Patents

Literature

380results about How to "Improve the flow field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

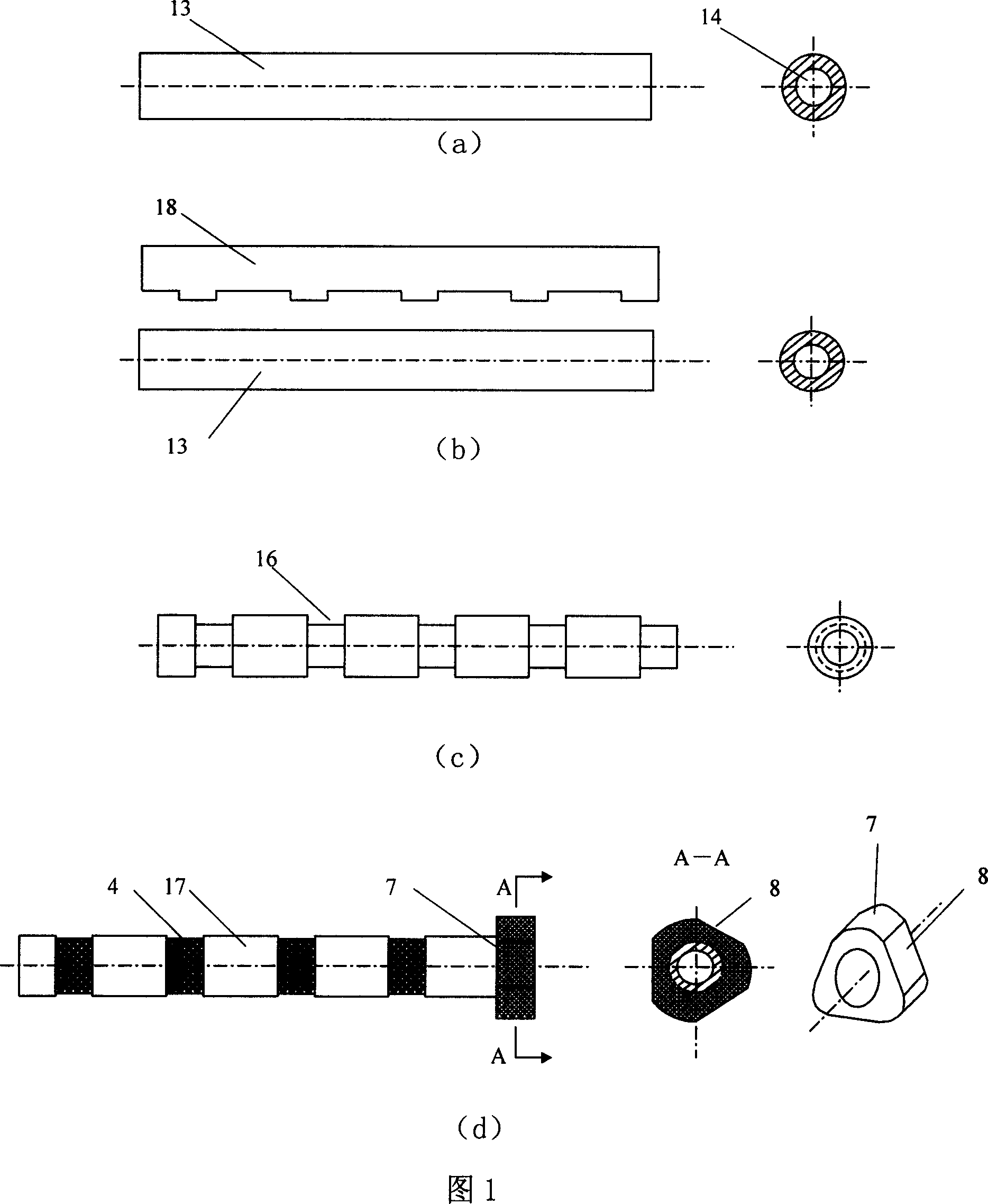

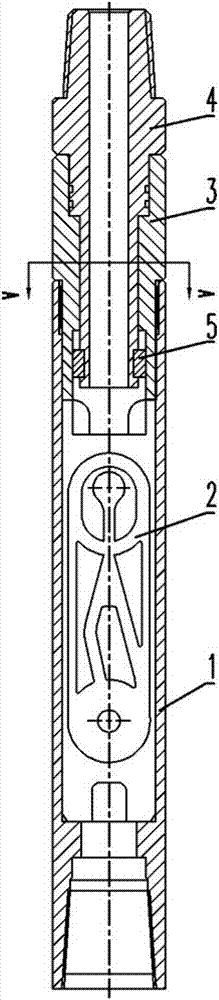

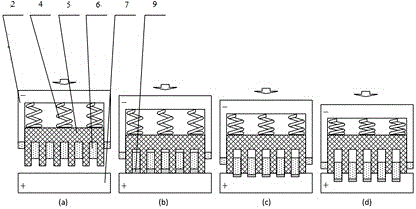

Electrolytic processing method for ribbed deep small holes and special tool cathode

InactiveCN1943951AImprove ECM EfficiencyEasy to prepareMachining electrodesElectrical-based machining electrodesMachining processSmall hole

The present invention is electrolytic processing method for ribbed deep small hole and its special tool cathode, and belongs to the field of electrolytic machining technology. The method includes the following steps: electrolytic machining one metal pipe with one reversely copied cathode to form notches in the surface of the metal pipe; coating epoxy resin glue into the notches; installing positioning rack to the end of the tool electrode to make the forming tool electrode; machining smooth hole in the workpiece; stretching the forming tool electrode into the deep smooth hole to machine the ribbed deep small hole. The present invention has simple machining of the forming tool electrode, high ribbed hole machining precision, high machining stability and other advantages.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

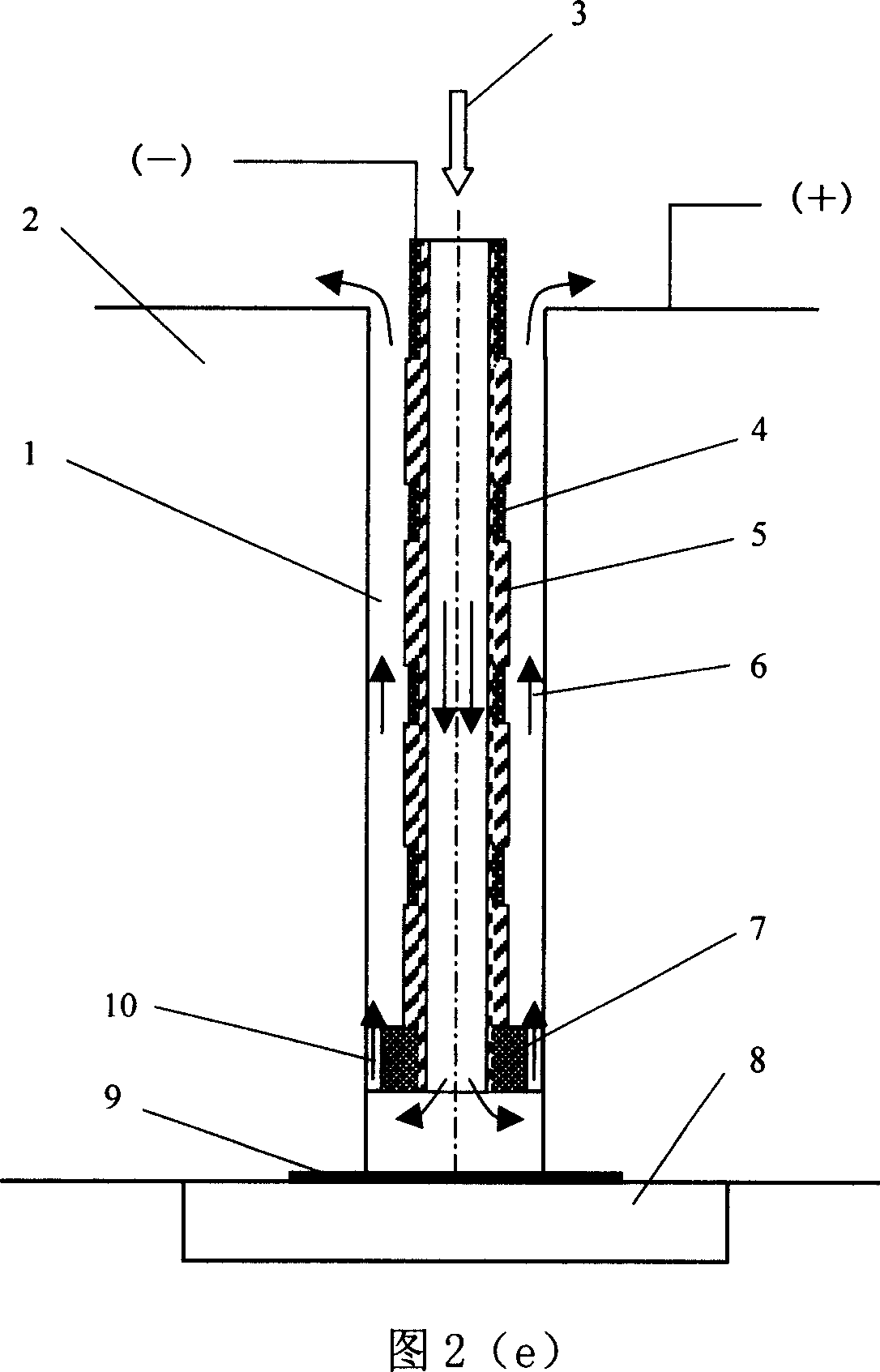

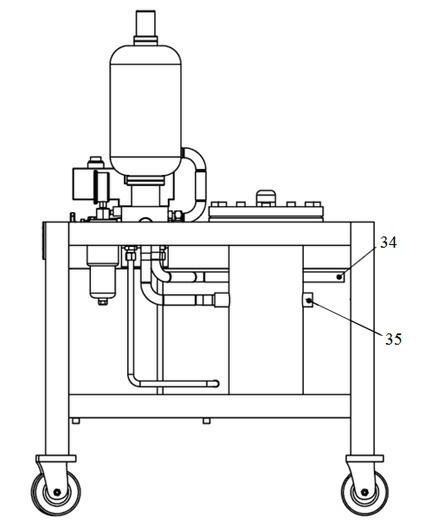

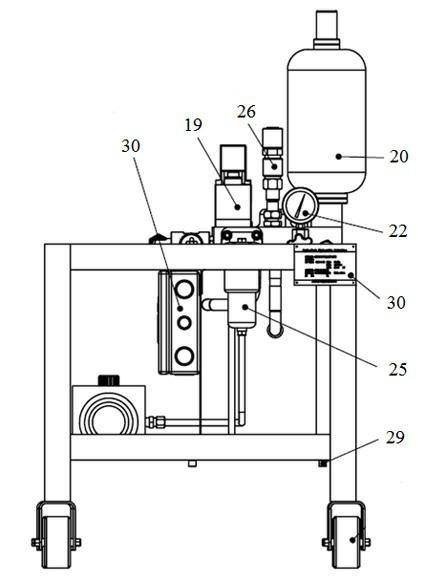

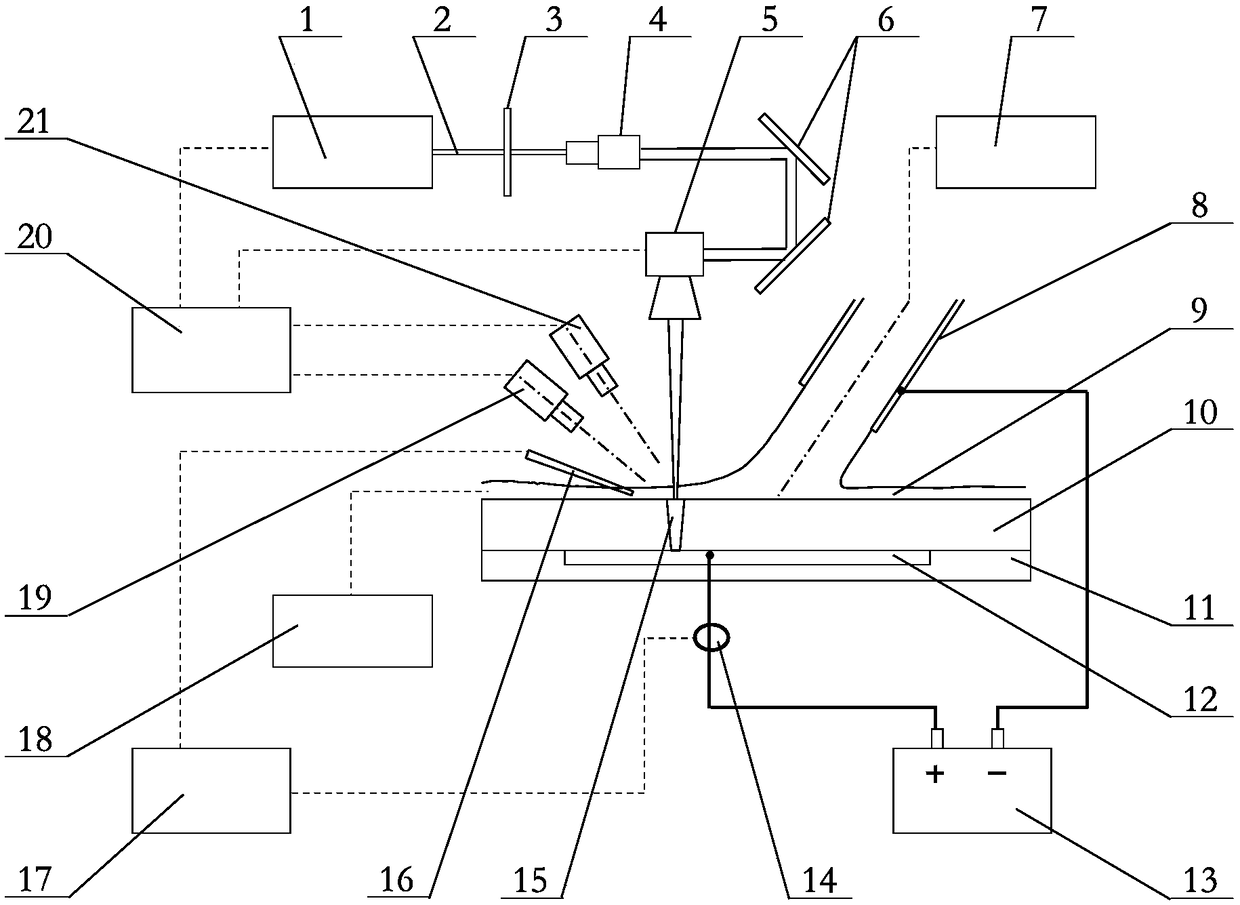

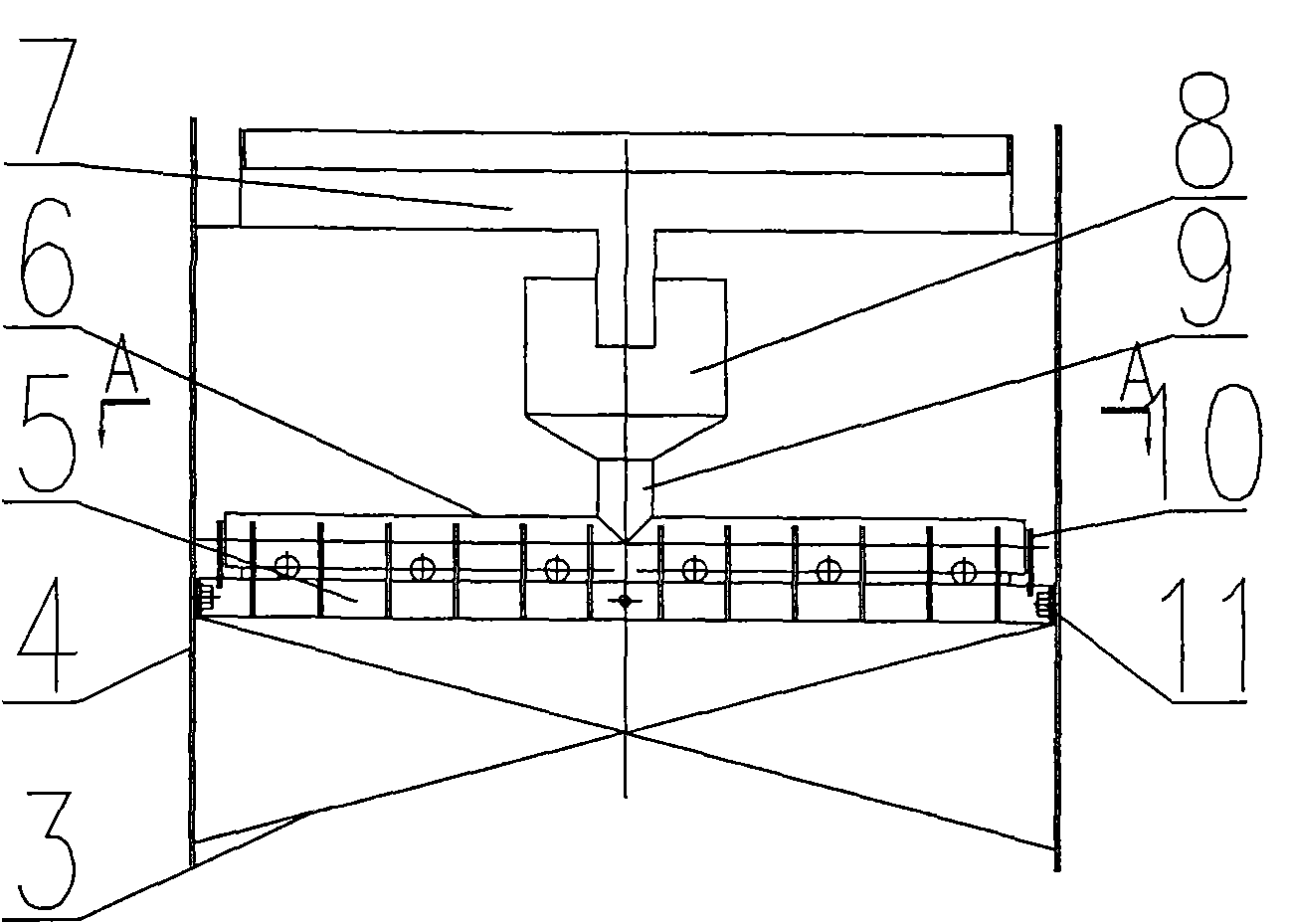

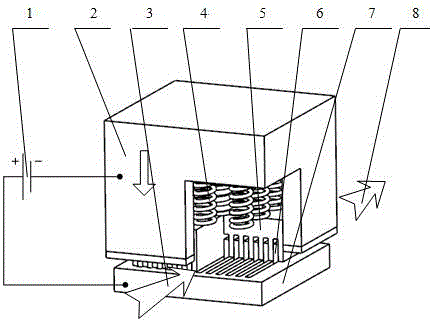

Electrochemical machining method and device for pulsating flow field tube electrode

ActiveCN102198549AReduce the "holding effect"Reduce the "squeeze effect"Machining working media supply/regenerationVoltage pulseElectrolysis

The invention relates to an electrochemical machining method and an electrochemical machining device for a pulsating flow field tube electrode, and belongs to the technical field of electrochemical machining. The method comprises the following steps of: 1, adjusting the flow and the pressure by controlling an action of a spool of a servo valve (9) by a pressure servo execution module (4), and outputting a pulsating electrolyte solution to an electrochemical machining area; 2, modulating a control instruction phase by using a control system of an electrochemical machining machine tool according to a pressure and voltage feedback signal, so that the pressure of the machining area is matched with the voltage pulse rhythm; and 3, dynamically adjusting a feeding speed and the machining voltage by using the control system of the electrochemical machining machine tool so as to machine a hole with a variable section in regular change. The method and the device provided by the invention have important meaning for increasing the flocculent product discharge rate and the machining stability of the electrochemical machining of a neutral saline solution deep hole tube electrode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

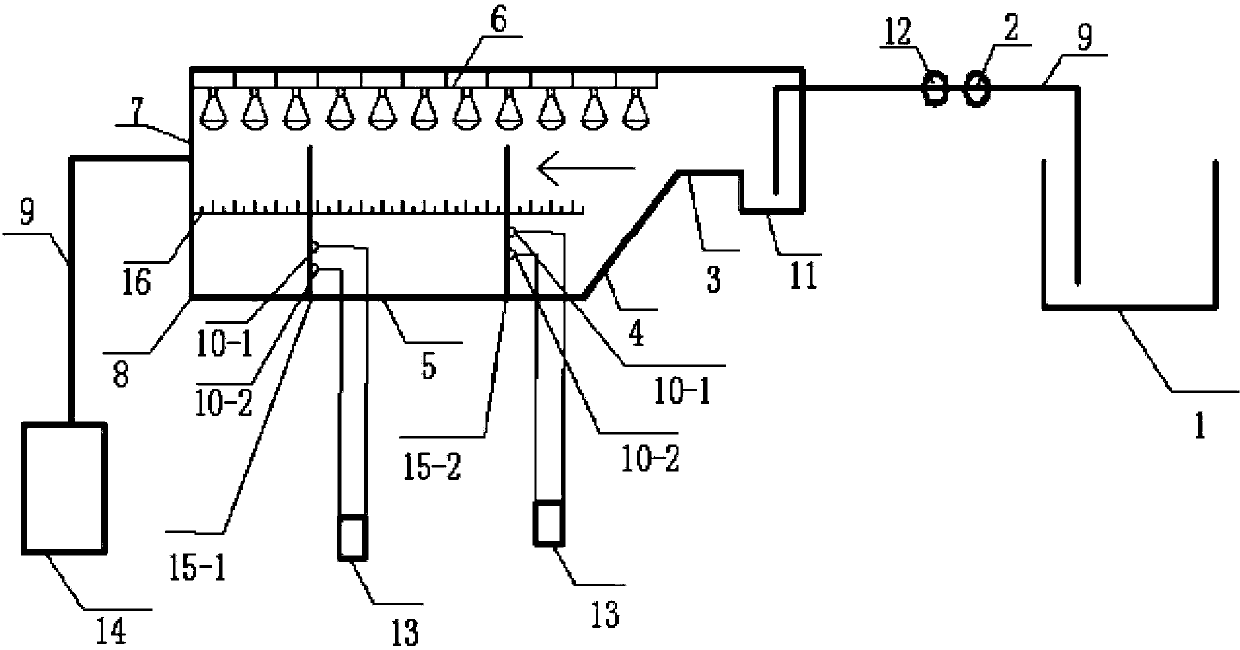

Temperature difference-sediment coupling density flow simulation test system

ActiveCN103424240ABeneficial technical effectReduce distractionsHydrodynamic testingHydraulic modelsSurface layerWater channel

The invention relates to a temperature difference-sediment coupling density flow simulation test system. The test system comprises a muddy water tank, a water pump, a heating device, a water channel, a turbine flowmeter, a plurality of thermographs and a circulating water pond; the water channel is connected with the water pump and the muddy water tank through a duct, the turbine flowmeter is connected with the duct, temperature probes of each thermograph are arranged at two vertical water temperature measurement positions of the side wall inside the water channel, and the heating device is installed above the water channel. The test system is simple in structure and convenient to operate; by the aid of the test system, the interference of the heating device to a flow field inside the water channel at the density flow test stage in the past is reduced, and the motion process of a sediment density flow in a temperature-layered water body is simulated successfully; special phenomena of advancing of the sediment density flow in the middle layer and the surface layer of the water channel under the influence of vertical water temperature laying are achieved, and in addition, the reliability and the accuracy of density flow analysis and research can be improved.

Owner:SICHUAN UNIV

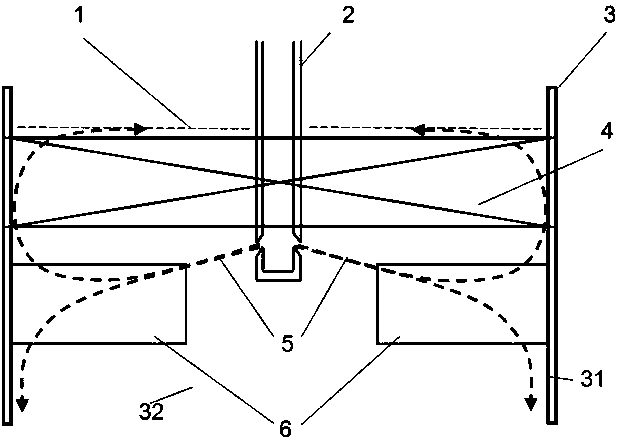

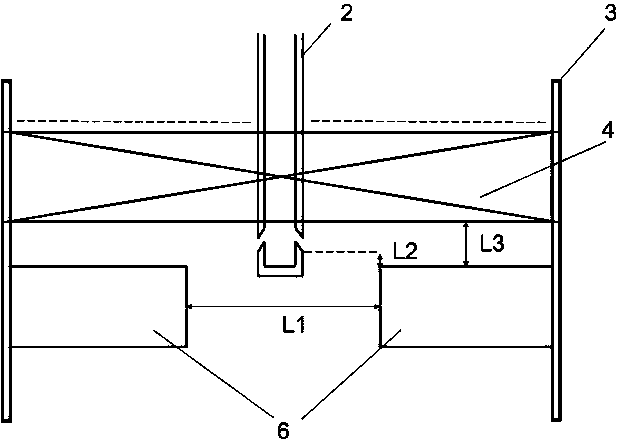

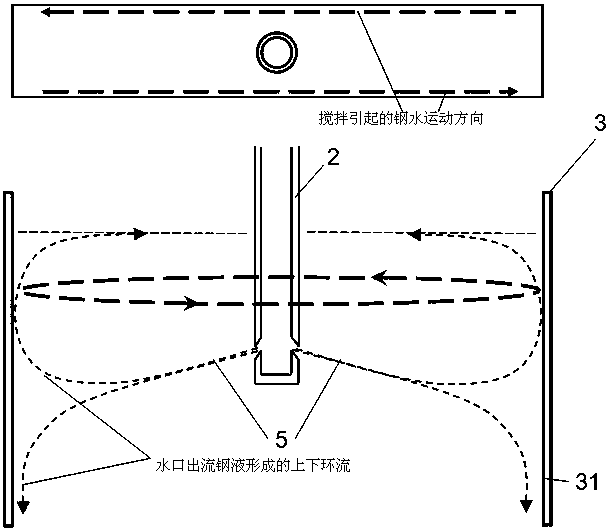

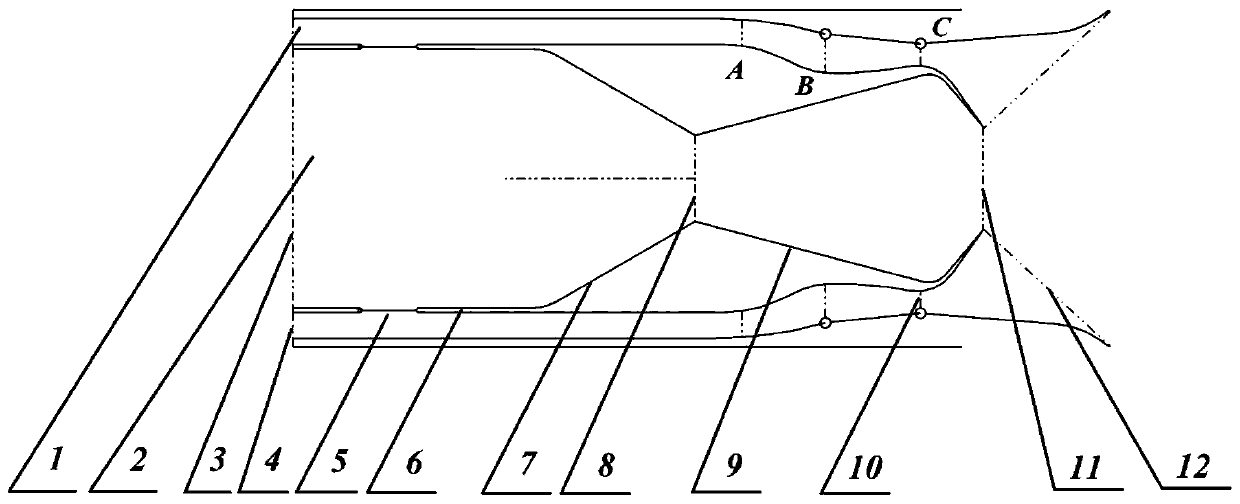

Slab continuous casting crystallizer flow field control method

The invention discloses a slab continuous casting crystallizer flow field control method. The slab continuous casting crystallizer flow field control method comprises the following steps that electromagnetic stirring devices and electromagnetic braking devices are used for controlling a slab continuous casting crystallizer flow field, the electromagnetic stirring devices are configured at the upper parts of the two sides of a crystallizer wide surface, the electromagnetic braking devices are configured at the lower parts of the two sides of the crystallizer wide surface, and the electromagnetic stirring devices at the upper parts and the electromagnetic braking devices at the lower parts are mutually independent; the electromagnetic stirring devices at the upper parts are installed betweena space above the upper edge of the outlet of a water gap, and a meniscus surface, and the electromagnetic braking devices at the lower parts adopt regional braking, are located at the positions, below the outlet of the water gap, of the two sides of the outlet of the water gap, and act on an area, where water gap outflow streams flow through, between the water gap and a crystallizer narrow surface; and the electromagnetic stirring devices at the upper parts and the electromagnetic braking devices at the lower parts are correspondingly powered through two sets of power supplies, and correspondingly and independently control the current intensity. The electromagnetic stirring devices at the upper parts adopt a traveling wave magnetic field mode, and correspondingly drive liquid steel to make relative horizontal motion in magnetic fields on the two sides of the crystallizer wide surface.

