Patents

Literature

126results about How to "High heat and mass transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for atomizing, freezing and drying for powder production by using low-temperature low-dew point gas

InactiveCN101403561AReduce manufacturing costParticle rulesDrying solid materials with heatDrying solid materials without heatComing outFreeze-drying

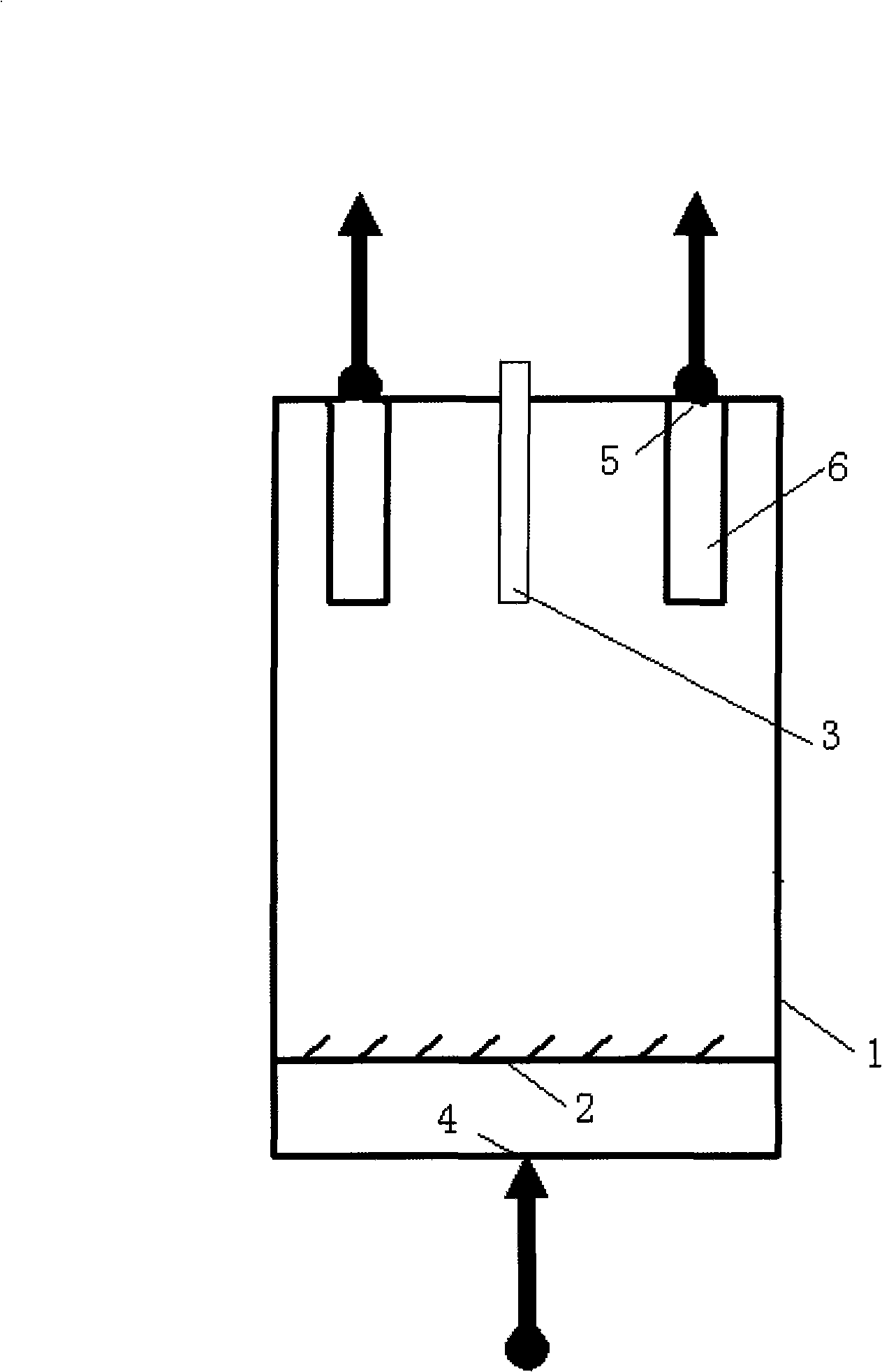

The invention discloses a method for milling by low temperature low dew point gas spray freeze drying which uses an atomizer for nebulizing liquid to be dried into 1 to 250 micron droplets which are frozen into ice powder in the gas with the low temperature of -60 DEG C and the dew point of -70 to -80 DEG C, then air-intake temperature is adjusted to 2 to 4 DEG C lower than the eutectic temperature of materials, the gas passes through a pore plate of a fluidized bed to lead the ice powder which stays on the fluidized plate to be fluidized, and simultaneously the solvent in the ice powder is sublimated. The sublimation drying process is completed until the dew point of the gas at the gas vent returns to -55 to -60 DEG C. The ice powder is dried for 1 to 2 hours into powder products when the temperature is increased to 30 to 50 DEG C. The gas coming out of the gas vent returns to the place for low temperature low dew point gas preparation for recirculation. The method is characterized by easy operation, continuous duty, and the like, and is especially suitable for the drying of materials such as medicine, food, biochemical product, and the like, guarantees the quality of products and can directly obtain the dried powder products; simultaneously the drying time of the method is greatly shortened compared with the vacuum freeze drying.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

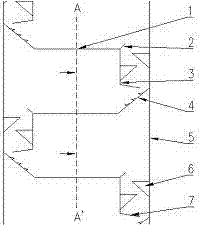

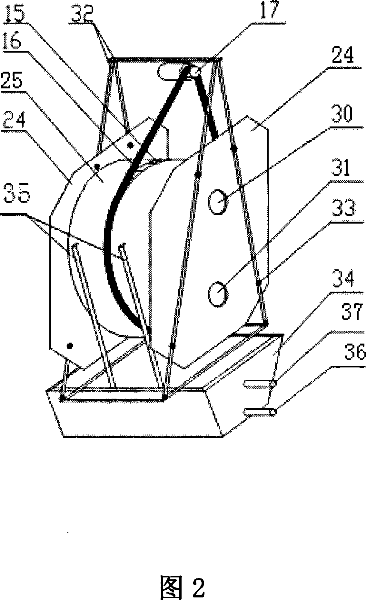

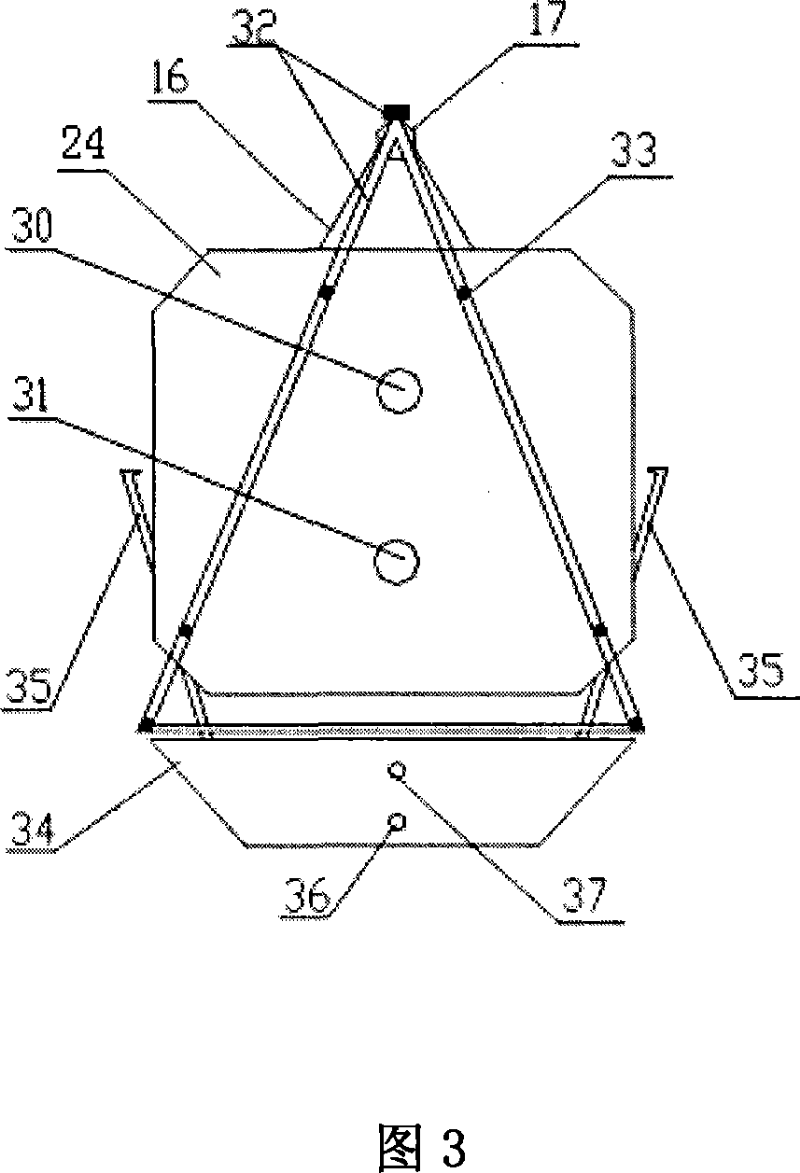

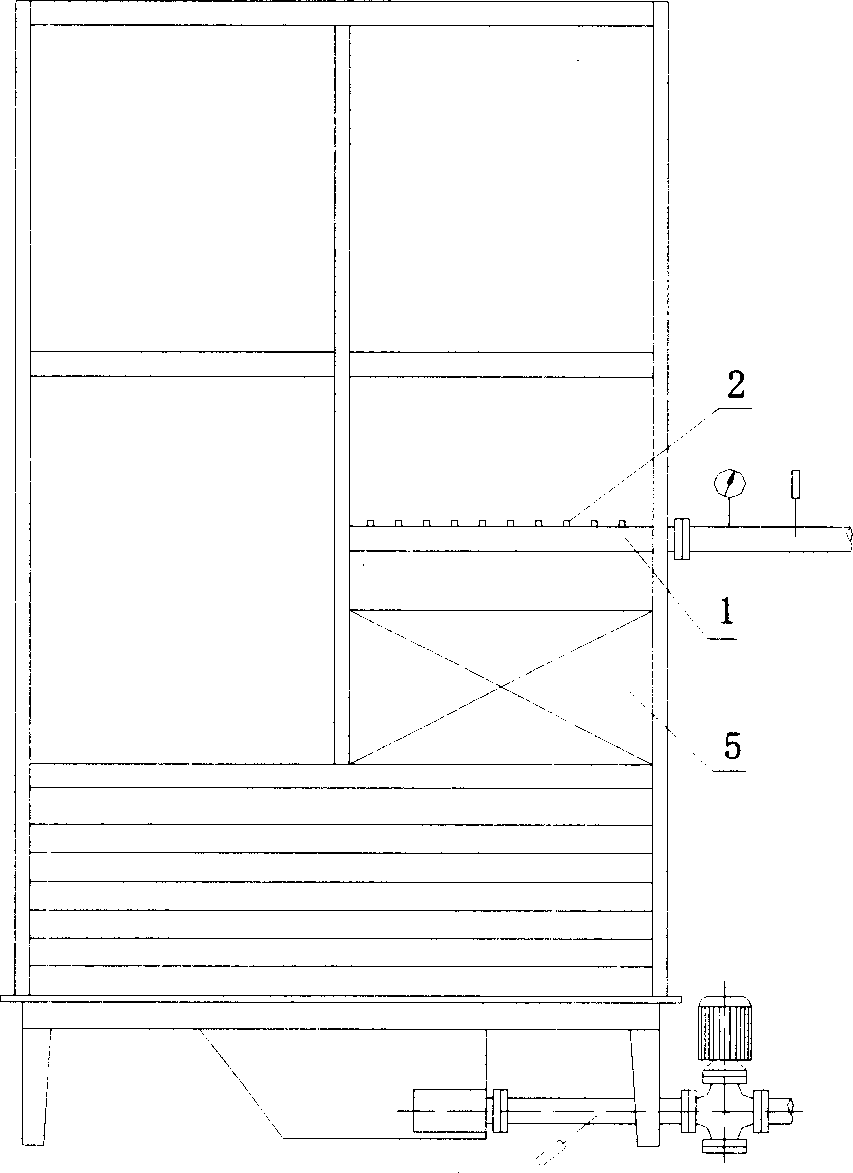

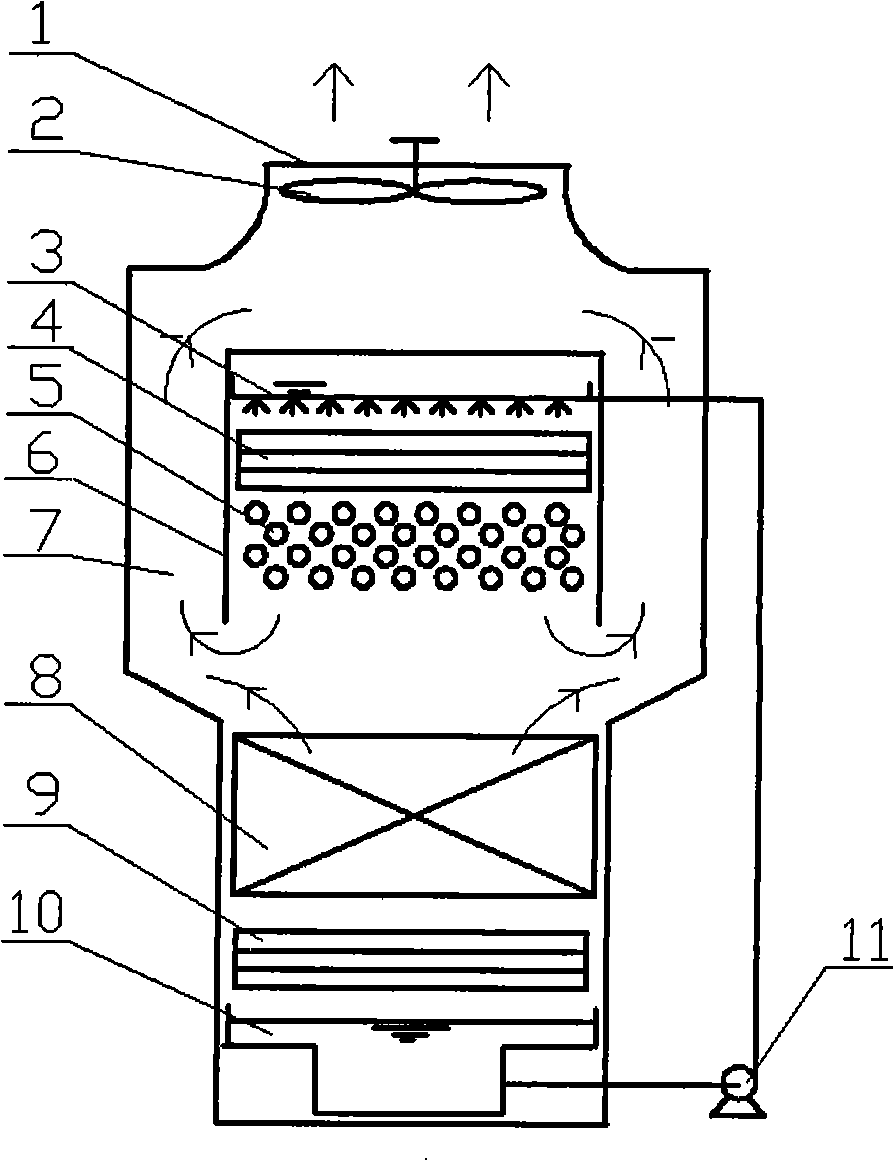

Evaporative cooling air conditioning unit provided with inertia filter and suitable for northwest districts

InactiveCN102635909AImprove filtering effectAdjustable air volumeEvaporators/condensersSpace heating and ventilation detailsEvaporative coolerEngineering

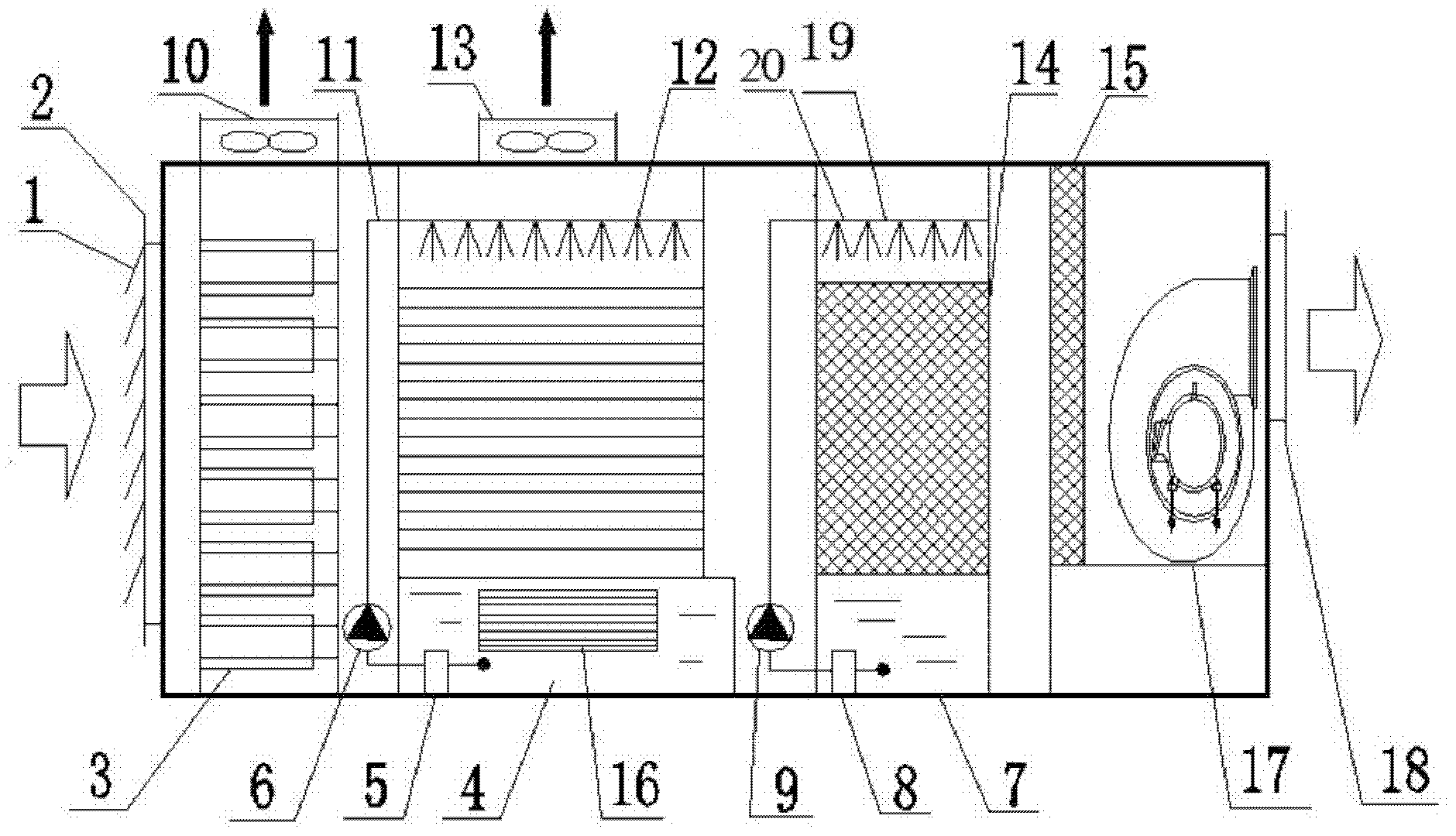

The invention discloses an evaporative cooling air conditioning unit provided with an inertia filter and suitable for northwest districts, and the evaporative cooling air conditioning unit comprises an air inlet and an air supply outlet, a shutter, an inertial filter, a tubular indirect evaporative cooler, a direct evaporative cooler, a filler b and an air supply fan, wherein the air inlet and the air supply outlet are respectively arranged on the opposite lateral walls of a unit shell; the shutter is arranged on the outer side of the air inlet; the inertial filter, the tubular indirect evaporative cooler, the direct evaporative cooler, the filler b and the air supply fan are sequentially arranged in the unit shell according to the air intake direction; the shell wall, corresponding to the upper part of the inertial filter, of the unit shell is provided with a filter air exhaust port; the wall, corresponding to the upper part of the tubular indirect evaporative cooler, of the unit shell is provided with a secondary air outlet; and the wall, corresponding to the lower part of the tubular indirect evaporative cooler, of the unit shell is provided with a secondary air return port. According to the evaporative cooling air conditioning unit provided by the invention, through the optimization design of a filtering section, a tubular indirect evaporative cooling section and a direct evaporative cooling section by utilizing an evaporative cooling technology, the purification and heat transfer and mass transfer effects of the evaporative cooler are improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

