Jeans label and preparation method and sheet impregnation detecting method thereof

A technology for jeans and latex, applied in textiles and papermaking, inorganic compound addition, reinforcement addition, etc., can solve the problems of unsafe, non-degradable, and polluted leather production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method for jeans label, comprising the steps of:

[0029] a.Put the plant fiber and appropriate amount of water into the hydropulper for pulping, after desanding and impurity grinding; until the beating degree of the plant fiber is ground to 10-20°SR, add iron oxide dyes and mix thoroughly Finally, obtain the slurry; b. mix the latex compounding agent, other auxiliary agents and water in the compounding tank, and send the mixed latex agent to the dipping tank; c. mix the slurry obtained in step a After molding and dehydration, it is soaked with the mixed latex in the dipping tank; the excess mixed latex is removed by a press, and dried at high temperature by a drying equipment; d. Finally, a jeans label is made by a surface finishing equipment.

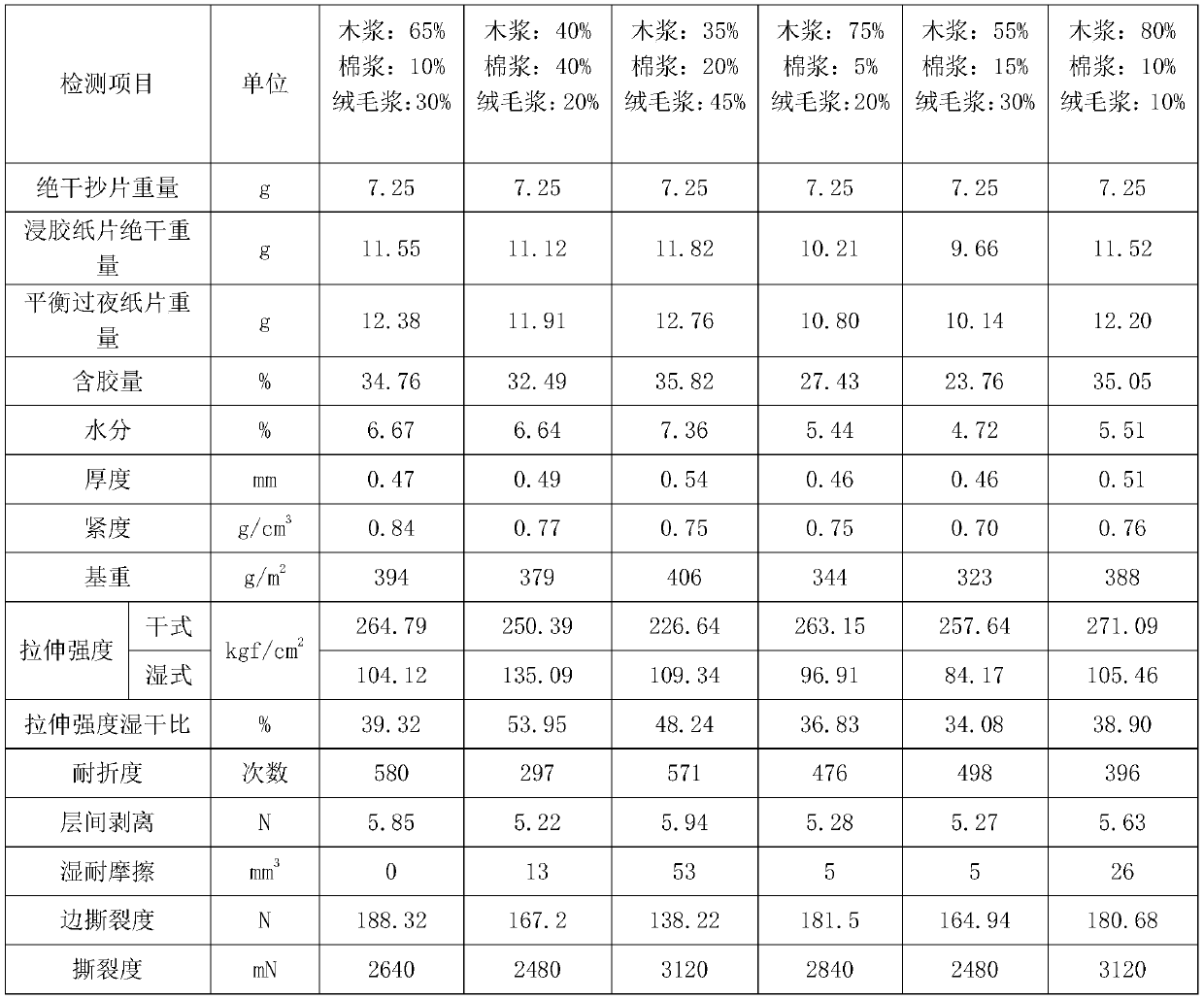

[0030] The embodiment that the jeans mark of concrete different percentage components is flattened is as follows:

