Patents

Literature

89results about How to "Improve temperature field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

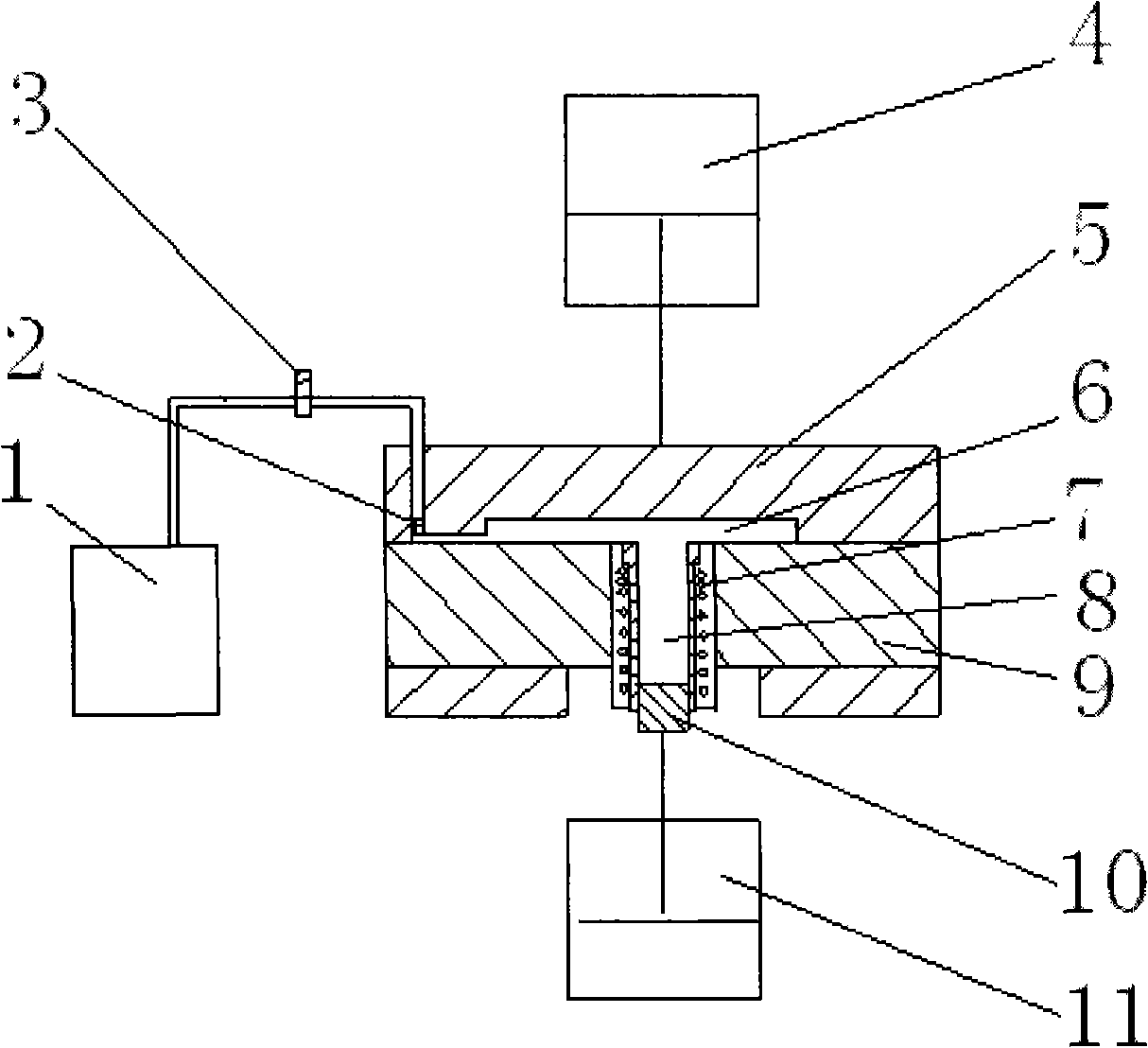

Low speed vacuum squeeze casting technology

The invention provides a low speed vacuum extruding casting technique which comprises the steps of: (1) the design of dies, a vacuum system and a hot runner; (2) the installation, the preheating and the coating of the hot runner and the dies; (3) the pouring of molten metal into the hot runner, die matching and vacuum pumping; (4) low speed and vacuum filling; (5) extruding and solidifying; (6) the opening of the dies to take finished products. The technical effects of the technique are the improvement of a temperature field during the casting process and the realization of the casting method of injection at low speed, solidification under high pressure and hole shrinkage without vacuum. The low speed vacuum extruding casting technique can effectively reduce the probability of containing pores and shrinkage and loose defects, heat treatment can be carried out to die casts, and both the tensile strength and the percentage elongation of the die casts after the heat treatment are increased by 25 percent, thereby greatly improving the quality of the die casts.

Owner:NANCHANG HANGKONG UNIVERSITY

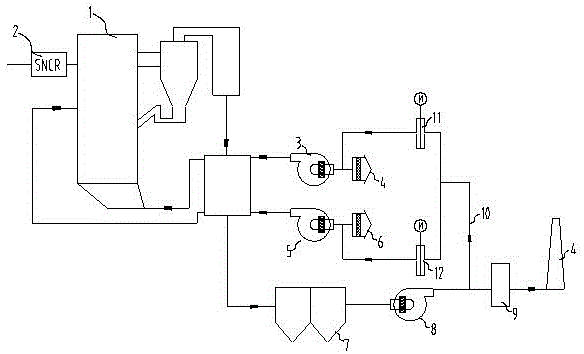

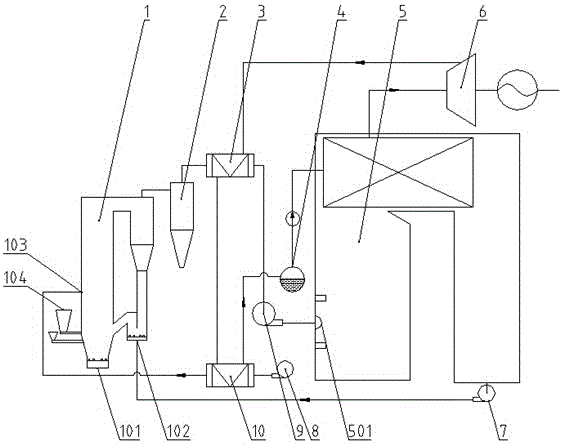

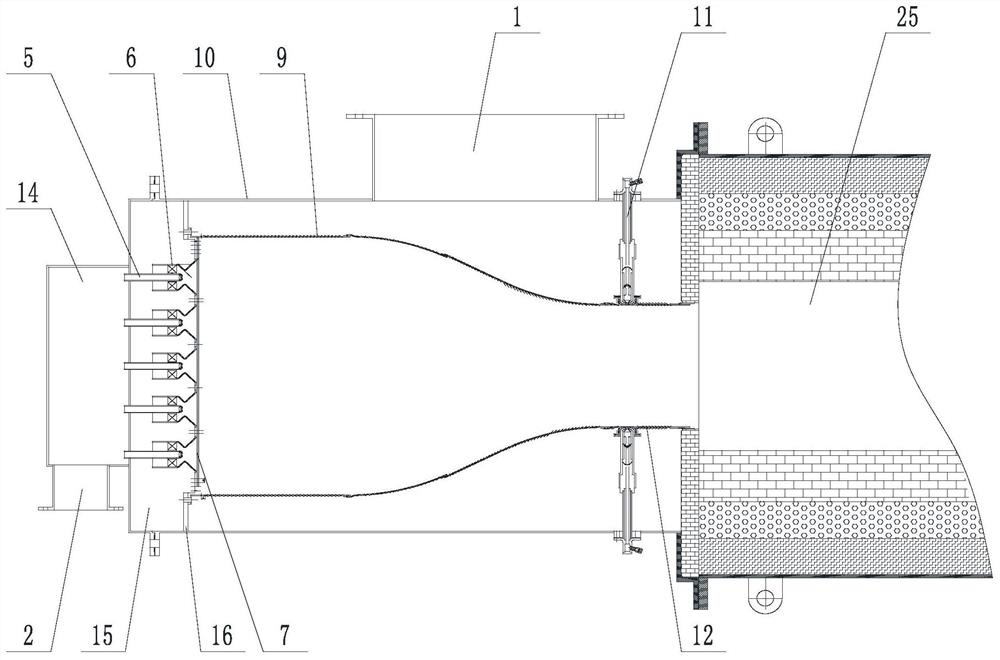

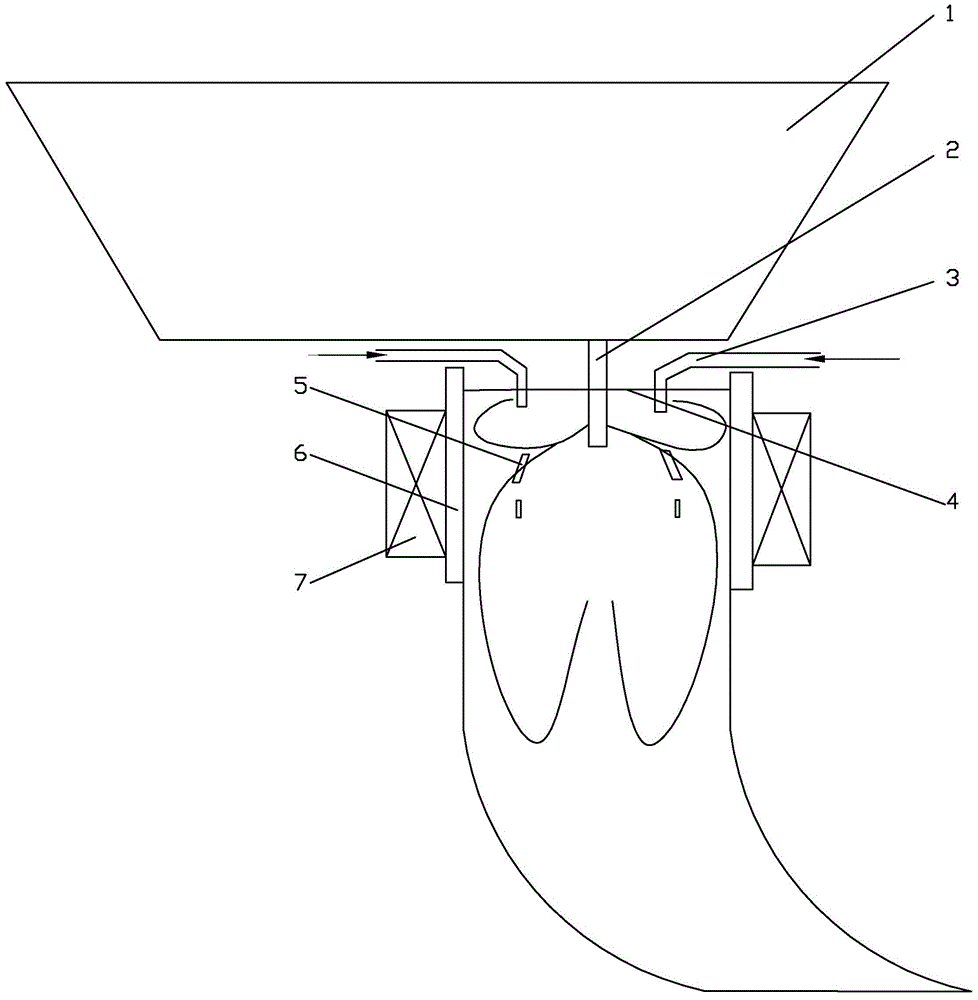

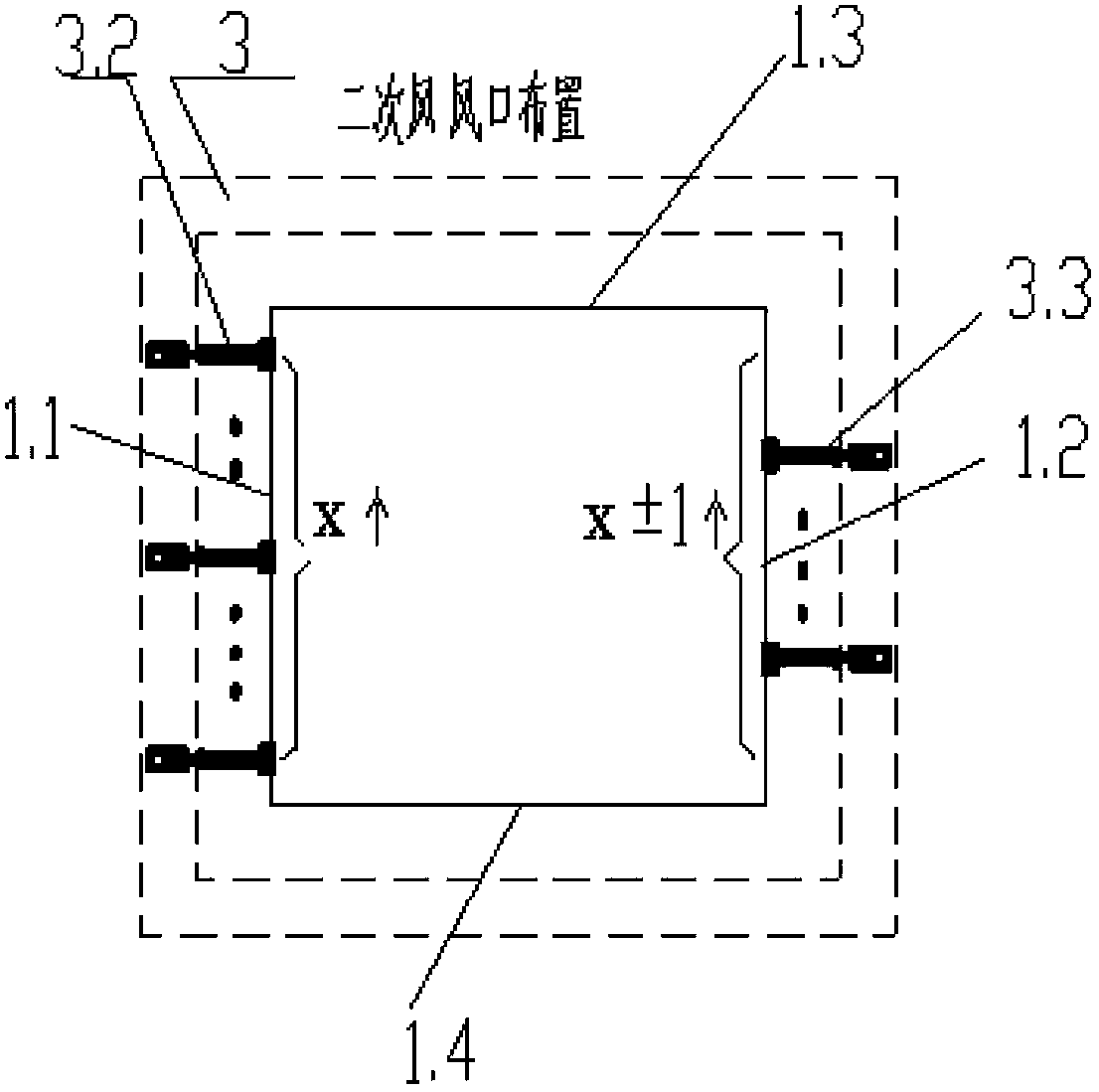

Flue gas recirculation-based wide load-wide coal deep denitrification system for CFB (circulating fluidized bed) boiler

InactiveCN105570883ALower combustion temperatureEmission reductionFluidized bed combustionFluegas recirculationCombustion chamberFlue gas

The invention provides a flue gas recirculation-based wide load-wide coal deep denitrification system for a CFB (circulating fluidized bed) boiler. The system comprises the boiler, an SNCR (selective non-catalytic reduction) system, a primary air blower, a secondary air blower, an induced draft fan, a recirculation flue, a primary air recirculation adjusting valve, a secondary air recirculation adjusting valve and the like. One end of the recirculation flue is connected with an outlet of the induced draft fan, the other end is connected with an inlet of the primary air blower and an inlet of the secondary air blower by the aid of the primary air recirculation adjusting valve and the secondary air recirculation adjusting valve, low-temperature flue gas is led out of the outlet of the induced draft fan, the low-temperature flue gas with the proper flow is sent to different positions of a combustion chamber by the blowers through control by the adjusting valves, distribution of temperature fields in the boiler is optimized by fine controlling content of oxygen of primary air and content of oxygen of secondary air on the basis of SNCR, pollutant emission is reduced, and the CFB boiler can realize low emission of NOx under wide load-wide coal conditions.

Owner:SICHUAN CHUANGUO BOILER

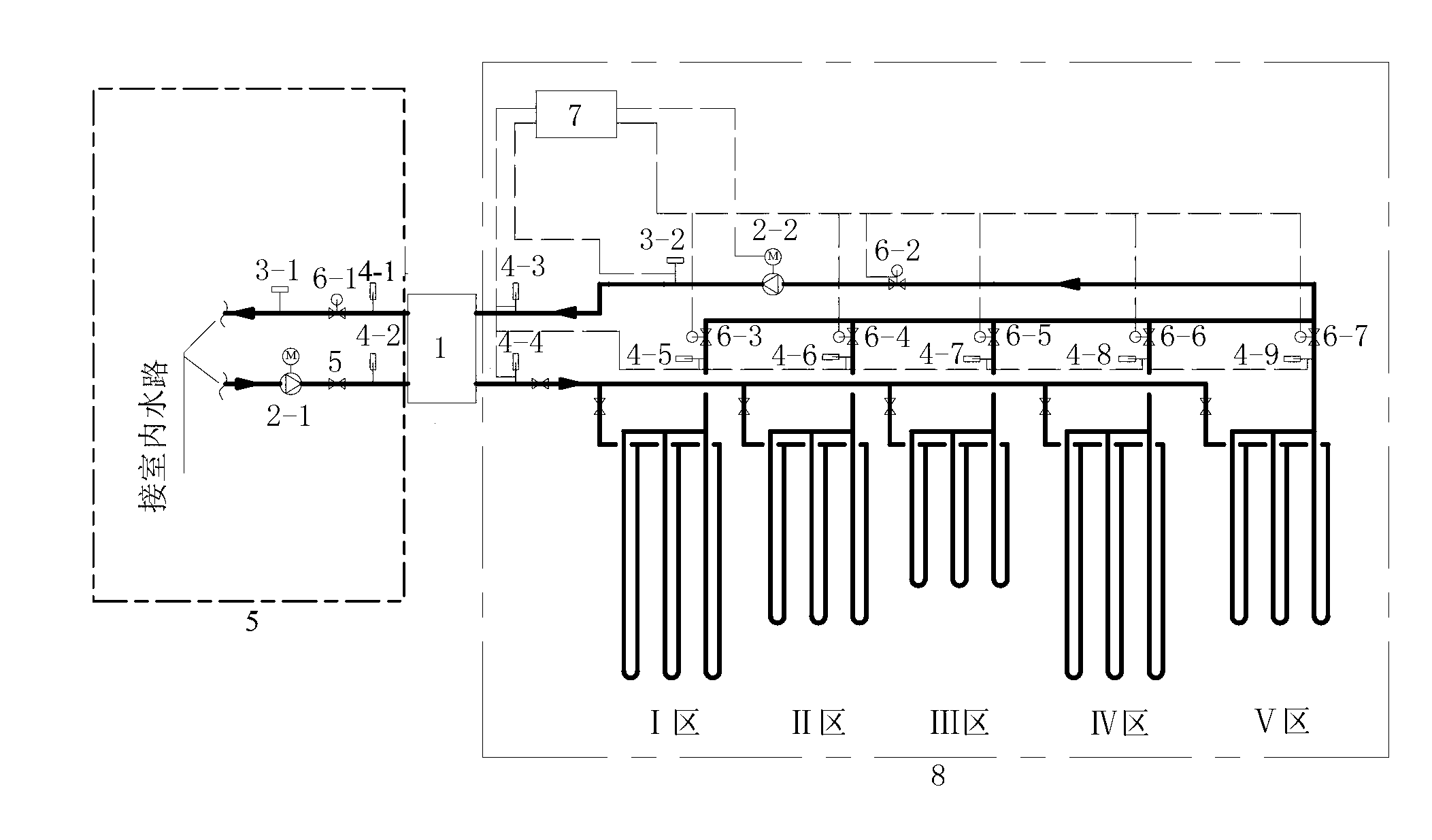

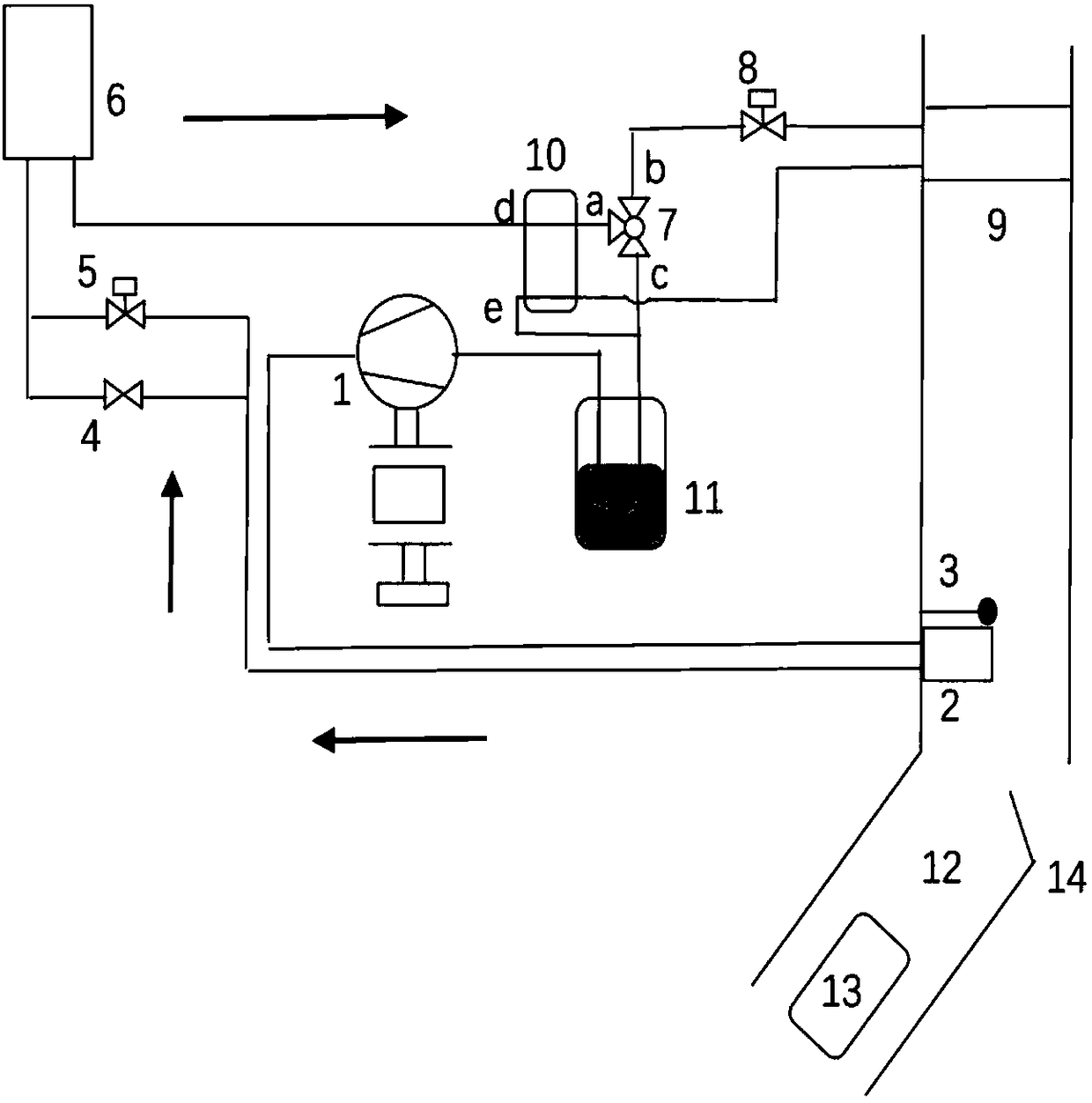

Ground source heat-pipe heat exchange system adapting to load change in operation cycle and control method

ActiveCN103017279AGuaranteed uptimeImprove temperature fieldSpace heating and ventilation safety systemsLighting and heating apparatusSocial benefitsPlate heat exchanger

The invention relates to a ground source heat-pipe heat exchange system and a control method. The system comprises an indoor water system, a variable frequency heat pump unit and a buried pipe heat exchange system, wherein the indoor water system is connected to the load side of the variable frequency heat pump unit, and the buried pipe heat exchange system is connected with the ground source side of the variable frequency heat pump unit; the buried pipe heat exchange system comprises a buried pipe heat exchanger, a flow sensor, a ground source side variable-frequency water pump, a plurality of pipeline electromagnetic valves, a plurality of temperature sensors and a controller, and the buried pipe heat exchanger is composed of a plurality of buried pipe subareas with different buried depths; the water main of each buried pipe is connected to a main water supply pipe, and a water return pipe is connected with a main water return pipe; the flow sensor and the ground source side variable-frequency water pump are connected with the main water return pipe, and each pipeline electromagnetic valve and each temperature sensor are respectively connected with the water mains and the main water supply pipe; and the controller is respectively connected with the flow sensor, the ground source side variable-frequency water pump, the pipeline electromagnetic valves and the temperature sensors. The ground source heat-pipe heat exchange system has the advantages of high heat exchange efficiency, low energy consumption and high economic and social benefits and can effectively facilitate the improvement on a soil temperature field.