Owner:BAOSHAN IRON & STEEL CO LTD

Bilateral opposite flushing inlet wet ammonia method for flue gas desulfurizing technology and device thereof

InactiveCN101053743AOptimizing the smoke flow fieldImprove desulfurization efficiencyDispersed particle separationChemistrySulfur dioxide

A wet ammonia method flue gas desulfurization process of two-side opposed inlet and device thereof, which makes the flue gas to form uniform upward opposed turbulence, then makes the flue gas to pass through flue gas antivortex baffle and ammonia desulfurizer cycle spraying layer which are staggered arranged to rapidly transmute the sulfur dioxide in the flue gas to be ammonium salt admixture, lastly, oxidates the ammonium sulfite in the ammonium salt admixture to be ammiaonia sulfate and outputs the clear flue gas after demisted. The device comprises an ammonia replenishment system and an air feeding device at the bottom of the thionizer, an opposed flue gas inlet at the lower of the thionizer, flue gas antivortex baffle and ammonia desulfurizer cycle spraying layer interleaving mounted at the middle of the thionizer, and a demister at upper of the thionizer, wherein the bottom of the thionizer is connected with the ammonia desulfurizer cycle spraying layer by cycle pump, the process and the device can improve the flue gas flow field effectively, enhance the gas-liquid mass transfer, and largely raise the desulfurization and the utilance of desulfurizer at the precondition without increasing the thionizer resistance and the consume of desulfurizer.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

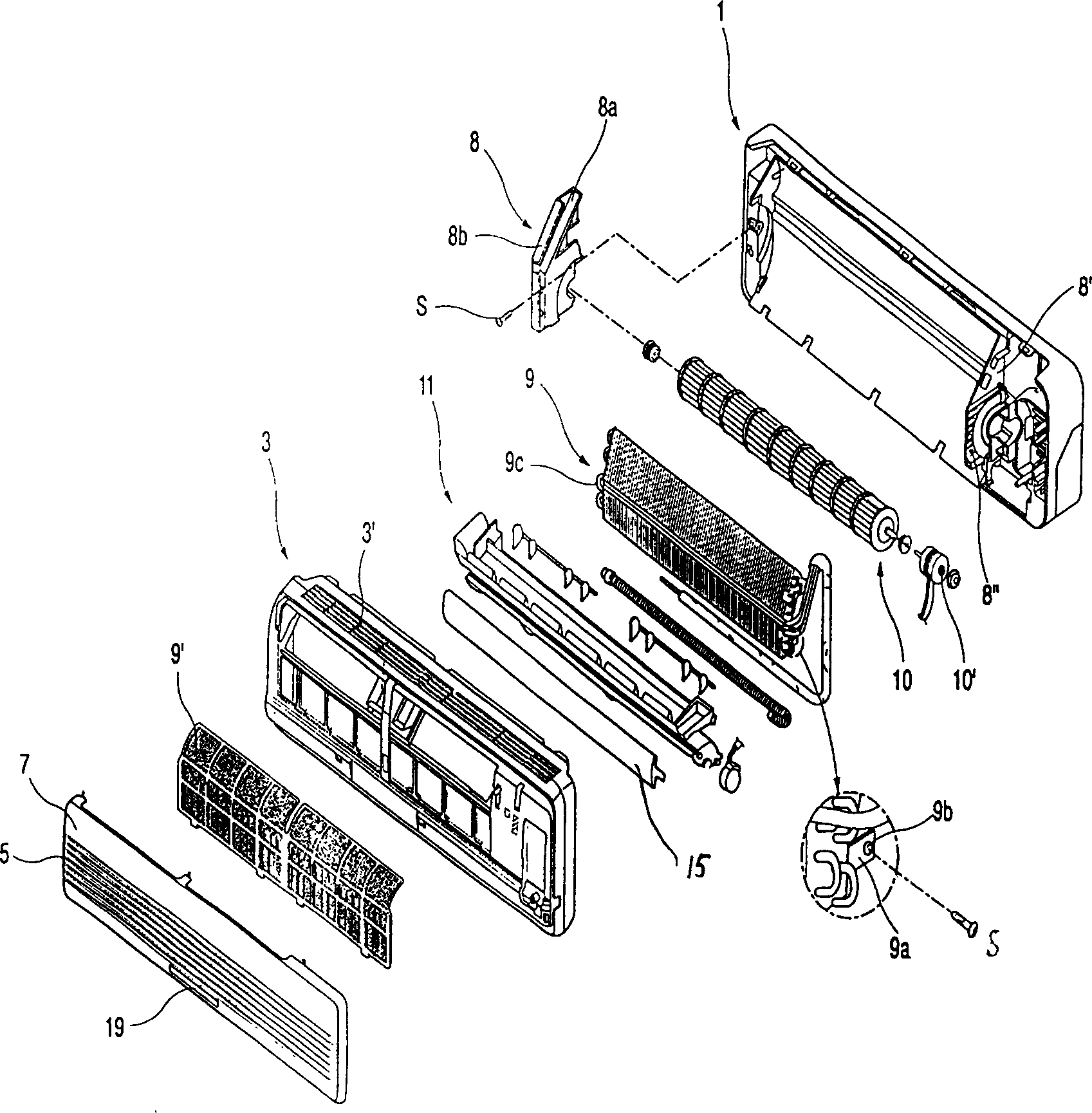

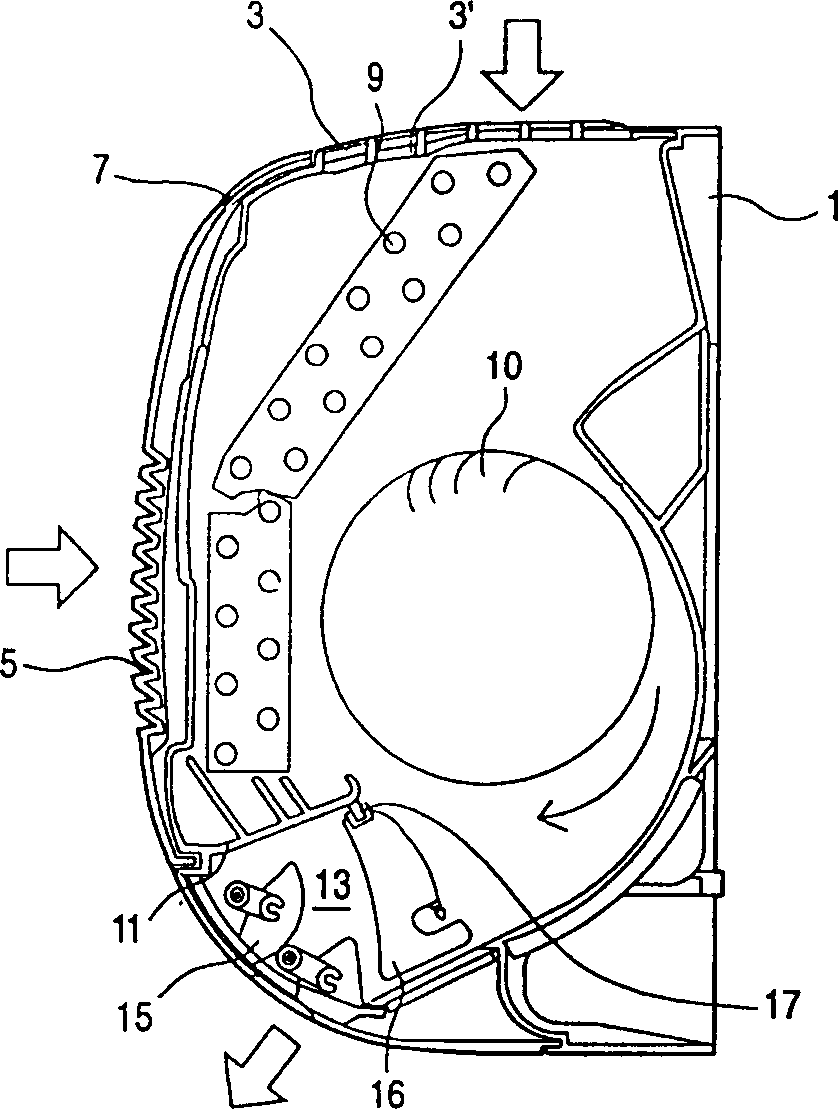

Flow guide plate structure of air outlet of air conditioner

The present invention discloses a kind of flow guide plate structure for air outlet of air conditioner, and the flow guide plate is provided with flow guide groove. The flow guide groove is circular, triangular, trapezoidal, rectangular, etc. The flow guide plate with flow guide groove can optimize the flow field and lower noise. The flow guide plate structure for air outlet is suitable for the indoor unit of split wall hung air conditioner as well as the indoor unit of split cabinet type air conditioner.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Dielectric barrier discharge (DBD) plasma trailing edge jetting device and method

InactiveCN102595758AImprove the flow fieldReduce flow lossAlighting gearPlasma techniqueJet flowAircraft landing

The invention discloses a dielectric barrier discharge (DBD) plasma trailing edge jetting device and method, relating to a flow control technology. The device comprises a plurality of groups of plasma exciters, insulating media and a high-voltage power supply and is used for improving the flowing at a wake area for the flow around a cylinder, wherein the plasma excitation of certain strength is applied to a proper position at a leeward of the cylinder, the movement of low-velocity flowing bodies in a boundary layer is accelerated to form jet flows on a wake space at the trailing edge of the cylinder, so that a wake low-velocity area can be flattened to further achieve the effects of improving a flow field at the wake area and reducing wake losses pneumatic noises, and the device can be applied to resistance reduction and noise reduction for an aircraft landing gear. The DBD plasma trailing edge jetting device disclosed by the invention has the advantages of simple and compact structure, high reaction speed, low energy consumption and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

