Modular thermal chemical reaction catalyst and manufacturing method thereof

A thermochemical reaction and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem of uneven temperature distribution of catalysts and beds, complicated catalyst replacement operations, and low catalyst utilization efficiency. and other problems, to achieve the effect of improving mass transfer and diffusion capacity, improving thermochemical reaction performance, and convenient catalyst loading and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

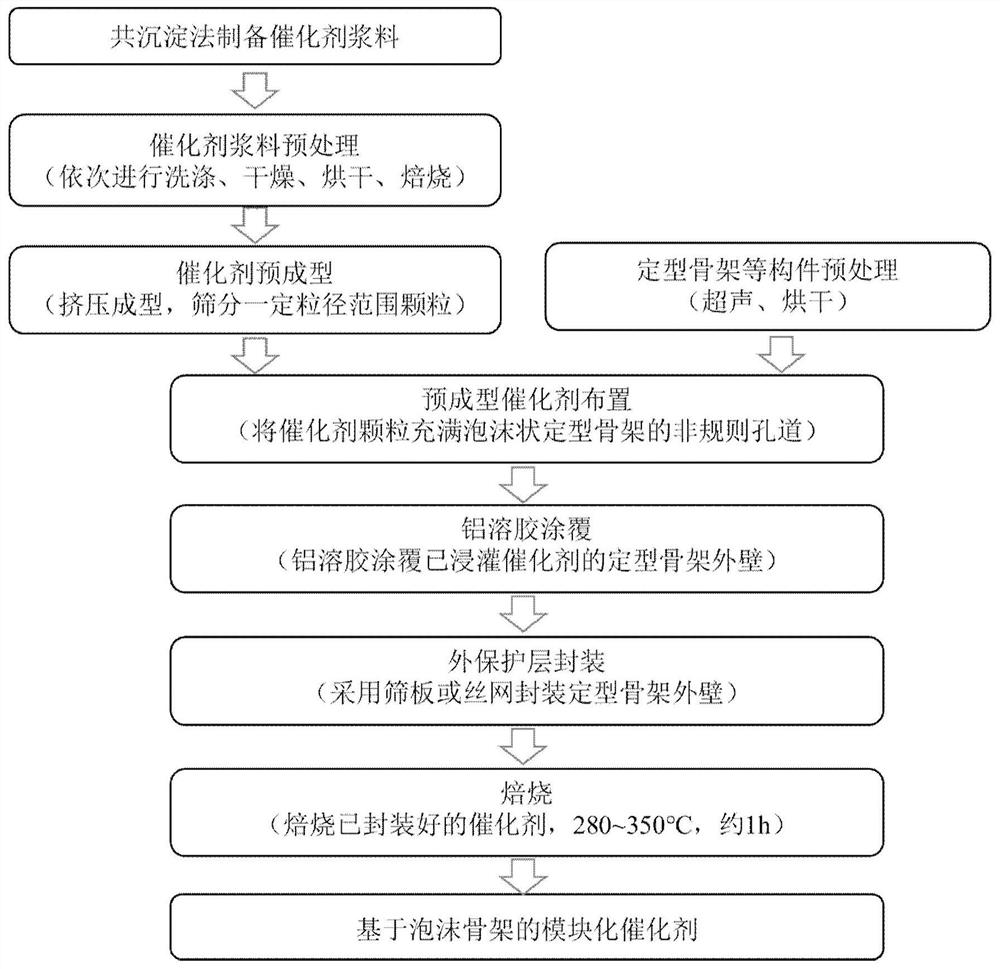

[0046] The invention discloses a preparation method of a modularized thermochemical reaction catalyst, comprising:

[0047] preparing preformed catalyst particles;

[0048] Shaped skeleton pretreatment;