Embodiment 1

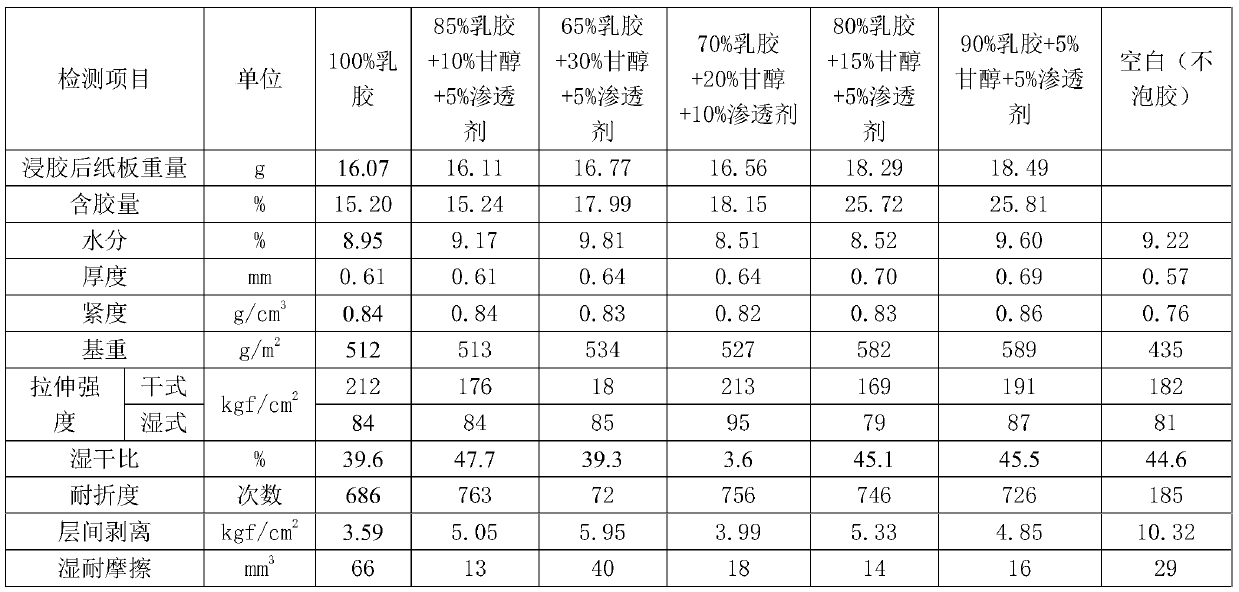

[0032] A jeans label, which is composed of the following components by weight percentage: plant fiber: 65%; latex compounding agent: 25%; iron oxide dyes are iron oxide red and iron oxide yellow: 0.1%; wet strength agent: 0.6% %; cross-linking agent: 2%; 50% sodium diisooctyl succinate sulfosulphate solution: 0.6%; and supplemented with water to 100%;

[0033] Wherein: the plant fiber is made up of the following weight percentage components: 55% wood pulp, 15% cotton pulp and 30% fluff pulp; the latex compound is made up of the following weight percentage components: 5% glycol, 5% Penetrant and 90% neoprene latex with glass transition temperature less than -10°C.

Embodiment 2

[0035] A jeans label, which is composed of the following components by weight percentage: plant fiber: 65%; latex compounding agent: 20%; iron oxide dyes are iron oxide red and iron oxide yellow: 0.1%; wet strength agent: 0.5% ; Cross-linking agent: 1%; 50% sodium diisooctyl succinate sulfosulphate solution: 0.5%; and supplemented with water to 100%;

[0036] Wherein: the plant fiber is made up of the following weight percentage components: 65% wood pulp, 10% cotton pulp and 25% fluff pulp; the latex compound is made up of the following weight percentage components: 10% glycol, 5% Penetrant and 85% neoprene latex with glass transition temperature less than -10°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com