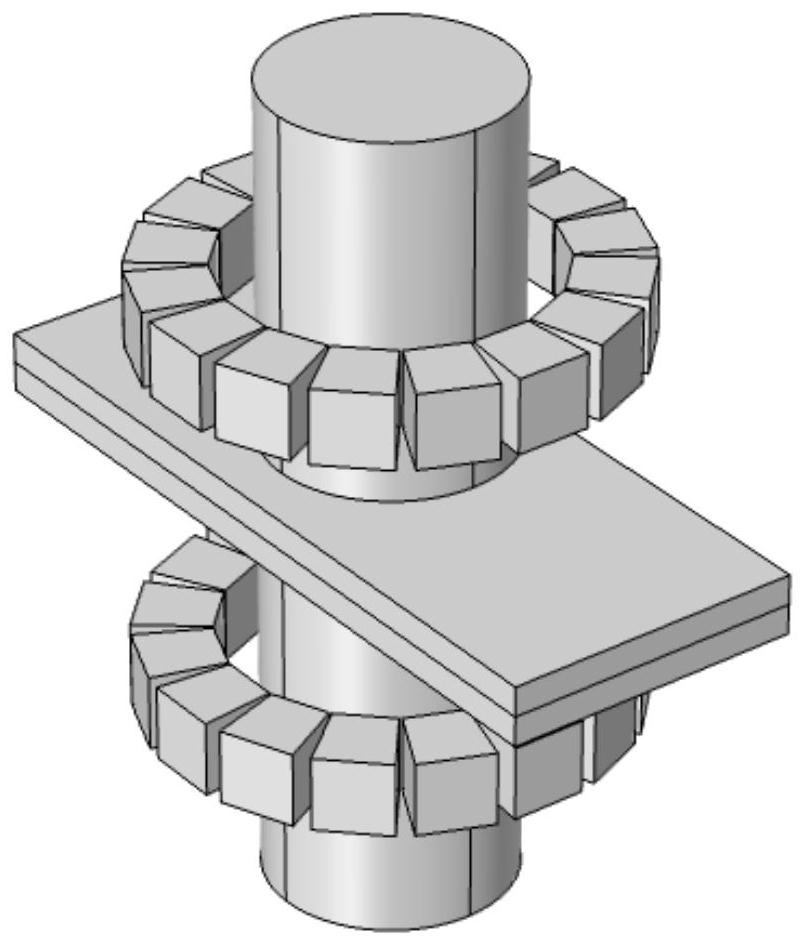

Magnetic field array auxiliary resistance spot welding device and method for sheet metal materials

An auxiliary resistance, sheet metal technology, applied in resistance welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of unmatched magnetic field mode conversion, low solute, low heat transfer rate, and low force on molten metal. Achieve the effect of improving heat and mass transfer capacity, improving comprehensive mechanical properties, and increasing the number of equiaxed crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