Owner:SHANGHAI JIAO TONG UNIV

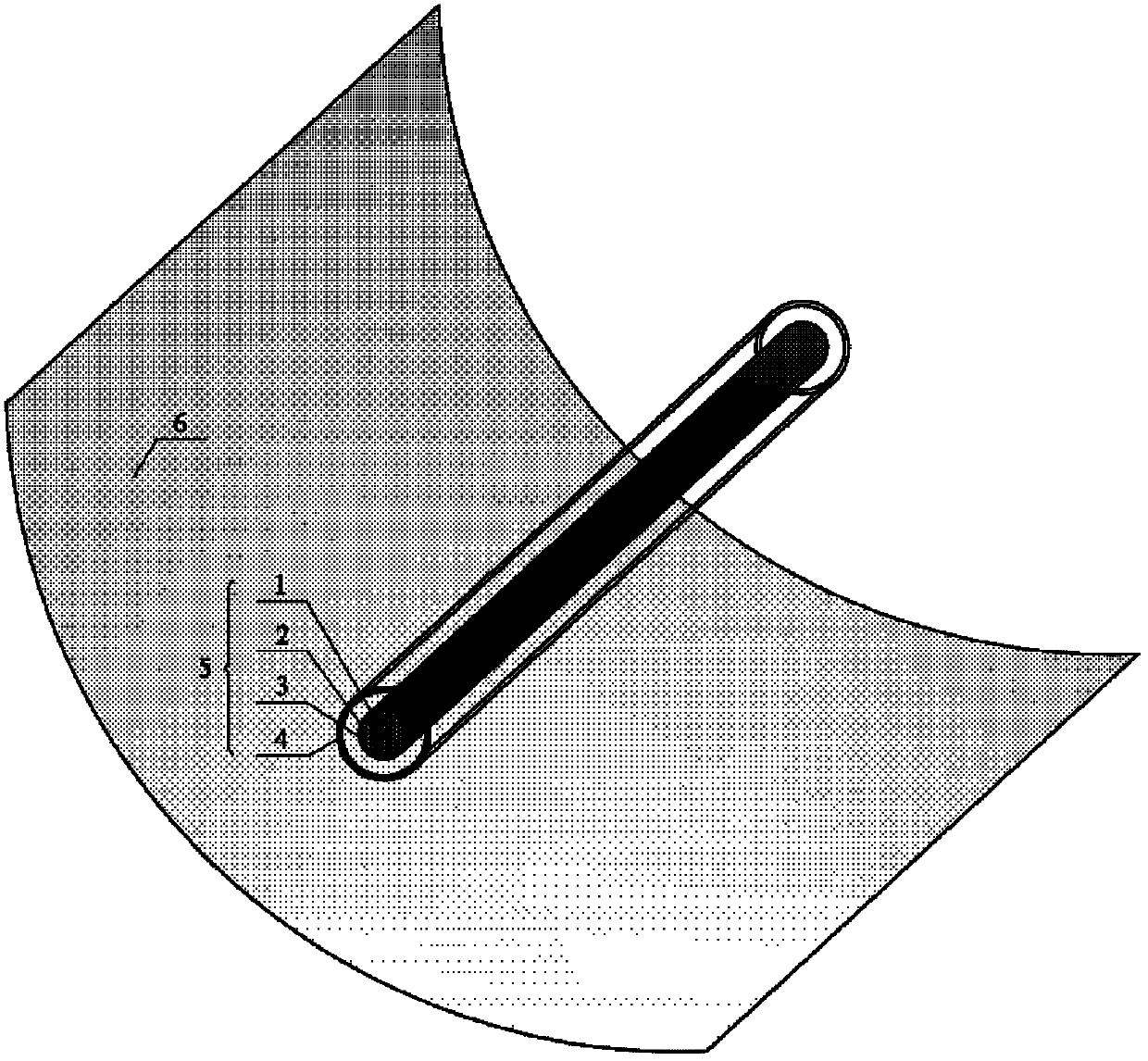

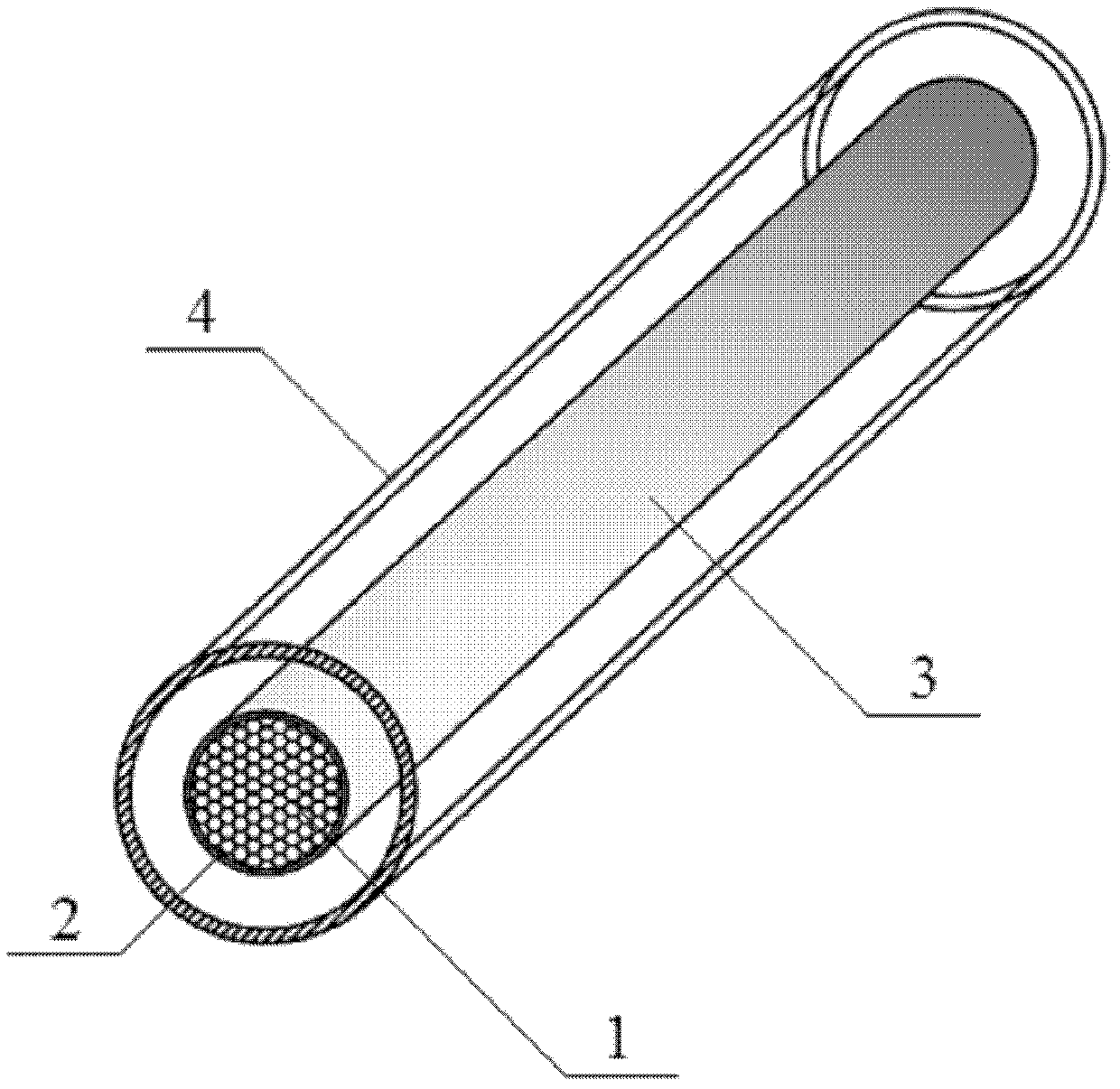

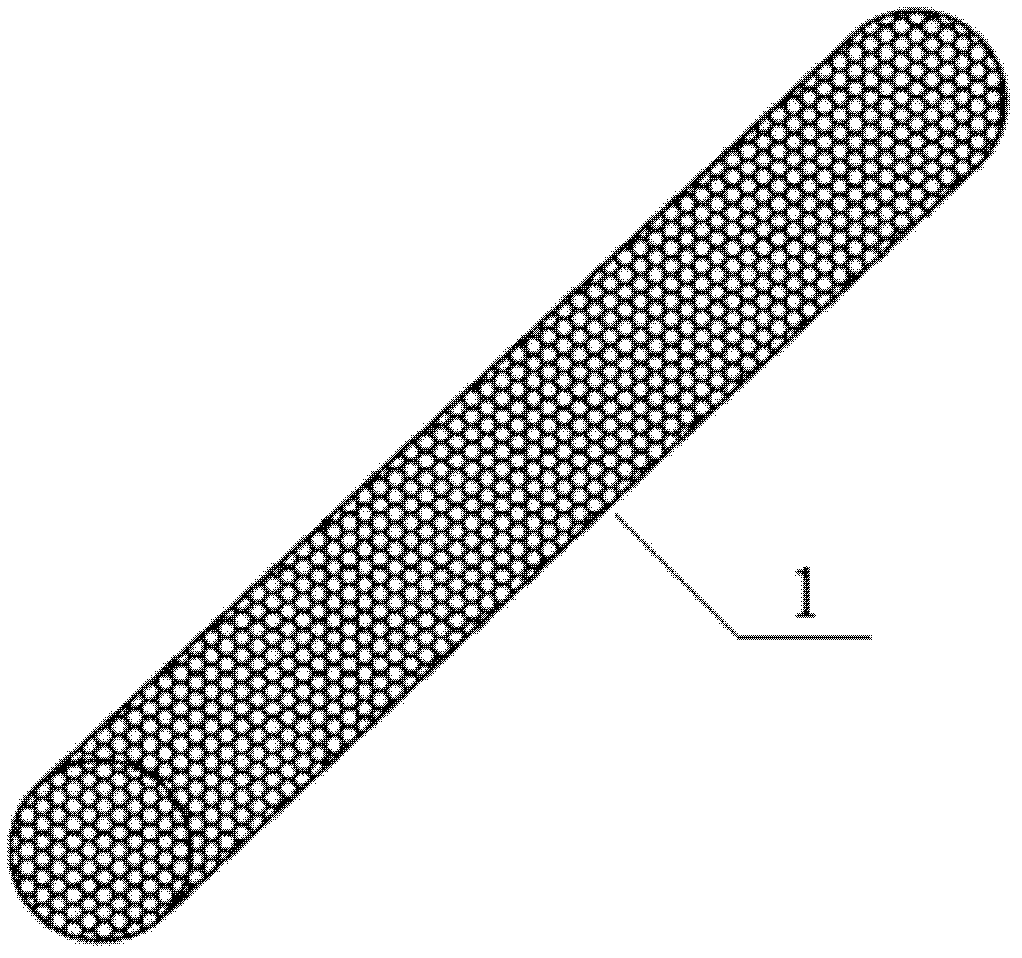

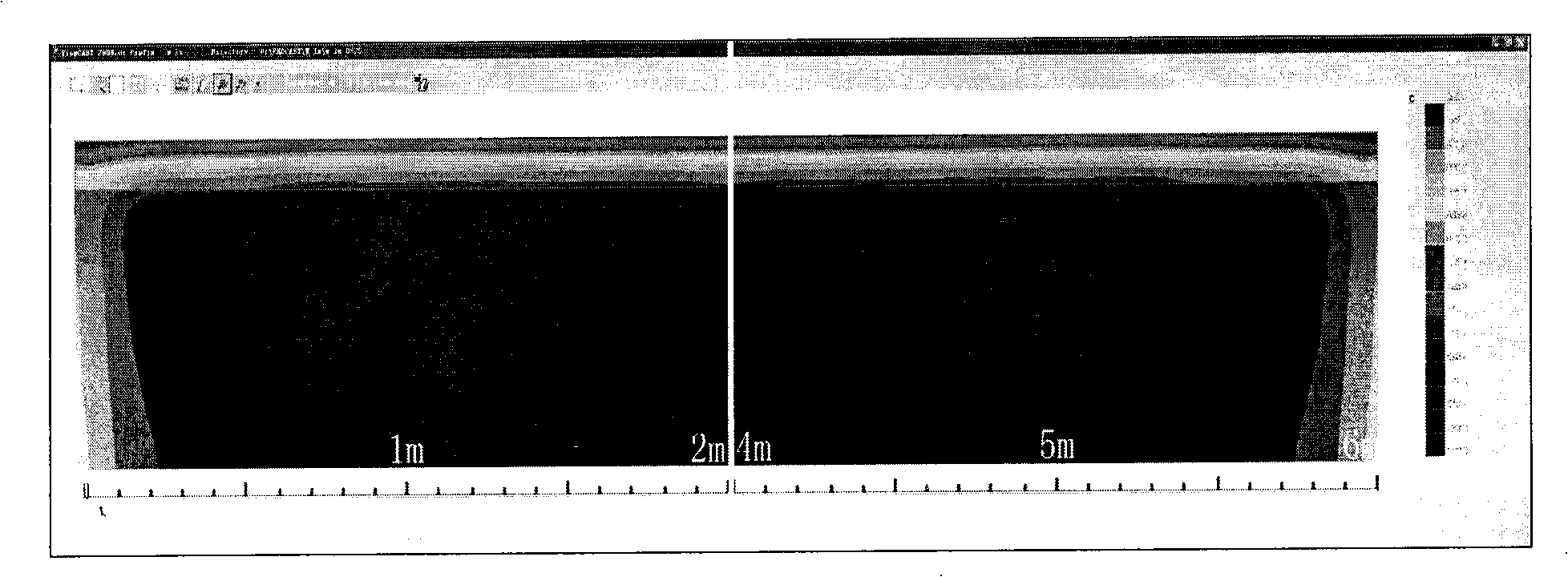

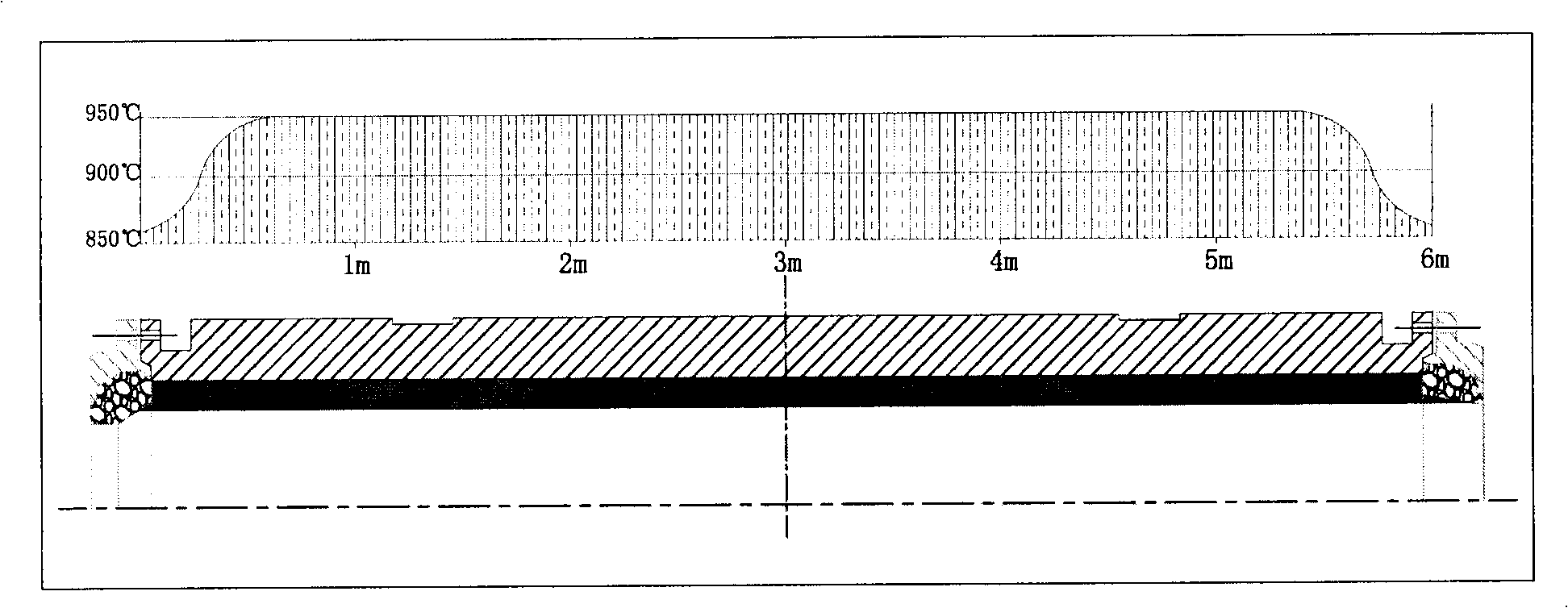

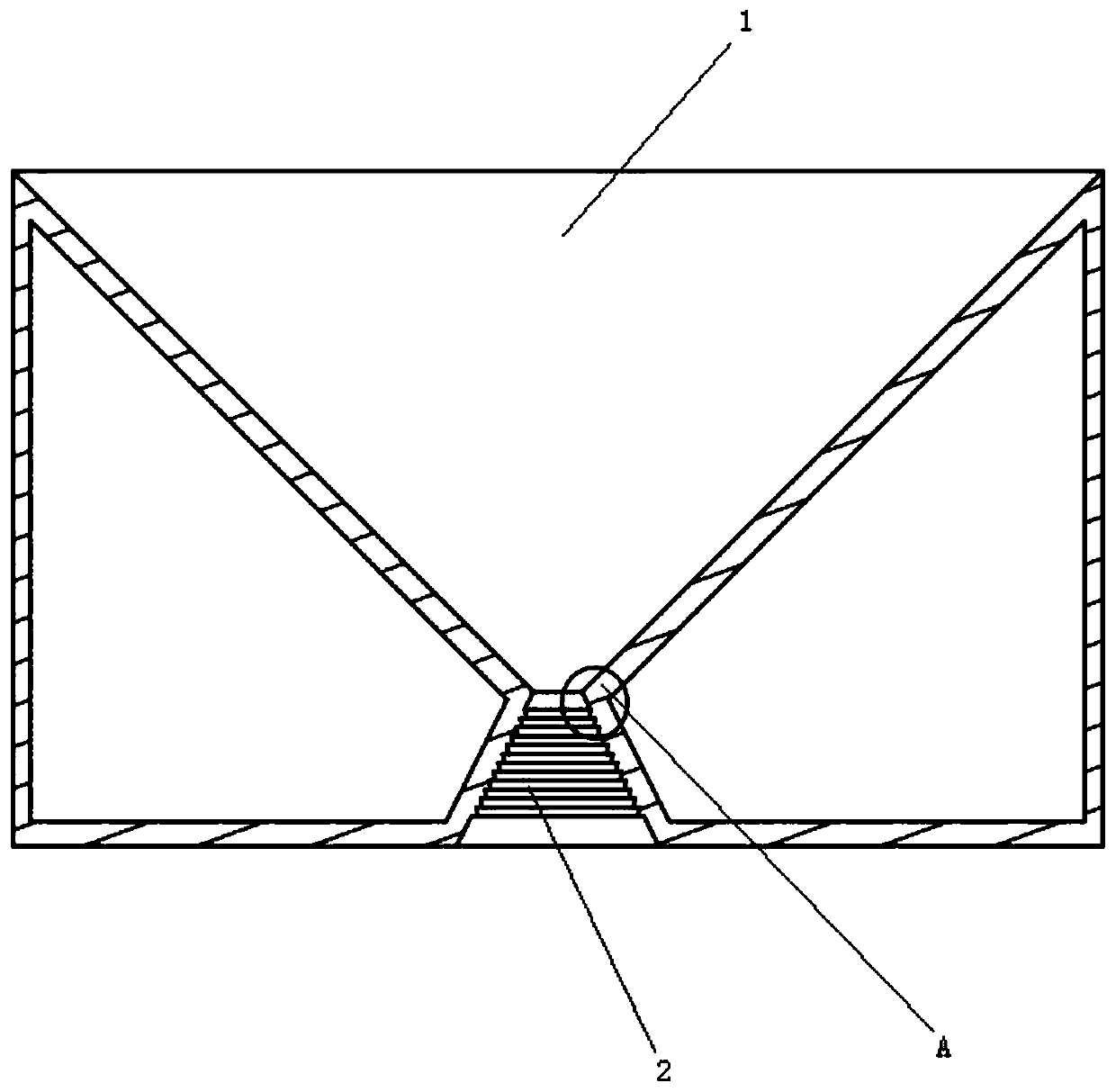

Metal foam carrier catalysis bed solar energy absorption reaction device

ActiveCN103372413AExtended service lifeEasy to fixEnergy based chemical/physical/physico-chemical processesThermal energyEngineering

The invention discloses a metal foam carrier catalysis bed solar energy absorption reaction device. The device comprises a linear solar energy absorption reactor and a parabolic trough-type solar energy condenser. The linear solar energy absorption reactor is arranged in the focal line of the parabolic troughtype solar energy condenser. The linear solar energy absorption reactor has a bushing structure, and comprises an external glass bushing, an internal metal tube, a selective coating on the surface of the metal tube through vacuum evaporation and a catalyst bed layer with metal foam materials as carriers and arranged inside the metal tube. The device makes the best of the space in the reactor. The catalyst bed layer structure can maintain uniformity and stabilization for long time, has a long service life, and has high efficiency of conversion from solar energy to thermal energy. The catalyst bed layer has a high specific surface area and good catalytic performance. The operations of change and regeneration of catalysts are simple. The device solves the problems of low specific surface area, uneven filling of internal catalysts, difficulty control of temperature field and flow field, difficulty maintenance and the like of reactor catalysts in the prior art.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

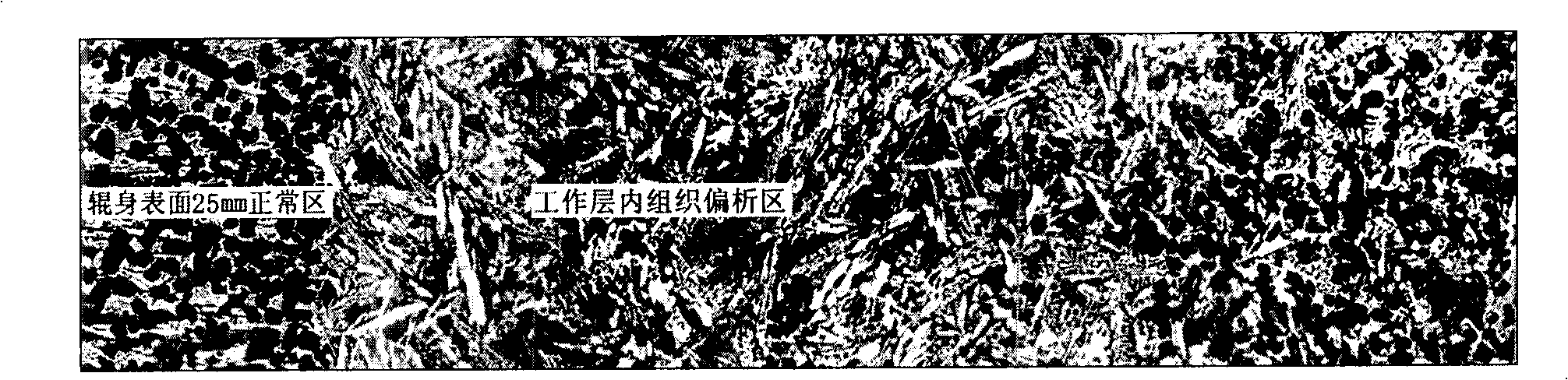

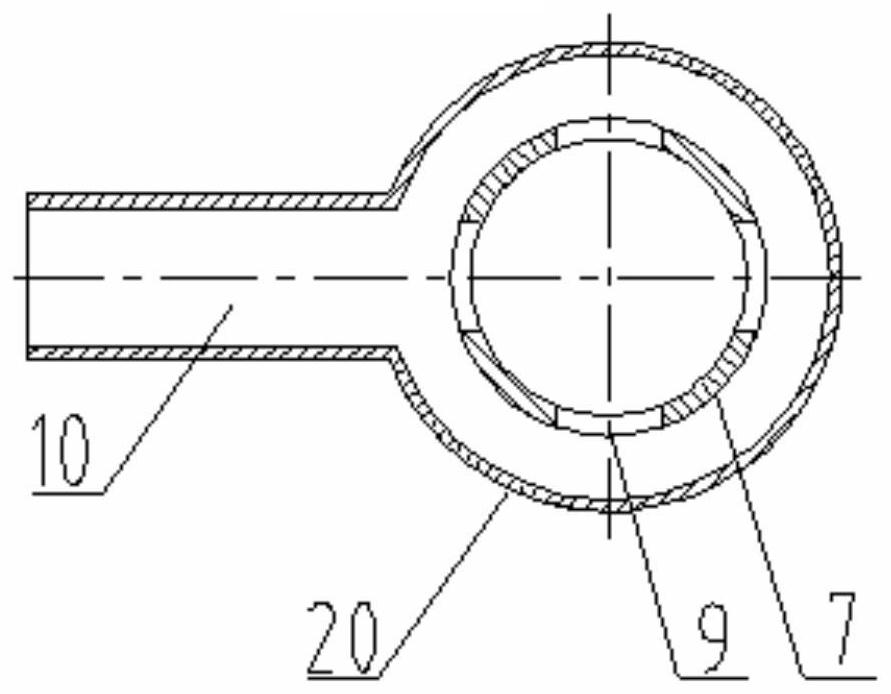

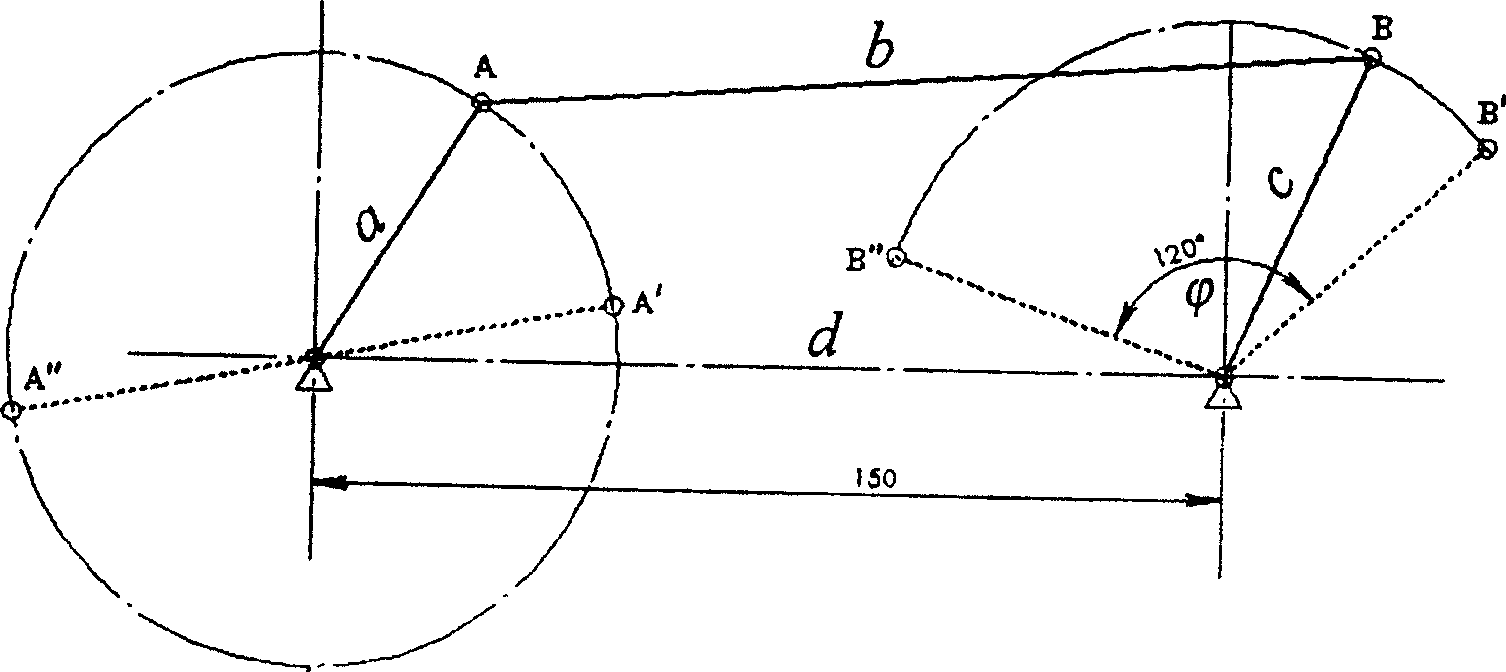

Centre spinning cold gas, fog cooling system and method

ActiveCN101402134AAchieve Cooling ControlEnsure sufficient strength and rigidity of the moldCasting moldEngineering