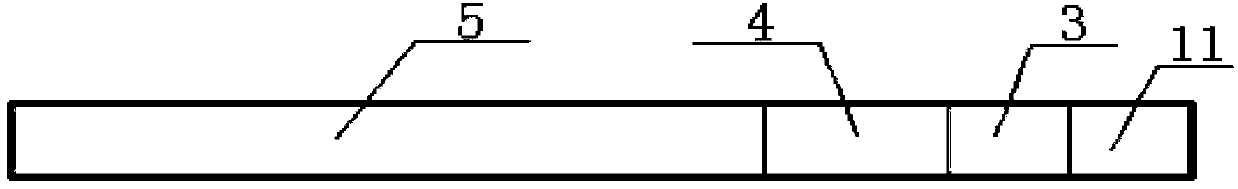

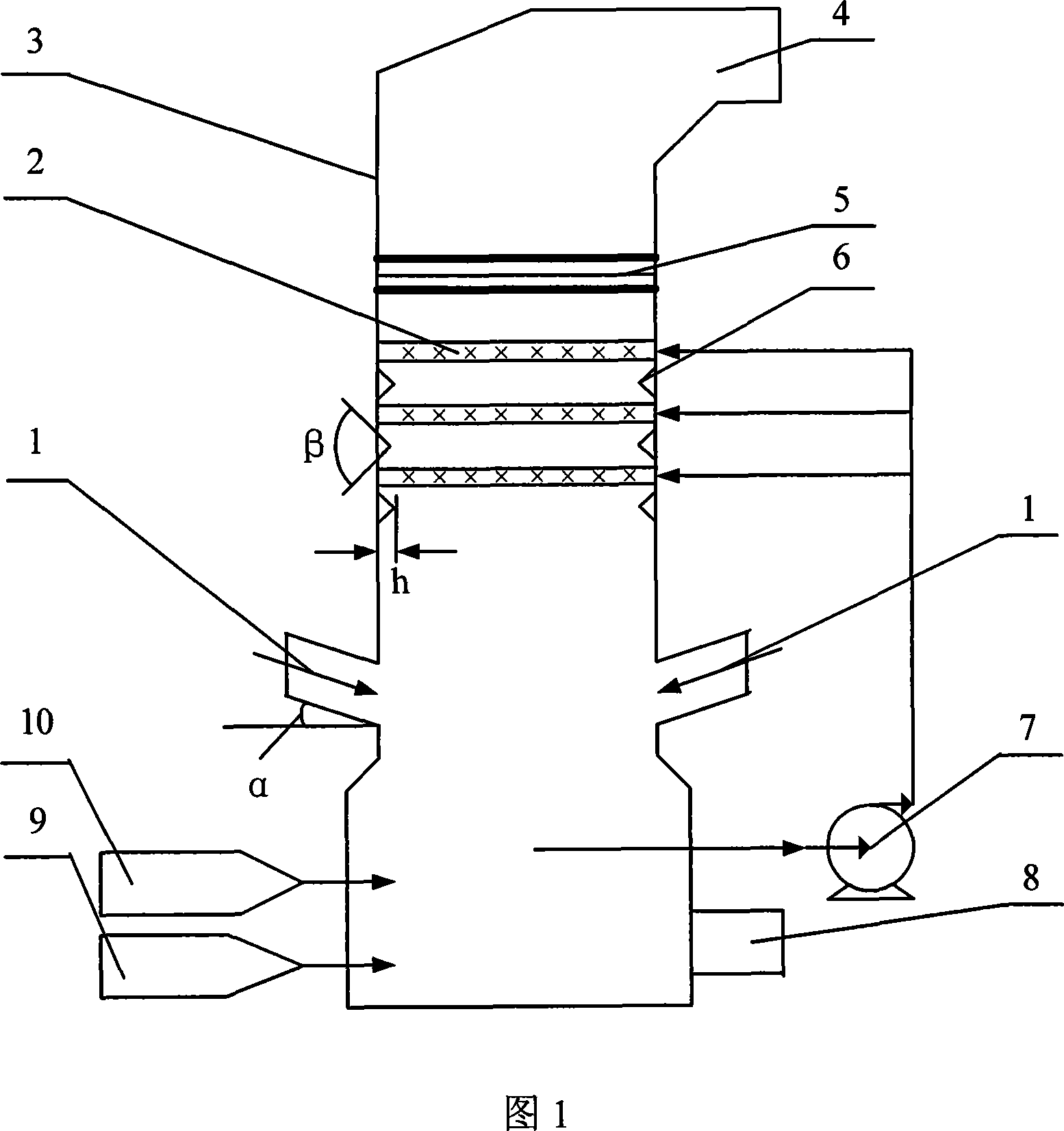

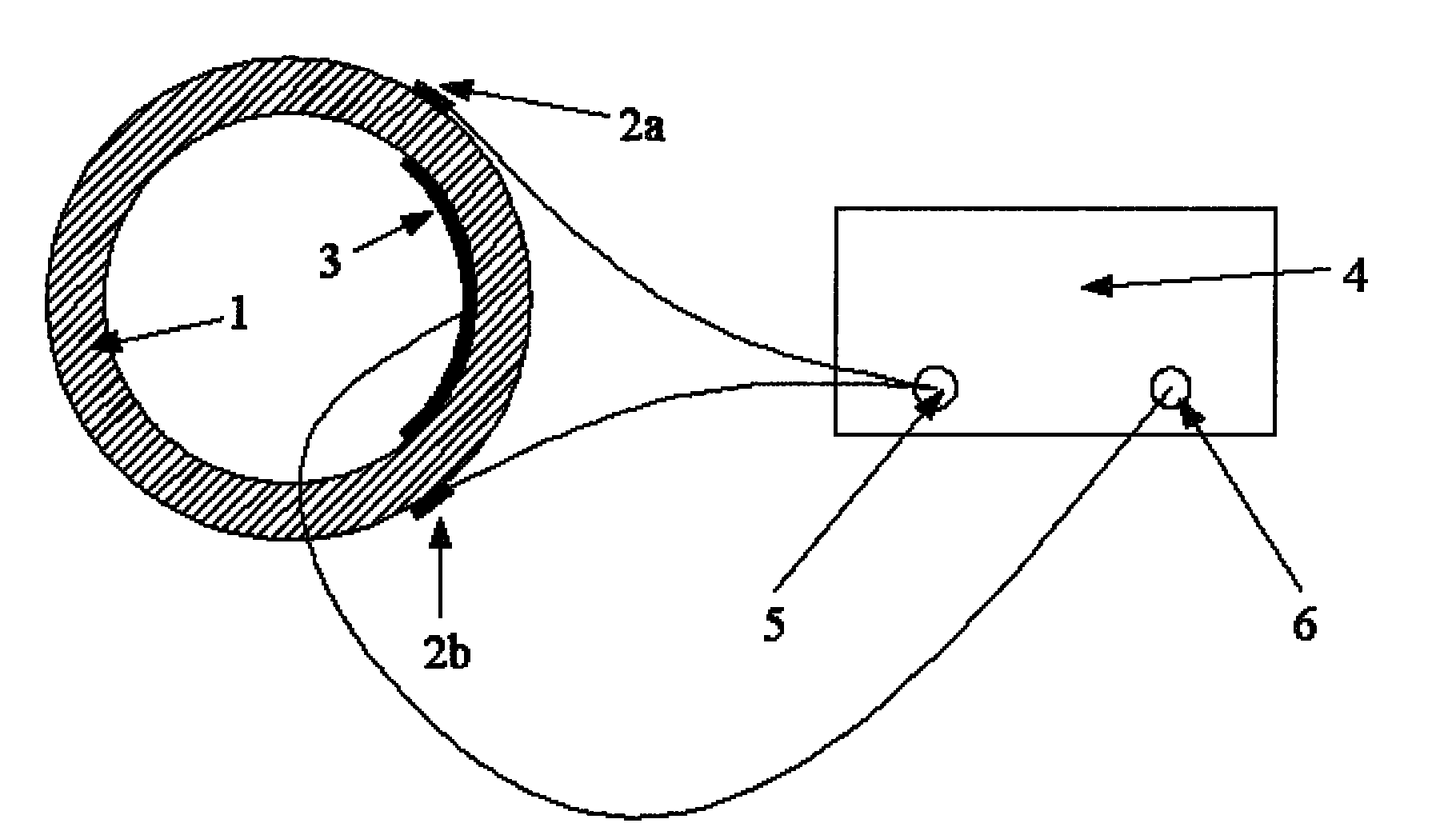

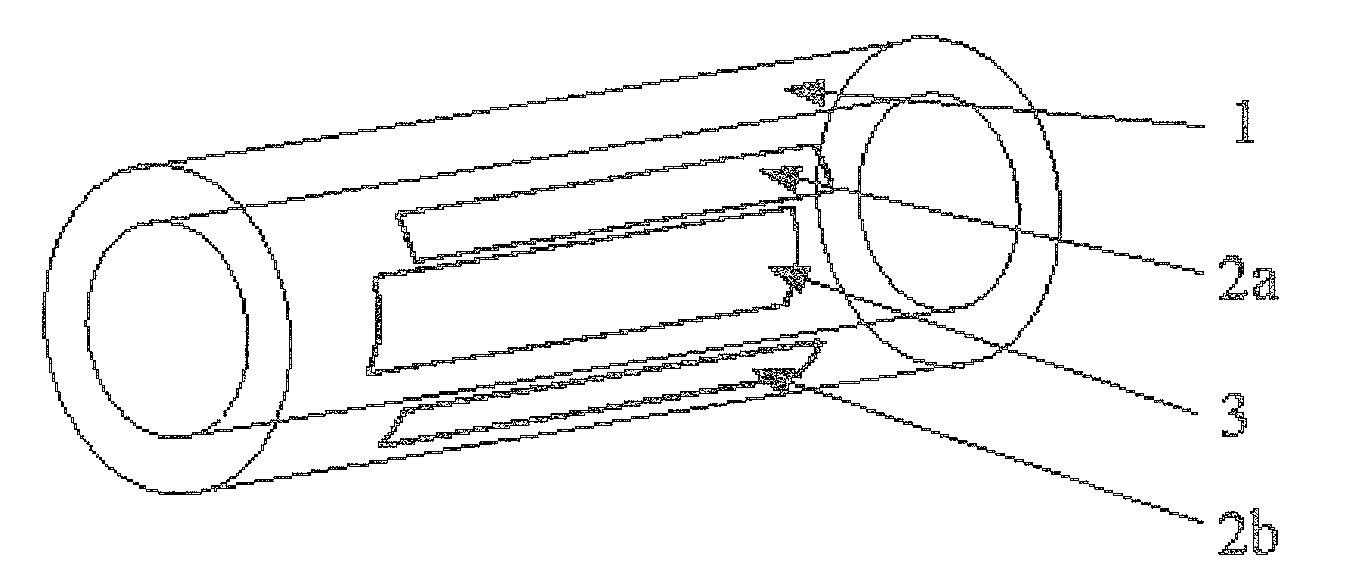

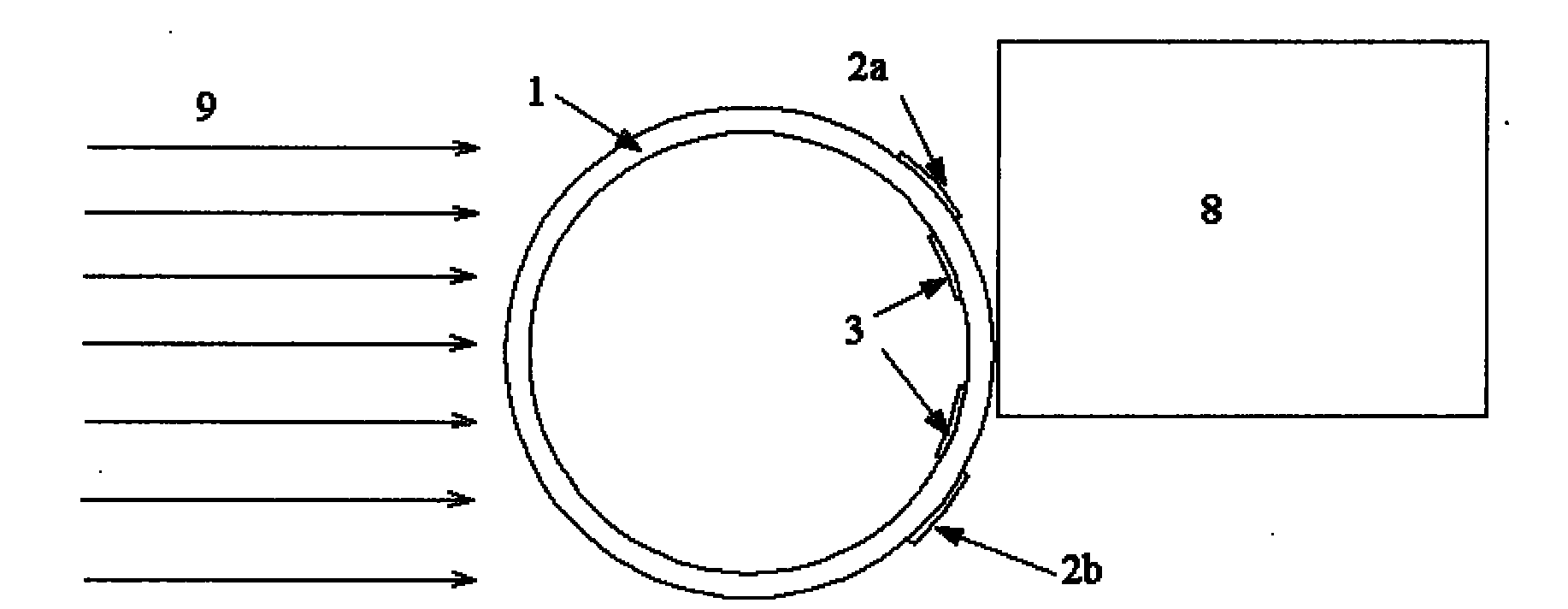

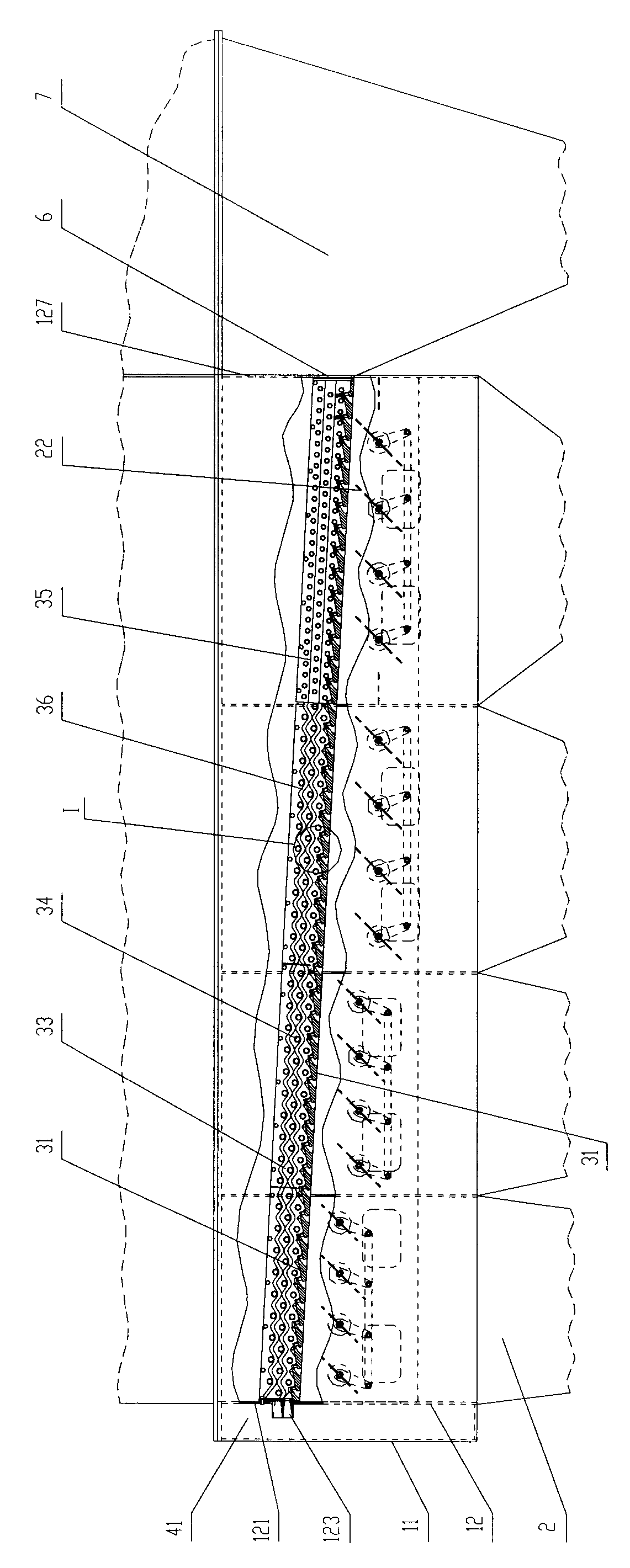

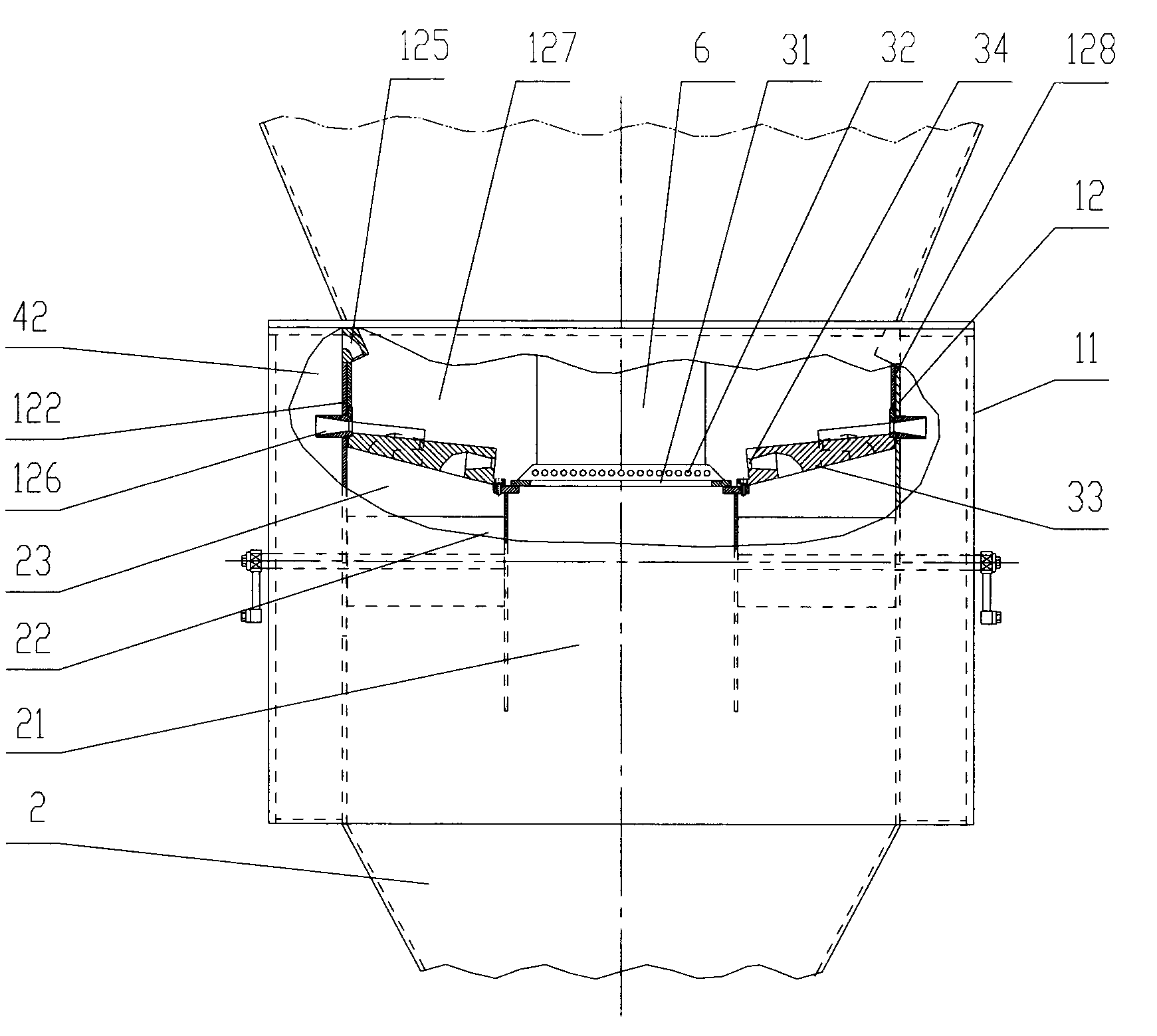

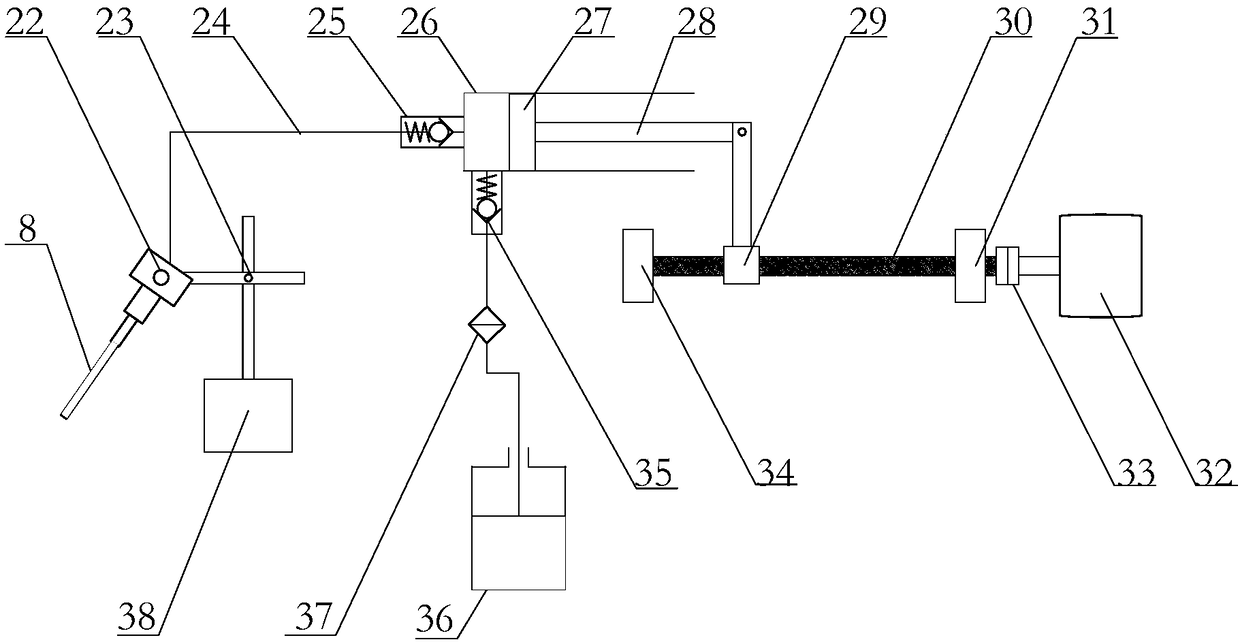

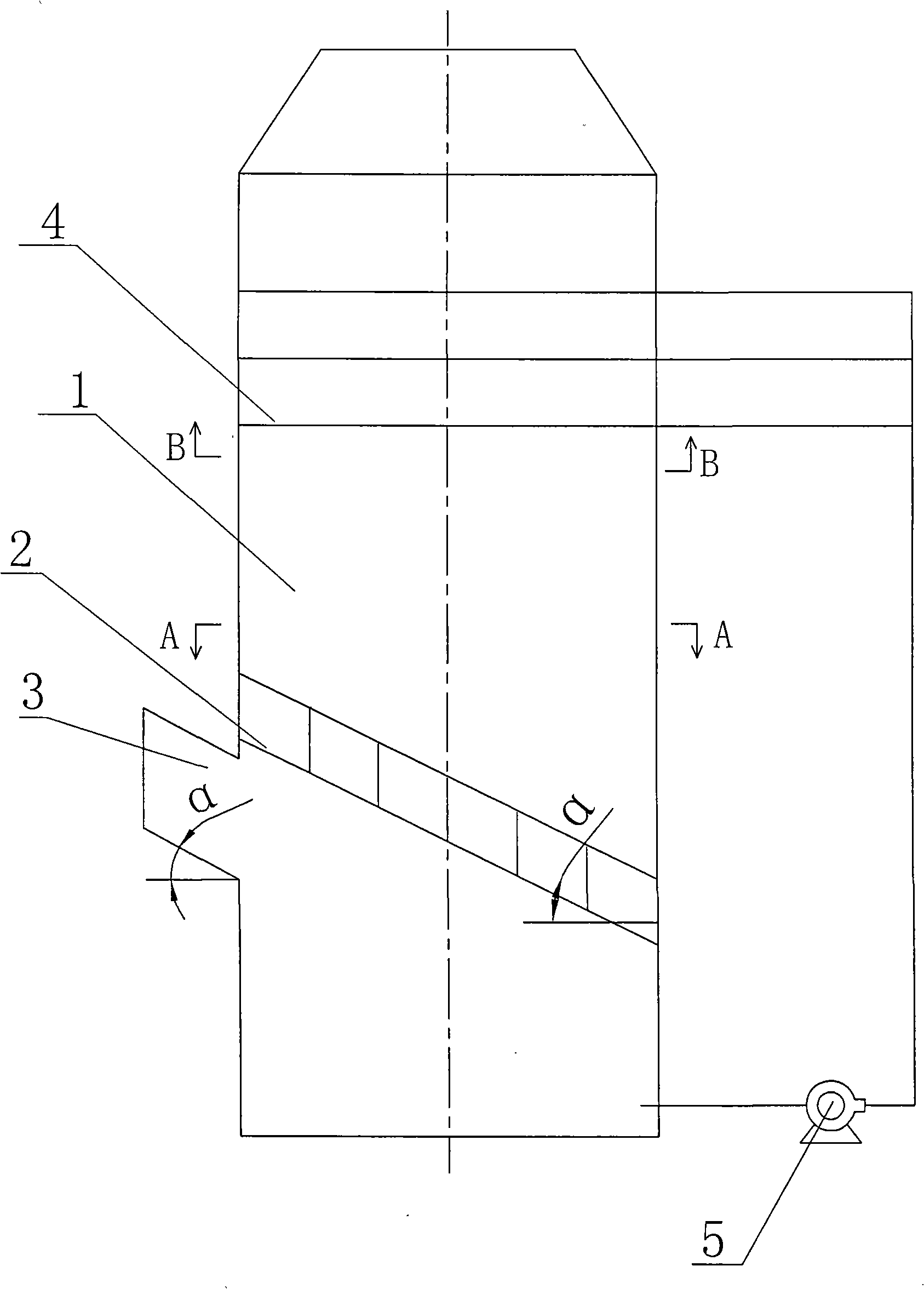

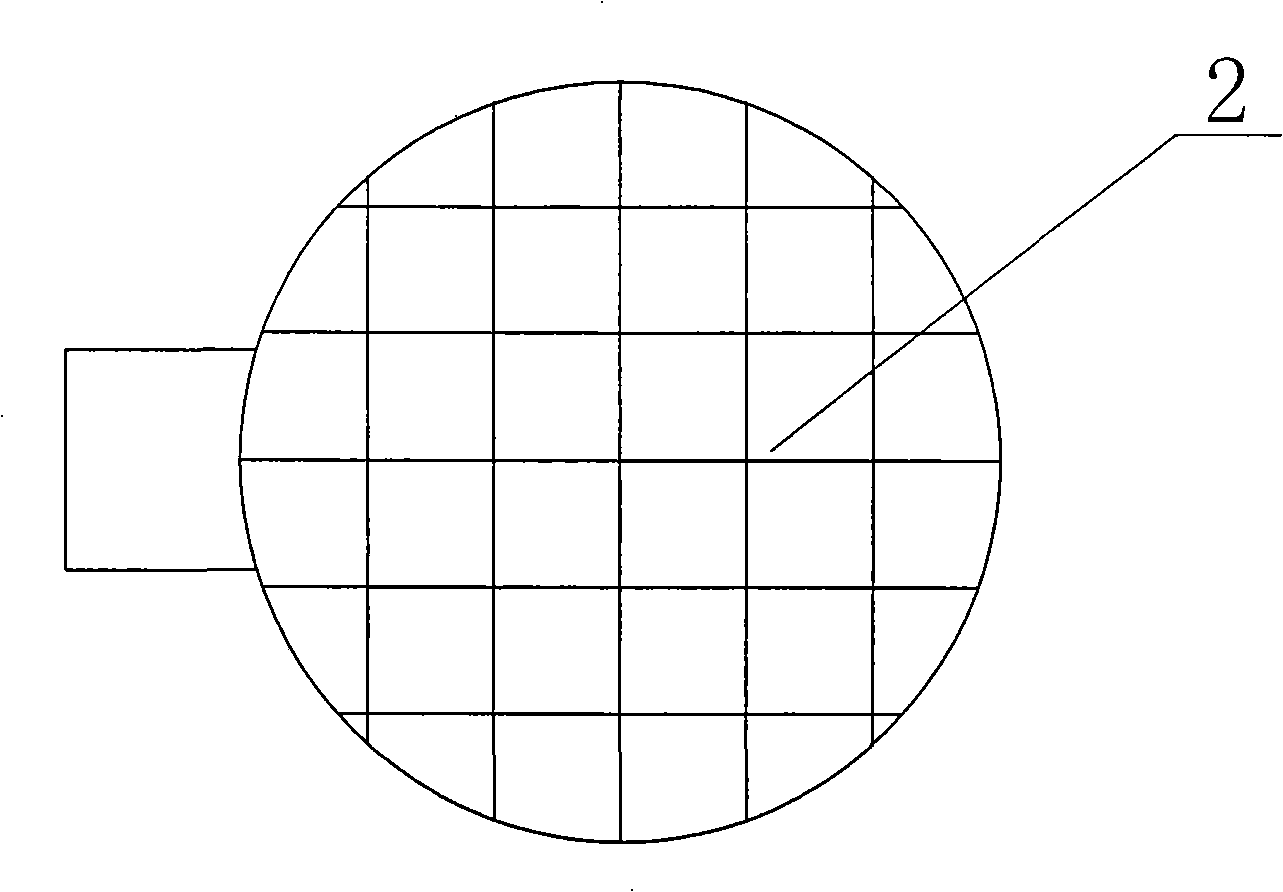

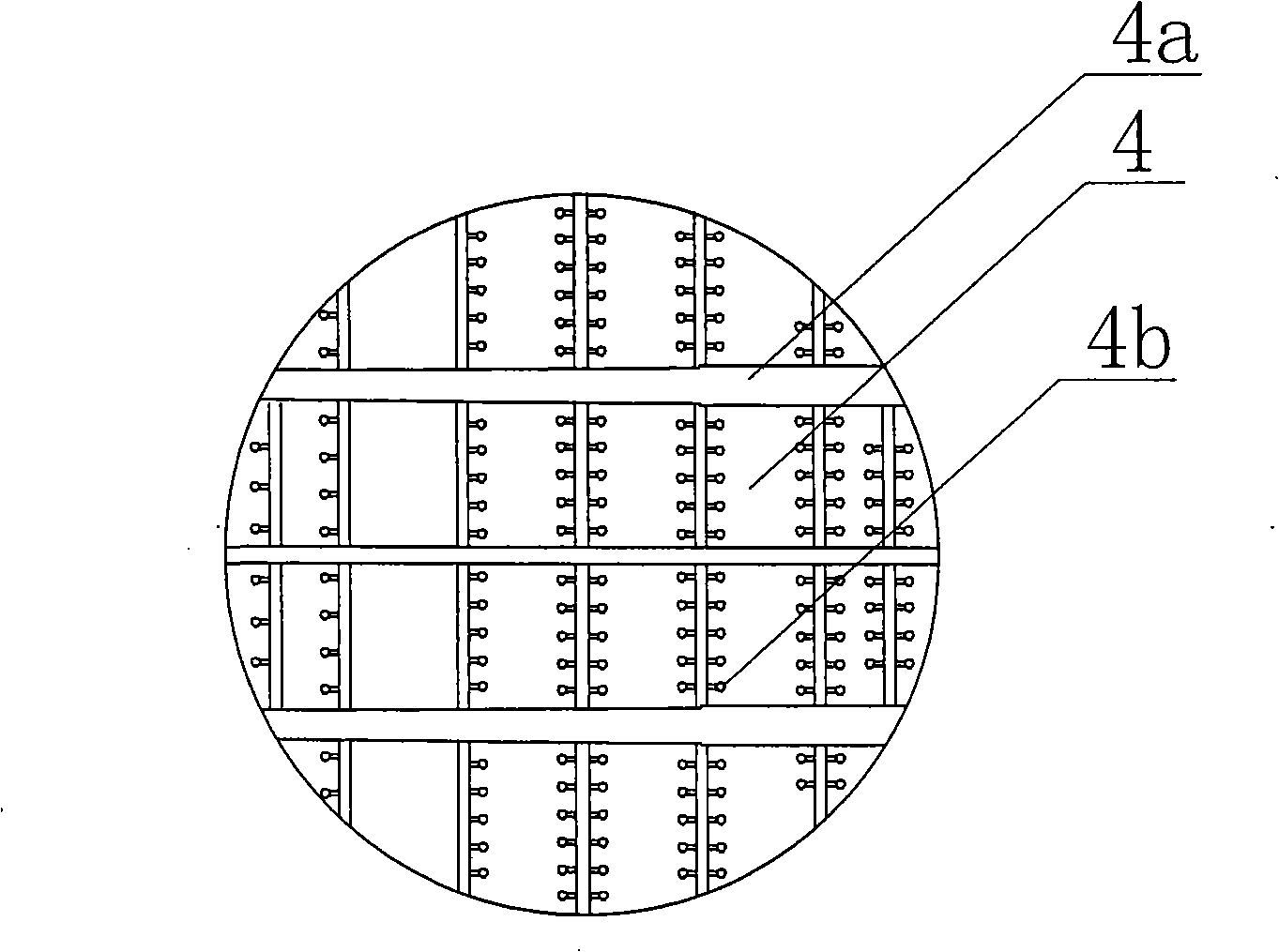

Covered argon blowing refining device for slab continuous casting tundish strip-shaped air brick and argon control method

The invention relates to a covered argon blowing refining device for a slab continuous casting tundish strip-shaped air brick and an argon control method. The device comprises a turbulent controller (1), a dipping cover (2), the strip-shaped air brick (3), a retainer wall (4) and an inclined hole stop dam (5); the dipping cover (2) is positioned rightly above the strip-shaped air brick (3); the lower end of the dipping cover (2) is dipped below a lowest pouring liquid level (9) of molten steel in a continuous-cast ladle exchange process tundish; an argon blowing control system PLC is adopted to collect and upload a pressure value of a first pressure gauge (22a), a flow value of a special metallurgy mass-flow controller (25) and a pressure value of a second pressure gauge (22b) into a continuous casting foundation automatic system database through ethernet communication; an argon flow automatic control instruction of the argon blowing control system PLC is performed; and the argon flow is automatically adjusted according to the net weight change of the molten steel in the tundish, so that the precise control is realized, and the effect of the tundish removing inclusions in the molten steel is improved.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

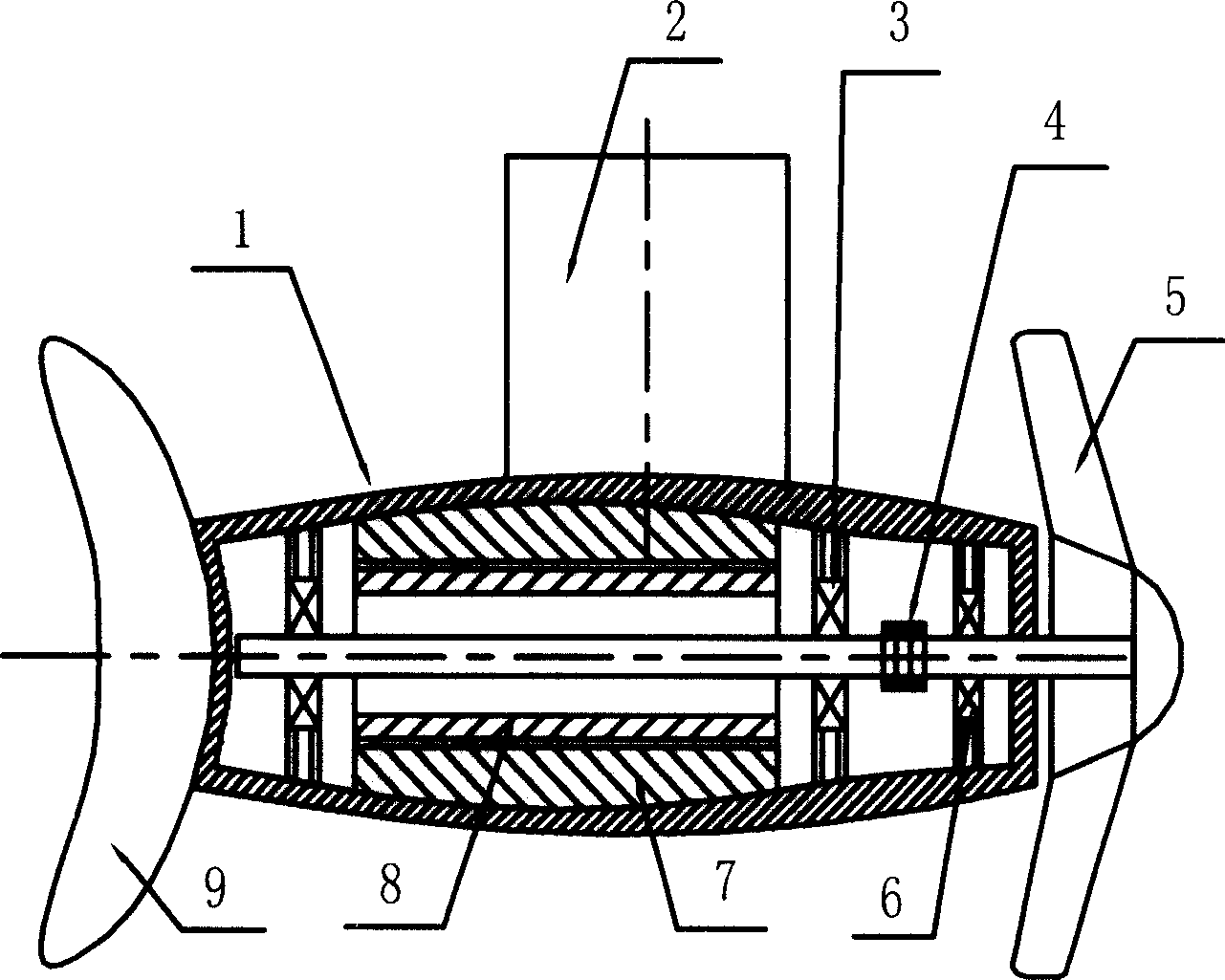

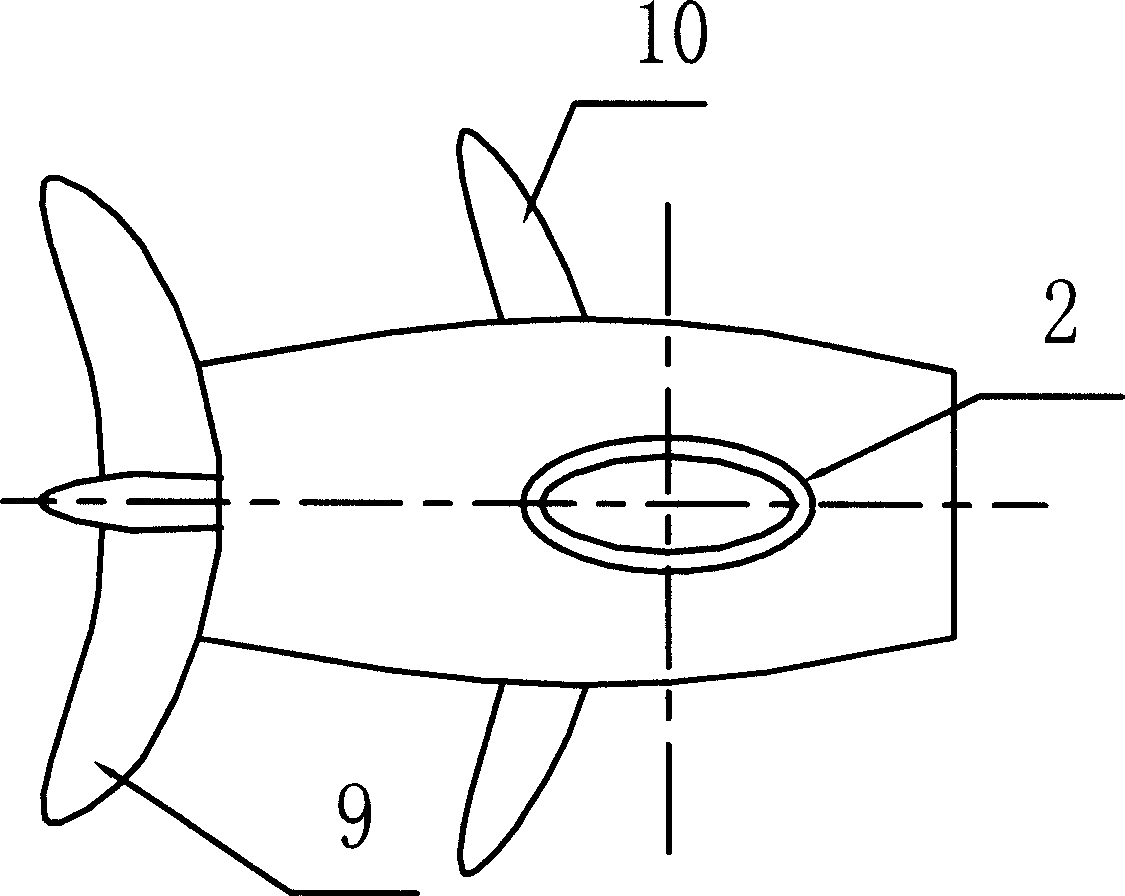

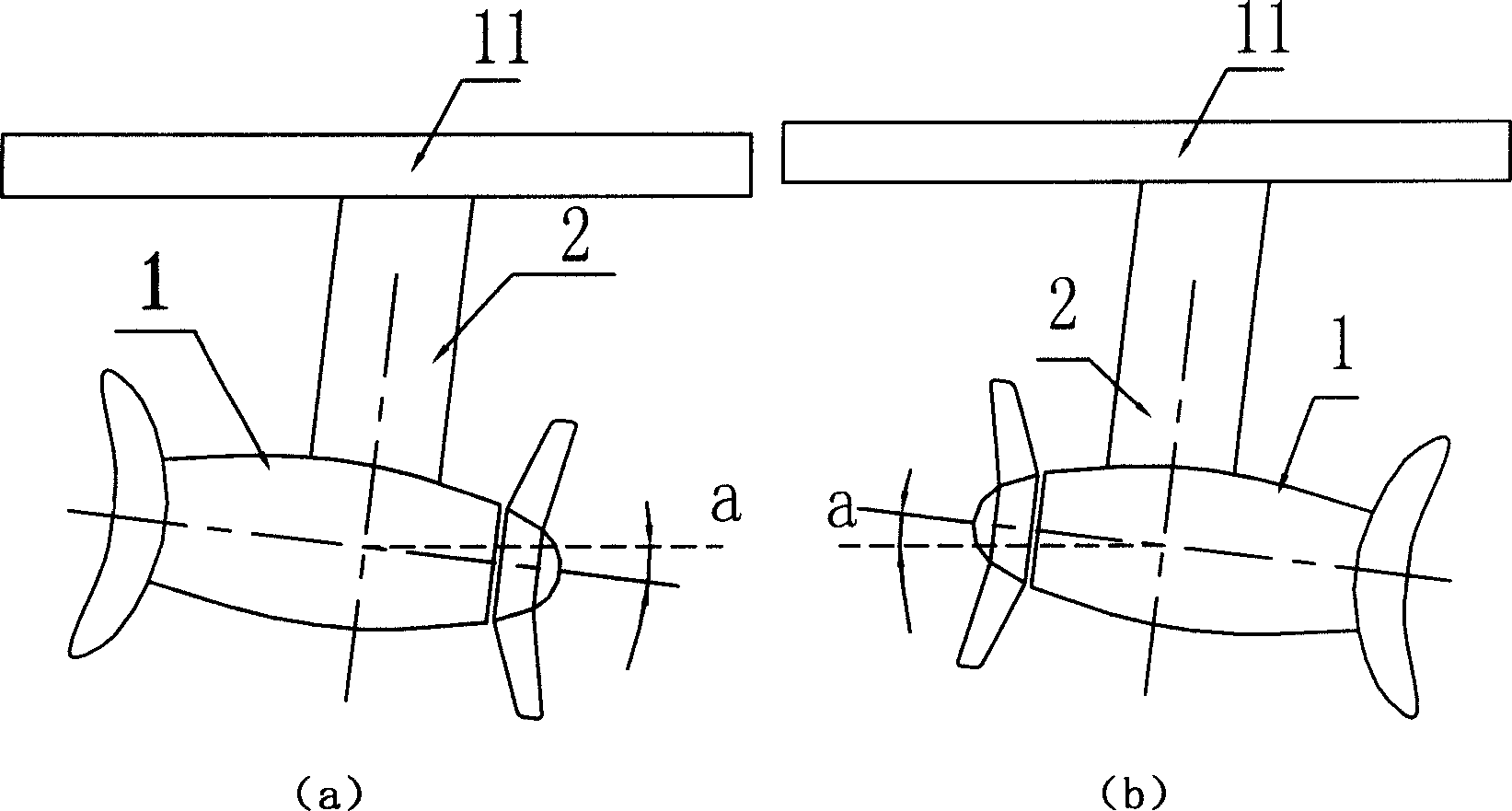

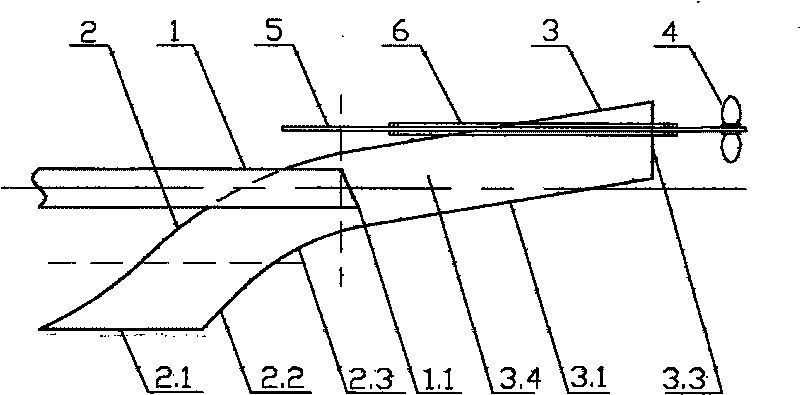

Fish shape simulating nacelle propeller

InactiveCN1749104AImprove wake fieldImprove propulsion efficiencyPropulsion power plantsOutboard propulsion unitsNacelleCoupling

The present invention is one kind of fish-shaped nacelle propeller and belongs to the field of ship propelling technology. The fish-shaped nacelle propeller of the present invention includes nacelle body, support, motor bearings, shaft coupling, screw propeller, screw propeller bearing, propelling motor stator, propelling motor rotor, tail fin and two side fins. The nacelle body is connected with the support; the screw propeller has one end fixed via the screw propeller bearing inside the nacelle body; the propelling motor stator is set via the motor bearings and the support inside the nacelle body; the propelling motor rotor shaft is connected to the shaft of the screw propeller via shaft coupling; and the tail fin and the side fins are connected to the nacelle body smoothly. The present invention has optimized streamline outer shape, effectively improved tail flow field, improved hydrodynamic performance, and raised propeller efficiency.

Owner:SHANGHAI JIAO TONG UNIV

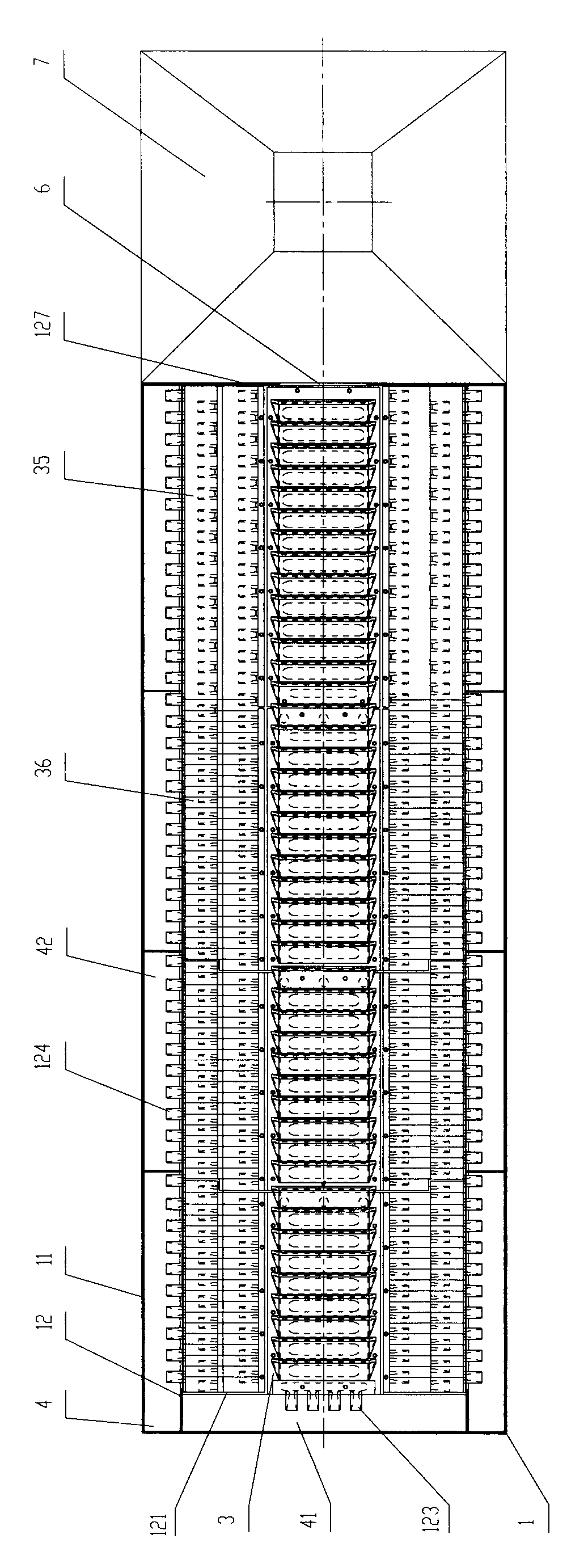

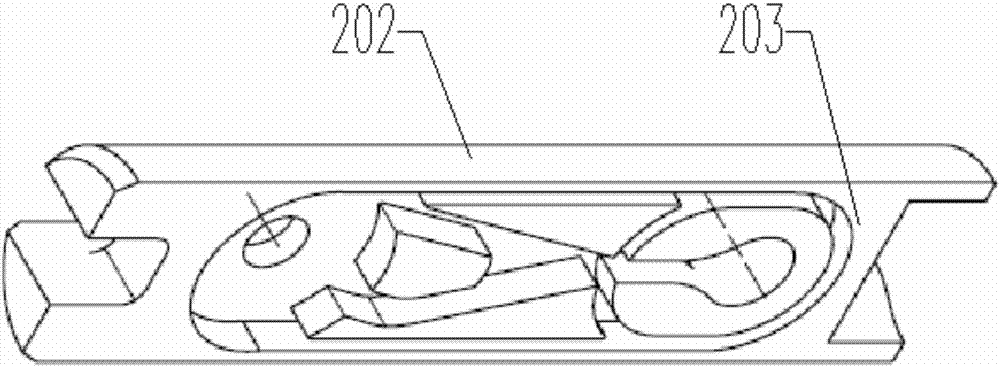

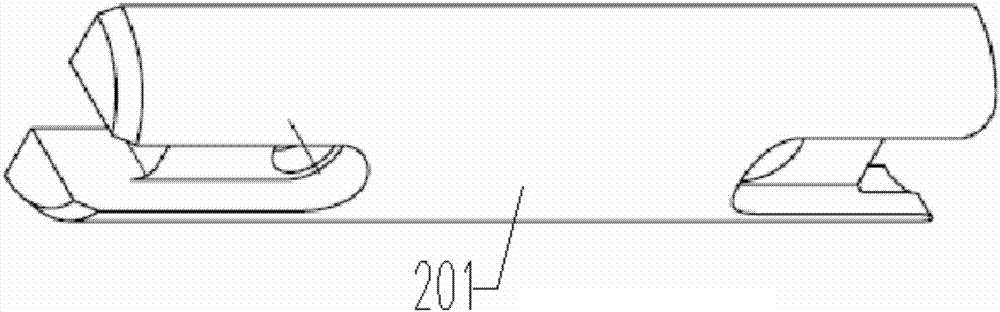

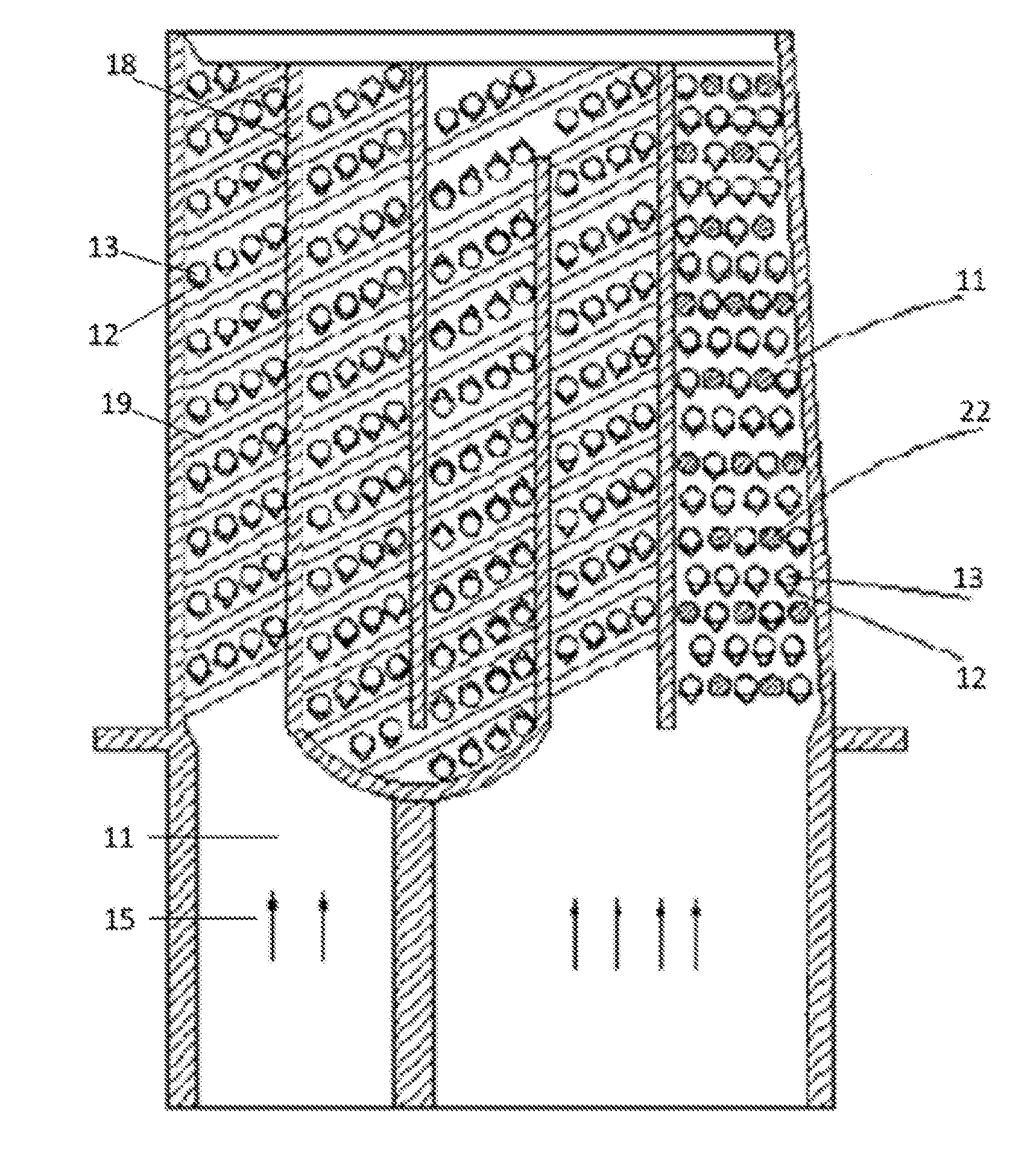

Body structure of boiling rotating fluidized bed

ActiveCN102230717ASmooth bed surfaceImprove the flow fieldDrying solid materials with heatHearth type furnacesWave shapeFluidized bed

