Patents

Literature

136results about How to "Reliable replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

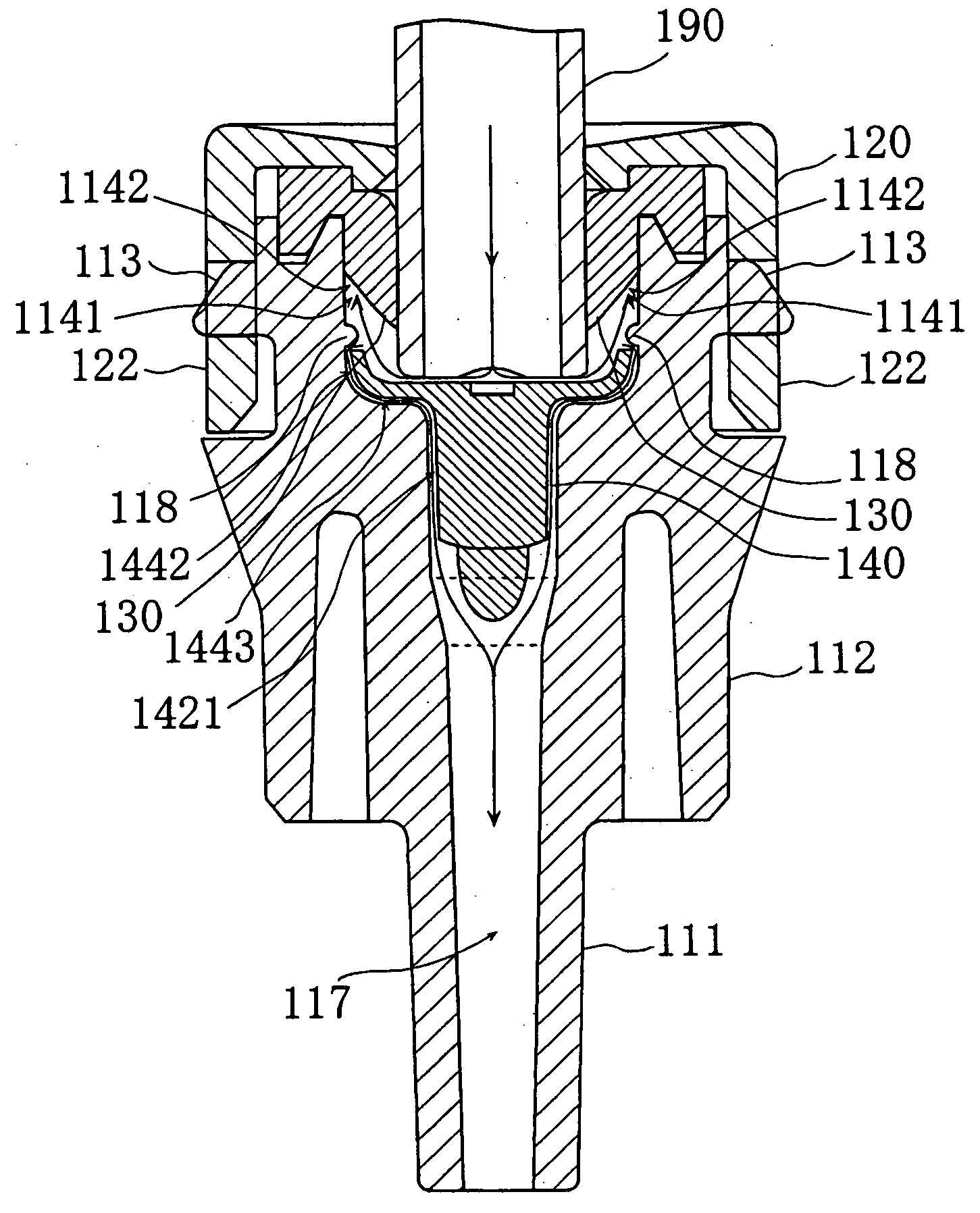

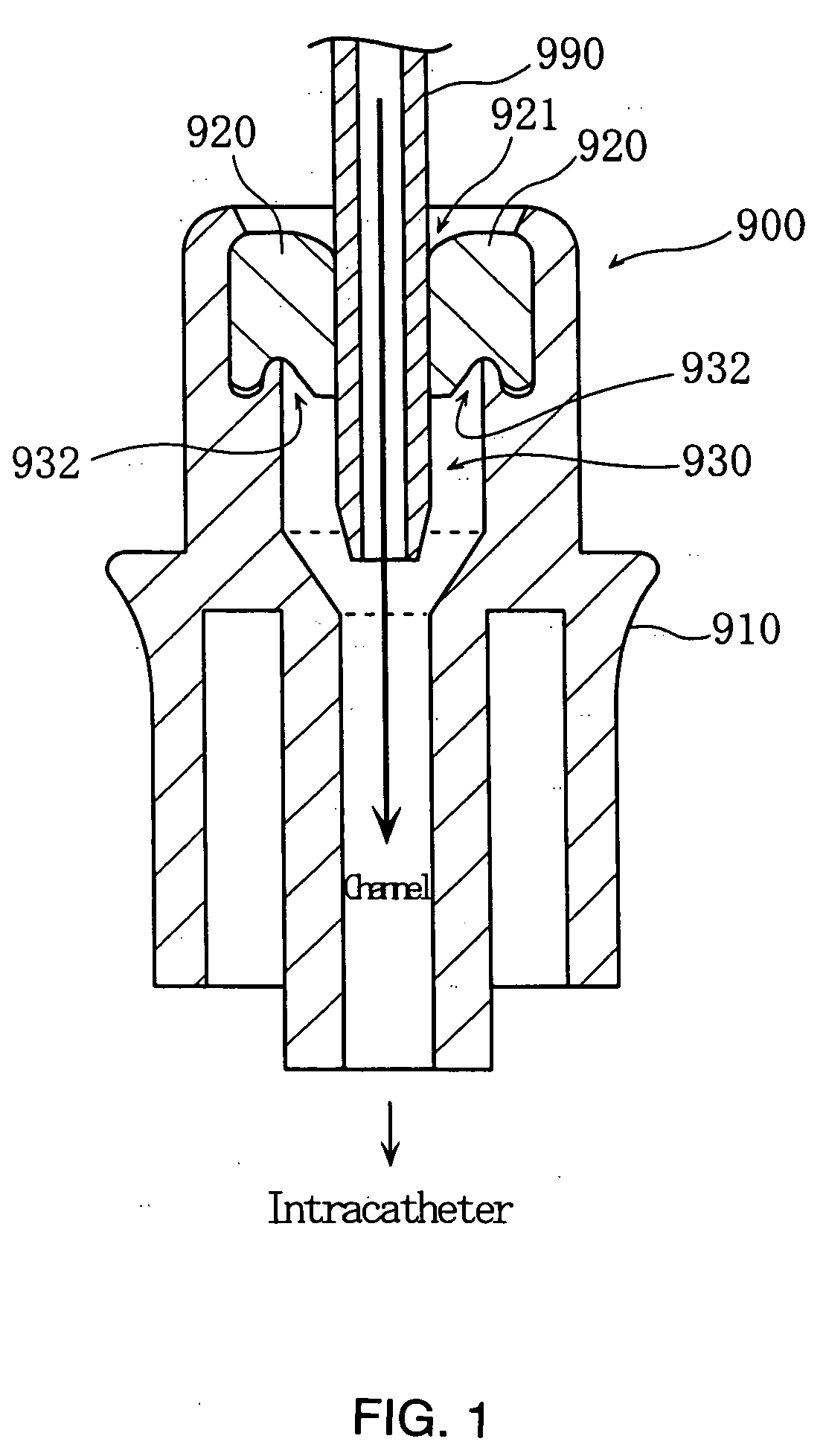

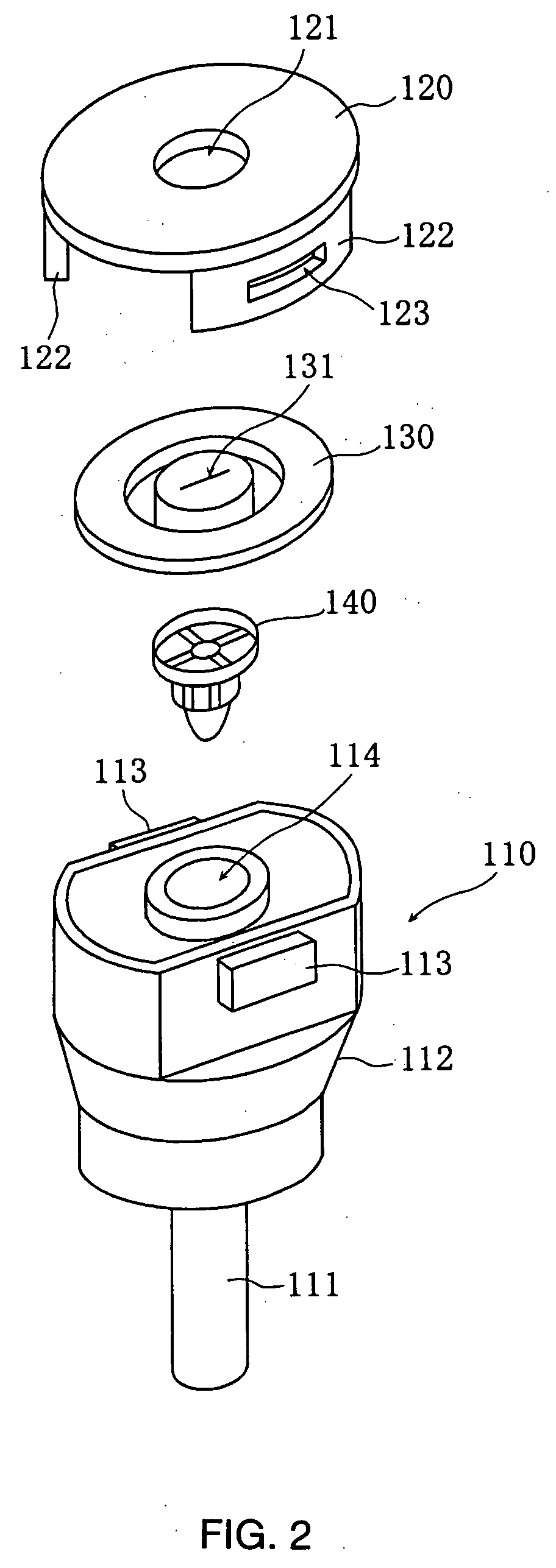

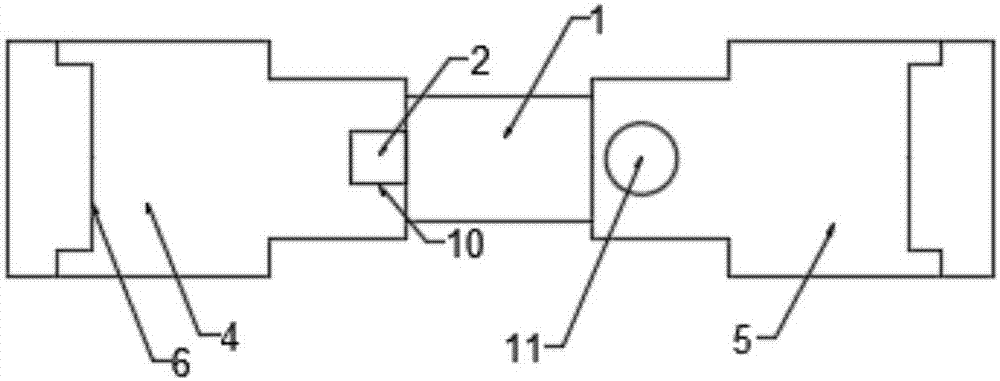

Mixture injection port

ActiveUS20060184140A1Stagnation be suppressSuppress stagnationInfusion syringesIntravenous devicesFluid accumulationBiomedical engineering

A mixture injection port is capable of suppressing the continuous accumulation of medical fluid or blood therein and allowing efficient internal cleaning. A recirculation part is formed at a step between an inner cavity and a narrow tube part. Even if the fluid is accumulated in a clearance area produced in the inner cavity when a luer is inserted into a slit, the fluid can be securely replaced with the fluid newly flowing therein through a septum and the continuous accumulation of the fluid can be suppressed. A more efficient internal cleaning can be realized by installing a fluid accumulation prevention part such as an annular rib between the septum and the inside wall of the inner cavity and burying the clearance area.

Owner:JMC

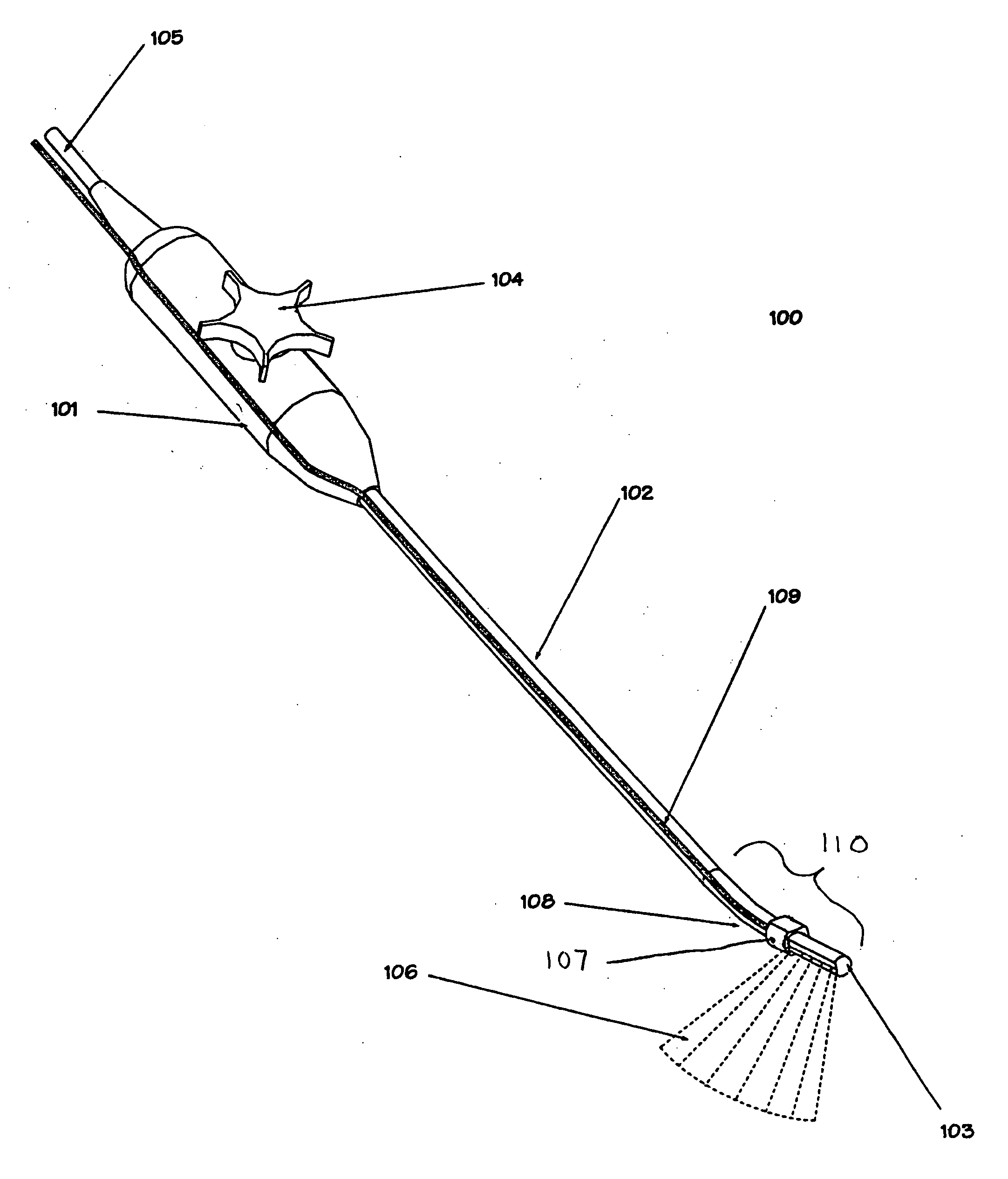

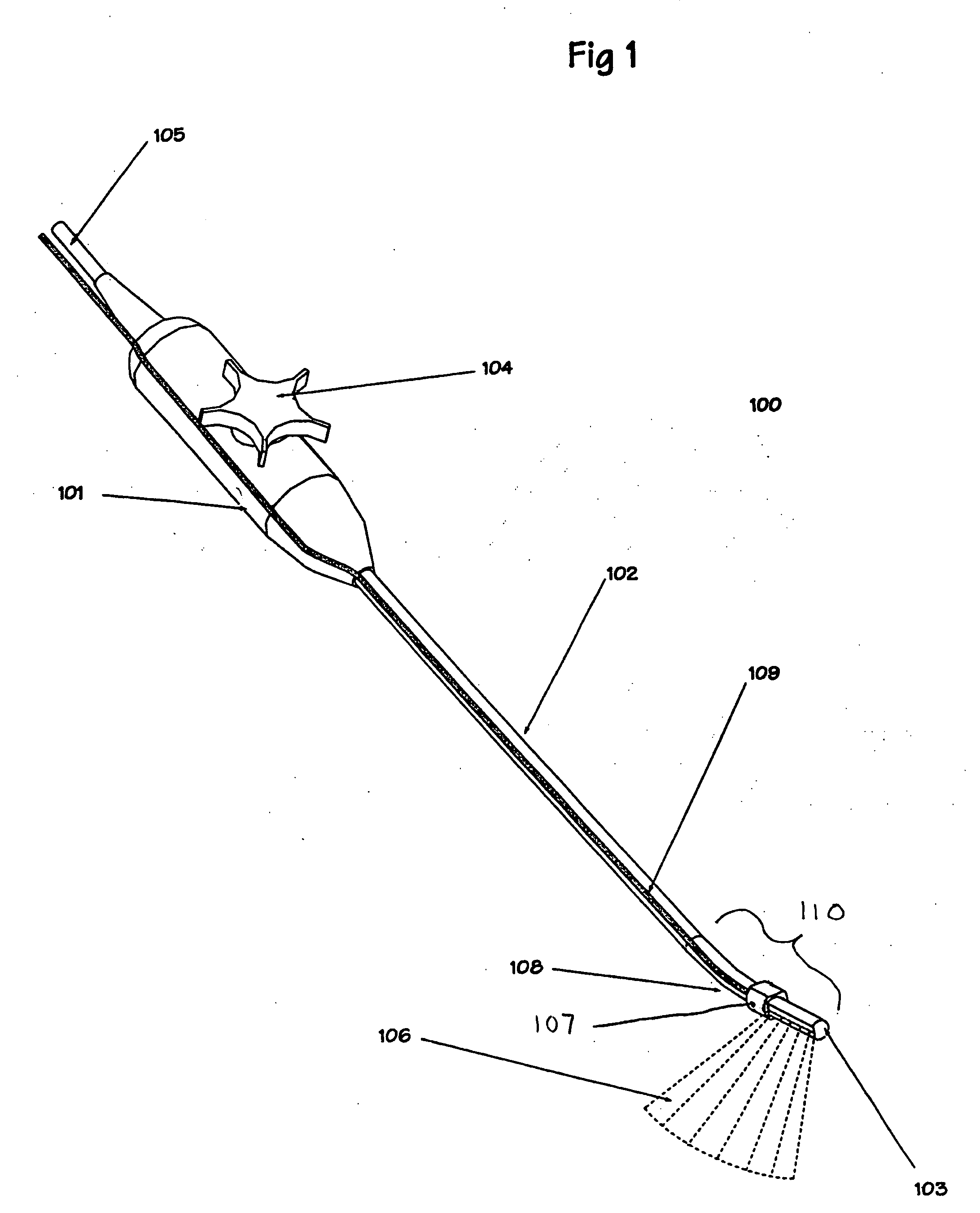

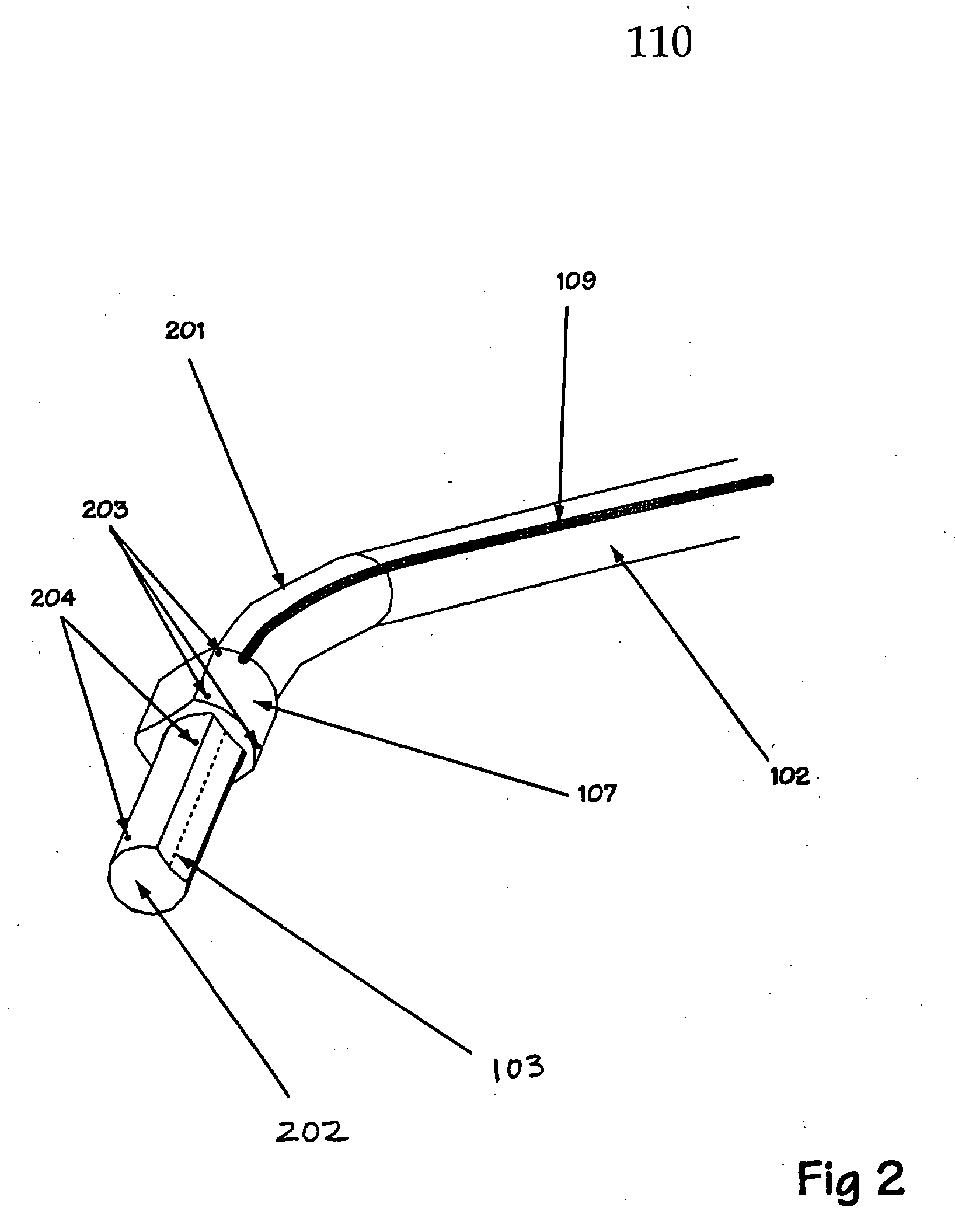

Device and method for a trackable ultrasound

ActiveUS20070167787A1Prevent movementReliable replacementCatheterInfrasonic diagnosticsUltrasound deviceEngineering

The invention provides a method for adjusting the calibration of a tracked ultrasound device using the measured difference between two sets of fiducial markings in two relative positions of a tracker and an scan head of the device. The invention also provides a trackable ultrasound device that enables repeatable attachment of a tracker to a scan head, thus preserving an initial calibration between the tracker and the scan head. Furthermore, the invention provides a calibration jig that can be used to repeatably attach a tracker to an ultrasound scan head or to measure the difference between two relative positions of a tracker and a scan head.

Owner:UNITED STATES OF AMERICA +1

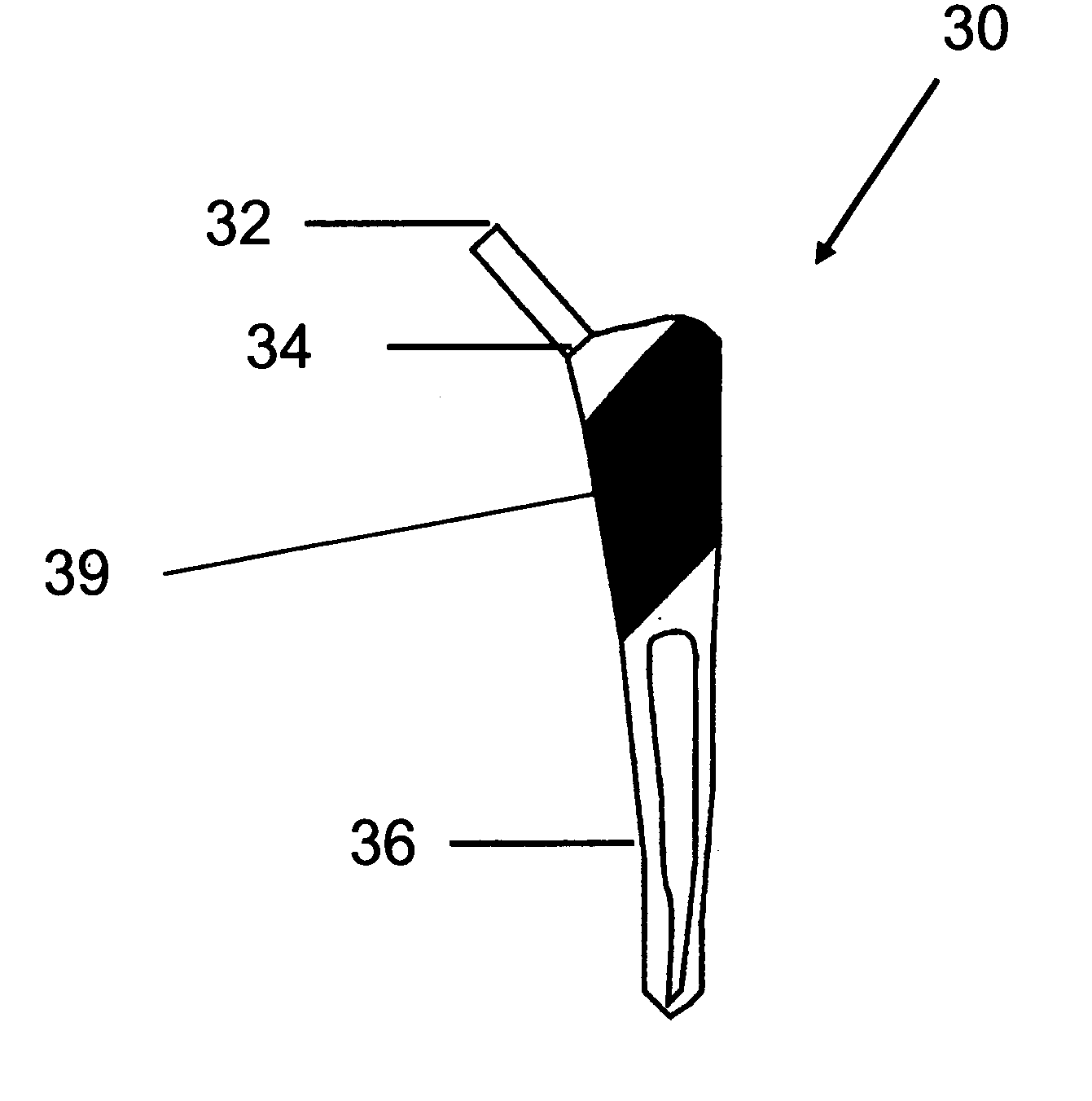

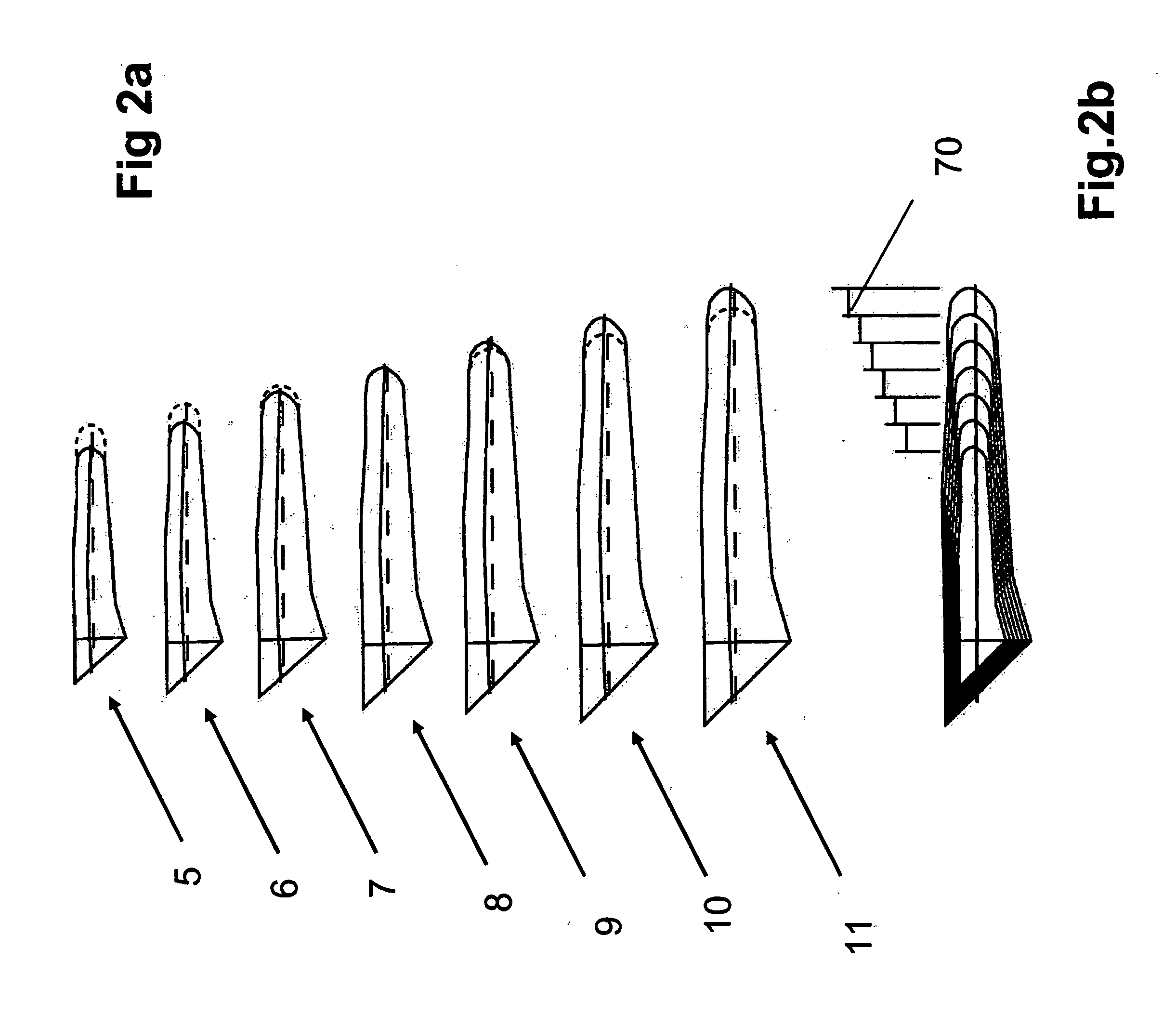

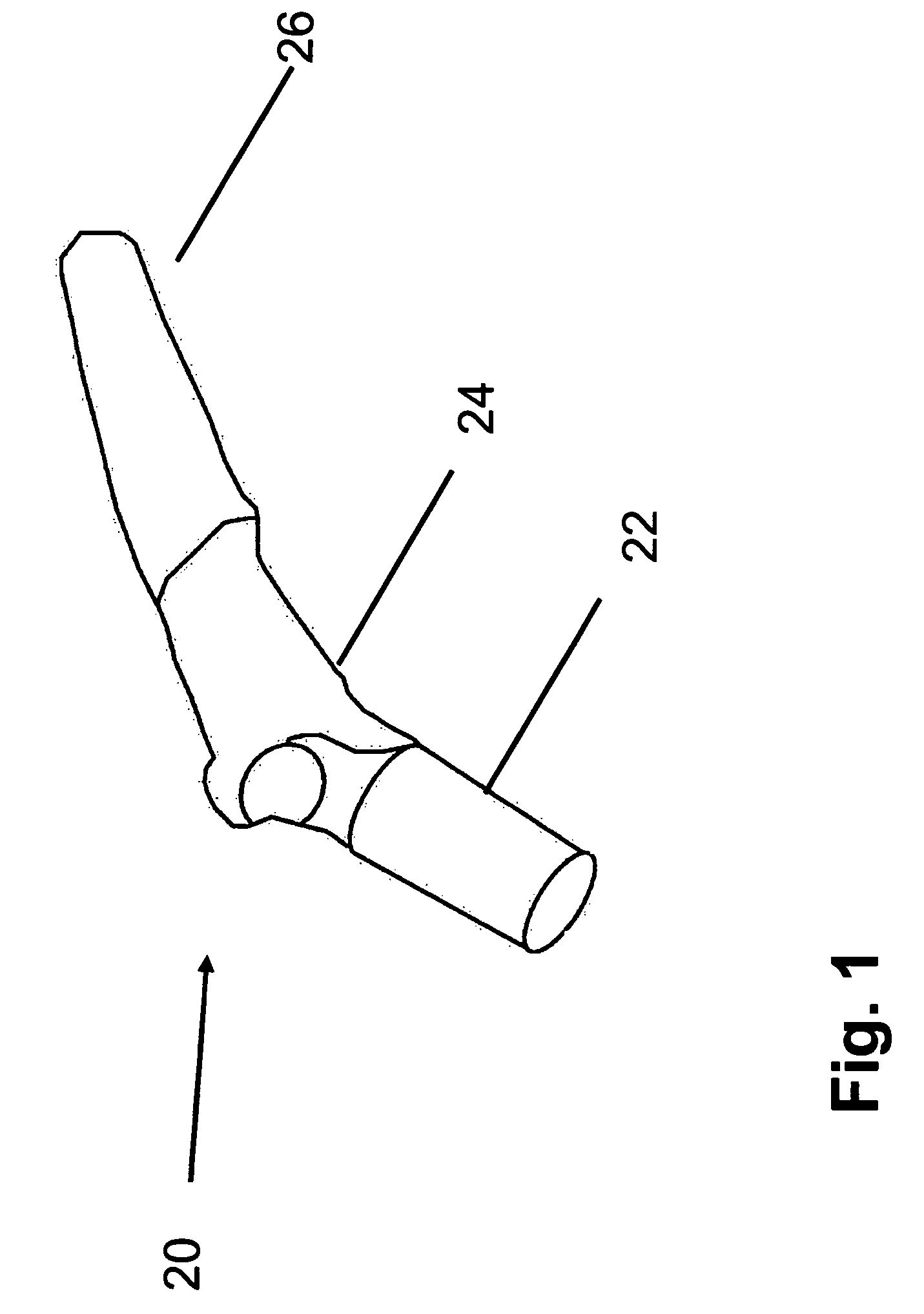

Canine femoral stem system

ActiveUS20050267586A1Increase in sizeReliable replacementSurgeryJoint implantsPorous coatingFemoral bone

A canine femoral stem system provides a set of sizes of stems designed to fit in a reamed femoral bone canal with controlled interference. The canine femoral stems can be implanted using either a cemented or cementless procedures. Cementless stems have a porous coating of sintered beads on the tapered proximal section providing interference with reamed femoral canal causing friction and initial stability. The distal end of the stem has a tapered fit and contacts the lower region of the reamed femoral bone canal due to curvature of the stem providing distal stability. The porous coating encourages bone ingrowth in the cementless system or cement penetration resulting in long term stability. The cementless system uses either cast cobalt chromium stems with 250±50 μm beads of cobalt chromium or Ti-6Al-4V stem with 250±50 μm beads of chemically pure titanium.

