Vortex type hydraulic pulse axial impact tool

A technology of hydraulic pulse and axial impact, which is used in drilling equipment, earth-moving drilling, driving devices for drilling in wellbore, etc., can solve the problems of vulnerable self-excited oscillating nozzles, small hydraulic pulse amplitude, and weakened hydraulic pulse. , to achieve the effect of optimizing the bottom hole flow field, improving the ROP and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

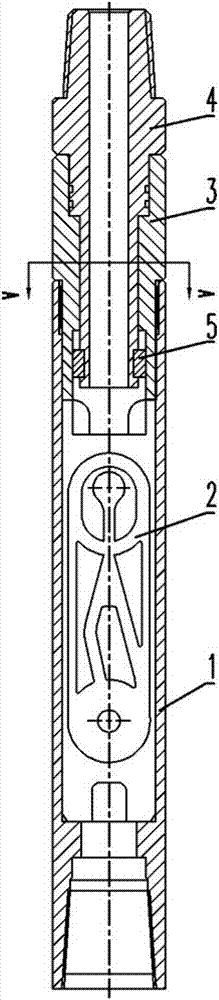

[0017] Such as figure 1 Among them, a vortex type hydraulic pulse axial impact tool includes a tubular shell 1, a hydraulic pulse generating device 2 is arranged in the shell 1, a casing 1 is connected with a jacket 3 to fix the hydraulic pulse generating device 2, and the casing 3 The mandrel 4 matched with it is set, the connection between the outer jacket 3 and the mandrel 4 can be a spline 6 or a polygon 7 connection, the lower end of the mandrel 4 is connected with the anti-drop nut 5, the lower end of the housing 1 is provided with a lower joint, and the mandrel 4 The upper end is provided with an upper joint, and the upper and lower joints can be male joints or female joints as required.

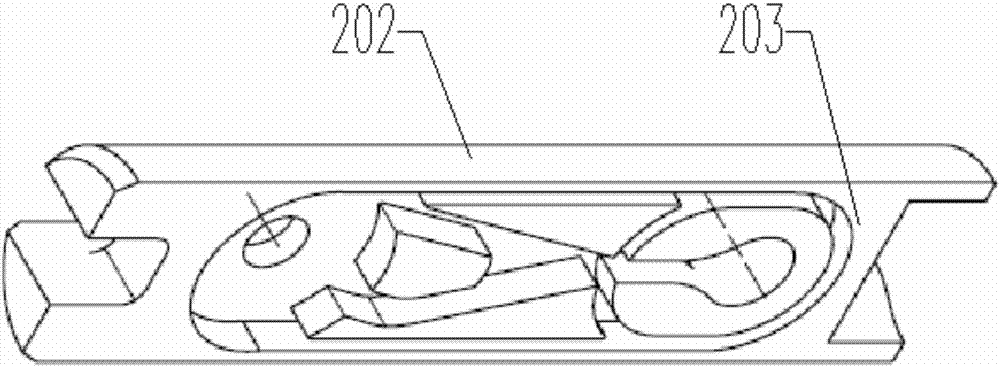

[0018] Such as figure 2 Among them, the hydraulic pulse generating device 2 is divided into two parts 201 and 202 along the diameter, and the section is 203 .

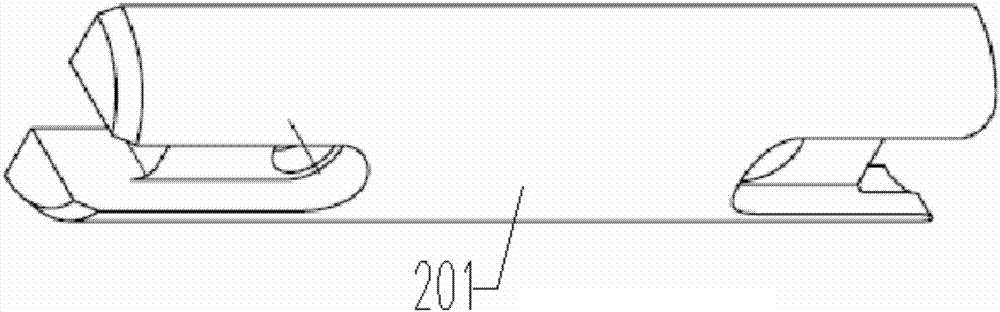

[0019] Such as image 3 Among them, a fluid inlet 204 and a fluid outlet 213 are provided on the section 203, and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com