Rotor structure, motor and compressor

一种转子结构、转子铁芯的技术,应用在转子结构,电机及压缩机领域,能够解决开孔空间有限、难以同时保证压缩机冷媒及油整体循环效率转子与转轴扭矩等问题,达到提高磁场强度、确保固定连接、降低噪音的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

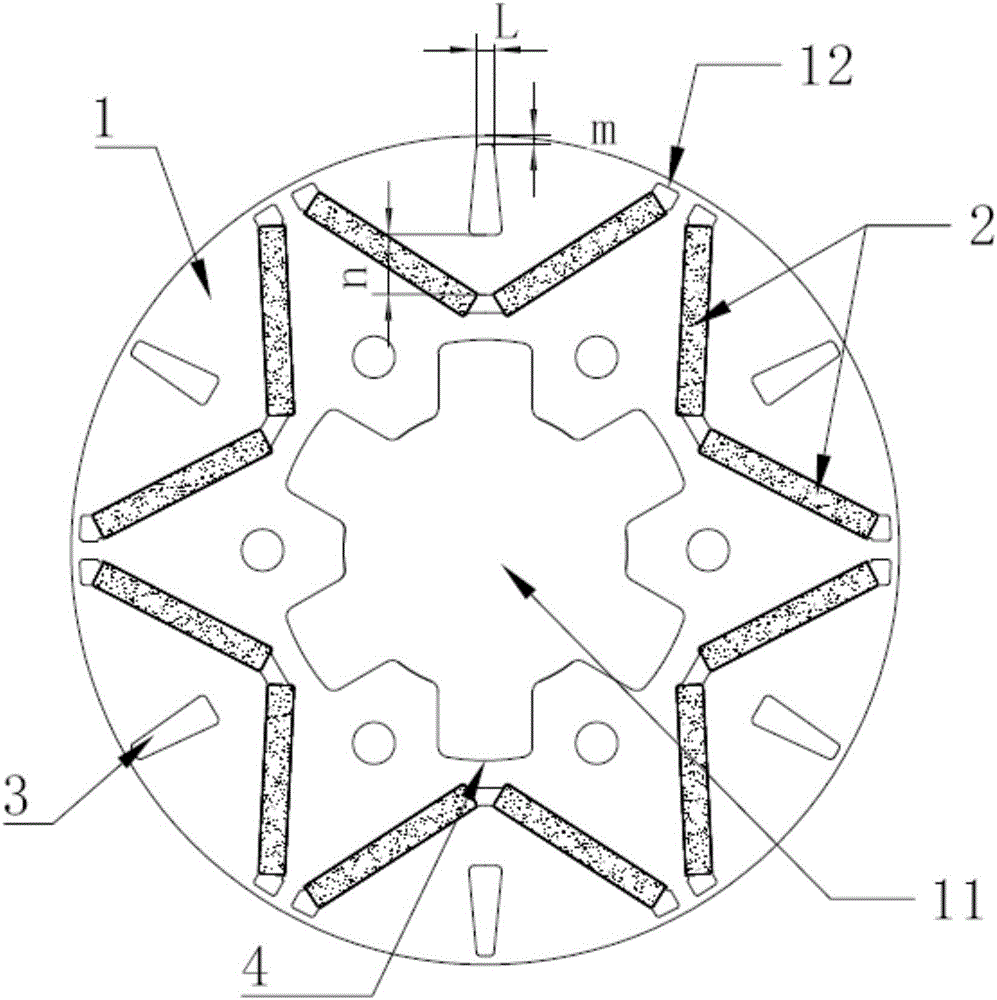

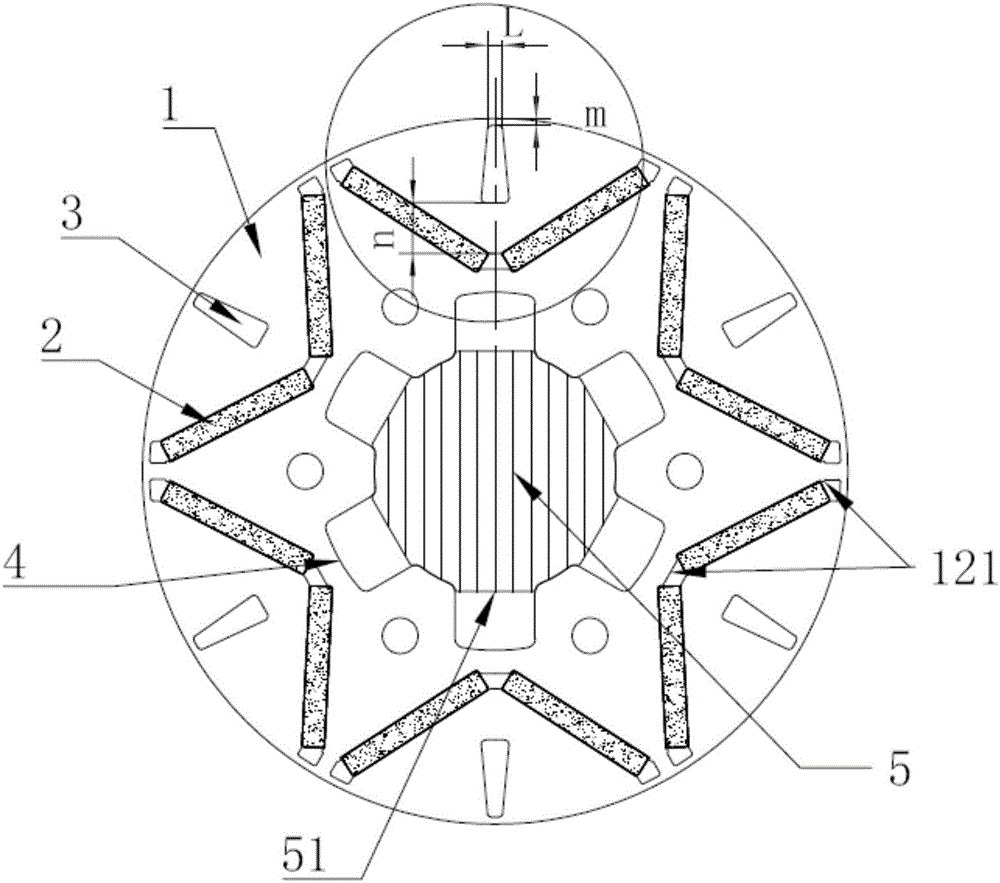

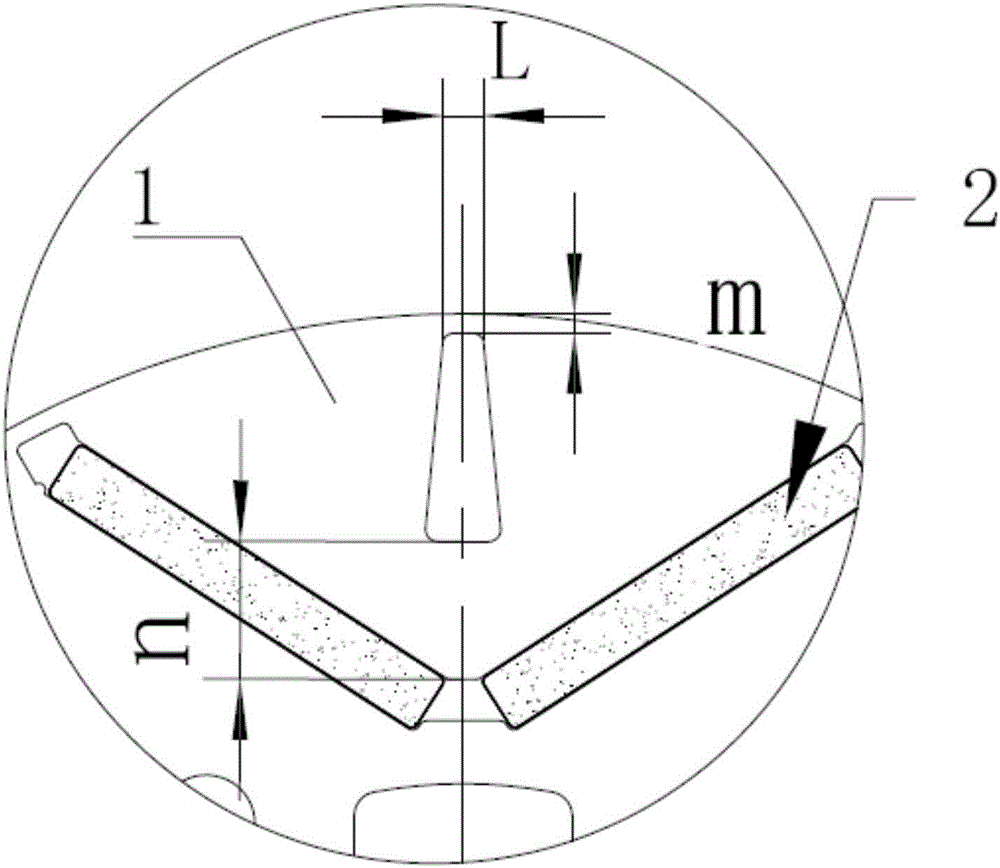

[0053] This embodiment provides a rotor structure, including a rotor core 1, a magnetic steel 2 and a limiting assembly.

[0054] Among them, such as figure 1 As shown, the rotor core 1 is formed with a shaft hole 11 for fixed connection with the rotating shaft 5 and six magnetic steel grooves 12 along its rotation axis. The magnetic steel grooves 12 are V-shaped grooves, and the six V-shaped grooves are formed in the The outer circumference of the shaft hole 11 is symmetrically distributed, the opening of the V-shaped groove is facing away from the side of the shaft hole 11, and the bottom near the shaft hole 11 is a horizontal connection part; two polarities are set in each V-shaped groove The same and symmetrically distributed magnetic steel 2, that is, two magnetic steel 2 with the same polarity are installed on the two inclined parts of the V-shaped groove respectively, and the polarity of the magnetic steel 2 in two adjacent magnetic steel grooves 12 On the contrary, fo...

Embodiment 2

[0074] This embodiment provides a motor, including a stator and a rotor structure disposed in the inner hole of the stator, and the rotor structure is any one of the rotor structures provided in Embodiment 1.

[0075] The motor in this embodiment adopts the rotor structure in Embodiment 1, so that the flow area of the inner rotor of the motor is increased, the heat dissipation speed of the motor iron core is accelerated, and the torque between the rotor and the rotating shaft 5 is ensured at the same time, and the rotation speed of the motor is reduced. Torque pulsation, reducing the noise generated by the vibration during the motor's working process.

Embodiment 3

[0077] This embodiment provides a compressor, including a motor, and the motor is any one of the motors provided in Embodiment 2.

[0078] The compressor in this embodiment adopts the motor provided in Implementation 2, so that the circulation area of the compressor’s refrigerant and oil on the rotor core 1 increases, improving the overall circulation efficiency of the compressor’s refrigerant and oil, while also being able to The torque between the rotor and the rotating shaft 5 is guaranteed, the torque ripple of the motor is reduced, the vibration noise during the operation of the motor is reduced, and the service life of the compressor and the motor is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com