Patents

Literature

34results about How to "Physical indicators improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-worsted ultra-thin double-faced overcoating wool fabric

The invention discloses a semi-worsted ultra-thin double-faced overcoating wool fabric. The fabric is formed by blending high-quality wool with tencel fibers, warp yarns and weft yarns of the fabric are semi-worsted yarns, the fabric keeps a double-faced wool style and each square meter of fabric is 530 to 550g. In a processing method, a coarse spinning and fine weaving mode is adopted, the warp yarns and the weft yarns of the fabric are the semi-worsted yarns, positive and negative fluffing double-evaporation multi-cutting process technology is adopted in the after finishing process, and ironing and preshrinking technology and a low-temperature multi-ironing process are adopted, so that the true color of the high-quality wool is displayed, and the positive and negative surfaces of the fabric have the same shrinkage due to the preshrinking process; and teasel inverse combined overcoating technology is adopted, and two teasels jointly work to finish a positive and negative overcoating process at one time inversely. The invention has the advantages that: the fabric can keep the double-faced wool style and meets the consumption requirement that people pursue health and fashion currently.

Owner:张家港市金陵纺织有限公司

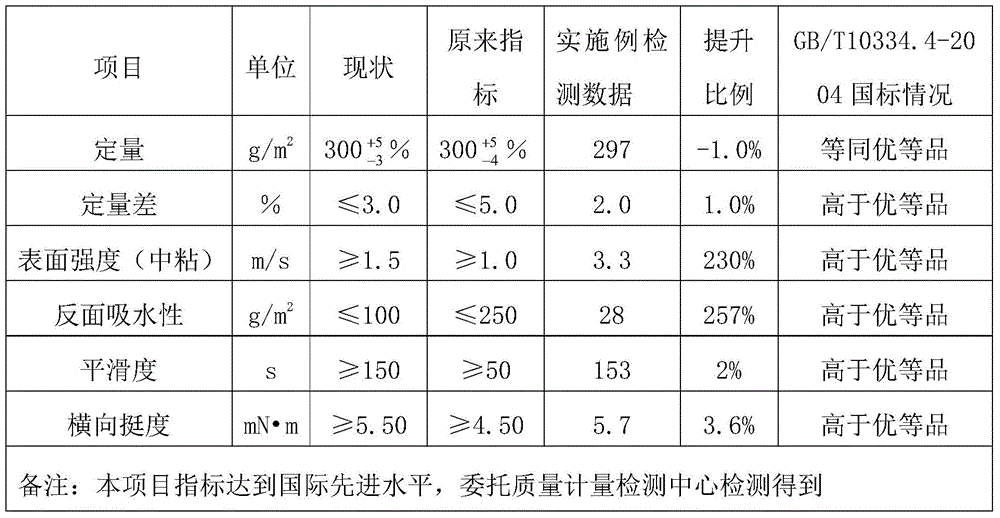

Liner paper for environment protection cigarette

InactiveCN1888308ANo smellNo toxicityFlexible coversCoatings with pigmentsPulp and paper industryPrinting ink

The present invention relates to an internal lining paper for environment-protecting cigarette. It is made up by coating water printing ink on the surface of raw paper. The smoothness of raw paper is greater than on equal to 1000S, unit area paper weight is 60-80g / sq.m, water content is less than 35g / sq.m, thickness is 0.05-0.07 mm and the dose of water printing ink (by solid content) is 4-7g / sq.m. The procedures for coating printing ink are successively as follows: placing paper, leveling, tensioning, coating, drying, calendaring and rolling up.

Owner:CHANGDE FURONG INDAL DEV

Preparation of organic anion particle for particulate retention aid and filtering aid system of papermaking and uses thereof

InactiveCN101492899ASpeed up water filtrationGuaranteed uptimeWater-repelling agents additionPaper/cardboardPolyamideChemistry

The invention relates to organic anion particles for a retention and drainage aid system for papermaking wet part particles, a preparation method thereof and application thereof. The organic anion particles are anion dendritic macromolecules prepared by modifying end groups of end ester-group semi-substituted dendritic polyamide-amine. The preparation method comprises a step that a tail end group -COOCH3 on the outer layer of the semi-substituted dendritic polyamide-amine is hydrolyzed under alkali conditions to become -COONa so as to prepare the anionic dendritic polyamide-amine. The anionic dendritic polyamide-amine as the organic particles is used for the retention and drainage aid system for the papermaking wet part particles, and is used as an anionic particle component separately or synergistically with colloid silicon dioxide, structural silicon dioxide or bentonite, so that the retention rate of paper is improved, the drainage property is improved, and the papermaking evenness and the physical property are good.

Owner:QILU UNIV OF TECH

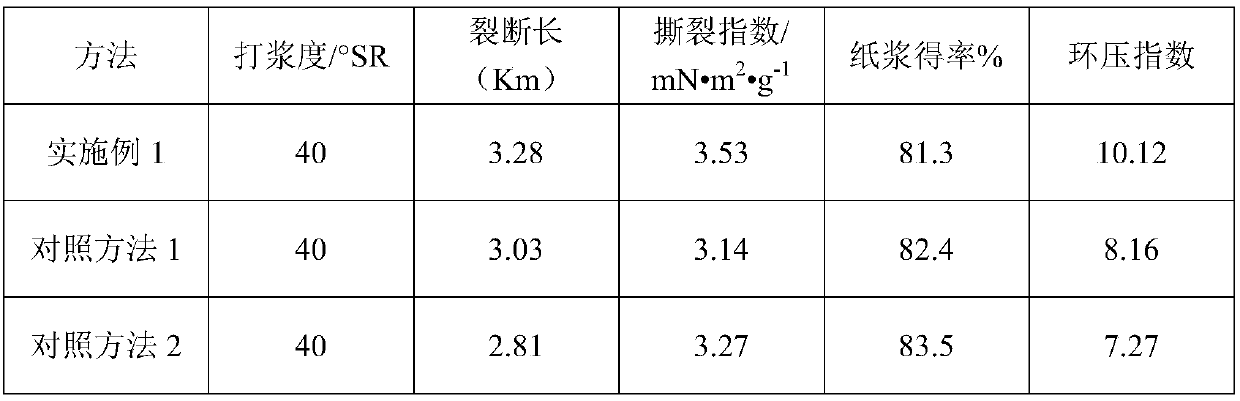

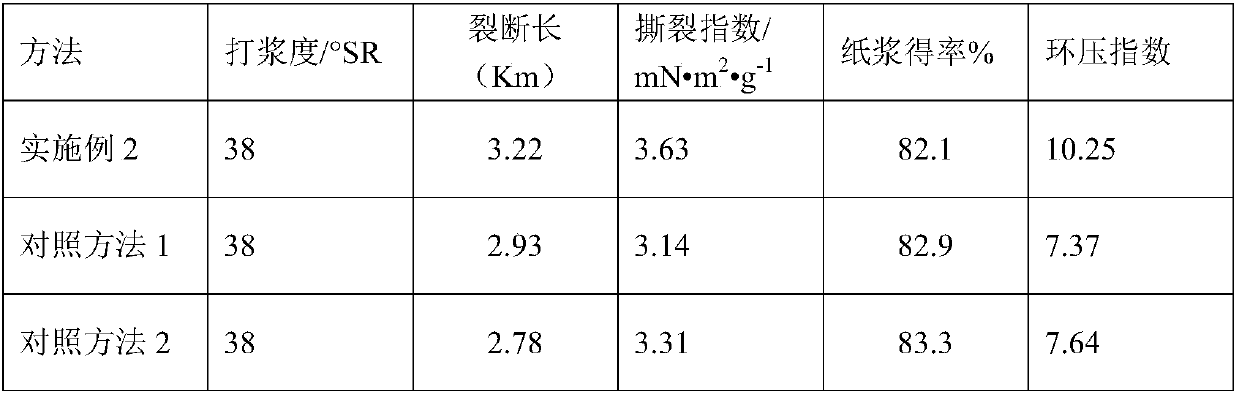

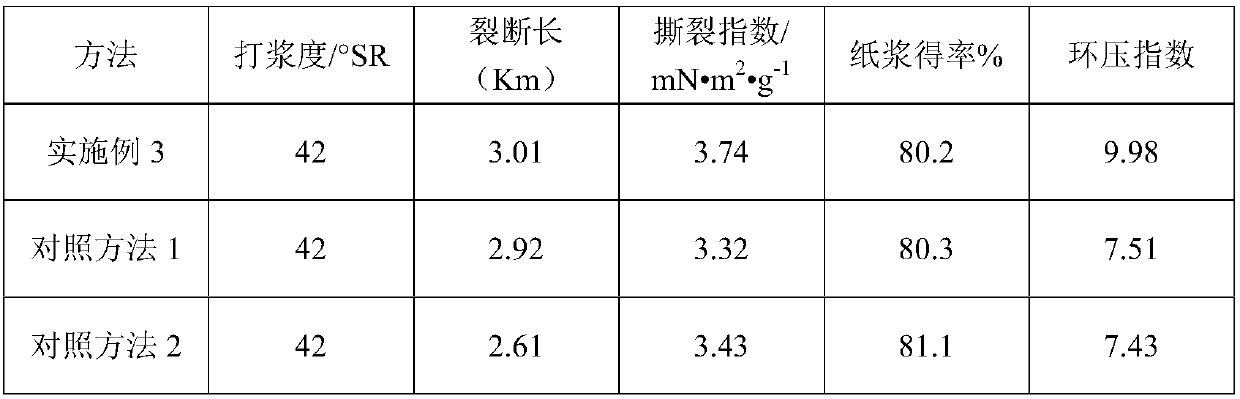

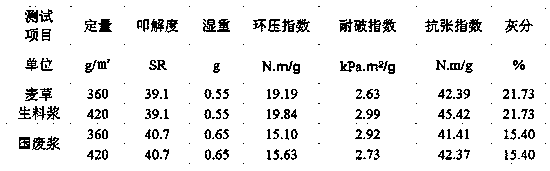

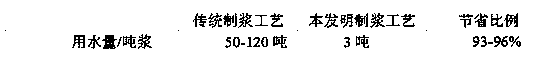

Method for preparing biomechanical unbleached pulp from wheat straw

ActiveCN109577072AAvoid pollutionSave resourcesPretreatment with water/steamPretreatment with alkaline reacting compoundsState of artPapermaking

The invention belongs to the field of papermaking technologies and novel materials, and particularly relates to a method for preparing biomechanical unbleached pulp from wheat straw. The method includes pretreating grass by hot water and hot steam; adding trace alkali into the grass and carrying out hot water saturation softening treatment on the grass; adding alkaline biological enzymes into thegrass and carrying out enzyme treatment, pulping and washing. The grass is used as a raw material for the biomechanical unbleached pulp. The method has the advantages that alkali recycling can be omitted in integral production procedures, and environmental pollution can be prevented from the source; the method conforms to the national industry policy of resource conservation, economic cycle, energy conservation and emission reduction; the problems of difficulty in recycling straw pulp alkali wastewater and severe pollution in the prior art can be solved by the aid of the method; the method hasimportant significance in industrial production of straw pulp and the development of the papermaking industry.

Owner:QILU UNIV OF TECH

Processing method for large-scale foaming decorating part

The invention discloses a processing method for a large-scale foaming decorating part. The method comprises the following steps: the material in a mixing and batching system is conveyed to a robot casting system via a foaming system; the material is continuously cast into lower molds of a combined mold vehicle through the robot system; according to program instructions, the upper mold set of the combined mold vehicle automatically complete the actions of turning over molds, closing molds and locking molds of the upper mold set; after the polyurethane product in the mold cavity is subjected to precuring operation, according to the program control instructions, the upper mold set automatically opens the molds, and at least completes exhaust action once; after the exhaust time controlled by the program is over, the upper mold set automatically closes and locks the molds, and locks the molds according to the program until the product is completely cured. The processing method for the large-scale foaming decorating part has the advantages that the exhaust working procedure is realized, the traveling and positioning of the mold vehicle are accurate, the void fraction of the formed product is low, the manufacturing precision of the formed product is high, the foaming density fluctuation of the product is low, and the physical index is high.