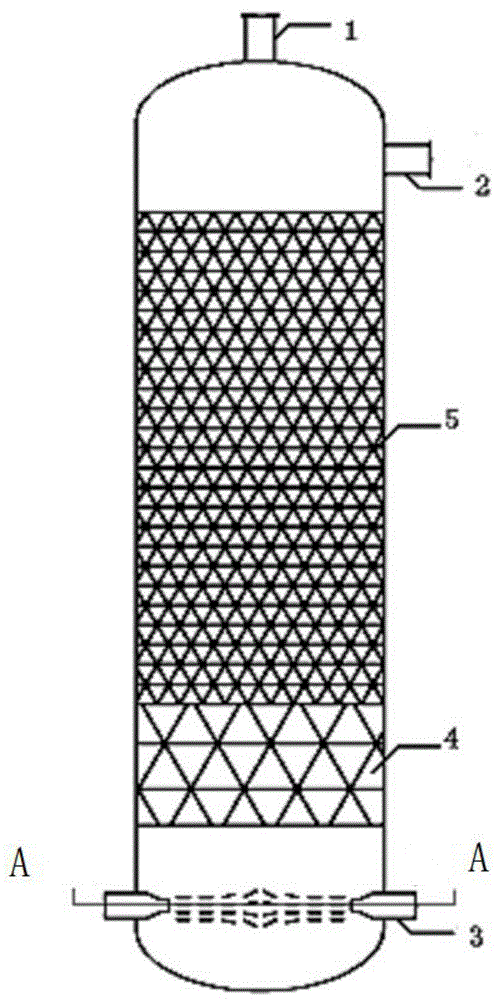

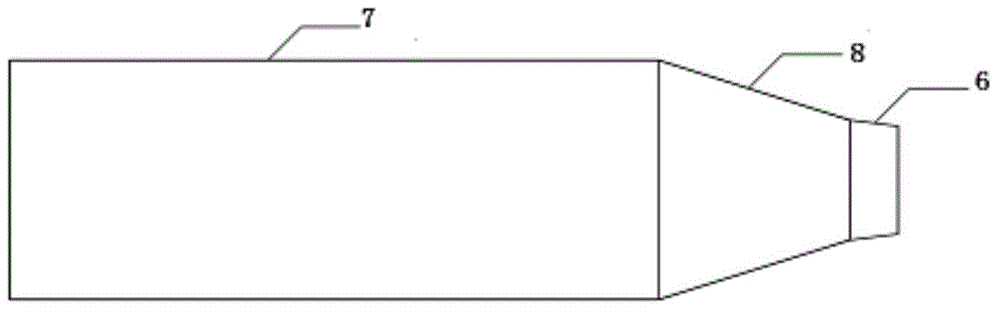

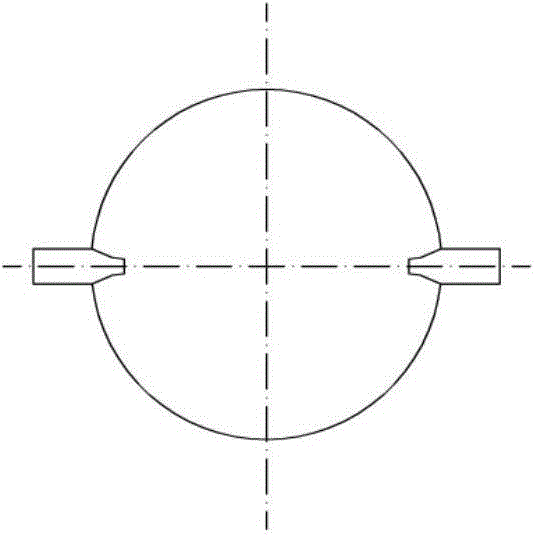

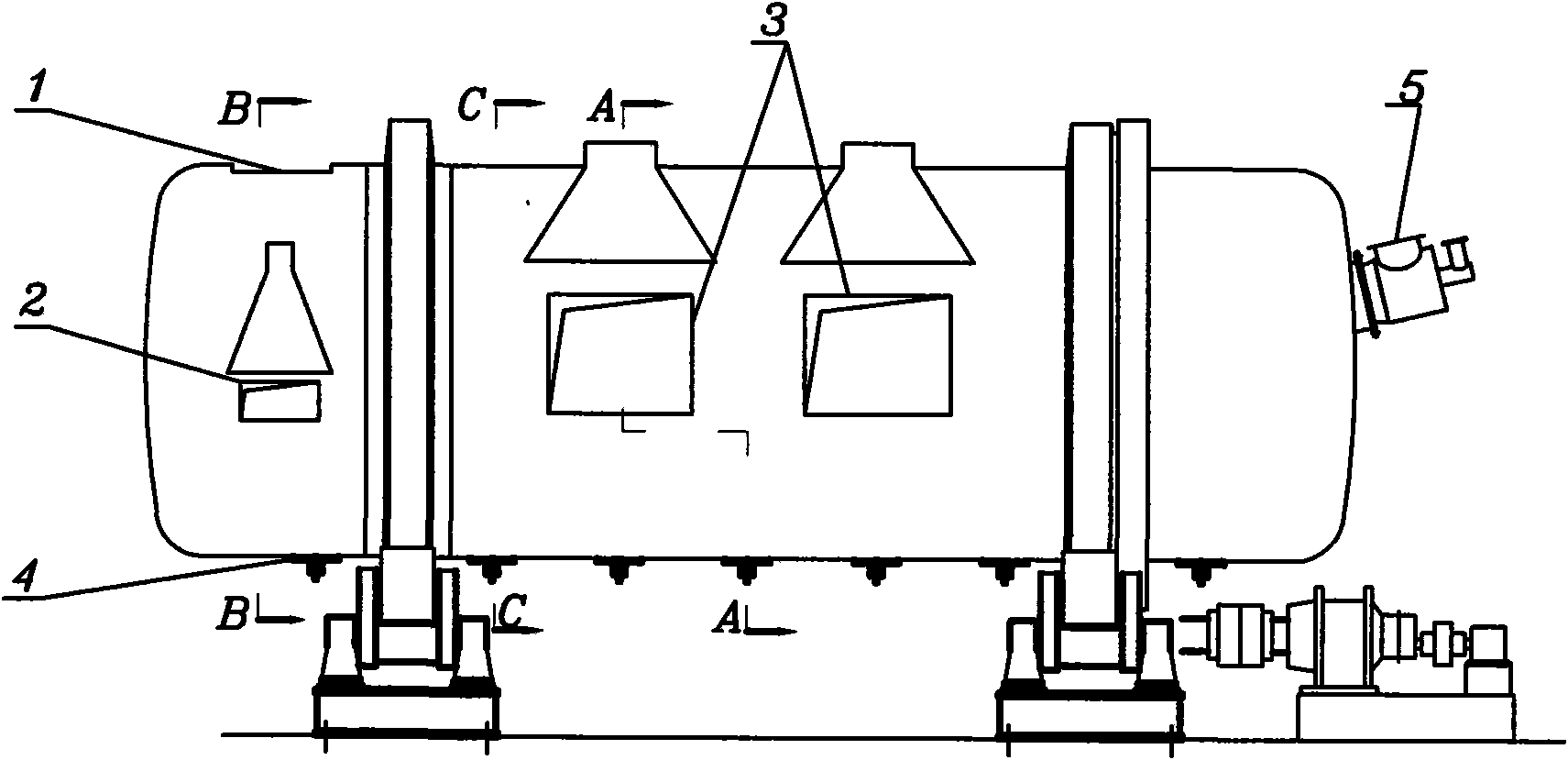

Reactor and method for preparing epoxypropane by reactor

ActiveCN104907009AIntensified interphase mixingHigh selectivityOrganic chemistryChemical/physical processesSpray nozzleFixed bed

The invention discloses a reactor. The middle of the reactor is filled with an epoxidation catalyst, the top wall of the reactor is provided with a gas outlet, the upper side wall of the reactor is provided with a liquid outlet, the lower side wall of the reactor is provided with one or two groups of injectors, each group of the injectors comprises two injectors symmetrically distributed on the same plane, the injector comprises a jet pipe and a nozzle connected to the jet pipe, the nozzle is frustoconical, the diameter of one end of the nozzle connected to the jet pipe is greater than that of the other end, the nozzle stretches into a fixed bed reactor, the jet pipe comprises two sections, the section of the jet pipe far away from the nozzle is cylindrical, the other section is frustoconical, and the diameter of one end of the jet pipe far away from the nozzle is greater than the diameter of one end of the jet pipe connected to the nozzle. The invention discloses a method for preparing epoxypropane by the reactor and a reaction system composed of the reactors connected in series. The reactor realizes reactant high-speed clashing mixing, improves reactant mixing effects, improves heat and mass transfer effects and improves a cumene hydroperoxide conversion rate and epoxypropane selectivity.

