Fluidize adsorption continuous refrigeration system and method thereof

A refrigeration system and fluidization technology, applied in the field of fluidized adsorption continuous refrigeration system, can solve the problems of small thermal conductivity, increased heat loss, large contact thermal resistance between adsorbent and heat transfer metal wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

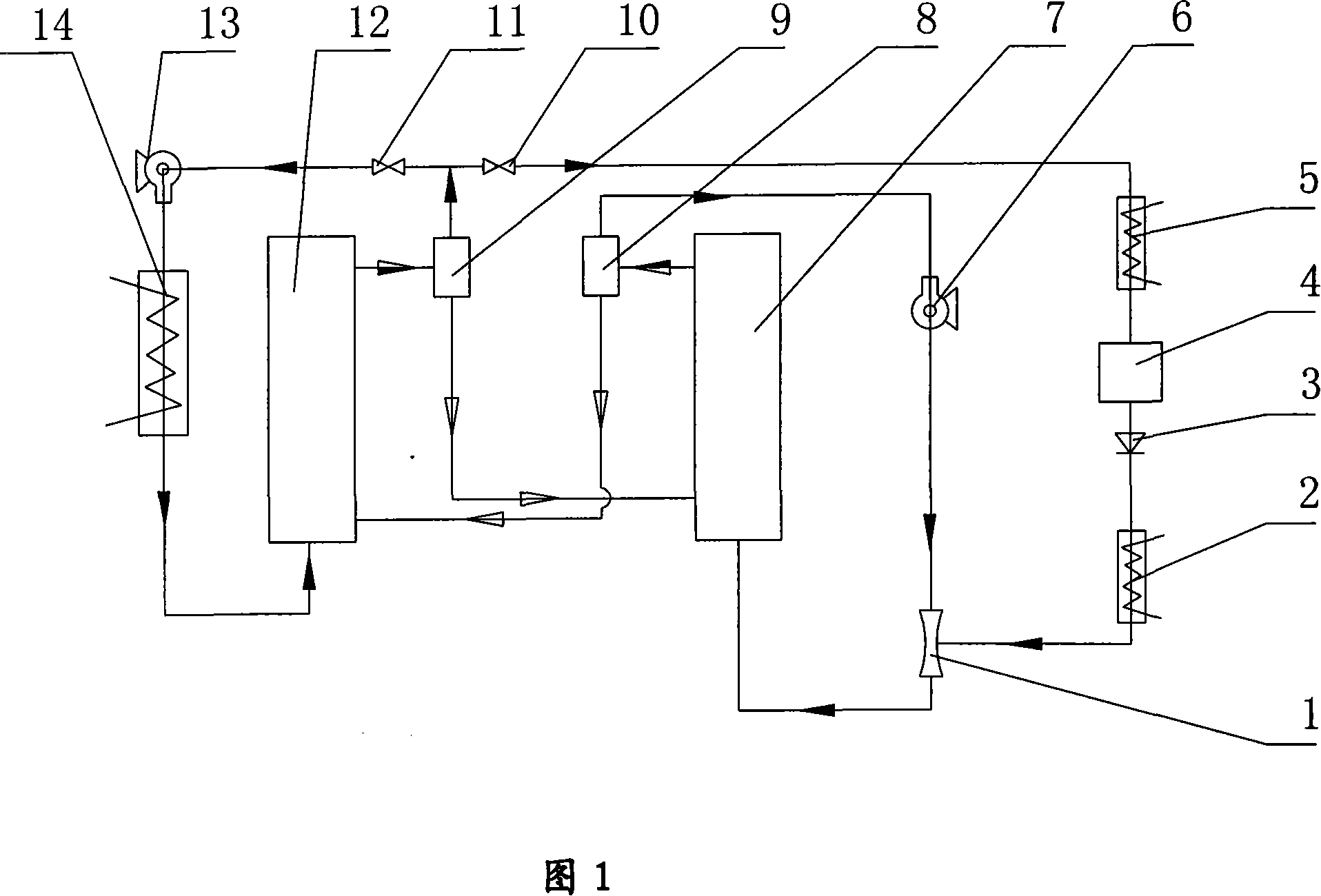

[0028] As shown in Figure 1: a fluidized adsorption continuous refrigeration system, including a refrigeration part that absorbs or releases heat to the outside, an adsorption part that makes the adsorbent absorb the refrigerant and cools down, and heats up the adsorbent and desorbs the refrigerant The desorption part;

[0029] The refrigerating part includes an evaporator 2, a throttle valve 3, a liquid storage tank 4 and a condenser 5;

[0030] The adsorption part includes a venturi tube 1, a compressor 6, an adsorption bed 7 and a gas-solid separator 8;

[0031] The desorption part includes a gas-solid separator 9, a vacuum valve 10, a vacuum valve 11, a desorption bed 12, a heat exchanger 14 and a compressor 13;

[0032] Wherein, one end of the vacuum valve 11 is connected to one end of the compressor 13 through a pipeline, the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com