The invention discloses a body structure of a boiling rotating fluidized bed, which comprises an outer housing and an air distributor. Due to the coverage of the outer housing and the air distributor, an accommodation chamber of the fluidized bed is formed. The air distributor is like a groove and tilts from the feeding end of the bed body to the discharging end. The air distributor mainly comprises an air distributor bottom board configured in the middle and air distributor sideboards configured on the two sides. A blowing bottom hole communicated with a sectionalized wind box is configured on the air distributor bottom board, and a blowing side hole communicated with the sectionalized wind box is configured on the air distributor sideboard. The air distributor is tooth-shaped or wave-shaped, the blowing bottom hole is configured between the teeth of a tooth-shaped air distributor bottom board or at the wave trough of a wave-shaped air distributor bottom board, and the opening of the blowing bottom hole faces the discharging end of the bed body. The opening of the blowing side hole on the air distributor sideboard faces the air distributor bottom board. The invention has the advantages of simple body structure, smooth bed surface and optimized flow field and can greatly improve the boiling rotating fluidized status. In addition, the invention can reduce more energy consumption.

Owner:长沙通发高新技术开发有限公司

Laser electrochemical compound micromachining method and device for semiconductor material

ActiveCN108526627AImprove processing efficiencyReduce heat damageLaser beam welding apparatusElectrolysisSemiconductor materials

The invention discloses a laser electrochemical compound micromachining method and device for a semiconductor material, and belongs to the field of special machining. The method comprises the steps that the semiconductor material is heated with laser beams through the characteristic that the electric conductivity of the semiconductor material such as monocrystalline silicon is significantly increased along with increasing of the temperature, the electric conduction property of the material near a machining area is locally enhanced, an electric conduction channel that currents pass preferentially is formed, on this basis, electrolytic machining is introduced in a bias electro-hydraulic beam mode, laser electrochemical self-coupling combined machining near the machining area is achieved, tool setting is not needed, therefore, it is guaranteed that no surface residue adhesion occurs in the laser machining process, the cooling effect can be strengthened, and the purposes of reducing heat damage and residual stress and improving the machining surface quality are achieved. The device comprises a laser, an external light path, an electrolytic power supply and a stable jet flow generatingdevice. The device can generate stable low-voltage electrolytic solution jet flow and achieve impact angle and position adjustment, and it is guaranteed that precise adjustment of the relative positions between the laser beams and the impact jet flow is achieved.

Owner:JIANGSU UNIV

Vortex type hydraulic pulse axial impact tool

The invention provides a vortex type hydraulic pulse axial impact tool, which comprises a tubular shell, a hydraulic pulse generating device is arranged in the shell, a jacket is connected to the casing to fix the hydraulic pulse generator, and a mandrel matched with it is arranged in the jacket , the connection between the jacket and the mandrel can be a spline or a polygonal connection, the lower end of the mandrel is connected with an anti-drop nut, and the characteristics of the pressure wave generated by the pulse generating device can be controlled by the growth and attenuation of the eddy current in the vortex cavity flow path, The flow path is a bistable jet switch, one flow path points to the tangential direction of the vortex cavity, and the other flow path points to the fluid outlet. By adopting the above structure, it has the following beneficial effects: the hydraulic energy at the bottom of the well increases the impact force of the drill bit, optimizes the flow field at the bottom of the well, improves the force condition of the drill bit and rock, and increases the mechanical penetration rate.

Owner:YANGTZE UNIVERSITY

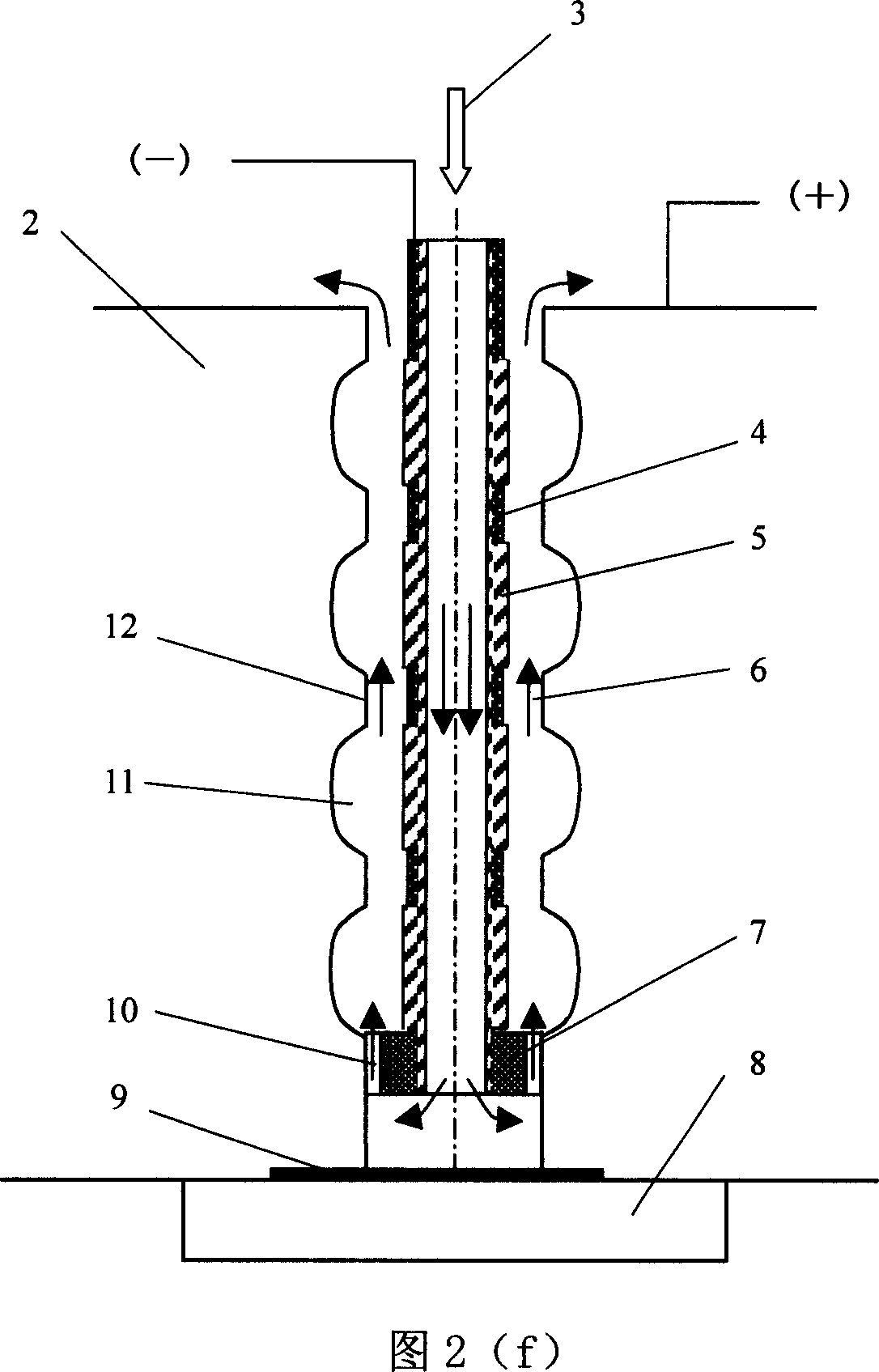

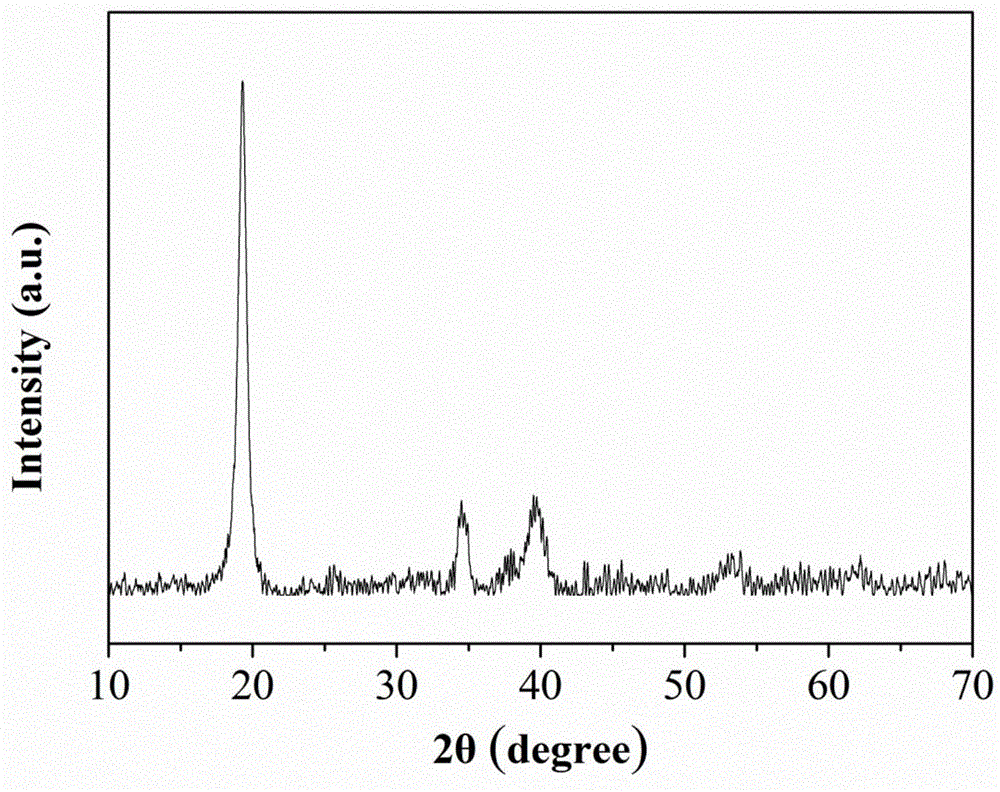

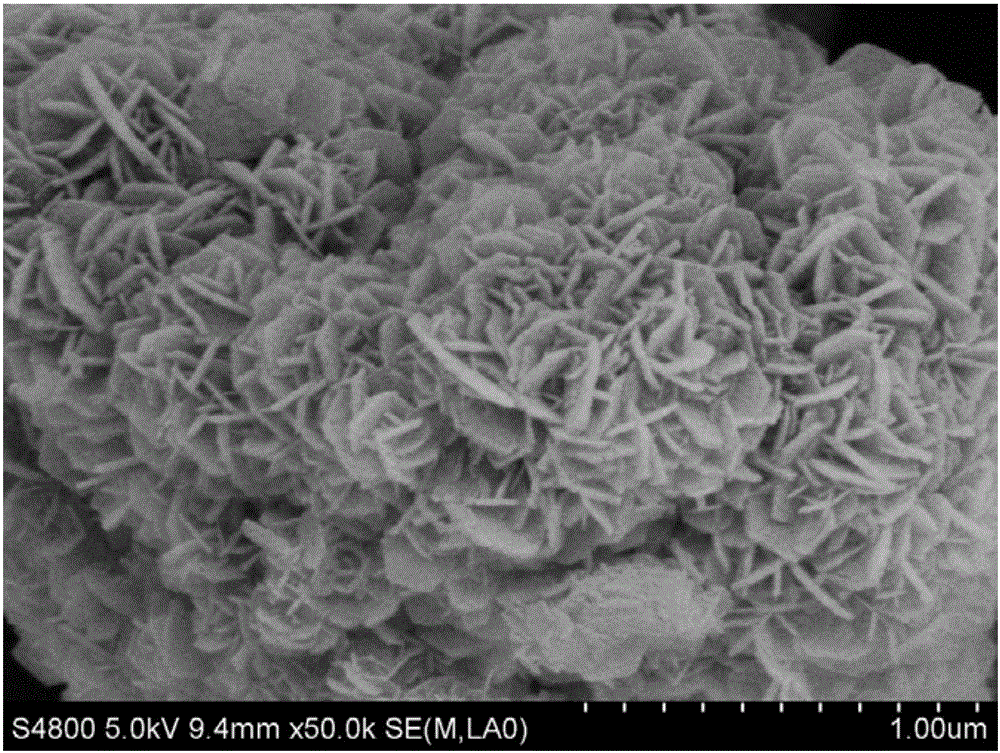

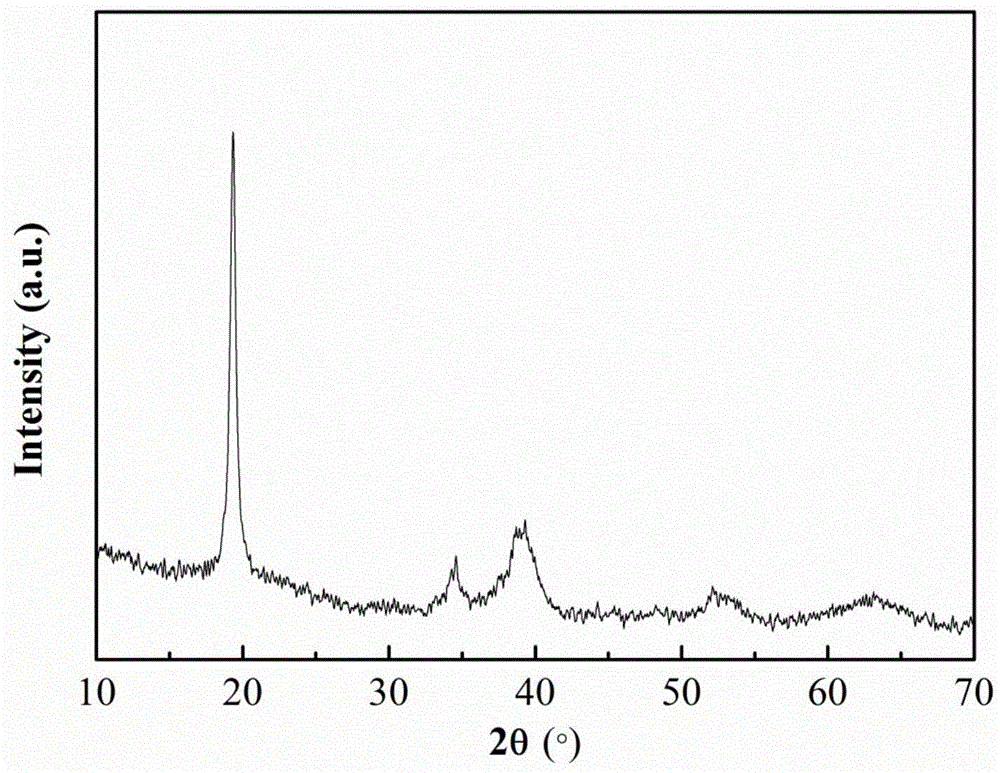

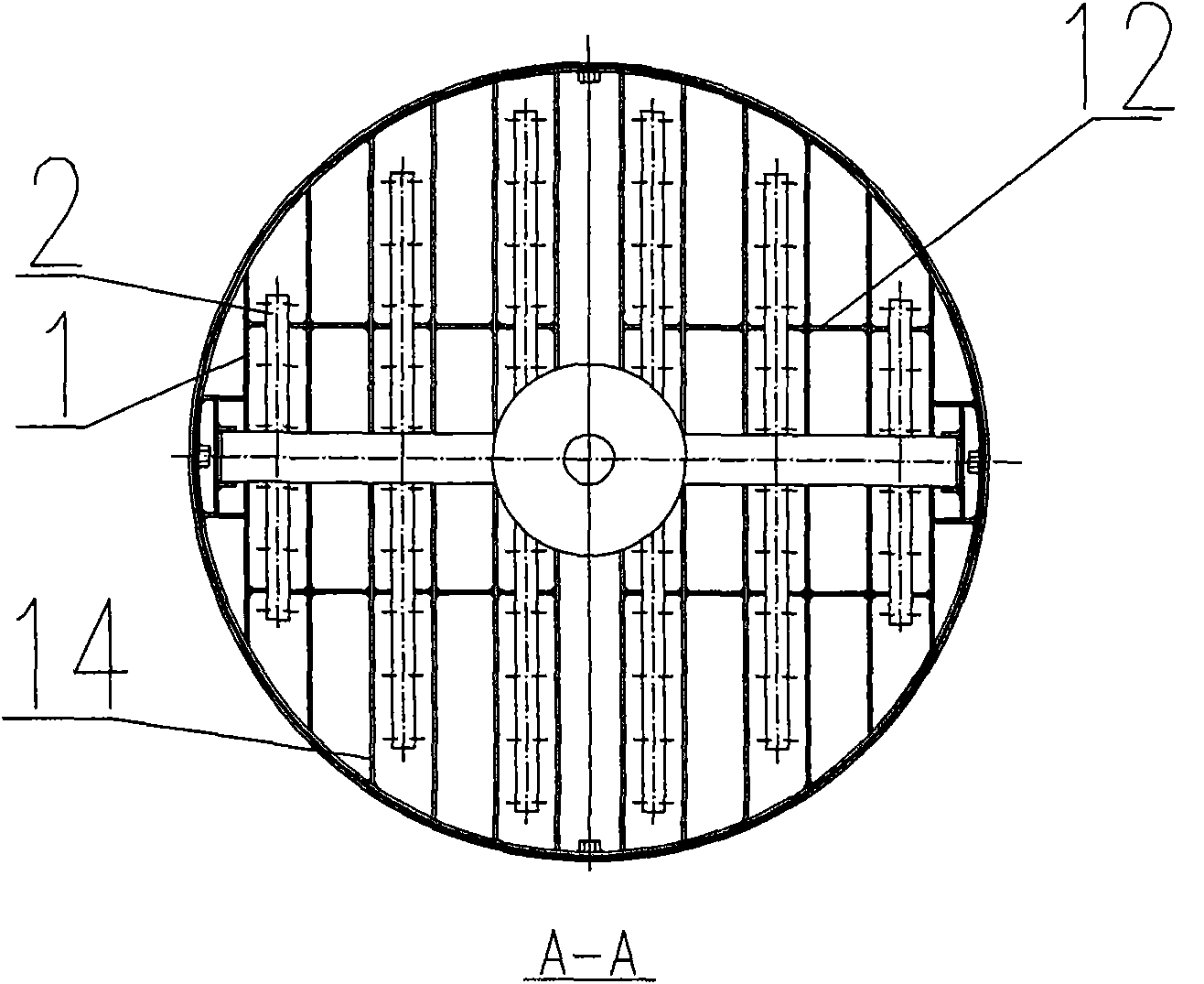

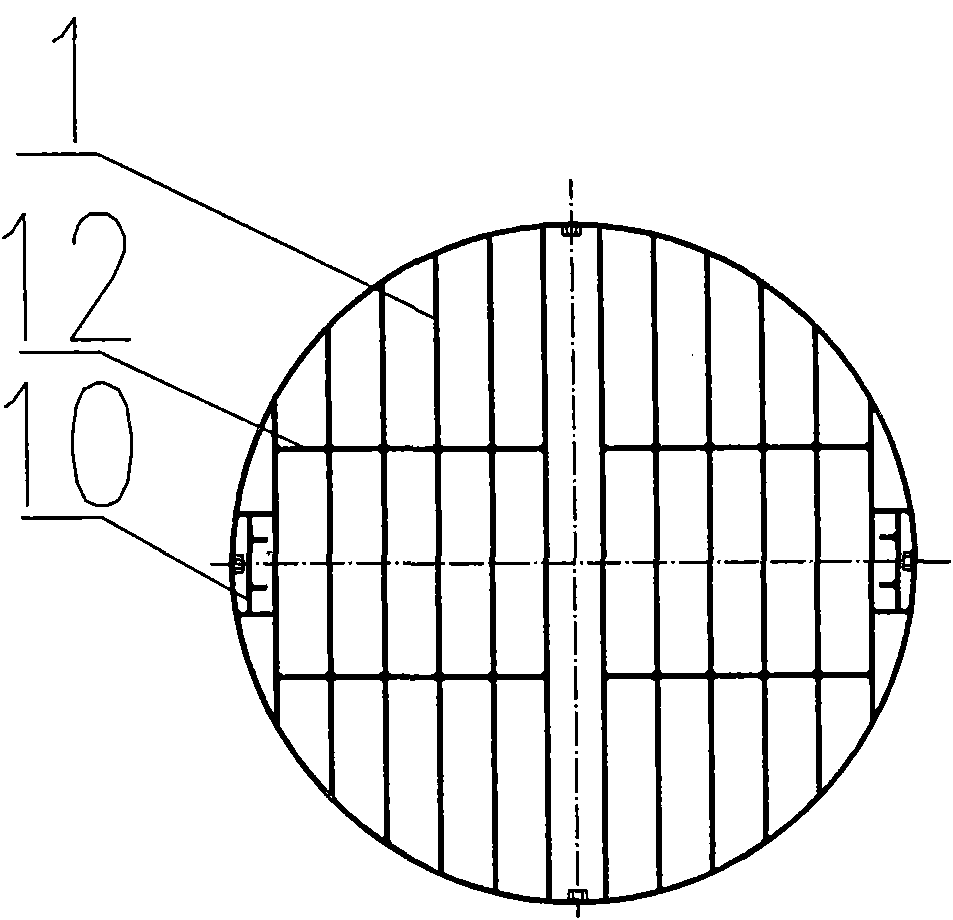

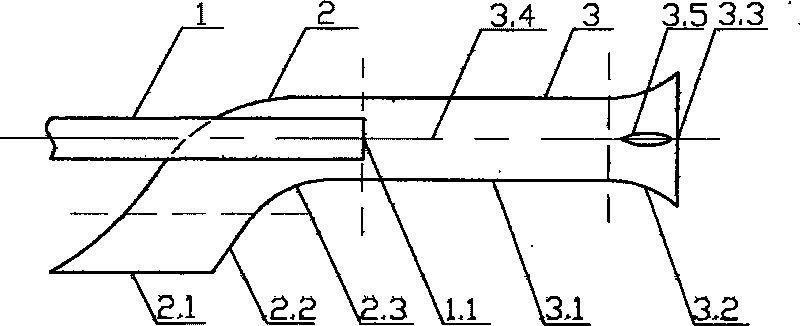

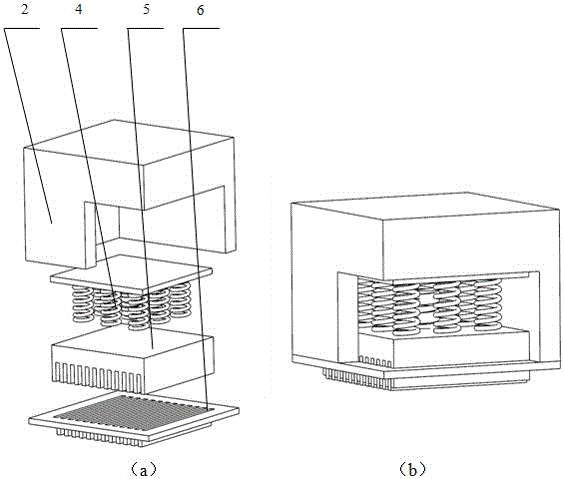

Method for continuously preparing nanoflower lithium ion battery layered anode material and reaction kettle thereof

InactiveCN106058237AWell mixedImprove the flow fieldMaterial nanotechnologyCell electrodesPrecipitationReagent

The invention provides a method for continuously preparing a nanoflower lithium ion battery layered anode material and a reaction kettle realizing the method. The method includes: (1), preparing a: preparing raw materials according to a chemical formula LiNixCoyMn1-x-yO2; (2), co-precipitating: using a co-precipitation method to obtain a reaction product, and subjecting the reaction product to aging, filtering, washing and drying to obtain precursor particles of a nanoflower structure; (3), calcining:calcining the precursor particles at high temperature to obtain the nanoflower lithium ion battery layered anode material. A template agent does not need to be added in the preparation process, and the particles are controllable in size, uniform in distribution and high in uniformity. Three layers of stirring paddles are arranged in the reaction kettle and stir at the same time, so that the materials are quick and uniform in reaction, and the particles are uniform and high in fluidity. By using the method, the lithium ion battery anode material in special nanoflower shape; the method is simple to operate, the reaction kettle is stable and reliable in structure, and industrial production is facilitated.