Owner:HONGBAOLI GRP CO LTD +1

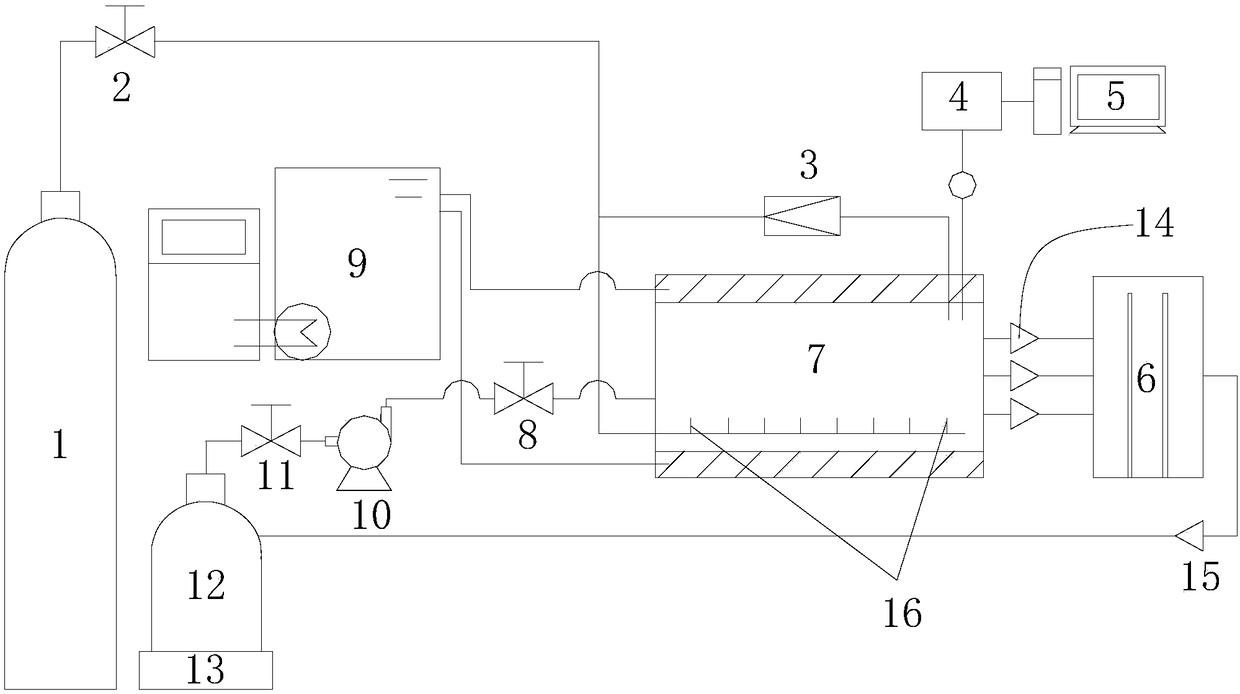

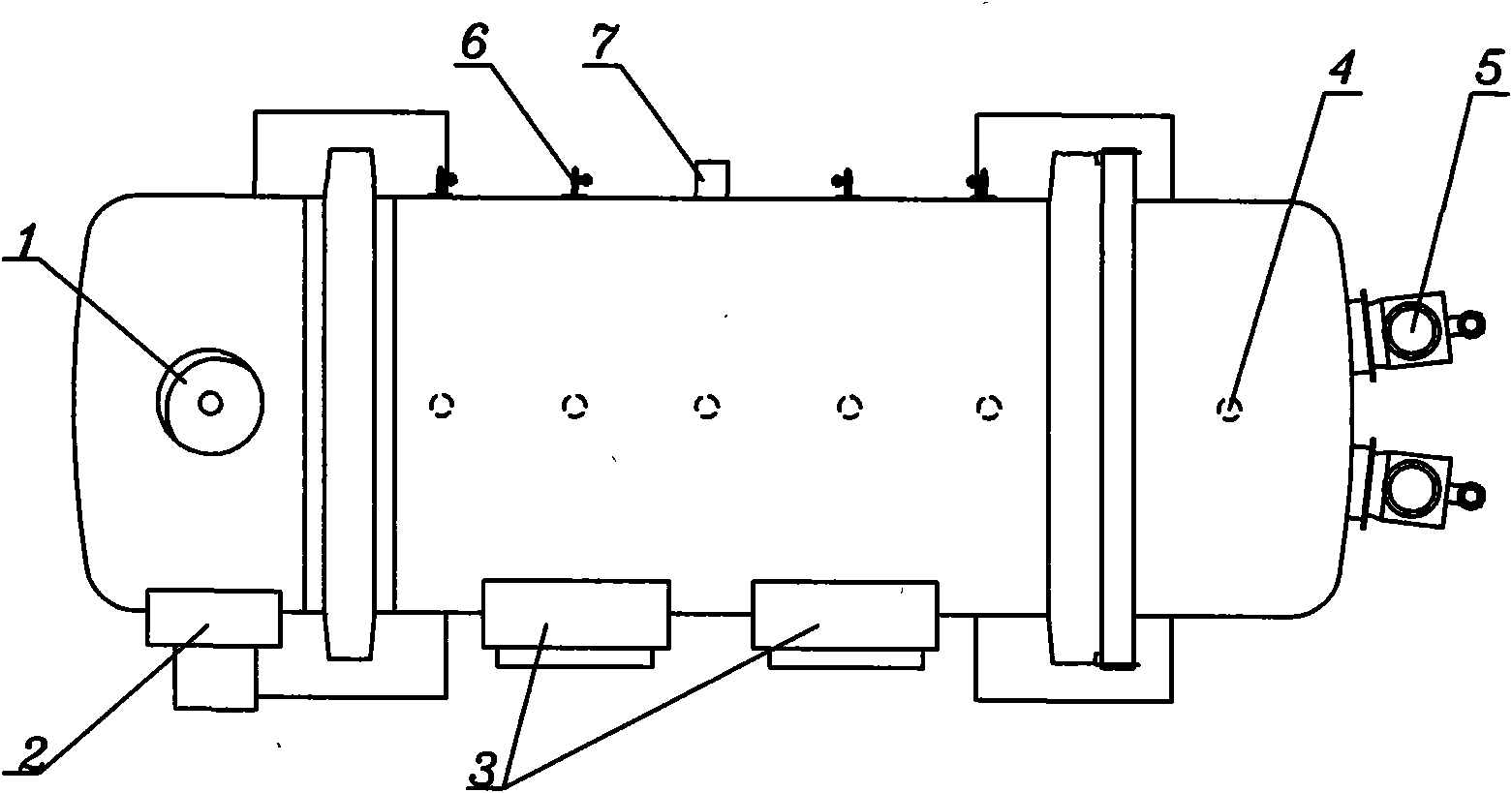

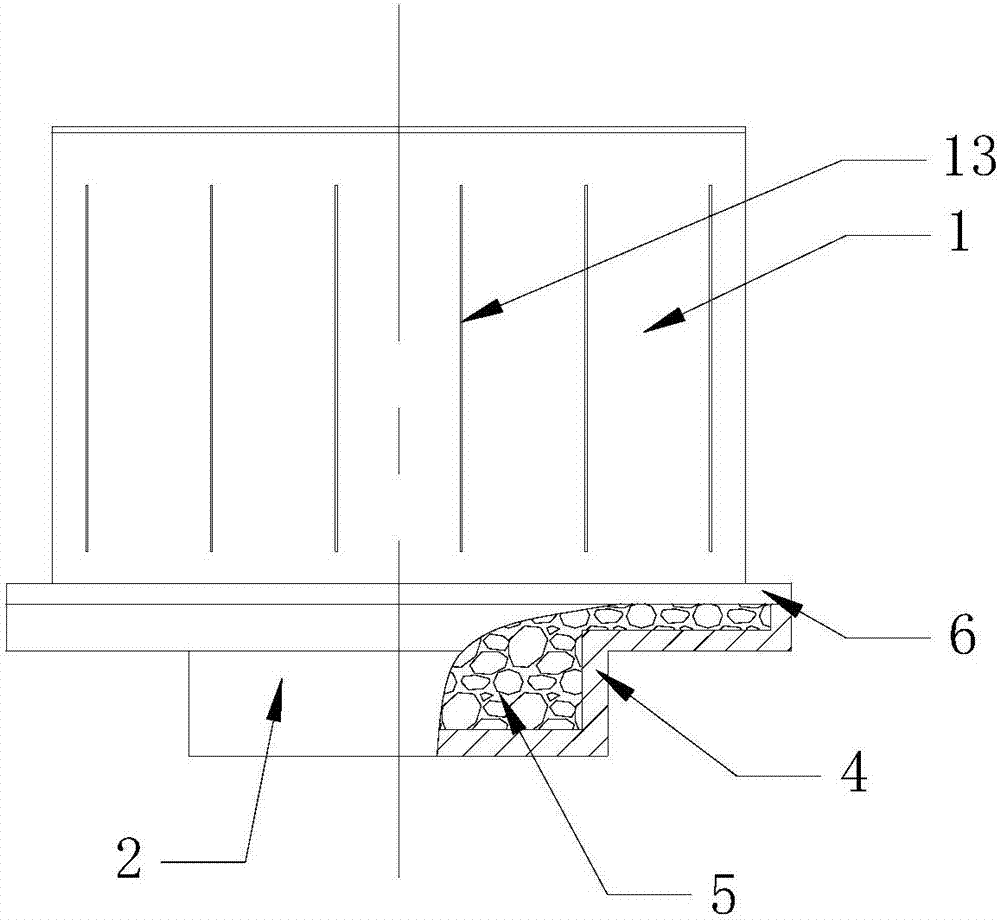

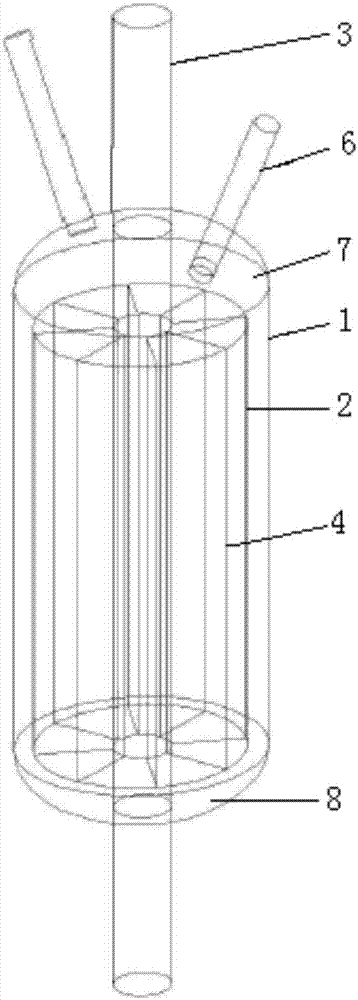

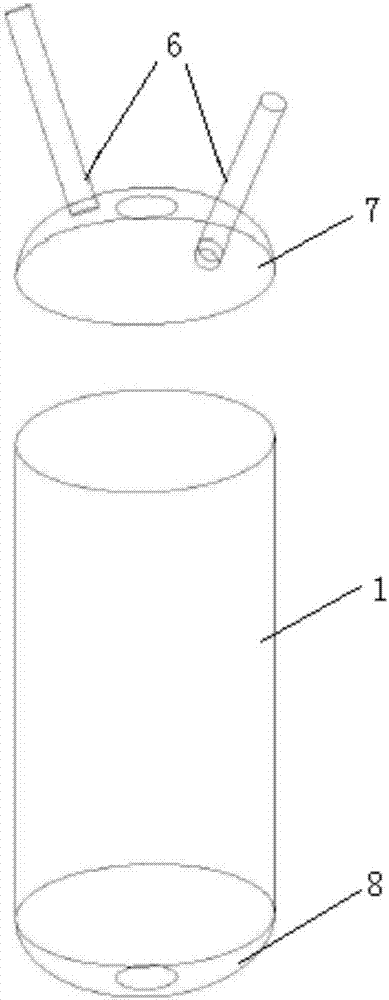

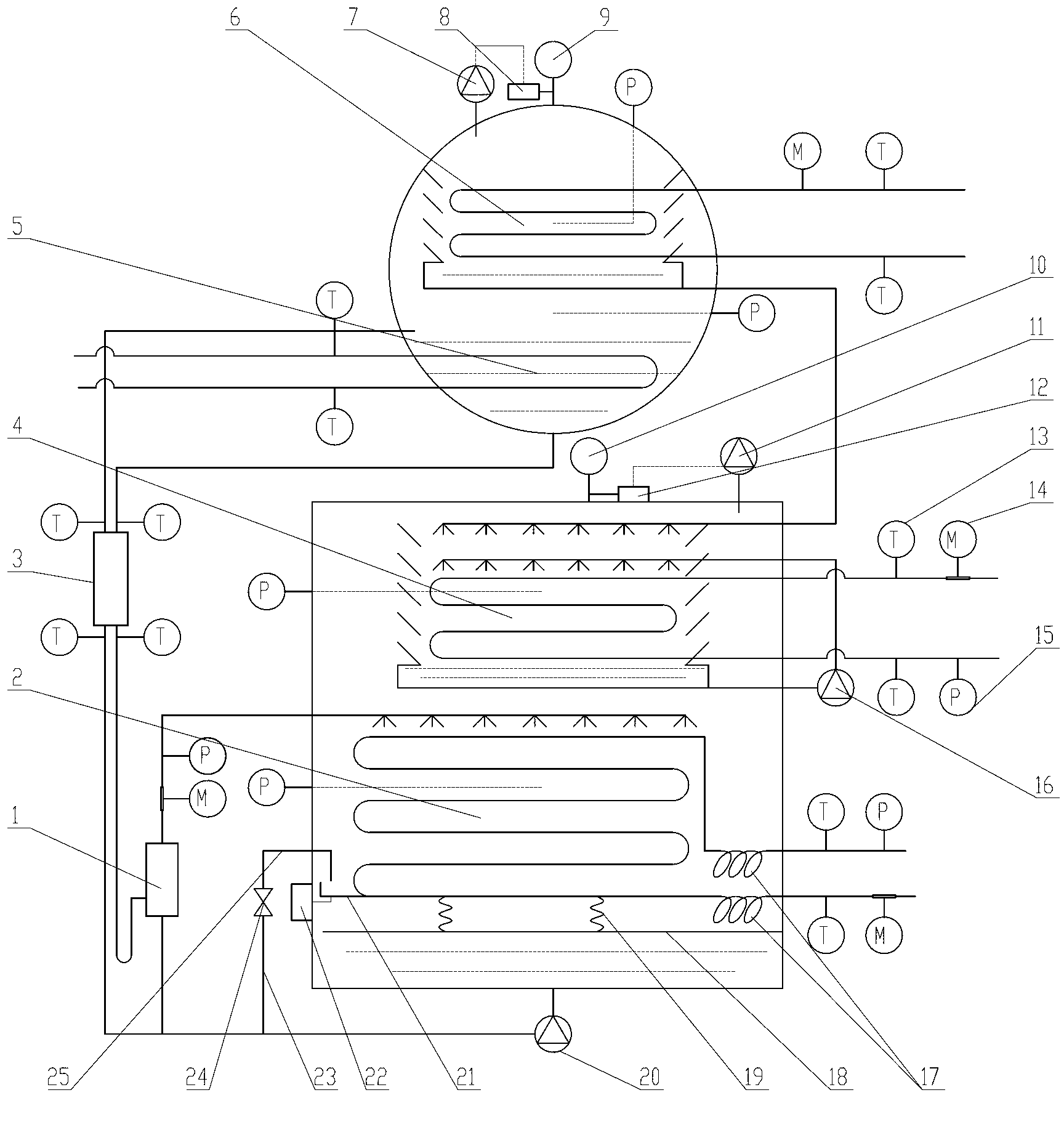

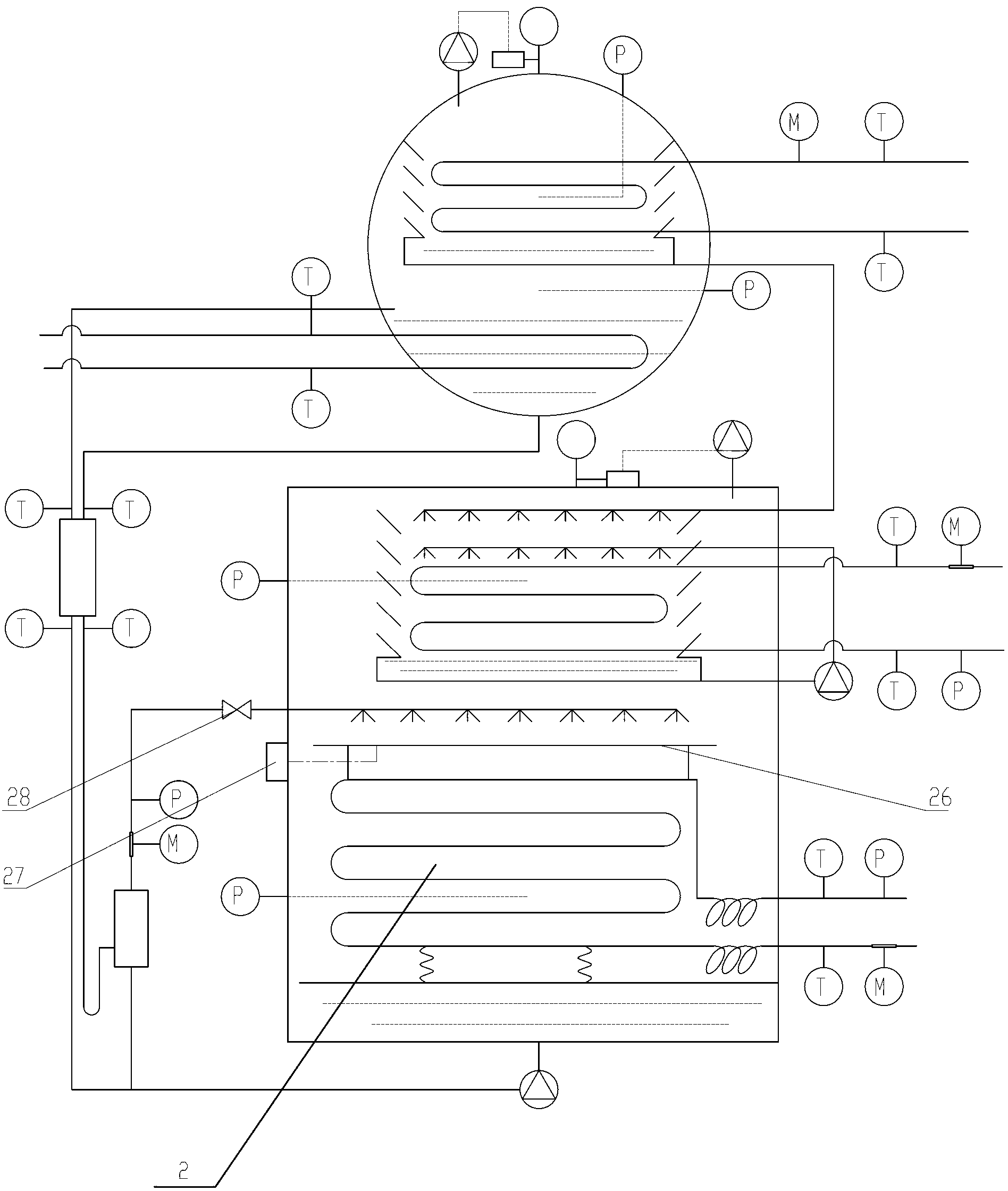

Device for rapidly and continuously preparing gas hydrate

InactiveCN108160003AImprove the efficiency of storage and transportationControl generationPressure vessel componentsPressure vessels for chemical processTemperature controlData acquisition

The invention discloses a device for rapidly and continuously preparing a gas hydrate. The device comprises a reactor with an outer water jacket, a gas supply unit for supplying a gas source to the reactor, an ice liquid supply unit for supplying an ice liquid to the reactor, a temperature control unit for controlling the temperature of the outer jacket, a hydrate filtering and collecting unit connected to the reactor and used for filtering and collecting produced hydrate crystals, and a data acquisition and processing unit for acquiring and recording the temperature and pressure data of the reactor. The rear end of the hydrate filtering and collecting unit is connected to the ice liquid supply unit through a quick-connecting valve. The device solves the problem that the conventional hydrate formation device has no a complete hydrate formation process, produces internal retention in the stirred slurry or on a magneton and has no a continuous reaction process. The experimental device issimple and economical, is easy to operate, produces a complete and uniform gas hydrate and improves the efficiency of gas storage and transportation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

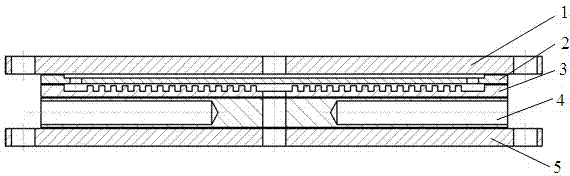

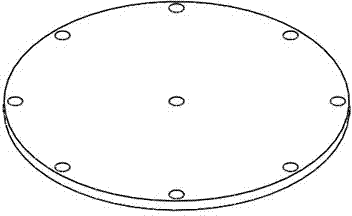

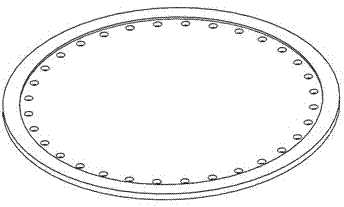

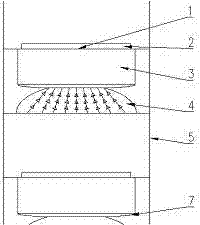

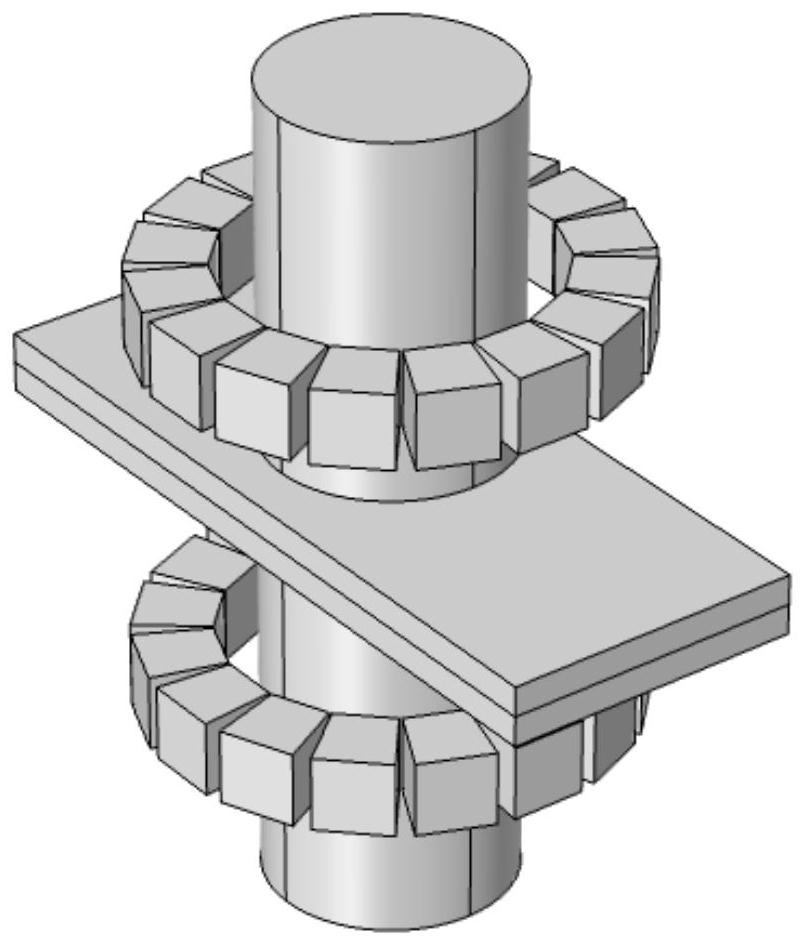

Reforming hydrogen production reactor of micro-bump structure with annular array

InactiveCN103569966AImprove distribution uniformityImprove reaction efficiencyHydrogenAlcoholEvaporation

The invention discloses a reforming hydrogen production reactor of a micro-bump structure with an annular array. The reforming hydrogen production reactor is composed of an inlet cover plate, an evaporation unit, a reaction carrier unit, a heating unit and an outlet cover plate which are stacked up from top to bottom in sequence, wherein reaction fluid flows into the micro-bump structure of the annular array through a plurality of inlets which are arranged into a circle and flows out from the center of circle, so that the distribution uniformity of the reaction fluid in the reaction carrier is improved, and the reaction efficiency of the reactor is favorably improved; the micro-bump structure of the annular array is used as the reaction carrier for the reforming hydrogen production reactor, so that the specific surface area of the reactor is increased, and meanwhile the heat transfer and mass transfer performance of the reaction are improved; the reforming hydrogen production reactor has a compact structure, is convenient to mount and lower in cost, can be widely used in the field of reforming hydrogen production of various alcohols such as hydrocarbon, methanol and alcohol.

Owner:ZHEJIANG UNIV

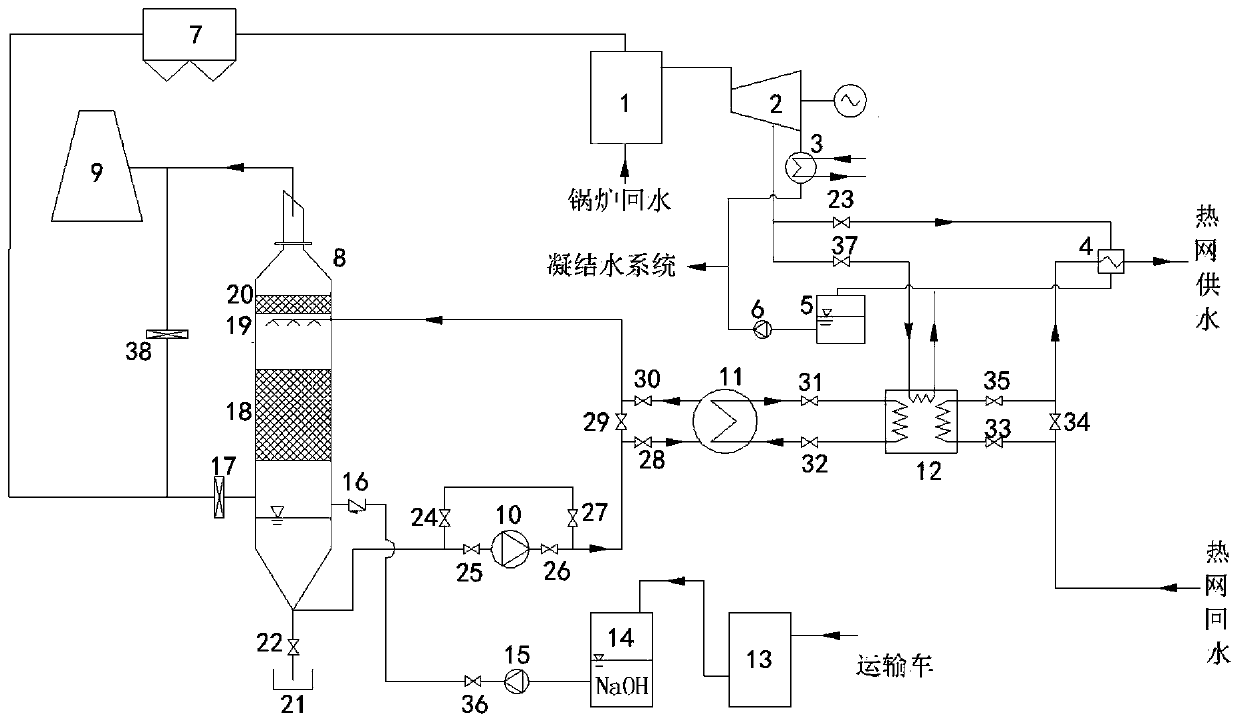

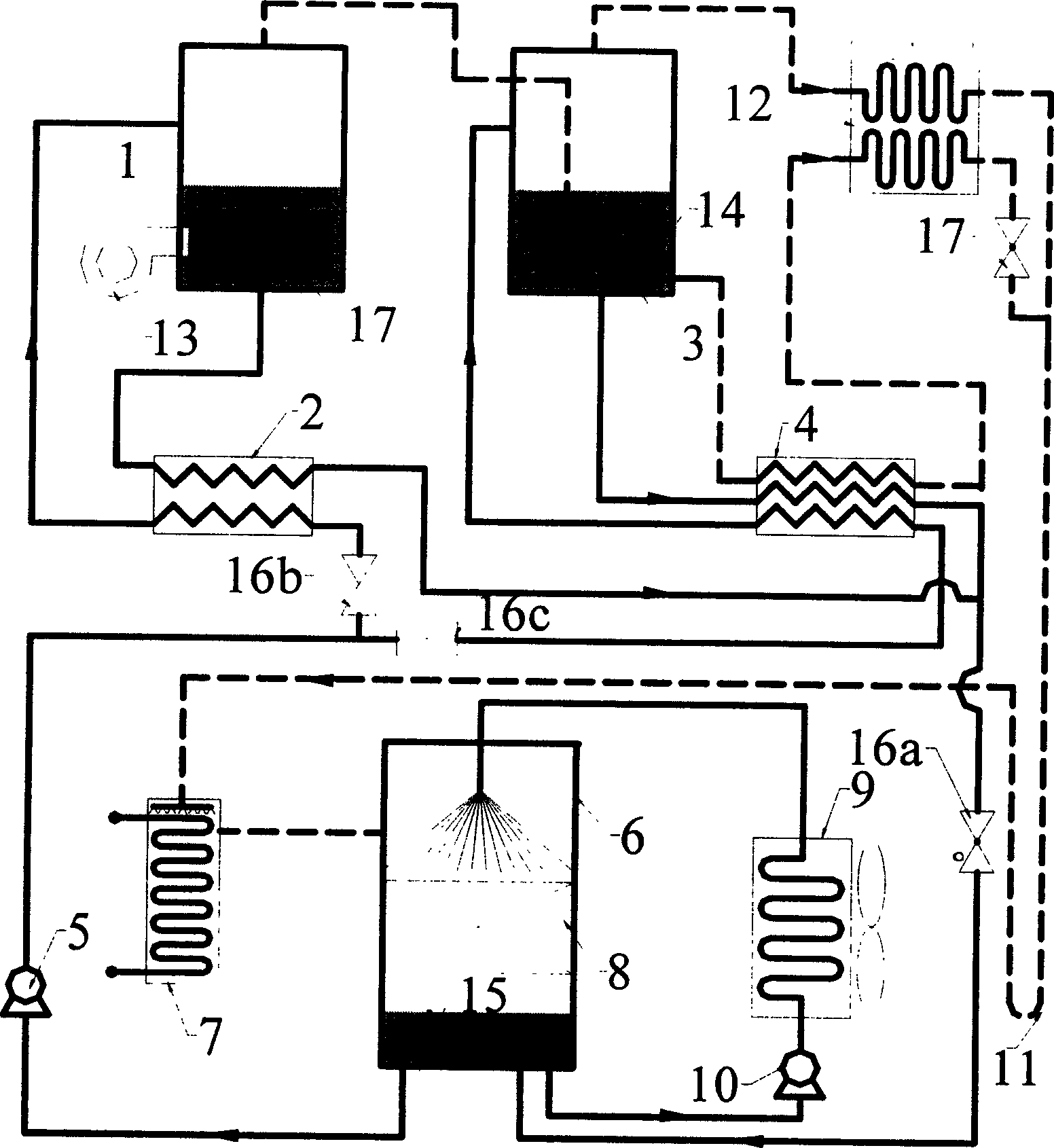

Energy saving system for adopting absorption heat pump to deeply recover smoke waste heat for central heating

PendingCN109945278AImprove work efficiencyEfficient Waste Heat RecoveryFeed water supplyEnergy efficient heating/coolingHeating systemSmoke