Owner:中国冶金科工股份有限公司

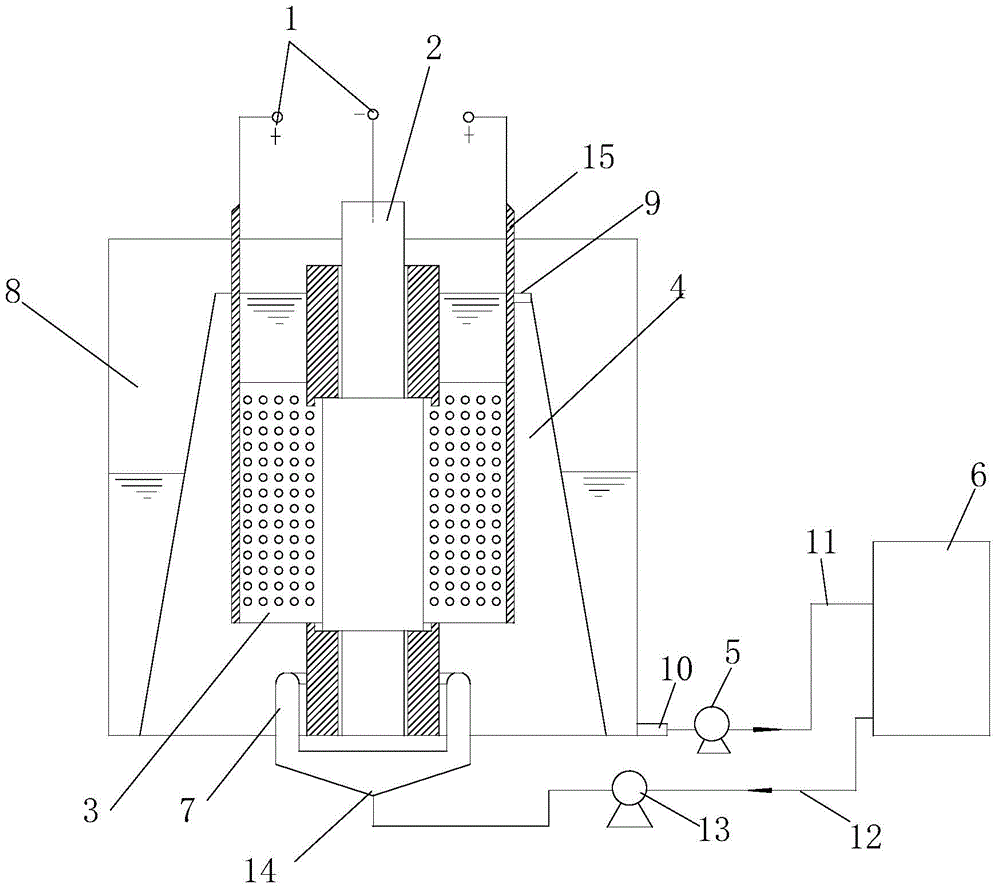

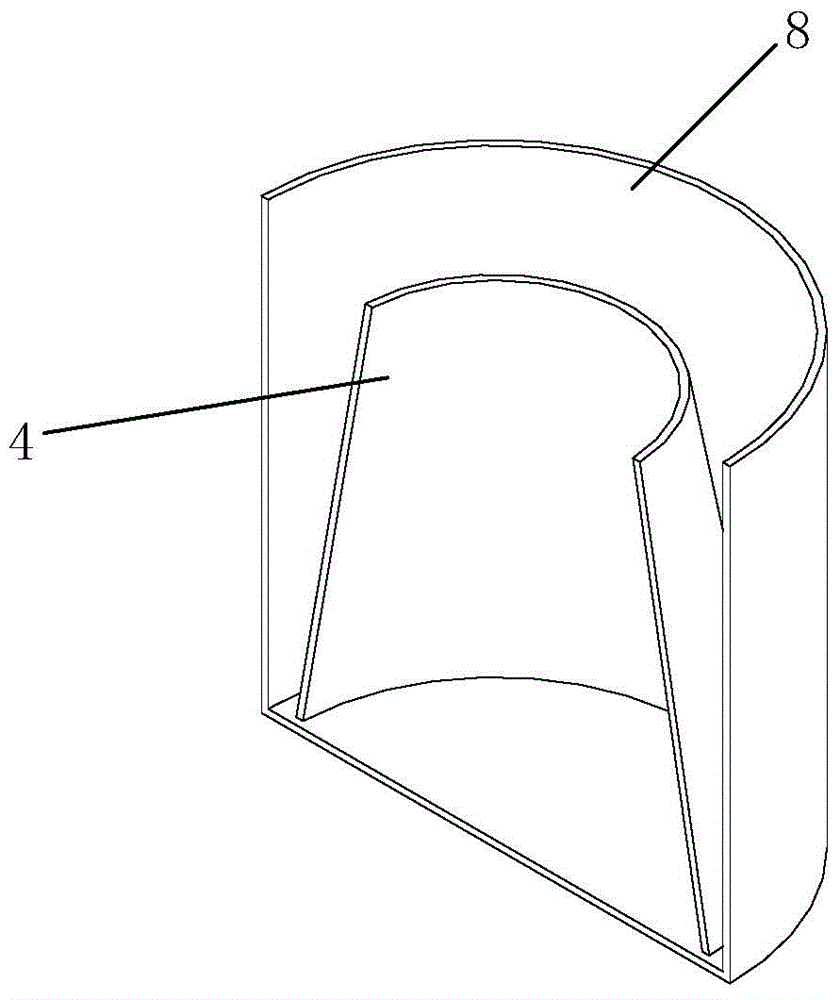

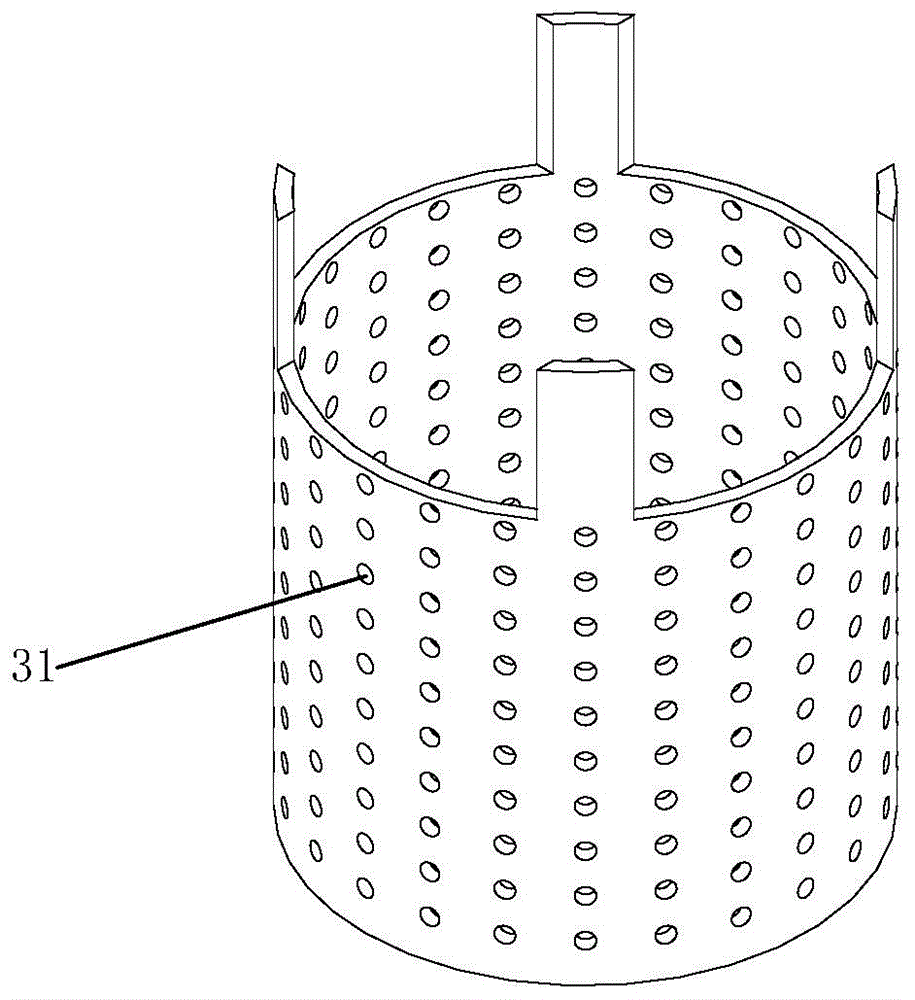

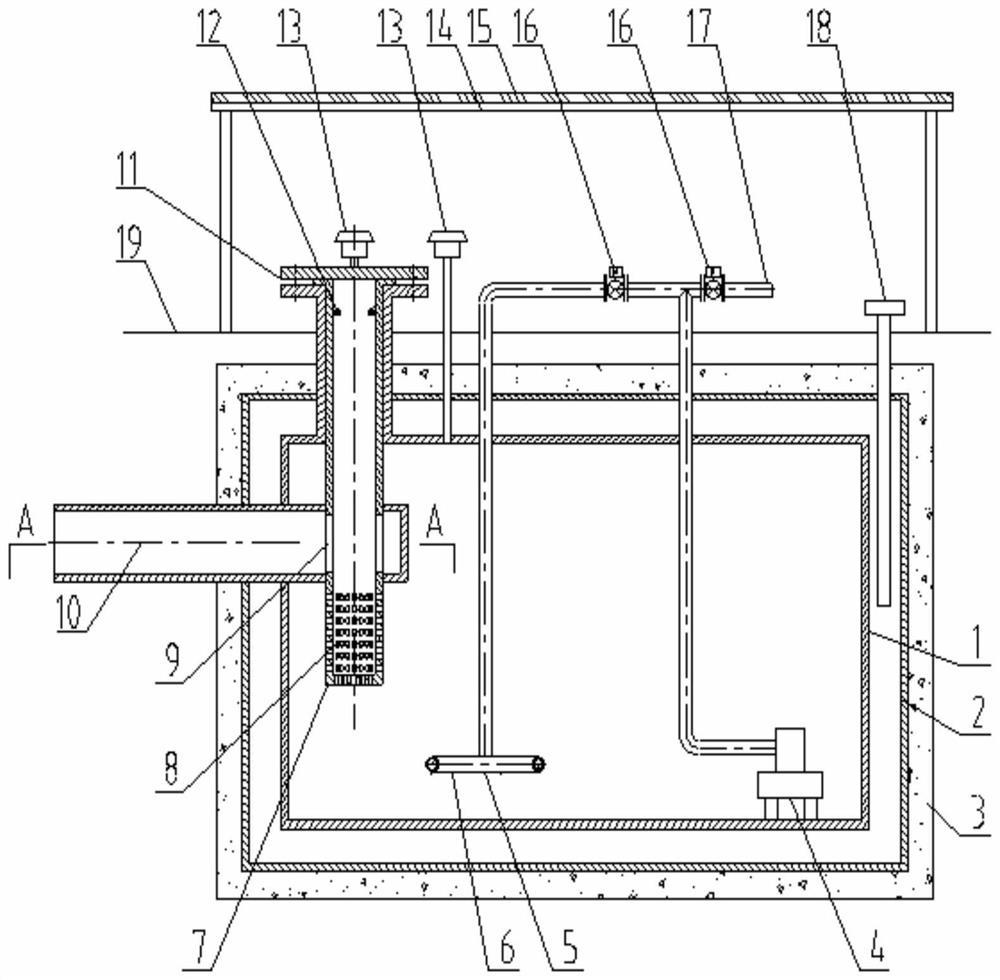

Electroplating device with optimized temperature field distribution and electroplating method thereof

The invention provides an electroplating device with optimized temperature field distribution and an electroplating method thereof. The electroplating device comprises elements of an electroplating power supply and the like; both a workpiece to be plated and an insoluble anode are connected with an output end of the electroplating power supply; the workpiece to be plated and the insoluble anode are located inside a working groove; a liquid discharging pump is connected with a liquid discharging pipe; a liquid overflow groove is located outside the working groove; a bottom liquid feeding device is located below the working groove; a liquid overflow port is located at the top of the wall of the working groove; a liquid storing groove is located at one side of the liquid overflow groove; the electroplating power supply is used for supplying power between the insoluble anode and the workpiece to be plated for electroplating process; the working groove contains an electrolyte and is a main place for electroplating; the insoluble anode is immersed in the electrolyte and carries out an anode reaction when power is on; the bottom liquid feeding device is an inlet for the electrolyte to enter the working groove; the liquid overflow groove is a place for collecting the electrolyte flowing out from the liquid overflow port when the electroplating process is completed. The electroplating device of the invention is simple in structure, and has the characteristics of low construction cost and optimized temperature field.

Owner:SHANGHAI JIAO TONG UNIV

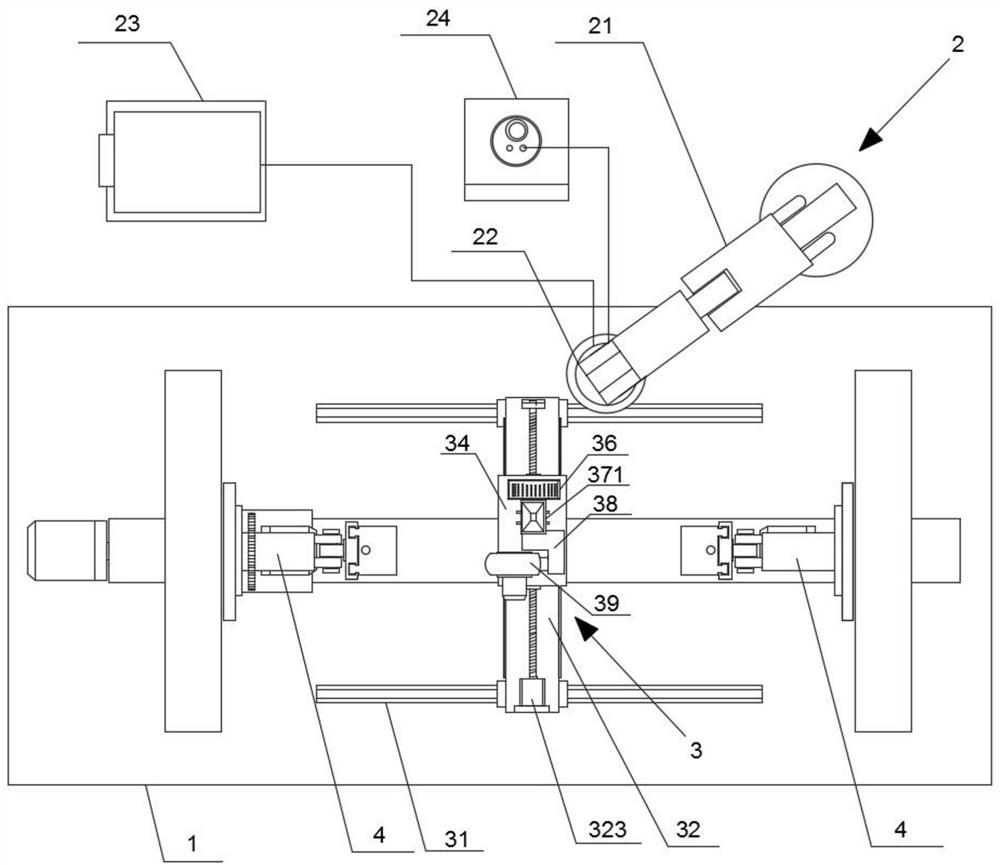

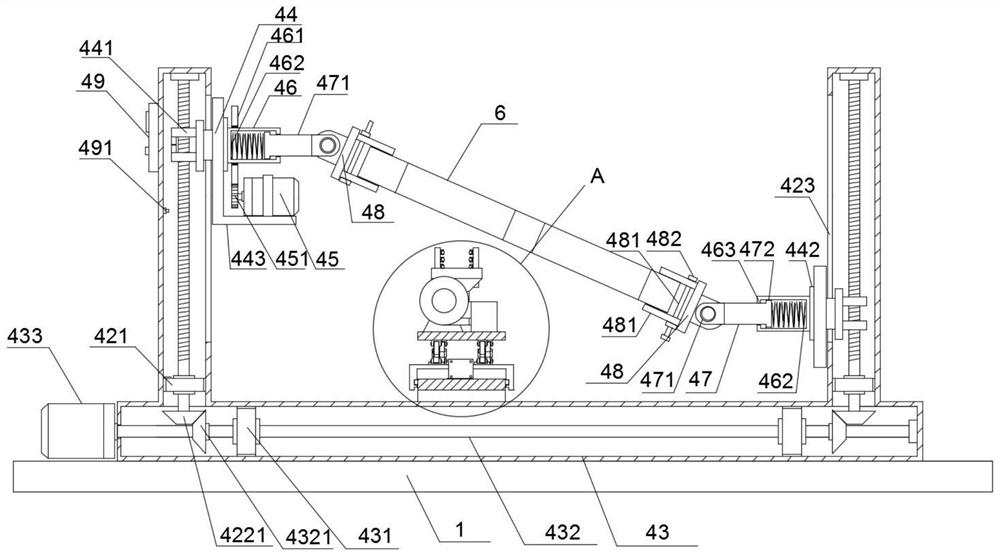

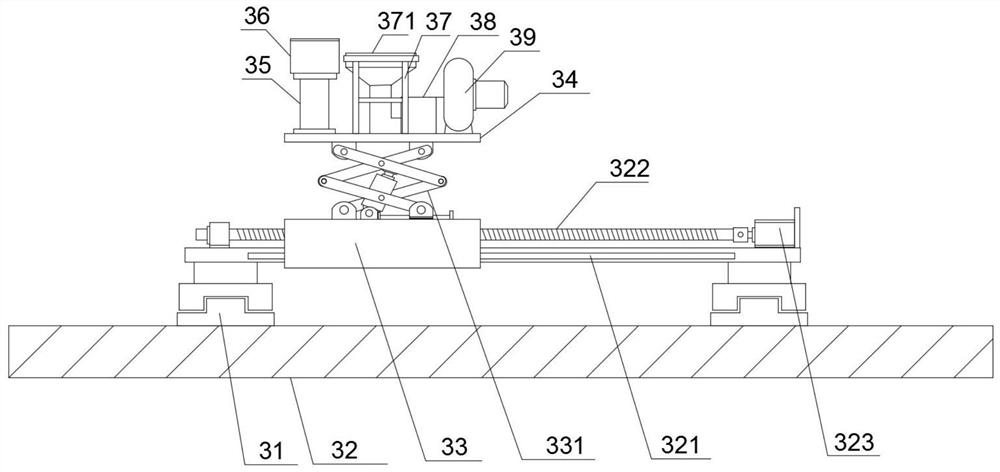

Laser cladding device applied to workpiece repair

ActiveCN112064012AAvoid crackingImprove temperature fieldMetallic material coating processesEngineeringMechanical engineering

The invention relates to a laser cladding device applied to workpiece repair. The device comprises a cladding platform, clamping equipment, cladding processing equipment and cladding treatment equipment, wherein the clamping equipment is arranged on the cladding platform, the cladding treatment equipment comprises a travelling mechanism, a heating device and a powder recovery device, the travelling mechanism comprises first guide rails, a travelling frame and a moving frame, the two first guide rails are distributed on the two sides of clamping mechanisms correspondingly, the bottoms of the two ends of the travelling frame are arranged on two second guide rails in a sliding mode, the moving frame is located above the travelling frame, a shear type lifting frame is arranged at the top of the moving frame, a mounting platform is arranged at the top end of the shear type lifting frame, and the heating device and the powder recovery device are arranged on the mounting platform. According to the laser cladding device, the heating device is driven by the travelling mechanism to move in the three-dimensional direction, a heating base is arranged on the outer side of a to-be-cladded position of a workpiece, the workpiece is locally preheated by means of an infrared heating pipe, and the cladding quality is effectively guaranteed.

Owner:江苏联宸激光科技有限公司

Front biomass ultra-high-speed self-balancing gasifying co-combustion device and method for coal-fired boiler

ActiveCN105889905AImprove raw material adaptabilityExpand the scope of useCombustion using gaseous and pulverulent fuelGaseous fuel feeder/distributionEngineeringHearth

The invention belongs to the technical field of utilization of biomass, and discloses a front biomass ultra-high-speed self-balancing gasifying co-combustion device and method for a coal-fired boiler. Biomass ultra-high-speed self-balancing gasifying equipment is used for gasifying biomass, and after being cooled and pressurized, fuel gas is delivered into a hearth of the coal-fired boiler and then is combusted. A fuel gas cooling medium is steam which is extracted from a medium-pressure section in a turbine and the temperature of the steam is 400 DEG C, after heat is exchanged between the steam and the fuel gas, secondary heat exchange between the steam and air is implemented, and high-temperature air is produced and supplied for a gasifier. A biomass gasifying coupling large coal-fired power generation system is realized, biomass power generation parameters and efficiency are improved by a high-capacity and high-parameter turbine power generation system, the problem that an existing biomass direct-fired technology is small in power generation scale and low in efficiency is solved, the front biomass ultra-high-speed self-balancing gasifying co-combustion device and method for the coal-fired boiler are suitable for high-alkalinity and high-moisture biomass, and the utilization range of biomass is expanded.

Owner:合肥德博电力有限公司

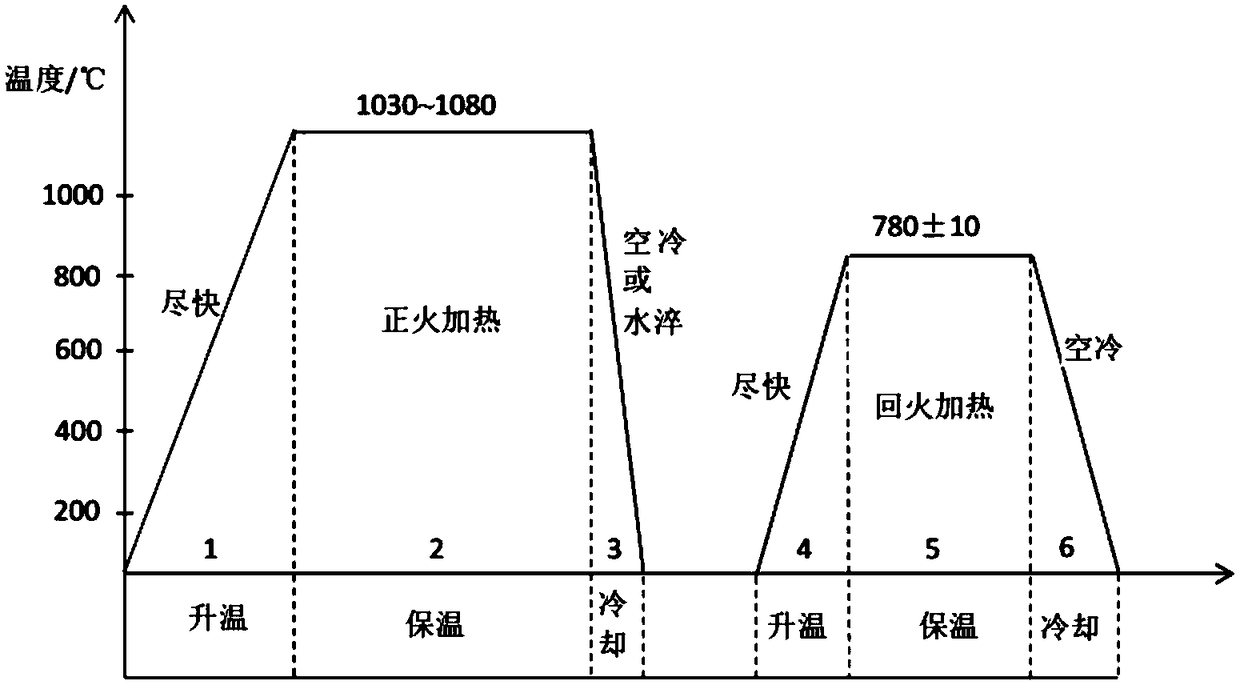

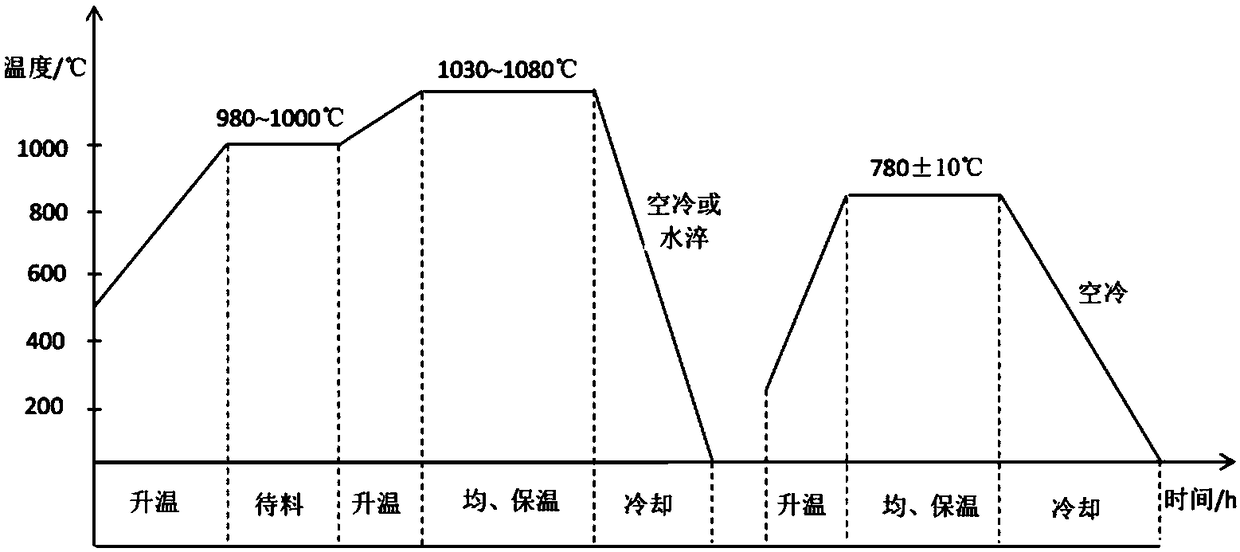

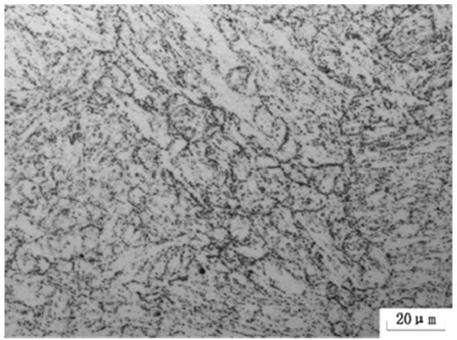

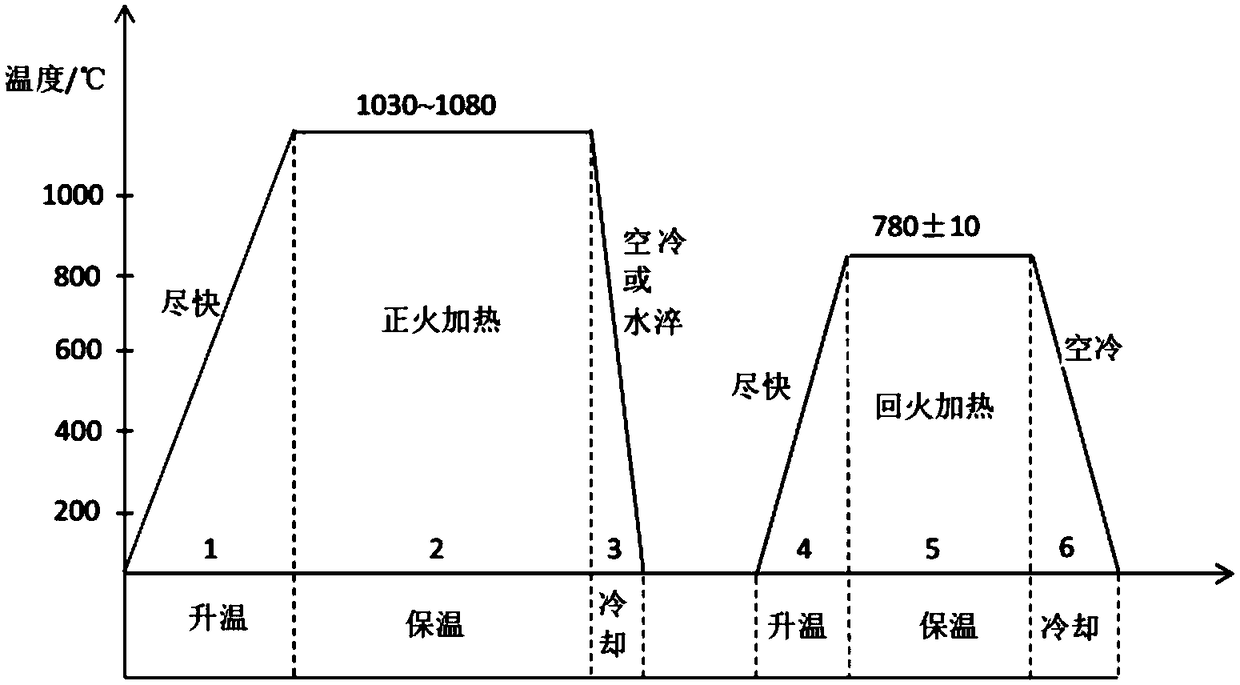

Method for improving radial structure and performance uniformity of G115 steel large-caliber thick-wall pipe

ActiveCN108950148AImprove radial temperature fieldImprove uniformityFurnace typesHeat treatment furnacesQuenchingCaliber

The invention discloses a method for improving radial structure and performance uniformity of a G115 steel large-caliber thick-wall pipe, and belongs to the technical field of steel materials. The process comprises the following steps of a normalizing system and a tempering system, wherein the normalizing system is characterized in that a tube blank subjected to hot-extrusion is adopted, chargingis carried out by using the temperature of 400-600 DEG C, warming is carried out with the heating speed of 100-120 DEG C / h until the temperature reaches 980-1000 DEG C, the hardening time is 0.5-1 min / mm, then warming is carried out with the heating speed of 130-150 DEG C until the temperature reaches 1030-1080 DEG C, then hardening is carried out, the hardening time is 0.5-0.8 min / mm, heat preservation is carried out for 1-3 hours after hardening, and air cooling or water quenching is carried out to the room temperature; and the tempering system is characterized in that charging is carried out by using the temperature less than or equal to 600 DEG C, warming is carried out with the heating speed of 120-150 DEG C / h until the tempering temperature reaches 780 + / - 10 DEG C, the time of heatpreservation is 3-5 hours, and air cooling is carried out to the room temperature. The method has the advantages that the radial temperature field of the thick-wall pipe is improved, moreover, the grain of the thick-wall pipe is not prone to coarsening, so that the radial structure and performance uniformity of the thick-wall pipe is greatly improved.