Owner:成都翔羽科技有限公司

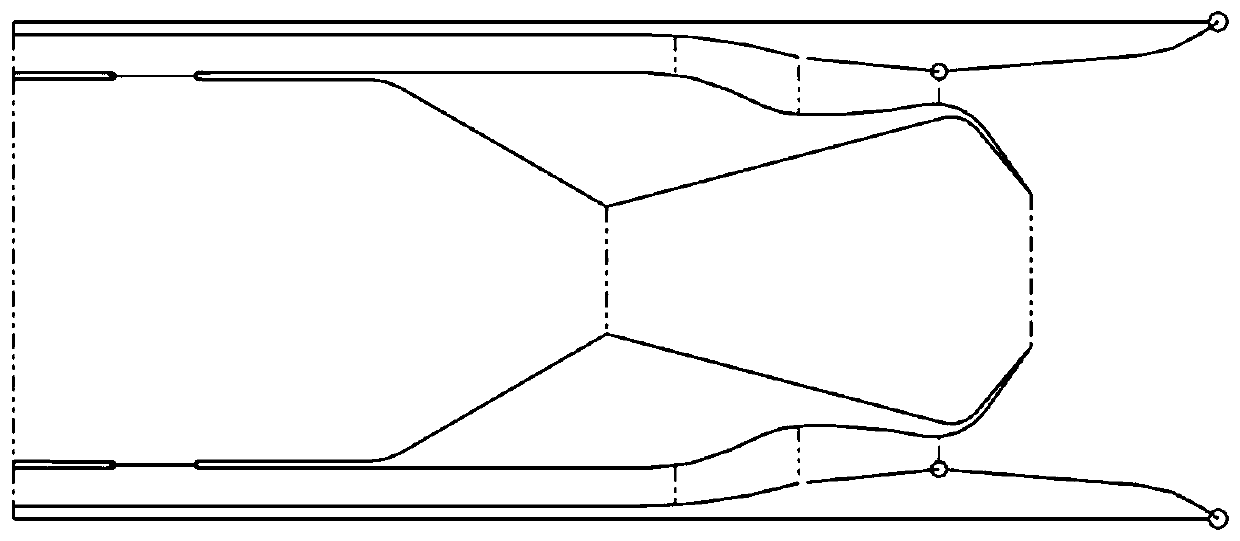

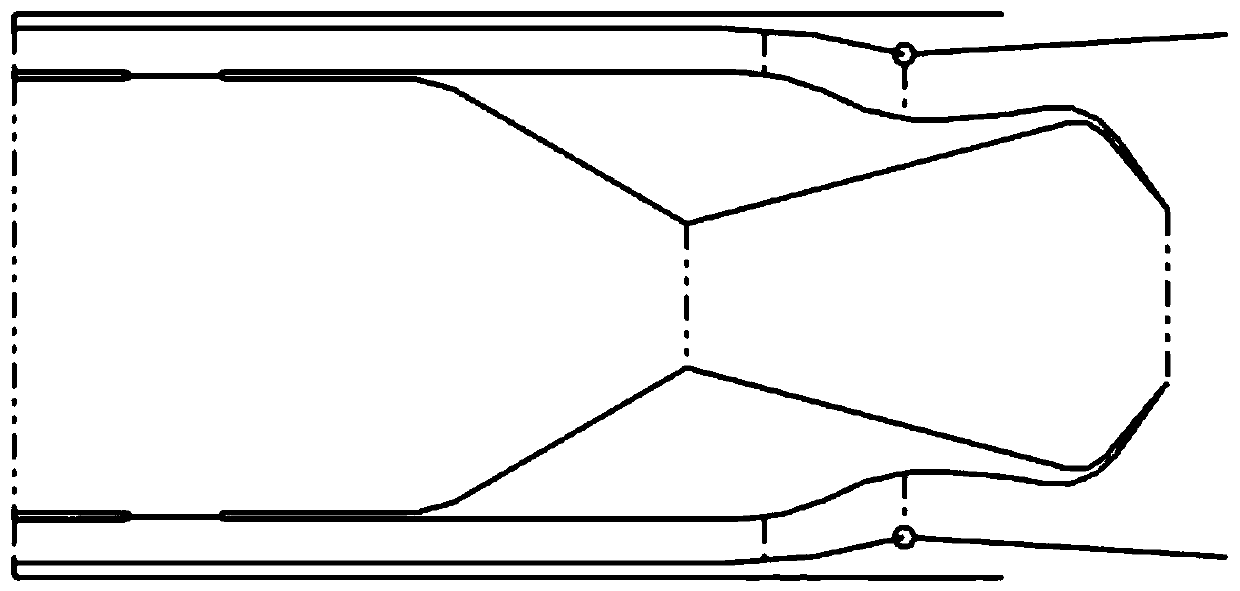

Parallel thrust vector exhaust system based on throat offset type pneumatic vector spray pipe

ActiveCN110284994AReduce flight resistanceReduce exhaust temperatureJet propulsion plantsAerospace engineeringWorking range

The invention discloses a parallel thrust vector exhaust system based on a throat offset type pneumatic vector spray pipe. The system comprises the throat offset type pneumatic vector spray pipe and an adjustable Laval spray pipe arranged on the outer side of the throat offset type pneumatic vector spray pipe, through an inner and outer nested parallel structure, the thrust vector is generated by the throat offset type pneumatic vector spray pipe, and the flow regulation function is realized by the Laval spray pipe connected in parallel on the outer side. According to the parallel thrust vector exhaust system based on the throat offset type pneumatic vector spray pipe, different functions of the spray pipes are realized by utilizing different parts, so that the spray pipes have the characteristics that the thrust vector is efficient, the wide-range flow is adjustable, and infrared signals are reduced; and the smooth transition molded surface is designed, so that the exhaust system has relatively good thrust performance and vector performance at the same time in a wide working range, then the evolution of a fixed geometric thrust vector spray pipe is realized, the flight envelope of an aircraft is expanded, and the use requirements of the aircraft are better met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

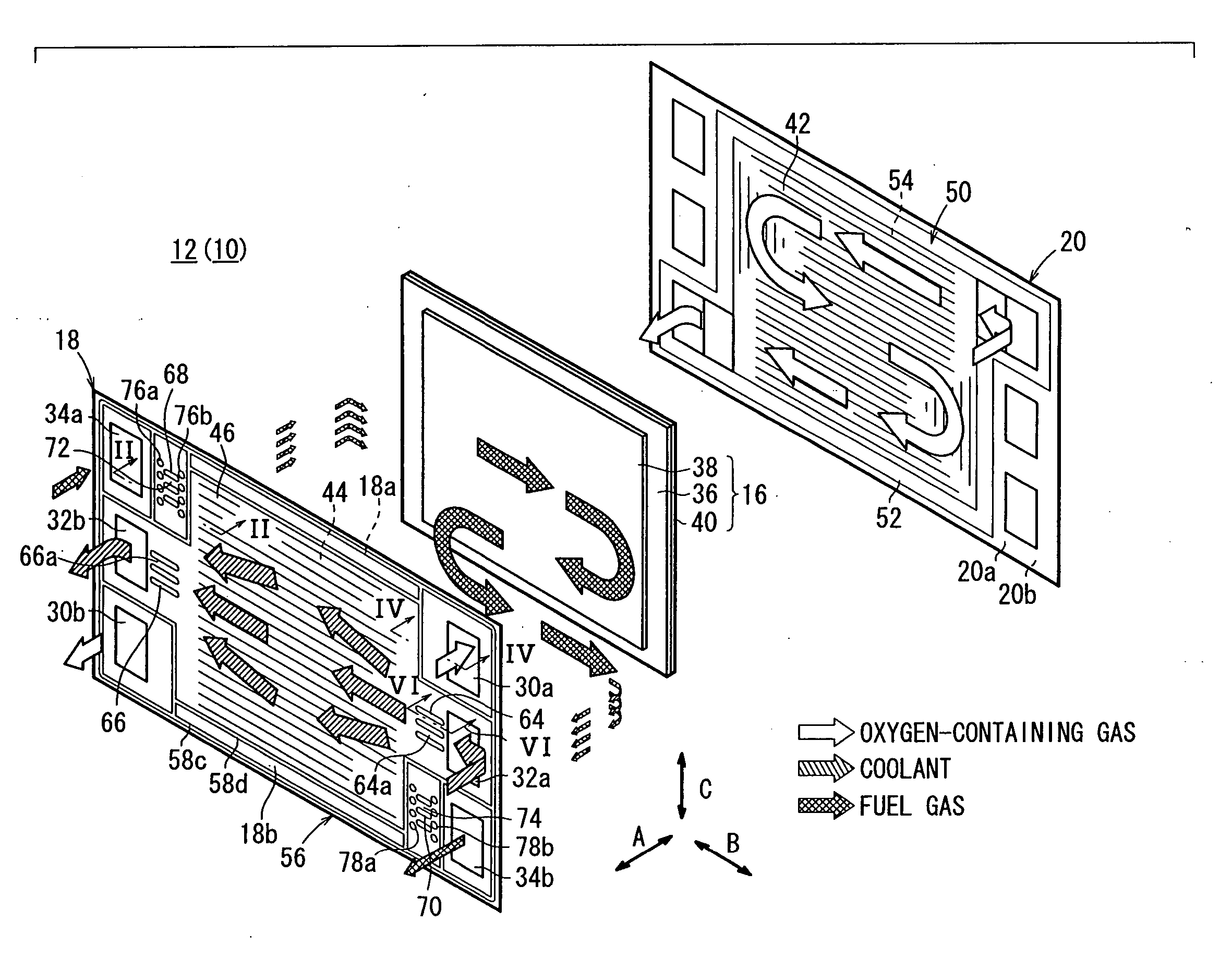

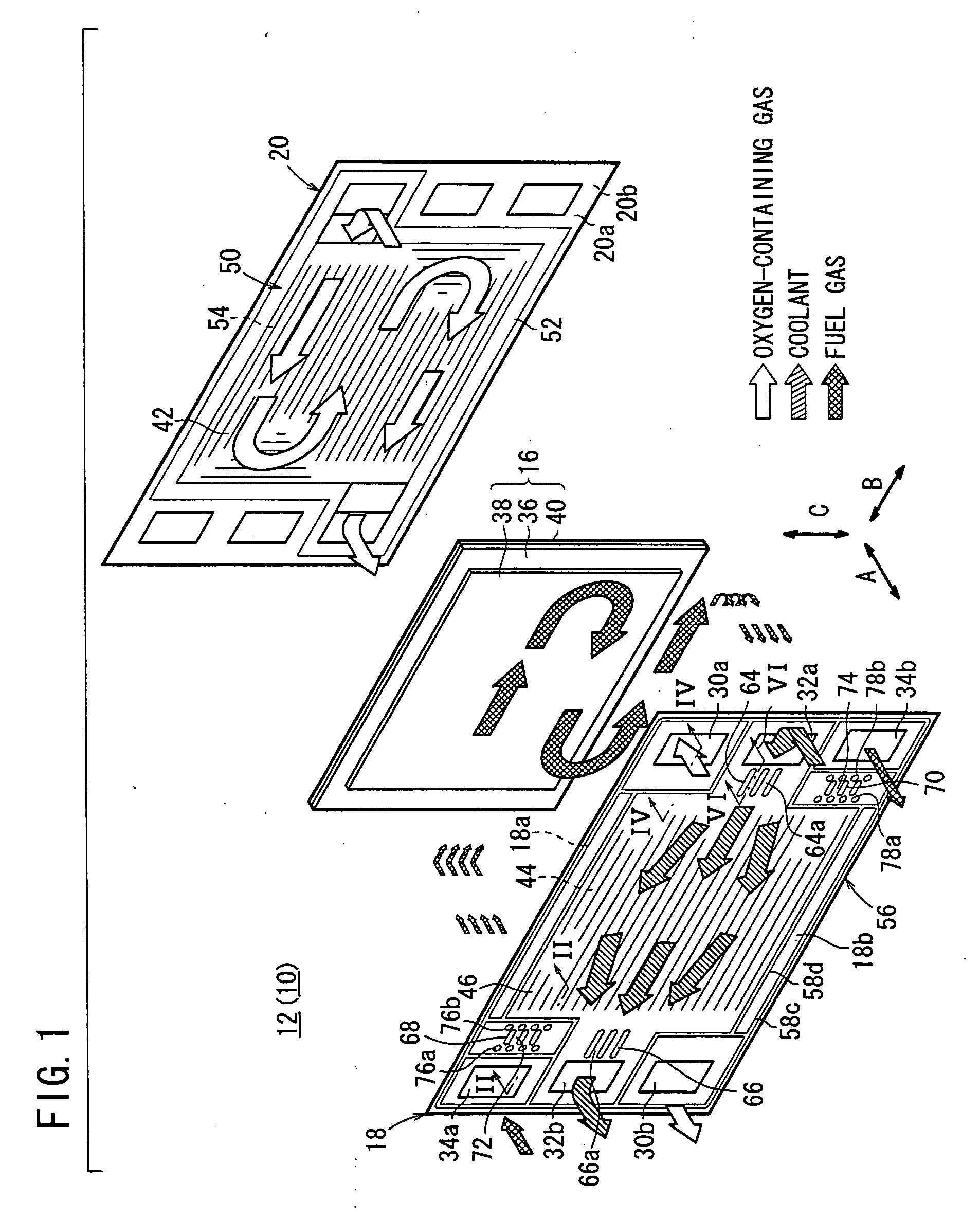

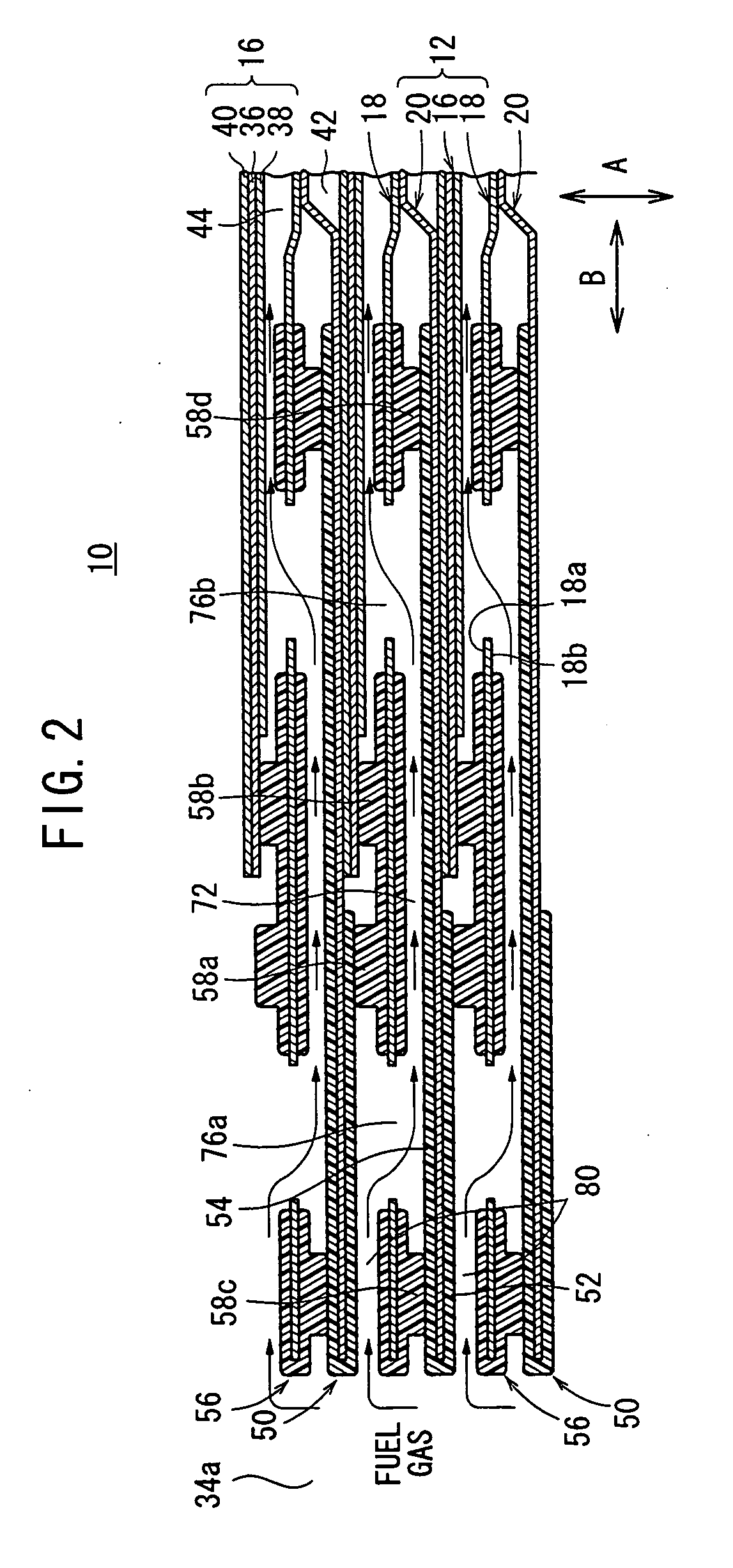

Fuel cell and separator for fuel cell

InactiveUS20070003816A1Simple and compact structureDesired performanceFuel cells groupingFuel cell auxillariesFuel cellsProcess engineering

A unit cell of a fuel cell includes a membrane electrode assembly and an anode side metal separator and a cathode side metal separator sandwiching the membrane electrode assembly. A plurality of first supply holes and a plurality of second supply holes extend through a channel unit of the anode side metal separator, and the channel unit connects a fuel gas supply passage and a fuel gas flow field. A fuel gas from the fuel gas supply passage flows into the first supply holes, and flows through an inlet connection channel. The fuel gas flows into the second supply holes connected to an end of the inlet connection channel. The fuel gas flows toward the side of the membrane electrode assembly, and then, the fuel gas is supplied to an anode.

Owner:HONDA MOTOR CO LTD

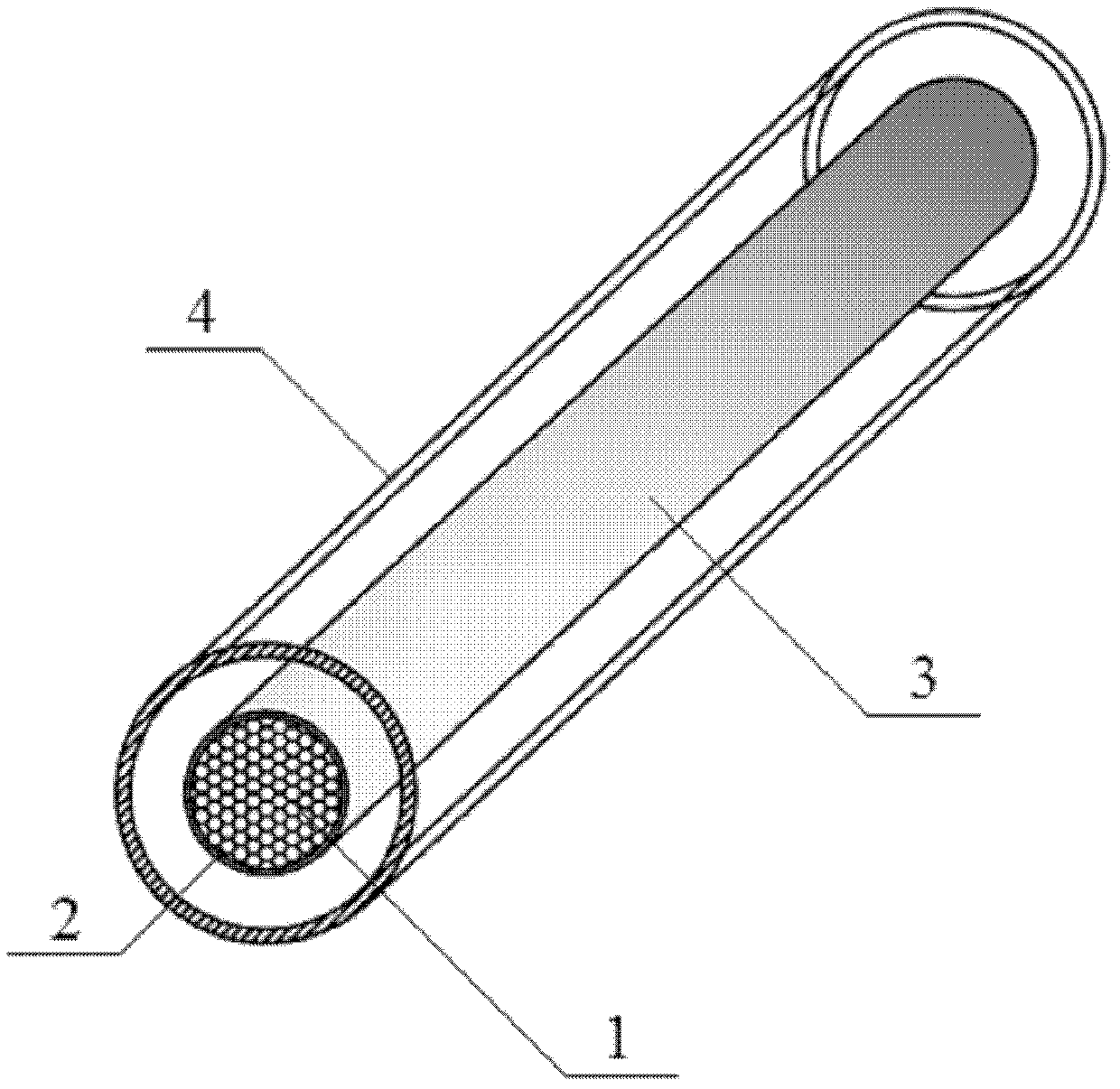

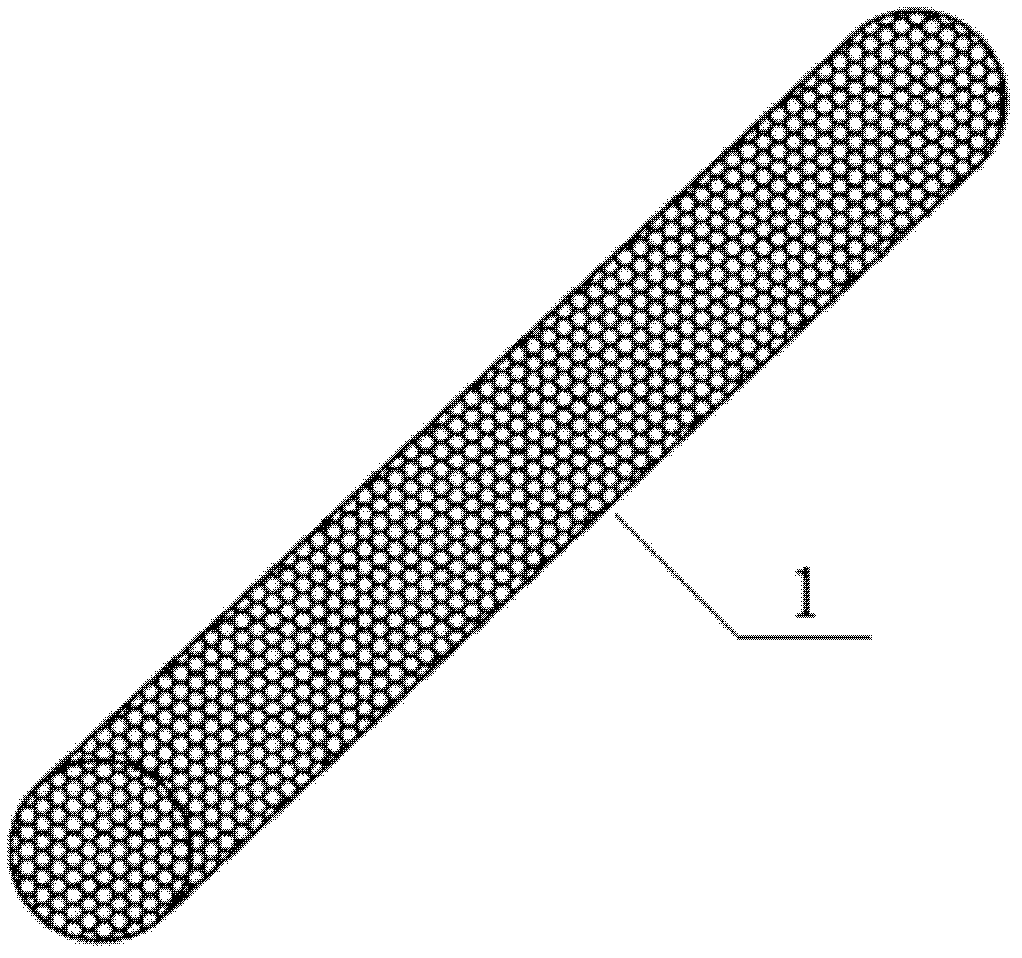

Metal foam carrier catalysis bed solar energy absorption reaction device

ActiveCN103372413AExtended service lifeEasy to fixEnergy based chemical/physical/physico-chemical processesThermal energyEngineering

The invention discloses a metal foam carrier catalysis bed solar energy absorption reaction device. The device comprises a linear solar energy absorption reactor and a parabolic trough-type solar energy condenser. The linear solar energy absorption reactor is arranged in the focal line of the parabolic troughtype solar energy condenser. The linear solar energy absorption reactor has a bushing structure, and comprises an external glass bushing, an internal metal tube, a selective coating on the surface of the metal tube through vacuum evaporation and a catalyst bed layer with metal foam materials as carriers and arranged inside the metal tube. The device makes the best of the space in the reactor. The catalyst bed layer structure can maintain uniformity and stabilization for long time, has a long service life, and has high efficiency of conversion from solar energy to thermal energy. The catalyst bed layer has a high specific surface area and good catalytic performance. The operations of change and regeneration of catalysts are simple. The device solves the problems of low specific surface area, uneven filling of internal catalysts, difficulty control of temperature field and flow field, difficulty maintenance and the like of reactor catalysts in the prior art.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