Owner:DALIAN UNIV OF TECH

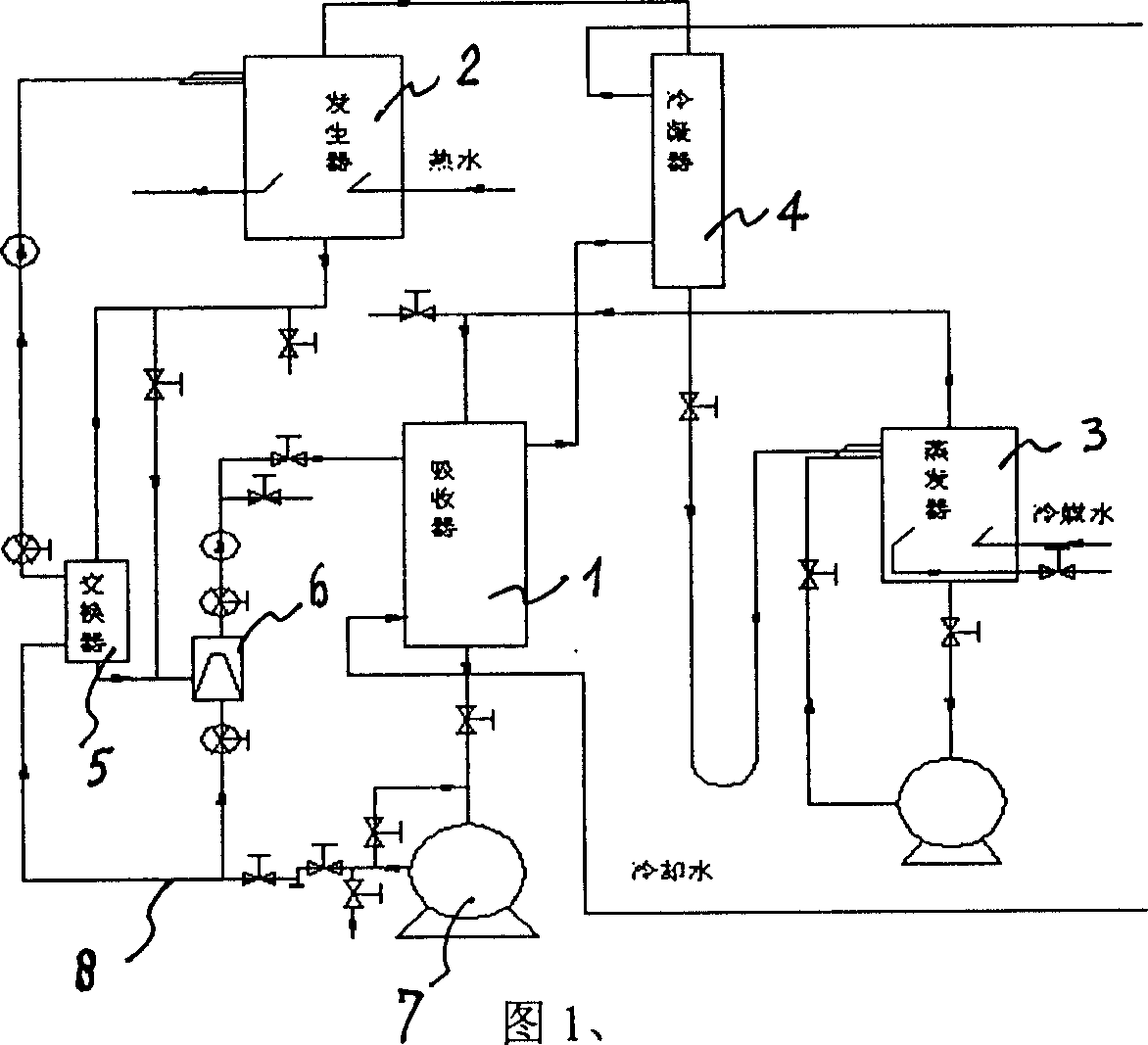

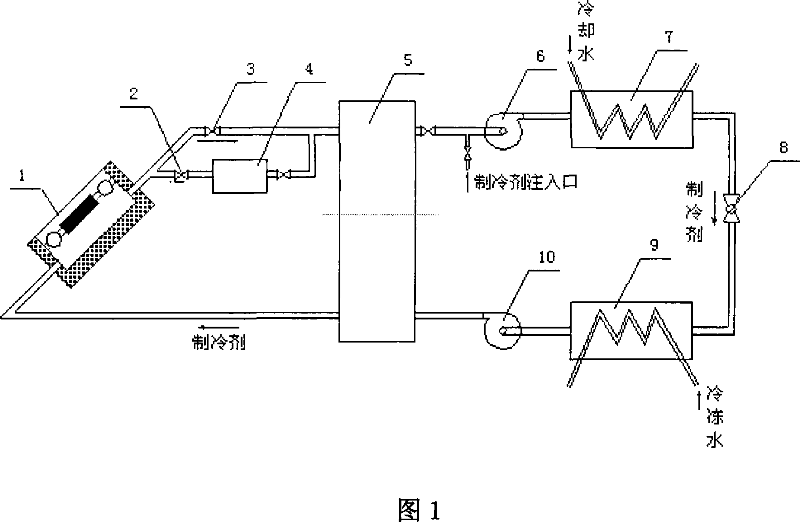

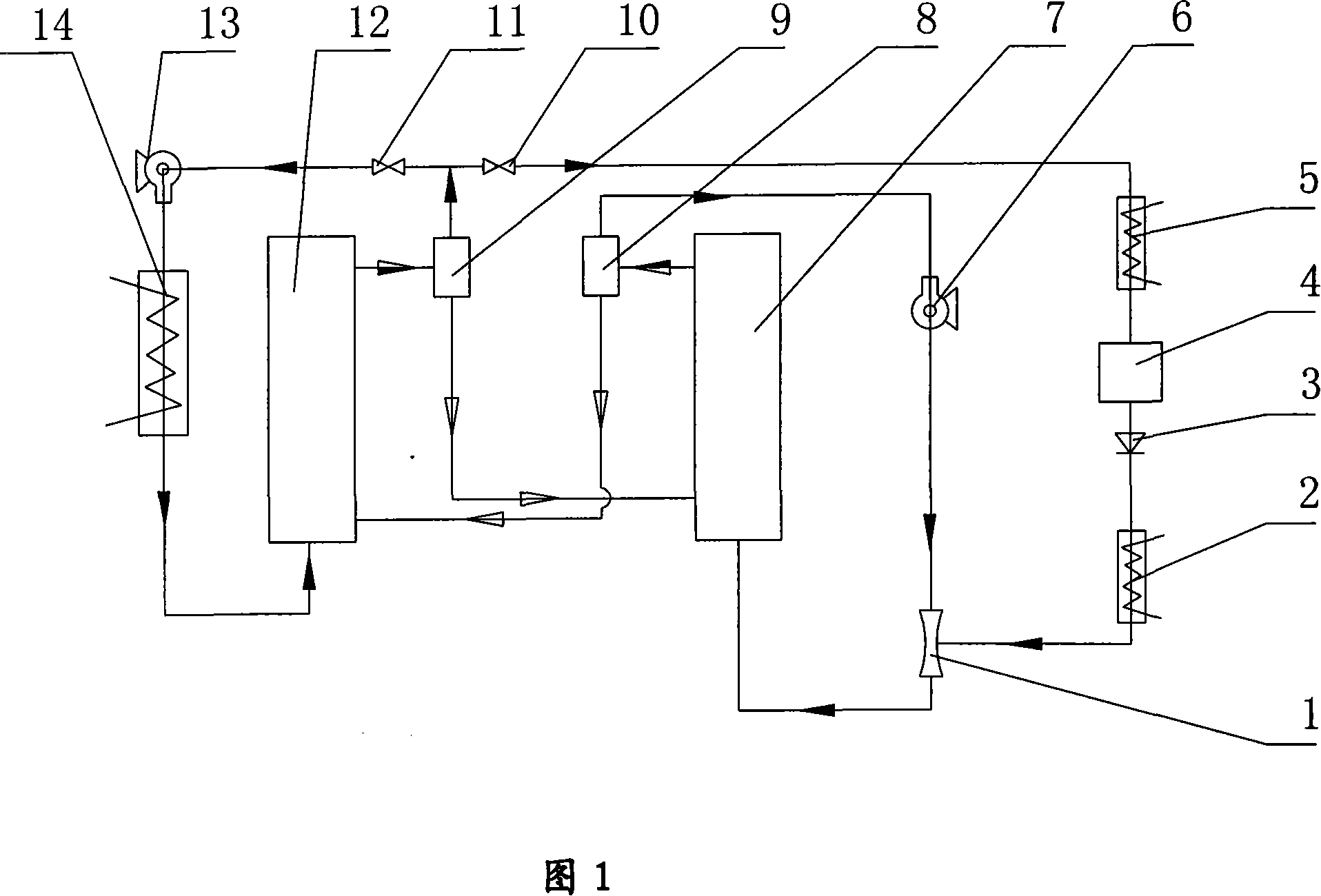

Small-sized energy-saving air-cooled thermal insulation absorption gas air-conditioning plant

InactiveCN1595016AAvoid potential hazardsOvercome inherent flawsClimate change adaptationEnergy efficient heating/coolingThermal insulationLow voltage

The invention supplies a minitype energy saving adiabatic fuel gas absorption air conditioning, comprising high voltage generator, low voltage generator, high temperature heat exchanger, low temperature heat exchanger, condenser, evaporator, absorption machine, air cooling machine, liquid pump and recycling pump. Residual heat of saturated cryogen of heat exchanger outlet of low voltage generator is recovered in low temperature heat exchanger, cryogen condenser and absorber liquid cooler both use air patenting method, absorber without heat exchanger in it has packing within. The heat transfer and mass transfer course is strengthened by using air patenting adiabatic absorption to divide the course into steps, and surface square of absorber is reduced, solving the problem exist in falling film of air patenting pipe and ensuring the system operating reliable and energy-saving, in addition , it avoids potential danger of refrigerant in electricity driving air conditioning, reducing electric power hill and dale difference in summer, eliminates all disadvantages exist in water cooling fuel gas air conditioning, it is safe and healthy, easy to control and has a wide use.

Owner:ZHEJIANG UNIV

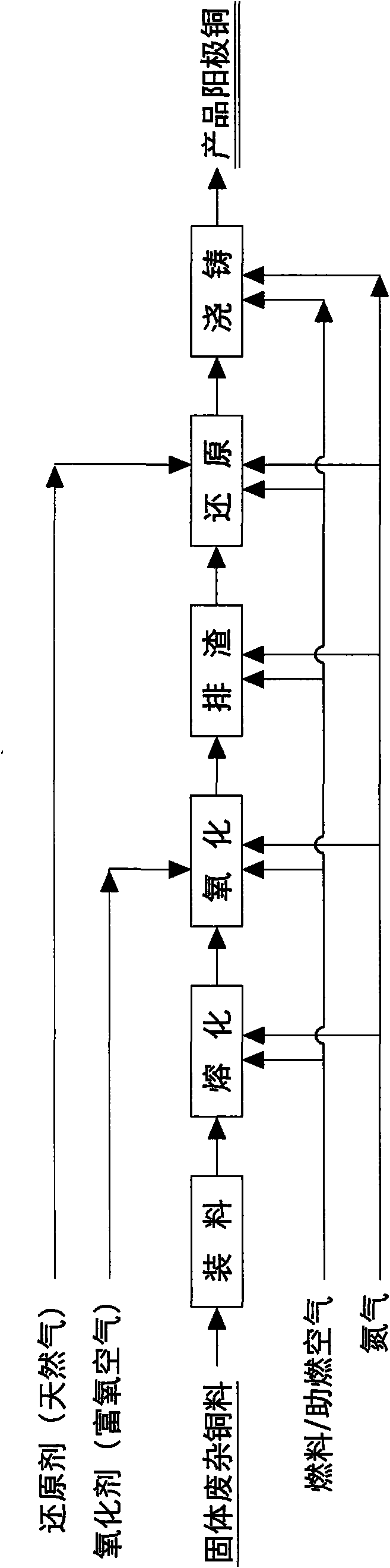

Process and apparatus thereof for refining copper scraps by using nitrogen gas stirring and oxygen-enriched oxygen gas

ActiveCN101638724ARefining reaction speed upIncrease productivityRotary drum furnacesProcess efficiency improvementNitrogen gasImpurity

Owner:CHINA NERIN ENG +1

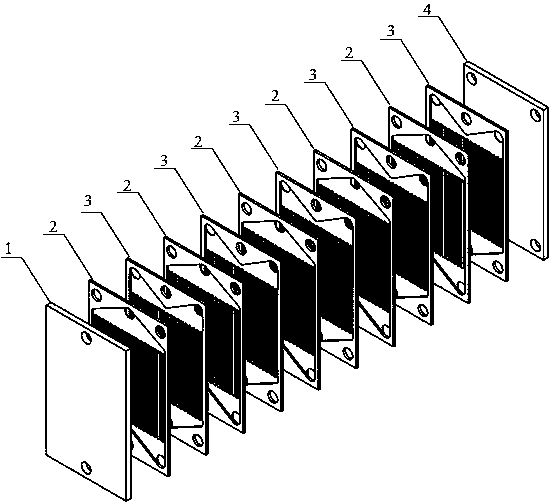

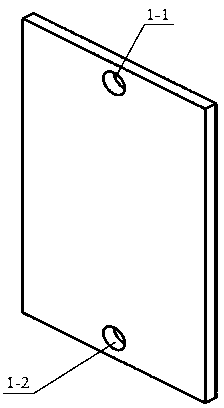

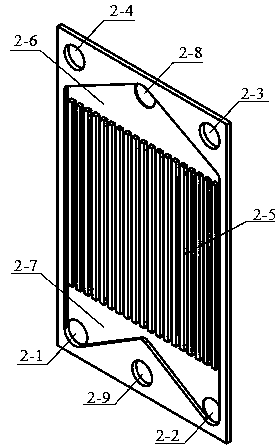

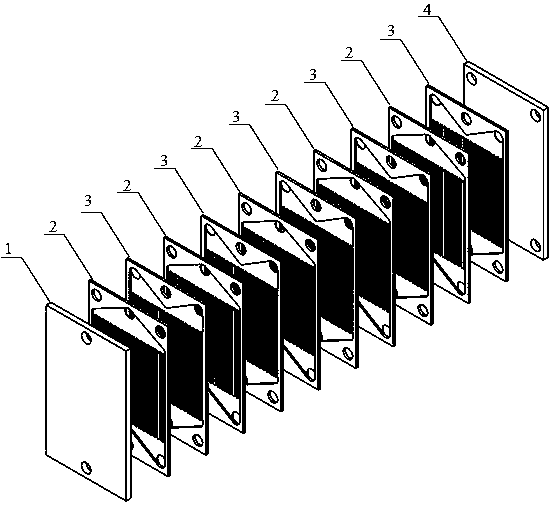

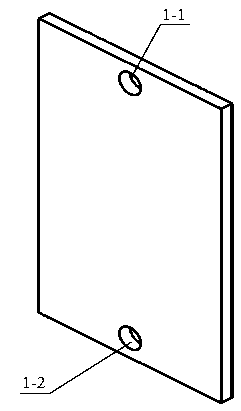

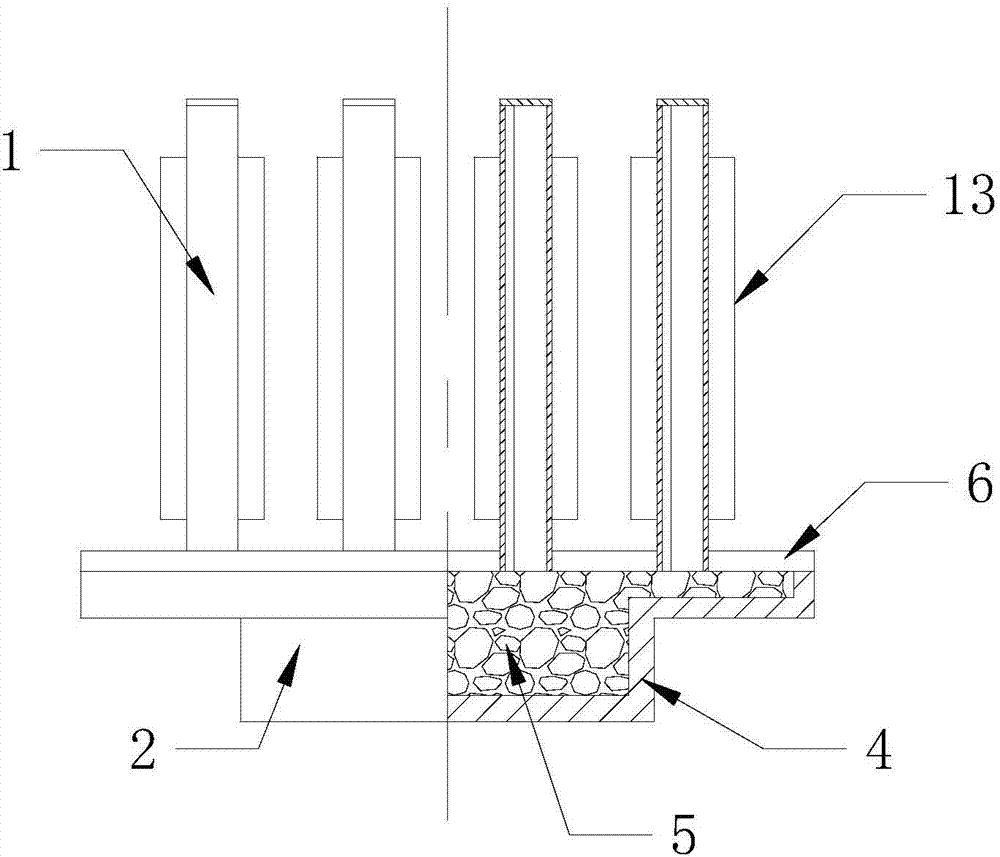

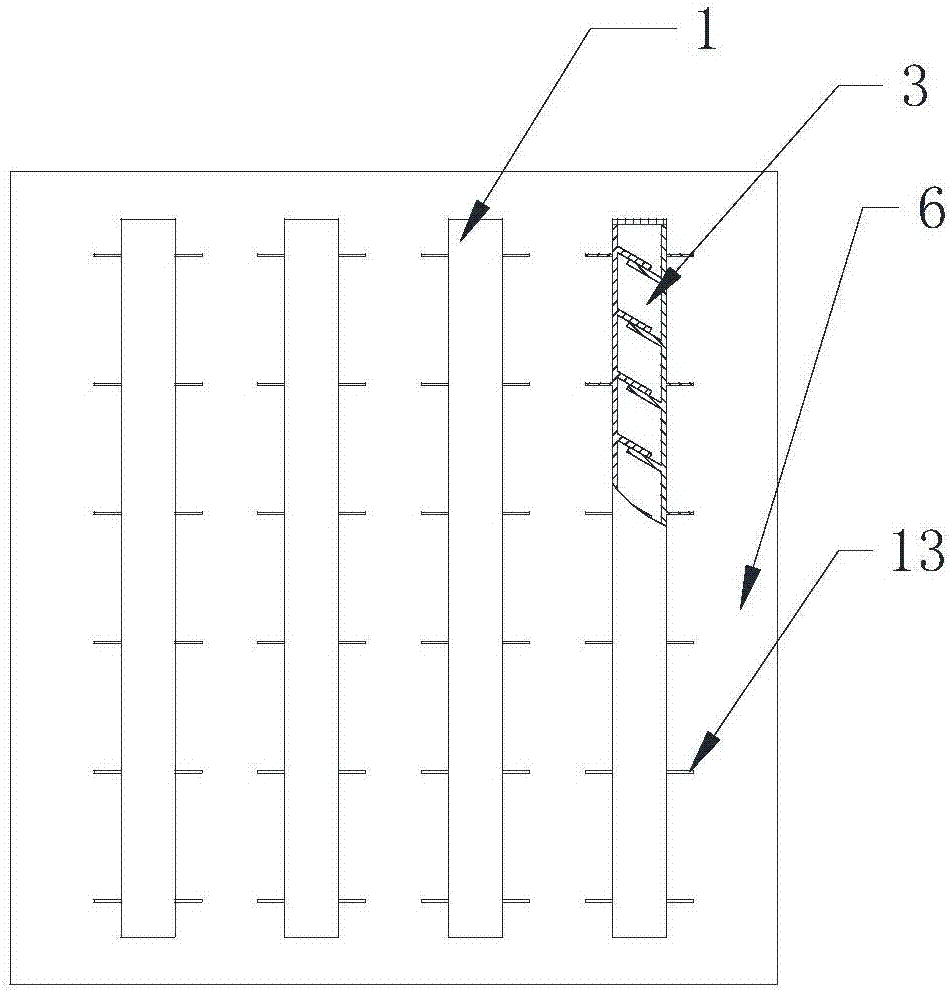

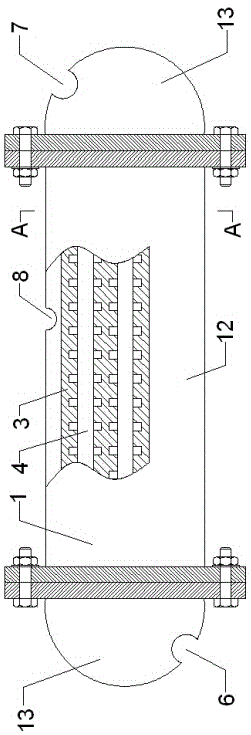

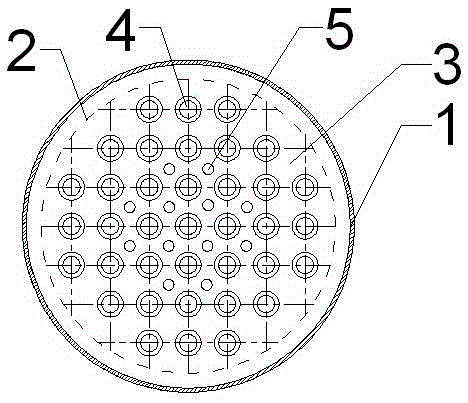

Layered micro-channel reactor with uniformly distributed micro-channel flow velocities

InactiveCN103418321BHigh heat and mass transferReduce distanceChemical/physical/physico-chemical processesEngineeringMultiple layer

Owner:ZHEJIANG UNIV

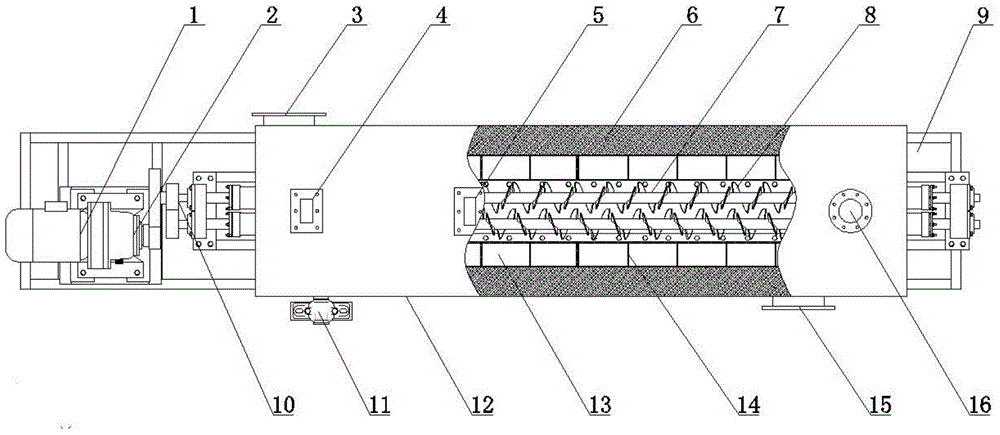

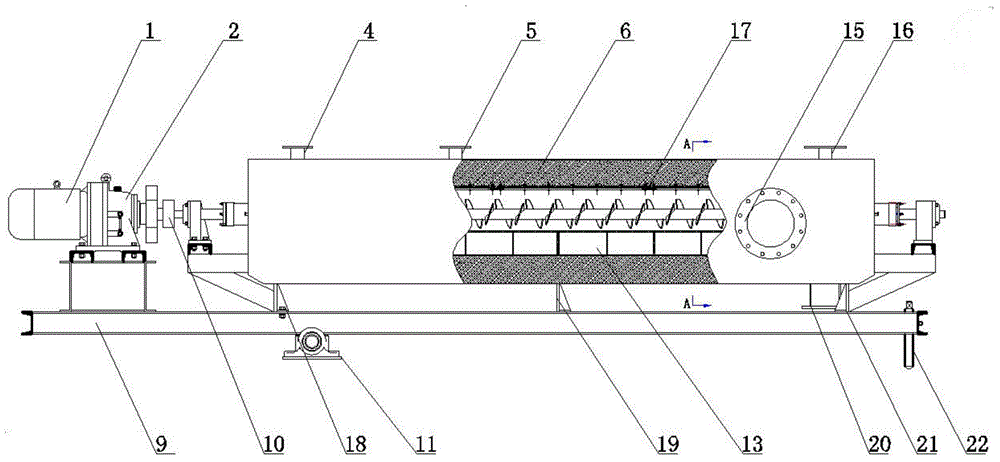

Biomass double-shaft screw pyrolysis device

InactiveCN104531227AThe experimental system is simpleImprove gasification efficiencyGasifier feeding meansCombustible gas productionSyngasBreathing

