Front biomass ultra-high-speed self-balancing gasifying co-combustion device and method for coal-fired boiler

A coal-fired boiler, self-balancing technology, applied in the direction of combustion method, granular/powdered fuel gasification, gasification process, etc., can solve the problems of long-term stable operation of the device, unstable biomass gasification, and feed jamming, etc. , to achieve the effect of improving the adaptability of raw materials, avoiding tar precipitation, and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

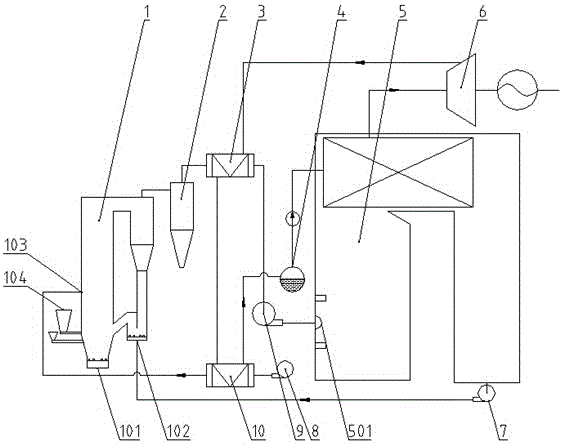

Embodiment 1

[0059] The raw material is twig wood, the length is 5cm, the water content is 25%, the K and Na content in the biomass ash are 5%, the bed material is quartz sand, the particle size is 1.2mm, and the biomass ultra-high speed is added through the inlet 104 with a pressure of -200Pa. Self-equilibrium gasification equipment 1, biomass ultra-high-speed self-equilibrium gasification equipment 1, the bottom cone speed is 3.5m / s, the temperature of the dense phase zone is 780°C, the temperature of the middle dilute phase zone is 825°C, and the temperature of the generated high-temperature gas is 790°C. After the cyclone separator 2 is dedusted, the gas passes through the gas heat exchanger 3 for heat exchange, and the temperature drops to 420°C. The high temperature gas blower 9 sends the cooled gas into the gas burner 501 in the furnace chamber of the boiler 5 for combustion. The combusted boiler exhaust gas is mixed into the return air with an oxygen content of 21% by the exhaust g...

Embodiment 2

[0061] The raw material is cotton stalk, the length is 5cm, the water content is 40%, the K and Na content in the biomass ash is 35%, the bed material is alumina pellets, the particle size is 3mm, and the biomass ultra-high-speed is added through the feeding port 104 with a pressure of 0Pa. Self-equilibrium gasification equipment 1, biomass ultra-high-speed self-equilibrium gasification equipment 1 bottom cone speed 7m / s, dense phase zone temperature 645 ℃, central dilute phase temperature 678 ℃, high temperature gas temperature 630 ℃, through the cyclone After the separator 2 is dedusted, the gas passes through the gas heat exchanger 3 for heat exchange, and the temperature drops to 400°C. The high temperature gas blower 9 sends the cooled gas into the gas burner 501 in the furnace chamber of the boiler 5 for combustion. The combusted boiler exhaust gas is mixed into the return air with an oxygen content of 1% through the exhaust gas pressurization mixing device 7, and is pas...

Embodiment 3

[0063] The raw material is rice husk, the moisture content is 12%, the K and Na content in the biomass ash is 6%, the bed material is alumina pellets, the particle size is 4mm, and the biomass is added through the feed port 104 with a pressure of -300Pa at an ultra-high-speed self-balancing Gasification equipment 1, biomass ultra-high-speed self-equilibrium gasification equipment 1 The bottom cone speed is 4.5m / s, the temperature of the dense phase zone is 780°C, the temperature of the middle dilute phase zone is 795°C, and the temperature of the generated high-temperature gas is 755°C, which is separated by a cyclone. After the dedusting in the device 2, the gas is heated by the gas heat exchanger 3, and the temperature drops to 450 °C. The high temperature gas blower 9 sends the cooled gas into the gas burner 501 in the furnace chamber of the boiler 5 for combustion. The combusted boiler exhaust gas is mixed into the return air with an oxygen content of 7% through the exhaus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com