Owner:SIDEBOTHAM CHRISTOPHER G

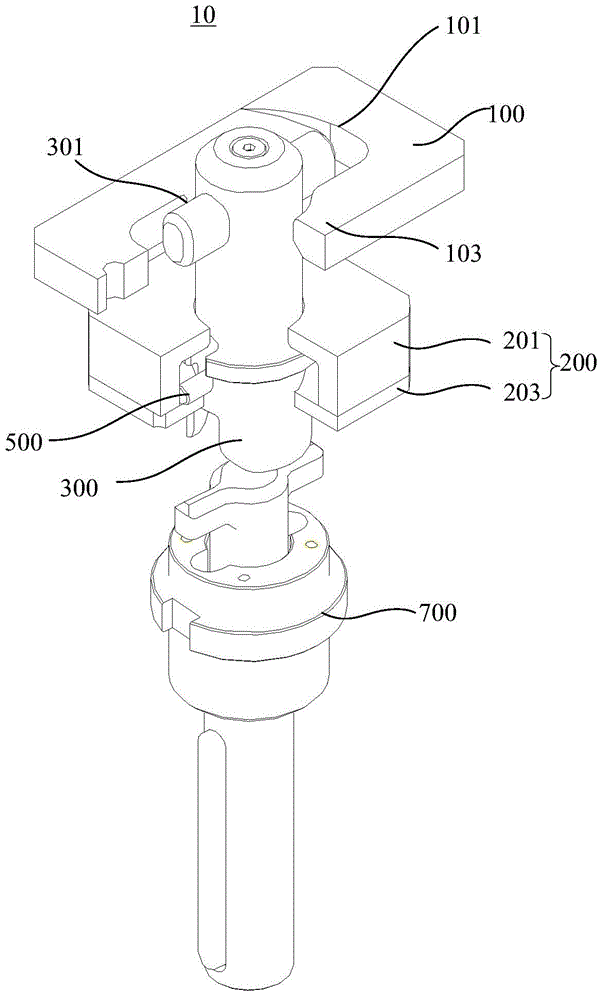

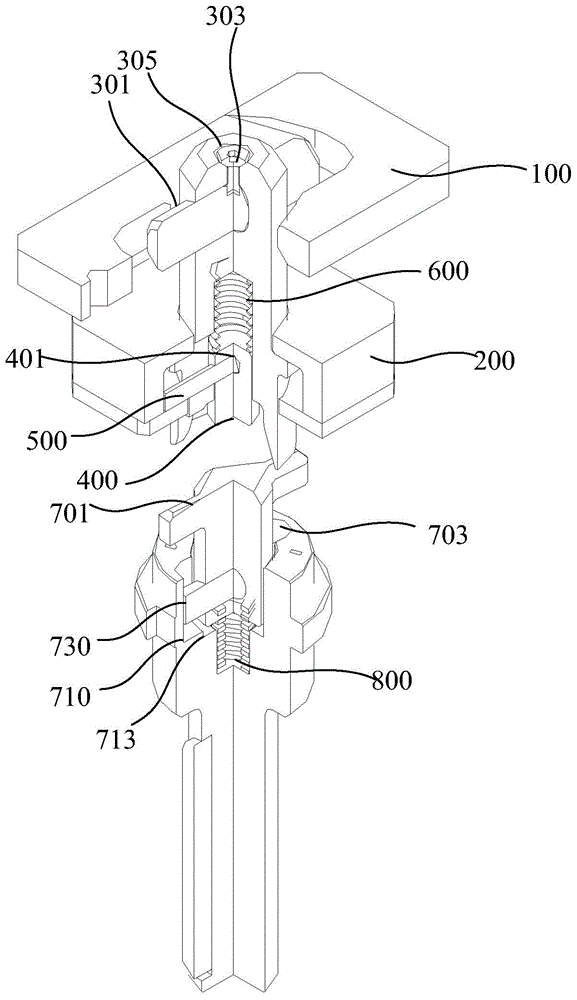

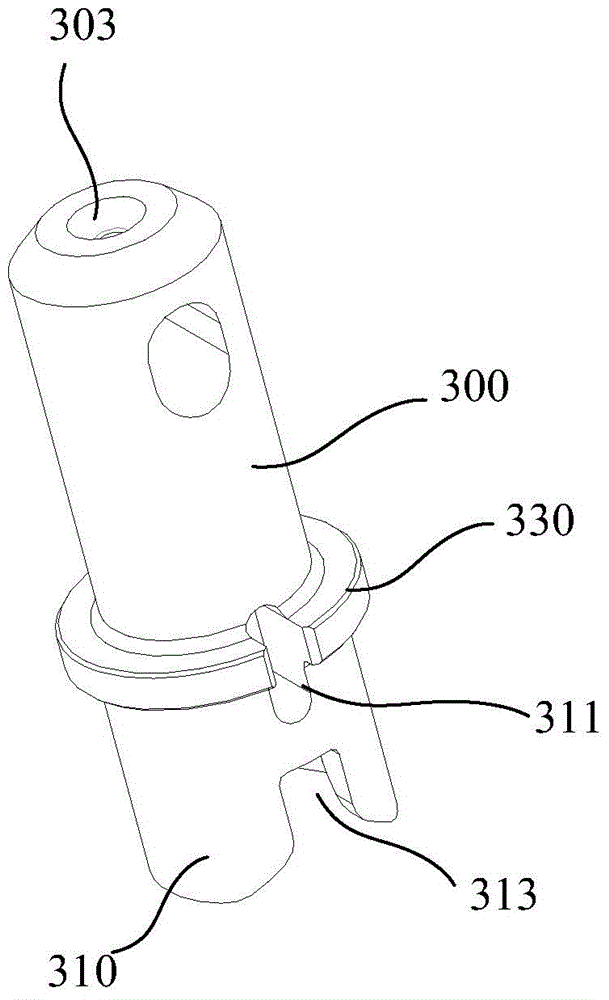

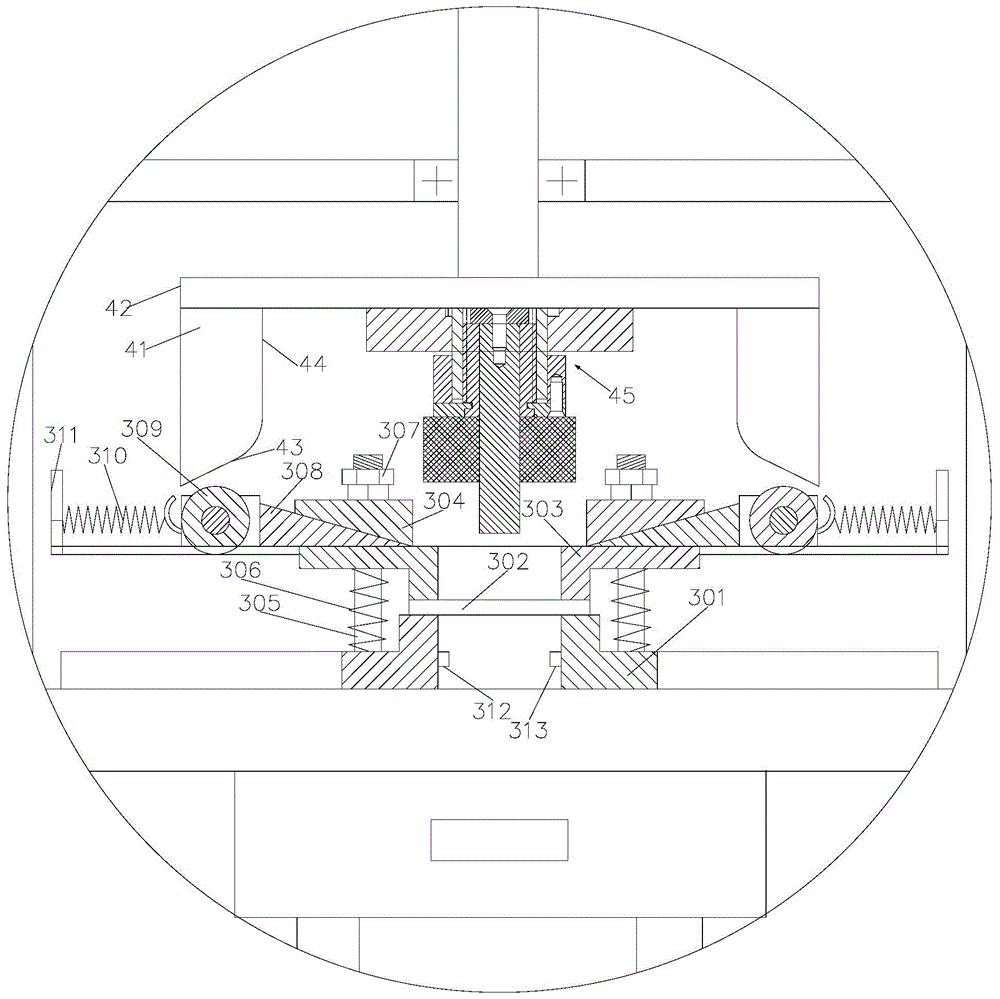

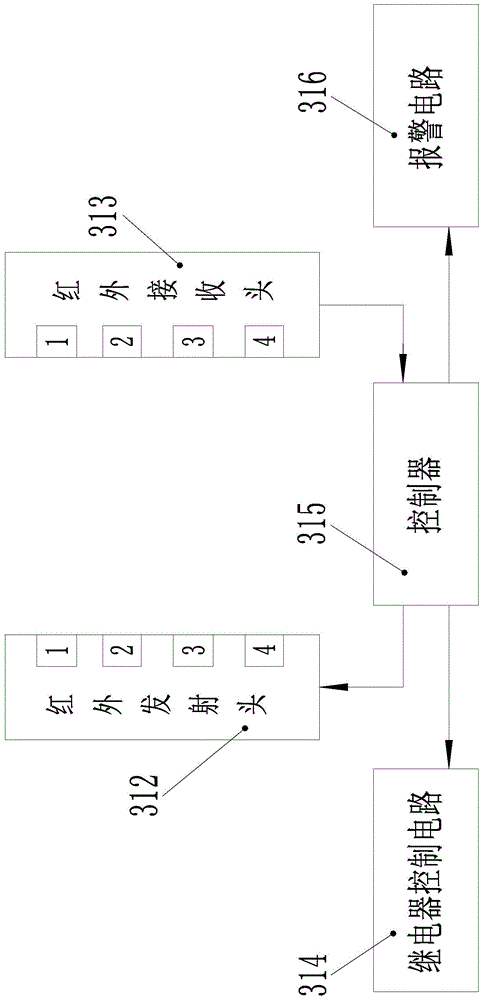

Battery locking mechanism

ActiveCN103600644AQuick changeSafe replacementElectric propulsion mountingLocking mechanismAutomotive battery

The invention provides a battery locking mechanism applied to a battery swap system for electric vehicle chassis. The battery locking mechanism comprises a hanger fastener, a rotating locker retaining box, a central pull shaft, an ejector pin, a clamp pin, and a drive shaft. A drive key of the drive shaft clamps a clamp groove and holds the ejector pin so as to drive the central pull shaft inside the rotating lock retaining box to rotate; meanwhile, the clamp on the central pull shaft is driven to rotate to a first limit groove of a lower cover of the rotating lock retaining box so as to lock the central pull shaft. With the battery locking mechanism, a battery of an electric vehicle can be changed quickly, safely and reliably.

Owner:SHENZHEN JINGZHI MACHINE

Ground guiding type unmanned aerial vehicle flying landing system and method based on LED dot matrix

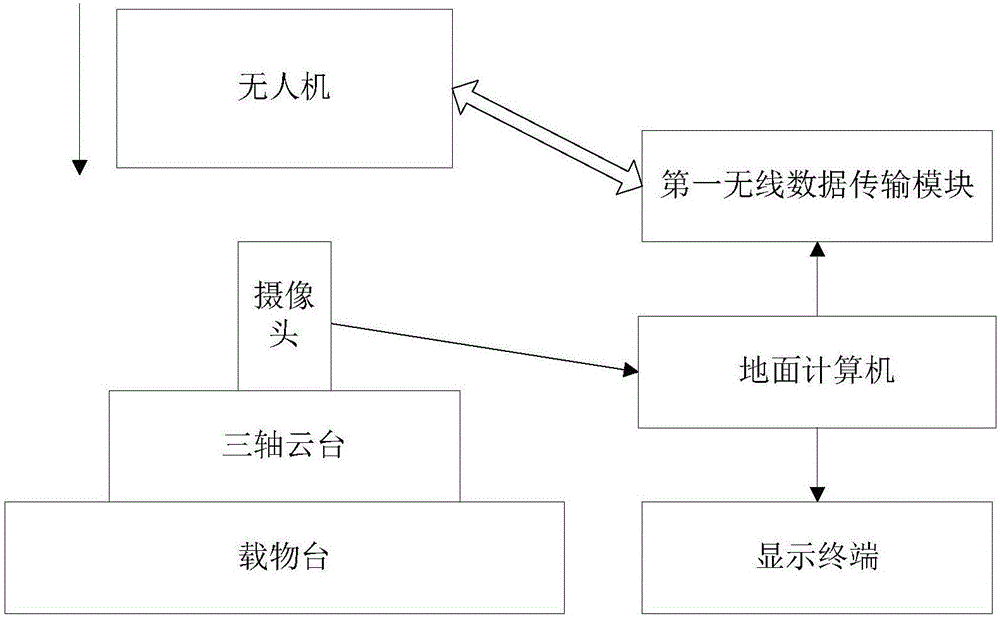

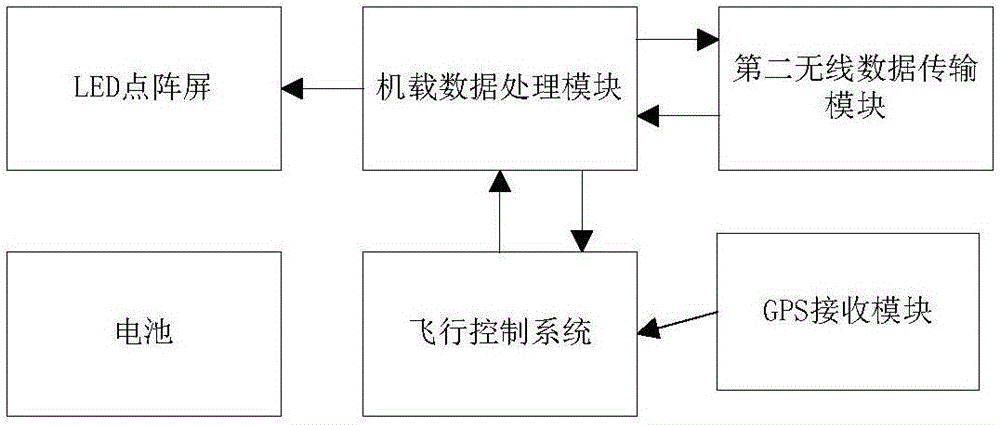

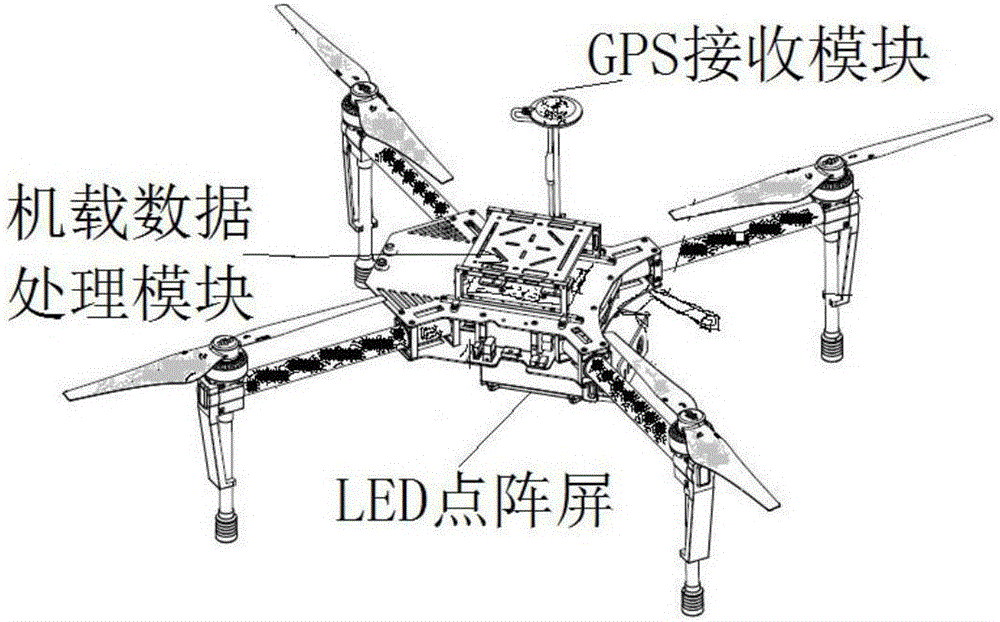

ActiveCN106628211ASolve the problem of easily overflowing the camera field of viewImprove recognition accuracyAircraft landing aidsGround installationsCamera lensDot matrix

The invention discloses a ground guiding type unmanned aerial vehicle flying landing system and method based on an LED dot matrix. The system comprises an unmanned aerial vehicle and an unmanned aerial vehicle taking-off and landing station. The unmanned aerial vehicle taking-off and landing station comprises a carrying table, a three-axis pan-tilt is installed on the carrying table, and a camera is installed on the three-axis pan-tilt; a lens of the camera is controlled by the three-axis pan-tilt to be always kept upward and unchanged in direction, and the camera is connected with a ground computer; and the ground computer controls the camera to carry out photographing. The ground guiding type unmanned aerial vehicle flying landing system and method based on the LED dot matrix have the beneficial effect that an all-weather centimeter-level precise landing function of the multi-rotor unmanned aerial vehicle is achieved through the color and shape recognition algorithm of the computer vision technology and the multi-section PID control technology.

Owner:SHANDONG UNIV +1

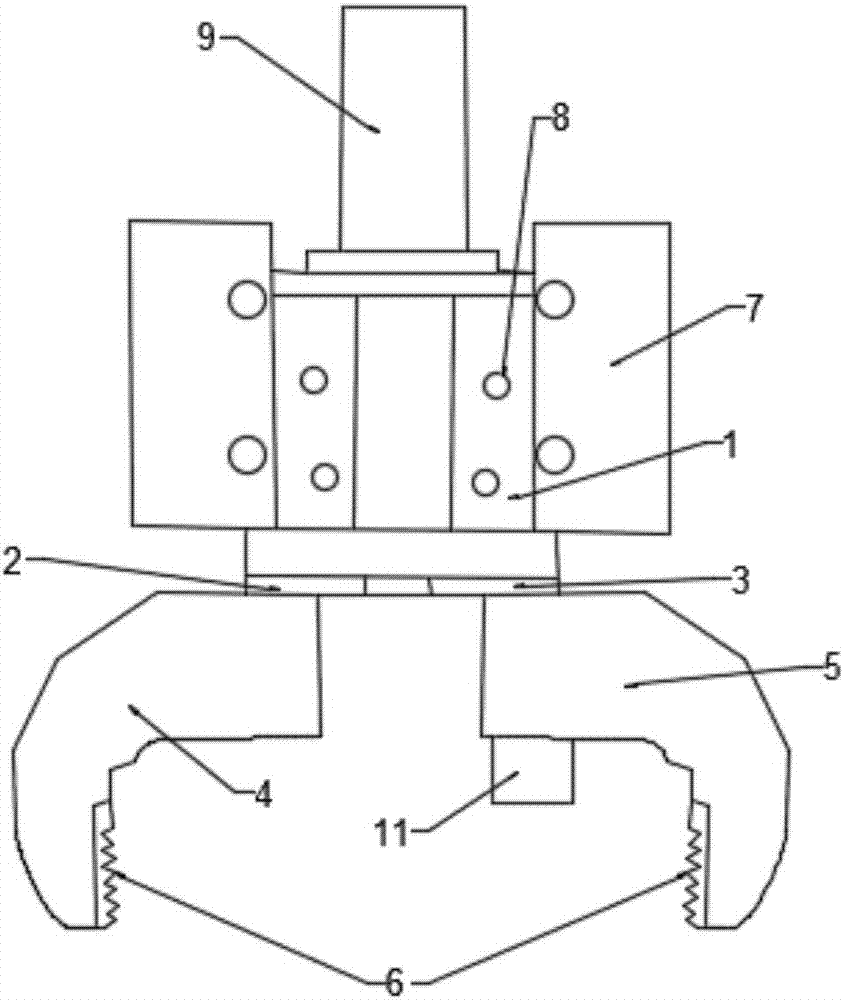

Battery clamping device and replacing device and method applied to autonomous cruising of unmanned aerial vehicle

ActiveCN106864766AAvoid changeReliable cooperationAnchoring installationsRemote controlled aircraftElectrical batteryUncrewed vehicle

The invention discloses a battery clamping device and a replacing device and method applied to autonomous cruising of an unmanned aerial vehicle to clamp and replace an unmanned aerial vehicle battery stably. Saw-toothed blocks are arranged on grippers and can be used for clamping the battery in a fastened mode, downward slipping of the battery during moving is effectively avoided, it can be guaranteed that the clamping depths and positions of the two sides of the battery are the same, and the situation that the clamping depths and positions are different, and consequentially the clamped battery deflects and cannot be mounted in a battery box or the unmanned aerial vehicle is avoided. According to the technical scheme, the battery clamping device comprises a clamping claw mechanism which comprises a clamping claw body; the clamping claw body is connected with a first clamping claw part and a second clamping claw part; the first clamping claw part is fixedly connected with the first gripper, and the second clamping claw part is fixedly connected with the second gripper; and the saw-toothed blocks are arranged on the opposite faces of the first gripper and the second gripper in a matched mode.

Owner:SHANDONG UNIV +1

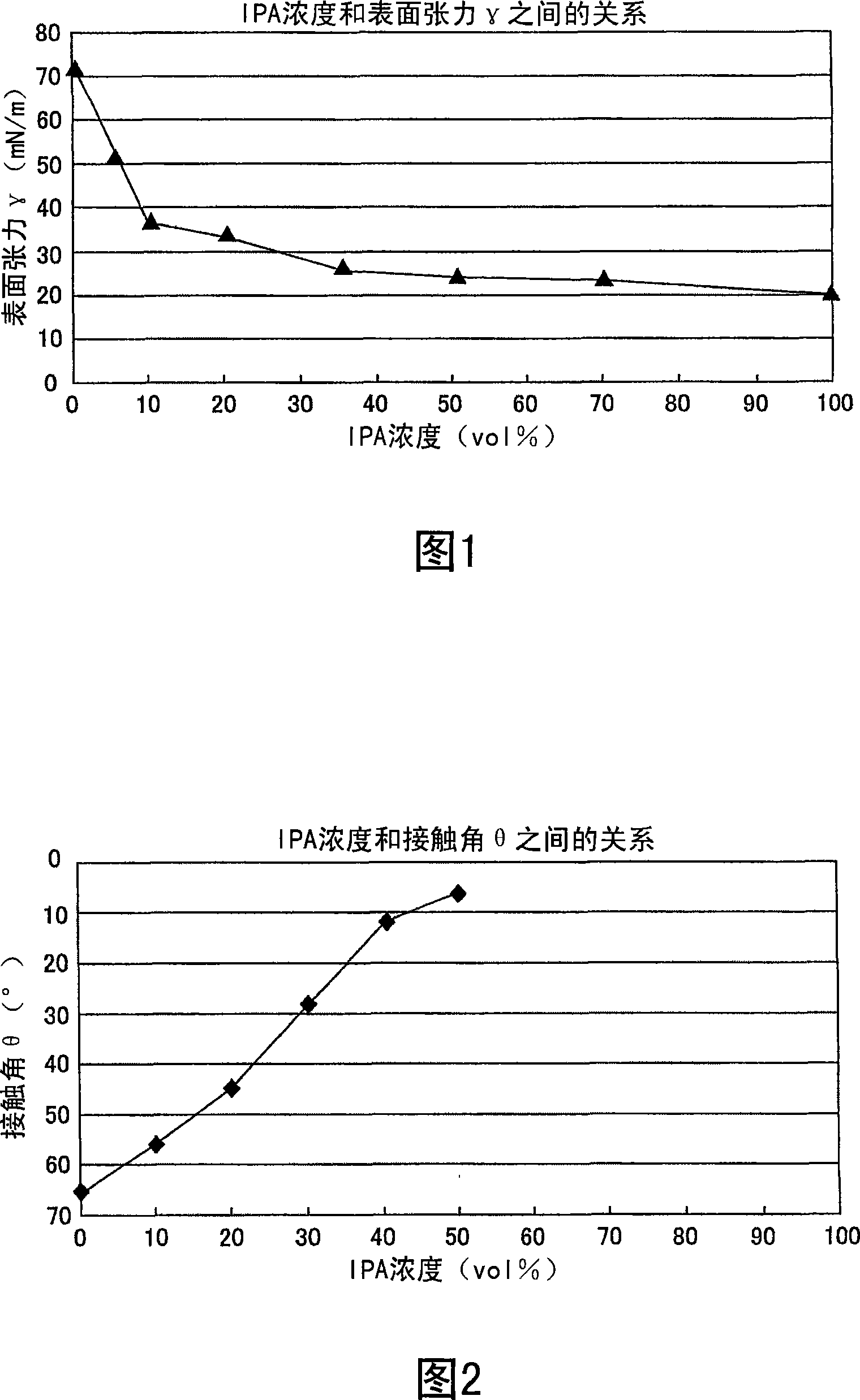

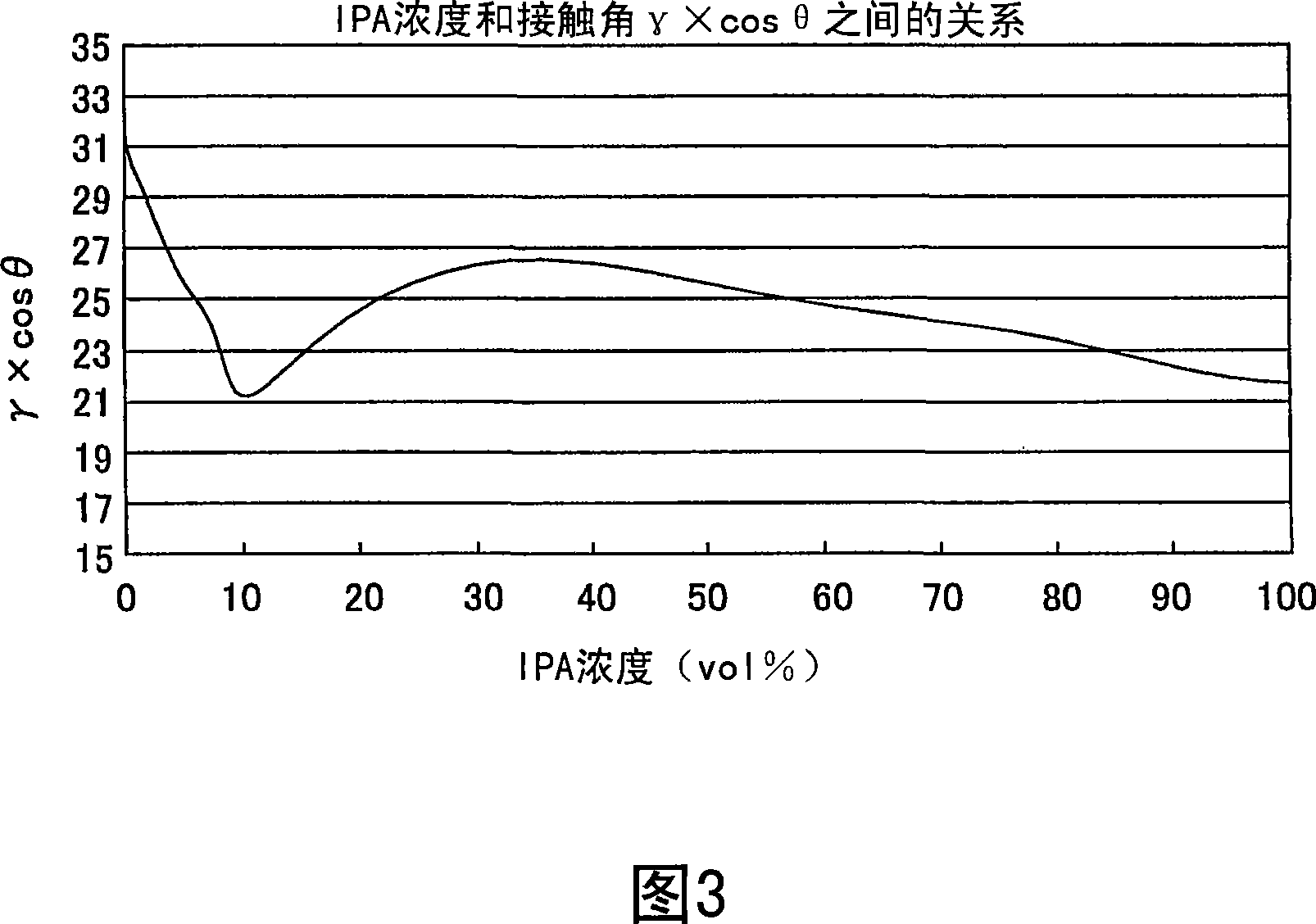

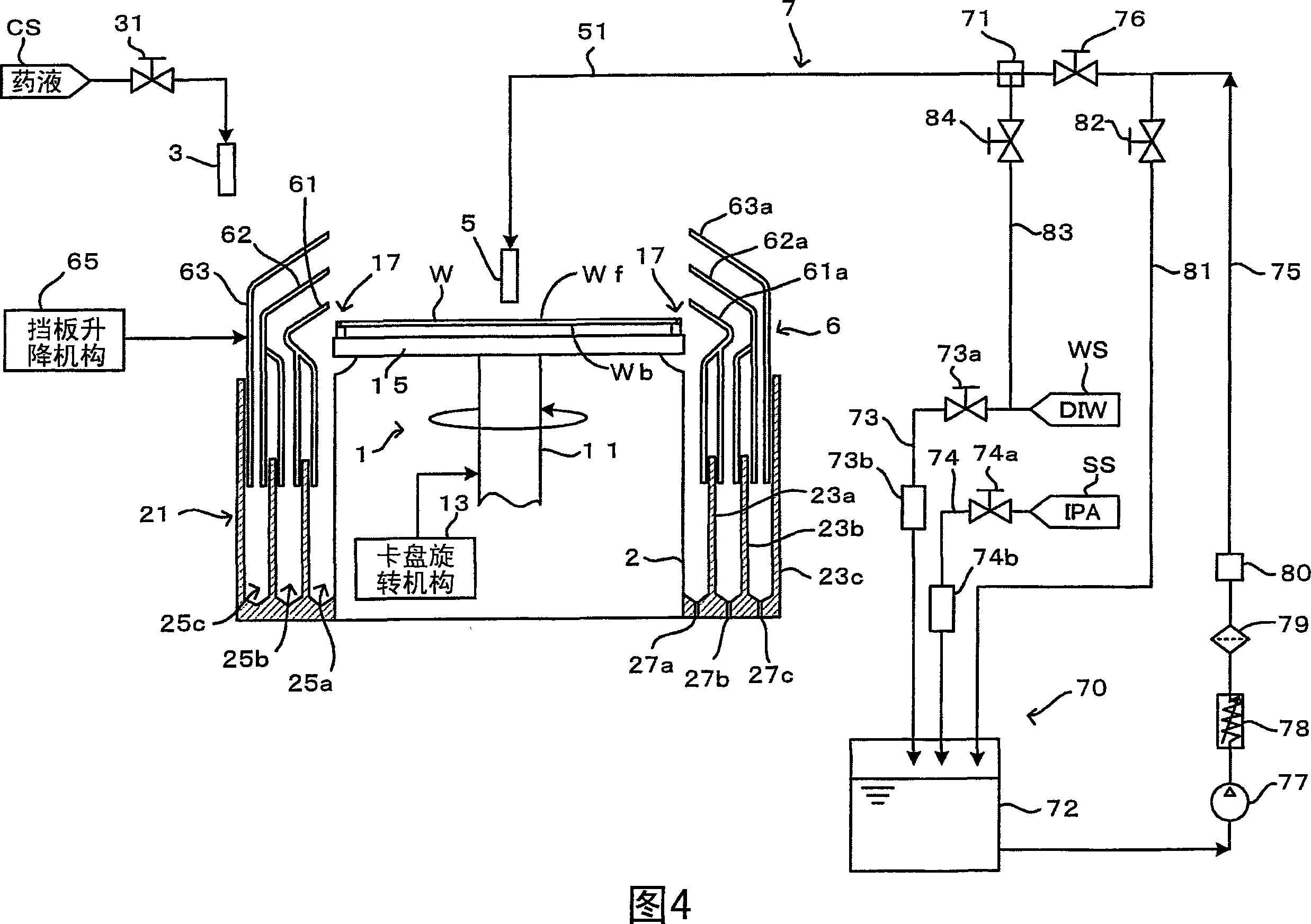

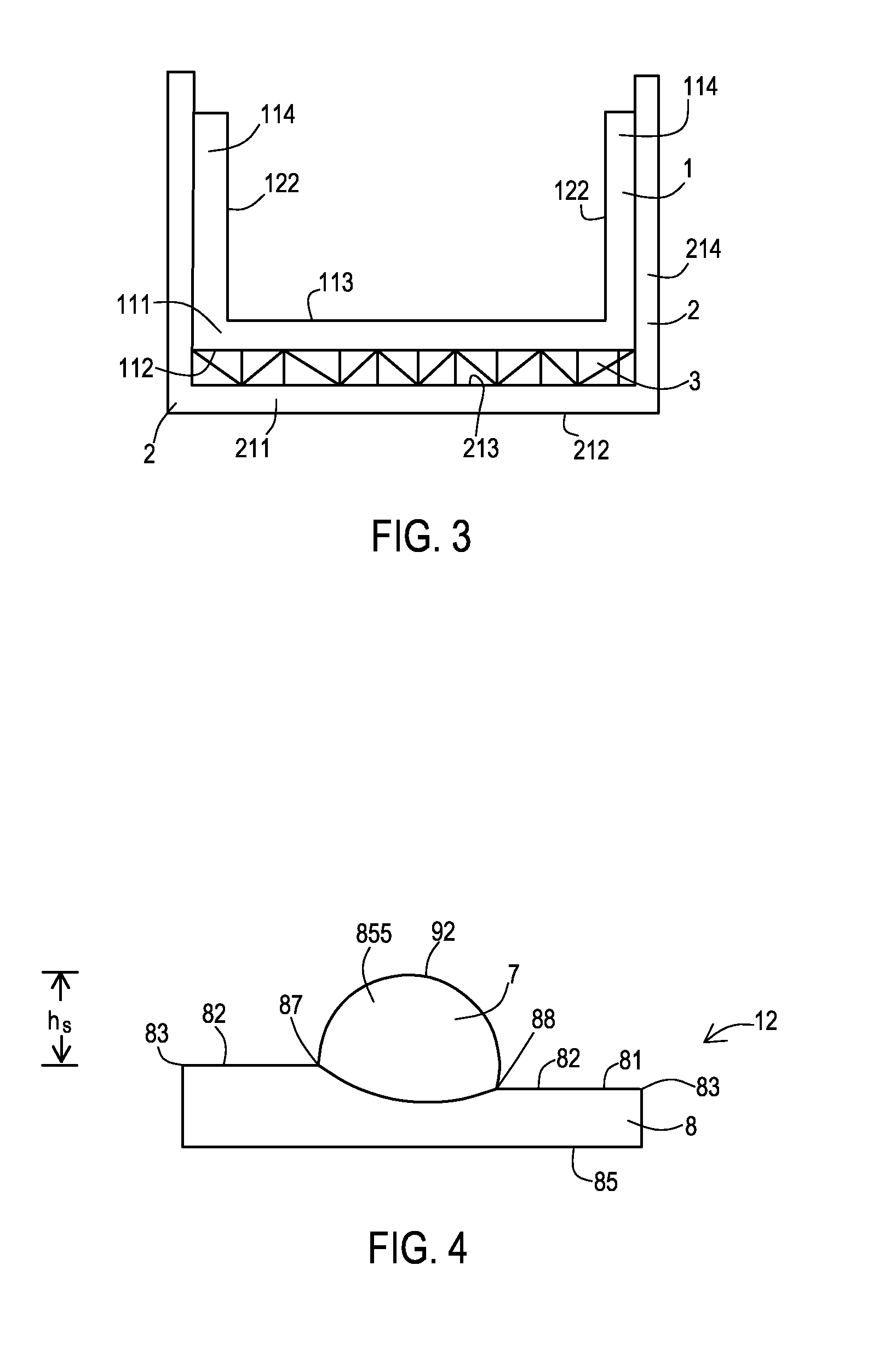

Substrate processing method and substrate processing apparatus

InactiveCN101097837AEfficient entryPrevent collapseSemiconductor/solid-state device manufacturingPhotosensitive material processingOrganic solventSubstrate surface

After rinsing, while rotating a substrate, a front layer part of a rinsing liquid (DIW) adhering to a substrate surface is drained and removed from the substrate surface. This is followed by supply to the substrate surface of a liquid mixture which is obtained by mixing IPA and DIW together. Since a majority of the rinsing liquid on the substrate surface is removed off from the substrate surface, even when micro patterns are formed on the substrate surface, the liquid mixture replaces the liquid component adhering to the gaps between the patterns. Further, the IPA concentration in the liquid mixture supplied to the substrate surface is set to 50% or below. Hence, it is possible to effectively prevent destruction of the patterns while suppressing the consumption amount .

