Patents

Literature

289results about How to "Applicable production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

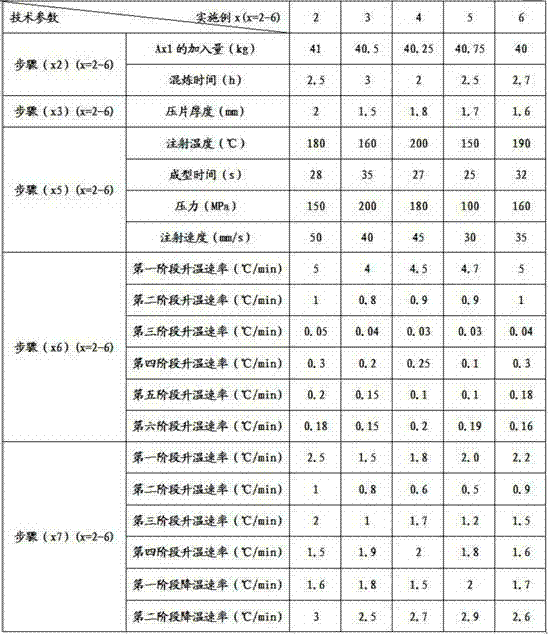

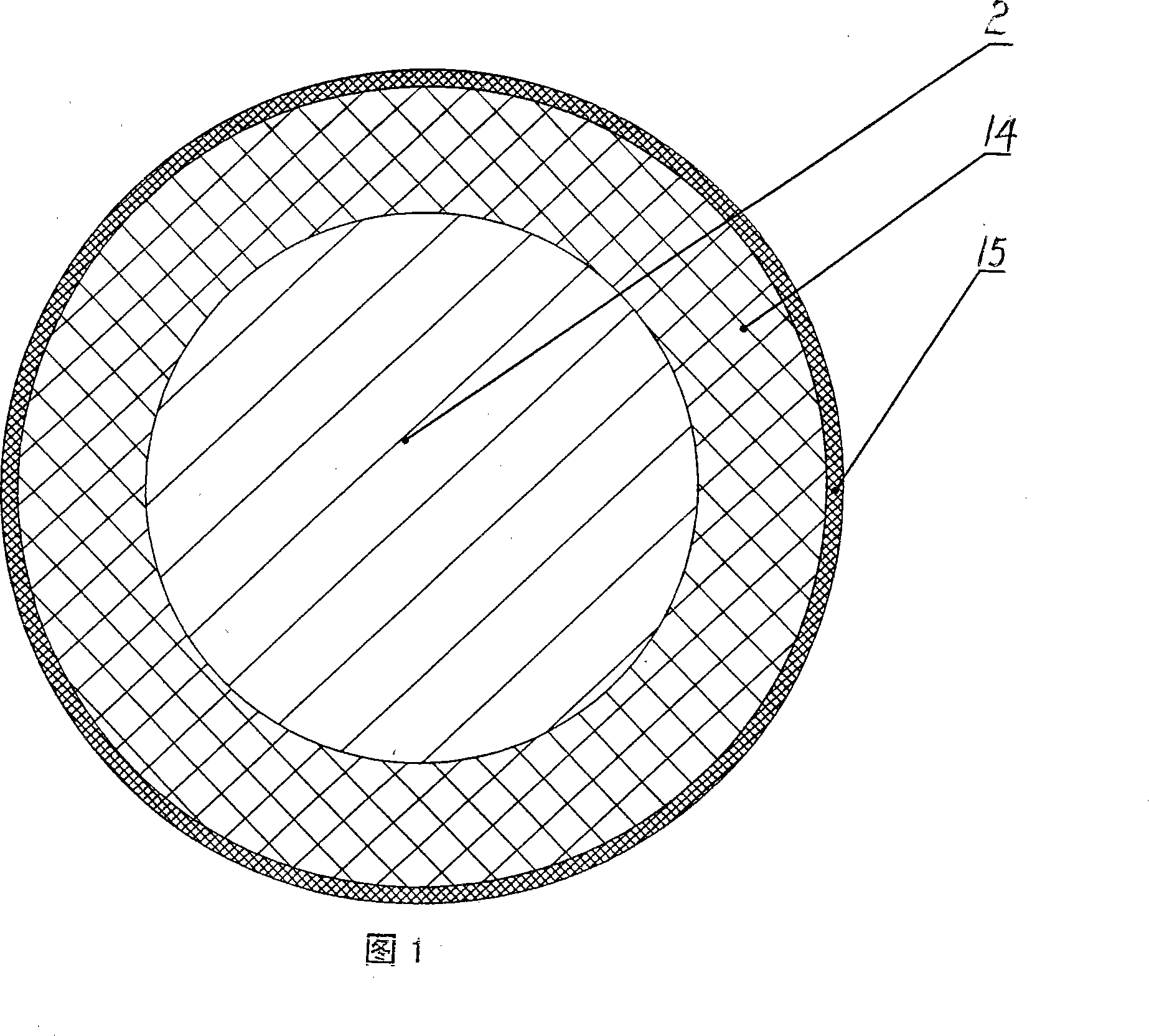

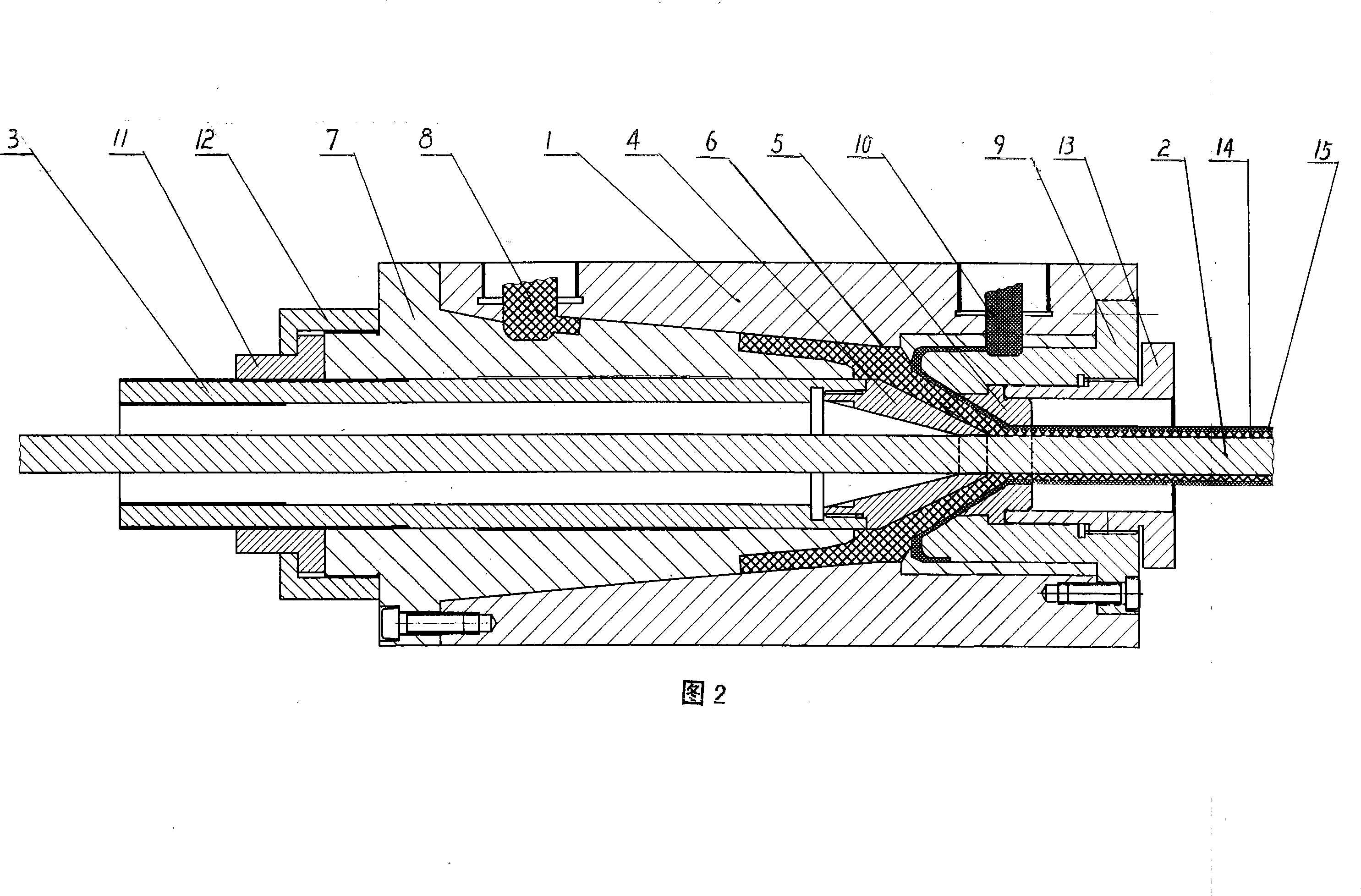

Zirconia ceramic ferrule and production process thereof

InactiveCN104261820AGuaranteed compactnessNo poresCeramic shaping apparatusMethacrylateInjection molding process

The invention discloses a zirconia ceramic ferrule. With zirconia ceramic powder as a main material, an ethylene-vinyl acetate copolymer, an oleic acid, polymethacrylate, atactic polypropylene and paraffin are added in the mixing process, and thus the prepared zirconia ceramic ferrule is good in abrasive resistance, strong in ageing resistance, strong in environmental adaptability, and high in strength. The invention also discloses a production process of the zirconia ceramic ferrule. The process comprises the following steps: sequentially drying, mixing, preforming, crushing, injection molding, thermal debinding, sintering, grinding and the like. High-pressure low-speed injection is adopted in the injection molding process; the compactness and absence of an air hole are ensured; the preparation method is simple, easy to control, low in cost, and high in production efficiency; the pass rate of the produced product is high; and the production process is suitable for production of the zirconia ceramic ferrule.

Owner:HEBEI SMART COMM TECH

Catalytic system for catalyzing and oxidizing alcohol to prepare aldehyde and ketone and method of preparing aldehyde and ketone

InactiveCN1651381AImprove efficiencyHigh selectivity andOxygen-containing compound preparationOrganic compound preparationHalogenPressure reactor

A catalyst system for preparing aldehyde and ketone by catalytic oxidization of alcohol is composed of the catalyst consisting of 2,2,6,6-tetramethylpiperidine-free oxygen radical, halogen and nitrite, and the oxidant. The process for preparing said aldehyde and ketone features the high-sensitivity oxidizing reaction between catalyst, alcohol and air or oxygen in pressure reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

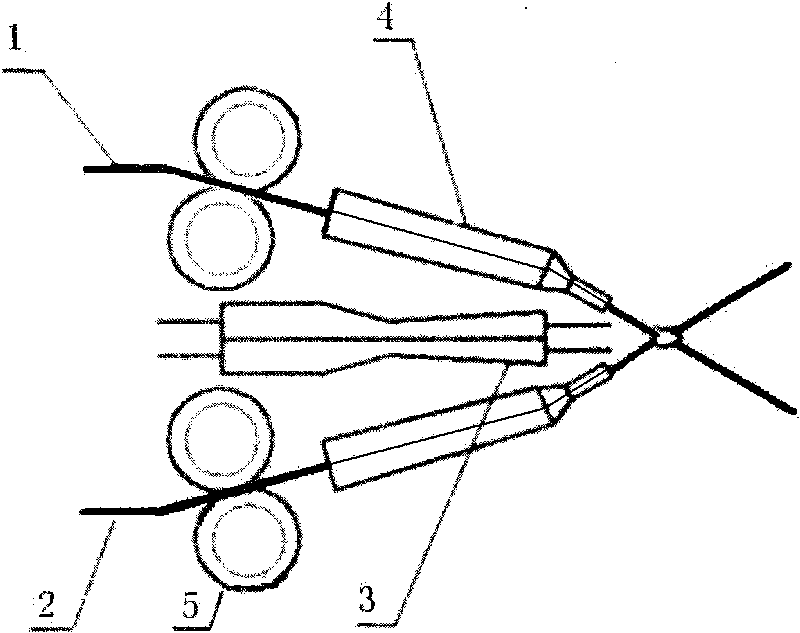

Magnalium special metal coating and preparation method thereof

InactiveCN101709448AImprove corrosion resistanceHigh hardnessMolten spray coatingElectrode potentialMetal coating

The invention belongs to the technical field of hot spraying, and relates to a preparation method of a special metal coating. The preparation method comprises the following steps: adopting electric arc spraying, plasma spraying or ultrasonic flame spraying; and performing electric arc spraying on magnesium wire or aluminum wire serving as two electrodes in the diameter ratio of 1:1-1:3, or performing plasma spraying or ultrasonic flame spraying on a mixture of magnesium powder with the particle size between 0.2 and 100mu m and aluminum powder serving as raw materials in a ratio of 1:1-1:9 to obtain the coating, wherein the coating comprises the following components by weight: 5.5 to 40.0 percent of Mg, 55.0 to 93.0 percent of Al and less than or equal to 10 percent of other components. The special coating has the advantages of having good cathode protection effect on steel and metals with lower electrode potential such as aluminum, zinc and the like. After being subjected to heat treatment at the temperature of between 200 and 470 DEG C for 30 to 150 minutes, the coating is rich in Al12Mg17 phase and Al3Mg2 phase, thereby further improving the rigidity and corrosion resistance of the coating.

Owner:DALIAN UNIV OF TECH

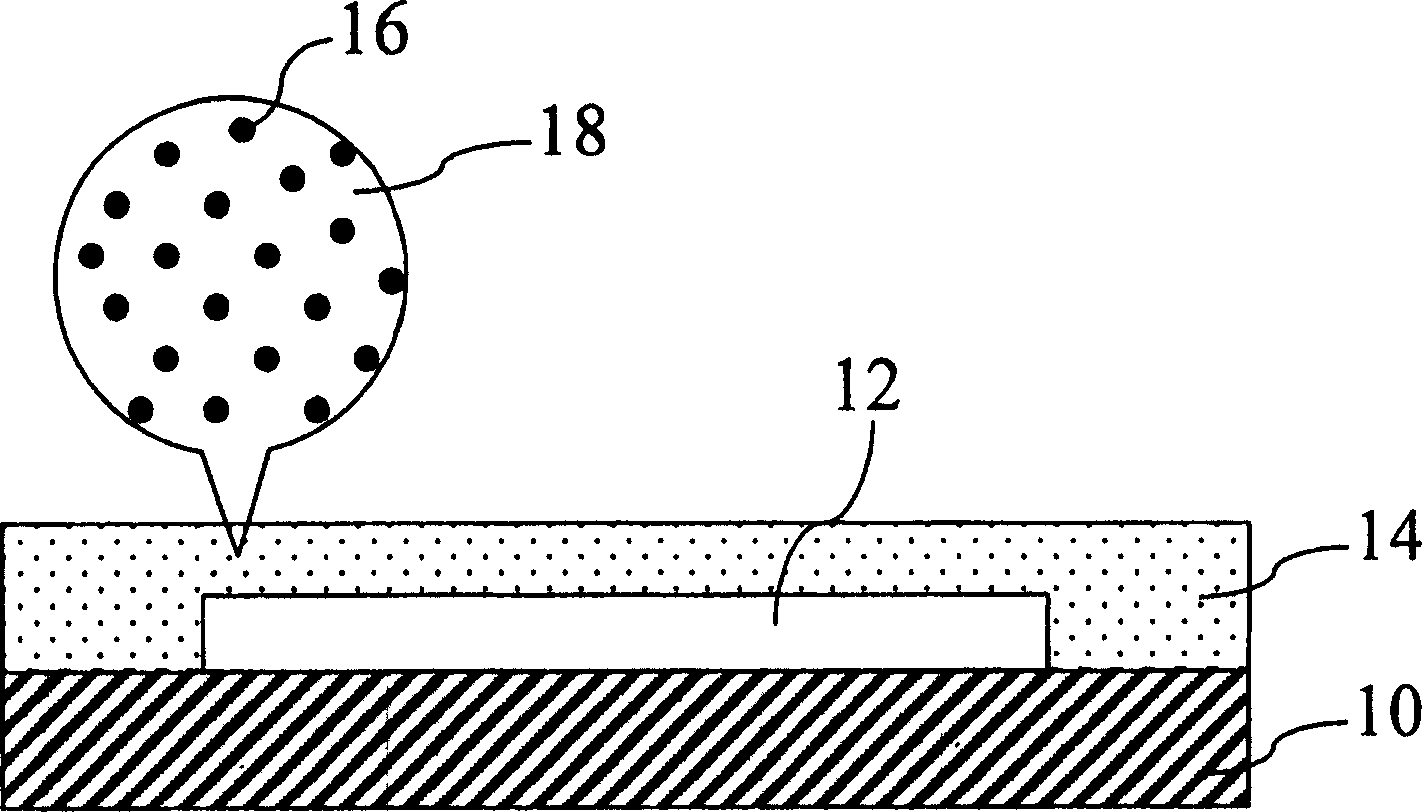

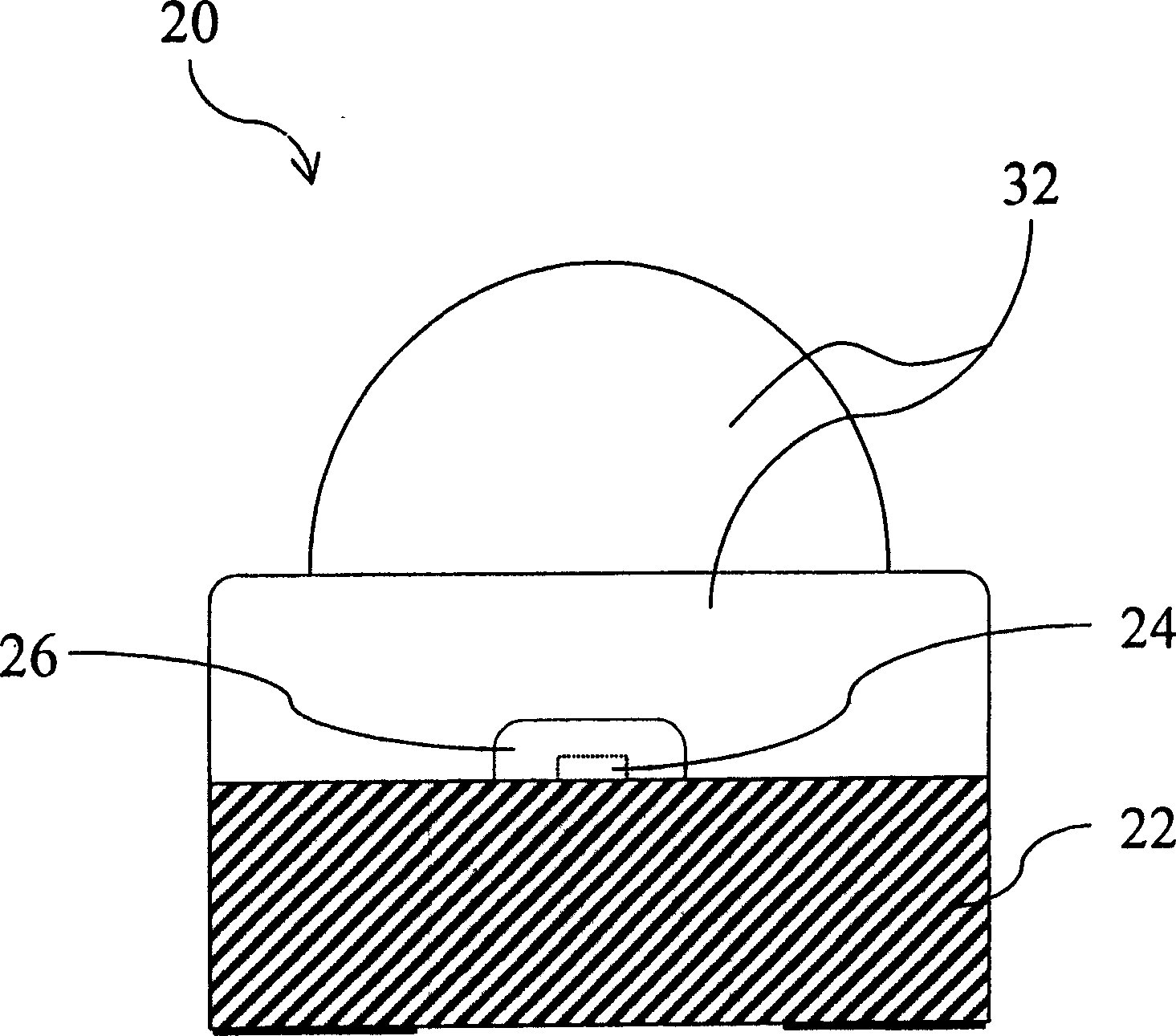

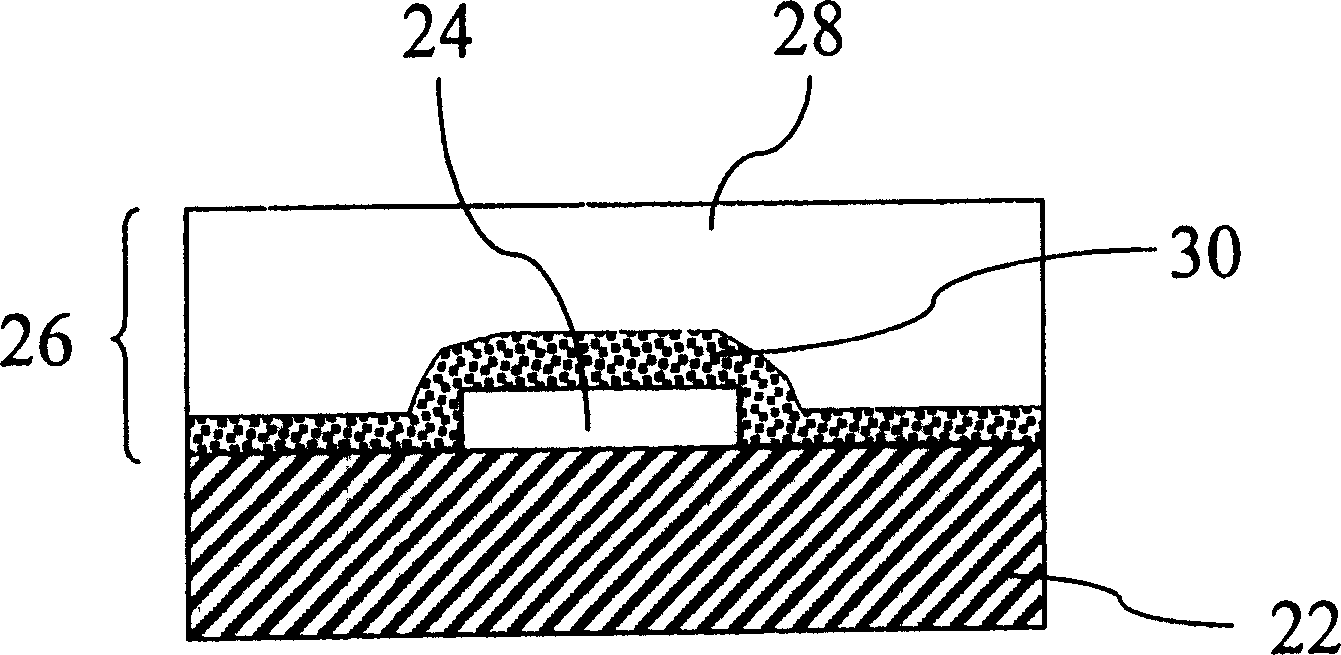

Packaging structure of LED and packaging method thereof

InactiveCN1547265AReduce light color leakage rateImprove the shortcomings of high light leakage rateSemiconductor devicesColloidSolvent

The invention provides a packaging structure and the method for a kind of illuminant diode, it uses the liquid phosphorus light agent glue as material, and uses the model-casting and forming method to carry on package, in the packaging process, the glue solvent is saturate and the solid phosphorus light agent is deposited, thus, a phosphorus light media layer covers the illuminant diode, the phosphorus media layer contains a packaging glue and a phosphorus light agent layer, the phosphorus light agent are coated on the illuminant diode. The invention can realize the low color leakage rate effect, at the same time, the size is standardized, the white light spectrum is stable, and it can save the materials.