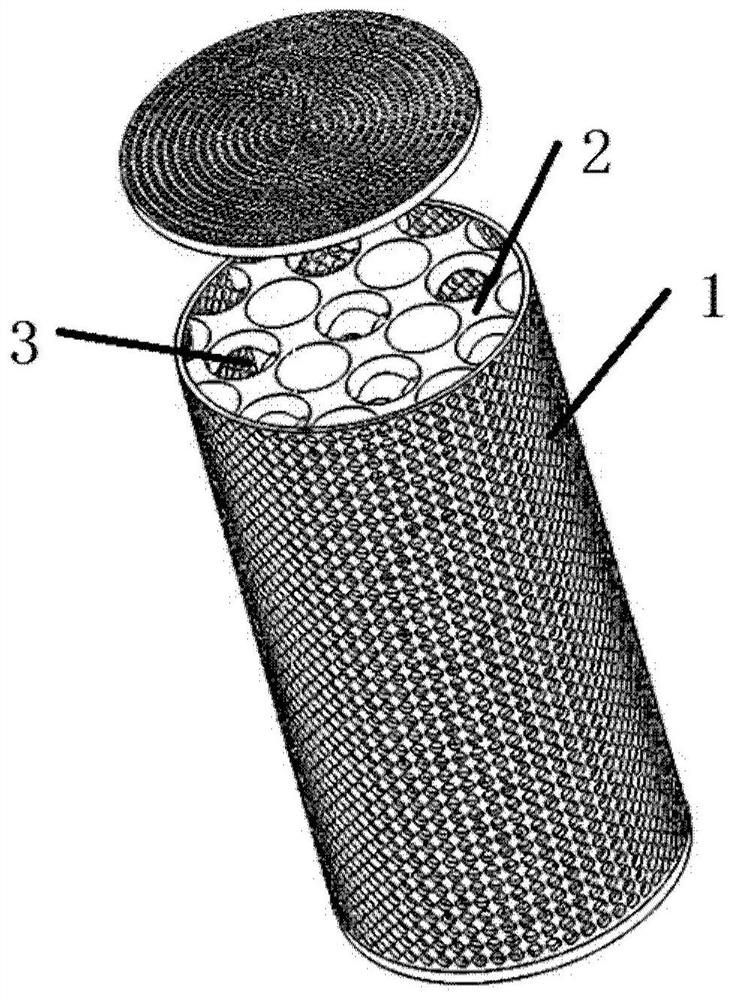

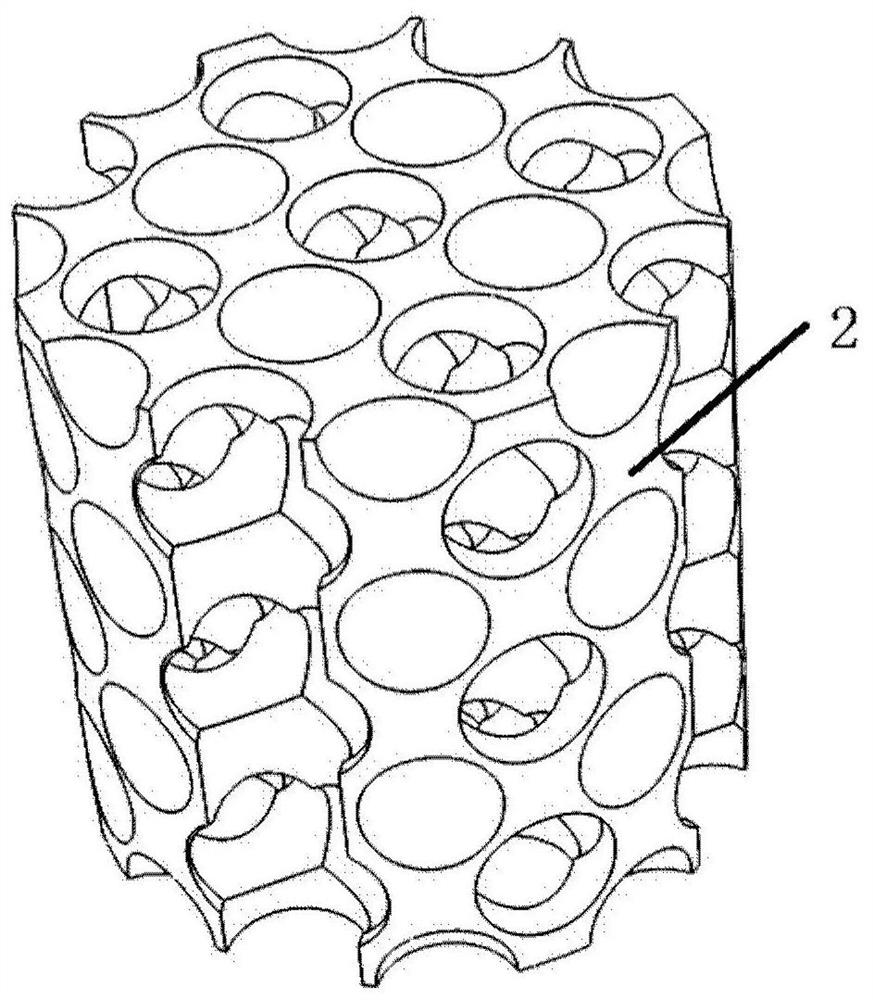

[0049] placing the preformed catalyst particles in the three-dimensional channels of the selected shaped framework;

[0050] Fixing the outer protective layer on the outer wall of the above-mentioned shaped skeleton;

[0051] The shaped framework with the outer protective layer fixed is fired to obtain the modularized thermochemical reaction catalyst.

[0052] In some embodiments of the present invention, the step of preparing preformed catalyst particles includes:

[0053] Prepare catalyst slurry;

[0054] Pretreating the catalyst slurry by washing, drying, and roasting to obtain catalyst powder;

[0055] The catalyst powder is mixed with the auxiliary forming material, and extruded, then crushed and sieved to obtain the preformed catalyst particles;

[0056] In some emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com