Owner:DAINIPPON SCREEN MTG CO LTD

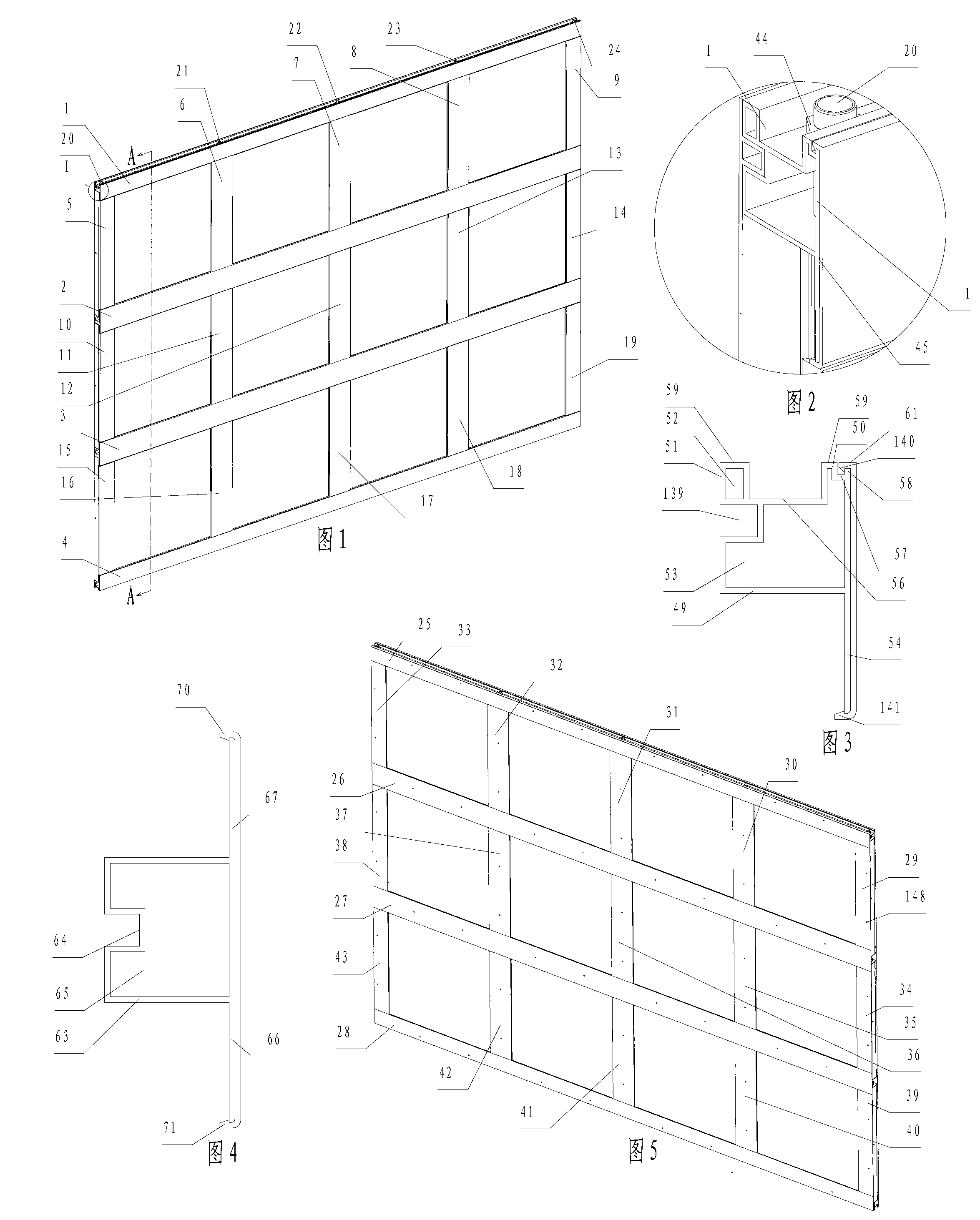

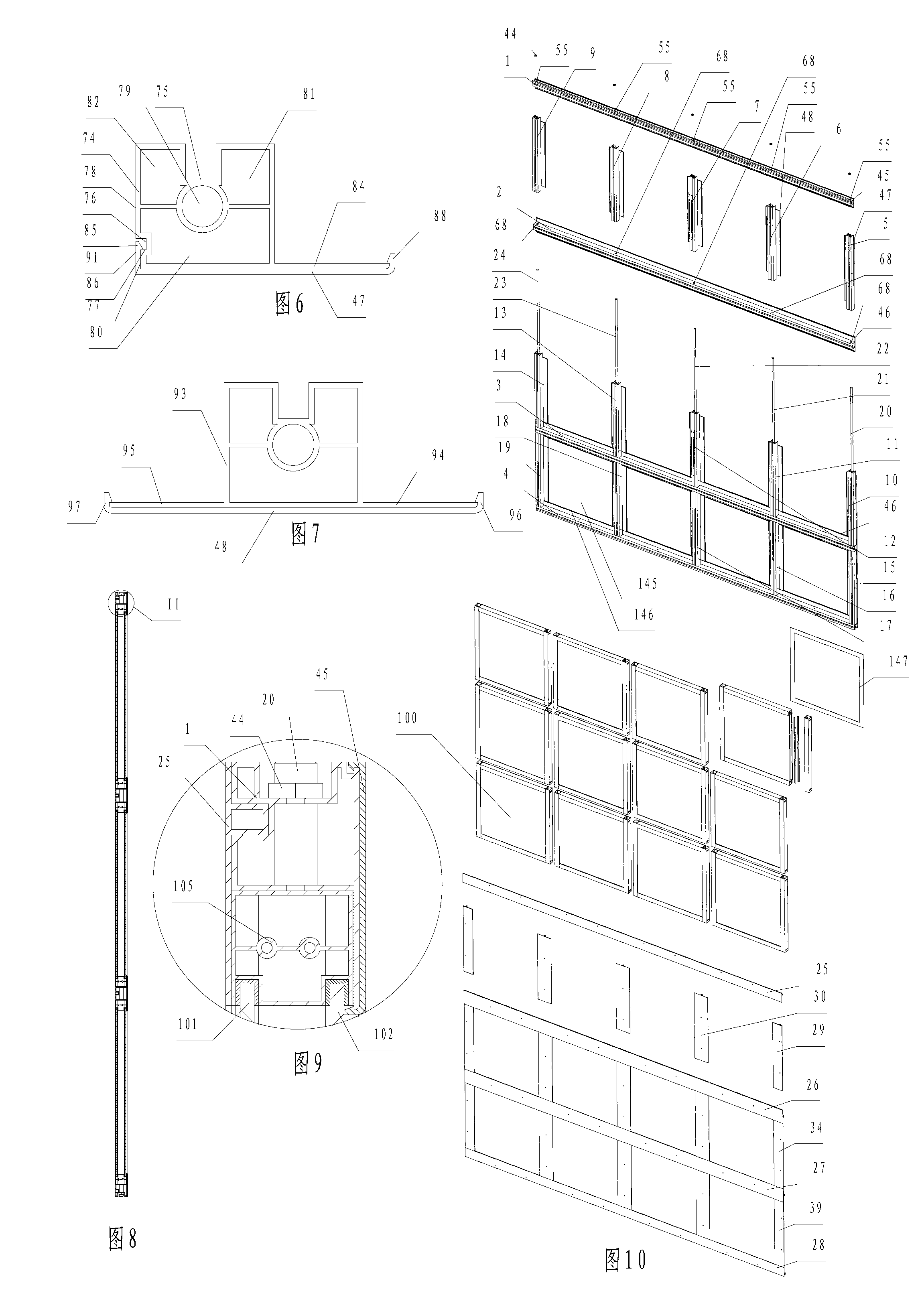

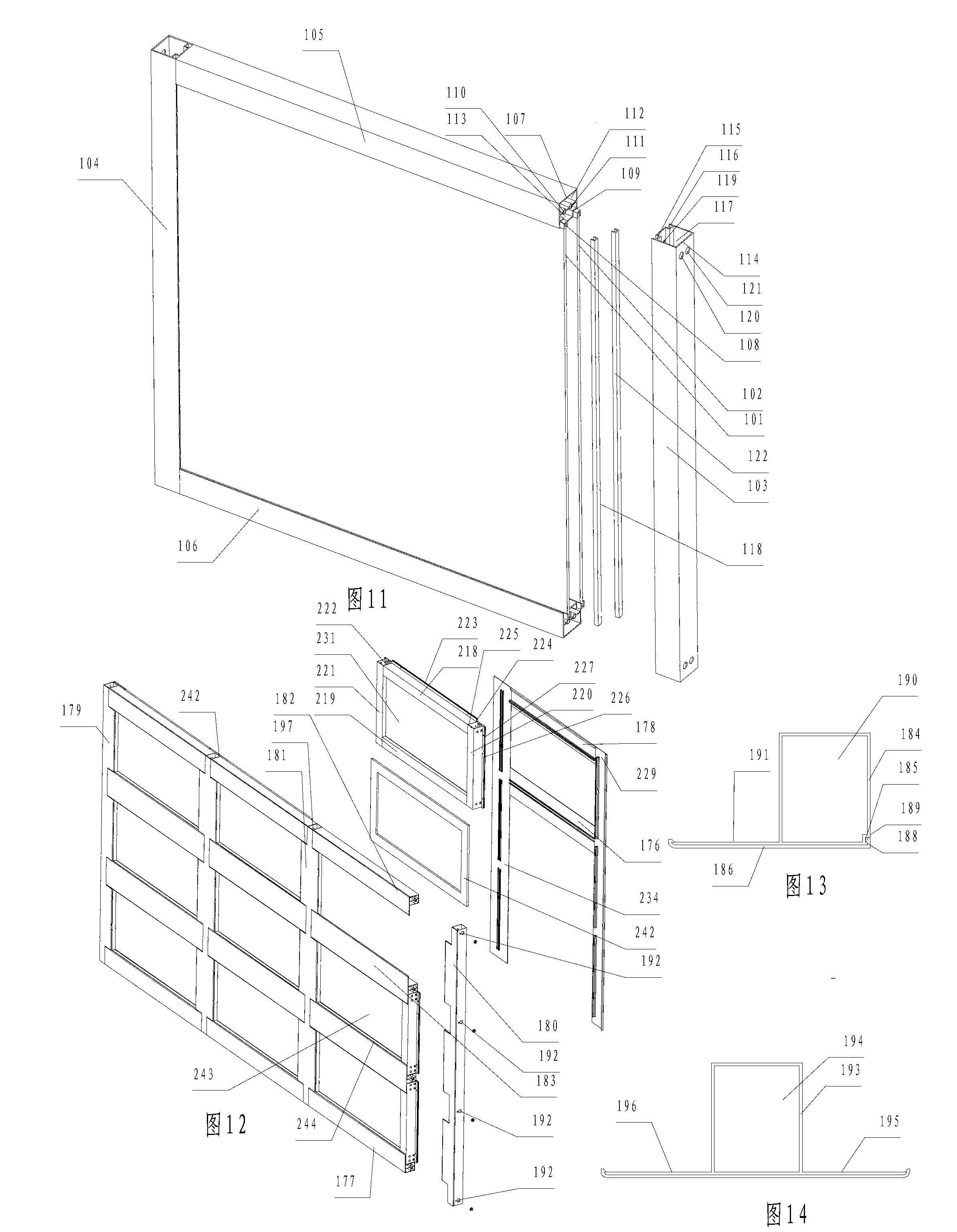

Combined construction structure

ActiveCN103075075AReduce aging speedEasy to replaceShutters/ movable grillesWallsIsolation effectKeel

The invention discloses a combined construction structure which comprises first keels, second keels and an interlayer module; the adjacent two first keels and the adjacent two second keels form a square frame for installing the interlayer module; flanges which are integrated with the corresponding first keels and second keels are arranged on four inner side surfaces opposite to the square frame; elastic buckle-type profile U-shaped first external spacer bars which are laterally buckled onto the first keels, and elastic buckled-type profile U-shaped second external spacer bars which are laterally buckled onto the second keels are also arranged; one of the two buckles of the first external spacer bar of the first keel on the outermost side is buckled on the related flange, and the other is buckled in a first slot; and one of the two buckles on the second external spacer of the second keel on the outermost side is buckled on the related flange, and the other is buckled on a second slot. The combined construction structure has the advantages of good heat isolation and sound isolation effects, convenience and quickness in installation, simple process, good strength and rigidity of main keels, and low cost.

Owner:深圳市华汇设计有限公司

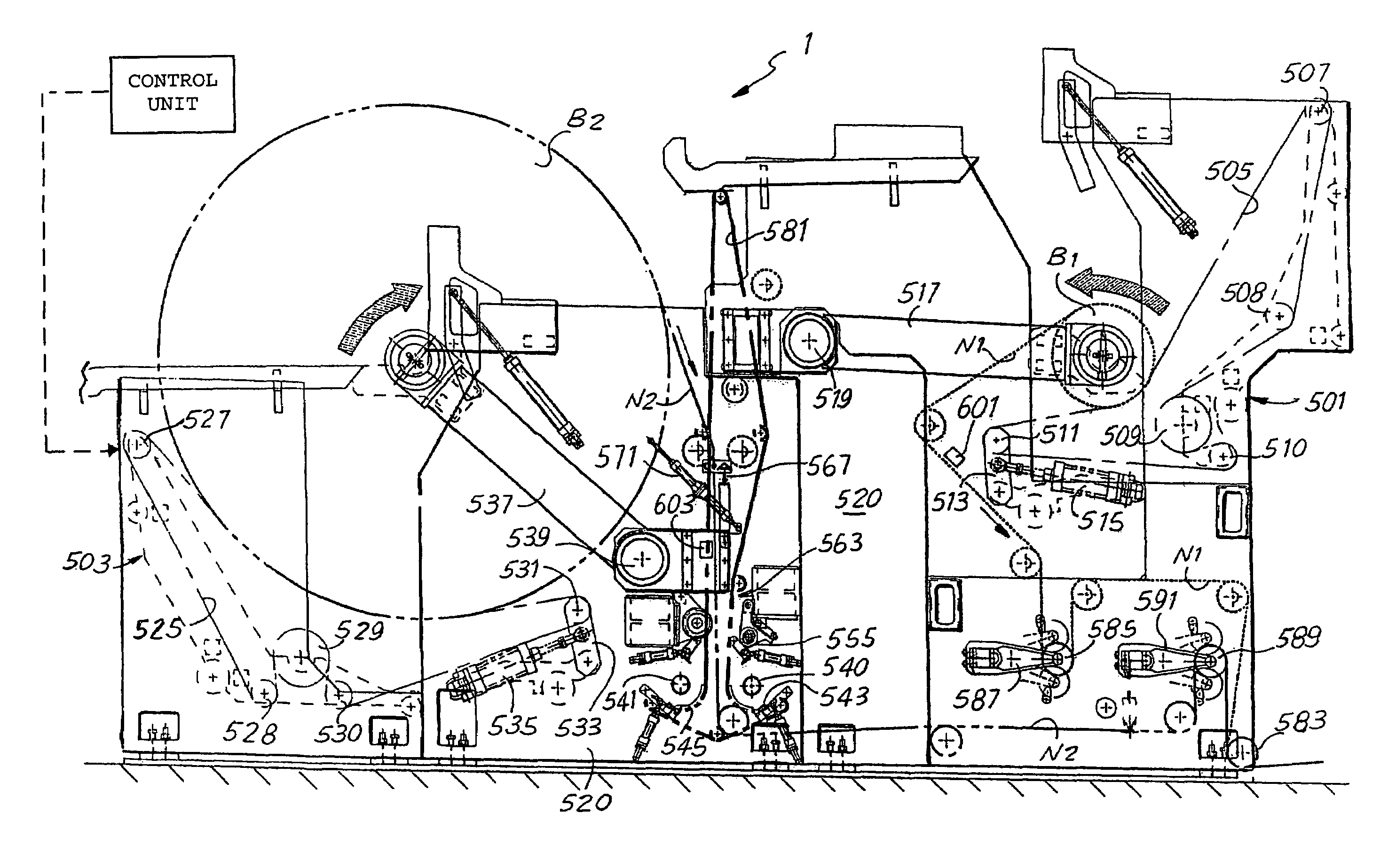

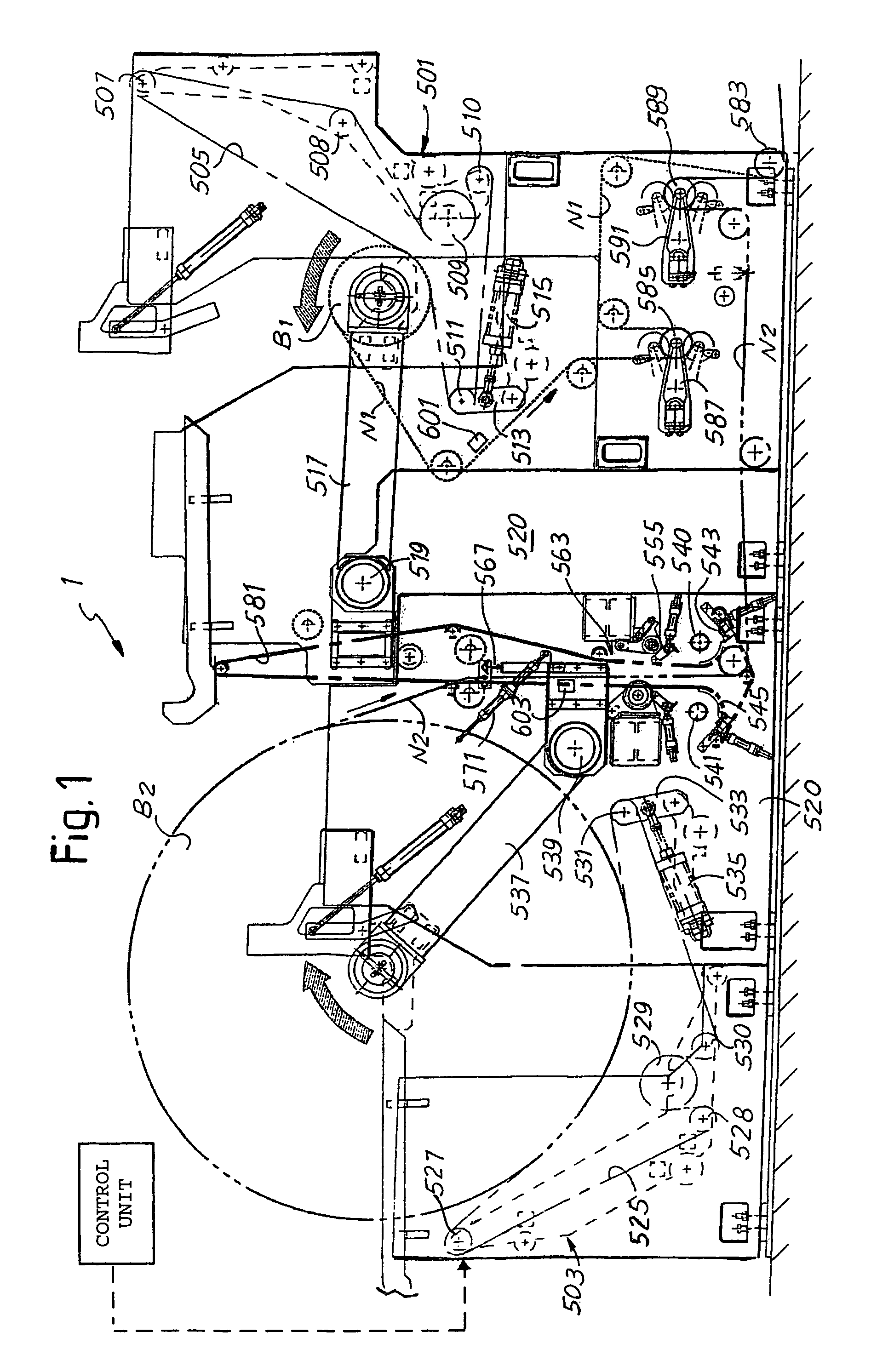

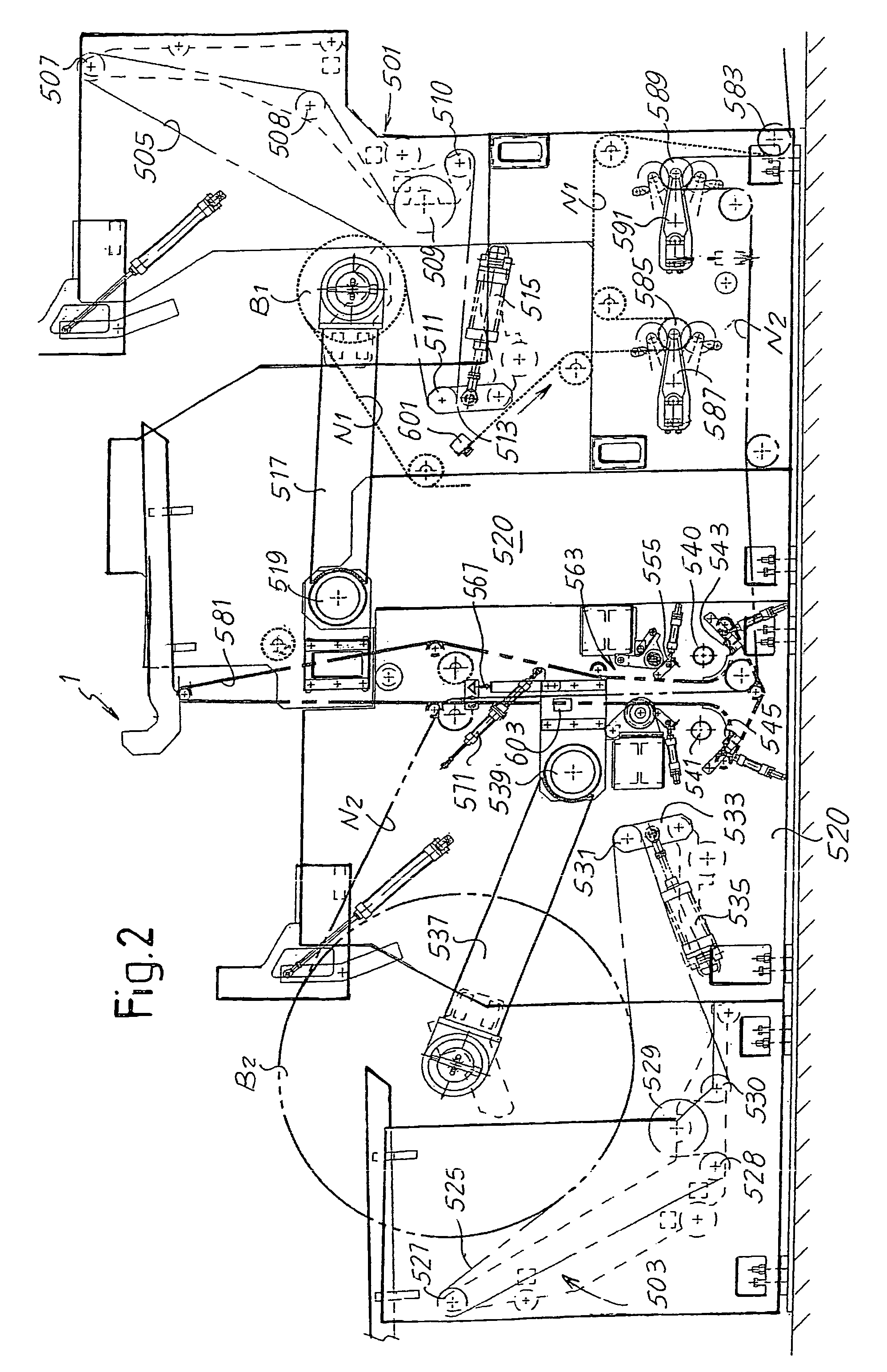

Multifunction unwinding device

ActiveUS7618004B2Reliable replacementFilament handlingWebs handlingEngineeringMechanical engineering

The unwinding device to unwind reels of web material includes: unwinding members to simultaneously unwind a first reel and a second reel; a splicing device to join together a first web material coming from the first reel and a second web material coming from the second reel; at least one accumulation member to accumulate the web material delivered from the second reel before splicing with the web material delivered from the first reel; a first path and a second path for the web material delivered simultaneously from the first and from the second reel towards a machine downstream.

Owner:FABIO PERINI SPA

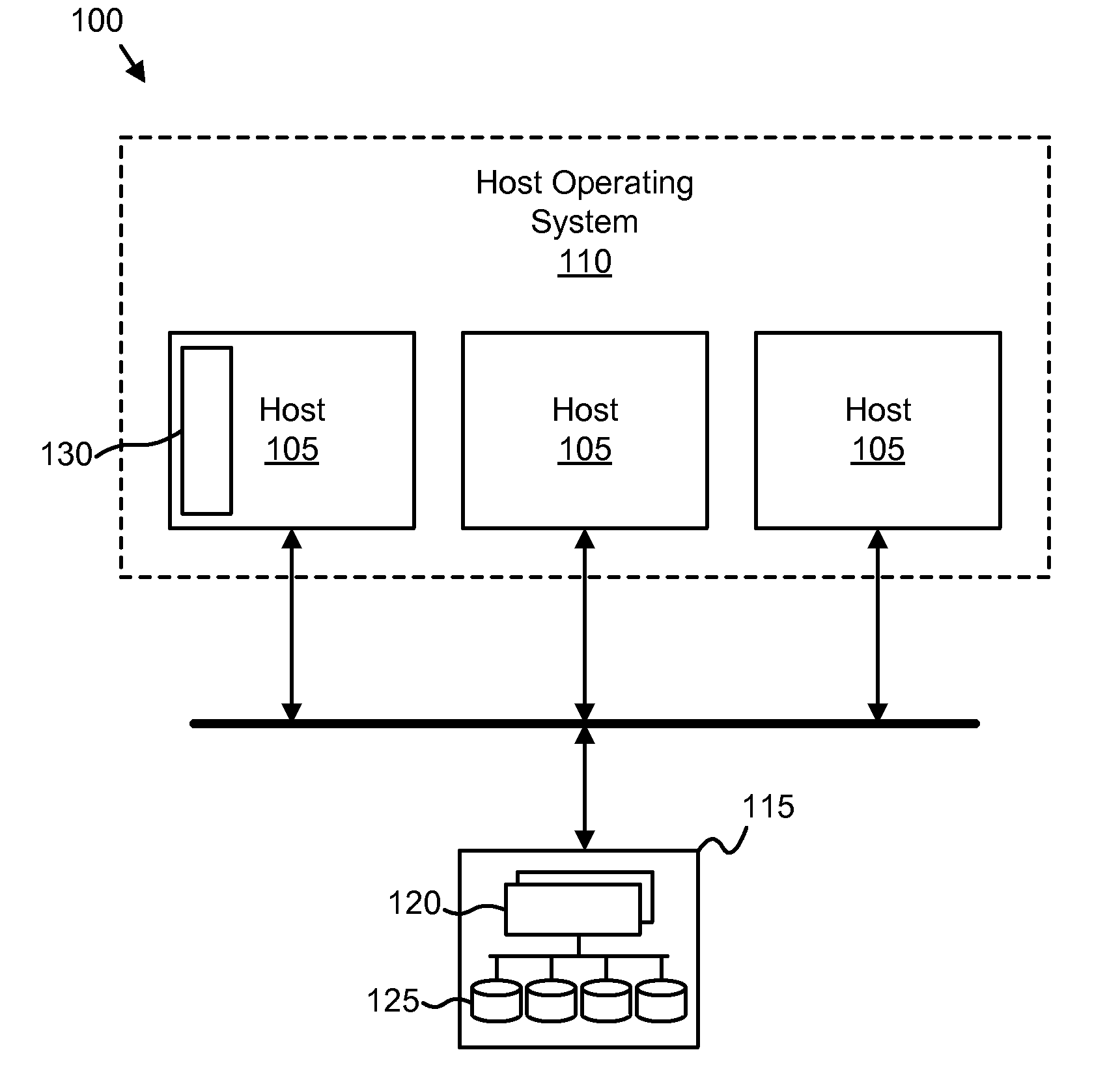

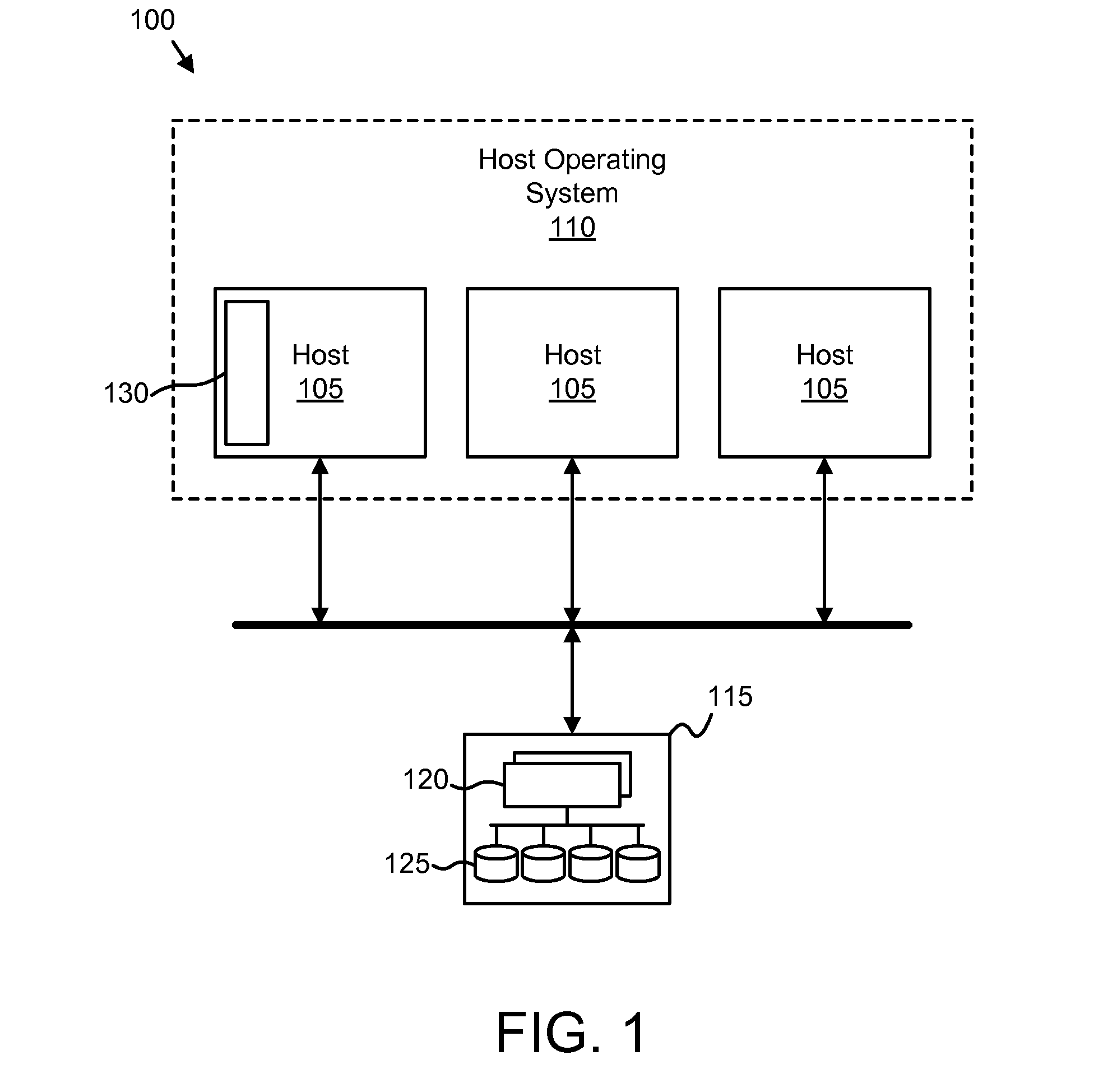

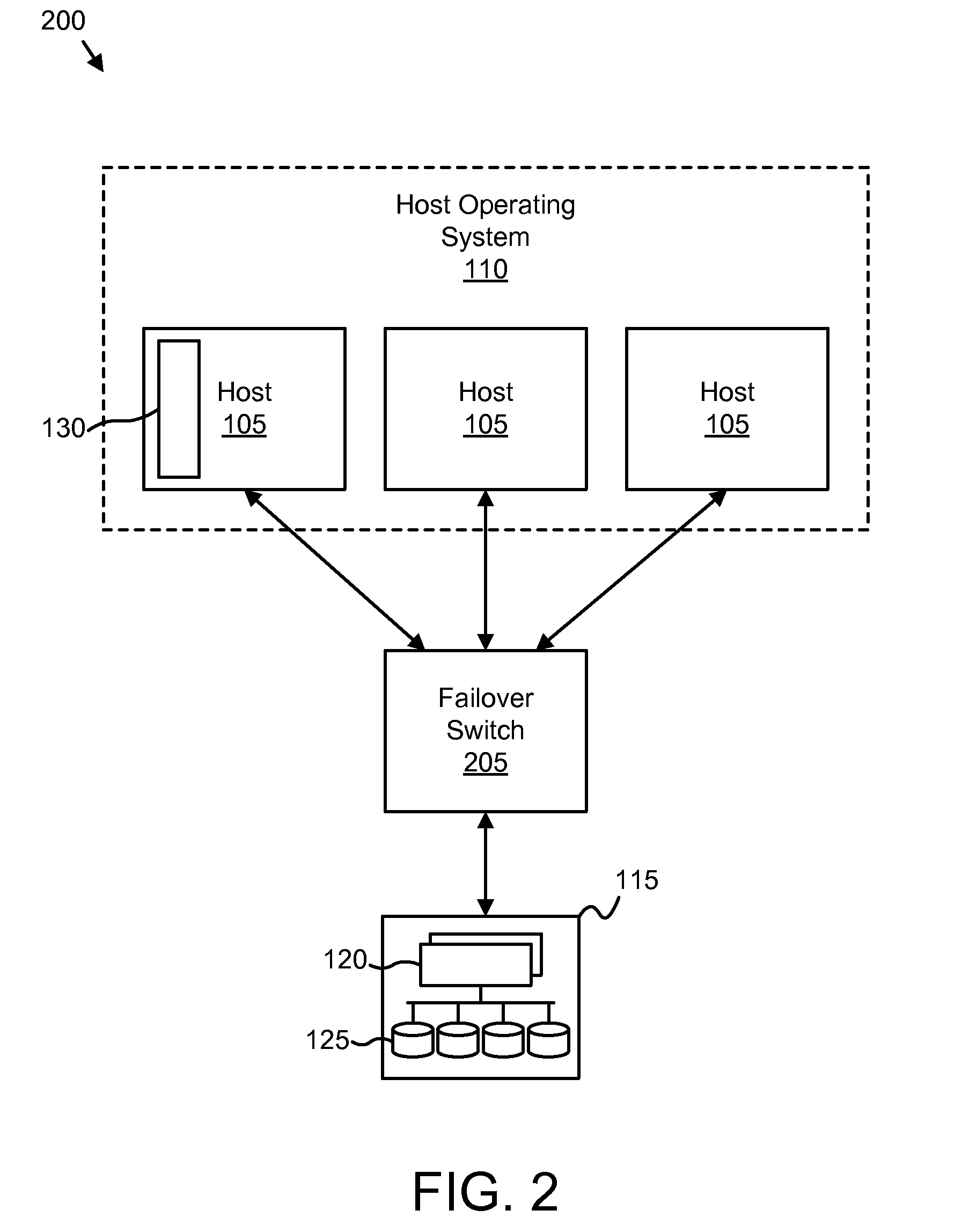

Apparatus, system, and method for automating adapter replacement

InactiveUS20080147895A1Simplifies replacementEasy to replaceError detection/correctionInput/output processes for data processingSystem configurationFailover

An apparatus, system, and method are disclosed for automating adapter replacement. An input module receives an identification of a first adapter. A storage configuration module removes the first adapter from a storage subsystem configuration. A host configuration module adds the second adapter to the host operating system configuration. In one embodiment, a failover configuration module removes the first adapter from a failover driver configuration. The host configuration module adds the second adapter to the host operating system configuration. The storage configuration module adds the second adapter to the storage subsystem configuration. Further the failover configuration module may add the second adapter to the failover driver configuration. The identifier module retrieves an identifier from the second adapter in the form of a world-wide port number from the second adapter.