Owner:TOPSON OPTOELECTRONICS SEMI CONDUCTOR

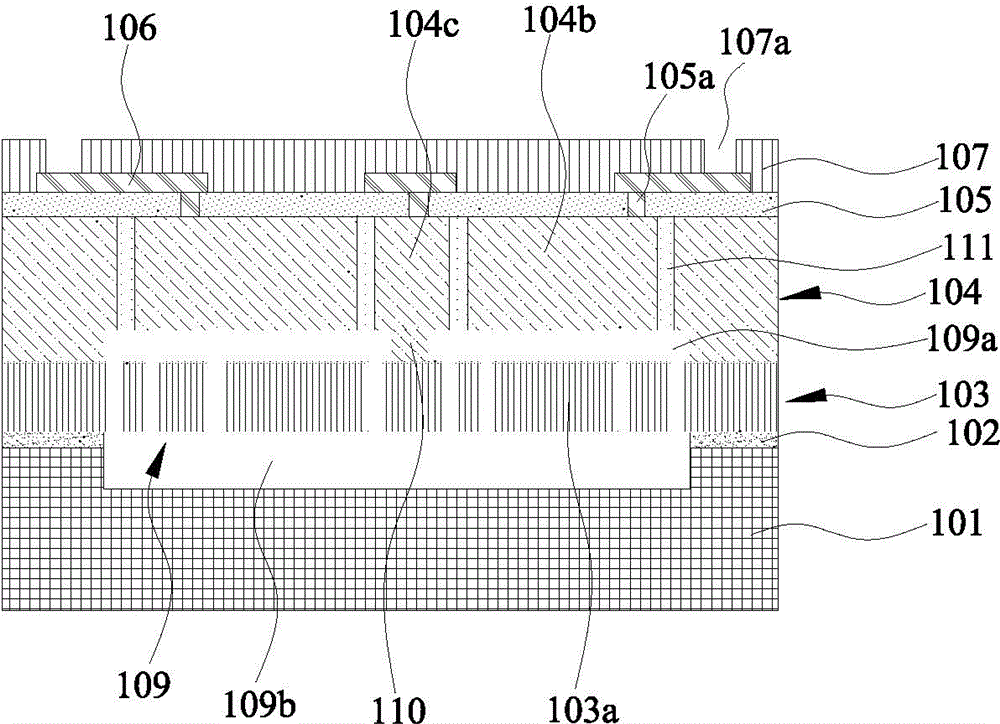

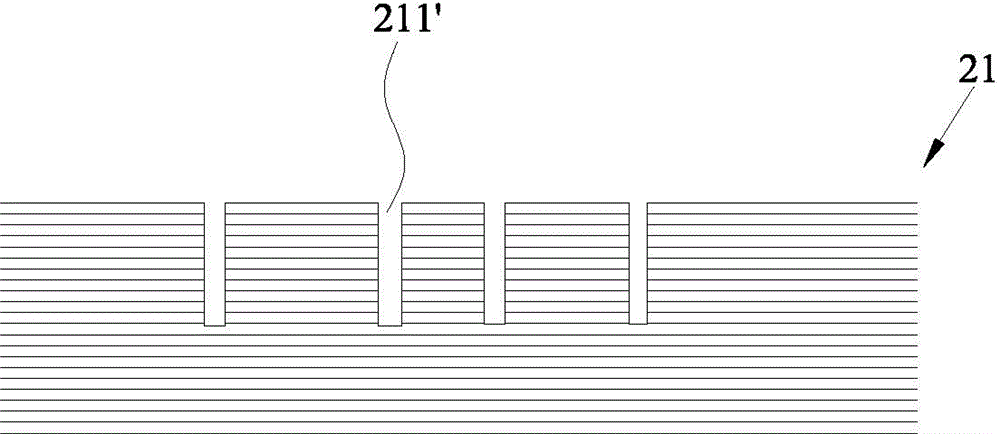

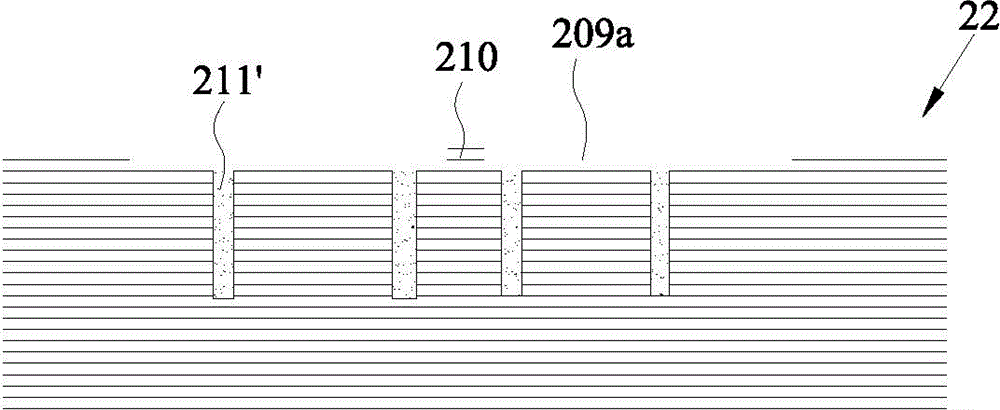

Wafer level packaging method for micro electromechanical system (MEMS) chip and single-chip micro-miniature type MEMS chip

InactiveCN103552980AReduce areaLow costTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringSingle chip

The invention discloses a wafer level packaging method for a micro electromechanical system (MEMS) chip and a single-chip micro-miniature type MEMS chip. The method comprises the steps of forming a silicon through-hole wafer, forming a first bonded wafer, forming a cover plate wafer, forming a second bonded wafer, forming an MEMS wafer and forming the single-chip micro-miniature type MEMS chip. According to the method, by reducing the depth of an upper cavity, part of a silicon through-hole layer can directly serve as a vertical electrode, and the process is simple. By additionally arranging a metal shielding layer, the influence on the performance of the MEMS chip caused by an environment interference signal is reduced. The prepared single-chip micro-miniature type MEMS chip is small in size and high in yield. By virtue of the metal shielding layer on the chip, the influence on the performance of the MEMS chip caused by the environment interference signal and packaging stress can be reduced.

Owner:ANHUI BEIFANG XINDONG LIANKE MICROSYST TECH

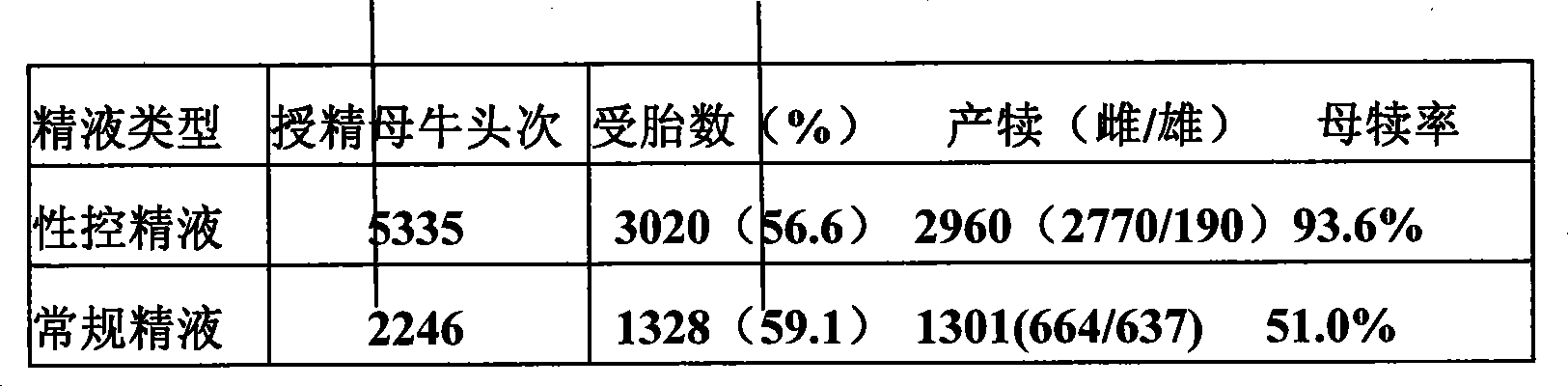

Freezing mixed sperm for controlling X/Y gender of milk cattle and preparation method thereof

InactiveCN101411722AIncrease productivityReduce manufacturing costDead animal preservationMammal material medical ingredientsSemenBeef cattle

The invention discloses a new technology for producing frozen mixed semen for controlling the gender of milk cow. Goat semen is used as foundation (2,000,000 to 3,000,000 pieces / 0.25 ml) and is added with X / Y separation semen (500,000 to 1,000,000 pieces / 0.25 ml) to produce the frozen semen for controlling the gender X / Y of the milk cow. The main content of the technology comprises the separation of milk cow X / Y sperms, the preparation of the basic goat semen (which can be substituted by the semen of pig, horse or deer with the equal number) and the production of the frozen semen for controlling the gender of the milk cow through the procedures of mixing and freezing two kinds of the semen according to requirements. The new technology can improve the production efficiency of the frozen semen for controlling the gender of the milk cow by 2 to 4 times and reduce the production cost by 50 to 70 percent simultaneously. The new technology improves the activity and the acrosome intact rate of sperms after the sperms are unfrozen, prolongs the time for having the insemination capacity after the frozen sperms are unfrozen so that the average pregnancy rate in a sexual period reaches over 50 percent; and the accuracy rate of gender control reaches over 90 percent. The new technology is also suitable for producing the frozen mixed semen for controlling the gender of beef cattle.

Owner:李喜和

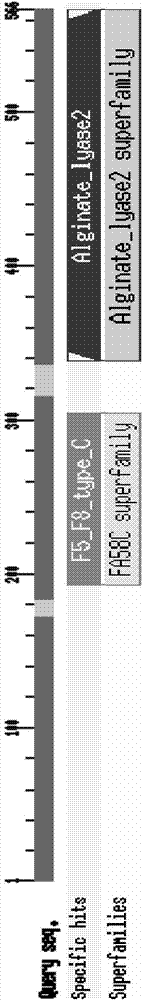

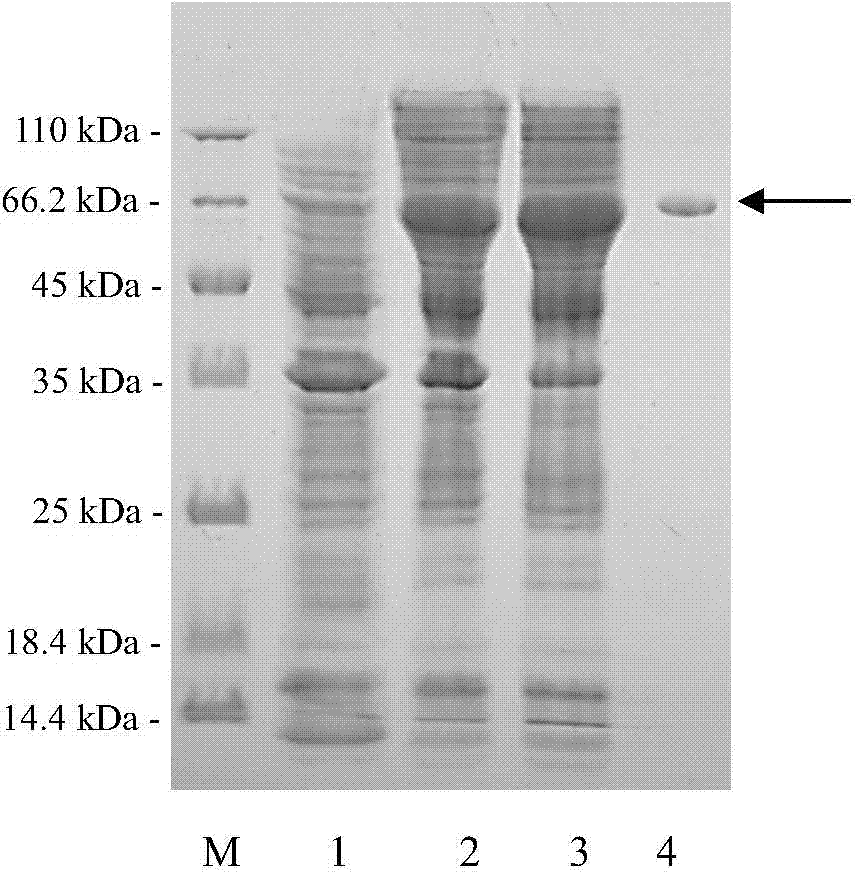

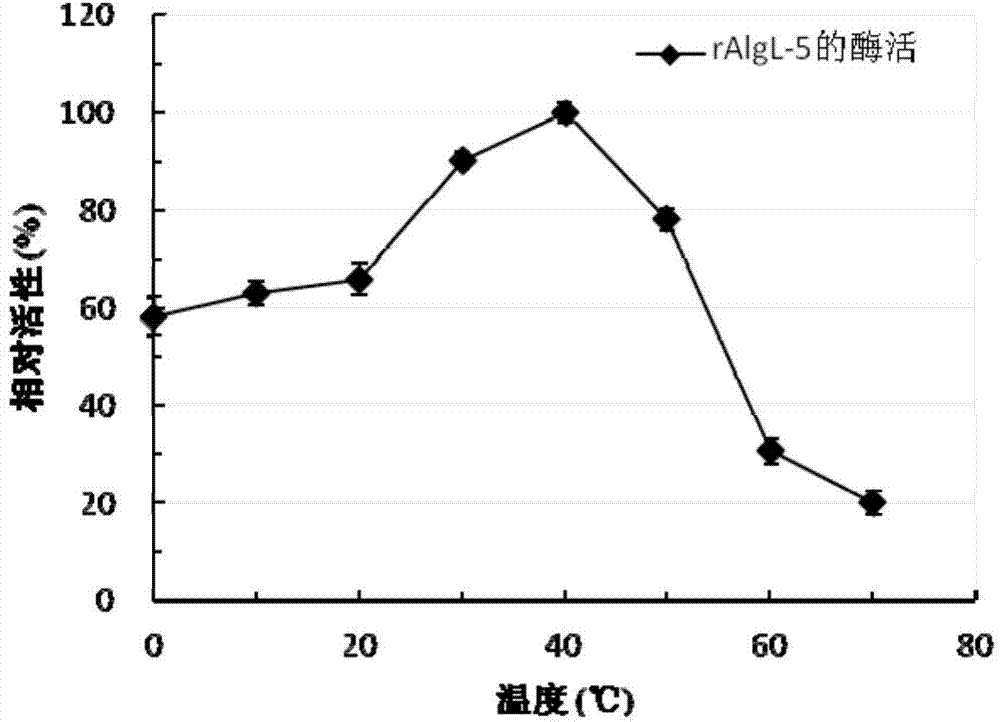

Incision-type sodium alginate lyase as well as encoding gene and application thereof

ActiveCN104293754AStable in naturePotential for industrial applicationsBacteriaFermentationTrisaccharideLyase

The invention relates to incision-type sodium alginate lyase as well as an encoding gene and application thereof. The amino acid sequence of the incision-type sodium alginate lyase AlgL-5 is as shown in SEQ ID NO.2. A gene for encoding the incision-type sodium alginate lyase AlgL-5 is as shown in SEQ ID NO.1. Main oligosaccharide products generated in a process of degrading sodium alginate by using the incision-type sodium alginate lyase AlgL-5 include unsaturated disaccharide, unsaturated trisaccharide, unsaturated tetrasccharide and unsaturated pentasaccharide. Pentasaccharide is the smallest unsaturated oligosaccharide substrate of lyase, and disaccharide is the smallest unsaturated oligosaccharide product of lyase. The recombinant enzyme is stable in property and has certain industrial application potential.

Owner:SHANDONG UNIV

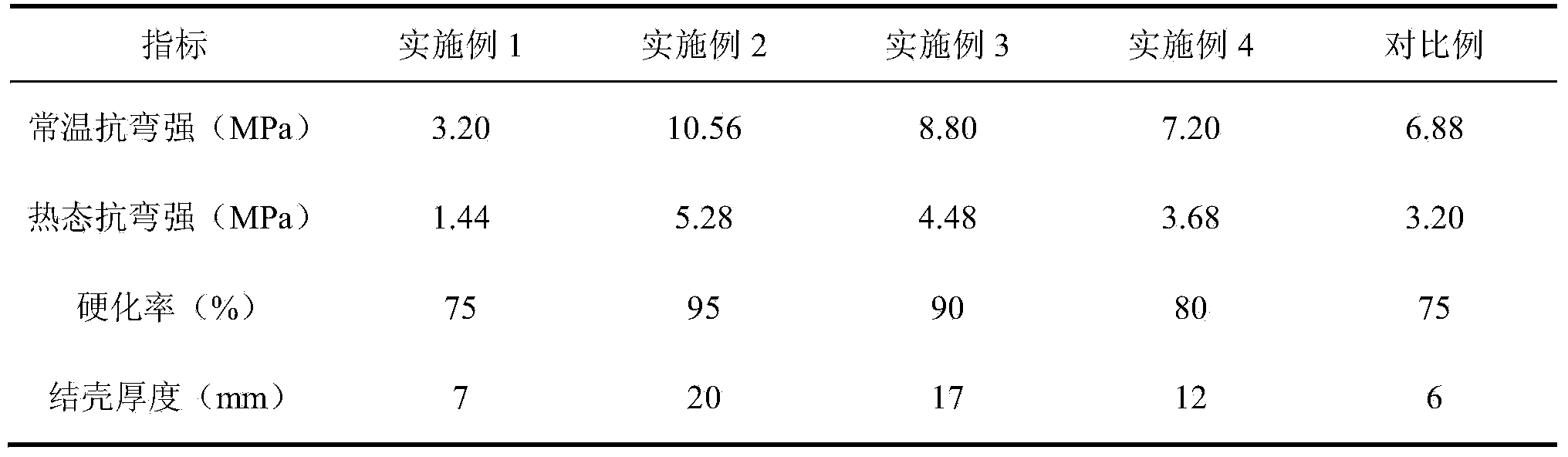

Shelling resistant pre-coated sand and preparation method thereof

ActiveCN104014718AFast curing rateIncrease hardening rateFoundry mouldsFoundry coresFirming agentUltimate tensile strength

The invention discloses shelling resistant pre-coated sand and a preparation method thereof. The shelling resistant pre-coated sand is characterized by comprising raw sand, a bonding agent the weight of which is 1-4% that of the raw sand, a curing agent the weight of which is 1-15% that of the bonding agent, 0.1-0.5% of coupling agent and 0.1-1.0% of additive. By adding the additive, the curing speed of the curing agent to the bonding agent is increased, the hardening rate of the pre-coated sand is improved and the shelling tendency is reduced; by optimizing the content of each component, the overall strength of the pre-coated sand is improved, the gas evolution amount of the pre-coated sand is greatly reduced and the defect of core piercing is alleviated; the shelling resistant pre-coated sand has strong shell resistance, is high in strength and low in gas evolution amount, is capable of remarkably alleviating or eliminating defects such as shelling and core piercing and effectively improving qualities of the inner and outer surface of a shell core, and is suitable for production of shell core sand cores.

