Array type silencer

A muffler and array technology, applied in rigid pipes, pipes, pipes/pipe joints/fittings, etc., can solve the problems of unsatisfactory noise reduction effect, inconvenient transportation and installation, large airflow resistance, etc., to reduce noise reduction cost and convenience. Transport and installation, effect of flow rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

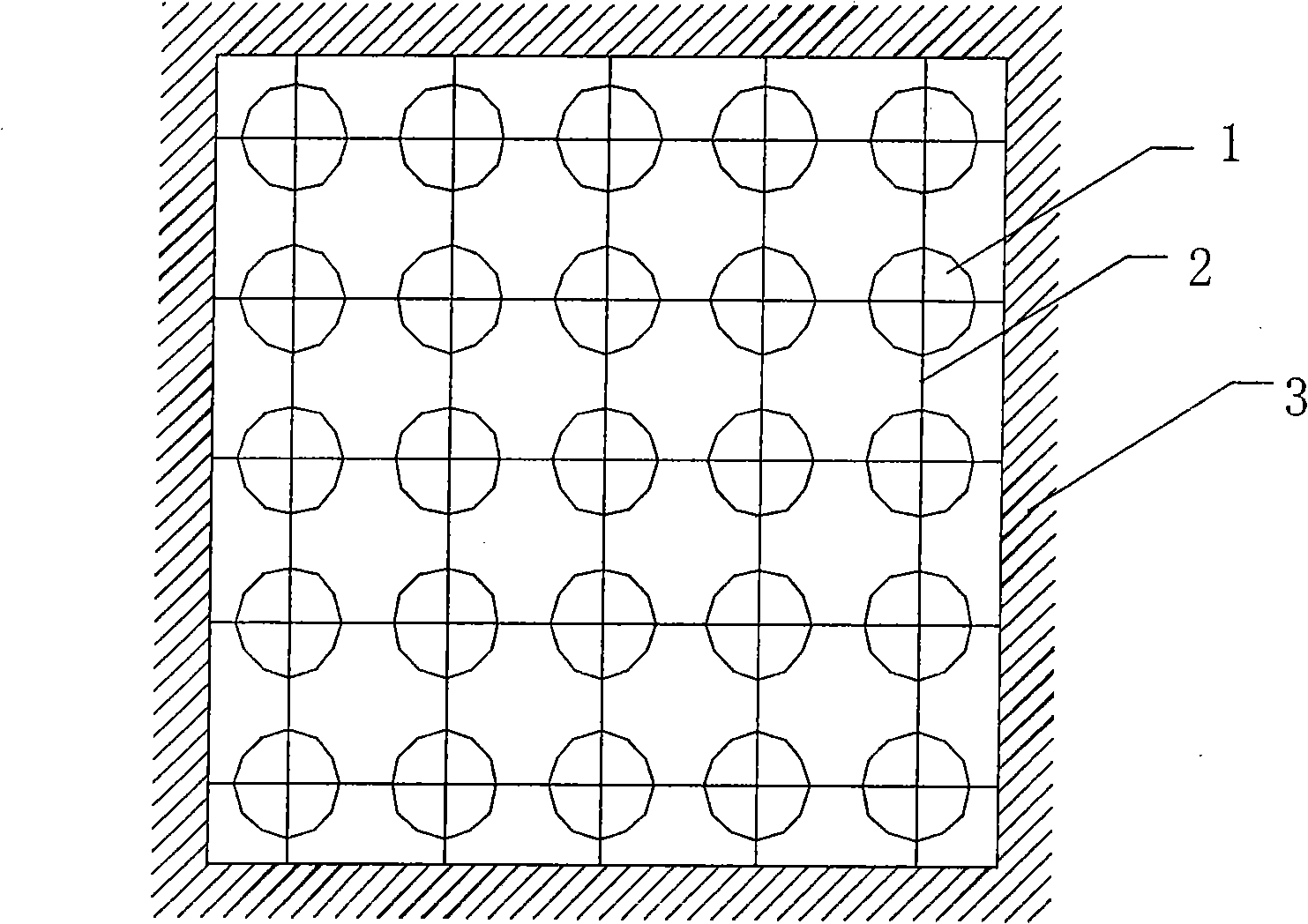

[0044] Embodiment one, such as figure 1 As shown, the array muffler of the present invention is composed of a sound-absorbing pipe body 1 and a bracket 2, the sound-absorbing pipe body 1 has a circular section, and both ends are arc-shaped shrouds, such as Figure 16-1 As shown in , the cross-sectional shape of the arc-shaped shroud is circular, such as Figure 16-1 Figure 16-2 to Figure 16-6 As shown, it can also be triangular, quadrangular, pentagonal, hexagonal or octagonal. The exterior of the sound-absorbing pipe body 1 is provided with a perforated plate along the surface of the pipe body, as shown in Figure 17, the shape of the perforated plate is circular, such as Figure 17-1 to Figure 17-3 As shown, it can also be triangular, quadrangular, pentagonal, hexagonal or octagonal. The interior of the sound-absorbing pipe body 1 is filled with sound-absorbing material, and the sound-absorbing material is mineral wool. The axes of adjacent sound-absorbing pipes 1 are ar...