Owner:湖南亚太实业有限公司

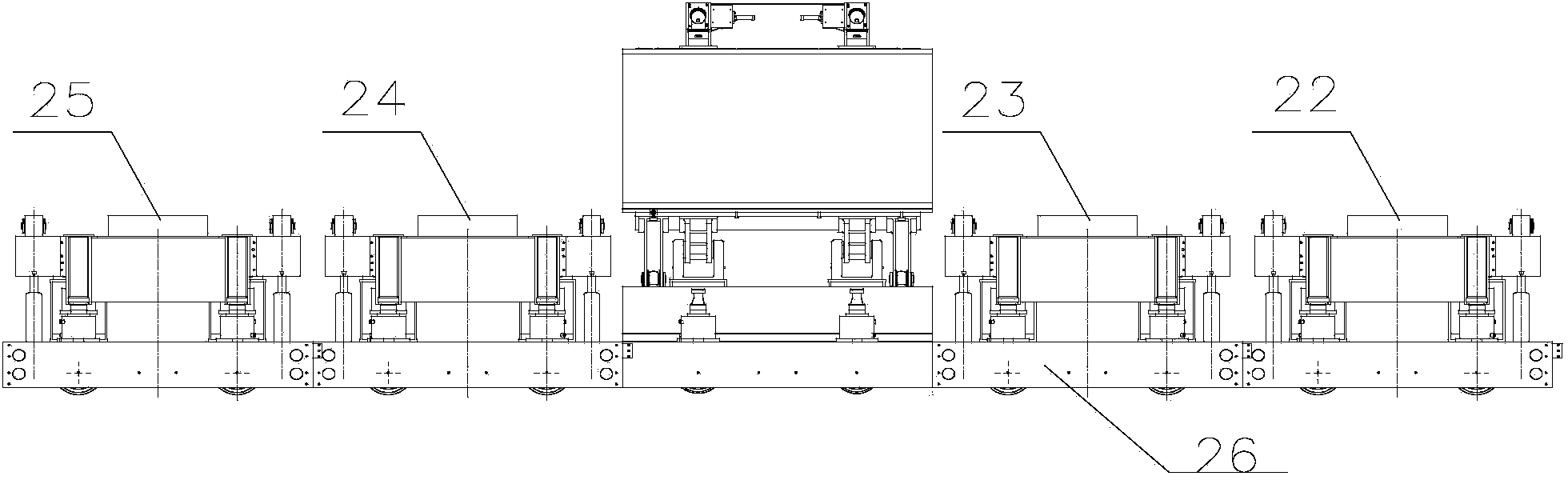

High-density doped trimanganese tetroxide and preparation method thereof

ActiveCN103050680AGood doping uniformityGood particle shapeCell electrodesManganates/permanganatesHigh densityRare earth

The invention discloses high-density doped trimanganese tetroxide. The chemical formula of the high-density doped trimanganese tetroxide is Mn3O4*zMxOy, wherein z is within the range of 0.01-0.3; and MxOy is one or several of MgO, Ni2O5, Co3O4, Cr2O3, Al2O3, ZrO2, V2O5 and TiO2, or rare earth oxide. The physical indexes of the high-density doped trimanganese tetroxide are as follows: D50 (particle size) is within the range of 3-25 microns; the tap density is within the range of 2.1-2.6 g / cm3; BET is within the range of 1 to 4 m<2> / g; and the particle morphology is a spherical shape. The invention further discloses a preparation method for the trimanganese tetroxide; the method enables manganese to be continuously agglomerated with doped oxide in the process of being converted to the trimanganese tetroxide; and the growth direction and the growth speed of agglomerates are controlled by using the pH value, the reaction temperature and the adding quantity of ammonium salt catalyst to obtain the doped trimanganese tetroxide with good doping uniformity, good particle morphology and high density.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

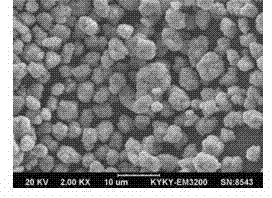

Elastic wick gray fabric weaving and dyeing-finishing process

InactiveCN102912647AReduce steam consumptionLow costBiochemical fibre treatmentBleaching apparatusEngineeringOxygen

The invention provides an elastic wick gray fabric weaving and dyeing-finishing process. The process comprises the following steps of: selecting raw materials; slashing; weaving by virtue of a machine; checking a gray fabric; brushing folding; singeing; boiling and dyeing; preshrinking; and stentering and sizing, so that a finished product is obtained. The step of boiling and dyeing adopts a method of cooling stacking, rinsing by using oxygen and dyeing under a cooling stacking condition, wherein the cooling stacking step is as follows: stacking the singeing gray fabric after being soaked by a desizing enzyme for 24 hours; the temperature for the rinsing by using the oxygen is 100-105 DEG C, and the rinsing time is 30-40 minutes; and the step of dyeing under a cooling stacking condition is as follows: soaking semi-rinsing fabric after the rinsing by using the oxygen in a dyeing agent tank for 3-5 minutes, taking out and stacking at the normal temperature for 24 hours. According to the elastic wick gray fabric weaving and dyeing-finishing process, the gray fabric cost and the dyeing cost can be greatly reduced on the premise that the finished product fabric can meet various index requirements.