Owner:IBM CORP

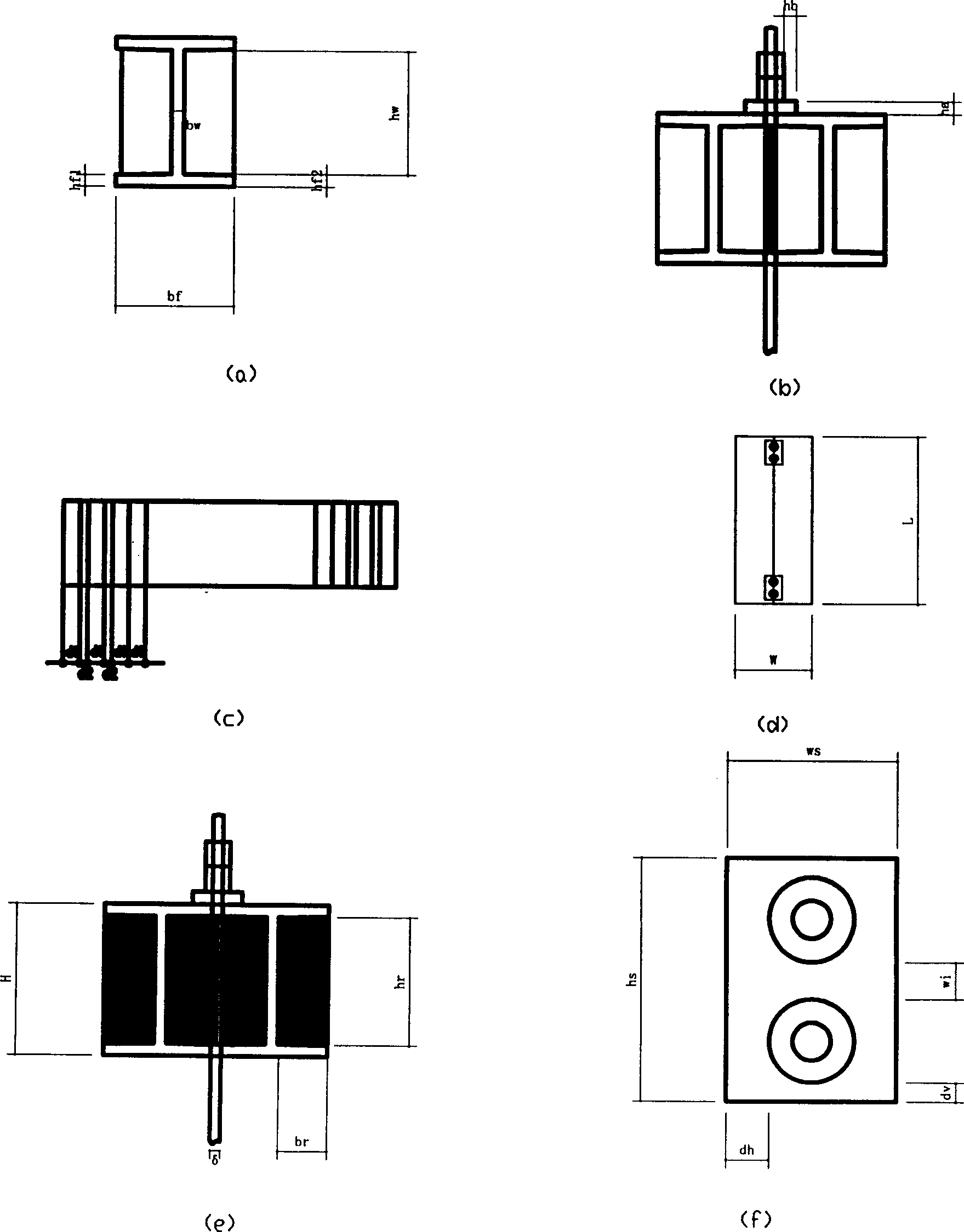

Processing inspection fixture for special steel tensile sample and inspection method

InactiveCN104865121AReduce consumptionReduce lossMaterial strength using tensile/compressive forcesEngineeringTower

The invention relates to a processing inspection fixture of a special steel tensile sample and an inspection method. The processing inspection fixture comprises an upper fixture and a lower fixture, wherein each of the upper fixture and the lower fixture is of a tower-shaped threaded sleeve structure, and is composed of clamping ends and threaded sleeves; the other ends of the upper and lower clamping ends are respectively mounted in a upper tester jaw and a lower tester jaw; the upper fixture and the lower fixture respectively fix one end of a tensile finished product sample with a threaded head; meanwhile, a tester extensometer is clamped on the tensile finished product sample with the threaded head. According to the invention, the technical problems that the short special steel tensile sample cannot clamp the extensometer and the clamp slipping affects the accuracy of inspection results are solved; the fixture is convenient and rapid to replace, can be recycled, and has long service life; the tensile batch inspection of the special steel products can be completed at low cost by using the processing inspection fixture for the special steel tensile sample and the inspection method.

Owner:SGIS SONGSHAN CO LTD

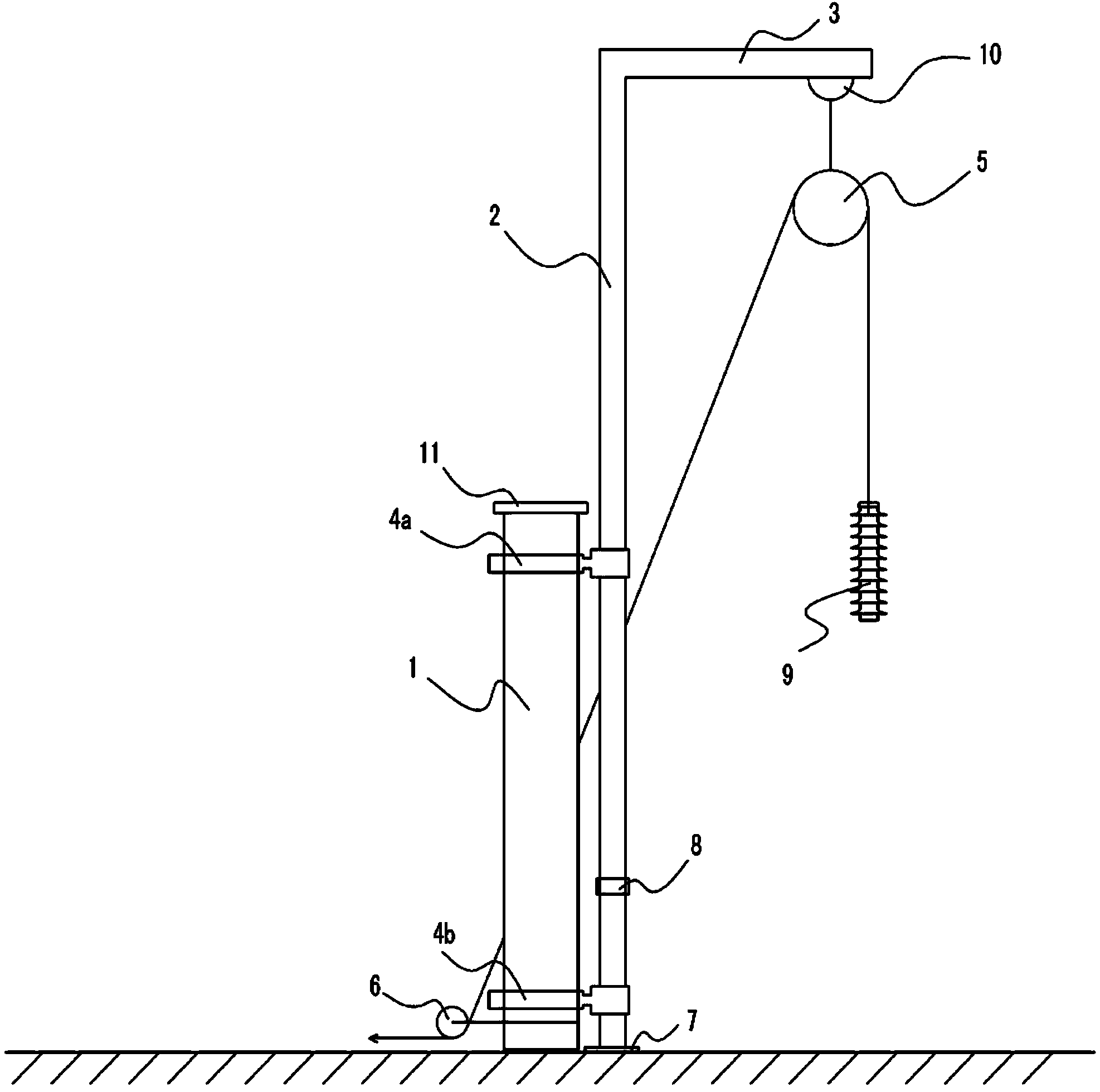

Detachable support applied to lifting of small-sized electric power device and construction method thereof

InactiveCN103523704AReduce labor intensitySimple structurePortable liftingSwitchgearArchitectural engineeringAlloy

The invention discloses a detachable support applied to lifting of a small-sized electric power device and a construction method of the detachable support applied to lifting of the small-sized electric power device. The detachable support applied to lifting of the small-sized electric power device is characterized in that the detachable support is vertically arranged on one side of a concrete pole support of the electric power device, the detachable support is an inverted-L-shaped support which is composed of a perpendicular stand rod and a transverse alloy beam fixed to the top of the perpendicular stand rod, a top fixed pulley is hung on the transverse alloy beam, the perpendicular stand rod is fixed to one side of the concrete pole support (1) through U-shaped hoops, a bottom fixed pulley is fixed to the lower portion of the concrete pole support through a steel wire rope, and a rope connected to the small-sized electric power device surrounds the top fixed pulley and the bottom fixed pulley in sequence. The detachable support applied to lifting of the small-sized electric power device and the construction method of the detachable support applied to lifting of the small-sized electric power device can achieve the purpose of lifting construction of the small-sized electric power device on the construction site with a narrow and small space, the area of a power outage of the construction site and influence on surrounding users are reduced, and construction efficiency and operation flexibility are improved.

Owner:STATE GRID CORP OF CHINA +1

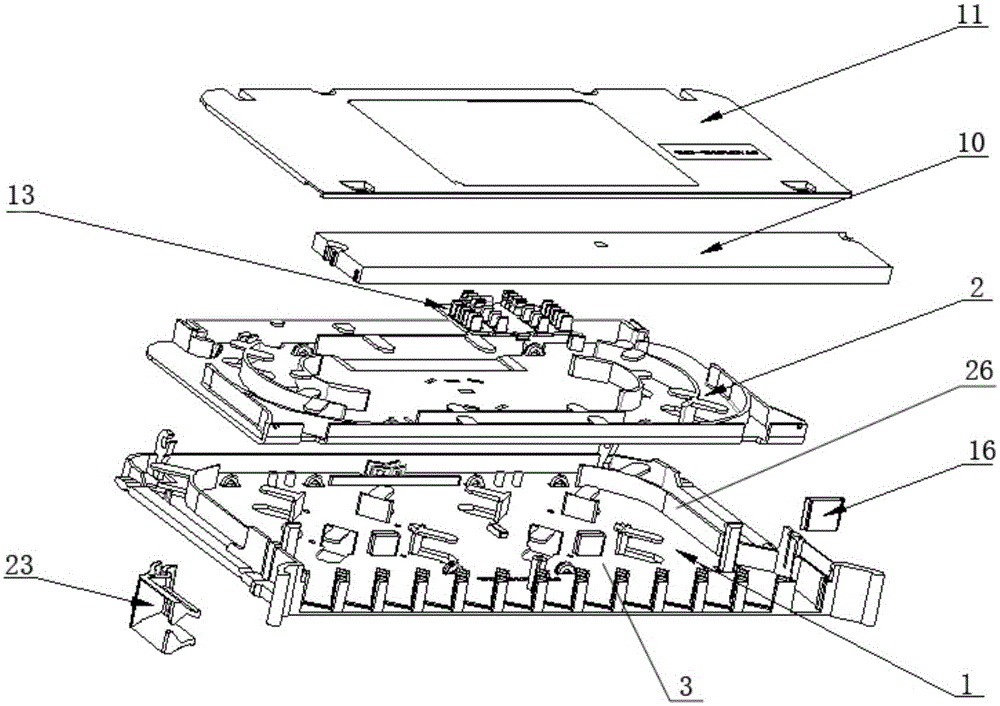

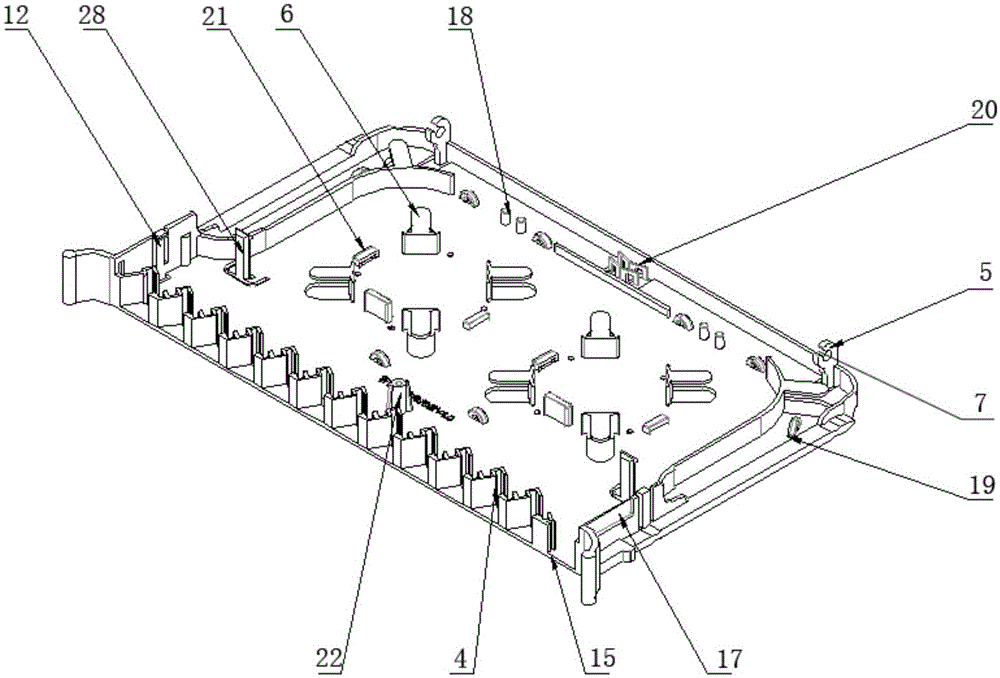

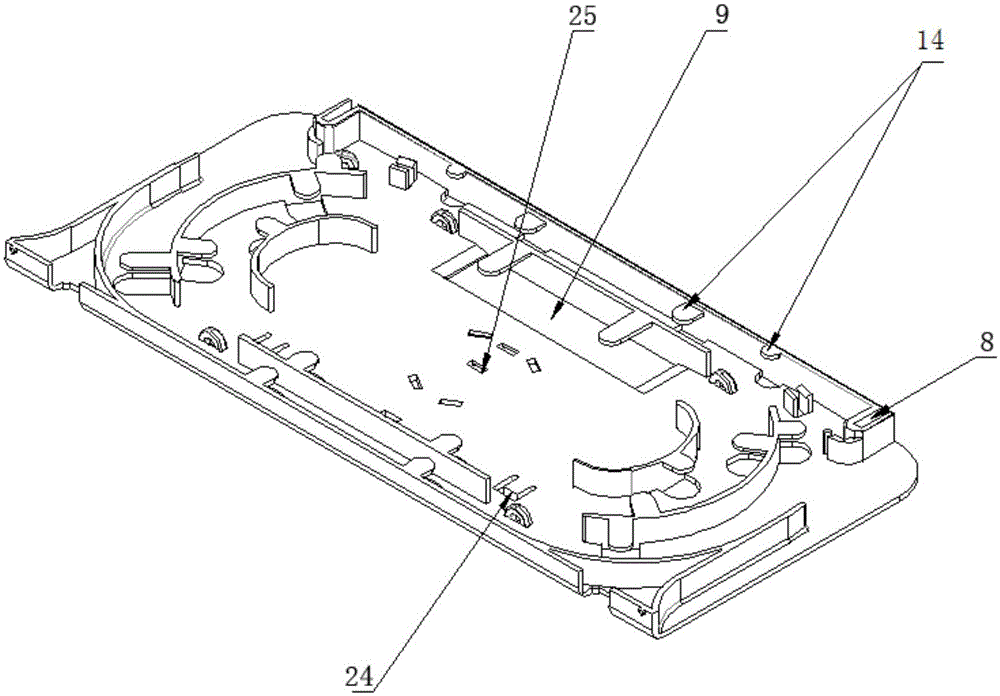

Optical fiber mix-melting integrated tray capable of being intelligently upgraded

InactiveCN105005114AReliable replacementConducive to intelligent upgrading and transformationCoupling light guidesFibre mechanical structuresEngineeringFiber

The invention provides an optical fiber mix-melting integrated tray capable of being intelligently upgraded. The optical fiber mix-melting integrated tray is not only suitable for a traditional optical fiber communication carrier tray but also suitable for the carrier tray capable of smoothly expanding intelligent optical fiber communication. The optical fiber mix-melting integrated tray can satisfy the use of a plurality of adapters and matched movable connectors, and includes a terminal tray, a melting tray, and a cover plate, wherein the terminal tray includes a melting tray supporting area, an adapter installation opening, rotating shaft bearers, and fiber-winding columns. The left and the right sides of the melting tray supporting area are respectively provided with upper convex bearing side walls. At least two groups of fiber-winding columns are respectively arranged in the melting tray supporting area. The two rotating shaft bearers are respectively arranged at two sides of the rear ends of the terminal tray and protrude upward. Gap structures are arranged at the oblique upward position inside the rotating shaft bears. Melting tray rotating shafts are arranged at the two sides of the rear ends of the melting tray. The melting tray rotating shafts are inserted in rotating shaft bearer installation holes under the corresponding position.

Owner:JIANGSU HENGTONG OPTICAL NETWORK TECH CO LTD +1

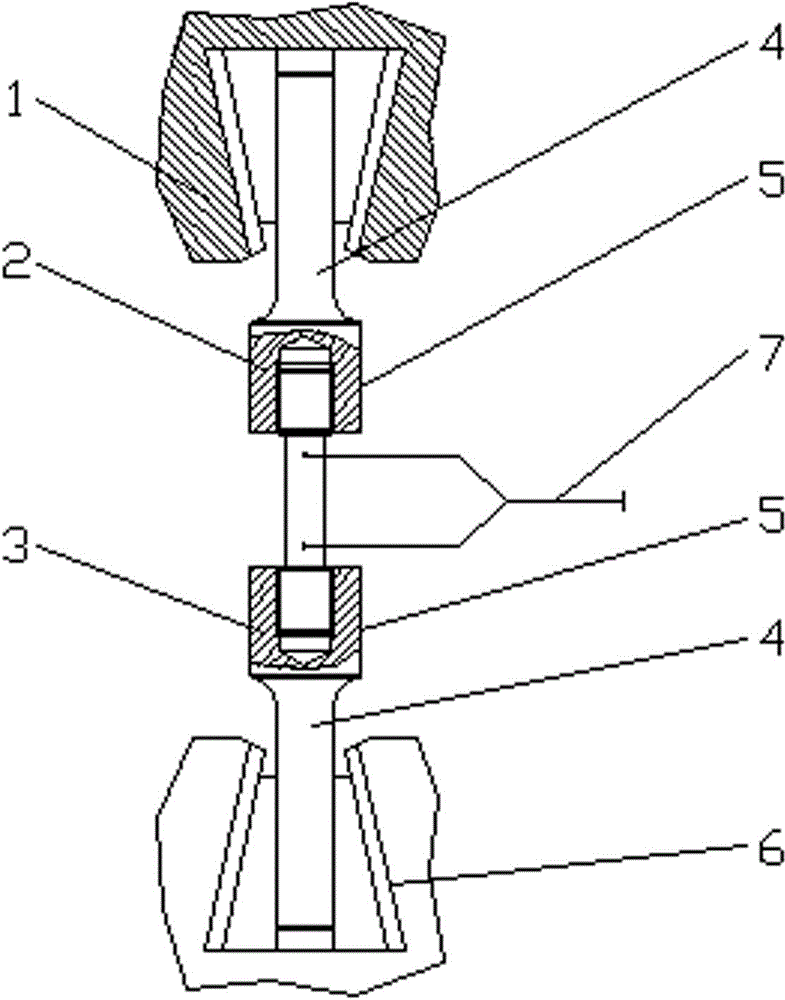

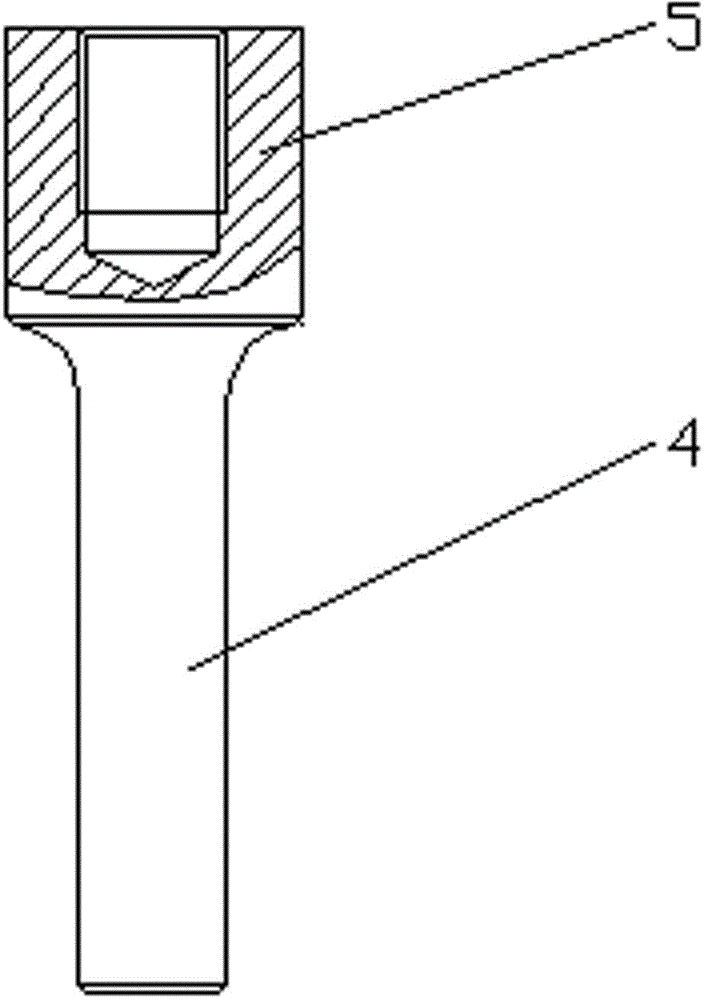

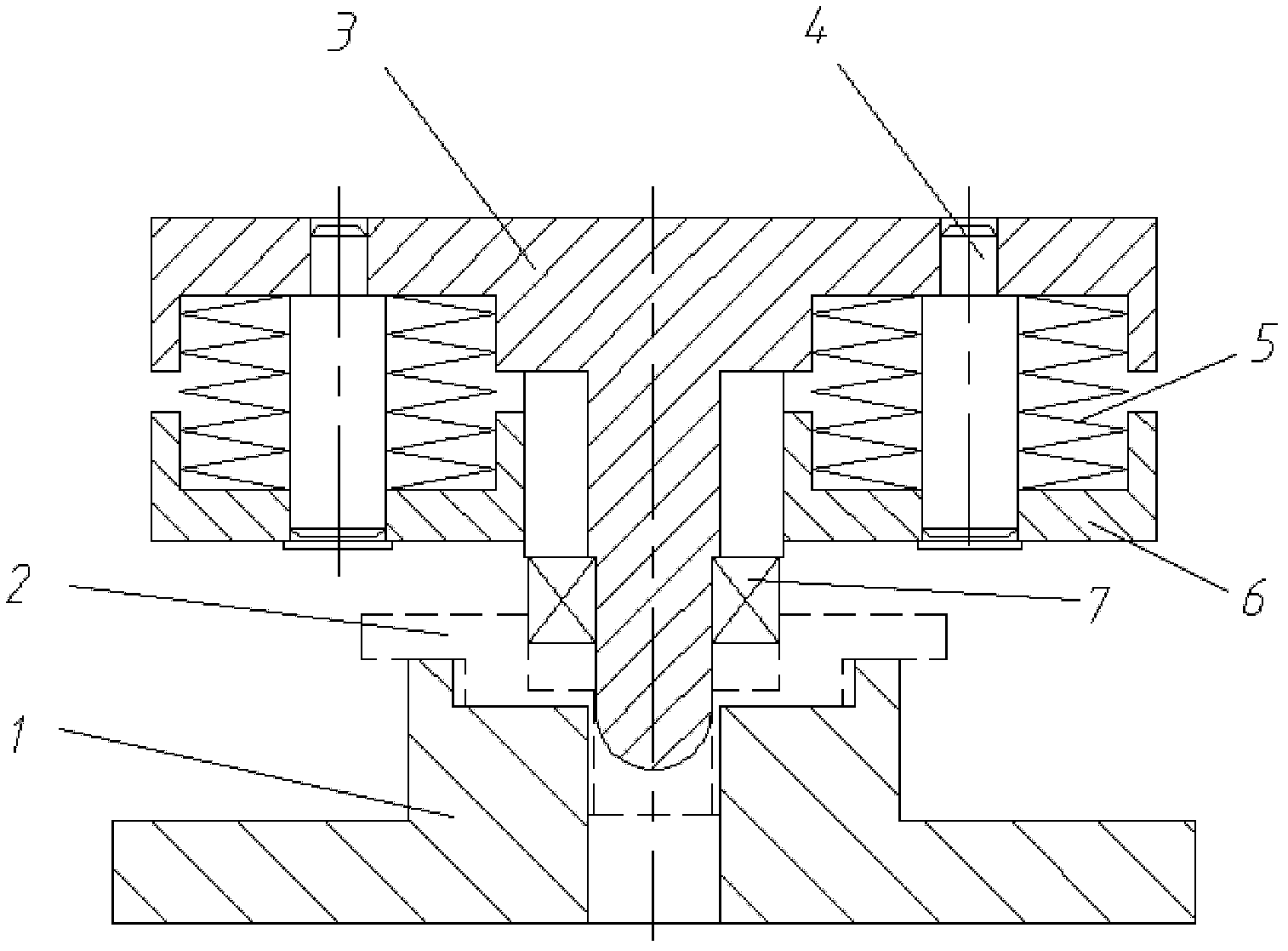

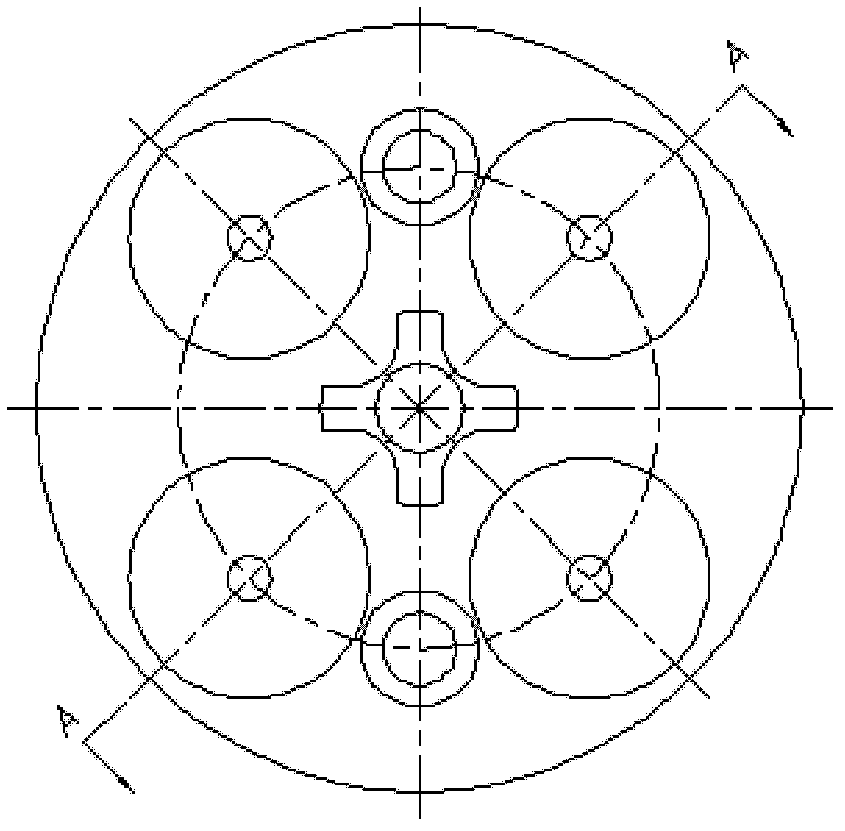

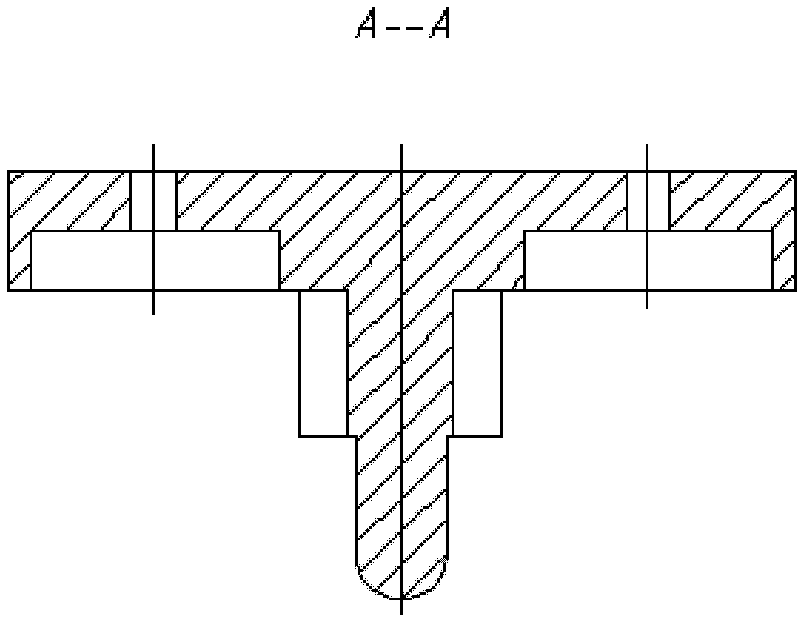

Bearing riveting and pressing tool

The invention provides a bearing riveting and pressing tool, which comprises a positioning sleeve, a press mold, ejector rods, disc springs and a discharge plate. The press mold is a circular plate structure, and a guiding positioning shaft head is arranged in the center of the circular plate structure; riveting and pressing ribs are arranged on the periphery of the guiding positioning shaft head; the discharge plate is a circular plate structure, the diameter of the circular plate structure is identical to that of the press mold, and a through hole is disposed in the center of the discharge plate; and a plurality of disc spring mounting grooves are arranged on the plate structure of the discharge plate and the plate structure of the press mold, each ejector rod is mounted in the center of the corresponding disc spring mounting groove, the disc springs are strung on the ejector rods, one end of each ejector rod is fixedly connected with the press mold, a flange is disposed at the other end of the ejector rod, the discharge plate is limited and can axially move along the ejector rod. The bearing riveting and pressing tool has functions of guiding, positioning, riveting, pressing, discharging and the like, is simple in structure as compared with an existing bearing riveting and pressing mold, workers operate the bearing riveting and pressing tool conveniently, materials are discharge easily, timely and accurately, and work efficiency can be greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