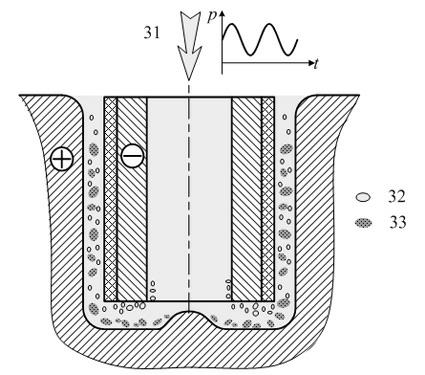

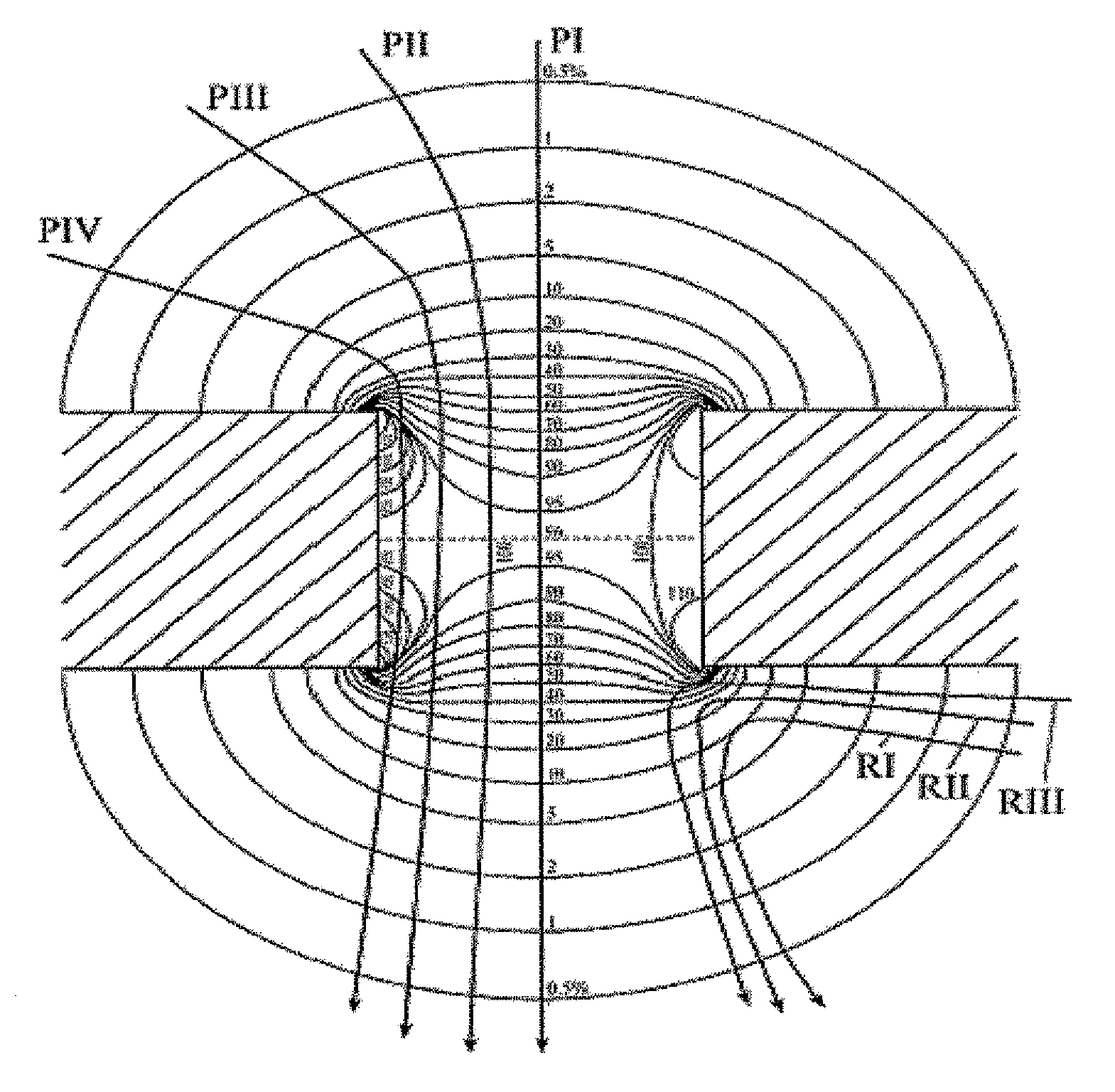

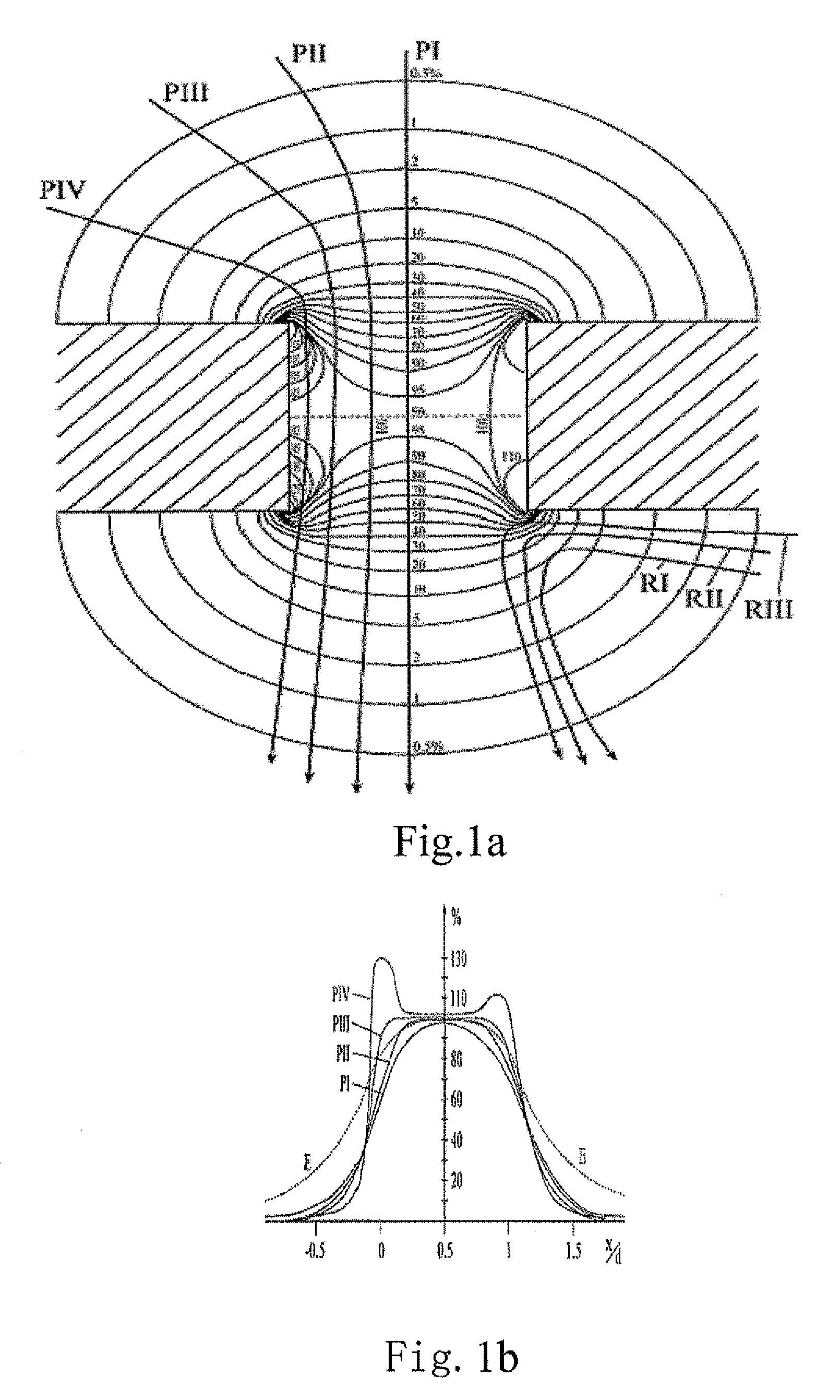

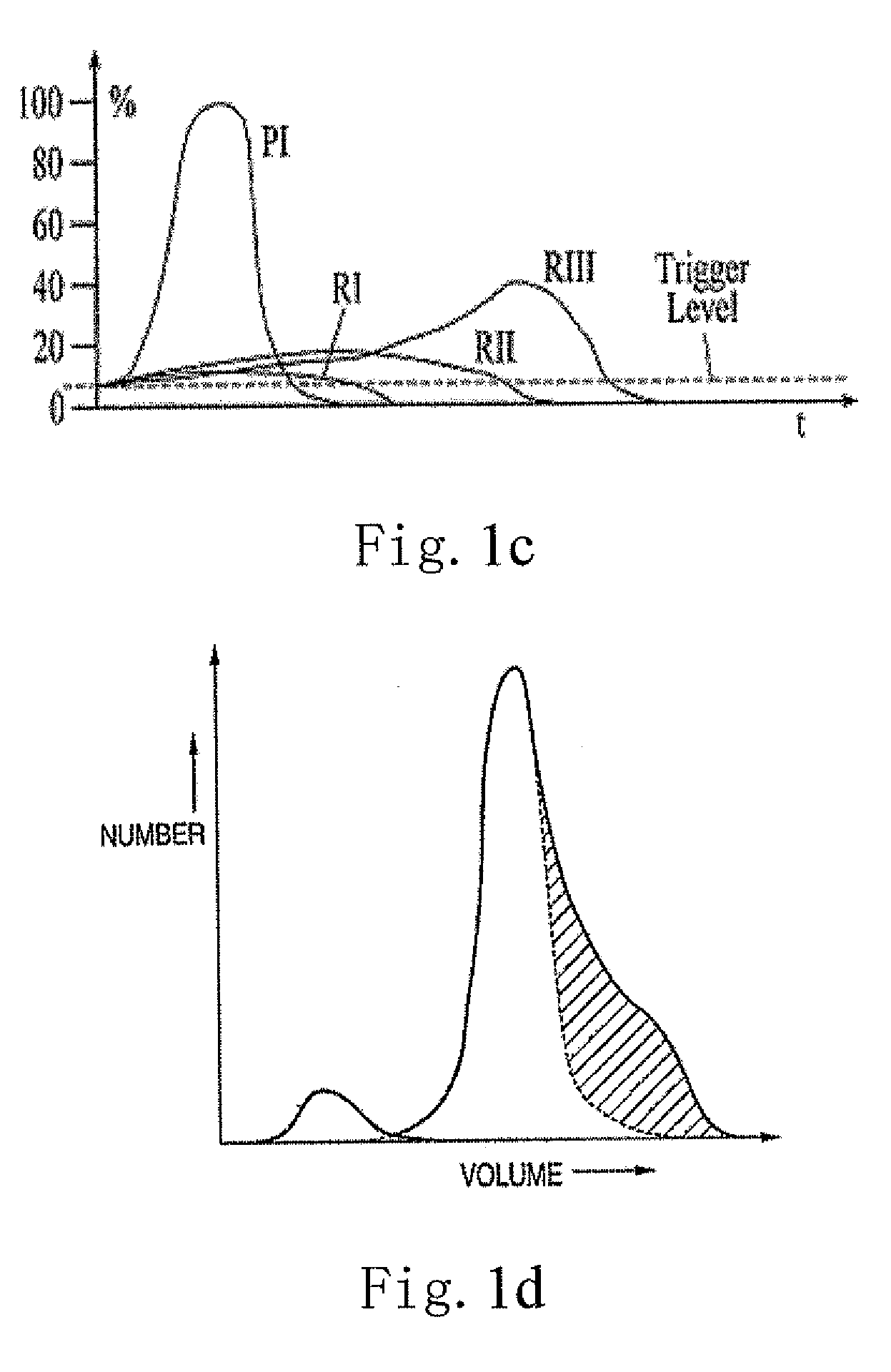

Device for determination of parameters of particles in conductive solution and microscopic hole assembly

ActiveUS20080093216A1Improve signal-to-noise ratioImprove the flow fieldImmobilised enzymesBioreactor/fermenter combinationsEngineeringBiomedical engineering

The present invention discloses a device for detecting blood cells and a microscopic hole sensor assembly thereof. The device includes a microscopic hole sensor assembly positioned between a front pool and a back pool. The microscopic hole sensor assembly further includes a microscopic hole plate with a microscopic hole positioned thereon for communicating the front pool and the back pool. The end surface of the inlet is a flow-guiding surface gradually narrowing from the front pool to the back pool. The end surface of the outlet is a downstream surface gradually distending and extending towards the back pool. A straight effective orifice area is formed connecting the ends of the flow-guiding surface and the downstream surface.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

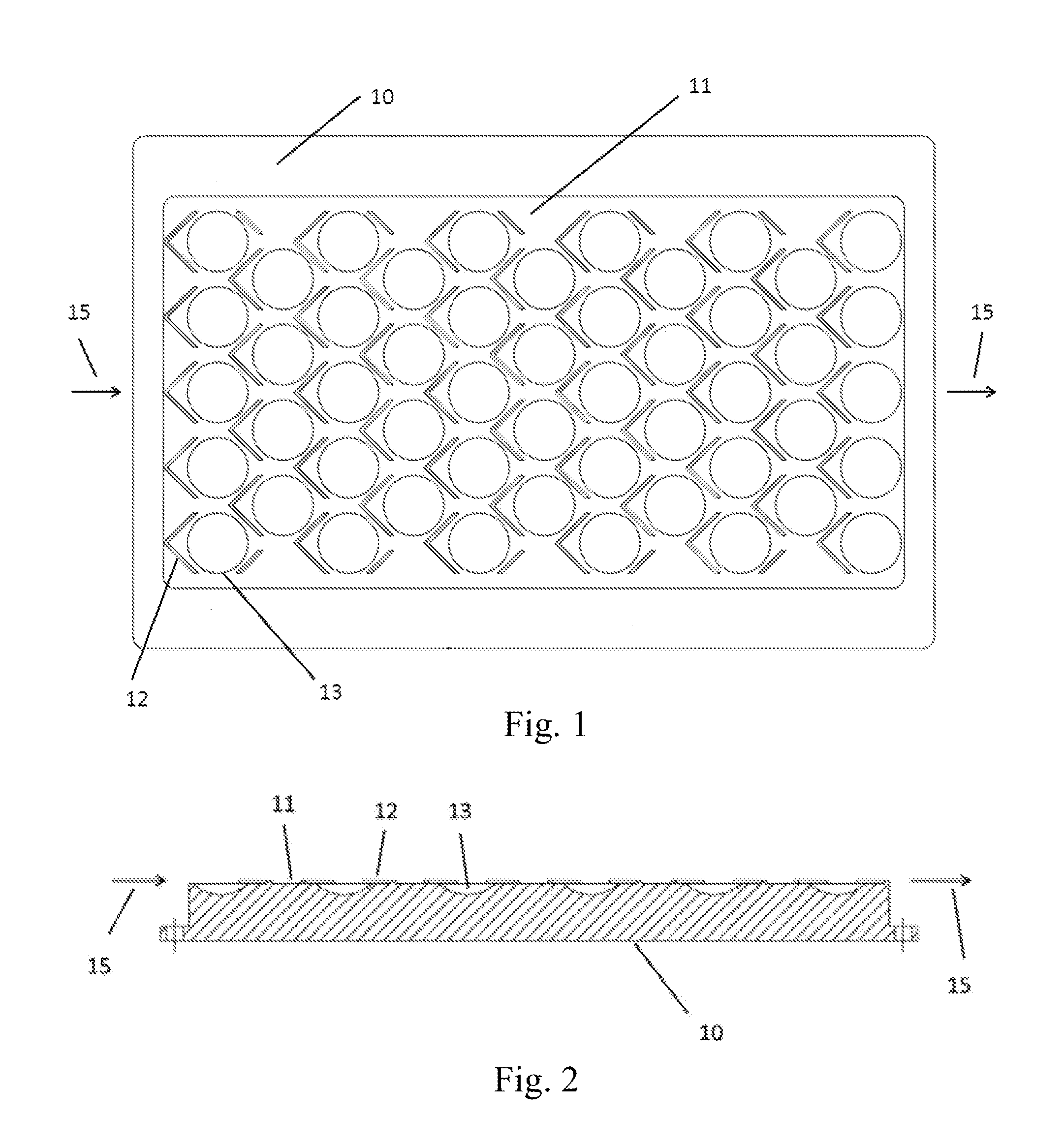

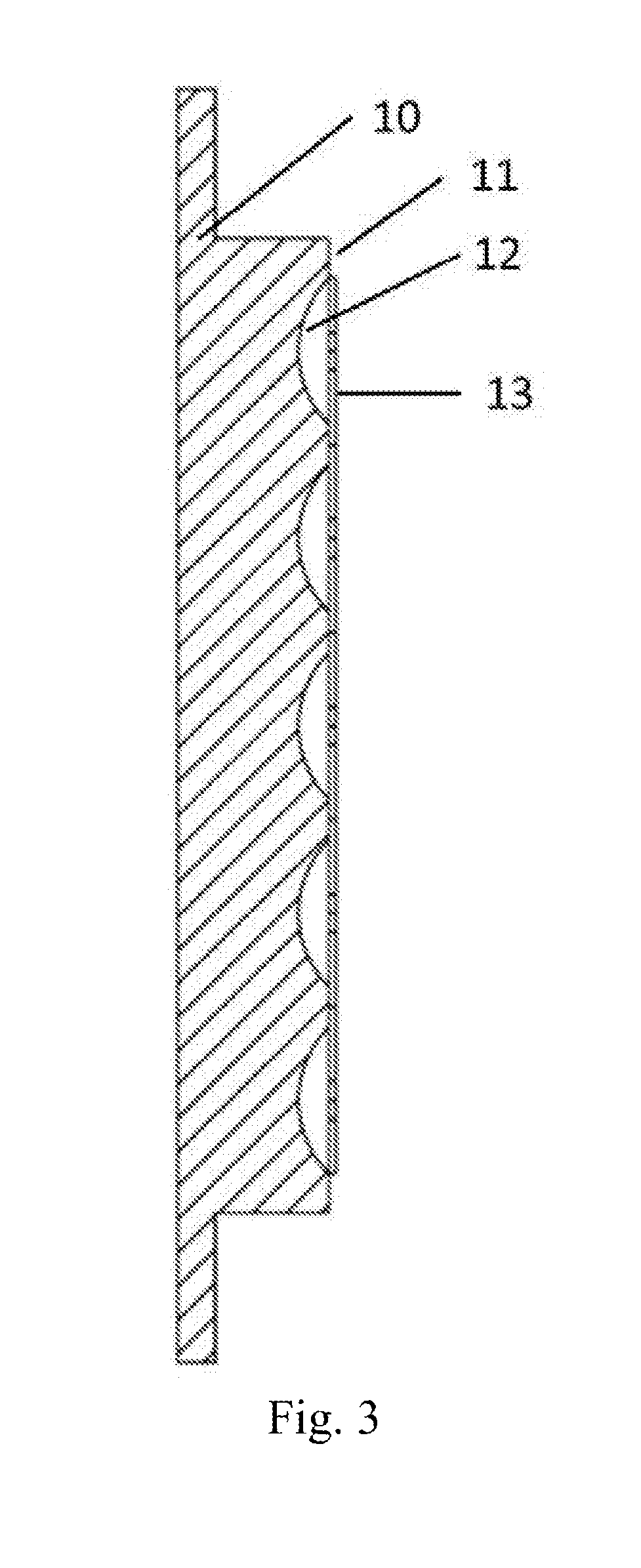

Cooling Device with Small Structured Rib-Dimple Hybrid Structures

ActiveUS20170030201A1Enhance flow turbulence energyImprove heat transfer performanceContinuous combustion chamberEngine manufactureEngineeringCooling channel

A cooling device with small structured rib-dimple hybrid structures, comprising a substrate, a cooling channel, a plurality of small structured ribs and a plurality of dimples. The cooling channel, the plurality of small structured ribs and the plurality of dimples are all disposed on the wall surface of the substrate; the plurality of dimples are in a staggered arrangement or in a longitudinal arrangement, forming a dimple array; an upstream wall surface of each dimple or a plurality of dimples is provided with the small structured ribs, thus forming an small structured rib-dimple hybrid structure.

Owner:SHANGHAI JIAO TONG UNIV

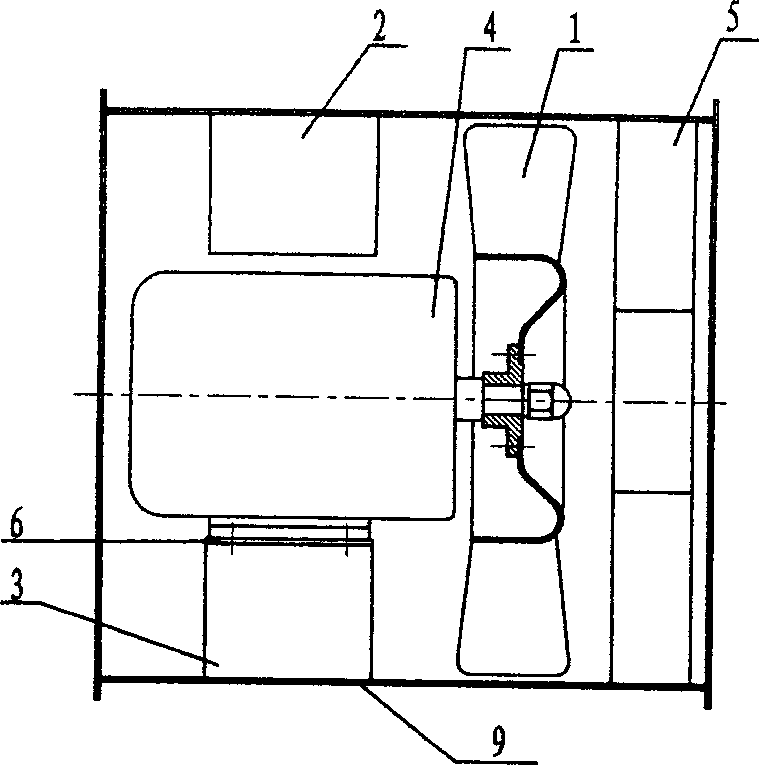

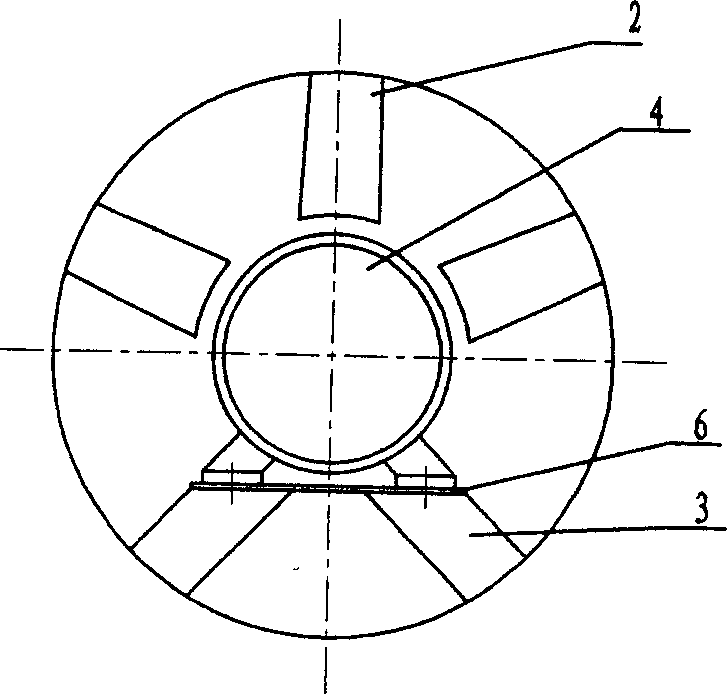

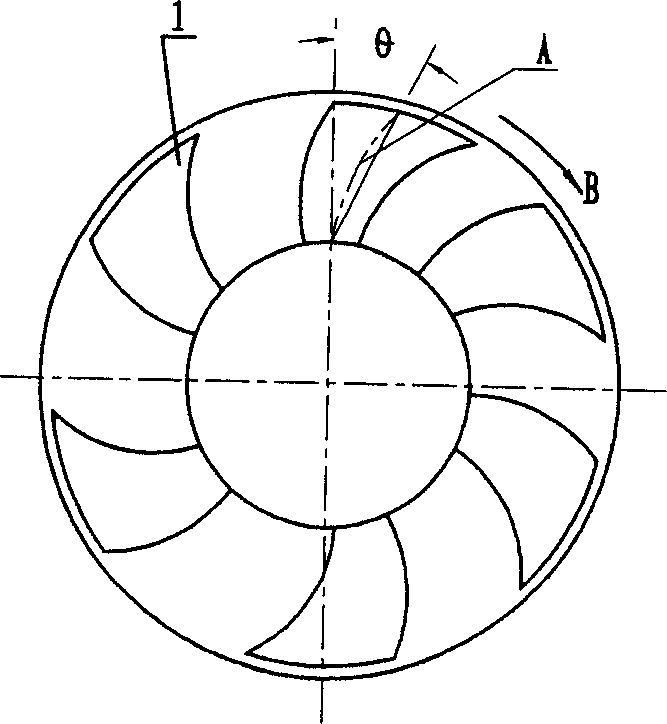

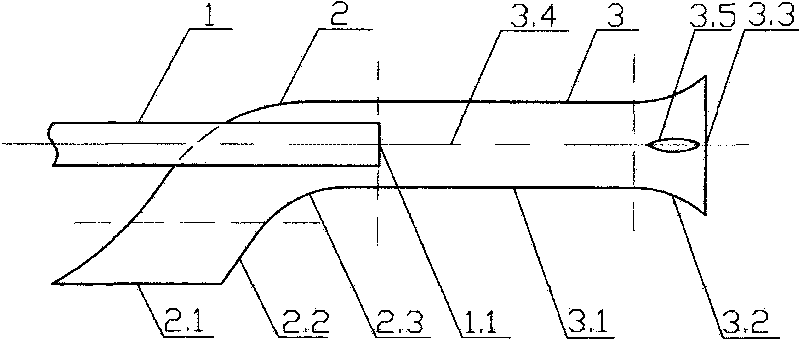

Single impellor axial fan of traction electric machine brake cooling system

InactiveCN1793666AImprove working abilityIncrease wind pressurePump componentsAxial flow pumpsImpellerElectric machine

The invention relates to a single-impeller axial fan in a dragging electric machine brake cooling system, replacing the two-stage impeller series operating structure with a single-impeller structure added with front guide vane, adopting a technical solution of front guide vane + impeller + rear guide vane, adding a reverse guide vane in front of the impeller, then changing axial support plate of the electric machine into streamlined guide plate designed according to air flow direction and improving vane profile design for the impeller, where the vane is wide outside and narrow inside and of a bent-swept combined shape, and the vanes are not equidistantly arranged. For improving flow field, it can further install the electric machine on the end cover of an inner cylinder body and the inner cylinder body is connected with the machine casing through the rear guide vane. As the fan runs, the air is pre-rotated through the reverse front guide vane and then flows into the impeller, thus improving work doing ability of the impeller, and the novel streamlined electric machine support plate and vane can improve fan operating conditions, raise fan efficiency, reduce air flow separation and save energy and reduce noises by a larger margin.

Owner:ZHEJIANG XINGYI VENTILATOR ELECTRICAL APPLIANCE

Linear liquid distributor

InactiveCN101837199AImprove anti-blocking performanceImprove distribution qualityDispersed particle separationDistillation separationWhole bodyGas phase

The invention relates to a linear liquid distributor. The distributor mainly comprises a tower wall, a filler, a filler pressing ring, a calandria liquid distributor, an annular collector and a funnel, wherein the filler is arranged in the tower wall; the upper part of the filler is pressed by the filler pressing ring; the filler pressing ring is fixed in the tower wall through bolts; the calandria liquid distributor is placed on the filler pressing ring and combined with the filler pressing ring into a whole body; the upper part of the calandria liquid distributor is sequentially provided with the funnel and the annular collector from the bottom to the top; the annular collector is communicated with the funnel; the lower part of the funnel is provided with a liquid level tube which is communicated with the calandria liquid distributor; and the filler pressing ring is provided with a flow guide plate. The distributor of the invention has the advantages of increasing the anti-block performance, improving the distribution quality of the liquid, increasing the circulation area, and reducing the using amount of the material; and parallel grid plates in the filler pressing ring are heightened to play a certain role in improvement of a flow field of vapor phase in a tower, make the air flow stably flow upwards and improve the distribution of the vapor phase.

Owner:ZHEJIANG UNIV OF TECH

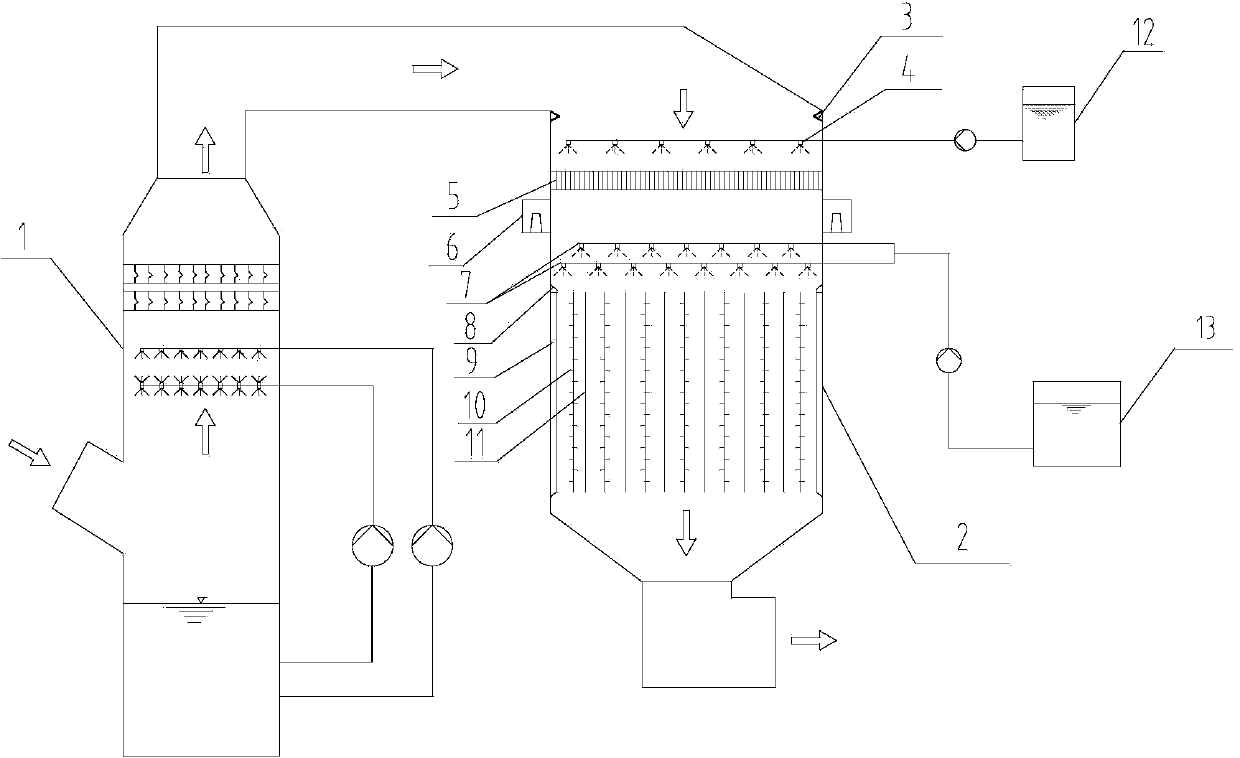

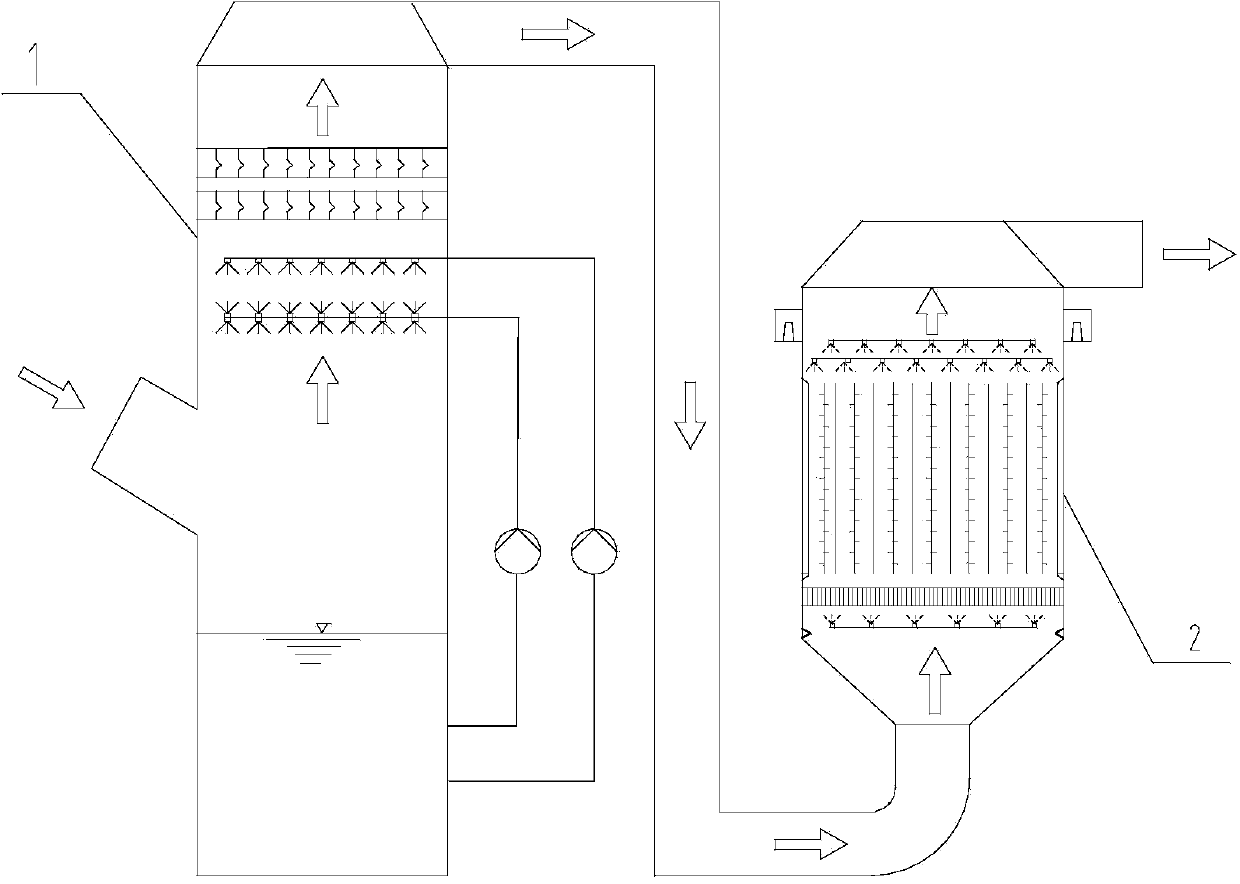

Vertical flow wet-type electric precipitator and wet electric precipitation method

The invention provides a vertical flow wet-type electric precipitator and wet electric precipitation method. The vertical flow wet-type electric precipitator comprises an annular plate, a spray humidifying layer, a flue gas uniform distribution device, a dust removing electric field area, washing and spraying layers, a plurality of insulator boxes, an atomization water tank and a process water tank, wherein the spray humidifying layer comprises a fine atomizing nozzle and a spray pipeline; flue gas sequentially passes through the annular plate, the spray humidifying layer and the flue gas uniform distribution device; the dust removing electric field area is used for blocking a baffle board of a flue gas blind area; the washing and spraying layers are arranged above the dust removing electric field area; the wet electric precipitation method comprises the following steps: a continuous manner is adopted to conduct atomization and humidification on inlet flue gas and conduct uniformly distributed optimization treatment on the flue gas; an intermittent or continuous manner is adopted to conduct sprinkling and cleaning on a dust-collecting electrode and a discharge electrode; a method of hot air sweeping is adopted to ensure insulation. The vertical flow wet-type electric precipitator and the wet electric precipitation method can effectively ensure the high-efficient and stable operation of the vertical flow wet-type electric precipitator, optimize the fluid field, and strengthen turbulence and atomization of the flue gas; local micro-mixing, and collision as well as crash coagulation of fine particles are promoted; the dust removal efficiency is improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

