Comb roller drafter of swirl spinner

A drafting device and spinning machine technology, applied in the field of swirl spinning machine, can solve the problems of limited sliver drafting and fiber transfer, many processes, long process, etc., so as to improve the adaptability of raw materials and wide adaptability , the effect of improving the straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

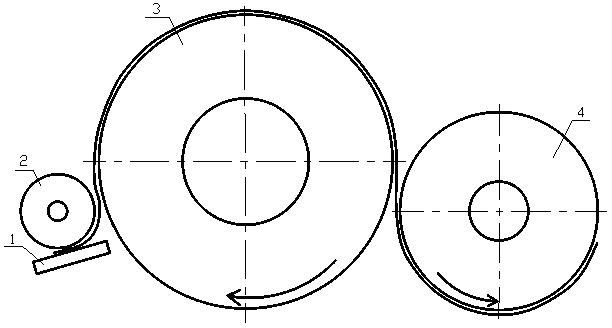

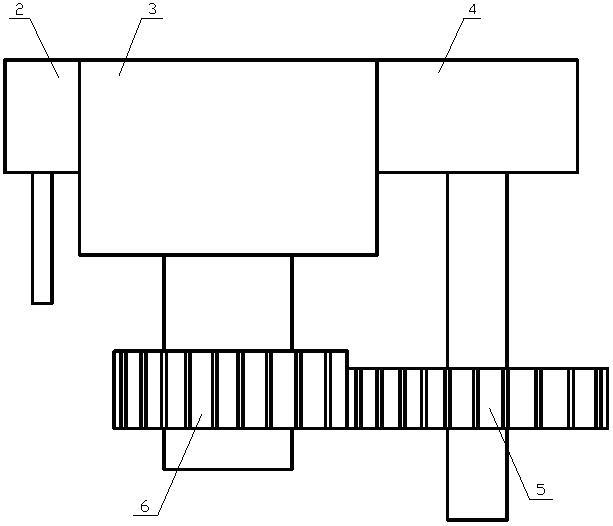

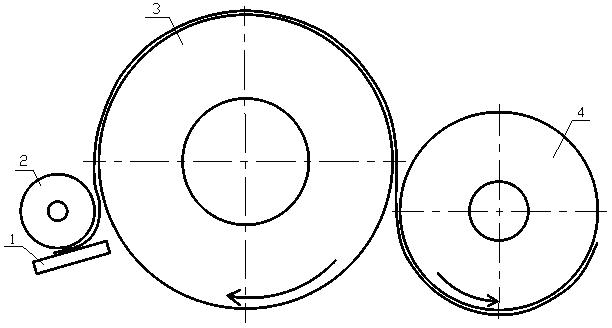

[0013] A carding device for a rotor spinning machine, comprising a cotton feeding plate 1 and a cotton feeding roller 2, the cotton feeding plate 1 is arranged below the cotton feeding roller 1, and a carding roller 3 is arranged behind the cotton feeding roller 2. A small opening roller 4 is added behind the roller 3, the large gear 6 is arranged on the rotating shaft of the opening roller 3, the pinion 5 is arranged on the rotating shaft of the small opening roller 4, the diameter of the feeding roller 2 is 70mm, and the opening roller The diameter of 3 is 280mm, and the diameter of little opening roller 4 is 230mm.

Embodiment 2

[0015] A carding device for a rotor spinning machine, comprising a cotton feeding plate 1 and a cotton feeding roller 2, the cotton feeding plate 1 is arranged below the cotton feeding roller 1, and a carding roller 3 is arranged behind the cotton feeding roller 2. A small opening roller 4 is added behind the roller 3, the large gear 6 is arranged on the rotating shaft of the opening roller 3, the pinion 5 is arranged on the rotating shaft of the small opening roller 4, the diameter of the feeding roller 2 is 80mm, and the opening roller The diameter of 3 is 320mm, and the diameter of little opening roller 4 is 270mm.

Embodiment 3

[0017] A carding device for a rotor spinning machine, comprising a cotton feeding plate 1 and a cotton feeding roller 2, the cotton feeding plate 1 is arranged below the cotton feeding roller 1, and a carding roller 3 is arranged behind the cotton feeding roller 2. A small opening roller 4 is added behind the roller 3, the large gear 6 is arranged on the rotating shaft of the opening roller 3, the pinion 5 is arranged on the rotating shaft of the small opening roller 4, the diameter of the feeding roller 2 is 100mm, and the opening roller The diameter of 3 is 400mm, and the diameter of little opening roller 4 is 350mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com