Owner:CHENGDE BEIYAN CASTING MATERIAL

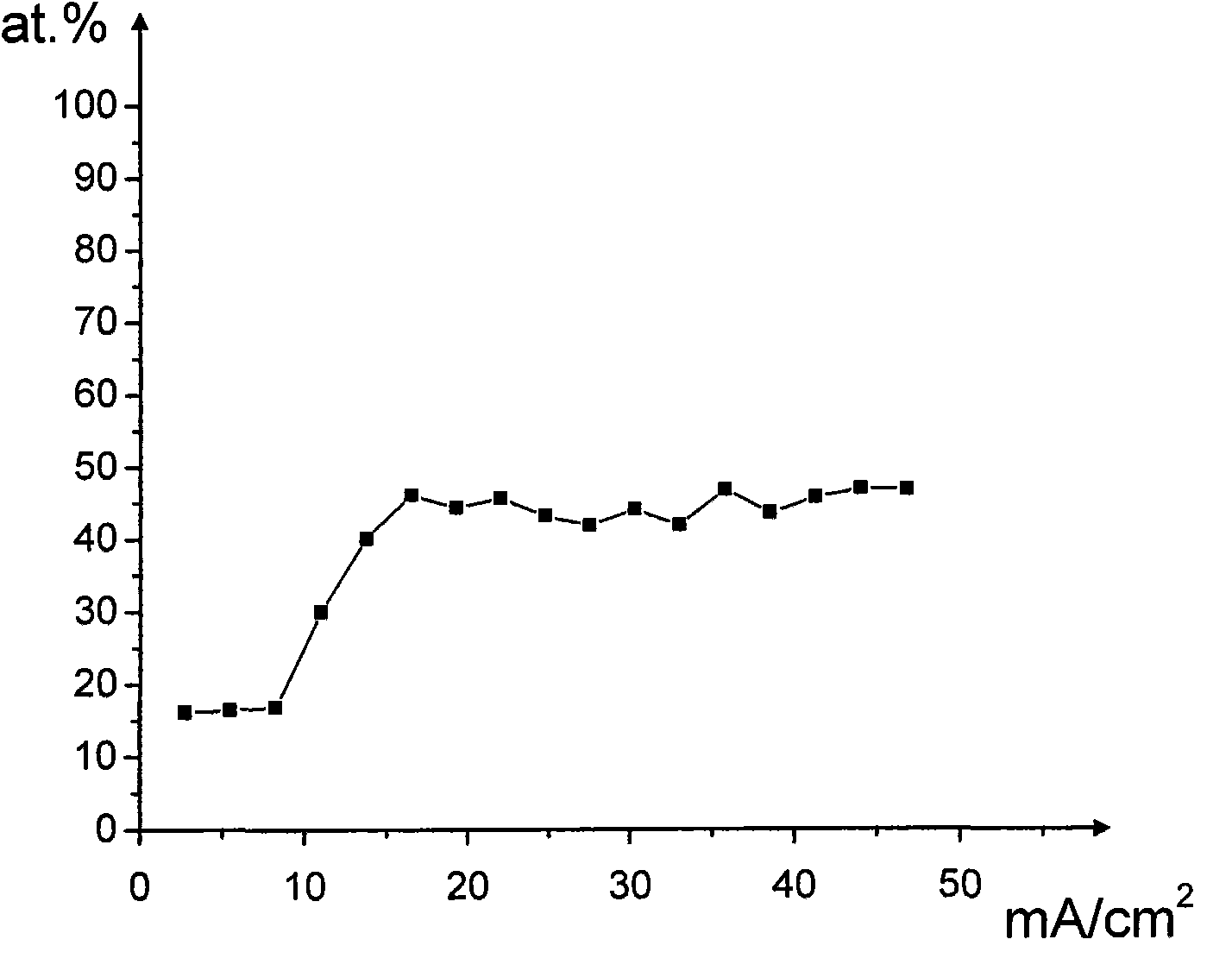

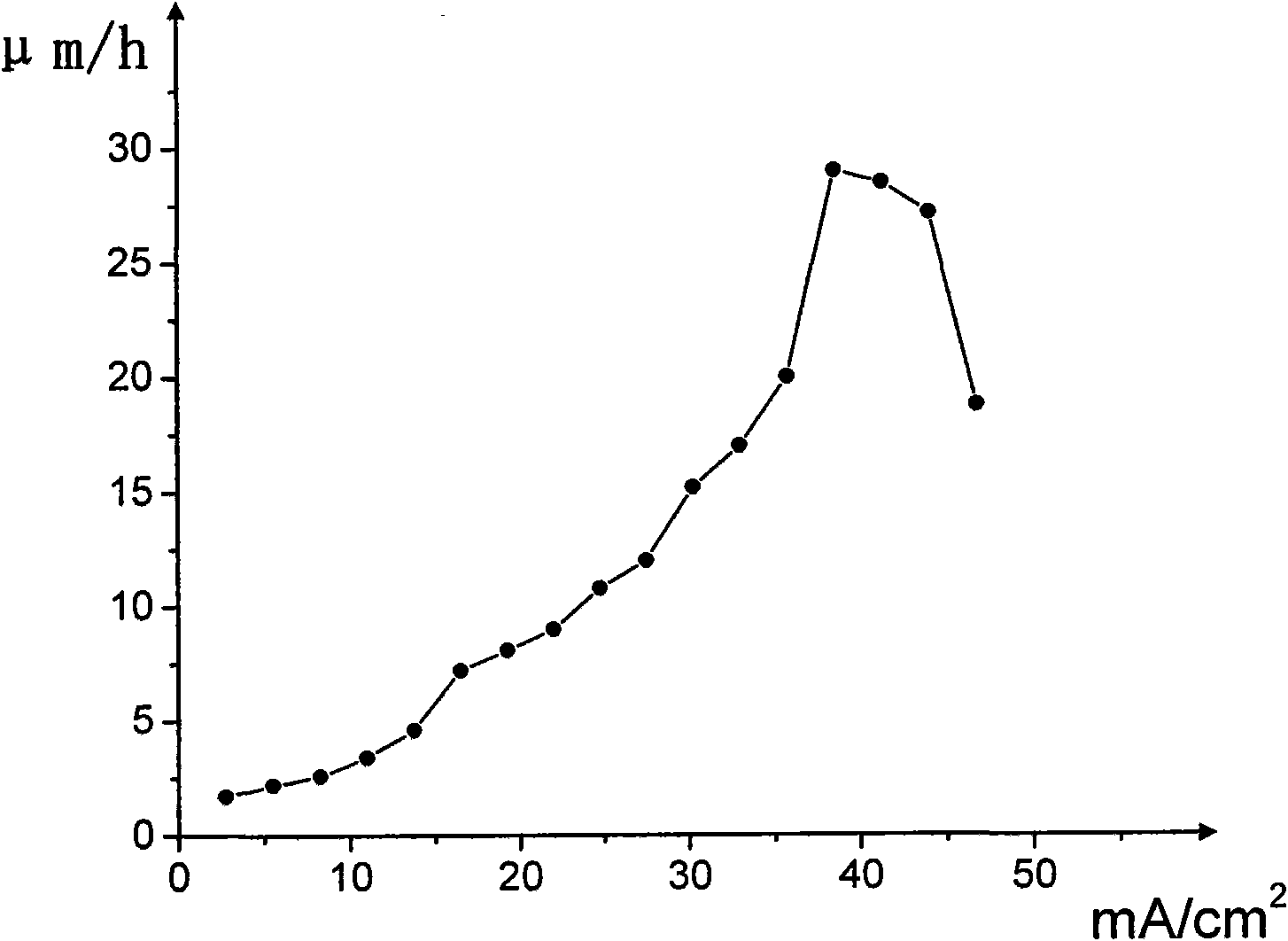

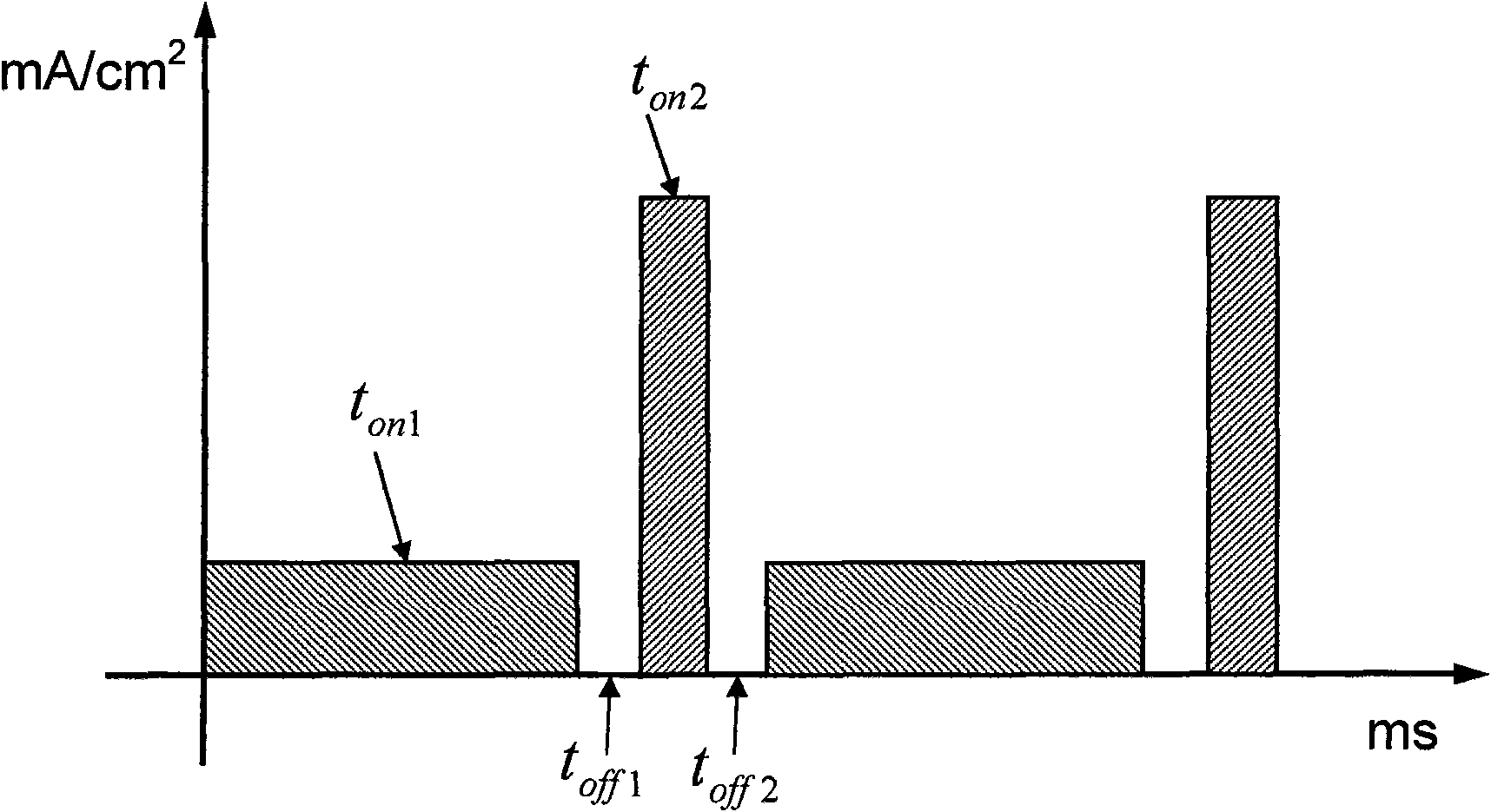

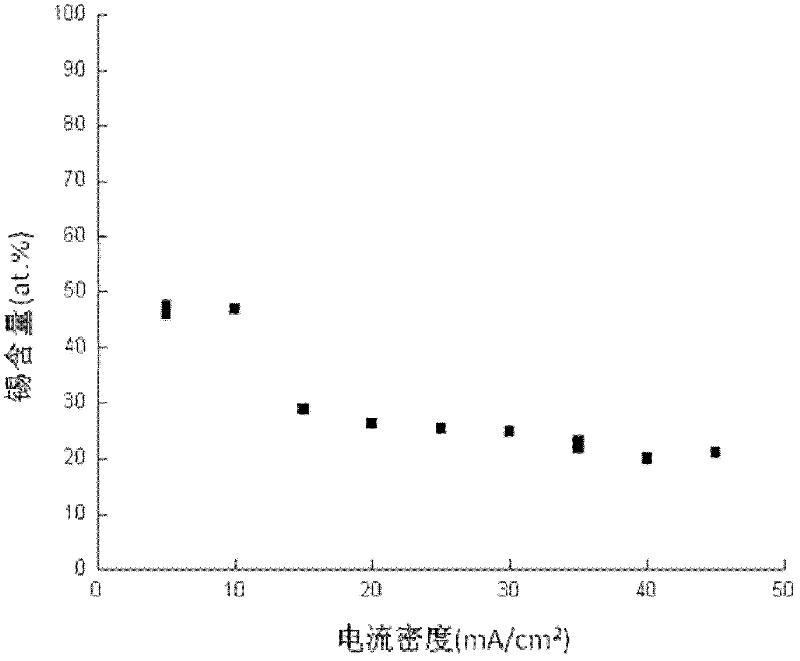

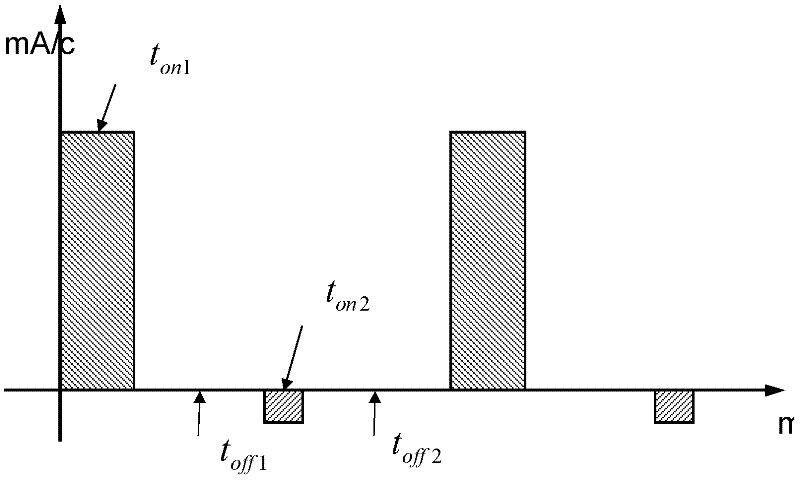

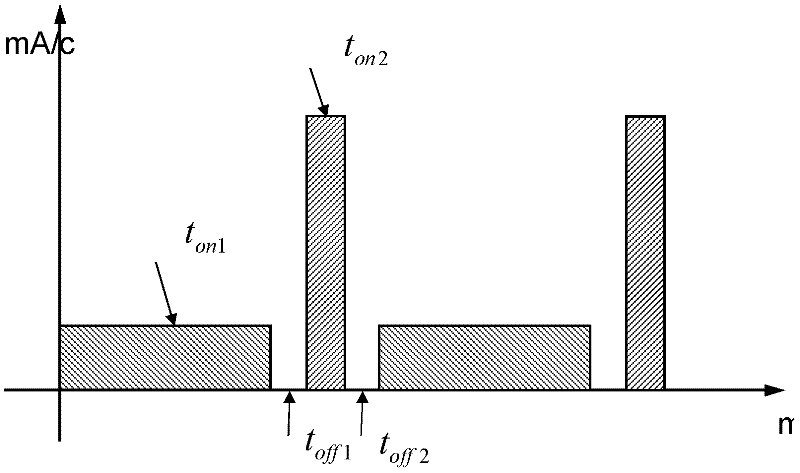

Co-deposition electroplating method with cyanogen-free Au-Sn alloy electrolyte

The invention relates to a co-deposition electroplating method for preparing Au-Sn alloy on an electroplating substrate and a cyanogen-free Au-Sn alloy electrolyte. The wave forms of electroplating current pulses are forward variable-amplitude pulses, namely that two different forward square wave pulses exist in one period, and the peak values and the conducting time of the electroplating current pulses respectively correspond to peak value current density and time which are required for generating Au5Sn and an Au-Sn alloy phase in a plating layer. In the electrolyte, sodium sulfite is adopted as a main complexing agent and ethylene diamine tetraacetic acid is adopted as an auxiliary complexing agent for the gold ion complexing agent, potassium pyrophosphate is used as a tin ion complexing agent, hydroquinone is used as an antioxidant, and the pH value of the electrolyte is from 8 to 9. When the method is used for preparing Au-30at.%Sn eutectic plated layer through electroplating, the plating speed reaches 13 mum / hour, the electrolyte is stable, the operation is simple, and the gold and tin content in the plated layer is easy to control. The method can be applied in microelectronics and photoelectron industry for connecting and encapsulating LED chips, connecting flip chips, forming welding pads or patterns on the surface of semiconductor devices or similar devices, etc.

Owner:DALIAN UNIV OF TECH

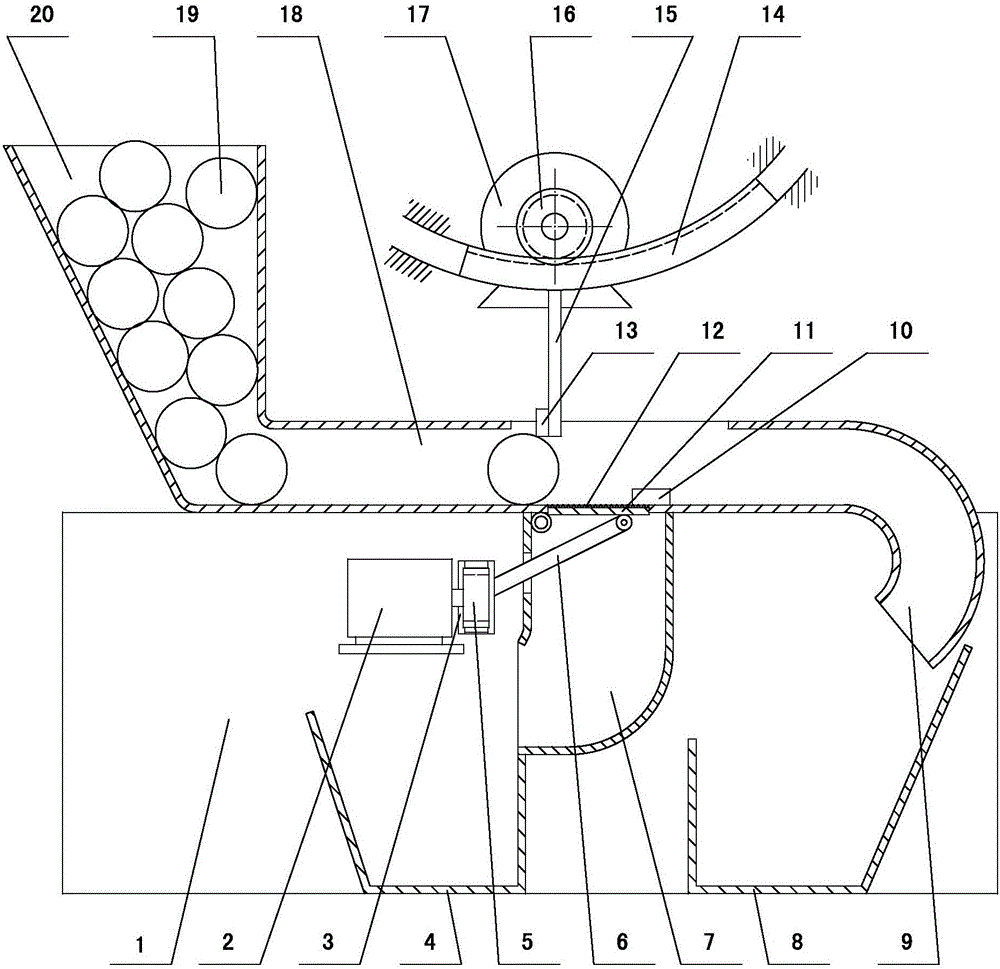

Automatic ball sorting machine

The invention discloses an automatic ball sorting machine. The automatic ball sorting machine comprises a machine frame, a charging barrel, a ball conveying pipe, a sorting device, a first material falling device and a second material falling device. The sorting device comprises a sensor, a baffle, an arc rack, a first gear and a first motor. An output shaft of the first motor drives the baffle to swing through engagement of the first gear and the arc rack. The lower end of the baffle is connected with the sensor. The distance between the sensing end and the bottom of the ball conveying pipe is equal to the diameter of balls. The first material falling device comprises a material falling plate, a first material falling pipeline, an oblique pulling rod, a sliding block, a second gear and a second motor. An output shaft of the second motor drives the material falling plate to overturn through engagement of the second gear and the rack and cooperation of the sliding block and the oblique pulling rod. By adopting the structure, manual sorting is replaced, the production efficiency is greatly improved, the sorting precision is higher, and operation is more convenient.

Owner:太仓吉井机械有限公司

Method for preparing anode material iron phosphate lithium of lithium ion battery

ActiveCN101118963AAvoid complicatedHigh crystallinityElectrode manufacturing processesChemical productsCrystallinity

The present invention relates to a method for producing LiFePO4 of positive pole of lithium ion battery. The invention is prominently characterized in that the method comprises three steps as follows: mixing the iron material, the lithium material and the phosphorus material uniformly to compound highly crystallized LiFePO4 in a high temperature first; adding a little diluted acid in the LiFePO4, after mixing and drying the processed LiFePO4 and conductive agent or pre-conductive agent, conducting ball mill for the mixture using a heavy ball; processing the mixture at a lower temperature and then the positive material LiFePO4 with excellent electrochemical performance can be gained. The gained LiFePO4 has favorable crystallinity and the electronic and the lithium ion conducting net is unique with excellent performance. The present invention uses cheap chemical product as raw material and the compounding art is simple thus is easy for producing on scale. The electrochemical character is favorable.

Owner:龚思源

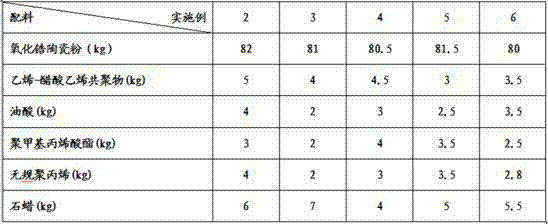

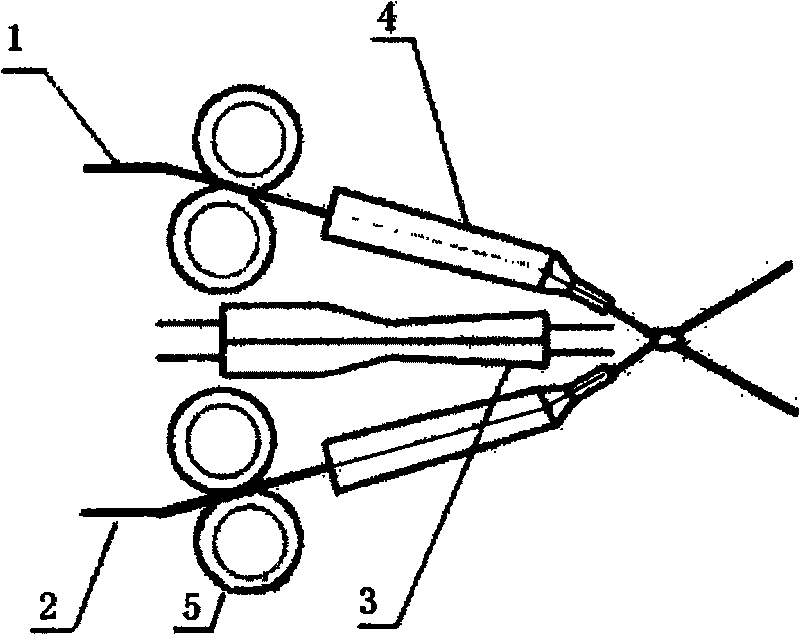

A production method for color cable core with color insulation layer

InactiveCN101236808AReduce in quantityRealize linkage operationInsulated cablesConductor/cable markingElectrical conductorInsulation layer

The invention relates to a manufacturing method for a dichroic cable core provided with a colored insulation material layer on the outside, wherein, when the insulation material layer is extruded on a conductor, two plastic extruding machines are used; one is a plastic extruding machine for uncolored insulation materials and the other is a plastic extruding machine for colored insulation materials; the two plastic extruding machines share a double-layer coextrusion handpiece; the uncolored insulation materials are taken as inner layer insulation materials, and the colored insulation materials are taken as outer layer insulation materials; two layers of insulation materials are combined in the same handpiece, and simultaneously extrusion of double-layer insulation materials is completed on a cable conductor. By adoption of the method for color changing of the insulating core, users only need to extrude colored insulation materials in a donkey engine completely, and obviously the means can greatly reduce the number of color changing wastes. By adoption of the method of the invention, the interlocking operation of the two plastic extruding machines is realized and the operating procedure is simplified.