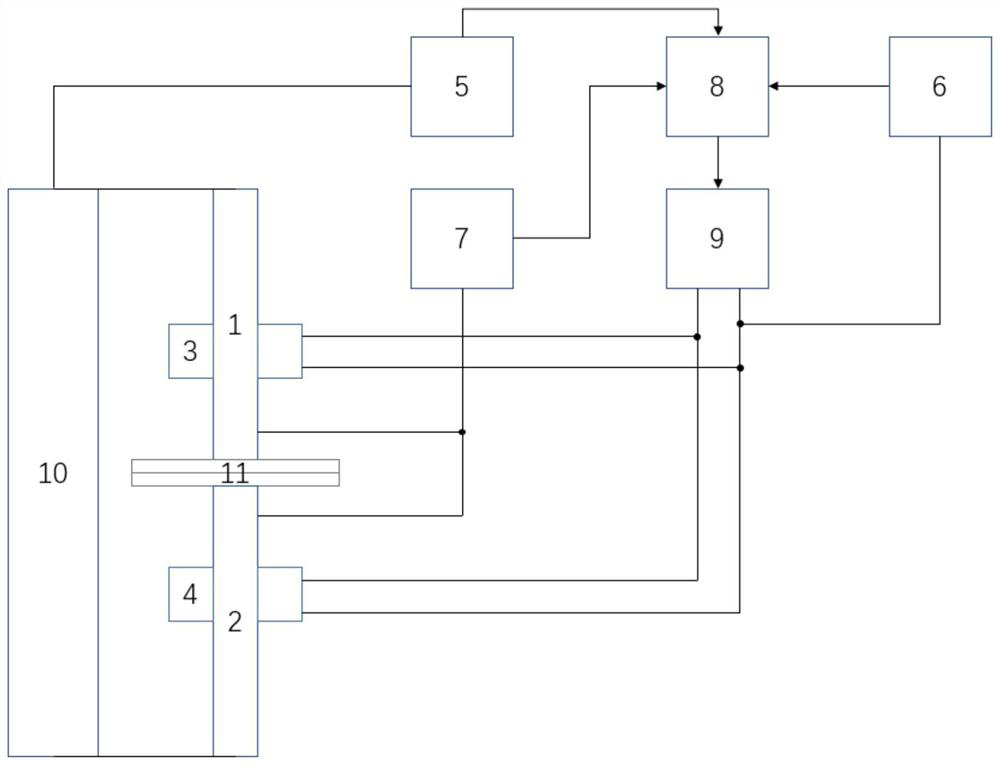

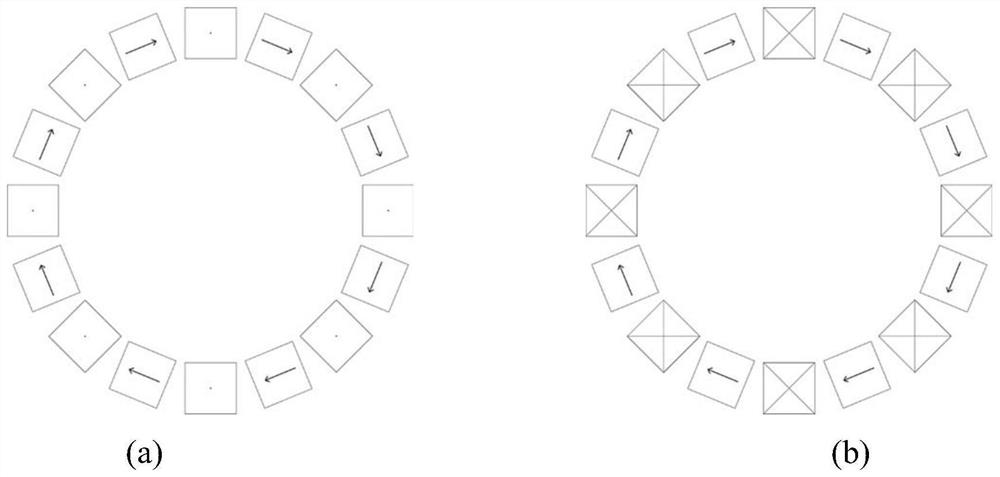

Embodiment 1

[0064] The resistance spot welding process in this example is divided into three stages: 0~t 1 is the preload stage, t 1 ~t 2 is the heating and welding stage, t 2 ~t 4 for the holding phase. Apply a stronger welding current I during the heating welding phase 1 , and the extension current i 1 , to drive the metal liquid phase to move in a circumferential direction, thereby increasing the diameter of the nugget; in the pressure-holding stage, a weaker auxiliary current I is applied 2 , and the stirring current i 2 , the synchronous system 8 takes the relative change speed of dynamic resistance as the criterion, converts and increases the nugget-type magnetic field and stirs the nugget-type magnetic field, increases the nugget with maximum efficiency, and strengthens the stirring effect, thereby refining the grain structure and eliminating components Segregation. During the entire resistance spot welding process, the upper and lower electrodes apply pressure F to the wor...

Embodiment 2

[0073] The workpiece 8 to be welded in this embodiment is a 6061 aluminum alloy with a plate thickness of 2mm+2mm.

[0074] The electrode pressure F in this embodiment is 3 kN.

[0075] The preload time t in this embodiment 1 , is 200 ms, welding time t 2150 milliseconds, holding time t 4 for 600 milliseconds.

[0076] The heating welding current I in this embodiment 1 , is 24000 amperes, auxiliary stirring current I 2 for 1600 amps.

[0077] Excitation current i in this example 1 , is 1800 mA, excitation current i 2 It is 4000 mA, all of which are DC waves.

[0078] The working process of this example is as follows: the workpiece 11 to be welded is placed on the welding fixture, and at 0 o'clock, it enters the preloading stage, and the resistance spot welding torch 10 applies a force F to the workpiece 11 to be welded through the upper and lower motors, and keeps The changing electrode force F remains unchanged until the end of the pressure holding process; at t 1 W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com