Metal foam carrier catalysis bed solar energy absorption reaction device

A solar energy absorption, metal foam technology, applied in the chemical/physical/physical-chemical process of applying energy, etc., can solve the problems of temperature field, flow field difficult to organize, uneven catalyst packing, large flow resistance loss, etc., to achieve catalytic performance. Excellent, improve the conversion efficiency, balance the effect of flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

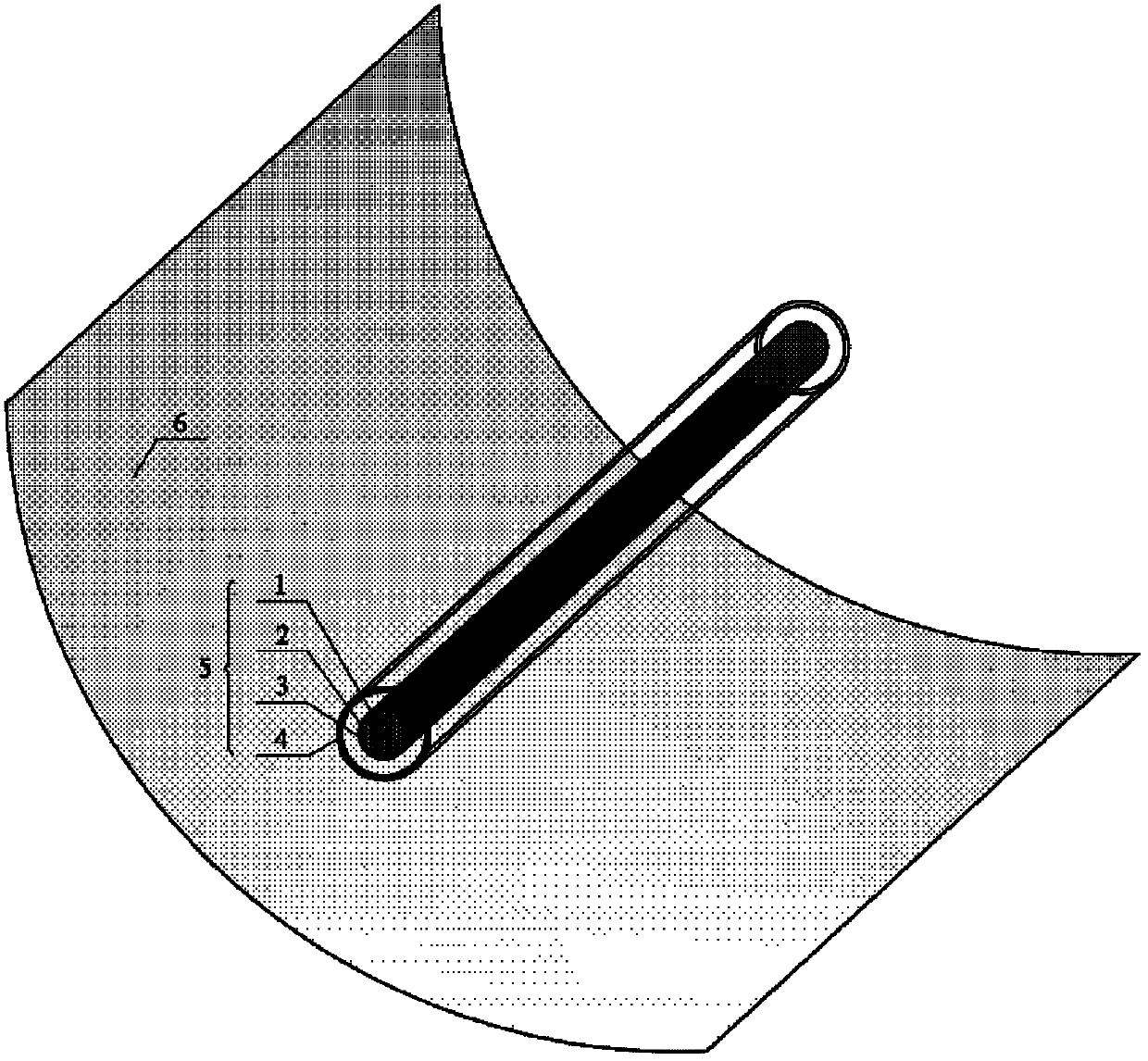

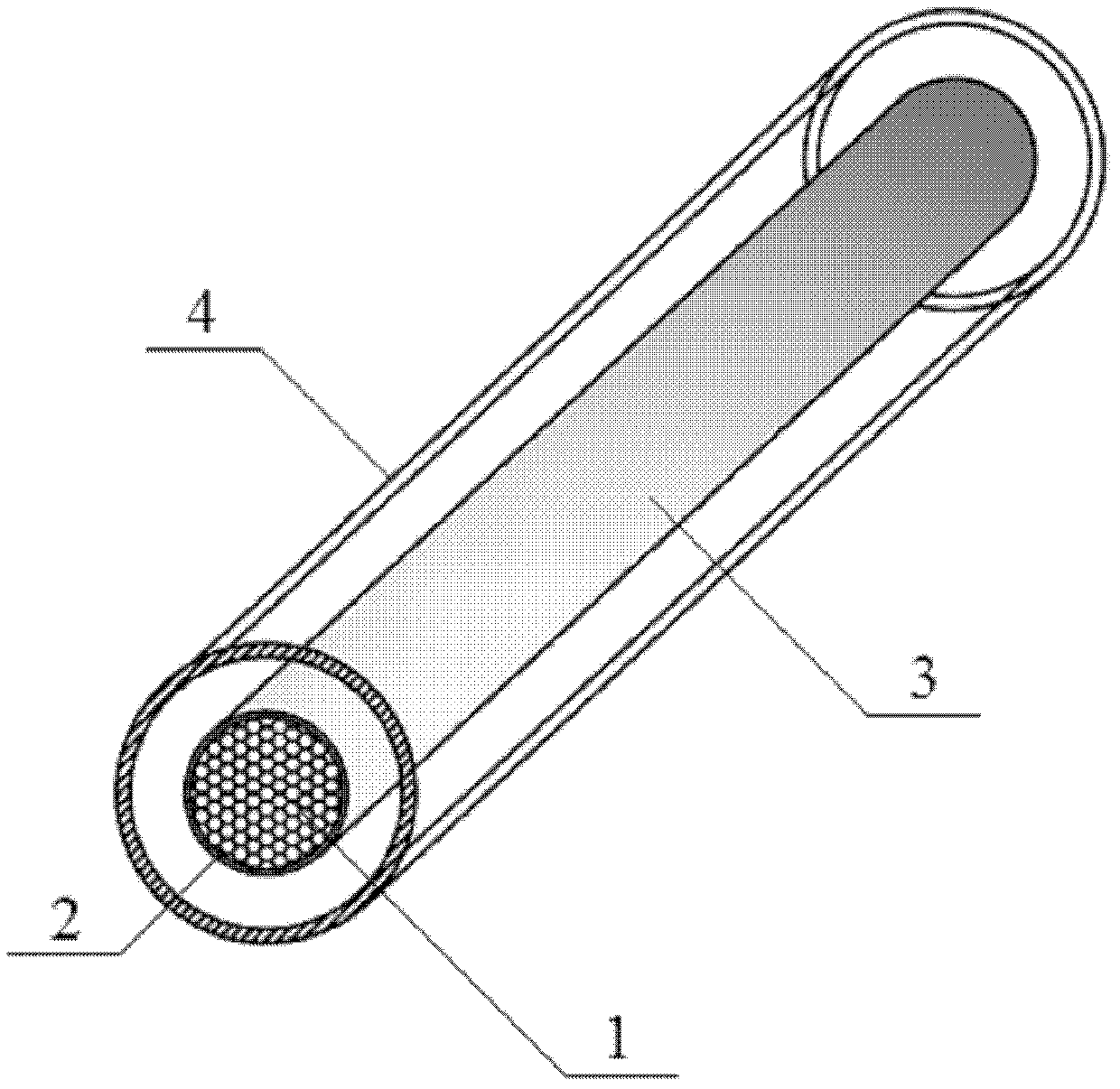

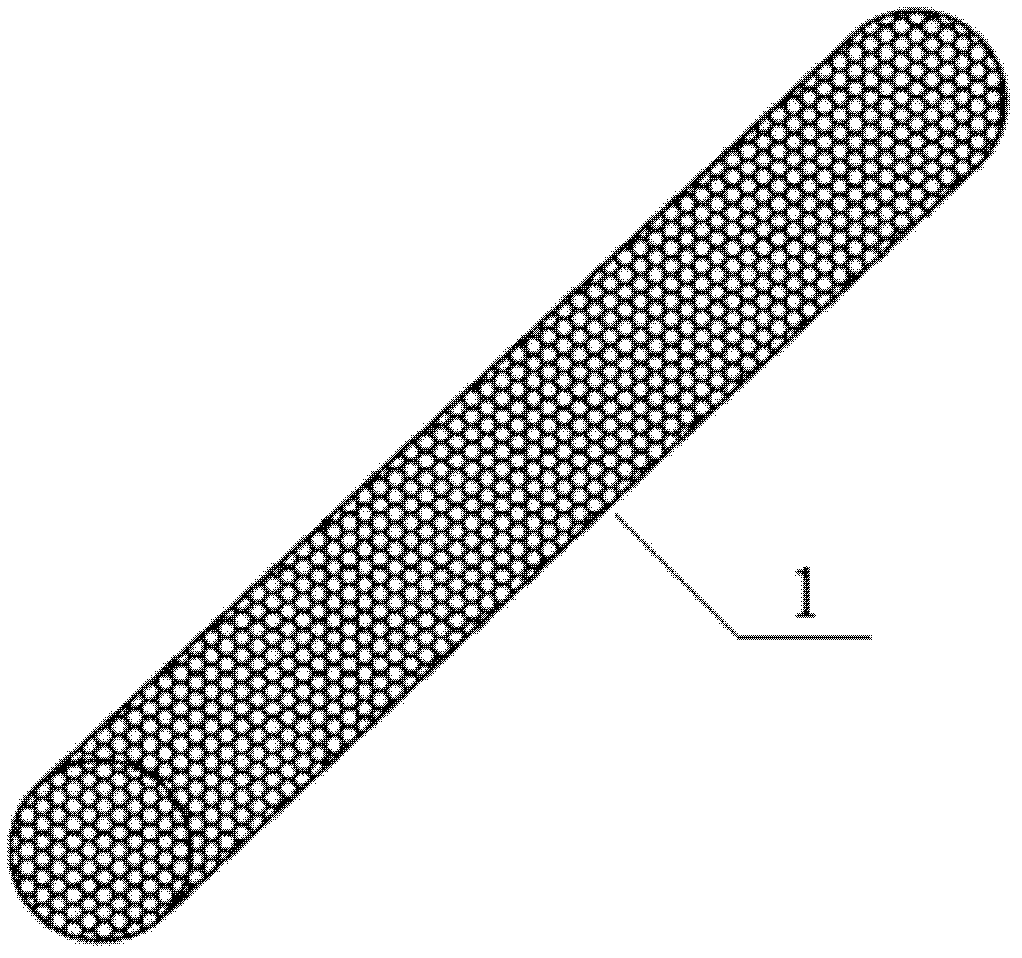

[0033] Such as figure 1 As shown, the present invention provides a metal foam carrier catalytic bed solar energy absorption reaction device, the device includes a linear solar energy absorption reactor 5 and a parabolic trough solar concentrator 6, the linear solar absorption reactor 5 is placed in the parabolic trough solar energy The focal line of the concentrator 6; the linear solar absorption reactor 5 is a sleeve structure, including an outer glass sleeve 4, an inner metal tube 2, a selective coating 3 deposited on the surface of the metal tube 2, and The metal tube 2 uses the metal foam material as the carrier of the catalyst bed 1, as well as the degassing ring and the bellows. Among them, the absorption rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com