Owner:高荣富

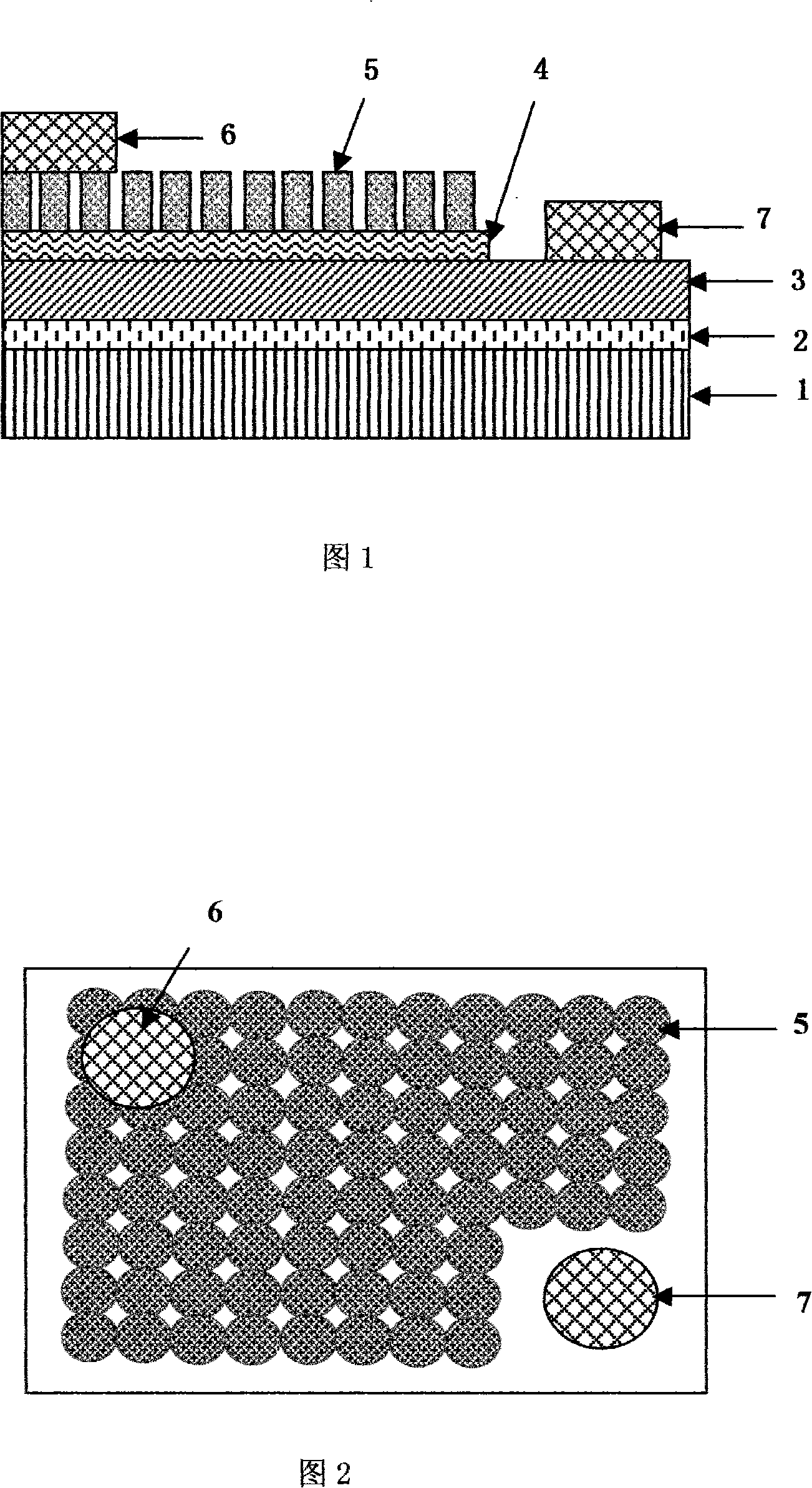

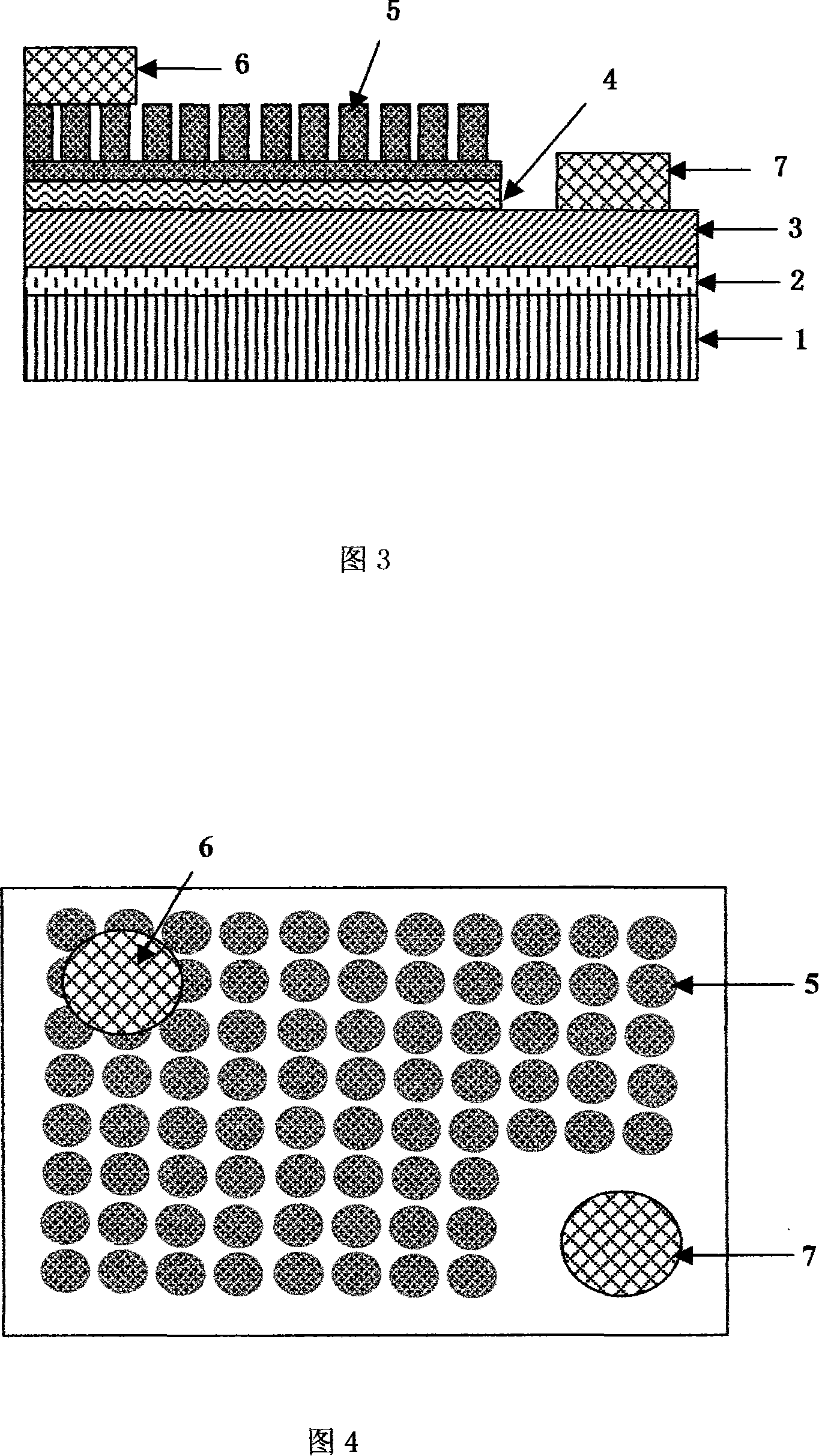

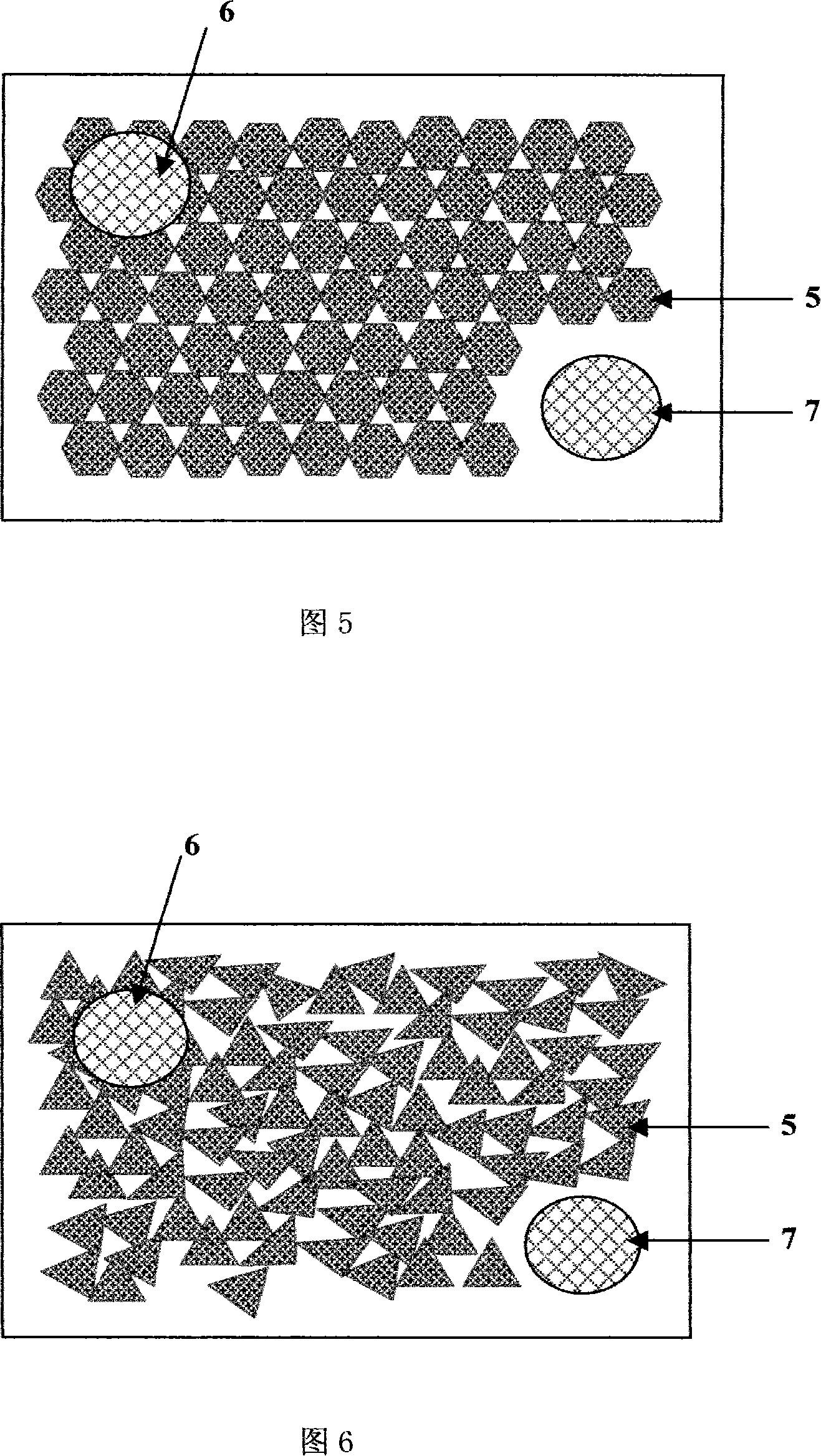

High efficiency light emitting diode with surface mini column array structure using diffraction effect

InactiveCN101110461AImprove light extraction efficiencyEfficient exportSolid-state devicesSemiconductor/solid-state device manufacturingDiffraction effectPhotonic crystal

A high-efficiency LED provided with a surface micro-column array structure and based on diffraction effect has a structure below: N type GaN grows on a cushioning layer of a sapphire substrate. A GaN active layer grows on the N type GaN layer. A P type GaN layer grows on the active layer. A micro-column array is etched on the P type GaN layer, which can be periodically or aperiodiclaly arranged two-dimensional structure. A P type electrode and a P type bonding pad are laid on the P type GaN layer. An N type electrode and an N type bonding pad are arranged on the N type GaN layer. The present invention has the advantages that light diffusion effect is utilized and light is fully exported through the micro-column to improve lighting efficiency and ensure even light distribution on a light surface. Compared with LED adopting two-dimensional photonic crystal, the structure needs simple production technique and lower production cost. Compared with traditional LED suffering roughly processed surfaces, the structure brings much higher light emission efficiency.

Owner:SHENZHEN UNIV +1

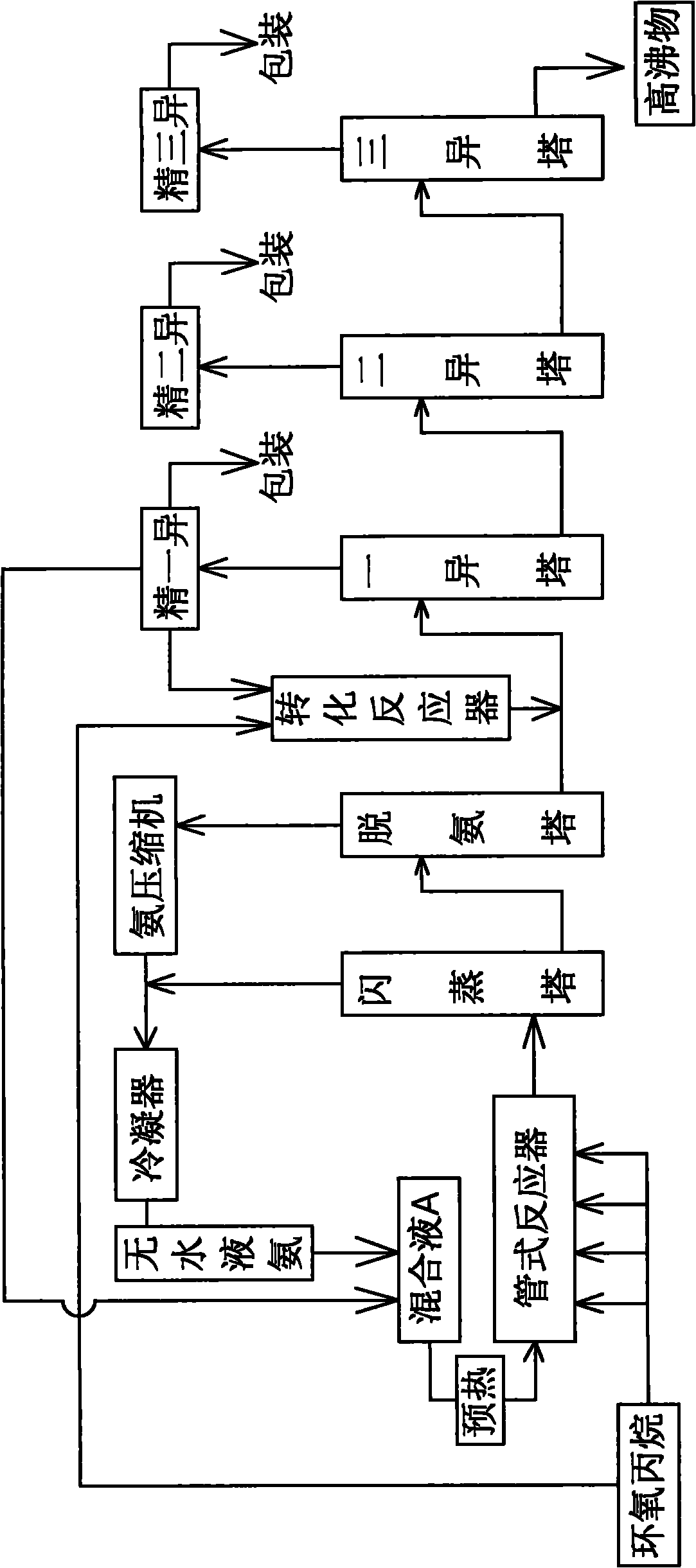

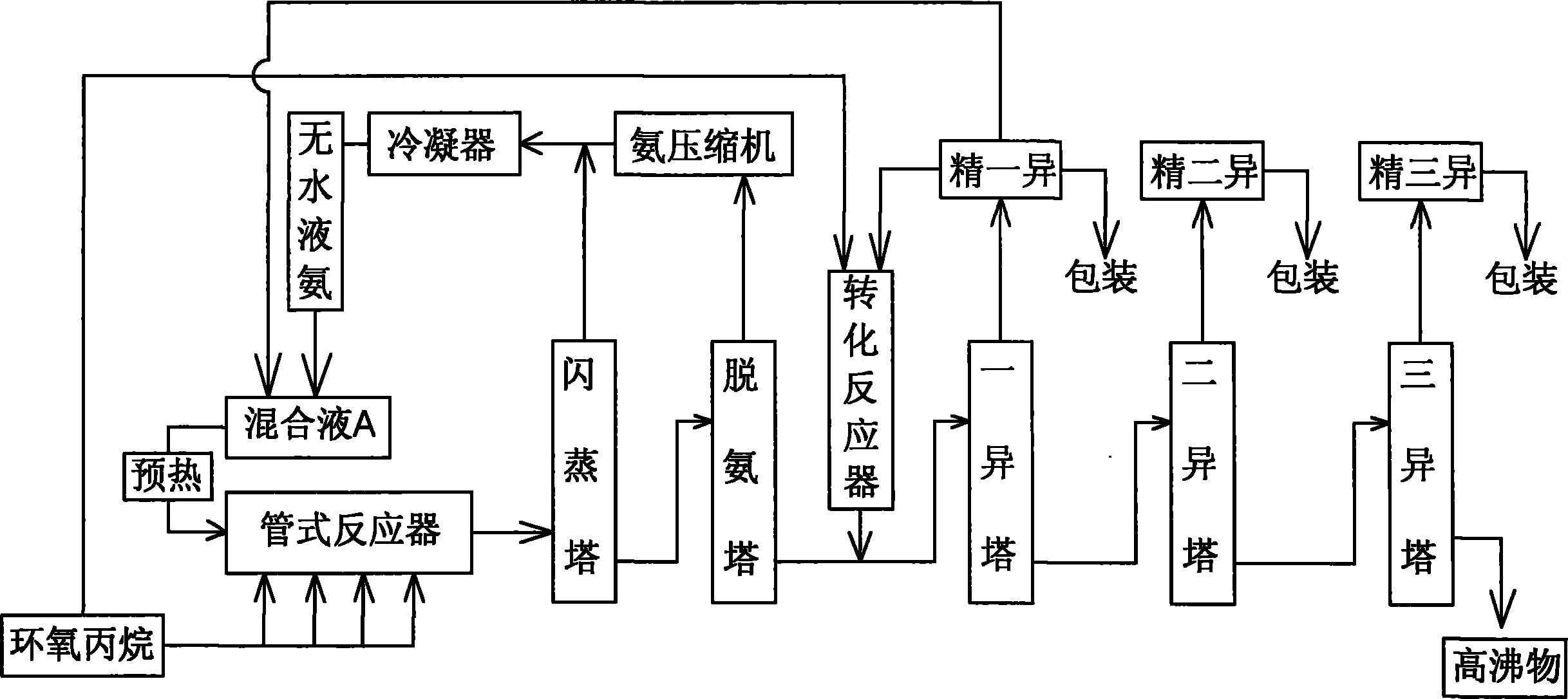

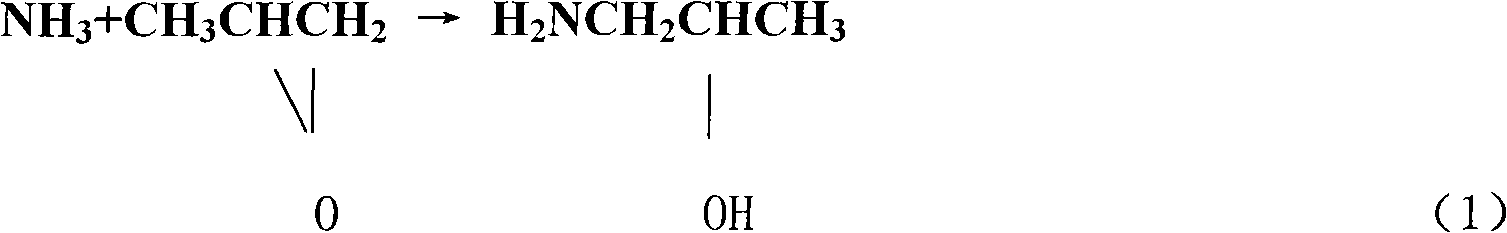

Isopropanolamine producing method

InactiveCN101786957ASave energyInhibition of hydrationOrganic compound preparationAmino-hyroxy compound preparationSide effectMonoisopropanolamine

The invention relates to an isopropanolamine producing method. As the present isopropanolamine producing method uses water as a catalyst, the energy consumption for subsequent dehydration is high and side effects can be easily caused. For this reason, the isopropanolamine producing method of the invention includes tubular reaction, flash evaporation, deamination and rectification, wherein isopropanolamine is used as the catalyst in the tubular reaction; before feeding, a liquid mixture A of anhydrous liquid ammonia and the catalyst is prepared according to the weight ratio of 96-99:1-4; finally, the liquid mixture A and propylene oxide are added according to the feeding speed ratio of 85-340:58. The isopropanolamine producing method realizes low energy consumption and less byproducts in the subsequent dehydration. The invention is applicable to producing the isopropanolamine.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

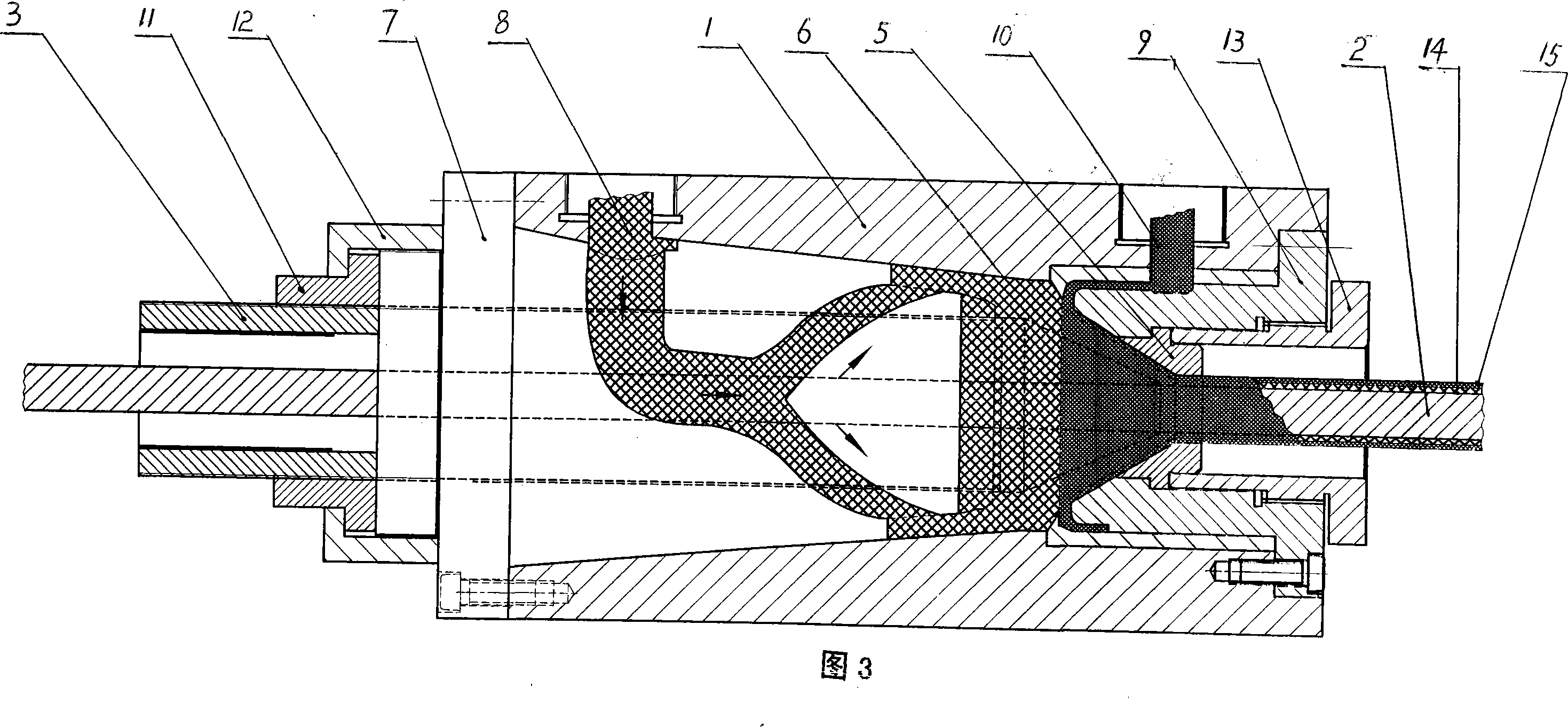

Crystalloid laminae composited from single crystal and directional column crystal and preparing method

