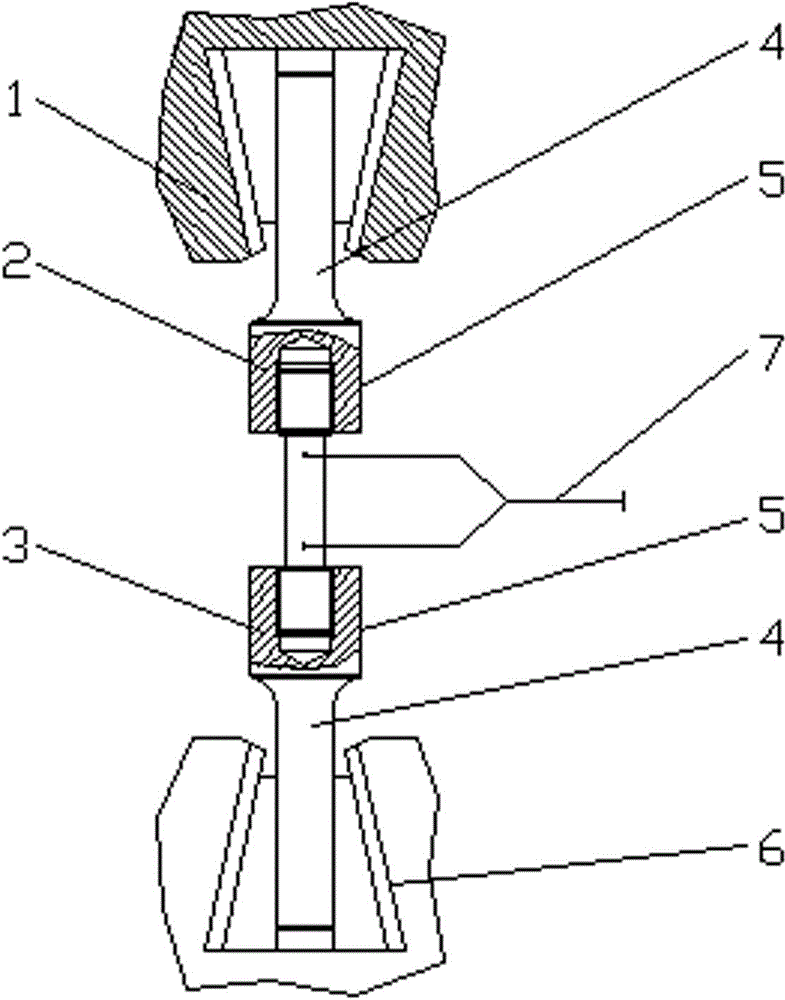

Processing inspection fixture for special steel tensile sample and inspection method

A technology for testing fixtures and fixtures, which is applied in the direction of strength characteristics, using stable tension/compression to test material strength, measuring devices, etc., can solve the problem of not being able to solve the needs of batch processing and testing of special steel tensile samples, and the inability to clamp extensometers Tensile test, affecting the accuracy of tensile performance data and other issues, to achieve accurate and reliable test results, improve heat treatment quality, reduce processing costs and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

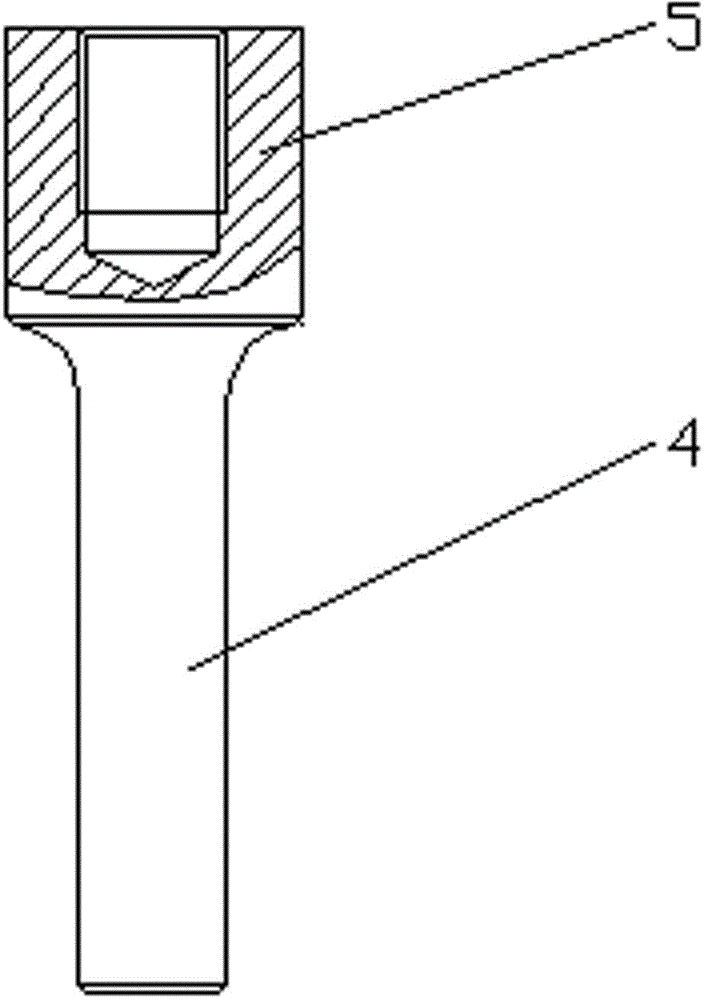

[0025] The threaded structure clamps 2 and 4 of the present invention are made of high-quality 42CrMo low-alloy structural steel, and the thread size can be designed in various specifications, such as: M20×2.5-6H, M16×2-6H, M14×2-6H, respectively applicable For stretched finished samples of different specifications, such as: M20×2.5-drawn finished samples with a diameter of 14mm in the parallel part; M16×2.0-drawn finished samples with a diameter of 10mm in the parallel part; M14×2.0-drawn finished samples with a diameter of 10mm in the parallel part stretched finished sample.

[0026] 1. The threaded structure fixtures 2 and 4 adopt a unique processing flow and heat treatment process to ensure good comprehensive performance of the fixtures and improve service life.

[0027] The fixture has good comprehensive performance after special heat treatment and processing technology. The hardness is 40-45HRC, which not only ensures the service life of the fixture, but also ensures the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com