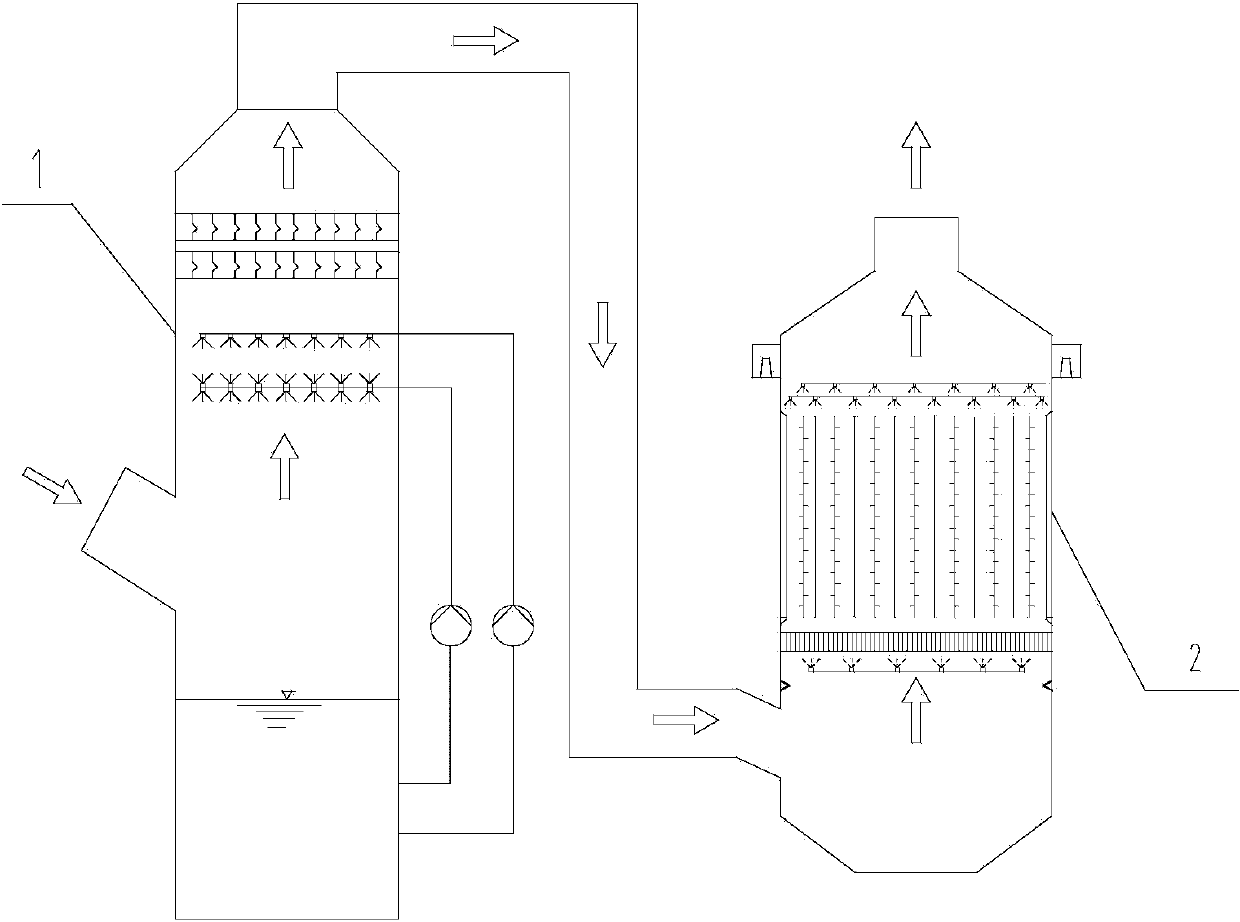

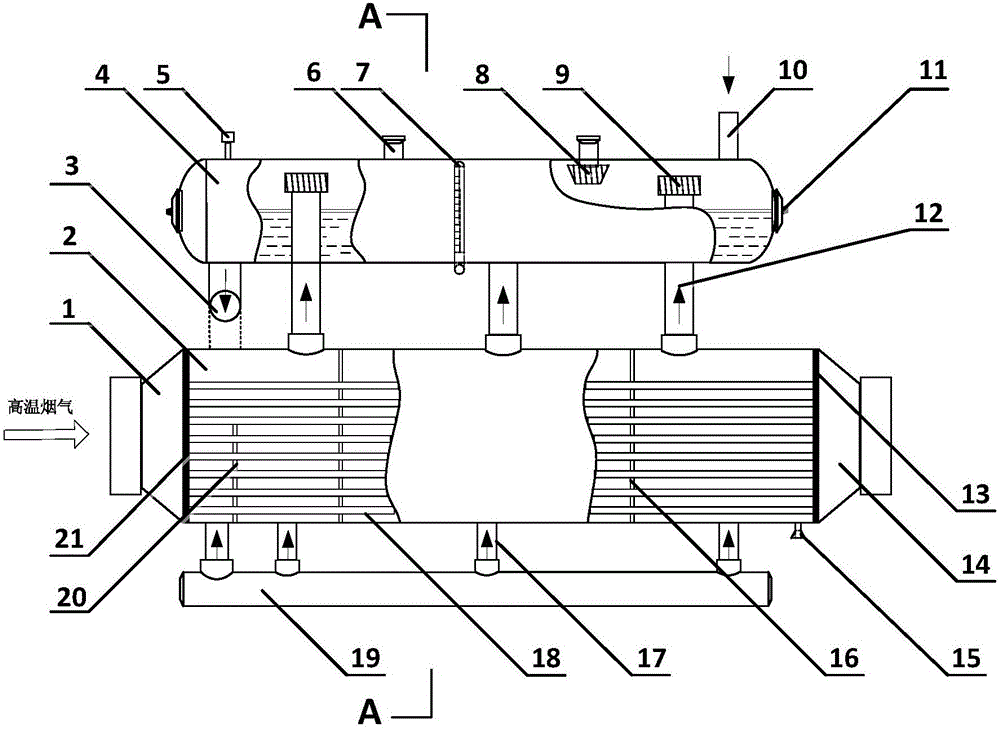

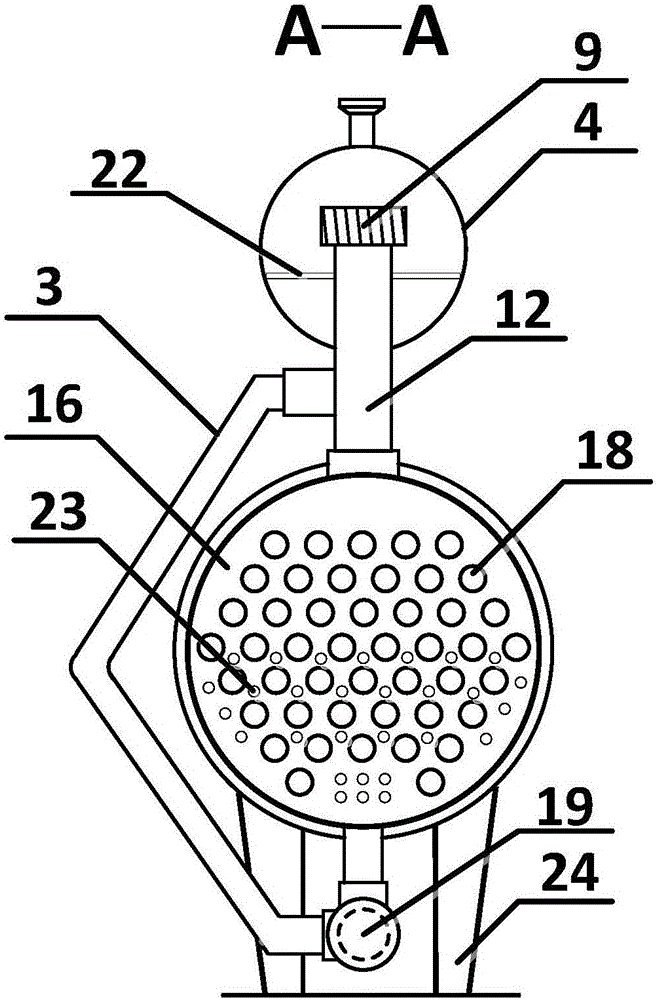

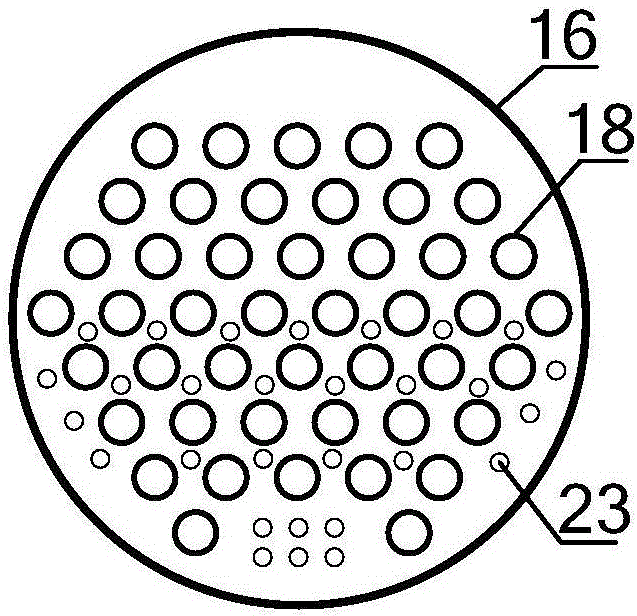

Natural circulation split tube-and-shell type waste heat boiler capable of optimizing flow field arrangement

ActiveCN106287627AAvoid flow turbulenceResolve disorderSteam separation arrangementsWater-tube boilersFlue gasEngineering

The invention relates to a natural circulation split tube-and-shell type waste heat boiler capable of optimizing flow field arrangement. The waste heat boiler comprises a boiler barrel and a steam pocket. The boiler barrel is partitioned into a flue gas inlet, a heat exchange cavity and a flue gas outlet. The heat exchange cavity is connected with a water collection pipe through a first water distribution pipe. A heat exchange pipe bundle is arranged in the heat exchange cavity. The heat exchange cavity is internally partitioned into multiple heat exchange units by arranging vertical support baffles. Each heat exchange unit is connected with the steam pocket through an ascending pipe. The upper end of each ascending pipe extends into the steam pocket and is always located above the liquid level in the steam pocket. Pipe holes used for allowing the heat exchange pipe bundle to penetrate are formed in the support baffles. Baffle holes are formed among the pipe holes in the lower portions of the support baffles. The steam pocket is provided with a steam pocket water replenishing opening and multiple steam outlets. The steam pocket is connected with the water collection pipe through a descending pipe. By means of the natural circulation split tube-and-shell type waste heat boiler, the problems that in a boiler barrel on the lower portion in a split tube-and-shell type waste heat boiler, steam-liquid two-phase flow is disorder, and in ascending pipes, steam-liquid two-phase flow stagnates and even backflow is caused can be solved.

Owner:XI AN JIAOTONG UNIV

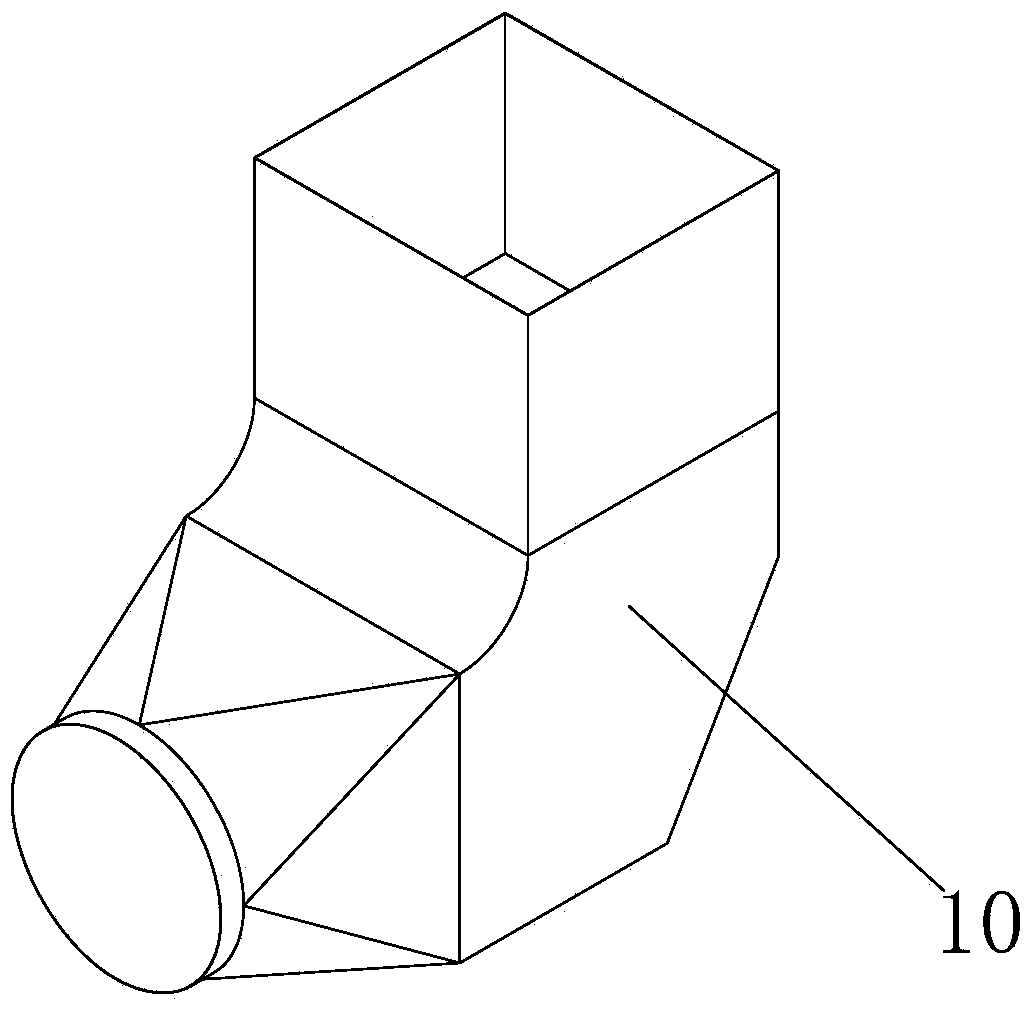

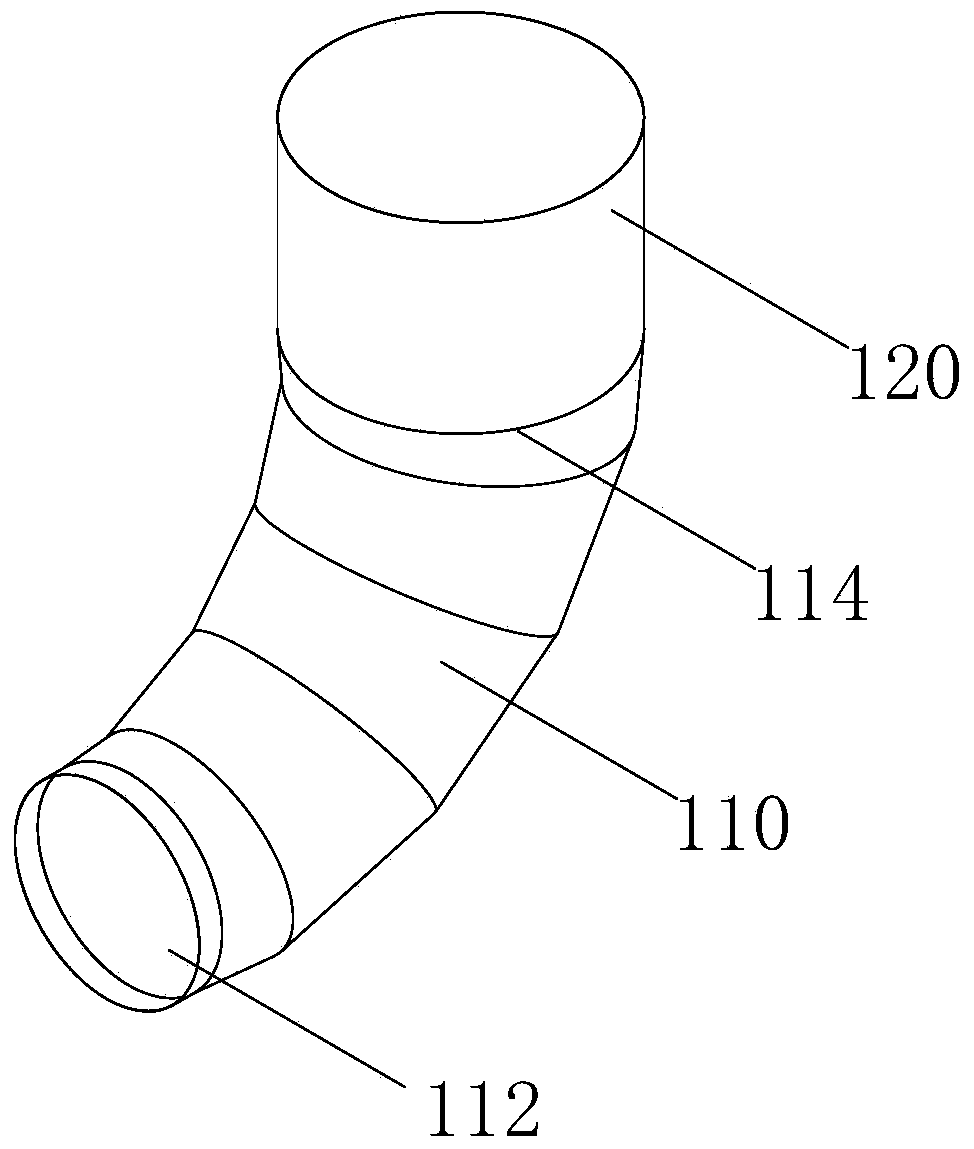

Wet desulphurization mechanism

ActiveCN103953939AImprove heat transfer efficiencyEliminate risks such as blockage downtimeChimneysPlate heat exchangerEngineering

The invention discloses a wet desulphurization mechanism. The wet desulphurization mechanism comprises an original smoke deflector and a smoke heat exchanger, wherein an original smoke opening is formed in the smoke heat exchanger, the cross section of the original smoke opening is rectangular, the original smoke deflector comprises a first elbow and a second elbow, the cross sections of the first elbow and the second elbow are round, and both the first elbow and the second elbow are mounted on the original smoke opening of the smoke heat exchanger. As the first elbow and the second elbow, of which the cross sections are round, are arranged at the original smoke opening of the smoke heat exchanger, smoke can be shunt by the first elbow and the second elbow before entering the smoke heat exchanger, and sufficient bending spaces are available at the first elbow and the second elbow. Besides, the first elbow and the second elbow have smaller round cross sections and great deflecting functions, the whole flow field becomes more uniform, the heat exchange efficiency of the smoke heat exchanger is effectively improved, and the risks that the easily torn deflector plate designed in the traditional rectangular runner causes corroded cracks, corroded flues, runner blocking shutdown and the like are eliminated.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Biphase rectification flue gas desulfurization technique

ActiveCN101244363AReduce resistanceDoes not cause reduced reflux reactionsDispersed particle separationReaction rateGas phase

The invention discloses a dual-phase rectification flue gas desulfurization technology, which comprises a plurality of steps that (1) an absorption tower is arranged, (2) the flue gas is injected, (3) the limestone slurry is pumped in, and (4) the reaction product is collected. The dual-phase rectification flue gas desulfurization technology is characterized in that (1) the nonuniformity of flow field inside the spray tower is utilized, (2) the even rectification of liquidoid and gas phase is not processed on account of the design of rectifying plate and spray layer intentionally, (3) the resistance of flue gas is decreased and the velocity of flow of flue gas is uninfluenced, and (4) the liquidoid and the gas phase are kept turbulent state consistently because of the nonuniformity of liquidoid and gas phase. The dual-phase rectification flue gas desulfurization technology has the advantages of fierce collision, intense reaction, enough absorption, good performance of desulfurization, high efficiency, fast reaction rate, good performance of counter-current reaction, optimization of flow field, low system pressure drop, energy-saving, low device cost and maintenance cost, and direct maintenance and shift of inner parts without building temporary maintenance platform in the process of maintenance of absorption tower inner parts.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

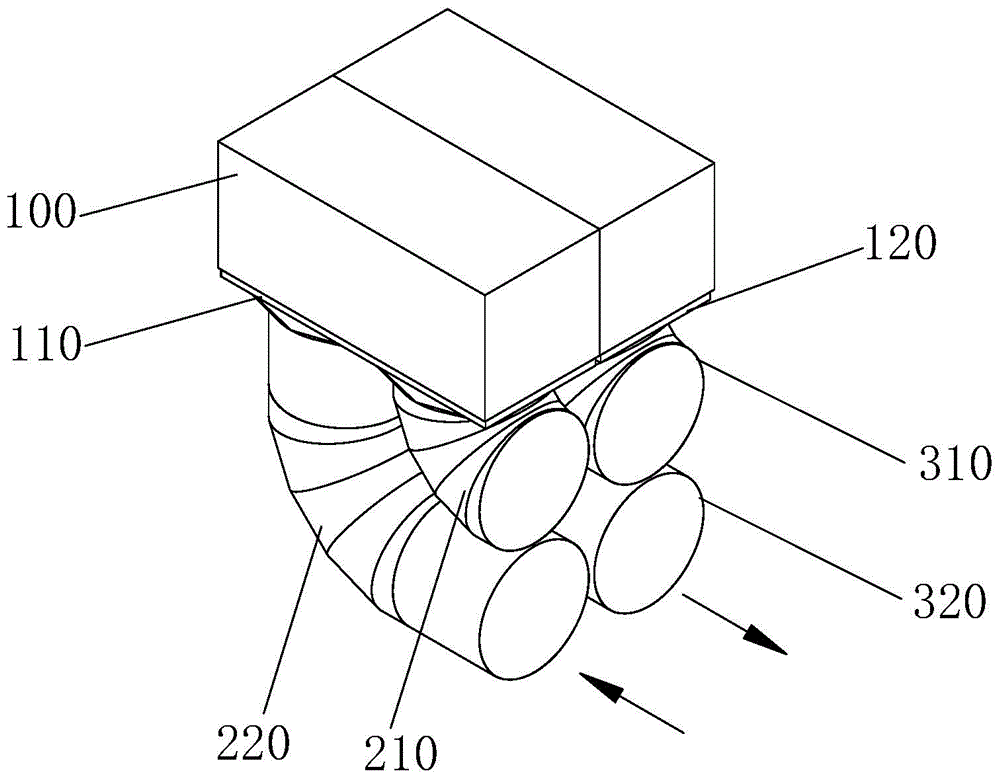

Smoke duct device and reducing elbow thereof

The invention discloses a reducing elbow which comprises a reducing section and a body section. The cross section of the reducing section and the cross section of the body section are circular, the reducing section comprises a large end and a small end, the diameter of the reducing section is gradually enlarged from the small end to the large end, the reducing section is curved, the large end of the reducing section is communicated with the body section, and the ratio of the curved radius of the reducing section to the diameter of the small end is 1.0-3.0. The cross section of the reducing section and the cross section of the body section are circular, the diameter of the reducing section is gradually enlarged from the small end to the large end, the reducing section is curved, the large end of the reducing section is communicated with the body section, and therefore reducing and turning are achieved synchronously, reducing has the enough diffusion section, turning has the enough turning radius, the reducing elbow is even in smoke flow field, and a smoke duct body is prevented from vibrating to generate noise. The conclusion that the resistance generated by the reducing elbow is far smaller than that generated by a traditional rectangular reducing elbow is obtained through FLUENT fluid simulation software analog computation. The invention further discloses a smoke duct device.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

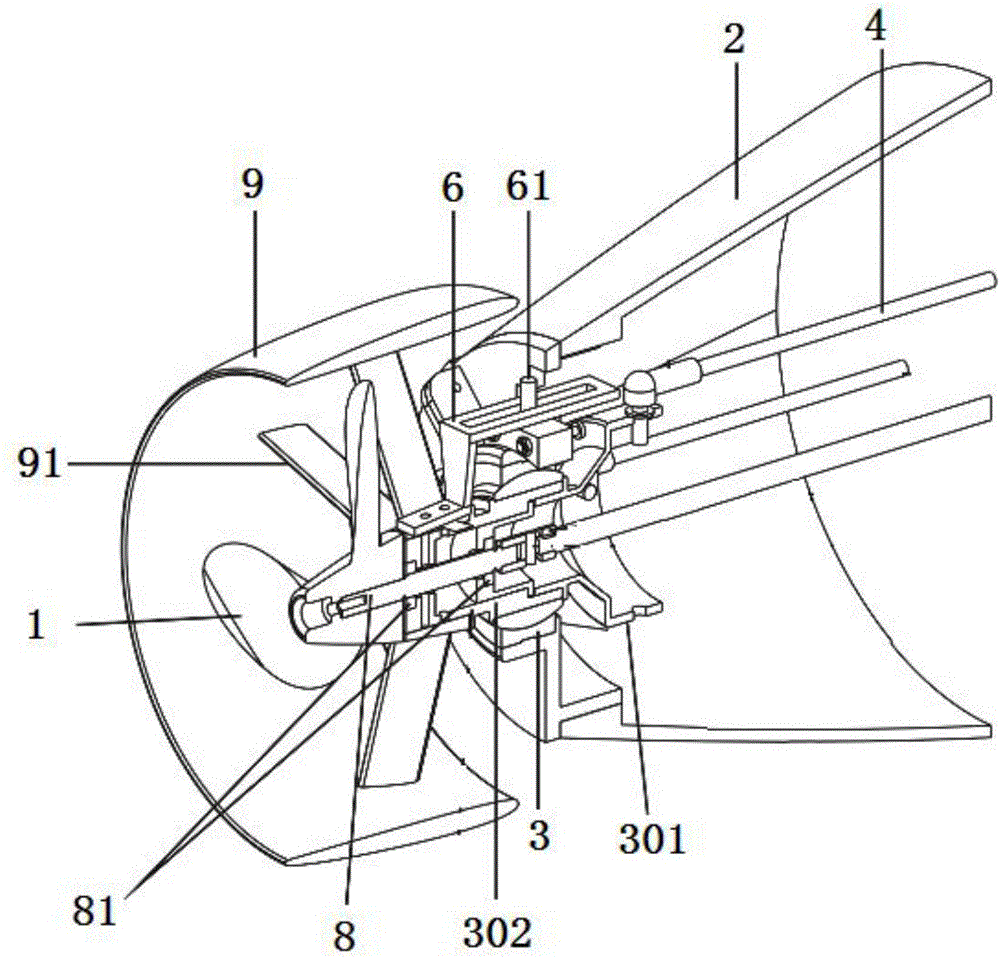

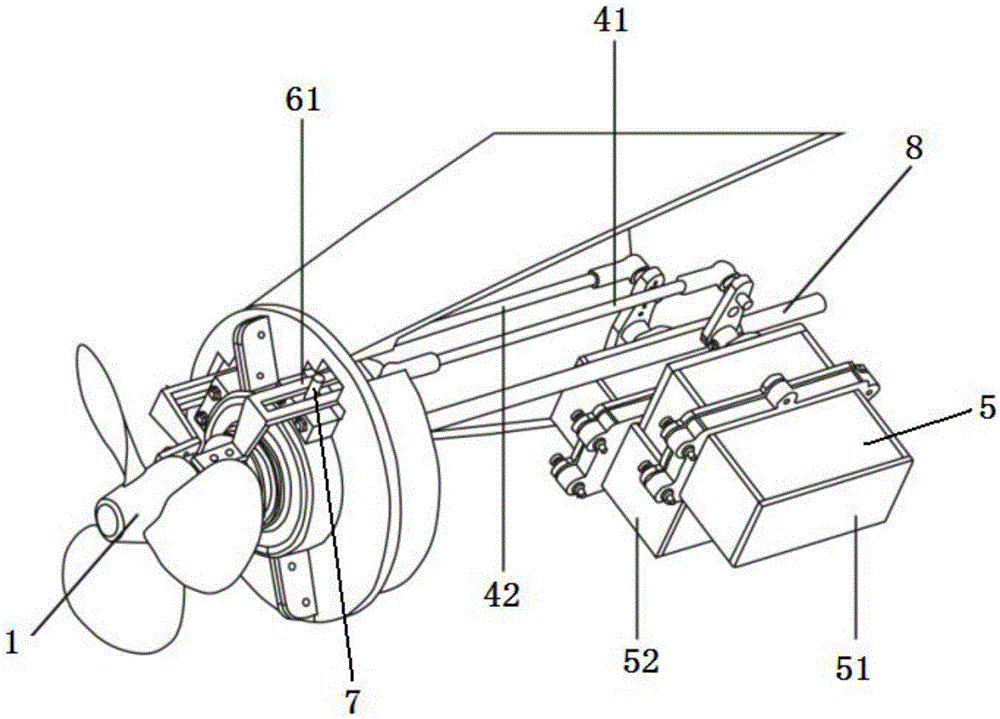

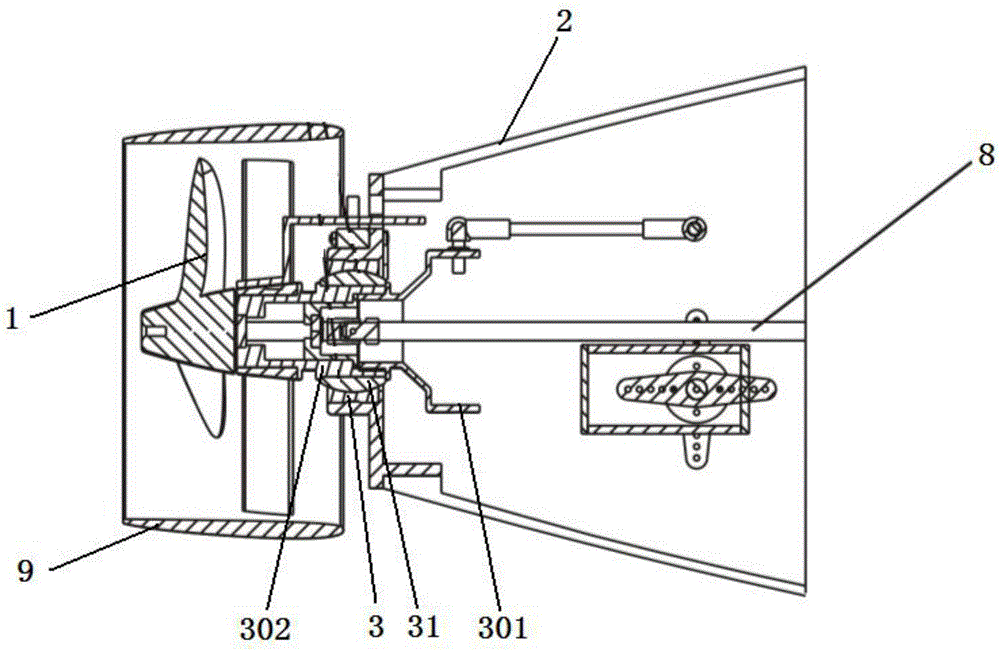

Universal thruster

The invention relates to the field of thrusters and discloses a universal thruster. The universal thruster comprises a shell (2) and a propeller (1). A joint bearing (3) is installed in the shell (2), the propeller (1) is installed on a spherical inner ring (31) of the joint bearing (3), a pushing guide rod (4) is installed on the spherical inner ring (31) and connected with a pushing motor (5), and the joint bearing (3) drives the propeller (1) to swing under the pushing function of the pushing guide rod (4). Steering of the universal thruster does not depend on steerage generated when water flow flows past a control surface but depends on vector thrust force which is more direct, so the steering radius is very small, and high steering torque can be generated even under a dead slow condition. The universal thruster has the advantage of being high in steerage and is particularly suitable for military unmanned underwater vehicles.