InactiveCN1660524AImprove performanceQuality improvementPolycrystalline material growthBlade accessoriesDirected crystallizationEngineering

A monocrystal and orientational cylindrical crystal combined blade used for gas turbine features that its middle region is orientational cylindrical crystals and its gas inlet and outlet edges have monocrystal form. Its manufacture method includes such steps as installing a composite crystallizer to the crystallizer of orientational crystallizing furnace, smelting by 100-150 of overheat, regulating the temp of mould heater to 1500-1530 deg.C for upper region and 1550-1580 deg.C for lower region, casting, and moving mould downward at 5-7 mm / S.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

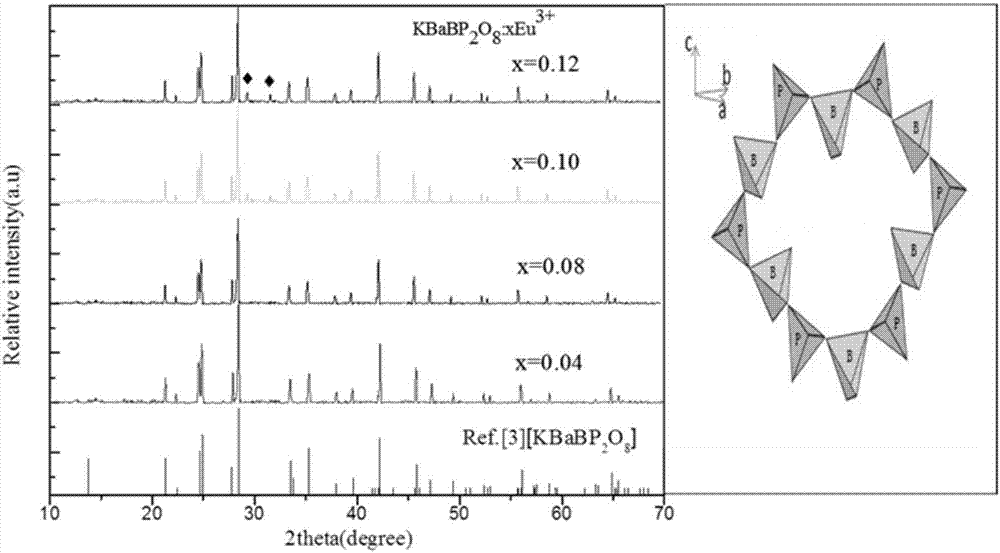

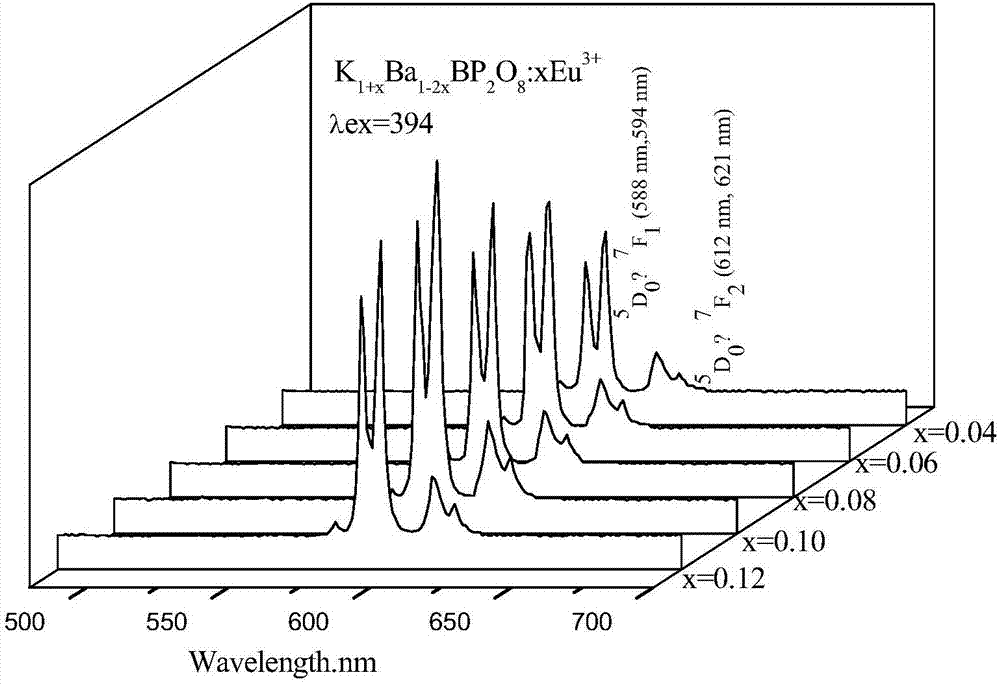

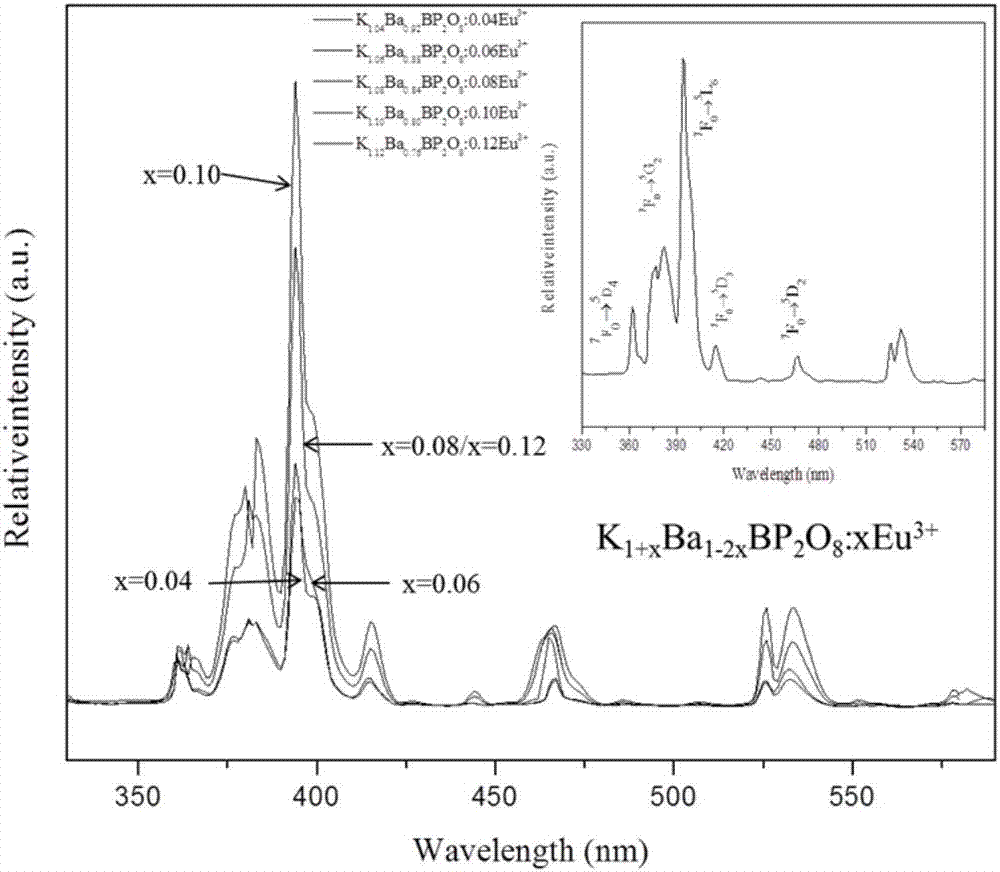

Near ultraviolet excited charge compensation type infrared light borophosphate luminescence material and preparation method thereof

ActiveCN107043625ASynthesis temperature is lowThermally and chemically stableLuminescent compositionsAir atmosphereLuminescence

The invention discloses a near ultraviolet excited charge compensation type infrared light borophosphate luminescence material and a preparation method thereof. The chemical composition of the material is K1+xBa1-2xBP2O8:xEu<3+>, K1+xBa1-2xBP2O8:xEu<3+>, F<-> or KBa0.8BP2O8:01Eu<3+>, 0.1R<+>, graphene, wherein Eu<3+> is the luminescent center, R<+> is a charge compensating agent, and x is 0.04 to 0.12. The preparation method using a high temperature solid phase technology comprises the following steps: accurately weighing raw materials according to the stoichiometric ratio of the target product, placing the raw materials in an agate mortar, and grinding the raw materials to make the raw materials uniform; placing the obtained pretreated mixed solid powder in a corundum crucible, heating the pretreated mixed solid powder to 600 DEG C in an air atmosphere, and keeping the temperature for 2 h; and rising the temperature 900 DEG C according to the same heating rate, keeping the temperature for 4 h, naturally cooling the obtained system with a furnace to room temperature, and further grinding the cooled powder to obtain the final product. The preparation method has the advantages of simplicity in operation, sufficient reaction and suitableness for production. The luminescence material prepared in the invention has the advantages of high luminescence efficiency, high brightness, excellent chroma and high stability.

Owner:SHAANXI UNIV OF SCI & TECH

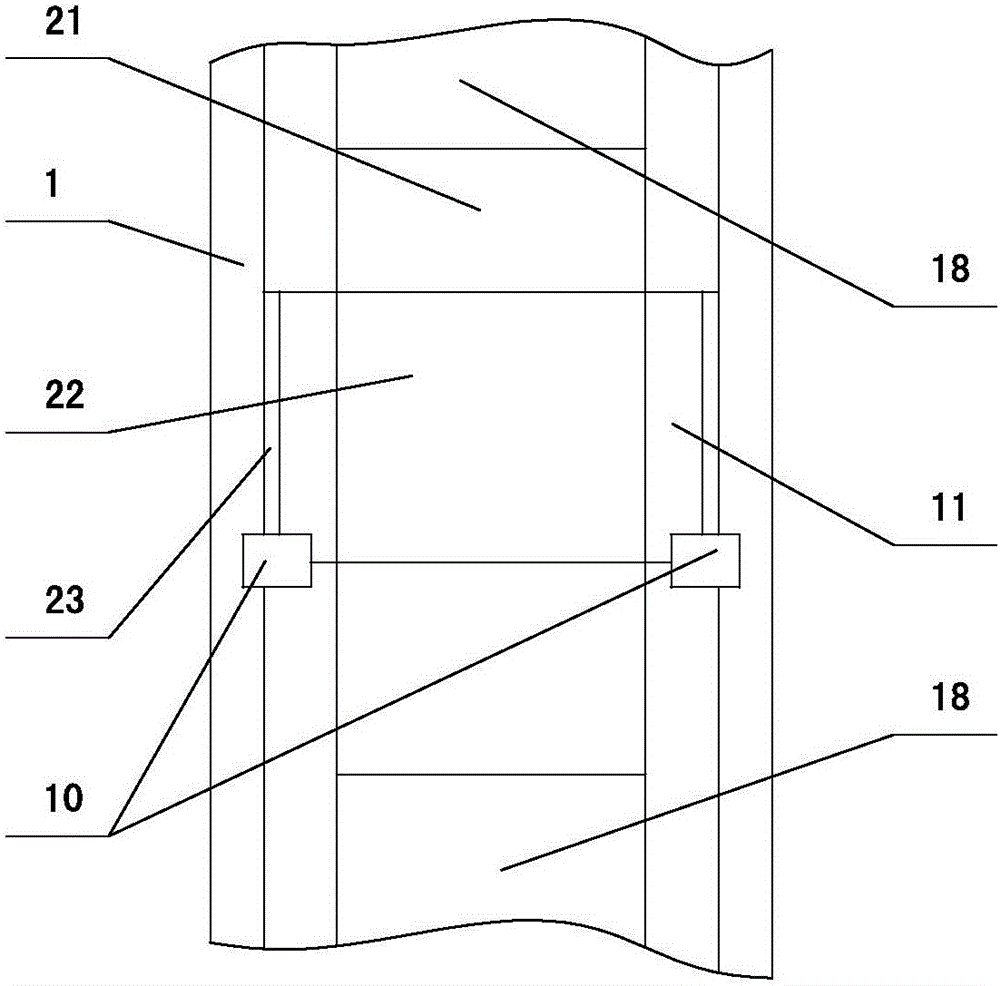

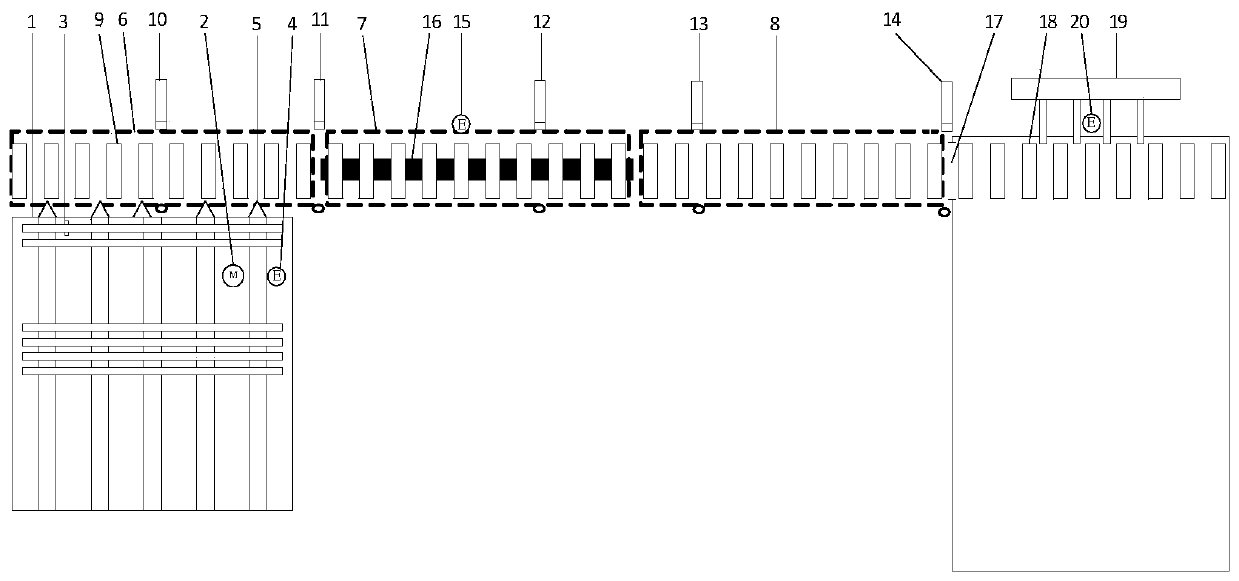

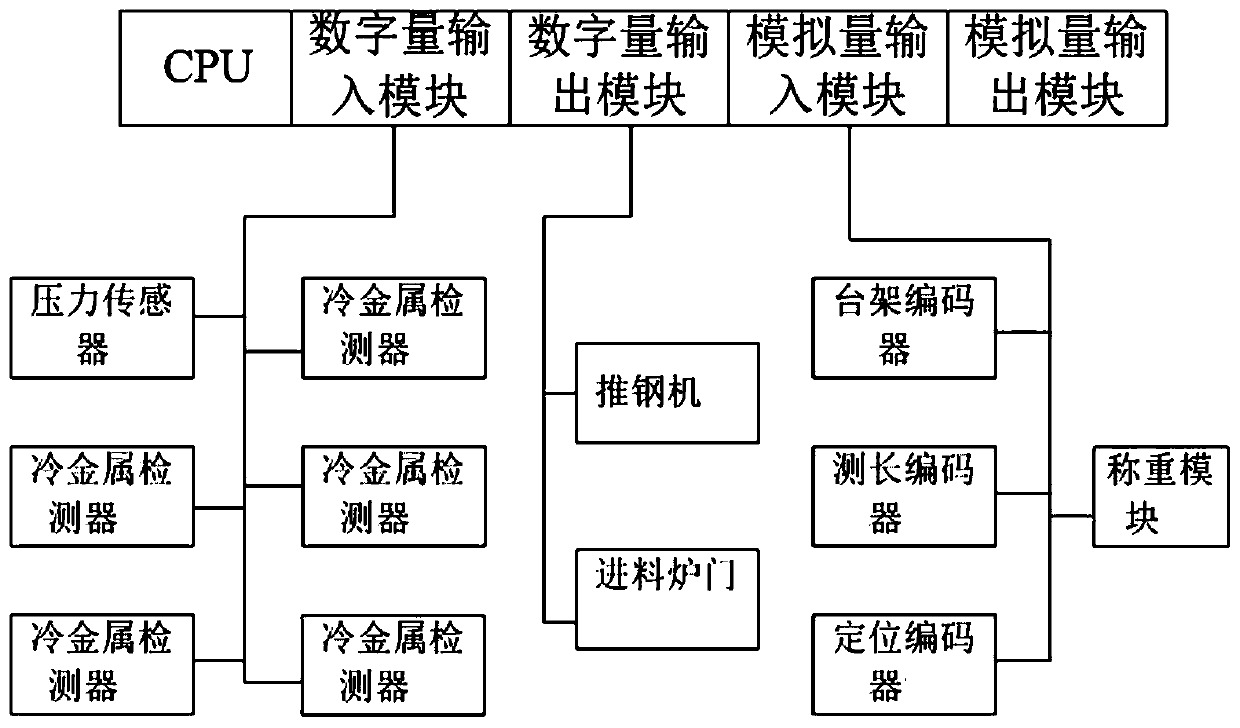

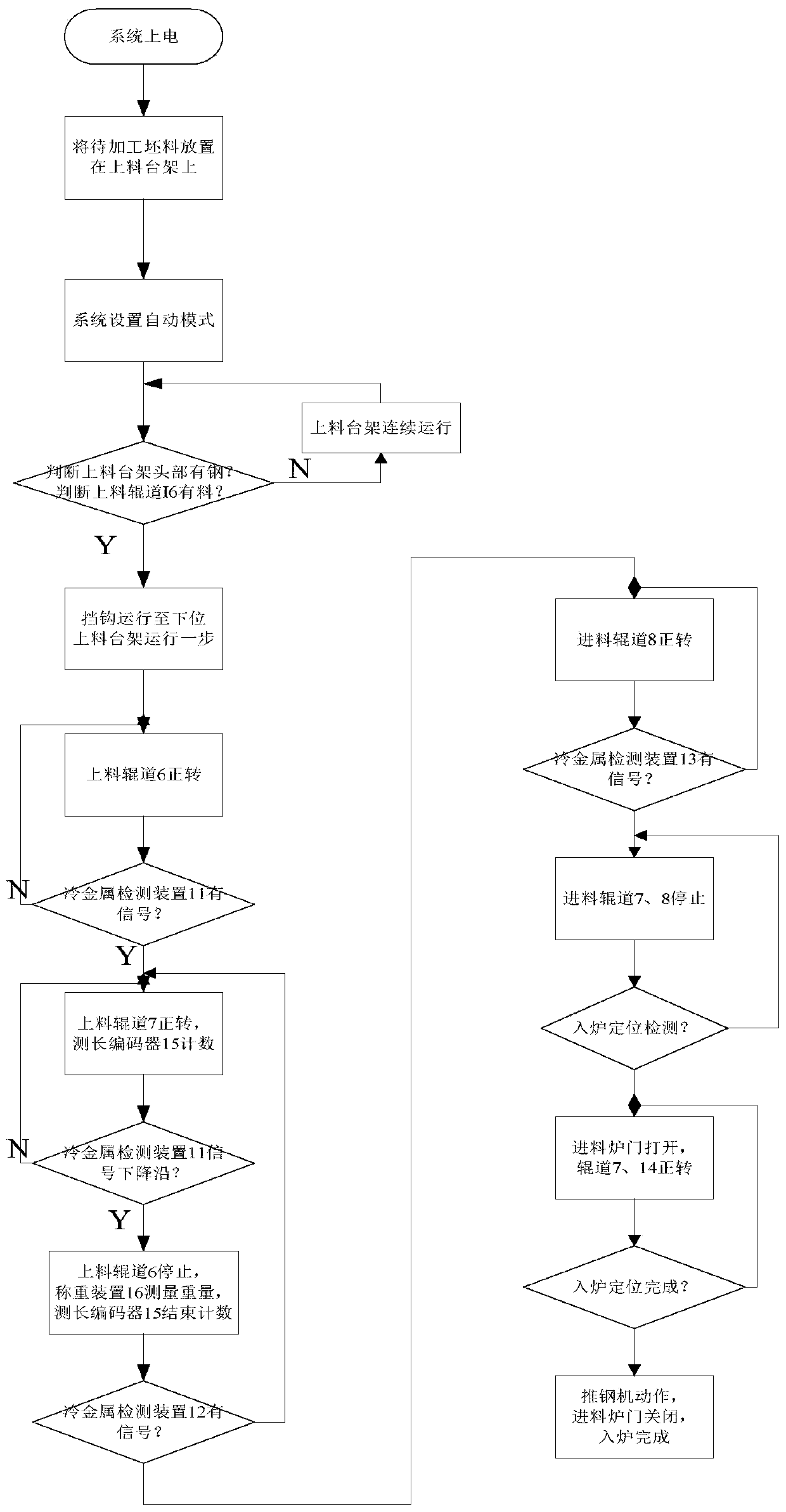

Feeding device and method of stepping beam heating furnace transmission

ActiveCN109855425ALow production costStrong reliabilityCharge manipulationFurnace typesRotary encoderEngineering

The invention discloses a feeding device and method of stepping beam heating furnace transmission. The feeding device of the stepping beam heating furnace transmission comprises a feeding table framemechanism, a feeding roller way device, a furnace entering device and a PLC control unit, wherein the feeding table frame mechanism comprises a feeding table frame main body, a feeding table frame motor, a pressure sensor, a feeding table frame encoder and a blocking hook; the feeding roller way device comprises a roller way motor, a cold metal detection device, a rotary encoder and a fixing weighing device; the furnace entering device comprises a feeding furnace door, inner-furnace cantilever rollers, a steel pushing machine and an in-furnace positioning encoder; the PLC control unit controlsthe feeding table frame to move in a reciprocating mode, so that blanks are conveyed to the roller way motor, the roller way motor is controlled to operate, the blanks are conveyed to a furnace doorof the heating furnace, when four conditions of a rolling line steel requirement signal, vacancies available in the furnace, a steel pushing machine at the rear position, and a step beam in the rear lower position, a furnace entering system is controlled to complete the processes of opening the furnace door, positioning the blanks, acting the steel pushing machine and the like so as to complete the automatic entering of the furnace.