Owner:TUNGGA LINENANDCOTTON CO LTD

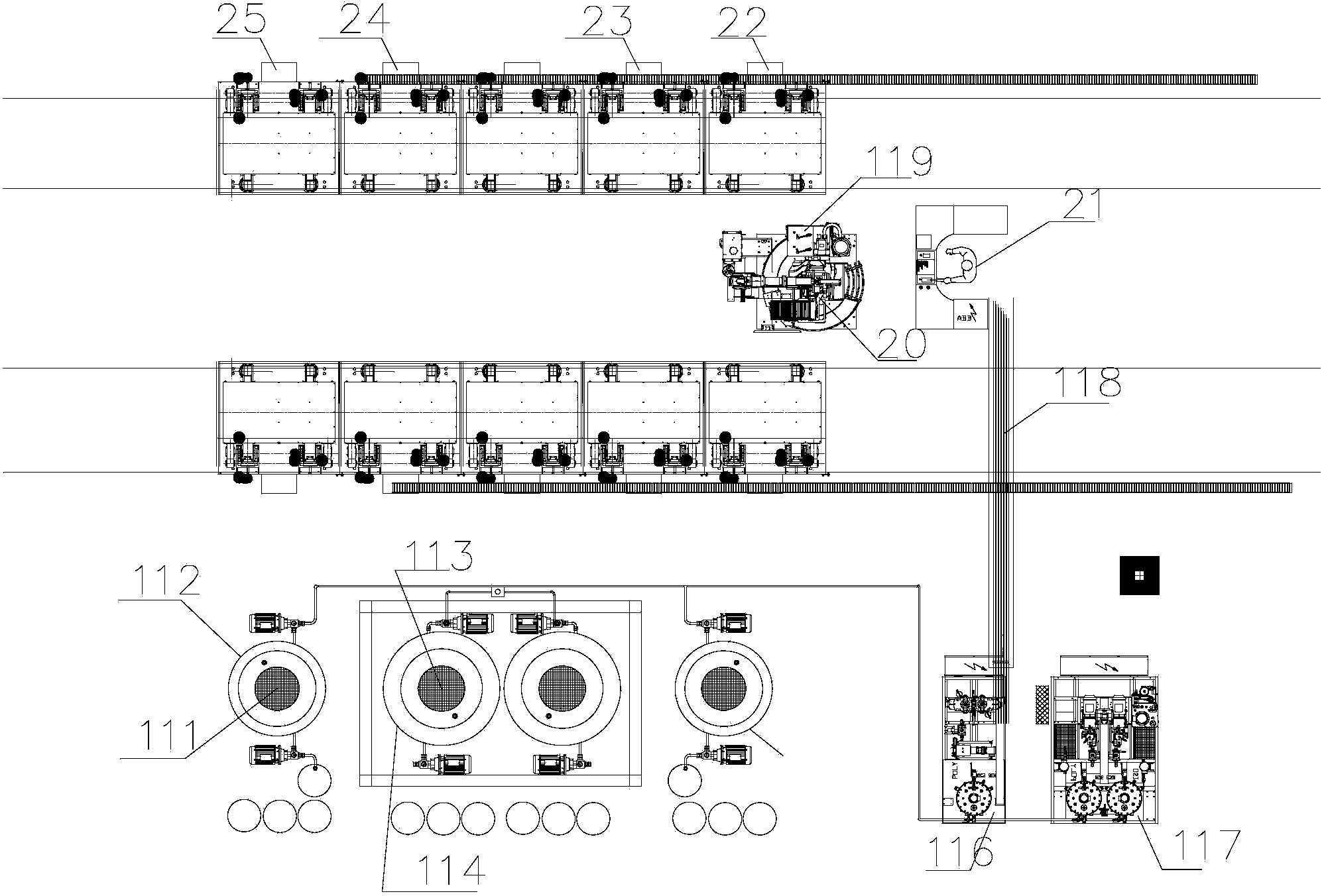

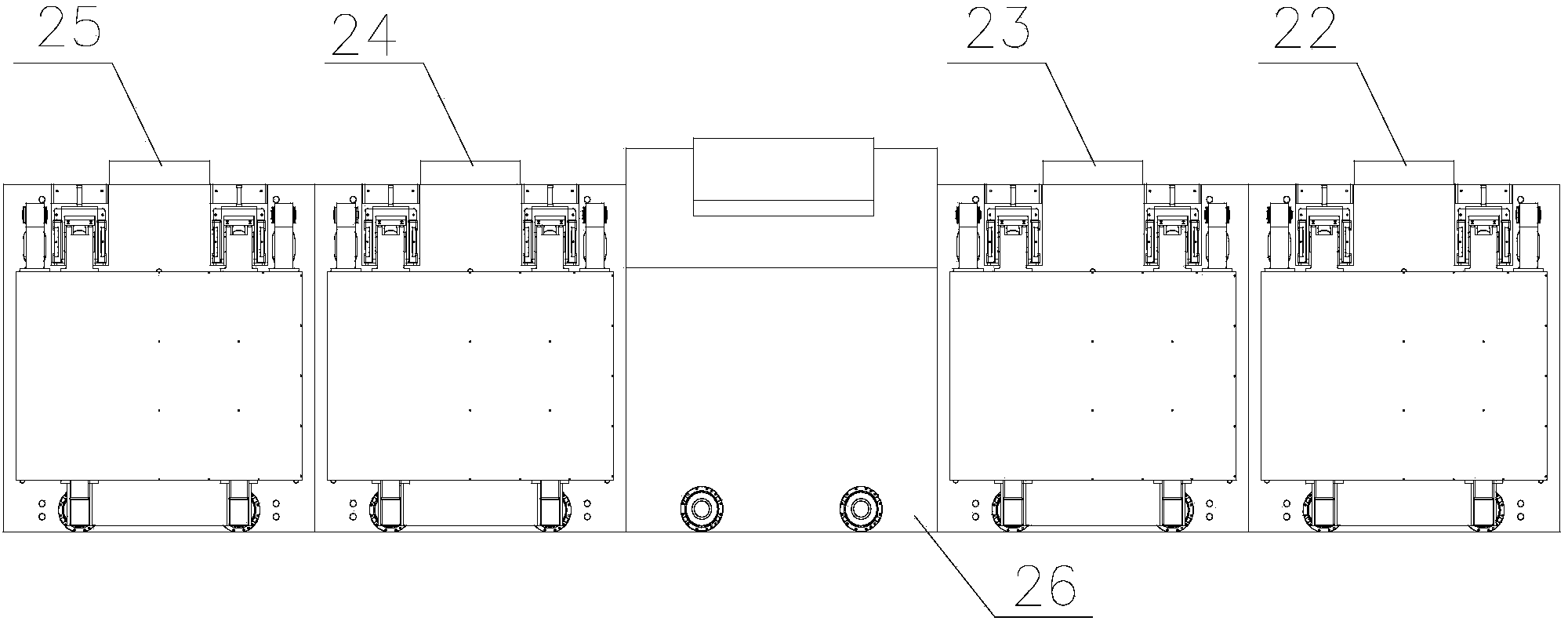

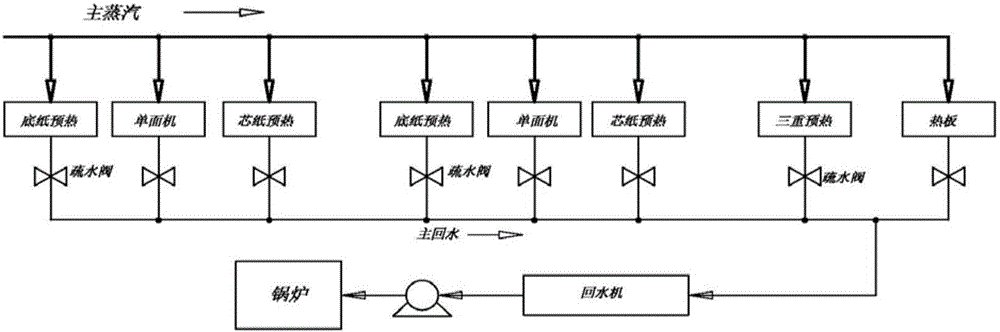

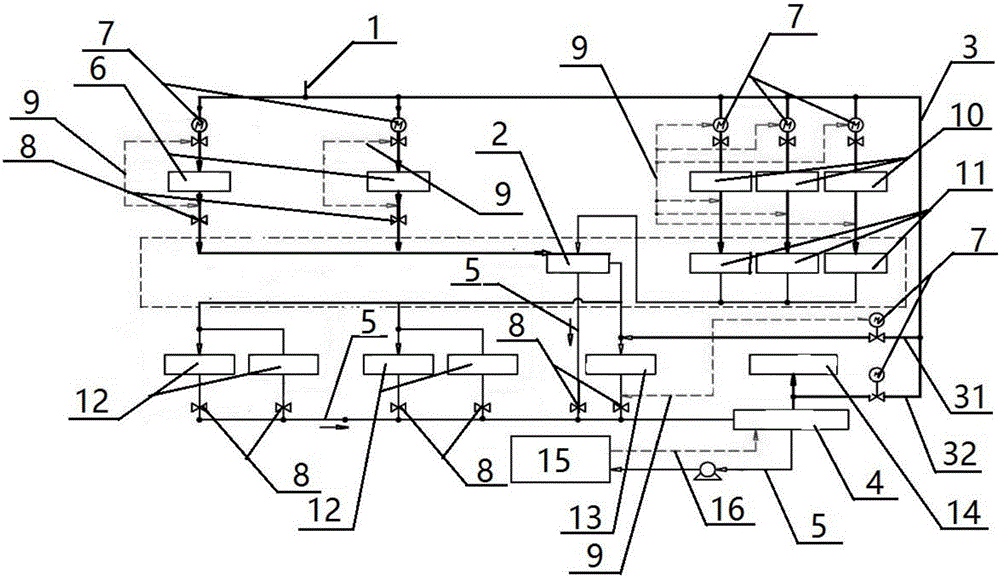

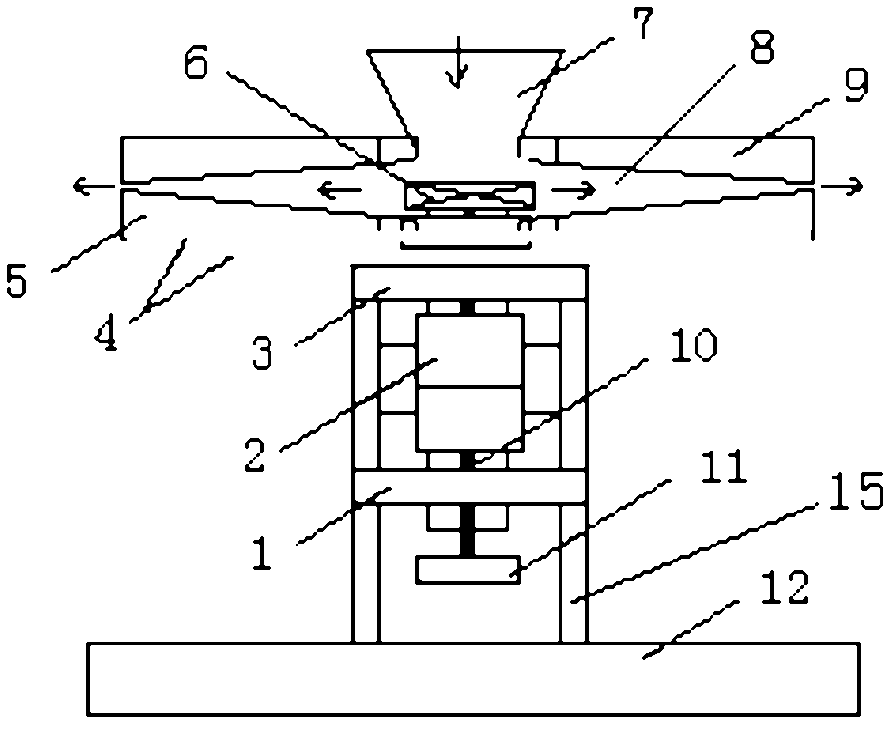

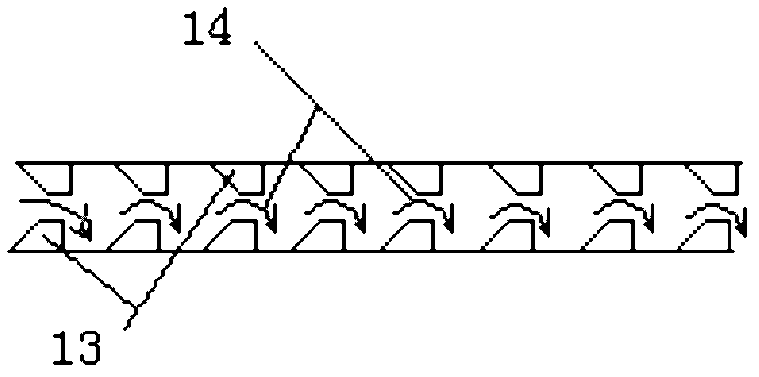

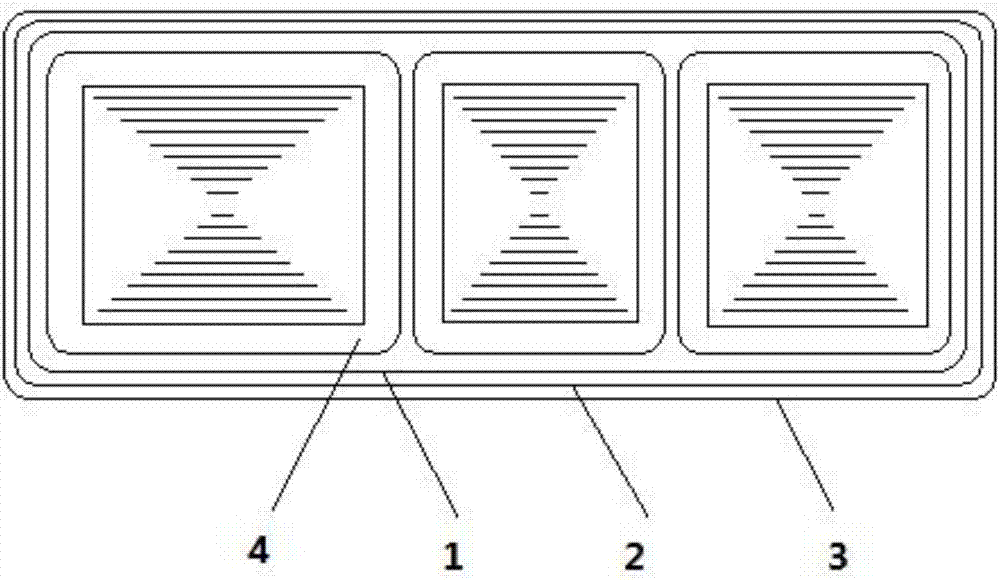

Corrugated paper board production line

InactiveCN106042460APhysical indicators improvedPress wellMechanical working/deformationFiberCardboard

The invention discloses a corrugated paper board production line. A single-face machine system, a multi-face machine system and an adjusting pipeline are arranged between a main vapor opening and water-vapor separation equipment in a parallel connection manner. The water-vapor separation equipment is connected with a water return machine, a paper board preheating system and a three-time utilization system. After water-vapor separation, vapor enters the paper board preheating system and the three-time utilization system, and vapor coming out of the paper board preheating system enters the water return machine through a water return pipeline. The adjusting pipeline is connected with the three-time utilization system. The corrugated paper board production line is provided with a pressure and temperature closed-loop feedback system, and therefore the temperature in the production process can be controlled to be below the temperature of the paper making process, damage to the water balance of body paper is the minimum, and body paper fibers can keep the original state; and therefore it is guaranteed that produced corrugated paper boards are smoother, the physical index is greatly increased, and the edge pressure and break resisting data of the corrugated paper boards are better.

Owner:KUNSHAN MINGPENG PAPER IND

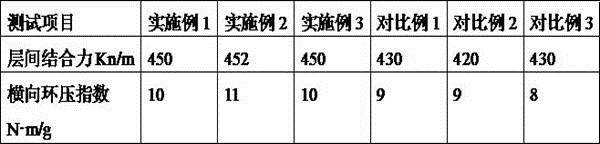

Preparation method of moisture-regaining-resistant anti-layering high-strength environment-friendly kraft liner cardboard paper

InactiveCN111979815AEasy to preparePhysical indicators improvedNon-fibrous pulp additionDryer sectionCardboardProcess engineering

The invention discloses a preparation method of moisture-regaining-resistant anti-layering high-strength environment-friendly kraft liner cardboard paper. The preparation method comprises the following steps of (1) pulping; (2) grading; (3) papermaking and forming; (4) squeezing and drying; and (5) sizing. The preparation method is simple, and the interlayer bonding force of the prepared finishedpaper reaches 450 KN / m; the water absorption degree of the finished paper reaches 40s / 50s on the front and back sides, and the complete penetration of the paper sheet is more than 180s; the energy consumption of the finished paper reaches 195 kgce / t and reaches the advanced value specified in GB 31825-2015 'pulping and papermaking unit product energy consumption limit'; and the physical index of the finished paper is higher than the quality requirement of GBT 13024-2016 'box board'.

Owner:JIANGSU LEE & MAN PAPER MFG

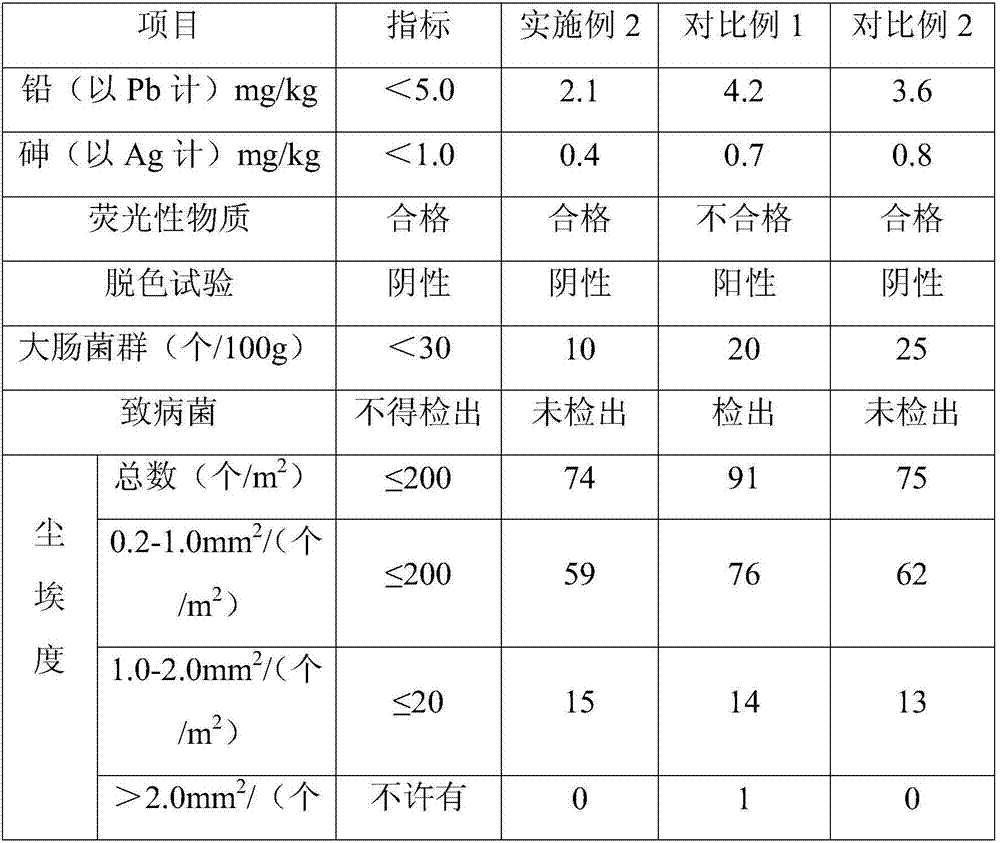

Non-wood unbleached pulp food warp paper and preparation method thereof

ActiveCN107090737ALow costReduce manufacturing costNon-fibrous pulp additionFlexible coversPaper sheetPapermaking