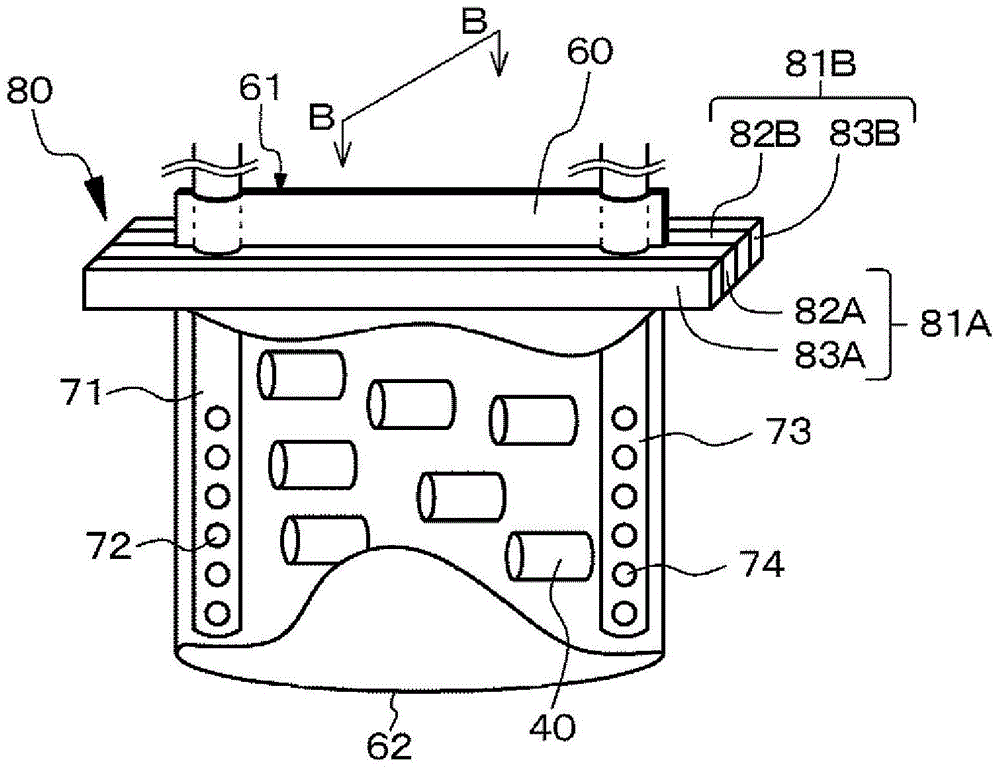

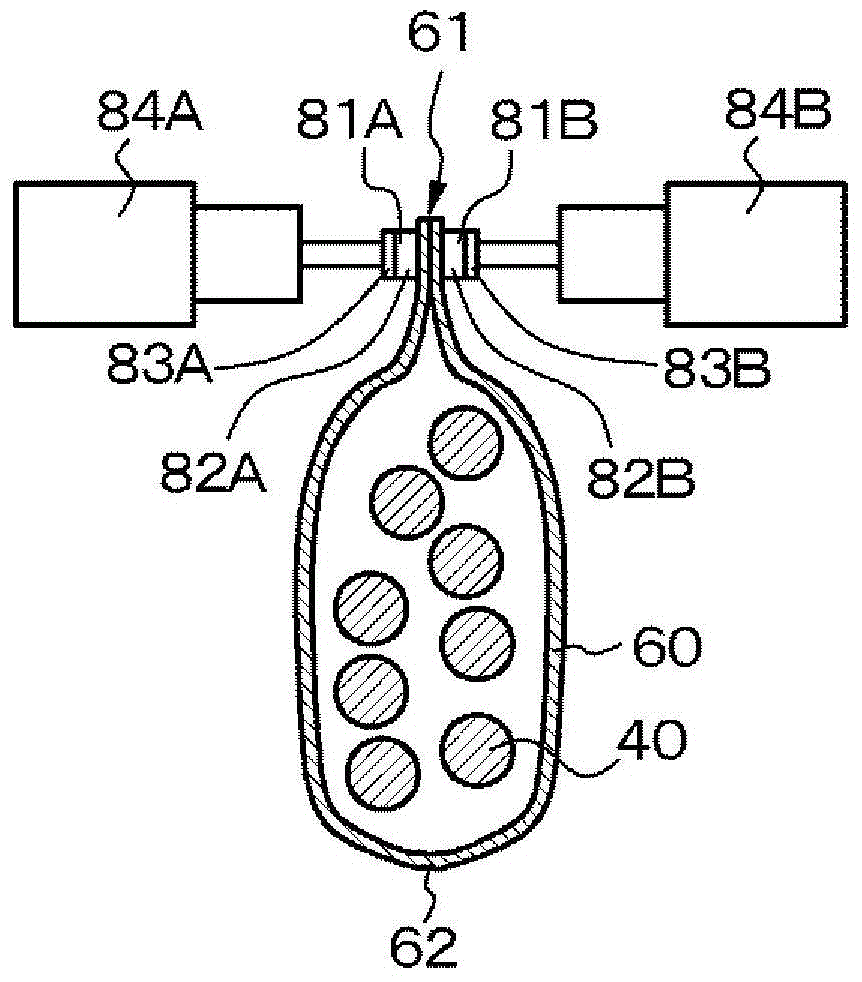

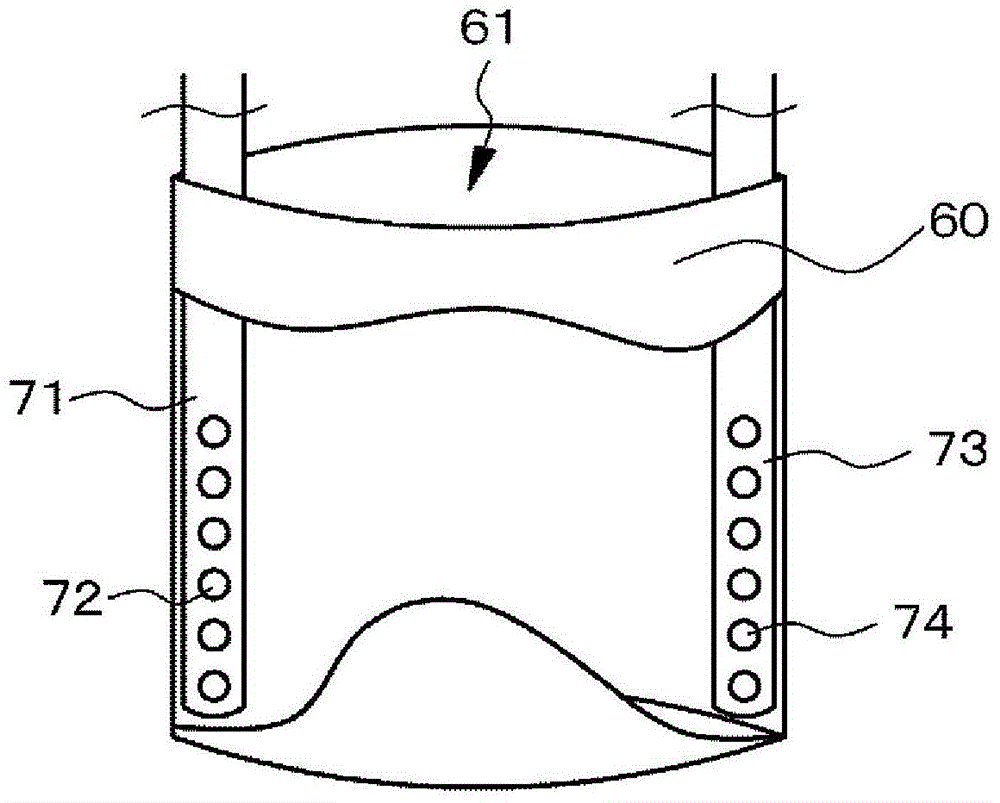

Packaging method for granular substance and device for packaging granular substance

InactiveCN104583081AReliable replacementIncreased dissolved oxygenPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringExhaust pipe

In this packaging method for a granular substance, an inert gas introduction pipe (71) and an inert gas exhaust pipe (73) are inserted into the interior of a sealed container (60). In a state where the interior of the sealed container (60) is filled with a granular substance (40), an opening (61) is temporarily closed, and then an inert gas is introduced into the interior of the sealed container (60) by way of the inert gas introduction pipe (71). The inert gas introduced into the interior of the sealed container (60) is expelled through the inert gas exhaust pipe (73), thereby replacing the interior of the sealed container (60) with inert gas, after which the inert gas introduction pipe (71) and the inert gas exhaust pipe (73) are removed from the sealed container (60) and the sealed container (60) is closed.

Owner:MITSUBISHI GAS CHEM CO INC

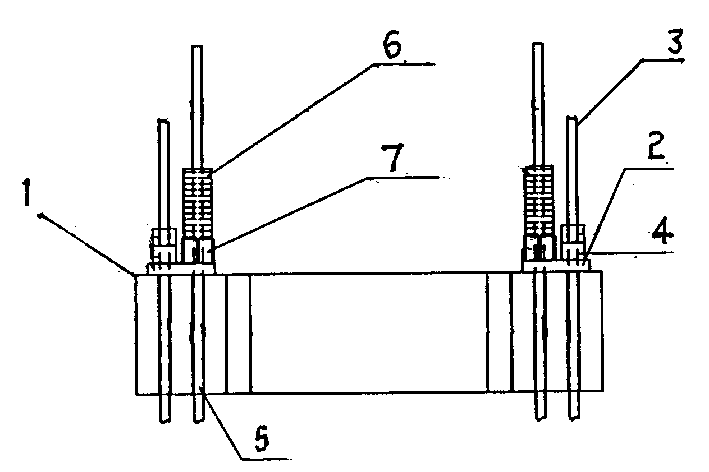

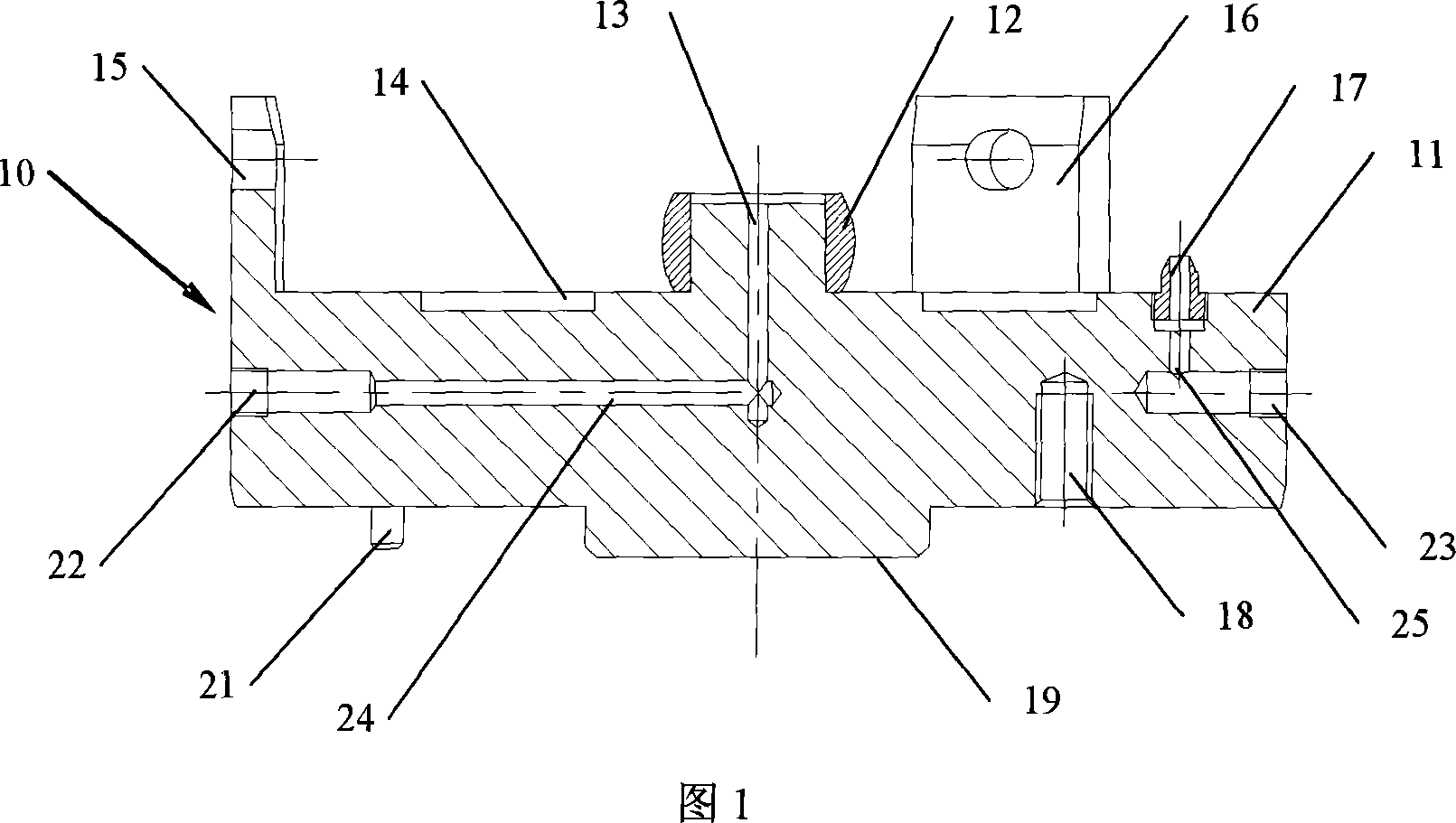

Detachable track connecting mechanism applied to nuclear fusion device

ActiveCN103824602AStable supportReliable maintenanceNuclear energy generationThermonuclear fusion reactorNuclear fusionEngineering

The invention discloses a detachable track connecting mechanism applied to a nuclear fusion device. In the technical field of nuclear fusion reactor engineering, the detachable track connecting mechanism is applied to an annular bearing track for remote operation and maintenance of a divertor component inside a nuclear fusion device; and with utilization of the detachable track mechanism, the divertor component is separated from a track disconnection portion for realizing transport to the outside of a vacuum chamber. The detachable track connecting mechanism mainly comprises annular fixed tracks, a main detachable track body, a track cover plate, a bearing plate, bolts, a rotating shaft, insertion hole pins, and push rods and the like. During the internal component maintenance process, track dismounting and mounting can be realized quickly by using a mechanical arm front-end executer; and the component at the internal track disconnection portion of the nuclear fusion device, together with the detachable track, can be moved out of or placed into the vacuum chamber. According to the invention, the structure is simple; and the mechanism can be dismounted or mounted conveniently and rapidly and can work reliably in a vacuum and radiation environment. The quick maintenance and replacement requirements of the internal component of the vacuum chamber of the nuclear fusion device can be met; and the equipment operation efficiency can be improved.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

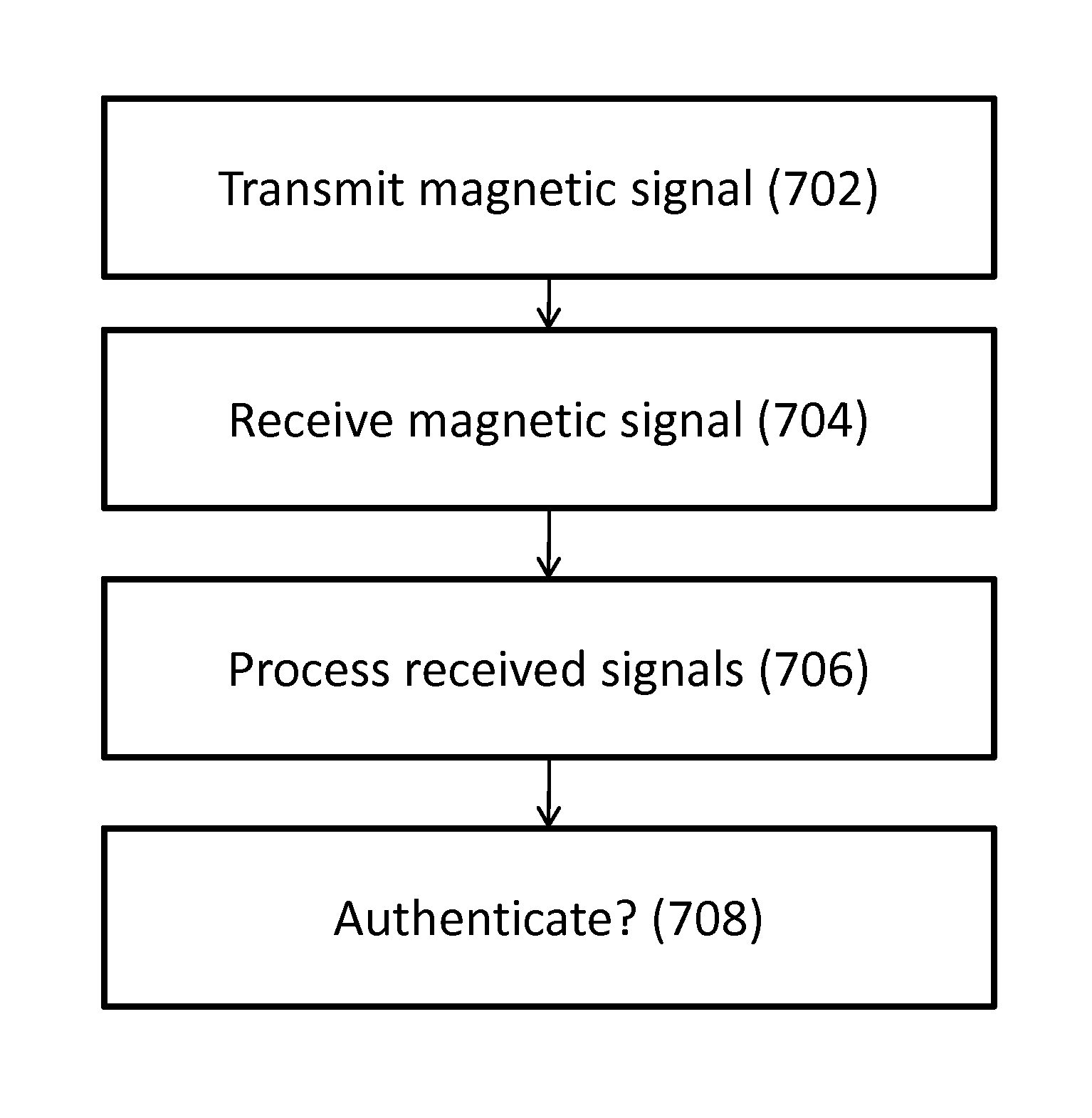

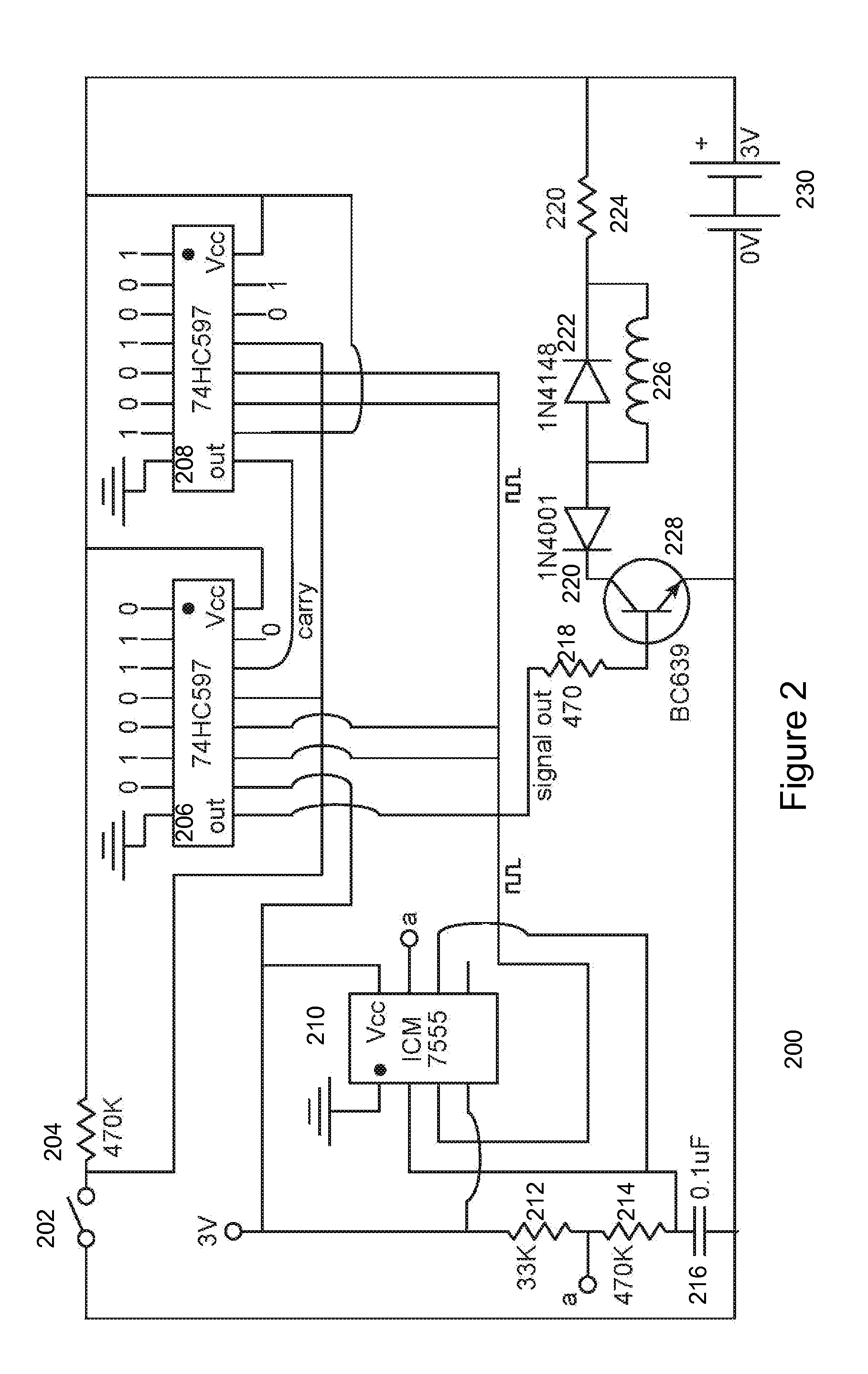

Method and System for Communication Between Devices

InactiveUS20120159604A1Less-expensive to maintainImprove securityDigital data processing detailsMultiple digital computer combinationsDigital dataEngineering

An embodiment of the present invention includes a system for communicating digital data from a preferably small battery powered device (e.g., key-chain or pocket-sized form-factor) to a personal electronic device (e.g., a smartphone such as an iPhone or a Nexus One). The communication mechanism of the present invention can be used as second factor authentication. The present invention can also be used as a key for accessing physical locations such as building. Alternatively, the present invention can be used as a manner for transmitting digital data to a personal electronic device such as a smart phone.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

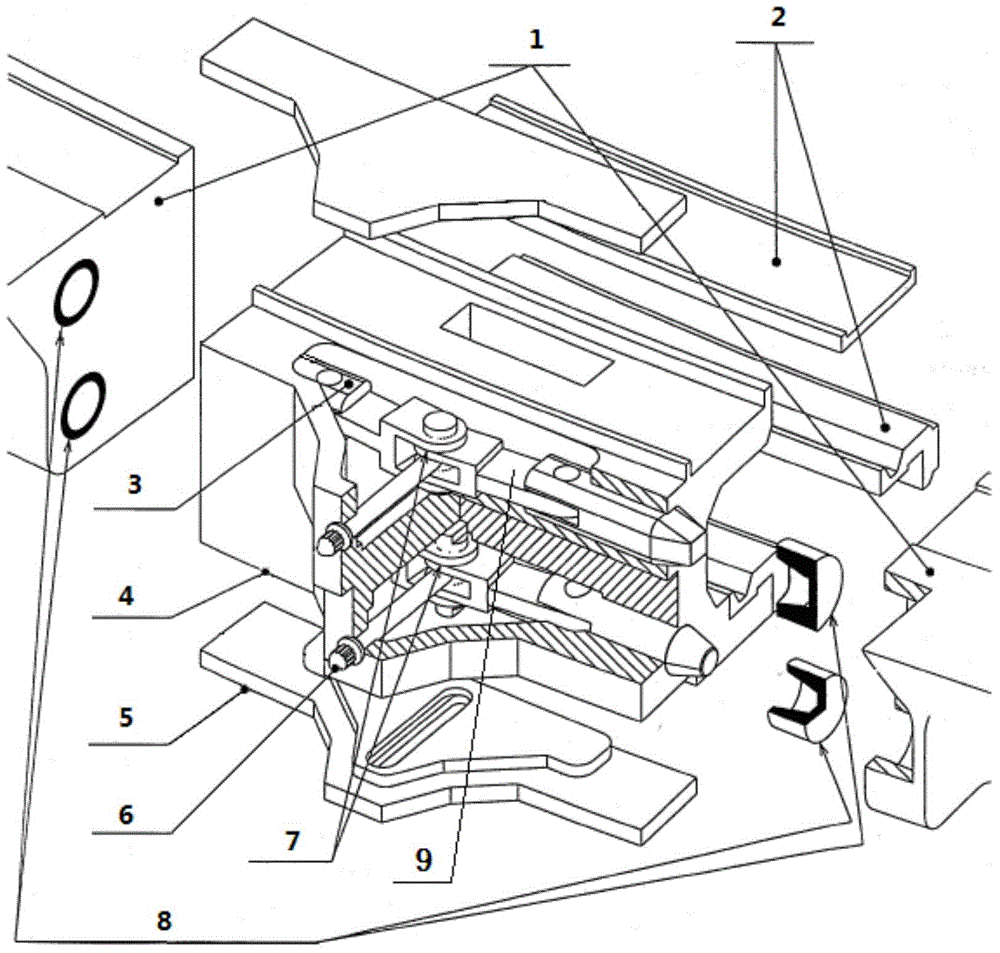

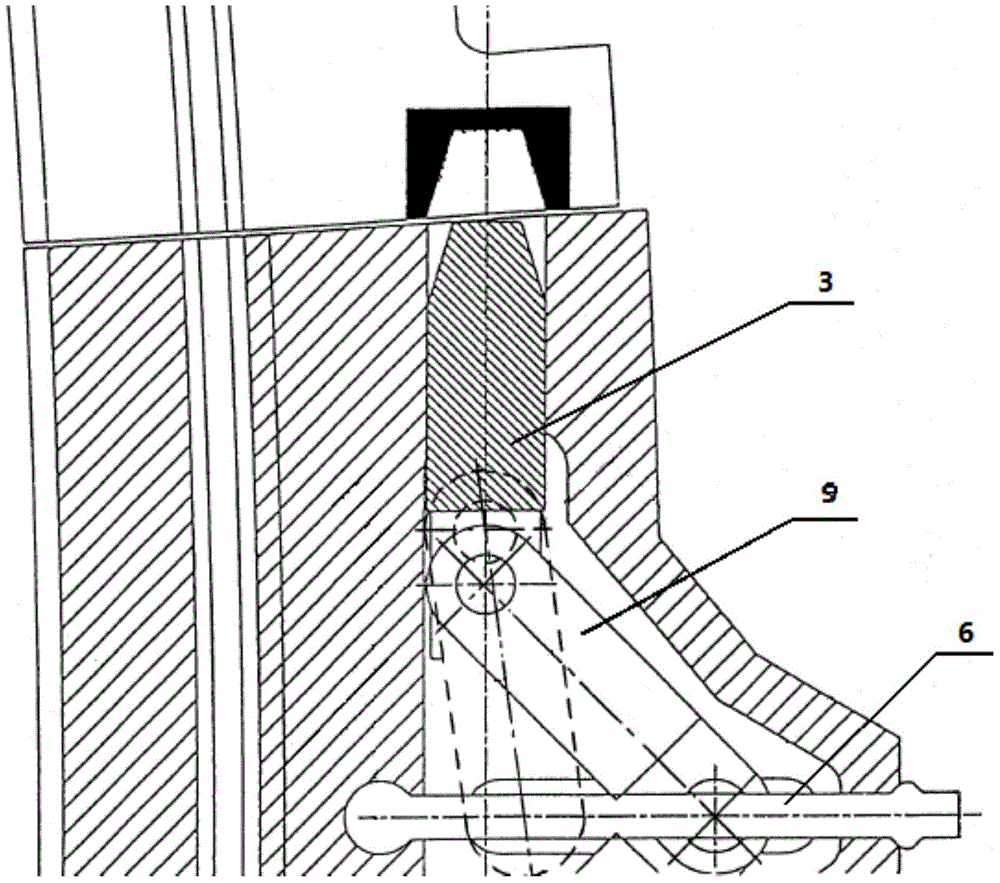

High-precision stamping die assembly with safety protection function

ActiveCN105127291AFirmly assembledReliable disassemblyShaping toolsShaping safety devicesEngineeringMechanical engineering

The invention discloses a high-precision stamping die assembly with a safety protection function. The high-precision stamping die assembly has reliable hydraulic power and has the reliable safety protection function, and meanwhile a male die can be replaced. The high-precision stamping die assembly comprises a rack, an upper die assembly and a lower die assembly, wherein the upper die assembly and the lower die assembly are arranged on the rack and opposite to each other, and the upper die assembly is located above the lower die assembly. The upper die assembly is driven through a hydraulic oil cylinder assembly to ascend and descend. The upper die assembly and the lower die assembly are provided with the male die and a female die which are matched with each other respectively. The upper die assembly further comprises a male die assembly fixed to the bottom face of a lifting board. The male die assembly comprises a fixing board fixedly connected to the bottom face of the lifting board. The fixing board is provided with a male die fixing base connection hole. A male die fixing base is connected into the male die fixing base connection hole. An axial connection hole is formed in the male die fixing base. A male die mechanism is connected into the axial connection hole in a matched manner. The side wall of the female die of the lower die assembly is provided with an infrared transmitting head and an infrared receiving head.

Owner:深圳市佳合丰科技有限公司

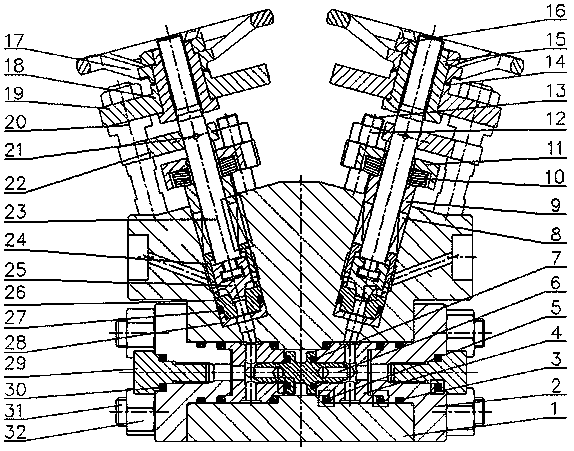

Method for dynamic control of nondestructive replacement of tied arch bridge hanger rod

InactiveCN1401854ASafe replacementReliable replacementBridge erection/assemblyBridge strengtheningArch bridgeDynamic control

A dynamic control method for nondestructive replacing of the boom of tied arch bridge includes determining the length of new boom and controlling tension, bridge floor reaction and force transfer. A special hanger rod for said control procedure is also disclosed.

Owner:TONGJI UNIV +1

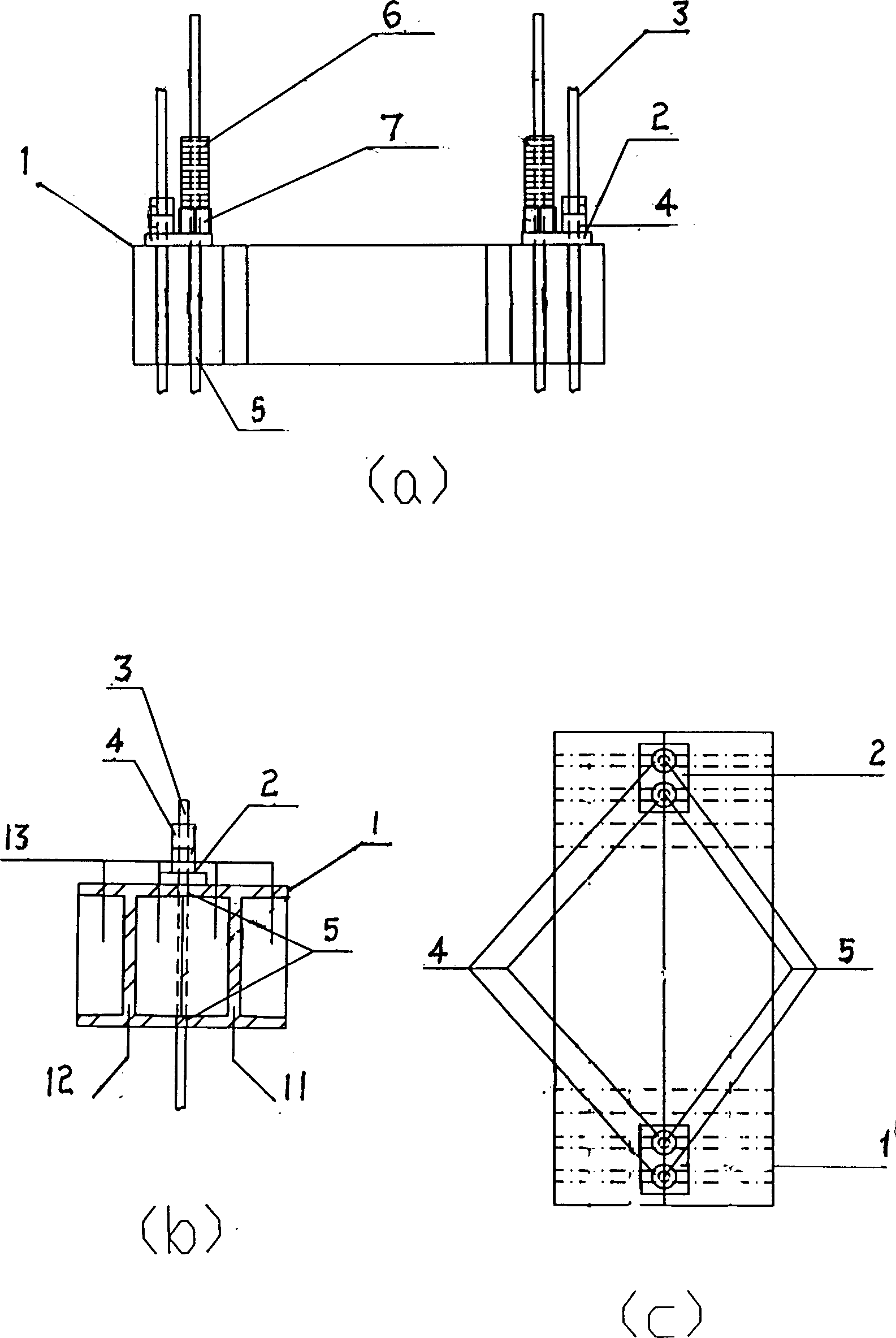

Exchanging interface device of automatization tool

InactiveCN101032798AEasy to replaceFor quick replacementWork holdersPositioning apparatusSelf lockingCompressed air

The present invention belongs to the field of automatic mechanical apparatus, and is especially one kind of interface device for connecting and replacing the executing tool of several kinds of automatic operation terminal. The present invention provides high precision centering interface with outer spherical surface and inside cylindrical surface, directional interface with fitted conic pin and inner cylinder, end vacuum sucking interface, vacuum sucking self-locking interface for lug with pinhole and elastic pin, compressed air supplying interface, and vacuum interface for use between the tool end device and the fixed end device. The present invention can replace executing tool in the automatic operation terminal conveniently and quickly and complete different operations, and possesses force limiting protection function.