The invention discloses a biomass double-shaft screw pyrolysis device. The biomass double-shaft screw pyrolysis device comprises a hollow cylindrical enclosure with a U-shaped cross section, wherein an opening of the hollow cylindrical enclosure is sealed by a seal cover of a machine cover, thereby forming a sealed reaction region; the reaction region formed in the enclosure in the axial direction is sequentially divided into a plurality of individual pyrolysis sub regions; the cylinder wall of the enclosure is of a hollow sandwiched structure so as to act as a flue gas channel; the enclosure is centrally provided with double-shaft screw packing augers which penetrate through the reaction region axially; the rotation directions of the two packing augers are opposite; biomass entering from a biomass inlet is mixed and conveyed by the double-shaft screw packing augers, is baked in the baking sub regions sequentially, and is respectively subjected to catalytic gasification and reforming in gasification sub regions and reforming sub regions, so that high-quality synthesized gas products are generated and are discharged from a pyrolysis gas outlet. The biomass double-shaft screw pyrolysis device intensifies the material mixing and heat transferring and mass transferring effects; biomass is gasified efficiently by adopting the inner and outer thermal combination and catalytic effect, so that the problem of axial and radial breathing of the screw pyrolysis device in running at high temperature is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

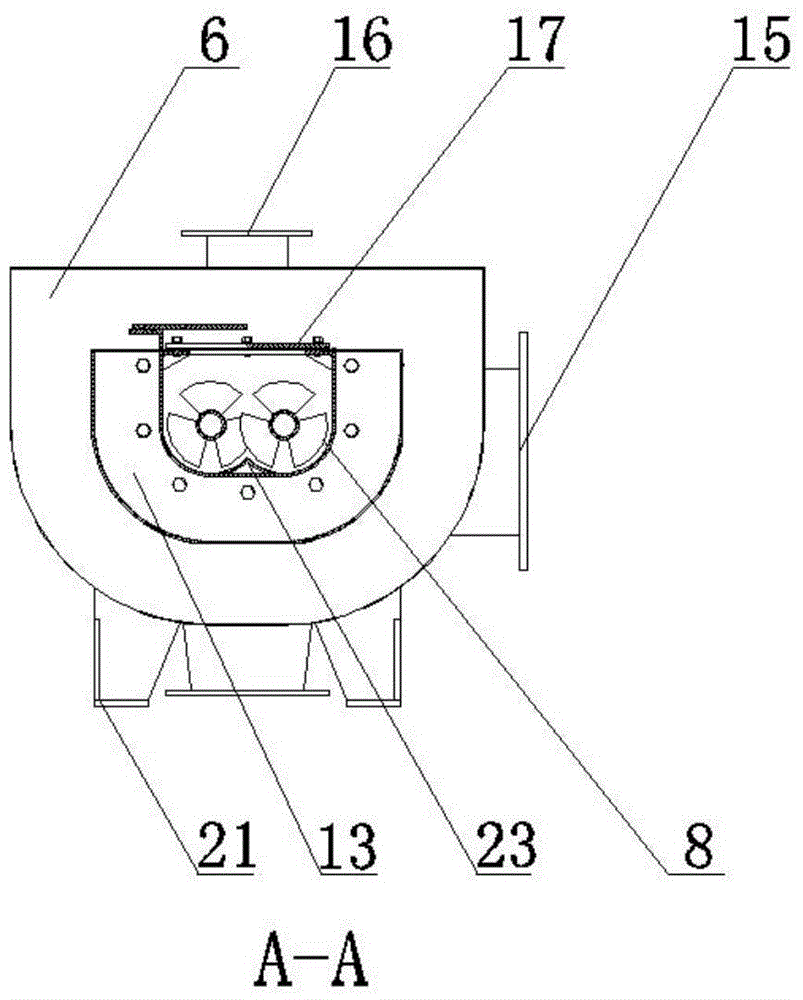

All fins heat-exchanger combined lithium bromide absorption refrigerator

InactiveCN1502954AImprove cooling effectEfficient heatingClimate change adaptationEnergy efficient heating/coolingLithium bromideEngineering

The present invention relates to a lithium bromide absorption type refrigeration equipment formed from all plate fin type thermal mass exchange. It mainly includes absorber, generator, evaporator, condenser and solution exchanger, etc. It is characterized by that the above-mentioned every component is formed from reasonably remoulded plate fin type thermal mass exchanger, and very componnet liquid can be effectively cooled or heated, so that its heat transfer and mass transfer capacity can be greatly raised.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

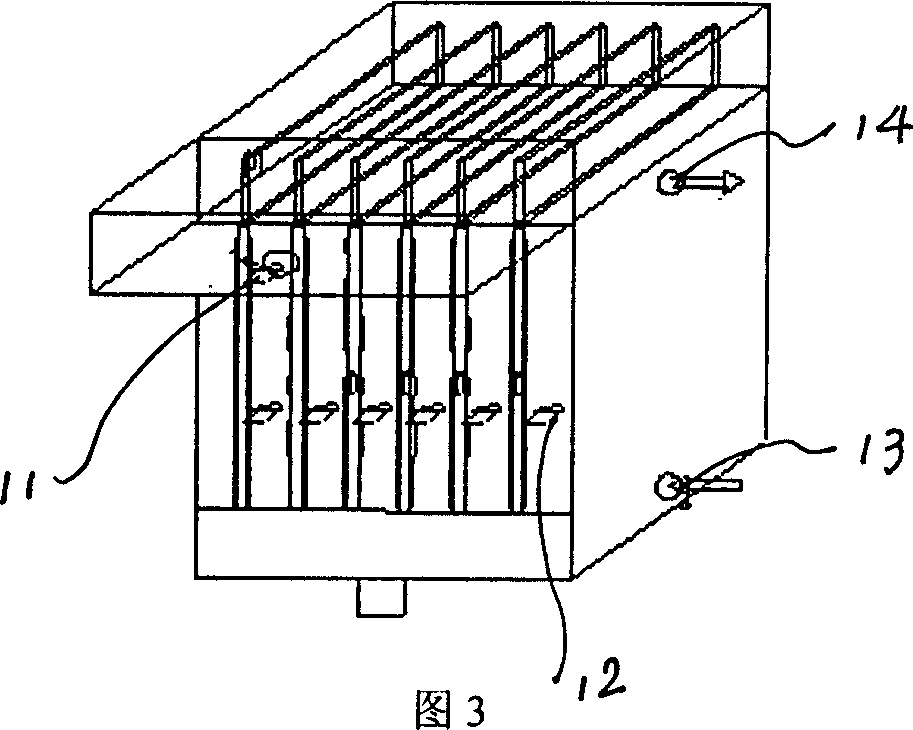

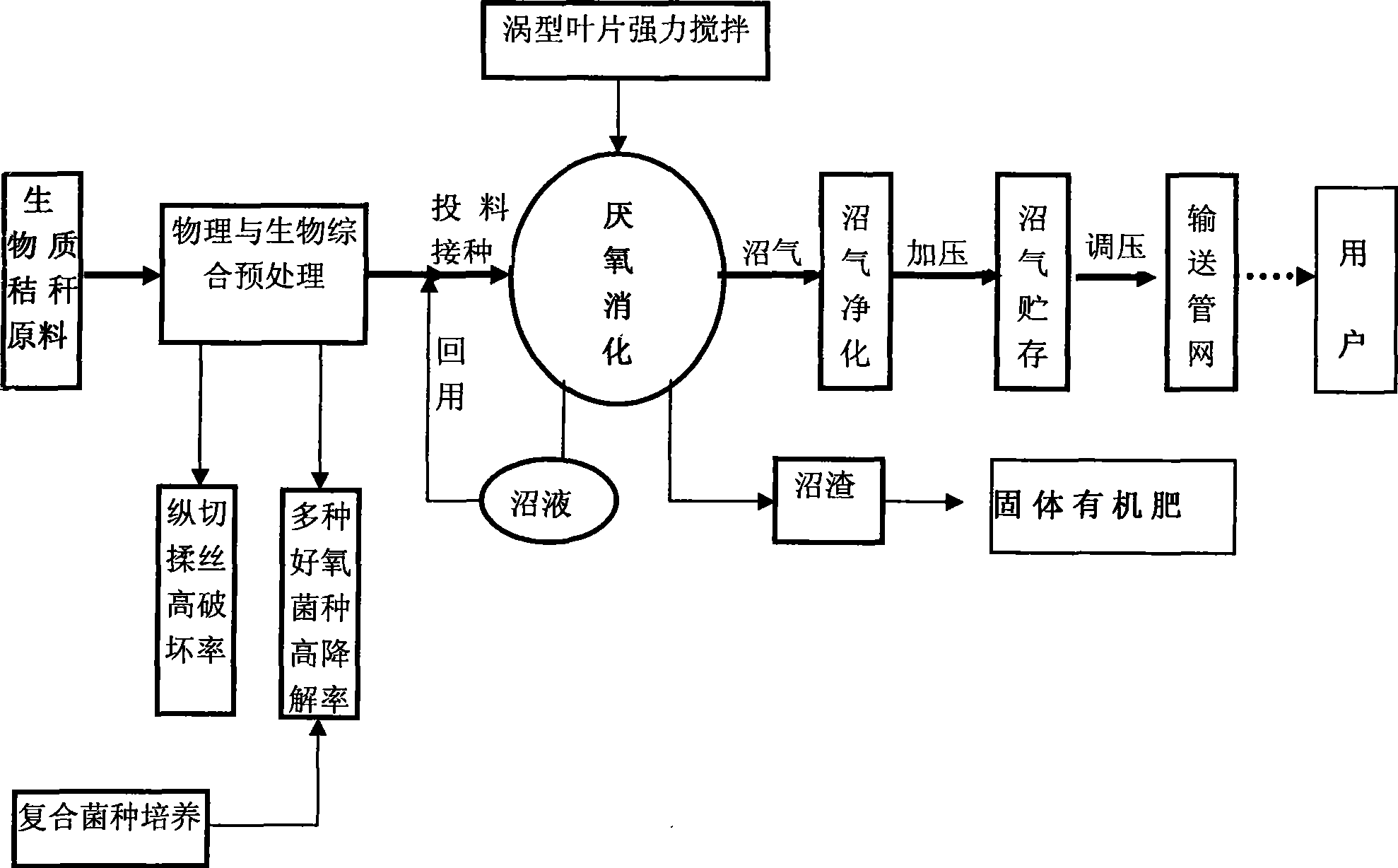

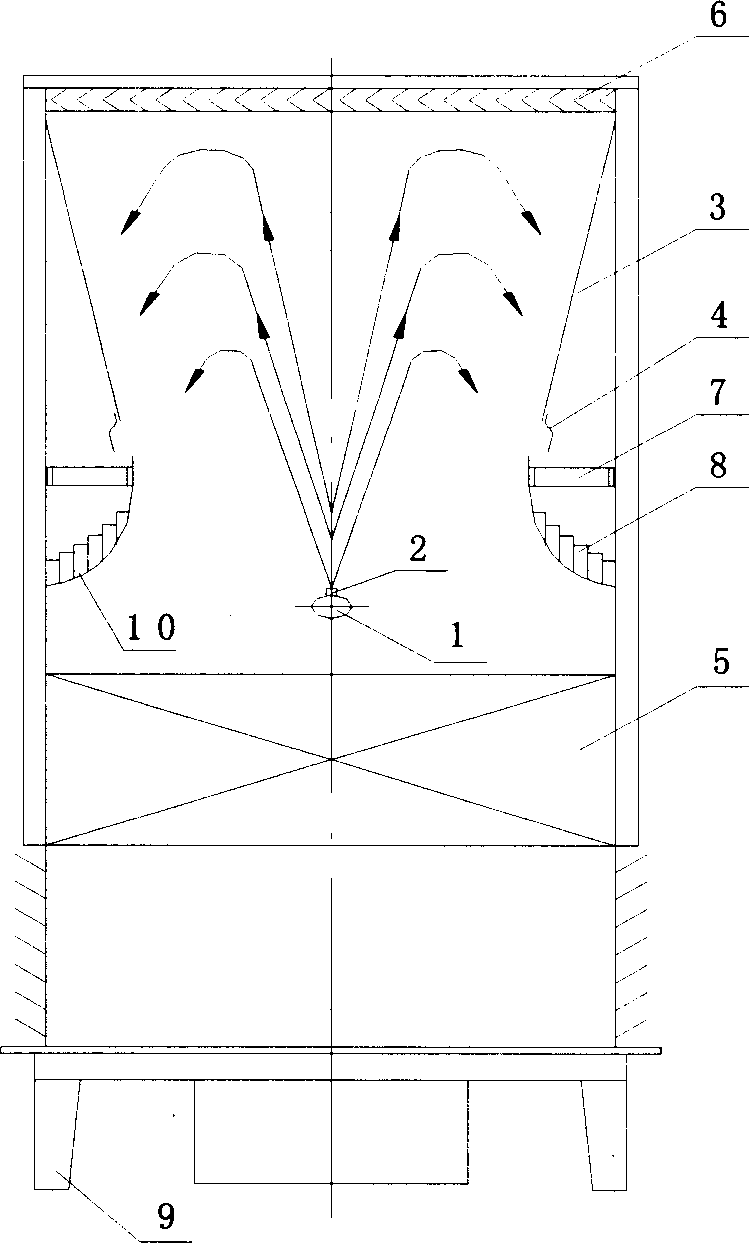

Pure stalk fermentation biogas preparation process and apparatus based on composite strain degradation

InactiveCN101497893AEasy to useEasy to transportBio-organic fraction processingClimate change adaptationMicroorganismPhysical separation

The invention relates to a technique for preparing methane through straw stalks fermentation only based on multi-microorganism degradation, which comprises the following steps: A. physical and biologic comprehensive pretreatment is carried out on biomass straw stalk raw materials; B. the biomass straw stalk raw materials which are comprehensively pretreated are thoroughly degraded and thrown into an anaerobic fermentation reactor together with fermentation inoculation strains for anaerobic reaction and methane preparation; C. the output methane of the step B is desulfurized, enters into a gas-storing device and is delivered to users through a transmission pipeline network; D. methane residues and methane liquid of the step B after the anaerobic reaction are discharged, the methane residues can be used as solid organic fertilizer through physical separation, and the methane liquid refluxes to the anaerobic fermentation reactor for reutilization. The invention also discloses a device for preparing the methane through straw stalks fermentation only based on multi-microorganism degradation. The time of traditional technique for straw stalks pretreatment is 10-15 days; however, the time of the technique for straw stalks pretreatment is only 5 days and the degradation efficiency of the technique is 1.3-1.5 times as high as that of the traditional technique.

Owner:SHANDONG UNIV

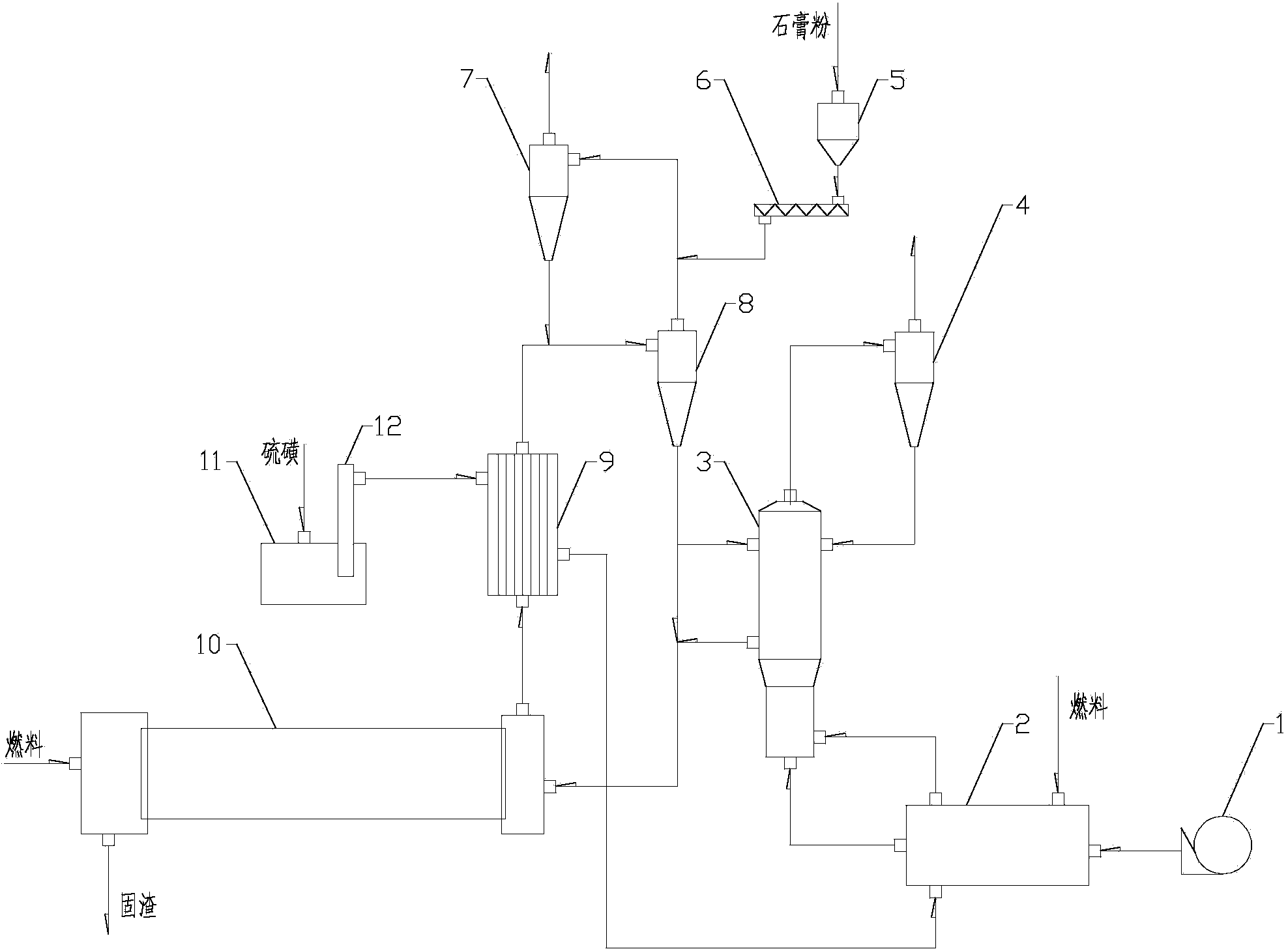

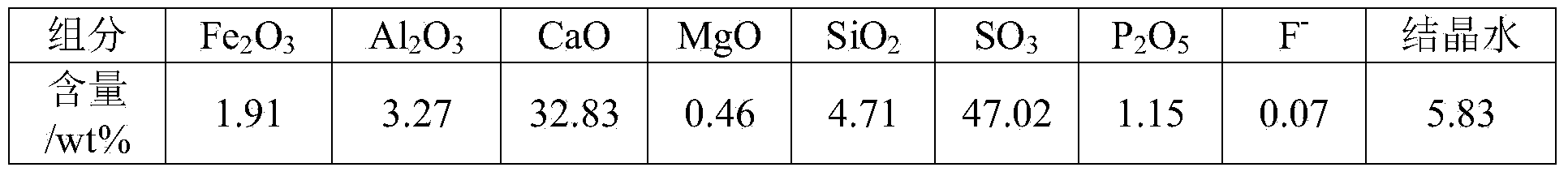

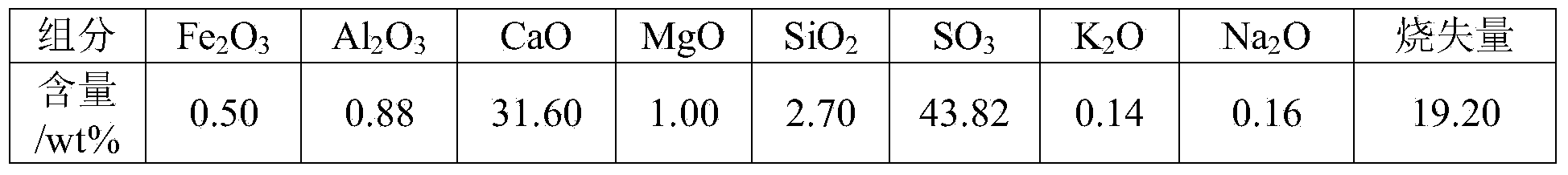

Process for decomposing gypsum through spraying and fluidizing

ActiveCN103818884AHigh partial pressure ratioIncrease contact areaChemical industrySulfur compoundsDecompositionCalcium sulfide

The invention relates to the technical field of fluidized decomposition and calcination of gypsum, and particularly discloses a process for producing sulfuric acid by spraying, fluidizing, decomposing and calcining gypsum efficiently. The process comprises the following steps: gasifying brimstone; preheating raw gypsum; spraying, fluidizing and decomposing gypsum to prepare calcium sulfide and sulfur dioxide; preparing sulfur dioxide by calcining and decomposing the prepared calcium sulfide and heated gypsum; preparing sulfuric acid by treating the tail gas. Through the adoption of spraying and fluidizing technology, out-kiln decomposition of gypsum during acid making is realized; the calcium sulfide can be prepared efficiently with low cost; then the calcium sulfide and the preheated gypsum are calcined together for decomposition to prepare the sulfur dioxide. Therefore, the process is absolutely an excellent process for industrialized continuous production, is high in economic benefits and energy utilization ratio.