The invention discloses a non-wood unbleached pulp food wrap paper and a preparation method thereof. Slurry of the non-wood unbleached pulp food wrap paper is prepared from unbleached straw pulp and unbleached bamboo pulp, the fixed quantity of the wrap paper ranges from 45 g / m<2> to 65 g / m<2>, and the content of synthetic papermaking additives accounts for 0.5%-2.5% of oven dry stock. The wrap paper is safe and environmentally friendly, the natural color of plant fiber is kept, dust and chips do not exist, no hazardous substance is produced in a papermaking technology, the waste water treatment cost is lowered, and the production cost is low.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

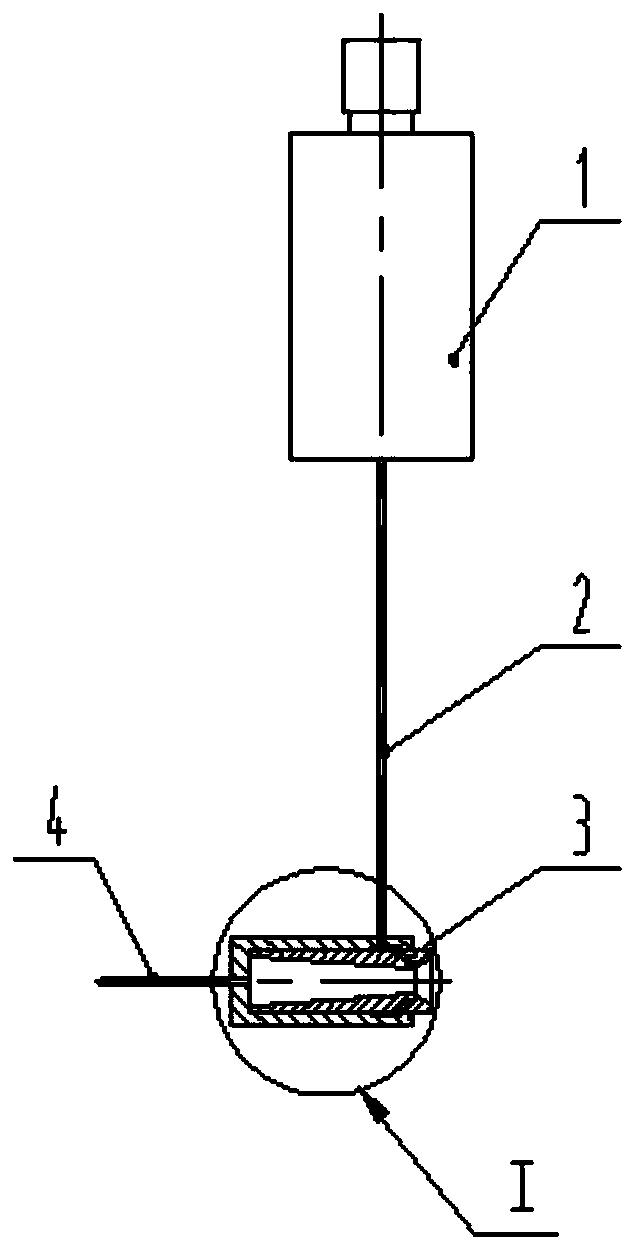

ZYX catalyst for preimpregnation catalysis of plant fiber pulping and process utilizing the same

ActiveCN109537352AHigh strengthUniform lengthCorrosion-inhibiting/anti-oxidant agent additionCellulose treatment using microorganisms/enzymesFiberSulfonate

The invention relates to the field of pulping and papermaking, and particularly relates to a ZYX catalyst for preimpregnation catalysis of plant fiber pulping and a process utilizing the same. The catalyst is environmentally friendly and efficient and includes anhydrous sodium sulfate, sodium hydroxide, sodium dodecyl sulfonate, cellulase, a fiber softening degrading agent, a preservative, and thelike. The pulping process utilizing the catalyst avoids heating, soaking and water emission, and allows a raw material to be naturally catalyzed, heated and softened; produced fiber pulp is uniform in fiber length, high in strength and good in toughness; waste liquid is low in emission and low in pH value, and can be recovered, thus avoiding passivation of secondary application effect, protectingthe environment, and achieving a low cost and a high efficiency. The process is a model for clean pulping.

Owner:郓城海沁纤维有限公司

High-strength colored organic flame-retardant regenerated cellulose fiber and preparation method thereof

ActiveCN105297164AHigh color fastnessAvoid pollutionArtificial filament washing/dryingMonocomponent cellulose artificial filamentPolymer scienceSpinning

The invention relates to the technical field of regenerated cellulose fibers, in particular to a preparation method of a high-strength colored organic flame-retardant regenerated cellulose fiber. The preparation steps include the procedure of preparing a spinning solution, the procedure of preparing flame-retardant spinning adhesives, the procedure of spinning, and the procedure of post-processing. In the procedure of preparing the flame-retardant spinning adhesives, flame retardants, denaturants and color paste need to be added after the procedure of preparing the spinning solution, organic pyrophosphate flame retardants are adopted as the flame retardants, polyoxyethylene fatty amine is adopted as the denaturants, and the particle size of the color paste is required to be smaller than or equal to 0.5 micron. The limit oxygen index of the flame-retardant fiber prepared through the method is larger than or equal to 28.0%, the cotton staining grade and the original sample color changing grade of the fiber are both higher than the fourth grade, and the color fastness is good. Environmental protection pressure caused by subsequent dyeing of downstream customers is greatly reduced, and the flame-retardant performance attenuation problem caused by high temperature dyeing is solved. The mode that drying is performed before cutting is adopted for the post-processing procedure, the mixing problem of fibers in different colors is avoided, and production cost is greatly reduced.

Owner:潍坊欣龙生物材料有限公司

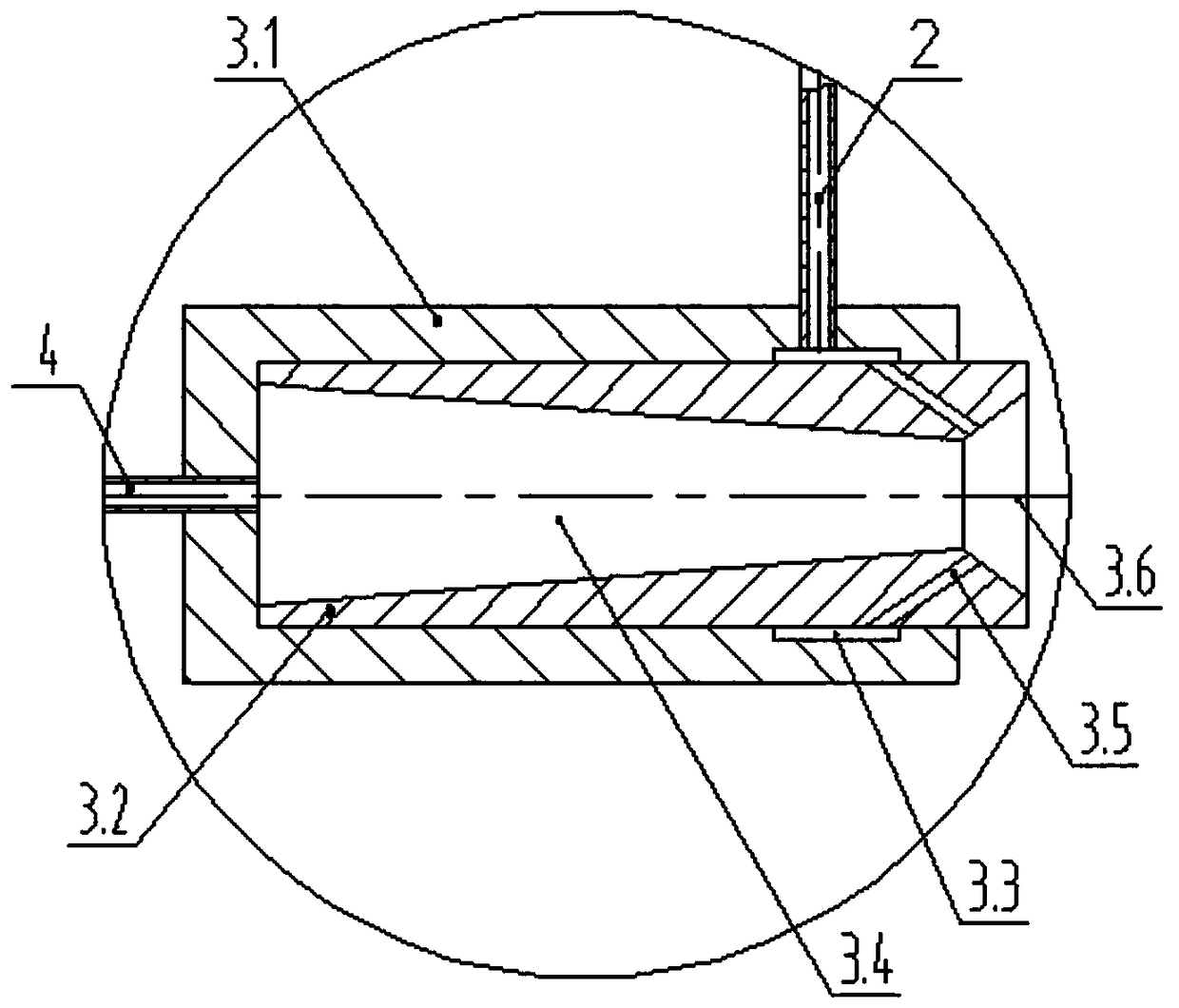

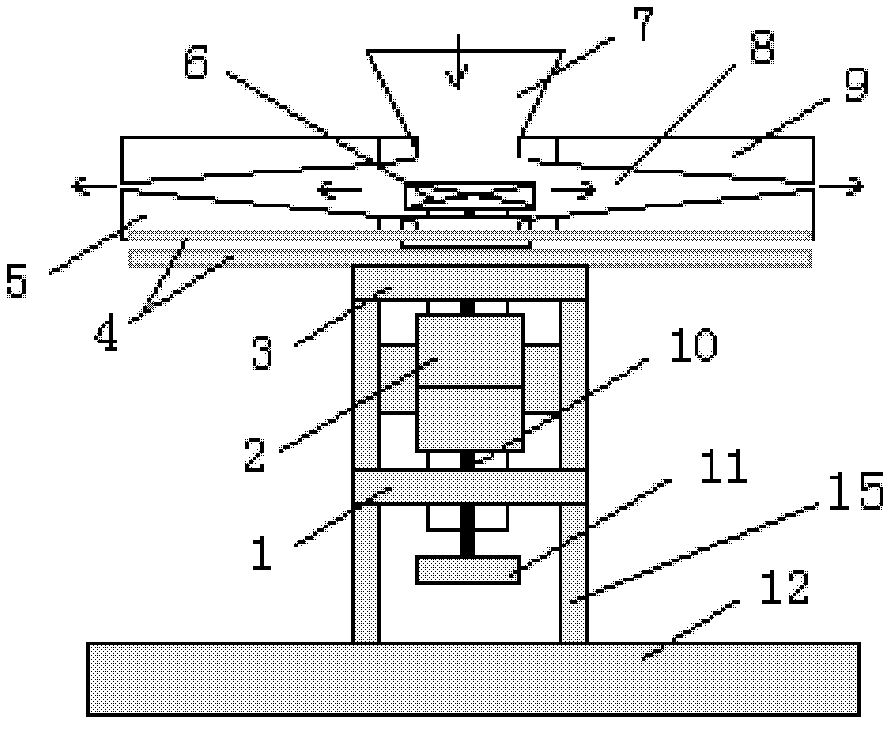

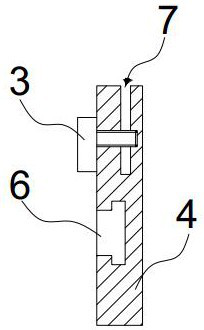

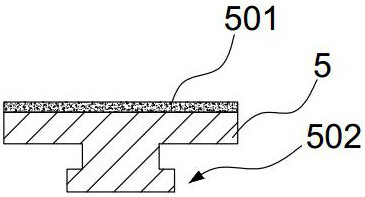

Water mist spraying device of air splicer

PendingCN109402809AHigh strengthPhysical indicators improvedPiercing arrangementsEngineeringWater spray