Owner:ANHUI UNIVERSITY +1

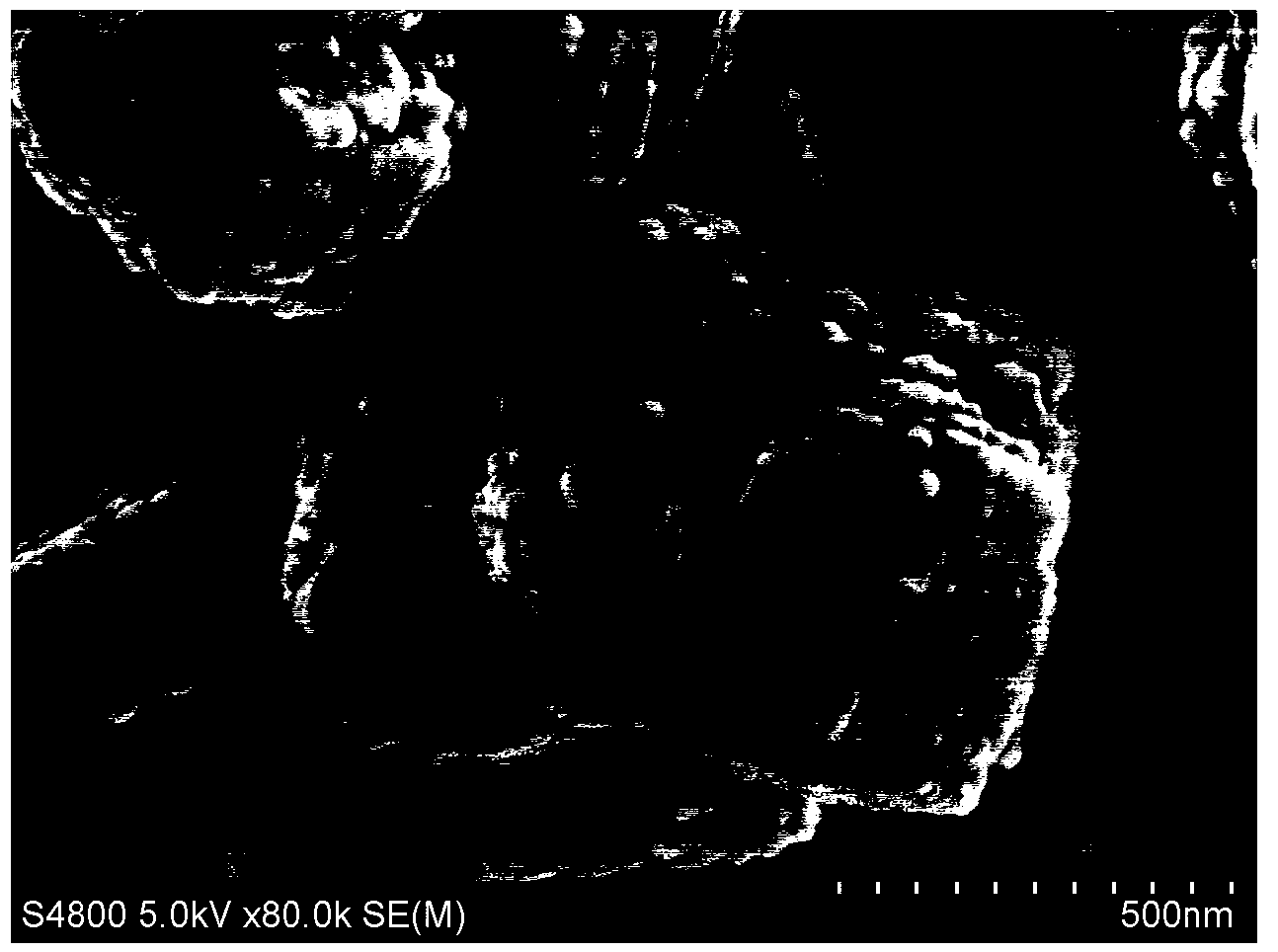

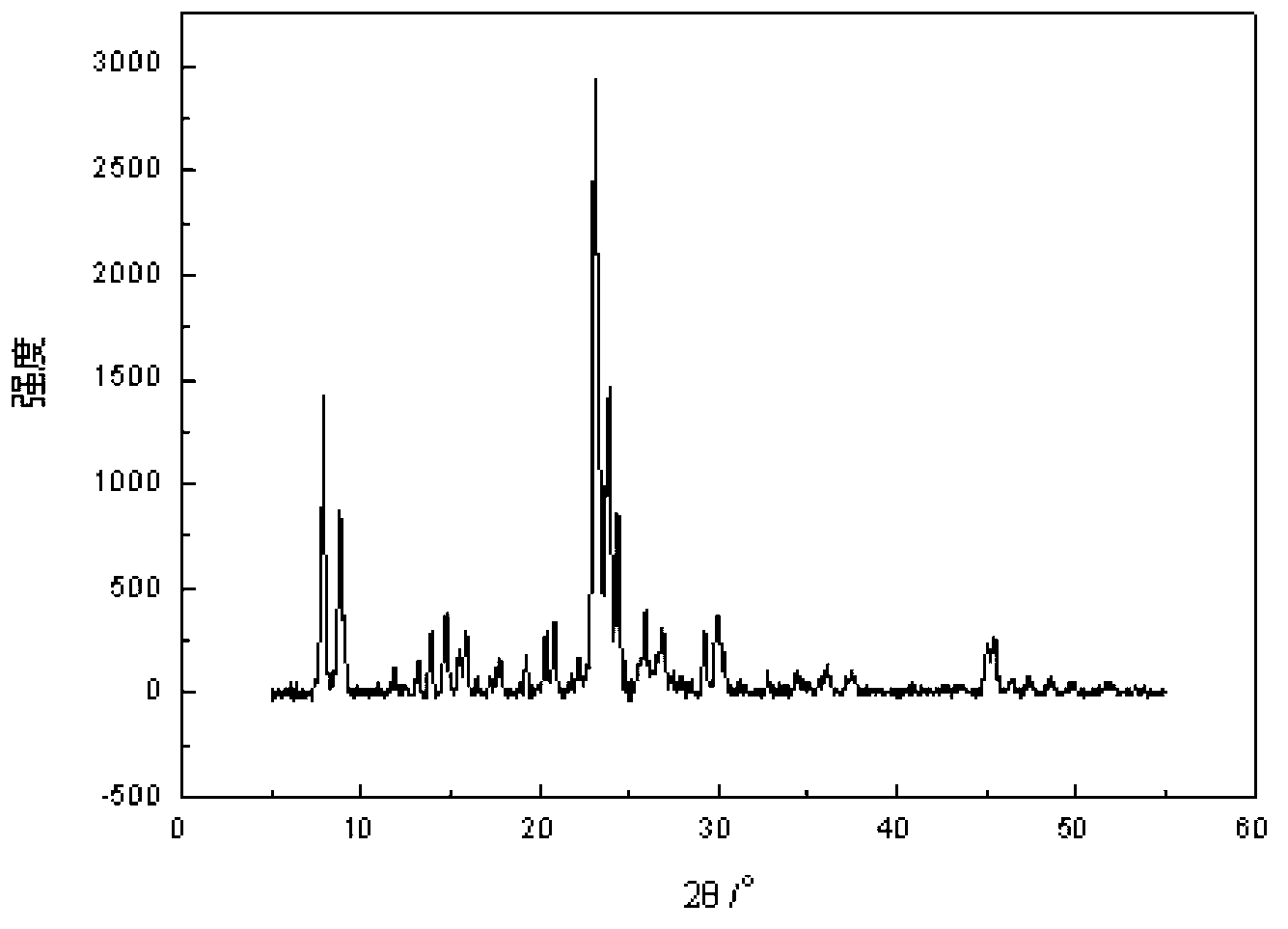

Method for preparing organic montmorillonite/polyurethane self-repair coating

ActiveCN104087141AIncrease spacingHigh densityAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceMontmorillonite

The invention discloses a method for preparing an organic montmorillonite / polyurethane self-repair coating. The method comprises the following steps: (1) organic treatment of montmorillonite, namely slowly adding an acidified modifier into an intensely stirred montmorillonite water solution, reacting at 80 DEG C for 24 hours, centrifuging, washing to obtain modified montmorillonite, then dissolving the modified montmorillonite into a mixed solvent (the ratio of ketone to deionized water is 1:1), intercalating a corrosion inhibitor into the modified montmorillonite, vacuumizing for 5 hours, washing, grinding, and sieving with a 350-mesh sieve to obtain organic montmorillonite; (2) preparation (parts by mass) of the organic montmorillonite / polyurethane self-repair coating, namely uniformly mixing 50-80 parts of hydroxyl resin, 1-5 parts of the organic montmorillonite, 1-40 parts of the mixed solvent and 3-10 parts of aid into a high-speed ball mill to obtain organic montmorillonite / hydroxyl resin, then uniformly mixing the modified hydroxyl resin and a curing agent at a certain mass ratio to obtain the organic montmorillonite / polyurethane self-repair coating, and drying and curing to form an organic montmorillonite / polyurethane self-repair coating layer.

Owner:STATE GRID CORP OF CHINA +2

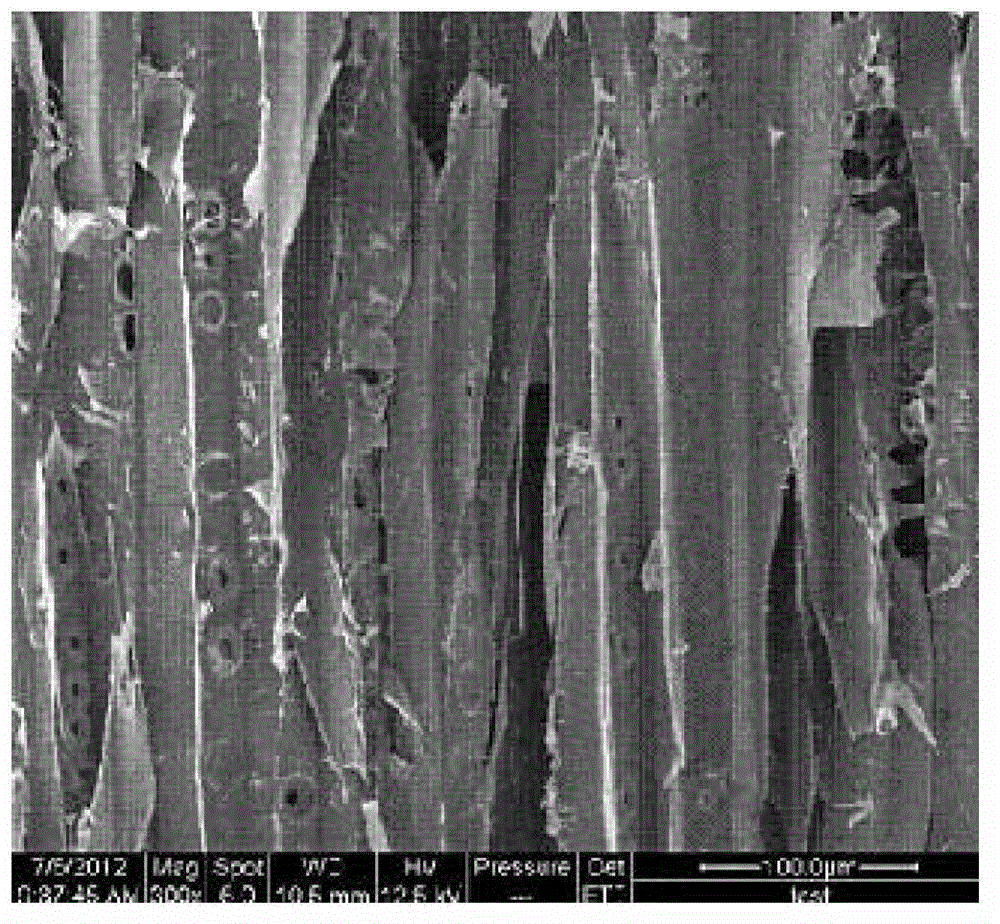

Fiber-reinforced biological resin adhesive composite material and preparation method thereof

ActiveCN106398119AImprove toughnessThe production process is simple and matureEpoxyWeather resistance

The invention discloses a fiber-reinforced biological resin adhesive composite material and a preparation method thereof. The composite material is prepared from 10-50 parts by weight of a biological resin adhesive and 50-100 parts by weight of fibers. The biological resin adhesive is prepared from 20-100 parts by weight of biomass oil-modified epoxy resin, 2-20 parts by weight of a diluent, 1-4 parts by weight of an emulsifier, 1-3 parts by weight of a coupling agent, 1-5 parts by weight of a release agent, 5-20 parts by weight of a filler, 1-4 parts by weight of a pigment and 10-20 parts by weight of a curing accelerator. The biological resin adhesive is prepared from the biomass oil-modified epoxy resin, then infiltrates fibers and then is cured so that the fiber-reinforced biological resin adhesive composite material with better toughness, better weather resistance and excellent mechanical properties is obtained. The method is used to prepare the composite material, utilizes easily accessible and cheap raw materials, has simple and mature processes and reduces a composite material cost.

Owner:四川景文材料科技有限公司

Calcium sulfate whisker modified polystyrene composite material, and preparation method thereof.

ActiveCN102234401AImprove impact resistanceImprove heat resistancePolystyreneButadiene-styrene rubber

The invention relates to a calcium sulfate whisker modified polystyrene composite material, and a preparation method thereof. The calcium sulfate whisker modified polystyrene composite material is prepared from the raw materials of, by weight: 100 parts of polystyrene, 10 to 40 parts of calcium sulfate whisker, 10 to 20 parts of styrene-butadiene block copolymer, 0.1 to 0.3 parts of anti-oxidant 1010, 0.1 to 1 parts of zinc stearate, and 1 to 3 parts of titanate coupling agent. The preparation method comprises the steps that: calcium sulfate whisker and titanate coupling agent are added into a high-speed mixer, and are mixed for 5 to 10 min; rest raw materials are added to the obtained modified calcium sulfate whisker, and the mixture is mixed for 5 to 10 min in the high-speed mixer; the obtained mixture is extruded and granulated by a double-screw extruder. The calcium sulfate whisker modified polystyrene composite material has good impact resistance and heat resistance. Therefore, the material is suitable to be applied in the manufacturing of electric appliance housings with strict requirements of impact resistance and heat resistance.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

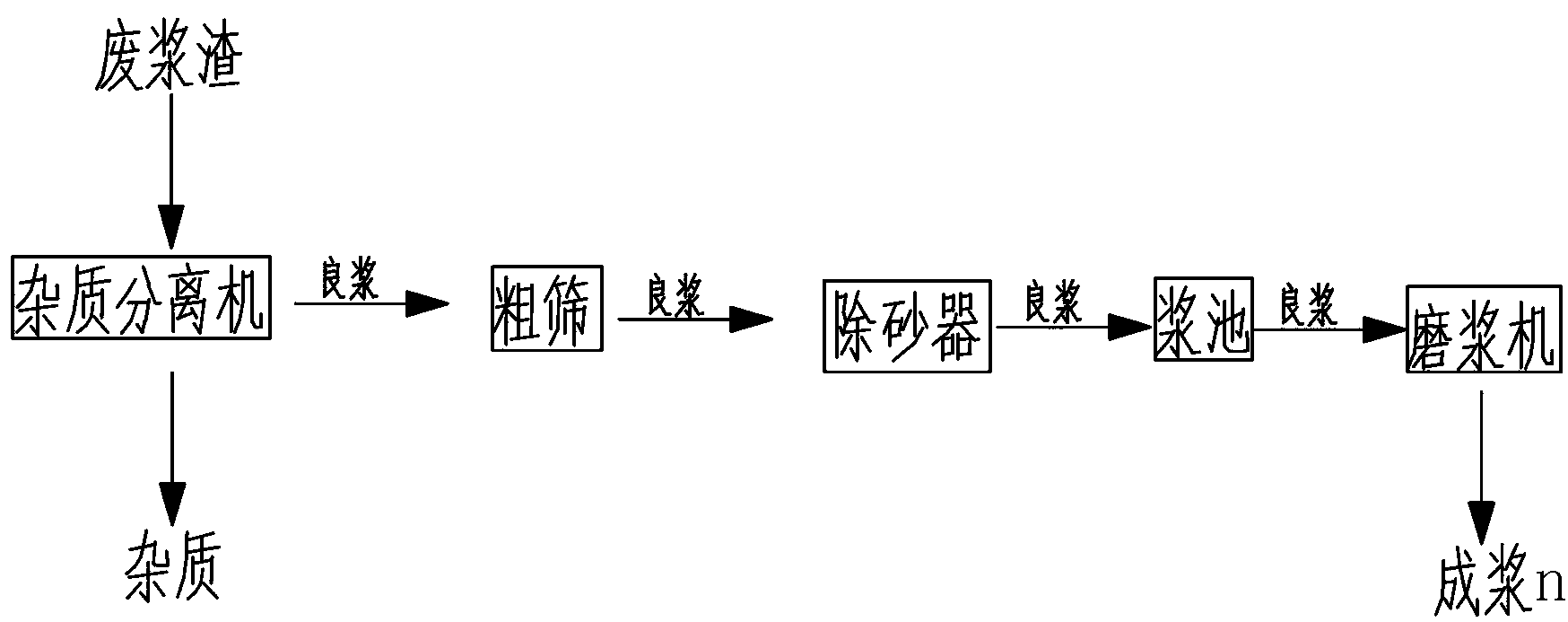

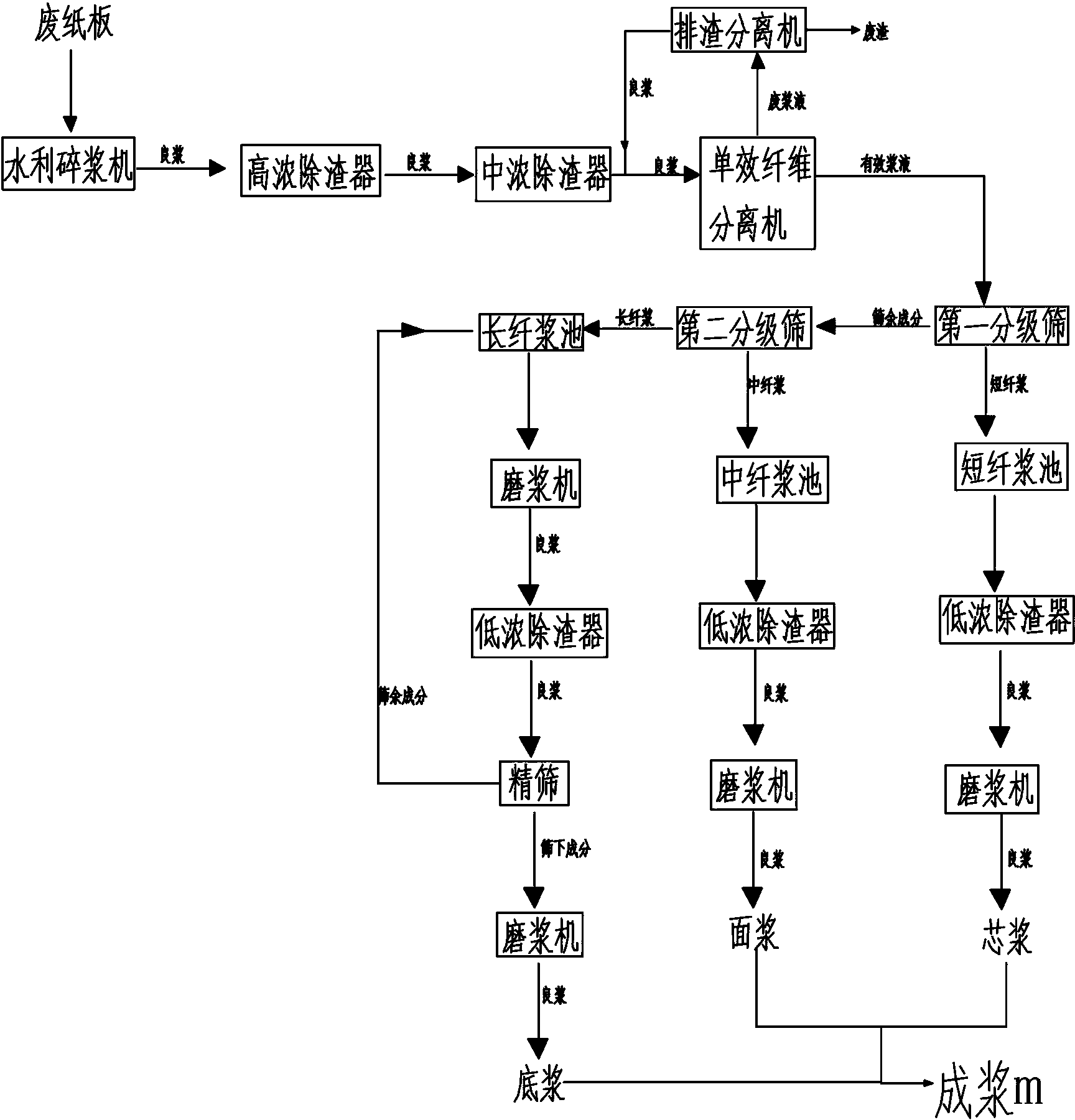

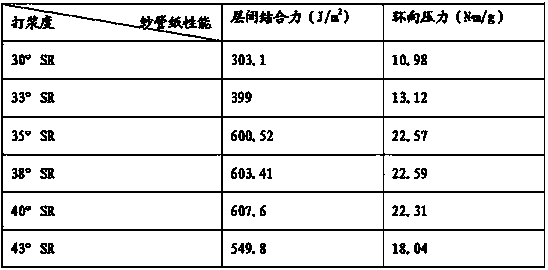

Method for forming full pulp by processing bobbin paper waste pulp residues and producing protoplasm by using formed full pulp

InactiveCN104213459AImprove bindingLarge hoop pressurePaper recyclingSecondary cellulose fibresFiberWaste paper

The invention discloses a method for forming a full pulp by processing bobbin paper waste pulp residues and producing protoplasm by using the formed full pulp. The method is characterized in that heating is carried out before pulping during the treatment of waste pulp residues, so it is in favor of fibrillation of filers in the waste pulp residues during pulping, a waste paper pulp is processed in grading to respectively prepare a core pulp, a surface pulp and a bottom pulp, the above three pulps are mixed to form a full pulp, and the waste paper pulp grading treatment is in favor of the fiber length equalization; and the full pulp obtained after processing the waste pulp residues is mixed with the full pulp prepared from waste paper boards in proportion to produce the bobbin paper protoplasm. The method changes the waste pulp residues into valuables and reduces the production cost of bobbin paper, and the bobbin paper prepared by using the protoplasm has high strength, and large interlayer bonding force and circumferential pressure. The method is suitable for producing the bobbin paper protoplasm.