Owner:杭州霆舟无人科技有限公司

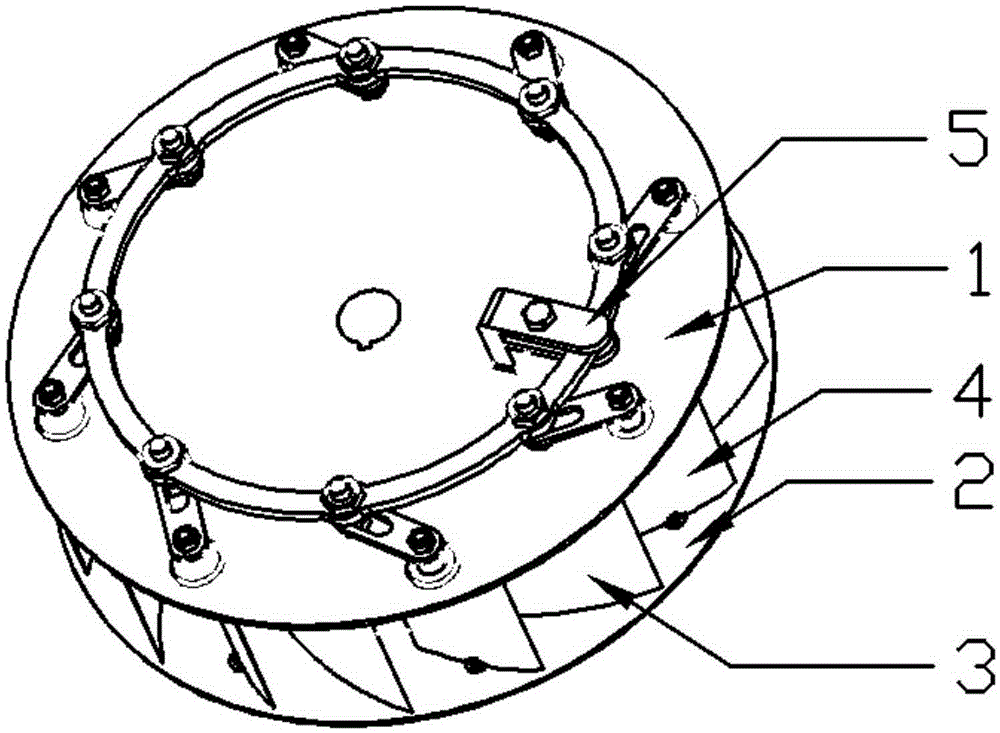

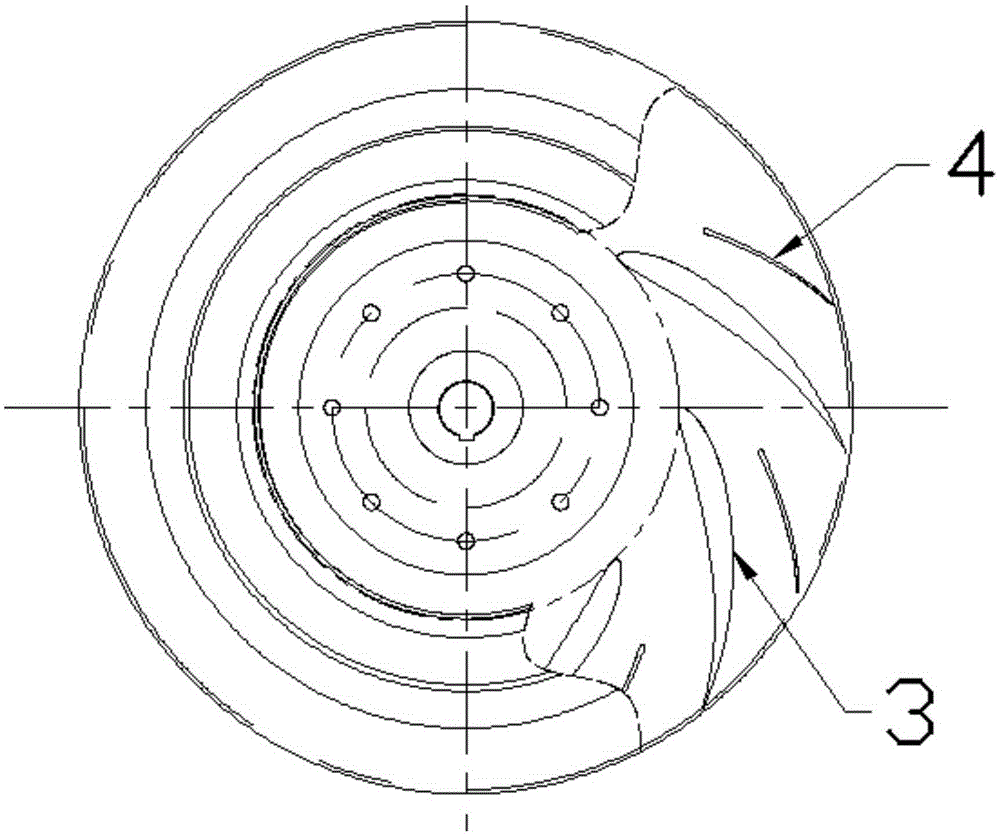

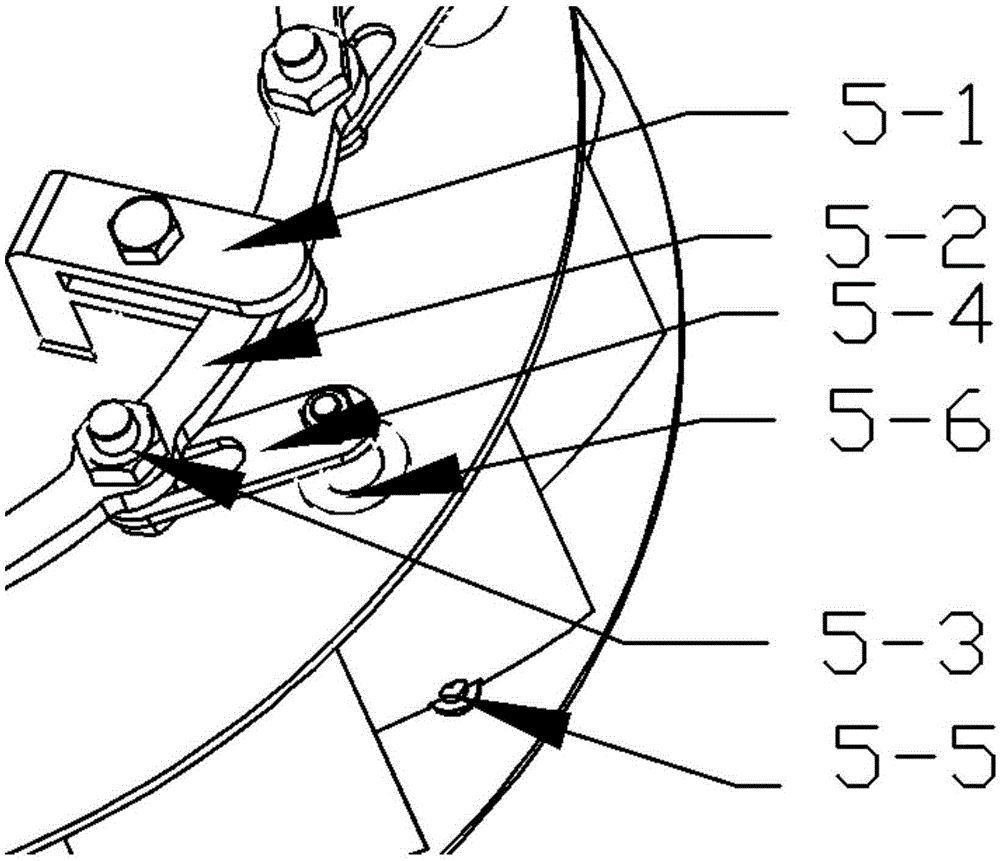

Centrifugal fan impeller capable of adjusting splitting vanes

InactiveCN105332945AImprove performanceImprove operational efficiencyPump componentsPumpsImpellerService efficiency

The invention discloses a centrifugal fan impeller capable of adjusting splitting vanes, and aims at solving the problems that the common working conditions of a current fan product in use do not match with the rated working conditions, thus the service efficiency of a fan is low, and the efficient operation range of the fan is reduced. The centrifugal fan impeller capable of adjusting the splitting vanes is characterized in that a circular guide ring and a wheel disc form a revolving pair; a main fixing frame which is provided with a circular guide ring fixing device is fixed to the wheel disc; the circular guide ring is connected to n upper fixing devices for the circular ring and the splitting vanes; the splitting vanes are connected to a wheel cover through upper fixing devices for the wheel cover and the splitting vanes, and the splitting vanes are connected with the wheel disc through upper fixing devices for the wheel disc and the splitting vanes; each upper fixing device for the circular ring and the splitting vanes is connected to the corresponding upper fixing device for the wheel disc and the splitting vanes through a splitting vane adjusting part. According to the centrifugal fan impeller, the circular guide ring can be rotated to drive the splitting vane adjusting parts to swing so as to adjust the angles of the splitting vanes, thus the maximum operation efficiency can be obtained according to different working conditions, and the maximum operation efficiency which can be achieved only under the rated working conditions can be obtained by a centrifugal fan under the off-rating conditions.

Owner:ZHEJIANG SCI-TECH UNIV

Mixed-flow device of ship diversion propelling system

InactiveCN101734361AReduce wave resistanceHarm reductionRotary propellersWatercraft hull designImpellerMixed flow

The invention discloses a mixed-flow device of a ship diversion propelling system, aiming at solving the problem of jet flow of the ship diversion propelling system. The mixed-flow device mainly consists of a jet pipe, a wake flow pipe and a mixed-flow pipe, wherein a nozzle of the jet pipe and an outlet of the wake flow pipe are communicated with the mixed-flow device; an inlet of the wake flow pipe is arranged at the lateral side of the jet pipe; the cross section of the jet pipe is less than that of the mixed-flow pipe; and jet flow and wake flow are acted and mixed together in a mixed-flow cavity. By comparing water flow at the outlet of the mixed-flow pipe with the water flow at the nozzle of the jet pipe, the invention reduces the speed and increases the flow so as to improve the stern flow field of the ship, reduce the wave making resistance of the stern, or improve the flow field of a propeller or a pump impeller, improve the propelling efficiency and reduce damage of vacuole and water attach. The induced velocity generated by the water flow at the outer side of the inlet of the wake flow pipe and the induced pressure converted thereby can be further used for improving the stern flow field of the ship and reducing the wave making resistance of the stern.

Owner:孙志伟

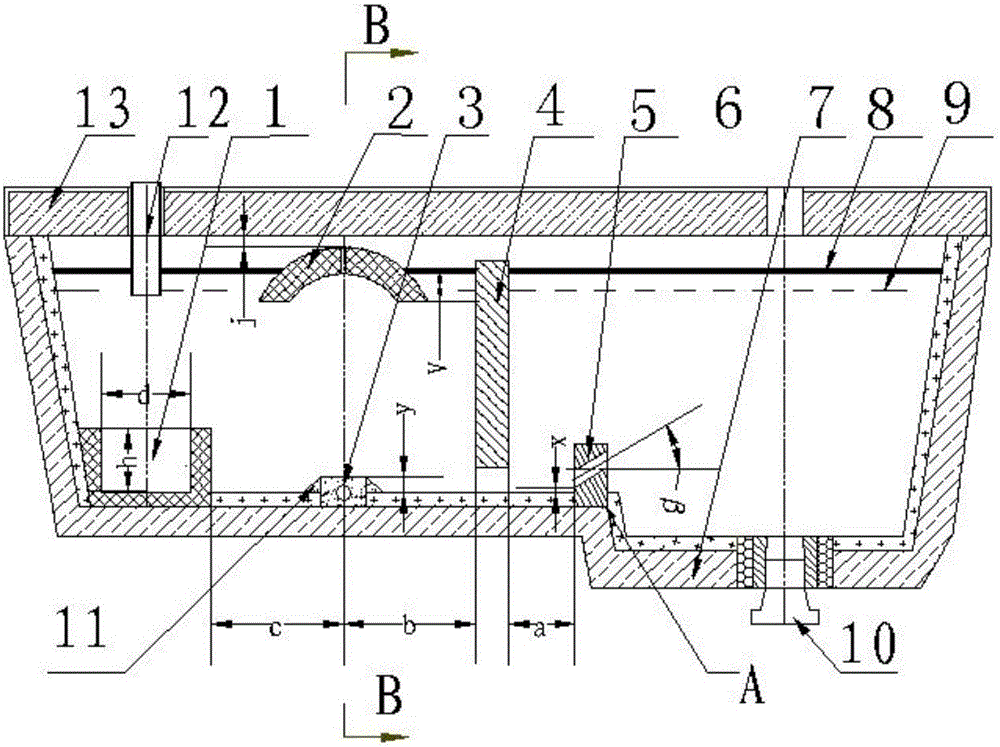

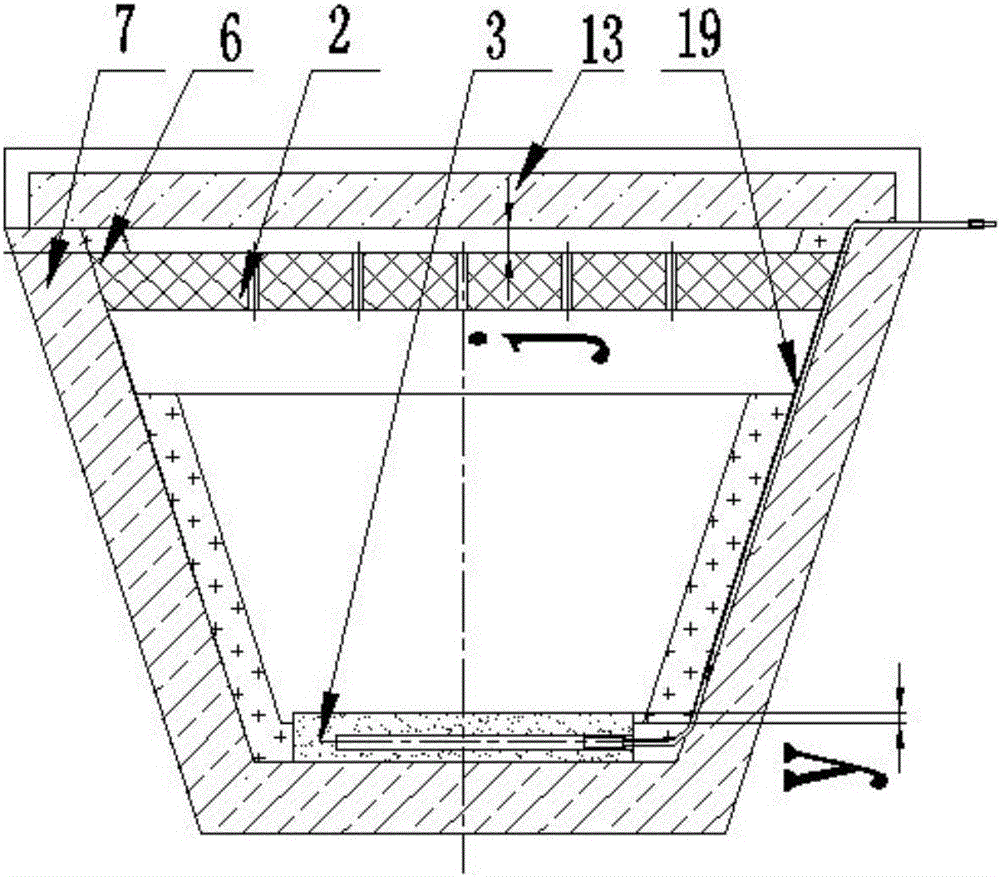

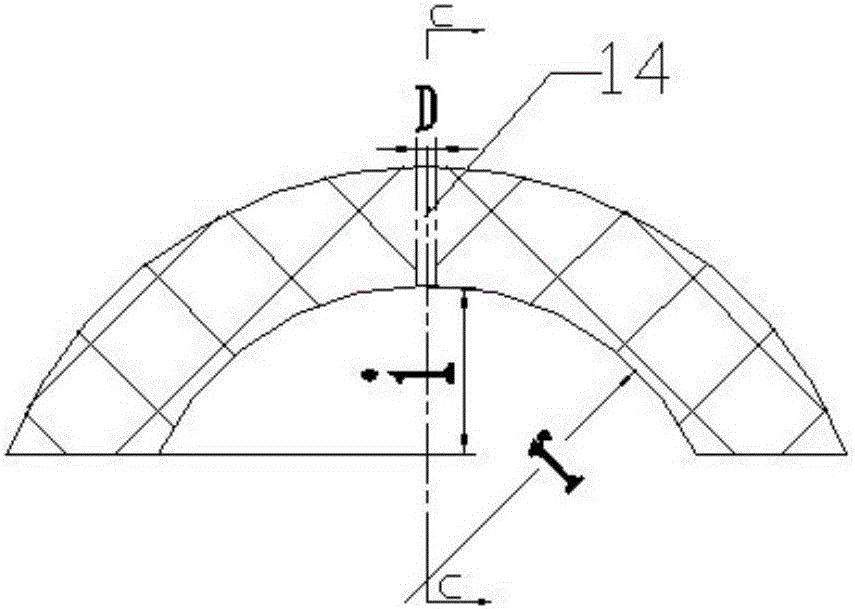

Electrolytic machining tool and method for groove group of expanding-comb-shaped liquid sealing structure

ActiveCN106670598AImprove electrolyte flow fieldImprove processing stabilityElectrical-based machining electrodesEngineeringElastomer

The invention relates to an electrolytic machining tool and method for a groove group of an expanding-comb-shaped liquid sealing structure, and belongs to the field of electrochemical machining. The tool comprises a tool base (2), an elastomer (4), a comb-shaped liquid sealing body (5) and a negative plate (6). The comb-shaped liquid sealing body (5) is made from an insulating material. The rear end of the comb-shaped liquid sealing body (5) is connected with the tool base (2) through the elastomer (4). The front end of the comb-shaped liquid sealing body (5) is provided with an ordered protruding structure matched with a hollowed-out seam group structure of the negative plate (6), and the height of the protruding structure is greater than the thickness of the negative plate. During working, the ordered protruding structure of the comb-shaped liquid sealing body (5) is inserted into the hollowed-out seam group structure of the negative plate (6) and can slide relative to the negative plate mutually. The sections (9) of electrolyte runners are a plurality of separated rectangular runners always until the groove group structure is machined and the problem that flow of electrolyte is split by clearance grooves during electrolytic machining for the groove group is thoroughly solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

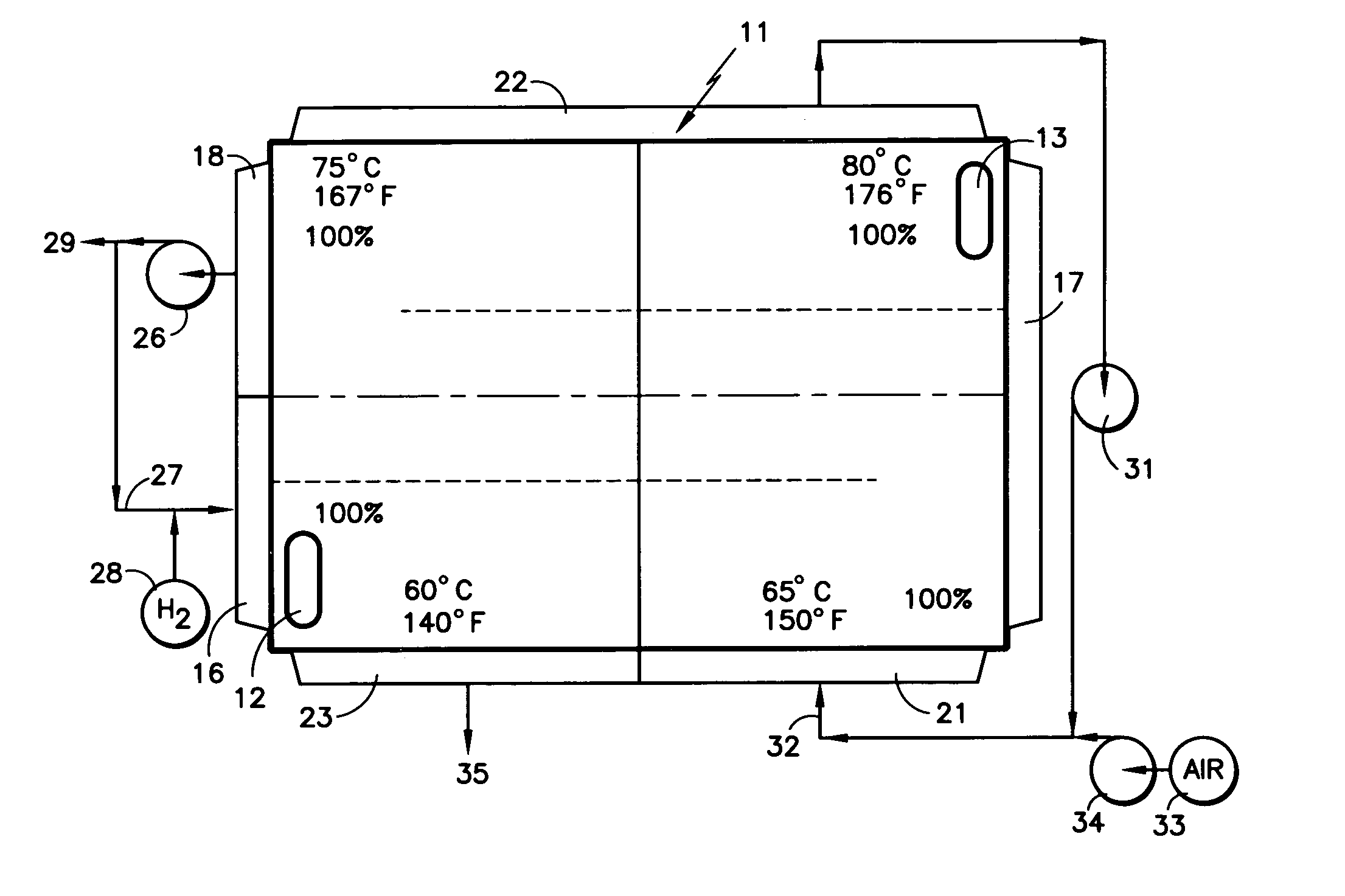

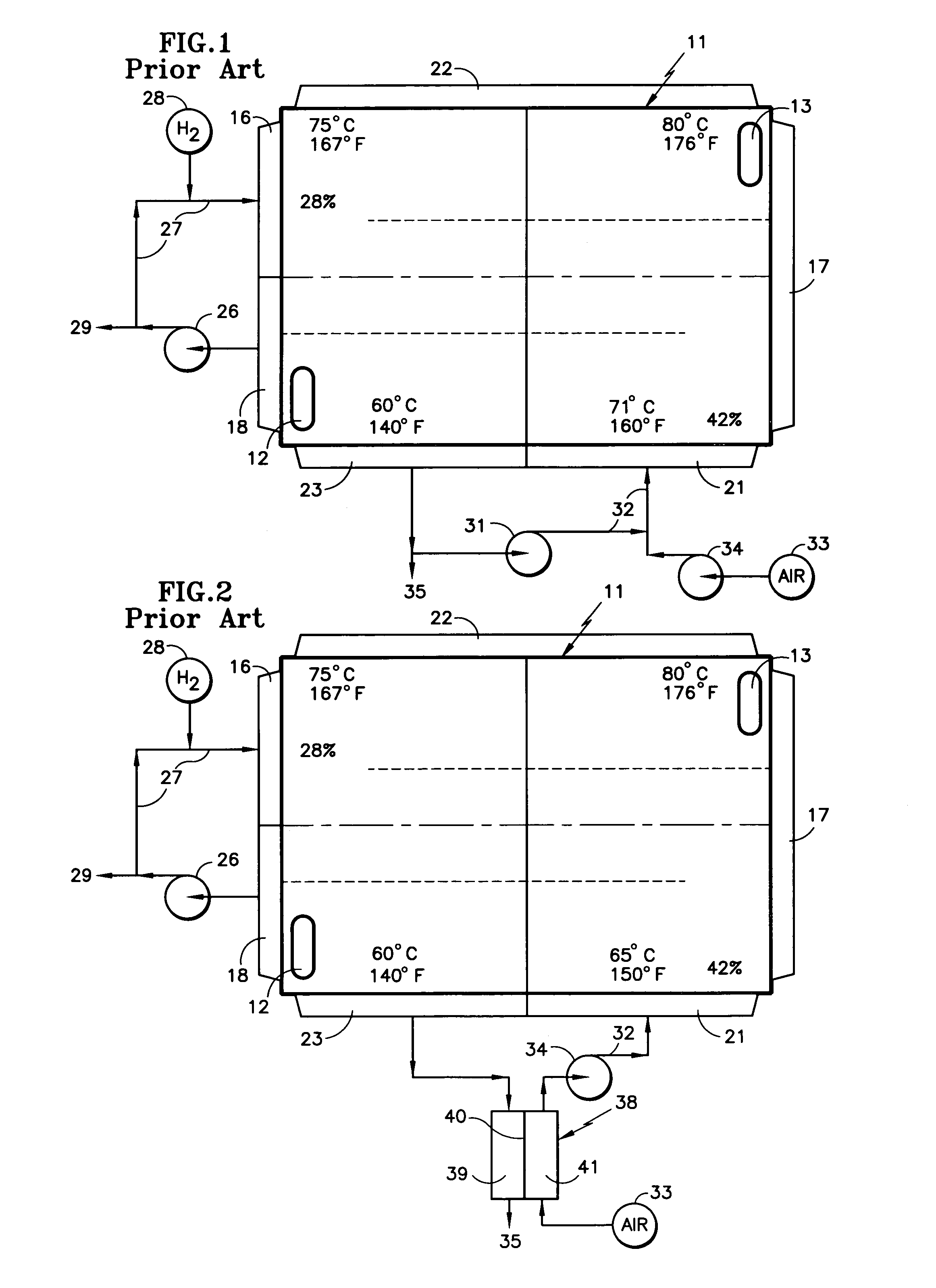

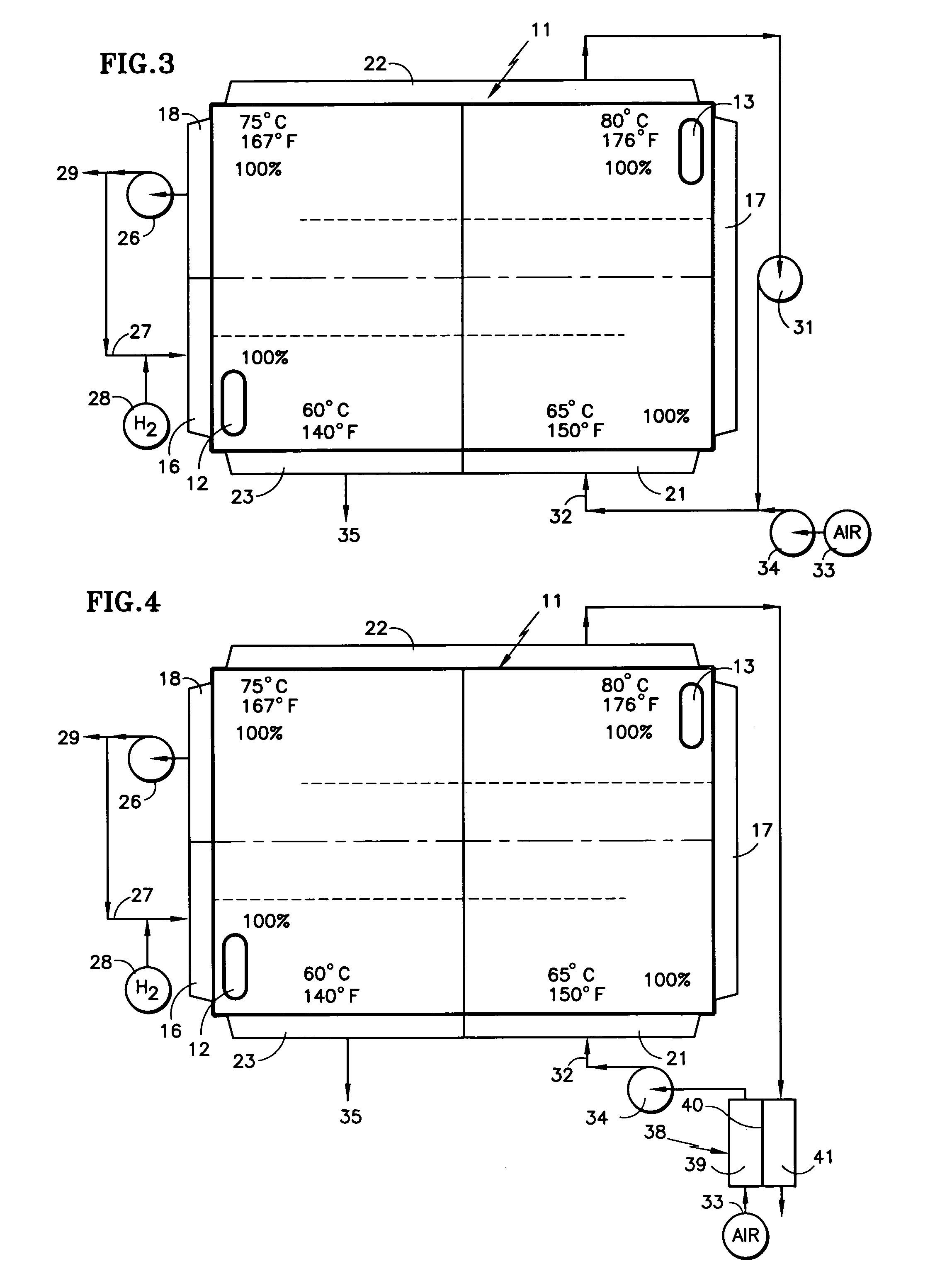

High temperature reactant recycling for PEM fuel cell humidification

InactiveUS7067209B2Easy to humidifyIncrease powerFuel cells groupingFuel cell auxillariesFuel cellsCirculator pump

A fuel cell stack has an air inlet manifold (21), an air turnaround manifold (22) and an air exit manifold (23); a coolant inlet is adjacent said air exit manifold; a fuel inlet manifold (16) is connected through a turnaround manifold (17) to a fuel exit manifold (18) remote from said coolant inlet. Fuel recycle is taken from the fuel manifold where the temperature is warmer than it is near the coolant inlet; recycle air for humidifying and heating inlet air is taken from the air turnaround manifold (22), and may either be recycled air provided by a recycle pump (31), or it may utilize an enthalpy recovery device (38) to transfer heat and humidity from an outflow chamber (41) to an inflow chamber (39).

Owner:AUDI AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com