The invention discloses a water mist spraying device of an air splicer. The device comprises a water storing device, a water conveying pipe, an air conveying pipe and a spraying head; the spraying head comprises an outer sleeve and an inner sleeve; the central axis of the inner sleeve is horizontal, a through hole is formed, and the right end of the through hole is expanded to the right end surface of the inner sleeve to form a trumpet-shaped hole; the central axis of the outer sleeve is horizontal, a blind hole with the closed left end is formed, and an annular groove is formed in the inner wall of the blind hole; the outer sleeve sleeves the left end of the inner sleeve, and the left end of the through hole of the inner sleeve is closed; the water storing device is arranged on the spraying head, and the upper end of the water conveying pipe is communicated with the lower end of the water storing device; the lower end of the water conveying pipe is communicated with the annular grooveof the outer sleeve; the air conveying pipe penetrates through the left end of the outer sleeve and is communicated with the through hole of the inner sleeve; several water spraying holes are formedin the side wall of the inner sleeve; the left ends of the water spraying holes are communicated with the annular groove of the outer sleeve, and the right ends of the water spraying holes are communicated with the trumpet-shaped hole at the right end of the inner sleeve; the further improved structure is that a hole at the left end of the trumpet-shaped hole at the right end of the inner sleeve is a tapered hole with the left large portion and the right small portion. The device can form better waste mist, and the evenness physical index of formed knots is significantly increased.

Owner:江苏罗曼罗兰集团有限公司

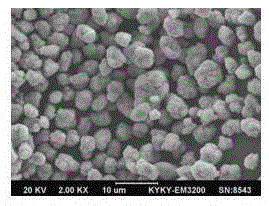

A kind of high-density doped manganese tetraoxide and its preparation method

ActiveCN103050680BPhysical indicators improvedEvenly dopedCell electrodesManganates/permanganatesHigh densityRare earth

The invention discloses high-density doped trimanganese tetroxide. The chemical formula of the high-density doped trimanganese tetroxide is Mn3O4*zMxOy, wherein z is within the range of 0.01-0.3; and MxOy is one or several of MgO, Ni2O5, Co3O4, Cr2O3, Al2O3, ZrO2, V2O5 and TiO2, or rare earth oxide. The physical indexes of the high-density doped trimanganese tetroxide are as follows: D50 (particle size) is within the range of 3-25 microns; the tap density is within the range of 2.1-2.6 g / cm3; BET is within the range of 1 to 4 m<2> / g; and the particle morphology is a spherical shape. The invention further discloses a preparation method for the trimanganese tetroxide; the method enables manganese to be continuously agglomerated with doped oxide in the process of being converted to the trimanganese tetroxide; and the growth direction and the growth speed of agglomerates are controlled by using the pH value, the reaction temperature and the adding quantity of ammonium salt catalyst to obtain the doped trimanganese tetroxide with good doping uniformity, good particle morphology and high density.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

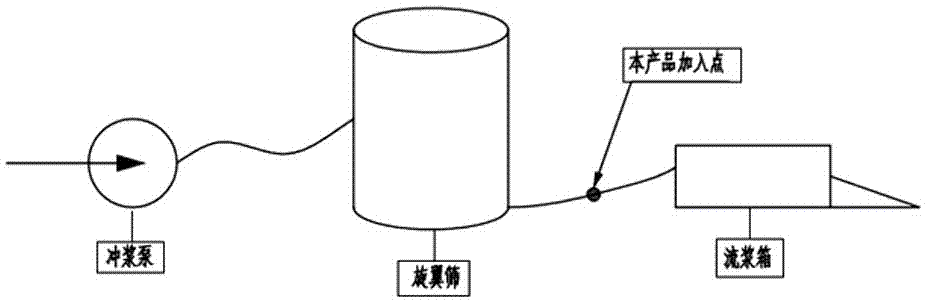

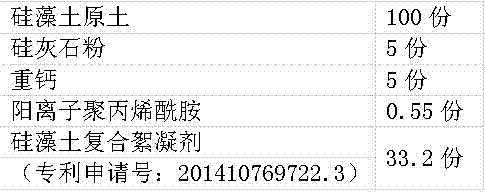

A functional filler additive used in the field of papermaking

The invention relates to a functional filler additive used in the field of papermaking. The filler additive is made of the following raw materials in proportion by weight: 100 parts of raw diatomite, 5 parts of wollastonite powder, 5 parts of heavy calcium, 0.55 parts of cationic polyacrylamide, 33.2 parts of diatomite composite flocculant (patent application number: 201410769722.3), the present invention has eight major functions, namely: increase the pulp saving rate, prolong the service life of felt and mesh cloth, ease the burden of sewage treatment, and increase production , Improve paper physical indicators (ring pressure strength, strength tensile force, surface finish, color), save energy, save drying steam, help retention and drainage, and cost-effective.

Owner:LINJIANG MINGSHENG DIATOMS NEW MATERIALS CO LTD

A production process of advanced coated white paperboard

InactiveCN103437232BEmission reductionHigh removal rateFats/resins/pitch/waxes removal in pulpWater-repelling agents additionControl systemQuality control system

The invention belongs to the technical field of a coating white paper board production method. A high-grade coating white paper board production process comprises the steps of pulping and paper making, wherein the pulping step adopts the separated and segmented beating modes including surface pulp beating, lining pulp beating, core pulp beating and bottom pulp beating, the paper making step comprises a net part, a squeezing part, a drying part and a coating and QCS (quality control system) control system, and in addition, a film transfer sizing machine is added in the middle of the drying part. Modes completely different from the traditional mode are adopted in the coating white paper board beating process and the paper making process, the process improvement is carried out on several key control points, the technical indexes are correspondingly regulated, the energy consumption is reduced, and the subsequent paper making quality is also improved, so the quality of finished product paper is always controlled to be higher than the nationally specified A grade (high grade) index.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP +1

Vertical high-concentration beating device

InactiveCN102199889AUniform feedingConserve waterPulp beating methodsHydraulic cylinderHigh concentration

The invention discloses a vertical high-concentration beating device. The device comprises a beating mechanism and a driving mechanism of the beating mechanism, wherein the beating mechanism comprises an upper beating refiner plate, a lower beating refiner plate and a permanent magnetic buoyancy plate in sequence from top to bottom; a feed inlet is arranged at the top of the upper beating refiner plate; a beating area is arranged between the upper beating refiner plate and the lower beating refiner plate; a stirring piece is arranged in the beating area; the driving mechanism comprises a support frame, a lower bearing block and bearing, a hydraulic cylinder, an upper bearing block and bearing and a main shaft; one end of the main shaft stretches into the beating area to be connected with the stirring piece; and the hydraulic cylinder is arranged between the lower bearing block and bearing and the upper bearing block and bearing and used for adjusting the extrusion pressure of the upper beating refiner plate and the lower beating refiner plate. The vertical high-concentration beating device has simple structure and is energy-saving and environmentally-friendly.

Owner:SOUTH CHINA UNIV OF TECH

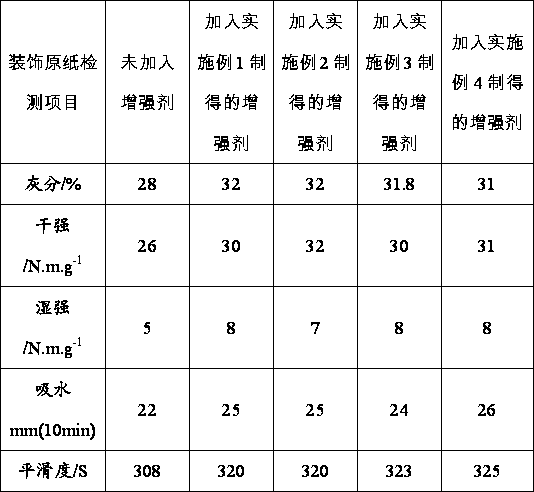

A kind of decorative base paper strengthening agent and preparation method thereof

The invention relates to the field of chemical engineering, in particular to a decorative base paper enhancer and a preparation method thereof. The enhancer comprises pigment, efficient adhesive, ammonia water, latex, defoaming agent and deionized water. The preparation method includes the following steps of adding pigment into a compounding pool to be dispersed at high speed, adding efficient adhesive and latex to water to conduct reaction at a temperature of 110-130 DEG C and to be mixed and dispersed for 15-20 min at high speed, adding ammonia water, adjusting PH with sodium hydroxide, and adding defoaming agent to be stirred for 10-25 min at low speed to obtain the enhancer product. The enhancer is an environment-friendly auxiliary, and the prepared decorative base paper enhancer is added to decorative base paper, so the addition of other chemical auxiliaries is reduced, and the shielding performance of titanium dioxide is improved. Due to the addition of the enhancer special for decorative paper, the addition of other auxiliaries is reduced, papermaking bleach can be more easily processed and reused, and water consumption is lowered. Due to the addition of pigment, wood pulp consumption can be reduced, and cost is saved.