Owner:TANGSHAN TIANZHENG IND

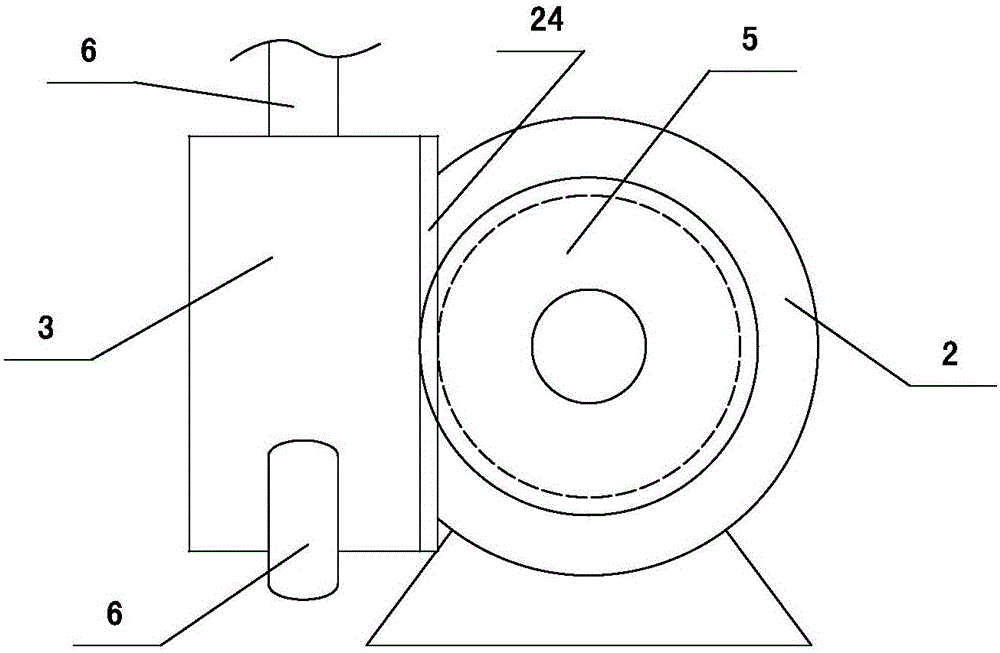

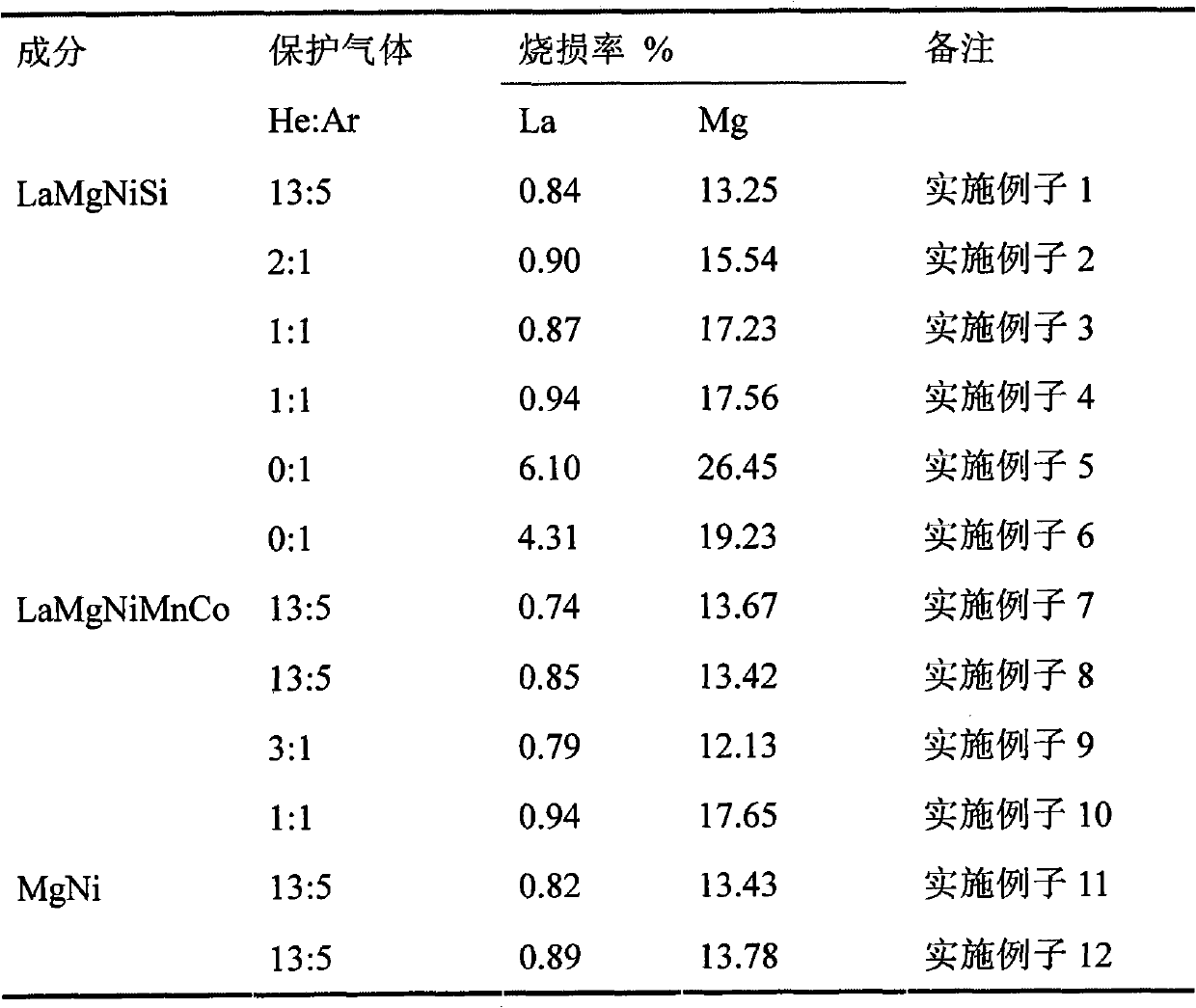

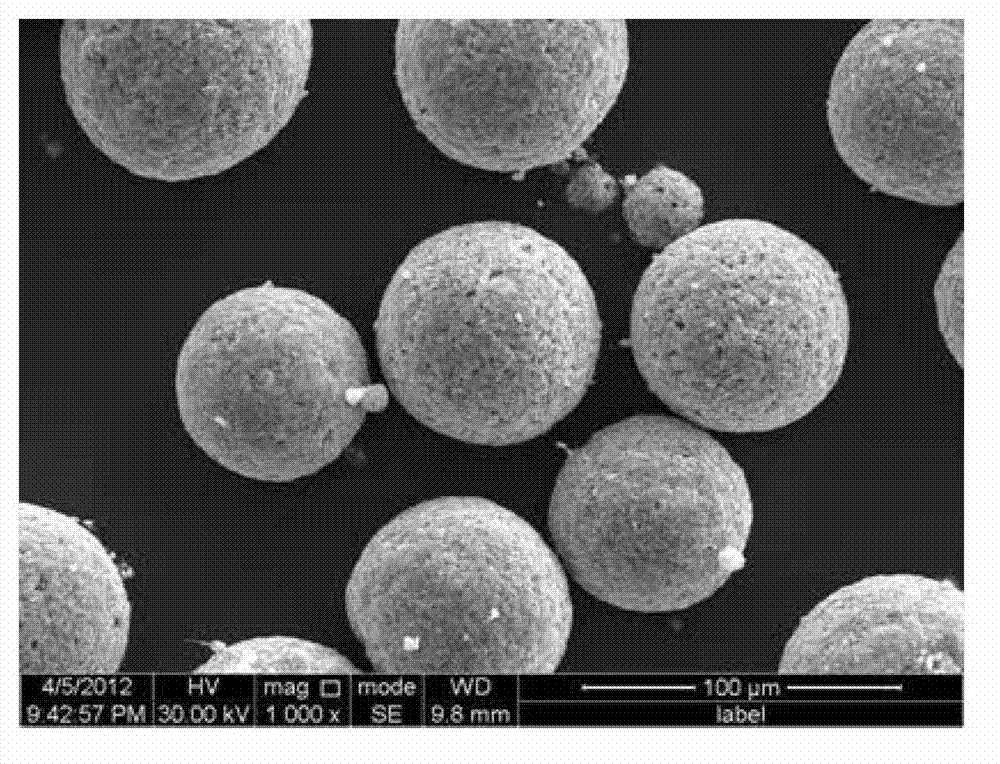

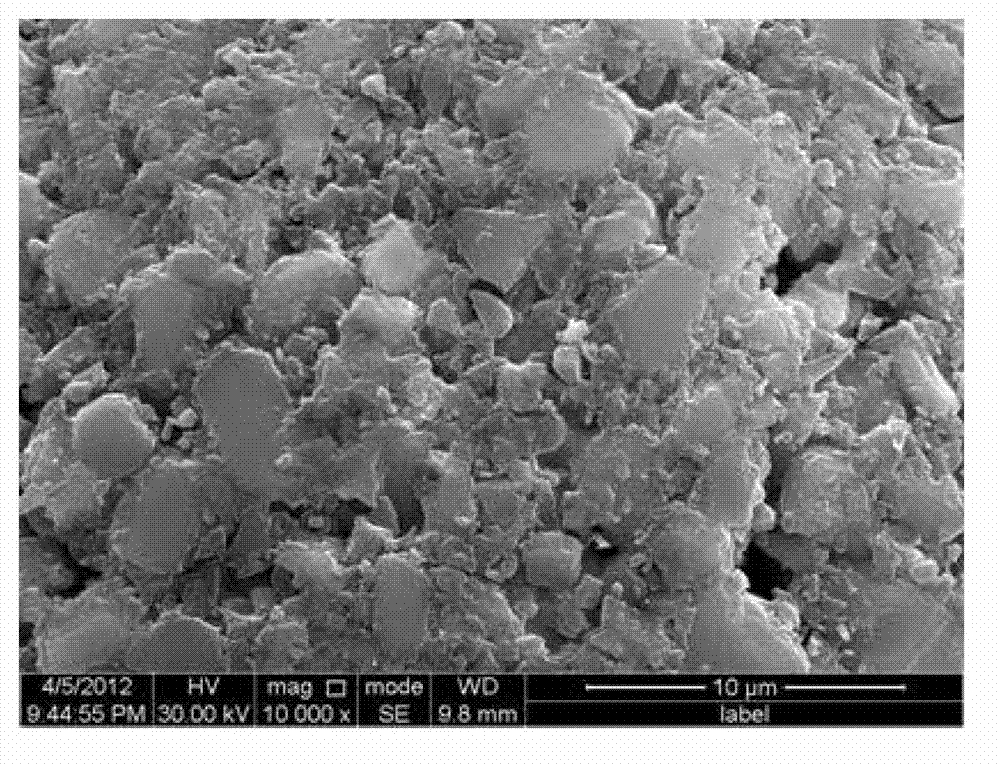

Preparation method of Mg-contained hydrogen storage alloy

The invention belongs to the technical field of functional metal alloy materials and relates to a smelting method applicable to La-Mg-Ni series and Mg2Ni type hydrogen storage alloys, which comprises the following concrete steps of: weighing the components of the La-Mg-Ni series hydrogen storage alloy as ABy according to a stoichiometric proportion, wherein the A is LaxMg1-x, the B is Niy-zCz, and the C is Mn, Fe, Mo, Co, Al, Ti, Si, V, Cr, Cu, Zn, Zr, Nb, W, Hf, Ta, B, P or / and Sn, La, Mg and Ni, adding into a crucible of a medium-frequency induction smelting furnace, and placing on a feeding device in the furnace after carrying out surface processing on Mg blocks; carrying out vacuum pumping until the vacuum degree is 10-2 Pa, introducing He and Ar protective gases mixed according to a certain proportion until the air pressure in the furnace reaches 0.01-0.1MPa, regulating the power range to be 15-35kW, and controlling the temperature at 600-1300 DEG C until metals are molten; and stopping electrifying for 1-10 minutes, adding the Mg into the crucible through the feeding device in the furnace, regulating the power range to be 15-35kW, controlling the temperature at 600-1300 DEG C and casting after smelting for 1-10 minutes. The process has simple operation, good controllability, stable components of the prepared hydrogen storage alloy and lower cost and can realize low-cost and large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

Hexaaluminate high-emissivity thermal protection coating layer and preparation method thereof

InactiveCN102815927ASolve the impactSolve the problem of thermal expansion mismatchMolten spray coatingEmissivityThermal expansion

The invention provides a hexaaluminate high-emissivity thermal protection coating layer and a preparation method of the hexaaluminate high-emissivity thermal protection coating layer, and relates to a thermal protection coating layer and a preparation method of the thermal protection coating layer, aiming at solving the problem that the existing high-emissivity thermal protection coating layer ispoor in thermal shock resistance, mismatched in thermal expansion and low in emissivity within a short-wave band. The thermal protection coating layer prepared by the invention has the chemical formula as shown in LaMg1-xMxAl11O19, wherein M is Mn, Fe, Co or Ni, x is larger than or equal to 0 and is less than or equal to 1. The preparation method comprises the following steps of: 1, preparing LaMg1-xMxAl11O19 feed material; 2, preparing a high-temperature alloy plate material base body; 3, preparing a NiCoCrAlYTa combination layer on the base body; and 4, preparing the LaMg1-xMxAl11O19 hexaaluminate high-emissivity thermal protection coating layer on the coating base body. The normal spectral emissivity of the thermal protection coating layer prepared by the invention is larger than 0.9 within the wave band of 7-14 mu m. The invention is suitable for the preparation of the metal material thermal protection coating layer.

Owner:HARBIN INST OF TECH

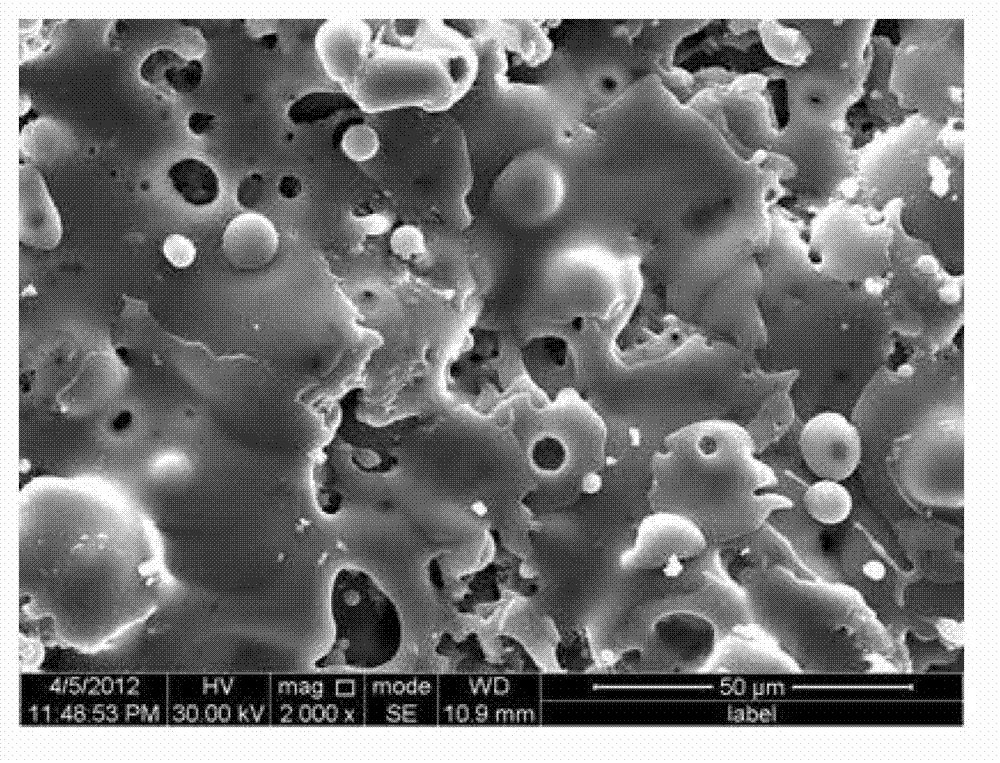

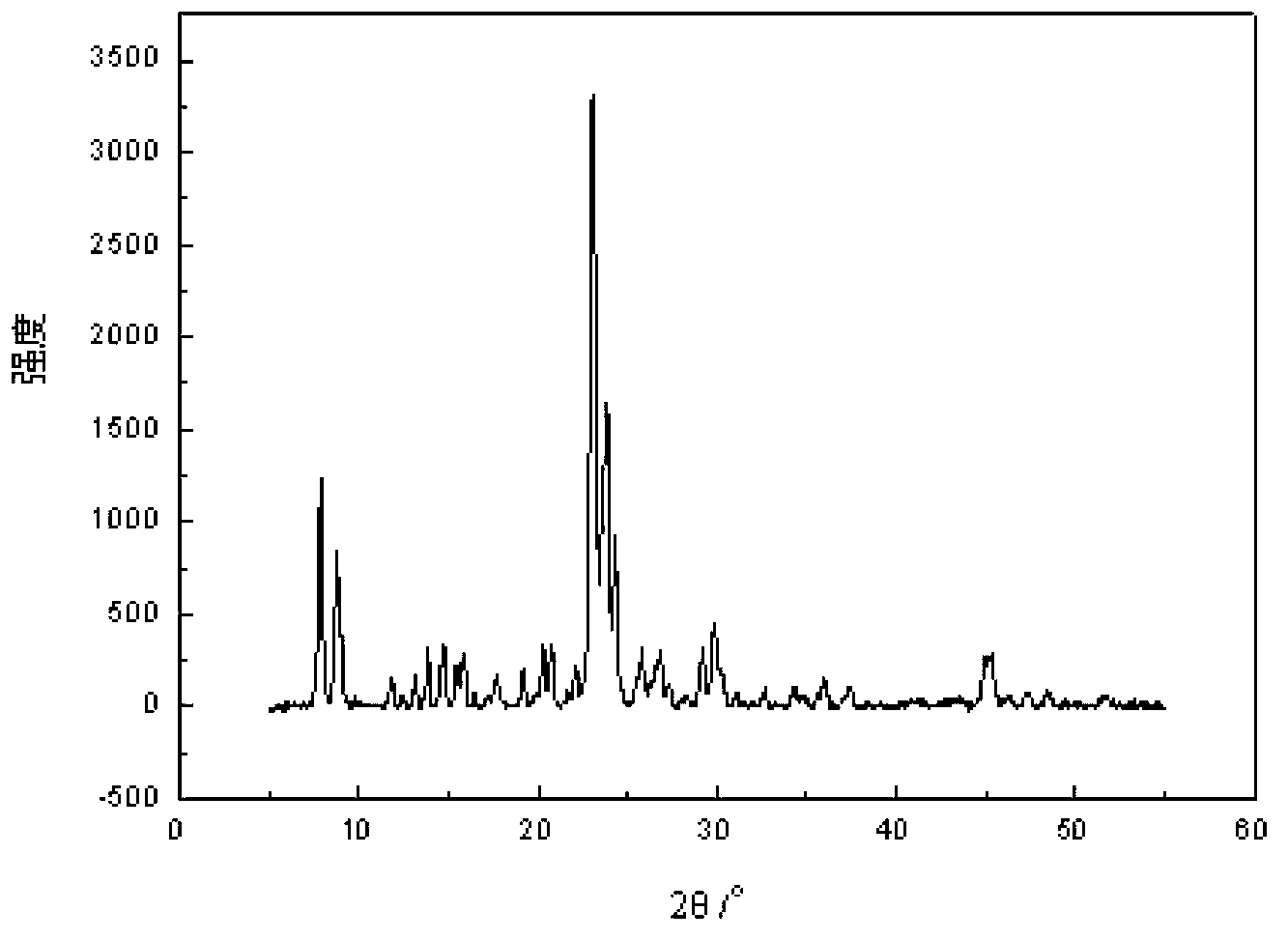

Preparation method of nanometer Zn/Al ZSM-5 molecular sieve

ActiveCN102795638AWide acidity adjustable rangeImprove pollutionPentasil aluminosilicate zeoliteMolecular sieveCentrifugation

The invention discloses a preparation method of a nanometer Zn / Al ZSM-5 molecular sieve, relates to the preparation method of a nanometer molecular sieve, and aims to solve the problems that the nanometer Zn / Al ZSM-5 molecular sieve is prepared by the existing method, the template agent usage amount is high, the template removing agent roasting time is long, the cost is high, the toxicity is high, and the pollution is serious. The preparation method comprises the following steps of: preparing gel by aluminum isopropoxide, tetrapropylammonium hydroxide, tetraethoxysilane and deionized water, and crystallizing the gel so as to obtain a pre-crystallized seed crystal; and adding the pre-crystallized seed crystal which takes up 1%-5% of the total mass of the gel into a mixed gel prepared by zinc nitrate hexahydrate, sodium hydroxide, partial sodium aluminate, deionized water and silica sol, thereby obtaining the nanometer Zn / Al ZSM-5 molecular sieve through centrifugation, washing, drying, roasting and cooling after crystallization. The nanometer Zn / Al ZSM-5 molecular sieve disclosed by the invention is low in template agent usage amount, short in template removing agent roasting time, low in cost, low in toxicity, and tiny in pollution. The nanometer Zn / Al ZSM-5 molecular sieve disclosed by the invention is suitable for production of the nanometer molecular sieve.

