Knitting method and knitted fabric of knitted fabric having a V-shaped neck point corner

A knitted fabric and collar technology, applied in the field of knitted fabrics, can solve the problems of excessive tension applied to branches, yarn elongation, yarn breakage, etc., and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

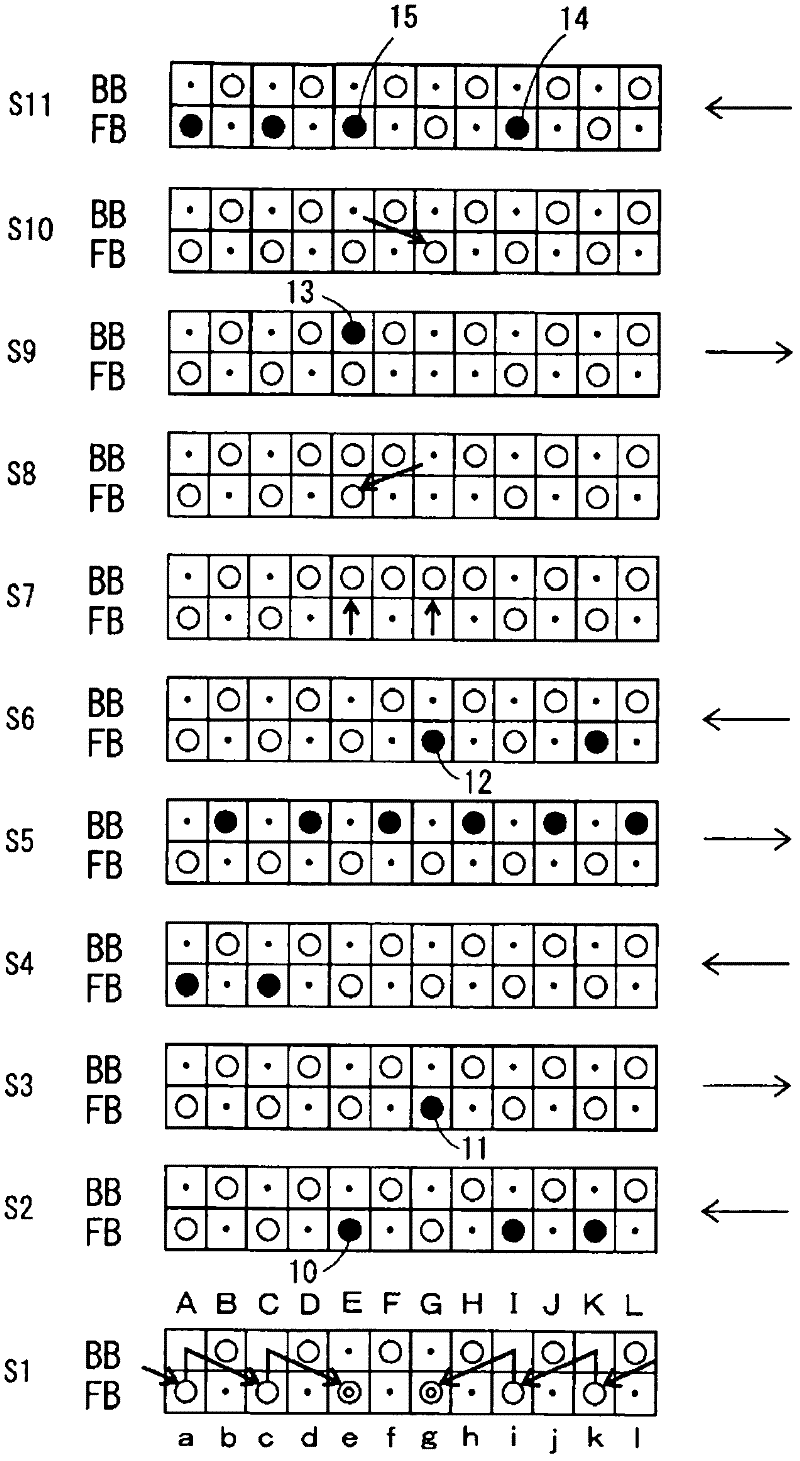

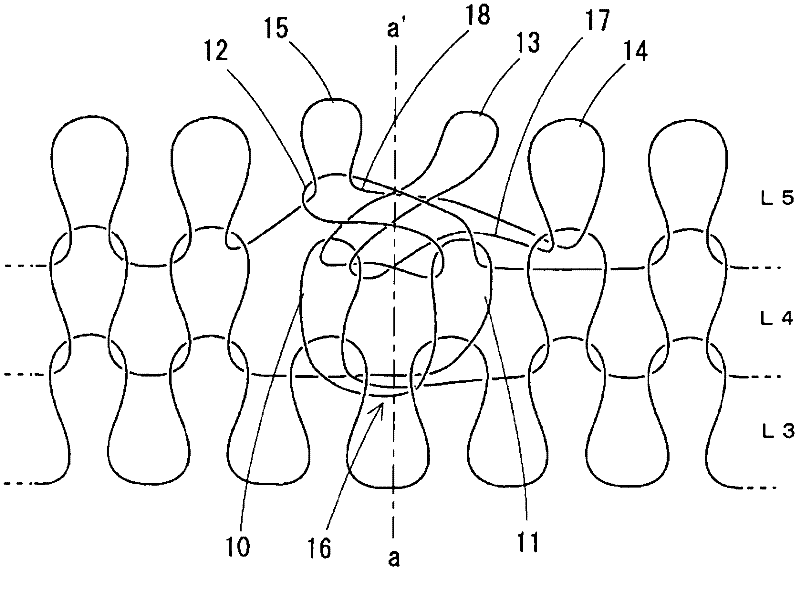

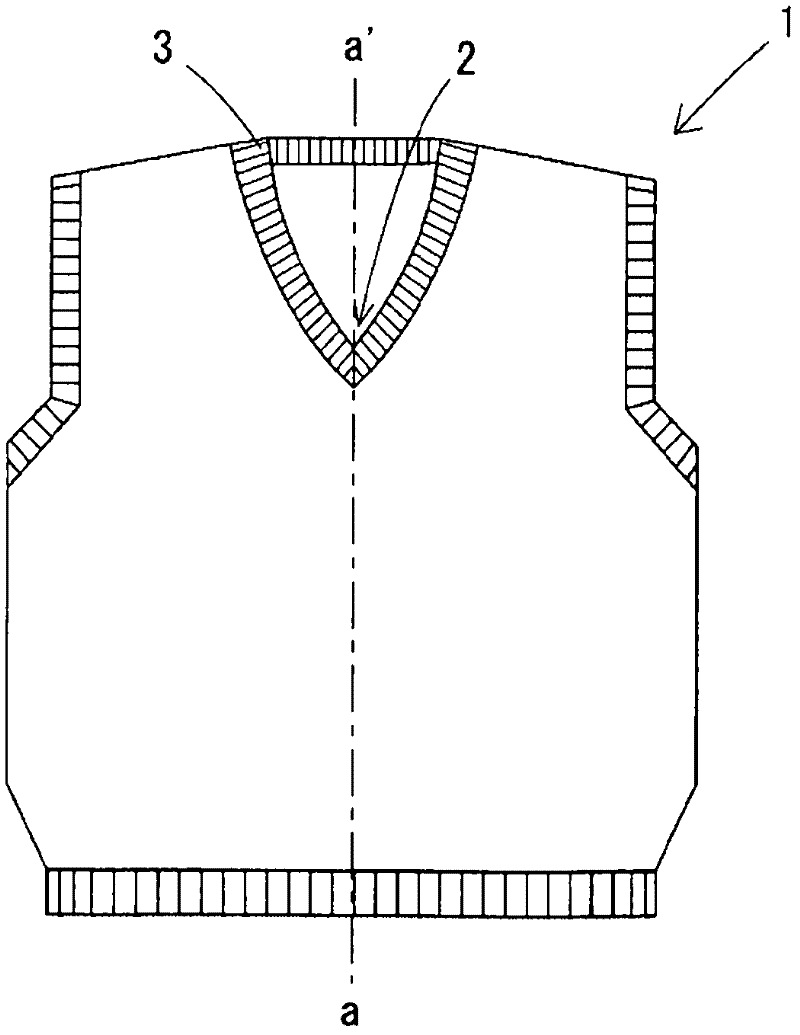

[0024] Next, using the V-shaped collar point corner 2 of the vest 1, the stitch row ( Figure 4 Examples of applying the knitting method of the present invention to L3 to L5) will be described. In this embodiment, a flatbed knitting machine having a pair of front and rear needle beds extending in the left-right direction and facing each other in the front-rear direction, and two needle beds capable of transferring stitches between the front and rear needle beds will be described. Hereinafter, the front needle bed provided in this flatbed knitting machine is denoted as FB, and the rear needle bed is denoted as BB. In addition, although not shown, this flatbed knitting machine has a carriage that reciprocates on the needle bed to move the thread supply port, or moves the knitting needles forward and backward by an internal cam.

[0025] figure 1 It is a weaving process diagram, figure 2 A part of the V-shaped neck corner 2 to which the present invention is applied is shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com