Owner:SHANDONG YUANGEN CHEM TECH RES & DEV CO LTD

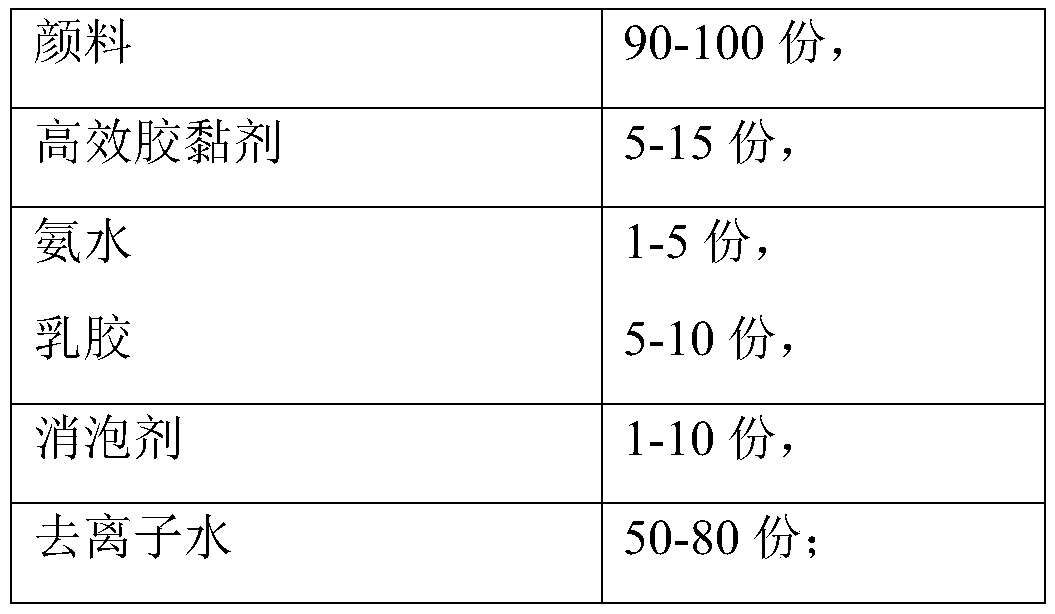

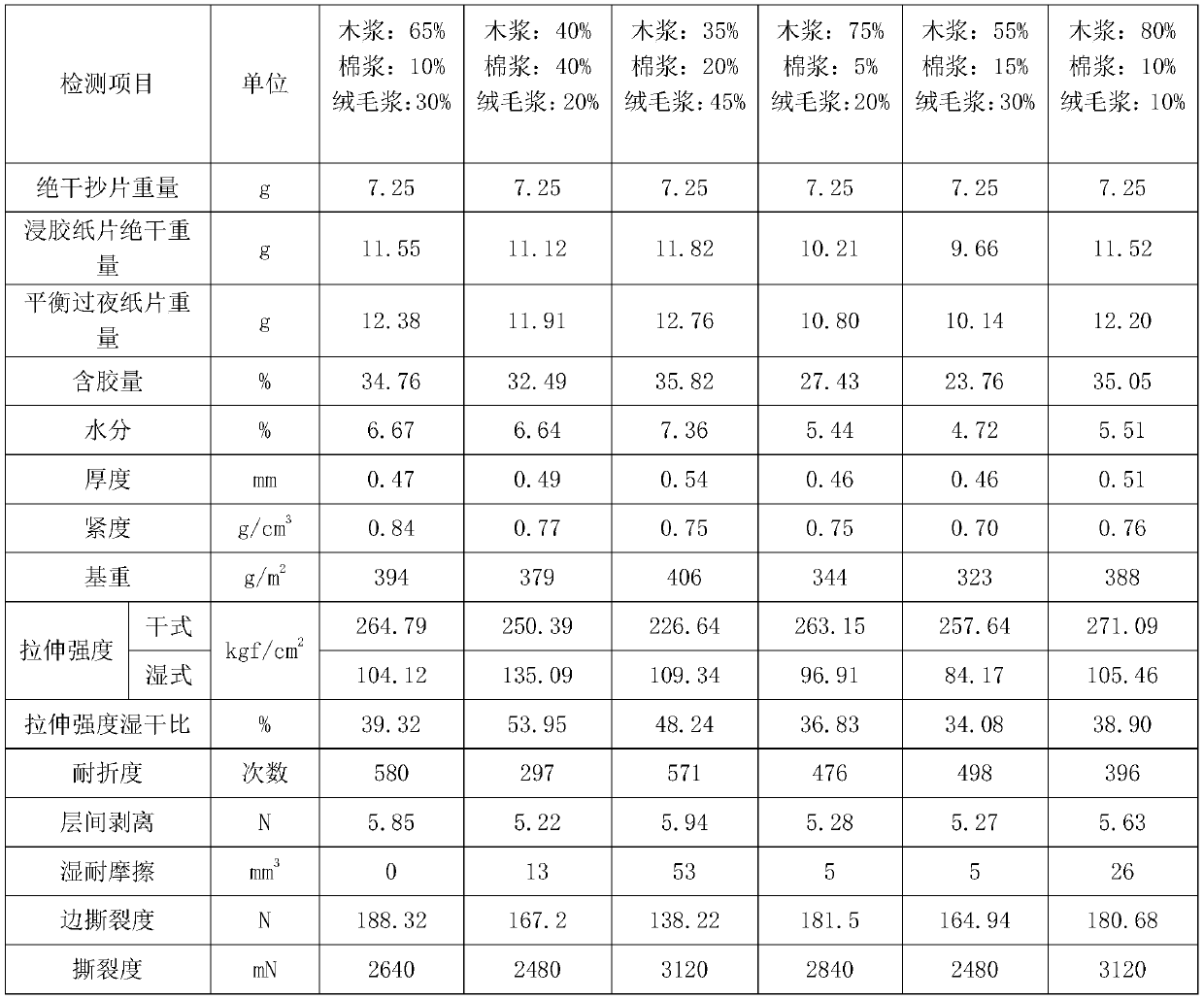

Jeans label and preparation method and sheet impregnation detecting method thereof

InactiveCN109736130APhysical indicators improvedApplicable productionReinforcing agents additionPaper/cardboardPlant fibreLatex rubber

The invention provides a jeans label and a preparation method and sheet impregnation detecting method thereof. The jeans label is prepared from, by weight, 65-70% of plant fibers, 20%-25% of a latex complexing agent, 0.1%-0.2% of an iron oxide dye, 2%-5.1% of other auxiliary agents and the balance water, wherein the total weight percent is 100%. The plant fibers are prepared from, by weight, 55%-75% of wood pulp, 5%-15% of cotton pulp and 20%-30% of fluff pulp. The latex complexing agent is prepared from, by weight, 5%-15% of ethylene glycol, 5% of a penetrating agent and 80%-90% of latex. Physical indexes of the jeans label prepared according to the preparation method are increased integrally, and high applicability to jeans label production and application is realized. By the sheet impregnation detecting method, jeans label detection accuracy can be remarkably improved.