Owner:SICHUAN HONGDA

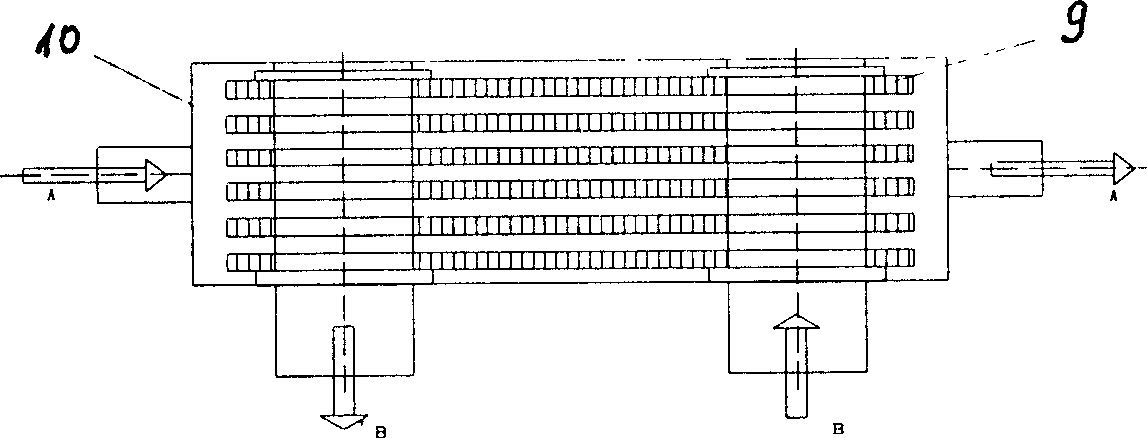

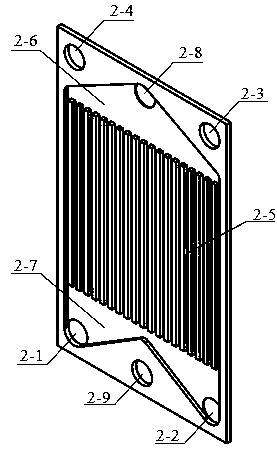

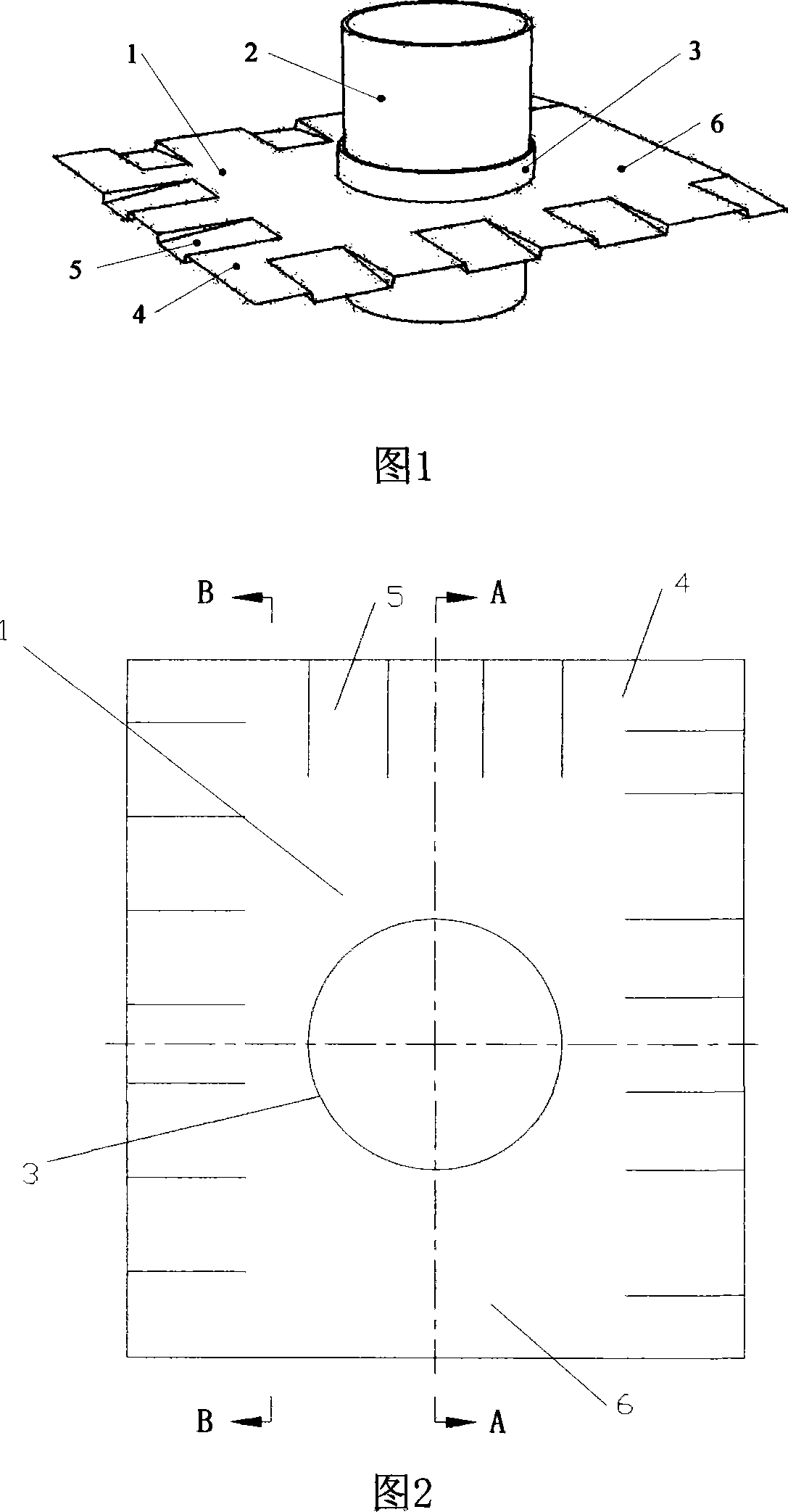

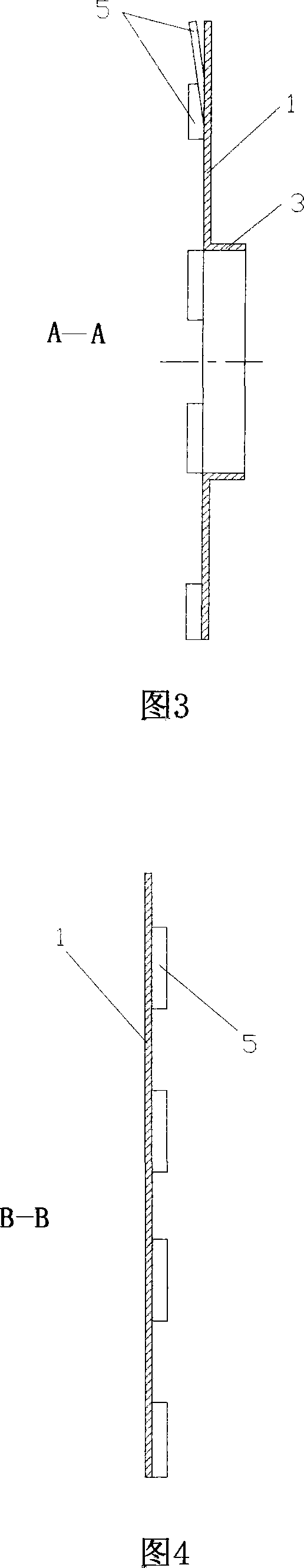

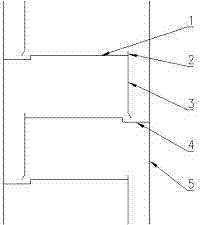

Layered micro-channel reactor with uniformly distributed micro-channel flow velocities

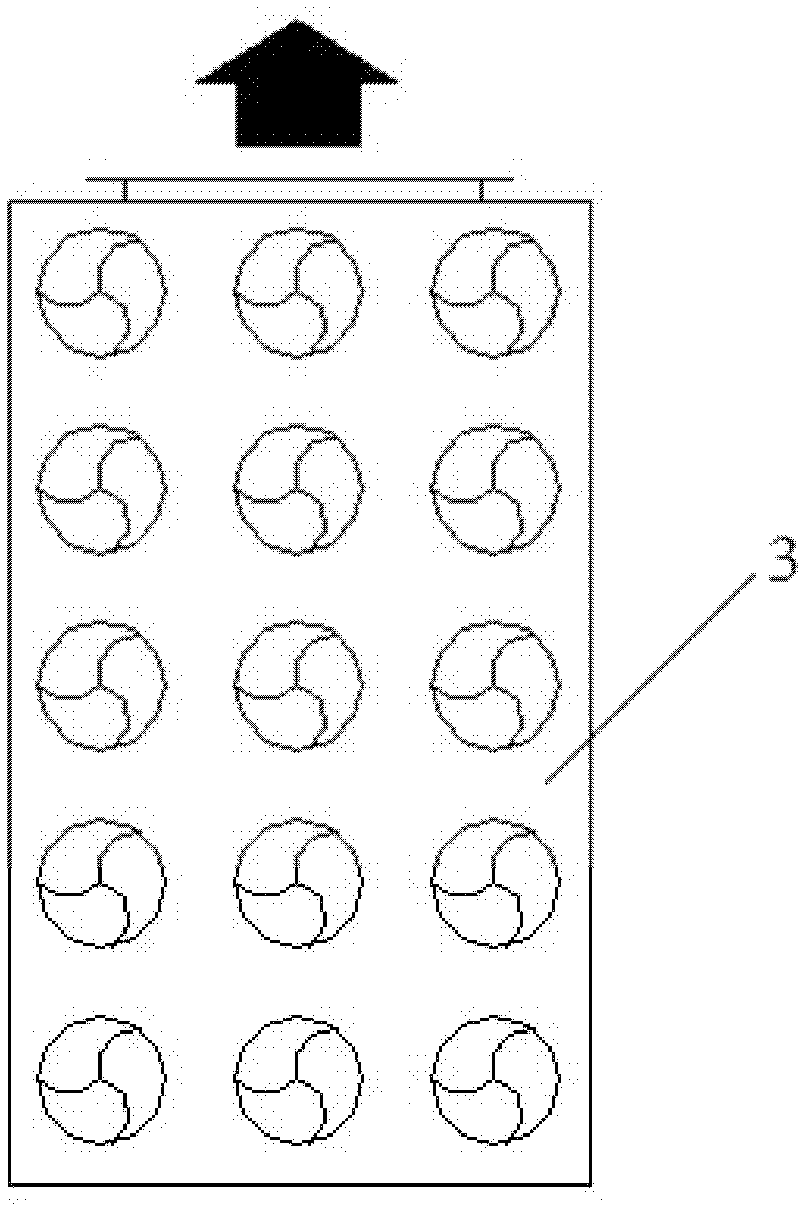

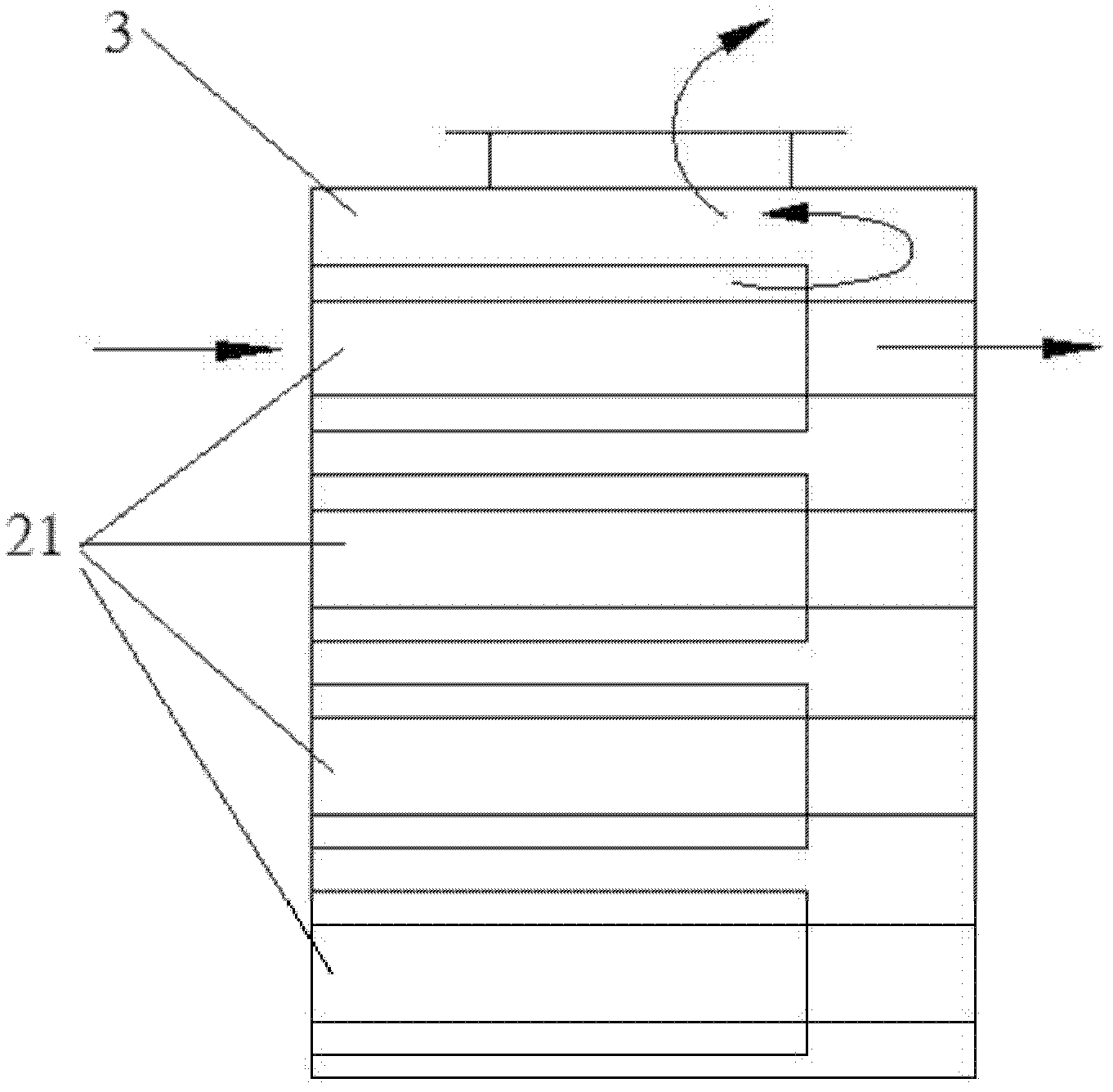

InactiveCN103418321AHigh heat and mass transferReduce distanceChemical/physical/physico-chemical processesEngineeringFluid pressure

The invention discloses a layered micro-channel reactor with uniformly distributed micro-channel flow velocities. The layered micro-channel reactor comprises an inlet cover plate, first reaction plates, second reaction plates and an outlet cover plate. Micro-channel arrays are machined on the first reaction plates and the second reaction plates, and the first reaction plates and the second reaction plates are alternately overlaid between the inlet cover plate and the outlet cover plate which are oppositely placed. Reaction fluid flows into the micro-channel arrays from an inlet and flows out of two outlets, the flow velocity distribution uniformity of the reaction fluid in the micro-channel arrays is improved, and accordingly the reaction efficiency of the micro-channel reactor can be effectively improved. Besides, pressure loss caused when the fluid flows through the micro-channel reactor can be effectively reduced owing to a distribution structure with the single inlet and the two outlets. The multiple layers of first reaction plates and the multiple layers of second reaction plates are overlaid, so that the reaction scope can be expanded, and the reaction efficiency can be improved. Compared with an existing micro-channel reactor with a single inlet and a single outlet, the layered micro-channel reactor has the advantages that the reaction uniformity can be improved, and the layered micro-channel reactor is high in reaction efficiency and low in fluid pressure loss.

Owner:ZHEJIANG UNIV

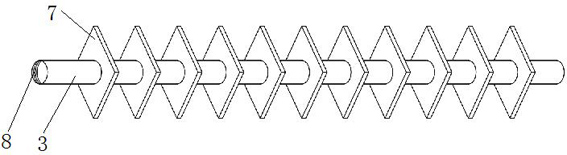

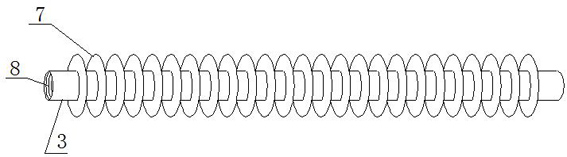

Rectangular offset strip fin heat transfer pipe and uses thereof

InactiveCN101216269AHigh heat and mass transferImprove heat transfer coefficientTubular elementsCondensation processEngineering

The invention provides a heat transfer tube with rectangular staggered fins and application thereof. The inventive heat transfer tube comprises a tube body and a plurality of rectangular staggered fins fixed on the tube body. The outer edge of the lee side of rectangular staggered fin is flat, and the other three outer edges are staggered in cross section along thickness direction and respectively provided with 5-8 sphenoid narrow grooves. The inventive heat transfer tube with the rectangular staggered fins can be used for heat and mass exchange equipment in gas-solid sublimation process and gas-liquid condensation process. The invention has simple structure and low manufacturing cost, can improve local turbulence, and can remarkably reinforce gas lateral heat exchange and phase-change heat transfer and mass transfer processes.

Owner:DONGGUAN UNIV OF TECH

Liquid-accommodation diversion type drop pipe

InactiveCN104722095AOutflow smoothlyFinely dispersedDispersed particle separationDistillation separationPlate pressureSingle stage

The invention discloses a liquid-accommodation diversion type drop pipe comprising a pipe body, overflow weirs, single-stage or multiple-stage liquid accommodating chambers clinging to the tower wall and pipe wall, liquid accommodating plates of the bottom of the pipe body and drop plates. According to the drop pipe, the liquid phase and gas phase flowing and contacting state in a tower is changed, the gas and liquid contacting and separating strength is enhanced, the purposes of improving the tower distillating efficiency and operational flexibility and increasing the tower flux can be achieved, the tower blockage prevention capability is improved, the tower plate pressure drop is reduced, energy consumption and equipment investment are reduced, and the comprehensive performances of the tower are improved.

