Packaging structure of LED and packaging method thereof

A technology of light-emitting diodes and packaging structures, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve problems such as difficult control of spectrum and offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

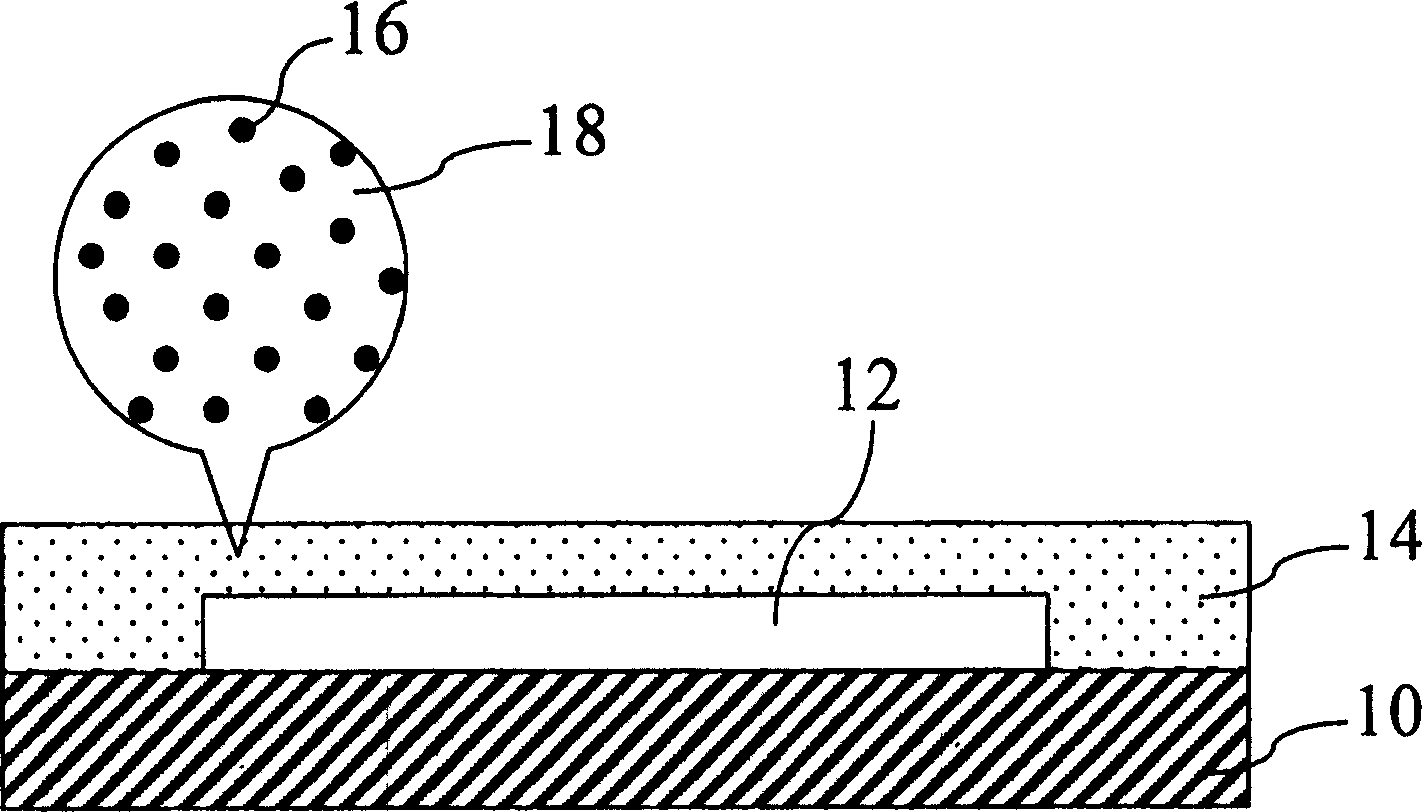

[0034] The light-emitting diode (LED) molding technology of the present invention uses liquid colloid containing phosphor (Phosphor) as the molding raw material, utilizes the casting method and is based on the solidification principle of the liquid-saturated solid sink, and manufactures the LED packaging structure.

