Wall flow-less jetting cooling tower

A cooling water tower and jet technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as affecting the flow state of the mainstream field, unable to cure wall flow, affecting air volume inhalation, etc. Achieve the effect of ensuring the amount of air entering the tower, improving the flow field in the tower, and eliminating the phenomenon of wall flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

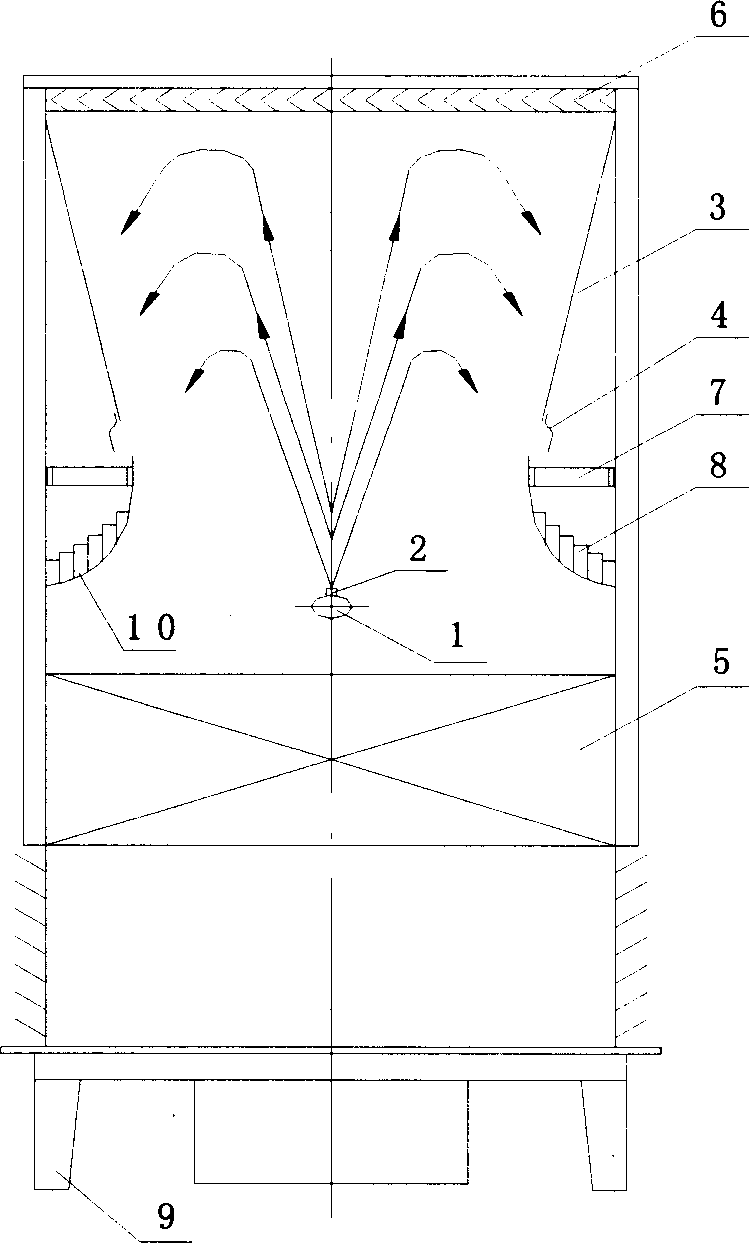

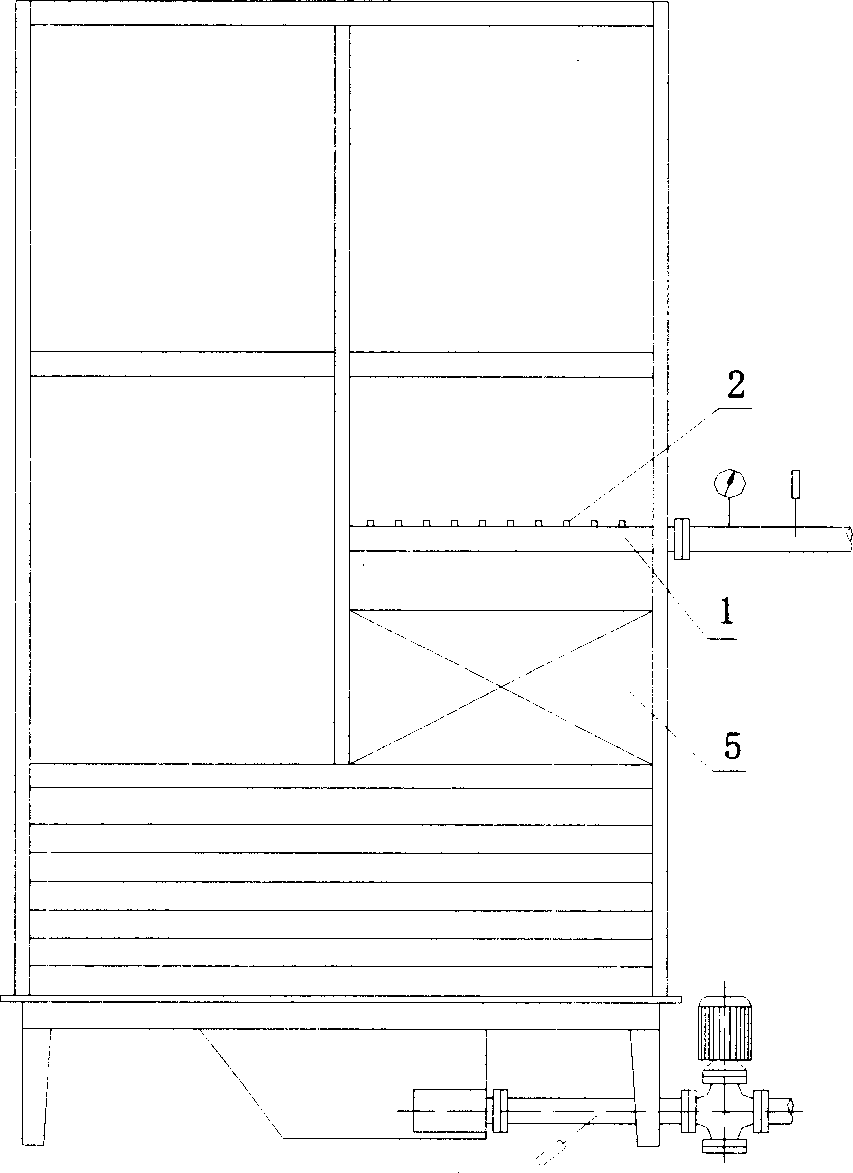

[0020] The structure of the wallless jet cooling water tower provided by the invention is as follows: figure 1 As shown, it includes a nozzle 1, a nozzle 2, a diffuser section 3, a deflector 4, a packing layer 5, a water eliminator 6, a sump 7, a compartment 8, a tower 9, and an arc deflector 10. Nozzles 1 are arranged in the middle of the cooling water tower, nozzles 2 are evenly arranged on the nozzles 1 at certain intervals, and a packing layer 5 is arranged below the nozzles 1 . There is a horizontal slit on the wall above the minimum cross-section of the lower end of the water tower diffuser section 3, and an outwardly protruding deflector 4 is installed on the outer side of the lower edge of the wall of the diffuser section 3, and the protruding distance is according to the cooling tower shower. Depends on the density of water. Below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com