Owner:万强

Heat pipe radiator with variable-section hot end and multiple pulsation cold ends

The invention provides a heat pipe radiator with a variable-section hot end and multiple pulsation cold ends. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends comprises the pulsation cold ends and the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is characterized in that each pulsation cold end is a heat dissipating plate internally provided with multiple pulsation channels, the hot end is a hollow cavity, the cavity is filled with a working medium and a capillary liquid absorbing core, an upper cover plate of the hot end hollow cavity is provided with multiple cold end connectors, each cold end connector is provided with one pulsation cold end, and the pulsation channels of the pulsation cold ends communicate with the hollow cavity of the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is simple in structure, easy to manufacture and capable of being transversely and vertically used, the variable-section structure is adopted, so that the pressure bearing capacity of heat pipes can be improved, especially the heat dissipating area of the cold ends is increased, the two thermal processes of evaporation and condensation adopt a pulsation heat transferring mode and a porous medium heat transferring mode correspondingly, the heat transferring performance and the medium transferring performance are effectively improved, backflow is uniform, the temperature uniformity is good, and the heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is suitable for industrial manufacturing.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

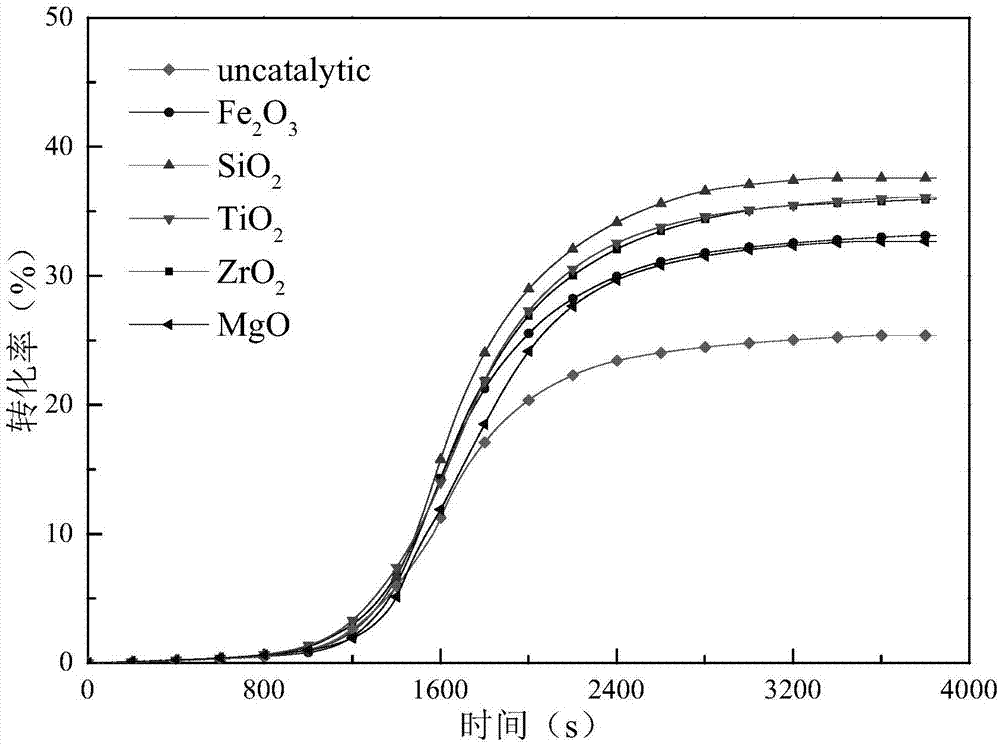

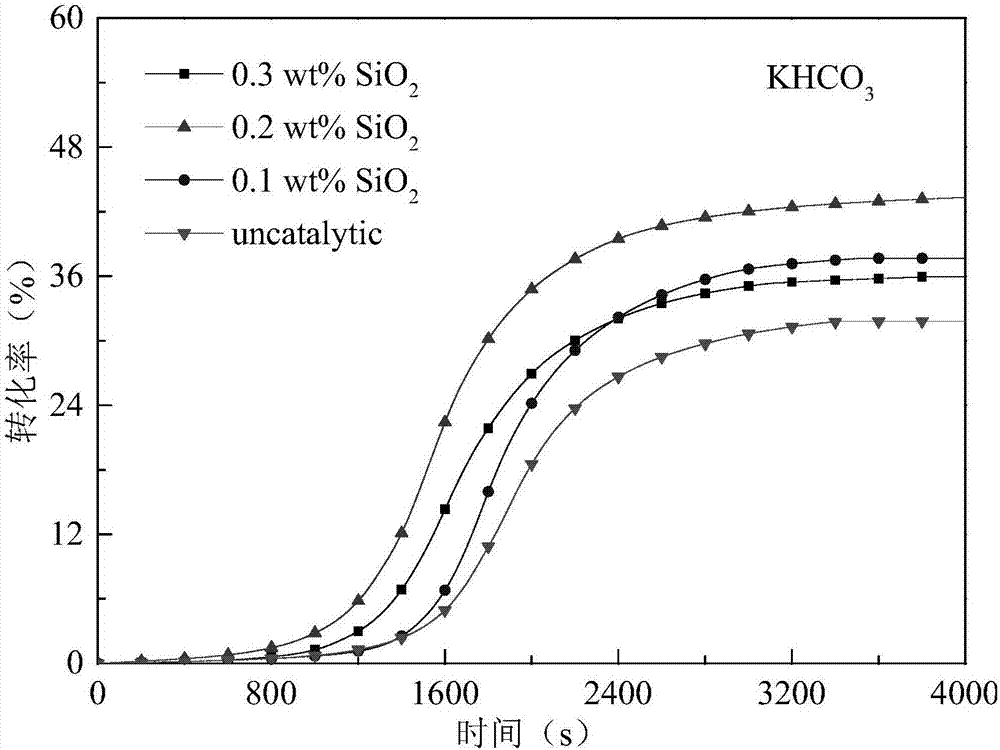

Alkali-metal-based nano fluid CO2 absorption solution

InactiveCN107261762AReduce energy consumptionNot volatileDispersed particle separationAir quality improvementBrown iron oxideMagnesium

The present invention discloses an alkali-metal-based nano fluid CO2 absorption solution. An aqueous solution of alkali-metal-based carbonate (potassium carbonate or sodium carbonate) is used as a base liquid of the absorption solution, the alkali-metal-based carbonate accounts for 5% to 70% of the total mass of the aqueous solution, one of nano silicon oxide, nano iron oxide, nano zirconia, nano titanium oxide and nano magnesium oxide is used as an additive, the additive accounts for 0.1% to 1% of the total mass of the aqueous solution, one of hydroxyethyl cellulose, sodium stearate and sodium dodecyl sulfate is used as a dispersant, and the dispersant accounts for 0.1% to 1% of the total mass of the aqueous solution. The absorption temperature of the CO2 absorption solution is 10 to 50 DEG C, the regeneration temperature is 60-150 DEG C, at the same time, the CO2 absorption solution is convenient to cycle and transport, not easy to wear, less in equipment corrosion, high in CO2 removal efficiency, low in energy consumption, energy-saving and environmentally-friendly.

Owner:NANJING UNIV OF SCI & TECH

Absorber used in solar refrigeration equipment

InactiveCN101038112AEnables continuous cooling processPrevent leakageAbsorbers/adsorbersEngineeringRefrigeration

The present invention provides a rotary absorber for solving the fault existing in heat exchanging and energy lost of existing solar solid absorber. The rotary absorber includes a rotary wheel, a cooling device and a rotary device. The rotary absorber is characterized in that the rotary wheel includes a rotary wheel housing connected to the rotary device, a wheel body and front, rear block plates fixed on the two end surfaces of the wheel body. The wheel body includes a rotary shaft and a wheel hub which is disposed with radiate wedge-shaped absorb beds on the circumferential direction. A wedge-shaped mass transfer passage is disposed between each two adjacent wedge-shaped absorb beds, the radiate end circle of the wedge-shaped absorb bed is fixed on the inner wall of the rotary wheel housing; the two end surfaces of the wheel body and the rotary wheel housing form a round concave, the inner side of the front and rear cover plates are respectively disposed with round platforms having the same diameter with the round concave. The round platforms are disposed with V shape clapboard and bearing seat, and are embedded into the round concave of the rotary wheel housing to divide the two end surface of the wheel body into upper and lower two regions.

Owner:CHANGAN UNIV

Shell tube type adsorption bed with puncture membrane type adsorption mass tubes

InactiveCN105333640AEnhanced Fluid DisturbanceEasy accessClimate change adaptationAbsorbers/adsorbersActivated carbonTubes types

A shell tube type adsorption bed with puncture membrane type adsorption mass tubes comprises a shell, and further comprises a metal mesh, activated carbon, heat conduction tubes and the puncture membrane type tubes, all of which are arranged in the shell. The shell is provided with a heat conduction liquid inlet and a heat conduction liquid outlet which are communicated with the two ends of each heat conduction tube respectively. The shell is provided with an air outlet hole, and the metal mesh is arranged on the inner side face of the shell. The diameter of holes in the metal mesh is smaller than the grain diameter of the activated carbon. The heat conduction tubes and the puncture membrane type tubes are arranged in parallel and alternately arranged. The activated carbon is arranged in gaps between the heat conduction tubes and the puncture membrane type tubes. The puncture membrane type tubes are made of membranes and comprise main mass transfer tubes and bypass branch tubes vertically arranged on the main mass transfer tubes. The main mass transfer tubes are provided with mass transfer holes, and the diameter of the mass transfer holes is smaller than the grain diameter of the activated carbon.

Owner:HENAN AGRICULTURAL UNIVERSITY +3

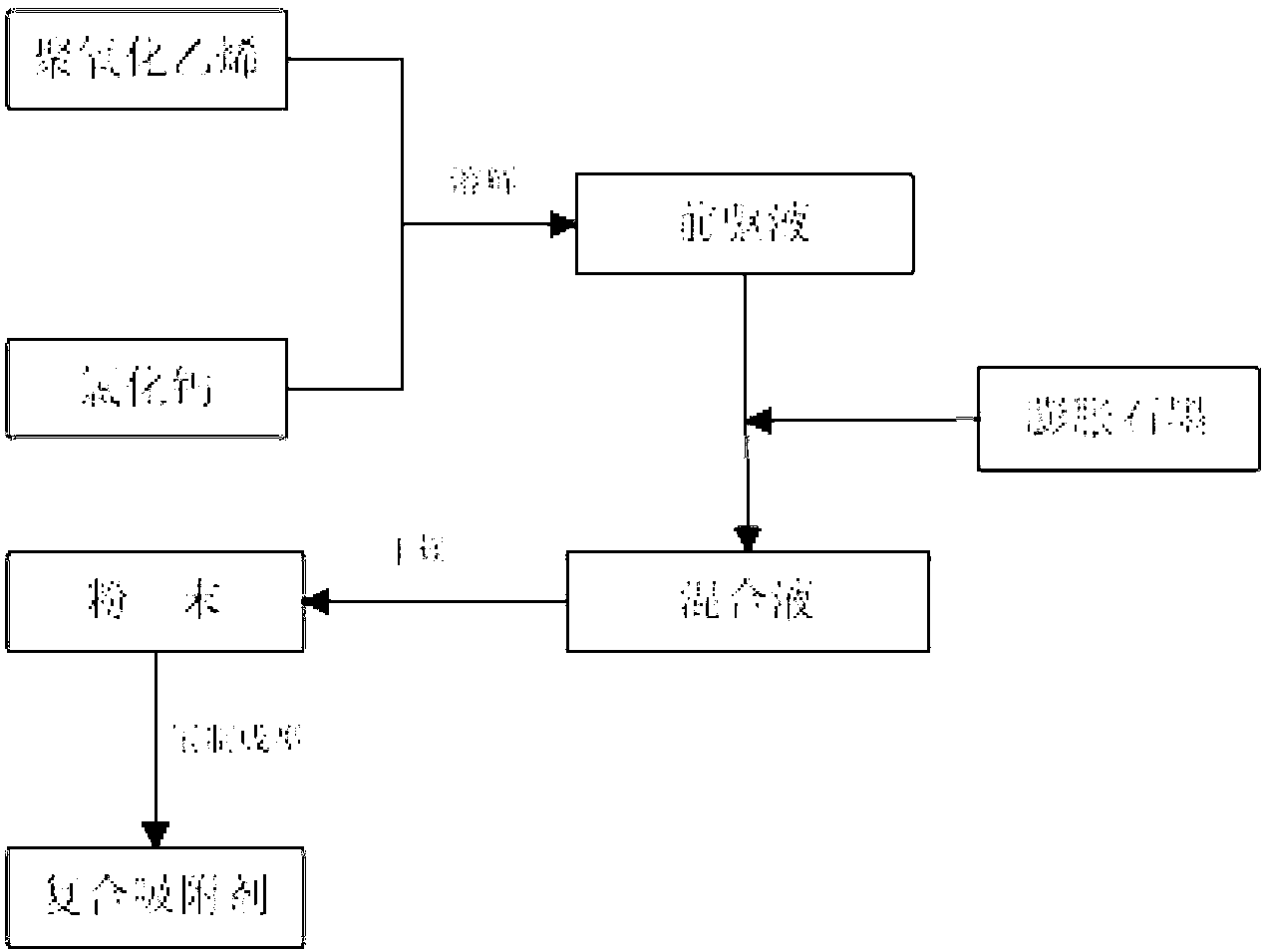

Composite adsorbent and preparation method thereof

InactiveCN103191704AHigh heat and mass transferImprove mechanical propertiesOther chemical processesPolyethylene oxideSorbent

The invention discloses a composite adsorbent and a preparation method thereof. The composite adsorbent comprises calcium chloride, expanded graphite and polyethylene oxide. According to the composite adsorbent and the preparation method thereof, the heat and mass transfer ability of the adsorbent is improved to prevent the agglomeration of the adsorbent through the mixing of the expanded graphite and the calcium chloride, and meanwhile, the phenomena of loosening, layering, falling off and the like of the adsorbent are avoided through the addition of the polyethylene oxide, and therefore the mechanical performance of the adsorbent is improved; the method for preparing the composite adsorbent provided by the invention is simple and feasible, and is conveniently popularized.

Owner:UNIV OF SCI & TECH OF CHINA

High-efficiency reactor for hydrated salt chemical energy storage

InactiveCN107289803AHigh reaction conversion rateHigh energy storage densityHeat storage plantsHydration reactionEngineering

The invention discloses a high-efficiency reactor for hydrated salt chemical energy storage. The high-efficiency reactor comprises a heat insulation container, a column body for wrapping hydrated salt, a heat exchange pipe, fins, hydrated salt and pipelines, wherein the column body is arranged in the heat insulation container; the heat exchange pipe is arranged at the center of the column body; the multiple fins are uniformly arranged between the heat exchange pipe and the column body; one end of each fin is connected with the outer wall of the heat exchange pipe, and the other end of the fin is connected with the inner wall of the column body; a space between the heat exchange pipe and the column body is filled with the hydrated salt; and the two pipelines are arranged on an upper end cover of the heat insulation container. The high-efficiency reactor for hydrated salt chemical energy storage disclosed by the invention can well enable reaction salt to react with steam; the reaction is faster and more thorough, and the heat transfer and mass transfer effect in a reaction process is obviously enhanced; irreversible loss caused by liquefaction of the hydrated salt due to excessive water absorption can be further effectively avoided, so that the number of times of recycling of an energy storage material is increased, and the service life of the material is prolonged; and meanwhile, the corrosion effect of the liquefied hydrated salt on the reactor is also avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

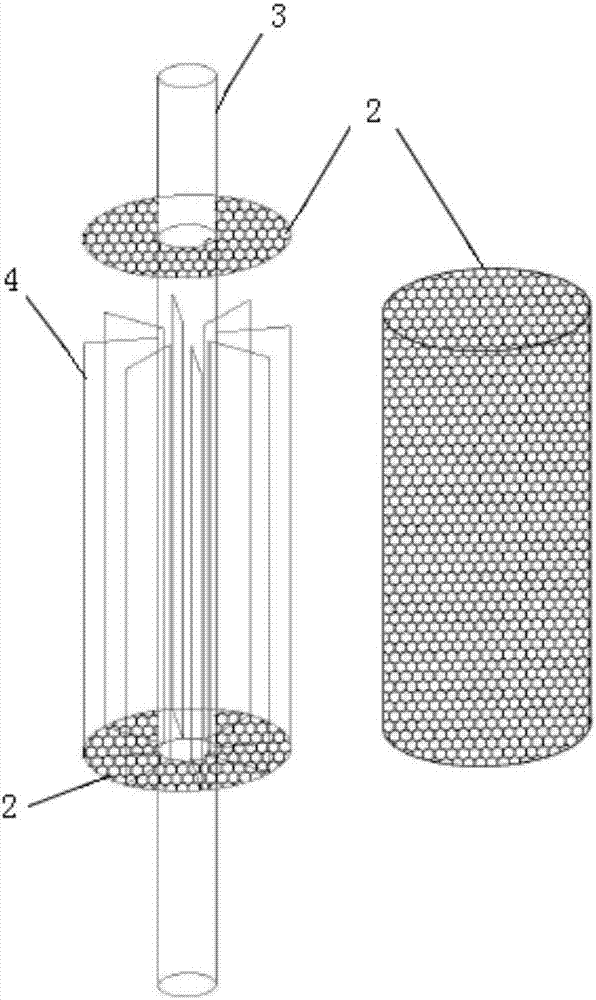

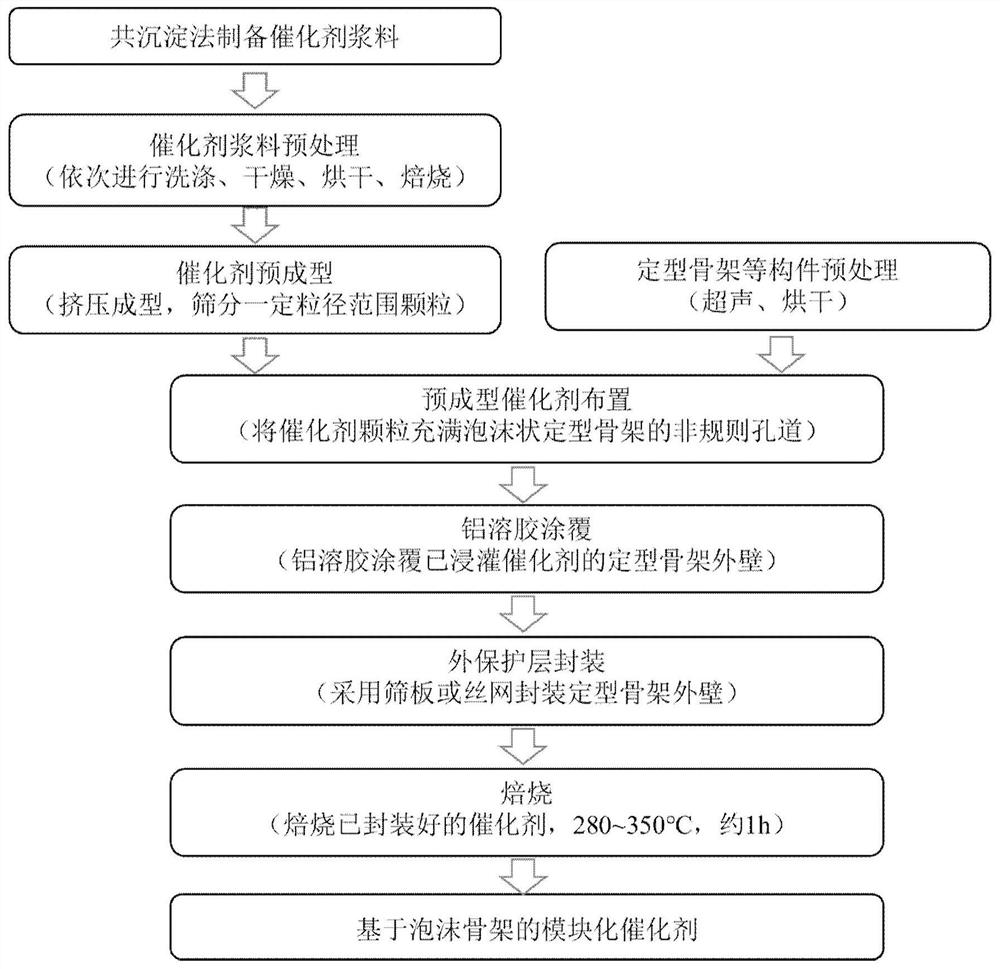

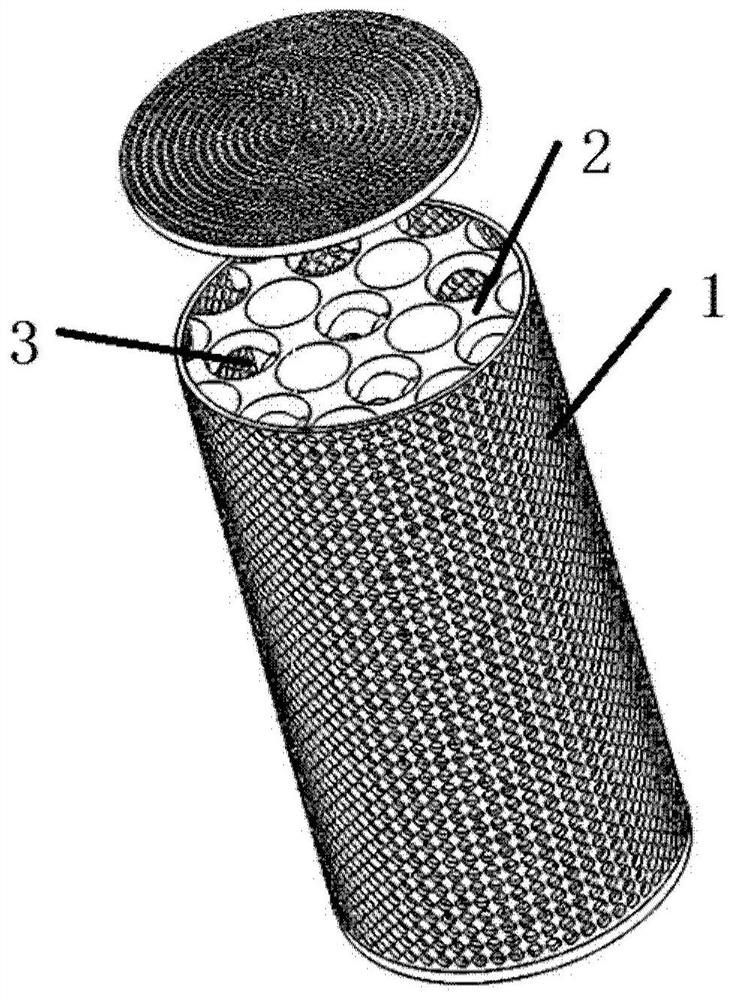

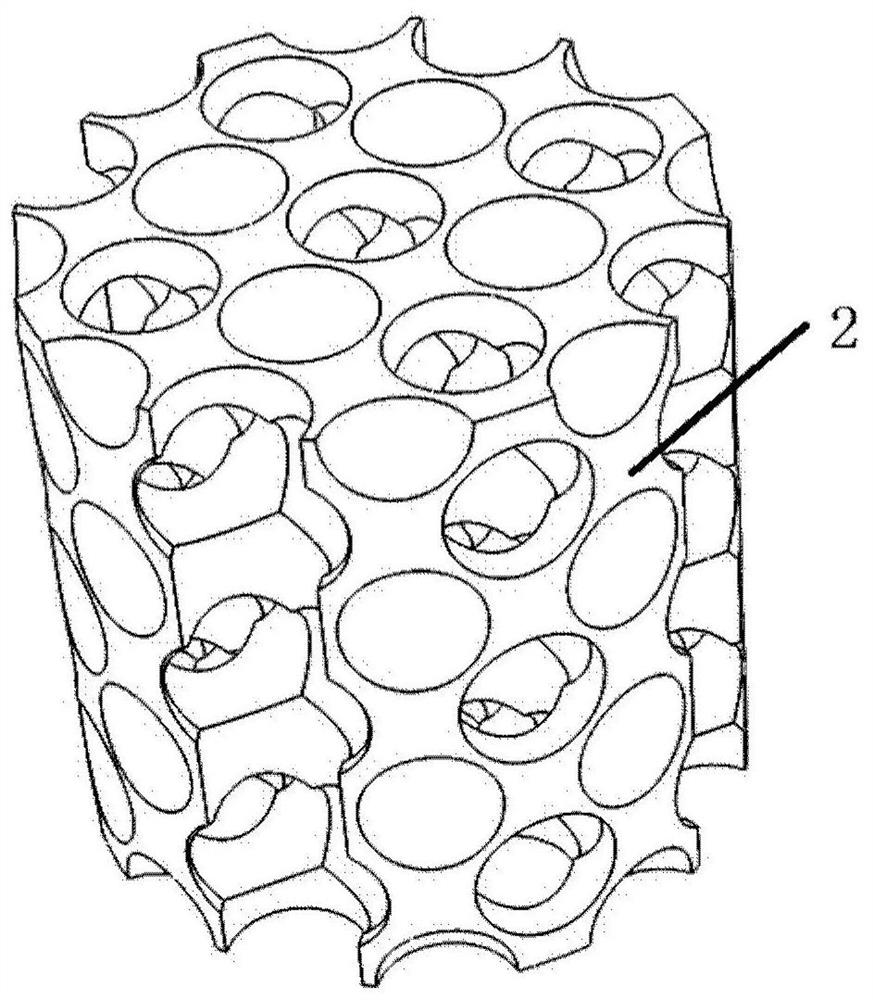

Modular thermal chemical reaction catalyst and manufacturing method thereof

PendingCN113083377AHigh heat and mass transferSmall pressure dropHydrogenCatalyst protectionPtru catalystThermochemical reaction