Owner:CENT IRON & STEEL RES INST

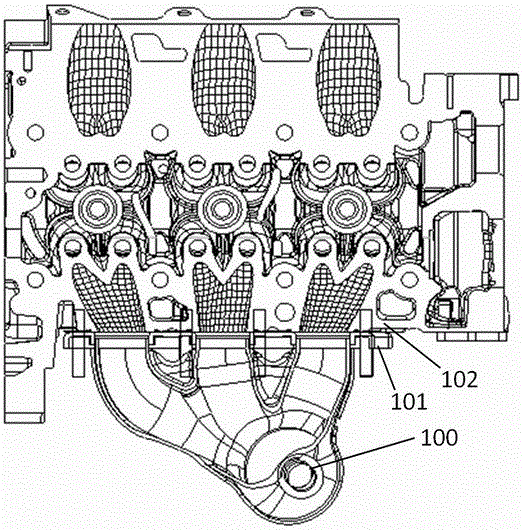

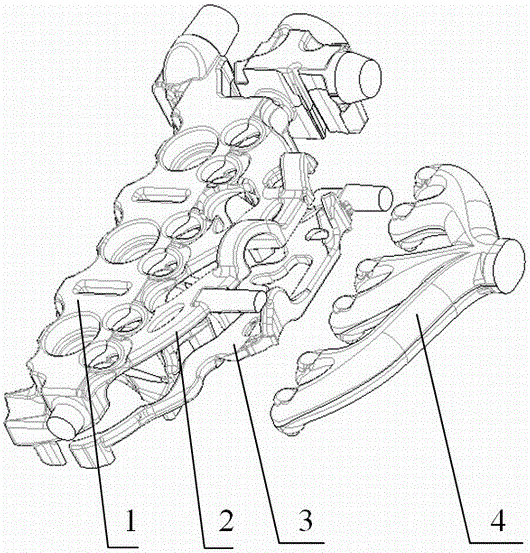

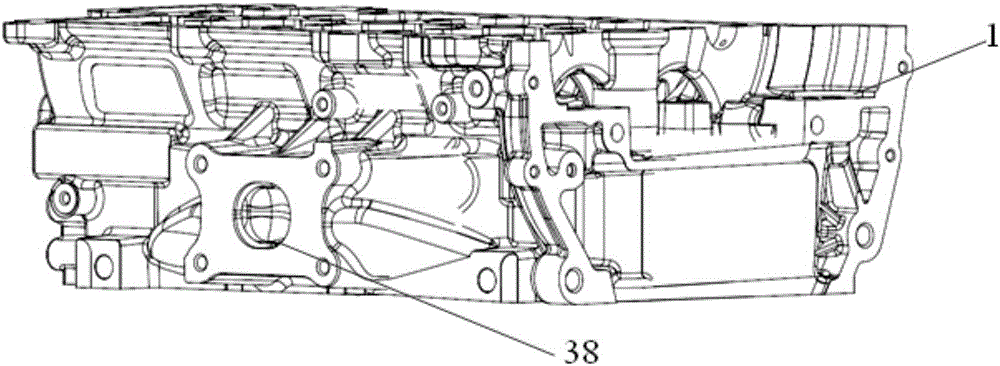

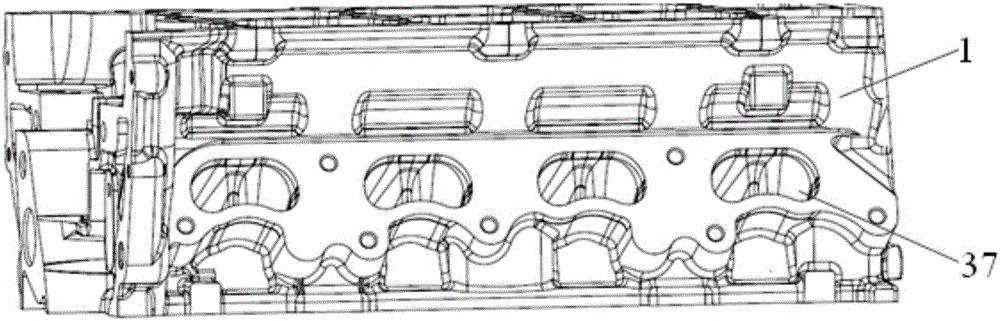

Integrated-designed engine cylinder cover

ActiveCN106368846AReduce exhaust temperatureImprove fuel economyCylinder headsExhaust gas recirculationIntegrated designOil consumption

The invention provides an integrated-designed engine cylinder cover. The engine cylinder cover integrates an exhaust manifold, an EGR cooling device and a secondary air channel device simultaneously. The exhaust manifold is integrated on the exhaust side of the engine cylinder cover. A gas inlet of the EGR cooling device is integrated on the exhaust manifold. A gas outlet of the EGR cooling device is integrated on the gas inlet side of the engine cylinder cover. The secondary air channel device is integrated on the exhaust manifold. The engine cylinder cover is installed as a whole, too many exhaust manifolds, external type EGR cooling devices, external type secondary air channel devices and other parts do not to be installed, through the highly integrated engine cylinder cover, the number and weight of parts of the complete machine are reduced, oil consumption and discharge performance of an engine is also improved significantly, meanwhile, the design of the complete machine is more compact, and the cost of the complete machine has more advantages.

Owner:CHERY AUTOMOBILE CO LTD

Air-cooled high-temperature alloy carbon black reaction furnace and carbon black preparation method

PendingCN112228872ATroubleshoot Build Quality IssuesProblems Affecting AtomizationPigmenting treatmentMaintainance of heating chambersCombustion chamberMetallurgy

The invention discloses an air-cooled high-temperature alloy carbon black reaction furnace and a carbon black preparation method. The air-cooled high-temperature alloy carbon black reaction furnace comprises a casing, an air inlet assembly and a gas fuel inlet assembly which are positioned on the casing, and a combustion chamber arranged in the casing, the combustion chamber is provided with a throat pipe section, a raw material oil nozzle is arranged on the throat pipe section, and the combustion chamber comprises a flame tube; and a plurality of cooling holes are formed in the flame tube, and the axes of the cooling holes incline in the downstream direction from outside to inside. The invention provides the air-cooled high-temperature alloy carbon black reaction furnace and the carbon black preparation method, the problems in the prior art that the cooling mode of a carbon black reaction furnace is insufficient and the generation quality of carbon black is influenced are solved, andthe purposes of reducing the gas scouring influence and improving the generation quality of carbon black are achieved.

Owner:成都轩鼎能源科技有限公司

Method for improving internal quality of casting blank by composite intervention

Provided is a method for improving internal quality of casting blank by composite intervention. The method comprises following steps: 1), machining pure iron or steel with the approximate content of steel grades to be an easily-melted cold bodies moving with molten steel and then drying; 2), baking feeding guide pipes which are made by refractory material and immersing them into a crystallizer below the molten steel surface; aligning feeding guide pipe openings to the center of steel streams as for round and square billets; utilizing two guide pipes for plate blank and distributing them on two sides of a wide surface of the crystallizer; 3), continuously injecting the dried cold bodies into a high-temperature region of a molten pool of the crystallizer, adding the cold bodies in the amount of 0.8-1.3% of casting blank; adopting the crystallizer to electromagnetically stir during the continuous casting process. The method for improving internal quality of casting blank by composite intervention has following beneficial effects: cold bodies are fed into the crystallizer such that superheat and temperature gradient of molten steel during mass production of continuous casting; the solidification structure of casting blank is improved; quality flaws of the internal quality of the casting blank is reduced; the temperature field of the crystallizer is improved; and therefore the purposes of increasing equiaxial crystal ratio and improving internal quality of the casting blank are fulfilled.

Owner:BAOSHAN IRON & STEEL CO LTD

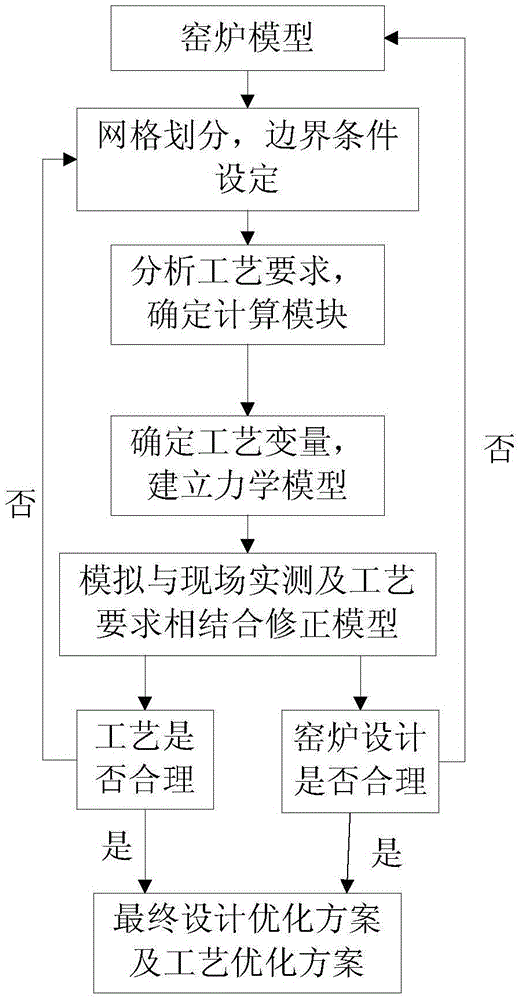

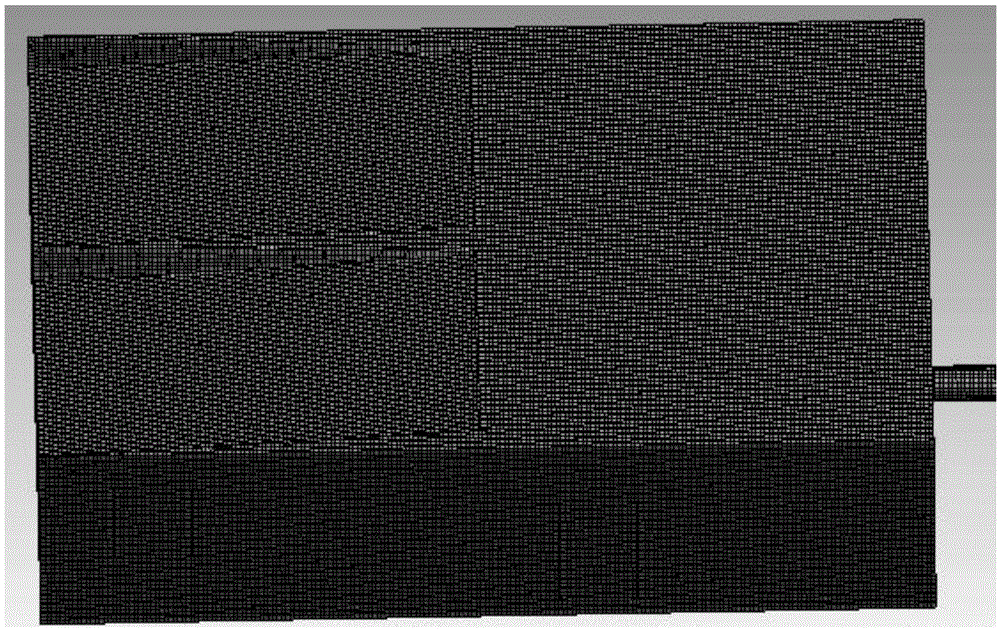

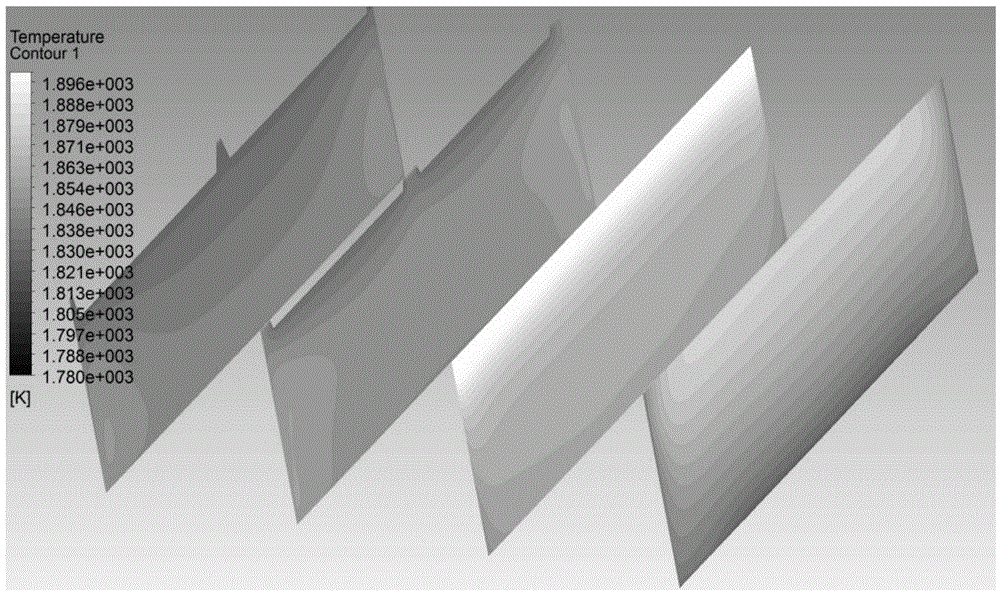

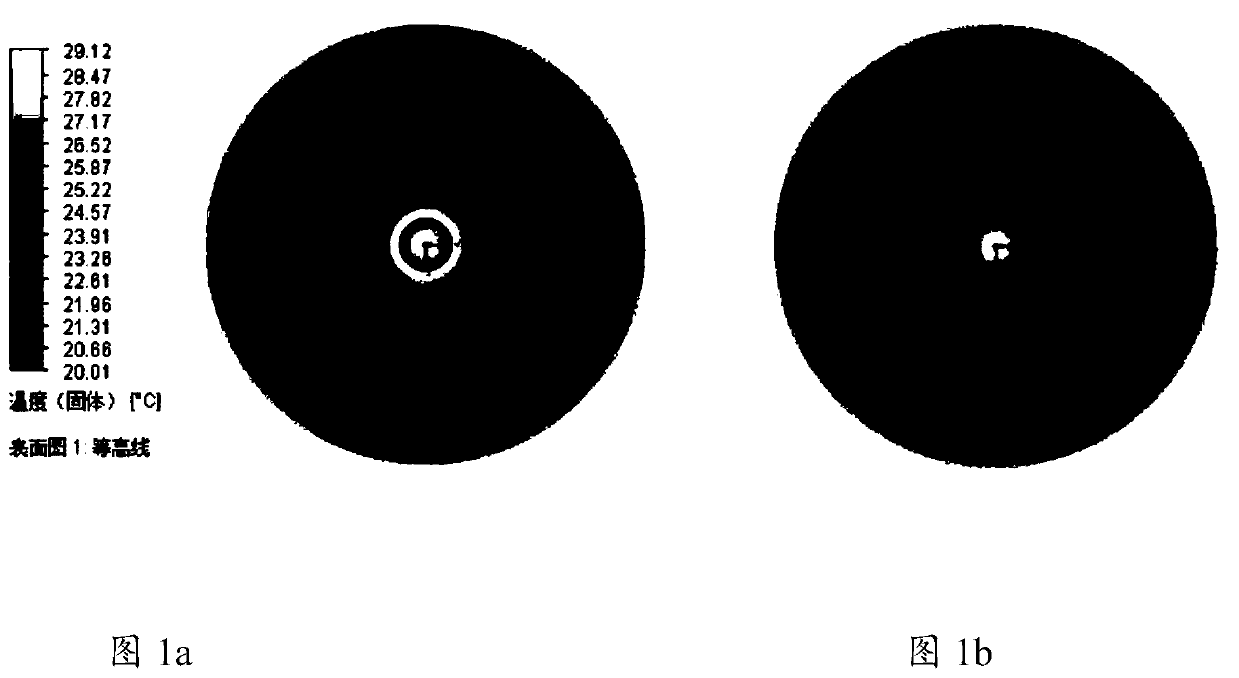

Electric glass melting furnace work simulating method and application thereof

ActiveCN105574280AReduce manufacturing costImprove temperature fieldSpecial data processing applicationsLiquid temperatureLiquid surfaces

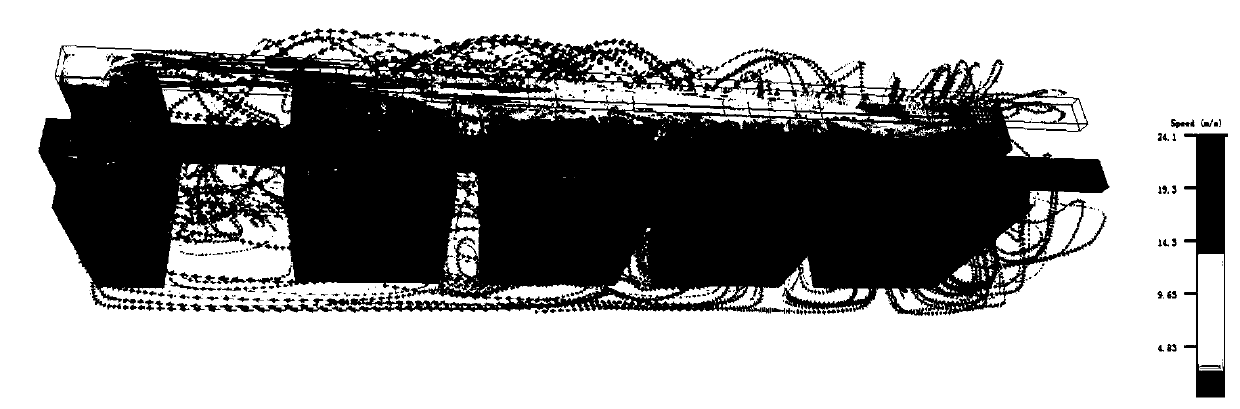

The invention discloses an electric glass melting furnace work simulating method and application thereof. The electric glass melting furnace work simulating method is based on a fluent software, and comprises the following steps: establishing a glass liquid geometric model, dividing grids, and drawing an obvious boundary between an electrode surface and a nearby adjacent insulating fire-resistant material area so as to add an electric field module; according to actual production situations, setting boundary conditions, and adding voltage boundary conditions to the electrode surface; simulating a temperature field, a flow field and an electric field of glass liquid to obtain glass liquid temperature field distribution, space flame temperature field distribution and speed field distribution conditions of different areas in the furnace; adopting a gabled temperature schedule as initial glass liquid surface temperature distribution, so as to obtain a final curve according to simulation coupling and curve coupling, and importing the final curve using a user-defined function for calculating; measuring a conductivity curve, a viscosity curve and heat conductivity coefficients, which change along with temperature, of the glass liquid in advance, and importing the conductivity curve, the viscosity curve and the heat conductivity coefficients into a model using the user-defined function. According to the electric glass melting furnace work simulating method and the application thereof, the working principle of the electric glass melting furnace is analyzed at a low cost.

