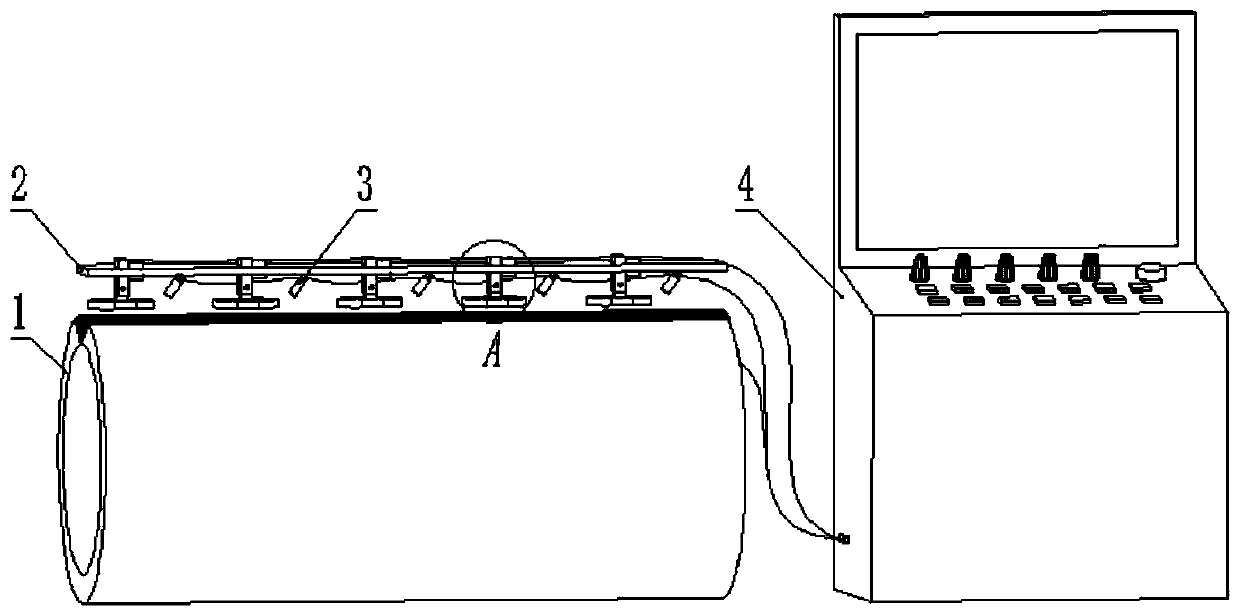

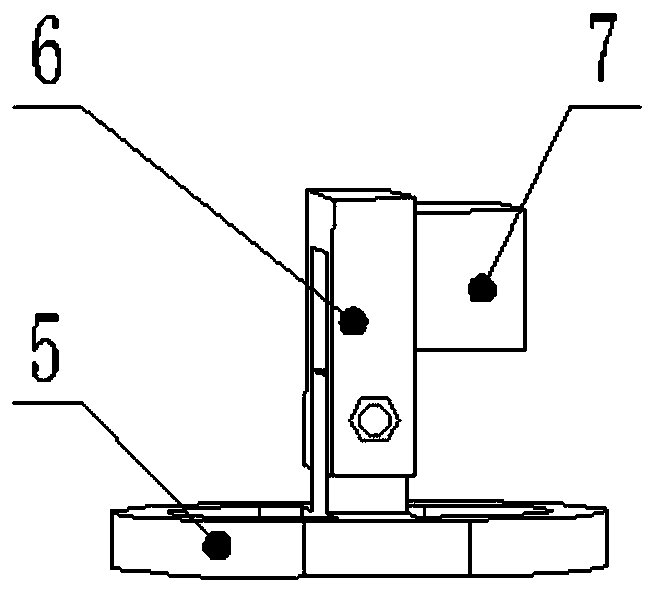

Discrete device and discrete method for heating straight welded pipe by coils

ActiveCN109971940AImprove heat treatment effectUniform temperature riseFurnace typesIncreasing energy efficiencyTreatment effectWeld seam

The invention discloses a discrete device and a discrete method for heating a straight welded pipe by coils. The device comprises a discrete induction heating device, a temperature measuring feedbackdevice and a control console. The discrete induction heating device comprises a coil bracket, a coil fixing sleeve, a control slide block and five horizontally arranged induction coils adjustable in separation distance. Each induction coil is controlled to be adjusted by the control console. The temperature measuring feedback device comprises an outer wall temperature measuring device and an innerwall temperature measuring device. The outer wall temperature measuring device comprises five infrared thermodetectors L1-L5. The inner wall temperature measuring device comprises five infrared thermodetectors L6-L10. Dynamic temperature measurement on heating points in various stages in welded pipe welding seam is carried out constantly, the control console receives a temperature feedback signalof the temperature measuring feedback device to control and adjust the positions of the induction coils constantly, and finally, the inner and outer temperatures at the weld seam of the welded pipe meet a heat treatment temperature demand synchronously, so that the heat treatment effect is optimized and the heat treatment quality is improved.