Embodiment 2

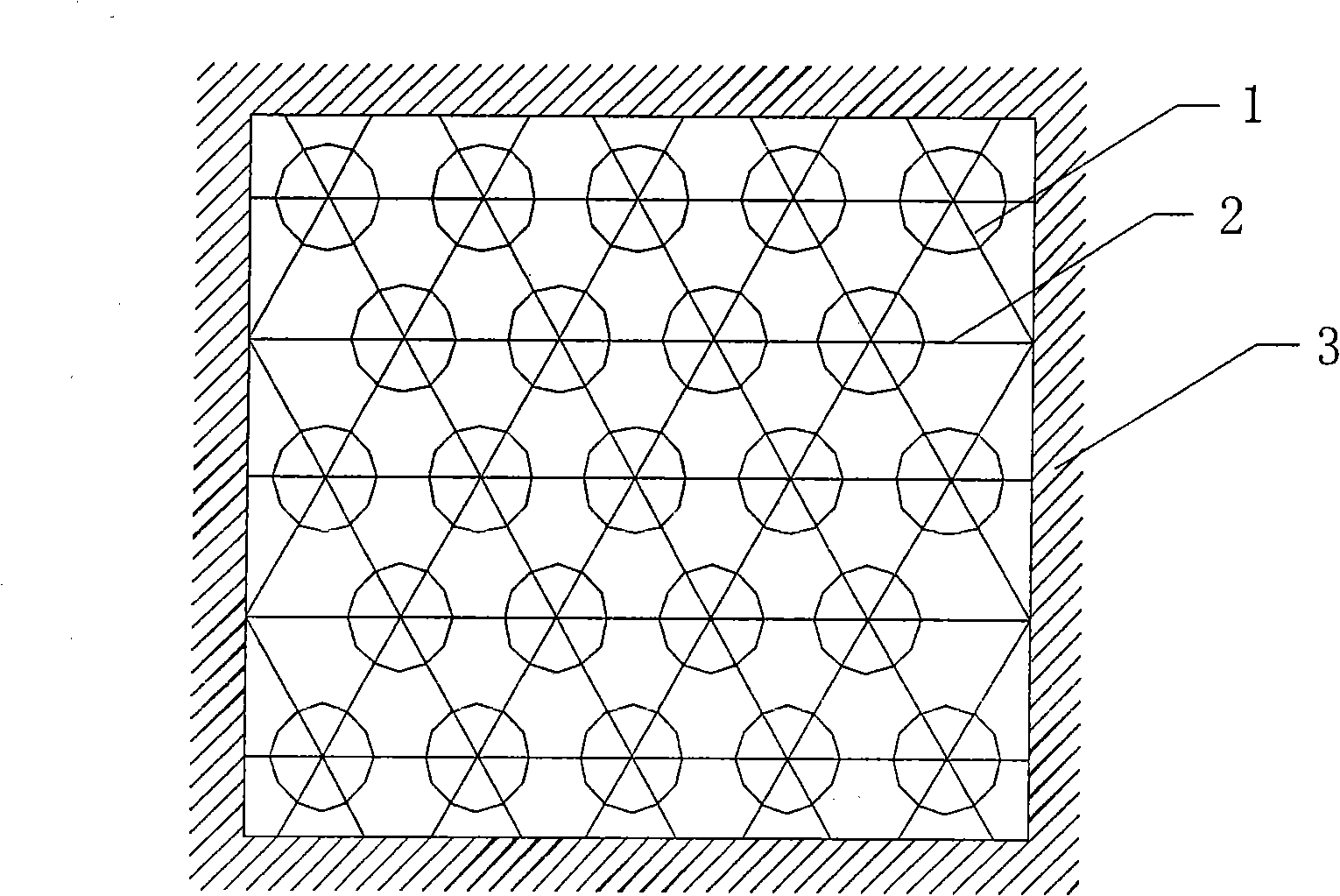

[0045] Embodiment two, such as figure 2 As shown, the array type muffler of the present invention is composed of a sound-absorbing pipe body 1 and a bracket 2. The sound-absorbing pipe body 1 has a circular section, two ends are arc-shaped shrouds, and the outer surface is provided with a perforated plate. The sound-absorbing pipe The interior of the body 1 is filled with sound-absorbing materials, and the axes of the adjacent sound-absorbing pipe bodies 1 are arranged in an equilateral triangle. 4 mm 2 The length is 1000mm. The sound-absorbing pipe body 1 is fixed and installed on the bracket 2 through bolts and other standard parts, and the bracket 2 is fixed in the ventilation pipe 3 of the civil construction by bolts. The axis of the sound-absorbing pipe body 1 adjacent to the wall of the ventilation pipe The distance between the 3 walls is 500mm.