Owner:GUANGDONG WALKKIND SPECIAL FIBERBOARD TECH

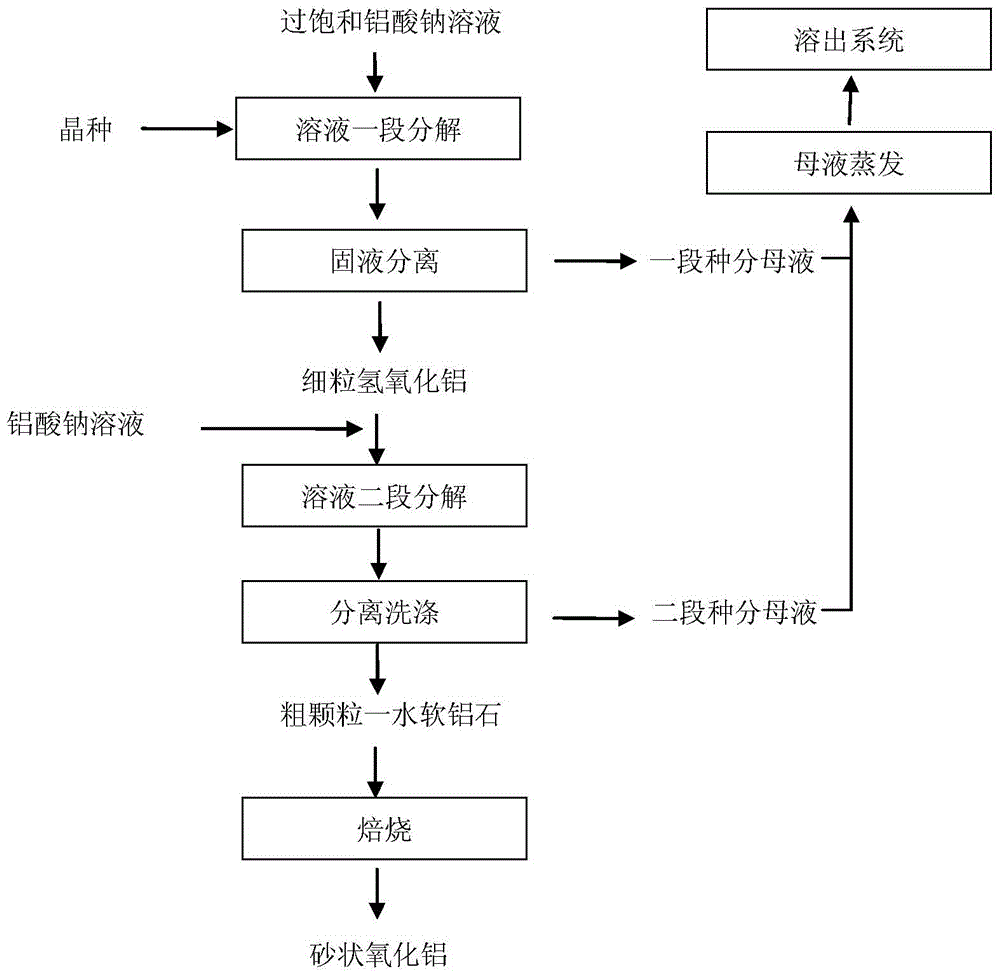

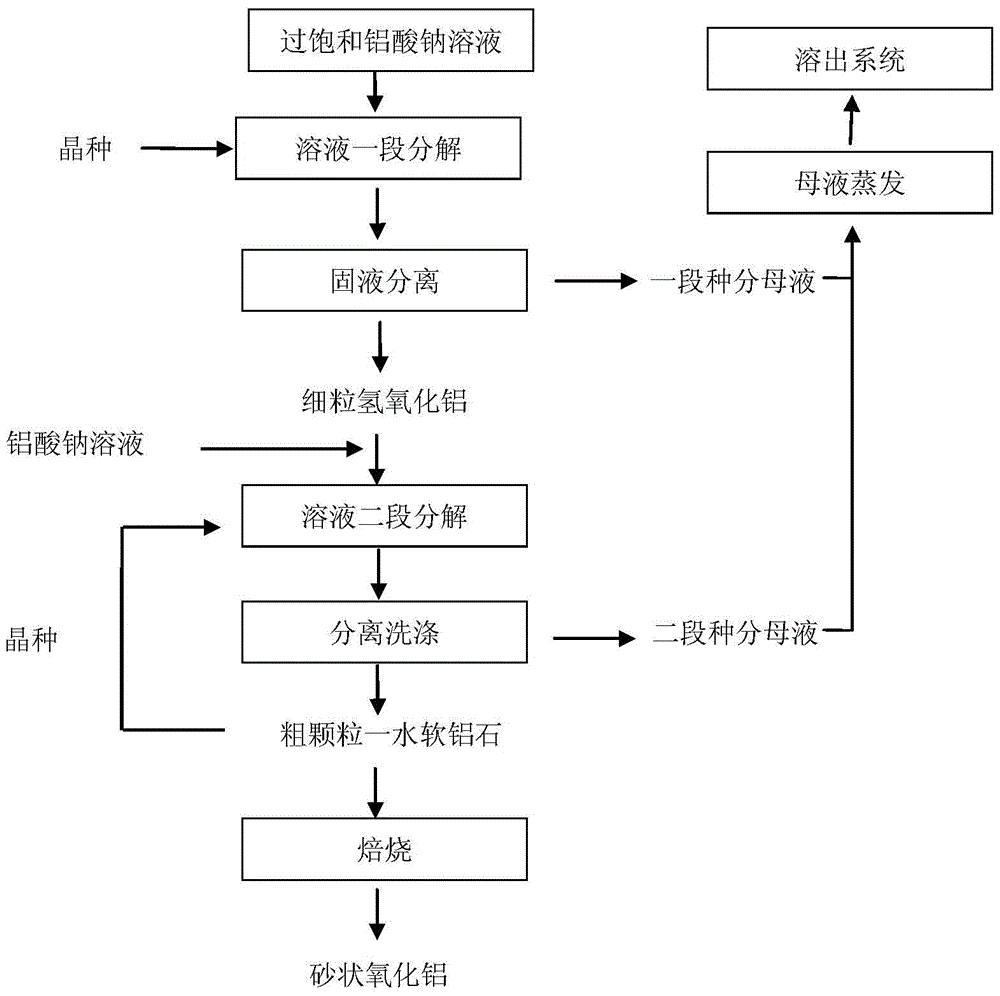

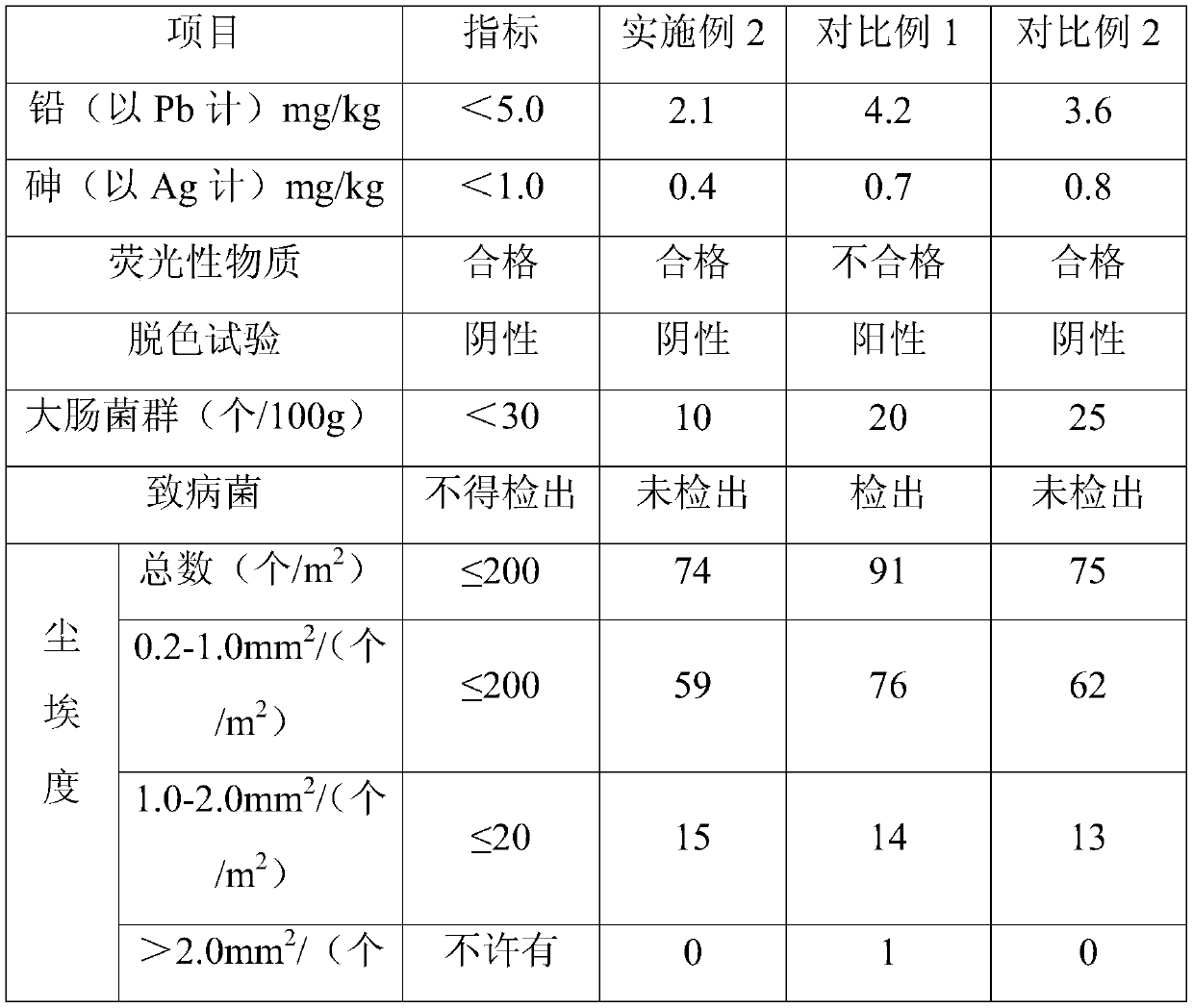

A method for preparing sandy alumina

ActiveCN104817100BImprove product qualityLow impurity contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideDecomposition

The invention discloses a method for preparing sand-shaped aluminum oxide. The method for preparing the sand-shaped aluminum oxide includes steps that 1) using supersaturated sodium aluminate solution as decomposition stock solution, and adding seed crystal to perform primary seed precipitation to obtain primary seed precipitation mother liquor and primarily decomposed aluminum hydroxide; 2) taking the primarily decomposed aluminum hydroxide and sodium aluminate solution to perform secondary seed precipitation to obtain secondary seed precipitation mother liquor and boehmite; 3) washing the boehmite and roasting to obtain the sand-shaped aluminum oxide. The sand-shaped aluminum oxide prepared by the method is featured with high decomposition rate, less impurity content, high product quality and the like, and meanwhile, the alpha-Al2O3 in the product is less, and the aluminum electrolysis is facilitated.

Owner:CENT SOUTH UNIV

Double-etherification modified starch and preparation method thereof

InactiveCN103242458BReduce total usageQuality improvementNon-fibrous pulp additionPaper/cardboardEpoxySodium chloroacetate

The invention discloses double-etherification modified starch and a preparation method thereof. The double-etherification modified starch is prepared from the following raw materials in parts by weight: 100 parts of starch, 0.010-0.020 part of epoxy chloropropane, 0.8-1.2 parts of water, 0.08-0.12 part of acrylic acid polyacrylamide, 16-18 parts of sodium chloroacetate, 7-8 parts of solid sodium hydroxide and 4-6 parts of industrial alcohol. The preparation method comprises the following steps of: adding the epoxy chloropropane into the starch at first; dispersing by using the acrylic acid polyacrylamide; carrying out a crosslinking reaction, wherein the pH value of the crosslinking reaction is controlled to be 10-10.5, and the temperature of the crosslinking reaction is 50-60 DEG C; then carrying out a carboxymethyl reaction; and adding the sodium chloroacetate, the solid sodium hydroxide and the industrial alcohol, wherein the pH is controlled to be 11-11.5, the reaction temperature is 50-80 DEG C, and the reaction time is 3-5 hours. According to the preparation method, a semi-dry method is adopted for production, and as intracytoplasmic addition, the modified starch is used by matching with cationic starch, so that the total consumption of the starch is lowered, and the quality of paper is greatly improved; and the modified starch is used as a coating starch bonding agent, and does not need gelatinization compared with common coating starch, so that the using effect of the modified starch is improved.

Owner:JIANGXI XINCHUAN IND

A kind of non-wood natural color paste food packaging paper and its preparation method

ActiveCN107090737BReduce the degree of beatingKeep natural colorNon-fibrous pulp additionFlexible coversFiberHazardous substance

The invention discloses a non-wood unbleached pulp food wrap paper and a preparation method thereof. Slurry of the non-wood unbleached pulp food wrap paper is prepared from unbleached straw pulp and unbleached bamboo pulp, the fixed quantity of the wrap paper ranges from 45 g / m<2> to 65 g / m<2>, and the content of synthetic papermaking additives accounts for 0.5%-2.5% of oven dry stock. The wrap paper is safe and environmentally friendly, the natural color of plant fiber is kept, dust and chips do not exist, no hazardous substance is produced in a papermaking technology, the waste water treatment cost is lowered, and the production cost is low.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Preparation of organic anion particle for particulate retention aid and filtering aid system of papermaking and uses thereof

InactiveCN101492899BSpeed up water filtrationGuaranteed uptimeWater-repelling agents additionPaper/cardboardParticulatesEnd-group

The invention relates to organic anion particles for a retention and drainage aid system for papermaking wet part particles, a preparation method thereof and application thereof. The organic anion particles are anion dendritic macromolecules prepared by modifying end groups of end ester-group semi-substituted dendritic polyamide-amine. The preparation method comprises a step that a tail end group-COOCH3 on the outer layer of the semi-substituted dendritic polyamide-amine is hydrolyzed under alkali conditions to become -COONa so as to prepare the anionic dendritic polyamide-amine. The anionicdendritic polyamide-amine as the organic particles is used for the retention and drainage aid system for the papermaking wet part particles, and is used as an anionic particle component separately orsynergistically with colloid silicon dioxide, structural silicon dioxide or bentonite, so that the retention rate of paper is improved, the drainage property is improved, and the papermaking evennessand the physical property are good.

Owner:QILU UNIV OF TECH

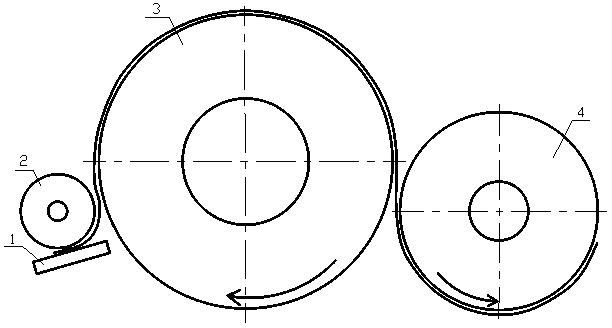

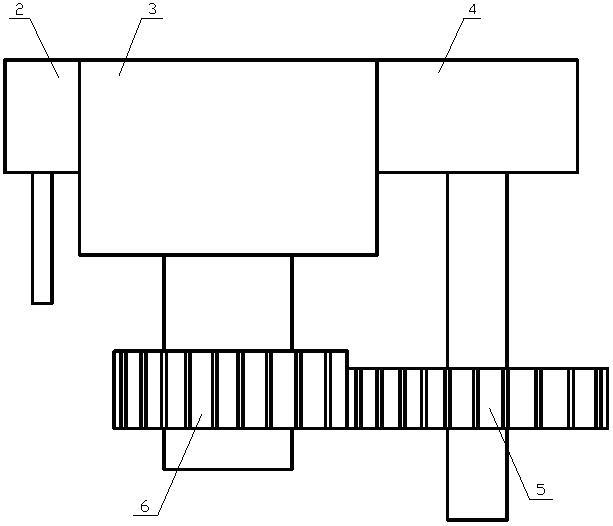

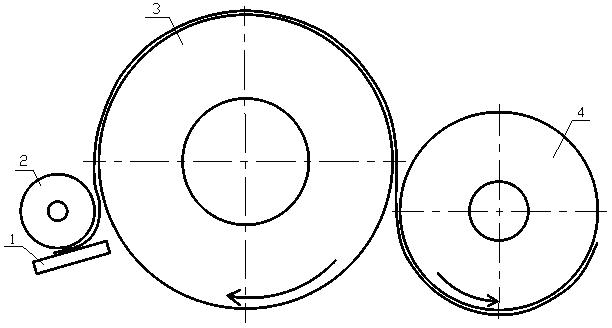

Comb roller drafter of swirl spinner

InactiveCN102493034AIncrease the diameterIncrease centrifugal forceContinuous wound-up machinesOpen-end spinning machinesYarnDrafter

The invention discloses a comb roller drafter of a swirl spinner, which comprises a feed plate and a feed roller. A feeding plate is arranged below the feeding roller. An opening roller is arranged at the rear of the feed roller, a small opening roller is added to the rear of the opening roller, a large gear is disposed on a rotary shaft of the opening roller, a small gear is disposed on a rotary shaft of the small opening roller, the feed roller is 60-100mm in diameter, the opening roller is 250-400mm in diameter, and the small opening roller is 200-350mm in diameter. The comb roller drafter has the advantages that raw materials are widely applicable, and various physical indexes of finished yarns are improved.

Owner:NANTONG UNIVERSITY

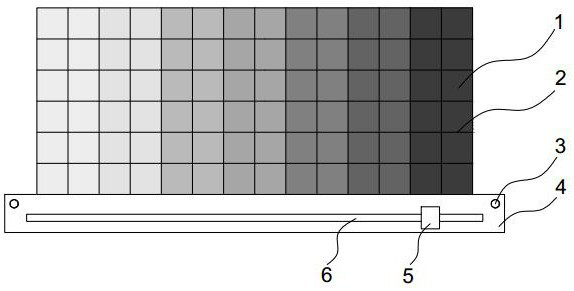

Plant petal/leaf standard color comparison paper

ActiveCN109680554BNot easy to tearExtended service lifeSpecial paperPulp beating methodsFiberHigh contrast

The invention discloses a plant petal / leaf standard colorimetric paper, comprising short fibers less than or equal to 180 microns and long fibers with a length greater than or equal to 180 microns, the width of the long and short fibers is 4.2-6.5 microns; the tightness of the colorimetric paper is 0.618~0.632g·cm ‑3 , the tear index is 4.92‑5.08mN m 2 g ‑1 . The invention uses corn stalks to prepare standard colorimetric paper, which has high comparison accuracy, is convenient to use, and can estimate the area of the contrasting object, and the prepared colorimetric paper has high appearance quality and physical indicators, reaching the standard of high-quality cultural paper.

Owner:海盐森植生物科技有限公司

Processing method of semi-worsted ultra-thin double-faced overcoating wool fabric

ActiveCN102061549BMeet consumer demandOptimize front and backWoven fabricsRougheningProcess engineeringIndustrial engineering

The invention discloses a semi-worsted ultra-thin double-faced overcoating wool fabric. The fabric is formed by blending high-quality wool with tencel fibers, warp yarns and weft yarns of the fabric are semi-worsted yarns, the fabric keeps a double-faced wool style and each square meter of fabric is 530 to 550g. In a processing method, a coarse spinning and fine weaving mode is adopted, the warp yarns and the weft yarns of the fabric are the semi-worsted yarns, positive and negative fluffing double-evaporation multi-cutting process technology is adopted in the after finishing process, and ironing and preshrinking technology and a low-temperature multi-ironing process are adopted, so that the true color of the high-quality wool is displayed, and the positive and negative surfaces of the fabric have the same shrinkage due to the preshrinking process; and teasel inverse combined overcoating technology is adopted, and two teasels jointly work to finish a positive and negative overcoating process at one time inversely. The invention has the advantages that: the fabric can keep the double-faced wool style and meets the consumption requirement that people pursue health and fashion currently.