Owner:WUHU DONGXU OPTOELECTRONICS EQUIP TECH +2

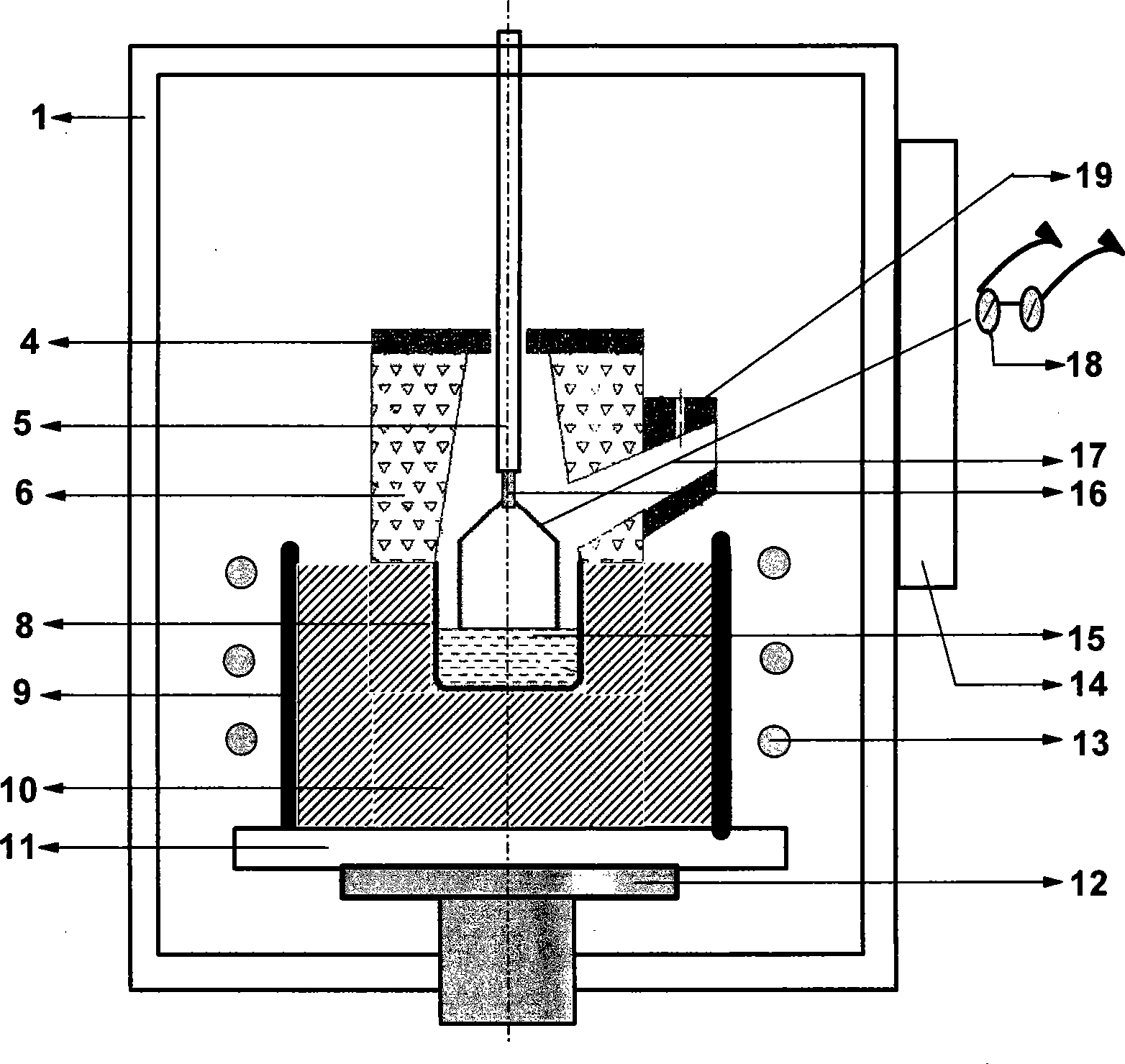

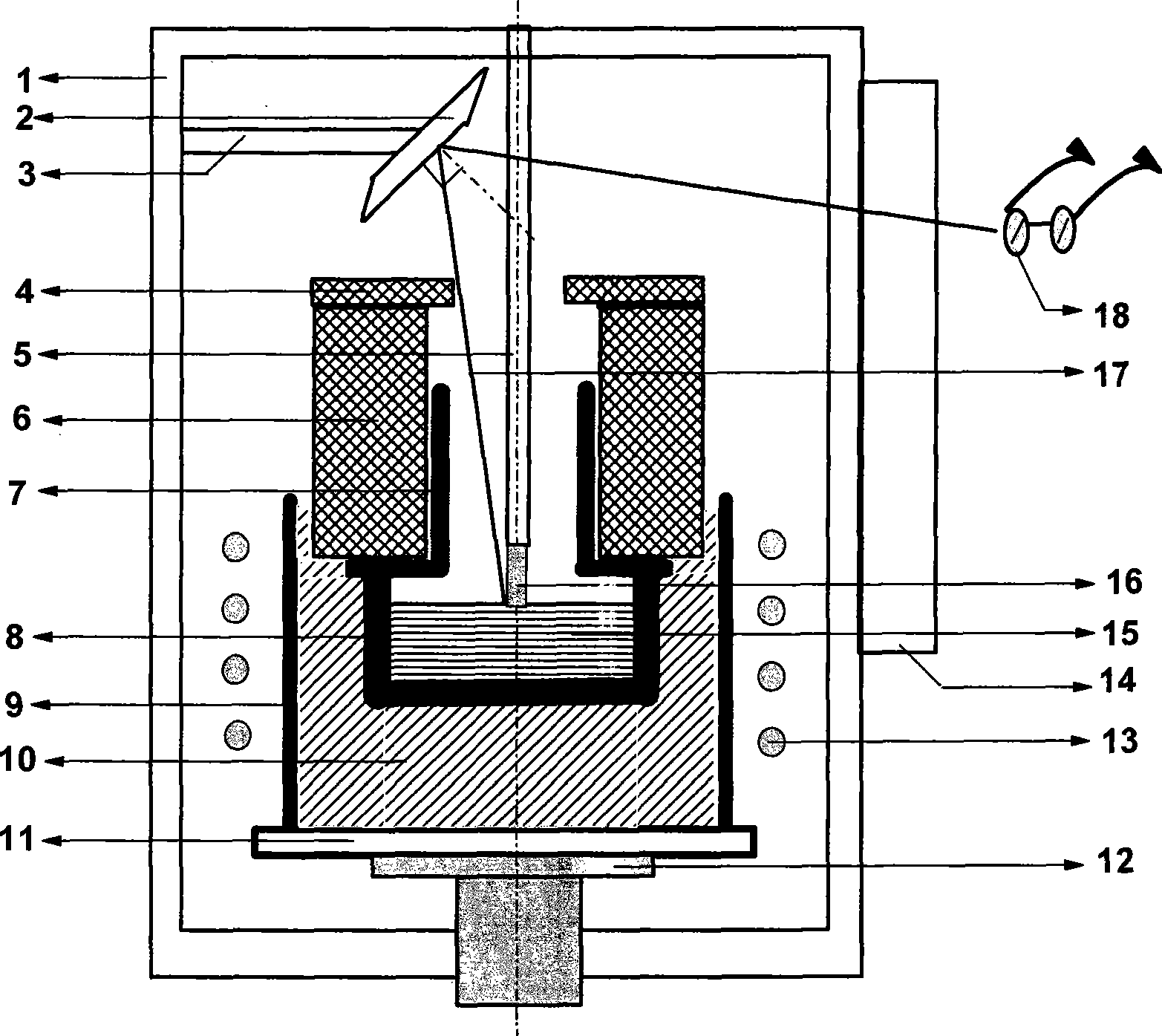

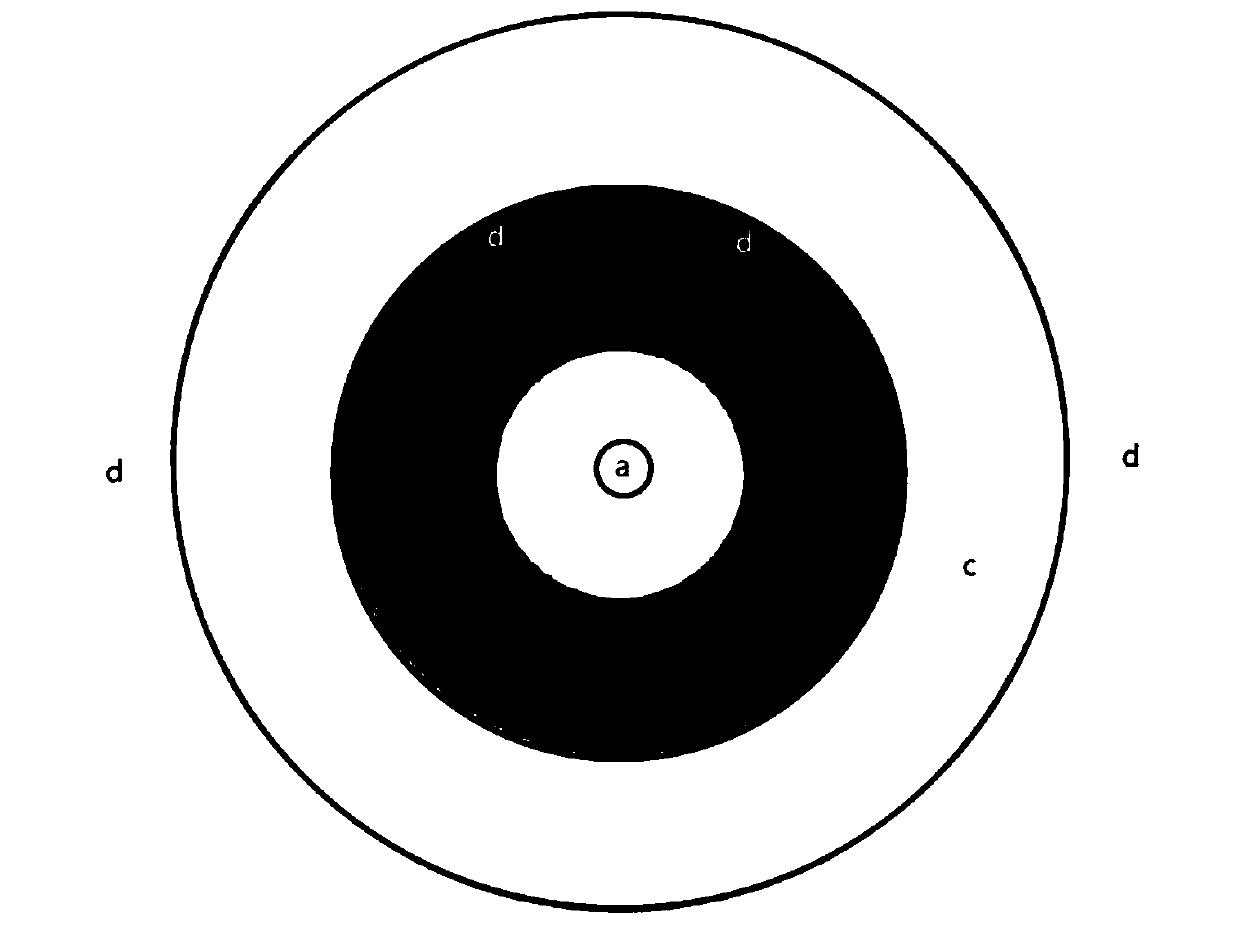

Apparatus for growing lithium aluminate crystal by czochralski method

InactiveCN101418468AImprove temperature uniformityGood symmetryPolycrystalline material growthBy pulling from meltIridiumCrucible

The invention provides a device for growing lithium aluminate crystals by a pulling method, which comprises a pulling-method single crystal growth furnace. The device is characterized in that the sidewall of a heat preservation cover of the single crystal furnace is intact and is provided with no observation window, and on the furnace wall opposite to an observation window, an observation mirror is erected above the heat preservation cover through a bracket, so as to observe a melt interface in an iridium crucible through the reflection of the observation mirror. The device has the advantages that the device can guarantee the uniformity and symmetry of a temperature field in a cavity of the heat preservation cover, effectively inhibit component volatilization in a process of growing the lithium aluminate crystals by the pulling method, and realize the growth of large-size and high-quality lithium aluminate crystals.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

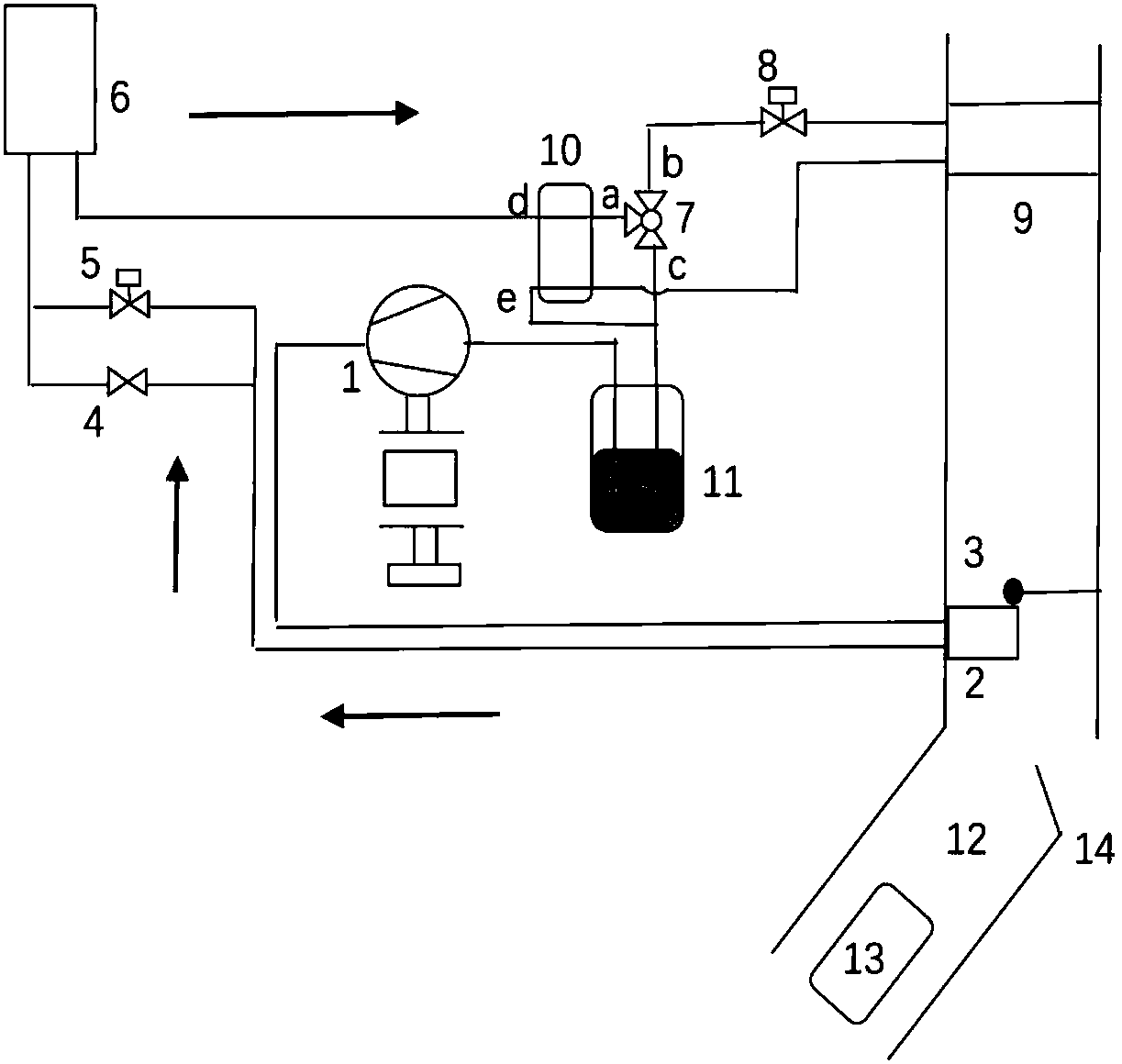

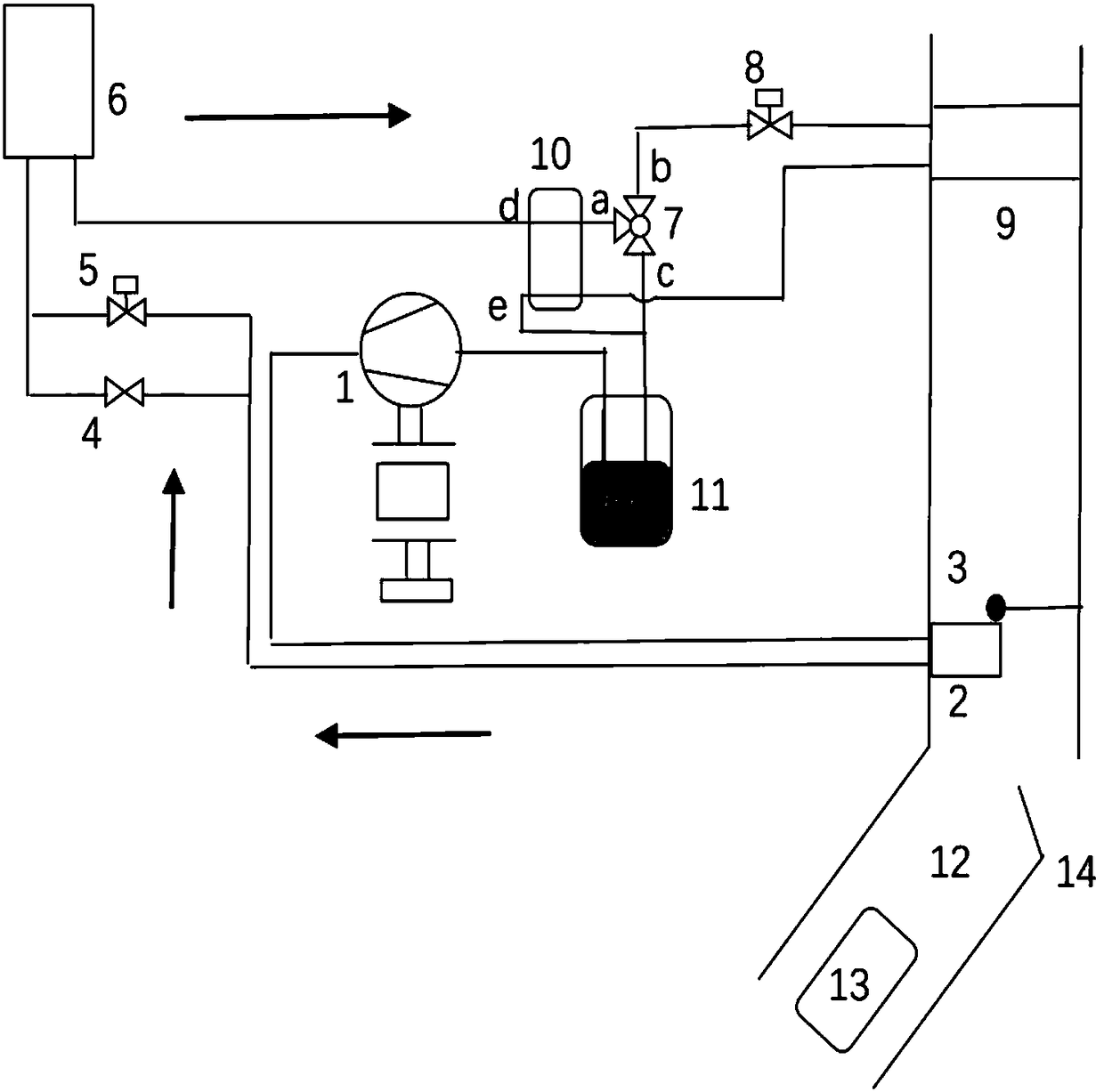

CO2 air conditioning heat pump system

ActiveCN108583204AImprove efficiencyExtend your lifeAir-treating devicesHeat recovery systemsGas coolerEngineering

The invention discloses a CO2 air conditioning heat pump system. An outlet of a compressor is connected with an inlet of an indoor gas cooler; an outlet of the indoor gas cooler is connected with inlets of a bypass valve and an expansion valve; an inlet of an outdoor heat exchanger is connected with outlets of the bypass valve and the expansion valve; a d-end inlet of a heat regenerator is connected with an outlet of the outdoor heat exchanger; a d-end outlet of the heat regenerator is connected with a port a of a three-way valve; a port b of the three-way valve is connected with one end of the expansion valve; a port c of the three-way valve is connected with an e-end outlet of the heat regenerator and an inlet of an energy accumulator; an inlet of an indoor heat exchanger is connected with the other end of the expansion valve; an outlet of the indoor heat exchanger is connected with an e-end inlet of the heat regenerator; the e-end outlet of the heat regenerator is connected with aninlet of the energy accumulator; and an outlet of the energy accumulator is connected with an inlet of the compressor. According to the CO2 air conditioning heat pump system, by reasonably arranging asystem process, the expansion valve and various electromagnetic valves are opened and closed by using a control unit; and therefore, conversion among three modes of a refrigeration mode, a heating mode and a dehumidification mode, and the functions of the unit are comprehensive.

Owner:XI AN JIAOTONG UNIV

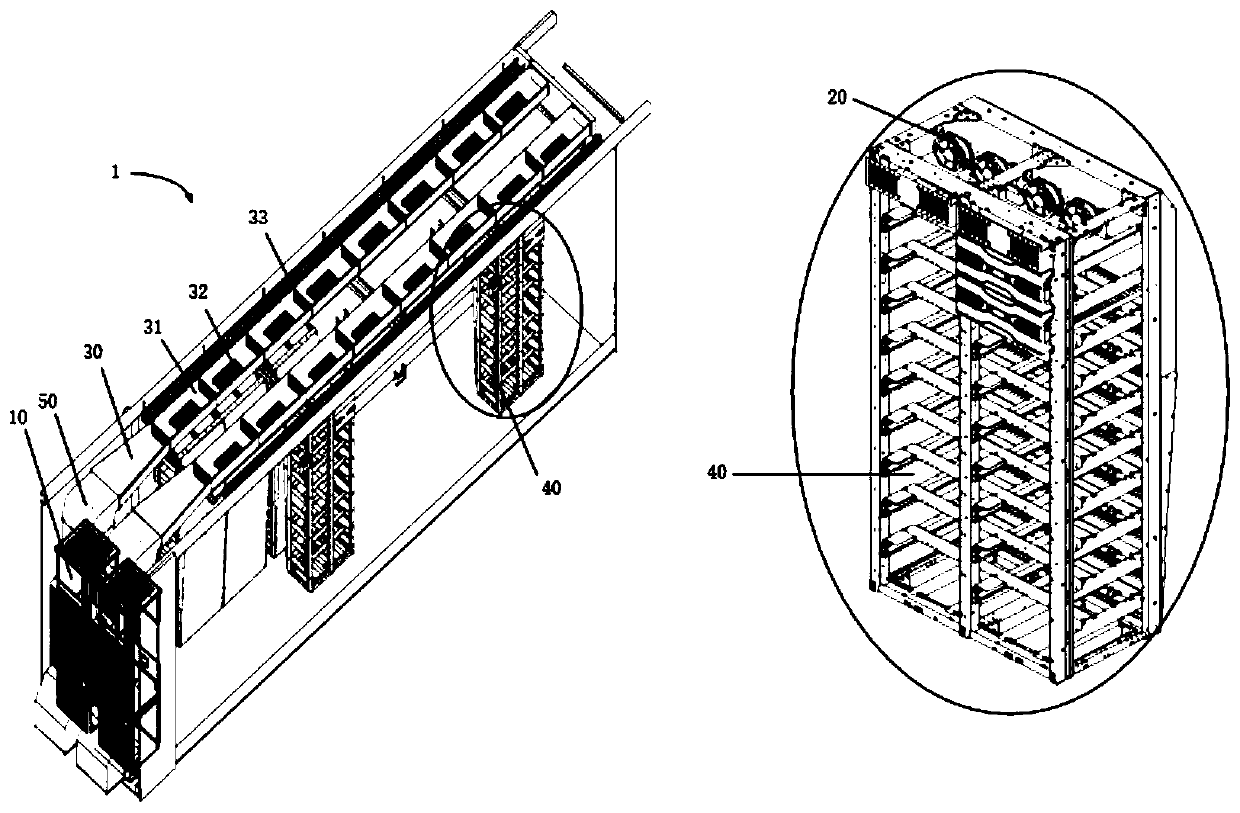

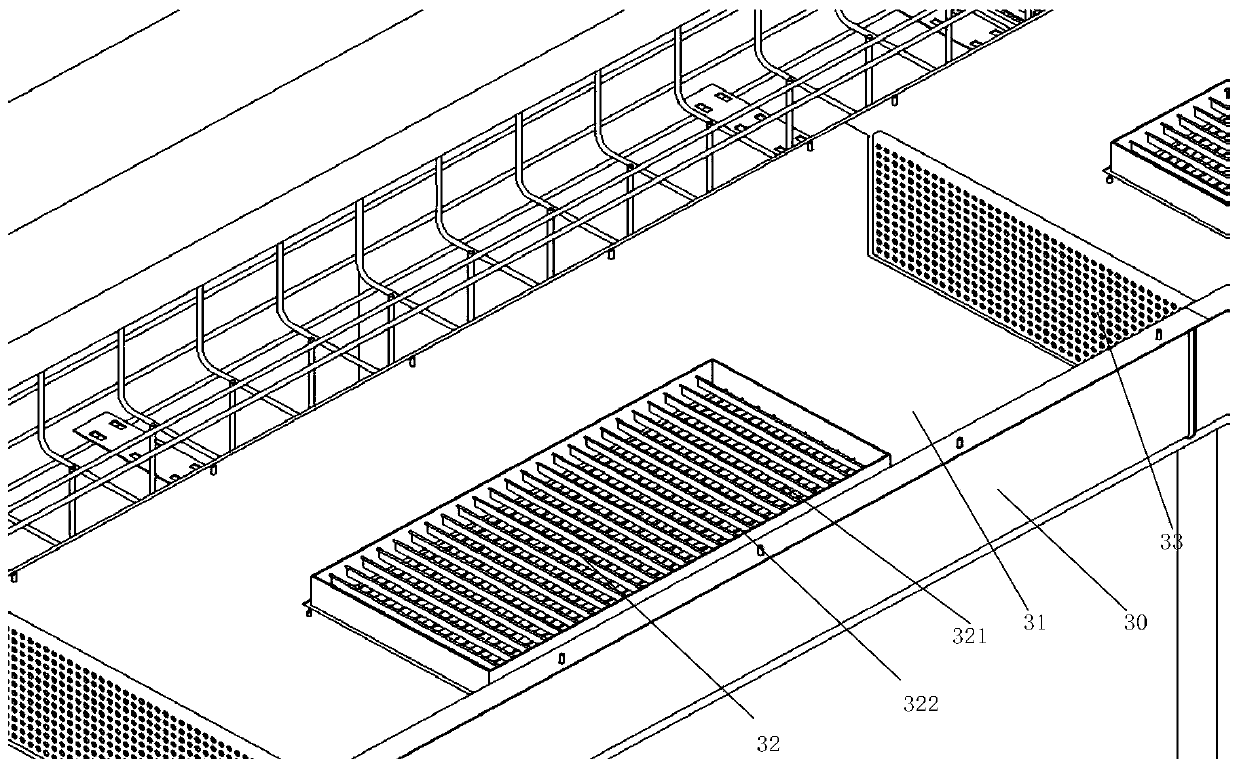

Temperature control system of energy storage box

InactiveCN111082184AImprove temperature fieldReduce air temperature differenceSecondary cellsPhysicsEngineering

The invention relates to a temperature control system of an energy storage box. The system comprises an air conditioner, a fan, an air duct and a battery rack, wherein an air outlet of the air conditioner is communicated with the air duct, the air duct is of a tubular structure defined by sequentially connecting air duct plates, the air duct is arranged above the fan, the fan is arranged above thebattery rack, the air duct plate is provided with an opening facing the fan, an adjustable shutter is arranged on the opening, and outlet air of the air conditioner is guided to the fan by the opening of the air duct and is blown to the battery rack by the fan. According to the mode, the purposes of improving the internal temperature of the energy storage box and reducing the temperature difference of air in the energy storage box can be achieved.

