Composite adsorbent and preparation method thereof

A composite adsorption and mixed liquid technology, which is applied in chemical instruments and methods, and other chemical processes, can solve problems such as easy agglomeration, looseness or delamination or peeling, poor mechanical properties, etc., to improve heat and mass transfer capabilities, The preparation method is simple and easy, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

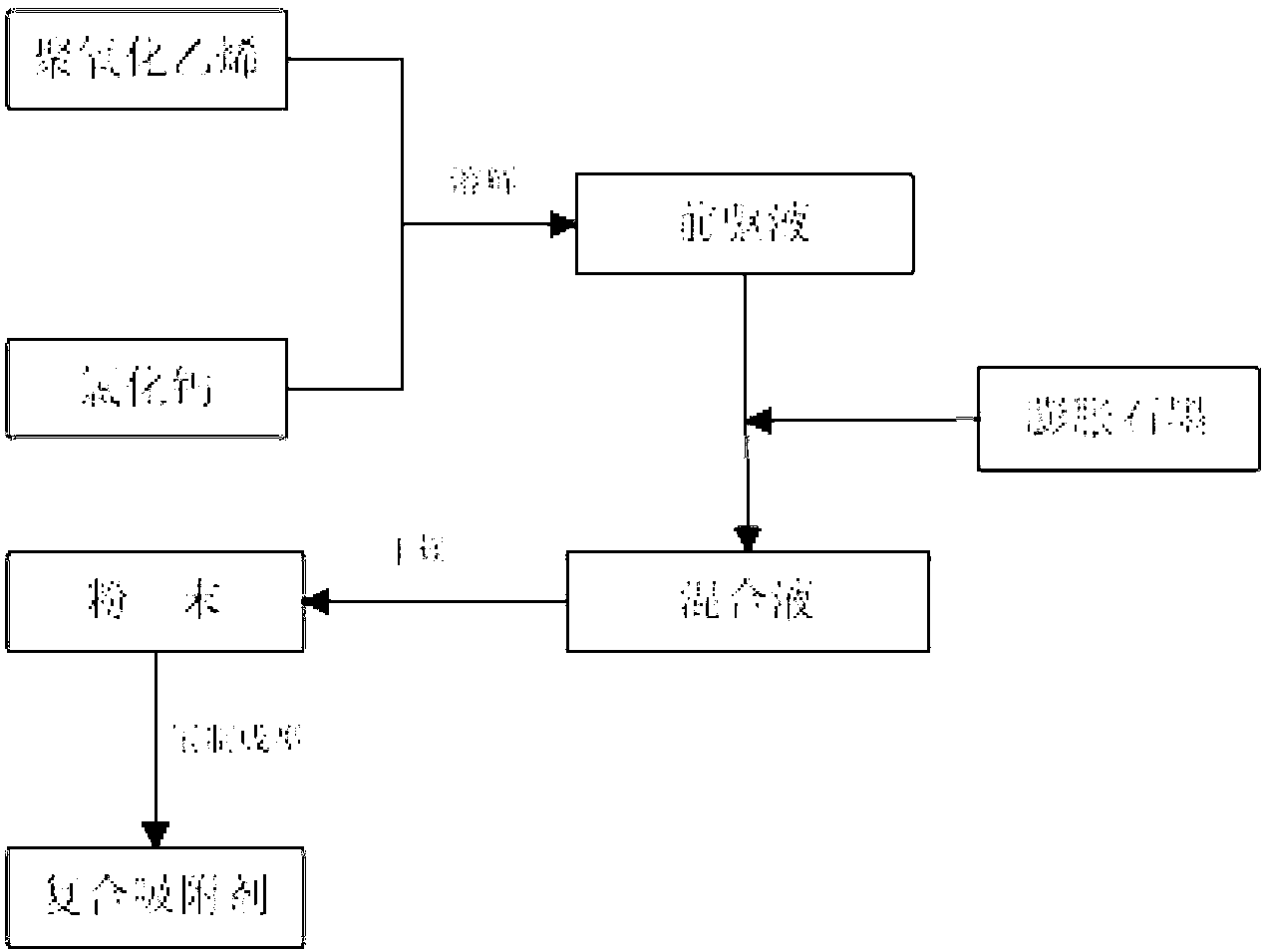

[0024] Correspondingly, the present invention also provides a kind of preparation method of above-mentioned composite adsorbent, comprises the following steps:

[0025] Step 1: Dissolve calcium chloride and polyethylene oxide to obtain a precursor solution. The method for dissolving calcium chloride and polyoxyethylene in the present invention is not particularly limited, methods well known to those skilled in the art can be used, such as dissolving calcium chloride first, then adding polyoxyethylene, or adding chloride chloride to water at the same time. Calcium and polyethylene oxide are dissolved together, and in order to make the dissolution more rapid, they may be stirred or heated during the dissolution.

[0026] The second step: adding expanded graphite to the precursor solution obtained in the first step to obtain a mixed solution. Those skilled in the art will easily know that in order to disperse the expanded graphite uniformly in the precursor solution, the precurs...

Embodiment 1

[0032] Take 1000ml of water, dissolve 8.00g of calcium chloride in it, weigh 4.00g of polyethylene oxide and slowly dissolve in the calcium chloride solution after the calcium chloride is completely dissolved, and dissolve the polyethylene oxide completely to obtain the precursor solution; Insulate at 500° C. for 8 minutes to prepare expanded graphite; then weigh 8.00 g of expanded graphite and put it into the precursor solution, and stir for 1 minute until the expanded graphite is evenly dispersed to obtain a mixed solution. Put the mixed solution in a drying oven at 95° C. for 2 to 3 days until the mixed solution is completely dried to obtain the mixed solution powder. Weigh 4.00g of the powder and place it in a mold and press it under a pressure of 20MPa for 5min to obtain a block-shaped composite adsorbent.

[0033] The obtained composite adsorbent is placed in an outdoor environment, and after 1 to 2 days, it is observed that the composite adsorbent does not have any loos...

Embodiment 2

[0035] Take 2500ml of water, dissolve 7.50g of calcium chloride in it, weigh 15.00g of polyethylene oxide and slowly dissolve in the calcium chloride solution after the calcium chloride is completely dissolved, and dissolve the polyethylene oxide completely to obtain the precursor solution; the expandable graphite Insulate at 700° C. for 12 minutes to prepare expanded graphite; then weigh 15.00 g of expanded graphite and put it into the precursor solution, and stir for 1 minute until the expanded graphite in the solution is uniformly dispersed to obtain a mixed solution. Put the mixed solution in a drying oven at 90° C. for 2 to 3 days until the mixed solution is completely dried to obtain the mixed solution powder. Weigh 3.50g of powder and place it in a mold and press it under 20MPa pressure for 5min to obtain block composite adsorbent.

[0036] The obtained composite adsorbent is placed in an outdoor environment, and after 1 to 2 days, it is observed that the composite adso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com