Full-counterflow enclosed cooling column with air intake at upper and lower part

A closed cooling tower, counter-flow technology, applied in the direction of water shower cooler, direct contact heat exchanger, heat exchanger type, etc., can solve the problem of small air circulation area, low heat transfer efficiency, spray water and fluid in the pipe Uneven temperature difference and other problems, to achieve uniform water distribution, increase the flow area, and improve the effect of heat and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

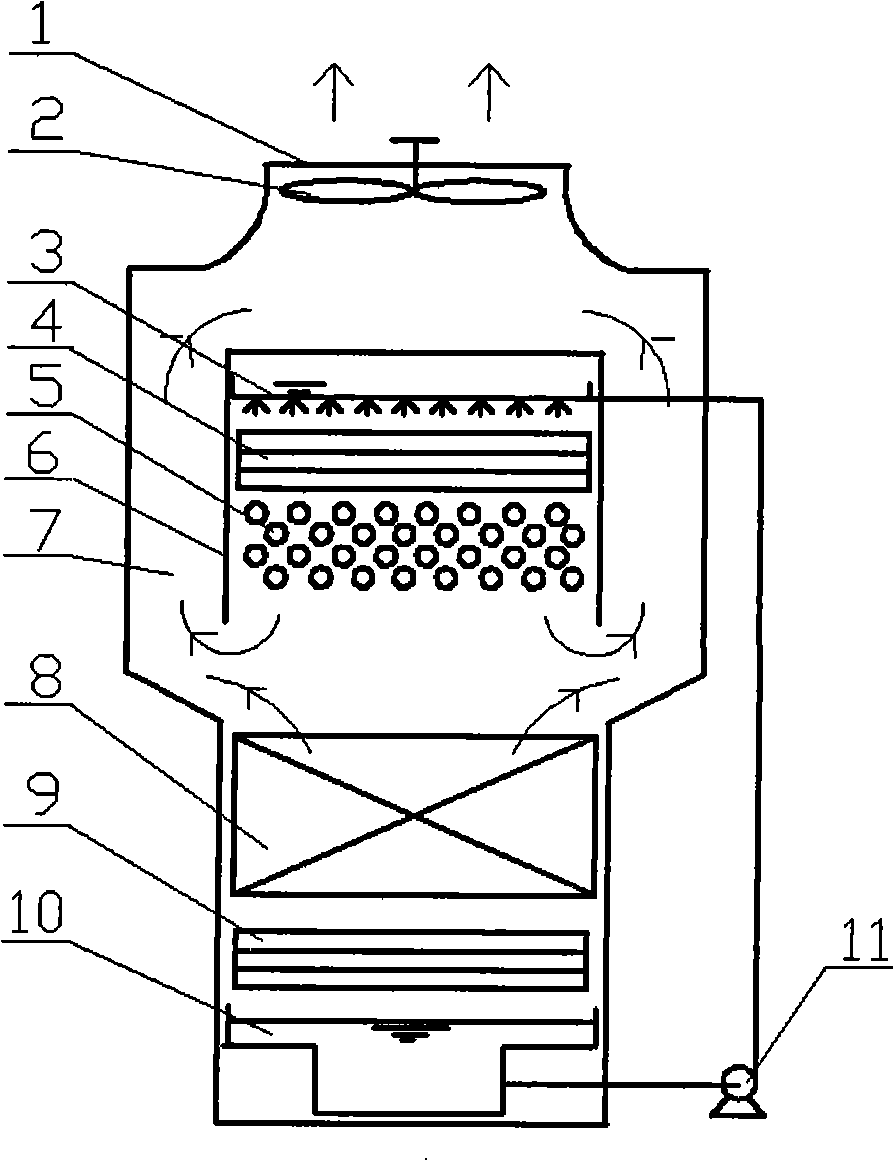

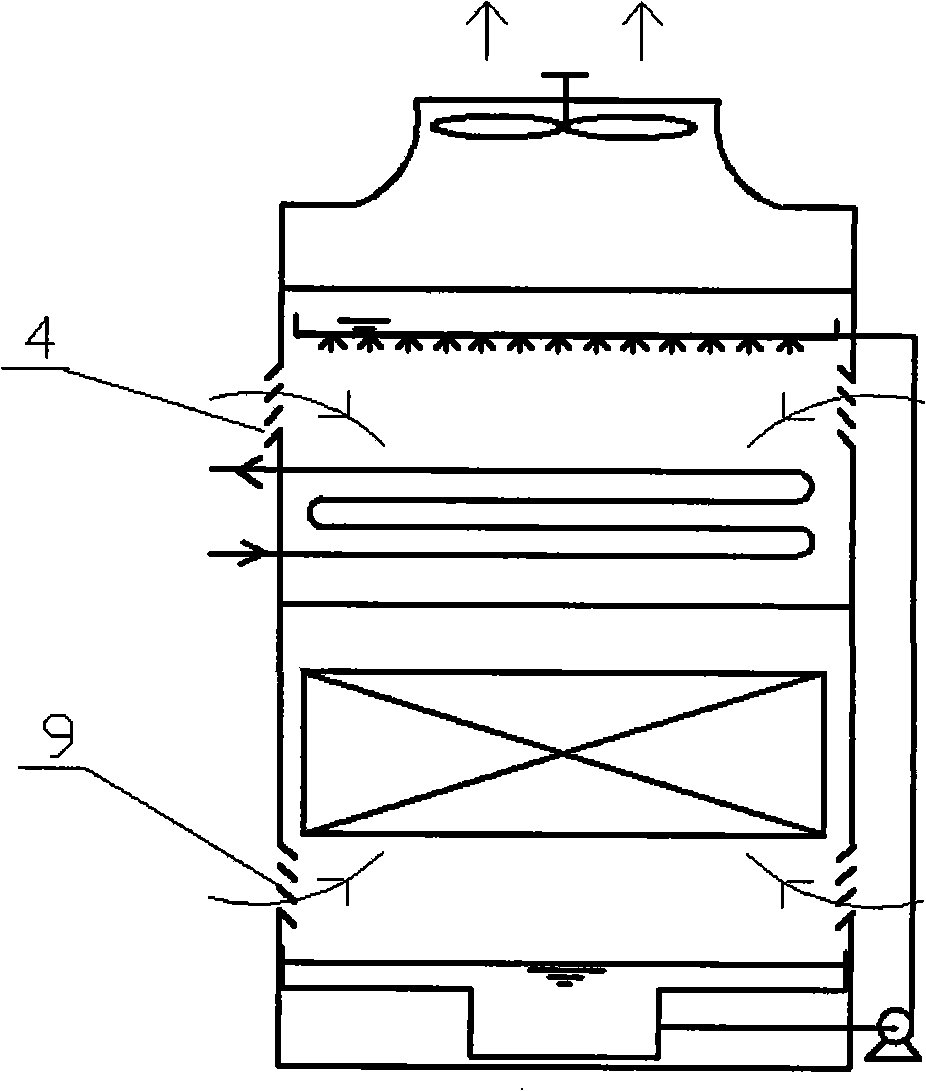

[0013] The upper and lower air inlet full counterflow closed cooling tower, which includes: air outlet 1, fan 2, water distributor 3, upper air inlet 4, tube bundle 5, channel partition 6, exhaust channel 7, packing 8, lower air inlet 9 , water collecting tray 10, water pump 11; tube bundle 5 is arranged in the upper area of the closed cooling tower, filler 8 is arranged in the lower area of the cooling tower, fan 2 is at the top of the tower body, water collecting tray 10 is at the bottom of the tower body, and the tube bundle is arranged above There is a water distributor 3, and the water collecting tray 10 is connected to the water distributor 3 through the water pump 11; the upper and lower two air inlets 4 and 9 are respectively opened on the upper and lower parts of the two sides of the cooling tower, and the other two air inlets are not opened. The side surface and the channel partition 6 form an exhaust channel 7, which communicates with the central area of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com