Owner:HEILONGJIANG UNIV

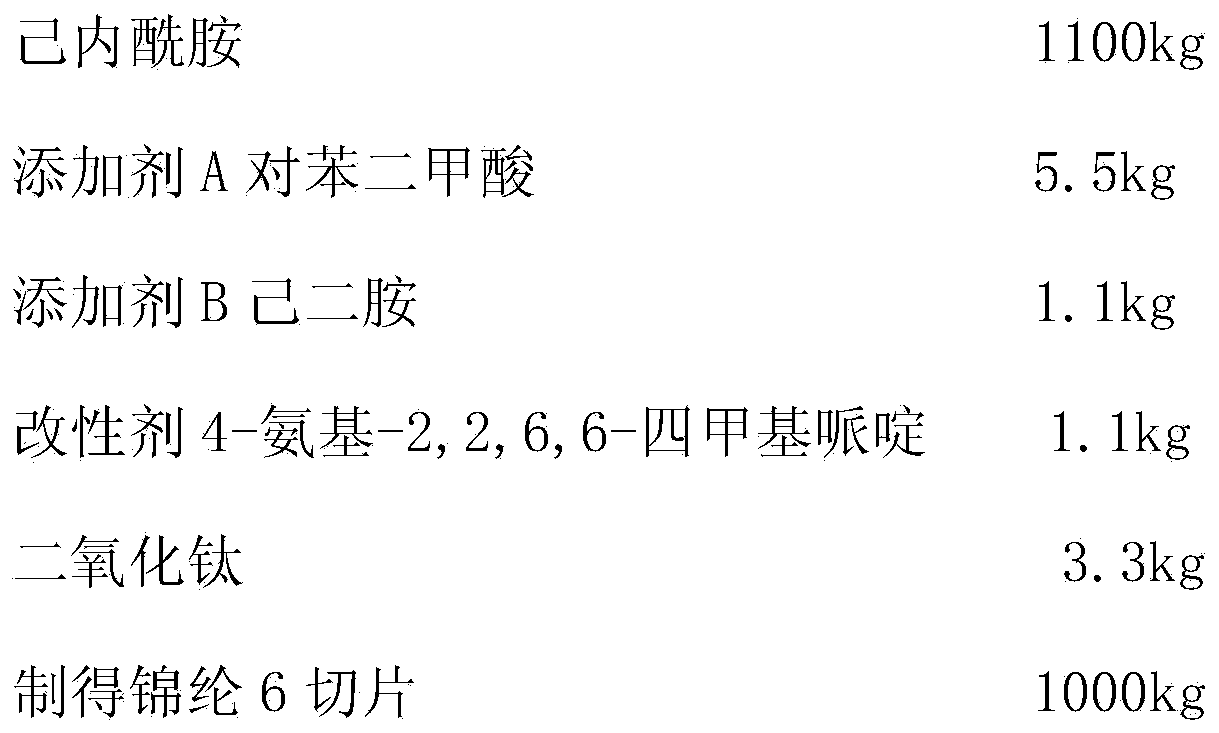

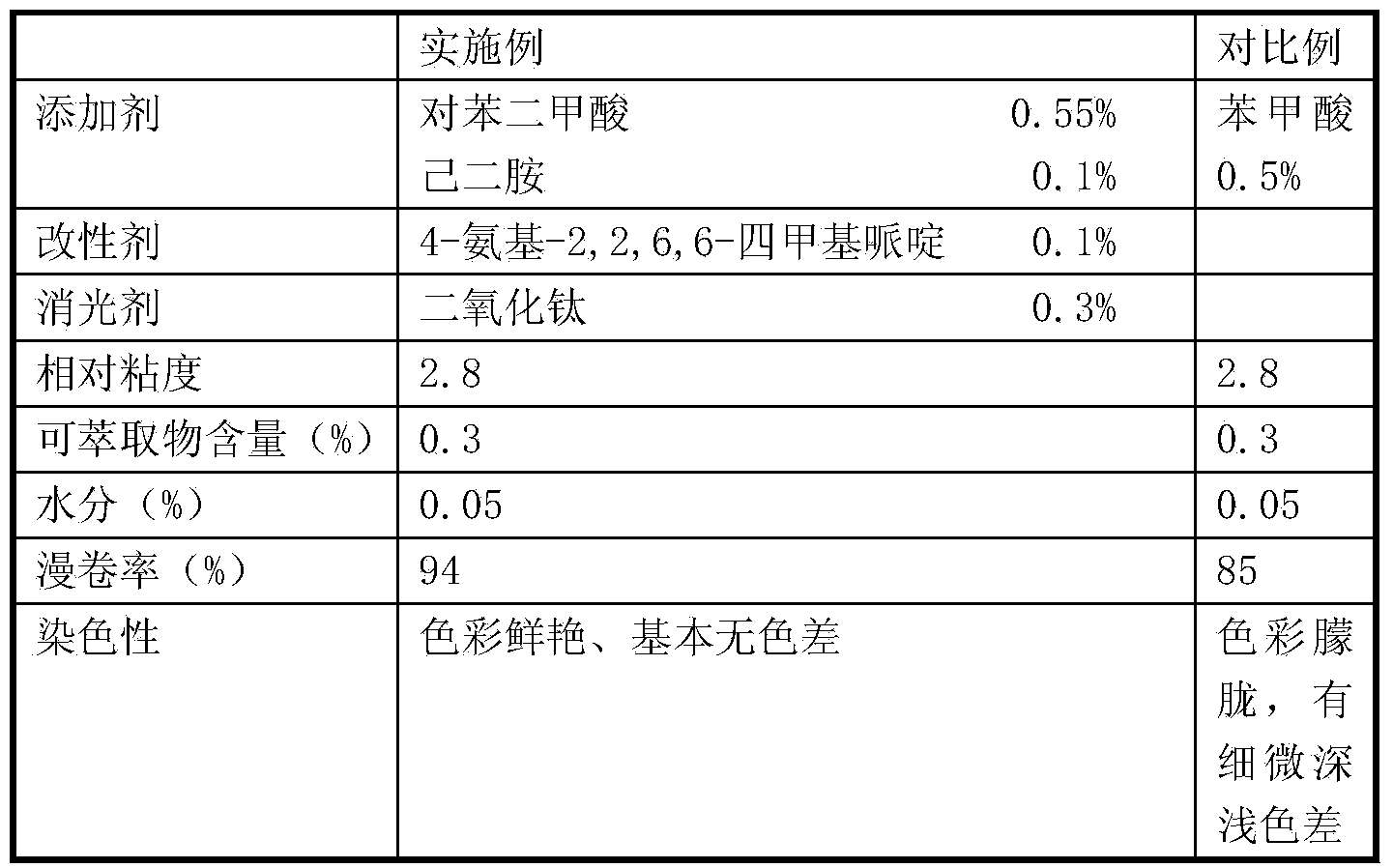

Chinlon 6 section for bromochlorodifluoromethane (BCF) carpet yarn and preparation method thereof

InactiveCN103408749AImprove stabilityImprove photostabilityArtifical filament manufactureMonocomponent polyamides artificial filamentYarnPolymer science

The invention discloses a chinlon 6 section for a bromochlorodifluoromethane (BCF) carpet yarn and a preparation method thereof. The chinlon 6 section is prepared from the following raw materials in percentage by weight: 99-100% of caprolactam, 0.02-1% of additive A, 0.02-1% of additive B, 0.05-0.6% of modifierand 0-0.5% of delustering agent; and the sum of the weight percents of all components is 100%. The preparation method of the section comprises the following steps: 1) preparation of solution of the additive A; 2) preparation of solution of the additive B; 3) preparation of modifier solution; 4) preparation of delustering agent dispersion liquid; 5) continuous polymerization; 6) extraction; and 7) drying. Compared with of the traditional section, the chinlon 6 section manufactured by the invention has the advantages the heat stability, the light stability and the dyeability are improved; the preparation step in a spinning process is reduced; the spinning stability, and the dyeability and the light stability of the BCF carpet yarn are improved; and the chinlon 6 section is especially suitable for production of the BCF carpet yarn.

Owner:JIANGSU HAIYANG CHEM FIBERS

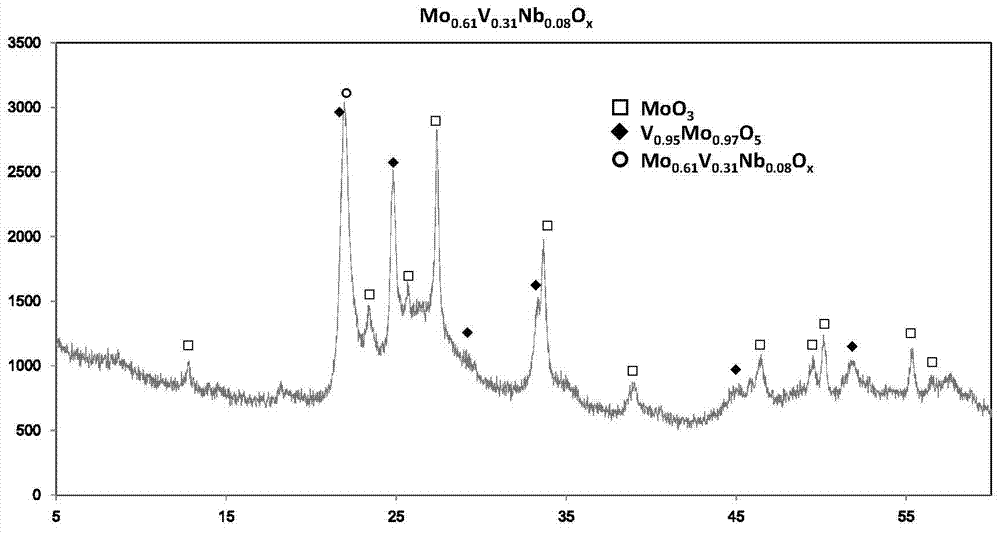

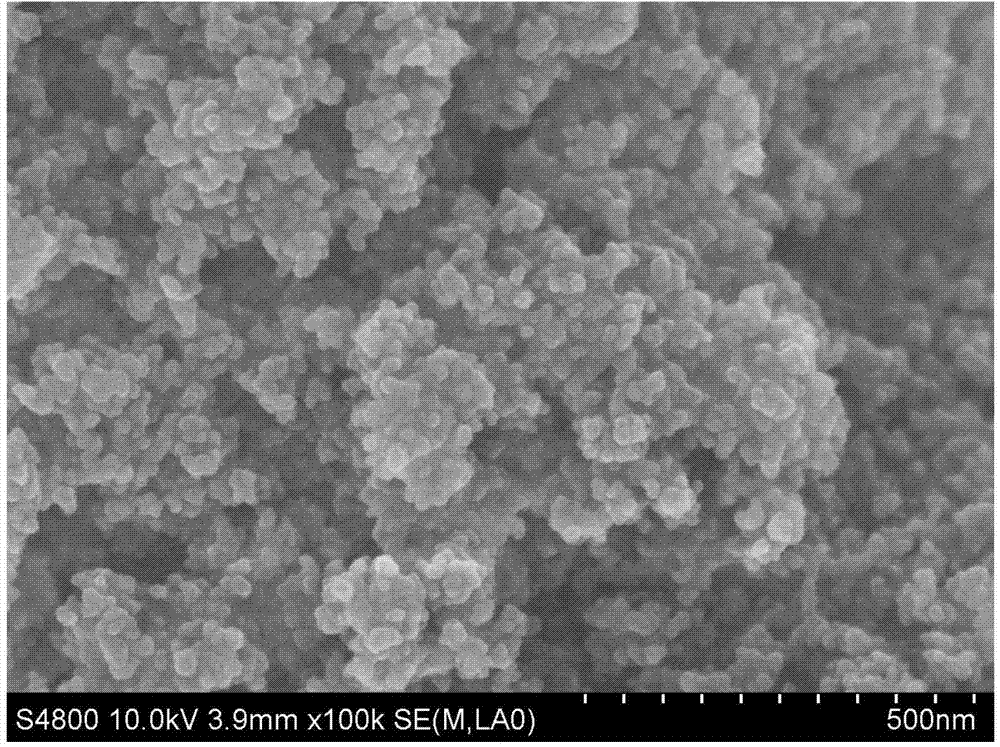

Molybdenum-vanadium based composite oxide catalyst and preparation and application thereof

ActiveCN103894179ANo pollution in the processReduce pollutionOrganic compound preparationWaste based fuelNiobiumPotassium

The invention relates to a molybdenum-vanadium based composite oxide catalyst and a preparation and an application thereof. The molybdenum-vanadium based composite oxide catalyst has the general formula of Mo1VaXbYcOd which is a composite metal oxide, wherein X is at least one element of niobium, antimony, bismuth, tellurium, tungsten, cobalt, nickel and neodymium; Y is at least one element of palladium, platinum, gold, silver, rhodium, potassium and cesium; a, b, c and d represent atomic ratios of vanadium, X, Y and oxygen to molybdenum respectively; a is 0.1-1.0, b is 0-0.3, c is 0-0.2, and d is a number which is determined by valence numbers of other elements existing in the composite metal oxide of the general formula and is the same as the valence numbers. The catalyst is used for selectively oxidizing lactic acid into pyruvic acid at the temperature of lower than 300 DEG C. The catalyst used in the method is easy to prepare and high in activity, and has high selectivity for the product pyruvic acid under the condition of semi-oxidation reaction. Compared with an existing method, the synthetic method of pyruvic acid has the advantages that the reaction materials are low in cost and easily available, the technological operation is simple, the reaction atom economy is high, and the selectivity for pyruvic acid is high.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Forming method of precise high-temperature alloy pipe with small caliber and thick wall for aviation

The invention discloses a forming method of a precise high-temperature alloy pipe with small caliber and thick wall for aviation. The forming method comprises the following steps: S1: cold rolling: carrying out multi-pass cold rolling on a qualified seamless tube to obtain a tube blank in transitional specification, wherein the outer diameter of the tube blank in the transitional specification is 1.14-1.17 times of that of a finished tube, the wall thickness of the tube blank is 0.97-0.985 times of that of the finished tube, and the dimensional deviation is controlled within a range of plus or minus 0.03mm; S2: manufacturing a pointed end: carrying out degreasing, heat treatment, acid cleaning, straightening and UT (ultrasonic) flaw detection on the tube blank with transitional specification sequentially, selecting the qualified tube blank obtained after UT flaw detection, and welding a pointed end with conicity at the end part of the qualified tube blank; S3: empty sinking: drawing the tube blank by the pointed end and deforming the tube blank under the extrusion of an outer mold to obtain a finished tube. The forming method makes up the technical gap of domestically producing the precise high-temperature alloy pipe with small caliber and thick wall, and has important economic benefit on the research and the production of a domestic aero-engine.

Owner:宝武特冶航研科技有限公司

Method for preparing nickel-containing silver electrode slurry

InactiveCN101877251AFast curingSmooth and fastNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver electrodeSlurry

The invention discloses a method for preparing nickel-containing silver electrode slurry, which comprises the following steps: (1) preparing silver-nickel mixed liquid; (2) preparing an organic carrier; and (3) preparing the nickel-containing silver electrode slurry. In the method, nickel powder, spherical silver powder and flaky silver powder form the conductive functional phase of the electrode slurry; and the electrical performance of the finally prepared silver electrode slurry can be regulated by changing the addition proportion of the nickel powder; the silver electrode slurry does not contain high-temperature melting compounds, so the silver electrode slurry is not harmful in the slurry producing and processing process, and is advantageous to environmental protection, energy conservation and exhaust reduction. Furthermore, the silver electrode slurry contains the nickel powder and other components, which have low cost, thus being favor for reducing the cost of the silver electrode slurry, and according with the megatrend of modern society development.

Owner:IRICO

Cyanogen-free Au-Sn alloy electroplating liquid

The invention relates to cyanogen-free Au-Sn alloy electroplating liquid, which belongs to the field of electroplating. The cyanogen-free Au-Sn alloy electroplating liquid comprises following components including non-cyanogen soluble monovalence gold salt, sulfite, organic polybasic acid, soluble divalent tin salt, pyrophosphate, a tin ion oxidation inhibitor, dihydric phosphate and cobalt salt. The electroplating liquid is stable, electroplating speed is fast, operation is simple, Au-Sn alloy ingredients are easy to be controlled, and the cyanogen-free Au-Sn alloy electroplating liquid is applicable to production.

Owner:DALIAN UNIV OF TECH

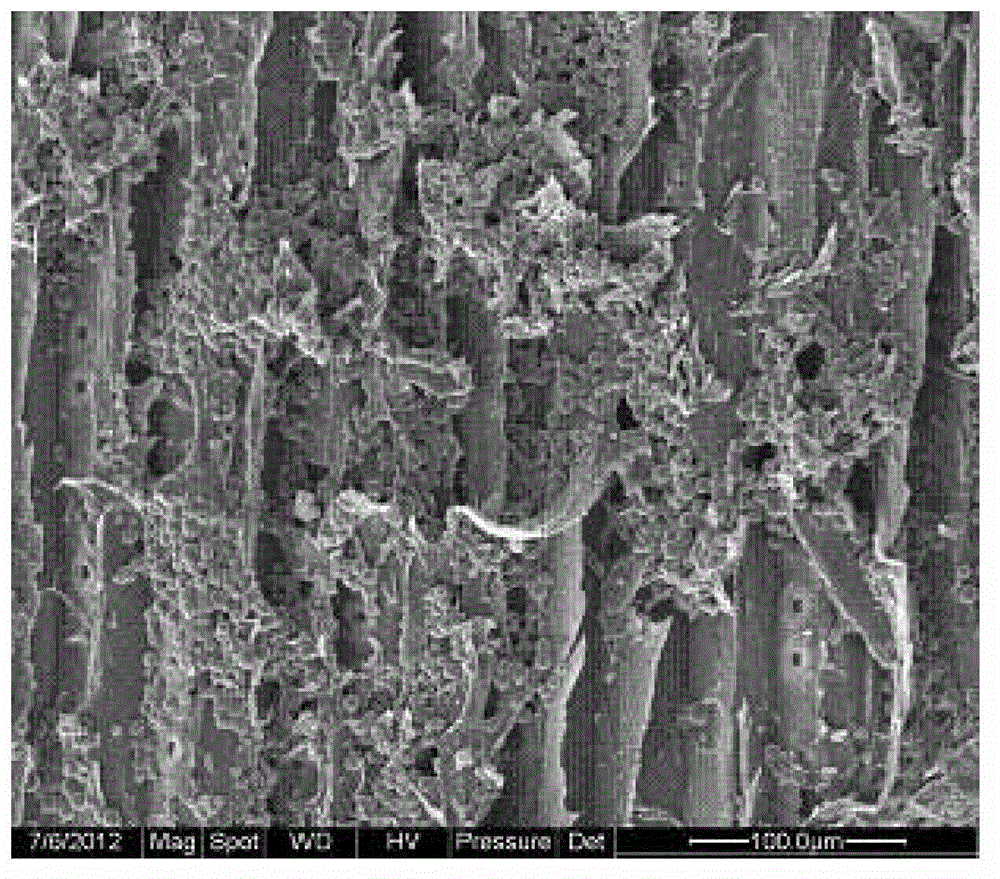

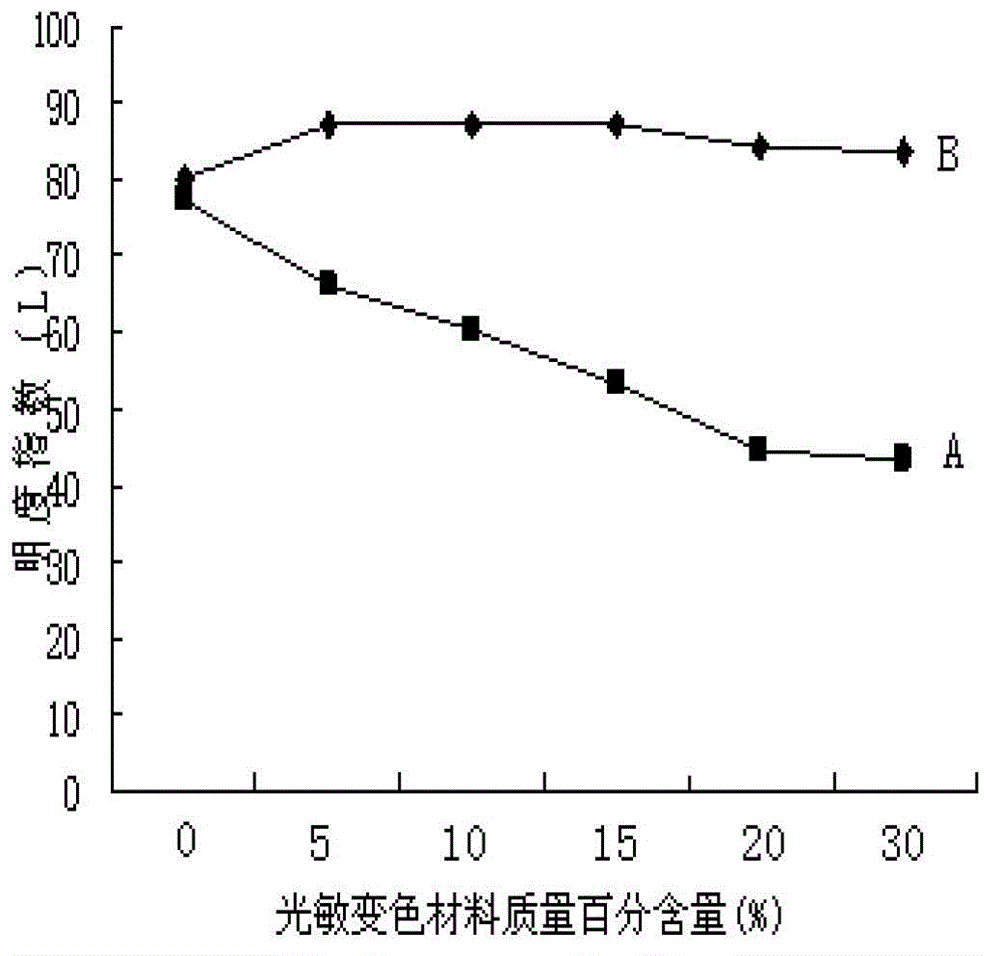

Wood-base photochromic composite preparation method

InactiveCN102873726ALight response time is fastTightly boundWood treatment detailsPressure impregnationPolyvinyl alcoholMegasonic cleaning

The invention relates to a photochromic composite preparation method, in particular to a wood-base photochromic composite preparation method which solves the problem that wood-base composites prepared by existing methods lack the photochromic function. The preparation method includes: firstly, polishing wood surface, ultrasonically cleaning, and drying to obtain a wood matrix; secondly, preparing polyvinyl alcohol aqueous solution; thirdly, preparing photochromic materials / polyvinyl alcohol film forming solution; and fourthly, using a full-cell process to impregnate the photochromic materials / polyvinyl alcohol film forming solution into the wood matrix, and drying to obtain the wood-base photochromic composite. The photochromic materials are impregnated to the surface of the wood matrix by means of the vacuum pressurizing full-cell process, and consequently the photochromic materials and the wood matrix are combined more closely while photochromic effects of the wood-base photochromic composite are unaffected. The wood-base photochromic composite preparation method is applicable to production of wood-base photochromic composites.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com