Owner:SHENZHEN CLOU ELECTRONICS

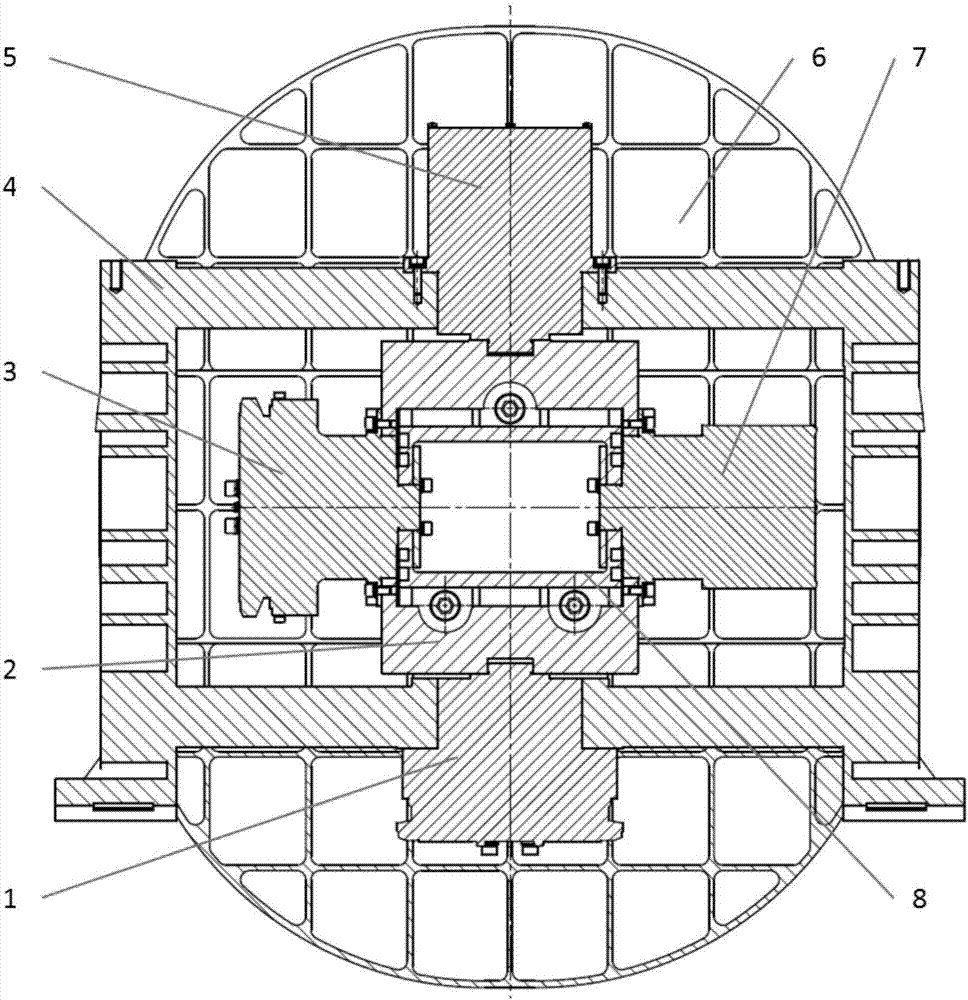

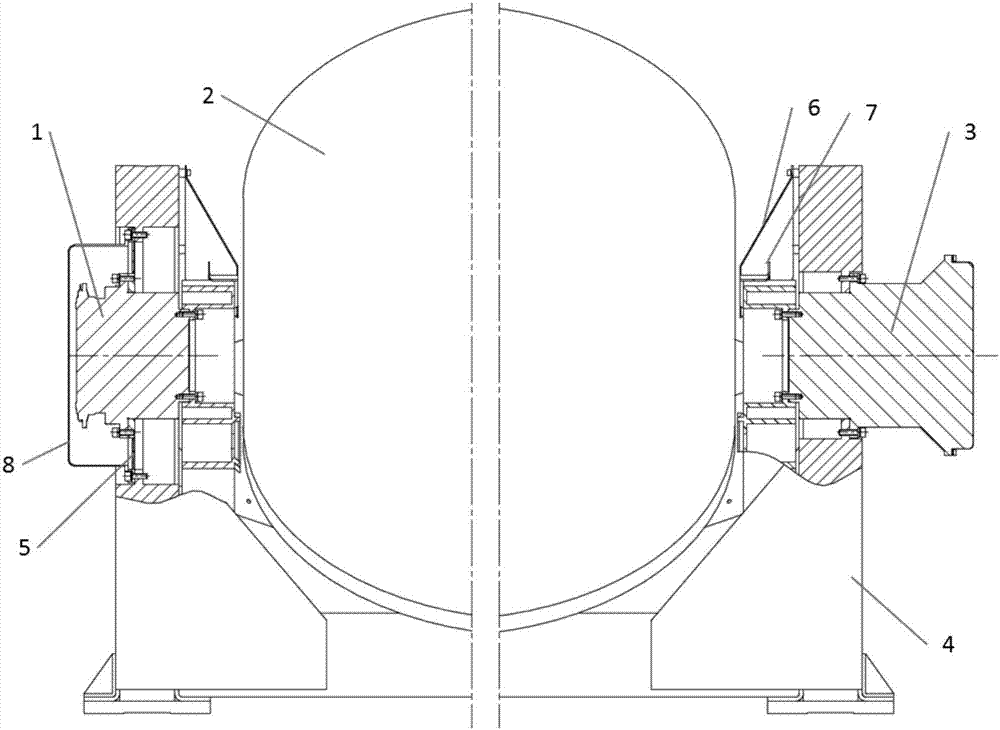

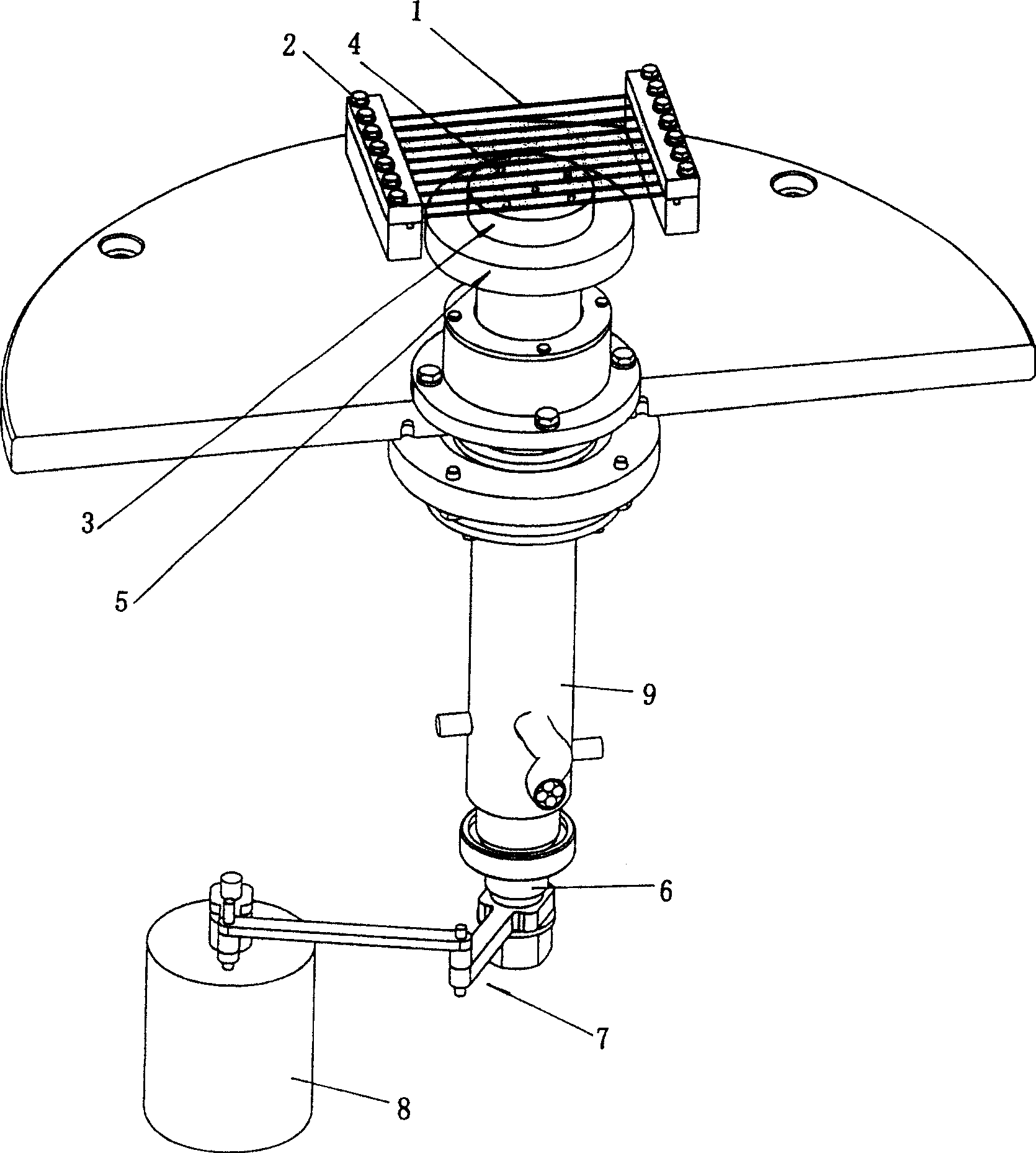

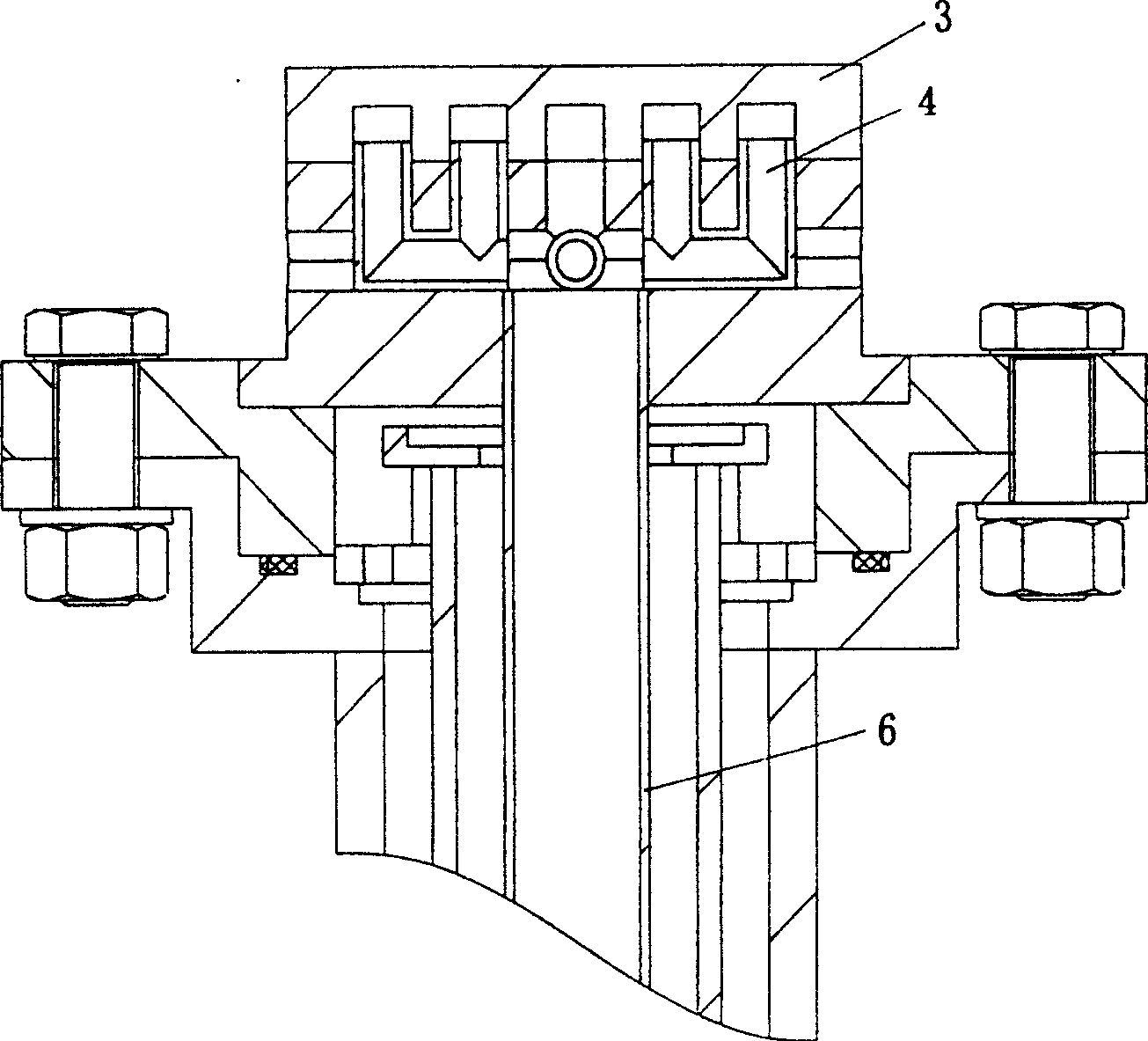

Two-dimensional directing mechanism for optical remote sensing instrument

ActiveCN107218960AImprove pointing accuracyLong axis decreaseMeasurement apparatus componentsGear wheelEngineering

The invention discloses a two-dimensional directing mechanism for an optical remote sensing instrument. The two-dimensional directing mechanism comprises an upper half shaft assembly, a lower half shaft assembly, a left half shaft assembly, a right half shaft assembly, a directing mirror assembly, an inner frame, an outer frame, a support frame and a counterweight. The lower half shaft assembly and the left half shaft assembly have the same structure. The upper half shaft assembly and right half shaft assembly have the same structure. The upper half shaft assembly, the lower half shaft assembly and the inner frame constitute a pitch axis system. The left half shaft assembly, the right half shaft assembly, the outer frame and the pitch axis system form an azimuth axis system. The two-dimensional directing mechanism is high in directing precision, light in weight, low in moment of inertia, small in interference torque of satellite platform, compact in structure, simple in structure, and directly driven to avoid a complex harmonic reducer or gear reduction mechanism, and highi in reliability.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

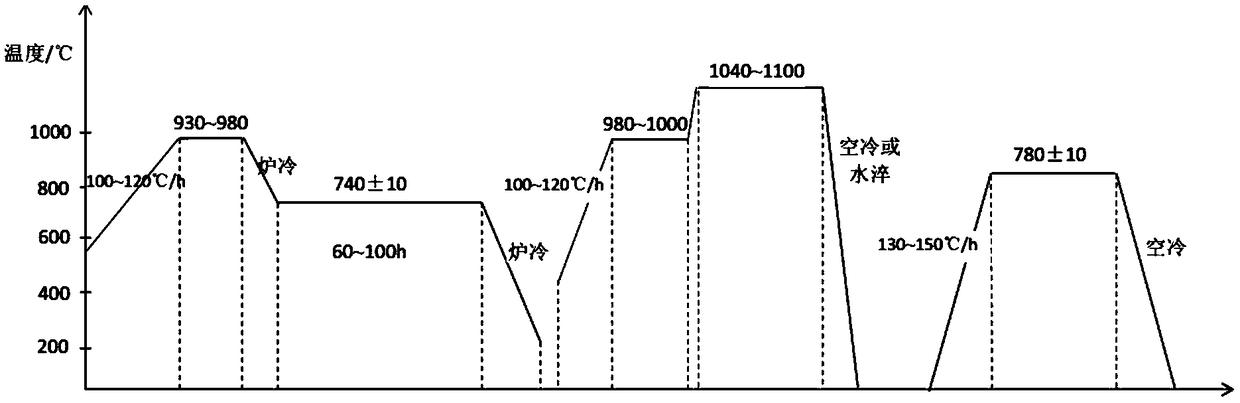

Method for improving radial structure uniformity of martensite heat-resistant steel large-caliber thick-wall pipe

ActiveCN108754084AEliminate heredityImprove radial temperature fieldFurnace typesHeat treatment furnacesRoom temperatureThick wall

The invention discloses a method for improving radial structure uniformity of a martensite heat-resistant steel large-caliber thick-wall pipe, and belongs to the technical field of steel and iron materials. The method comprises the following steps that a pipe blank subjected to hot extrusion is adopted, is placed into a furnace, is heated to 930-980 DEG C by taking the heating speed of 100-120 DEGC per hour, then undergoes heat preservation for 1-6 hours, then is cooled to 740 DEG C + / - 10 DEG C, then undergoes heat preservation for 60-100 hours, and then is cooled along with the furnace; thepipe blank obtained through the above step is placed into the furnace, is heated to 980-1000 DEG C by taking the heating speed of 100-120 DEG C per hour, then is heated to 1040-1100 DEG C as soon aspossible, undergoes heat preservation for 1-3 hours after undergoing hardening, and then undergoes air cooling or water quenching to reach the room temperature; then the pipe blank obtained through the last step undergoes the tempering system, wherein the pipe blank is placed into the furnace is heated to the tempering temperature of 780 + / - 10 DEG C by taking the heating speed of 130-150 DEG C per hour, undergoes heat preservation for 3-5 hours, and then undergoes air cooling to reach the room temperature. The method has the advantages that the structure heredity is eliminated, the radial temperature field of the thick-wall pipe is improved, moreover, the grain is refined, and the uniformity of the radial structure and the performance of the thick-wall pipe is greatly improved.

Owner:CENT IRON & STEEL RES INST

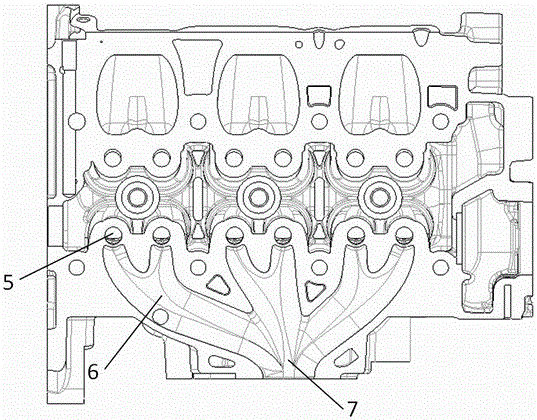

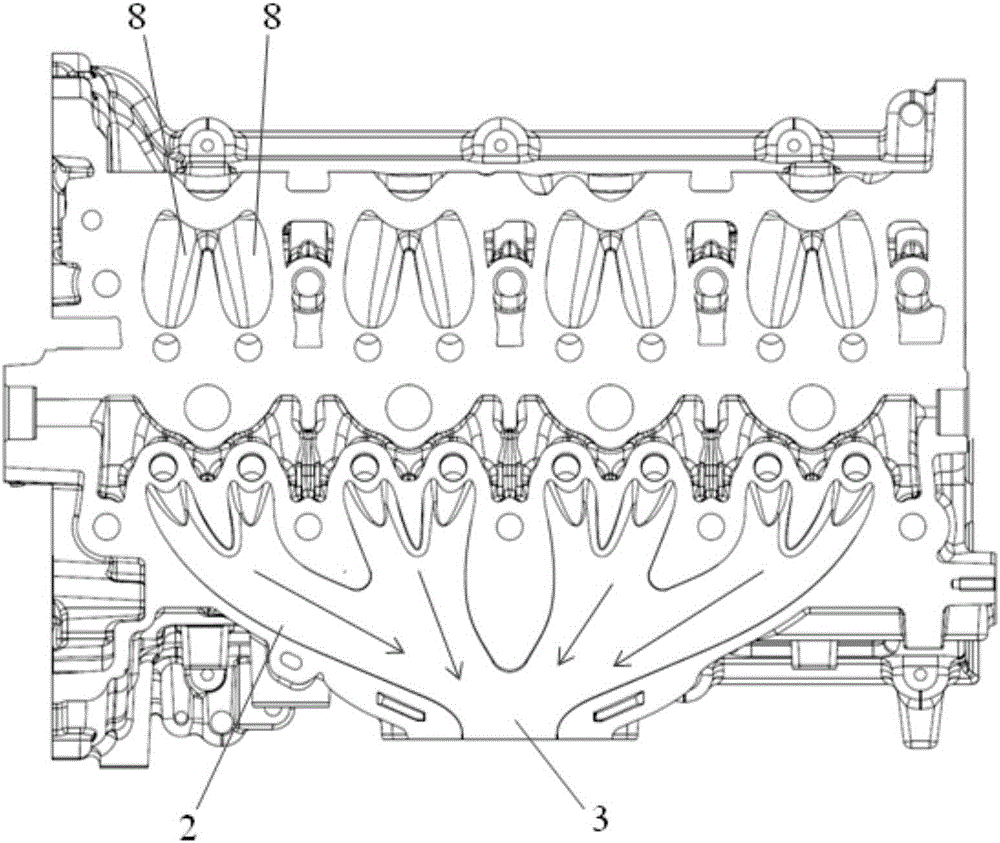

Air cylinder cover of automobile engine

InactiveCN106224079AIncrease temperaturePromote combustionCylinder headsCombustion enginesParticulatesCombustion chamber

The invention discloses an air cylinder cover of an automobile engine. The air cylinder cover comprises air inlet channels, exhaust channels, an exhaust manifold, a water jacket and a combustion chamber. The air inlet channels and the exhaust channels are connected with the combustion chamber. A combustion chamber step structure is arranged in the combustion chamber, and combustion chamber steps are arranged at the positions, facing the upper portion of the combustion chamber, of seat ring holes. According to the technical scheme, the air inlet channels and the combustion chamber are optimized, and therefore the low-speed tumble ratio is increased, in-cylinder combustion is improved, and the wall wetting condition is reduced to the largest degree; oil consumption is reduced, and particle emissions are reduced; branches of the exhaust channels of all cylinders are slightly lengthened and are finally gathered to a general branch, and an assembly type exhaust manifold is omitted; the exhaust manifold is integrated on a cylinder cover body, exhaust heat is fully utilized, the temperature of the engine is increased fast, and driving and taking comfort is improved; the complete engine frictional work is reduced, and therefore oil consumption of the complete engine is reduced; and by means of the water jacket structure, the water flow manner is adjusted, the temperature field of the cylinder cover body and the part integrated with the exhaust manifold is improved, and the cylinder cover body and the exhaust integration structure are fully cooled.

Owner:CHERY AUTOMOBILE CO LTD

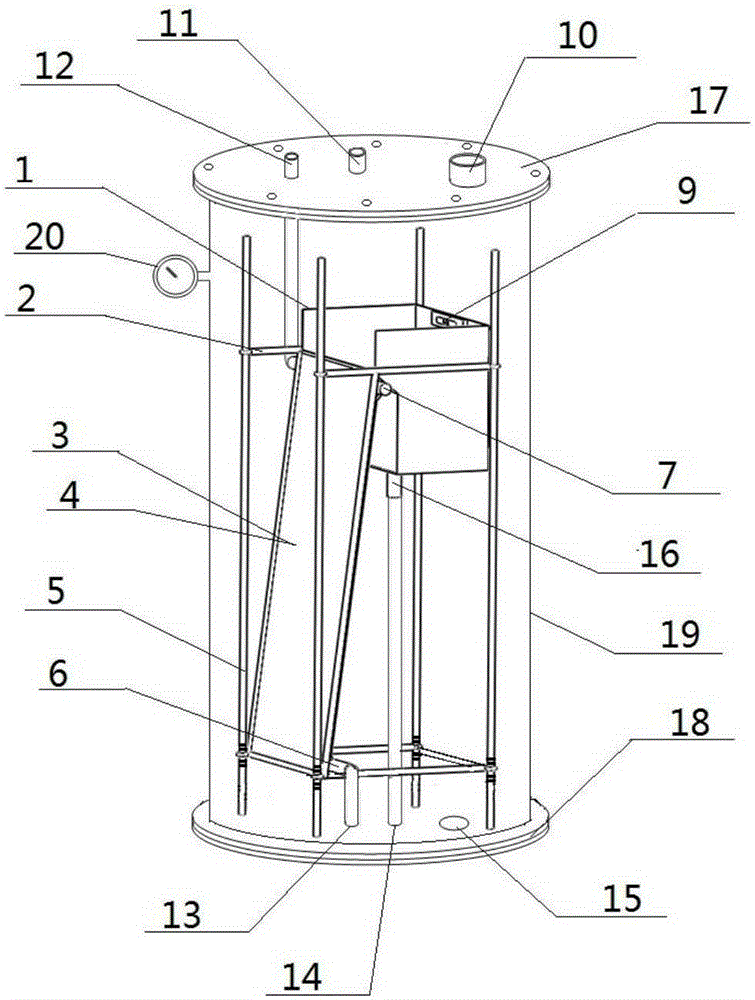

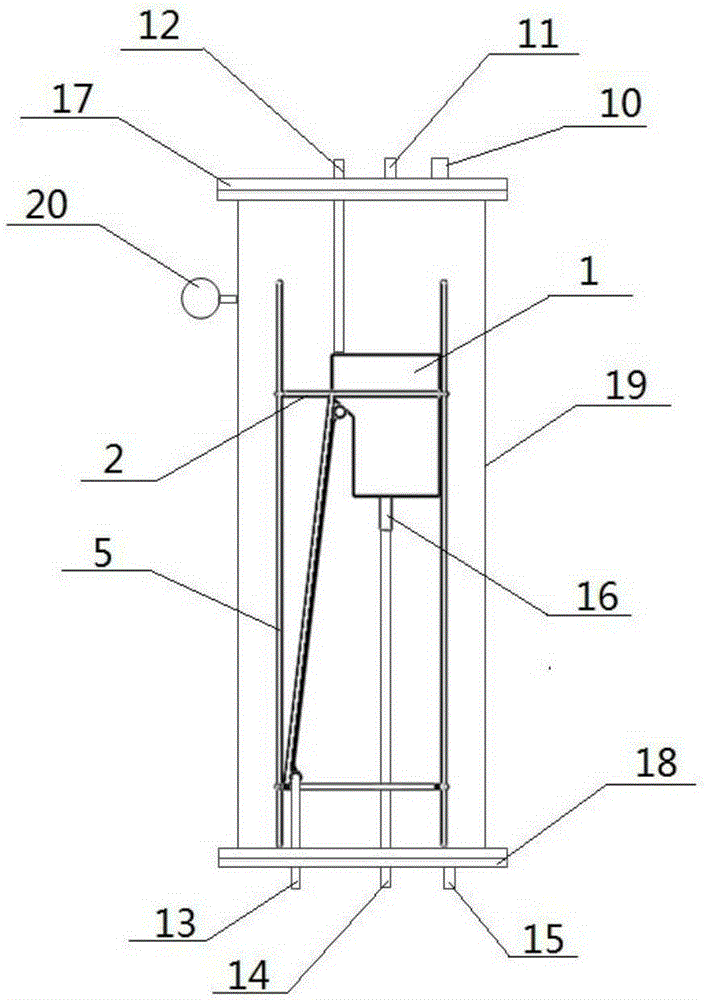

Adjustable inner-cooling type falling film absorption experimental device

ActiveCN105157279ACompact structureEasy to operateEnergy efficient heating/coolingClimate change adaptationWater pipeBolt connection

The invention discloses an adjustable inner-cooling type falling film absorption experimental device. The adjustable inner-cooling type falling film absorption experimental device is composed of an upper end cover, a lower end cover, a cylinder body and a falling film implement. The upper end cover, the lower end cover and the cylinder body are all in bolt connection to form an absorption bin. The falling film implement is placed in the absorption bin. The falling film implement is composed of a liquid overflow groove, a support, a liquid absorption layer, a falling film plate, adjusting rods, a water collecting pipe, a water distributing pipe, capillary tubes and a gradienter. According to the experimental device, the falling film implement can be horizontally adjusted through the thread connection of the four corners of the support, and the inclination, caused by installation or an uneven bottom contact surface, of the falling film implement is avoided; the uniformity of a liquid film in the falling film absorption process is ensured by arranging the gradienter to monitor whether the falling film plate is horizontal; a stable temperature field in the falling film absorption process is ensured by welding a same-course type cooling water pipeline on the lower surface of the falling film plate; the stability of liquid flow and the uniformity of the liquid film are ensured by bonding the liquid absorption layer with the upper surface of the falling film plate.