Owner:张家港市金陵纺织有限公司

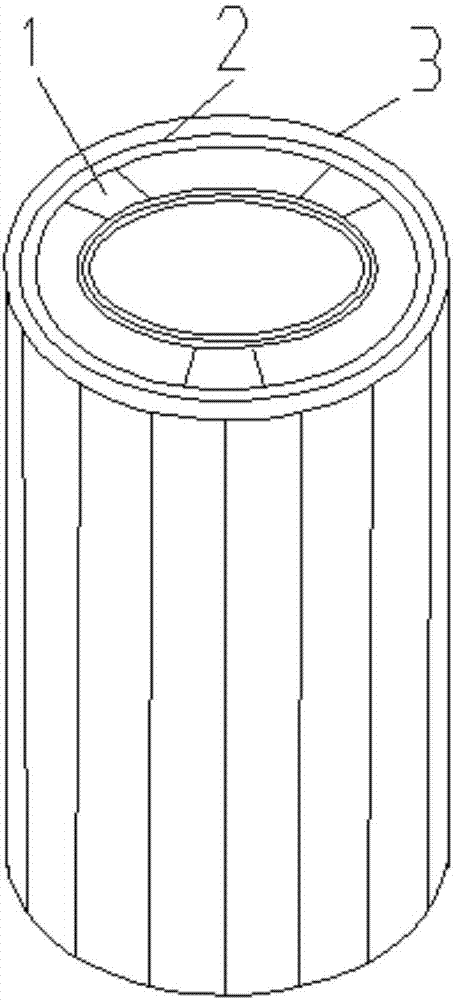

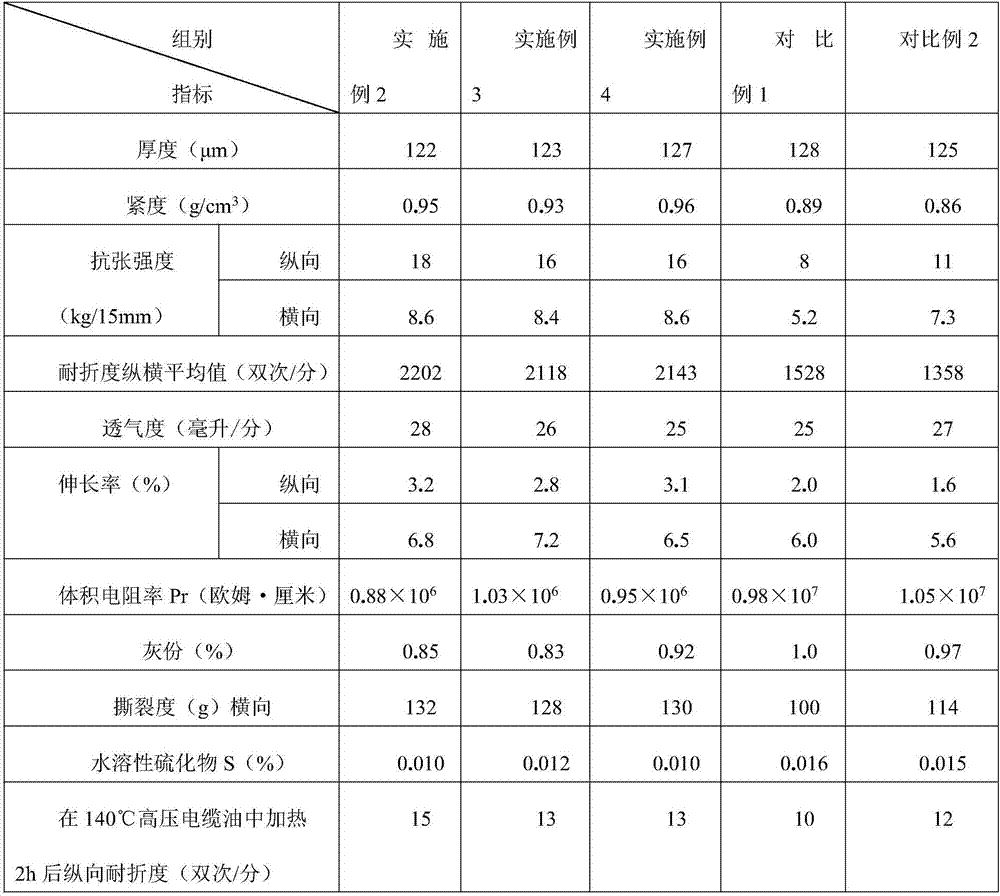

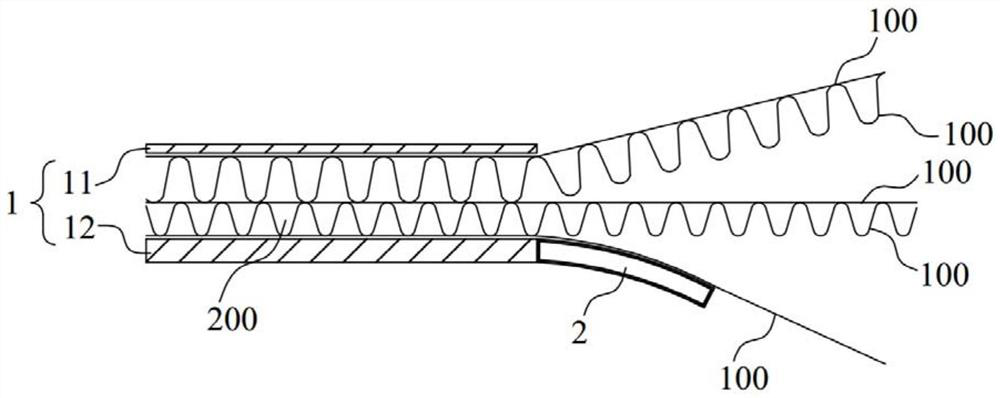

Semi-conductive paper and its preparation method and overall shielding structure of multi-winding current transformer

ActiveCN106835809BImprove electrical performanceHigh mechanical strengthTransformersReinforcing agents additionEpoxyConductor Coil

The invention belongs to the field of current transformers, and in particular relates to semiconducting paper and a preparation method thereof, and a bulk shielding structure for a multi-winding current transformer. The semiconducting paper comprises the following components in parts by weight: 65 to 100 parts of unbleached softwood kraft pulp, 15 to 25 parts of acetylene black, 2 to 4 parts of magnesium borate whiskers, 1 to 5 parts of modified anionic starch and 20 to 45 parts of an ethanol solution with the concentration of 5%. The semiconducting paper has an excellent electrical property, maintains high mechanical strength and achieves remarkable progress as compared with the control group. In addition, the invention also provides the bulk shielding structure for the multi-winding current transformer. Bubble gaps between secondary windings caused by the fact that epoxy resin cannot permeate completely during pouring can be effectively reduced, local discharging of the product is reduced and the quality of the product is improved.

Owner:GUANGDONG SIHUI INSTR TRANSFORMER WORKS

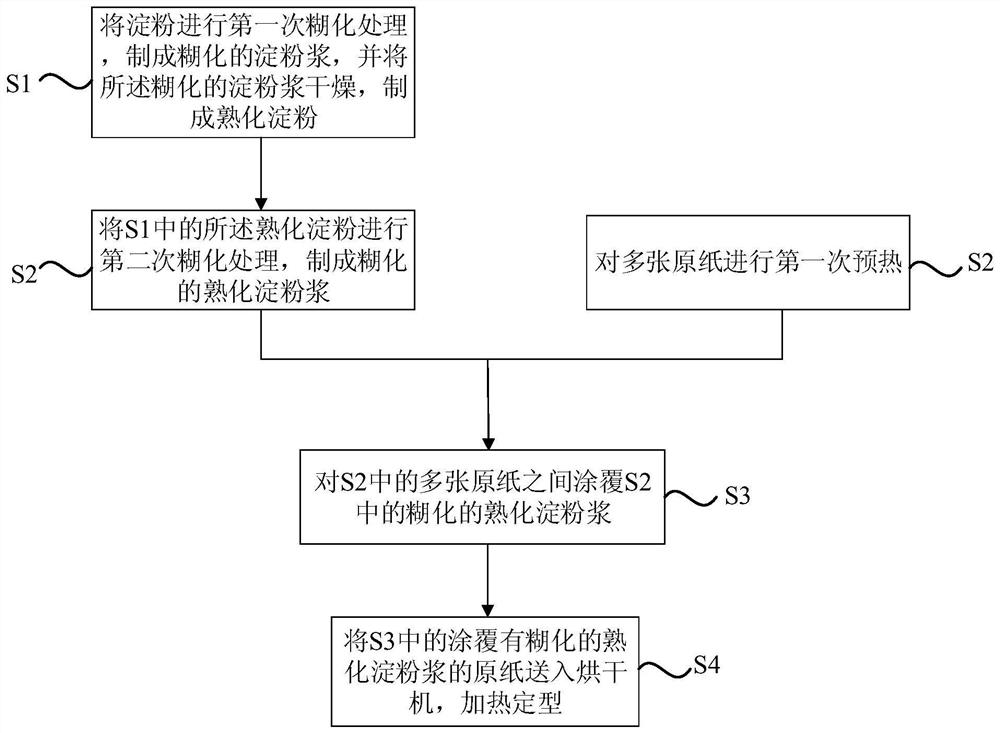

A kind of cardboard production process and dryer

ActiveCN108570879BReduce the temperatureLow heating temperaturePhysical paper treatmentBiotechnologyPaperboard

The invention discloses a cardboard production process and a dryer, and relates to the technical field of cardboard production. The cardboard production process includes: S1, subjecting starch to the first gelatinization treatment to produce gelatinized starch slurry, and drying the gelatinized starch slurry to produce mature starch; S2, subjecting the mature starch in S1 to the second Secondary gelatinization treatment, making gelatinized matured starch slurry, and simultaneously preheating multiple base papers for the first time; S3, coating the gelatinized matured starch slurry in S2 between multiple base papers in S2; S4: Send the base paper coated with the gelatinized mature starch slurry in S3 to a dryer, and heat and set it. Also disclosed is a dryer, which adopts the above process. This process can reduce the gelatinization temperature of the starch slurry and increase the viscosity, saving energy, and at the same time, the dryer can improve the physical index of the cardboard surface.

Owner:KUNSHAN MINGPENG PAPER IND

Liner paper for environment protection cigarette

InactiveCN100412268CNo smellNo toxicityFlexible coversCoatings with pigmentsPulp and paper industryPrinting ink

The present invention relates to an internal lining paper for environment-protecting cigarette. It is made up by coating water printing ink on the surface of raw paper. The smoothness of raw paper is greater than on equal to 1000S, unit area paper weight is 60-80g / sq.m, water content is less than 35g / sq.m, thickness is 0.05-0.07 mm and the dose of water printing ink (by solid content) is 4-7g / sq.m. The procedures for coating printing ink are successively as follows: placing paper, leveling, tensioning, coating, drying, calendaring and rolling up.

Owner:CHANGDE FURONG INDAL DEV

High-strength colored organic flame-retardant regenerated cellulose fiber and its preparation method

ActiveCN105297164BHigh color fastnessAvoid pollutionArtificial filament washing/dryingMonocomponent cellulose artificial filamentAdhesiveLimiting oxygen index

The invention relates to the technical field of regenerated cellulose fibers, in particular to a preparation method of a high-strength colored organic flame-retardant regenerated cellulose fiber. The preparation steps include the procedure of preparing a spinning solution, the procedure of preparing flame-retardant spinning adhesives, the procedure of spinning, and the procedure of post-processing. In the procedure of preparing the flame-retardant spinning adhesives, flame retardants, denaturants and color paste need to be added after the procedure of preparing the spinning solution, organic pyrophosphate flame retardants are adopted as the flame retardants, polyoxyethylene fatty amine is adopted as the denaturants, and the particle size of the color paste is required to be smaller than or equal to 0.5 micron. The limit oxygen index of the flame-retardant fiber prepared through the method is larger than or equal to 28.0%, the cotton staining grade and the original sample color changing grade of the fiber are both higher than the fourth grade, and the color fastness is good. Environmental protection pressure caused by subsequent dyeing of downstream customers is greatly reduced, and the flame-retardant performance attenuation problem caused by high temperature dyeing is solved. The mode that drying is performed before cutting is adopted for the post-processing procedure, the mixing problem of fibers in different colors is avoided, and production cost is greatly reduced.

Owner:潍坊欣龙生物材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com