Embodiment 3

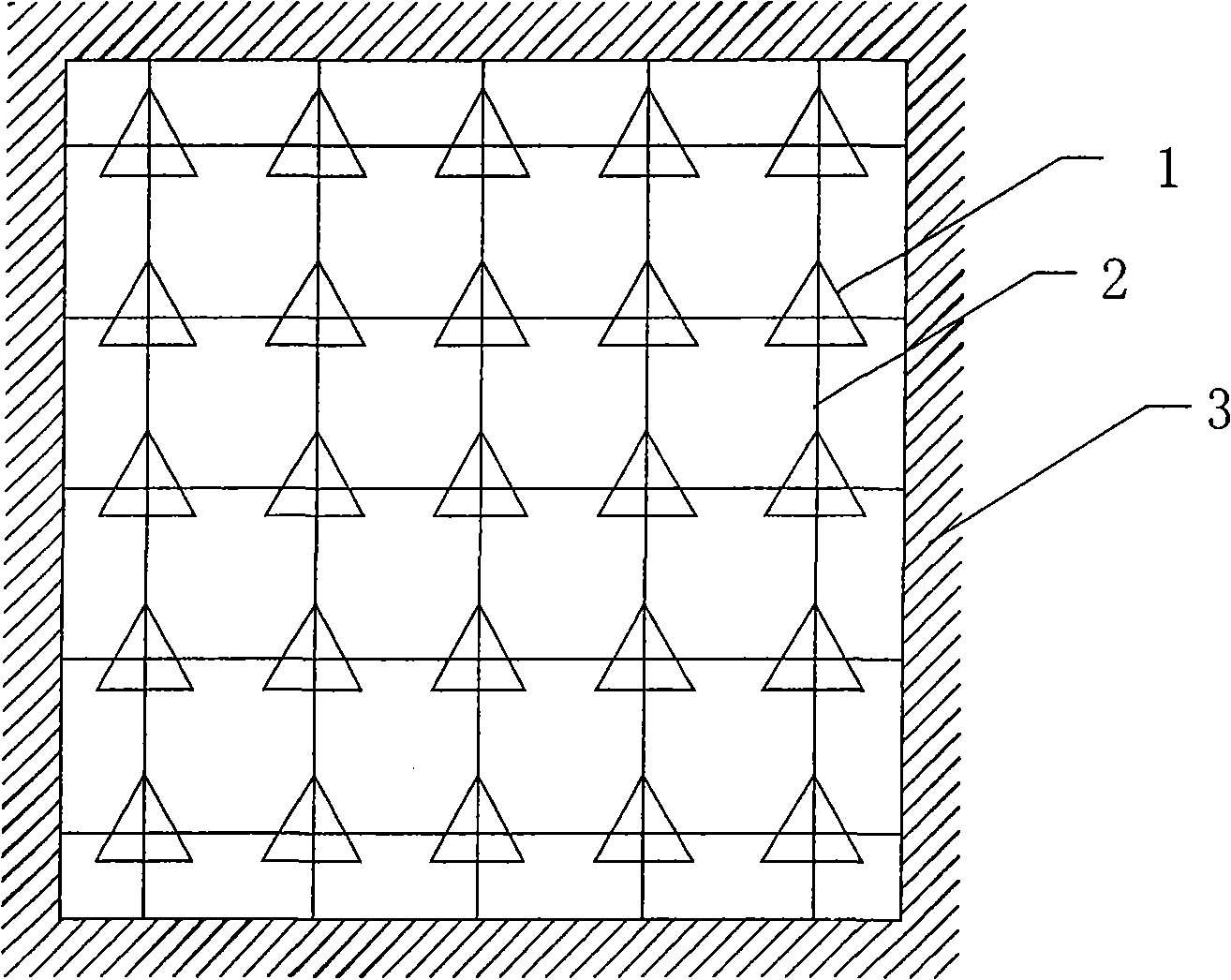

[0046] Embodiment three, such as image 3 As shown, the array muffler of the present invention is composed of a sound-absorbing pipe body 1 and a bracket 2. The section of the sound-absorbing pipe body 1 is an equilateral triangle, and the two ends are arc-shaped shrouds. The rest of the surface is a perforated plate, and the perforated plate is an equilateral triangle. The sound-absorbing pipe body 1 is filled with sound-absorbing materials, and the adjacent sound-absorbing pipe body 1 axes are arranged in an equilateral quadrilateral. The distance is 600mm, and the cross-sectional area of the sound-absorbing pipe body 1 is 1.6x10 5 mm 2 , 2000mm in length, the sound-absorbing pipe body 1 is fixedly installed on the bracket 2 through bolts and other standard parts, and the bracket 2 is fixed in the civil ventilation duct 3 by bolts, and the axis of the sound-absorbing pipe body 1 adjacent to the ventilation duct 3 wall is in line with the ventilation duct The distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com