Owner:中国人民解放军第二炮兵装备研究院第四研究所

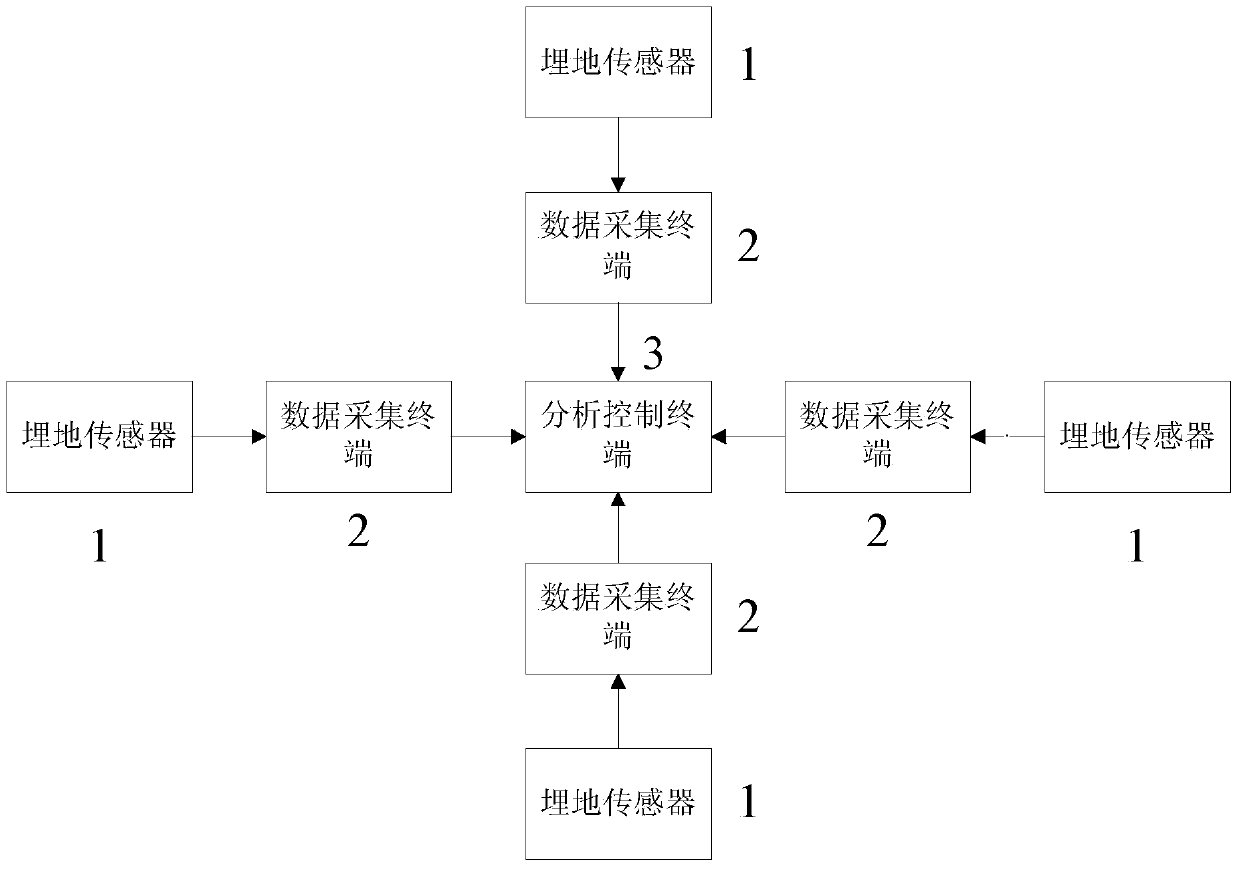

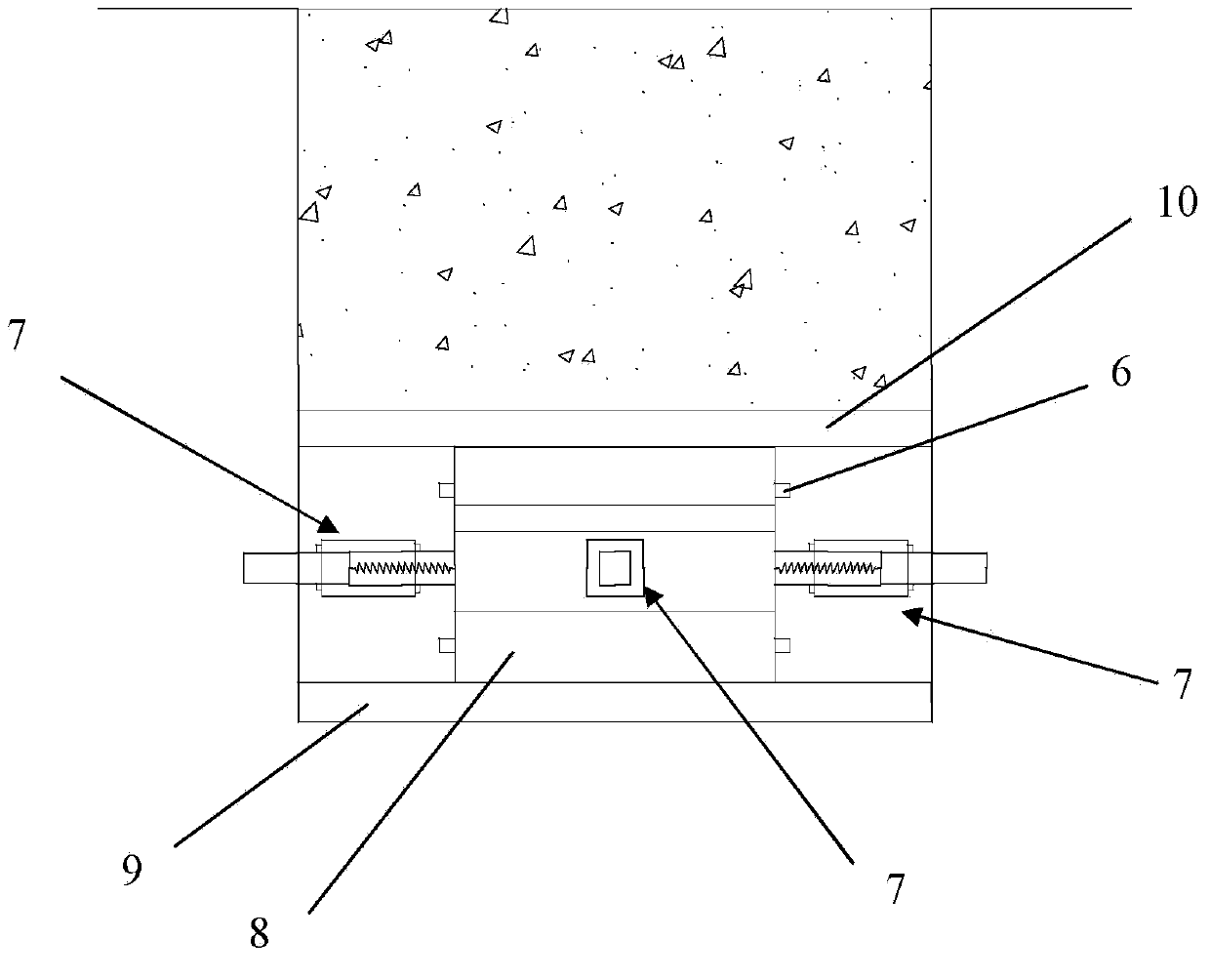

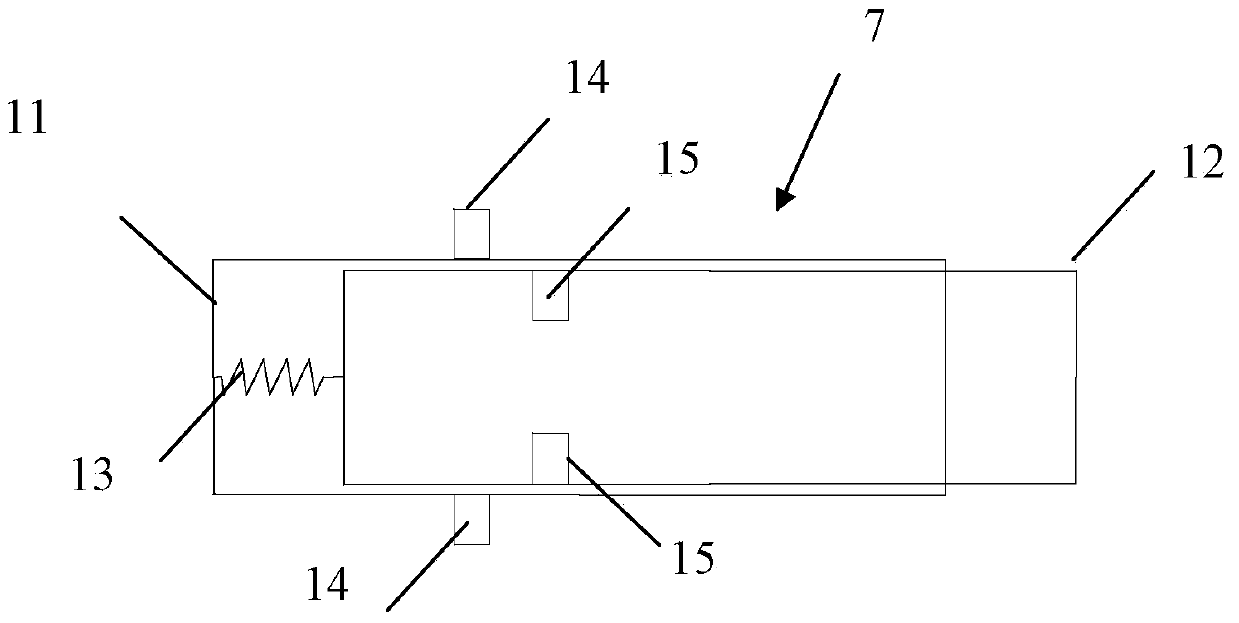

Real-time plane taxiing position positioning system and control method

InactiveCN103808318AExtended service lifeAvoid failureNavigation instrumentsMicrocontrollerData acquisition

The invention provides a real-time plane taxiing position positioning system and a control method. The system comprises a plurality of embedded sensors, a plurality of data collection terminals and an analysis control terminal, wherein each embedded sensor is connected with one data collection terminal; the data collection terminals are connected with the analysis control terminal mounted on a control center in a wireless manner; each embedded sensor comprises a columnar shell, a controller for a single chip microcomputer, at least one vibration sensor, a plurality of limiters, a lithium battery, a lower fixing base and an upper detachable cover plate; each limiter comprises a fixing sleeve, a stretchable limiting rod, a high-strength spring, at least one fixed limiting pin, at least one stretchable limiting pin and a limiting sleeve. According to the real-time plane taxiing position positioning system and the control method provided by the invention, a plane taxiing position on an airport pavement can be dynamically monitored in real time. The real-time plane taxiing position positioning system and the control method have the advantages of security, reliability, simplicity and convenience in construction, and simplicity and convenience in implementation; the service life of the system is long.

Owner:CIVIL AVIATION UNIV OF CHINA

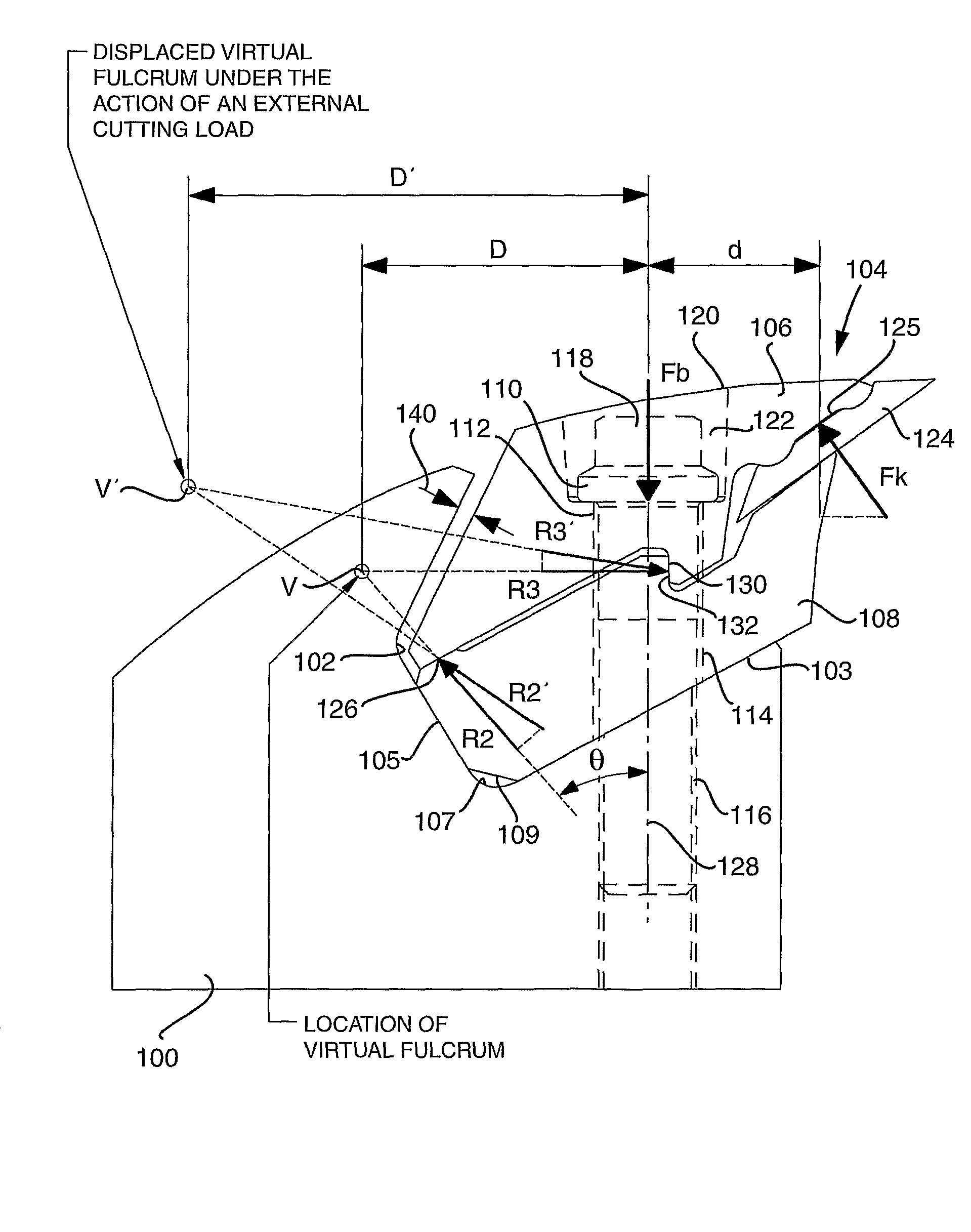

Clamping assembly for woodworking knife

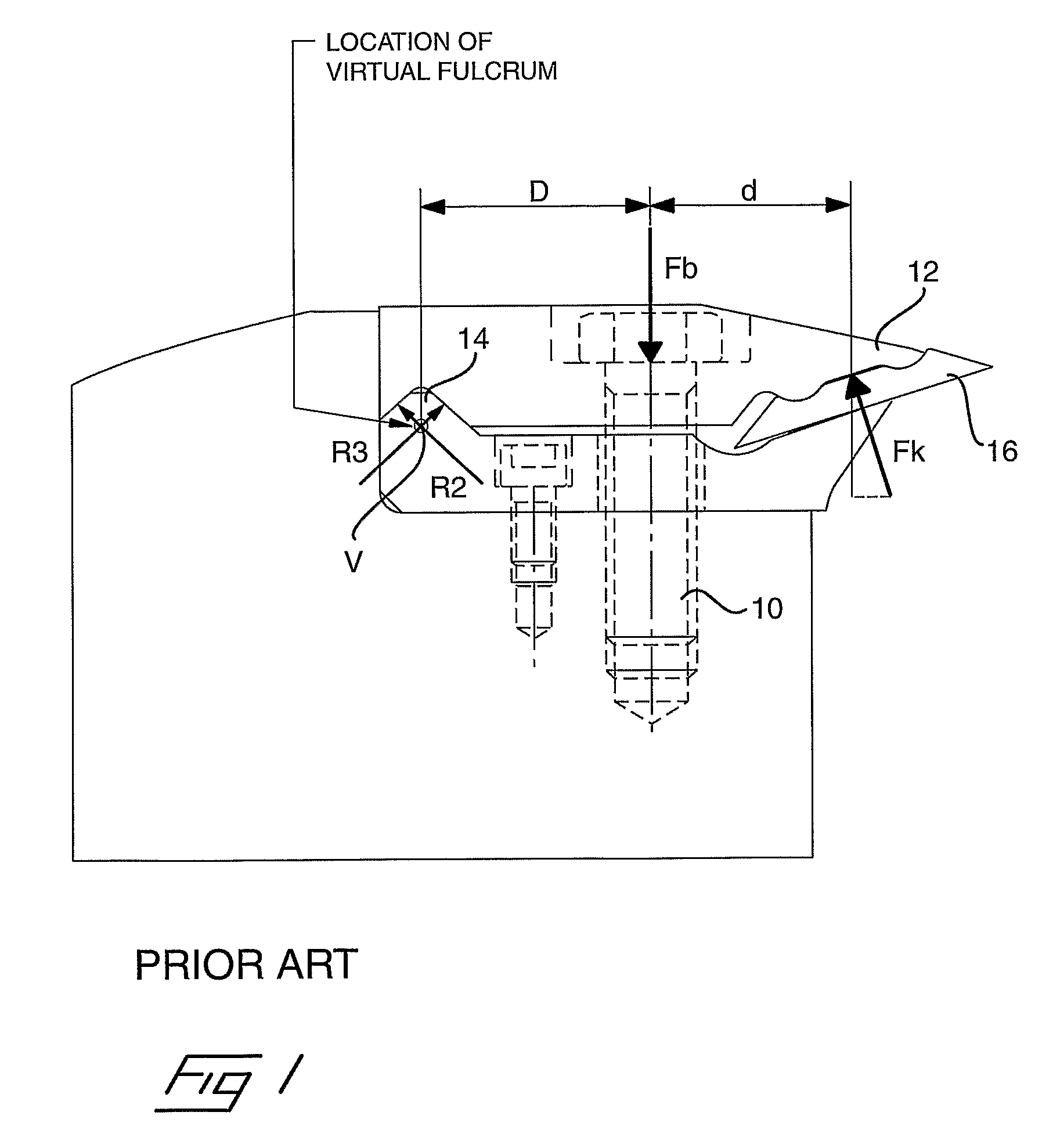

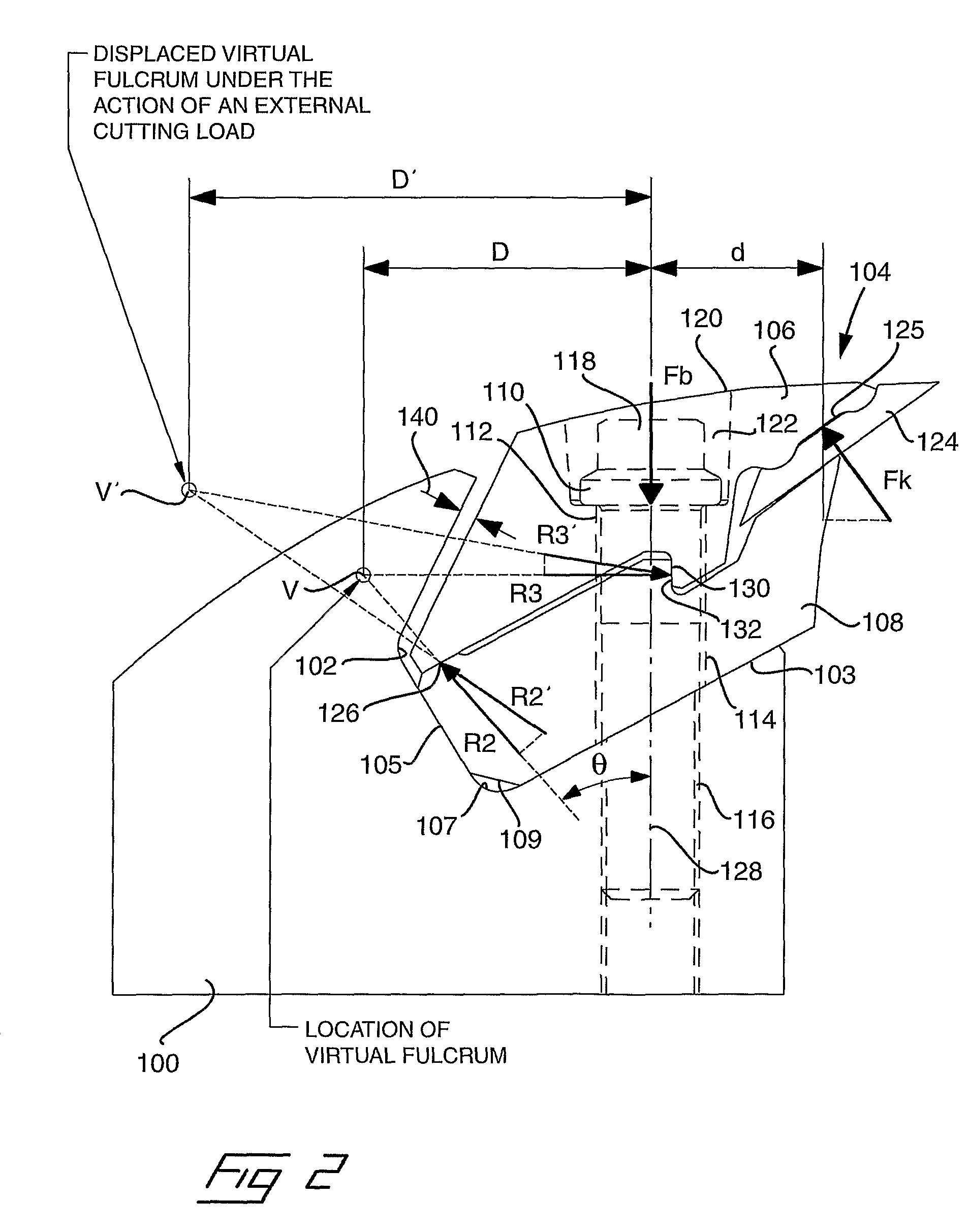

ActiveUS8205650B2Easy to adaptDurable in constructionMulti-purpose machinesCocoaWoodworking machineContact position

A clamping assembly to hold a woodworking knife in place in a woodworking machine. The clamping assembly comprises a clamping component comprising a body and an actuator. The body has three discrete contact positions distributed thereon: 1) a fulcrum located generally at one end, 2) a knife abutting portion located generally at the other end, and 3) a bearing surface located elsewhere. The actuator is for applying a clamping force to the body along a clamping axis located intermediate of the knife abutting portion and the fulcrum. The fulcrum is a surface having a normal that is at an angle to the clamping axis. The bearing surface is a surface wherein a line normal to the bearing surface intersects the line normal to the fulcrum at a position outside of the clamping component at a location farther askew of the clamping axis than the fulcrum.