Owner:山东康宅超净空气设备有限公司

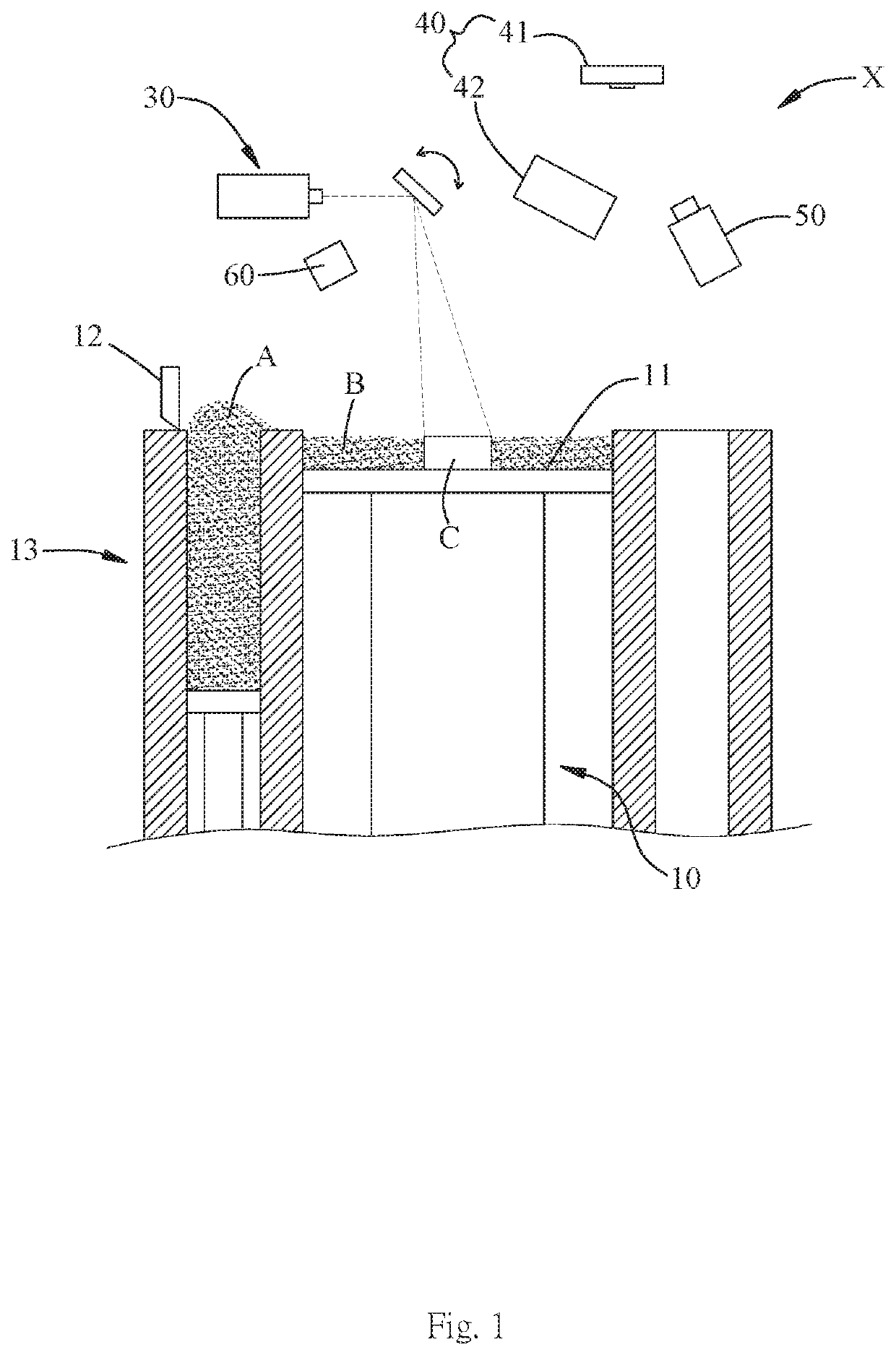

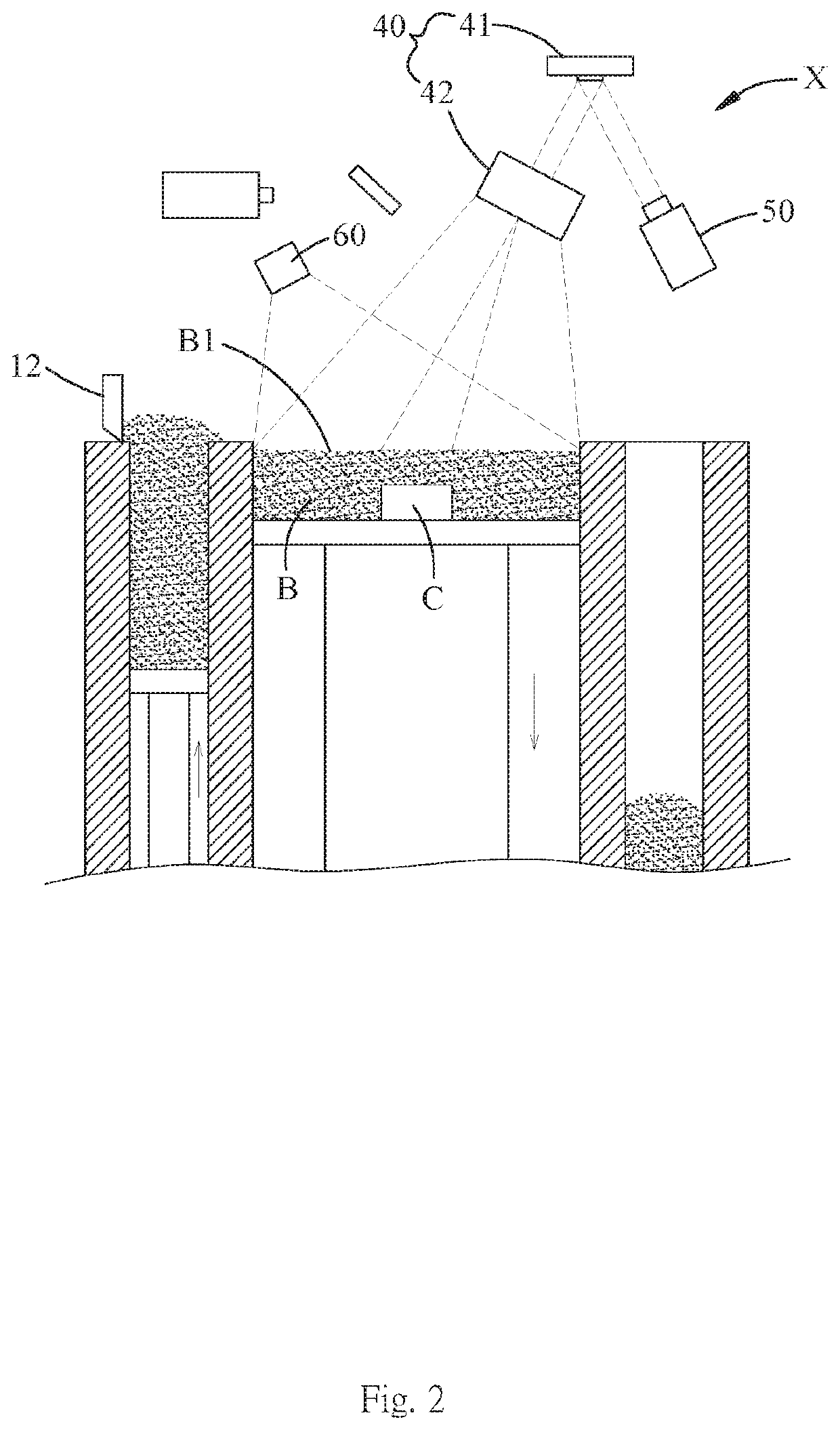

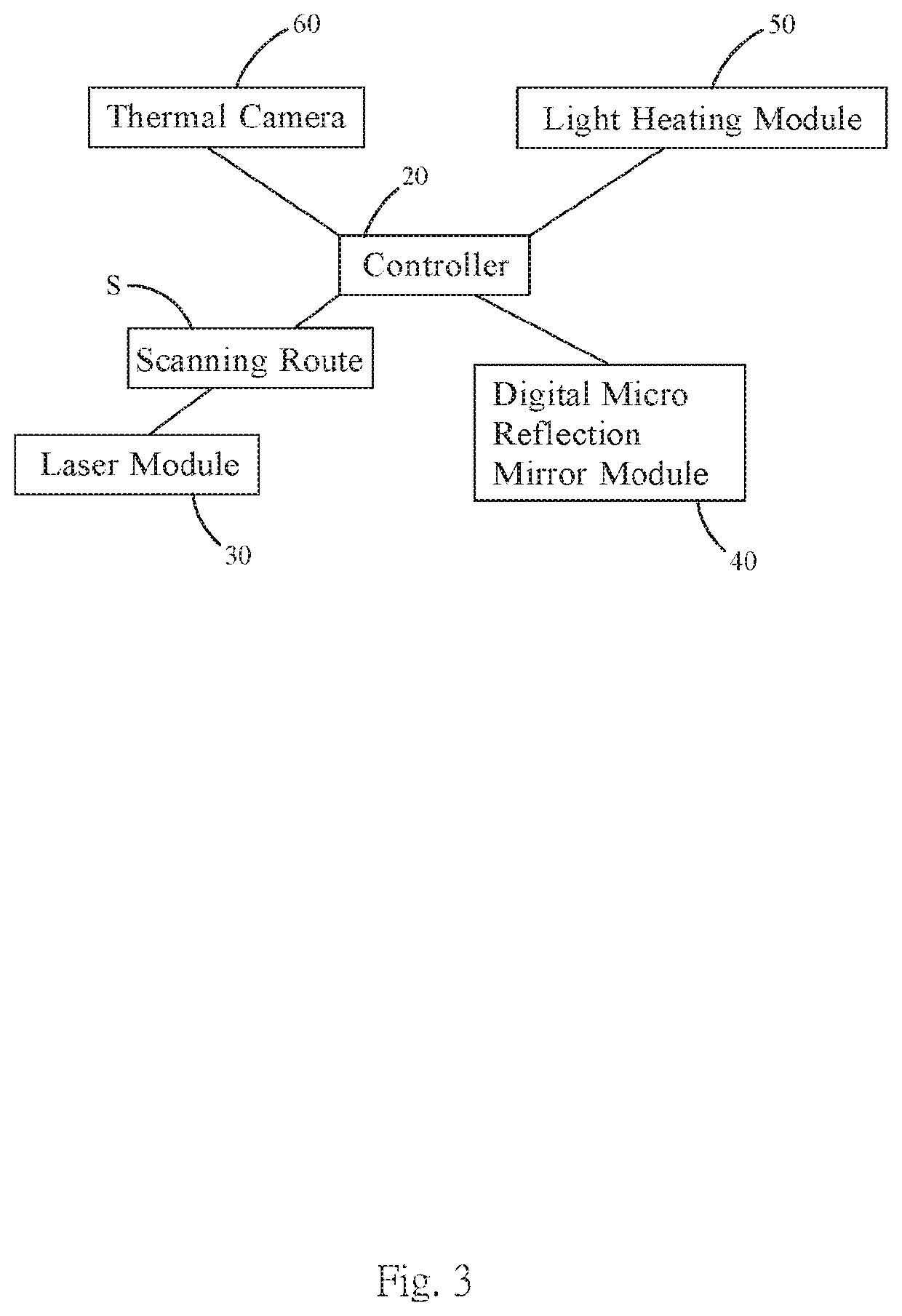

Laser Sintering 3D Printing Thermal Compensation System and Method

InactiveUS20210060645A1Reduce temperature differenceAvoid Interface DefectsAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringTemperature difference

A laser sintering 3D printing thermal compensation system is provided and includes a controller and a heating device and a temperature field sensing device respectively connected to the controller, in which the temperature field sensing device is configured to determine a detection result by detecting within a printing region, the detection result includes a high temperature region and a relatively low-temperature region, and the controller is configured to control the heating device to heat the relatively low-temperature region for conducting thermal compensation, thereby reducing the temperature difference between the high temperature region and the relatively low-temperature region, and overcoming drawbacks of conventional arts having inaccurate control of the temperature field, causing interface defects due to temperature unevenness, and, consequently, greatly reducing the printing quality.

Owner:AIC RD TECH CO LTD

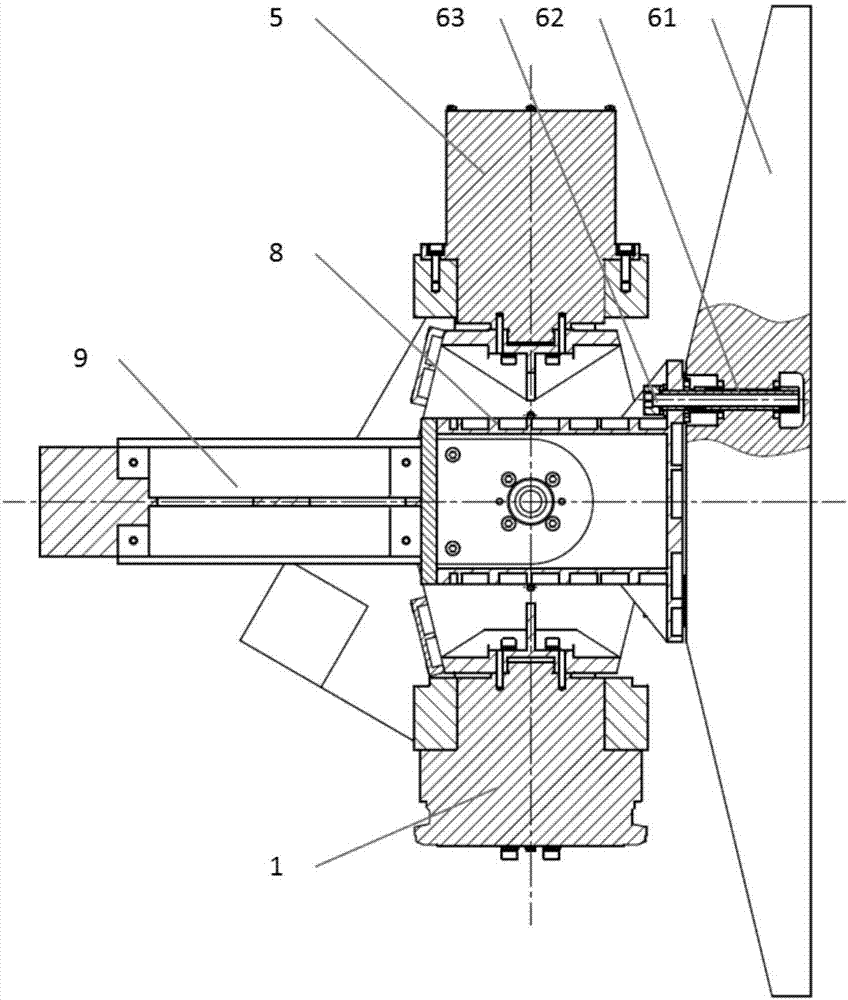

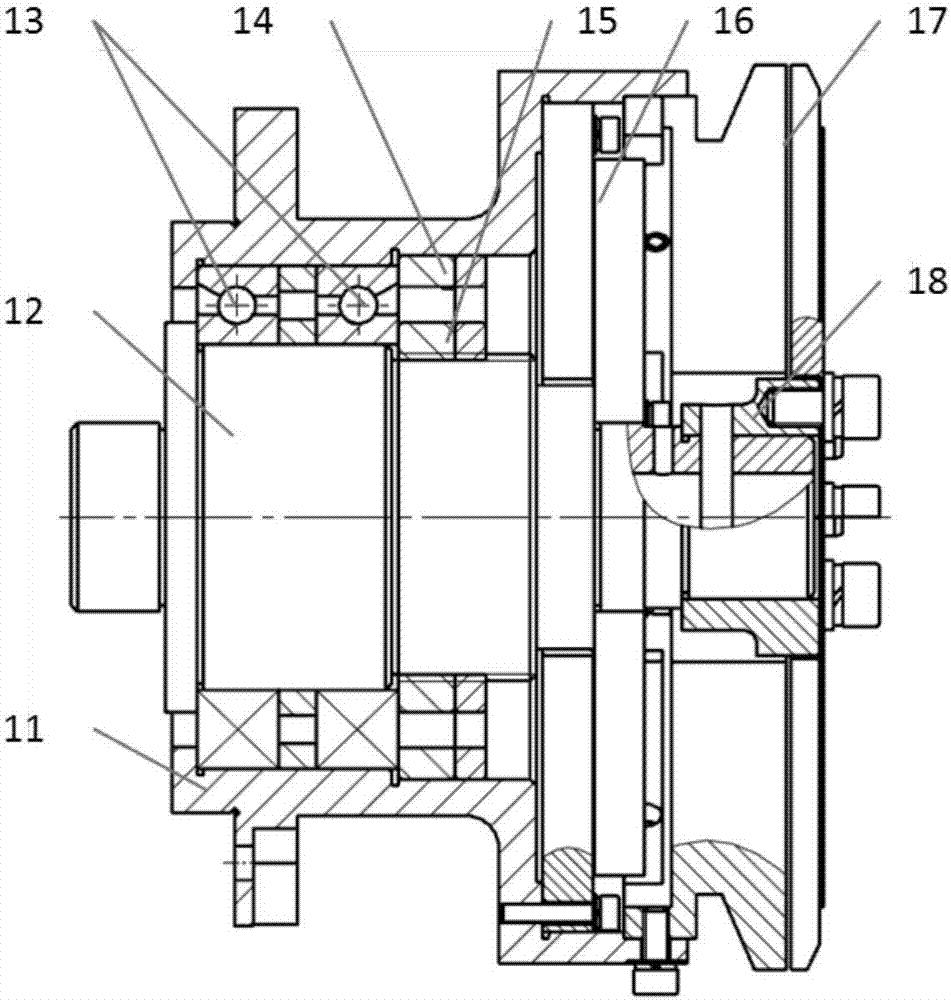

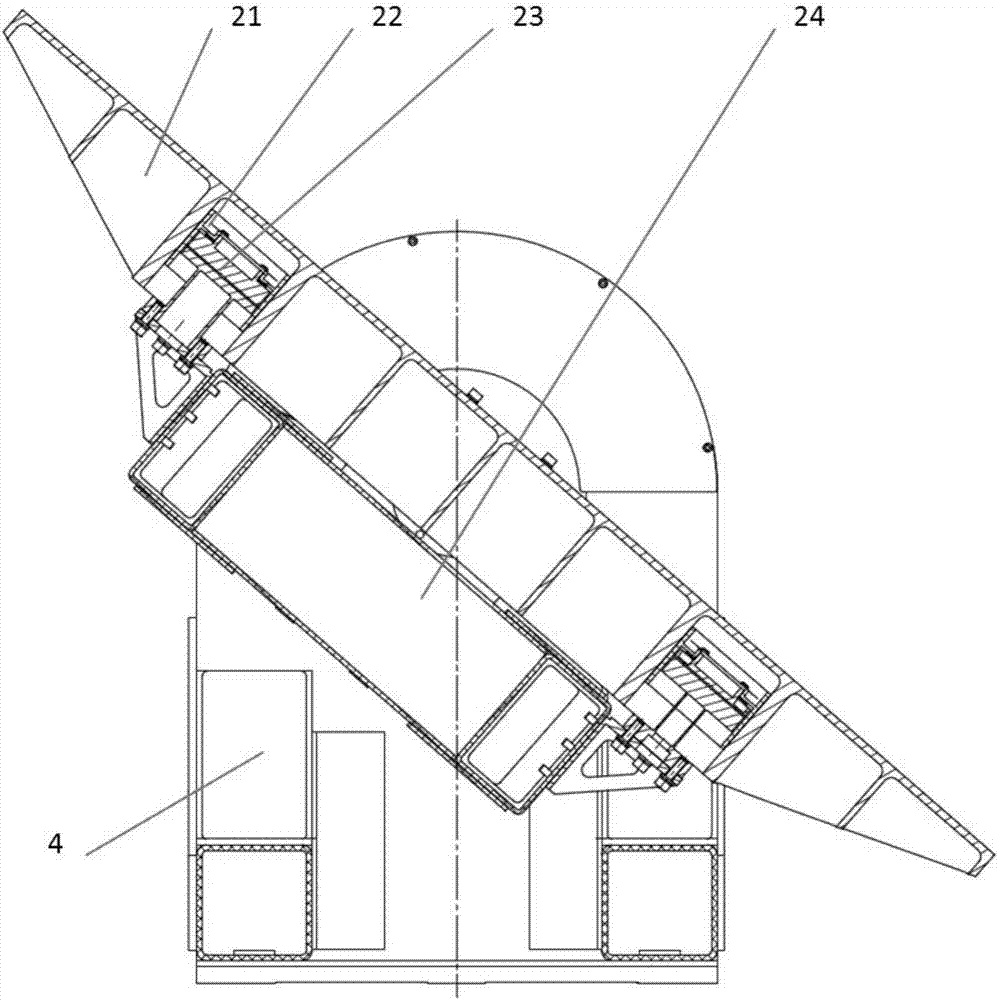

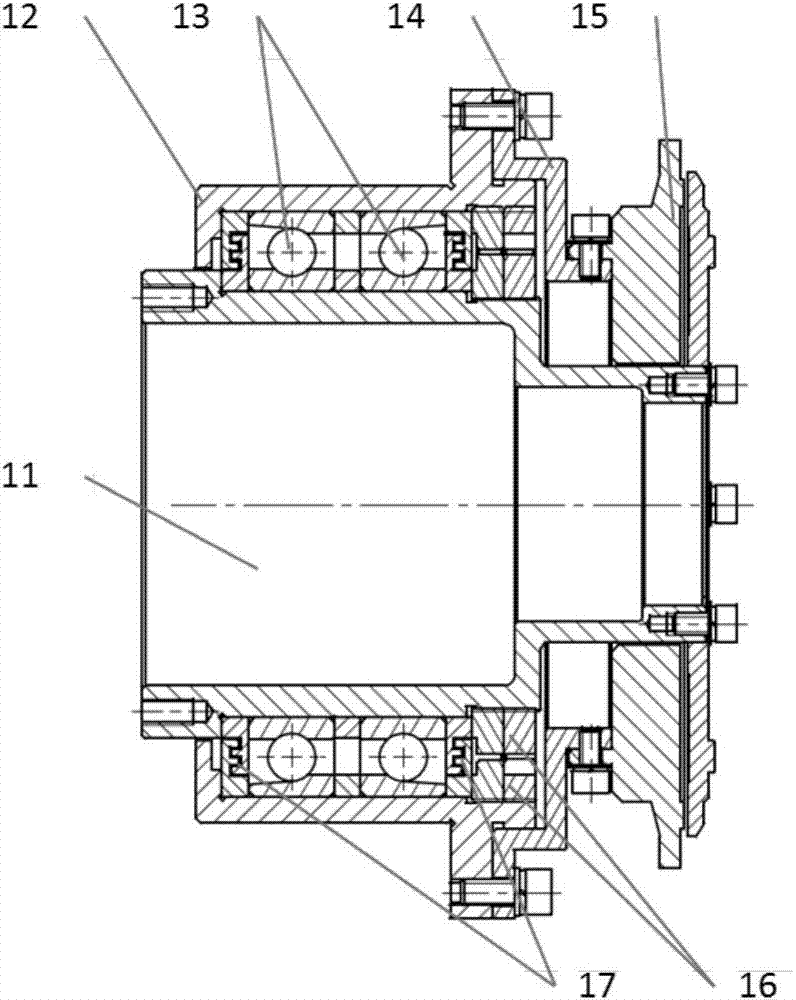

Scanning mechanism used for optical remote sensing instrument

The invention discloses a scanning mechanism used for an optical remote sensing instrument. The scanning mechanism includes a scanning mirror assembly, a scanning mechanism support, a drive shaft assembly, a moving shaft assembly, a thin film support, a support light shade, a shaft light shade and a locking device protecting cover. The scanning mirror assembly includes a scanning mirror, a gluing bush, a flexible support and a scanning mirror support. The moving shaft assembly includes a moving half shaft, in-pair angular contact ball bearings, a switching flange, an electromagnetic locker, a bearing lock nut and a maze seal ring. The drive shaft assembly includes a drive half shaft, in-pair angular contact ball bearings, a bearing seat, a drive motor, a motor housing, a magnetic shielding shade, a round induction synchronizer, a synchronizer protection shade, a bearing locking nut and a maze seal ring. The scanning mechanism is advantaged in that the scanning rate is high and the efficiency is high; the scanning detection field is large; the scanning precision is high; the temperature adaptability is good; the structure is simple; the reliability is improved since direct drive is adopted and use of a speed reduction mechanism with a complex structure is avoided.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

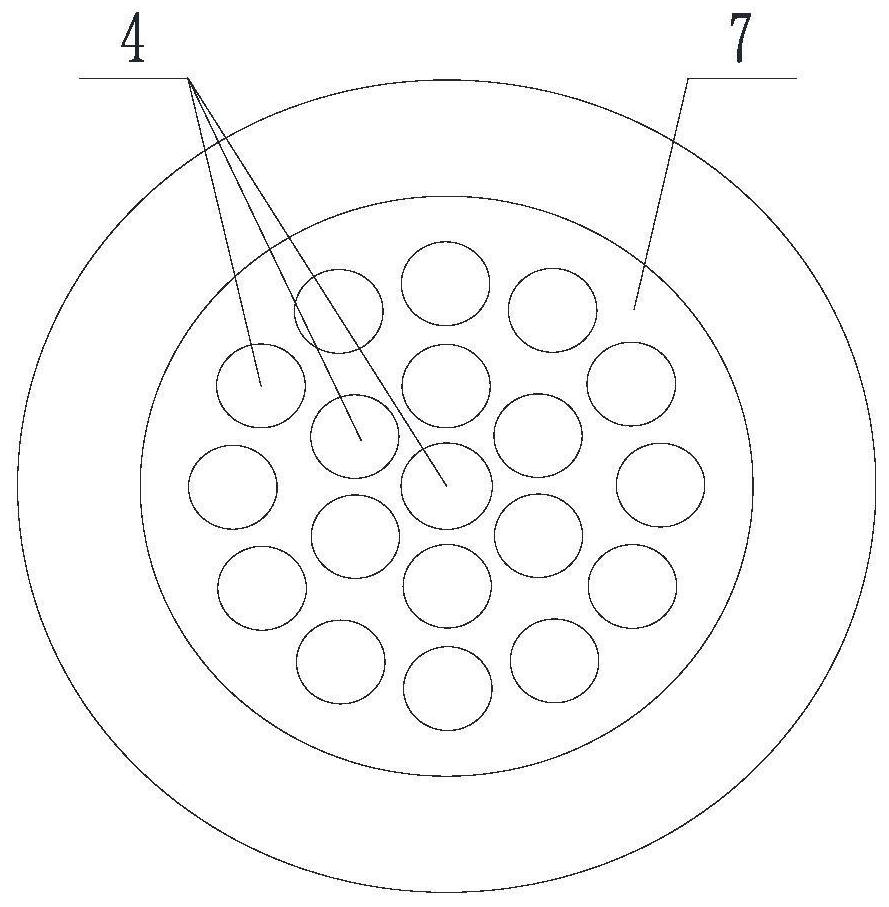

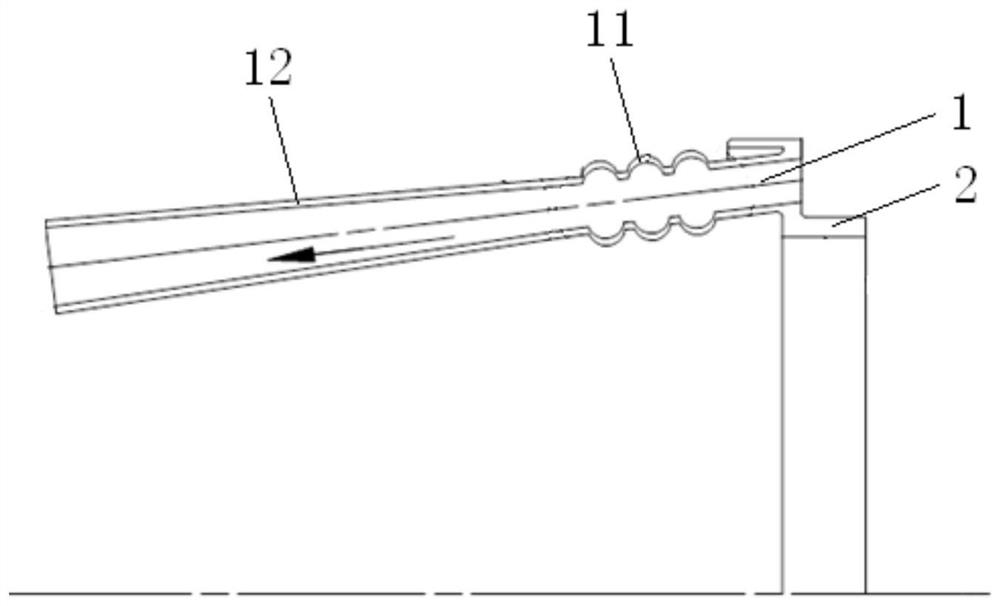

Integrated structure of evaporation tubes, evaporation tube type combustion chamber and miniature turbojet engine

ActiveCN111853854AImprove evaporation effectEnhance the effect of atomization and evaporationContinuous combustion chamberJet propulsion plantsEngineeringEvaporation duct

The invention discloses an integrated structure of evaporation tubes, an evaporation tube type combustion chamber and a miniature turbojet engine. The integrated structure of the evaporation tubes isused to impact and mix fuel sprayed from fuel nozzles through high-speed airflow to form a fuel-air mixture and spray the fuel to the head area of the combustion chamber. The integrated structure of the evaporation tubes comprises a plurality of evaporation tubes integrated with a support ring of the combustion chamber, wherein the evaporation tubes are evenly arranged on the support ring of the combustion chamber in the circumferential direction, first ends of the evaporation tubes are inlet ends for inputting the high-speed airflow, second ends of the evaporation tubes are outlet ends for spraying the fuel-air mixture, the evaporation tubes comprise corrugated sections close to the inlet ends, the corrugated sections are provided with corrugated cavities protruding outwards in the radialdirections of the evaporation tubes, and the fuel nozzles are inserted from the outlet ends of the evaporation tubes into the corrugated sections of the evaporation tubes, so that the fuel sprayed from the fuel nozzles is impacted and mixed by the high-speed airflow in the corrugated sections to form the fuel-air mixture, and then the fuel is sprayed from the outlet ends of the evaporation tubesto the head area of the combustion chamber.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

