Flame tube structure of thrust combustion chamber used for supercharger test

A technology for flame tube and test, which is applied in the field of flame tube structure of thrust combustion chamber for supercharger test, which can solve problems such as unreasonable structure of thrust combustion chamber, plastic deformation of flame tube, overtemperature of flame tube, etc., and improve heat dissipation effect , Improve the temperature resistance, and the effect of sufficient secondary combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

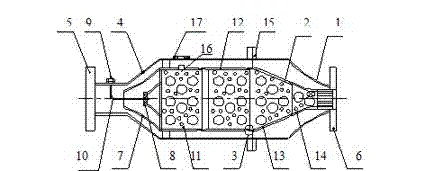

[0044] A thrust combustion chamber flame tube structure for a supercharger test, including two parts, the flame tube outer shell and the flame tube inner shell, and also includes functional structures such as a film cooling tank structure, a nozzle swirler, and a secondary diffuser;

[0045] The outer shell of the flame tube and the inner shell of the flame tube are both symmetrical about the same central axis, and the radius of each section of the outer shell of the flame tube is greater than the radius of each section of the corresponding position of the inner shell of the flame tube;

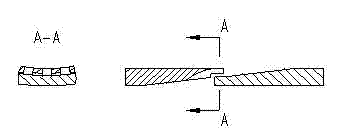

[0046] The shell of the flame tube is a continuous spindle shape, which can be divided into 4 sections according to the shape: the first and third sections are cylindrical, and the second and fourth sections are conical (the cross section can be isosceles triangle or curved triangle); the radius of the third section is greater than that of the first section; the second section is a diffuser, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com