Owner:IGGESUND TOOLS

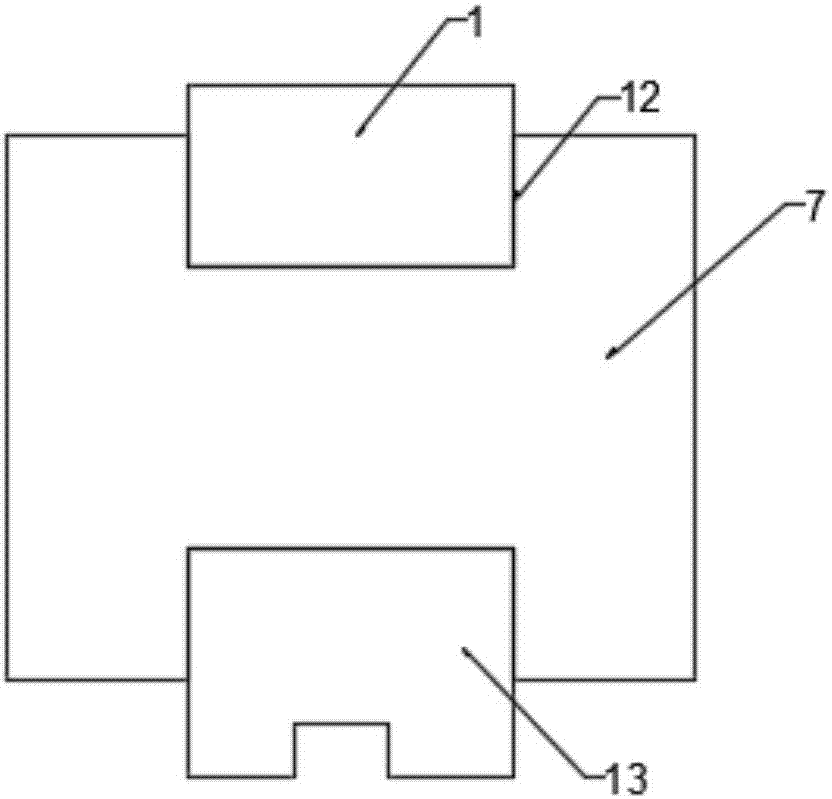

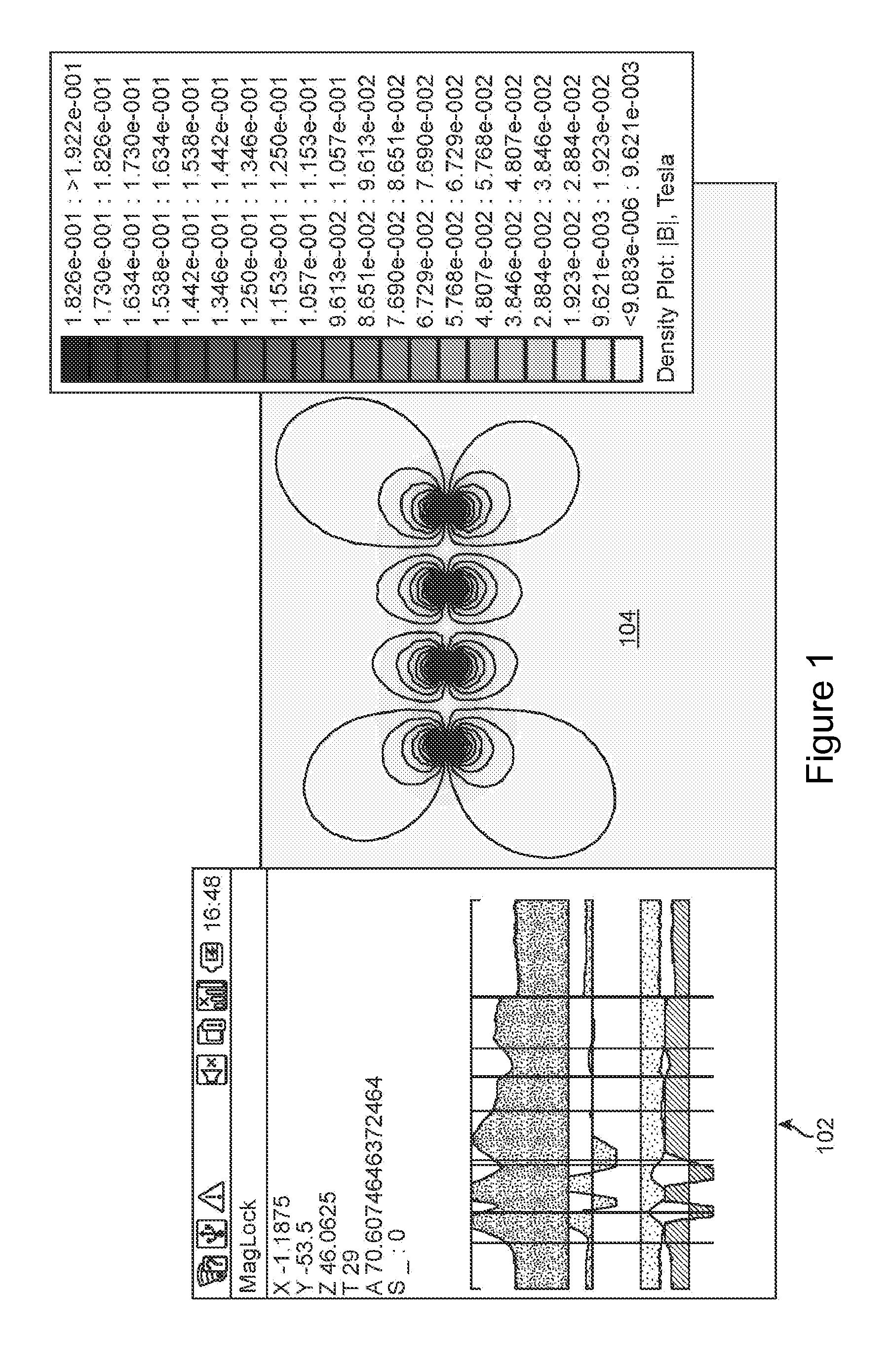

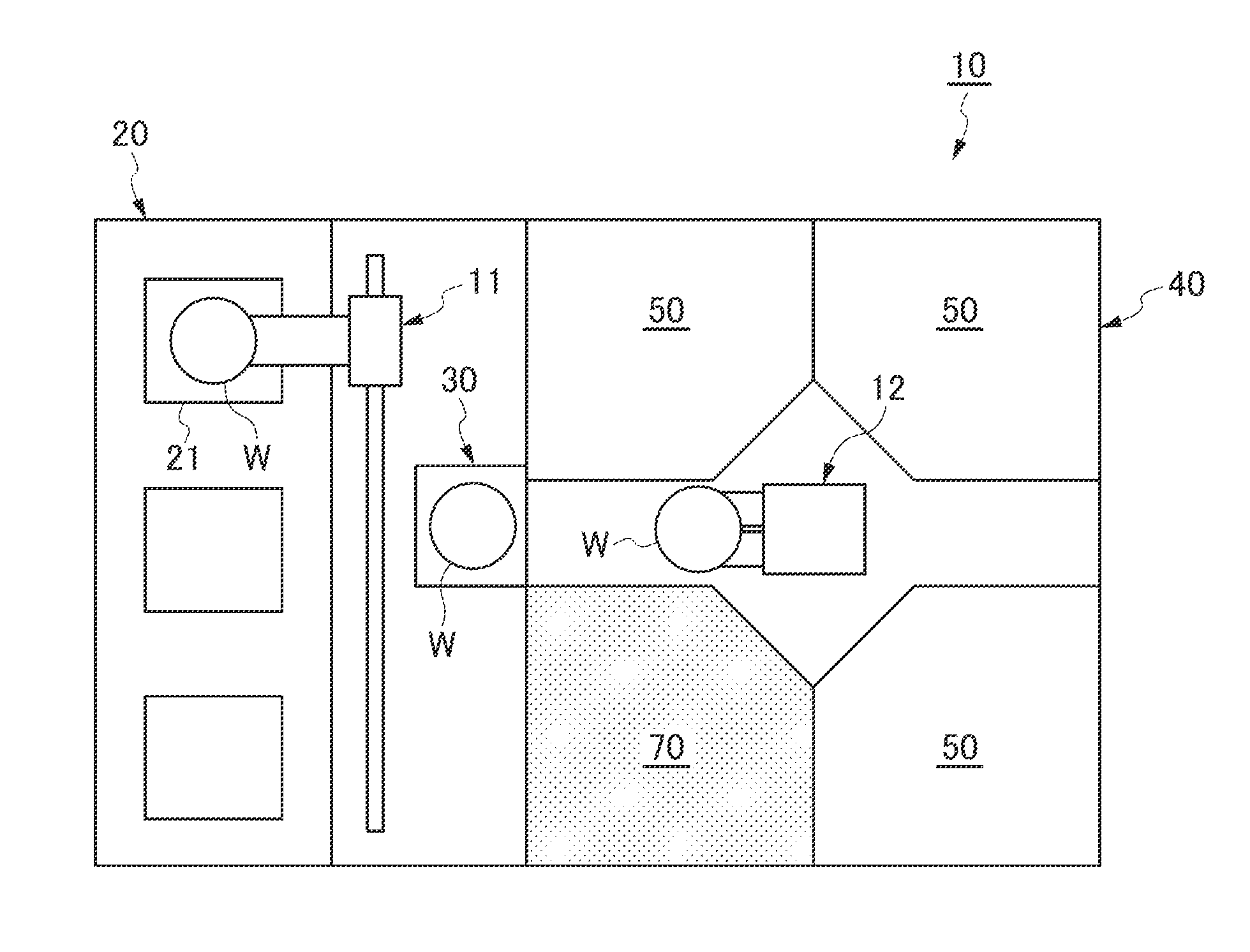

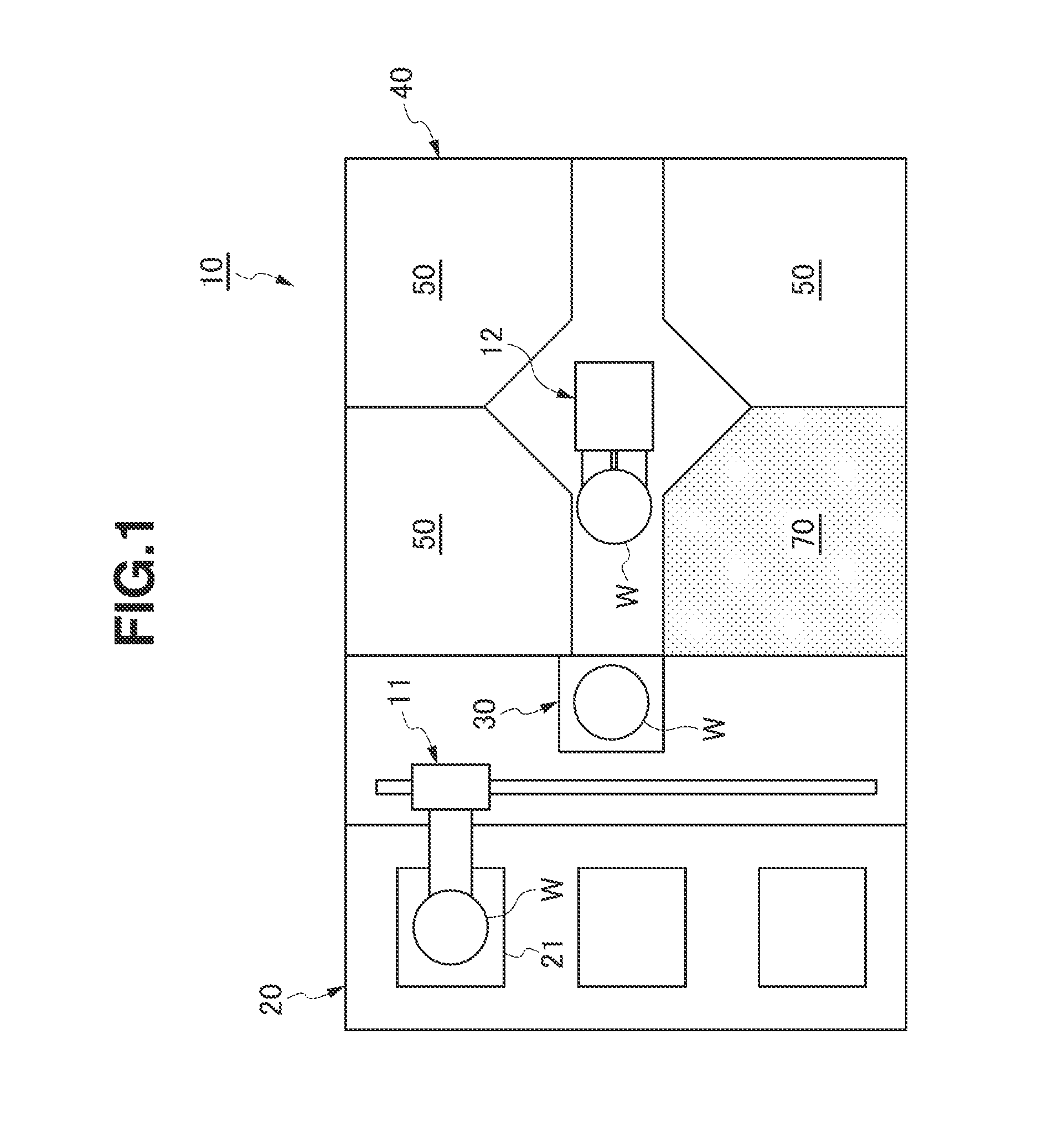

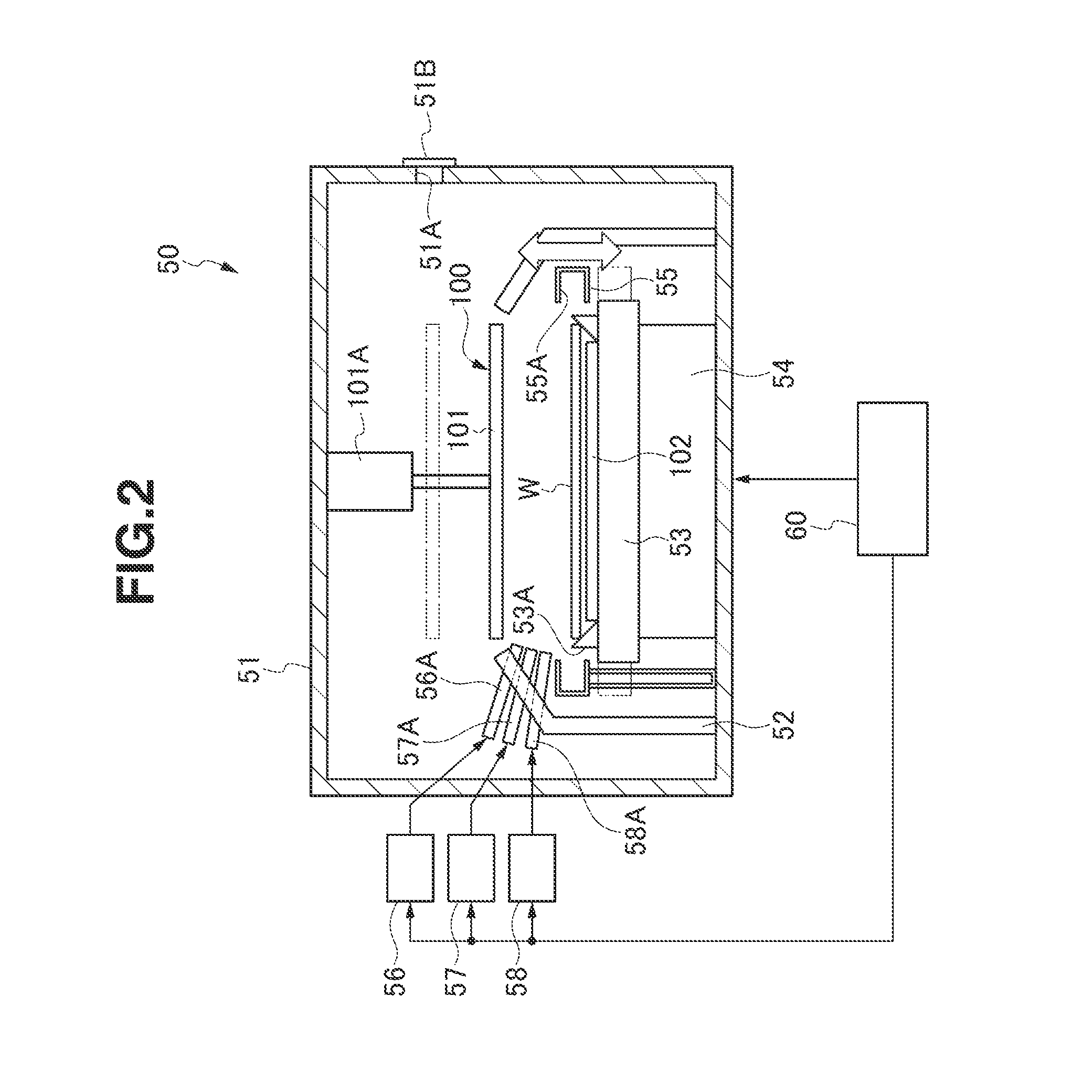

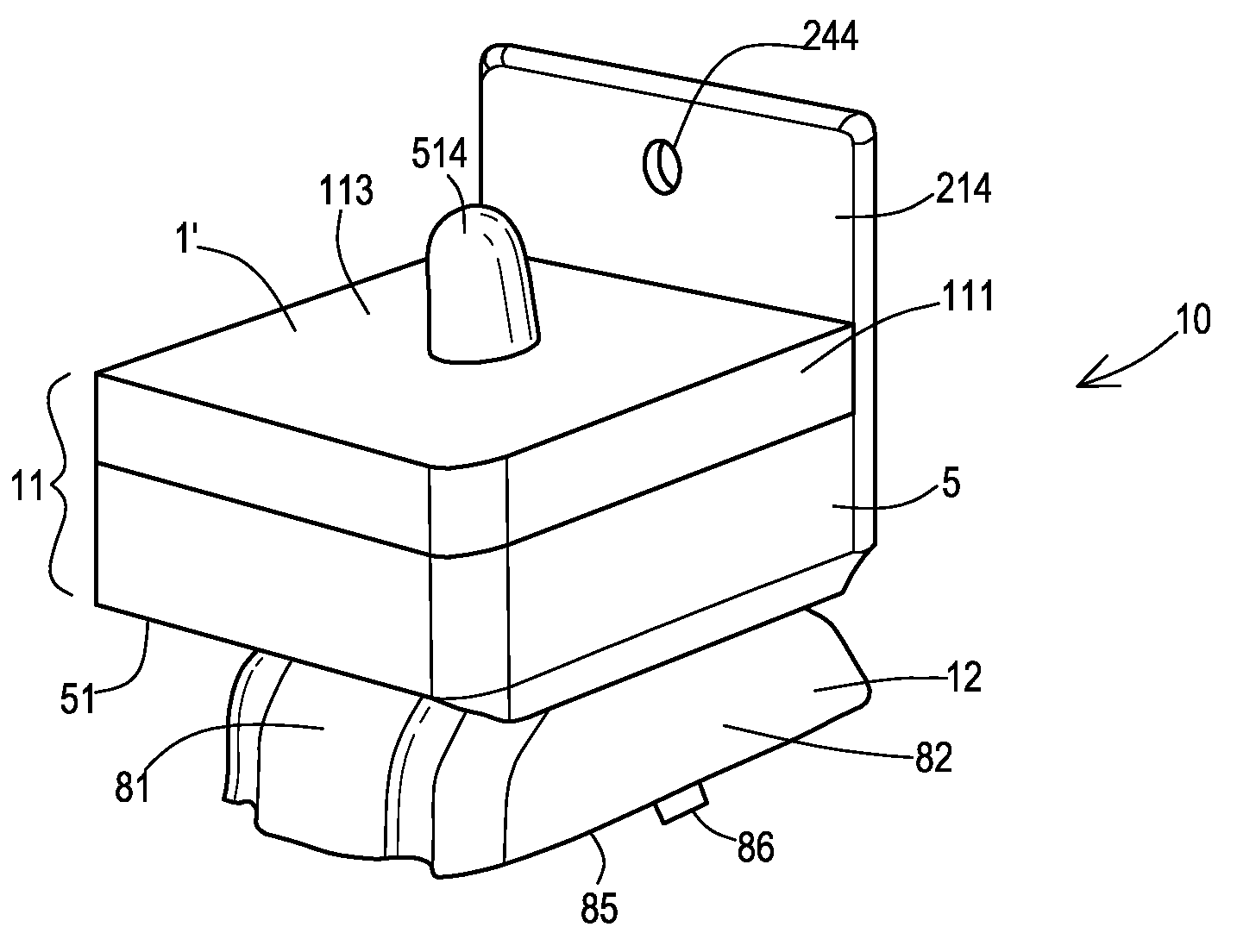

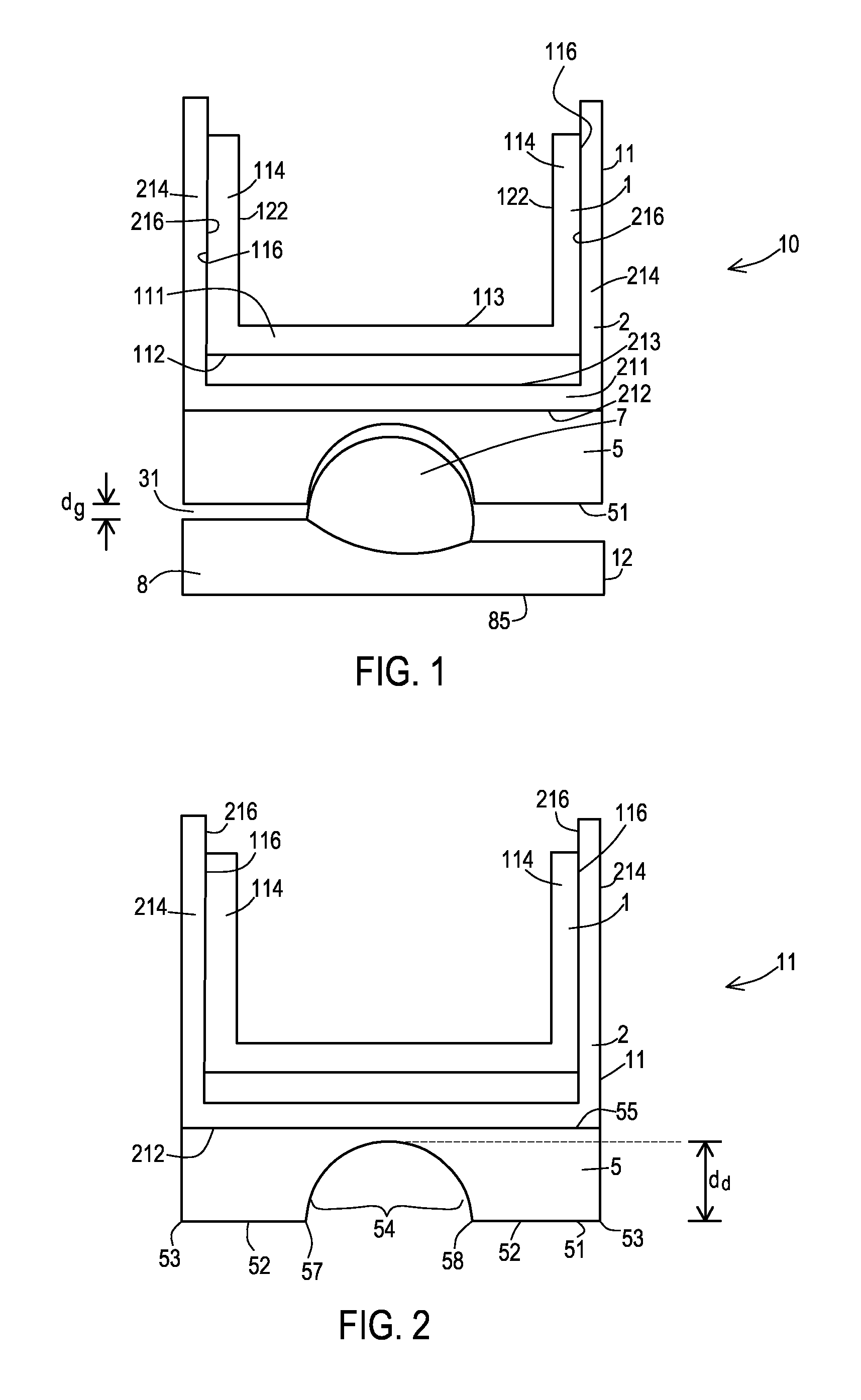

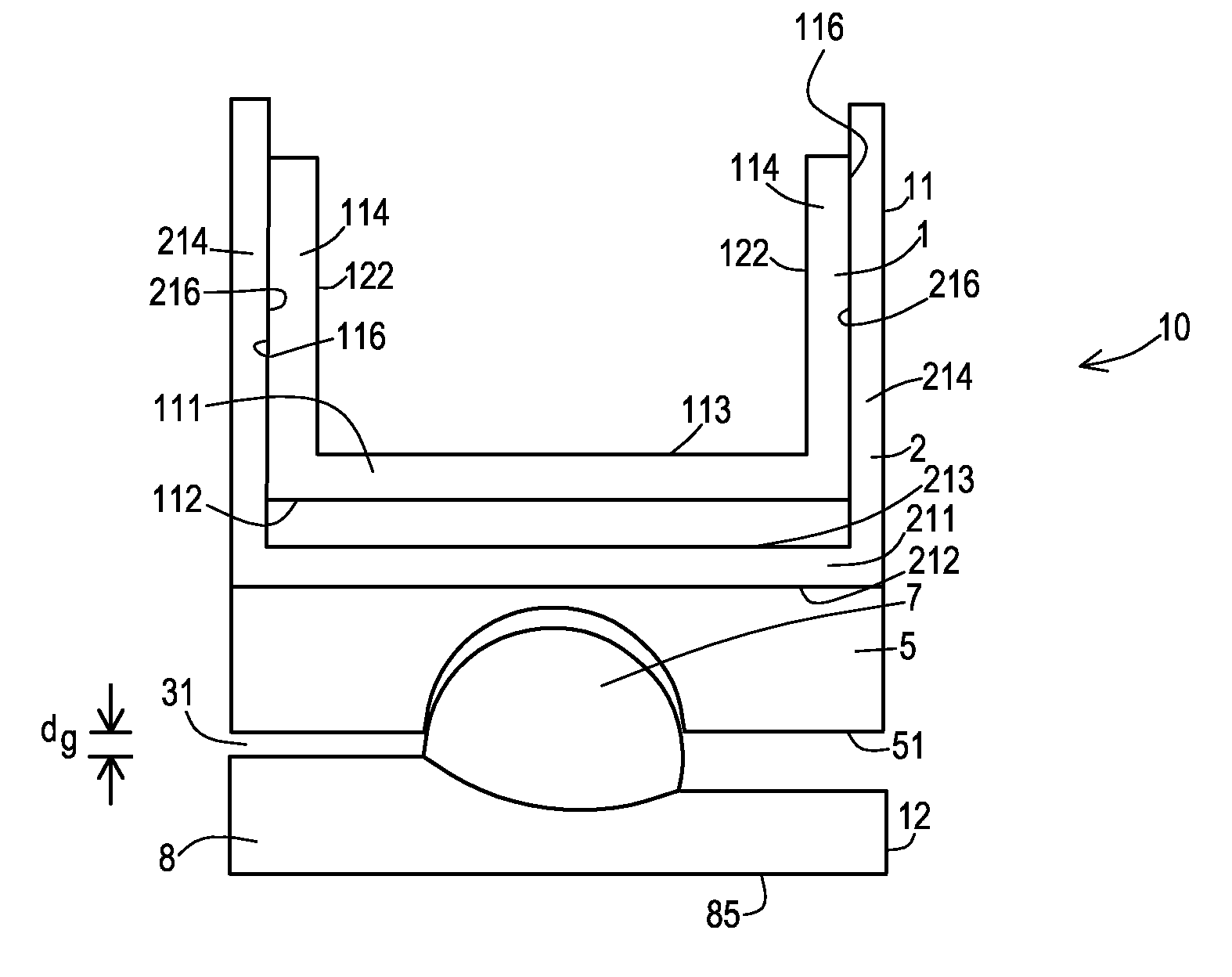

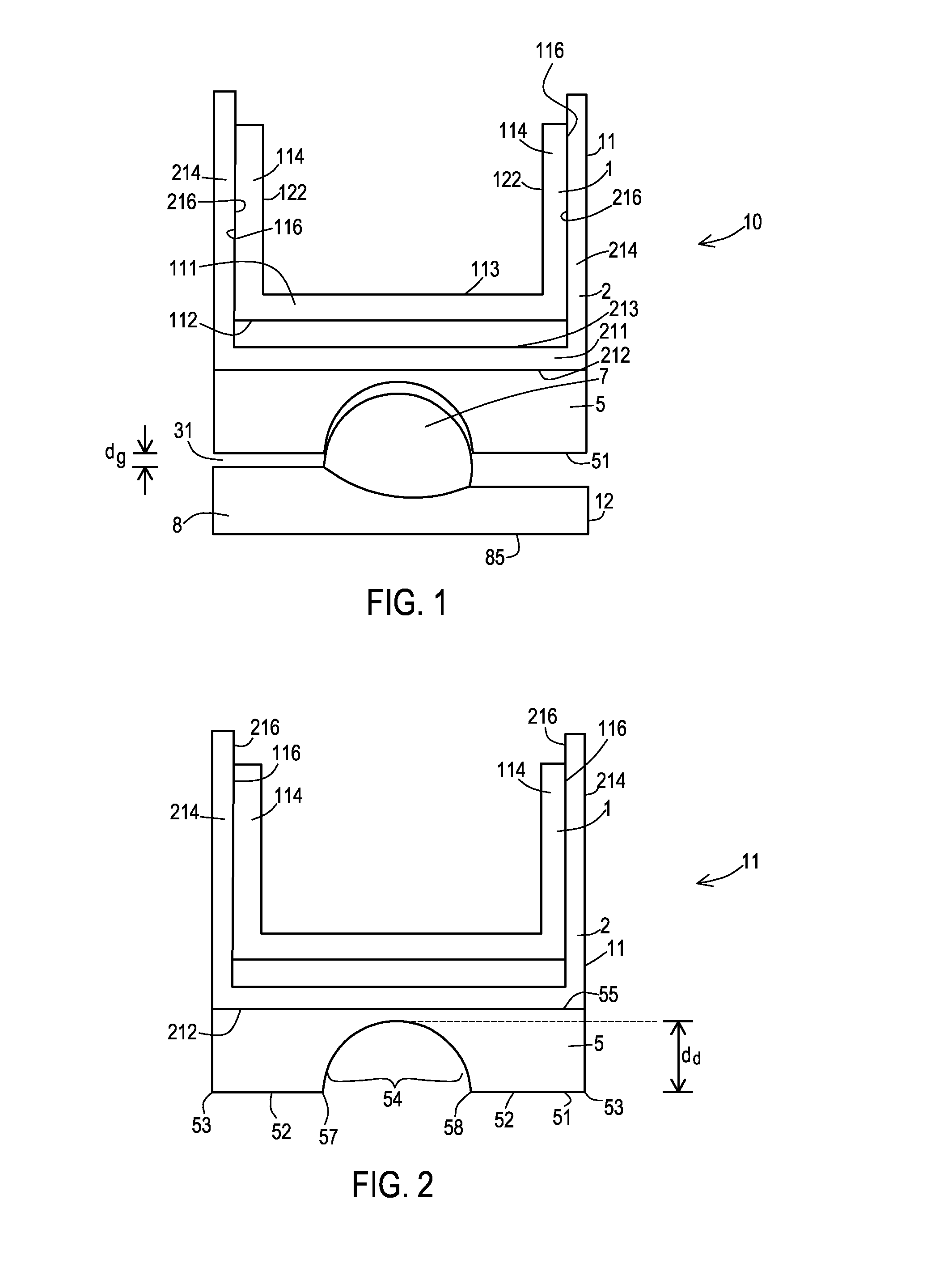

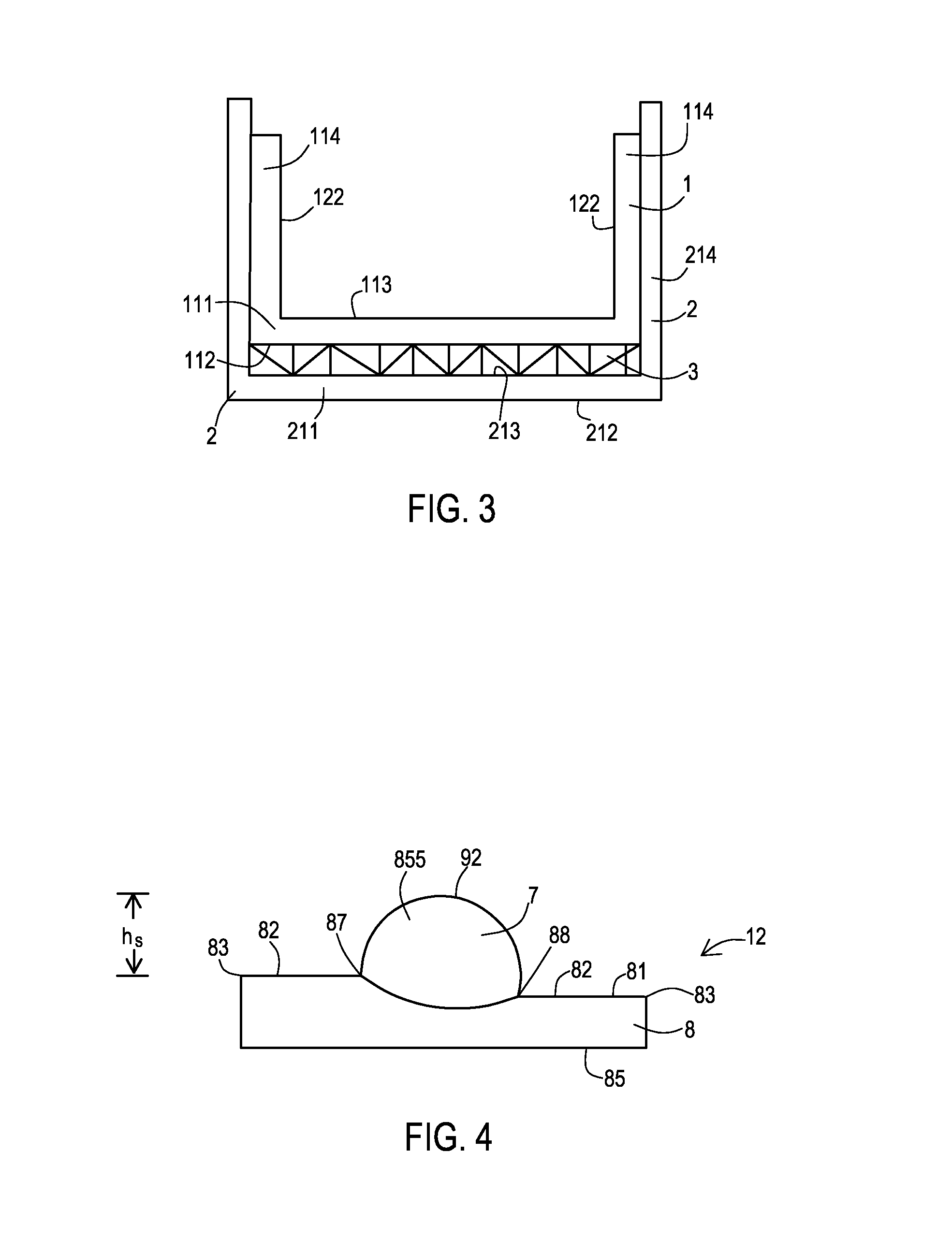

Substrate processing device and substrate processing method

InactiveUS20150090298A1Reliable replacementEffectively prevent the pattern collapse during the substrate dryingLighting and heating apparatusSemiconductor/solid-state device manufacturingEngineeringVolatile solvents

In a substrate processing device 10, a magnetic field forming unit is added to a solvent supply unit 58. The magnetic field forming unit 100 applies a magnetic field to a surface of a substrate W on which a cleaning liquid and a volatile solvent coexist. The magnetic field forming unit stirs and mixes the cleaning liquid and the volatile solvent on the surface of the substrate W to promote replacement of the cleaning liquid with the volatile solvent.

Owner:SHIBAURA MECHATRONICS CORP

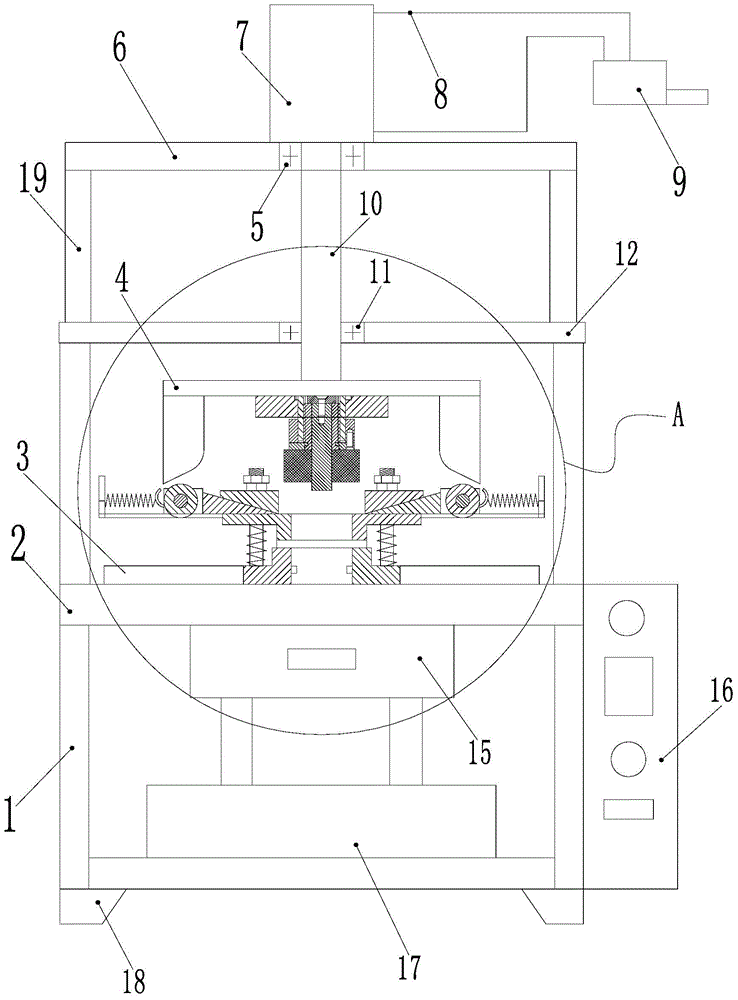

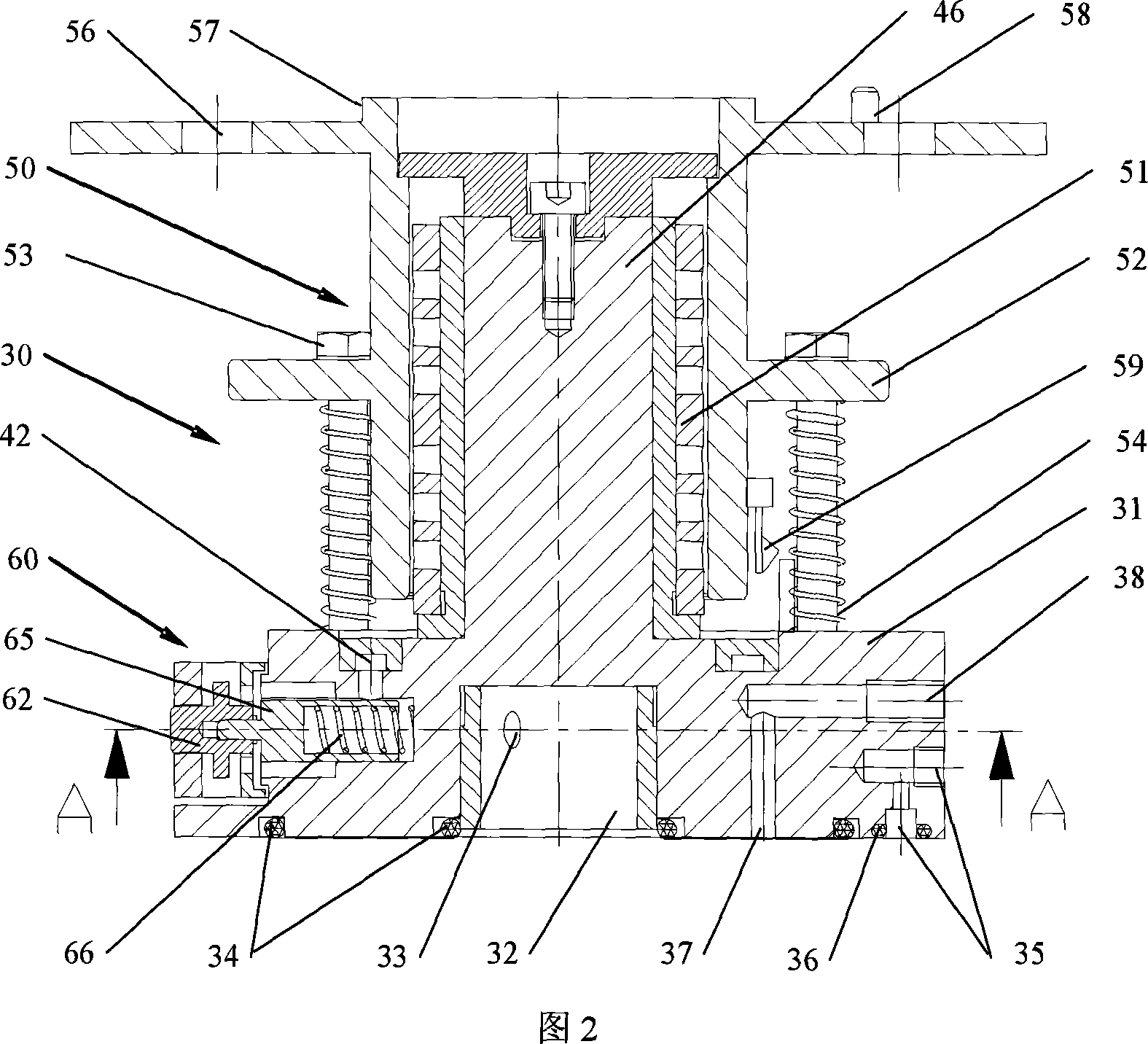

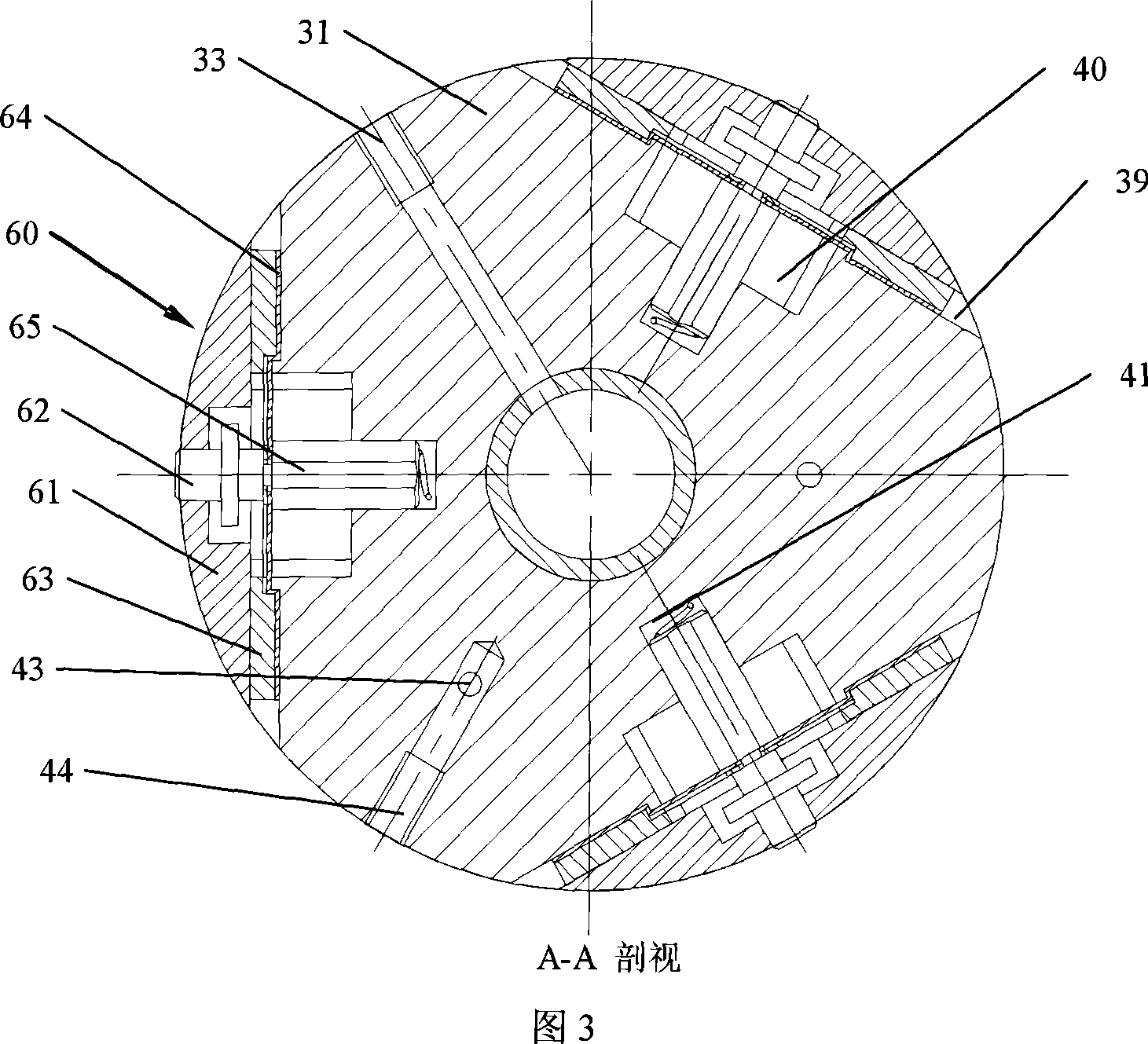

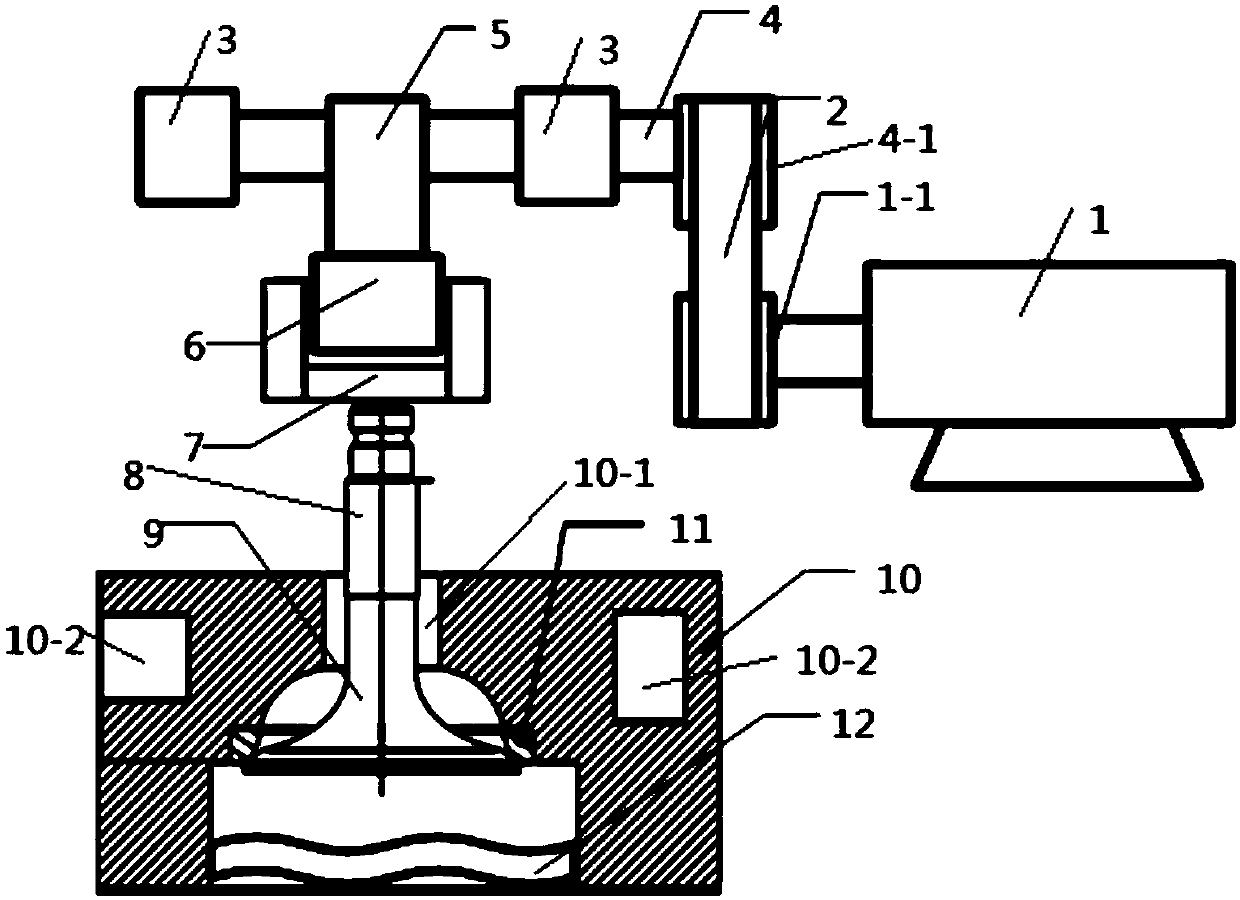

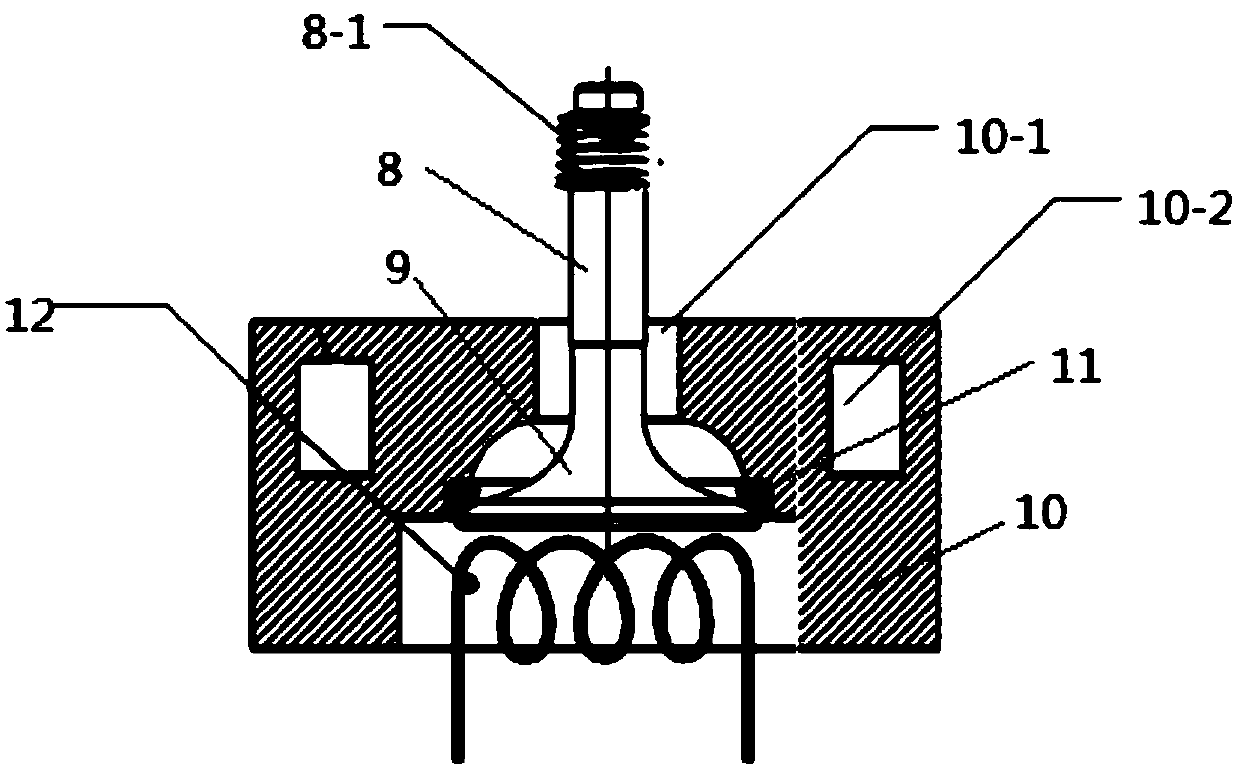

Gas distribution mechanism double friction pair composite simulation experiment system