The invention relates to a modular thermal chemical reaction catalyst and a manufacturing method thereof. The modular thermal chemical reaction catalyst comprises a shaped skeleton, wherein the interior of the shaped skeleton is provided with a three-dimensional irregular pore channel, which is filled in the whole reaction area in a reactor; preformed catalyst particles, which are filled in the three-dimensional irregular pore channel of the shaped skeleton; and an outer protection layer, which is arranged on the outer wall of the shaped skeleton. According to the invention, the irregular pore channel formed by the shaped skeleton are filled with the catalyst particles, so that compared with a direct packed bed of the catalyst particles, the mass transfer diffusion capability of a reaction medium on a catalyst bed layer is improved, and the pressure drop of the catalyst bed layer is reduced; the heat transfer performance of the catalyst bed layer is improved, the temperature distribution non-uniformity of the catalyst bed layer is reduced, and the thermal chemical reaction performance of the bed layer is improved; uniform distribution of the catalyst in a reaction area is facilitated, and collapse and channeling of a catalyst bed layer are prevented; and meanwhile, the structure form of a catalyst bed layer is convenient to construct, and the filling, unloading or replacing process of the catalyst is simplified.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

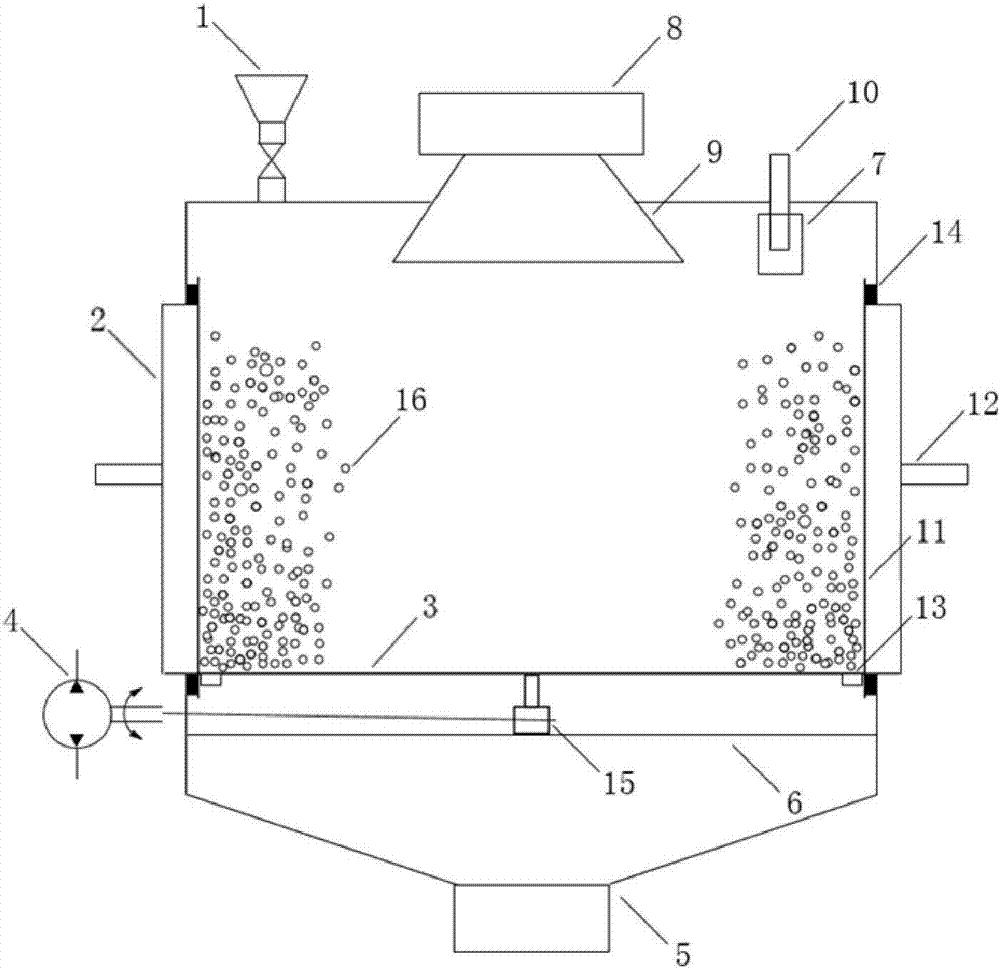

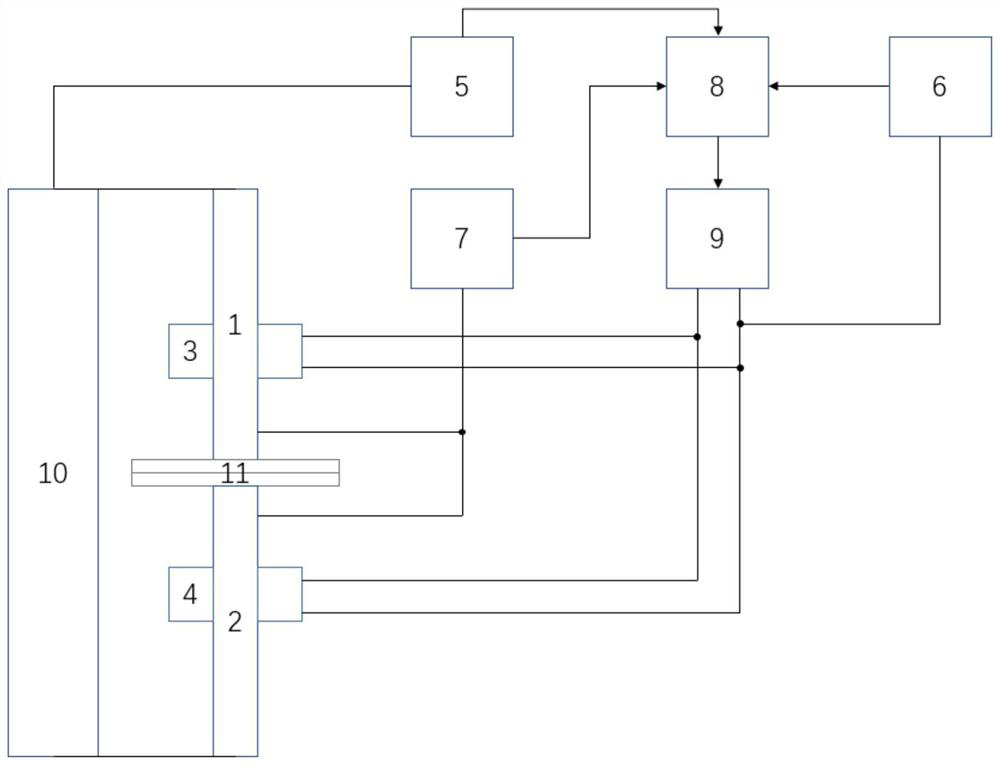

Device for cooperatively enhancing fluidization of nanoparticles by centrifugal field and sound field

InactiveCN106994322AOvercoming AdhesionGood fluidization behaviorEnergy based chemical/physical/physico-chemical processesBaghouseNanoparticle

The invention provides a device for cooperatively enhancing the fluidization of nanoparticles by a centrifugal field and a sound field. The device comprises a feeding hopper (1), an annular air inlet chamber (2), a centrifugal fluidized bed body (3), a stepping motor (4), a discharging hopper (5), a bed body supporting frame (6), a cloth bag dust collector (7), a sounder (8), a loudspeaker (9), an air outlet (10), an annular air distribution plate (11), an air inlet (12), an inner discharging hole (13), a sealing gasket (14) and a right-angle transmission gear box (15). According to the device provided by the invention, the fluidization of the nanoparticles is enhanced through the centrifugal field and the sound field, and abnormal fluidization phenomena including channeling, slugging even normal fluidization and the like of the nanoparticles in a fluidized bed can be effectively eliminated; an agglomeration-crushing process of particle agglomeration is enhanced and mixing between the particles is enhanced; the heat and mass transportation capability between the particles and a main body is improved; process application and amplification are easy to realize; the device has strong operation controllability and is stable to operate.

Owner:SOUTHEAST UNIV

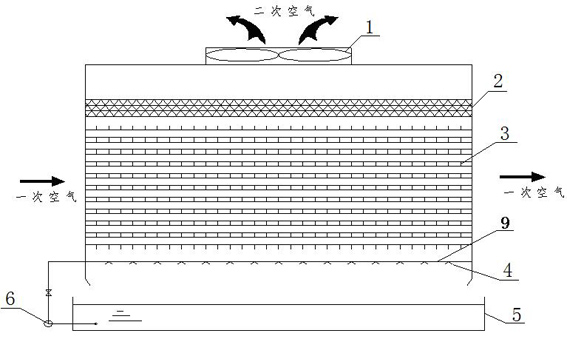

Spray reinforcing low-finned tube indirect evaporative cooler

InactiveCN101818997AReduced amount of atomized waterExtended flow pathStationary conduit assembliesTubular elementsEvaporative coolerEngineering

The invention discloses a spray reinforcing low-finned tube indirect evaporative cooler which comprises a secondary air fan, water retaining material, a heat exchange tube group formed by a plurality of rows and lines parallel heat exchange tubes, a spray water pipe and a water tank that are sequentially arranged from top to bottom, wherein the radial direction of the arranged heat exchange tubes is the same as the flowing direction of horizontally entering primary air; air inlet surfaces of the secondary air are respectively arranged along the four directions between the spray water pipe and the water tank; the spray water pipe is provided with a plurality of spray heads spraying downwards; and the indirect evaporative cooler also comprises a circulating water pump which is communicated with the water tank and the spray water pipe by a pipeline. The tube indirect evaporative cooler uses the indirect evaporative cooling technology, and improves the heat transfer and mass transfer effects of the tube indirect evaporative cooler by the optimization design of structure.

Owner:XI'AN POLYTECHNIC UNIVERSITY

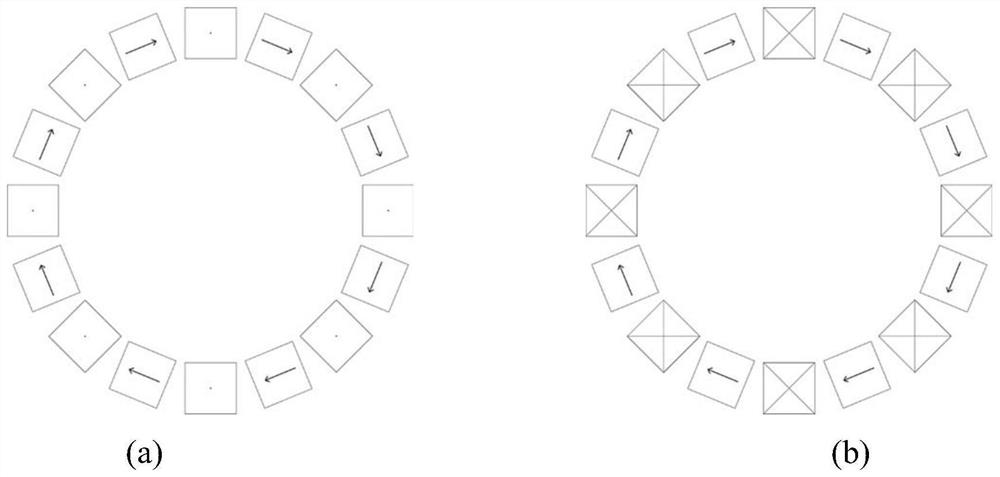

Magnetic field array auxiliary resistance spot welding device and method for sheet metal materials

PendingCN114043055AIncrease the magnetic field strengthIncrease forceResistance welding apparatusMetallic materialsEngineering

The invention relates to a magnetic field array auxiliary resistance spot welding device and method for sheet metal materials. According to the device and method of the invention, on the basis of basic magnetic control resistance spot welding equipment, an exciting coil is replaced by a Halbach magnetic field array, a dynamic feedback system is additionally arranged, the system and the equipment can convert the magnetic field array; a nugget expansion mode magnetic field is formed in the pre-solidification stage of the resistance spot welding process in a non-contact mode, a circumferential acting force is applied to liquid metal in a resistance spot welding nugget to increase the size of a welding spot; the moment when the nugget begins to solidify is truly judged through the dynamic feedback system; the magnetic field array mode is converted when the nugget begins to solidify, a stirring enhanced magnetic field is formed; crystalline grains are refined, chemical components are homogenized, and crack sensitivity is improved; and finally, the comprehensive mechanical performance of a resistance spot welding joint is improved.

Owner:BEIJING UNIV OF TECH

Wall flow-less jetting cooling tower

A cooling water tower of injection and wall stream free type is featured as opening horizontal seam on wall surface of pressure expansion section at cooling rower and setting stream guide plate at bottom edge of said wall surface for leading water from said wall surface to water collection tank, dropping water out from holes of said tank to separation chambers of arc shaped stream guide plate under said tank, flowing water out in uniform speed from holes at bottom of said separation chamber for entering water into packing layer uniformly.

Owner:SHANGHAI JIAO TONG UNIV

Lithium bromide absorption type refrigerating device with impact and vibration auxiliary heat and mass transfer function

InactiveCN102853577AReduce thicknessHigh heat and mass transferClimate change adaptationEnergy efficient heating/coolingVibration controlLithium bromide

The invention discloses a lithium bromide absorption type refrigerating device with an impact and vibration auxiliary heat and mass transfer function, and provide a refrigerating device capable of sucking mechanical energy into an absorber from outside and enabling a heat exchange pipe in the absorber to generate micro vibration, so that the film thickness is reduced; the heat and mass transfer coefficient effect is increased; and the absorption efficiency is improved. An impact and vibration device is connected on the absorber. The impact and vibration device comprises a guide pipe, a valve for vibration control and a spraying pipe; one end of the valve for the vibration control is connected with an outlet of the guide pipe, and the other end of the valve for the vibration valve is connected with an inlet of the spraying pipe; an inlet of the guide pipe is connected with a liquid outlet of the absorber or a shielding pump at the bottom of the absorber; an impact baffle is arranged on the heat exchange pipe of the absorber; and liquid sprayed from the spraying pipe impacts the impact baffle, so as to generate the micro vibration. The micro vibration is generated by the heat exchange pipe of the absorber through the impact and vibration device connected on the absorber, so that the film thickness is reduced, and the refrigeration effect is improved.

Owner:TIANJIN UNIV OF COMMERCE

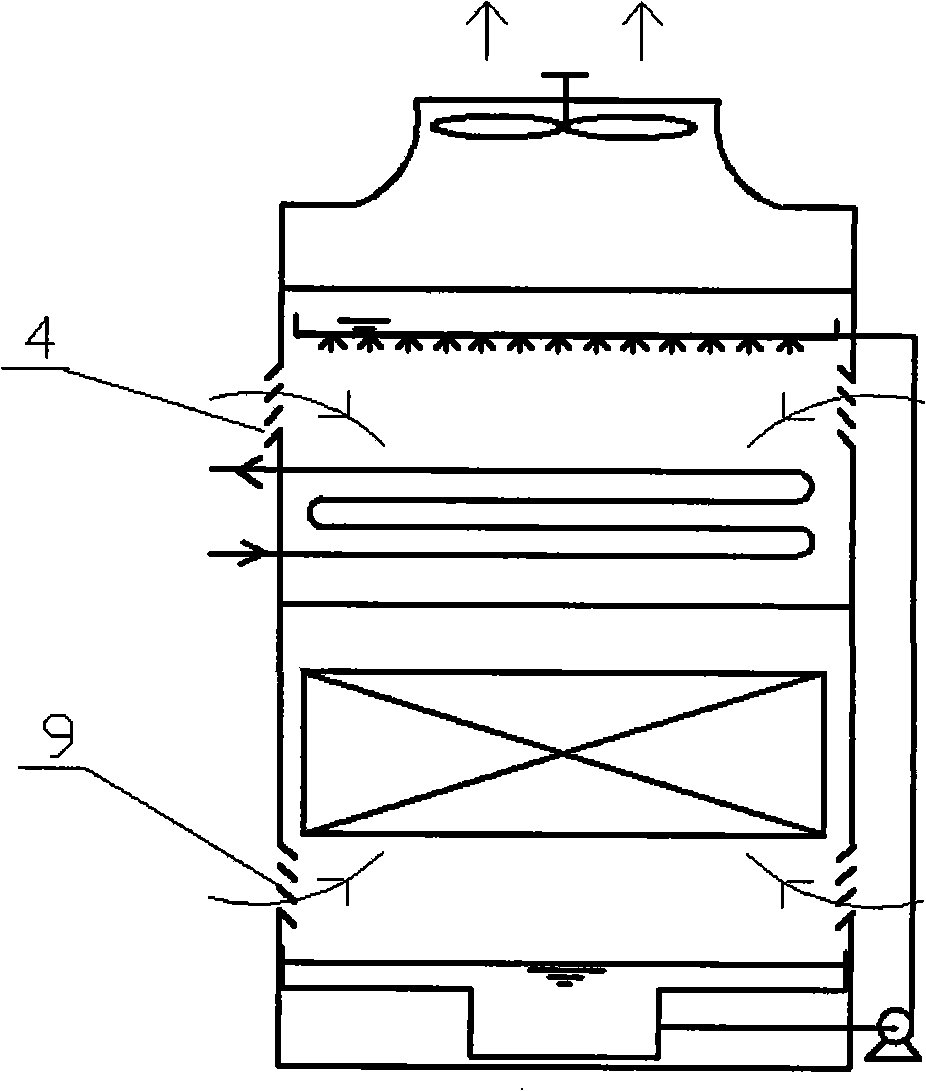

Fluidize adsorption continuous refrigeration system and method thereof

InactiveCN101140113AHigh heat and mass transferHighlight substantive featuresEnergy efficient heating/coolingClimate change adaptationGas solidDesorption

The invention provides a fluidized adsorption continuous refrigeration system and its method, wherein the system comprises a refrigeration part composed of an evaporator (2), a throttle valve (3), a liquid storage tank (4) and a condenser (5), an adsorption part resulting in that an adsorbent adsorbs a refrigerant and is cooled down by the refrigerant, and a desorption part resulting in that the adsorbent is heated up and the refrigerant is desorbed; the adsorption part comprises a venturi tube (1), a compressor (6), an adsorption bed (7) and a gas-solid separator (8); the desorption part comprises a gas-solid separator (9), a vacuum valve (10), a vacuum valve (11), a desorption bed (12), a heat exchanger (14) and a compressor (13); the method comprises a heat-absorbing temperature rise, desorption, circulation, refrigeration, adsorption, recirculation and other steps. The system directly implements heat exchange and material exchange with the refrigerant and the adsorbent, which realizes the simultaneous implementation of heat transfer and mass transfer in order to result in that the capacity of heat transfer and mass transfer is strengthened, and realizes the continuous refrigeration or heating and improves the heat utilization efficiency.

Owner:ZHENGZHOU UNIV

Full-counterflow enclosed cooling column with air intake at upper and lower part

InactiveCN101319852AIncrease the circulation areaIncrease temperature differenceTrickle coolersCooling towerDistribution system

The invention relates to complete countercurrent closed cooling tower with air inlets on an upper and a lower parts. A tube bundle is arranged on the upper part of the closed cooling tower, and fillers are arranged on the lower part. A fan is arranged on the top of the tower. A water collection disc is arranged on the bottom of the tower. The upper part of the tube bundle is provided with a water distributor. The water collection disc is connected with the water distributor by a pump. The upper and the lower parts of the two lateral sides of the cooling tower are separately provided with two air inlets-the upper air inlet and the lower air inlet. The other two lateral sides and a channel separator form an air exhaust channel. The air that enters into the cooling tower from the upper air inlet and flows downwards, after the air passes through the tube bundle, the air meets the air that enters into the cooling tower from the lower air inlet, flows upwards and passes through the fillers. The direction of the air is changed in the middle of the cooling tower. The air flows upwards through the air exhaust channel and is discharged from the top of the cooling tower. The air in the fillers flows along a reverse direction with the spray water which flows from top to bottom. The air in the tube buddle flows along a same direction with the spray water and flow along a reverse direction with the cooled fluid in the tube buddle. The countercurrent closed cooling tower can use pool typed water distribution system. The closed cooling tower can increase the flow area and the flow quantity of the air. The water distribution is uniform, and the effects of the heat transfer and mass transfer are improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com