Double-flexible-grinding-head magnetorheological polishing device

A magnetorheological polishing and polishing device technology, which is used in grinding drive devices, grinding/polishing equipment, and parts of grinding machine tools, etc., can solve the problem of inability to meet the requirements of CPP processing, large removal function shape, and lack of large diameter Optical components processing ability and other issues, to achieve significant engineering application value, meet static and dynamic stiffness, and achieve the effect of effective matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

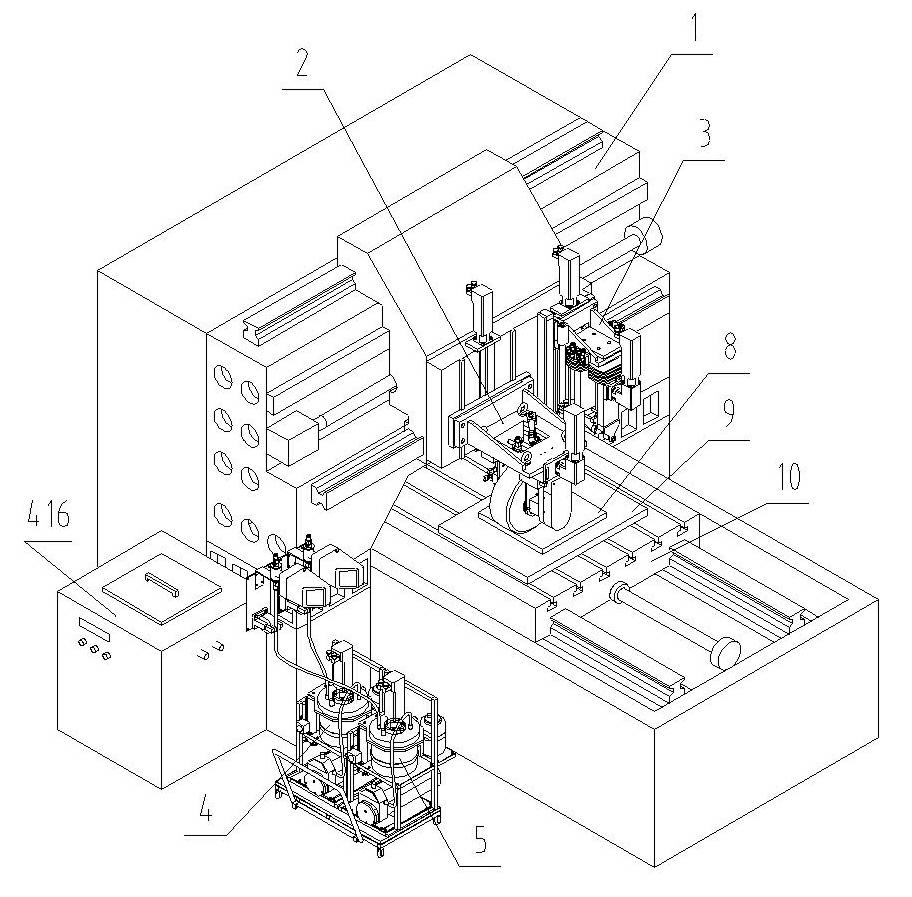

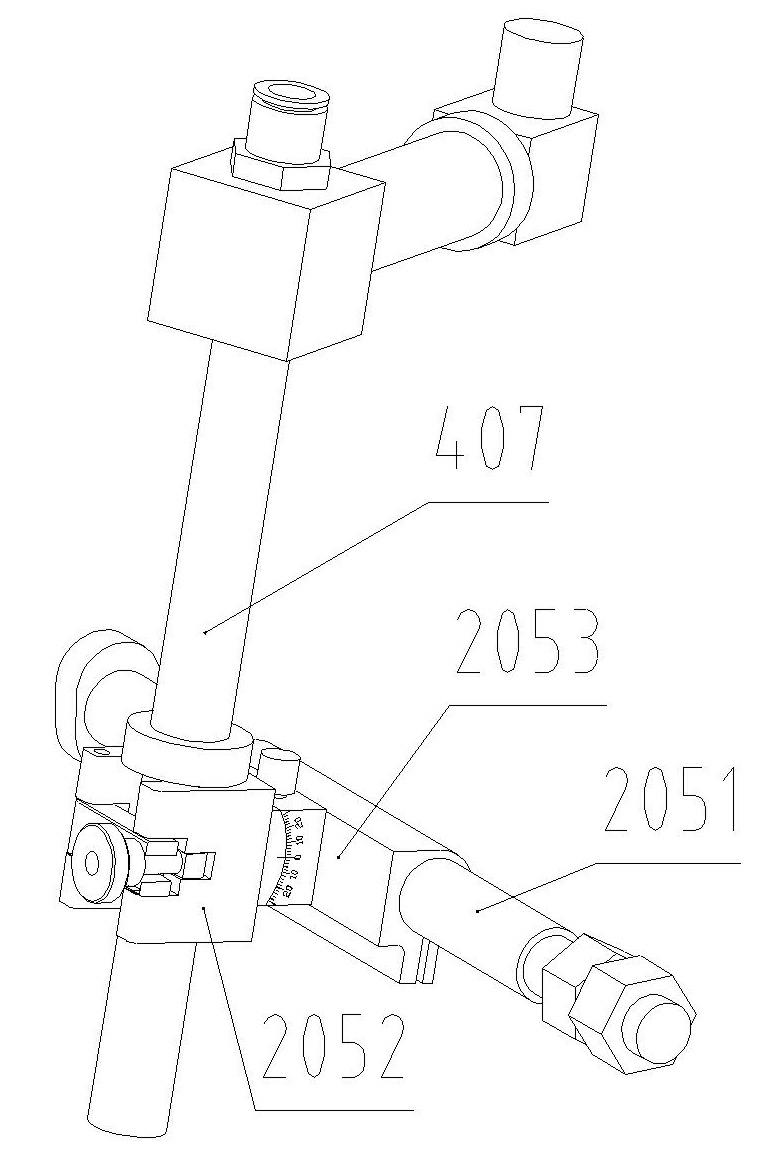

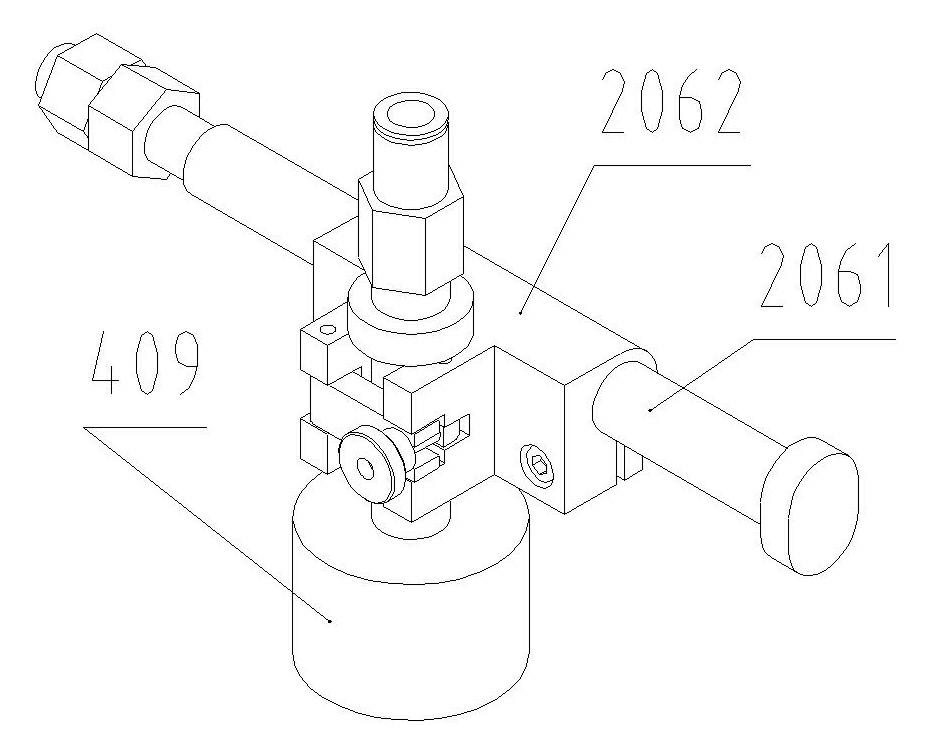

[0053] figure 1 It is a structural schematic diagram of the dual flexible grinding head magnetorheological polishing device of the present invention, figure 2 It is the appearance layout diagram of the dual flexible grinding head magnetorheological polishing device of the present invention, image 3 It is a schematic diagram of the bed structure of the present invention. Such as Figure 1-Figure 3 As shown, the magnetorheological polishing device with dual flexible grinding heads of the present invention includes a bed 1, a large flexible grinding head 2, a small flexible grinding head 3, a large flow circulation system 4, a small flow circulation system 5, a cleaning system 6, The protective cover 7 and the measurement and control system connected with the above-mentioned parts. The bed 1 includes a horizontal base 101 , a vertical gantry 102 , an X axis 103 , a Y axis 104 , a first Z axis 105 and a second Z axis 106 . The vertical gantry 102 is fixed on the horizontal b...

Embodiment 2

[0068] The basic structure of this embodiment is the same as that of Embodiment 1, except that the diameter of the outer surface of the large polishing wheel 2022 in this embodiment is φ300mm, and the diameter of the small polishing wheel 3032 is φ50mm.

Embodiment 3

[0070] The basic structure of this embodiment is the same as that of Embodiment 1, except that the diameter of the outer surface of the large polishing wheel 2022 in this embodiment is φ400mm, and the diameter of the small polishing wheel 3032 is φ80mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com