Owner:河北华洋钢管有限公司

Composite carbon tool steel/plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life

InactiveCN102154537AHigh hardnessImprove uniformityIncreasing energy efficiencyFurnace typesHigh resistanceWear resistant

The invention discloses a composite carbon tool steel / plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life. Aiming at characteristics of an explosive composite wear-resistant material and operating requirements of a metallurgical wear-resistant lining board, the surface induction heating principle and the metal phase transformation theory are used for controlling the depth of heat penetration, the hardness of an appropriate layer interface, and the depth and uniformity of a quench hardening layer so that the hardness of the composite layer is distributed in gradient, and the complete martensite phase change is avoided from occuring in the composite interface layer during quenching so to reduce the structure stress formed on the interface and keep the original combination state of the composite board to the greatest extend. The composite metallurgical lining board with high resistance, high uniformity and long service life has surface hardness of larger than 61HRC (rockwell hardness) and uniformity of hardness of less than 3 HRC (rockwell hardness); A 5mm place of the composite layer in the thickness direction has a hardness value of larger than 50HRC (rockwell hardness); and the three fifth to four fifth place of the composite layer thickness has the hardness value of less than 35HRC (rockwell hardness).

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

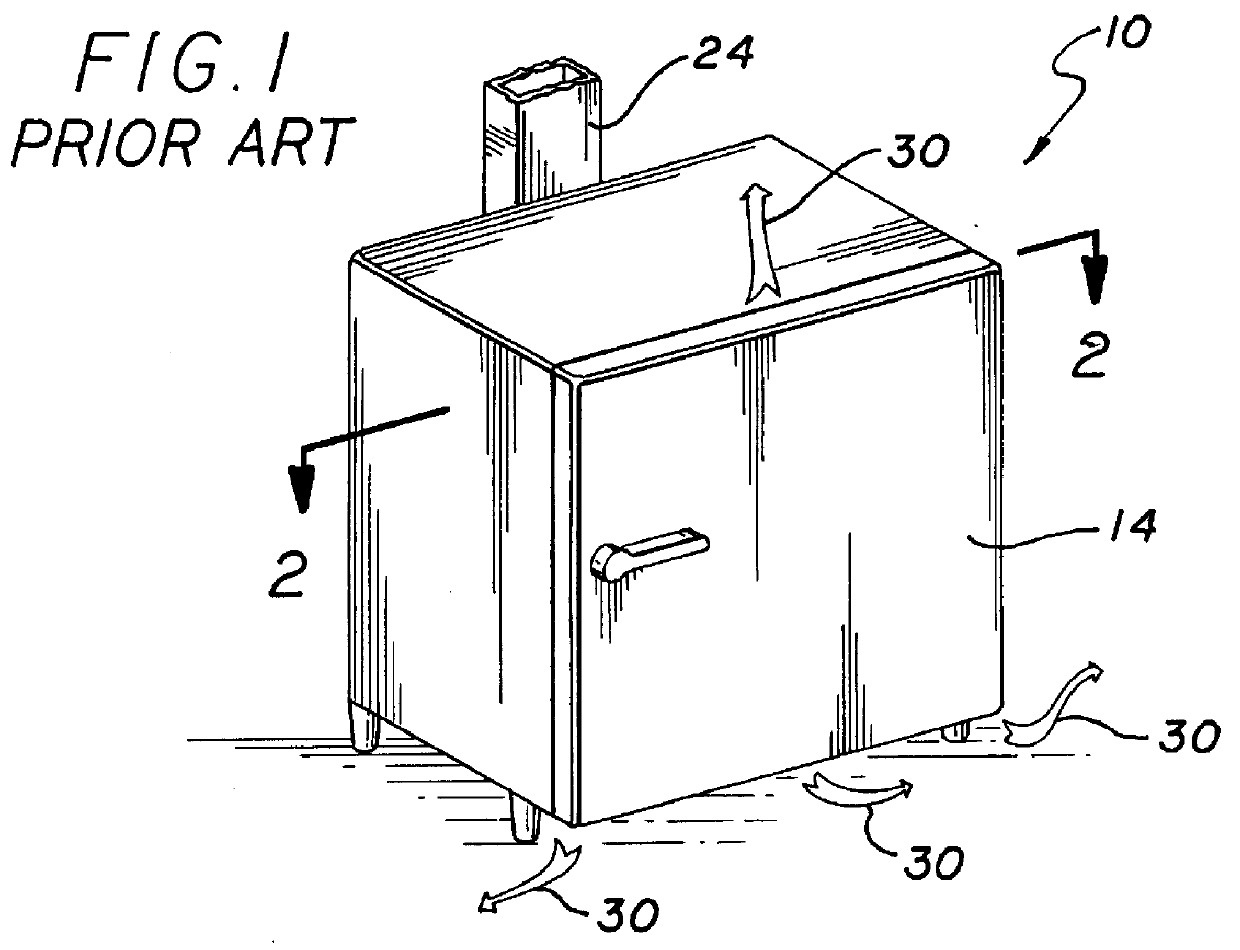

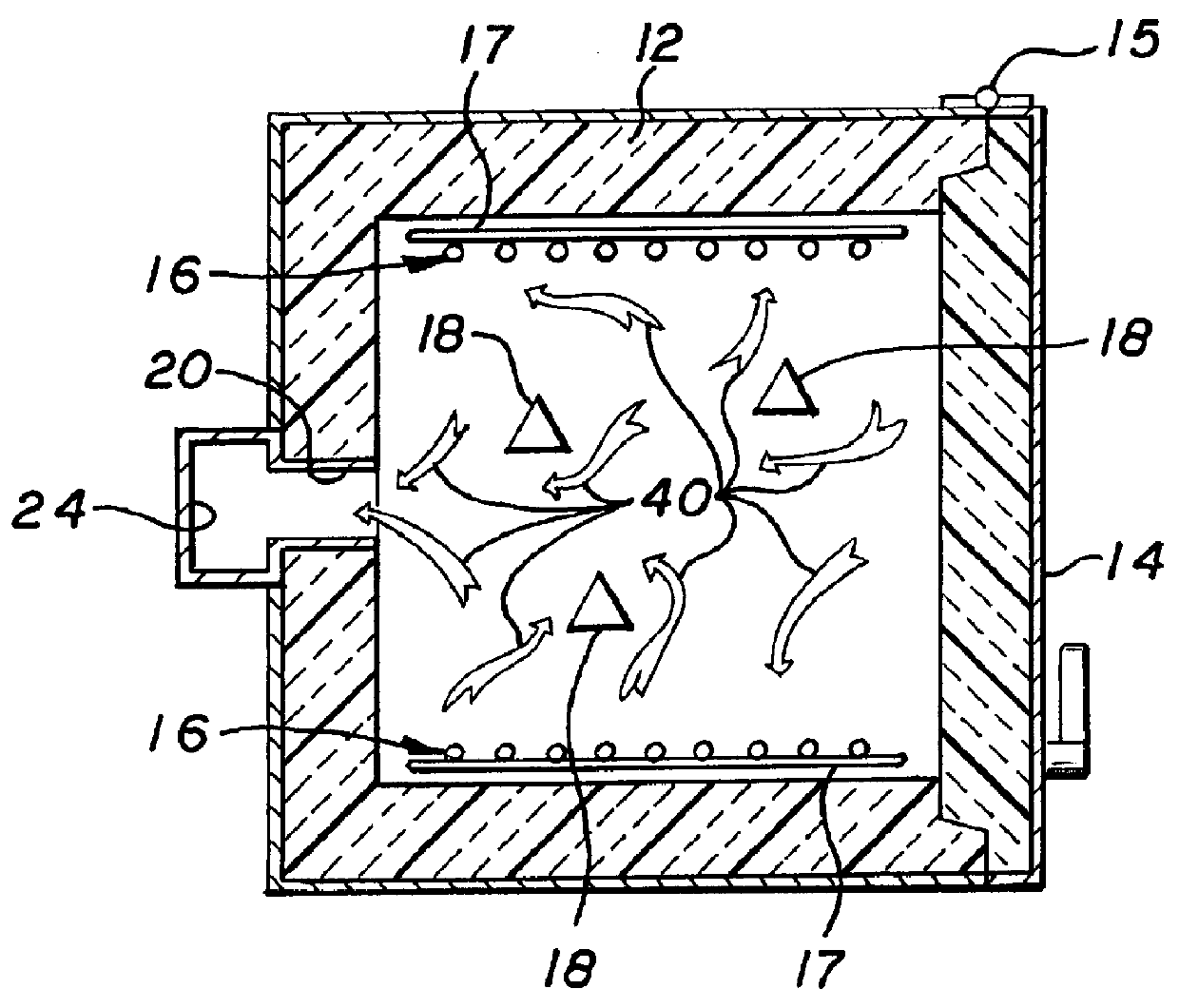

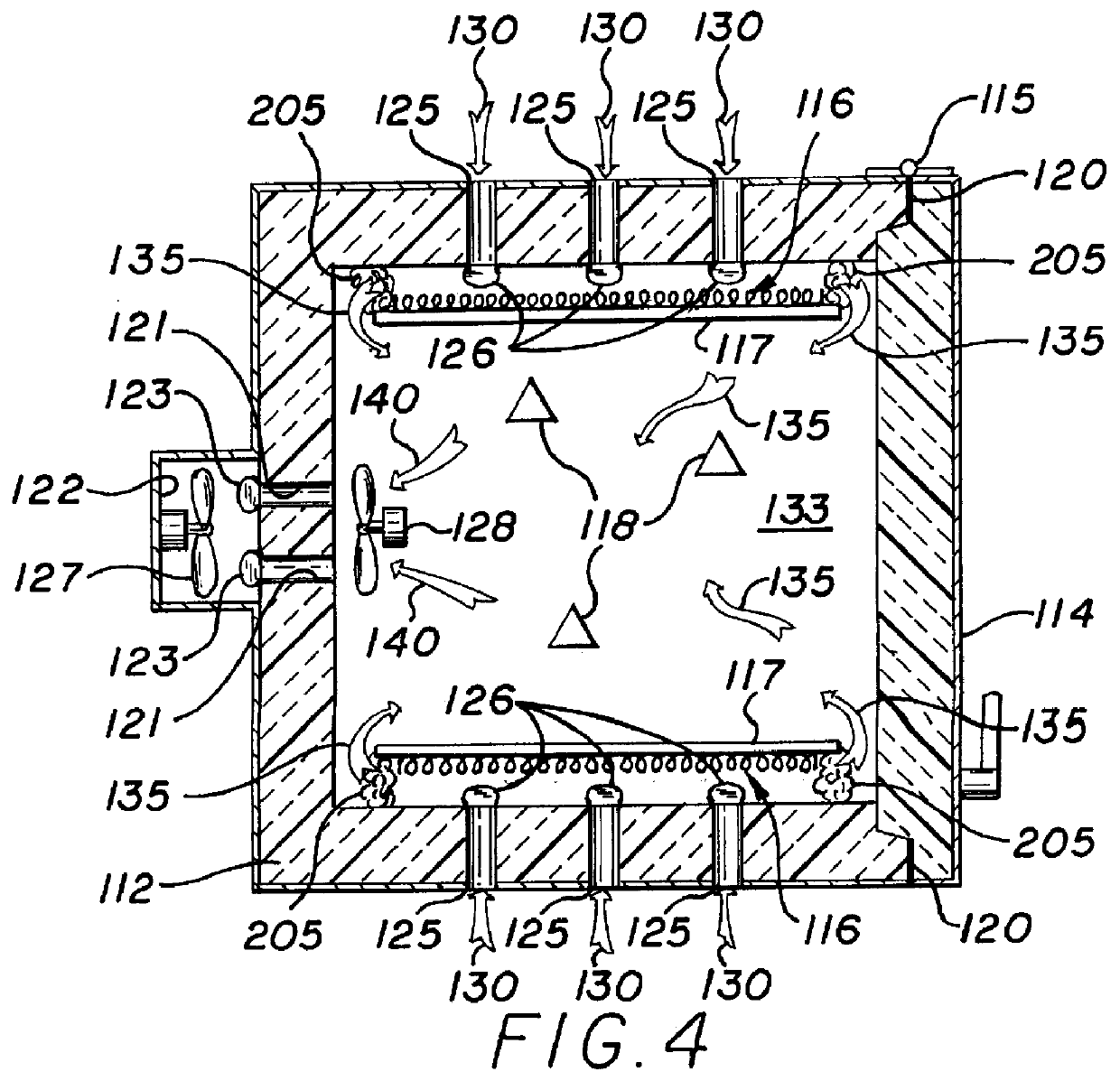

Furnace exhaust method and apparatus

InactiveUS6111227AExtended service lifeImprove the quality of heat treatmentBaking ovenMaintainance of heating chambersAir cycleAtmospheric air

An electrically heated furnace wherein electrical heating elements are mounted and supported so that they face the inner furnace walls and are isolated from direct communication with articles being treated within the furnace such that clean air flows over the heating elements providing oxygen to create an aluminum oxide coating on the heating elements and maintains a clean atmosphere about the heating elements. Air circulation from exterior the furnace is through ports in the furnace walls and over the electrical heating elements; exhaust from the furnace is through ports in the furnace walls into a plenum and out through a flue creating pressure differentials with the pressure in the furnace area where articles are being subjected to heat is lower than the atmosphere and the area in which the heating elements are located.

Owner:CRESS STEVEN B

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com