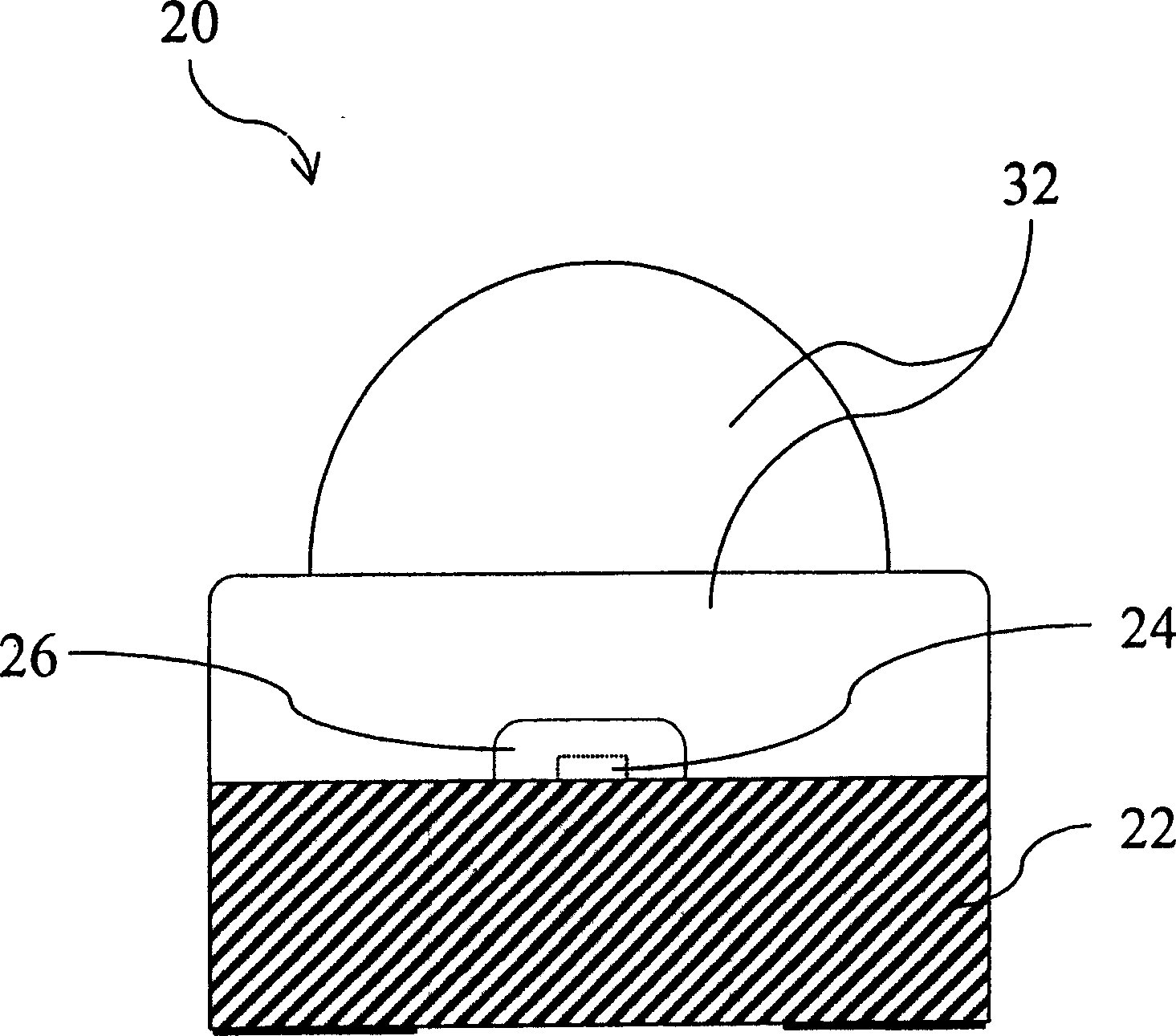

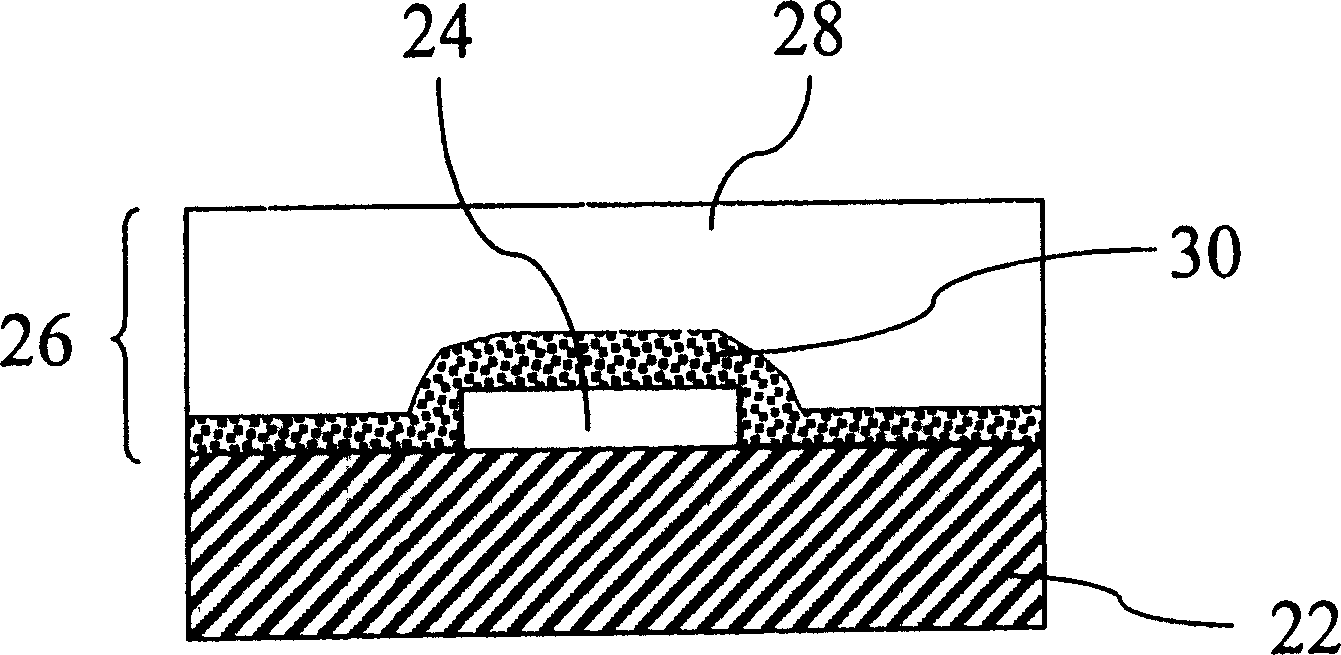

[0035] Please refer to figure 2 As shown, it is a cross-sectional view of the LED packaging structure of the present invention. An LED packaging component 20 includes a substrate 22, which is usually a printed circuit board (PCB) or a metal frame (metal frame). A light-emitting diode (LED) unit is installed on it, which is an LED crystal grain 24, and a phosphorescent medium layer 26 is coated on the substrate 22 to cover the LED crystal grain 24, and an external encapsulant 32 is coated on the phosphorescent outside the dielectric layer 26; wherein the phosphorescent dielectric layer 26 is as image 3 As shown, an encapsulant 28 is included, and a phosphor prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com