PendingCN107560861ACompact structureStable structureMachine part testingInternal-combustion engine testingInterference fitCylinder head

The invention discloses a gas distribution mechanism double friction pair composite simulation experiment system. The gas distribution mechanism double friction pair composite simulation experiment system comprises a motor, a belt, a fixed shaft base, a camshaft, a cam, a roller, a tappet body, a valve push rod, a valve, a cylinder head, a valve seat ring and a heating coil. The cam is in interference fit with the camshaft, the roller is rotatably connected with the upper end of the tappet body through a pin, the upper end of the valve push rod is connected with the tappet body, the lower endof the valve push rod is connected with the valve, and the valve push rod is sleeved by a valve spring. The cam and the roller form a higher pair friction pair under the action of the elastic restoring force of the valve spring, the cylinder head is provided with a valve guide pipe, the valve push rod traverses the valve guide pipe, the valve seat ring is arranged on the lower end of the valve guide pipe, the valve and the valve seat ring form an impact wear kinematic pair under the action of the elastic restoring force of the valve spring, the heating coil is arranged in the cylinder head under the valve, and wear tests of two friction pairs are achieved at the same time. The gas distribution mechanism double friction pair composite simulation experiment system is stable and reliable in structure and high in efficiency, simulation approaches actual working conditions, and the experiment data is powerful and reliable.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

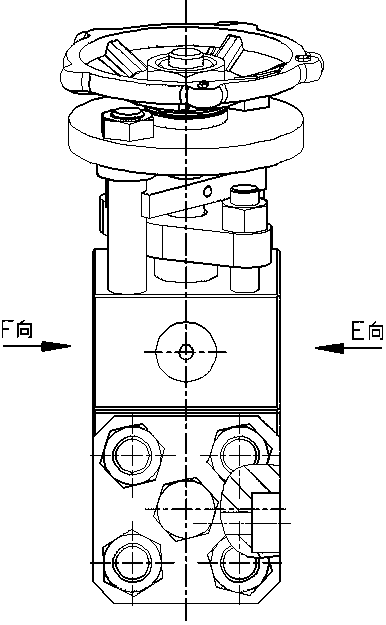

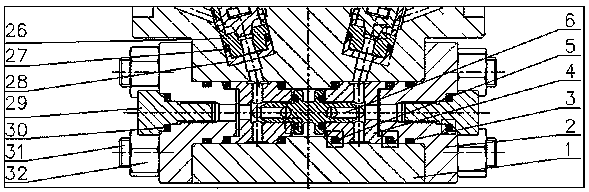

Two-way check valve

The invention relates to a two-way check valve, in particular to a single-flap dual-base sliding two-way check valve with a blocking function. The two-way check valve is used as a by-pass valve of a nuclear island sluice valve, comprises a check valve part and an instrument stop valve part, is provided with three connecting ends, respectively the entry end, the middle end and the exit end, and isconnected with bases of instrument stop valve at the entry end and the exit end separately through check valve flaps; the two-way check valve can achieve that the middle end is kept to be communicatedwith the end, with higher pressure, of the valve entry end or the exit end of the valve all the time when the instrument stop valves at the two ends are kept to be opened; meanwhile, by closing the instrument stop valve at any end, the other two ends can be forced to keep communication; the two-way check valve has both the function of stop valves and the function of check valves, and particularly, when the two-way check valve is used as the by-pass valve of the sluice valve, a middle cavity of the sluice cavity is kept to be always communicated with the end, with the higher pressure, of the entry end or the exit end of the sluice valve. The two-way check valve has the function of avoiding abnormal pressure increasing in the middle cavity of the sluice valve, and guarantee is provided forsafe running of the valve.

Owner:DALIAN DAGAO VALVE

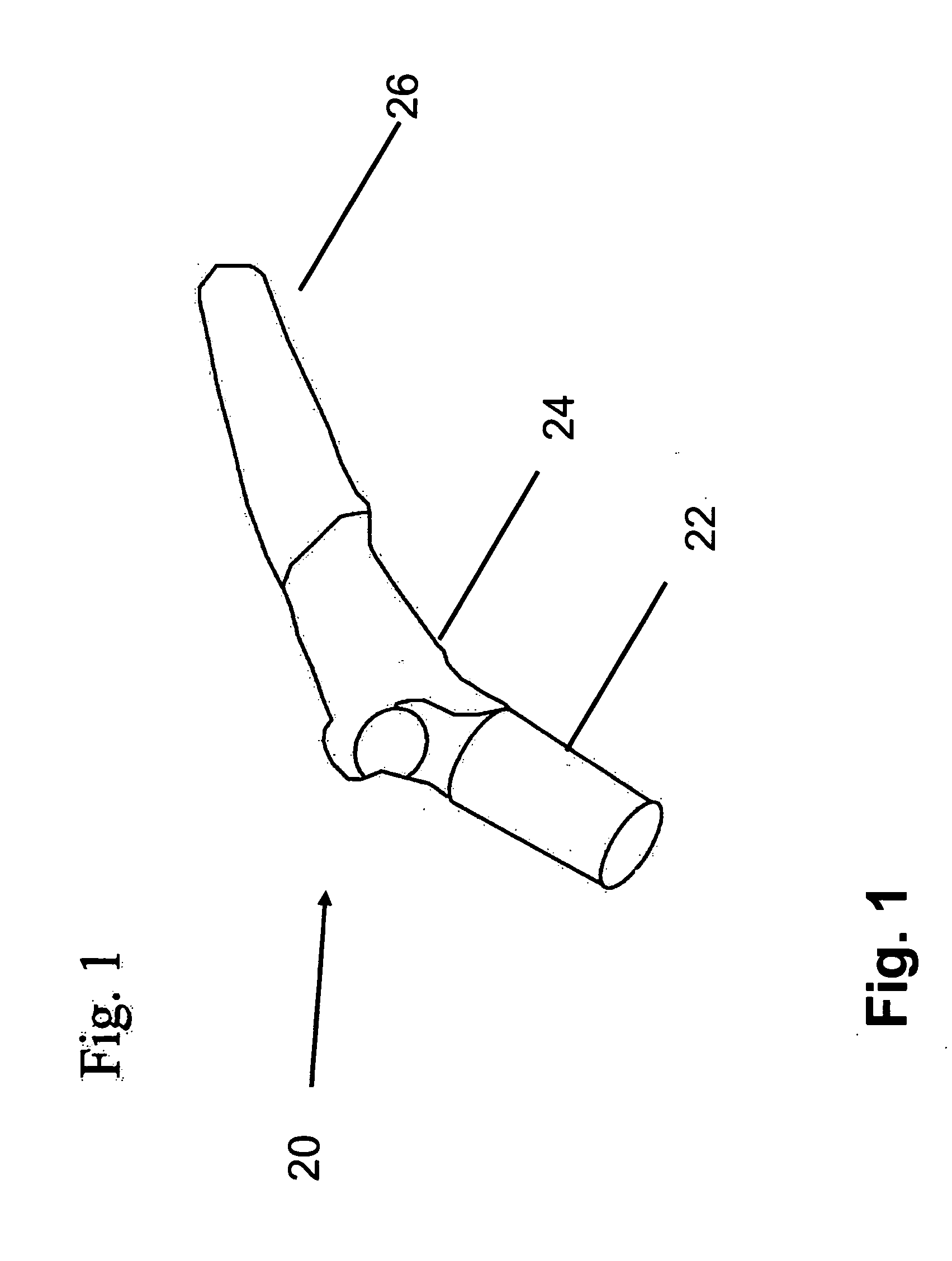

Ankle replacement devices and methods of making and using the same

ActiveUS9144500B2Minimizing length variation of the lower extremitiesReliable replacementAnkle jointsJoint implantsAnkle replacementBiomedical engineering

Owner:HARDING JR MICHAEL G

Canine femoral stem system

ActiveUS7547328B2Increase in sizeReliable replacementSurgeryJoint implantsPorous coatingFemoral bone

A canine femoral stem system provides a set of sizes of stems designed to fit in a reamed femoral bone canal with controlled interference. The canine femoral stems can be implanted using either a cemented or cementless procedures. Cementless stems have a porous coating of sintered beads on the tapered proximal section providing interference with reamed femoral canal causing friction and initial stability. The distal end of the stem has a tapered fit and contacts the lower region of the reamed femoral bone canal due to curvature of the stem providing distal stability. The porous coating encourages bone ingrowth in the cementless system or cement penetration resulting in long term stability. The cementless system uses either cast cobalt chromium stems with 250±50 μm beads of cobalt chromium or Ti- 6Al- 4V stem with 250±50 μm beads of chemically pure titanium.

Owner:SIDEBOTHAM CHRISTOPHER G

Ankle Replacement Devices and Methods of Making and Using the Same

ActiveUS20140180427A1Minimizing length variation of the lower extremitiesReliable replacementAnkle jointsJoint implantsAnkle joint replacementBiomedical engineering

Owner:HARDING JR MICHAEL G

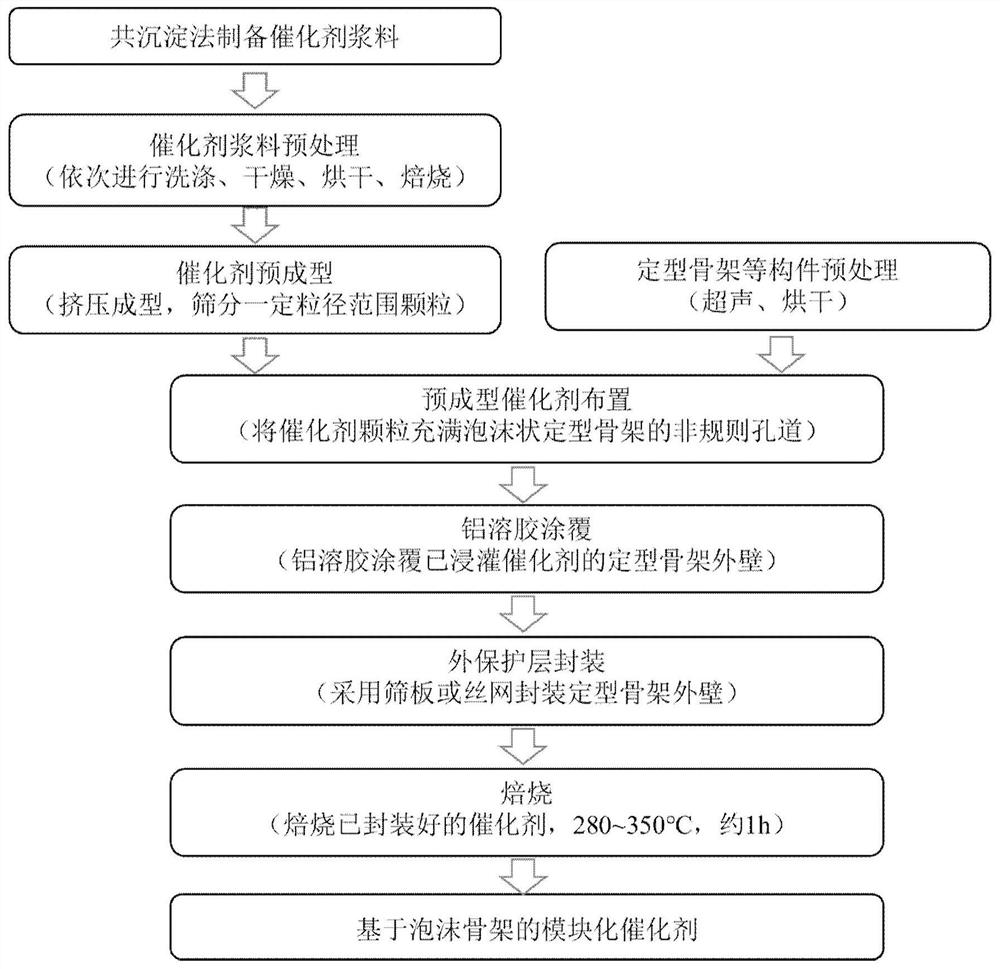

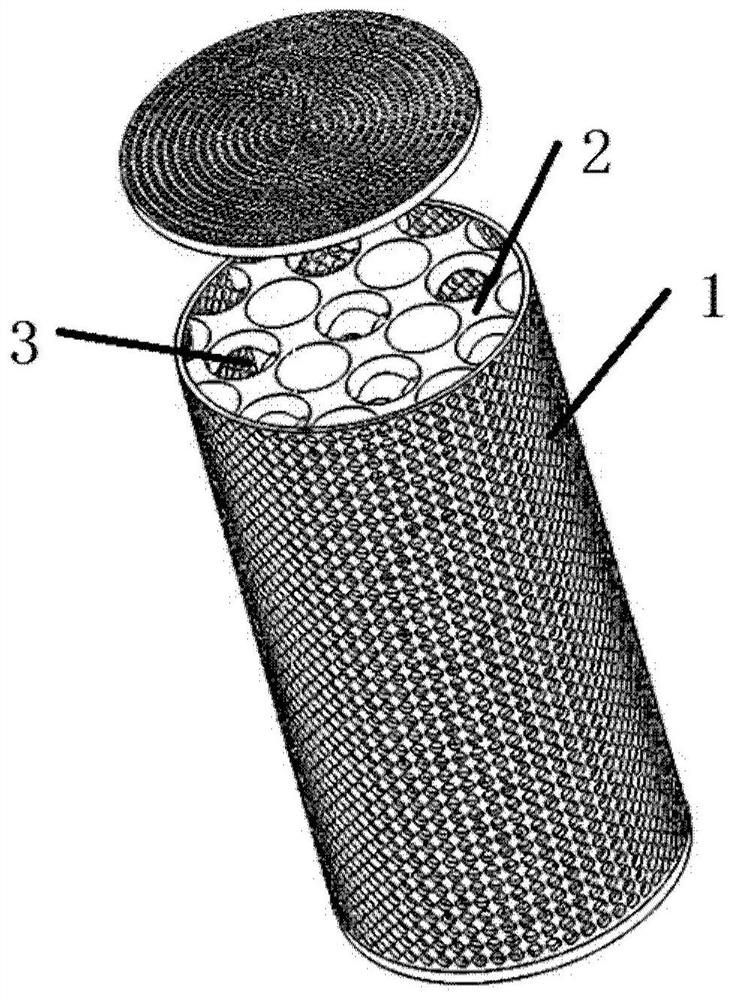

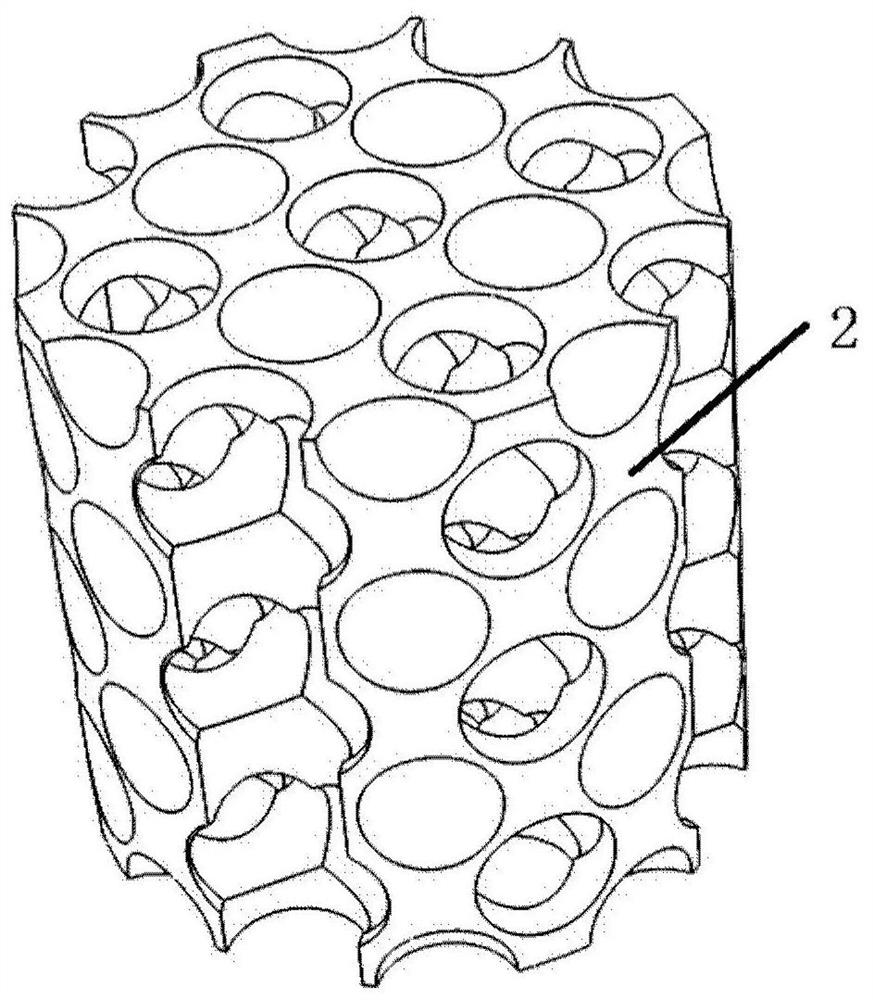

Modular thermal chemical reaction catalyst and manufacturing method thereof

PendingCN113083377AHigh heat and mass transferSmall pressure dropHydrogenCatalyst protectionPtru catalystThermochemical reaction

The invention relates to a modular thermal chemical reaction catalyst and a manufacturing method thereof. The modular thermal chemical reaction catalyst comprises a shaped skeleton, wherein the interior of the shaped skeleton is provided with a three-dimensional irregular pore channel, which is filled in the whole reaction area in a reactor; preformed catalyst particles, which are filled in the three-dimensional irregular pore channel of the shaped skeleton; and an outer protection layer, which is arranged on the outer wall of the shaped skeleton. According to the invention, the irregular pore channel formed by the shaped skeleton are filled with the catalyst particles, so that compared with a direct packed bed of the catalyst particles, the mass transfer diffusion capability of a reaction medium on a catalyst bed layer is improved, and the pressure drop of the catalyst bed layer is reduced; the heat transfer performance of the catalyst bed layer is improved, the temperature distribution non-uniformity of the catalyst bed layer is reduced, and the thermal chemical reaction performance of the bed layer is improved; uniform distribution of the catalyst in a reaction area is facilitated, and collapse and channeling of a catalyst bed layer are prevented; and meanwhile, the structure form of a catalyst bed layer is convenient to construct, and the filling, unloading or replacing process of the catalyst is simplified.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

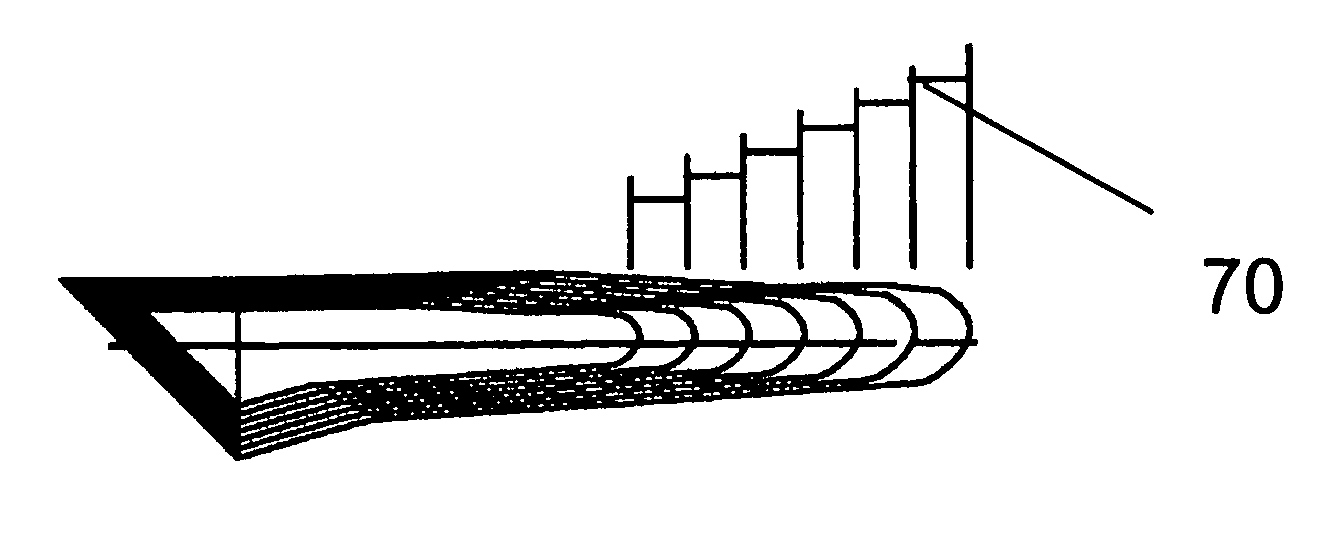

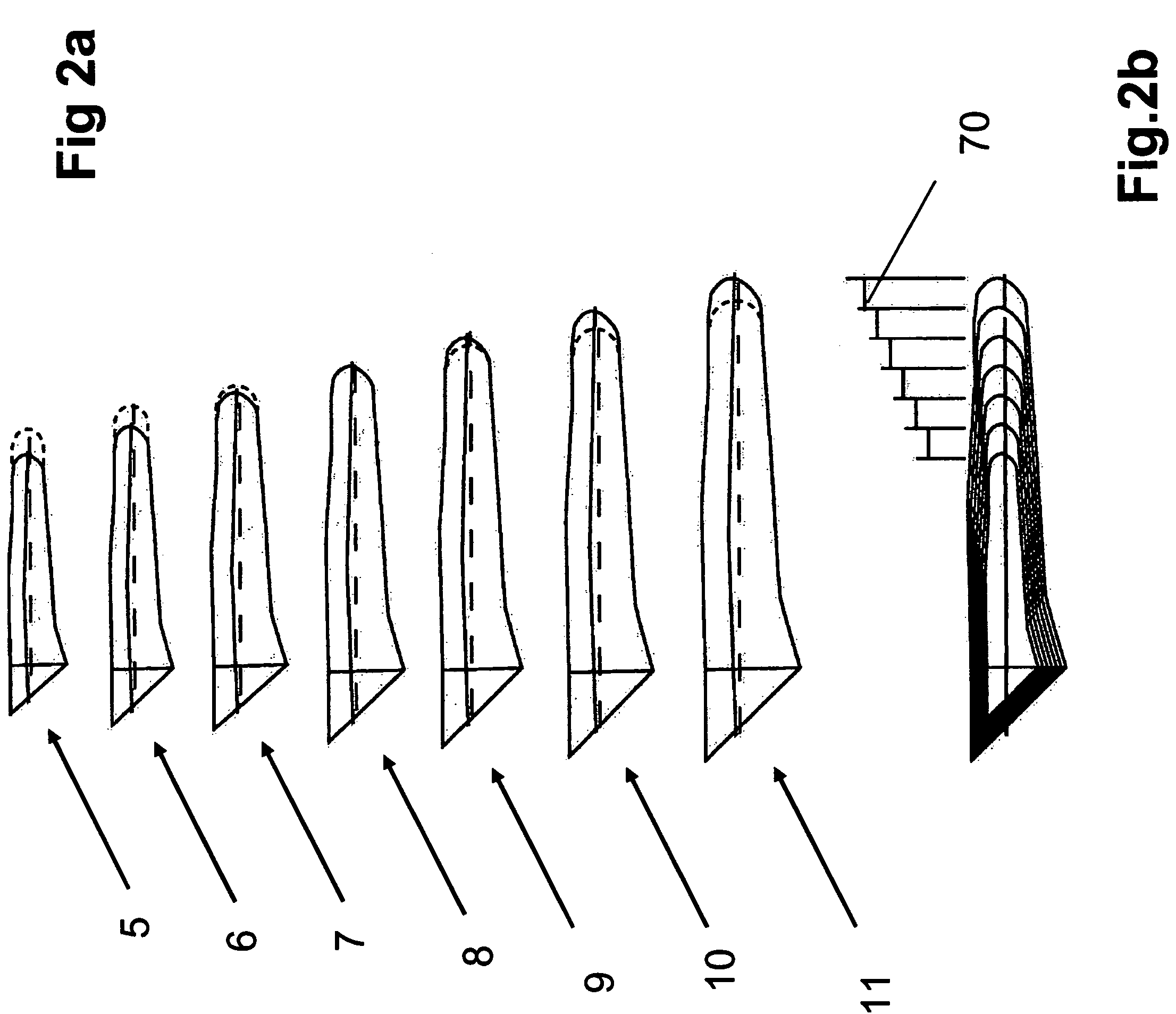

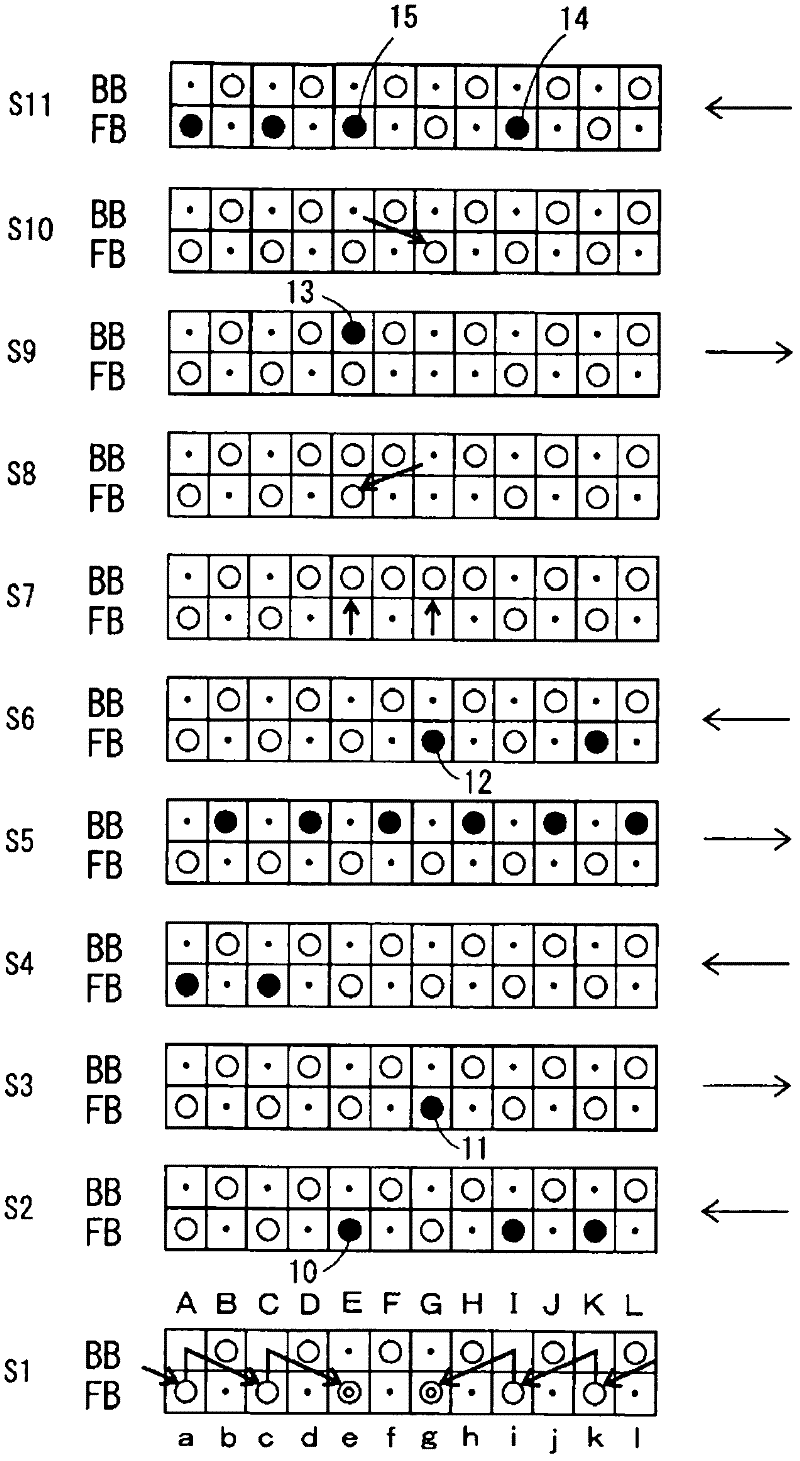

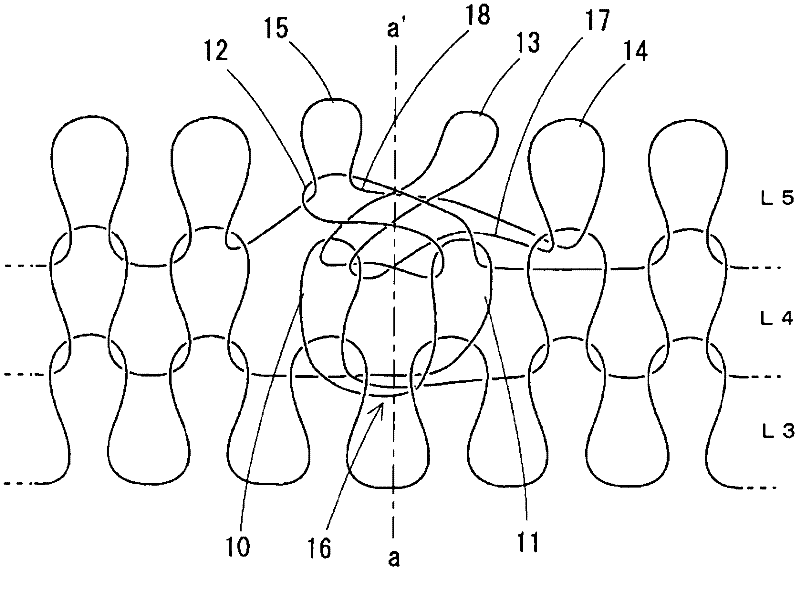

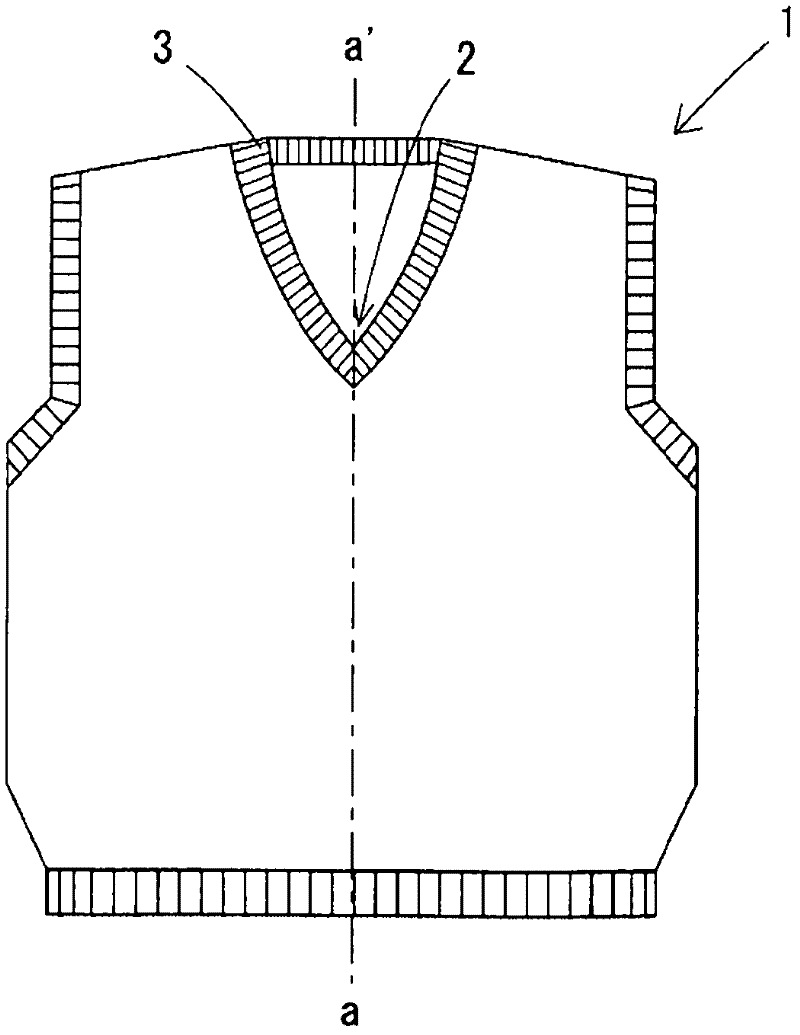

Knitting method and knitted fabric of knitted fabric having a V-shaped neck point corner

InactiveCN102264964APrevent pull awayReliable replacementWeft knittingGarmentsMechanical engineeringBraid

Provided is a knitting method by which two adjacent stitches with the branch center line of a V-neck point interposed therebetween are prevented from being separated outward from each other and the strength of the branch portion is improved. Also provided is a knitted fabric knitted by the knitting method. Specifically, the method comprises, regarding two adjacent stitches with the branch center line of a V-neck point interposed therebetween, a step for changing the travel direction of a carriage from one to the other, and forming a miss stitch on the front side of the two adjacent stitches with respect to the travel direction of the carriage, and a knit stitch on the back side with respect to the travel direction of the carriage, and a step for interchanging and crossing the positions ofat least one of the two adjacent stitches and a stitch adjacent to said stitch.

Owner:SHIMA SEIKI MFG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com