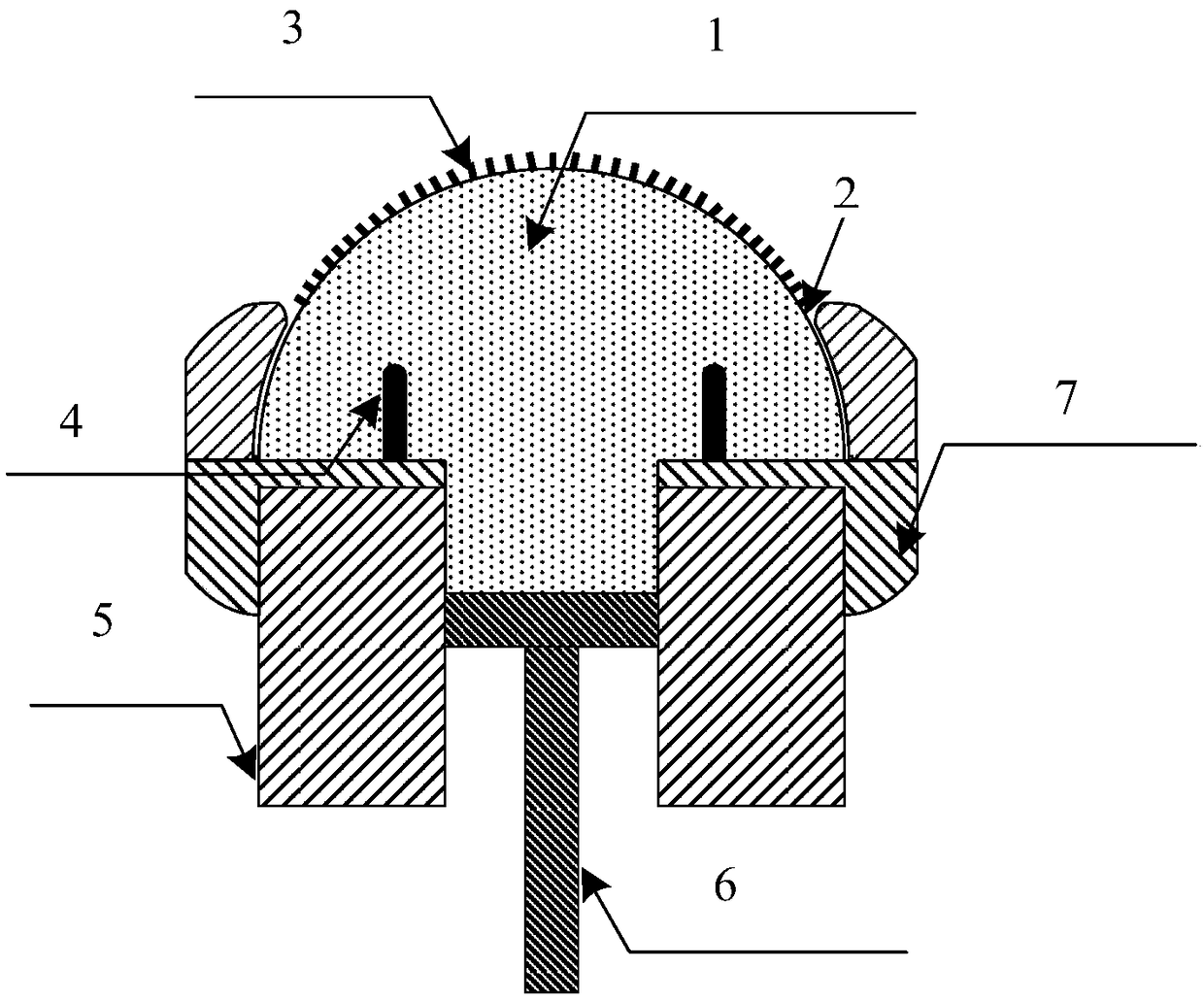

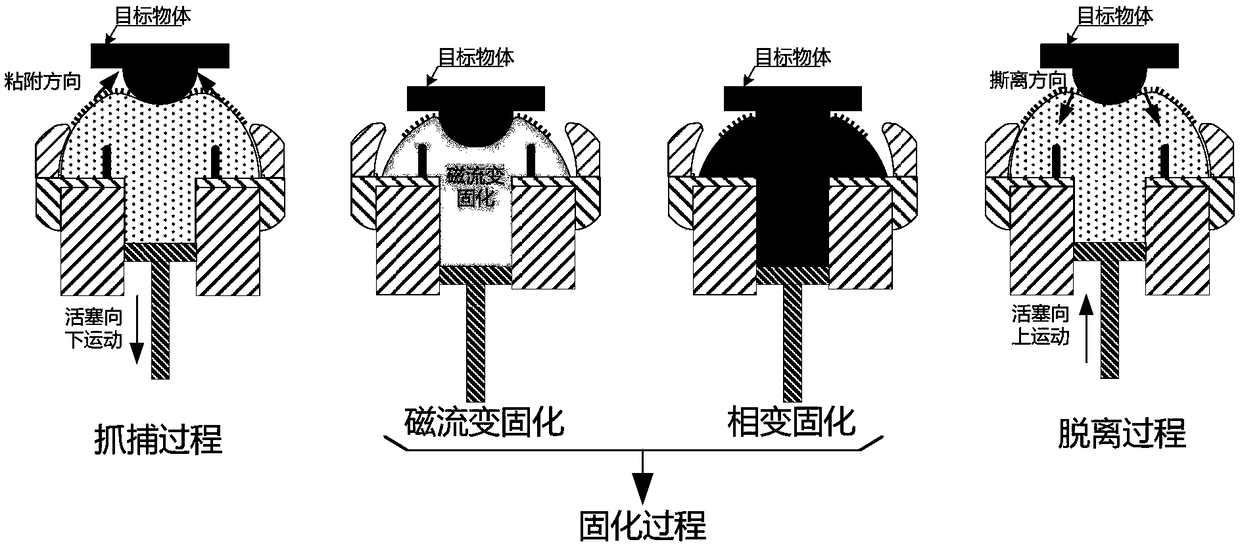

Flexible catching mechanism

ActiveCN109230524AChange the stiffnessReduce stiffnessPackagingConveyor partsPhase changeBiomedical engineering

The present invention relates to the technical field of target catching and specifically discloses a flexible catching mechanism, specifically including a flexible capsule device, a phase change magnetorheological material, a surface microstructure, an electromagnet, a heating structure, a piston structure and a support structure; wherein the flexible capsule device is filled with the phase changemagnetorheological material; the surface microstructure is disposed on the outer surface of the upper end of the flexible capsule device; the heating structure is disposed inside the flexible capsuledevice; the piston structure is disposed on the lower end of the flexible capsule device, and is axially movable along the un-down direction of the flexible capsule device; the support structure is used for supporting the flexible capsule device; and the piston structure and the support structure are configured to seal the flexible capsule device. The invention provides the novel catching mechanism, which can catch targets having different shapes, surfaces and motion characteristics.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

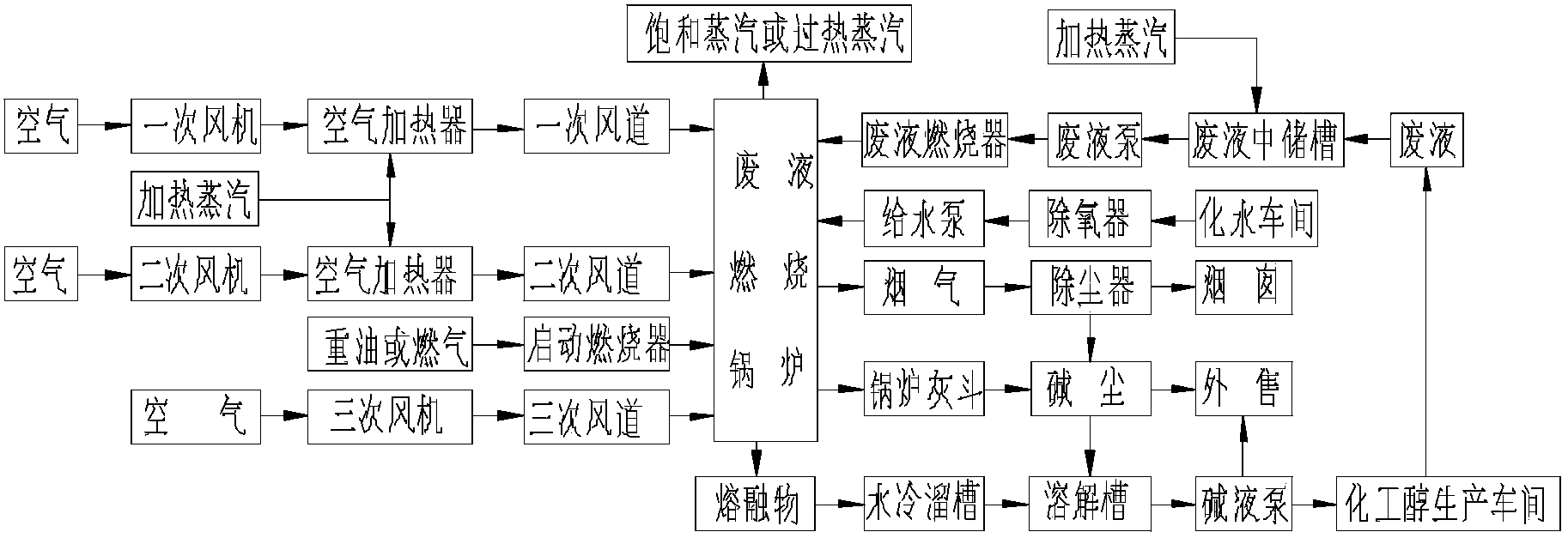

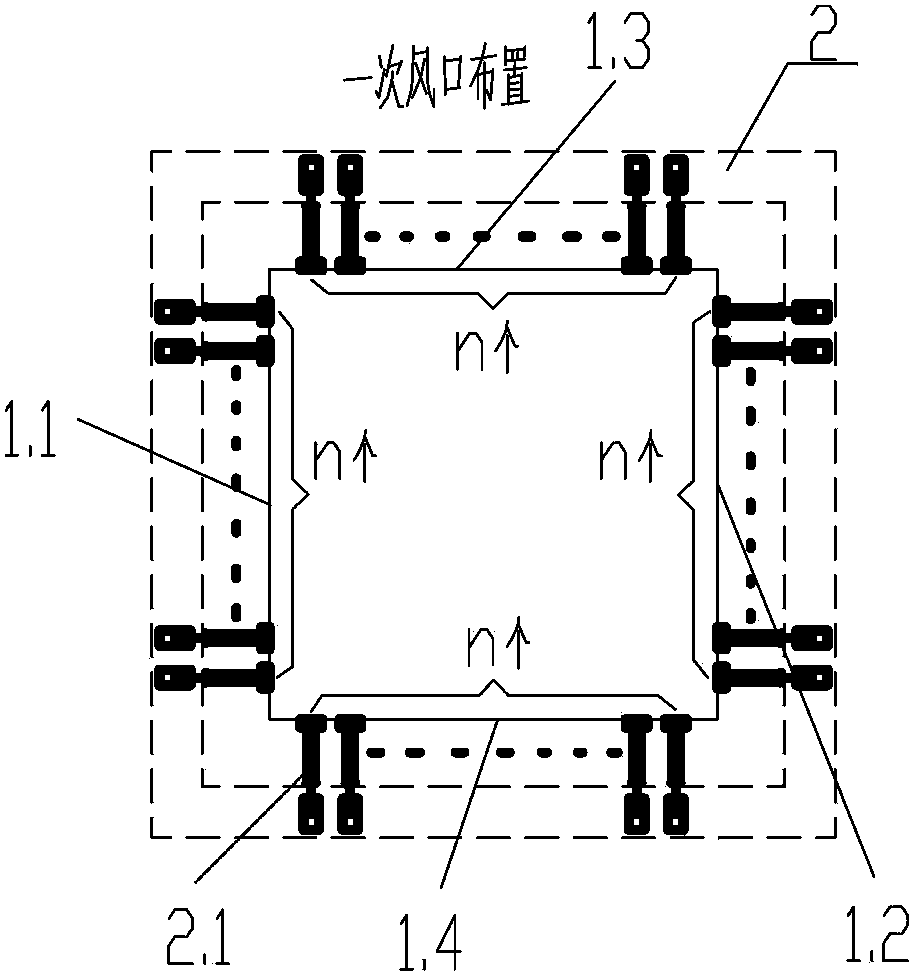

Boiler combustion method of biochemical industry alcohol waste liquid

InactiveCN103486573ALow costImprove utilization efficiencyAir supply regulationIndirect carbon-dioxide mitigationLiquid wasteAlcohol

The invention discloses a boiler combustion method of a biochemical industry alcohol waste liquid. The method is as follows: preheated air is sent into a boiler furnace through a first air-delivery duct and a secondary air-delivery duct which are successively arranged from bottom to top in the boiler furnace, and is mixed with the biochemical industry alcohol waste liquid sprayed into the boiler furnace for combustion; the temperature of the preheated air is 80-150 DEG C; the air pressure of the first air-delivery duct is 500Pa-1200Pa, and the first air rate is 0.35-0.6; the air pressure of the secondary air-delivery duct is 1500Pa-3000Pa, and the secondary air rate is 0.3-0.5; the sum of the secondary air rate and the secondary air rate is 1; and the spraying pressure of the biochemical industry alcohol waste liquid is 0.05-0.2MPa. The waste liquid combustion efficiency is high, the combustion is sufficient, the purity of produced sodium carbonate is above 98% and the boiler thermal efficiency is high and can reach above 75%.

Owner:武汉锅炉集团工程技术有限公司

Thermal diaphragm suitable for annular solar telescope

The invention provides a thermal diaphragm suitable for an annular solar telescope. One end of the thermal diaphragm suitable for the annular solar telescope toward the direction of light incidence isa reflective surface, and the other end is a bottom surface; the reflective surface of the thermal diaphragm suitable for the annular solar telescope is an inverted cone shape, and the bottom surfaceis a positive cone shape; the reflective surface with the inverted cone shape and the bottom surface with the positive cone shape are tangent at the vertexes of the two cones to form a light passinghole; and the cone angle of the inverted cone of the reflective surface is 88 to 93 degrees. The thermal diaphragm structure design provided by the invention strengthens the thermal control ability near the light passing hole, optimizes the temperature field near the light passing hole, reduces stray light to the greatest extent, and suppresses a ghost image; and the thermal diaphragm suitable forthe annular solar telescope has good temperature control effect, no ghost image and good stray light suppression effect, which ensures the imaging quality of the telescope.

Owner:YUNNAN ASTRONOMICAL OBSERVATORY CHINESE ACAD OF SCI

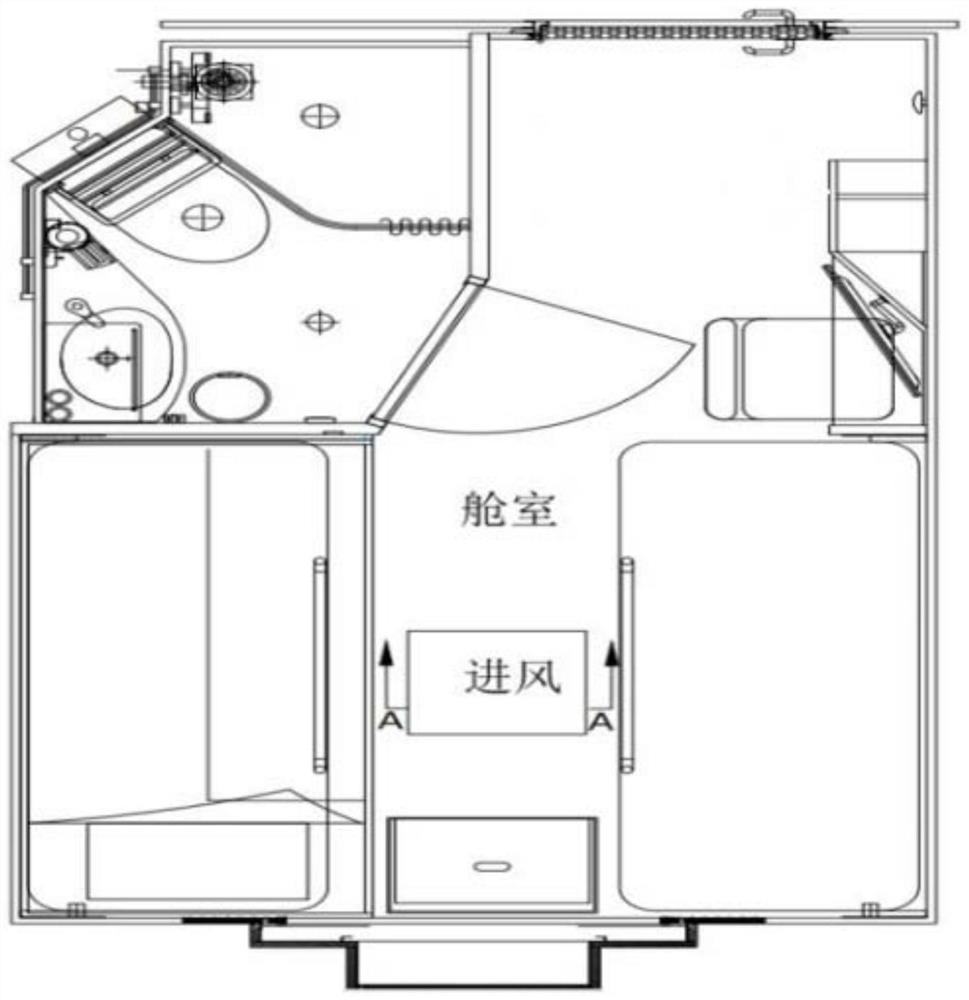

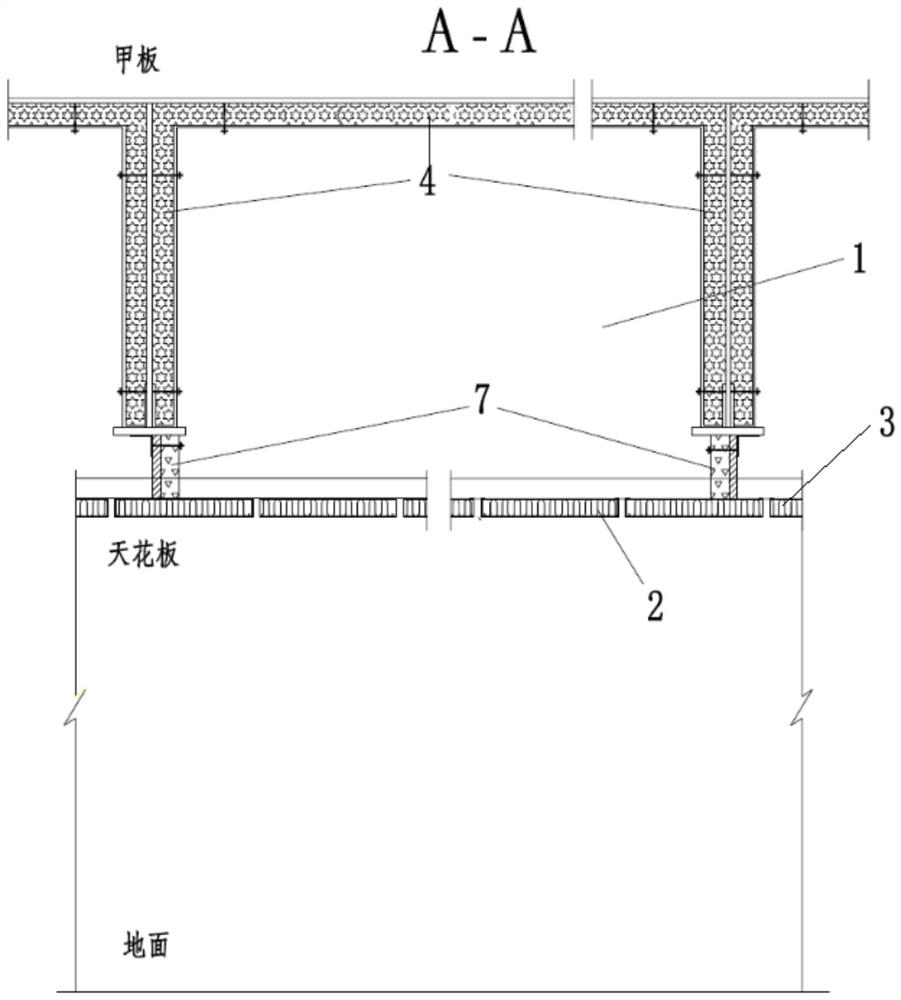

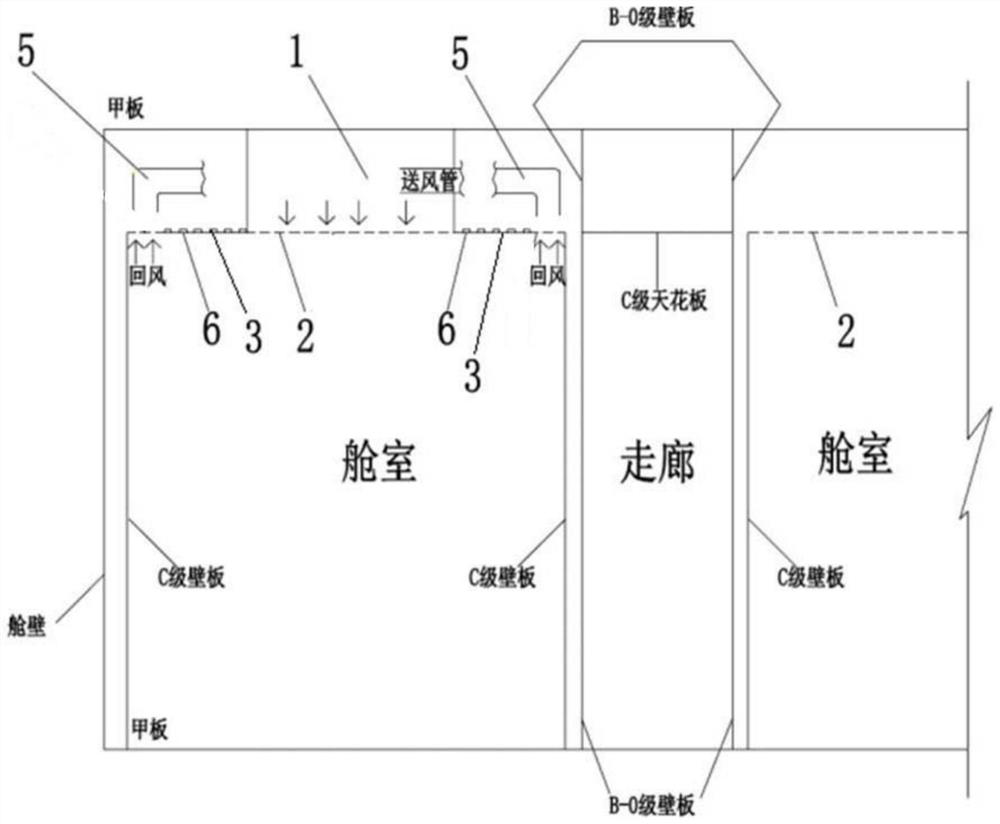

Ship cabin rain falling type air supply and return system and ship

PendingCN113525660AIncrease the air outlet areaUniform windAuxillariesVessel ventillation/heating/coolingAir volumeEnvironmental geology

The invention belongs to the field of ship ventilation and interior decoration, and provides a ship cabin rain-down type air supply and return system and a ship, and the system comprises a static pressure silencing box which is arranged below a deck of a ship cabin and is communicated with an air supply pipeline of the ship cabin; a first rain down ceiling which is arranged on the bottom face of the static pressure silencing box, and a first gap with the void ratio determined based on the air supply amount of the air conditioner is formed in the first rain down ceiling; and a second rain descending ceiling which communicates with an air return pipeline of the ship cabin, and a second gap with the void ratio determined based on the air return amount of the air conditioner is formed in the second rain descending ceiling; return air passes through the second rain down ceiling and then is sent back to the return air pipeline through the outside of the static pressure box silencing box. The air outlet area of the air conditioner is increased, air outlet of the air conditioner is uniform, the temperature field is good, and the air speed is reduced, so that noise reduction is achieved, and the comfort and experience of personnel in a cabin are improved; a grid does not need to be additionally arranged on a cabin door to serve as an air return opening, and privacy of personnel in a cabin is protected.

Owner:中船邮轮科技发展有限公司

Method for efficiently and synergistically recycling chromium-containing waste slag and carbon-containing waste materials

ActiveCN112853091ARealize resourcesImprove temperature fieldProcess efficiency improvementBlast furnace smeltingProcess engineering

The invention discloses a method for efficiently and synergistically recycling chromium-containing waste slag and carbon-containing waste materials. The method comprises the following steps that raw materials including the chromium-containing waste slag and the carbon-containing waste materials are uniformly mixed and pelletized to obtain spherical materials; meanwhile, raw materials including an iron-containing raw material, a flux and fuel are uniformly mixed and granulated to obtain granules; and the spherical materials and the granules are mixed and then distributed in a layered manner to a sintering machine for air draft sintering to obtain the chromium-containing sintered ore. According to the method, the chromium-containing waste slag and the carbon-containing waste materials are efficiently and synergistically utilized in a resource mode in the iron-containing raw material sintering process, not only can thorough detoxification of the chromium-containing waste slag be achieved in one step, but also the chromium-containing waste slag and the carbon-containing waste materials can be utilized in the resource mode, high-quality furnace burden is provided for blast furnace smelting of chromium-containing molten iron, and obvious economic and environmental benefits are achieved.

Owner:CENT SOUTH UNIV

Wellhead heating storage tank

PendingCN112027386AImprove insulation effectAvoid direct heatingLarge containersTank wagonsWater jacketThermal safety

The invention provides a wellhead heating storage tank, and relates to the technical field of oil extraction equipment. A water jacket is arranged on the outer side of the storage tank and buried underground, and an electric heater is arranged in the water jacket; an output pump is arranged in the storage tank, and an outlet of the output pump is connected with two electric valves in parallel andconnected with an output pipe and a back flushing pipe. The wellhead heating storage tank has the following advantages that produced liquid in the storage tank is indirectly heated, the heating safetyis high, the purpose of flowing output is achieved, and potential safety hazards caused by the fact that crude oil is directly heated by the electric heater are prevented; a spray head arranged at the bottom of the storage tank impacts liquid at the bottom of the storage tank upwards to form hydraulic stirring, the liquid in the whole storage tank is stirred and output in a homogeneous state, thetendency of impurity deposition at the bottom of the storage tank is reduced, and the homogeneous produced liquid is beneficial for subsequent treatment; terrestrial heat is stored and released through the energy storage performance of a phase change energy storage material, and the temperature field outside the water jacket is improved; and meanwhile, energy is supplemented to the storage tank through solar energy, and energy consumption is reduced.

Owner:大庆市普罗石油科技有限公司

No-brush temperature measuring method and device with CVD system substrate

InactiveCN100523295CSimple structureImprove reliabilityChemical vapor deposition coatingChemical physicsPhysical chemistry

The present invention is no-brush temperature measuring method and device for measuring the temperature of CVD system substrate dynamically. The present invention has swinging, rather than rotating, substrate bench to ensure the homogeneity of temperature on substrate surface and facilitate temperature measurement with thermocouple, and modified no-brush thermocouple structure for real-time monitoring on the temperature of substrate surface.

Owner:海安常科技术转移中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com